Thermal Performance of Insulated Constructions—Experimental Studies

Abstract

1. Introduction

1.1. Background—Challenges in Buildings with Thick Insulation Layers

1.2. Moisture—Effects on Insulation Material Effectiveness

1.3. Convection—Effects on Insulation Material Effectiveness

1.4. Convection and the Effect on Thermal Performance in Walls and Roofs

1.5. Convection and the Effect on Moisture Transport

1.6. Objective and Scope

2. Methodology—Experimental Work—Simulations and Sample Descriptions

2.1. Material Level Measurements

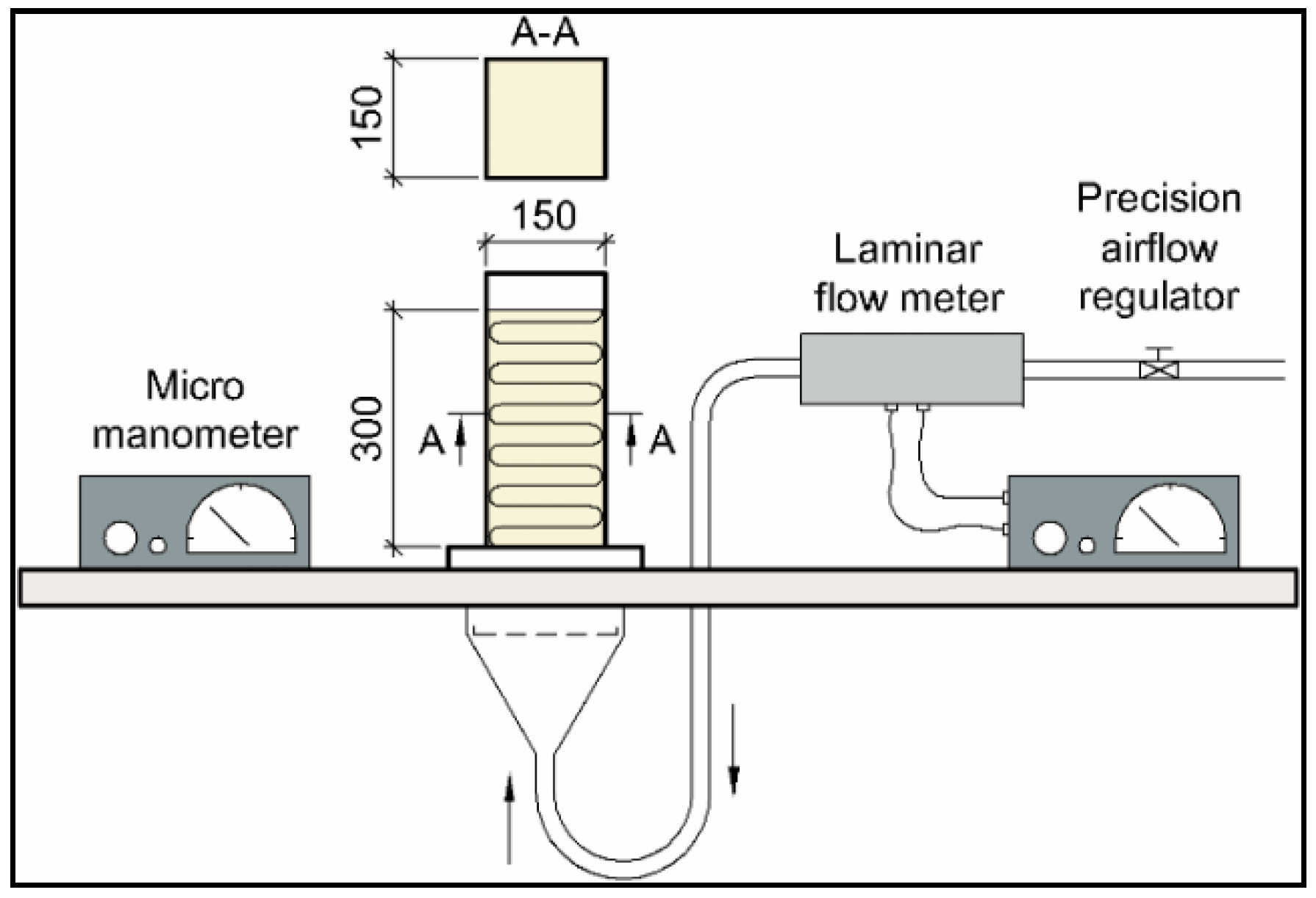

2.1.1. Air Permeability

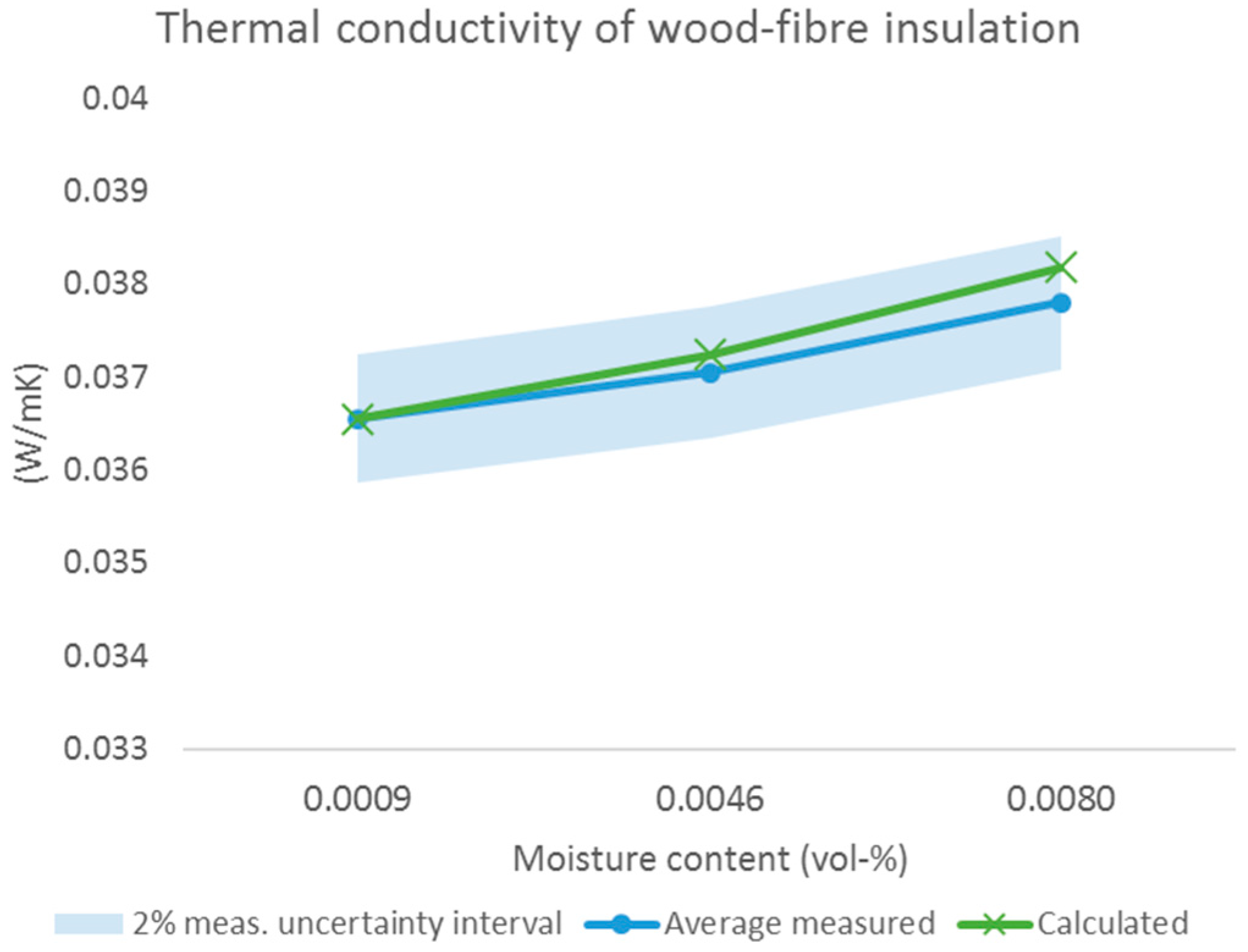

2.1.2. Measurement of Thermal Conductivity

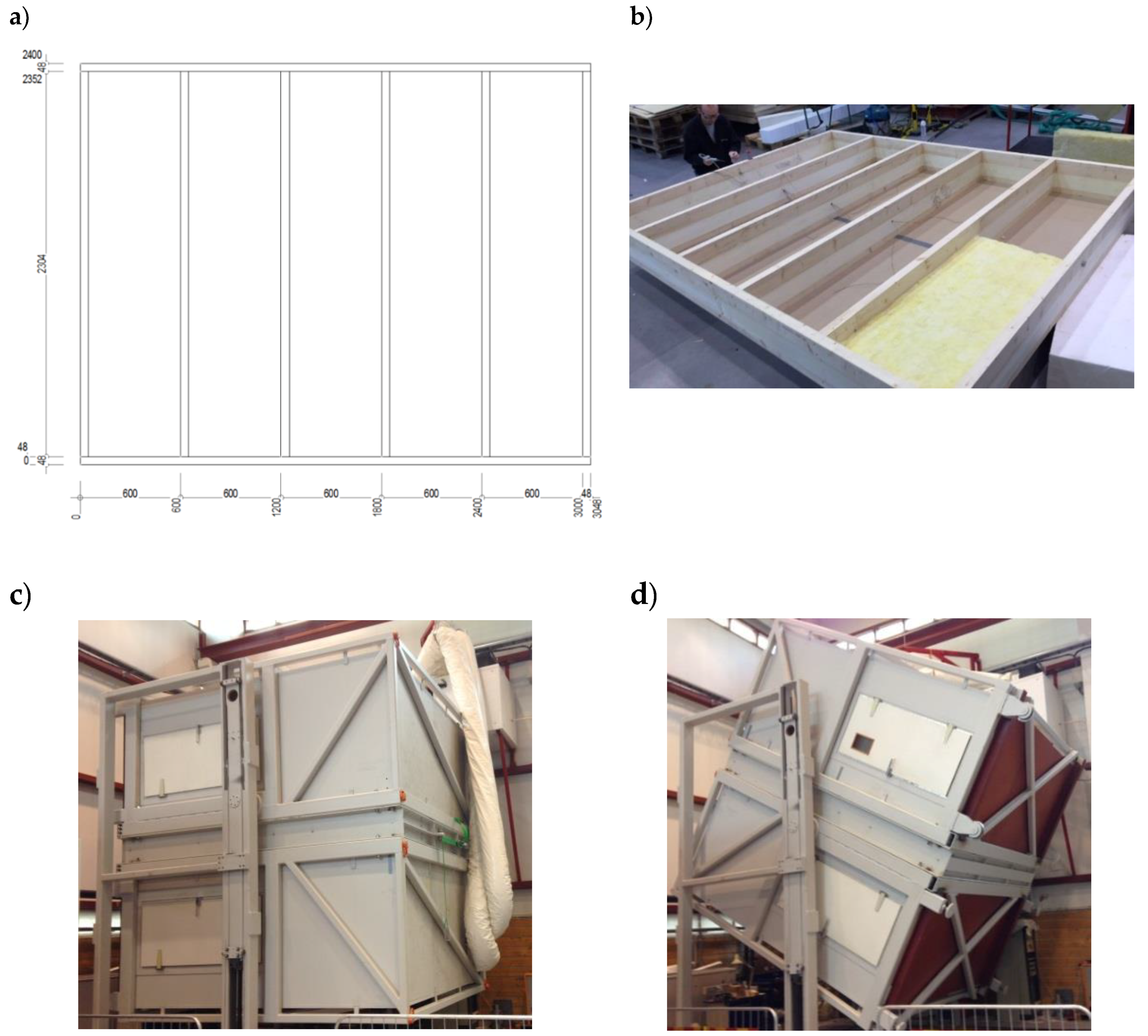

2.2. Full-Size Measurements—Test Field and Sample Descriptions

2.3. Boundary Conditions and Test Configurations

2.4. Expressing Convection—The Modified Rayleigh and Nusselt Numbers

2.5. Uncertainty Assessment of Hot-Box Measurements

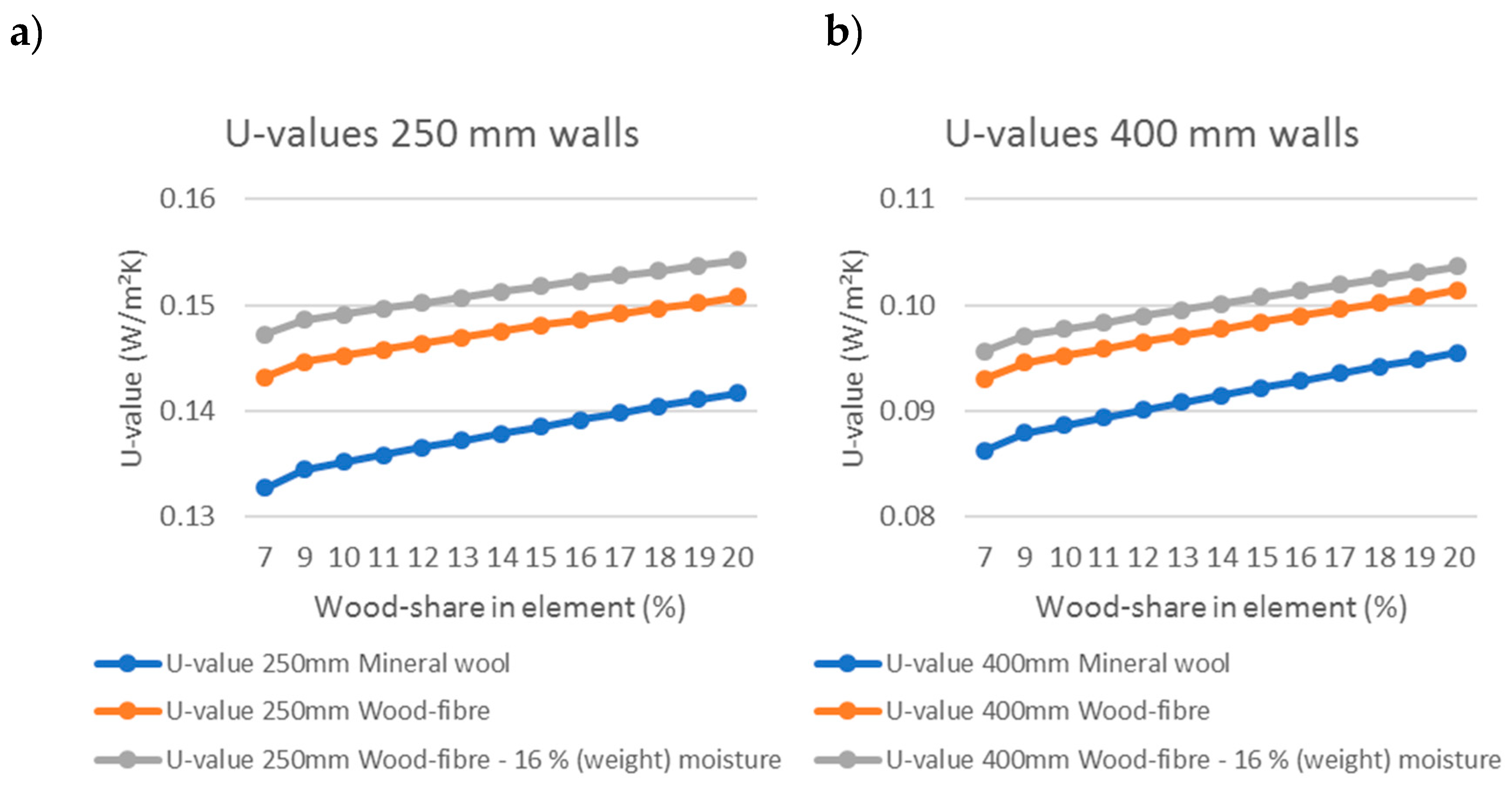

2.6. Simulation and Calculation of U-Values

3. Results and Discussion

3.1. Air Permeability

3.2. Material Level Results—Measured Values and Numbers from Literature

3.3. Full-Size Measurements

3.3.1. Angle of Inclination

3.3.2. Temperature Difference

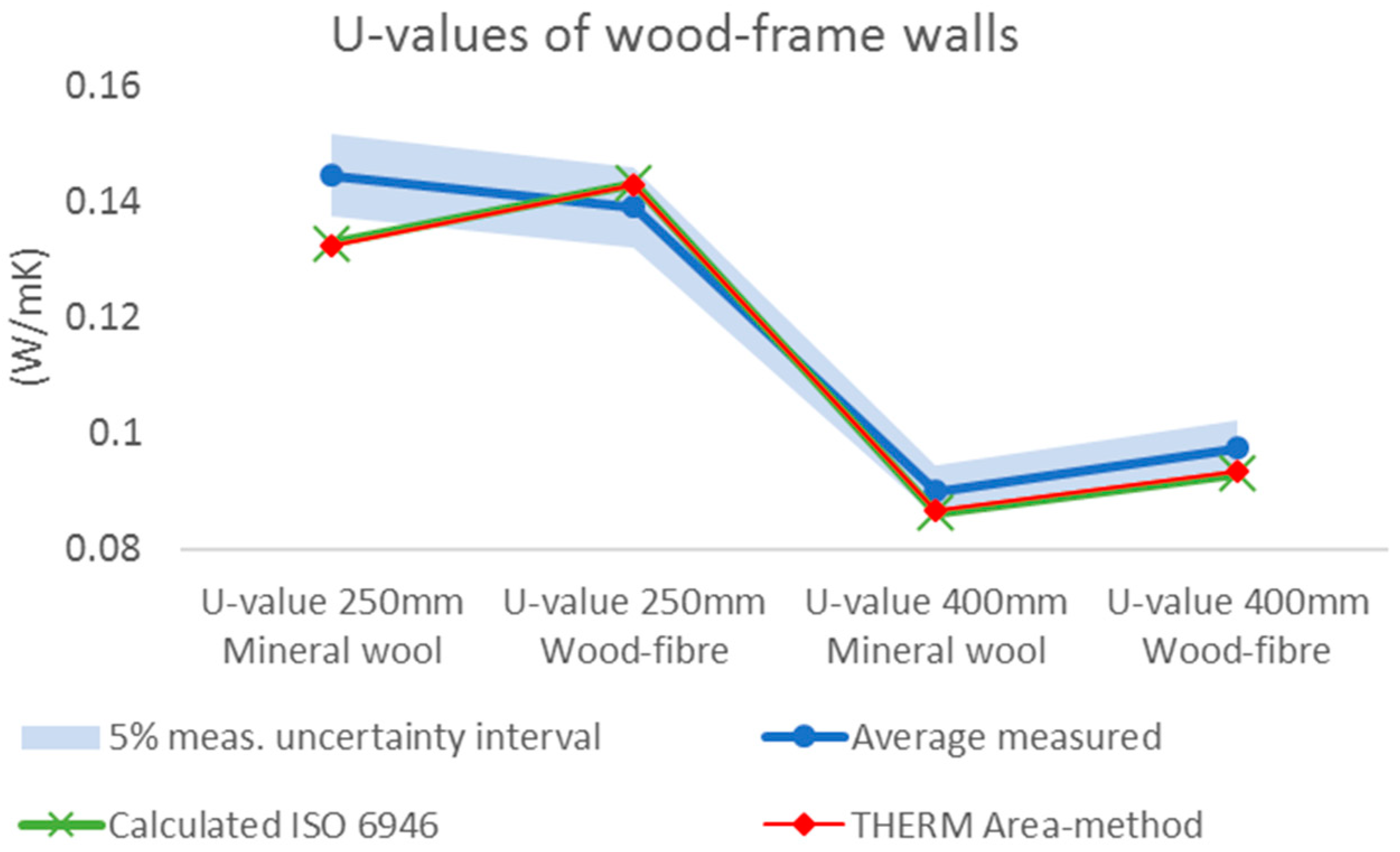

3.3.3. Measurements vs. Simulation Results

4. Conclusions

- Measurements of thermal conductivity showed that the thermal performance of the insulation is unaffected by moisture in the hygroscopic range.

- Air permeability of wood-fibre insulation was found to be somewhat higher to that of mineral wool despite a higher density.

- The largest U-values and Nusselt numbers was measured for the wall configurations. A smaller effect of natural convection was found in wood-fibre compared to mineral wool insulation.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sustainable Neighbourhoods with Zero Greenhouse Gas Emissions. 2018. Available online: https://fmezen.no/ (accessed on 31 August 2018).

- Hestnes, A.G.; Eik-Nes, N.L. Zero Emission Buildings; Fagbokforlaget: Bergen, Norway, 2017. [Google Scholar]

- Budaiwi, I.; Abdou, A. The impact of thermal conductivity change of moist fibrous insulation on energy performance of buildings under hot–humid conditions. Energy Build. 2013, 60, 388–399. [Google Scholar] [CrossRef]

- Jiřičková, M.; Černý, R. Effect of hydrophilic admixtures on moisture and heat transport and storage parameters of mineral wool. Constr. Build. Mater. 2006, 20, 425–434. [Google Scholar] [CrossRef]

- Vololonirina, O.; Coutand, M.; Perrin, B. Characterization of hygrothermal properties of wood-based products–Impact of moisture content and temperature. Constr. Build. Mater. 2014, 63, 223–233. [Google Scholar] [CrossRef]

- NS-EN ISO 10456. Hygrothermal Properties—Tabulated Design Values and Procedures for Determining Declared and Design Thermal Values; Standard Norge: Oslo, Norway, 2017. [Google Scholar]

- Uvsløkk, S.H.; Skogstad, B.; Grynning, S. How to prevent natural convection causing extra heat lodd and moisture problems in thick insulation layers. In Proceedings of the 3rd Nordic Passive House Conference by Passivehus Norden, Aalborg, Denmark, 7–8 October 2010. [Google Scholar]

- Gullbrekken, L.; Geving, S.; Time, B.; Andresen, I.; Holme, J. Moisture conditions in well-insulated wood-frame walls. Simulations, laboratory measurements and field measurements. Wood Mater. Sci. Eng. 2015, 10, 232–244. [Google Scholar] [CrossRef]

- Geving, S. Fuktskader Årsaker, Utbedringer og tiltak; SINTEF Byggforsk: Trondheim, Norway, 2011. [Google Scholar]

- Bankvall, C. Natural Convective Heat Transfer in Insulated Structures; Report 38; Division of Building and Technology, Lund Institute of Technology: Lund, Sweden, 1972. [Google Scholar]

- Lecompte, J. The influence of natural convection on the thermal quality og insulated cavity construction. J. Cib 1990, 6, 349–354. [Google Scholar]

- Johannessen, E. Hot-Box Målinger på Høyisolerte Bygningskonstruksjoner. Master’s Thesis, Norwegian Techniqual School (NTH), Trondheim, Norway, 1995. [Google Scholar]

- Jordanger, G.O. Naturlig Konveksjon i Vegger Laboratorieforsøk. Master’s Thesis, Norwegian Techniqual School (NTH), Trondheim, Norway, 1995. [Google Scholar]

- Bjerkevoll, G.O. Hot-Box Måliner på Høyisolerte Bygningskonstruksjoner. Master’s Thesis, Norwegian Techniqual School (NTH), Trondheim, Norway, 1994. [Google Scholar]

- Uvsløkk, S.; Skogstad, H.B.; Aske, I.J. Natural Convection in Timber Frame Walls with Thick Thermal Insulation Layer; VTT Building Technology: Espoo, Finland, 1996. [Google Scholar]

- Janssen, H. Thermal Performance of Highly Insulated Wood Frame Walls. Master’s Thesis, Katholieke Universiteit Leuven, Leuven, Belgium, 1997. [Google Scholar]

- Shankar, V.; Hagentoft, C.E. A Numerical Study of Effect of Natural Convection on Thermal Properties of Horizontal Oriented Porous Insulation. J. Build. Phys. 2000, 24, 155–167. [Google Scholar] [CrossRef]

- Dyrbøl, S.; Svendsen, S.; Elmroth, A. Experimental Investigation of the Effect of Natural Convection on Heat Transfer in Mineral Wool. J. Build. Phys. 2002, 26, 153–164. [Google Scholar] [CrossRef]

- Wahlgren, P. Overview and Literature Survey of Natural and Forced Convection in Attic Insulation. J. Build. Phys. 2007, 30, 351–370. [Google Scholar] [CrossRef]

- Gullbrekken, L.; Uvslokk, S.; Kvande, T.; Time, B. Hot-Box measurements of highly insulated wall, roof and floor structures. J. Build. Phys. 2017, 41, 58–77. [Google Scholar] [CrossRef]

- Roels, S.; Langmans, J. Highly insulated pitched roofs resilient to air flow patterns: Guidelines based on a literature review. Energy Build. 2016, 120, 10–18. [Google Scholar] [CrossRef]

- Geving, S.; Uvsløkk, S. Moisture conditions in timber frame roof and wall structures. In Project Report 273; Norwegian Building Research Institute: Trondheim, Norway, 2000. [Google Scholar]

- Økland, Ø. Convection in Highly-Insulated Building Structures. Ph.D. Thesis, Department of Civil and Transport Engineering, Norwegian University of Science and Technology, Trondheim, Norway, 1998. [Google Scholar]

- Langmans, J.; Klein, R.; Roels, S. Hygrothermal risks of using exterior air barrier systems for highly insulated light weight walls: A laboratory investigation. Build. Environ. 2012, 56, 192–202. [Google Scholar] [CrossRef]

- Kalamees, T.; Kurnitski, J. Moisture Convection Performance of External Walls and Roofs. J. Build. Phys. 2010, 33, 225–247. [Google Scholar] [CrossRef]

- British Standards Institution. Thermal Insulation—Determination of Steady-State Thermal Transmission Properties—Calibrated and Guarded Hot Box; Standard Norge: Oslo, Norway, 1996. [Google Scholar]

- NS-ISO 9053. Acoustics Materials for Acoustical Applications Determination of Airflow Resistance; Standard Norge: Oslo, Norway, 1993. [Google Scholar]

- ISO 8301. Thermal insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus; Standard Norge: Oslo, Norway, 1991. [Google Scholar]

- NS-EN 12667:2001. Byggematerialers og produkters termiske egenskaper—Bestemmelse av varmemotstand ved skjermet og uskjermet varmestrømmåler—Produkter med høy og middels varmemotstand; Standard Norge: Oslo, Norway, 2001. [Google Scholar]

- NS-EN 13171:2012. Thermal Insulation Products for Buildings Factory Made Wood Fibre (WF) Products Specification; Standard Norge: Oslo, Norway, 2012. [Google Scholar]

- Grynning, S.; Misiopecki, C.; Uvsløkk, S.; Time, B.; Gustavsen, A. Thermal performance of in-between shading systems in multilayer glazing units: Hot-box measurements and numerical simulations. J. Build. Phys. 2015, 39, 147–169. [Google Scholar] [CrossRef]

- NS-EN ISO 6946:2017. Building Components and Building Elements Thermal Resistance and Thermal Transmittance Calculation Methods; Standard Norge: Oslo, Norway, 2017. [Google Scholar]

- THERM Version 7.6.1. Available online: https://windows.lbl.gov/software/therm (accessed on 20 February 2019).

- NS-EN 10211:2017. Thermal Bridges in Building Construction Heat Flows and Surface Temperatures Detailed Calculations; Standard Norge: Oslo, Norway, 2017. [Google Scholar]

| Sample Number | Material | t (mm) | ρ (kg/m3) | T (°C) | RH (%) |

|---|---|---|---|---|---|

| 1 | Wood fibre | 100 | 51. | 23 | 50 |

| 2 | Wood fibre | 150 | 54.2 | 23 | 50 |

| 3 | Wood fibre | 100 | 56.4 | 23 | 75 |

| 4 | Wood fibre | 150 | 53.6 | 23 | 75 |

| 5 | Wood fibre | 100 | 47.8 | 20 | 20 |

| 6 | Wood fibre | 150 | 50.5 | 20 | 20 |

| 7 | Mineral wool | 100 | 17.4 | 20 | 20 |

| 8 | Mineral wool | 150 | 17.0 | 20 | 20 |

| Test Variant | Angle of Inclination | Temperature Cold Room | Temperature Warm Room | Insulation Type | Insulation Thickness | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 30 | 90 | 180 | 0 | −10 | 20 | 30 | Min. | Wood | 250 | 400 | |

| 1 | x | x | x | x | x | ||||||

| 2 | x | x | x | x | x | ||||||

| 3 | x | x | x | x | x | ||||||

| 4 | x | x | x | x | x | ||||||

| 5 | x | x | x | x | x | ||||||

| 6 | x | x | x | x | x | ||||||

| 7 | x | x | x | x | x | ||||||

| 8 | x | x | x | x | x | ||||||

| 9 | x | x | x | x | x | ||||||

| 10 | x | x | x | x | x | ||||||

| 11 | x | x | x | x | x | ||||||

| 12 | x | x | x | x | x | ||||||

| 13 | x | x | x | x | x | ||||||

| 14 | x | x | x | x | x | ||||||

| 15 | x | x | x | x | x | ||||||

| 16 | x | x | x | x | x | ||||||

| 17 | x | x | x | x | x | ||||||

| 18 | x | x | x | x | x | ||||||

| 19 | x | x | x | x | x | ||||||

| 20 | x | x | x | x | x | ||||||

| 21 | x | x | x | x | x | ||||||

| 22 | x | x | x | x | x | ||||||

| 23 | x | x | x | x | x | ||||||

| 24 | x | x | x | x | x | ||||||

| Thermal Conductivity (W/mK) | Moisture Content (weight-%) | |||

|---|---|---|---|---|

| dry | 18.7 | 92.4 | Saturated | |

| Measured | 0.037 ± 0.001 | 0.037 ± 0.001 | 0.038 ± 0.001 | |

| Calculated according to NS-EN ISO 10456 | 0.037 | 0.037 | 0.037 | 0.038 |

| Insulation Thickness (mm) | θi (C) | θi (C) | θi (C) | Δθie (C) | Angle (deg) | Measured U-Value (W/m2 K) | Calculated U-Value (W/m2 K) | Modified Rayleigh Number (-) | Nusselt Number (-) | |

|---|---|---|---|---|---|---|---|---|---|---|

| Min. wool | 250 | 20 | 0 | 10 | 20 | 90 | 0.144 ± 0.008 | 0.133 | 1.338 | 1.015 |

| 250 | 30 | −10 | 10 | 40 | 90 | 0.148 ± 0.008 | 2.676 | 1.038 | ||

| 250 | 20 | 0 | 10 | 20 | 30 | 0.142 ± 0.008 | 1.338 | 0.998 | ||

| 250 | 30 | −10 | 10 | 40 | 30 | 0.145 ± 0.008 | 2.676 | 1.014 | ||

| 250 | 20 | 0 | 10 | 20 | 180 | 0.142 ± 0.008 | 1.338 | 1.000 | ||

| 250 | 30 | −10 | 10 | 40 | 180 | 0.143 ± 0.008 | 2.676 | 1.000 | ||

| Wood fibre | 250 | 20 | 0 | 10 | 20 | 90 | 0.139 ± 0.008 | 0.143 | 1.676 | 0.953 |

| 250 | 30 | −10 | 10 | 40 | 90 | 0.148 ± 0.008 | 3.352 | 1.001 | ||

| 250 | 20 | 0 | 10 | 20 | 30 | 0.142 ± 0.008 | 1.676 | 0.974 | ||

| 250 | 30 | −10 | 10 | 40 | 30 | 0.146 ± 0.008 | 3.352 | 0.992 | ||

| 250 | 20 | 0 | 10 | 20 | 180 | 0.146 ± 0.008 | 1.676 | 1.000 | ||

| 250 | 30 | −10 | 10 | 40 | 180 | 0.147 ± 0.008 | 3.352 | 1.000 | ||

| Min. wool | 400 | 20 | 0 | 10 | 20 | 90 | 0.090 ± 0.005 | 0.087 | 1.676 | 1.074 |

| 400 | 30 | −10 | 10 | 40 | 90 | 0.097 ± 0.005 | 3.352 | 1.068 | ||

| 400 | 20 | 0 | 10 | 20 | 30 | 0.091 ± 0.005 | 1.676 | 1.083 | ||

| 400 | 30 | −10 | 10 | 40 | 30 | 0.093 ± 0.005 | 3.352 | 1.022 | ||

| 400 | 20 | 0 | 10 | 20 | 180 | 0.084 ± 0.005 | 1.676 | 1.000 | ||

| 400 | 30 | −10 | 10 | 40 | 180 | 0.091 ± 0.005 | 3.352 | 1.000 | ||

| Wood fibre | 400 | 20 | 0 | 10 | 20 | 90 | 0.097 ± 0.005 | 0.093 | 2.666 | 1.011 |

| 400 | 30 | −10 | 10 | 40 | 90 | 0.103 ± 0.006 | 5.331 | 1.014 | ||

| 400 | 20 | 0 | 10 | 20 | 30 | 0.096 ± 0.005 | 2.666 | 0.995 | ||

| 400 | 30 | −10 | 10 | 40 | 30 | 0.103 ± 0.006 | 5.331 | 1.014 | ||

| 400 | 20 | 0 | 10 | 20 | 180 | 0.096 ± 0.005 | 2.666 | 1.000 | ||

| 400 | 30 | −10 | 10 | 40 | 180 | 0.102 ± 0.006 | 5.331 | 1.000 |

| U-Values (W/m2 K) | Wall Configuration | |||

|---|---|---|---|---|

| 250 mm Mineral Wool | 250 mm Wood-Fibre | 400 mm Mineral Wool | 400 mm Wood-Fibre | |

| Measured * | 0.145 ± 0.007 | 0.139 ± 0.007 | 0.090 ± 0.005 | 0.098 ± 0.005 |

| Calculated according to THERM Area-method | 0.132 | 0.143 | 0.087 | 0.093 |

| Moist insulation (16 weight-%) | 0.148 | 0.096 | ||

| Calculated according to NS-EN ISO 6946 | 0.133 | 0.143 | 0.086 | 0.093 |

| Moist insulation (16 weight-%) | 0.147 | 0.096 | ||

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gullbrekken, L.; Grynning, S.; Gaarder, J.E. Thermal Performance of Insulated Constructions—Experimental Studies. Buildings 2019, 9, 49. https://doi.org/10.3390/buildings9020049

Gullbrekken L, Grynning S, Gaarder JE. Thermal Performance of Insulated Constructions—Experimental Studies. Buildings. 2019; 9(2):49. https://doi.org/10.3390/buildings9020049

Chicago/Turabian StyleGullbrekken, Lars, Steinar Grynning, and Jørn Emil Gaarder. 2019. "Thermal Performance of Insulated Constructions—Experimental Studies" Buildings 9, no. 2: 49. https://doi.org/10.3390/buildings9020049

APA StyleGullbrekken, L., Grynning, S., & Gaarder, J. E. (2019). Thermal Performance of Insulated Constructions—Experimental Studies. Buildings, 9(2), 49. https://doi.org/10.3390/buildings9020049