Laboratory Mix Design of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt and Virgin Aggregates

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Material Characterization

2.2.1. Aggregates

2.2.2. Residual Bitumen in Reclaimed Asphalt

2.2.3. Bitumen Emulsion

2.3. Emulsion Asphalt Mix Design

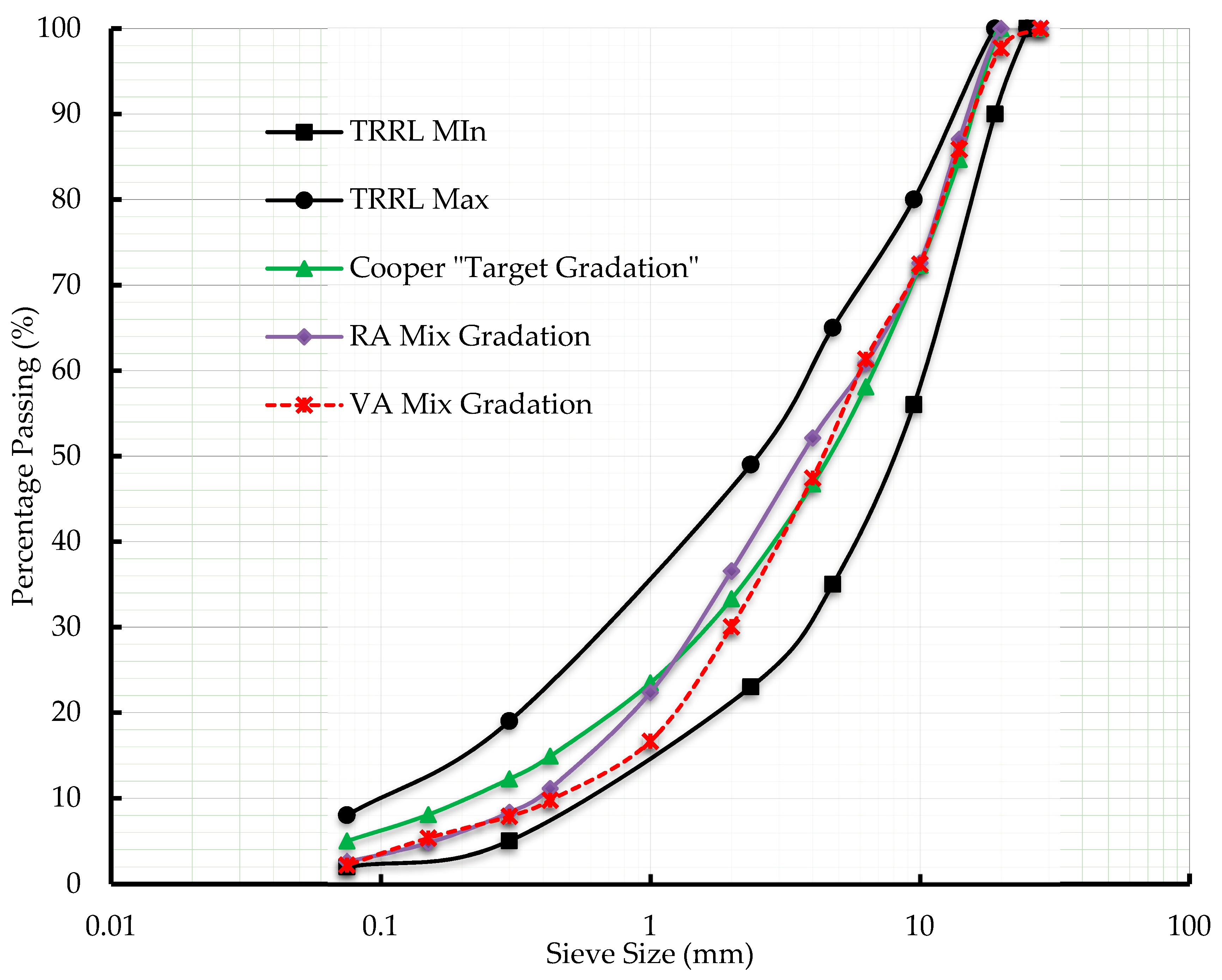

2.3.1. Combined Aggregates Gradation

2.3.2. Initial Emulsion Content (IEC)

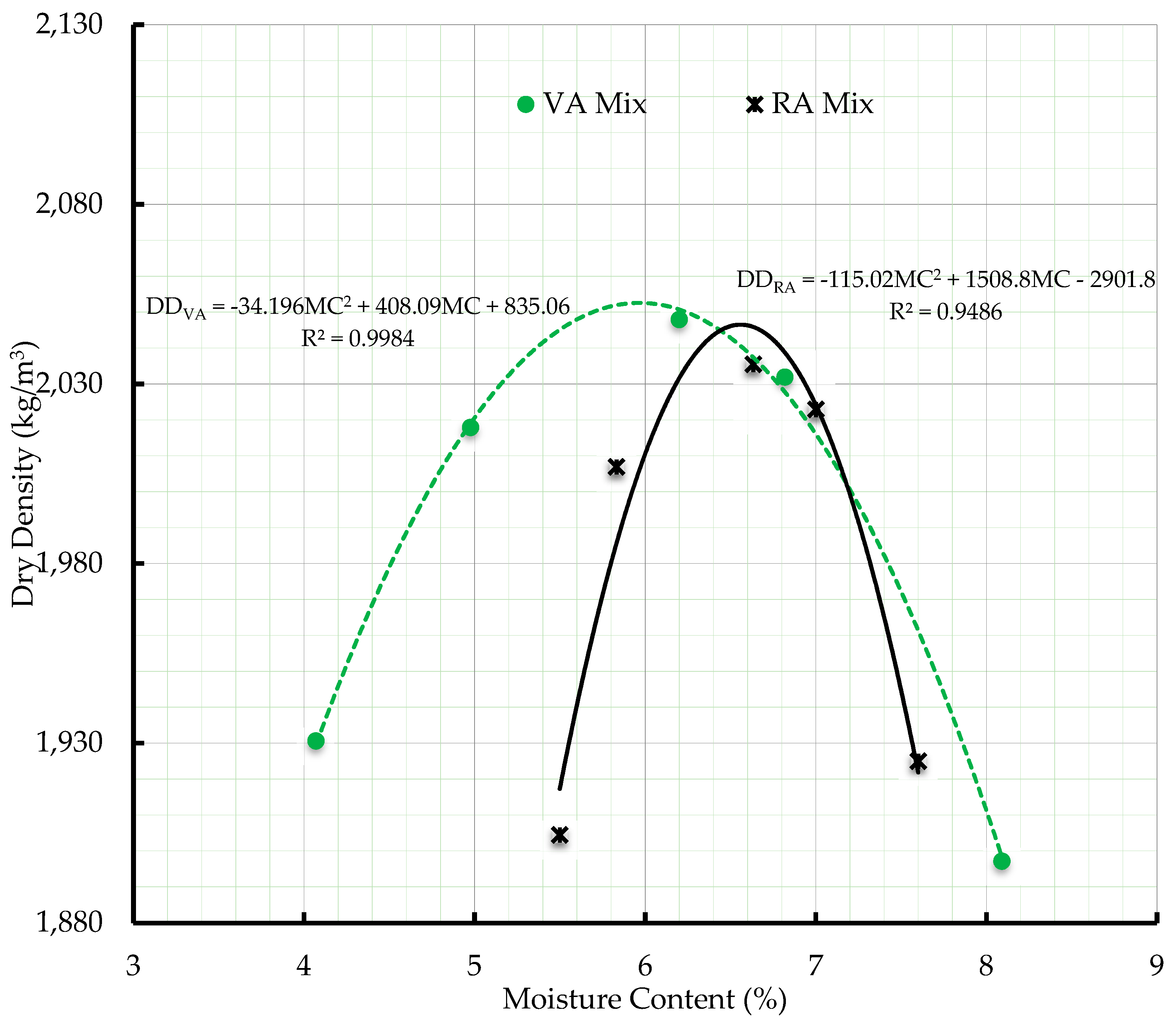

2.3.3. Moisture-Density Relationships

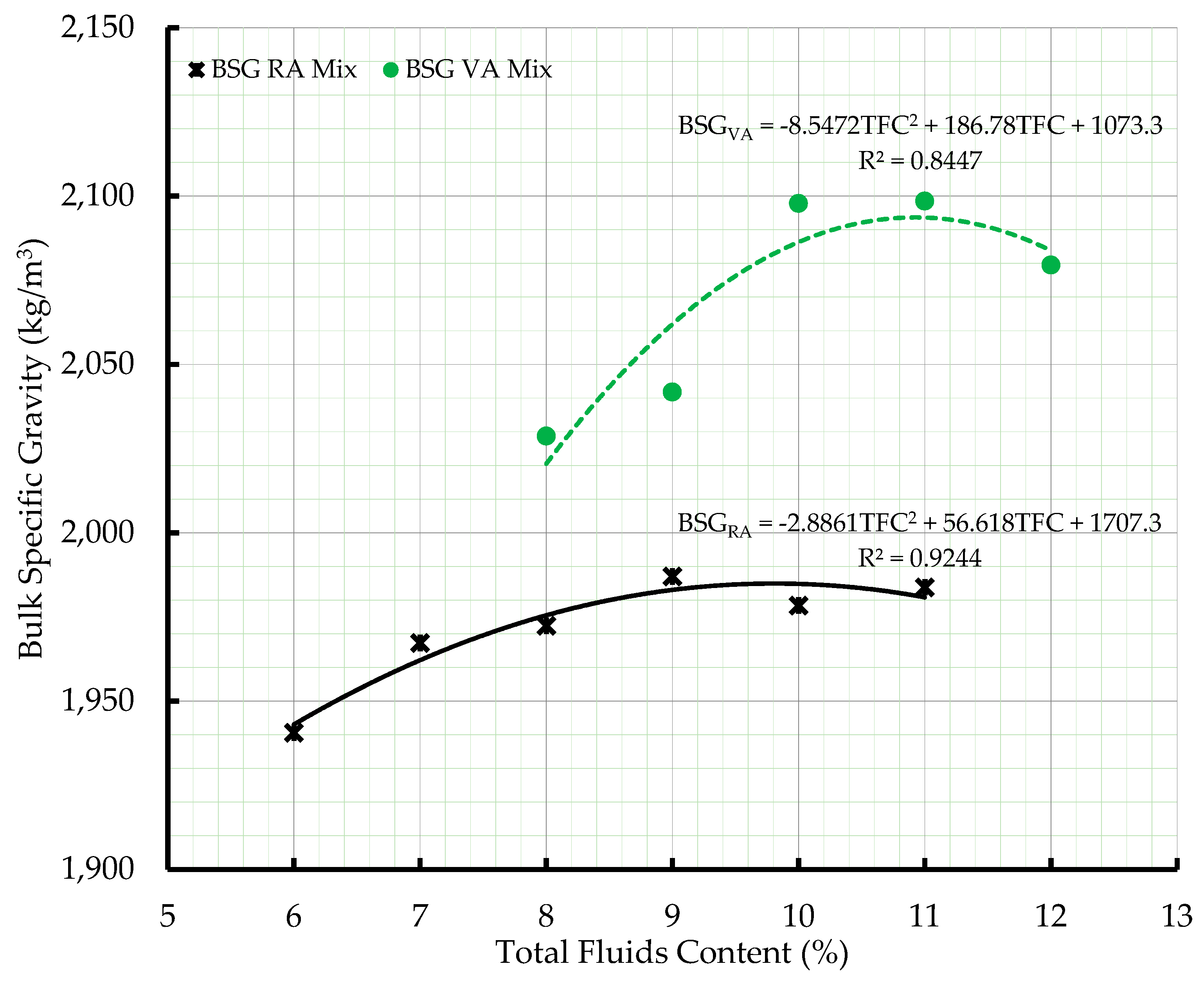

2.3.4. Optimum Total Fluid Content

2.3.5. Optimum Bitumen Emulsion Content

2.3.6. Compaction Characteristics

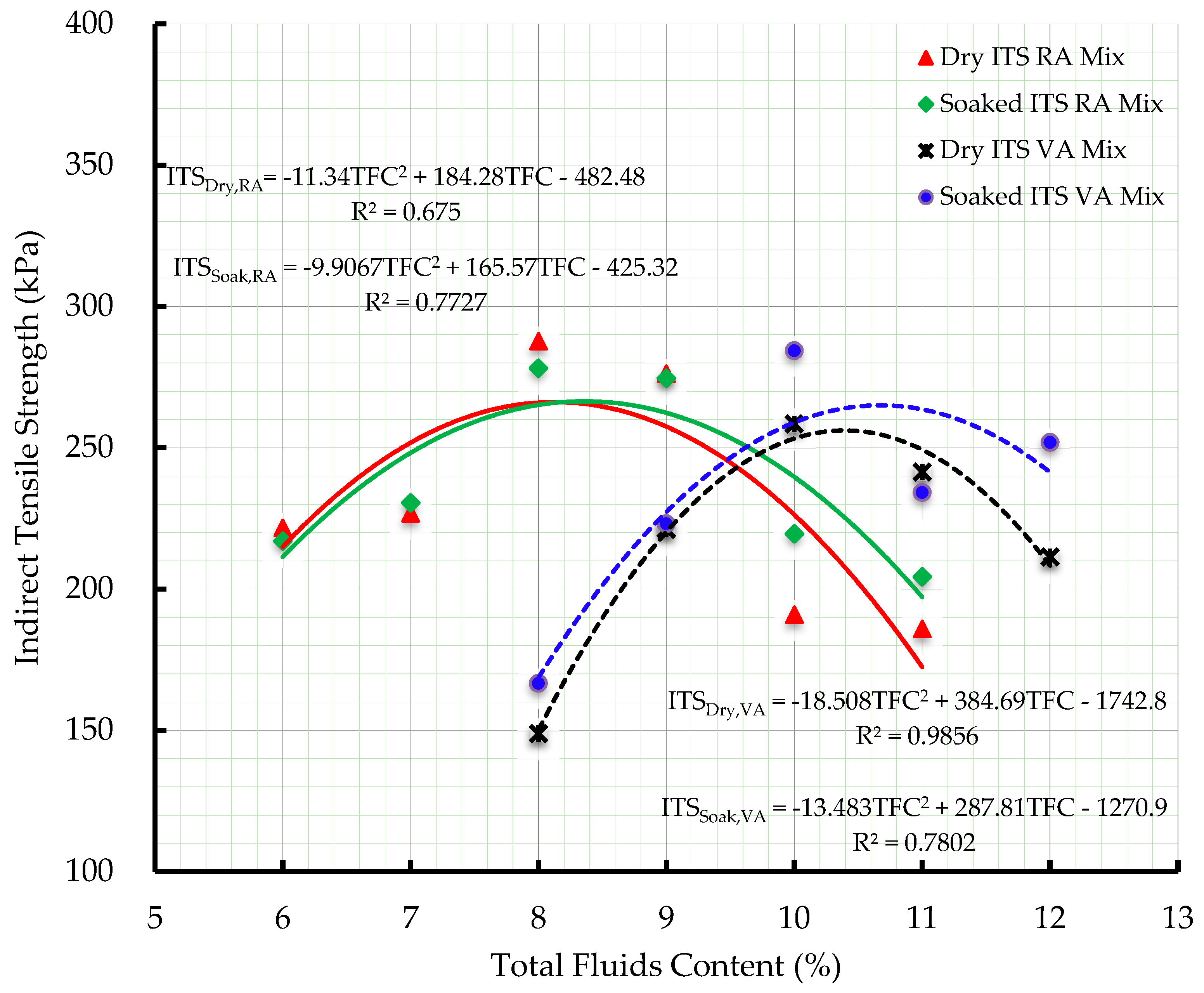

2.3.7. Moisture Susceptibility

3. Results and Discussions

3.1. Moisture-Density Relationships

3.2. Optimum Total Fluid Content

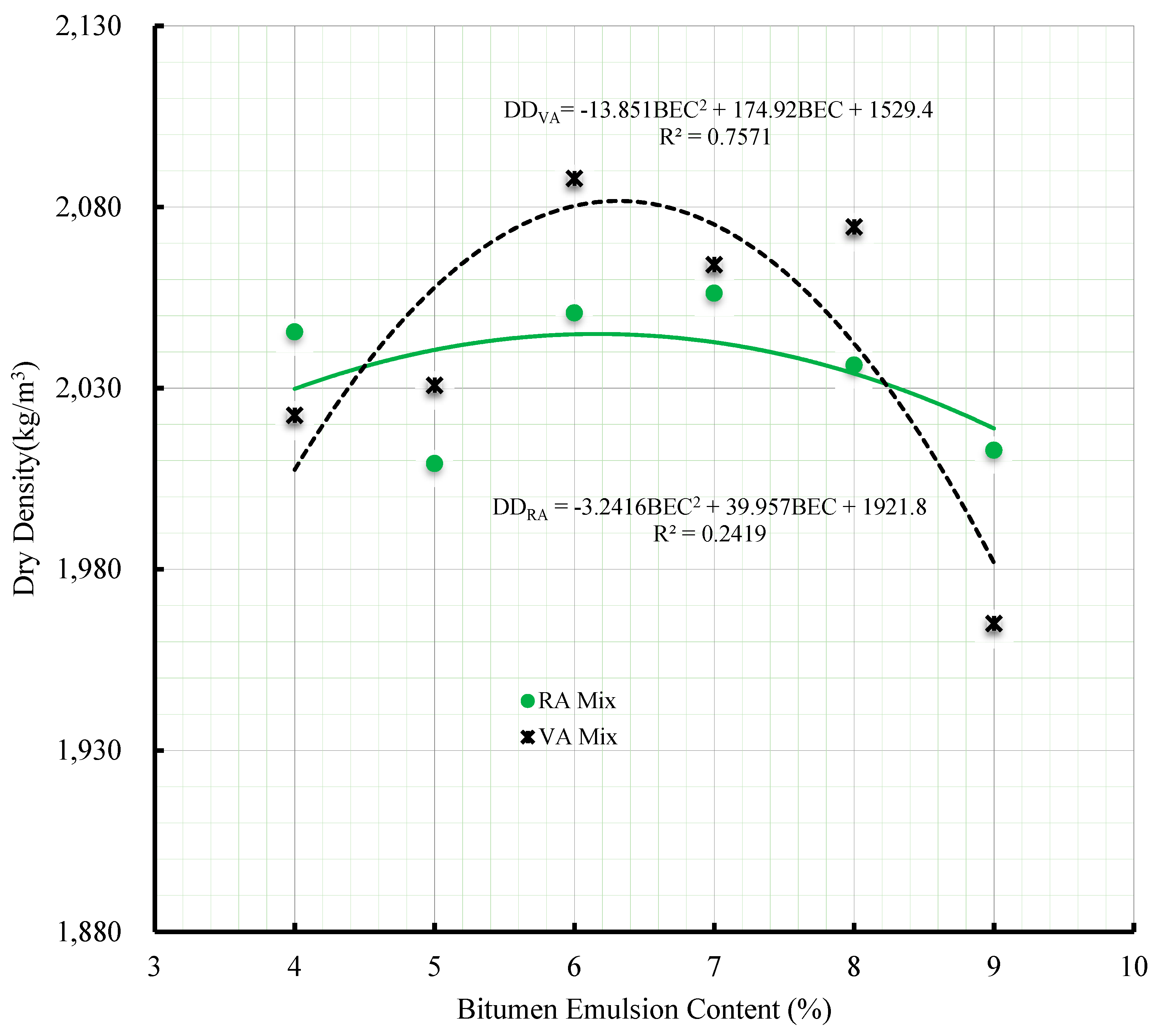

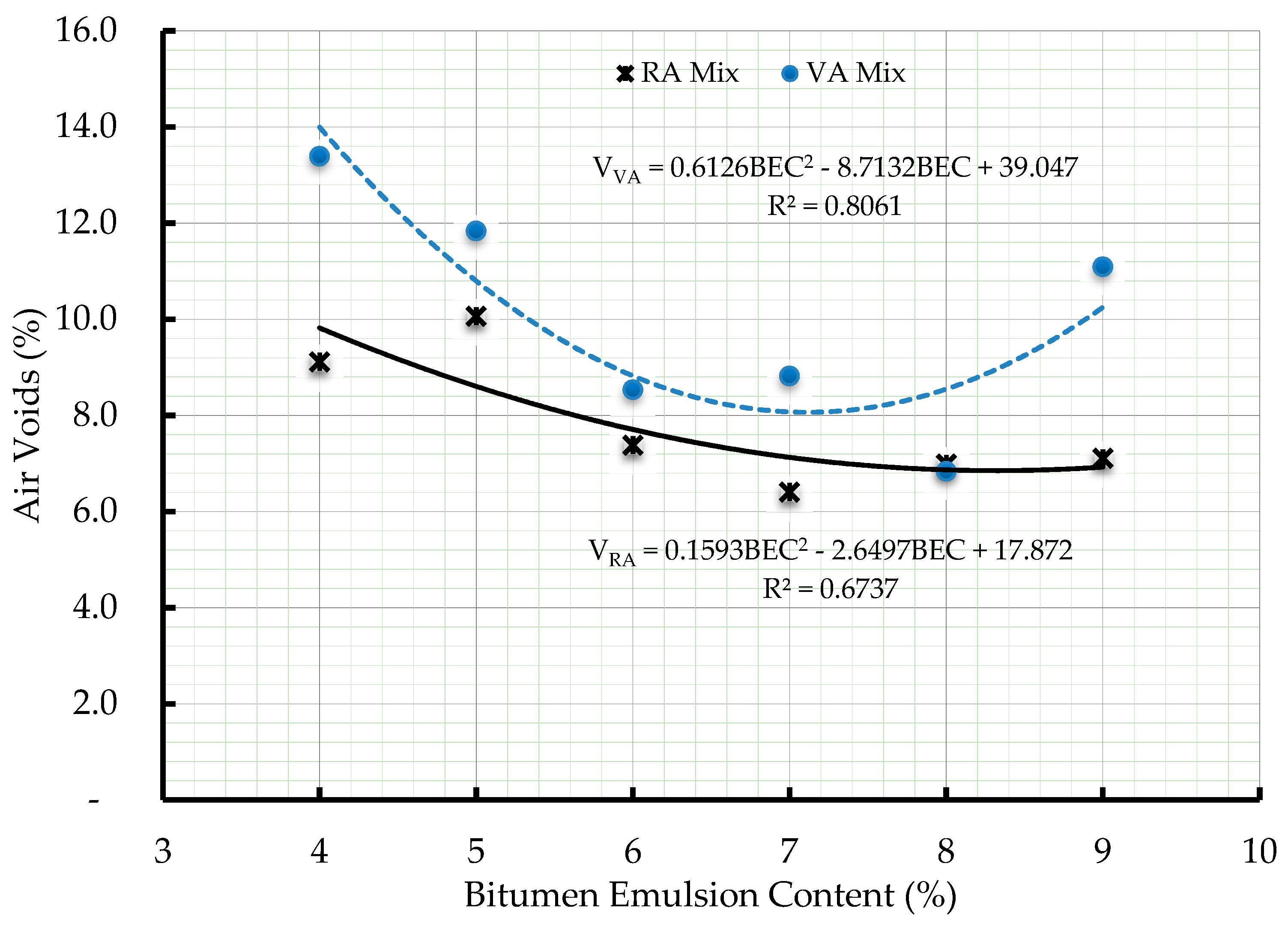

3.3. Optimum Emulsion Content

3.4. Compaction Characteristics

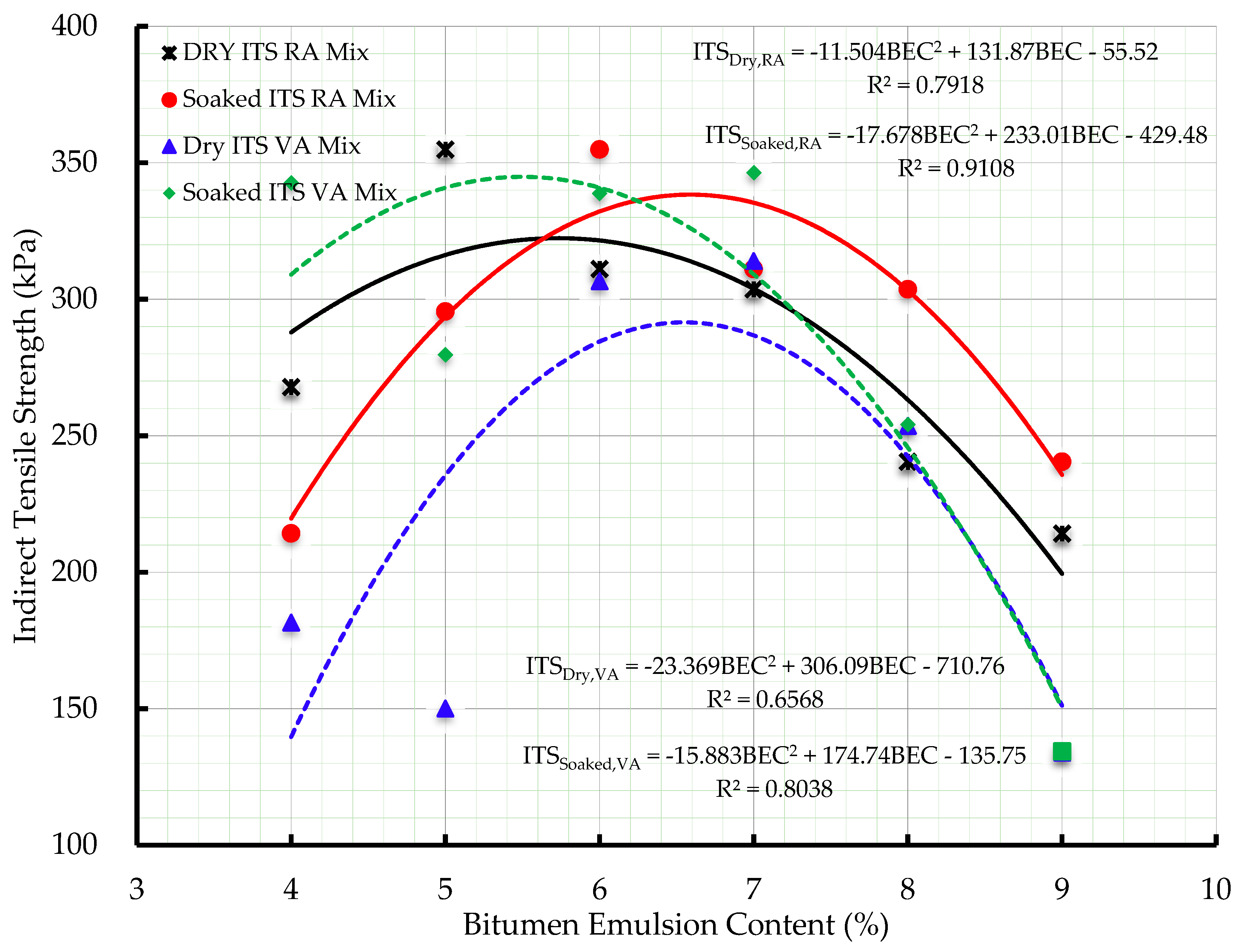

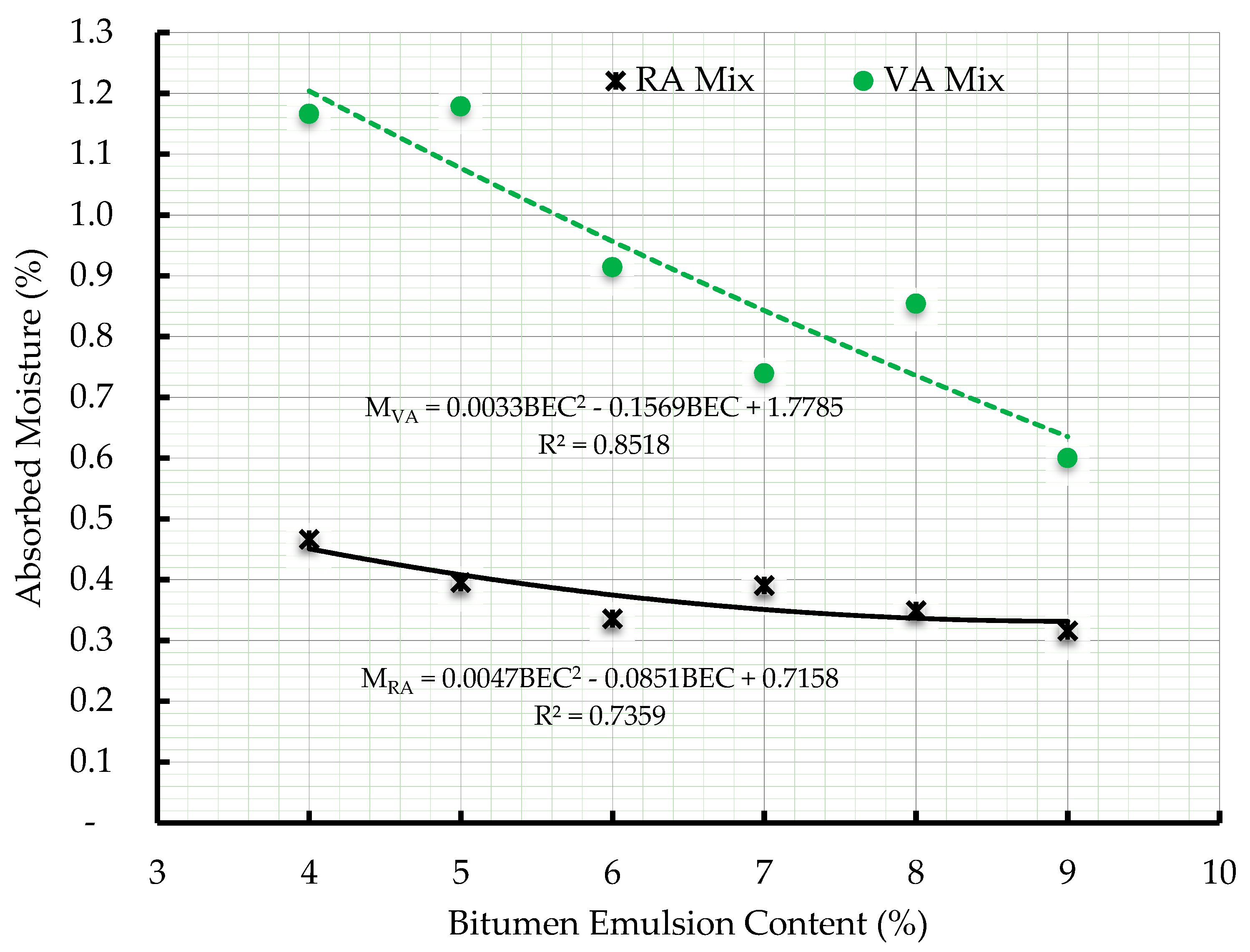

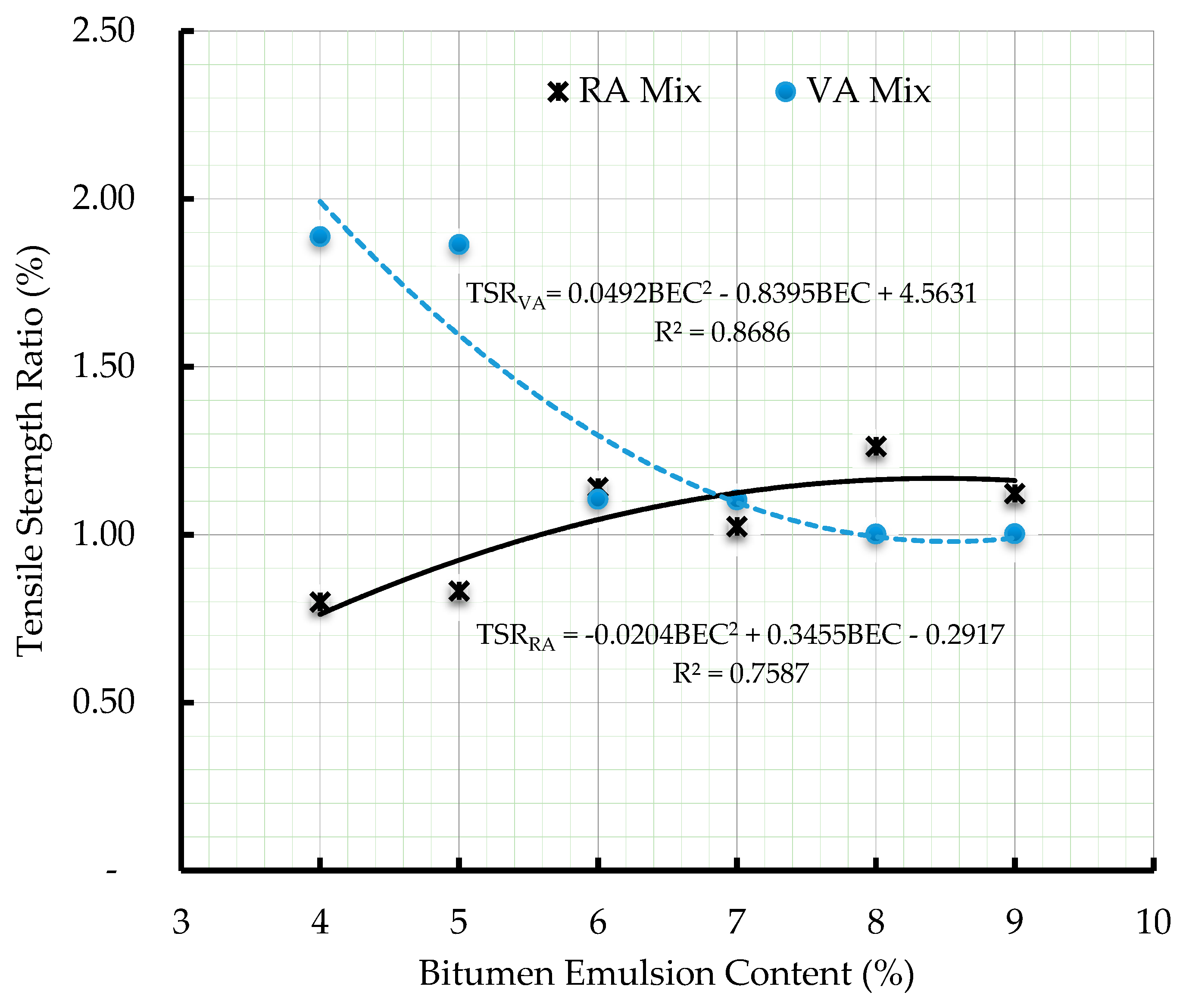

3.5. Moisture Susceptibility

4. Conclusions

- When properly designed, emulsion asphalt incorporating as high as 55% reclaimed asphalt aggregates can perform as satisfactorily as conventional VA emulsion asphalt mixtures.

- Incorporation of reclaimed asphalt aggregates, with proper optimization of the binder and pre-mix water, results in reduced porosity and reduced water absorption of the mix, which leads to a reduction in moisture susceptibility of emulsion asphalt mix.

- Emulsion asphalts incorporating reclaimed asphalt aggregates have lower densities than conventional virgin aggregates emulsion mixtures.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Sieve Size (mm) | 0/6 mm Virgin | 0/6 mm RAP | 6/10 mm RAP | 10/14 mm RAP | 14/20mm RAP | Reclaimed Asphalt Mix Gradation | Cooper “Target Gradation” |

|---|---|---|---|---|---|---|---|

| 28 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 20 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| 14 | 100 | 100 | 100 | 99 | 19 | 88 | 85 |

| 10 | 100 | 100 | 100 | 17 | 1 | 73 | 72 |

| 6 | 99 | 99 | 13 | 1 | - | 61 | 58 |

| 4 | 92 | 70 | 1 | - | - | 52 | 47 |

| 2 | 67 | 43 | - | - | - | 37 | 33 |

| 1 | 42 | 26 | - | - | - | 23 | 23 |

| 0.425 | 19 | 14 | - | - | - | 11 | 15 |

| 0.300 | 14 | 10 | - | - | - | 8 | 12 |

| 0.150 | 7 | 6 | - | - | - | 4 | 8 |

| 0.075 | 4 | 2 | - | - | - | 2 | 5 |

Appendix B

| Sieve Size (mm) | 0/6 mm Virgin | 6/10 mm Virgin | 10/14 mm Virgin | 14/20mm Virgin | Virgin Aggregates Mix Gradation | Cooper “Target Gradation” |

|---|---|---|---|---|---|---|

| 28 | 100 | 100 | 100 | 100 | 100 | 100 |

| 20 | 100 | 100 | 100 | 83 | 97 | 100 |

| 14 | 100 | 100 | 96 | 8 | 86 | 85 |

| 10 | 100 | 87 | 11 | - | 74 | 72 |

| 6 | 99 | 6 | - | - | 56 | 58 |

| 4 | 92 | - | - | - | 50 | 47 |

| 2 | 67 | - | - | - | 37 | 33 |

| 1 | 42 | - | - | - | 23 | 23 |

| 0.425 | 19 | - | - | - | 11 | 15 |

| 0.300 | 14 | - | - | - | 8 | 12 |

| 0.150 | 7 | - | - | - | 4 | 8 |

| 0.075 | 4 | - | - | - | 2 | 5 |

References

- Salomon, D.R. Asphalt Emulsion Technology; Transportation Research Board: Washington, DC, USA, 2006. [Google Scholar]

- Ojum, C.; Kuna, K.; Thom, N.H.; Airey, G. An investigation into the Effects of Accelerated Curing on Cold Recycled Bituminous Mixes. In Asphalt Pavements—Proceedings of the International Conference on Asphalt Pavements, ISAP 2014; CRC Press: Raleigh, NC, USA, 2014; Volume 2, pp. 1177–1188. [Google Scholar]

- Oqueli, C.L. Laboratory Specimen Preparation for Cold Recycled Asphalt; Victoria University of Technology: Melbourne, Australia, 1997. [Google Scholar]

- Willis, R.; Tran, N.H. Bring Life Back to Aging. In Asphalt Pavement Magazine; National Asphalt Pavement Association: Washington, DC, USA, July 2015; pp. 36–41. [Google Scholar]

- Thanaya, I.E.A.; Zoorob, S.E.; Forth, J.P. A laboratory study on cold-mix, cold-lay emulsion mixtures. Proc. Inst. Civ. Eng. Transp. 2009, 162, 47–55. [Google Scholar] [CrossRef]

- Kandhal, R.B.; Mallick, P.S. Pavement Recycling Guidelines for State and Local Governments—Participant’s Reference Book; Report No. FHWA-SA-98-042; National Center for Asphalt Technology: Auburn, AL, USA, 1997. [Google Scholar]

- Thanaya, I.N.A. Review and recommendation of cold asphalt emulsion mixtures CAEMS design. Civ. Eng. Dimens. 2007, 9, 49–56. [Google Scholar]

- Oke, O.L.; Parry, T.; Thom, N.H.; Parry, T.; Thom, N.H. Fatigue Characteristics of Cold Recycled Bituminous Emulsion Mixtures Using the Nottingham Asphalt Tester in the ITFT Mode of Testing. In Proceedings of the Second International Conference on Advances in Civil, Structural and Mechanical Engineering—CSM 2014, Birmingham, UK, 16–17 November 2014; pp. 135–143. [Google Scholar]

- Al-jumaili, M.A.; Issmael, O.D. Sustainability of Cold Recycled Mixture with High Reclaimed Asphalt Pavement Percentages. Appl. Res. J. 2016, 2, 344–352. [Google Scholar]

- Barbod, B.; Shalaby, A. Laboratory Performance of Asphalt Emulsion Treated Base for Cold Regions Applications. In Proceedings of the 2014 Transportation Association of Canada (TAC) Conference, Montreal, QC, Canada, 28 September–1 October 2014; pp. 1–11. [Google Scholar]

- Gao, L.; Ni, F.J.; Yang, M.K. Mixed-mode fracture characteristics of cold recycling mixes with emulsified asphalt. Appl. Mech. Mater. 2012, 204–208, 1678–1683. [Google Scholar] [CrossRef]

- Tebaldi, G.; Dave, E.V.; Marsac, P.; Muraya, P.; Hugener, M.; Pasetto, M.; Graziani, A.; Grilli, A.; Bocci, M.; Marradi, A.; et al. Synthesis of standards and procedures for specimen preparation and in-field evaluation of cold-recycled asphalt mixtures. Road Mater. Pavement Des. 2014, 15, 272–299. [Google Scholar] [CrossRef]

- Twagira, L.J.; Jenkins, M.E.; Ebels, K.J. Characterisation of Fatigue Performance of Selected Cold Bituminous Mixes. In Proceedings of the 10th International Conference on Asphalt Pavements, Quebec City, QC, Canada, 12–17 August 2006; pp. 429–438. [Google Scholar]

- Tia, M.; Wood, L.E. Use of asphalt emulsion and foamed asphalt in cold-recycled asphalt paving mixtures. Transp. Res. Rec. 1983, 898, 315–321. [Google Scholar]

- Oke, O.O. A Study on The Development of Guidelines for the Production of Bitumen Emulsion; The University of Nottingham: Nottingham, UK, 2010. [Google Scholar]

- Serfass, J.P.; Poirier, J.E.; Henrat, J.P.; Carbonneau, X. Influence of curing on cold mix mechanical performance. Mater. Struct. Constr. 2004, 37, 365–368. [Google Scholar] [CrossRef]

- Asphalt Academy. Technical Guideline: Bitumen Stabilised Materials—A Guide for the Design and Construction of Bitumen Emulsion and Foamed Bitumen Stabilised Materials, 2nd ed.; Asphalt Academy: Pretoria, South Africa, 2009. [Google Scholar]

- Jitareekul, P. An Investigation into Cold In-Place Recycling of Asphalt Pavements; The University of Nottingham: Nottingham, UK, 2009. [Google Scholar]

- Ndinyo, C.S.; Gariy, Z.A.; Mulei, S.M. Suitability of reclaimed asphalt concrete as a cold mix surfacing material for low volume roads. Int. J. Eng. Adv. Technol. 2013, 3, 354–367. [Google Scholar]

- BSI. BS EN 13808: Bitumen and Bituminous Binders. Framework for Specifying Cationic Bituminous Emulsions; British Standards Institution: London, UK, 2005. [Google Scholar]

- Wirtgen. Wirtgen Cold Recycling Technology; Wirtgen GmbH: Windhagen, Germany, 2012. [Google Scholar]

- Nassar, A.I.; Mohammed, M.K.; Thom, N.; Nassar, A.I.; Mohammed, M.K.; Thom, N. Characterisation of high-performance cold bitumen emulsion mixtures for surface courses. Int. J. Pavement Eng. 2018, 19, 509–518. [Google Scholar] [CrossRef]

- Oruc, S.; Celik, F.; Akpinar, M.V. Effect of cement on emulsified asphalt mixtures. J. Mater. Eng. Perform. 2007, 16, 578–583. [Google Scholar] [CrossRef]

- Ling, C.; Hanz, A.; Bahia, H. Evaluating moisture susceptibility of cold-mix asphalt. Transp. Res. Rec. J. Transp. Res. Board 2014, 244, 60–69. [Google Scholar] [CrossRef]

- ASTM. ASTM C127-15, Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate; ASTM: West Conshohocken, PA, USA, 2012. [Google Scholar]

- BSI. BS 812-103.1 Testing Aggregates, Part 103: Methods for Determination of Particle Size Distribution; British Standards Institution: London, UK, 2002. [Google Scholar]

- BSI. BS EN 12697-1:2012: Bituminous Mixtures. Test Methods for Hot Mix Asphalts. Soluble Binder Content; BSI: London, UK, 2012. [Google Scholar]

- BSI. BS EN: 12697-3:2013-Bituminous mixtures—Test Methods for Hot Mix Asphalt: Part 3: Bitumen Recovery: Rotary Evaporator; BSI: London, UK, 2013. [Google Scholar]

- BSI. BS 2000:49-2007 Bitumen and Bituminous Binders—Determination of Needle Penetration; BSI: London, UK, 2007. [Google Scholar]

- BSI. BS EN 1427: Bitumen and Bituminous Binders-Determination of the Softening Point: Ring and Ball Method; BSI: London, UK, 2015. [Google Scholar]

- ASTM. ASTM D6934-08: Standard Test Method for Residue by Evaporation of Emulsified Asphalt; ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Asphalt Institute. Asphalt Cold-Mix Manual: Manual Series No. 14 (MS 14); Asphalt Institute: Lexington, KY, USA, 1977. [Google Scholar]

- Thanaya, I.N.A. Evaluating and improving the performance of cold asphalt emulsion mixes. Civ. Eng. Dimens. 2007, 9, 64–69. [Google Scholar]

- Thanaya, I.N.A. Utilization of Sustainable Materials in Cold Asphalt Emulsion Mixture for Lightly Trafficked Road. In Proceedings of the 6th International Student Conference at Ibaraki University ISCIU6, Ibaraki, Japan, 13–14 November 2010; pp. 1–12. [Google Scholar]

- Moloto, K.P. Accelerated Curing Protocol for Bitumen Stabilized Materials; Stellenbosch University: Stellenbosch, South Africa, 2010. [Google Scholar]

- Asphalt Institute. The Basic Emulsion Manual, Manual Series No. 19 (MS-19), 3rd ed.; Asphalt Institute: Lexington, KY, USA, 2004. [Google Scholar]

- Oke, O.L. Some guidelines for the production and use of cold recycled asphalts in hot tropical regions. Int. J. Dev. Sustain. 2013, 2, 998–1010. [Google Scholar]

- Ebels, L. Characterisation of Material Properties and Behaviour of Cold Bituminous Mixtures for Road Pavements; Stellenbosch University: Stellenbosch, South Africa, 2008. [Google Scholar]

- Ibrahim, H.E.-S.M. Assessment and Design of Emulsion-Aggregate Mixtures for Use in Pavements; The University of Nottingham: Nottingham, UK, 1998. [Google Scholar]

- BSI. BS 1377:1990-Compaction Using Vibrating Hammer; BSI: London, UK, 1990. [Google Scholar]

- Katman, H.Y.; Ibrahim, M.R.; Matori, M.Y.; Norhisham, S.; Ismail, N.; Omar, R.C. Tensile strength of reclaimed asphalt pavement. Int. J. Civ. Environ. Eng. 2012, 12, 14–19. [Google Scholar]

- Iwański, M.; Chomicz-kowalska, A. Application of Recycled Aggregates to the Road Base Mixtures with Foamed Bitumen in the Cold Recycling Technology. In Proceedings of the 9th International Conference on Environmental Engineering, Vilnius, Lithuania, 22–23 May 2014; pp. 1–8. [Google Scholar]

- ASTM. ASTM D6931-12: Standard Test Method for Indirect Tensile (IDT) Strength of Bituminous Mixtures; ASTM: Washington, DC, USA, 2012. [Google Scholar]

- Dash, S.S. Effect of Mix Parameters on Performance and Design of Cold Mix Asphalt; National Institute of Technology: Rourkela, India, 2013. [Google Scholar]

- AASHTO. AASHTO T 166-16: Standard Method of Test for Bulk Specific Gravity (Gmb) of Compacted Hot Mix Asphalt (HMA) Using Saturated Surface-Dry Specimens; AASHTO: Washington, DC, USA, 2016. [Google Scholar]

- Du, S. Performance characteristic of cold recycled mixture with asphalt emulsion and chemical additives. Adv. Mater. Sci. Eng. 2015, 2015, 1–9. [Google Scholar] [CrossRef]

- Buczyński, P.; Iwański, M. Fatigue life comparison of recycled cold mixes with foamed bitumen and with bitumen emulsion. Procedia Eng. 2017, 172, 135–142. [Google Scholar] [CrossRef]

- Ojum, C.K. The Design and Optimisation of Cold Asphalt Emulsion Mixtures; The University of Nottingham: Nottingham, UK, 2015. [Google Scholar]

- Maccarrone, S.; Holleran, G.; Leonard, D.J.; Hey, S. Pavement Recycling Using Foamed Asphalt. In Proceedings of the 17th ARRB Conference, Gold Coast, Australia, 15–19 August 1994; pp. 349–365. [Google Scholar]

- Kennedy, T.W.; Anagnos, J.N. Wet-Dry Indirect Tensile Test for Evaluating Moisture Susceptability of Asphalt Mixtures; Center for Transoportation Research, University of Texas at Austin: Austin, TX, USA, 1984. [Google Scholar]

- Oliviero Rossi, C.; Teltayev, B.; Angelico, R. Adhesion promoters in bituminous road materials: A review. Appl. Sci. 2017, 7, 524. [Google Scholar] [CrossRef]

| Size (mm) | 0/6 | 6/10 | 10/14 | 14/20 |

|---|---|---|---|---|

| Bulk Specific Gravity (kg/m3) | 2252 | 2339 | 2340 | 2365 |

| Water Absorption (%) | 4.4 | 3.2 | 3.0 | 2.2 |

| Size (mm) | 0/6 | 6/10 | 10/14 | 14/20 |

|---|---|---|---|---|

| Bulk Specific Gravity (kg/m3) | 2405 | 2485 | 2487 | 2491 |

| Water Absorption (%) | 5.5 | 2.3 | 2.4 | 1.5 |

| Chemical Composition | % in Reclaimed Asphalt Aggregates | % in Virgin Aggregates |

|---|---|---|

| SiO2 | 65.497 | 62.503 |

| Al2O3 | 22.870 | 23.267 |

| K2O | 4.746 | 4.866 |

| Fe2O3 | 3.132 | 3.212 |

| MgO | 1.970 | 3.712 |

| CaO | 0.942 | 1.061 |

| Ti | 0.370 | 0.283 |

| Mn | 0.152 | 0.503 |

| Cl | 0.018 | 0.203 |

| Others elements | 0.303 | 0.39 |

| Property | BS Designation | Test Result |

|---|---|---|

| Penetration (dmm) | BS 2000-49 | 16.3 |

| Softening Point (°C) | BS EN 1427 | 63.4 |

| Percentage in total mix (%) | BS EN 12697-1 | 4.1 |

| Property | ASTM/BS Designation | Test Result |

|---|---|---|

| Penetration (dmm) | BS 2000-49 | 58.25 |

| Softening Point (°C) | BS EN 1427 | 54.5 |

| Residue by distillation (%) | ASTM D6934 | 70.0 |

| Particle charge (litmus paper) | +ve |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chelelgo, K.; C. Abiero Gariy, Z.; Muse Shitote, S. Laboratory Mix Design of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt and Virgin Aggregates. Buildings 2018, 8, 177. https://doi.org/10.3390/buildings8120177

Chelelgo K, C. Abiero Gariy Z, Muse Shitote S. Laboratory Mix Design of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt and Virgin Aggregates. Buildings. 2018; 8(12):177. https://doi.org/10.3390/buildings8120177

Chicago/Turabian StyleChelelgo, Kiplagat, Zachary C. Abiero Gariy, and Stanley Muse Shitote. 2018. "Laboratory Mix Design of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt and Virgin Aggregates" Buildings 8, no. 12: 177. https://doi.org/10.3390/buildings8120177

APA StyleChelelgo, K., C. Abiero Gariy, Z., & Muse Shitote, S. (2018). Laboratory Mix Design of Cold Bitumen Emulsion Mixtures Incorporating Reclaimed Asphalt and Virgin Aggregates. Buildings, 8(12), 177. https://doi.org/10.3390/buildings8120177