2. Focus on Energy Efficiency

For some 40 years now the building sector has targeted energy “reduction” measures. At first packages of separate measures were introduced, such as making buildings and houses airtight, introducing double glazing and insulating floors and roofs. This was followed by a more integral approach, supported and stimulated by government regulation and legislation about methodology, setting mandatory targets in energy demand for houses and offices.

More recently a race has started to maximize the reduction in energy demand. Reduction has been brought to the extreme with the introduction of the so-called Passive House standard, requiring less than 15 kWh/m2 for heating.

In recent years an additional option has become widely available: energy generation by renewable sources. Off and on-site solar collectors for heating experienced a fast introduction in sunny countries like Greece and Israel, followed by a breakthrough for solar electricity panels, “Photovoltaic (PV) panels”, mainly because the Chinese were able to break open the protected industrialized world market for Photovoltaic panels with a rapid decrease of consumer prices.

Thus, a “double” approach to tackle fossil fuels became possible: reducing operational energy demand on one side and producing renewable energy to supply that reduced demand on site, on the other side, resulting in the quest for 0-energy houses and buildings. This combination will change the playing field drastically, and, as this paper will show, optimizing building designs for operational energy only has become sub-optimizing.

The exact definition of a 0-energy house is not the subject of this paper. It has been studied by many, among others by the International Energy Agency (IEA) annex 52 work, and an in depth analysis of the term was performed earlier by the author [

2,

3]. The definition that is used in this paper is that a 0-energy building produces as much renewable energy on site (

i.e., below or behind the building) as it requires operationally, with the electricity grid to balance overproduction and shortages due to seasonal and temporal differences.

The main reason for the initial race towards extreme energy reduction in buildings was, and still is, (the side effects of) the use of fossil fuels. The environmental impact on a global scale of fossil fuels consumption on a small scale and with low population levels might not be significant, but with a global population of 7 billion people (and growing) in combination with a fossil fuel based society, the notion has evolved that we are significantly disrupting our own appreciated environment, climate change being the most visible and threatening effect on a global scale. Other side effects include air pollution, by sulfur and nitrogen oxides, smog in the world’s cities, and air pollution by fine-dust, creating health problems. There are a range of other, often more local, negative side effects, such as large scale oil spills, tar sand extraction, mountain top removal, and virgin forest removal. These side effects ruin nature on a regular basis.

This is not to speak of causing wars, with oil and gas stocks as the major cause of clashes [

4]. In the end, we even face depletion of these fossil fuel resources, which would not only eliminate an energy resource, but create a problem in the production of other valuable products, for instance medicines and some plastics.

Despite the focus on energy efficiency, mankind has not been very successful in reducing fossil fuel use: up to today the demand is still on the rise. When assessing buildings it can be concluded that houses are heated more efficiently, but at the same time have largely increased in number and size eliminating the achievements while at the same time raising in required comfort standards. An Amsterdam canal-house in 1900 required the same amount of energy for heating as a well insulated Dutch reference house of the year 2000 [

5]. The difference is that the family in the Amsterdam canal house only heated one room, and only in the evening when all the family was sitting together. In the year 2000 all (and larger) rooms are heated for a comfortable 20 degrees all day long. The increase in efficiency is lost in rebound effects such as more heated space, higher temperatures and for longer periods [

6].

2.1. Energy and Materials Use

The race for ever more energy efficiency led to the development of the “Passive-house concept”. This original German approach, aims to reduce energy demand for heating as rigorously as possible, setting targets for new housing at less than 15 kWh/m

2 and at less than 25 kWh/m

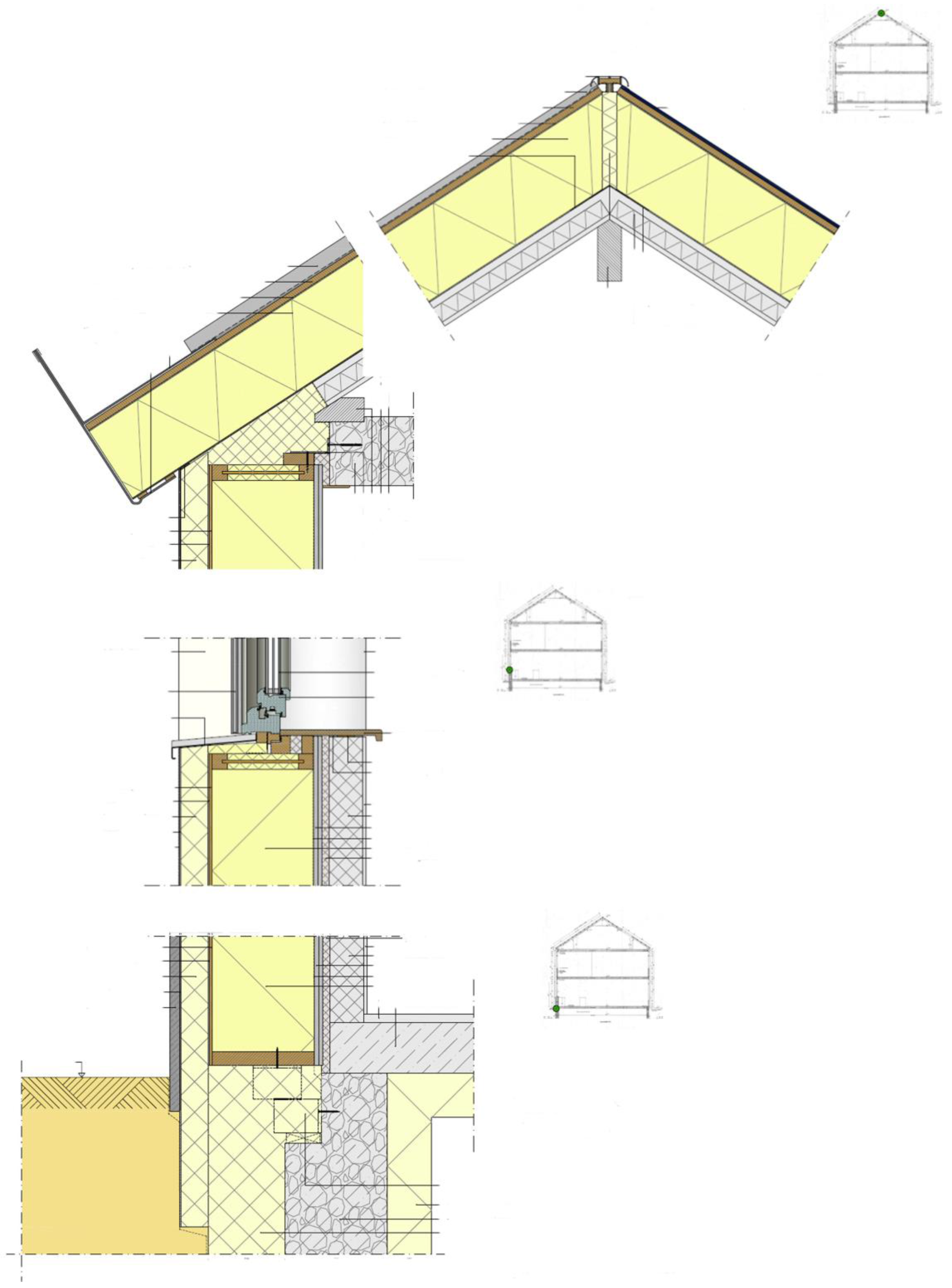

2 for existing, renovated dwellings. In order to reach these levels of efficiency, thick insulation packages are applied, of up to 40–50 cm with traditional materials, as well as extreme airtightness and cold bridge interruption (

Figure 1).

Consequently, extreme reduction measures require enormous amounts of materials investments. The (fossil) energy impacts are reduced, but at the cost of increasing material impacts.

It seems a logical approach, when the only aim is to reduce fossil fuel consumption, and the material consumption is left out of the evaluation.

To bridge the gap between this low energy demand and 0(-fossil fuels)-energy buildings, building connected renewable energy production is introduced, requiring additional installations and conversion devices like PV panels, inverters, solar heat collectors, heat storage tank, or aquifer devices, compared to centralized energy production.

Reaching 0-energy, therefore, implies two things change: firstly, fossil fuels (related impacts) have no relevance anymore in the evaluation of operational energy decisions, since there are none involved anymore; and secondly, the step from low (fossil demand) to 0 (fossil demand) requires a drastic increase in materials use. This is where the paradigm shift in approach starts: for 0-energy buildings, operational energy, in general, is not an issue of relevance anymore. Evaluating energy demand has become obsolete: the sole question resulting is that of optimizing materials related impacts.

Figure 1.

Passive house level renovation in a local project showing the large additional layer of materials needed for energy reduction only (yellow) [

7]

Figure 1.

Passive house level renovation in a local project showing the large additional layer of materials needed for energy reduction only (yellow) [

7]

This requires a complete shift in focus for environmental optimization of our buildings, geared towards a minimal balance between demand and production, in materials impact.

In fact, energy demand for a 0-energy house does not imply in any way a low energy level. The energy balance can exist at any level, low, average or high demand: The balance between demand and supply is determined by the lowest impact of the combined material investments in demand reduction and supply devices and materials.

The situation is best illustrated with imagining the design of a new building: Why in the conceptual design phase, would you start with insulation levels and wall thickness, when no fossil fuel based energy is planned to be used? Reducing (operational energy) emissions is not a target. They (the emissions) are absent by definition. As a designer you will have to start finding ways to maximize energy generation on site, and use the productive/conversion elements in the design. From there, the next step is to find out how much of the possible demand can be covered. From there, the balancing act begins: finding the optimum between materials to reduce energy consumption and materials to produce energy.

This paradigm shift has consequences for the way in which we assess buildings, the way we measure and value energy impacts, and ultimately how legislation is developed.

2.2. Energy Reduction versus Energy Production

A first observation is, that in case of 0-energy buildings, the energy quest, related to the environmental impacts of fossil fuels, is limited to fossil fuels used to harvest and produce materials and products for buildings.

Fossil energy embodied in materials and products will become the only contributor to climate change and fuel depletion from buildings. The focus therefore shifts to embodied energy (from still fossil fuels), and material impacts in the broad sense. To create/construct “m² of shelter” a basic level of materials consumption is unavoidable, however, in order to optimize the energy-impact performance of that building, by means of the input of materials to limit energy demand or increase energy production on site, has now become a materials balance question. How much materials, is invested for energy demand reduction, and how much for on-site energy production? More of one decreases the need for the other, and vice versa. The main question is: Where is the balance?

A Dutch national reference terraced house of the 1970s was chosen to explore this balance in retrofitting the house for a 0-energy performance [

8]. To reduce energy demand four possible levels of insulation were defined: (1) no insulation; (2) cavity wall insulation plus floor and roof between beams; (3) one level of outside skin insulation added; (4) second extra layer of outdoor insulation, requiring a supporting framework. This leads to four levels of (reduced) energy demand. To reach the 0-energy performance status, a certain amount of m² PV has to be installed, depending on the level of insulation and remaining heating demand. This leads to four combined packages: the amount of materials for insulation going up, the amount of materials for PV panels going down. The resulting calculation showed that the optimal strategy is to only insulate the cavity wall (40 mm). The optimal balance, in terms of lowest embodied energy for the combined materials input (insulation for reduction and solar panels for production) turns out to be at the second highest level of operational energy.

The total required operational energy decreases with each step, unmistakably, but that is not relevant because it is solar radiation! This operational energy is included in the PV panels: using PV panels, the material/product comes inclusive with free non-polluting energy output. So it is no issue anymore in the evaluation, and only embodied energy (from fossil fuels) is the fair impact evaluation (energy wise).

Even if we include (materials for) on site storage of energy (instead of using the (free-riding) grid for balancing energy), and accept losses in conversion steps, the optimum remains level 2 (cavity wall insulation).

More calculations have to be made for different cases, but the trend is obvious: only optimizing for operational energy is sub-optimizing: the materials impacts have become the decisive factor.

With (energy embodied in) materials becoming a main material related decisive factor for fossil fuels related CO2 emissions, a subsequent question could be, can we develop a “0-embodied energy building”, in other words, a 0-fossil-fuels-embodied-energy building, as an addition to the 0-fossil-fuels-operational-energy building?

4. Materials: A Broader Perspective

Besides the focus on embodied energy, (being the remaining fossil fuel based fraction), the use of materials resources itself has many impacts: depletion of (re-)sources, pollution by production processes , and not to forget the so called “rucksack” effects: to mine materials comes with side effects like biotic and abiotic resource investments, air and water use, land degradation,

etc. [

8]. The availability of materials has never been part of the main discussion in the building sector, or the side effects. In the light of the 0-energy paradigm shift they will, however, become the major issue to address. This coincides with current developments in global materials stocks, which will require changes in materials treatment.

There are many discussions amongst scientists whether we will run out of (some of our) resources through current consumption patterns [

12], sometimes related to money, sometimes related to geopolitical situations, sometimes based on the assumptions of still to discover large quantities [

13,

14].

However, for many important metals and minerals the situation is actually getting critical, since ore grades are reducing steadily, all over the world [

15], and have sometimes reached 0.5%, while coming from a 2%–5% grade. There are not much signs for improvement, as can be seen by the discovery rates of new mining areas [

16]. With population and consumption growing, the situation will only get worse. Even more threatening is the fact that this seems a trend for all metal sources. These all show the same trend in decreasing ore grades. This implies that the amount of energy invested in mining and treating ores is increasing fast. The current ore grade of 0.5% requires ~100 MJ/ton copper, which is more or less double from that of ore grade of 1% [

17]. From 0.5 to 0.25, this will double again. So the point is not only scarcity, but concentration levels, directly influencing the power input to make more and more diluted resources available.

This requires industry to increase energy input to make materials available, which implies that embodied energy per unit product is not a fixed amount, but over time progressively growing per unit of material due to ore grade dilution. Whether that will be fossil energy or renewable energy is not so relevant: the first has nasty side effects and depletes, the other requires—again—large material inputs for capture and conversion devices. Even if industry would succeed in producing more and more with renewable energy, this again will require lots of materials for renewable energy generation (PV panels, wind turbines, etc.). The materials consumption is to be seen as a runaway process.

There are a few strategies that provide a way out of this rebound effect from 0-energy building:

- -

Reorganization of functions and services;

- -

Reducing the amount of materials consumption;

- -

The use of renewable materials: These (can) have no depletion effects (if regenerated), come with a smaller rucksack effect and on average lead to a lower embodied energy (for providing the same function). In fact it comes down to the same strategy we applied for years for the (operational) energy quest, but now solely targeted for materials: reduction and use of renewables;

- -

Reuse and recycling.

The most important and effective strategy is changing the way services are provided. A case study in a regional neighborhood seemed to point to the impossibility of reaching a 0-target for an existing urban district, while maintaining all the functions and services that people were used to. Rethinking the way the district functioned, revealed that many functions could be provided with the same outcome, but using a different strategy, as, for instance, for cleaning clothes. The solution is not in more energy efficient laundry machines, individually in each house, to reduce energy demand, but in laundry shops at district level: making all laundry machines (and their materials and energy burden) obsolete, and replaced by one, more industrial sized type. It also adds to local employment (with a zero energy pick up and delivery service). It decreases the energy and materials impacts combined, while maintaining the desired service: cleaning cloth. More options have been identified in this research [

18].

An example of a reduction strategy is the one that was investigated in the 1980s, when energy efficiency had just been launched as a topic: it was about compartmentalization of houses: during a cold winter period it was seen as wise not to heat the whole house, but only main living areas. It could become the main strategy again, when we start optimizing 0-energy approaches in the sense described above.

The third option is change to renewable resources, also known currently as “biobased building”. It has growing interest and formal and governmental policies already addressed this approach. Renewable and or biobased materials have in general a much lower embodied energy, and rucksack effects are much lower on average as well. Average contemporary housing is around 5 GJ/m

2 floor embodied energy [

19,

20] while a mainly renewable materials based house can go down to 3 GJ/m

2 and even lower [

9,

21]. The IEA-SBC annex 57 working group recently established is especially addressing the use of embodied energy data for practitioners. Part of the work is bringing together literature and cases with embodied energy calculations [

22].

Recycling and re-use are well known options. They do, however, not fully replace the impacts from new virgin resources. More research will be required when it comes to deciding how to deal with the first time use impacts: recycled materials are in principle nothing else than prolonged use, decreasing the impact per unit of service in time, but not free of impact [

23].

5. Consequences for Assessment

The trend for 0-energy buildings will influence how buildings, and more in detail energy and materials performances of buildings, need to be evaluated. A few of the consequences for assessment methods and common indicators are discussed here.

5.1. CO2

CO2 emissions are a side-effect from (fossil) energy use, and are currently used as a favorite structuring indicator. Focusing on CO2 emissions as parameters for improvement is focusing on an end of pipe effect from a specific cause. A cause, fossil fuel use, that has more indirect effects: for instance resource depletion. CO2 focused approaches, can for instance lead to carbon capture and storage (CCS): in that case you score on reduction of CO2, (and limit climate change possibly) but this has no effect regarding all other effects of the same cause, like (fossil) fuel depletion. This is in two ways not very wise: CCS is an end of pipe approach neglecting cause (and not even a real solution, it is “sweeping the dirt under the carpet”, one day you will have to confront yourself with it again—compare this with nuclear waste), and secondly resources are still depleted, (and wars fought over it remain).

Not to mention that more and more discussion is ongoing about the fact that CO

2 (reduction) is not the effective measure to fight climate change that it was thought to be [

24].

As the example of the 0-energy buildings paradigm shift shows, it is however of no use even to continue to address the CO2 measure as the guiding principle for building evaluation. It might reduce CO2 emissions, but not fossil fuel use, and overlooks the fact that the materials balance becomes guiding instead of operational energy. It makes no sense to assess a 0-energy building in terms of CO2 for operational energy.

5.2. Primary Energy

Primary energy has been developed as a way to calculate system optimization from an energy point of view, assuming a limited system (for instance a building) and assuming fossil fuels are available and referred to as the highest energy density input. The “impact history” of fossil fuels is left out of the evaluation: fossil fuels are renewable energy as well, since they originate from biomass. Primary energy may have worked in the past century, but since we will be running out of fossil fuels, and are in a global transition towards 100% renewable energy by 2050 (if all goes well), with buildings at the forefront of running only on renewable energy, it is counterproductive and outdated to continue referring to primary (fossil) energy: calculations should be based on final energy, and how this can be provided with renewable sources. We would even like to make the case here to reverse it and relate it to prime solar radiation, to make a scientific proper comparison. First steps in that direction have been made already by Odum in the 1980s, known as the “Emergy” approach [

25,

26], and recently by our research group, known as the “Maxergy” approach using Embodied Land© as indicator. In this “Maxergy” project, materials (depletion and compensation) are introduced into the equation, with land use (to make “exergy” available via solar radiation) as the common denominator [

27]. More work has to be done in this field.

5.3. Towards a New Assessment Methodology

In summary: As we want to become independent from fossil fuels somewhere towards 2050, we always have to optimize from an energy and materials combined evaluation, in which energy is in all cases provided with renewable energy. Ergo, the energy as such is not the issue, but the materials invested to reduce demand and harvest the renewable energy, for producing conversion devices. The whole optimization comes down to a materials evaluation. Besides the consequences for construction and production as above described, this has significant implications for many established evaluation approaches.

With the transition towards renewable energy and soon accompanied by a focus at renewable/biobased materials, the old reference model of CO2 and primary energy will be obsolete. Assessment has to go through a transition as well.

- -

For most prevailing assessment tools, the development towards 0-energy buildings and better, will require a re-focus on the actual parameters measured, and how they are integral valued without weighing factors.

- -

An even more drastic change would be the practice of using benchmark buildings: many assessment tools refer to a benchmark building, and measure relative improvement form this past. This, however, has been designed and optimized from a fossil fuel optimized design perspective. The playing field has changed, and therefore the benchmark has to change as well: assessments should shift from relating to an old benchmark, with outdated references, to measuring how far of the building’s performance is from the 0-situation. This will require the calculation the materials balance, knowing that, even if the building is not 0-energy today, somewhere in future it will be. Focusing today on only fossil fuels or CO2 (-benchmarks), leads to sub-optimization, with devastating effects for the materials impacts and stocks.

- -

Data currently in use to evaluate materials and products have to be adapted. As argued before, the data are mostly given in primary energy. This is hindering the shift in approach, since it makes it difficult to compare solar energy-based activities with fossil fueled activities. Since the transition toward renewable energy will count for all energy used, the data should become available in final or end use energy for any function, to be able to compare the required input from solar radiation (and related material impacts). If not, we will continue measuring with two different systems, and delay transition enormously. If the data are shown in end use energy, both ways of calculation are possible, with the primary energy approach being phased out gradually.

5.4. Policies and Legislation

The transition will also affect the way we enforce developments with legislation. The mandatory Energy Performance Coefficient (EPC) in the Netherlands is further strengthened by January 2015 from 0.6 to 0.4 (requiring another 50% increase in efficiency). However, focusing only on energy is shifting an enormous burden to the materials part. Its intended that in future this EPC goes to 0, but again, without addressing the materials impact. As we argued in this paper, reducing energy demand is not the issue anymore when fossil fuels are no longer involved in operational energy. The EPC has done its work over the past years, but should be replaced with a materials indicator, in order to avoid increasing environmental impact overall instead of reducing only energy demand.

A similar issue is at stake with the European Union (EU) legislation, more specifically, the directive known as the Energy Performance of Buildings Directive (EPBD) recast, dating from 2010, which requires countries to take measures to be implemented by 2018 and beyond [

1]. The directive requires that all public buildings from 2018 on, and all other buildings from 2020 on, should be (near) 0-energy. The article 2 in the EPBD states that [

1]:

“Nearly zero-energy building” means a building that has a very high energy performance. The nearly zero or very low amount of energy required should be covered to a very significant extent by energy from renewable sources, including energy from renewable sources produced on-site or nearby.

The term “nearly” will cause much discussion, as it has already in many EU countries preparing for this. However, that is not the main point, since in due time the near-0 will become real-0 anyhow. More worrying is where it states “very low amount of energy required” to be “covered significantly by renewables”. In going to 0-energy and beyond, it has been shown that low energy demand is not the right focus anymore, and a guarantee for sub optimizing environmental impact approaches overall is more important. It is even more worrying knowing that the EU is developing strong policies targeted at materials, has a biobased materials road map, and is preparing a method to value materials with footprint style indicators. Separating the policies for energy and material creates friction and does not lead to the intended lower environmental impact, overall.

A practical solution for EU countries could be to require buildings (and renovations) to be designed as real 0-energy buildings (with the balanced materials approach), and in construction leave some room for partial implementation of the design, for instance due to limited investment possibilities. The building could be completed without PV panels, but prepared for it when additional funds become available in future, thereby avoiding sub optimization and disinvestments.