Contractor-Based Evaluation of Construction Cost Overrun Factors Using Matrix Analysis

Abstract

1. Introduction

2. Literature Review

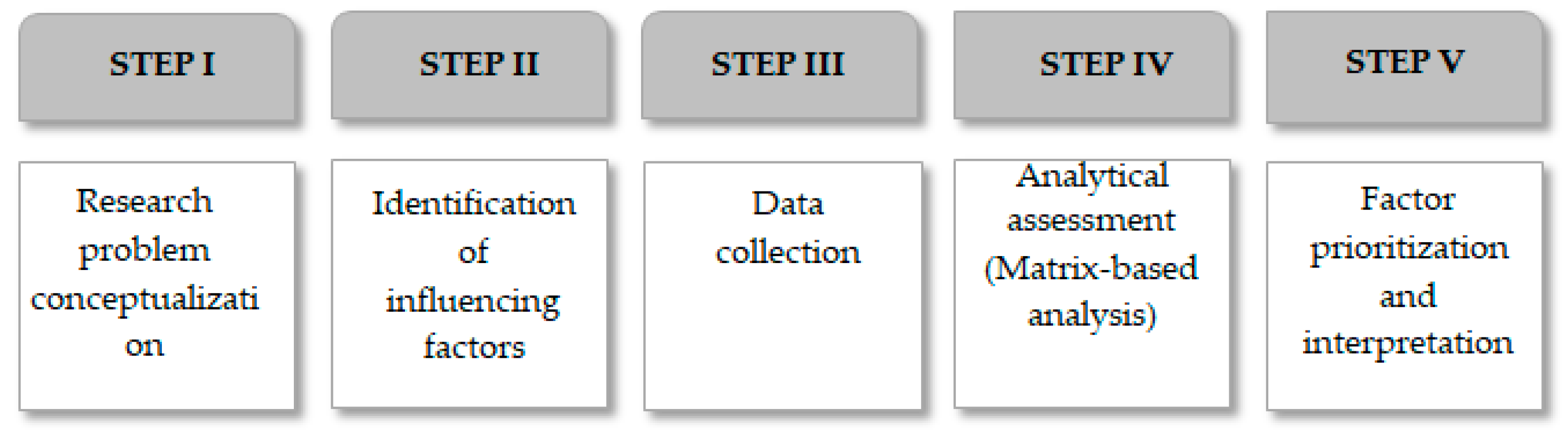

3. Research Methodology

4. Results

4.1. General Data of Construction Cost Overruns

4.2. Evaluate the Factor for Each Pairwise Combination

5. Discussions

5.1. A #1 Ranking Factor: Labor Shortages

5.2. A #2 Ranking Factor: Variation Order

5.3. A #3 Ranking Factor: Financial Capacity

5.4. A #4 Ranking Factor: Material Price Fluctuation

5.5. A #5 Ranking Factor: Drawing Conditions

5.6. A #6 Ranking Factor: Material Shortages

5.7. A #7 Ranking Factor: Government Requirement

5.8. A #8 Ranking Factor: Management Conditions

5.9. A #9 Ranking Factor: Poor Maintenance of the Machine

5.10. A #10 Ranking Factor: Poor Communication

5.11. A #11 Ranking Factor: Facilities and Space Available

5.12. A #12 Ranking Factor: Unsafe Working Conditions

5.13. A #13 Ranking FACTOR: Unpredictable Weather and Protests

6. Conclusions

- The 13 critical factors that a contractor prioritizes are labor shortages, variation order, financial capacity, material price fluctuation, drawing conditions, material shortages, government requirement, management conditions, poor maintenance of the machine, poor communication, facilities and space available, unsafe working conditions, and unpredictable weather and protests. These factors led 40 construction contractor companies to incur construction cost overruns on four residential-type projects: high-rise condominium, low-rise condominium, single-family home, and townhouse.

- The five factors are the significant causes impacting construction cost overruns due to the average high percentage and importance weight. Labor shortages, variation in order, financial capacity, material price fluctuations, and drawing conditions are the top five factors ranked in order of importance, with weights of 0.1687, 0.1262, 0.1029, 0.0956, and 0.0827, respectively. These five factors had average cost overrun percentages of 18.3%, 15.7%, 12.8%, 10.2%, and 9.0%, respectively. The significant factors that impact construction cost overruns will be considered to guide contractor companies in sequential processing.

- To mitigate construction cost overruns, contractors should prioritize strategies for improving labor retention and recruitment, including enhancing wage stability and working conditions, as the labor shortage significantly impacts project timelines and financial outcomes.

- The construction industry should advocate for more flexible regulatory frameworks for migrant labor, ensuring compliance with labor standards while addressing the structural constraints of labor availability in Bangkok’s competitive market, ultimately leading to more efficient project delivery.

- This study demonstrates that empirical managerial attitudes influencing construction cost overruns can be systematically ranked using a matrix analysis method, extending prior descriptive and causal research toward actionable decision-support. The ranked results provide practical guidance for contractors in prioritizing labor management, variation order control, financial capacity planning, material price risk mitigation, and design coordination.

- While the empirical evidence is derived from residential construction projects in Bangkok and metropolitan areas of Thailand, the proposed matrix-based framework is transferable to other construction markets, subject to contextual calibration across different project types, locations, and institutional settings.

- The study focuses on large contractors and residential projects, which may limit generalizability across stakeholders, project scales, and regions. Future research should apply the framework to other construction sectors, stakeholder groups, and geographical contexts to enhance robustness and external validity.

7. Research Limitations

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

- How many years of experience do you have in construction contracting business, specifically in residential construction projects?

- 2.

- What type of project will you be providing information about?

- ⎕

- High-rise condominium

- ⎕

- Low-rise condominium

- ⎕

- Single-family home

- ⎕

- Townhouse

- 3.

- The contract value of a project was…………………………….… Thai Bath

- 4.

- The actual cost of work paid for a project was…………………. Thai Bath

- 5.

- The total of project cost overrun was………………….% divided into the factors of,

- -

- Variation order……………………………………%

- -

- Drawing conditions………………………………%

- -

- Management conditions…………………………%

- -

- Material shortages………………………………..%

- -

- Labor shortages…………………………………...%

- -

- Poor maintenance of the machine………………%

- -

- Financial capacity…………………………………%

- -

- Unpredictable weather and protests……………%

- -

- Poor communication……………………………...%

- -

- Government requirement………………………..%

- -

- Material price fluctuation………………………..%

- -

- Facilities and space available…………….……...%

- -

- Unsafe working conditions……………….……..%

| Pairs | Factors | High  Low Low | Equal | Low  High High | Factors | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Drawing conditions |

| 2 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Management conditions |

| 3 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material shortages |

| 4 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Labor shortages |

| 5 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor maintenance of the machine |

| 6 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Financial capacity |

| 7 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 8 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 9 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 10 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 11 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 12 | Variation order | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 13 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Management conditions |

| 14 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material shortages |

| 15 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Labor shortages |

| 16 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor maintenance of the machine |

| 17 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Financial capacity |

| 18 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 19 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 20 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 21 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 22 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 23 | Drawing conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 24 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material shortages |

| 25 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Labor shortages |

| 26 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor maintenance of the machine |

| 27 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Financial capacity |

| 28 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 29 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 30 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 31 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 32 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 33 | Management conditions | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 34 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Labor shortages |

| 35 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor maintenance of the machine |

| 36 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Financial capacity |

| 37 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 38 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 39 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 40 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 41 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 42 | Material shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 43 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor maintenance of the machine |

| 44 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Financial capacity |

| 45 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 46 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 47 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 48 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 49 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 50 | Labor shortages | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 51 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Financial capacity |

| 52 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 53 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 54 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 55 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 56 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 57 | Poor maintenance of the machine | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 58 | Financial capacity | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unpredictable weather and protests |

| 59 | Financial capacity | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 60 | Financial capacity | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 61 | Financial capacity | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 62 | Financial capacity | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 63 | Financial capacity | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 64 | Unpredictable weather and protests | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Poor communication |

| 65 | Unpredictable weather and protests | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 66 | Unpredictable weather and protests | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 67 | Unpredictable weather and protests | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 68 | Unpredictable weather and protests | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 69 | Poor communication | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Government requirement |

| 70 | Poor communication | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 71 | Poor communication | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 72 | Poor communication | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 73 | Government requirement | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Material price fluctuation |

| 74 | Government requirement | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 75 | Government requirement | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 76 | Material price fluctuation | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Facilities and space available |

| 77 | Material price fluctuation | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

| 78 | Facilities and space available | 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | Unsafe working conditions |

References

- Trangkanont, S.; Wichaiphruek, T.; Yongkiadtikan, K.; Wannasiriwong, P.; Uttaraphon, P. Root causes of construction project disputes in Thailand. Int. J. Concept. Mech. Civ. Eng. 2016, 4, 2357–2752. [Google Scholar]

- Nguyen, V.T.; Do, S.T.; Tran, C.N.N.; Van Pham, L. Analysis of interrelationships among constructs of cost overrun causes in consortium projects between construction contractors. Int. J. Constr. Manag. 2025, 25, 1596–1608. [Google Scholar] [CrossRef]

- Abdelalim, A.M.; Salem, M.; Salem, M.; Al-Adwani, M.; Tantawy, M. An analysis of factors contributing to cost overruns in the global construction industry. Buildings 2025, 15, 18. [Google Scholar] [CrossRef]

- Ghosh, S.; Jintanapakanont, J. Identifying and assessing the critical risk factors in an underground rail project in Thailand: A factor analysis approach. Int. J. Proj. Manag. 2004, 22, 633–643. [Google Scholar] [CrossRef]

- Ogunlana, O.S.; Promkuntong, K.; Jearkjirm, V. Construction delays in a fast-growing economy: Comparing Thailand with other economies. Int. J. Proj. Manag. 1996, 14, 37–45. [Google Scholar] [CrossRef]

- Héctor, A.; Ignacio, M.; Bautista, L.F. Analysis of causes of delays and cost overruns as well as mitigation measures to improve profitability and sustainability in turnkey industrial projects. Sustainability 2023, 16, 1449. [Google Scholar] [CrossRef]

- Kog, Y.C. Construction delays in Indonesia, Malaysia, Thailand, and Vietnam. Pract. Period. Struct. Des. Constr. 2019, 24, 04019013. [Google Scholar] [CrossRef]

- Ayudhya, N.; Israngkura, B. Common disputes related to public work projects in Thailand. Songklanakarin J. Sci. Technol. 2011, 33, 565–573. [Google Scholar]

- Sheamar, S.; Wedawatta, G.; Tennakoon, M.; Palliyaguru, R.; Antwi-Afari, M.F. The potential of new models of construction procurement to counter cost overruns in construction projects: An exploratory study from a contractors’ perspective. J. Financ. Manag. Prop. Constr. 2024, 29, 211–228. [Google Scholar] [CrossRef]

- Toor, R.S.; Ogunlana, O.S. Critical COMs of success in large-scale construction projects: Evidence from Thailand construction industry. Int. J. Proj. Manag. 2008, 26, 420–430. [Google Scholar] [CrossRef]

- Saaty, L.T. Decision making with the analytic hierarchy process. Int. J. Serv. Sci. 2008, 1, 83–98. [Google Scholar] [CrossRef]

- Katre, Y.V.; Ghaitidak, M.D. Elements of cost and schedule overrun in construction projects. Int. J. Eng. Res. Dev. 2016, 12, 64–68. [Google Scholar]

- Olatunde, A.N.; Alao, O.O. Quantitative appraisal of cost and time performance of construction projects in public and private universities in Osun State, Nigeria. J. Eng. Des. Technol. 2017, 15, 619–634. [Google Scholar] [CrossRef]

- Adam, A.; Josephson, B.E.P.; Lindahl, G. Aggregation of factors causing cost overruns and time delays in large public construction projects trends and implications. Eng. Constr. Arch. Manag. 2017, 24, 393–406. [Google Scholar] [CrossRef]

- Senouci, A.; Ismail, A.; Eldin, N. Time delay and cost overrun in Qatari public construction projects. Procedia Eng. 2016, 164, 368–375. [Google Scholar] [CrossRef]

- Anibire, S.O.M.; Zin, M.R.; Olatunji, O.S. Machine learning model for delay risk assessment in tall building projects. Int. J. Constr. Manag. 2020, 22, 2134–2143. [Google Scholar] [CrossRef]

- Doloi, H. Cost overruns and failure in project management: Understanding the roles of key stakeholders in construction projects. J. Constr. Eng. Manag. 2013, 139, 267–279. [Google Scholar] [CrossRef]

- Heravi, G.; Mohammadian, M. Investigating cost overruns and delay in urban construction projects in Iran. Int. J. Constr. Manag. 2019, 21, 958–968. [Google Scholar] [CrossRef]

- Famiyeh, S.; Amoatey, T.C.; Adaku, E. Major causes of construction time and cost overruns A case of selected educational sector projects in Ghana. J. Eng. Des. Technol. 2017, 15, 181–198. [Google Scholar]

- Sweis, J.G.; Sweis, R.; Rumman, A.M.; Hussein, A.R.; Dahiyat, E.S. Cost overruns in public construction projects: The case of Jordan. J. Am. Sci. 2013, 9, 134–141. [Google Scholar]

- Muneeswaran, G.; Manoharan, P.; Awoyera, O.P.; Adesina, A. A statistical approach to assess the schedule delays and risks in Indian construction industry. Int. J. Constr. Manag. 2020, 20, 450–461. [Google Scholar] [CrossRef]

- Niazi, A.G.; Painting, N. Significant factors causing cost overruns in the construction industry in Afghanistan. Procedia Eng. 2017, 182, 510–517. [Google Scholar] [CrossRef]

- Dong, S.; Ahmed, M.; Chatpattananan, V. Analysis of key factors of cost overrun in construction projects based on structural equation modeling. Sustainability 2025, 17, 2119. [Google Scholar] [CrossRef]

- Vaardini, S. Study on cost overruns in construction projects—A review. Int. J. Appl. Eng. Res. 2016, 11, 356–363. [Google Scholar]

- Shehu, Z.; Endut, R.I.; Akintoye, A.; Holt, D.G. Cost overrun in the Malaysian construction industry projects: A deeper insight. Int. J. Proj. Manag. 2014, 32, 1471–1480. [Google Scholar] [CrossRef]

- Shehu, Z.; Endut, R.I.; Akintoye, A. Factors contributing to project time and hence cost overrun in the Malaysian construction industry. J. Financ. Manag. Prop. Constr. 2014, 19, 55–75. [Google Scholar] [CrossRef]

- Polat, G.; Okay, F.; Kray, E. Factors effective cost overruns in micro-scaled construction companies. Procedia Eng. 2014, 85, 428–435. [Google Scholar] [CrossRef]

- Elawi, G.S.A.; Algahtany, M.; Kashiwagi, D. Owners’ perspective of factors contributing to project delay: Case studies of road and bridge projects in Saudi Arabia. Procedia Eng. 2016, 145, 1402–1409. [Google Scholar] [CrossRef]

- Gardezi, S.S.S.; Manarvi, A.I.; Gardezi, S.J.S. Time extension factors in construction industry of Pakistan. Procedia Eng. 2014, 77, 196–204. [Google Scholar] [CrossRef]

- Plebankiewicz, E. Model of predicting cost overrun in construction projects. Sustainability 2018, 10, 4387. [Google Scholar] [CrossRef]

- Saidu, I.; Shakantu, W. An investigation into cost overruns for ongoing building projects in Abuja, Nigeria. Acta Structilia 2017, 24, 53–72. [Google Scholar] [CrossRef]

- Hurlimann, C.A.; Warren-Myers, G.; Browne, R.G. Is the Australian construction industry prepared for climate change. Build. Environ. 2019, 153, 128–137. [Google Scholar] [CrossRef]

- Afana, O.; Al Zubaidi, R.; Abu Dabous, S.; Ibrahim, F. Categories and factors of cost overrun in construction projects: A systematic review. Eng. Technol. Appl. Sci. Res. 2024, 14, 18330–18347. [Google Scholar] [CrossRef]

- Frimpong, Y.; Oluwoye, J.; Crawford, L. Causes of delay and cost overruns in construction of groundwater projects in a developing countries; Ghana as a case study. Int. J. Proj. Manag. 2003, 21, 321–326. [Google Scholar] [CrossRef]

- Rauzana, A. Factors causing cost overruns in construction projects. Int. J. Eng. Technol. Manag. Res. 2022, 9, 1–9. [Google Scholar] [CrossRef]

- Wu, Q.; Khatibi, A.; Tham, J. Study on the factors affecting construction project cost overrun. Int. J. Glob. Econ. Manag. 2025, 6, 53–59. [Google Scholar] [CrossRef]

- Ramadhan, J.S.; Waty, M. Impact of change orders on cost overruns and delays in large-scale construction projects. Eng. Technol. Appl. Sci. Res. 2023, 15, 20291–20299. [Google Scholar] [CrossRef]

- Sohu, S.; Md Kassim, T.R.; Sohu, N.; Loganathan, K. Critical factors affecting cost and time overrun of construction projects in Pakistan. Int. J. Sustain. Constr. Eng. Technol. 2024, 15, 221–232. Available online: https://penerbit.uthm.edu.my/ojs/index.php/ijscet/article/view/21044 (accessed on 25 January 2026).

- Xie, W.; Deng, B.; Yin, Y.; Lv, X.; Deng, Z. Critical factors influencing cost overrun in construction projects: A fuzzy synthetic evaluation. Buildings 2022, 12, 2028. [Google Scholar] [CrossRef]

- Daoud, A.O.; El Hefnawy, M.; Wefki, H. Investigation of critical factors affecting cost overruns delays in Egyptian mega construction projects. Alex. Eng. J. 2023, 83, 326–334. [Google Scholar] [CrossRef]

- Wu, Q. Research on the influencing factors of cost overruns in construction projects. Int. J. New Dev. Eng. Soc. 2024, 8, 18–23. [Google Scholar] [CrossRef]

| Key Factors Highlighted | Authors | Countries |

|---|---|---|

| Contractor-related: | ||

| The contractor lacks financial liquidity, improper planning, insufficient knowledge to manage a construction project, poor performance, a shortage of manpower, experience, and qualifications, and a delay in material supply. | [2,3,6,9,12,13,14,19,20,23,24,25,27,30,31,33,35,36,37,38,40,41] | Nigeria, Kuwait, Australia, Vietnam, Thailand, Indonesia, Malaysia, UK, Egypt, India, Ghana, Turkey, South Africa, Jordan, and Pakistan |

| Designer- and consultant-related: | ||

| The designer’s lack of extra details in the blueprint, the delay in checking and ratifying design documents, and the consultant’s shortage of staff and an unsuitable bidding system. | [3,12,27,33,39] | India, Turkey and China |

| Owner-related: | ||

| The owner needs to change the design, acquire the land, and address the payment delay. | [2,6,12,19,20,26,27,28,30,33,36,38,40,41] | Malaysia, Jordan, Ghana, Turkey, Saudi Arabia, India Vietnam, Egypt and Pakistan |

| Unpredictable factor-related: | ||

| Climate change and domestic problems such as political protestation, terrorism, etc. | [2,17,23,29,32,33,38,39] | Vietnam, Thailand, China, Pakistan and Australia |

| Intensity of Importance | Definition | Explanation |

|---|---|---|

| 1 | Equal importance | Two factors contribute equally to the objective. |

| 3 | Somewhat more important | Experience and judgment are slightly in favor of one over the other. |

| 5 | Much more important | Experience and judgment strongly favor one over the other. |

| 7 | Very much more important | Experience and judgment very strongly favor one over the other. Its importance is demonstrated in practice. |

| 9 | Absolutely more important | The evidence favoring one over the other is of the highest possible validity. |

| 2, 4, 6, 8 | Intermediate values | When compromise is needed. |

| N | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 |

| RI | 0.00 | 0.00 | 0.58 | 0.90 | 1.12 | 1.24 | 1.32 | 1.41 | 1.45 | 1.49 | 1.51 | 1.48 | 1.56 | 1.57 | 1.59 |

| Residential Types and No. | Project Cost Overruns (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | Average | |

| High-rise condominium | 112 | 132 | 105 | 121 | 182 | 124 | 109 | 147 | 151 | 116 | 129.9 |

| Low-rise condominium | 130 | 110 | 118 | 125 | 114 | 142 | 117 | 122 | 130 | 127 | 123.5 |

| Single-family home | 165 | 109 | 148 | 110 | 114 | 106 | 153 | 135 | 119 | 125 | 128.4 |

| Townhouse | 105 | 123 | 114 | 118 | 116 | 139 | 141 | 128 | 111 | 109 | 120.4 |

| Factors | Cost Overruns (%) | ||||

|---|---|---|---|---|---|

| High-Rise Condominium | Low-Rise Condominium | Single-Family Home | Townhouse | Average | |

| F1: Variation order | 10.9 | 14.7 | 23.5 | 13.7 | 15.7 |

| F2: Drawing conditions | 12.5 | 10.9 | 8.8 | 3.8 | 9.0 |

| F3: Management conditions | 6.8 | 5.5 | 5.1 | 4.9 | 5.6 |

| F4: Material shortages | 4.4 | 5.1 | 6.5 | 10.5 | 6.6 |

| F5: Labor shortages | 11.4 | 15.8 | 19.2 | 26.8 | 18.3 |

| F6: Poor maintenance of the machine | 6.3 | 5.9 | 5.2 | 3.3 | 5.2 |

| F7: Financial capacity | 8.9 | 10.6 | 11.4 | 20.1 | 12.8 |

| F8: Unpredictable weather and protests | 1.8 | 1.5 | 1.2 | 0.6 | 1.3 |

| F9: Poor communication | 6.3 | 4.2 | 3.5 | 2.9 | 4.2 |

| F10: Government requirement | 8.2 | 6.1 | 3.8 | 4.5 | 5.6 |

| F11: Material prices fluctuation | 13.2 | 12.9 | 7.8 | 6.9 | 10.2 |

| F12: Facilities and space available | 6.5 | 4.9 | 2.8 | 1.2 | 3.8 |

| F13: Unsafe working condition | 2.8 | 1.9 | 1.2 | 0.8 | 1.7 |

| Factor | F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | Row totals | Eigenvector | Quotients |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 0.0071 | 0.0194 | 0.0114 | 0.0088 | 0.0163 | 0.0091 | 0.0101 | 0.0084 | 0.0075 | 0.0093 | 0.0064 | 0.0036 | 0.087 | 0.1261 | 0.1262 | 0.9992 |

| F2 | 0.0045 | 0.0097 | 0.0082 | 0.0037 | 0.0145 | 0.0043 | 0.0128 | 0.0069 | 0.0035 | 0.0035 | 0.0039 | 0.0046 | 0.0038 | 0.0839 | 0.0827 | 1.0145 |

| F3 | 0.0036 | 0.0046 | 0.0050 | 0.0041 | 0.0090 | 0.0036 | 0.0054 | 0.0039 | 0.0049 | 0.0036 | 0.0055 | 0.0057 | 0.0056 | 0.0645 | 0.0634 | 1.0173 |

| F4 | 0.0059 | 0.0053 | 0.0072 | 0.0057 | 0.0105 | 0.0037 | 0.0060 | 0.0037 | 0.0082 | 0.0031 | 0.0035 | 0.0082 | 0.0056 | 0.0766 | 0.0778 | 0.9846 |

| F5 | 0.0066 | 0.0098 | 0.0126 | 0.0092 | 0.0239 | 0.0119 | 0.0265 | 0.0125 | 0.0110 | 0.0108 | 0.0102 | 0.0140 | 0.0092 | 0.1672 | 0.1687 | 0.9911 |

| F6 | 0.0038 | 0.0031 | 0.0078 | 0.0028 | 0.0057 | 0.0028 | 0.0086 | 0.0041 | 0.0021 | 0.0034 | 0.0042 | 0.0032 | 0.0041 | 0.0557 | 0.0573 | 0.9720 |

| F7 | 0.0054 | 0.0058 | 0.0079 | 0.0067 | 0.0113 | 0.0052 | 0.0109 | 0.0085 | 0.0103 | 0.0104 | 0.0061 | 0.0087 | 0.0079 | 0.1051 | 0.1029 | 1.0213 |

| F8 | 0.0025 | 0.0022 | 0.0035 | 0.0042 | 0.0031 | 0.0022 | 0.0026 | 0.0011 | 0.0031 | 0.0027 | 0.0023 | 0.0024 | 0.0026 | 0.0345 | 0.0312 | 1.1057 |

| F9 | 0.0038 | 0.0026 | 0.0042 | 0.0036 | 0.0049 | 0.0025 | 0.0040 | 0.0014 | 0.0041 | 0.0032 | 0.0042 | 0.0032 | 0.0035 | 0.0452 | 0.0484 | 0.9338 |

| F10 | 0.0089 | 0.0069 | 0.0061 | 0.0054 | 0.0065 | 0.0044 | 0.0052 | 0.0034 | 0.0069 | 0.0049 | 0.0059 | 0.0058 | 0.0028 | 0.0731 | 0.0722 | 1.0124 |

| F11 | 0.0097 | 0.0094 | 0.0041 | 0.0126 | 0.0063 | 0.0018 | 0.0107 | 0.0036 | 0.0121 | 0.0027 | 0.0127 | 0.0059 | 0.0039 | 0.0955 | 0.0956 | 0.9989 |

| F12 | 0.0036 | 0.0034 | 0.0043 | 0.0015 | 0.0022 | 0.0019 | 0.0040 | 0.0046 | 0.0024 | 0.0033 | 0.0021 | 0.0022 | 0.0020 | 0.0375 | 0.0381 | 0.9842 |

| F13 | 0.0031 | 0.0035 | 0.0039 | 0.0018 | 0.0024 | 0.0021 | 0.0041 | 0.0019 | 0.0028 | 0.0020 | 0.0022 | 0.0028 | 0.0025 | 0.0351 | 0.0355 | 0.9887 |

| λmax | 13.0237 | |||||||||||||||

| Reasonable Value | Value |

|---|---|

| Consistency Index (CI) | 0.0020 |

| Random Index (RI) | 1.5600 |

| Consistency Ratio (CR) | 0.0013 |

| 0.0013 < 0.1 (Reasonable) | |

| Factors | Eigenvector Value | Average Cost Overruns (%) | Ranking |

|---|---|---|---|

| F5: Labor shortages | 0.1687 | 18.3 | 1 |

| F1: Variation order | 0.1262 | 15.7 | 2 |

| F7: Financial capacity | 0.1029 | 12.8 | 3 |

| F11: Material price fluctuation | 0.0956 | 10.2 | 4 |

| F2: Drawing conditions | 0.0827 | 9.0 | 5 |

| F4: Material shortages | 0.0778 | 6.6 | 6 |

| F10: Government requirement | 0.0722 | 5.7 | 7 |

| F3: Management conditions | 0.0634 | 5.6 | 8 |

| F6: Poor maintenance of the machine | 0.0573 | 5.2 | 9 |

| F9: Poor communication | 0.0484 | 4.2 | 10 |

| F12: Facilities and space available | 0.0381 | 3.9 | 11 |

| F13: Unsafe working conditions | 0.0355 | 1.7 | 12 |

| F8: Unpredictable weather and protests | 0.0312 | 1.3 | 13 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Namjan, T.; Monkaew, S.; Kongchasing, N.; Chatveera, B.; Chaimahawan, P.; Ahmad, A.; Sua-Iam, G. Contractor-Based Evaluation of Construction Cost Overrun Factors Using Matrix Analysis. Buildings 2026, 16, 607. https://doi.org/10.3390/buildings16030607

Namjan T, Monkaew S, Kongchasing N, Chatveera B, Chaimahawan P, Ahmad A, Sua-Iam G. Contractor-Based Evaluation of Construction Cost Overrun Factors Using Matrix Analysis. Buildings. 2026; 16(3):607. https://doi.org/10.3390/buildings16030607

Chicago/Turabian StyleNamjan, Tanapat, Sunun Monkaew, Nutchapongpol Kongchasing, Burachat Chatveera, Preeda Chaimahawan, Afaq Ahmad, and Gritsada Sua-Iam. 2026. "Contractor-Based Evaluation of Construction Cost Overrun Factors Using Matrix Analysis" Buildings 16, no. 3: 607. https://doi.org/10.3390/buildings16030607

APA StyleNamjan, T., Monkaew, S., Kongchasing, N., Chatveera, B., Chaimahawan, P., Ahmad, A., & Sua-Iam, G. (2026). Contractor-Based Evaluation of Construction Cost Overrun Factors Using Matrix Analysis. Buildings, 16(3), 607. https://doi.org/10.3390/buildings16030607