Research on the Benefits of Intelligent Construction Site Applications—A Case Study in Nanjing City

Abstract

1. Introduction

2. Literature Review

2.1. Application of Intelligent Construction Sites

2.2. Application Benefit Analysis of Intelligent Construction Site

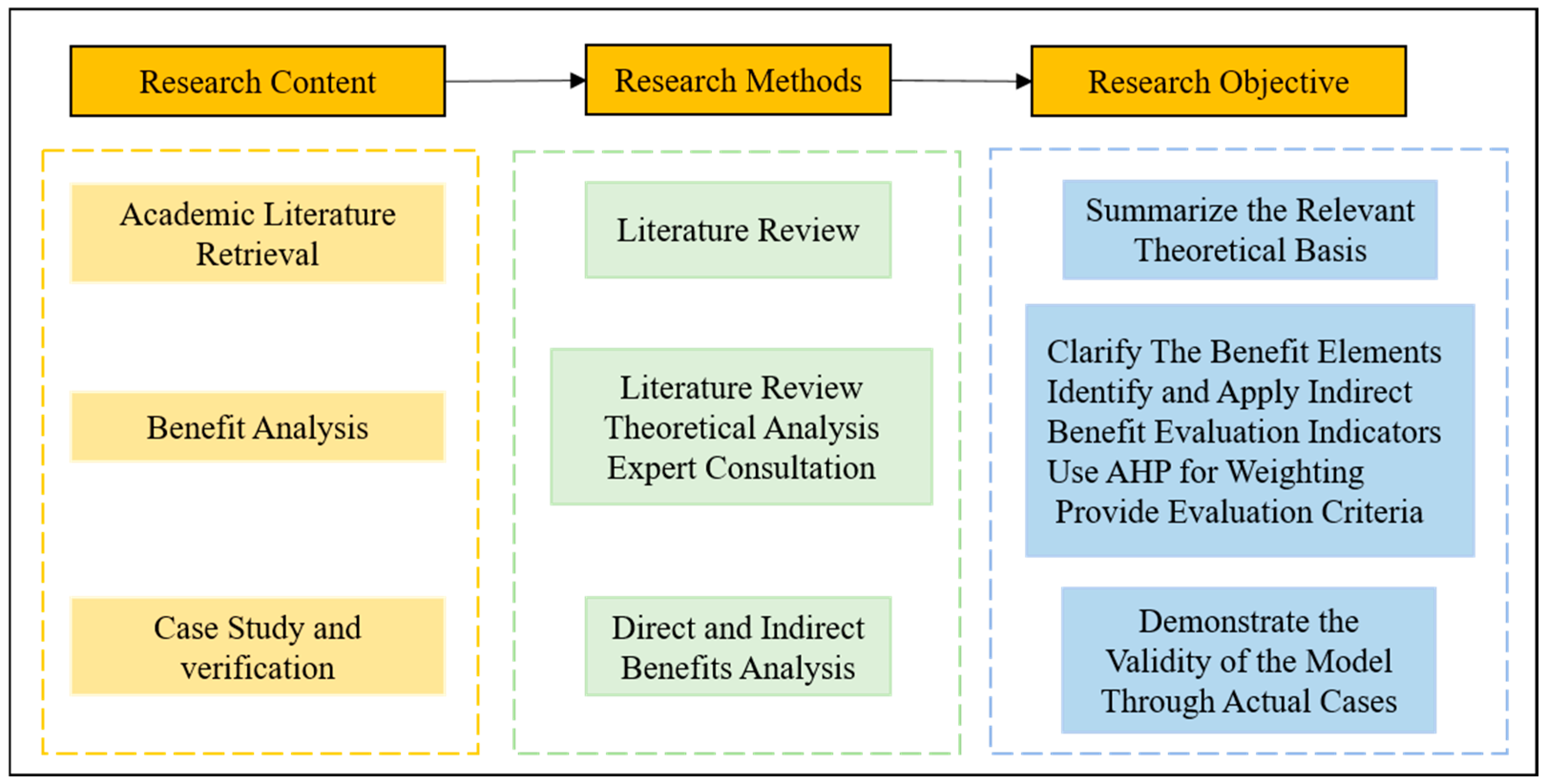

3. Methodology

3.1. Direct Benefit Method

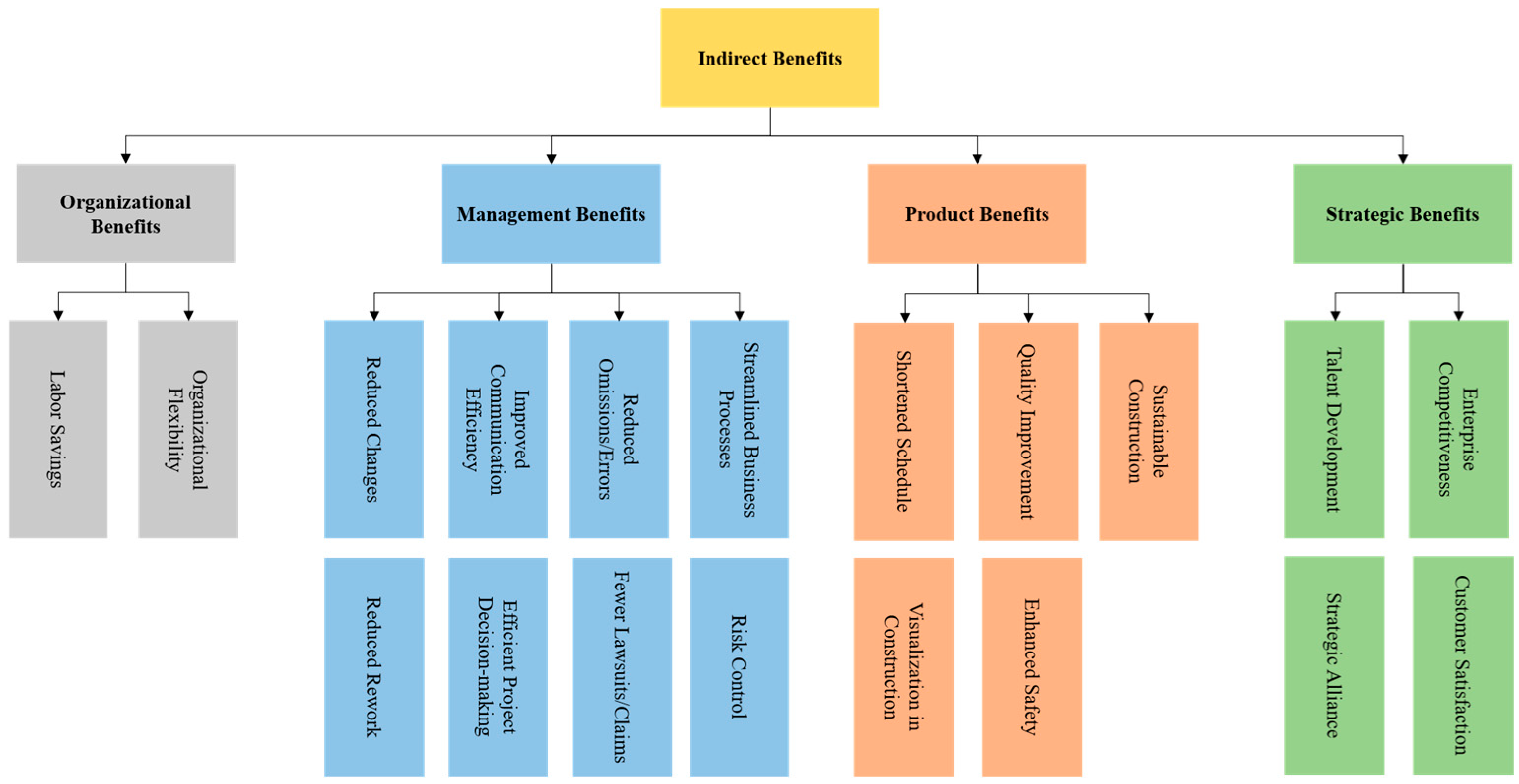

3.2. Indirect Benefit Method

- (1)

- Establishing the Hierarchical Structure Model

- (2)

- Constructing Judgment Matrices for Each Level

- (3)

- Hierarchical Single Ranking and Consistency Testing

- (4)

- Synthesizing Weights to Obtain Evaluation Indicator Weights

4. Case Study and Results

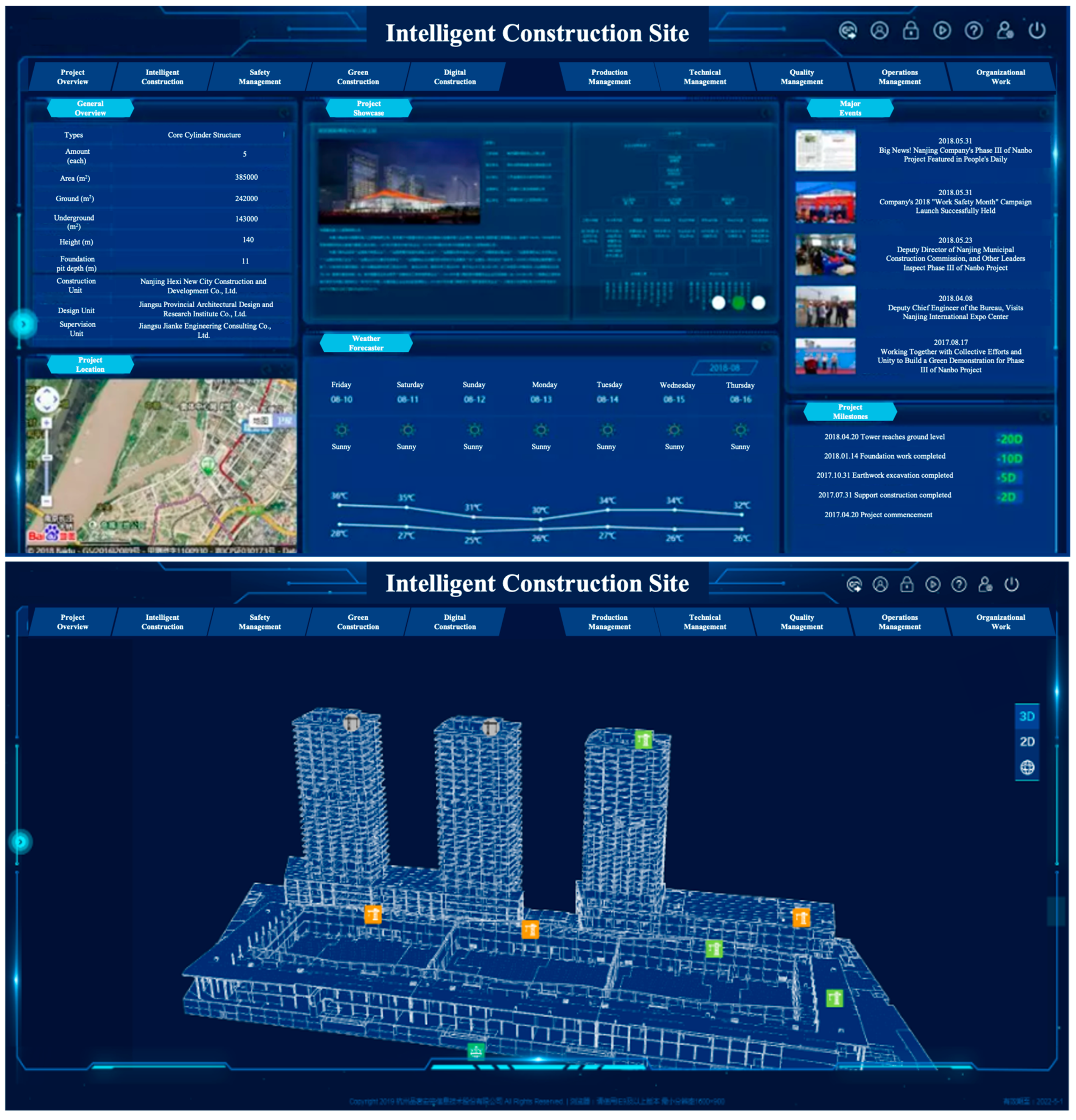

4.1. Case Background

4.2. Intelligent Construction Site Implement

4.3. Benefit Results

5. Discussion

5.1. Analysis of Direct Benefits

5.2. Analysis of Indirect Benefits

5.3. Implications for Intelligent Construction Site Adoption

5.4. Research Contributions

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Heredia Morante, R.A.; del Río Merino, M.; Ros Serrano, A. The Accident Rate in the Construction Sector: A Work Proposal for Its Reduction through the Standardization of Safe Work Processes. Buildings 2024, 14, 2399. [Google Scholar] [CrossRef]

- Naji, K.K.; Gunduz, M.; Alhenzab, F.H.; Al-Hababi, H.; Al-Qahtani, A.H. A Systematic Review of the Digital Transformation of the Building Construction Industry. IEEE Access 2024, 12, 31461–31487. [Google Scholar] [CrossRef]

- Meng, Z. Research on the application of intelligent construction site in construction Site management. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 768, p. 062005. [Google Scholar]

- Qin, L.; He, P. Intelligent Construction Quality Remote Management Integrating Intelligent Construction Sites and PDCA Cycle. Intell. Build. Int. 2025, 1–16. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, S.; Hou, Y.; Xiahou, X.; Li, Q. Analyzing Critical Influencing Factors of the Maturity of Smart Construction Site Applications. Buildings 2024, 14, 1910. [Google Scholar] [CrossRef]

- Deng, H.; Xu, Y.; Deng, Y.; Lin, J. Transforming knowledge management in the construction industry through information and communications technology: A 15-year review. Autom. Constr. 2022, 142, 104530. [Google Scholar] [CrossRef]

- Balasubramanian, S.; Shukla, V.; Islam, N.; Manghat, S. Construction Industry 4.0 and Sustainability: An Enabling Framework. IEEE Trans. Eng. Manag. 2024, 71, 1–19. [Google Scholar] [CrossRef]

- Yang, L.-R.; O’Connor, J.T.; Chen, J.-H. Assessment of automation and integration technology’s impacts on project stakeholder success. Autom. Constr. 2007, 16, 725–733. [Google Scholar] [CrossRef]

- Zhou, Z.C.; Su, Y.K.; Zheng, Z.Z.; Wang, Y.L. Analysis of factors of willingness to adopt intelligent construction technology in highway construction enterprises. Sci. Rep. 2023, 13, 19339. [Google Scholar] [CrossRef]

- Turečková, K.; Nevima, J. The Cost Benefit Analysis for the Concept of a Smart City: How to Measure the Efficiency of Smart Solutions? Sustainability 2020, 12, 2663. [Google Scholar] [CrossRef]

- Zhenxu, G.; Lihong, L. A Conceptual Framework for Collaborative Development of Intelligent Construction and Building Industrialization. Front. Environ. Sci. 2022, 10, 904518. [Google Scholar] [CrossRef]

- Yang, J.-B.; Chou, H.-Y. Subjective benefit evaluation model for immature BIM-enabled stakeholders. Autom. Constr. 2019, 106, 102908. [Google Scholar] [CrossRef]

- Won, J.; Lee, G. How to tell if a BIM project is successful: A goal-driven approach. Autom. Constr. 2016, 69, 34–43. [Google Scholar] [CrossRef]

- Chou, H.-Y.; Chen, P.-Y. Benefit Evaluation of Implementing BIM in Construction Projects. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 062049. [Google Scholar]

- Zhang, L.; Li, Y.; Pan, Y.; Ding, L. Advanced informatic technologies for intelligent construction: A review. Eng. Appl. Artif. Intell. 2024, 137, 109104. [Google Scholar] [CrossRef]

- Olanipekun, A.O.; Sutrisna, M. Facilitating Digital Transformation in Construction—A Systematic Review of the Current State of the Art. Front. Built Environ. 2021, 7, 660758. [Google Scholar] [CrossRef]

- China Publishes Five-Year Plan for Construction Industry. Xinhua, 25 January 2022. Available online: https://english.news.cn/20220125/4fab4ec0b8544d0e82db74b284a69a93/c.html (accessed on 5 January 2025).

- He, Q.; Ghofrani, F.; Gao, T.; Wang, P.; He, C.; Li, Y.; Ai, C. Intelligent construction for the transportation infrastructure: A review. Intell. Transp. Infrastruct. 2022, 1, liac007. [Google Scholar] [CrossRef]

- Liu, X.; Gao, T. The Application of BIM+IOT Technology in the Background of Intelligent Construction. In Smart Applications and Sustainability in the AIoT Era; Al-Turjman, F., Ed.; SAS-AIoT 2024, Sustainable Civil Infrastructures; Springer: Cham, Switzerland, 2024. [Google Scholar] [CrossRef]

- Zhou, D.; Pei, B.; Li, X.; Jiang, D.; Wen, L. Innovative BIM technology application in the construction management of highway. Sci. Rep. 2024, 14, 15298. [Google Scholar] [CrossRef]

- Khan, A.M.; Alrasheed, K.A.; Waqar, A.; Almujibah, H.; Benjeddou, O. Internet of things (IoT) for safety and efficiency in construction building site operations. Sci. Rep. 2024, 14, 28914. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Li, X.; Guo, Y.; Wang, J.; Ren, Z.; Wang, M.; Yang, Z. Natural language processing for smart construction: Current status and future directions. Autom. Constr. 2022, 134, 04059. [Google Scholar] [CrossRef]

- Xia, H.; Liu, Z.; Efremochkina, M.; Liu, X.; Lin, C. Study on city digital twin technologies for sustainable smart city design: A review and bibliometric analysis of geographic information system and building information modeling integration. Sustain. Cities Soc. 2022, 84, 104009. [Google Scholar] [CrossRef]

- Jiang, W.; Ding, L.; Zhou, C. Cyber physical system for safety management in smart construction site. Eng. Constr. Archit. Manag. 2021, 28, 788–808. [Google Scholar] [CrossRef]

- Sowiński, P.; Rachwał, K.; Danilenka, A.; Bogacka, K.; Kobus, M.; Dąbrowska, A.; Paszkiewicz, A.; Bolanowski, M.; Ganzha, M.; Paprzycki, M. Frugal Heart Rate Correction Method for Scalable Health and Safety Monitoring in Construction Sites. Sensors 2023, 23, 6464. [Google Scholar] [CrossRef]

- Gan, W.; Gu, K.; Geng, J.; Qiu, C.; Yang, R.; Wang, H.; Hu, X. A Novel Three-Stage Collision-Risk Pre-Warning Model for Construction Vehicles and Workers. Buildings 2024, 14, 2324. [Google Scholar] [CrossRef]

- Han, K.K.; Golparvar-Fard, M. Appearance-based material classification for monitoring of operation-level construction progress using 4D BIM and site photologs. Autom. Constr. 2015, 53, 44–57. [Google Scholar] [CrossRef]

- Pradhananga, N.; Teizer, J. Automatic spatio-temporal analysis of construction site equipment operations using GPS data. Autom. Constr. 2013, 29, 107–122. [Google Scholar] [CrossRef]

- Lee, C.; Park, J.; Seol, S. Development and demonstration of smart construction safety technology using drones. Forum Public Saf. Cult. 2023, 24, 93–105. [Google Scholar] [CrossRef]

- Kumar, S.S.; Cheng, J.C.P. A BIM-based automated site layout planning framework for congested construction sites. Autom. Constr. 2015, 59, 24–37. [Google Scholar] [CrossRef]

- Jin, R.; Hancock, C.; Tang, L.; Chen, C.; Wanatowski, D.; Yang, L. Empirical Study of BIM Implementation-Based Perceptions among Chinese Practitioners. J. Manag. Eng. 2017, 33, 040170255. [Google Scholar]

- Wasmi, H.A.; Castro-Lacouture, D. Potential Impacts of BIM-Based Cost Estimating in Conceptual Building Design: A University Building Renovation Case Study. Constr. Res. Congr. 2016, 2016, 408–417. [Google Scholar]

- Lee, S.; Yu, J. Comparative Study of BIM Acceptance between Korea and the United States. J. Constr. Eng. Manag. 2016, 142, 050150163. [Google Scholar] [CrossRef]

- Wang, J.; Wang, X.; Shou, W.; Chong, H.Y.; Guo, J. Building information modeling-based integration of MEP layout designs and constructability. Autom. Constr. 2016, 61, 134–146. [Google Scholar] [CrossRef]

- Bradley, A.; Li, H.; Lark, R.; Dunn, S. BIM for infrastructure: An overall review and constructor perspective. Autom. Constr. 2016, 71, 139–152. [Google Scholar] [CrossRef]

- Wong, J.K.W.; Zhou, J. Enhancing environmental sustainability over building life cycles through green BIM: A review. Autom. Constr. 2015, 57, 156–165. [Google Scholar] [CrossRef]

- Czmoch, I.; Pekala, A. Traditional Design versus BIM Based Design. Procedia Eng. 2014, 91, 210–215. [Google Scholar] [CrossRef]

- Volk, R.; Stengel, J.; Schultmann, F. Building Information Modeling (BIM) for existing buildings—Literature review and future needs. Autom. Constr. 2014, 43, 204. [Google Scholar]

- Babatunde, S.O.; Ekundayo, D.; Babalola, O.; Jimoh, J.A. Analysis of the drivers and benefits of BIM incorporation into quantity surveying profession: Academia and students’ perspectives. J. Eng. Des. Technol. 2018, 16, 750–766. [Google Scholar]

- Xu, H.; Feng, J.; Li, S. Users-orientated evaluation of building information model in the Chinese construction industry. Autom. Constr. 2014, 39, 32–46. [Google Scholar] [CrossRef]

- Mahammad, A.A. Study on the Impact of Building Information Modeling (BIM) in AEC (Architecture, Engineer, Construction) Industry. Int. J. Res. Appl. Sci. Eng. Technol. 2023, 11, 1339–1346. [Google Scholar] [CrossRef]

- Masood, R.; Kharal, M.K.N.; Nasir, A.R. Is BIM Adoption Advantageous for Construction Industry of Pakistan? Procedia Eng. 2014, 77, 229–238. [Google Scholar] [CrossRef]

- Francom, T.C.; El Asmar, M. Project Quality and Change Performance Differences Associated with the Use of Building Information Modeling in Design and Construction Projects: Univariate and Multivariate Analyses. J. Constr. Eng. Manag. 2015, 141, 040150289. [Google Scholar] [CrossRef]

- Cao, D.; Wang, G.; Li, H.; Skitmore, M.; Huang, T.; Zhang, W. Practices and effectiveness of building information modelling in construction projects in China. Autom. Constr. 2015, 49, 113–122. [Google Scholar] [CrossRef]

- Monteiro, A.; Meda, P.; Martins, J.P. Framework for the coordinated application of two different integrated project delivery platforms. Autom. Constr. 2014, 38, 87–99. [Google Scholar] [CrossRef]

- Zhou, Y.; Ding, L.; Rao, Y.; Luo, H.; Medjdoub, B.; Zhong, H. Formulating project-level building information modeling evaluation framework from the perspectives of organizations: A review. Autom. Constr. 2017, 81, 44–55. [Google Scholar] [CrossRef]

- Nath, T.; Attarzadeh, M.; Tiong, R.L.K.; Chidambaram, C.; Yu, Z. Productivity improvement of precast shop drawings generation through BIM-based process re-engineering. Autom. Constr. 2015, 54, 54–68. [Google Scholar] [CrossRef]

- Fazli, A.; Fathi, S.; Enferadi, M.H.; Fazli, M.; Fathi, B. Appraising effectiveness of Building Information Management (BIM) in project management. Procedia Technol. 2014, 16, 1116–1125. [Google Scholar] [CrossRef]

- Nepal, M.P.; Jupp, J.R.; Aibinu, A.A. Evaluations of BIM: Frameworks and Perspectives. Comput. Civ. Build. Eng. 2014, 769–776. [Google Scholar]

- Pishdad-Bozorgi, H.A.P. Trends of Assessing BIM Implementation in Construction Research. ASCE J. Comput. Civil Build. Eng. 2014, 496–503. [Google Scholar]

- Stowe, K.; Zhang, S.; Teizer, J.; Jaselskis, E.J. Capturing the Return on Investment of All-In Building Information Modeling: Structured Approach. Pract. Period. Struct. Des. Constr. 2015, 20, UNSP 040140271. [Google Scholar]

- Lu, W.; Fung, A.; Peng, Y.; Liang, C.; Rowlinson, S. Cost-benefit analysis of Building Information Modeling implementation in building projects through demystification of time-effort distribution curves. Build. Environ. 2014, 82, 317–327. [Google Scholar]

- National Development and Reform Commission; Ministry of Construction. Methods and Parameters for Economic Evaluation of Construction Projects, 3rd ed.; China Planning Press: Beijing, China, 2006.

- Damodaran, A. Investment Valuation: Tools and Techniques for Determining the Value of Any Asset; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Ross, S.A.; Westerfield, R.W.; Jaffe, J. Corporate Finance; McGraw-Hill: Columbus, OH, USA, 2019. [Google Scholar]

- Aigbe, F.; Aigbavboa, C.; Aliu, J.; Amusan, L. Understanding the Future Competitive Advantages of the Construction Industry. Buildings 2024, 14, 1616. [Google Scholar] [CrossRef]

- Das, K.; Khursheed, S.; Paul, V.K. The impact of BIM on project time and cost: Insights from case studies. Discov. Mater. 2025, 5, 25. [Google Scholar] [CrossRef]

- Gharaibeh, L.; Matarneh, S.; Lantz, B.; Eriksson, K. Quantifying the influence of BIM adoption: An in-depth methodology and practical case studies in construction. Results Eng. 2024, 23, 102555. [Google Scholar] [CrossRef]

- Datta, S.D.; Tayeh, B.A.; Hakeem, I.Y.; Abu Aisheh, Y.I. Benefits and Barriers of Implementing Building Information Modeling Techniques for Sustainable Practices in the Construction Industry—A Comprehensive Review. Sustainability 2023, 15, 12466. [Google Scholar] [CrossRef]

- Saaty, T.L. The Analytic Hierarchy Process: Planning, Priority Setting, Resource Allocation; McGraw-Hill: Columbus, OH, USA, 1980. [Google Scholar]

| Category | Estimation Method |

|---|---|

| Schedule Reduction | Collaborative design shortens the design cycle days × Bd |

| Visualization reduces the number of bidding and tendering days × Bd | |

| Automatic statistics of engineering quantities shorten the number of days for cost estimation × Bd | |

| Reduced engineering changes and shortened construction period × Bd | |

| Other shortened construction period days × Bd | |

| Cost Saving | Material quantity reduced through parametric design × Material unit price |

| Pipeline quantity reduced through MEP coordination optimization × Pipeline unit price | |

| Operational cost saving | |

| Other cost saving | |

| Quality Improvement | Reduced engineering change costs by clash detection |

| Reduced engineering change costs by MEP detailed design | |

| Reduced engineering change costs by other quality improvement |

| Organizational Benefits | Management Benefits | Product Benefits | Strategic Benefits | |

|---|---|---|---|---|

| Organizational Benefits | 1.00 | 0.50 | 0.50 | 2.00 |

| Management Benefits | 2.00 | 1.00 | 1.00 | 3.00 |

| Product Benefits | 2.00 | 1.00 | 1.00 | 3.00 |

| Strategic Benefits | 0.50 | 0.33 | 0.33 | 1.00 |

| Evaluation Object | Criteria Level | Criteria Level Weight | Indicator Level | Indicator Level Weight (Relative) | Indicator Level Weight (Absolute) |

|---|---|---|---|---|---|

| Indirect Benefits of Intelligent Construction Site Application | Organizational Benefits | 0.19 | Labor Savings | 0.75 | 0.14 |

| Organizational Flexibility | 0.25 | 0.05 | |||

| Management Benefits | 0.35 | Reduced Changes | 0.13 | 0.05 | |

| Improved Communication Efficiency | 0.13 | 0.05 | |||

| Reduced Rework | 0.22 | 0.08 | |||

| Efficient Project Decision-making | 0.13 | 0.05 | |||

| Reduced Omissions/Errors | 0.22 | 0.08 | |||

| Streamlined Business Processes | 0.07 | 0.03 | |||

| Fewer Lawsuits/Claims | 0.05 | 0.02 | |||

| Risk Control | 0.05 | 0.02 | |||

| Product Benefits | 0.35 | Shortened Schedule | 0.16 | 0.06 | |

| Quality Improvement | 0.3 | 0.1 | |||

| Enhanced Safety | 0.3 | 0.1 | |||

| Visualization in Construction | 0.15 | 0.05 | |||

| Sustainable Construction | 0.09 | 0.03 | |||

| Strategic Benefits | 0.11 | Talent Development | 0.23 | 0.02 | |

| Enterprise Competitiveness | 0.23 | 0.02 | |||

| Strategic Alliance | 0.12 | 0.01 | |||

| Customer Satisfaction | 0.42 | 0.05 |

| Level | Excellent | Good | Fair | Fail | Poor |

|---|---|---|---|---|---|

| Measurement | (9, 10] | (7, 9] | (5, 7] | (3, 5] | (0, 3] |

| Cost Category | Technical Service Fee | Project Management Fee | Software and Hardware Purchase Fee | Employee Training Fee |

|---|---|---|---|---|

| Amount (RMB/10,000 yuan) | 229.5 | 195 | 1.4 | 11.08 |

| Item | Year/Detail | Nominal (10,000 RMB) | Discount Factor | PV (10,000 RMB) |

|---|---|---|---|---|

| I. Cost Present Value Calculation | ||||

| Annual Cost Components: | ||||

| Technical Service Fee | 2017–2020 | 57.38/yr | — | — |

| Project Management Fee | 2017–2020 | 48.75/yr | — | — |

| Software and Hardware | 2017–2020 | 0.35/yr | — | — |

| Employee Training | 2017–2020 | 2.77/yr | — | — |

| Annual Total | 109.24 | — | — | |

| Year-by-Year Discounting: | ||||

| 2017 (t = 1) | 109.24 | 0.9259 | 101.15 | |

| 2018 (t = 2) | 109.24 | 0.8573 | 93.66 | |

| 2019 (t = 3) | 109.24 | 0.7938 | 86.72 | |

| 2020 (t = 4) | 109.24 | 0.735 | 80.3 | |

| Cost Subtotal (C) | 436.98 | 361.83 | ||

| II. Benefit Present Value Calculation | ||||

| B1. Construction Period Savings: | ||||

| Clash Detection Savings | 100 × 2 | 200 | — | — |

| Schedule Reduction | 387,000 × 36/1460 × 4% | 381.7 | — | — |

| Subtotal (at t = 4) | 581.7 | 0.735 | 427.57 | |

| B2. Operation Period Savings: | ||||

| Maintenance Labor | 400 days × 150 yuan | 6.00/yr | — | — |

| Maintenance Material | 40 × 7000 yuan | 28.00/yr | — | — |

| Annual Savings | 34 | — | — | |

| Annuity PV (50 yr, 8%) | (1–1.08−50)/0.08 | — | 12.2335 | 415.94 |

| Discount to t = 0 | 415.94 | 0.735 | 305.73 | |

| Benefit Subtotal (B) | 733.29 | |||

| III. ROI Calculation | ||||

| Total Benefits PV (B) | 733.29 | |||

| Total Costs PV (C) | 361.83 | |||

| Net Present Value (B-C) | 371.46 | |||

| ROI = (B-C)/C × 100% | 102.70% | |||

| IV. Sensitivity Analysis | ||||

| Discount Rate | Cost PV | Benefit PV | ROI | |

| 6% | 378.55 | 885.25 | 133.90% | |

| 8% (Baseline) | 361.83 | 733.29 | 102.70% | |

| 10% | 346.29 | 627.56 | 81.20% | |

| Parameter | Value | |||

| Social Discount Rate | 8% | |||

| Base Year | 2017 (t = 0) | |||

| Construction Period | 4 years | |||

| Operation Period | 50 years | |||

| Criteria Layer | Criteria Weight | Indicator Layer | Indicator Weight (Relative) | Indicator Weight (Absolute) | Average Expert Score | Weighted Average Expert Score | |

|---|---|---|---|---|---|---|---|

| Indirect Benefits of Intelligent Construction Site Application | Organizational Benefits | 0.19 | Labor Savings | 0.75 | 0.14 | 9 | 1.26 |

| Organizational Flexibility | 0.25 | 0.05 | 8 | 0.4 | |||

| Management Benefits | 0.35 | Reduced Changes | 0.13 | 0.05 | 8 | 0.4 | |

| Improved Communication Efficiency | 0.13 | 0.05 | 10 | 0.5 | |||

| Reduced Rework | 0.22 | 0.08 | 10 | 0.8 | |||

| Efficient Project Decision-making | 0.13 | 0.05 | 8 | 0.4 | |||

| Reduced Omissions/Errors | 0.22 | 0.08 | 10 | 0.8 | |||

| Streamlined Business Processes | 0.07 | 0.03 | 8 | 0.24 | |||

| Fewer Lawsuits/Claims | 0.05 | 0.02 | 10 | 0.2 | |||

| Risk Control | 0.05 | 0.02 | 8 | 0.16 | |||

| Product Benefits | 0.35 | Shortened Schedule | 0.16 | 0.06 | 10 | 0.6 | |

| Quality Improvement | 0.30 | 0.10 | 10 | 1 | |||

| Enhanced Safety | 0.30 | 0.10 | 10 | 1 | |||

| Visualization in Construction | 0.15 | 0.05 | 10 | 0.5 | |||

| Sustainable Construction | 0.09 | 0.03 | 8 | 0.24 | |||

| Strategic Benefits | 0.11 | Talent Development | 0.23 | 0.02 | 8 | 0.16 | |

| Enterprise Competitiveness | 0.23 | 0.02 | 9 | 0.18 | |||

| Strategic Alliance | 0.12 | 0.01 | 8 | 0.08 | |||

| Customer Satisfaction | 0.42 | 0.05 | 10 | 0.5 | |||

| Total | 9.42 | ||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

You, J.; Ding, X.; Liu, P.; Xiahou, X. Research on the Benefits of Intelligent Construction Site Applications—A Case Study in Nanjing City. Buildings 2026, 16, 550. https://doi.org/10.3390/buildings16030550

You J, Ding X, Liu P, Xiahou X. Research on the Benefits of Intelligent Construction Site Applications—A Case Study in Nanjing City. Buildings. 2026; 16(3):550. https://doi.org/10.3390/buildings16030550

Chicago/Turabian StyleYou, Jun, Xingyuan Ding, Ping Liu, and Xiaer Xiahou. 2026. "Research on the Benefits of Intelligent Construction Site Applications—A Case Study in Nanjing City" Buildings 16, no. 3: 550. https://doi.org/10.3390/buildings16030550

APA StyleYou, J., Ding, X., Liu, P., & Xiahou, X. (2026). Research on the Benefits of Intelligent Construction Site Applications—A Case Study in Nanjing City. Buildings, 16(3), 550. https://doi.org/10.3390/buildings16030550