Abstract

Magnesite tailings are by-products of magnesite mining, yet their utilization rate remains extremely low. Although previous studies have explored their basic physical properties and potential use in cementitious or geotechnical materials, research on cement-stabilized magnesite tailings-particularly regarding their mechanical behavior, engineering applicability, and microstructural evolution-remains limited. Key scientific gaps include the lack of systematic evaluation of their compaction characteristics, strength development, stiffness evolution, and bearing capacity, as well as insufficient understanding of the stabilization mechanisms governing their performance. Addressing these gaps is essential for assessing their feasibility as road construction materials. In this study, magnesite tailings were selected as the primary raw material and mixed with ordinary Portland cement to prepare mixtures for evaluating their suitability as highway subgrade fillers. The compaction characteristics, unconfined compressive strength (UCS), ultrasonic pulse velocity (UPV), and California Bearing Ratio (CBR) of the mixtures were systematically examined. Furthermore, the evolution of composition and stabilization mechanisms of the mixtures was analyzed using X-ray diffraction, scanning electron microscopy, and thermogravimetric analysis. The results show that cement incorporation effectively improves the poor particle gradation of magnesite tailings, leading to a denser and more homogeneous structure. Adding 7% cement increases the maximum dry density and optimum moisture content by 3.7% and 5.1%, respectively. The unconfined compressive strength rises by 100.9–126.3% within 3–28 days, and the maximum uniaxial stress is 119.6% higher than that of the 1% cement mixture. These improvements demonstrate the potential of cement-stabilized magnesite tailings as a sustainable subgrade material and provide insight into their microstructural and mechanical behavior.

1. Introduction

With continuous advancements in mining technologies [1,2], the exploitation and utilization of mineral resources have increased substantially. Magnesite [3,4], a magnesium-bearing carbonate mineral belonging to the calcite group, is widely used as an essential industrial raw material. Global magnesite reserves are estimated at approximately 8.5 billion tons, with major deposits located in Russia, China, and Australia. During magnesite beneficiation and processing, large volumes of tailings are produced, consisting primarily of unrefined magnesite particles and associated waste soil. Currently, open dumping remains the dominant disposal method, leading to a series of environmental problems, such as elevated soil pH, depletion of essential nutrients, and potential groundwater contamination [5,6].

The rapid expansion of highway networks has generated a growing demand for natural aggregates, resulting in resource depletion and increased construction costs [7,8,9,10]. To address these challenges, the utilization of industrial by-products and tailings—such as blast furnace granular slag (GBFS), fly ash, rice husk ash, and other waste materials—has been increasingly recognized as an effective and sustainable alternative [11,12,13,14,15,16,17,18]. These materials not only serve as substitute fillers for roadbed and subgrade construction but also reduce the environmental burden associated with waste accumulation [19,20]. For example, blast furnace dust has been shown to enhance the physical and mechanical properties of granular base and sub-base materials, with an optimal content of 6% identified for road construction applications [11,21,22]. Similarly, lime-activated GBFS can significantly improve the strength, stiffness, and microstructural characteristics of high-swelling clay soils, with a 15% dosage effectively reducing swelling potential and increasing load-bearing capacity [19,23,24,25]. Other industrial wastes, such as fly ash and rice husk ash, have also been widely applied as low-cost and environmentally friendly stabilizers in expansive soils and subgrade engineering [14,18]. Compared with conventional cement- or lime-based stabilization methods, which are effective but energy-intensive and associated with high CO2 emissions, these alternative materials offer more sustainable and cost-effective solutions, demonstrating strong potential for large-scale infrastructure applications [19,20].

Previous studies have explored diverse reuse pathways for magnesite tailings. Masindi et al. [26] demonstrated, through adsorption kinetics and geochemical modeling, that magnesite tailings can effectively neutralize acid mine drainage and remove multiple contaminants, highlighting their potential for environmental remediation. Karhu et al. [27] evaluated talc tailings containing impurities for use in magnesia–alumina spinel refractories, showing that such tailings can serve as viable magnesium-source raw materials. Cui et al. [28] investigated the high-temperature mechanical behavior and microstructural evolution of mortar incorporating magnesite tailings using multi-scale testing and U-net image analysis, revealing strong strength retention and promising high-temperature performance. Shanmugasundaram et al. [29,30,31] systematically evaluated the physical, chemical, mineralogical, mechanical, durability, and environmental properties of magnesite tailings, confirming their feasibility as construction materials and stabilizing agents in subgrade soils. Although these studies confirm the general applicability of magnesite tailings in construction and environmental engineering, most existing research focuses on single-scale mechanical performance or material feasibility, with limited attention to the coupled macro–micro mechanisms governing strength development and structural integrity under highway subgrade service requirements.

To address this research gap and expand the application potential of magnesite tailings, this study systematically investigates their feasibility for highway subgrade engineering. Cement-stabilized magnesite tailings mixtures are prepared, and their macroscopic engineering performance is evaluated through compaction tests, unconfined compressive strength tests, ultrasonic pulse velocity measurements, and California Bearing Ratio tests. Unlike previous studies, this work establishes an integrated multi-scale testing framework that explicitly links non-destructive UPV measurements with UCS and CBR results, enabling a quantitative assessment of internal structural integrity and load-bearing performance. In addition, microstructural and compositional analyses—including X-ray diffraction (XRD), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA)—are conducted to reveal the evolution of hydration products, pore structure densification, and cement–tailings interaction mechanisms responsible for strength gain and material stabilization. By integrating macro-scale engineering performance with micro-scale material characterization, this study provides new mechanistic insights into the performance control of cement-stabilized magnesite tailings and demonstrates their practical feasibility as sustainable highway subgrade materials, thereby offering a clear technical basis for large-scale engineering applications.

2. Raw Materials and Test Methods

2.1. Raw Materials

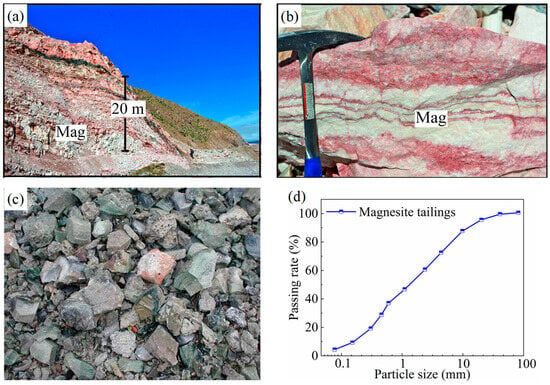

The magnesite tailings and their precursor materials are illustrated in Figure 1a–c. The tailings exhibit a specific gravity of 2.85 and an MgO content of 45.3%. The particle size distribution curve of the tailings is provided in Figure 1d. Analysis of the distribution curve reveals that the gravel-sized fraction constitutes 29.95%, while the coarse particle fraction accounts for 66.96%. Based on the classification criteria outlined in the Test Methods of Soils for Highway Engineering (JTG 3430-2020) [32], the magnesite tailings are classified as poorly graded sand. For the experimental investigations, tailings passing through a 4.75 mm sieve were selected. The binder employed in this study is ordinary Portland cement (P.O 42.5), which was evaluated in accordance with the Testing Methods of Cement and Concrete for Highway Engineering (JTG 3420-2020) [33]. The test results confirmed that all performance indices of the cement met the corresponding specification requirements.

Figure 1.

Magnesite tailings and particle size distribution curve: (a) field magnesite tailings; (b) mining of magnesite tailings; (c) magnesite Tailings Product and (d) particle size distribution curve.

2.2. Specimen Preparation

To investigate the performance and cost-effectiveness of magnesite tailings as subgrade materials under varying cement contents, four cement dosage levels were selected for this study. Cement was incorporated into the tailings at rates of 1%, 3%, 5%, and 7% of the dry mass of the tailings, with the mixing water determined based on the optimum moisture content obtained from the compaction test [34]. Cylindrical specimens measuring 50 × 100 mm were prepared (the cylindrical samples are 50 mm in diameter and 100 mm in height, giving a height-to-diameter ratio of 2:1, which complies with standard testing procedures), compacted, sealed in polyethylene film, and cured at 20 ± 2 °C for periods of 3, 7, and 28 days.

To ensure the reproducibility of the experimental program, the specimen preparation, curing, and testing procedures were strictly controlled as follows.

For the unconfined compressive strength (UCS) test, five parallel specimens were prepared for each mixture. After mixing and static compaction, all UCS specimens were demolded immediately after fabrication, wrapped with plastic film to prevent moisture loss, and then transferred to a standard curing chamber. Standard curing was conducted at 20 ± 2 °C and 95% relative humidity for 3, 7, and 28 days. For soaked UCS specimens, samples were subjected to 6 or 27 days of standard curing followed by 24 h of water immersion, with the water level maintained 1–2 cm above the specimen surface.

For the ultrasonic pulse velocity (UPV) test, five specimens were prepared for each group. These specimens were demolded after 1 day of initial curing, followed by standard curing and soaking as required. After soaking, specimens were placed in an ultra-low-temperature freezer and cooled at a rate of 0.5 °C/min to the target temperatures (−20 °C, −30 °C, and −50 °C), maintained for 6 h, and then wrapped with plastic film and stored at room temperature for 1 day prior to UPV testing. It should be noted that this low-temperature conditioning was applied solely to investigate the influence of temperature on UPV measurements and does not represent a freeze–thaw durability assessment. Potential long-term risks, such as brucite-induced expansion or other hydration-related volume changes, are acknowledged but were not addressed in this short-term study and will be investigated in future work.

For the California Bearing Ratio (CBR) test, five parallel specimens were prepared for each mixture. The specimens were compacted in three layers with 98 blows per layer and demolded immediately after compaction. CBR specimens were subjected to 7 days of standard curing, followed by 4 days of water soaking, during which swelling was monitored. Standard curing conditions were maintained at 20 ± 2 °C and 95% relative humidity.

2.3. Test Methods

The ultrasonic pulse velocity (UPV) test was first conducted to evaluate the internal integrity of the cured mixtures and to identify potential defects. A pair of contact transducers with a central frequency of 50 kHz was attached to the specimen surfaces, with a transmission path length of 70 mm. Vaseline was applied between the transducers and the non-cast faces of the specimens to minimize contact errors during testing. During the test, an HC-U91 ultrasonic pulse velocity meter (Figure 2a) was used to generate a 500 V input signal. For each mix condition, three parallel specimens were tested, and the average UPV value was calculated and adopted as the final result.

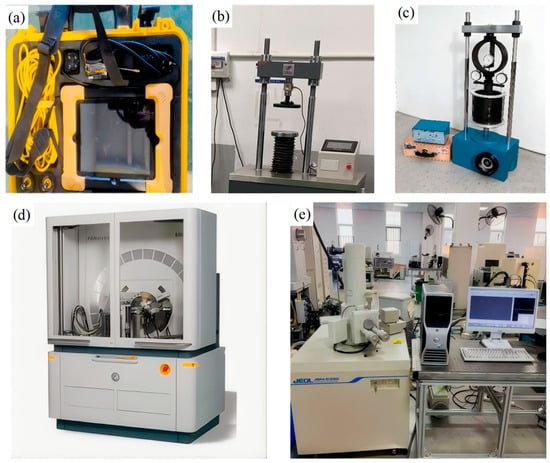

Figure 2.

The devices and equipment: (a) ultrasonic pulse velocity meter; (b) unconfined compressive strength tester; (c) California bearing ratio tester; (d) X-ray diffractometer; (e) scanning electron microscopy.

The mechanical properties of the mixtures were evaluated through unconfined compressive strength (UCS) and California Bearing Ratio (CBR) tests [32]. The UCS test was conducted using a TKAWCY-1F automatic unconfined compressive strength tester (Nanjing Taikeao Technology Co., Ltd., Nanjing, China), as shown in Figure 2b. The device is equipped with an automatic pressure-control system and a computer-based data acquisition unit for generating full stress–strain curves. The test system consists of a lifting platform, base, and stress sensor. The main equipment specifications include a loading rate adjustable between 1 and 9.9 mm/min, a maximum axial stress capacity of 5000 kPa, and a maximum axial strain of 20%. The CBR test was performed using an STCBR-1 California Bearing Ratio tester, illustrated in Figure 2c. Its test system comprises a lifting platform, a pressure sensor, a dial indicator, and a data acquisition/output system. The device provides a measuring range of 30 kN and a standard penetration rate of 1 mm/min.

For the CBR tests, two curing conditions were considered: (1) conventionally cured specimens and (2) specimens subjected to an additional 96 h water immersion after conventional curing, to simulate potential field wetting and evaluate moisture-related durability. For both UCS and CBR tests, three parallel specimens were tested for each condition, and the average value was adopted as the final result to ensure reliability and minimize experimental variability. The 96 h soaking test provides a preliminary evaluation of moisture resistance; however, it should be noted that field subgrades are exposed to cyclic wetting, seasonal moisture variations, and freeze–thaw cycles, which may influence long-term performance. The formation of brucite (Mg(OH)2) can induce slight internal expansion, potentially affecting volume stability. Previous studies [35] have demonstrated that cement stabilization generally enhances the durability of magnesium-bearing tailings, but further investigation under realistic field conditions is needed to fully assess long-term performance. Additionally, magnesite tailings are inherently heterogeneous, with properties that may vary by source in terms of mineralogy, fines content, and reactivity. This study focuses on one representative type; future work will explore variability, standardization, and pre-treatment strategies to improve the applicability of cement-stabilized tailings in subgrade construction.

To elucidate the evolution of mineral composition and the stabilization mechanisms of the mixtures, X-ray diffraction (XRD), scanning electron microscopy (SEM), and thermogravimetric analysis (TGA) were conducted. XRD testing was performed using an Empyrean-6000X diffractometer manufactured by PANalytical (Almelo, The Netherlands), as shown in Figure 2d. Prior to testing, the materials were finely ground using an agate mortar, and the resulting powder was mounted onto glass slides for analysis. XRD was carried out on both untreated magnesite tailings (0% cement) and specimens cured for 28 days with 7% cement content. SEM was used to examine microstructural development and morphological changes. Following the UCS tests, approximately 5 g of material was scraped from each specimen and freeze-dried. After dehydration, the samples were trimmed into 1 mm × 1 mm × 1 mm cubes and mounted on conductive adhesive. Loose debris was removed using an air blower, and the samples were subsequently vacuum-treated and coated with a thin layer of gold. SEM observations were performed using a JSM-6360LV scanning electron microscope (JEOL, Tokyo, Japan), as shown in Figure 2e.

In addition, thermogravimetric analysis (TGA) [36] was performed using a thermal analyzer to characterize the thermal decomposition behavior of the materials and further clarify the hydration and stabilization mechanisms.

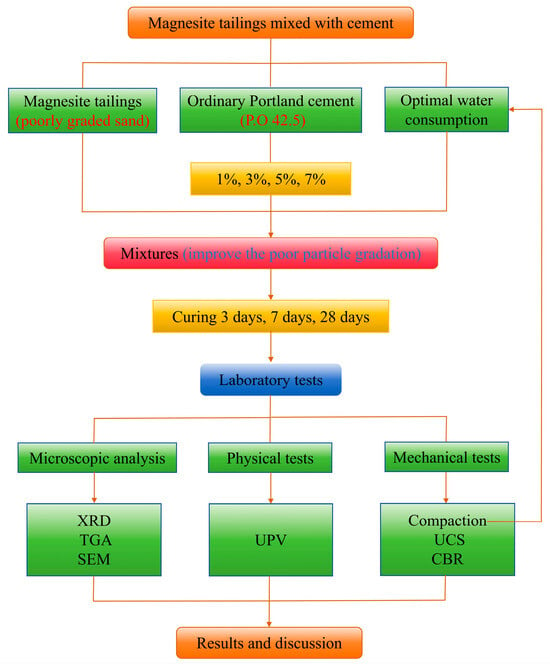

A methodological flowchart is provided in Figure 3 to present the sample preparation parameters, variable factors, and the determined properties evaluated in this study.

Figure 3.

The methodological flowchart.

3. Results and Discussion of Tests

3.1. Compaction Characteristics

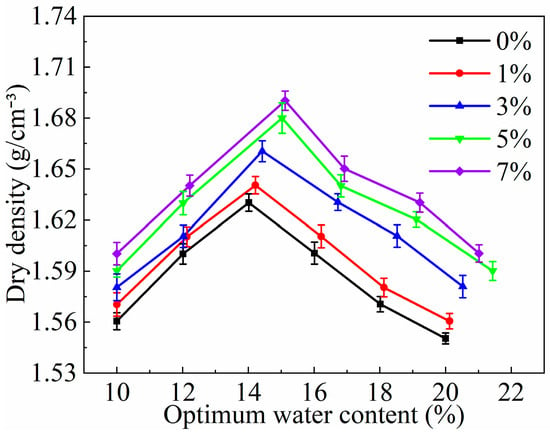

The compaction curves of magnesite tailings-based subgrade mixtures at different cement contents are shown in Figure 4. As shown, both the optimum water content and the maximum dry density of the mixtures increase with increasing cement dosage. The rise in maximum dry density can be attributed to the higher specific gravity of cement particles compared to the tailings. Additionally, the finer cement particles and their hydration products fill the voids between the coarser tailings particles, refining the pore structure and further enhancing the overall density of the mixture. Specifically, the maximum dry density of the magnesite tailings roadbed material mixed with 7% cement is 3.7% higher than that of the material without cement, while the optimum water content is 5.1% higher, further verifying the strengthening effect of cement incorporation. The increase in fine particle content with higher cement content also contributes to the observed rise in optimum water content. These findings are consistent with previous studies [37], confirming that the incorporation of cement not only improves the compaction characteristics of tailings-based mixtures but also highlights the role of cement hydration products in pore refinement. It should be noted, however, that this study does not include long-term durability tests, which limits the assessment of performance under extended service conditions.

Figure 4.

Compaction curves of the magnesite tailings subgrade mixtures under different cement contents.

3.2. Uniaxial Compressive Strength (UCS) Characteristics

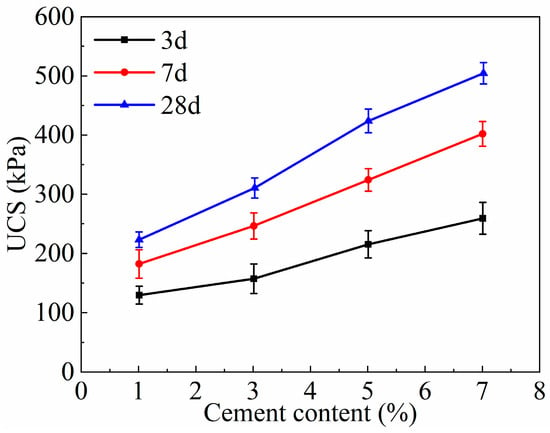

Figure 5 illustrates the development of unconfined compressive strength (UCS) of magnesite tailings-based subgrade mixtures under different cement contents and curing durations. Error bars represent the standard deviation of five replicate specimens. Variability is slightly higher for lower cement contents due to weaker bonding and less uniform particle packing, while overall, the results remain consistent and reproducible. The results show that, for a given curing age, UCS increases markedly with cement content, while for a fixed cement dosage, strength gradually develops with curing time. Quantitatively, as cement content increases, the mixture strength increases by 126.3%, 121.8%, and 100.9% after 28, 7, and 3 days of curing, respectively, demonstrating the pronounced contribution of cement to early- and mid-term strength development. However, previous studies have reported that when cement is used as the primary binder, strength gain beyond 28 days tends to slow down [38]. This indicates that either increasing binder content or extending curing duration can help meet strength requirements at later construction stages, although excessive cement addition would significantly increase construction costs. It should be noted that UCS is not a mandatory design criterion for traditional roadbed materials, for which CBR serves as the primary controlling indicator. In engineering practice, UCS values in the range of 0.1–0.5 MPa are generally associated with improved roadbed materials rather than untreated subgrade soils.

Figure 5.

Unconfined compressive strength of magnesite tailings-based subgrade mixtures under different cement contents and curing durations.

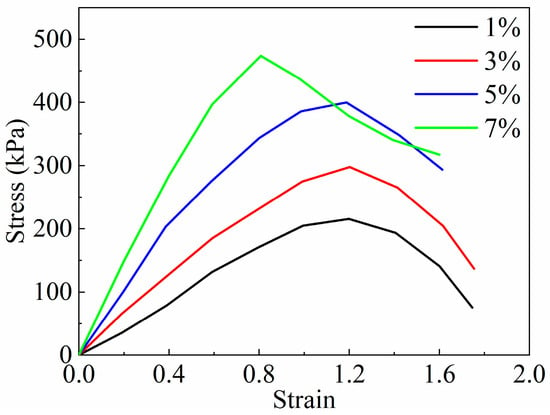

Figure 6 presents the stress–strain responses of the mixtures cured for 28 days with different cement contents. It is evident that the UCS peak increases while the corresponding peak strain decreases with increasing cement content, indicating enhanced stiffness and a more pronounced brittle failure behavior. Specifically, the maximum uniaxial stress of the mixture containing 7% cement is 119.6% higher than that of the mixture with 1% cement, confirming the strong strengthening effect of higher cement dosage. After reaching peak stress, continued loading results in progressive strain accumulation accompanied by stress softening. Notably, the post-peak stress reduction rate decreases as cement content increases, implying that higher cement dosages improve residual stress-bearing capacity.

Figure 6.

Stress–strain curves of mixtures cured for 28 days under different cement contents.

In summary, the incorporation of an appropriate cement content significantly enhances the load-bearing capacity, stiffness, and post-peak performance of magnesite tailings mixtures, thereby providing more reliable mechanical support for highway subgrade construction. Through rational optimization of cement dosage, it is possible to achieve a balance between mechanical performance and construction cost, while maximizing the engineering utilization of magnesite tailings as a sustainable subgrade material.

3.3. Wave Characteristics

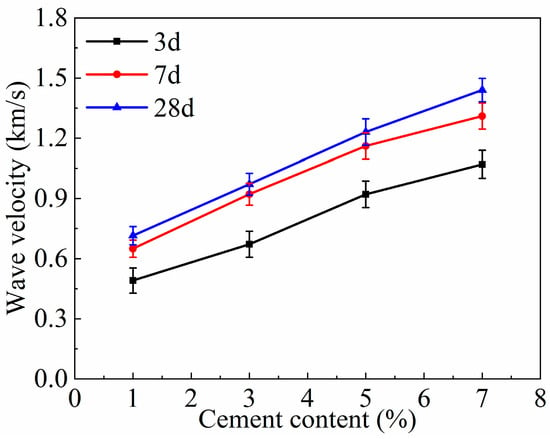

Figure 7 shows the variation in ultrasonic pulse velocity (UPV) in magnesite tailings-based mixtures with different cement contents and curing durations. As observed, UPV increases with both cement content and curing time, following a trend consistent with the unconfined compressive strength (UCS), which indicates a strong correlation between the two parameters. Quantitatively, UPV increases by 118.5%, 101.4%, and 101.7% after 3, 7, and 28 days of curing, respectively, with increasing cement content, reflecting enhanced internal compactness. This increase is mainly attributed to cement hydration products bonding tailings particles and reducing internal porosity, which improves density, stiffness, and wave propagation efficiency. These results indicate that cement-stabilized magnesite tailings exhibit good mechanical integrity and compactness, and that UPV testing provides a rapid and non-destructive means of evaluating internal structural quality.

Figure 7.

Wave velocity values of different cement content mixtures at different curing ages.

From an engineering perspective, such mixtures offer adequate load-bearing capacity and durability while enabling resource recycling, highlighting their potential as sustainable subgrade materials.

3.4. California Bearing Ratio (CBR) Characteristics

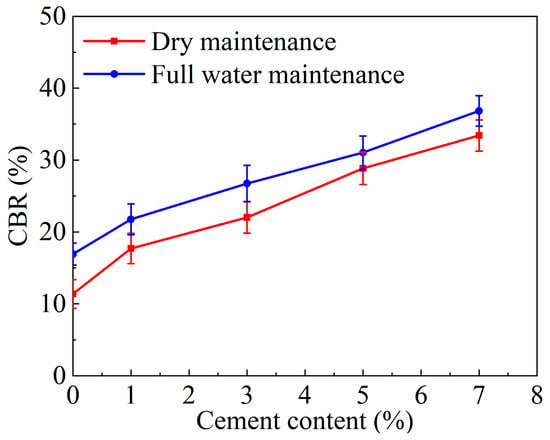

The California Bearing Ratio (CBR) results of mixtures with different cement contents after 28 days of curing under dry and post-soaking conditions are presented in Figure 8. The results indicate that CBR increases monotonically with cement content, while for a given cement dosage, soaking leads to a moderate reduction in CBR, reflecting moisture-induced strength loss. When the cement content reaches 7%, the maximum CBR values are 36.9% under dry conditions and 33.4% after soaking.

Figure 8.

CBR values of mixtures with different cement contents after 28 days of curing under dry and soaked conditions.

Although the CBR values of the magnesite tailings–cement mixtures are slightly lower than those of conventional subgrade materials [39], their performance still satisfies the technical requirements for subgrade fill (CBR > 8%) [40]. Moreover, the limited CBR reduction after soaking indicates that the mixtures retain a relatively stable bearing capacity under moisture exposure, demonstrating acceptable durability and serviceability [41]. These results highlight the feasibility of using cement-stabilized magnesite tailings as a sustainable alternative for highway subgrade construction.

Compared with cementitious materials incorporating other industrial by-products, such as fly ash, slag, and mineral tailings, the mixtures in this study exhibit a comparable strength enhancement trend, albeit with distinct characteristics. Specifically, the UCS and CBR of materials incorporating magnesite tailings increase by 12.1% and 9.8%, respectively, compared with conventional coarse-aggregate concrete [18,22,29,30]. While this improvement is slightly lower than that achieved using highly reactive pozzolanic materials, it is greater than that reported for inert or low-activity tailings. These differences are attributed to the unique mineral composition and relatively fine particle morphology of magnesite tailings, which enhance particle packing and densify the interfacial transition zone, thereby improving load-bearing capacity. Overall, these comparative results emphasize the distinct advantages of magnesite tailings as a sustainable aggregate alternative and indicate that, based on their measured performance relative to conventional subgrade materials, the material is most suitable for use as an improved subgrade or subbase rather than as the primary subgrade layer.

4. Microscopic Mechanism Analysis

4.1. X-Ray Diffraction (XRD) Analysis

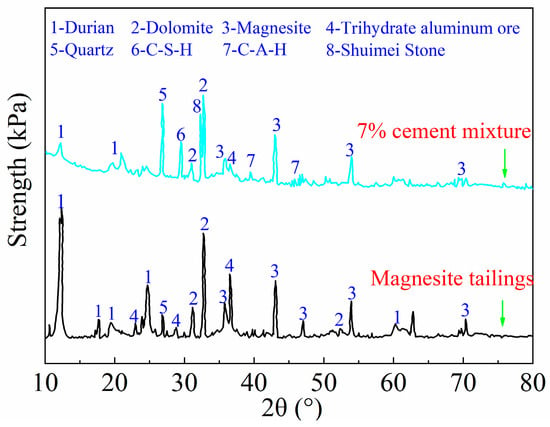

Figure 9 compares the XRD patterns of natural magnesite tailings and the mixture containing 7% cement after 28 days of curing. The results indicate that the natural tailings are predominantly composed of magnesite, accompanied by garnet, dolomite, gibbsite, and quartz. After cement addition, the diffraction peaks of garnet, gibbsite, and magnesite exhibit noticeable reductions, suggesting that these minerals undergo varying degrees of consumption or transformation during curing. Meanwhile, new hydration products—including calcium silicate hydrate (C-S-H), calcium aluminate hydrate (C-A-H), and brucite-are detected in the cement-stabilized mixture [42].

Figure 9.

XRD patterns of magnesite tailings and the mixture containing 7% cement after 28 days of curing.

The presence of C-S-H and C-A-H confirms the occurrence of cement hydration reactions, whereas the formation of brucite indicates that an alkali–magnesite reaction takes place within the system. Collectively, these hydration and transformation products contribute to pore filling and improved interparticle bonding, thereby enhancing the internal structure of the mixture. From a mineralogical perspective, these findings provide strong evidence that cement addition effectively improves the structural stability and mechanical performance of magnesite tailings mixtures, supporting their suitability for use as road construction materials.

4.2. Thermogravimetric Analysis (TGA)

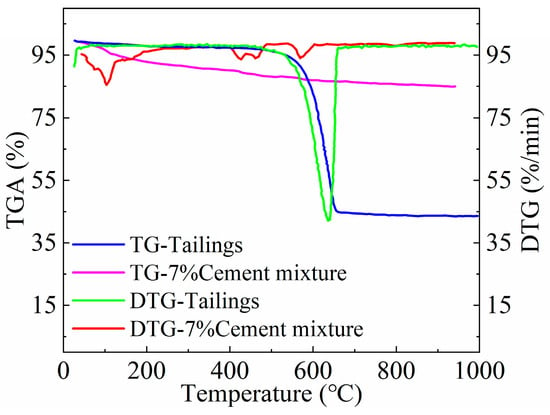

Figure 10 presents the thermogravimetric analysis (TGA) and derivative thermogravimetric (DTG) results of natural magnesite tailings and mixtures containing 7% cement cured for 28 days. For both samples, the first major mass loss occurs at approximately 105 °C, which is attributed to the evaporation of free water.

Figure 10.

TGA and DTC of magnesite tailings and tailings mixture with 7% cement content.

For the natural tailings, a sharp decrease in mass-from 96.7% to 45.05% is observed within the temperature range of 490–660 °C. This behavior corresponds to the thermal decomposition of magnesite (MgCO3), during which CO2 is released at elevated temperatures. Accordingly, the DTG curve of the tailings exhibits a pronounced endothermic peak near 640 °C, confirming that magnesite is the dominant mineral phase.

In contrast, the mixture containing 7% cement shows a more substantial mass loss between 105 and 400 °C. This loss primarily results from dehydration and dehydroxylation of free water and cement hydration products, particularly calcium silicate hydrate (C–S–H). Consequently, a sharp and dense endothermic peak appears in the DTG curve within this temperature range. Additionally, two distinct mass-loss events are evident at approximately 420 °C and 480 °C, corresponding to the dehydroxylation of brucite (Mg(OH)2) and portlandite (Ca(OH)2), respectively, and producing two clear endothermic peaks in the DTG profile.

Furthermore, in the 500–650 °C temperature range, the remaining magnesite in the mixture decomposes and releases CO2, producing another DTG endothermic peak around 570 °C. Compared with natural tailings, this peak exhibits reduced intensity, indicating that a portion of the original magnesite has participated in earlier reactions to form brucite and other new mineral phases.

Overall, the combined TGA and DTG results demonstrate that the addition of cement leads to the formation of abundant hydration products and brucite generated through alkali–magnesite reactions. These newly formed phases effectively fill internal voids and enhance interparticle bonding, representing the primary mechanism responsible for the improved strength and densification of the mixture. This conclusion is consistent with the XRD analysis and further confirms that the magnesite tailings develop a more stable microstructure under cement stabilization, thereby supporting their suitability as a subgrade fill material.

4.3. Scanning Electron Microscopy (SEM) Results

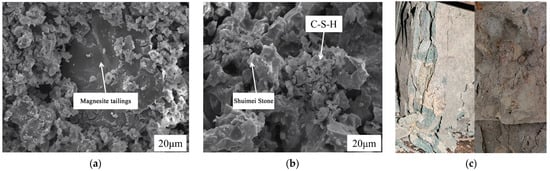

The microstructural morphology of natural magnesite tailings and the mixture containing 7% cement after 28 days of curing, along with a macroscopic photograph of the failed specimen, is presented in Figure 11. The natural tailings exhibit large magnesite particles accompanied by minor amounts of dolomite and other minerals, with the particles loosely packed and displaying a pronounced porous structure, which corresponds to their relatively low mechanical strength observed in macroscopic tests.

Figure 11.

SEM results of magnesite tailings and tailings mixture with 7% cement content: (a) Magnesite tailings; (b) 7% cement content mixture, and (c) macroscopic photograph of specimen failure.

In contrast, the cement-stabilized mixture shows substantial microstructural transformations. Although some unreacted magnesite particles remain visible, their surfaces are covered with abundant plate-like and fibrous calcium silicate hydrate (C–S–H) as well as flocculent brucite (Mg(OH)2). The formation of C–S–H results from cement hydration, while the presence of brucite indicates ongoing alkali–magnesite reactions, consistent with the XRD and TGA results. These hydration products deposit on and bridge adjacent particles, filling intergranular voids and significantly improving the compactness of the mixture.

This transition from a loose, porous structure to a densely bonded microstructure directly explains the observed improvements in mechanical strength, such as increased unconfined compressive strength and California Bearing Ratio. The bridging and filling effect of C–S–H and brucite enhances particle interlocking and cohesion, demonstrating a clear link between the microstructural evolution and the macroscopic performance of the cement-stabilized tailings mixture.

In addition, the macroscopic failure photograph reveals a typical shear-splitting failure mode, characterized by vertical cracking, lateral spalling, and the detachment of edge fragments during loading. This failure pattern is consistent with the densified yet brittle nature of cement-stabilized materials, further corroborating the microstructural evidence obtained from SEM.

Overall, the SEM observations further corroborate that cement stabilization substantially enhances the internal structure of magnesite tailings, thereby improving their performance as a viable subgrade material.

5. Conclusions

In this study, magnesite tailings were employed as the primary raw material, and the engineering performance of cement-stabilized tailings mixtures for highway subgrade applications was systematically investigated. The compaction behavior, mechanical properties, and ultrasonic pulse velocity characteristics were comprehensively evaluated, and microstructural analyses were conducted to elucidate the mechanisms governing strength development. This study integrates macro-scale mechanical testing with microstructural characterization and UPV measurements, providing a multi-scale understanding of strength development. The main conclusions are as follows:

- (1)

- Magnesite tailings exhibit the characteristics of a poorly graded sand with a relatively high proportion of coarse particles. The incorporation of cement significantly enhances the packing structure by filling interparticle voids with fine cement grains and hydration products, resulting in a denser and more stable particle skeleton. This densification effect, quantified by a 3.7% increase in maximum dry density and a 5.1% increase in optimum moisture content with 7% cement, highlights the microstructural basis for improved compaction. With increasing cement content, the combined effects of fine-particle enrichment and hydration-induced bonding further improve compaction behavior. Consequently, both the optimum moisture content and maximum dry density increase with cement dosage, providing a theoretical basis for mixture design and field compaction optimization.

- (2)

- The mechanical performance of the mixtures improves markedly with increasing cement content. The UCS, CBR, and ultrasonic pulse velocity consistently increase with cement dosage and curing time, indicating enhanced stiffness, strength, and internal compactness. The observed quantitative correlation between UPV and UCS/CBR provides a novel approach to predict mechanical performance through non-destructive testing. This trend is quantitatively demonstrated by strength increases of 100.9%, 121.8%, and 126.3% after 3, 7, and 28 days of curing, respectively, as well as a 119.6% increase in maximum uniaxial stress for the mixture containing 7% cement compared with that containing 1% cement. These results confirm the pronounced strengthening effect of cement incorporation, particularly during early- and mid-term curing stages. Although the mechanical indices remain slightly lower than those of conventional subgrade materials, the results demonstrate that magnesite tailings, when properly stabilized, satisfy the requirements for subgrade fillers. In addition, the mixtures exhibit acceptable resistance to moisture-induced strength degradation, indicating reliable durability under typical service conditions.

- (3)

- Microstructural analyses (XRD, TGA, and SEM) confirm the formation of C–S–H, C–A–H, and brucite phases within the cement-stabilized mixtures. These products originate from cement hydration and alkali–magnesite reactions, jointly contributing to strength enhancement. SEM observations further reveal that hydration products bridge adjacent tailings particles and fill internal voids, demonstrating that microstructural densification and improved particle bonding are the dominant mechanisms controlling macro-scale mechanical performance.

Overall, the study demonstrates that cement-stabilized magnesite tailings exhibit favorable engineering performance and durability, highlighting the scientific novelty of linking multi-scale testing results to internal material mechanisms and their potential as a sustainable subgrade material. From an engineering perspective, they show promise for large-scale infrastructure applications, while from a materials science perspective, the insights into microstructural evolution and mixture optimization provide guidance for developing higher-performance composite subgrade materials.

Author Contributions

Conceptualization, B.Y. and T.Z.; methodology, B.Y.; software, L.C.; validation, B.Y., C.Z. and T.Z.; formal analysis, B.Y. and C.Z.; investigation, B.Y.; resources, C.Z.; data curation, T.Z.; writing—original draft preparation, B.Y., T.Z. and L.C.; writing—review and editing, T.Z. and C.Z.; visualization, L.C.; supervision, C.Z.; project administration, B.Y.; funding acquisition, C.Z. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 51404184 and General Project of Natural Science Research in Colleges and Universities of Jiangsu Province, grant number 21KJD420001.

Data Availability Statement

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Acknowledgments

We acknowledge the support of the Key Laboratory of Concrete and Prestressed Concrete Structures of the Ministry of Education.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Silva, D.S.F.; Boisvert, J.B. Mineral resource classification: A comparison of new and existing techniques. J. S. Afr. Inst. Min. Metall. 2014, 114, 265–273. [Google Scholar]

- Eggenkamp, H.G.M.; Marques, J.M. A comparison of mineral water classification techniques: Occurrence and distribution of different water types in Portugal (including Madeira and the Azores). J. Geochem. Explor. 2013, 132, 125–139. [Google Scholar] [CrossRef]

- Wang, J.Z.; Jing, M.C.; Zhao, B.H.; Zhai, W.J.; Cai, S.Q. Research progress of the flotation chemistry of magnesite and its gangue minerals. Chin. J. Nonferrous Met. 2022, 32, 3823–3842. (In Chinese) [Google Scholar]

- Zheng, H.L.; Ma, C.K.; Li, T.Y.; Fu, X.W.; Song, F.Y.; Wang, J.N.; Huang, Y.J.; Zhao, Q.Q. Removal of ammonia nitrogen and phosphate from livestock wastewater by magnesite tailings modified biochar: Performance and mechanisms. Appl. Water. Sci. 2025, 15, 248. [Google Scholar] [CrossRef]

- Chen, X.J.; Wang, R.Q.; Chen, F.X.; Styszko, K. Transport and removal of viruses in soil: Evaluating low-cost filtering materials for groundwater protection. J. Hazard. Mater. 2025, 496, 139538. [Google Scholar] [CrossRef]

- Pugazhendhi, A.; Govindasamy, C.; Sharma, A. Heavy metal accumulation in root and shoot tapioca plant biomass grown in agriculture land situated around the magnesite mine tailings. Environ. Res. 2024, 257, 119287. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.T.; She, W.; Yang, G.T.; Pan, L.; Cai, D.G.; Jiang, J.Y.; Hu, H. Mechanism of cement on the performance of cement stabilized aggregate for highspeed railway roadbed. Constr. Build. Mater. 2017, 144, 347–356. [Google Scholar] [CrossRef]

- Zhou, X.L.; Chen, Y.; Liu, C.W.; Wu, F. Preparation of artificial lightweight aggregate using alkali-activated incinerator bottom ash from urban sewage sludge. Constr. Build. Mater. 2022, 341, 127844. [Google Scholar] [CrossRef]

- Yin, P.B.; Wang, J.J.; He, W.; Wang, S.Q.; Li, X.; Jia, Z. Machine learning-based study on the mechanical properties and embankment settlement prediction model of nickel-iron slag modified soil. Constr. Build. Mater. 2024, 431, 136468. [Google Scholar] [CrossRef]

- Soe, K.; Yang, R.C.; Zhang, Y.X. A review of recent advances in MgO-Based cementitious composites for green construction: Mechanical and durability aspects. Buildings 2025, 15, 3513. [Google Scholar] [CrossRef]

- Ochoa-Diaz, R. Use of blast furnace dust to improve the properties of granular material for pavements. UIS Ing. 2021, 20, 135–144. [Google Scholar] [CrossRef]

- Zada, U.; Jamal, A.; Iqbal, M.; Eldin, S.M.; Almoshaogeh, M.; Bekkouche, S.R.; Almuaythir, S. Recent advances in expansive soil stabilization using admixtures: Current challenges and opportuni ties. Case Stud. Constr. Mater. 2023, 18, e01985. [Google Scholar] [CrossRef]

- Barwar, A.; Chandrappa, A.K.; Umesh, C.; Sahoo, U.C. Laboratory investigations on stabilization of weak clay soil using rice husk ash and cement. Innov. Infrastruct. Solut. 2022, 7, 327. [Google Scholar] [CrossRef]

- Ahmad, S.; Ghazi, M.S.A.; Syed, M.; Al-Osta, M.A. Utilization of fly ash with and without secondary additives for stabilizing expansive soils: A review. Results Eng. 2024, 22, 102079. [Google Scholar] [CrossRef]

- Vakili, A.H.; Salimi, M.; Keskin, İ.; Jamalimoghadam, M. A systematic review of strategies for identifying and stabilizing dis persive clay soils for sustainable infrastructure. Soil Tillage Res. 2024, 239, 106036. [Google Scholar] [CrossRef]

- Fadugba, O.G.; Adeniran, J.K.; Alaneme, G.U.; Oluyemi-Ayibiowu, B.D.; Omomomi, O.J.; Adetukasi, A.O. Compaction and com pressibility characteristics of snail shell ash and granulated blast furnace slag stabilized local bentonite for baseliner of landfill. Sci. Rep. 2024, 14, 7167. [Google Scholar] [CrossRef]

- Driss, A.A.-E.; Harichane, K.; Ghrici, M.; Gadouri, H. Assessing the effect of moulding water content on the behaviour of lime stabilised an expansive soil. Geomech. Geoengin. 2022, 17, 896–908. [Google Scholar] [CrossRef]

- Pushpakumara, B.H.J.; Mendis, W.S.W. Suitability of rice husk ash (RHA) with lime as a soil stabilizer in geotechnical applications. Int. J. Geo-Eng. 2022, 13, 4. [Google Scholar] [CrossRef]

- Habal, A.H.Y.; Medjnoun, A.; Djerbal, L.; Bahar, R. Mechanical and microstructure behavior of expansive soil treated by lime-activated granulated blast furnace slag. Indian Geotech. J. 2025, 55, 1661–1677. [Google Scholar] [CrossRef]

- Ashfaq, M.; Lal, M.H.; Moghal, A.A.B.; Murthy, V.R. Carbon footprint analysis of coal gangue in geotechnical engineering applications. Indian Geotech. J. 2020, 50, 646–654. [Google Scholar] [CrossRef]

- Sruthi, S.; Gayathri, V. Synthesis and evaluation of eco-friendly, ambient-cured, geopolymer-based bricks using industrial by-products. Buildings 2023, 13, 510. [Google Scholar] [CrossRef]

- Oke, J.A.; Abuel-Naga, H. Engineering and durability properties of sustainable bricks incorporating lime kiln dust, ground granulated blast furnace slag, and tyre rubber wastes. Buildings 2025, 15, 2079. [Google Scholar] [CrossRef]

- Li, B.L.; Tang, Z.Y.; Huo, B.B.; Liu, Z.J.; Cheng, Y.Z.; Ding, B.Z.; Zhang, P. The early age hydration products and mechanical properties of cement paste containing GBFS under steam curing condition. Buildings 2022, 12, 1746. [Google Scholar] [CrossRef]

- Zeng, Q.W.; Gao, P.W.; Li, K.; Dong, G.Q.; Jin, G.L.; Sun, X.W.; Zhao, J.W.; Chen, L.F. Experimental research on the properties and formulation of fly ash based geopolymer grouting material. Buildings 2022, 12, 503. [Google Scholar] [CrossRef]

- El-Attar, M.M.; Ibrahim, H.H.A.; Darwish, S.F.A. Investigating the viability of recycling rice husk ash and plastic bag waste to enhance durability of lightweight concrete. Buildings 2023, 13, 1350. [Google Scholar] [CrossRef]

- Masindi, V. A novel technology for neutralizing acidity and attenuating toxic chemical species from acid mine drainage using cryptocrystalline magnesite tailings. J. Water. Process. Eng. 2016, 10, 66–67. [Google Scholar] [CrossRef]

- Karhu, M.; Lagerbom, J.; Solismaa, S.; Huttunen-Saarivirta, E. Magnesite-rich mining tailings as a raw material for refractory ceramics-microstructural and thermal analysis. Proc. Est. Acad. Sci. 2019, 68, 145–149. [Google Scholar] [CrossRef]

- Cui, X.W.; Chen, M.; Ma, M.Y.; Lv, Z.Y.; Zhang, T. Deep learning-based petrographic analysis of magnesite mine tailings mortar after exposure to elevated temperatures. Constr. Build. Mater. 2025, 492, 142845. [Google Scholar] [CrossRef]

- Shanmugasundaram, V.; Shanmugam, B. Characterisation of magnesite mine tailings as a construction material. Environ. Sci. Pollut. Res. 2021, 28, 45557–45570. [Google Scholar] [CrossRef]

- Shanmugasundaram, V.; Shanmugam, B. Application of cement treated magnesite mine tailings as subgrade. Constr. Build. Mater. 2023, 365, 130064. [Google Scholar] [CrossRef]

- Shanmugasundaram, V.; Shanmugam, B.; Kulanthaivel, P.; Perumal, P. Sustainable reuse of magnesite mine tailings in cement-treated expansive soil for enhanced subgrade performance: Geotechnical and environmental analysis. J. Taibah. Univ. Sci. 2024, 18, 2397861. [Google Scholar] [CrossRef]

- JTG 3430-2020; Test Methods of Soils for Highway Engineering. Industry Standards of the People’s Republic of China: Beijing, China, 2020.

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Industry Standards of the People’s Republic of China: Beijing, China, 2020.

- GB/T 50123-2019; Standard for Geotechnical Testing Method. Standardization Administration of China: Beijing, China, 2019.

- Ding, S.; Unluer, C.; Li, L.H.; Li, N.; Wang, H.; Hu, Z.L.; Liu, J.P. Sequential mechanisms of swelling and crystallization pressures on microstructure and deformation evolution in cement-based materials mixed with MgO. Constr. Build. Mater. 2025, 490, 142587. [Google Scholar] [CrossRef]

- Zhang, X.W.; Gao, Y.H.; Wang, P.; Li, J.S.; Liu, S.Y.; Lang, L.; Lie, X.W. Experimental study on the synergistic preparation of pavement base material by electrolytic manganese slag-domestic waste incineration bottom slag. Bull. Chin. Ceram. Soc. 2023, 42, 1363–1373. (In Chinese) [Google Scholar] [CrossRef]

- Kutanaei, S.S.; Choobbasti, A.J. Effects of nanosilica particles and randomly distributed fibers on the ultrasonic pulse velocity and mechanical properties of cemented sand. J. Mater. Civil. Eng. 2017, 29, 04016230. [Google Scholar] [CrossRef]

- Zhou, X.L.; Liu, C.W.; Feng, B.; Guo, B.B.; Lu, Y.H.; Zhang, L.W. The effect of dry-wet cycle on cement-based composite filling materials. Chin. J. Eng. 2019, 41, 1609–1617. (In Chinese) [Google Scholar] [CrossRef]

- AASHTO T 99-25; Standard Method of Test for Sieve Analysis of Soils. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2025.

- JTG D30-2015; Specifications for Design of Highway Subgrades. Industry Standards of the People’s Republic of China: Beijing, China, 2015.

- Zhen, Y.J.; Zhang, S.; Luo, Z.L.; Gao, Y.; Wang, Y.B.; Yuan, H.H. Study on physical and mechanical properties of phase change material modified loess subgrade under freeze-thaw cycle. Highway 2022, 67, 36–43. (In Chinese) [Google Scholar]

- Liu, Y.J.; Sun, J.J.; Meng, Q.F. Study on preparation of magnesium silicate cement from magnesite tailings. Bull. Chin. Ceram. Soc. 2013, 32, 1126–1130. (In Chinese) [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.