Study on the Influence of the Sintering Process on the Performance of Paper-Mill Sludge–Shale Bricks

Abstract

1. Introduction

2. Experimental Program

2.1. Materials

2.1.1. Paper-Mill Black Sludge

2.1.2. Shale

2.2. Principles and Scheme of Material Proportioning

2.2.1. Proportioning Principle of Paper-Mill Sludge and Shale

2.2.2. Mix Proportion Scheme of Paper-Mill Black Sludge and Shale

2.3. Selection of Preparation Parameters

2.3.1. Experimental Design Method for Preparation Parameters

2.3.2. Orthogonal Experimental Analysis

- (1)

- Determination of Factors and Levels

- (2)

- Orthogonal Experimental Design

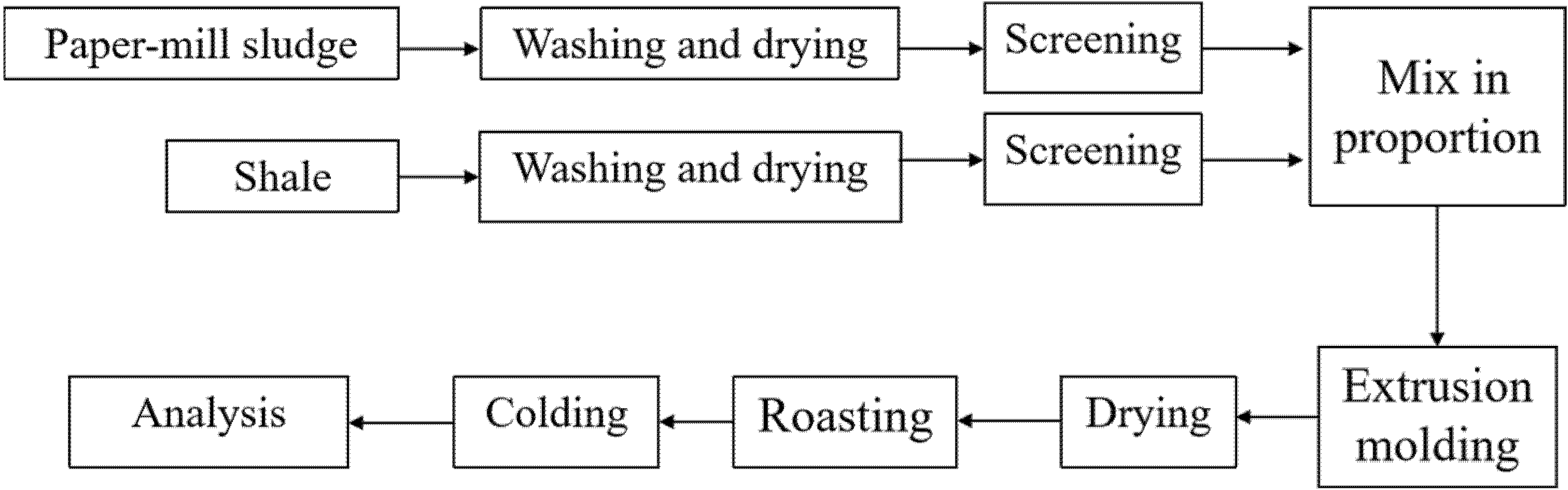

2.4. The Manufacturing and Performance Testing of Bricks

2.4.1. The Preparation of Bricks

2.4.2. The Performance Testing of Bricks

- (1)

- Compressive Strength Determination

- (2)

- Determination of Flexural Strength

- (3)

- Bulk Density Determination

- (4)

- Water Absorption Test

3. Experimental Results and Analysis

3.1. Orthogonal Test Results and Analysis

- (1)

- Experimental Results and Calculations

- (2)

- Analysis of Experimental Results

- Regarding Compressive Strength, the factors are ranked by their degree of influence as follows: raw material ratio > Temperature > Holding Time, corresponding to factors B, A, and C, respectively. Regarding Water Absorption, the order of influence is Temperature > Holding Time > raw material ratio, corresponding to factors A, C, and B, respectively. Overall, the raw material ratio and temperature are identified as the most significant factors;

- For Compressive Strength, the optimal combination of raw material ratio, Temperature, and Holding Time is B1, A2, and C1, respectively. For Water Absorption, the optimal combination is B1, A3, and C1. Since the Holding Time has the minimal impact on performance, the selection of level C1 results in negligible differences. Therefore, considering time efficiency and production costs, C1 is selected as the final parameter.

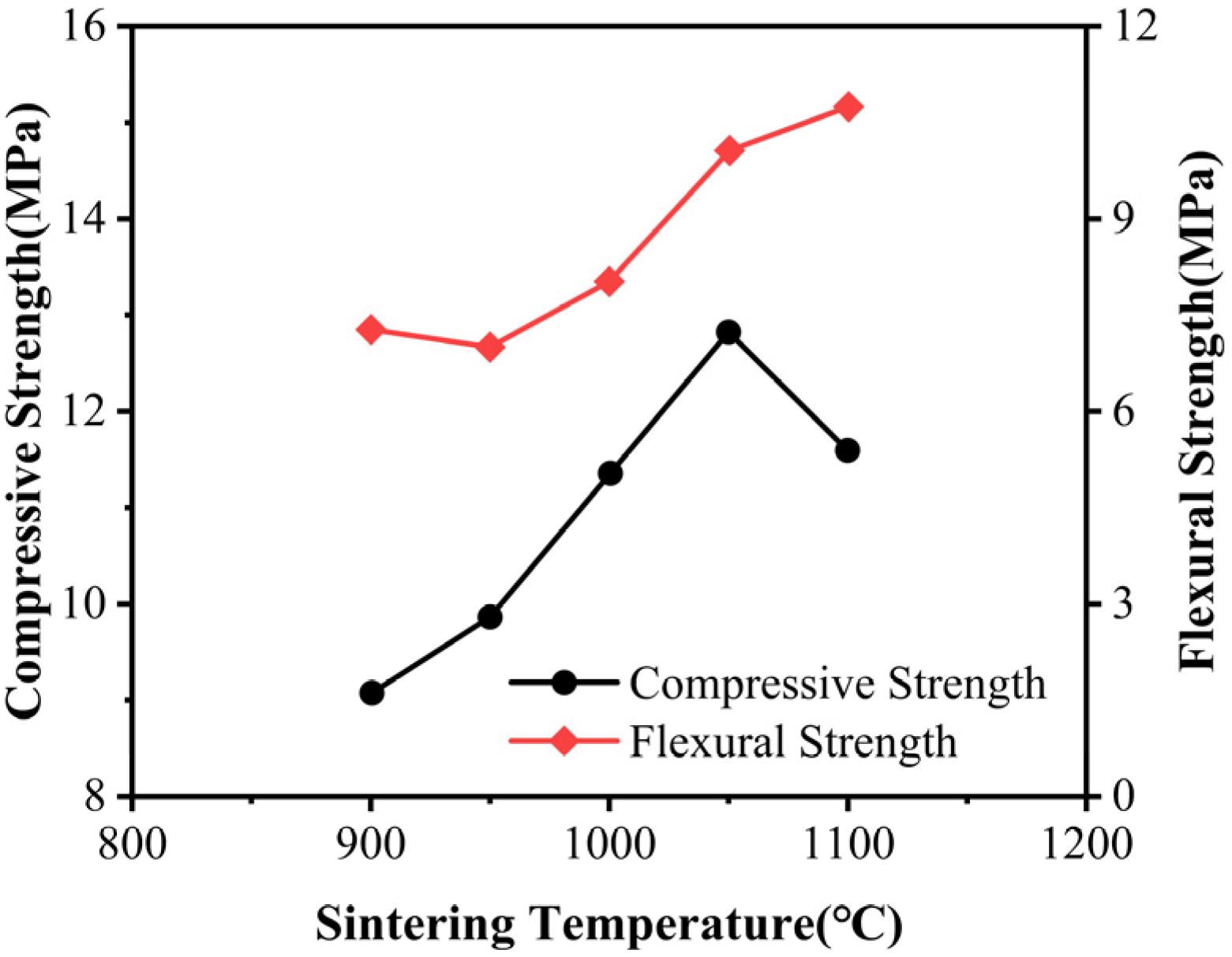

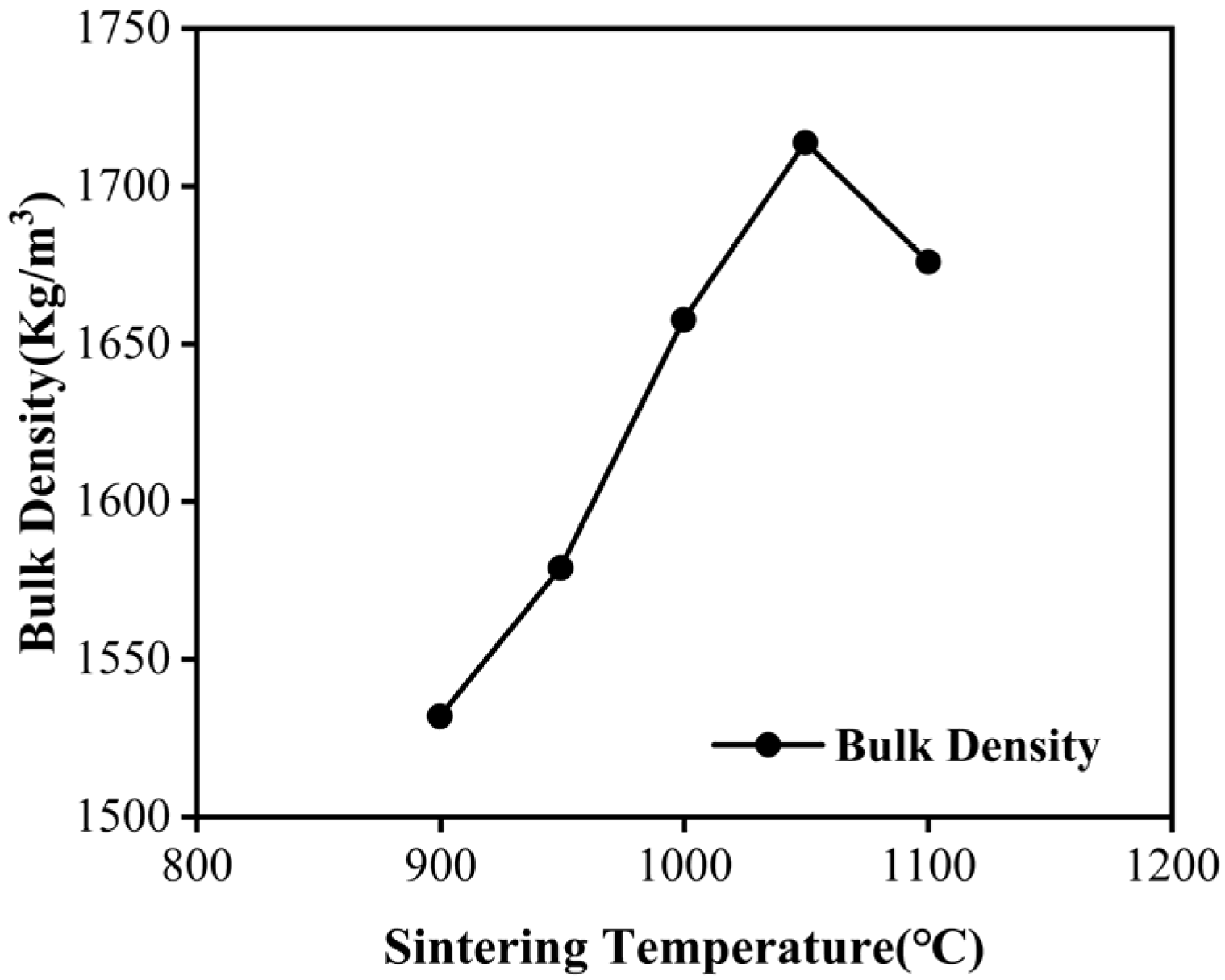

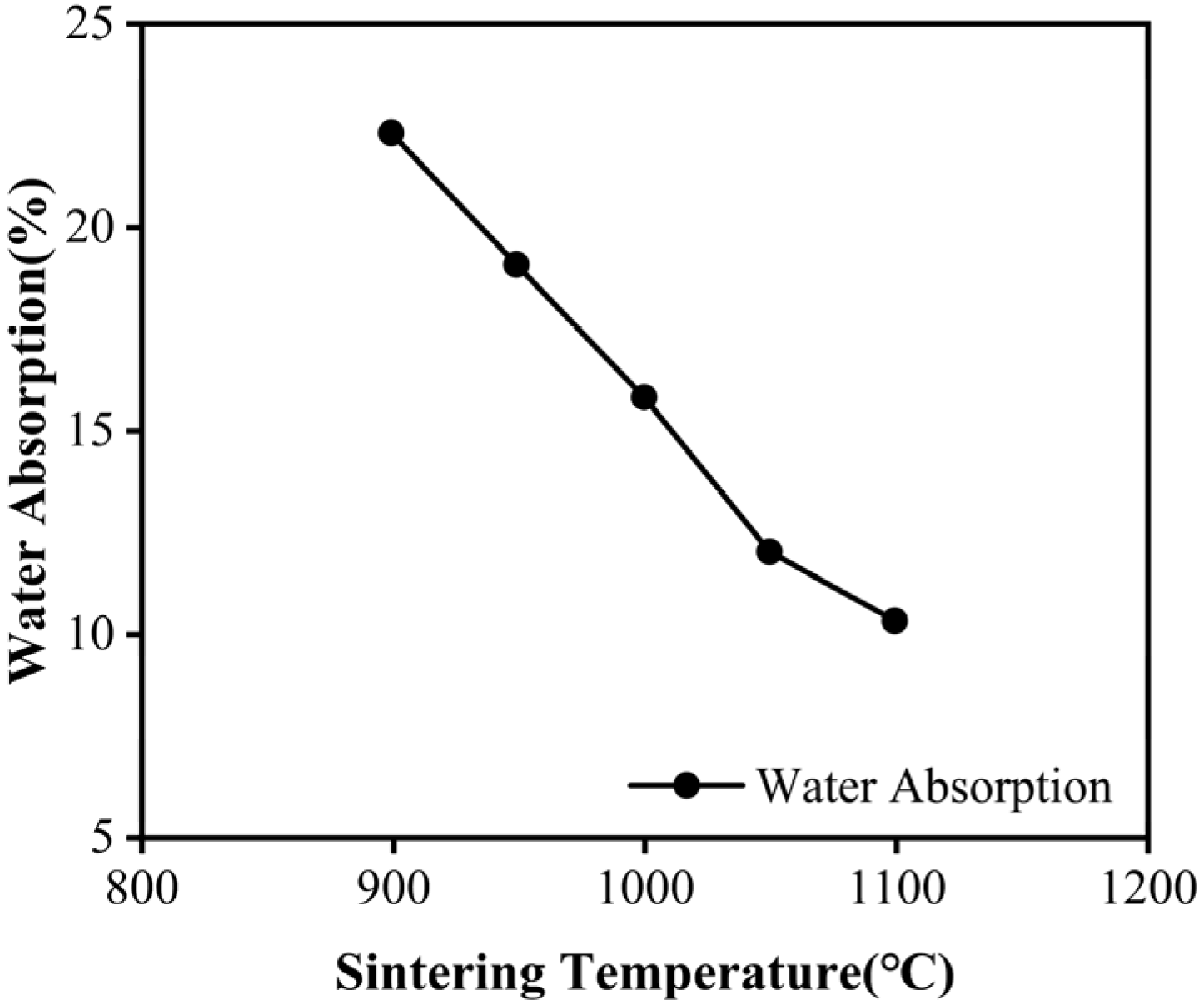

3.2. Influence of Sintering Temperature on the Properties of Paper-Mill Sludge-Shale Bricks

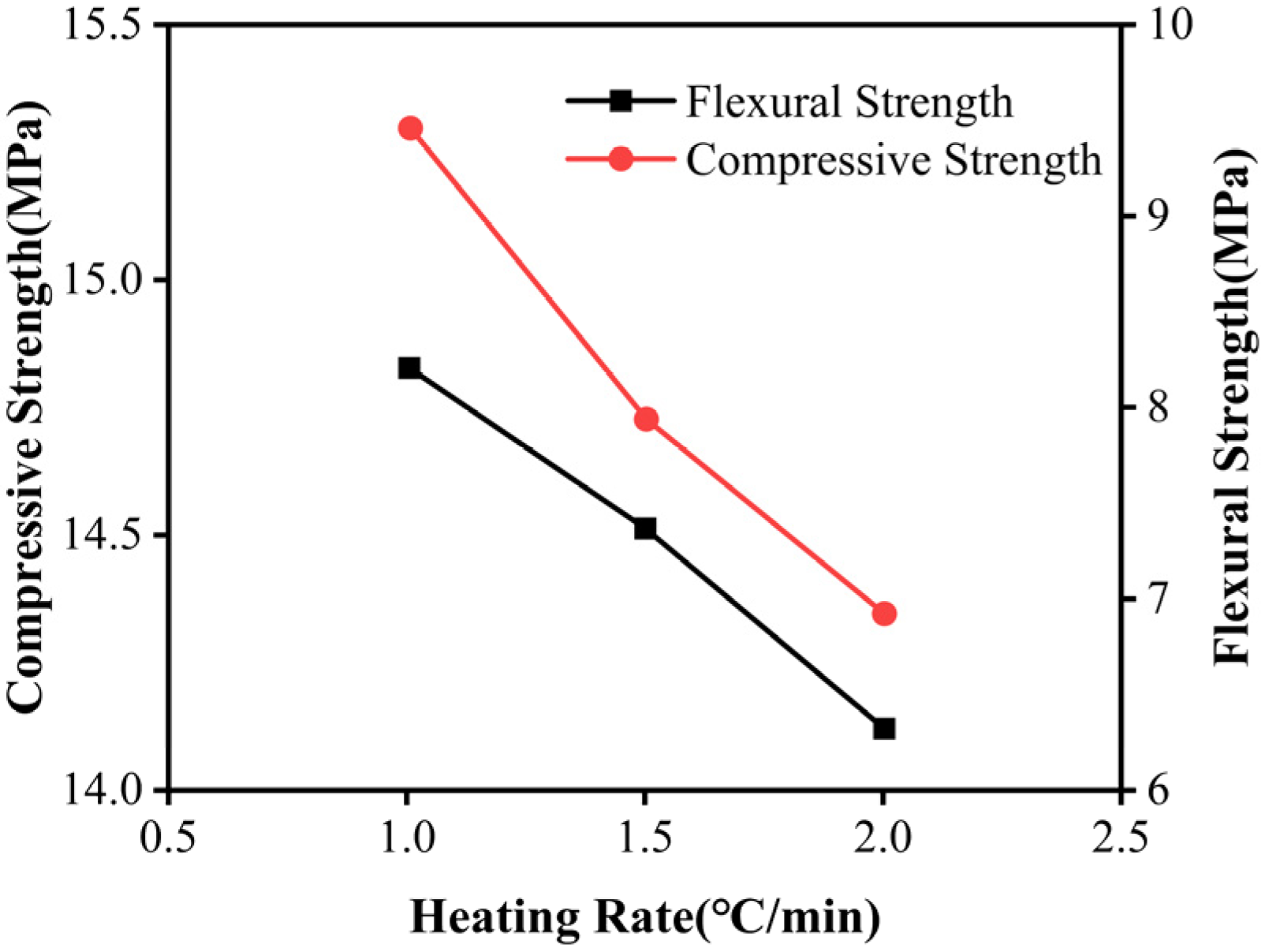

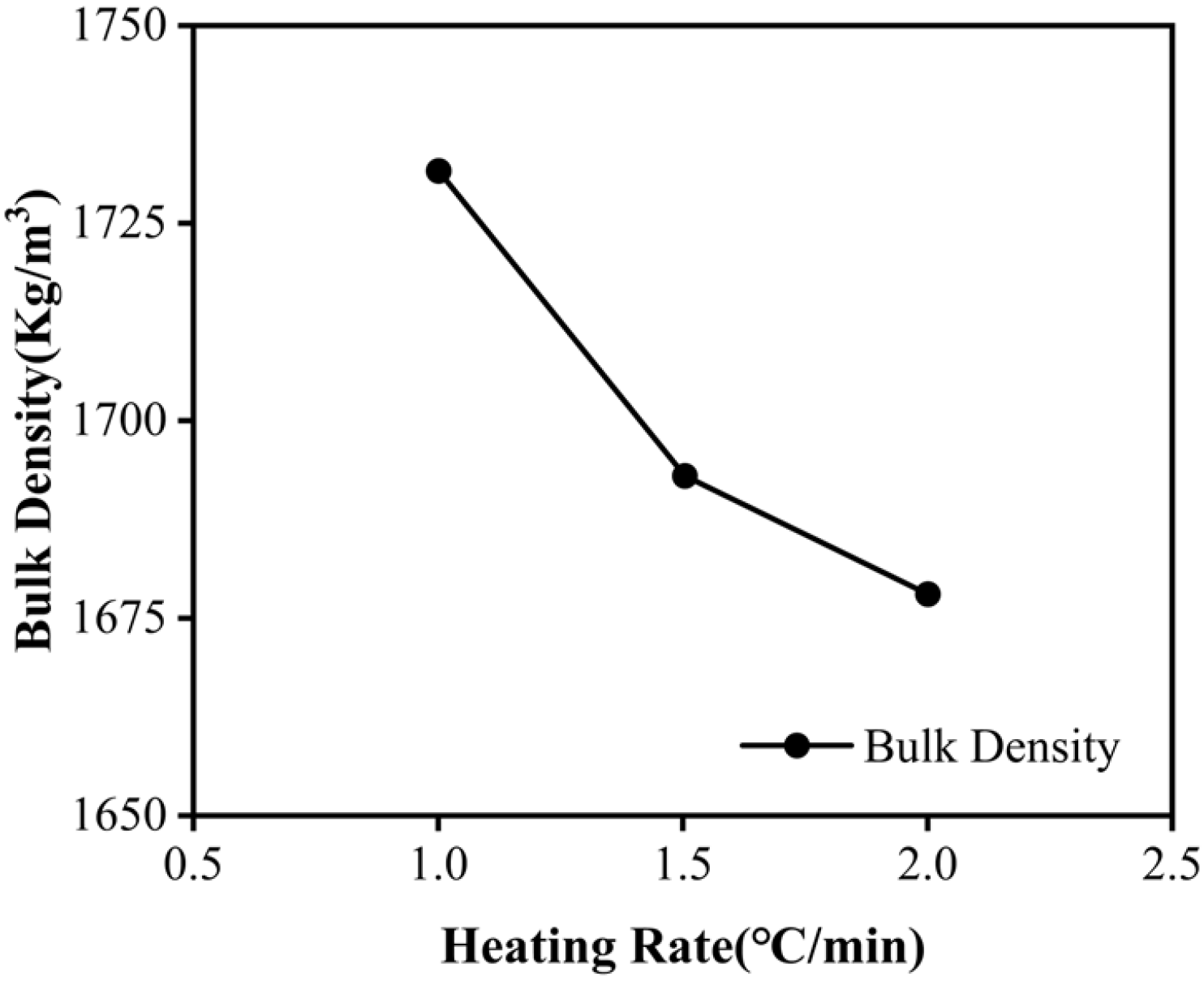

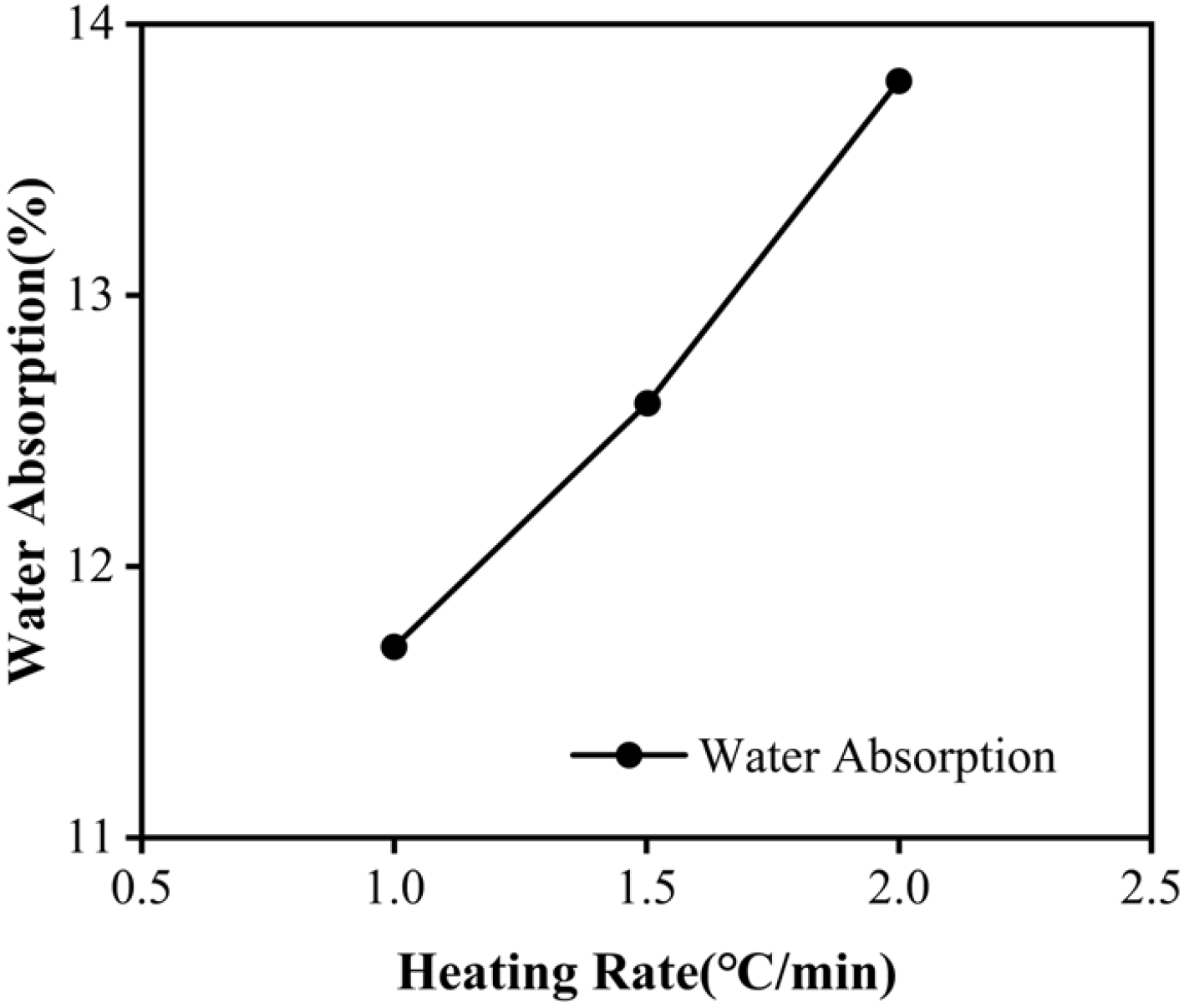

3.3. Influence of Heating Rate on the Properties of Paper-Mill Sludge-Shale Bricks

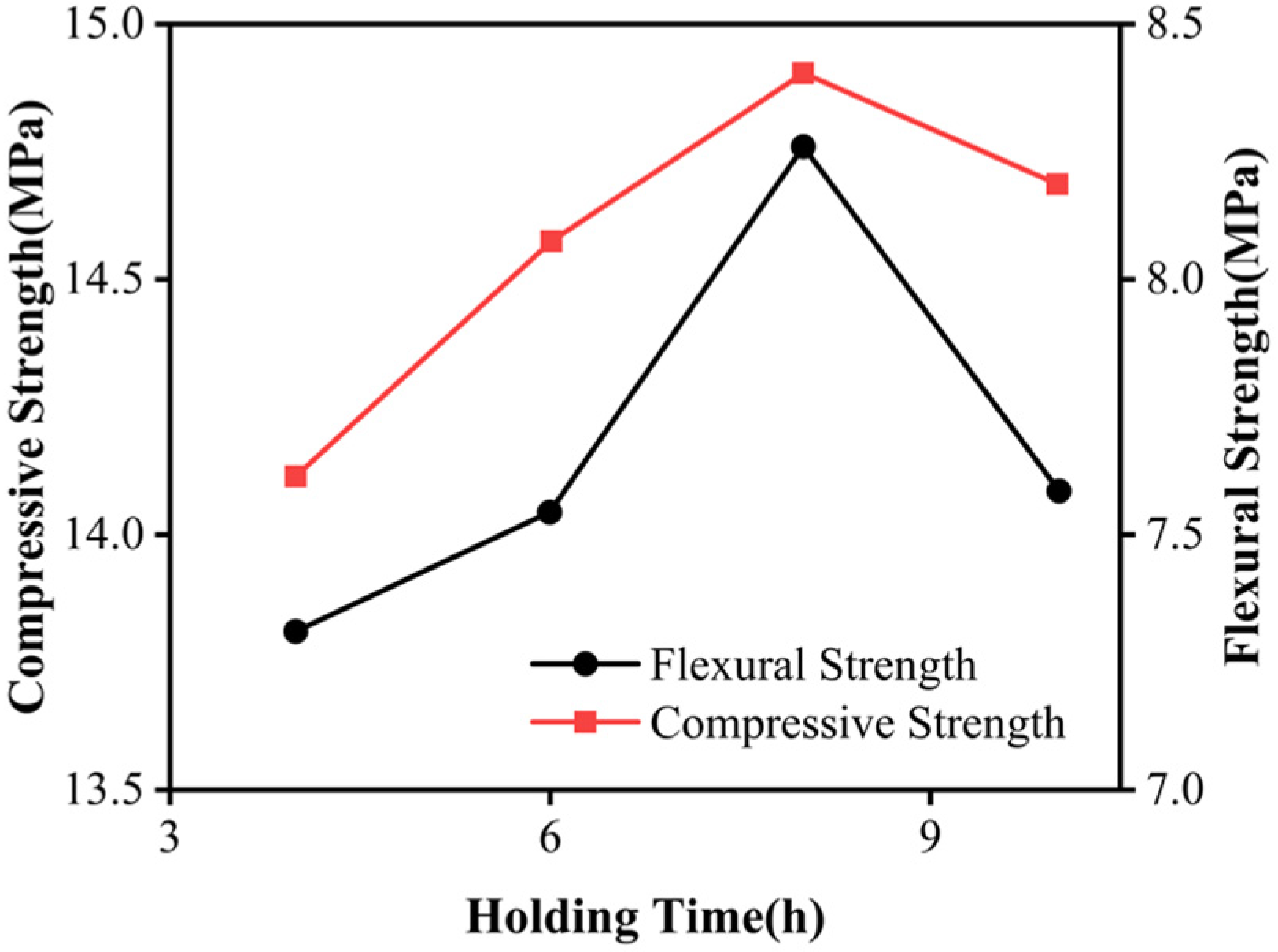

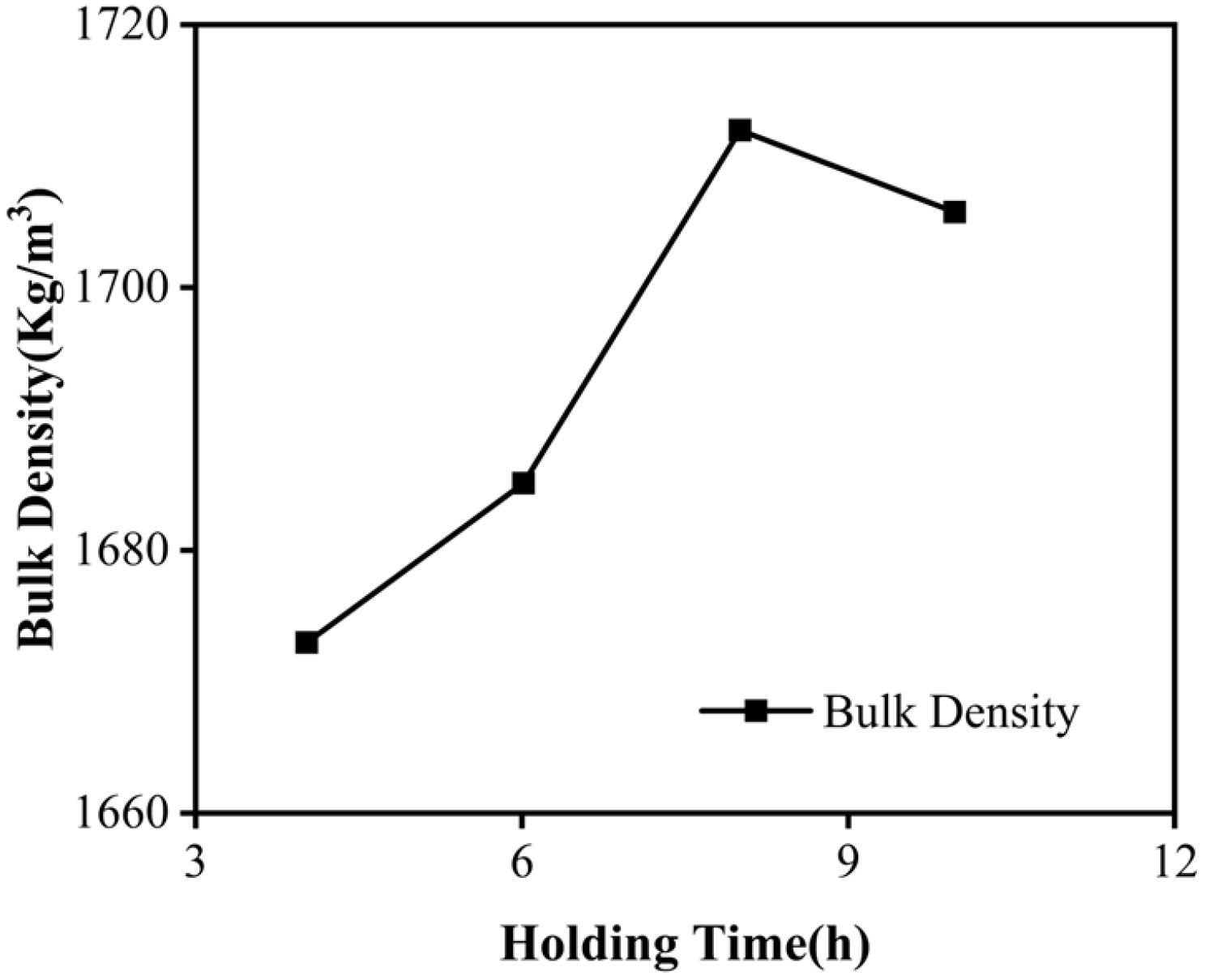

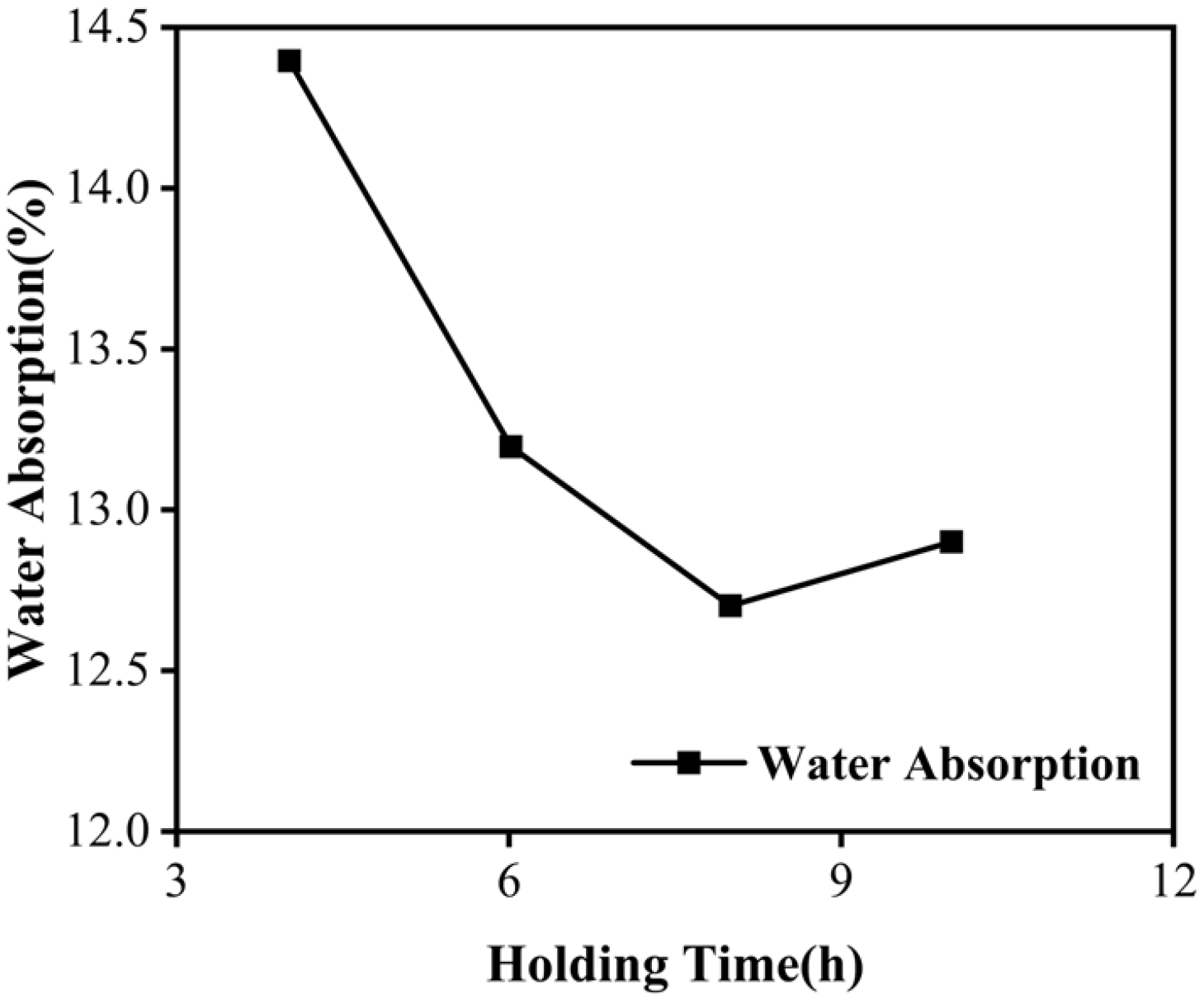

3.4. Influence of Holding Time on the Properties of Paper-Mill Sludge-Shale Bricks

3.5. Determination of the Sintering Process

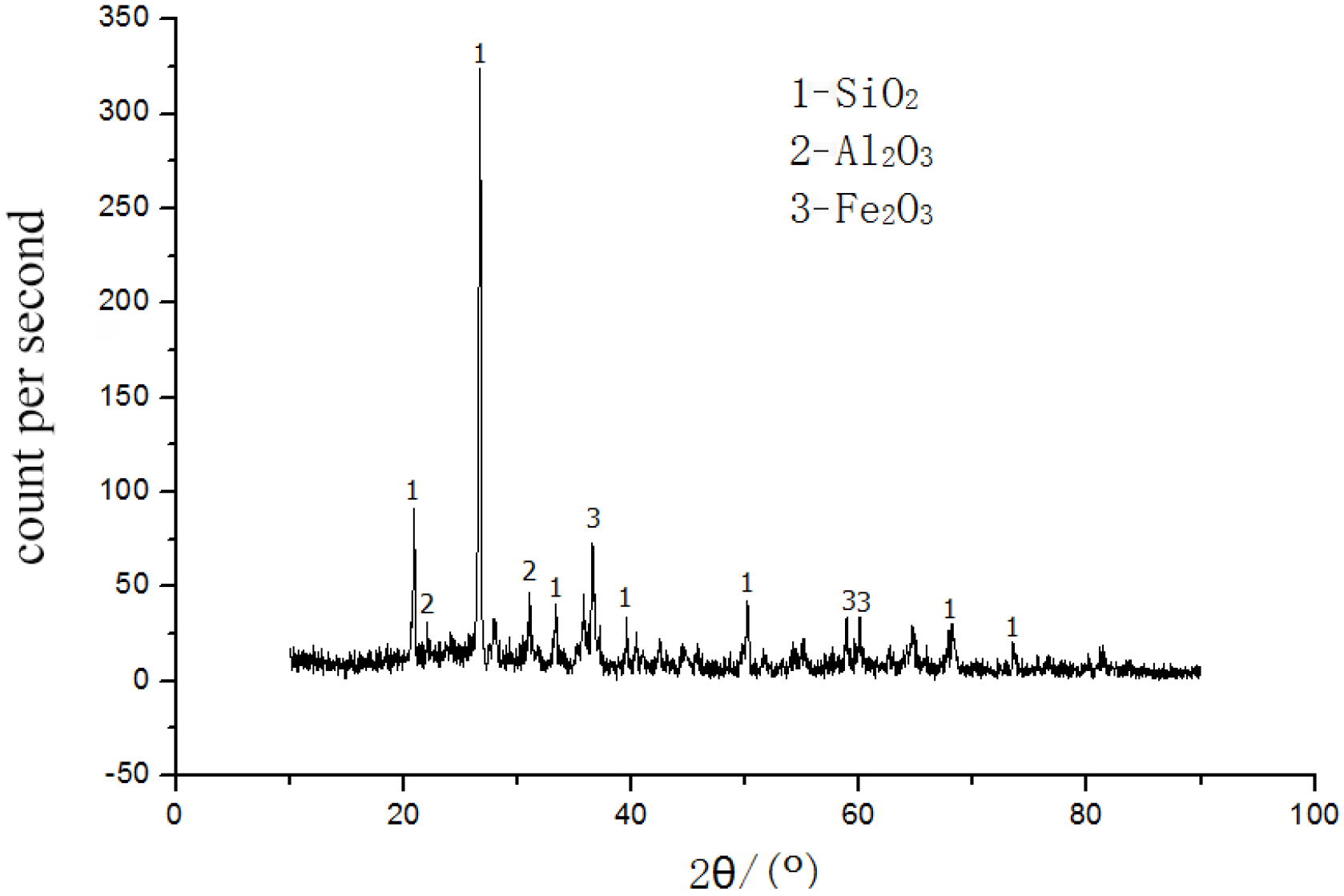

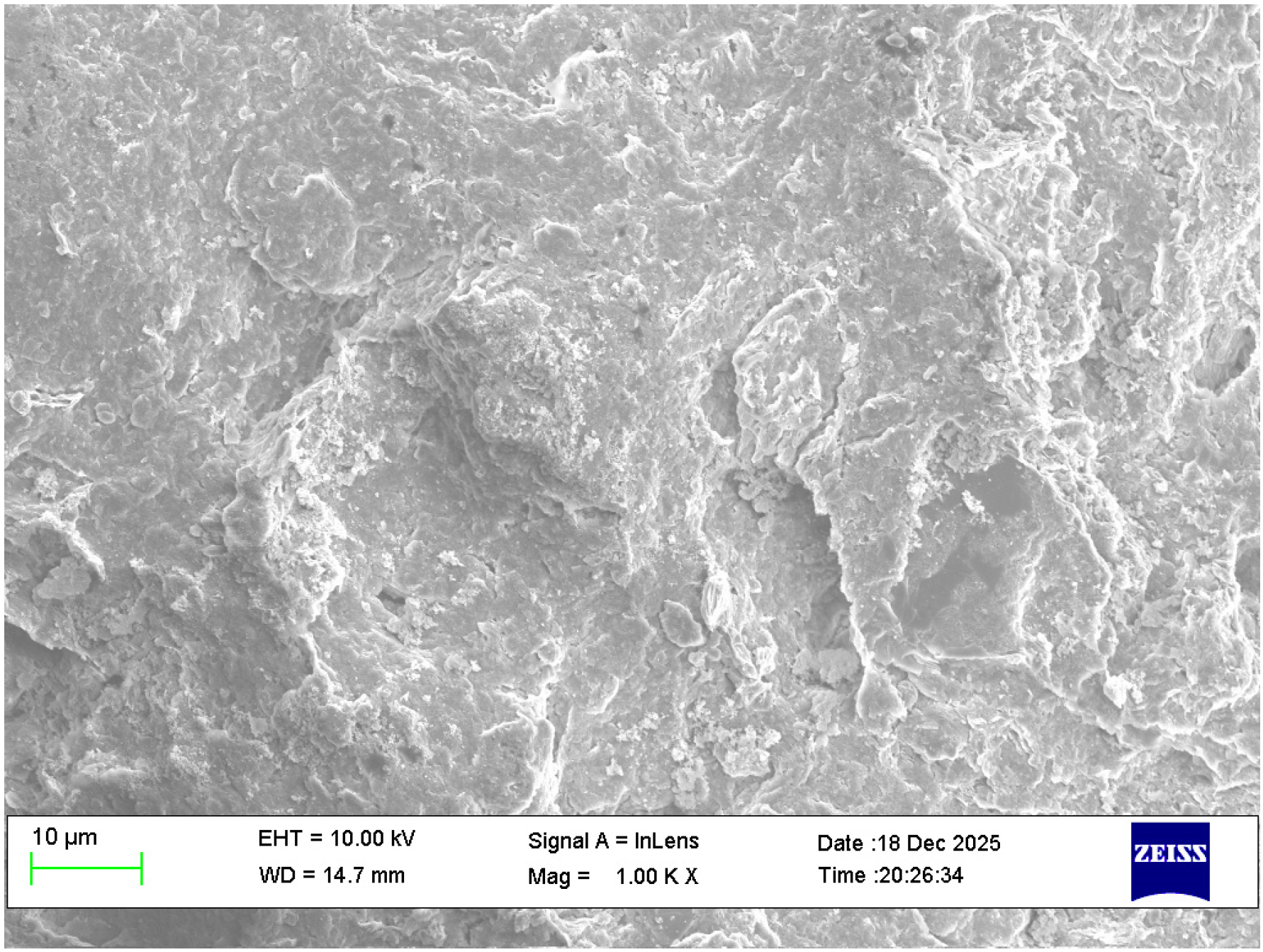

3.6. Microscopic Characterization of the Optimal Brick

4. Conclusions

- (1)

- When the sintering temperature is 1050 °C, the strength of the resulting Paper-mill Sludge-Shale Bricks can meet the requirements for Grade MU10 strength. Bricks with higher corresponding crystallinity tend to produce more molten material. The study concluded that the holding time within the range of 4 h to 10 h and the heating rate between 1 °C/min and 2 °C/min do not significantly affect the performance of the Shale bricks.

- (2)

- The optimal process parameters for the Paper-mill Sludge-Shale Bricks determined in the experiment are a holding time of 8 h, a heating rate of 1 °C/min, a sintering temperature of 1050 °C, and a cooling period of 12 h. Sintering experiments conducted using the aforementioned optimal parameters yielded the following best performance indices: compressive strength of 14.91 MPa, flexural strength of 8.26 MPa, water absorption of 12.7%, and bulk density of 1712 kg/m3. The Paper-mill Sludge-Shale Bricks sintered using this optimal process satisfy the requirements of Standard [18].

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Gottumukkala, L.D.; Haigh, K.; Collard, F.X.; Görgens, J. Opportunities and prospects of biorefinery-based valorisation of pulp and paper sludge. Bioresour. Technol. 2016, 215, 37–49. [Google Scholar] [CrossRef]

- China Paper Association. China paper industry 2019 annual report. China Pulp Pap. 2019, 38, 24–34. (In Chinese) [Google Scholar]

- Zhang, R.; Han, Q.; Hou, T.M. Research on fundamental characteristics of OCC pulp and paper sludge. China Pulp Pap. 2014, 32, 8–13. (In Chinese) [Google Scholar]

- Run, K.F. Developing high-quality sintered hollow products to meet the needs of energy-saving building walls (I). Brick Tile 2006, 1, 8–11. (In Chinese) [Google Scholar]

- Shanmugamoorthy, M. Eco-Synergy: Transforming of Agro- and Industrial Waste into Biofuel Briquettes—A Review. Indian J. Environ. Prot. 2024, 44, 1117. [Google Scholar]

- Vieira, C.M.F.; Pinheiro, R.M.; Rodriguez, R.J.S.; Candido, V.S.; Monteiro, S.N. Clay bricks added with effluent sludge from paper industry: Technical, economical and environmental benefits. Appl. Clay Sci. 2016, 132, 753–759. [Google Scholar] [CrossRef]

- Peña Rey, F.O.; Forero-Garcia, E.F.; Quezada Romero, D.A. Use of papermaking sludge in the manufacture of bricks for the construction of non-structural walls. Ingeniare Rev. Chil. Ing. 2023, 31, 25. [Google Scholar] [CrossRef]

- Makni, H.; Khlif, M.; Bradai, C. Effect of Deinking Paper Sludge on Thermal, Energetic, and Mechanical Properties of Fired Clay Bricks. J. Mater. Civ. Eng. 2024, 36, 04023610. [Google Scholar] [CrossRef]

- Zhao, D.Z. Using paper sludge for firing building bricks. China Pulp Pap. 2010, 31, 87. (In Chinese) [Google Scholar]

- Govindan, B.; Kumarasamy, V. Sustainable valorization through the reuse of incinerated paper mill sludge ash in building brick production. Constr. Build. Mater. 2024, 439, 137291. [Google Scholar] [CrossRef]

- Mekbel, S.; Debieche, M.; Nechnech, A. The potential of sludge from wastewater treatment plants to improve the mechanical properties of bricks. J. Mater. Cycles Waste Manag. 2023, 25, 3286–3302. [Google Scholar] [CrossRef]

- Moulato, K.; Ammari, M.; Ben Allal, L. Performance of sewage sludge reuse in the manufacturing of fired bricks. Glob. J. Environ. Sci. Manag. 2023, 9, 477–496. [Google Scholar]

- Hong, S.W.; Barakat, R.; Alhilali, A.; Baaj, H. Hydrophobic concrete using waste paper sludge ash. Cem. Concr. Res. 2015, 70, 9–20. [Google Scholar] [CrossRef]

- Dong, H.G.; Wang, C.G.; Tu, D.W.; Guo, X.P. Preparation and performance analysis of veneer-reinforced paper sludge wood-based panel. For. Prod. Ind. 2014, 41, 27–29. (In Chinese) [Google Scholar]

- Qin, Z.D.; Jin, L.L.; Wang, J.H.; Yi, S.L. Preparation of sludge fiberboard using Spartina alterniflora fiber and paper sludge mixture. Chin. J. Bioprocess Eng. 2014, 12, 65–68. (In Chinese) [Google Scholar]

- Gao, H.; Zhou, K.; Su, D.; Zhang, B.; Cheng, F. Sludge-based baking-free brick prepared by sewage sludge with high moisture content: Influence of process parameters and environmental risk assessment. J. Environ. Chem. Eng. 2022, 10, 108576. [Google Scholar] [CrossRef]

- Wu, J.; Yin, S.; Zhang, L.; Song, X. Manufacture of sustainable fired shale bricks using sewage sludge as raw material. Mater. Res. Express 2021, 8, 095510. [Google Scholar] [CrossRef]

- GB/T 5101-2017; Sintered Common Bricks. Standardization Administration of China: Beijing, China, 2017.

- GB/T 2542-2012; Test Methods for Masonry Bricks. Standardization Administration of China: Beijing, China, 2012.

- Li, L.P. Optimization of the configuration of 290 × 140 × 90 hollow clay bricks with 3-D numerical simulation by finite volume method. Energy Build. 2008, 40, 1790–1798. [Google Scholar] [CrossRef]

- Veiseh, S.; Yousefi, A.A. The use of polystyrene in lightweight brick production. Iran. Polym. J. 2003, 12, 323–329. [Google Scholar]

- Diaz, J.J.C. Analysis and optimization of the heat-insulating light concrete hollow brick walls design by the finite element method. Appl. Therm. Eng. 2007, 27, 1445–1456. [Google Scholar] [CrossRef]

- Bettzieche, H. Pore-forming in brick making clay by means of expanded glass granules. Ziegelind. Int. 2000, 5, 41–53. [Google Scholar]

- Li, J.N.; Huang, B.Z.; Hou, R.L.; Liu, Y. Experimental study on shear strength of paper sludge sintered shale brick masonry. New Build. Mater. 2022, 49, 88–91. (In Chinese) [Google Scholar]

- Zhang, X.J.; Zhu, H.Y.; Tang, S. Investigation and analysis of the production status of sintered shale bricks in Guangxi. Build. Energy Effic. 2013, 4, 42–45. (In Chinese) [Google Scholar]

- Wang, Q. Research on the Utilization Technology of Municipal Sewage Treatment Plant Sludge in Building Materials. Master’s Thesis, Chang’an University, Xi’an, China, 2010. (In Chinese). [Google Scholar]

- Liu, R.J.; Zhang, Y.W.; Wen, C.W.; Tang, X. Research on orthogonal experimental design and analysis method. Exp. Technol. Manag. 2010, 27, 52–55. (In Chinese) [Google Scholar]

- Fang, K.T.; Ma, C.X. Orthogonal and Uniform Experimental Design; Science Press: Beijing, China, 2001. (In Chinese) [Google Scholar]

| Test Item | Test Result |

|---|---|

| Lead/(mg·kg−1) | 0.4 |

| Cadmium/(mg·kg−1) | 1.0 |

| Chromium/(mg·kg−1) | 0.3 |

| Arsenic/(mg·kg−1) | 1.0 |

| Mercury/(mg·kg−1) | 0.15 |

| Potassium/(mg·kg−1) | 0.37 |

| Nitrogen/% | 2.07 |

| Phosphorus/% | 0.25 |

| Organic matter/% | 25.62 |

| Sodium/% | 2.0 |

| Moisture Content/% | 53 |

| Ignition loss | 13.84 |

| PH | 8.3 |

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | K2O | MgO | CaO | Na2O | Ignition Loss |

|---|---|---|---|---|---|---|---|---|

| Percentage | 54.60% | 23.15% | 10.52% | 2.60% | 1.35% | 1.22% | 1.20% | 5.36% |

| Material Composition | 1 | 2 | 3 | 4 |

|---|---|---|---|---|

| Shale | 100% | 90% | 80% | 70% |

| Black Sludge | 0% | 10% | 20% | 30% |

| Factors | Temperature (°C) | Paper-Mill Sludge:Shale | Holding Time (h) |

|---|---|---|---|

| Level 1 | 1050 | 30:70 | 8 |

| Level 2 | 1000 | 20:80 | 7 |

| Level 3 | 950 | 10:90 | 6 |

| Test No.\Factors | A | B | C |

|---|---|---|---|

| Temperature | Paper-Mill Sludge:Shale | Holding Time | |

| 1 | 1050 | 30:70 | 8 |

| 2 | 1050 | 20:80 | 6 |

| 3 | 1050 | 10:90 | 7 |

| 4 | 1000 | 30:70 | 6 |

| 5 | 1000 | 20:80 | 7 |

| 6 | 1000 | 10:90 | 8 |

| 7 | 950 | 30:70 | 7 |

| 8 | 950 | 20:80 | 8 |

| 9 | 950 | 10:90 | 6 |

| No. | A | B | C | Results | |

|---|---|---|---|---|---|

| Water Absorption (%) | Compressive Strength (MPa) | ||||

| 1 | 1 | 1 | 1 | 12.2 | 14.54 |

| 2 | 1 | 2 | 3 | 19.1 | 8.1 |

| 3 | 1 | 3 | 2 | 21.5 | 5.5 |

| 4 | 2 | 1 | 3 | 14.4 | 10.6 |

| 5 | 2 | 2 | 2 | 16.3 | 12.4 |

| 6 | 2 | 3 | 1 | 20.3 | 6.5 |

| 7 | 3 | 1 | 2 | 18.2 | 8.6 |

| 8 | 3 | 2 | 1 | 15.2 | 11.8 |

| 9 | 3 | 3 | 3 | 17.5 | 8.6 |

| Evaluation Indicator | Computed Value | Temperature (°C) | Black Sludge:Shale | Holding Time (h) |

|---|---|---|---|---|

| Compressive Strength | k1 | 9.38 | 11.25 | 10.95 |

| k2 | 9.83 | 10.77 | 8.83 | |

| k3 | 9.67 | 6.87 | 9.10 | |

| R | 0.45 | 4.38 | 2.12 | |

| Factor Priority Ranking | B > A > C | |||

| Optimal Parameter Combination | A2B1C1 | |||

| Water Absorption | k1 | 17.60 | 14.93 | 15.90 |

| k2 | 17.00 | 16.87 | 18.67 | |

| k3 | 16.97 | 19.77 | 17.00 | |

| R | 0.63 | 4.84 | 2.77 | |

| Factor Priority Ranking | A > C > B | |||

| Optimal Parameter Combination | A3B1C1 | |||

| Temperature T (°C) | Compressive Strength Rp (MPa) | Flexural Strength Rc (MPa) | Bulk Density ρ (kg/m3) | Water Absorption W (%) |

|---|---|---|---|---|

| 900 | 11.84 | 4.27 | 1532 | 22.3 |

| 950 | 11.57 | 5.13 | 1579 | 19.1 |

| 1000 | 12.48 | 6.79 | 1657 | 15.8 |

| 1050 | 14.31 | 8.43 | 1714 | 12.1 |

| 1100 | 14.92 | 7.05 | 1677 | 10.4 |

| Heating Rate (°C/min) | Compressive Strength (MPa) | Flexural Strength (MPa) | Bulk Density (kg/m3) | Water Absorption (%) |

|---|---|---|---|---|

| 1 | 15.21 | 8.35 | 1732 | 11.7 |

| 1.5 | 14.67 | 7.43 | 1692 | 12.6 |

| 2 | 14.32 | 6.34 | 1678 | 13.8 |

| Holding Time (h) | Flexural Strength (MPa) | Water Absorption (%) | Compressive Strength (MPa) | Bulk Density (kg/m3) |

|---|---|---|---|---|

| 4 | 7.31 | 14.5 | 14.12 | 1673 |

| 6 | 7.55 | 13.2 | 14.58 | 1685 |

| 8 | 8.26 | 12.7 | 14.91 | 1712 |

| 10 | 7.59 | 12.9 | 14.69 | 1706 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2026 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Meng, Q.-P.; Zeng, J.-Y.; Wu, Y.; Li, L. Study on the Influence of the Sintering Process on the Performance of Paper-Mill Sludge–Shale Bricks. Buildings 2026, 16, 238. https://doi.org/10.3390/buildings16010238

Meng Q-P, Zeng J-Y, Wu Y, Li L. Study on the Influence of the Sintering Process on the Performance of Paper-Mill Sludge–Shale Bricks. Buildings. 2026; 16(1):238. https://doi.org/10.3390/buildings16010238

Chicago/Turabian StyleMeng, Qing-Peng, Jun-Yi Zeng, You Wu, and Li Li. 2026. "Study on the Influence of the Sintering Process on the Performance of Paper-Mill Sludge–Shale Bricks" Buildings 16, no. 1: 238. https://doi.org/10.3390/buildings16010238

APA StyleMeng, Q.-P., Zeng, J.-Y., Wu, Y., & Li, L. (2026). Study on the Influence of the Sintering Process on the Performance of Paper-Mill Sludge–Shale Bricks. Buildings, 16(1), 238. https://doi.org/10.3390/buildings16010238