Condensation Risk Under Different Window-Opening Behaviours in a Residential Building in Changsha During Plum Rains Season

Abstract

1. Introduction

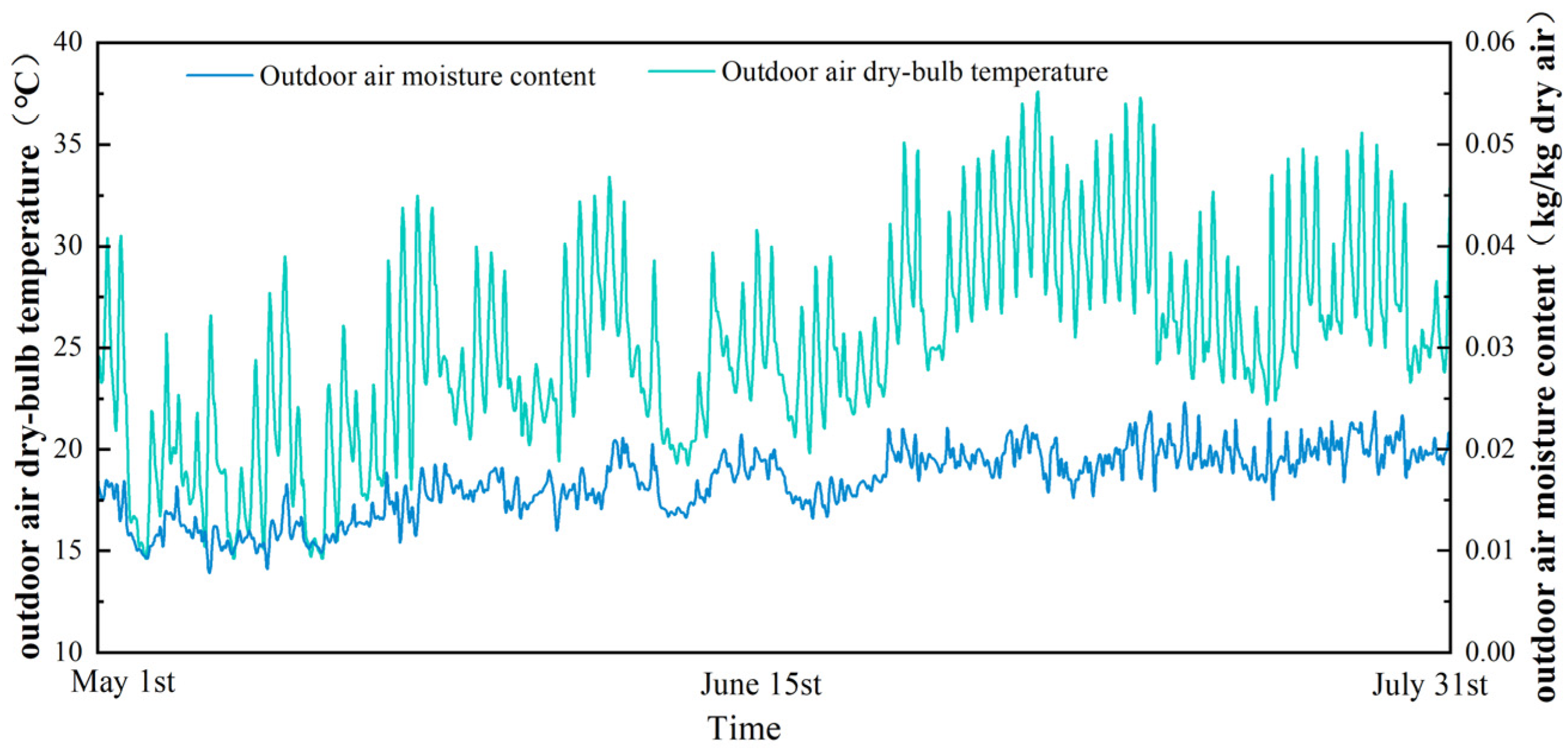

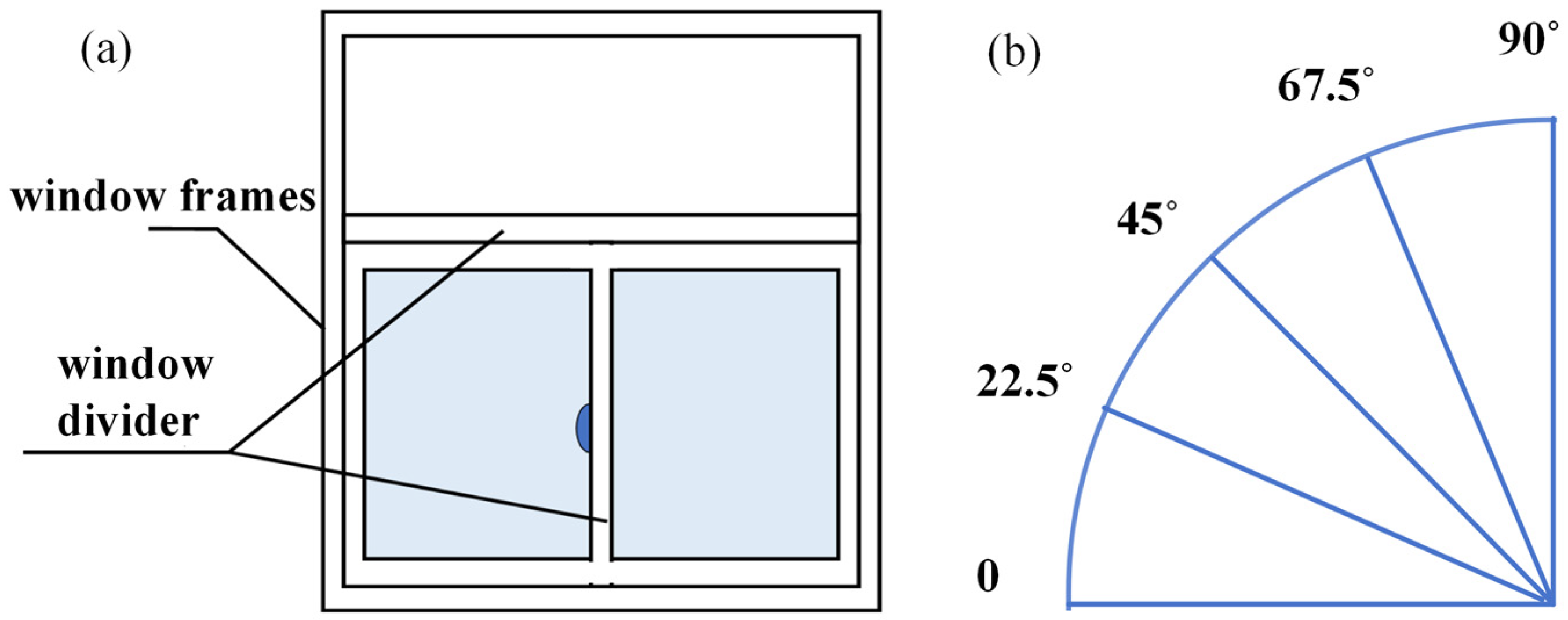

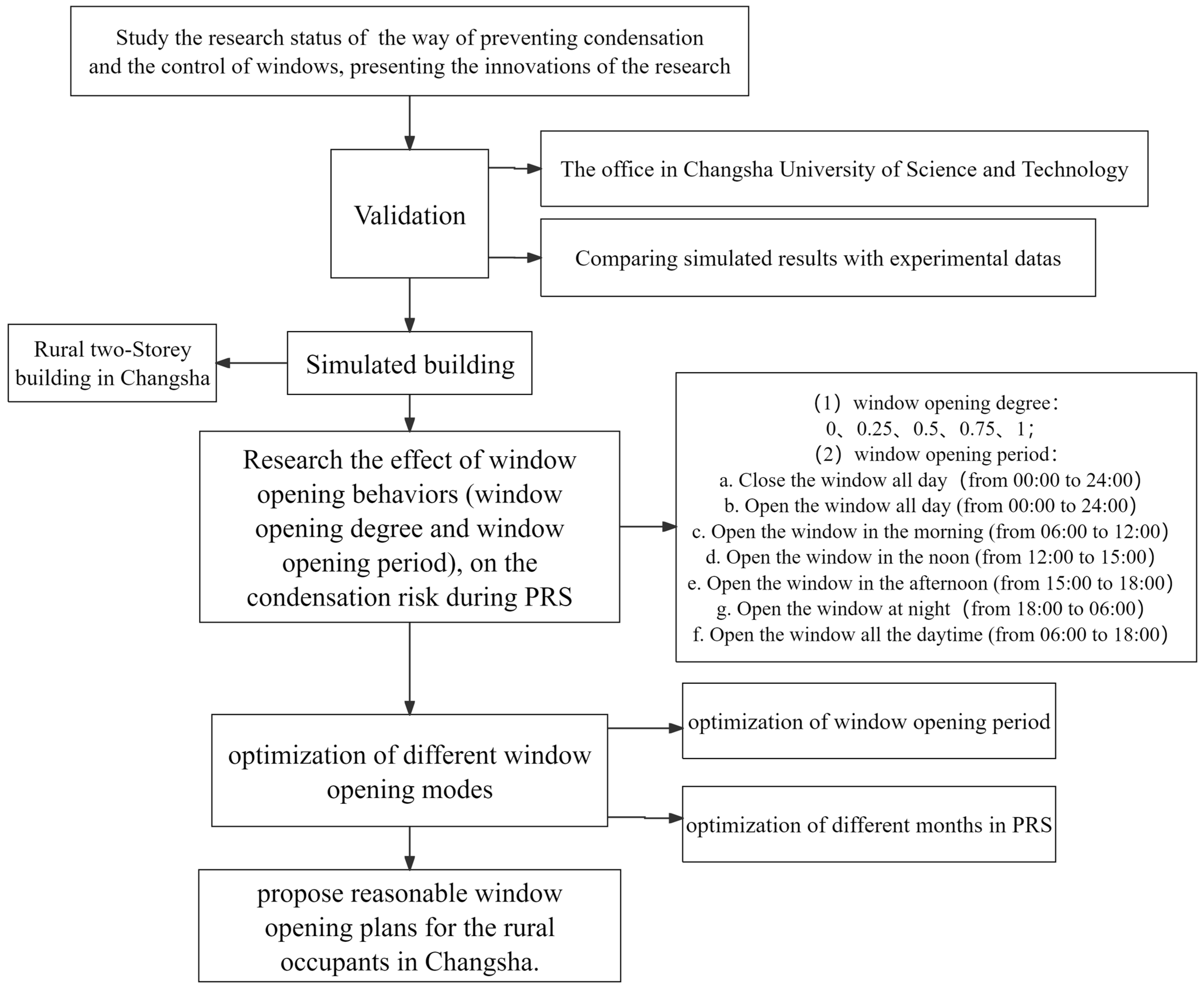

2. Materials and Methods

2.1. Experimental Building

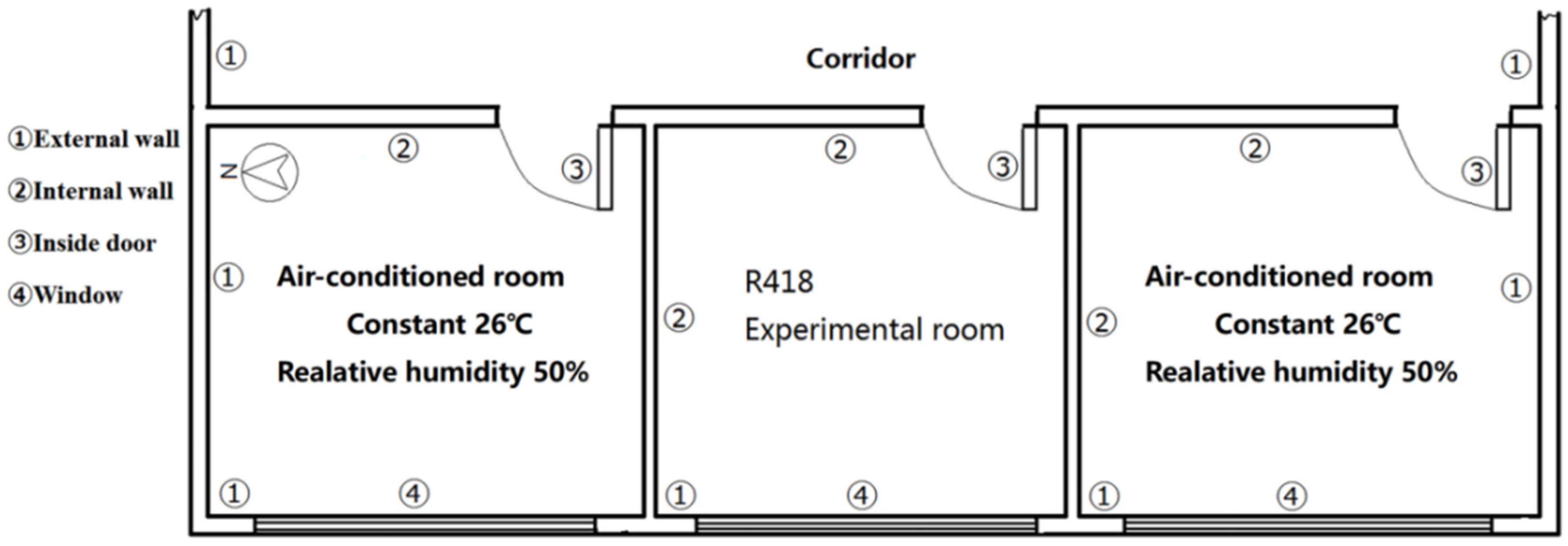

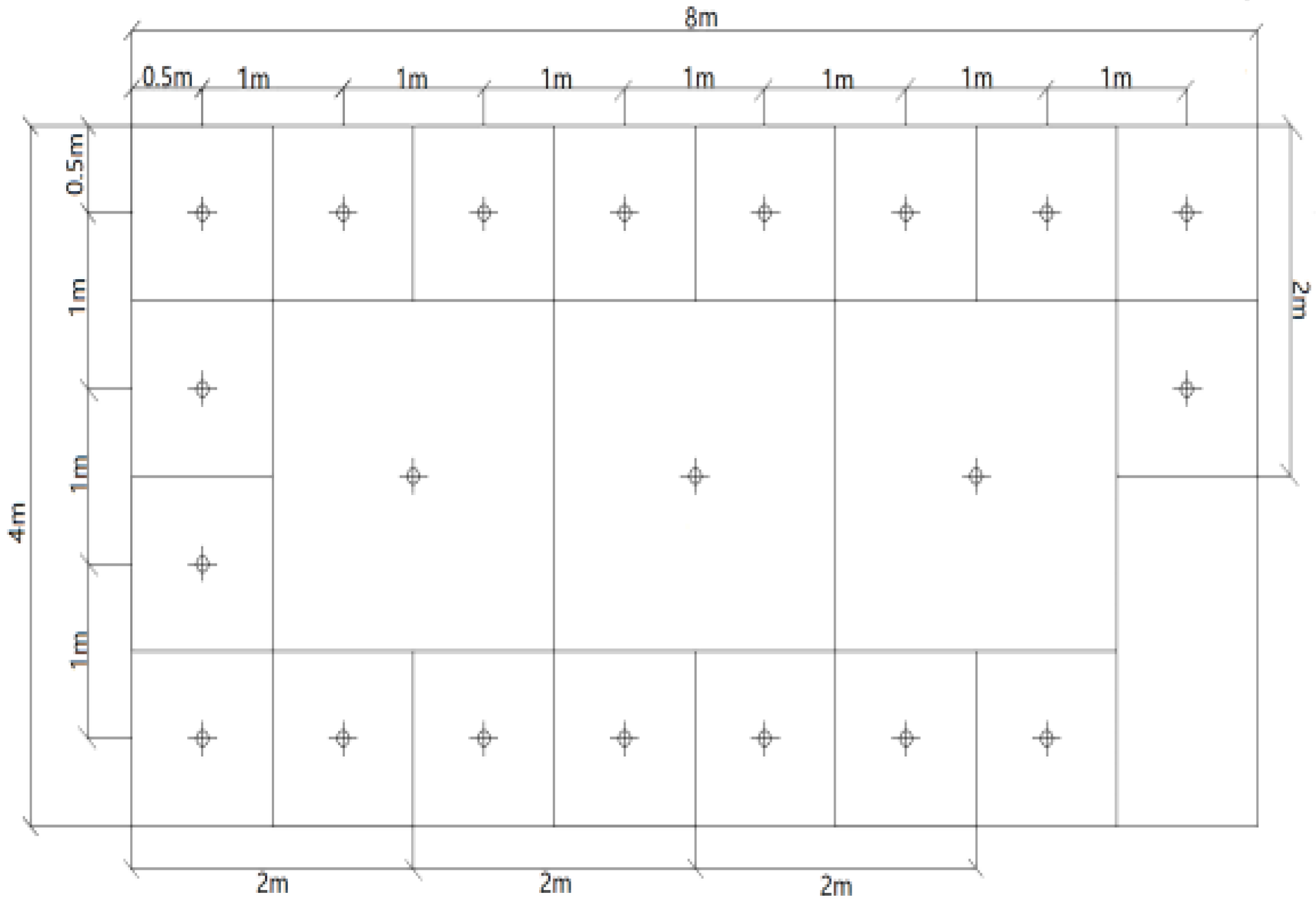

2.2. Measurement

- 1.

- Measurement of indoor air temperature

- 2.

- Measurement of indoor air moisture content

- 3.

- Measurement of the internal surface temperature of individual walls

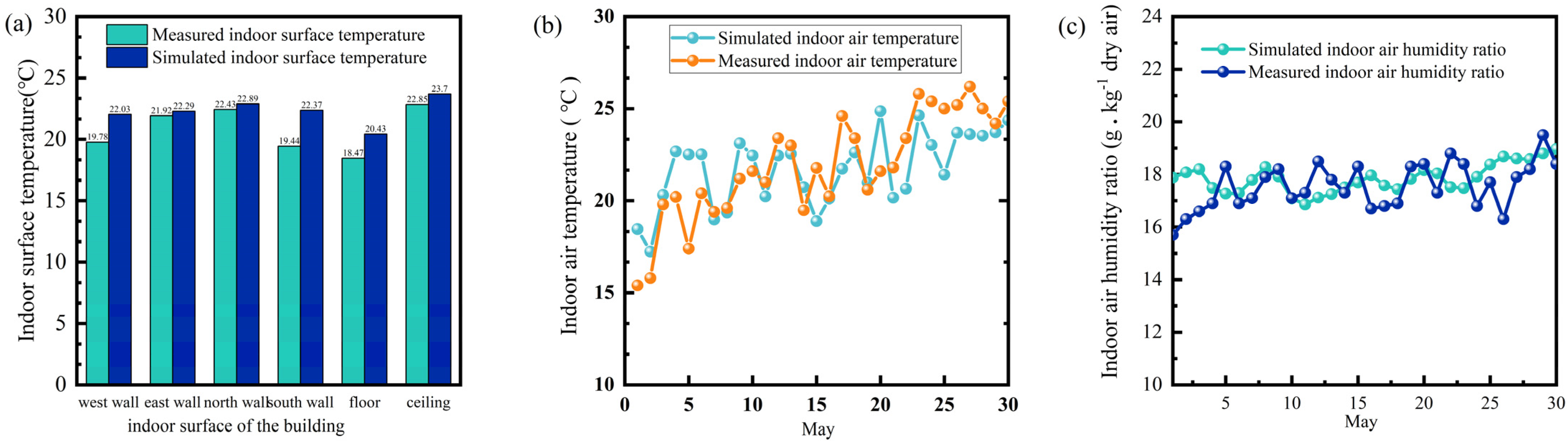

2.3. Comparison of Measurement and Simulation Results

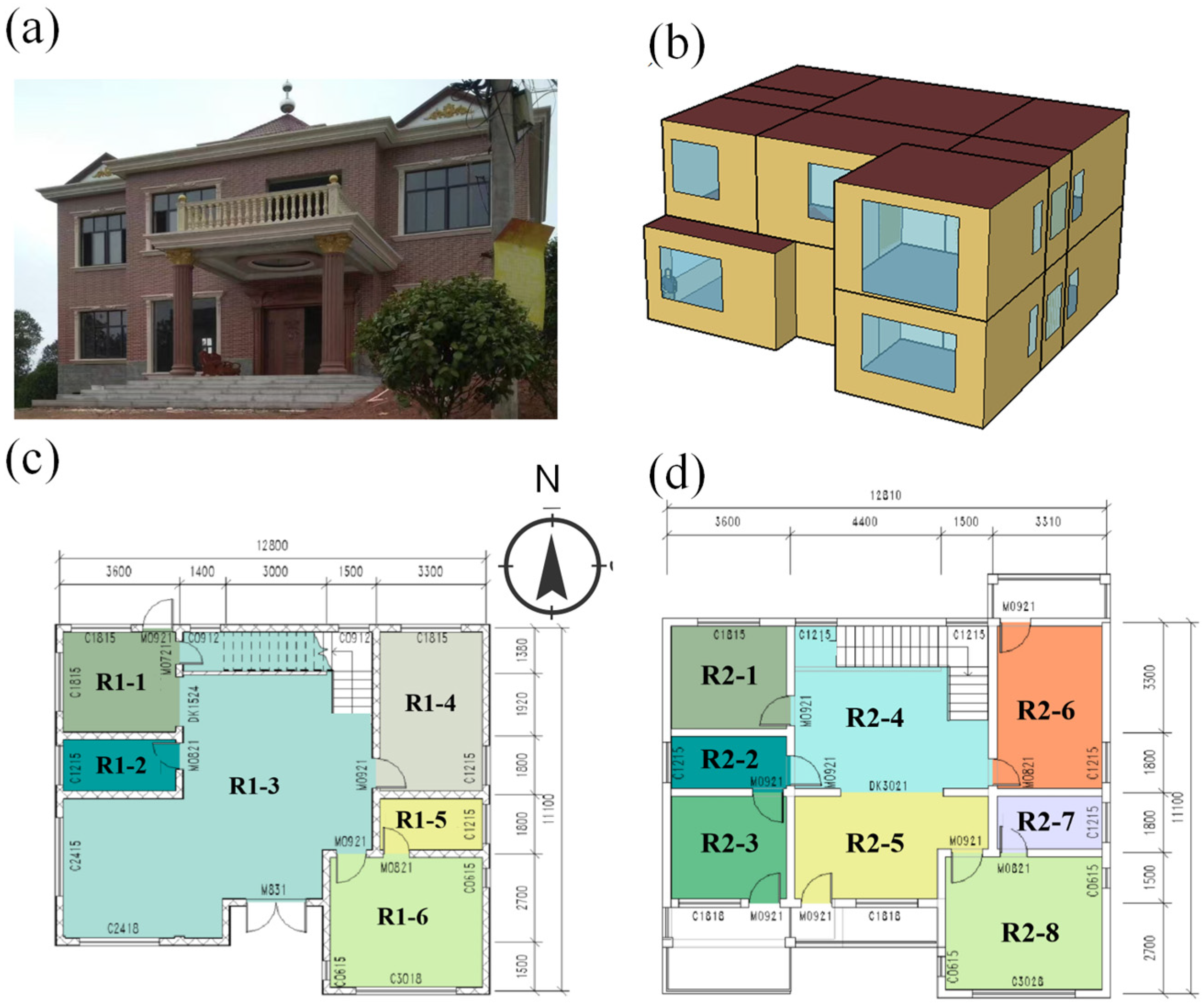

2.4. Rural Residential Building Model

2.5. Building Model Parameter Settings

2.6. Indicators for Evaluating Condensation Conditions

2.7. Simulation Procedures

3. Results and Discussion

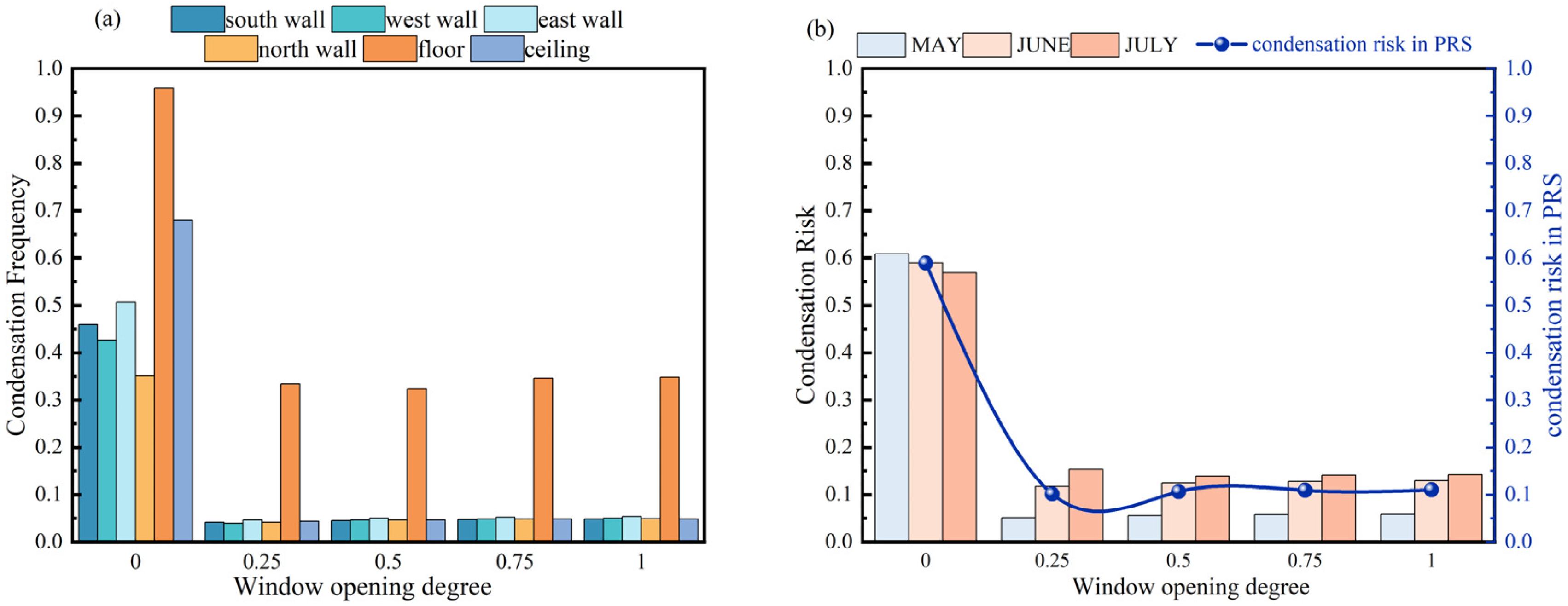

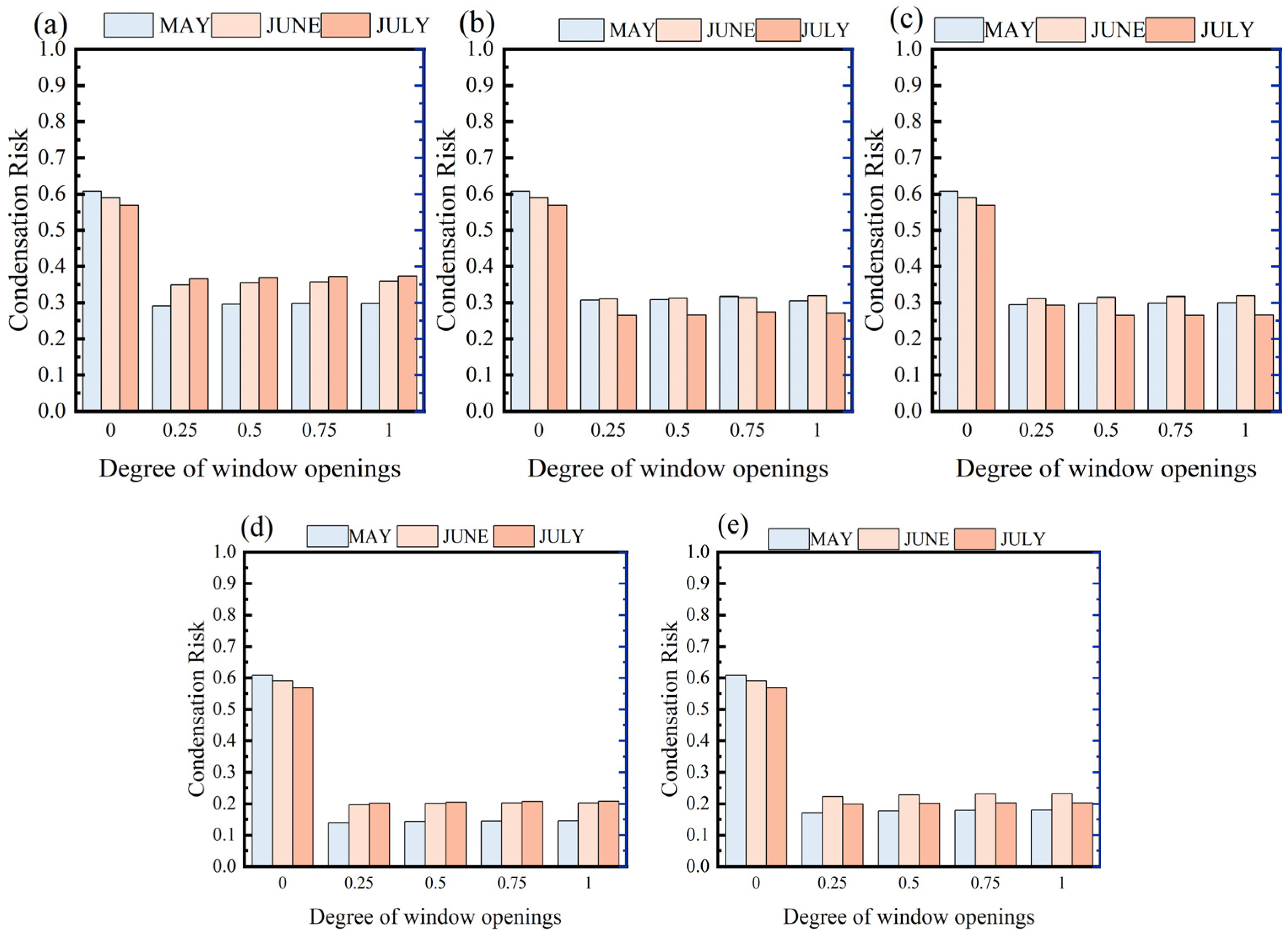

3.1. Effect of Windows Opening Degree on Indoor Humidity Environment

3.2. Effect of Window Opening Duration on Indoor Humidity Environment

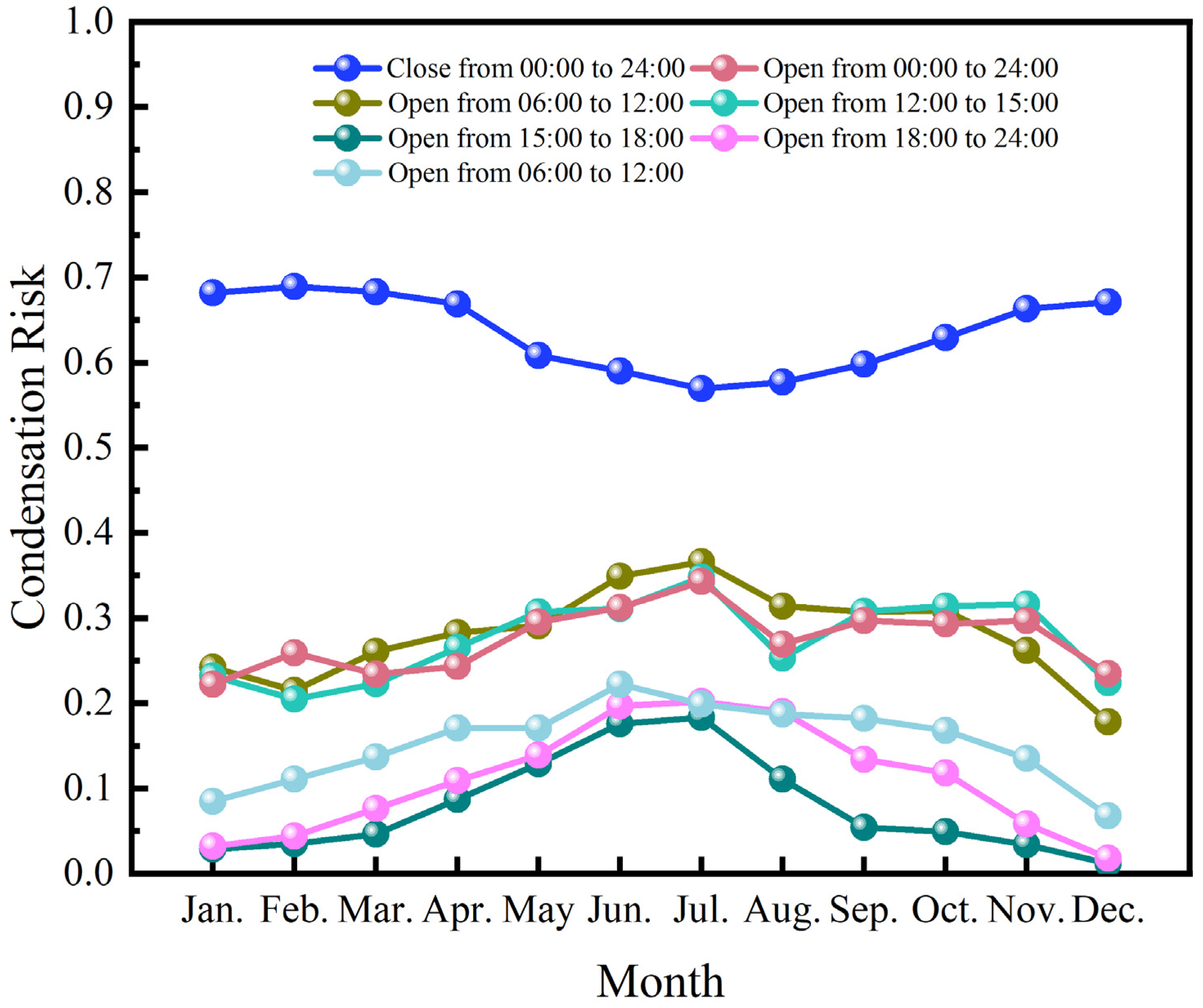

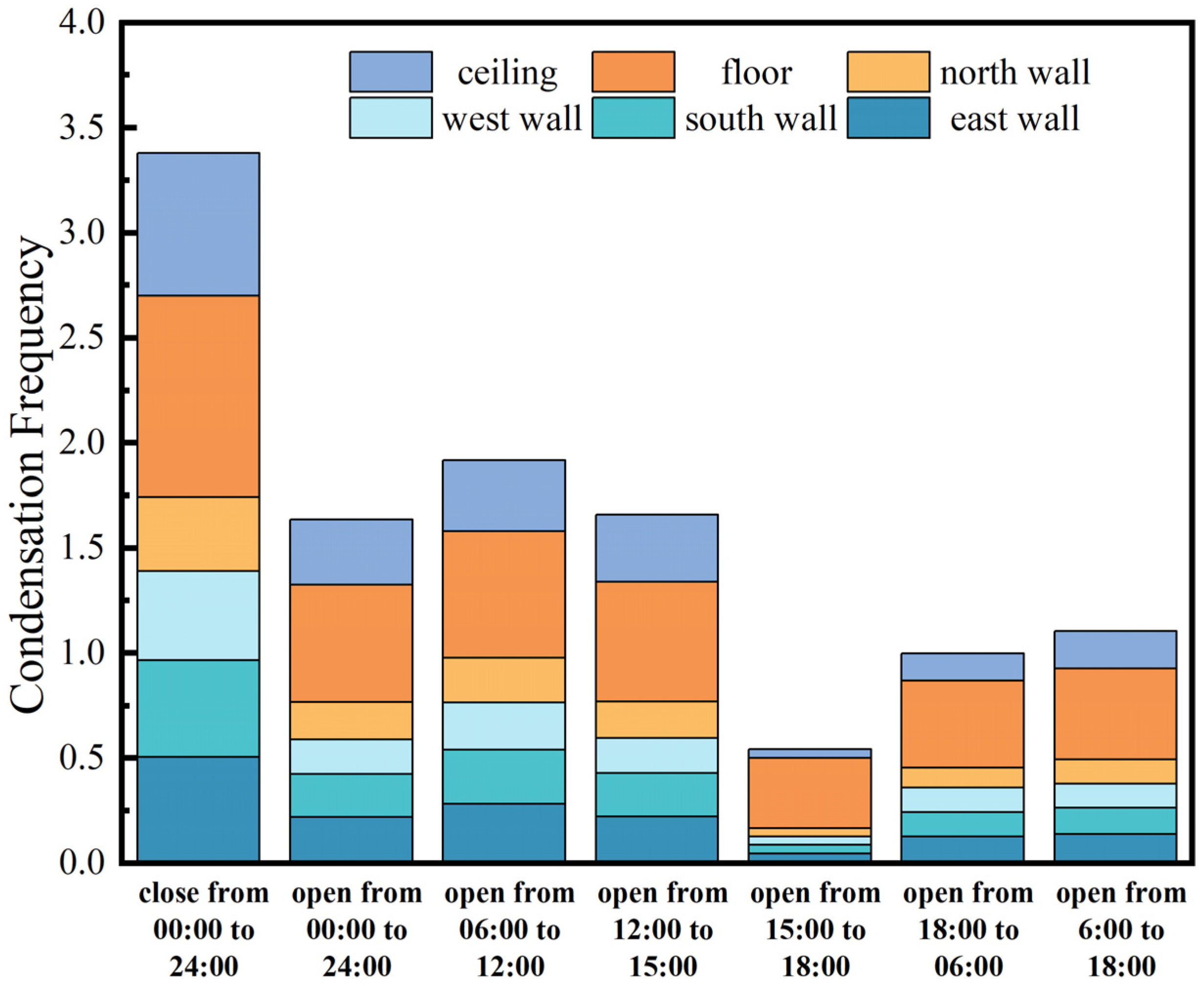

- Long-term window closing prevents moisture generated by indoor occupant activities from escaping, and the accumulated moisture could significantly increase the CR on the interior surfaces. Thus, the CR curve for all-day and all-night window closures was much higher than other periods.

- When the window was open in the morning, in the noon and in the late afternoon during the PRS, their annual CRs were 0.335, 0.294 and 0.149, respectively. The CR of window opening in the morning was the highest of three, which was affected by the daily cycle of variations in temperature and humidity. The air temperature and humidity rise rapidly in the morning, while the ground temperature and the internal surface temperatures of the enclosure structure rise slowly so that when the window is open in the morning, condensation is more likely to occur. Furthermore, the humidity of early morning in PRS is close to saturation, and the cold, moist outdoor air is denser; when sinking and rapid contact with low-temperature surfaces, a sudden increase in local humidity accelerates condensation. In the afternoon, when the outdoor air temperature is higher, warm and humid air mobility is stronger, so the indoor environment is mixed more uniformly, and moisture is not easy to gather local condensation. Moreover, the surface temperature rises after heat absorption. Therefore, compared with the other two time periods during the daytime during the PRS, windows should be open in the afternoon to alleviate the risk of indoor surface condensation.

- The annual CR of windows opening during the daytime and windows opening at night was 0.153 and 0.150, respectively. The CR curve of windows opening during the daytime was higher than windows openings at night, which is due to the fact that when windows are open during the daytime, more water vapour is fed into the room in a short period of time than at night, resulting in a rapid rise in dew point temperature. Because outdoor air temperature is high, barometric pressure gradients are high; air movement is fast, so the rate of air exchange is higher in the daytime. At the same time, the air temperature in daytime in PRS is high (28–32 °C) with high moisture content (20–22 g/kg dry air). Although the relative humidity may be slightly lower than at night, the dew point temperature of the air is higher because of the high temperature in the daytime.

- The annual CR of all-day and all-night window openings was 0.289, while the highest CR was 0.343 in July. The CR rose during the PRS due to increased outdoor air moisture content during PRS and the entire exchange of outdoor air with indoor air when the windows were fully open throughout the day and night.

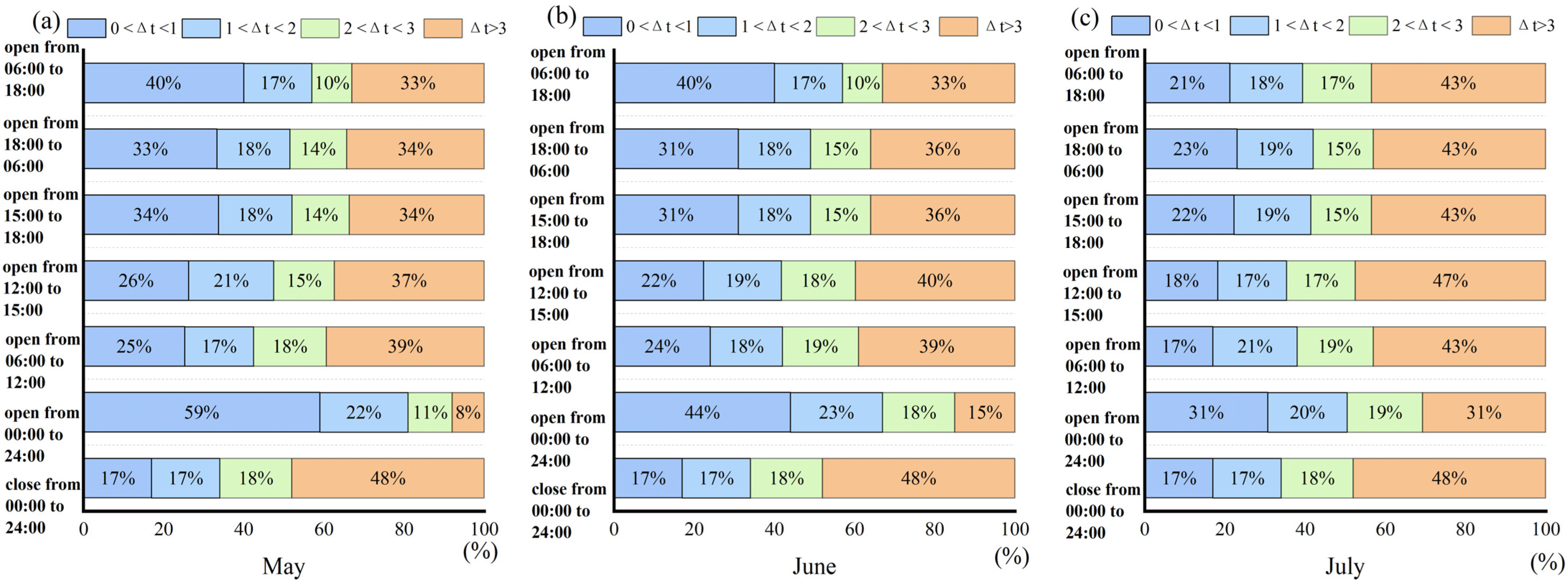

- In May, condensation intensity in the range of 1 °C < ≤ 3 °C accounted for less, and the condensation intensity in the range of ≤ 1 °C accounted for more. With the rise of outdoor air temperature, the temperature difference between the inner surface and indoor air dew-point temperature increases, the proportion of condensation intensity in the range of ≤ 1 °C reduces, and the proportion of condensation intensity in the range of > 3 °C increases. In July, the proportion of > 3 °C accounted for the largest; at this time, the condensation period is longer, and the condensation intensity is larger, which means the condensation problem is severe.

- All-day and all-night window closures have the opposite percentage of the range of condensation intensity compared with window openings during this period, with more intensity distributed in the range of > 3 °C. It has the typical characteristics of long condensation duration, high condensation intensity, and severe condensation problems.

- The condensation intensity of light condensation is mainly distributed between 0 °C < ≤ 1 °C, while the condensation intensity of serious condensation is primarily distributed at > 3 °C.

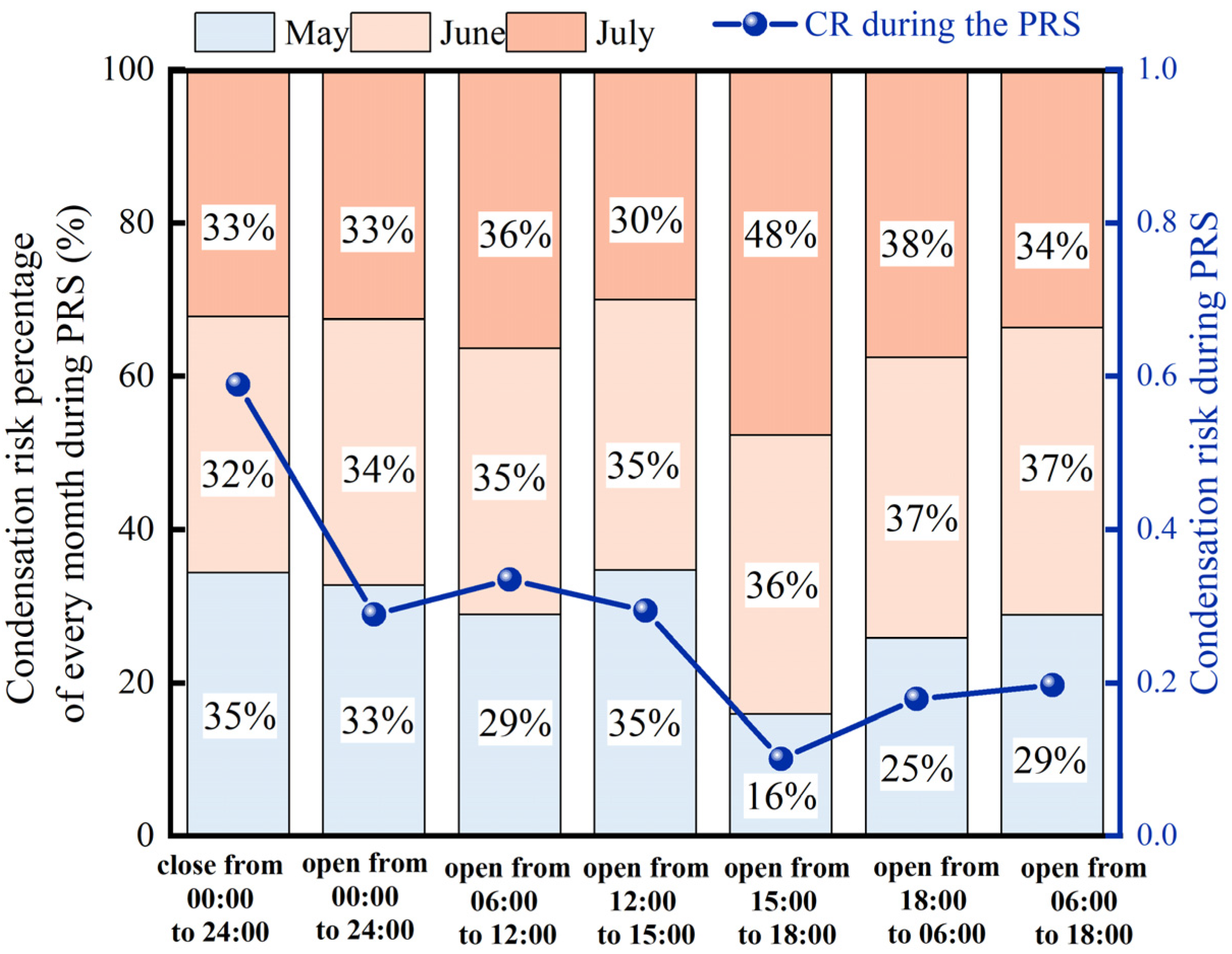

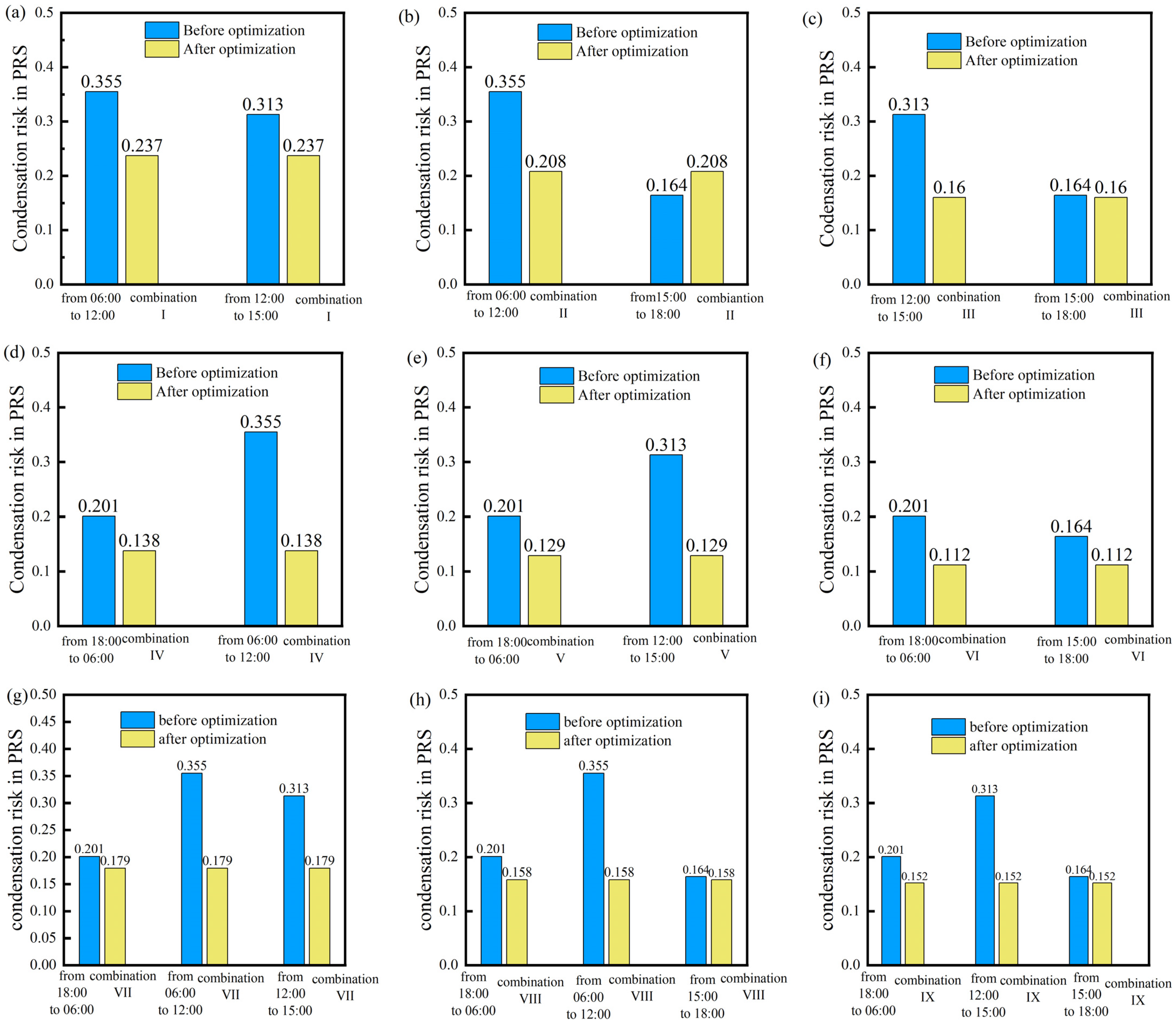

3.3. Optimised Combination of Window Opening Modes

3.3.1. Optimised Combination of Window Opening Duration

- When the continuous window opening period was too long, and the outdoor air temperature suddenly rose, keeping the window open could aggravate the condensation on the inner surface.

- When the windows are closed for a long time, the moisture generated by indoor personnel activities cannot be discharged promptly, and the condensation situation is aggravated.

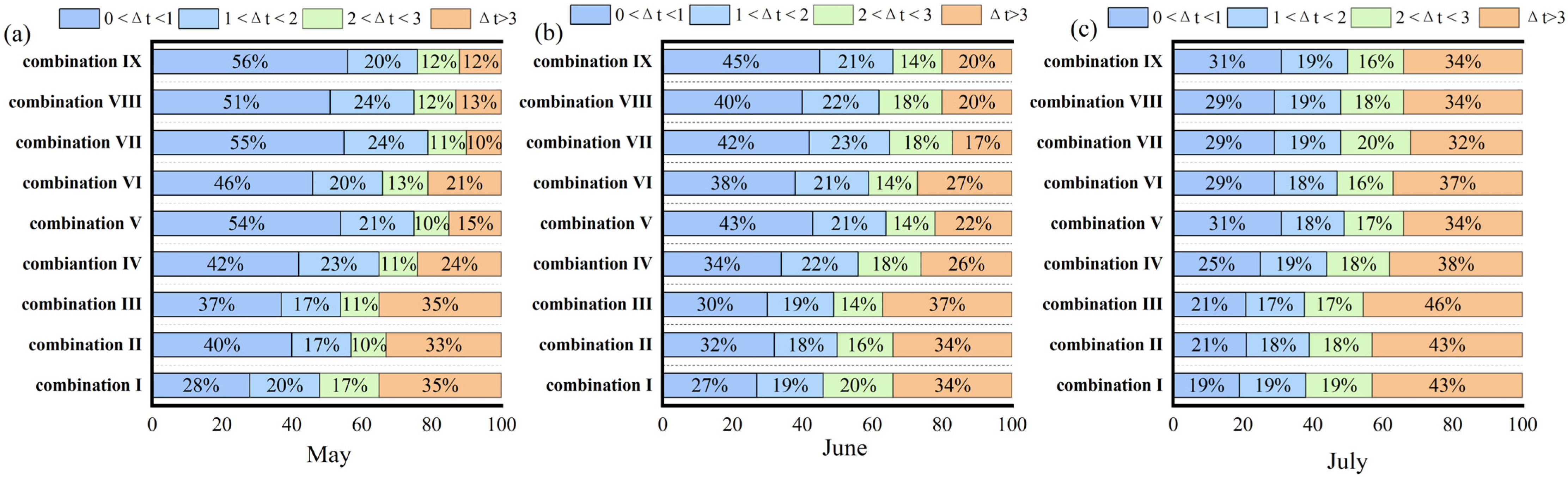

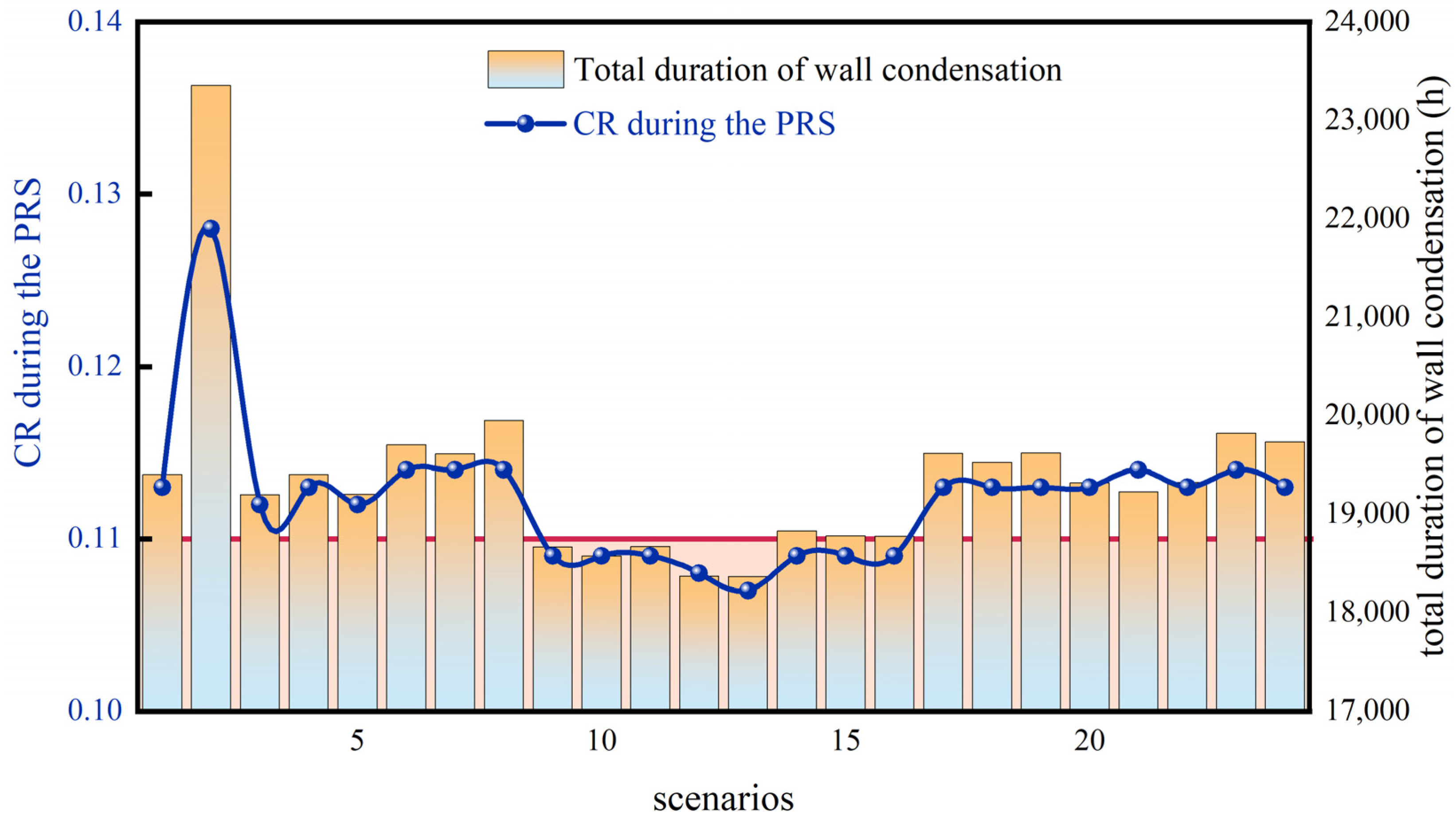

3.3.2. Optimised Combination of Window Opening Time Periods of Different Months

4. Conclusions

- Windows should be open and ventilated reasonably during the PRS, but prolonged window opening or closing behaviour needs to be avoided.

- CR is higher when windows are open in the morning during the day than in the middle of the day and in the afternoon. CR is lower when windows are fully open throughout the night than throughout the daytime.

- The CR of the window open in the afternoon was the lowest of all open duration before the duration combination; thus, opening windows in the afternoon is recommended.

- Amongst different window openings, the overall CR on the inner surface of the building wall during PRS when the window opening was 0 was higher than 0.50, while the rest of the window openings of 0.25, 0.5, 0.75 and 1 did not have significant changes on CR. The degree of window opening has less impact on the indoor humid environment compared to window opening duration.

- After optimising the window opening duration, CR was reduced compared with the pre-optimisation period. Amongst them, the CR of Combination IV, V and VI was less than 0.15. After adopting different open durations in different months, the CR of a total of 8 window opening modes was equal to and less than 0.11, of which the CR of Combination VII, taken in May and June, and Combination VI, taken in July, was only 0.107.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Singh, J.; Yu, C.W.F.; Kim, J.T. Building pathology investigation of sick buildings: Toxic moulds. Indoor Built Environ. 2010, 19, 40–47. [Google Scholar] [CrossRef]

- Takaoka, M.; Suzuki, K.; Norbäck, D. The home environment of junior high school students in Hyogo, Japan: Associations with asthma, respiratory health, and reported allergies. Indoor Built Environ. 2016, 25, 81–92. [Google Scholar] [CrossRef]

- Hu, M.; Chen, Y.; Guo, X. The effect of growth of mold on building and IAQ and control strategy. Build. Energy Environ. 2006, 25, 15–21. (In Chinese) [Google Scholar]

- Zhang, X.; Wang, J.; Li, P. Dampness and mold in homes across China: Associations with rhinitis, ocular, throat, and dermal symptoms, headache and fatigue among adults. Indoor Air 2019, 29, 30–42. [Google Scholar] [CrossRef]

- Wu, X.; Yang, F.; Lu, G.; Zhao, X.; Chen, Z.; Qian, S. A breathable and environmentally friendly super hydrophobic coating for anti-condensation applications. Chem. Eng. J. 2021, 412, 128725. [Google Scholar] [CrossRef]

- Gong, G.; Xu, C.; Jiao, J.; Liu, Y.; Xie, S. Investigation of moisture condensation on papermaking plant envelopes in high humidity environment by orthogonal analysis and CFD simulation. Build. Environ. 2011, 46, 1639–1648. [Google Scholar] [CrossRef]

- Li, H.; Gong, G.; Xu, C. Thermal and humid environment and moisture condensation characteristics of cold surfaces. Indoor Built Environ. 2014, 23, 474–484. [Google Scholar] [CrossRef]

- Wang, F.; Zhao, X.; Pang, D.; Li, Z.; Liu, M.; Du, W.; Guo, W. Cooling performance of radiant air conditioning with an infrared-transparent membrane. Energy Build. 2023, 291, 113124. [Google Scholar] [CrossRef]

- Sahin, C.; Rastgeldi Dogan, T.; Yildiz, M.; Sofuoglu, S.C. Indoor environmental quality in naturally ventilated schools of a dusty region: Excess health risks and effect of heating and desert dust transport. Indoor Air 2022, 32, 13068. [Google Scholar] [CrossRef]

- Wang, Z.; Shaw, D.; Kahan, T.; Schoemaecker, C.; Carslaw, N. A modeling study of the impact of photolysis on indoor air quality. Indoor Air 2022, 32, 13054. [Google Scholar] [CrossRef]

- Dong, J.; Lan, H.; Liu, Y.; Yu, C. Indoor environment of nearly zero energy residential buildings with conventional air conditioning in hot-summer and cold-winter zone. Energy Built Environ. 2022, 3, 129–138. [Google Scholar] [CrossRef]

- Wang, Y.; Lian, Z.; Chang, H. The correlation between the overall thermal comfort, the overall thermal sensation and the local thermal comfort in non-uniform environments with local cooling. Indoor Built Environ. 2022, 31, 1822–1833. [Google Scholar] [CrossRef]

- Mao, Y.; Zhu, K.; Zheng, Z.; Fang, Z. Evaluation of the thermal comfort in different commercial buildings in Guangzhou. Indoor Built Environ. 2024, 33, 391–413. [Google Scholar] [CrossRef]

- Yang, Z.; Zhang, W.; Qin, M.; Liu, H. Comparative study of indoor thermal environment and human thermal comfort in residential buildings among cities, towns, and rural areas in arid regions of China. Energy Build. 2022, 273, 112373. [Google Scholar] [CrossRef]

- Wang, P.; Liu, Z.; Wu, J.; Liao, H.; Chen, H. Experimental and numerical study of adaptive ventilation and sunlight regulation building envelope combining variable transparency shape-stabilized phase change material. Build. Environ. 2024, 248, 111095. [Google Scholar] [CrossRef]

- Liu, T.; Lee, W.L. Influence of window opening degree on natural ventilation performance of residential buildings in Hong Kong. Sci. Technol. Built Environ. 2020, 26, 28–41. [Google Scholar] [CrossRef]

- Liao, C.; Delghust, M.; Wargocki, P.; Laverge, J. Effects of window opening on the bedroom environment and resulting sleep quality. Sci. Technol. Built Environ. 2021, 27, 995–1015. [Google Scholar] [CrossRef]

- Gu, Y.; Cui, T.; Liu, K.; Yang, F.; Wang, S.; Song, H.; Li, Y. Study on influencing factors for occupant window-opening behavior: Case study of an office building in Xi’an during the transition season. Build. Environ. 2021, 200, 107977. [Google Scholar] [CrossRef]

- Li, C.; Chen, Y. A multi-factor optimization method based on thermal comfort for building energy performance with natural ventilation. Energy Build. 2023, 285, 112893. [Google Scholar] [CrossRef]

- Abdullah, H.K.; Alibaba, H.Z. Open-plan office design for improved natural ventilation and reduced mixed mode supplementary loads. Indoor Built Environ. 2022, 31, 2145–2167. [Google Scholar] [CrossRef]

- Kitagawa, H.; Asawa, T.; Hirayama, Y. Optimum window-opening control for naturally ventilated buildings with phase change materials in the hot and humid climate of Indonesia. Build. Environ. 2023, 245, 110898. [Google Scholar] [CrossRef]

- Tan, Y.; Peng, J.; Curcija, C. Study on the impact of window shades’ physical characteristics and opening modes on air conditioning energy consumption in China. Energy Built Environ. 2020, 1, 254–261. [Google Scholar] [CrossRef]

- Yazarlou, T.; Barzkar, E. Louver and window position effect on cross-ventilation in a generic isolated building: A CFD approach. Indoor Built Environ. 2022, 31, 1511–1529. [Google Scholar] [CrossRef]

- Yu, C.; Du, J.; Pan, W. Impact of window and air-conditioner operation behaviour on cooling load in high-rise residential buildings. Build. Simul. 2022, 15, 1955–1975. [Google Scholar] [CrossRef]

- Kocik, S.; Psikuta, A.; Ferdyn-Grygierek, J. Influence of window and door opening on office room environment and human thermal sensation during different seasons in moderate climate. Build. Environ. 2024, 259, 111669. [Google Scholar] [CrossRef]

- Qian, H.; Tang, M.; Wang, D.; Fang, J. Effect of insulation ground on anti-condensation in rural residence. Procedia Eng. 2017, 180, 91–98. [Google Scholar] [CrossRef]

- Zhang, B.; Sun, Q.; Su, L.; Dong, K.; Luo, W.; Guan, H.; Wu, W. Anti-Condensation Temperature Control Strategy of the Concrete Radiant Roof. Energies 2023, 16, 4826. [Google Scholar] [CrossRef]

- Zhang, C.; Xu, X.; Yu, J.; Tang, X.; Yu, Z. Condensation risk-based applicability analysis and design of a dynamic thermal insulation window with ventilated airflow in different climates. Build. Eng. 2024, 86, 108913. [Google Scholar] [CrossRef]

- Wu, Y.; Zhang, C. Analysis of anti-condensation mechanism on superhydrophobic anodic aluminum oxide surface. Appl. Therm. Eng. 2013, 58, 664–669. [Google Scholar] [CrossRef]

- Wan, Y.; Zhang, C.; Zhang, M.; Xu, J. Anti-condensation behavior of bamboo leaf surface (backside) and its bionic preparation. Mater. Res. Express 2021, 8, 055002. [Google Scholar] [CrossRef]

- Liu, J.; Ding, Y.; Feng, Y. A novel research for restraining the condensation of radiant air conditioner by superhydrophobic surface. Energy Build. 2023, 296, 113398. [Google Scholar] [CrossRef]

- Deng, T.; Shen, X.; Cheng, X.; Liu, J. Investigation of window-opening behaviour and indoor air quality in dwellings situated in the temperate zone in China. Indoor Built Environ. 2021, 30, 938–956. [Google Scholar] [CrossRef]

- Dhalluin, A.; Limam, K. Comparison of natural and hybrid ventilation strategies used in classrooms in terms of indoor environmental quality, comfort, and energy savings. Indoor Built Environ. 2014, 23, 527–542. [Google Scholar] [CrossRef]

- Bayoumi, M. Impacts of window opening grade on improving the energy efficiency of a façade in hot climates. Build. Environ. 2017, 119, 31–43. [Google Scholar] [CrossRef]

- Sorgato, M.J.; Melo, A.P.; Lamberts, R. The effect of window opening ventilation control on residential building energy consumption. Energy Build. 2016, 133, 1–13. [Google Scholar] [CrossRef]

- GB 50176-2016; Thermal Design Code for Civil Building. China Construction Industry Press: Beijing, China, 2016.

- Lu, Y. HVAC Design Guide; China Construction Industry Press: Beijing, China, 1996. [Google Scholar]

- Cho, W.; Iwamoto, S.; Kato, S. Condensation risk due to variations in airtightness and thermal insulation of an office building in warm and wet climate. Energies 2016, 9, 875. [Google Scholar] [CrossRef]

- Li, K.; Tang, M. Simulation Study on Ground Temperature and Condensation Prevention for Rural Residences in Chongqing Area. Build. Sci. 2014, 8, 100–105. (In Chinese) [Google Scholar]

| Building Structure | Material Name and Thickness | Heat Transfer Coefficient, W/m2·K |

|---|---|---|

| External wall | Heavy mortar clay (240 mm) + The pure gypsum board (10 mm) + Polystyrene foam material (60 mm) + The pure gypsum board (10 mm) | 0.564 |

| Internal wall | Cement mortar (20 mm) + Ceramsite concrete (180 mm) + Cement mortar (20 mm) | 1.515 |

| Roof | Cement mortar (20 mm) + Reinforced concrete (200 mm) + Polystyrene (46 mm) + Cement mortar (20 mm) | 0.595 |

| Ground | Cement mortar (20 mm) + Gravel or pebbles (40 mm) | N/A |

| Door | single-layer solid wood (25.3 mm) | 0.350 |

| Window | single-layer glass (6 mm) | 5.7 |

| Floor | Cement mortar (20 mm) + Reinforced concrete (100 mm) + Cement mortar (20 mm) | 2.963 |

| Parameter Name | Specific Values |

|---|---|

| Sunlight transmittance of the glass | 0.67 |

| Shading factor of the dark cloth curtain | 0.65 |

| window frame correction factor | 1.07 |

| Location correction coefficient in Changsha [36] | 1.4 |

| Measuring Instrument | Measurement Accuracy |

|---|---|

| Automatic temperature and humidity recorder (TH22R-EX) | 0.1 °C, 1.5% RH |

| non-contacting infrared thermometer (AS842A-0-1) | 0.1 °C |

| Mercury thermometer | 0.1 °C |

| Building Structure | Material Name | Material Thickness mm | Heat Transfer Coefficient W/m2·K |

|---|---|---|---|

| External wall | Lime mortar | 20 | 0.93 |

| Bituminous vermiculite slate | 20 | 0.033 | |

| Concrete perforated brick | 200 | 0.22 | |

| Lime mortar | 20 | 0.93 | |

| Internal wall | Ceramsite concrete | 190 | 0.25 |

| Ground | Lime mortar | 20 | 0.93 |

| Bituminous vermiculite slate | 20 | 0.042 | |

| Reinforced concrete | 120 | 1.74 | |

| Cement mortar | 20 | 0.87 | |

| Floor | Reinforced concrete | 200 | 1.74 |

| Window | Low-E | 6 | - |

| Air | 12 | 1.8 | |

| Low-E | 6 | - |

| Room Type | Time Period | Number of Persons | Average Moisture Production per Person, (g·h−1) | Average Calorie Production per Person, (W) |

|---|---|---|---|---|

| Bedroom (R1-6 R2-3 R2-8 R2-6) | 00:00~8:00 | 4 | 61 | 68 |

| 08:00~12:00 | 0 | |||

| 12:00~14:00 | 4 | |||

| 14:00~24:00 | 0 | |||

| Secondary bedroom (R1-1 R2-1) | 00:00~8:00 | 4 | 61 | 68 |

| living rooms (R1-3 R2-4) | 08:00~24:00 | 0 | 61 | 68 |

| 00:00~12:00 | 0 | |||

| 12:00~22:00 | 6 | |||

| 22:00~24:00 | 3 | |||

| drawing rooms (R1-5 R2-7) | 00:00~8:00 | 0 | 61 | 68 |

| 08:00~9:00 | 2 | |||

| 09:00~24:00 | 0 | |||

| Kitchen (R1-4) | 00:00~10:00 | 0 | 102 | 65 |

| 10:00~12:00 | 2 | |||

| 12:00~17:00 | 0 | |||

| 17:00~18:00 | 2 | |||

| 18:00~24:00 | 0 | |||

| Recreation room (R2-5) | 00.00~20:00 | 0 | 61 | 68 |

| 20:00~24:00 | 4 |

| Room Type | Time Period | Lighting Power Density, W/m2 |

|---|---|---|

| Bedroom (R1-6 R2-3 R2-8 R2-6) | 0:00~8:00 | 6 |

| 8:00~22:00 | ||

| 22:00~24:00 | ||

| Secondary bedroom (R1-1 R2-1) | 0:00~8:00 | 6 |

| 8:00~22:00 | ||

| 22:00~24:00 | ||

| living rooms (R1-3 R2-4) | 0:00~12:00 | 6 |

| 12:00~22:00 | ||

| 22:00~24:00 | ||

| drawing rooms (R1-5 R2-7) | 0:00~8:00 | 6 |

| 8:00~9:00 | ||

| 9:00~24:00 | ||

| Kitchen (R1-4) | 0:00~10:00 | 6 |

| 10:00~12:00 | ||

| 12:00~17:00 | ||

| 17:00~18:00 | ||

| 18:00~24:00 | ||

| Recreation room (R2-5) | 00.00~20:00 | 6 |

| 20:00~24:00 |

| Windows Opening Duration | Windows Opening Degree | |||

|---|---|---|---|---|

| 0.25 | 0.5 | 0.75 | 1 | |

| 00:00–24:00 open | 30.1 | 30.4 | 30.4 | 30.5 |

| 06:00–12:00 open | 34.9 | 35.5 | 35.7 | 35.9 |

| 12:00–15:00 open | 31.1 | 31.3 | 31.4 | 31.8 |

| 15:00–18:00 open | 15.3 | 15.4 | 15.7 | 15.9 |

| 18:00–06:00 open | 19.7 | 20.1 | 20.3 | 20.3 |

| 06:00–18:00 open | 22.2 | 22.7 | 23.0 | 23.1 |

| Combination | Window Opening Period |

|---|---|

| I | Windows open during 06:00–12:00 and 12:00–15:00 |

| II | Windows open during 06:00–12:00 and 15:00–18:00 |

| III | Windows open during 12:00–15:00 and 15:00–18:00 |

| IV | Windows open during 18:00–06:00 and 06:00–12:00 |

| V | Windows open during 18:00–06:00 and 12:00–15:00 |

| VI | Windows open during 18:00–06:00 and 15:00–18:00 |

| VII | Windows open during 18:00–06:00, 06:00–12:00 and 12:00–15:00 |

| VIII | Windows open during 18:00–06:00, 06:00–12:00 and 15:00–18:00 |

| IX | Windows open during 18:00–06:00, 12:00–15:00 and 15:00–18:00 |

| Scenarios | Combination of Window-Opening Months | Scenarios | Combination of Window-Opening Months |

|---|---|---|---|

| 1 | combination IV in May + combination IV in June + combination V in July | 13 | combination V in May + combination V in June + combination VI in July |

| 2 | combination IV in May + combination IV in June + combination VI in July | 14 | combination V in May + combination VI in June + combination IV in July |

| 3 | combination IV in May + combination V in June+ combination IV in July | 15 | combination V in May + combination VI in June + combination VI in July |

| 4 | combination IV in May + combination V in June + combination V in July | 16 | combination V in May + combination VI in June + combination VI in July |

| 5 | combination IV in May + combination V in June + combination VI in July | 17 | combination VI in May + combination IV in June + combination IV in July |

| 6 | combination IV in May + combination VI in June + combination IV in July | 18 | combination VI in May + combination IV in June + combination VI in July |

| 7 | combination IV in May + combination VI in June + combination V in July | 19 | combination VI in May + combination IV in June + combination VI in July |

| 8 | combination IV in May + combination VI in June + combination VI in July | 20 | combination VI in May + combination V in June + combination IV in July |

| 9 | combination V in May + combination IV in June + combination IV in July | 21 | combination VI in May + combination V in June + combination V in July |

| 10 | combination V in May + combination IV in June + combination V in July | 22 | combination VI in May + combination V in June + combination VI in July |

| 11 | combination V in May + combination IV in June + combination VI in July | 23 | combination VI in May + combination V in June + combination IV in July |

| 12 | combination V in May + combination V in June + combination IV in July | 24 | combination VI in May + combination VI in June + combination V in July |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Y.; Liu, M.; Zhao, Z.; Li, S.; Zhang, X.; Zhou, J. Condensation Risk Under Different Window-Opening Behaviours in a Residential Building in Changsha During Plum Rains Season. Buildings 2025, 15, 1536. https://doi.org/10.3390/buildings15091536

He Y, Liu M, Zhao Z, Li S, Zhang X, Zhou J. Condensation Risk Under Different Window-Opening Behaviours in a Residential Building in Changsha During Plum Rains Season. Buildings. 2025; 15(9):1536. https://doi.org/10.3390/buildings15091536

Chicago/Turabian StyleHe, Yecong, Miaomiao Liu, Zhigang Zhao, Sihui Li, Xiaofeng Zhang, and Jifei Zhou. 2025. "Condensation Risk Under Different Window-Opening Behaviours in a Residential Building in Changsha During Plum Rains Season" Buildings 15, no. 9: 1536. https://doi.org/10.3390/buildings15091536

APA StyleHe, Y., Liu, M., Zhao, Z., Li, S., Zhang, X., & Zhou, J. (2025). Condensation Risk Under Different Window-Opening Behaviours in a Residential Building in Changsha During Plum Rains Season. Buildings, 15(9), 1536. https://doi.org/10.3390/buildings15091536