An Innovative Approach to Enhancing Concrete Sustainability: Utilising Unprocessed Steel Slag with Low CaO and High SiO2 Content

Abstract

1. Background

2. Materials and Experimental Procedure

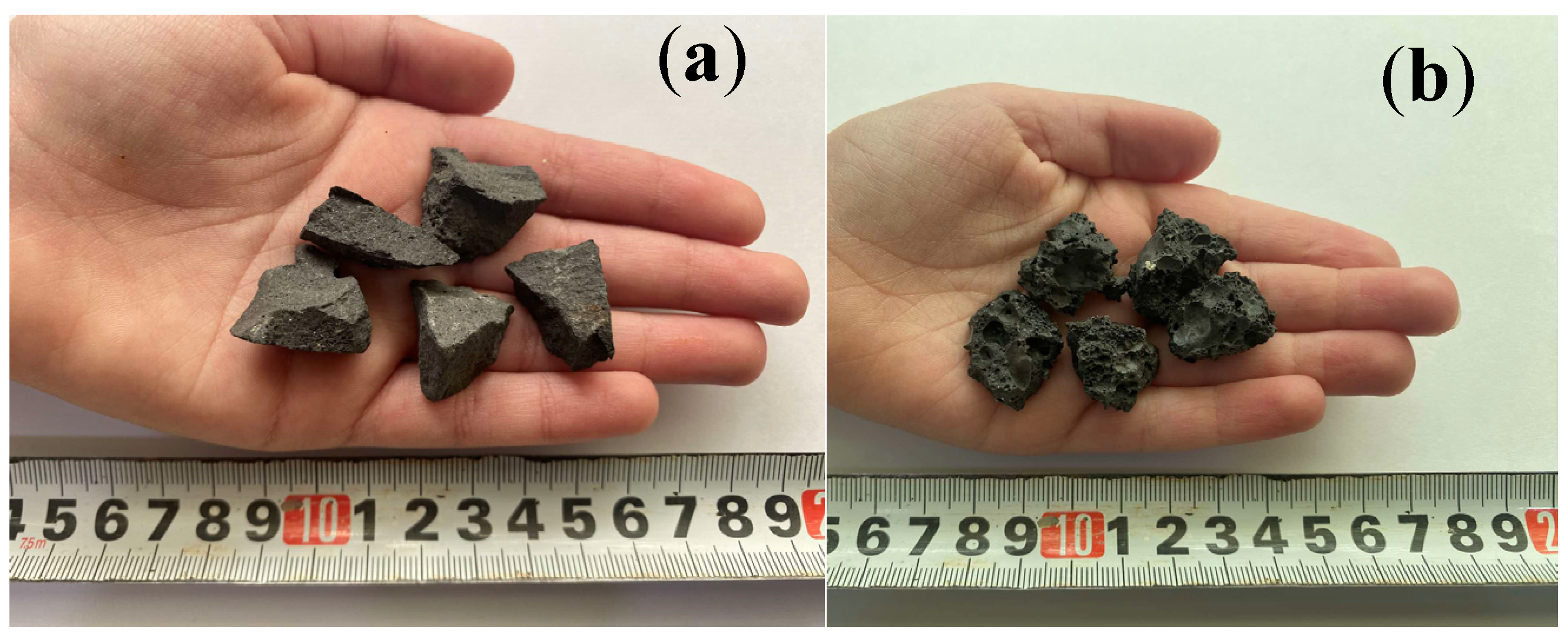

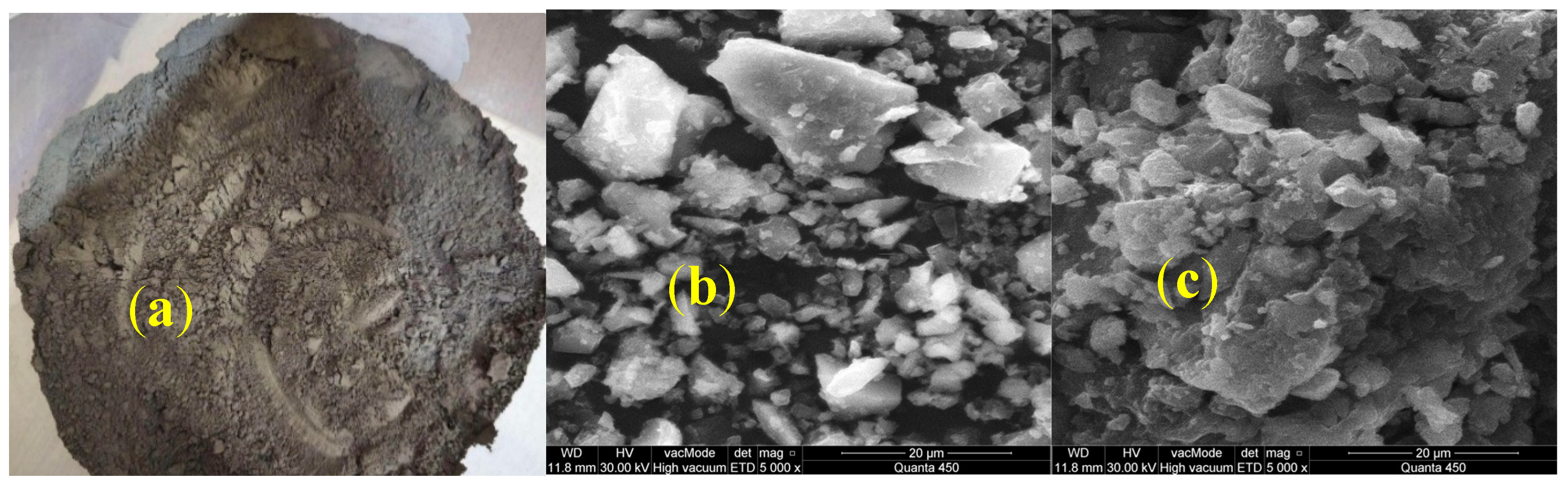

2.1. Steel Slag (SS)

2.2. Cement

2.3. Fine and Coarse Aggregates

2.4. Mix Proportions

2.5. Workability and Density

2.6. Compressive, Tensile, and Flexural Strengths

2.7. Ultrasonic Pulse Velocity (UPV) and Water Absorption (WA)

2.8. Freeze–Thaw (FT)

3. Results and Discussion

3.1. Workability and Density

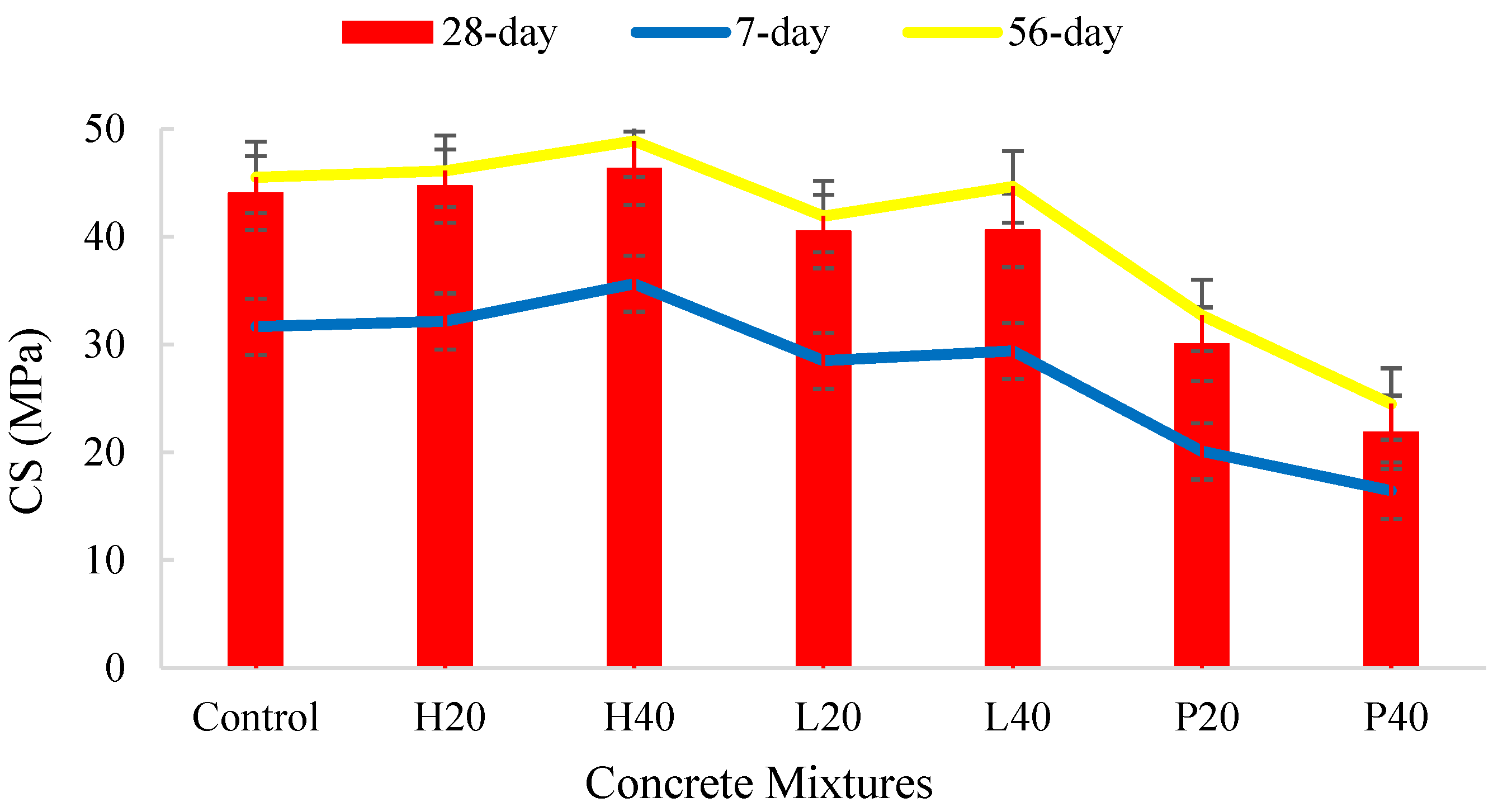

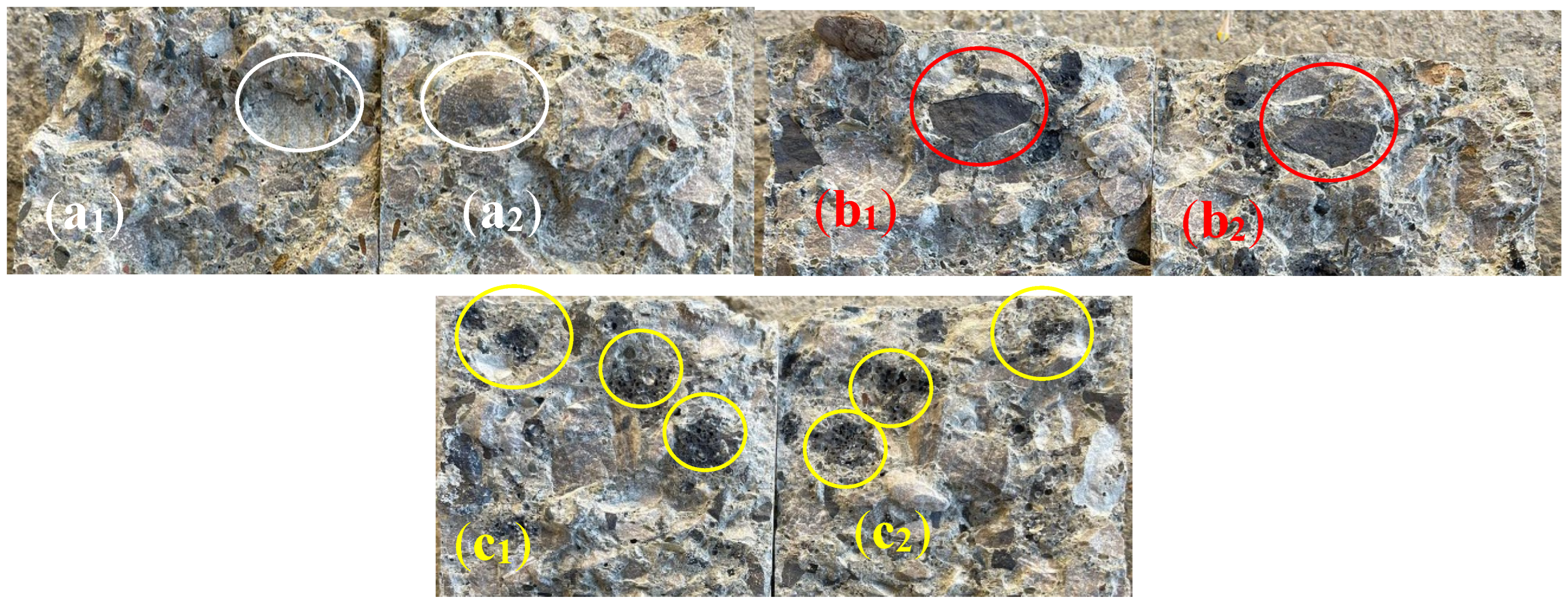

3.2. Compressive Strength (CS)

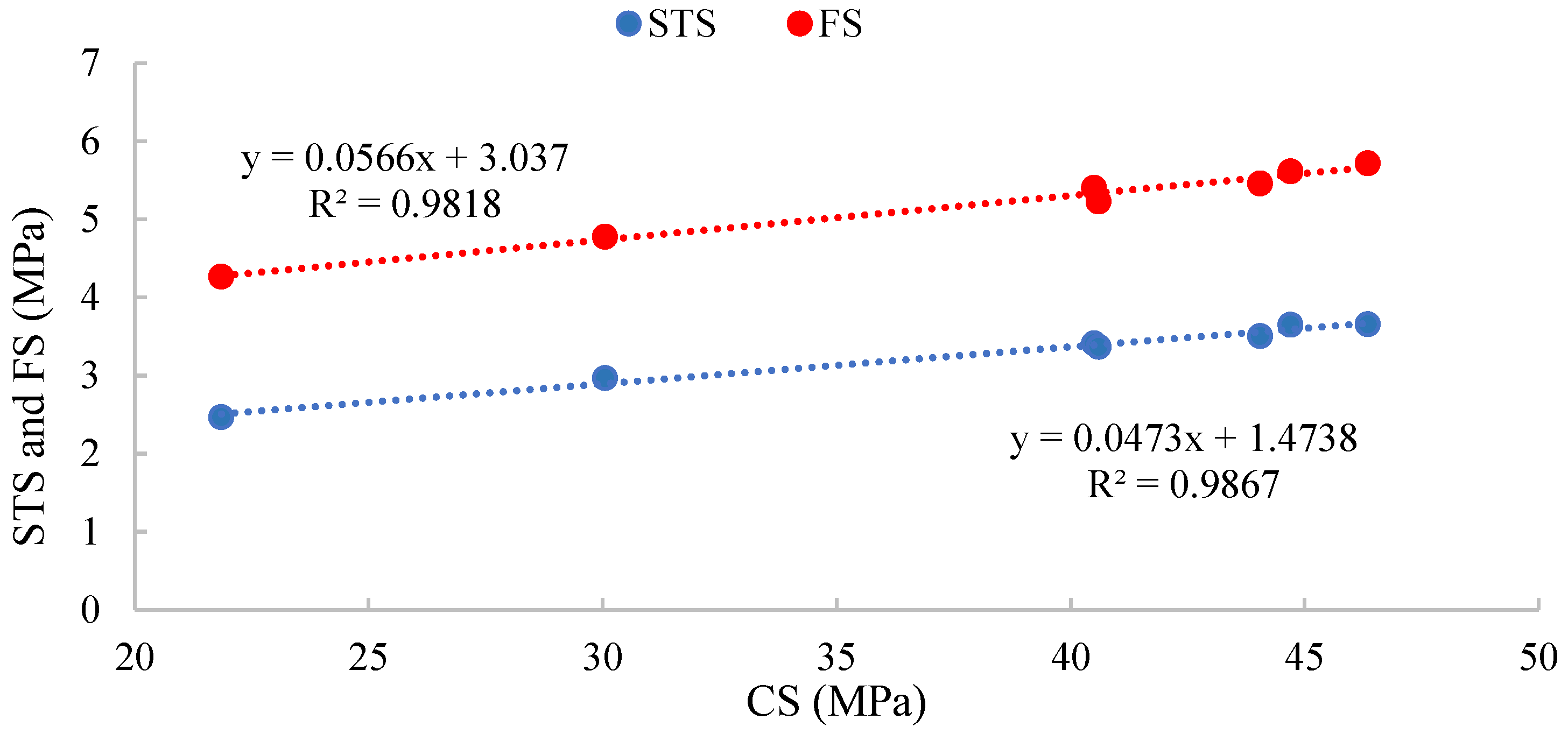

3.3. Splitting Tensile Strength (STS)

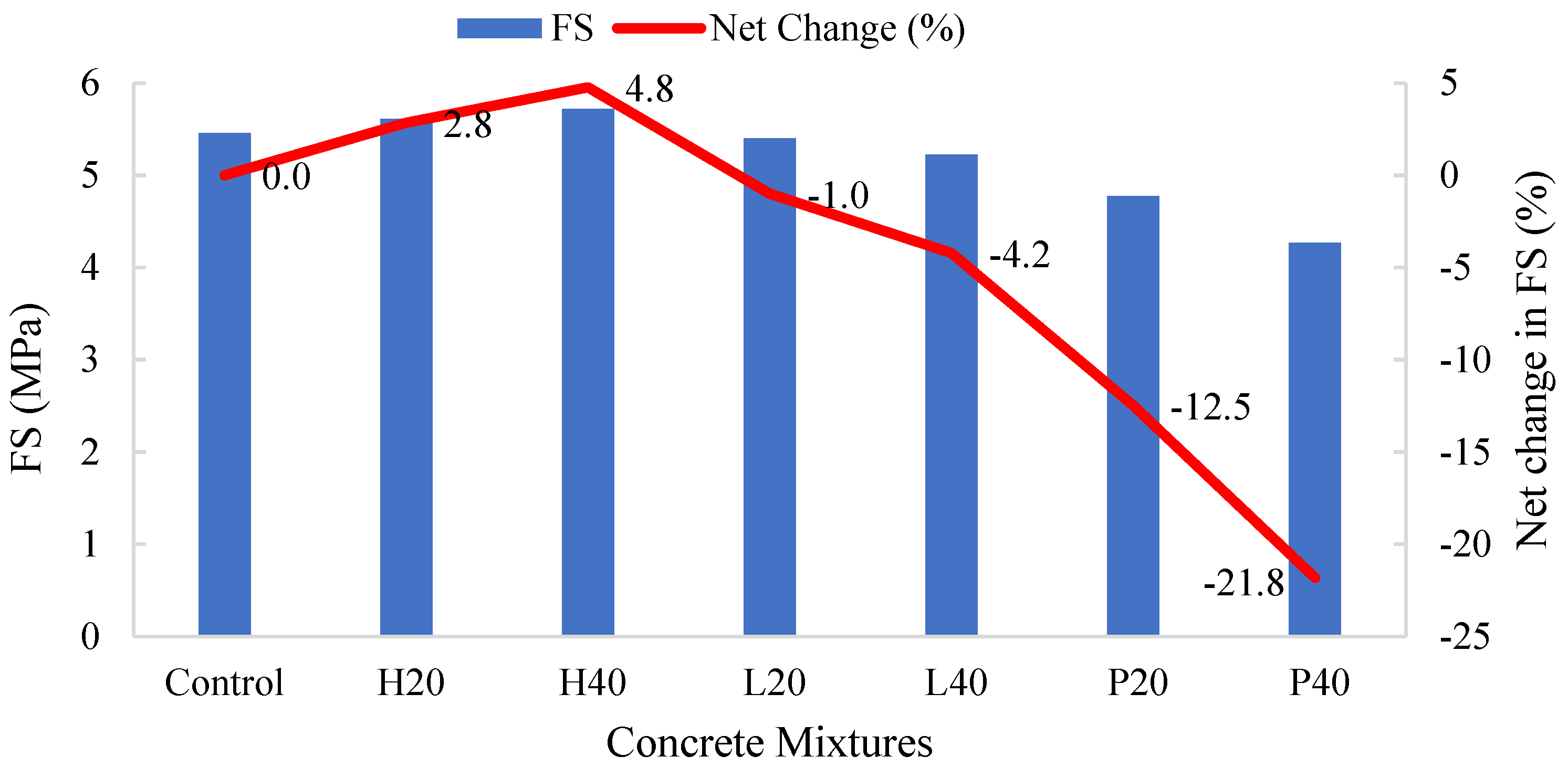

3.4. Flexural Strength (FS)

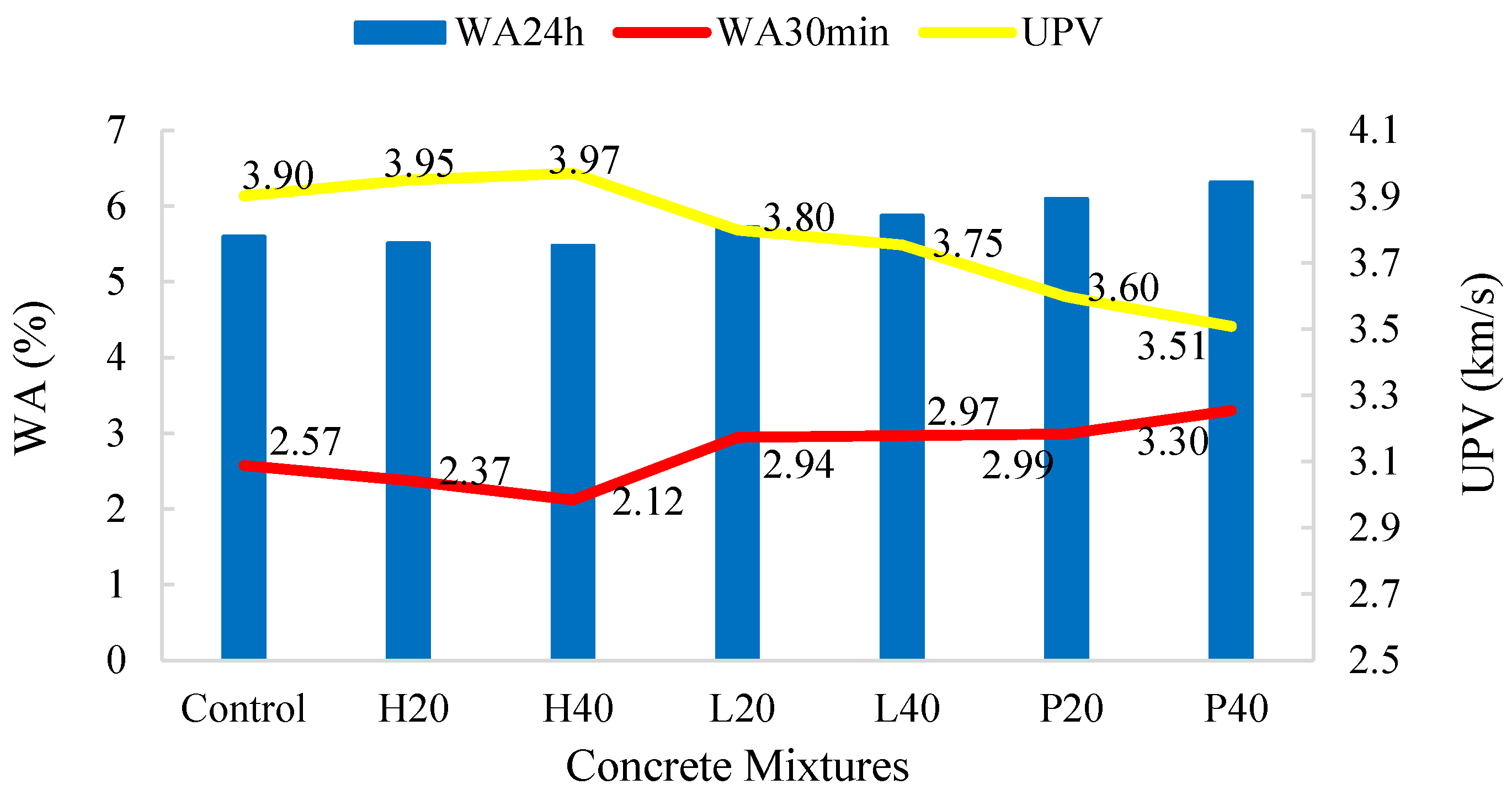

3.5. Ultrasonic Pulse Velocity (UPV)

3.6. Water Absorption (WA)

3.7. Freeze–Thaw (FT)

4. Conclusions

- Using LDSS and SSP replacement reduced workability more than replacing HDSS in the concrete mixture; this could be because LDSS’s porose structure and angularity absorb more water than natural coarse aggregate, but this issue is easily resolved with superplasticizer.

- The high density of concrete with high amounts of SS is an advantage for structures such as retaining walls, bases, earthwork blocks, sound insulation, and radiation shields.

- The use of HDSS in concrete resulted in an increase in the mechanical properties. At 20% and 40%, the value of compressive strength was improved by 1.5% and 5.2%, respectively. The trend is similar for other mechanical properties.

- The use of LDSS and SSP in concrete mixtures resulted a decrease in the durability and mechanical performance. At 20% and 40% LDSS, the value of compressive strength was decreased by 8.1% and 7.8%, respectively. The trend is similar for other mechanical and durability properties.

- Due to the very low reactivity of this type of slag, SSP is not recommended to be used in concrete production as a cement replacement material.

- Compared to the control concrete, the freeze–thaw cycles reduced the UPV and compressive strength of concrete with varying types and amounts of SS. The durability is slightly compromised and can be considered lower in all mixes containing SS.

- Using 40% HDSS substitution in concrete led to the best results when the mechanical and durability characteristics of the current investigation were considered. Nonetheless, depending on the application, an acceptable strength for various types and replacement levels can be attained with the appropriate mix design.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CS | Compressive Strength |

| FS | Flexural Strength |

| FT | Freeze–Thaw |

| HDSS | High-Density Steel Slag |

| IF | Induction Furnace |

| LDSS | Low-Density Steel Slag |

| SEM | Scanning Electron Microscopy |

| SP | Superplasticiser |

| SS | Steel Slag |

| SSP | Steel Slag Powder |

| STS | Splitting Tensile Strength |

| UPV | Ultrasonic Pulse Velocity |

| WA | Water Absorption |

References

- Li, J.; Pan, S.Y.; Kim, H.; Linn, J.H.; Chiang, P.C. Building green supply chains in eco-industrial parks towards a green economy: Barriers and strategies. J. Environ. Manag. 2015, 162, 158–170. [Google Scholar] [CrossRef] [PubMed]

- Gencel, O.; Karadag, O.; Oren, O.H.; Bilir, T. Steel slag and its applications in cement and concrete technology: A review. Constr. Build. Mater. 2021, 283, 122783. [Google Scholar] [CrossRef]

- Baban, M. Climate Change in Iraq and the Kurdistan Region: Consequences of Increased Oil, Electricity, Cement, and Iron Production on Water. Rudaw Research Centre. 2023. Available online: https://rudawrc.net/en/pdf/article/climate-change-in-iraq-and-the-kurdistan-region-consequences-of-increased-oil-electricity-cement-and-iron-production-on-water-2023-10-18 (accessed on 20 March 2025).

- Guo, J.; Bao, Y.; Wang, M. Steel slag in China: Treatment, recycling, and management. Waste Manag. 2018, 78, 318–330. [Google Scholar] [CrossRef]

- Üksel, İ. A review of steel slag usage in construction industry for sustainable development. Environ. Dev. Sustain. 2017, 19, 369–384. [Google Scholar] [CrossRef]

- Wang, Q.; Yan, P.; Yang, J.; Zhang, B. Influence of steel slag on mechanical properties and durability of concrete. Constr. Build. Mater. 2013, 47, 1414–1420. [Google Scholar] [CrossRef]

- Wang, Q.; Yang, J.W.; Yan, P.Y. Influence of initial alkalinity on the hydration of steel slag. Sci. China Technol. Sci. 2012, 55, 3378–3387. [Google Scholar] [CrossRef]

- Dhoble, Y.N.; Ahmed, S. Review on the innovative uses of steel slag for waste minimization. J. Mater. Cycles Waste Manag. 2018, 20, 1373–1382. [Google Scholar] [CrossRef]

- Reddy, A.S.; Pradhan, R.K.; Chandra, S. Utilization of basic oxygen furnace (BOF) slag in the production of a hydraulic cement binder. Int. J. Miner. Process. 2006, 79, 98–105. [Google Scholar] [CrossRef]

- Mayes, W.M.; Younger, P.L.; Aumônier, J. Hydrogeochemistry of alkaline steel slag leachates in the UK. Water Air Soil Pollut. 2008, 195, 35–50. [Google Scholar] [CrossRef]

- Shi, C.; Qian, J. High performance cementing materials from industrial slags—A review. Resour. Conserv. Recycl. 2000, 29, 195–207. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, Q.; Wei, J.; Li, J.; Zhang, P. Preparation of high performance blended cements and reclamation of iron concentrate from basic oxygen furnace steel slag. Resour. Conserv. Recycl. 2011, 56, 48–55. [Google Scholar] [CrossRef]

- Jiang, Y.; Ling, T.-C.; Shi, C.; Pan, S.-Y. Characteristics of steel slags and their use in cement and concrete—A review. Resour. Conserv. Recycl. 2018, 136, 187–197. [Google Scholar] [CrossRef]

- Netinger, I.; Bjegović, D.; Vrhovac, G. Utilisation of steel slag as an aggregate in concrete. Mater. Struct. 2011, 44, 1565–1575. [Google Scholar] [CrossRef]

- Kalpavalli, A.; Naik, S.M. Use of demolished concrete wastes as coarse aggregates in high strength concrete production. Int. J. Eng. Res. Technol. 2015, 4, 1040–1045. [Google Scholar] [CrossRef]

- Liu, X.; Liu, X.; Zhang, Z.; Ai, X. Effect of carbonation curing on the characterization and properties of steel slag-based cementitious materials. Cem. Concr. Compos. 2024, 154, 105769. [Google Scholar] [CrossRef]

- Ilyushechkin, A.Y.; Roberts, D.G.; French, D.; Harris, D.J. IGCC Solids Disposal and Utilisation; Final Report for ANLEC Project 5-0710-0065; CSIRO: Canberra, Australia, 2012. [Google Scholar]

- Yi, H.; Xu, G.; Cheng, H.; Wang, J.; Wan, Y.; Chen, H. An overview of utilization of steel slag. Procedia Environ. Sci. 2012, 16, 791–801. [Google Scholar] [CrossRef]

- Mitwally, M.E.; Elnemr, A.; Shash, A.; Babiker, A. Utilization of steel slag as partial replacement for coarse aggregate in concrete. Innov. Infrastruct. Solut. 2024, 9, 175. [Google Scholar] [CrossRef]

- Maslehuddin, M.; Sharif, A.M.; Shameem, M.; Ibrahim, M.; Barry, M.S. Comparison of properties of steel slag and crushed limestone aggregate concretes. Constr. Build. Mater. 2003, 17, 105–112. [Google Scholar] [CrossRef]

- Pellegrino, C.; Gaddo, V. Mechanical and durability characteristics of concrete containing EAF slag as aggregate. Cem. Concr. Compos. 2009, 31, 663–671. [Google Scholar] [CrossRef]

- Qasrawi, H. The use of steel slag aggregate to enhance the mechanical properties of recycled aggregate concrete and retain the environment. Constr. Build. Mater. 2014, 54, 298–304. [Google Scholar] [CrossRef]

- Manso, J.M.; Polanco, J.A.; Losañez, M.; González, J.J. Durability of concrete made with EAF slag as aggregate. Cem. Concr. Compos. 2006, 28, 528–534. [Google Scholar] [CrossRef]

- Sharba, A.A. The Efficiency of Steel Slag and Recycled Concrete Aggregate on the Strength Properties of Concrete. KSCE J. Civ. Eng. 2019, 23, 4846–4851. [Google Scholar] [CrossRef]

- Sabapathy, Y.K.; Balasubramanian, V.B.; Shiva Shankari, N.; Yeshwant Kumar, A.; Ravichandar, D. Experimental investigation of surface-modified EOF steel slag as coarse aggregate in concrete. J. King Saud. Univ. Eng. Sci. 2017, 29, 388–393. [Google Scholar] [CrossRef]

- Herki, B.M.A. Environmental Hazards in the Kurdistan Region–Iraq. Rudaw Research Centre. 2022. Available online: https://rudawrc.net/sorani/article/metrsyie-jingeyiekan-le-heremi-kwrdstan (accessed on 20 March 2025).

- Herki, B.M.A. Strength and Absorption Study on Eco-Efficient Concrete Using Recycled Powders as Mineral Admixtures under Various Curing Conditions. Recycling 2024, 9, 99. [Google Scholar] [CrossRef]

- Herki, B.M.A.; Khatib, J.M.; Hamadamin, M.N.; Kareem, F.A. Sustainable Concrete in the Construction Industry of Kurdistan-Iraq through Self-Curing. Buildings 2022, 12, 1318. [Google Scholar] [CrossRef]

- Herki, B.M.A. Combined Effects of Densified Polystyrene and Unprocessed Fly Ash on Concrete Engineering Properties. Buildings 2017, 7, 77. [Google Scholar] [CrossRef]

- Herki, B.M.A. Absorption Characteristics of Lightweight Concrete Containing Densified Polystyrene. Civ. Eng. J. 2017, 3, 594–609. [Google Scholar] [CrossRef]

- Qasrawi, H.; Shalabi, F.; Asi, I. Use of low CaO unprocessed steel slag in concrete as fine aggregate. Constr. Build. Mater. 2009, 23, 1118–1125. [Google Scholar] [CrossRef]

- Yu, X.; Tao, Z.; Song, T.-Y.; Pan, Z. Performance of concrete made with steel slag and waste glass. Constr. Build. Mater. 2016, 114, 737–746. [Google Scholar] [CrossRef]

- Azeez, A.; Hassan, M.; Atiyah, A. Evaluation of the Performance of Steel Slag and Waste Glass as a Cement Replacement. Eng. Technol. J. 2023, 41, 1567–1577. [Google Scholar] [CrossRef]

- Ravikumar, H.; Dattatreya, J.K.; Shivananda, K.P. Experimental Investigation on Replacement of Steel Slag as Coarse Aggregate in Concrete. J. Civ. Eng. Environ. Technol. 2015, 2, 58–63. [Google Scholar]

- Alizadeh, R.; Chini, M.; Ghods, P.; Hoseini, M.; Montazer, S.; Shekarchi, M. Utilization of Electric Arc Furnace Slag as Aggregates in Concrete-Environmental Issue. In Proceedings of the 6th CANMET/ACI International Conference on Recent Advances in Concrete Technology, Bucharest, Romania, 8–11 June 2003; pp. 451–464. [Google Scholar]

- Li, Y.; Liu, F.; Yu, F.; Du, T. A review of the application of steel slag in concrete. Structures 2024, 63, 106352. [Google Scholar] [CrossRef]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Pearson Education Limited: Harlow, UK, 2004. [Google Scholar]

- Lang Pang, L.; Liao, S.; Wang, D.; An, M. Influence of steel slag fineness on the hydration of cement-steel slag composite pastes. J. Build. Eng. 2022, 57, 104866. [Google Scholar] [CrossRef]

- Yew, M.K.; Mahmud, H.B.; Ang, B.C.; Yew, M.C. Effects of heat treatment on oil palm shell coarse aggregates for high strength lightweight concrete. Mater. Des. (1980–2015) 2014, 54, 702–707. [Google Scholar] [CrossRef]

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of content and particle size of waste pet bottles on concrete behaviour at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef]

| Constituent | Composition (%) | Designation (SS) | Property | |||

| Cement | SS | Shape | HDSS | Highly angular | ||

| SiO2 | 19.83 | 38.73 | LDSS | Highly angular and porosity | ||

| Fe2O3 | 2.32 | 25.87 | Surface texture | Rough | ||

| CaO | 61.66 | 15.61 | Colour | Light black | ||

| Al2O3 | 4.48 | 9.84 | Combustibility | Non-combustible | ||

| MgO | 3.14 | 5.21 | ||||

| MnO | 0.31 | 2.10 | Specific Gravity | HDSS | 3.1 | |

| K2O | 0.68 | 0.83 | LDSS | 2.7 | ||

| TiO2 | 0.32 | 0.51 | Water Absorption (%) | HDSS | 3.3 | |

| Other | 7.26 | 1.3 | LDSS | 3.9 | ||

| Mix | Mix Code | Cement (kg/m3) | FA (kg/m3) | CA (kg/m3) | SS (%) | SS Type | Water (kg/m3) | SP (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | Control | 400 | 800 | 1200 | 0 | - | 200 | 0.5 |

| 2 | H20 | 400 | 800 | 960 | 20 | HDSS | 200 | 0.5 |

| 3 | H40 | 400 | 800 | 720 | 40 | HDSS | 200 | 0.5 |

| 4 | L20 | 400 | 800 | 960 | 20 | LDSS | 200 | 0.5 |

| 5 | L40 | 400 | 800 | 720 | 40 | LDSS | 200 | 0.75 |

| 6 | P20 | 320 | 800 | 1200 | 20 | SSP | 200 | 0.75 |

| 7 | P40 | 240 | 800 | 1200 | 40 | SSP | 200 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herki, B.M.A.; Ali, A.I.; Smail, Y.S.; Omer, K.M. An Innovative Approach to Enhancing Concrete Sustainability: Utilising Unprocessed Steel Slag with Low CaO and High SiO2 Content. Buildings 2025, 15, 1514. https://doi.org/10.3390/buildings15091514

Herki BMA, Ali AI, Smail YS, Omer KM. An Innovative Approach to Enhancing Concrete Sustainability: Utilising Unprocessed Steel Slag with Low CaO and High SiO2 Content. Buildings. 2025; 15(9):1514. https://doi.org/10.3390/buildings15091514

Chicago/Turabian StyleHerki, Bengin M. A., Ali Ibrahim Ali, Yousif Sadiq Smail, and Karwan Maroof Omer. 2025. "An Innovative Approach to Enhancing Concrete Sustainability: Utilising Unprocessed Steel Slag with Low CaO and High SiO2 Content" Buildings 15, no. 9: 1514. https://doi.org/10.3390/buildings15091514

APA StyleHerki, B. M. A., Ali, A. I., Smail, Y. S., & Omer, K. M. (2025). An Innovative Approach to Enhancing Concrete Sustainability: Utilising Unprocessed Steel Slag with Low CaO and High SiO2 Content. Buildings, 15(9), 1514. https://doi.org/10.3390/buildings15091514