1. Introduction

In construction, every layer and detail play a crucial role. At the end of the construction stage, the focus shifts to surface treatments, where coatings play a pivotal role. The most used wall coatings are mortars with paint, ceramic tile, or stone finishes. These types of coatings are widely used due to their low cost, their ease of execution, and being aesthetically acceptable [

1,

2,

3].

Among the construction systems used in civil construction in several countries, facade wall coatings using mortars hold a prominent position [

3,

4]. The external coatings play a crucial role in the building’s appearance and value [

5,

6], contributing to the protection of the building envelope, whose main functions are to protect the construction against degradation agents and guarantee the users’ comfort [

5,

7]. The durability of buildings is significantly influenced by the quality of the layers comprising the facade system. If these layers are of poor quality or inadequately installed, they may fail to provide adequate protection, leading to accelerated deterioration of the building structure. Thus, ensuring the high quality of facade layers is essential for maintaining the long-term durability and integrity of buildings.

Although mortar appears to be a simple material, extensively used as a coating, it is, in fact, a complex material comprising multiple phases, including crystalline and amorphous components, as well as inert and reactive aggregates. This fact highlights the complexity of understanding the behavior of this material, especially due to the varying composition of mortars [

8]. The lack of technical knowledge of the material results in inadequate specification, monitoring, and supervision during the execution of the mortar coating process [

6,

7,

8,

9]. Furthermore, there is a lack of research dedicated to the study of mortars, especially with regard to their properties, considering that adhesion can be influenced by several factors, such as the state of the mortar (fresh or hardened), the execution process, the constituent materials, the exposure conditions, and the evaluation method, among others [

9,

10,

11]. It is common for detachments to occur due to the lack of adhesive strength between the layers of a building’s facade system [

12]. These defects compromise the adequate performance of the system and contribute to reducing the service life of the building [

13].

Thamboo and Dhanasekar [

14] and Lima et al. [

6] refer that the most relevant property of coating mortars is adhesion. Since the phenomena that occur at the interface between the substrate and the mortar strongly influence facade system performance, further studies in this area are vital. The bond between the layers of the facade system can be evaluated by the adhesion property. Tensile adhesive strength is defined as the maximum stress supported by a limited area of the coating at the evaluation interface when subjected to orthogonal tensile stress [

15].

While significant research has been conducted on mortar coatings, construction challenges persist, underscoring the need for further studies to enhance the understanding of this material’s behavior [

11,

16,

17]. Therefore, this study aims to evaluate the tensile adhesive strength of mortar for facades with paint and ceramic tile finishes and analyze the influence of interactions between the design, execution, and environmental exposure conditions. This research includes 912 samples resulting from 76 tensile adhesive strength tests carried out during inspections of buildings in use. The findings from this comprehensive dataset serve as indicators of process quality and construction performance, offering valuable insights derived from completed product testing.

2. Background

The facade of buildings is the first durability layer and the primary defense against various degradation agents, whether of mechanical, climatic, or biological origin [

18,

19]. Ensuring the quality and performance of the facade coatings is paramount to fulfilling the functions of the facade system, which are related to users’ health and comfort, as well as the durability of the building [

7,

20]. In adhered coating systems, it is common to use a layer of mortar before the finish, regardless of the type of finish.

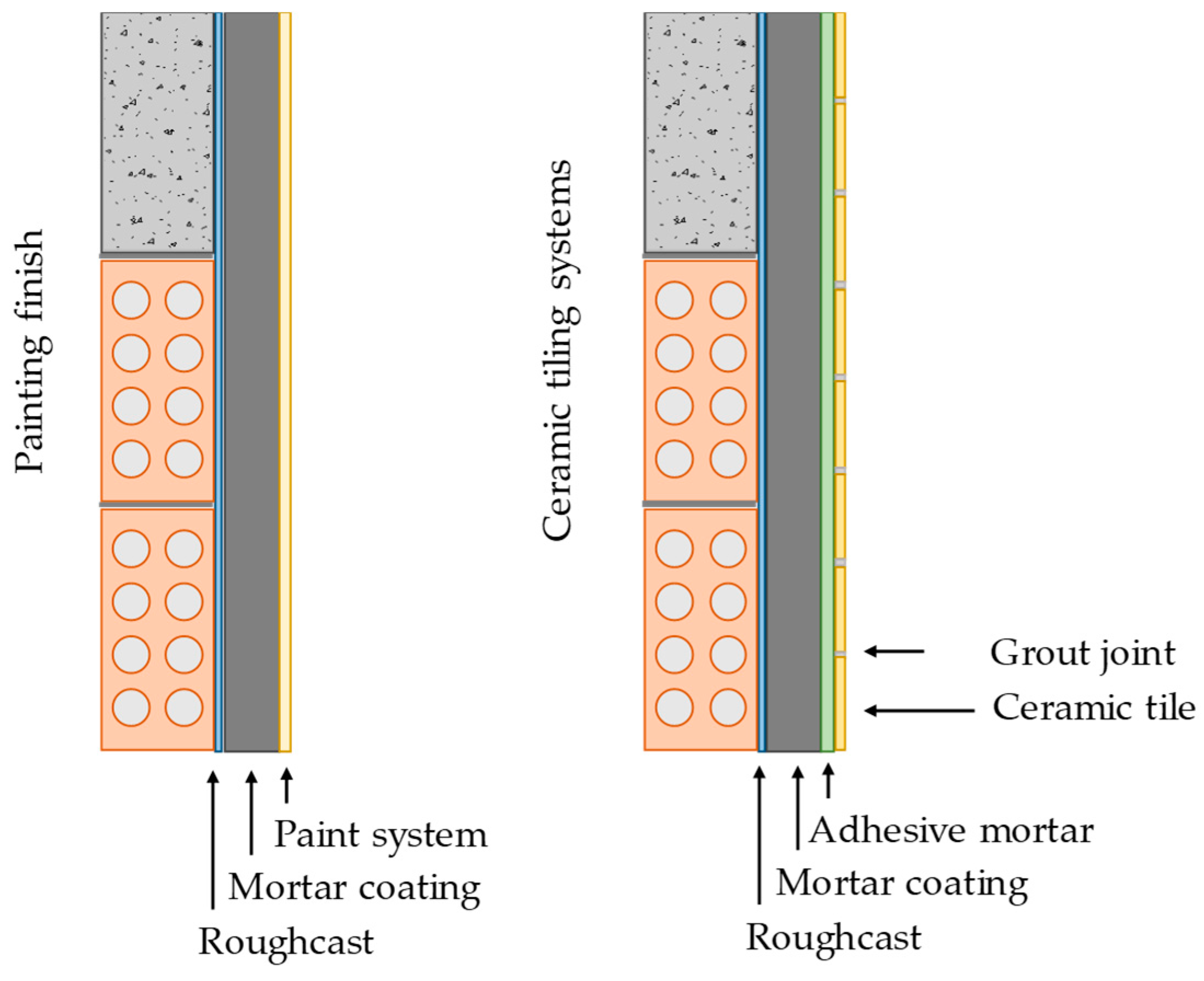

Figure 1 illustrates the most common finishes in adhered coating systems.

Although mortar is extensively used in wall coating systems, numerous challenges arise when assessing the required performance of facade systems [

16,

21]. Pathological manifestations frequently emerge in these systems due to various design, execution, and climatic factors. Among the most common defects observed in facade systems, detachment, cracking, and pulverulence are the most frequent [

5,

22]. Degradation mechanisms, resulting from a sequence of physical and chemical changes, significantly impact the materials’ properties and therefore the performance of the entire coating system. According to Andrade et al. [

19], the intensity of degradation mechanisms varies, with each construction system exhibiting unique characteristics and specific sensitivities to degradation. The occurrence of these anomalies is often associated with the quality of the plaster mortar used.

Since the onset and evolution of defects in the facade coating system can cause risks to users, the main property of the mortar evaluated is adhesive strength resistance [

20,

23]. The application of the mortar to the substrate generates an interface where interactions occur even in the fresh state and over time. Due to the hydration kinetics and the absorption of the mortar by the substrate, the mortar adheres to the substrate [

2,

20]. Consequently, the behavior of the mortar is influenced by the characteristics of the substrate and the interface created. The performance quality of coating systems can be assessed by the adhesion between the layers [

8]. However, according to Stolz et al. [

17], the adhesion behavior of plaster mortar is influenced by microadhesion (namely adhesion) and macroadhesion (namely adherence). Adhesion occurs when mortar absorbs into contact with a porous substrate, filling the pores and establishing mechanical anchorage. Adherence, on the other hand, involves the mortar filling recesses on the substrate’s surface, maintaining anchorage. There is a difference between adhesion and adherence in a mortar coating system. Adhesion evaluates the ability to remain on the substrate in a fresh state, while adherence is defined as the material’s property in the hardened state to resist stresses at the surface or interface with the substrate [

15,

24]. Despite this, in this research, the term adhesion is adopted, in accordance with the BS EN 1015-12 (2016) [

25] standard.

Adhesion is a very complex property that depends on several factors, such as substrate characteristics and properties, mortar composition, application technique, and climatic conditions [

23,

26,

27]. On concrete substrates, the adhesive strength of the mortar depends mainly on the interface characteristics between the mortar and the substrate, as the resistance is influenced by surface roughness and chemical reactions [

2]. In accordance with Lima et al. [

6], surface roughness is the most critical parameter when evaluating adhesion strength. Haddad et al. [

20] state that substrate absorption, sand particle size, and roughness significantly affect the adhesion of the mortar to the substrate.

There is a direct and positive relationship between water transport in different layers and adhesive strength, as when cement-based mortar is applied, changes occur in the internal structure of the material due to water transport in the mortar [

13,

26]. The movement of water in the first hours after mixing and in the early ages is essential for the development of the coating’s properties.

The application of roughcast is essential in a facade coating system, by controlling the amount of water transported from the mortar to the substrate. The execution of this layer considerably increases the surface area [

13]. Furthermore, as it is applied with high fluidity, the roughcast is easily absorbed by the substrate, promoting both adhesion and adhesion, maximizing the final efficiency of the system [

28].

The way in which the mortar is applied to the substrate is a factor that affects the behavior of the coating, particularly concerning the adhesion mechanism [

15]. Mechanically projected mortars can have higher adhesive strength values and a lower coefficient of variation compared to manually applied mortars. This occurs because mechanical projection provides a larger contact surface and enhanced compactness post-application, thereby reducing the porosity and permeability of the coatings [

15].

According to Lima et al. [

6], the direct application of mortar onto concrete leads to non-uniform adhesion due to the porous nature of the concrete surface. However, homogeneity in adhesion is achieved when the mortar is applied to roughcast. This fact reinforces the importance of using roughcast on a concrete substrate, which aims to facilitate adhesion between the mortar and the substrate. Curing also affects the properties of the mortar. Thamboo and Dhanasekar [

14] observed that the increase in adhesion resistance diminishes after 14 days.

The tensile adhesive strength tests are frequently carried out to characterize the adhesion strength of mortars and infer their mechanical resistance quality. However, some researchers suggest that the test method can influence the adhesive strength results [

20,

29]. According to the Brazilian standard ABNT NBR 13528-2 [

15], the application of a metal mesh to the coating layer can prevent the test piece from being cut, thus preventing the test from being carried out. The standard also states that the humidity of the coating at the time of the test influences the adhesive strength values and coefficients of variation. However, this standard still states that the variability of results can be reduced when water is used in the specimen-cutting procedure. Furthermore, the variation in adhesive strength values may stem from factors such as operator ergonomics during testing or the bricklayer’s ergonomics during mortar application [

30].

Various studies [

13,

31,

32] analyzed the interface between the mortar and the substrate and the factors that can influence adhesive strength, but most research is carried out in laboratory experiments, resulting in a lack of research carried out in real-world building environments. It is important to state that the behavior of mortar in the laboratory is not the same as the behavior when applied to real substrates in real buildings, whose specific characteristics influence mortars’ performance [

2,

23].

The study of the adhesion of facade mortars can significantly contribute to construction practices and maintenance strategies, impacting the design phase through to the durability of the building. Some forms of application include adequate selection of more suitable materials, considering the compatibility between a mortar and substrate, adjustments in application methods for different climate conditions considering substrate preparation, control of layer thickness, application techniques, and adequate application time. In the context of maintenance, this study assists in the choice of predictive maintenance strategies, based on monitoring adhesion over time, in defining adequate periods for inspection and maintenance. In addition, it can support reviews and improvements in technical standards on mortar coatings.

3. Materials and Methods

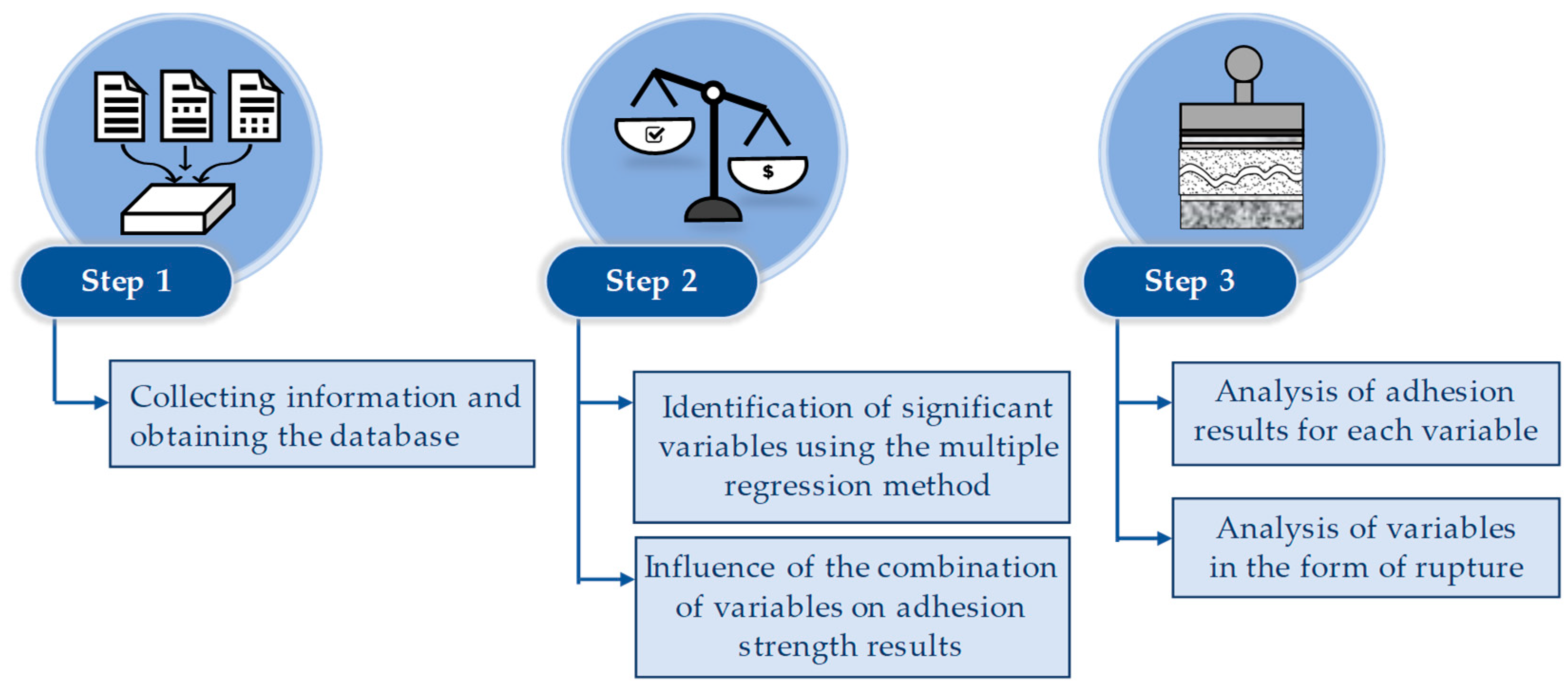

The research methodology adopted consists of the separate and joint assessment of variables that can influence the adhesive strength of mortars on building facades (

Figure 2). The study variables include design, execution, and environmental exposure conditions.

Initially, a database was built in order to evaluate the adhesive strength. The cases included in the database refer to on-site inspections of buildings in use located in Brasília, a central-western city in Brazil. The adhesive strength of the facade coating system was obtained in accordance with the test preconized in the Brazilian standard ABNT NBR 13528-2 (2019) [

15]. The test procedure to obtain adhesive strength involves applying orthogonal tensile stress to 12 specimens with identical characteristics, including the same type and preparation of the substrate, coating mortar, method of application, and age [

15]. The distribution of the specimens must be random and may include joints and blocks with a minimum distance of 50 mm. According to this standard, the test must be conducted with the test specimens in a dry condition, as the humidity of the coating at the time of testing can influence adhesion values and coefficients of variation.

The minimum adhesive strength that the mortar must present varies for each type of coating system finish, in addition to being different for each nation. The Brazilian standard ABNT NBR 13281-1 [

33] determines that external coating mortars must have a minimum potential adhesive strength to the substrate of 0.3 MPa. Brazilian standard ABNT NBR 13755 [

34] determines that in a ceramic coating system, the mortar layer must have an adhesive strength greater than 0.5 MPa. When the adhesion result is between 0.3 MPa and 0.5 MPa, the designer must be consulted, and values lower than 0.3 MPa condemn the coating system. Acceptance of the external coating occurs when, at a coating age greater than 28 days, at least eight resistance values for every twelve tests carried out are greater than 0.3 MPa for painting or ceramic finishing [

35].

The rupture forms of the adhesive strength test for a roughcast coating system are illustrated in

Figure 3. It is worth noting that rupture does not always occur at the interface between the coating and the substrate [

13,

14].

The types of ruptures can be grouped into cohesion and adhesion fractures, where cohesion fracture reflects on the property of the material and adhesion fracture on the adhesion between the layers. The roughcast must be applied in a very thin layer, and when rupture occurs in the roughcast (type C), it indicates a failure in the construction process, potentially due to the excessive thickness of the roughcast layer. When the rupture occurs at the interface between the roughcast and the mortar (type D) or between the roughcast and the substrate (type B), the value obtained in the test can be considered the value of the tensile adhesion strength of the facade system. Rupture in the mortar layer (type E) or in the substrate layer (type A) does not reflect adhesive strength but rather reflects material properties. Caution should be exercised when evaluating the facade system in these cases, as it may reveal shortcomings in the execution process, in materials’ properties, or other factors. When rupture occurs on the surface of the mortar (type F) or at the interface between the adhesive layer and the pull-head plate (type G), it indicates bonding imperfections and failure in the test procedure. In these instances, the test result must be discarded.

The tests were carried out on facade coatings of buildings over 10 years old. The buildings are in a tropical climate with dry winters, according to the Köppen climate classification, as there is normally a long dry period throughout the year. Nascimento et al. [

36] refer that in this city, around 39% of the hours of the year have high relative humidity (above 75% RH) and an average temperature of 21.1 °C.

The information contained in the database covers the results of 76 adhesive strength tests on facade coatings of 17 buildings obtained during on-site inspections and from the respective design, executive, and climatic characteristics. The characteristics of the building are translated into parameters such as age, finishing type, substrate type, test zone, building height, layer thickness, solar orientation, temperature, and relative humidity. Subsequently, the behavior of adhesive strength is evaluated for each variable, evaluating the intensity, frequency, and physical significance. Significant variables impacting tensile bond strength are identified by linear multiple regression analysis. Multiple regression is widely used in research to explore the effect of two or more independent variables on a dependent variable and to obtain predictive models. Moreover, this statistical technique also allows for identifying the relative importance of the predictor variables in explaining the dependent variable [

37,

38].

Table 1 presents the criteria for quantifying the variables since to perform the regression analysis, it is necessary for the variables to be quantitative. Once the variables with the greatest significance have been identified, a joint analysis of variables is carried out in order to check whether the combination of any variable reflects the adhesive strength of the building facades.

4. Results

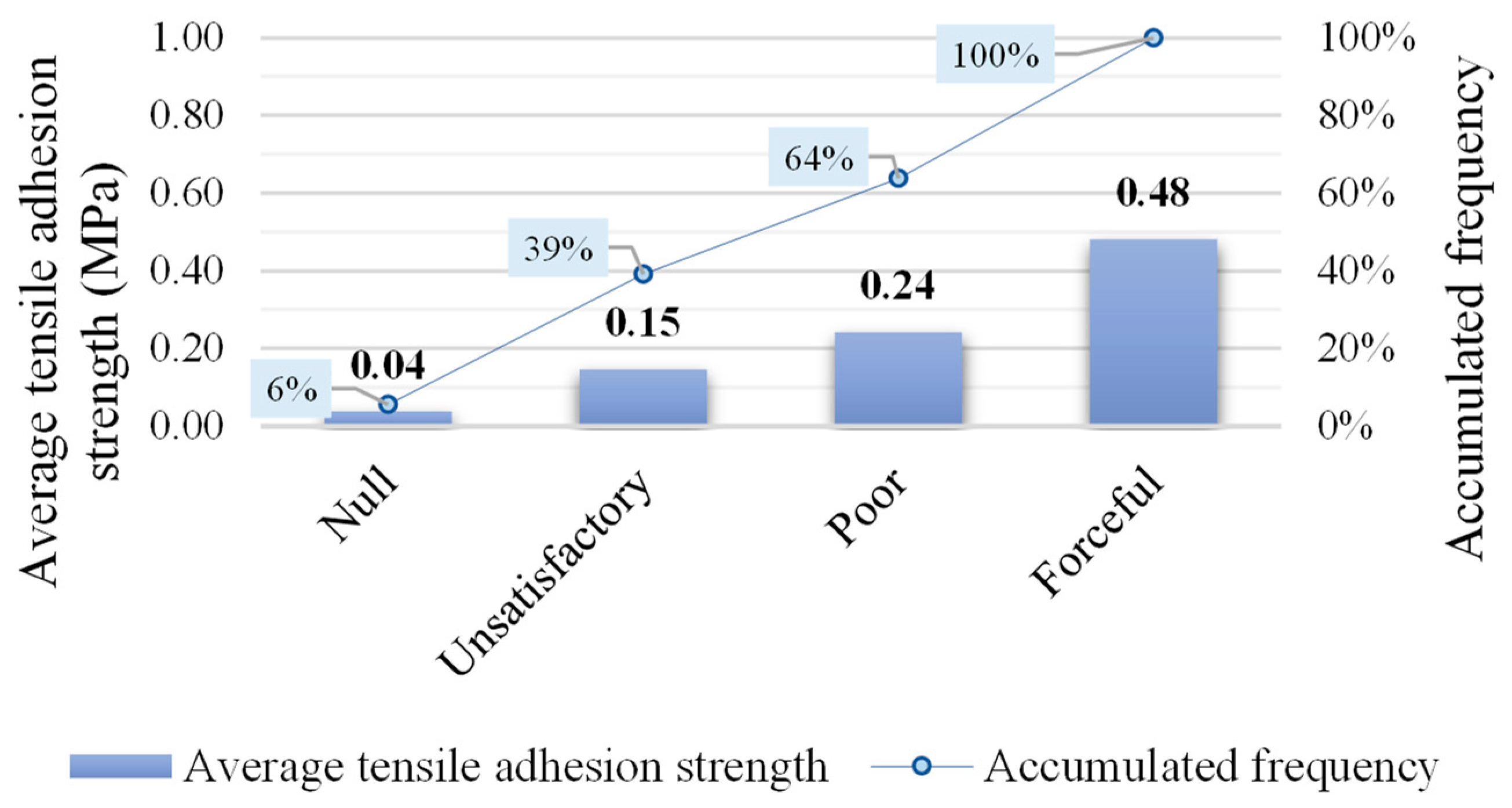

Average adhesive strength is classified into ranges such as zero or almost zero (less than 0.1 MPa), unsatisfactory (between 0.1 MPa and 0.2 MPa), poor (between 0.2 MPa and 0.3 MPa), and forceful (greater than 0.3 MPa). The accumulated frequency and average tensile adhesion strength for each class are presented in

Figure 4.

The average adhesive strength for each classification tends to be the intermediate value of the class and the frequency of cases for each class tends to be the same, except for the zero or almost zero class, which represents only 6% of cases. More than 60% of cases did not reach the minimum strength limit proposed by the Brazilian standard ABNT NBR 13281-1 [

33]. However, a study conducted in Portugal [

39], focused on mortars applied to plasters and external coatings of old buildings, recorded adhesion strength values ranging from 0.61 to 1.66 MPa.

The adopted regression model is represented as

. All study variables are included in the multiple regression analysis. The regression statistics (

Table 2) indicate a correlation coefficient (r) equal to 0.827. According to Abbad and Torres [

37], the r value indicates a strong correlation between the independent variables and the dependent variable included in the model.

The quality of the research model is assessed by the value of the coefficient of determination (r2 = 0.683 and r2a = 0.679). These values mean that the variables considered relevant and included in the regression model are able to explain approximately 68% of the variance in the adhesive strength of the building facades analyzed. The standard error is equal to 0.195, indicating that the model has an average error of ±0.195 MPa.

The analysis of variance (ANOVA) of the regression (

Table 3) presents a

p-value equal to 2.01 × 10

−218. Considering a significance level of 0.05, this indicates that the independent variables included in the model are indeed related to the dependent variable. However, it is important to note that in multiple regression analysis, the ANOVA test alone is not conclusive, as it does not specify which variables are significant. Therefore, the

t-test is typically employed, as it assesses each regression parameter individually.

Table 4 presents the coefficients and

t-test results.

p-values lower than 0.05 indicate that the independent variable is significant and contributes to explaining the dependent variable. Consequently, in the regression model obtained, the variables related to the building’s height, layer thickness, and substrate type are not statistically significant.

While regression coefficients describe the relationship between each independent variable and the dependent variable, it is important to note that variables with larger coefficients are not necessarily more important because the different variables present different units (the variables are not standardized). In this sense, the

t-test is used to verify the contribution resulting from the inclusion of the predictor variable corresponding to the coefficient, making this test one of the ways to assess the importance of each predictor variable.

Figure 5 presents the absolute values of the

t-test for each variable included in the model. Among the significant variables in the model, orientation, age, and finish type are identified by the

t-test as the most important variables in the regression model.

Although the results did not indicate the type of substrate as a statistically significant variable, some researchers refer that the texture of the substrate influences adhesion [

17]. According to Lima et al. [

6], cementitious materials tend to have lower adhesion resistance compared to other materials due to their low roughness. Furthermore, the contact length plays a significant role in enhancing adhesion. However, increasing the potential contact area between the mortar and the substrate does not necessarily result in an increase in tensile adhesion strength [

17]. Although the

t-test did not indicate the thickness as a significant variable, this variable influences adhesion. The thicker mortar layer results in increased load on the system, consequently leading to heightened tension at the interface. Hence, many professionals recommend incorporating a metal mesh in the mortar when it attains considerable thickness.

Properties that significantly influence the increase in the effective contact area are related to the roughness of the substrate and the rheology of the mortar. The interfacial contact between the mortar and the substrate can be influenced by the substrate texture, as the angle formed by the substrate textures can influence wetting and, consequently, adhesion [

17]. According to Zanelato et al. [

13], adhesion constitutes a highly complex system that depends on several factors, including the curing conditions to which the coating is exposed, the coating application technique, the characteristics and properties of the porous materials that serves as a base, and the properties of the mortar and constituent materials.

Pretto [

40] and Lukovic and Ye [

41] mentioned that merely increasing surface texture may not be sufficient to improve adhesion if the mortar fails to penetrate the substrate, indicating the influence of substrate absorption on the mortars’ adhesion. Loss of water through the substrate reduces the effective water–cement ratio and the degree of hydration of the applied material. Therefore, dry substrates result in more voids at the interface. Stolz and Masuero [

42] refer that surface tension, application force, and rheological properties of mortars significantly influence the development of tensile adhesion strength.

While standards ABNT NBR 13755 [

34] and ABNT NBR 13749 [

35] specify the thickness of the mortar layer and stress the importance of ensuring coating adhesion, the thickness of the plaster layer is not considered as a significant variable in tensile adhesion strength, as shown in

Figure 5. The

t-test identified temperature as a significant variable. This result is consistent since exposure to high temperatures of cement-based materials, such as mortar applied to the coating, undergoes physical and chemical changes. These changes degrade the material and reduce the durability of the system since high temperatures cause the evaporation of water present in the cementitious materials, increasing the size of the pores of the dehydrated cement paste, characterizing a microcrack and, consequently, influencing the properties of the coating and adhesion [

43,

44].

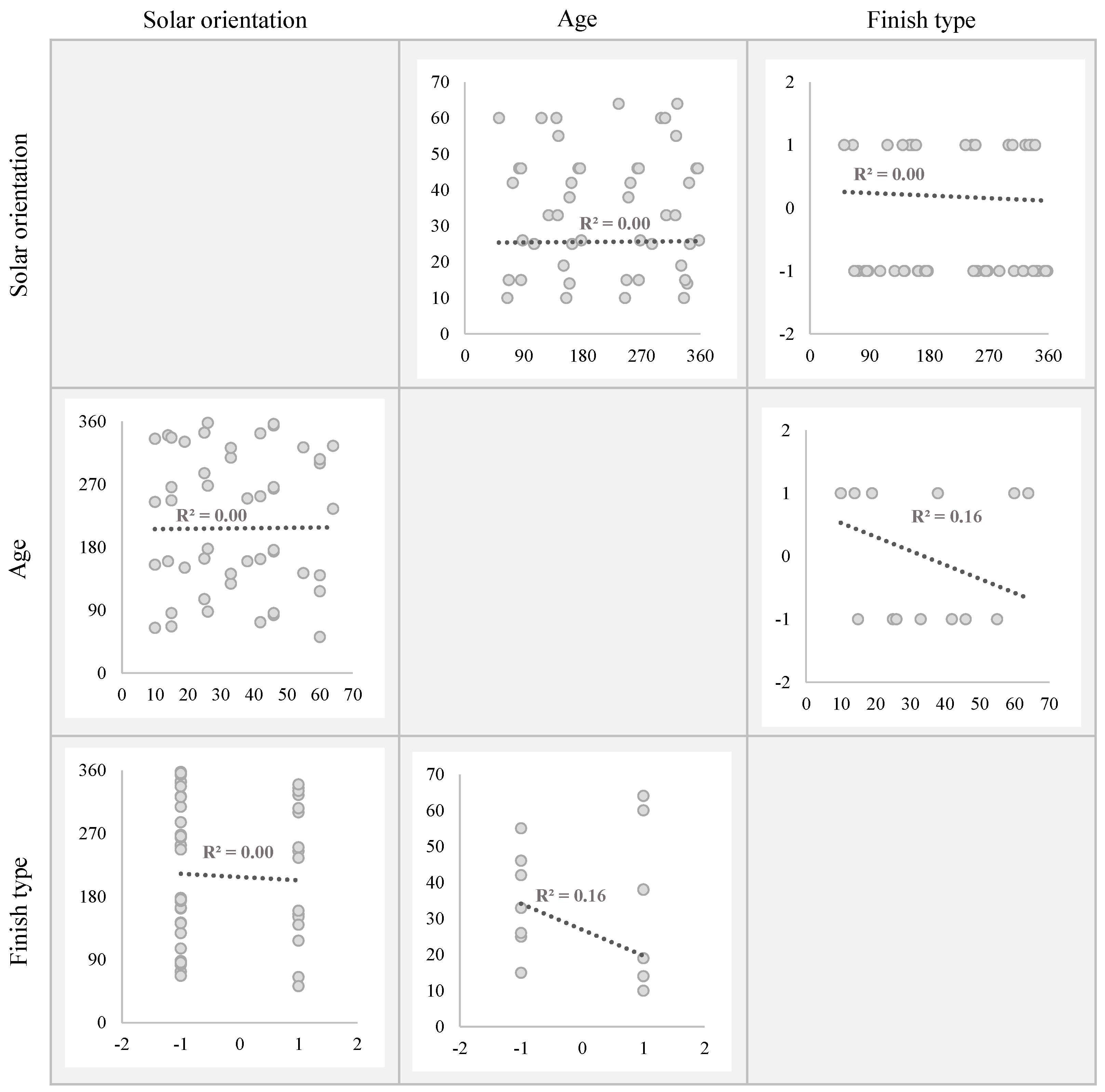

Myers [

45] mentioned that the correlation between the independent variables (multicollinearity) does not significantly affect the goodness-of-fit of the model. However, the objective of regression analysis in this research is not to obtain the model but to identify the significant variables and their relative importance. Multicollinearity can lead to confusing and even meaningless analyses of the regression model. According to Maroco [

46], multicollinearity can be verified by the bivariate correlation matrix between variables, in which the bivariate correlation between independent variables must be less than 0.75. The correlation matrix between the significant variables, presented in

Figure 6, indicates that there is no correlation between the independent variables.

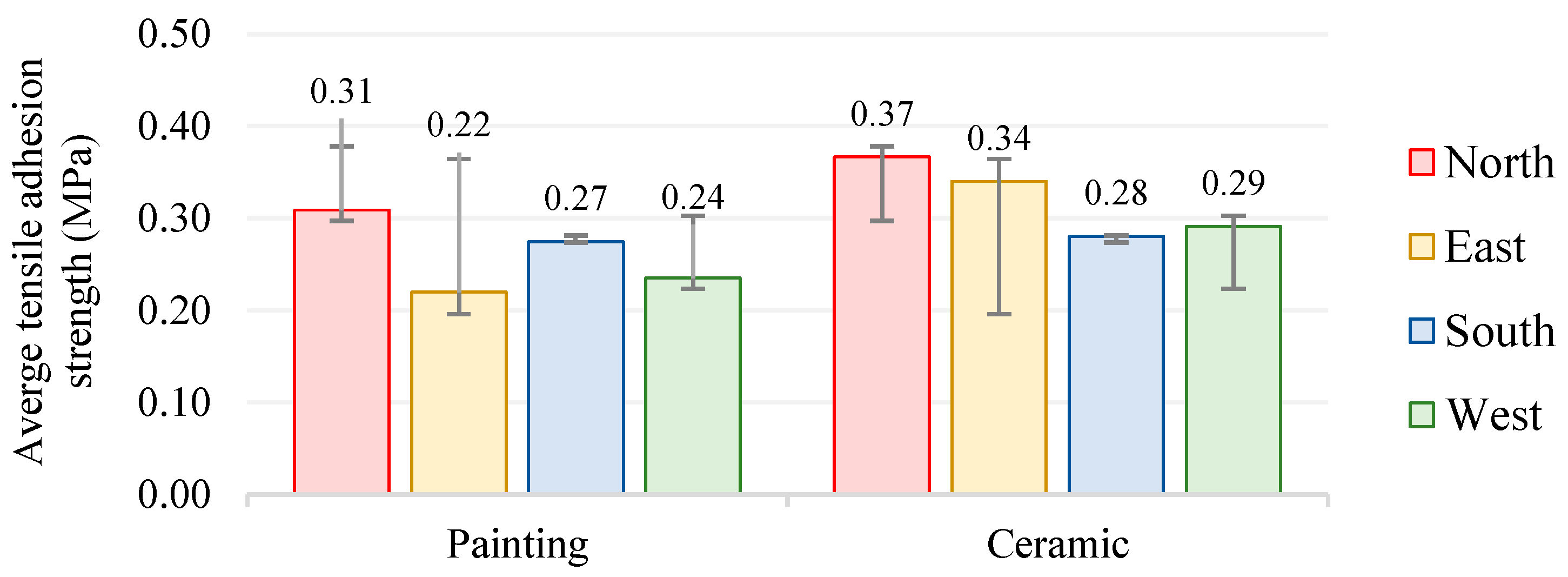

According to the standard ABNT NBR 13749 [

35], the coating system should present a pattern of decreasing or uniform mechanical resistance, starting from the first layer in contact with the substrate. This requirement is essential to ensure the durability and final finish of the coating, without compromising its overall integrity. Considering the type of finish, the average tensile adhesion strength for each solar orientation is shown in

Figure 7.

There is a notable disparity in tensile adhesion strength across various finish types. Specifically, the average tensile adhesion strength in systems with paint finishes consistently proves lower than those with ceramic tile finishes, regardless of solar orientation. According to Ferreira et al. [

47], coating systems with a paint finish tend to have a shorter service life than systems coated with ceramic coatings. This discrepancy stems from the inherent characteristics of each material; while painting systems serve as physical barriers with relatively lower resistance to weathering, ceramic tiles applied with ACIII adhesive mortar offer a more durable surface. In paint finish systems, the material’s lower physical resilience facilitates the formation of dust during the humidification and drying processes, characterized by mechanisms such as bubble formation and loss of paint adhesion.

Regarding solar orientation, the north orientation consistently yields the highest adhesive strength regardless of the type of finish. However, no discernible trend is observed for other orientations. Notably, east and west orientations tend to exhibit the lowest adhesive strength values, particularly in paint finishes. Conversely, for ceramic tile finishes, south and west orientations typically yield lower results.

Several international standards, including Canadian, North American, European, and Brazilian standards, establish methods for assessing the adhesion of coatings. However, these standards often apply to specific coating systems, limiting their comparative scope. The European standard EN 1015 [

25], due to its wide adoption in several countries and similarity in test procedures, emerges as a potential reference for comparing the results obtained in this study. However, EN 1015 [

25] delegates the definition of the evaluation criteria to the manufacturer, which can vary considerably. Considering that the data in this research refer to buildings constructed with Brazilian materials, the Brazilian standard NBR 13281-1 [

33], which establishes a minimum accuracy limit of 0.30 MPa, is more suitable for defining the approval criteria. Furthermore, it is crucial to emphasize that most research on adhesion focuses on laboratory environments, while this study evaluates adhesion in the field. Consequently, there is very little research exploring adhesion strength in relation to solar orientation, making this research particularly relevant.

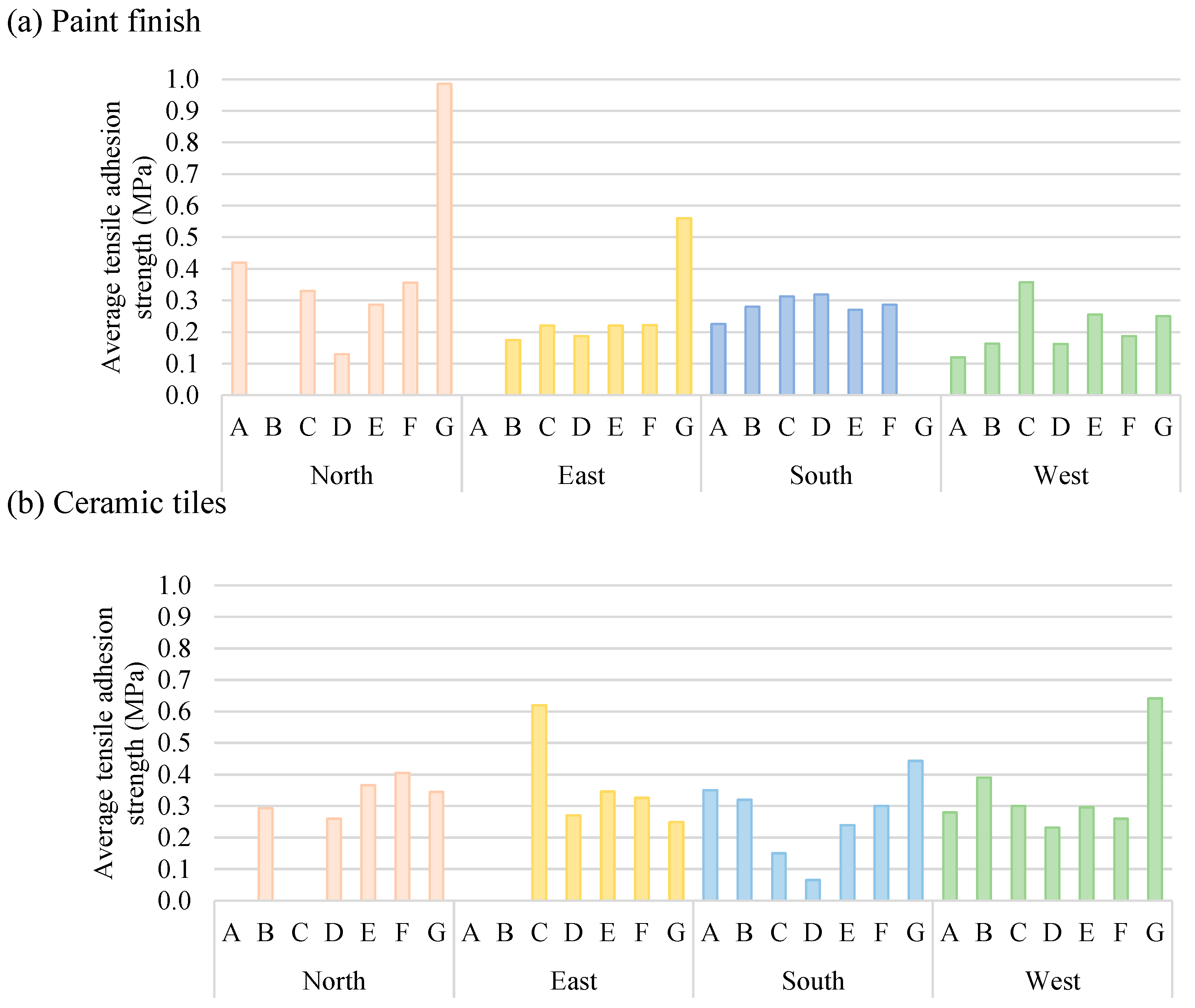

The rupture form of the adhesive strength test is relevant to the adhesion analysis.

Figure 8 illustrates the average adhesive strength of each type of rupture for each solar orientation and type of finish.

Since a type A rupture refers to a cohesive rupture due to breaking through the substrate, this type of rupture does not represent the adhesive strength. However, when values are higher than 0.3 MPa, they indicate that the other layers have higher resistance. The average values obtained for this type of rupture were lower than 0.3 MPa, except for the south orientation with ceramic tile finishing.

The tensile adhesion strength of the building facade is represented by the rupture at the interface between the substrate and the roughcast (type B), by the rupture in the roughcast (type C), or by the rupture at the interface between the mortar and the roughcast (type D). Considering only adhesive ruptures (Type B, C, or D), in coating systems with a paint finish, only the east orientation did not show adhesive strength results greater than 0.3 MPa, and in coating systems with a ceramic tile finish, only the north orientation did not reveal results of tensile adhesion strength higher than 0.3 MPa.

The highest values of adhesive strength for coatings with ceramic tiles occur in the west (0.36 MPa) and north (0.33 MPa) orientations. This result indicates the influence of solar radiation since these orientations receive the most solar radiation throughout the year. For paint coatings, the highest values of tensile adhesion strength occur in the east (0.62) and west (0.39) orientations. This result indicates less influence of solar radiation on this type of finish in coating systems. In the results found by Haddad et al. [

20] most of the failures occurred between the mortar and the concrete block substrate, implying greater resistance of the mortar compared to adhesion to the substrate.

Type E and type F ruptures occur in the mortar or at the interface between the mortar and the adhesive layer. Most tensile adhesion strength test results are cohesive as they focus on type E and type F ruptures. However, when this type of rupture occurs, the results of the adhesive strength test indicate values referring to the property of the mortar rather than the adhesion strength. Since tests are generally carried out at ambient temperature, this aligns with research by Bueno et al. [

44], which suggests that cohesive ruptures are common at ambient temperature, whereas adhesive failures are more prevalent under thermal exposure. The average tensile adhesion strength for type E and F ruptures exceeded 0.3 MPa only for the north orientation in coatings with a ceramic tile finish. A type G rupture occurs at the interface between the adhesive layer and the tablet, indicating test failure when observed.

5. Conclusions

In this study, a comprehensive analysis was performed, to assess the tensile adhesion strength of mortar coatings for facade systems, considering various influencing factors such as substrate type, finish type, and solar orientation.

The results reveal that the type of finish significantly influenced the tensile adhesion strength, with ceramic tile finishes exhibiting higher values compared to paint finishes. This discrepancy can be attributed to the physical characteristics of the materials, where ceramic tiles offer greater resistance to weathering and provide a more robust surface for mortar adhesion. Solar orientation also presents a crucial role, particularly in paint coatings, with the east and west orientations displaying lower adhesion strength. This result underscores the impact of solar radiation on coating systems, influencing their performance and durability over time, since adhesion failure is strongly influenced by the differentiated dimensional variation between the layers of the system, caused by exposure to solar radiation. Throughout the year, direct solar radiation presents two distinct behaviors in the city under study. During the rainy season, the east orientation is less affected. However, in the dry season, this same orientation is the one that receives a greater amount of direct solar radiation.

Moreover, the type of rupture observed during the tests provided valuable insights into the behavior of the mortar and its interaction with the substrate. Cohesive ruptures predominated, indicating the inherent strength of the mortar material itself. However, adhesive ruptures became more prevalent under thermal exposure, highlighting the importance of considering environmental factors in assessing coating performance.

It is also worth noting that improving performance through the formulation of materials or construction techniques is necessary to improve the performance and durability of these coating systems. Although this research does not focus on the study of mortar composition materials, it is important to highlight the need for studies that evaluate the practical implications of mortar in construction. As a ceramic material with low cement content, brittle behavior, and susceptibility to various execution processes, mortar presents several challenges. Among them, a low deformation capacity, increasing the risk of coating detachment due to stresses induced by thermal and hygrothermal movements; variations in cement content—whether excessive or insufficient—can affect both the mechanical strength and shrinkage of the mortar; execution techniques, such as waiting time between layers and application pressure, directly impact performance; even inadequate curing can lead to premature dehydration, reducing strength and exacerbating shrinkage.

Additionally, this study shed light on the limitations of certain test methods, such as the inability to differentiate between adhesive and cohesive failures in some cases. This underscores the need for rigorous testing protocols and further research to refine our understanding of coating behavior. This study emphasizes the significance of analyzing the type of rupture in assessing the tensile adhesion strength of facade coatings. It is crucial to recognize that a test result falling below the minimum normative value does not automatically imply compromised adhesion of the facade system. This is particularly pertinent considering the nature of mortar as a ceramic material with low cement content, exhibiting a fragile behavior and susceptibility to various executive processes from dosing to curing. The inherent fragility of mortar increases the likelihood of defects and introduces variability in test results. Therefore, careful consideration of rupture type and an understanding of mortar behavior are essential for accurate evaluation and informed decision-making in facade construction and maintenance practices.

Overall, the findings of this study contribute to our knowledge of facade coating systems and provide valuable insights for architects, engineers, and construction professionals involved in building design and maintenance. By better understanding the factors influencing tensile adhesion strength, stakeholders can make informed decisions to optimize coating performance and enhance the durability of building facades in diverse environmental conditions.