1. Introduction

Steel exhibits exceptional tensile strength, while concrete demonstrates superior performance under compressive forces. The combination of these two materials creates a synergistic effect, significantly enhancing structural efficiency. Consequently, steel–concrete composite structures have gained widespread application in bridge engineering and construction projects. Despite their advantages, steel–concrete composite beams (SCBs) are subjected to a combination of sustained loading, environmental effects, and material property degradation during their long-term service [

1,

2,

3]. These factors introduce significant complexities in predicting their long-term behavior, posing critical challenges in the design, analysis, and maintenance of such structures.

As inherent time-dependent characteristics of concrete, creep and shrinkage have a significant impact on the performance of SCBs. Research on these phenomena has been ongoing since the early 20th century, leading to the development of numerous calculation methods and predictive models [

4]. Among these, the age-adjusted effective modulus method (AEMM) [

5], the CEB-FIP series of models [

6], and the B3 model [

7] are widely recognized. Bradford and Gilbert [

8] incorporated the AEMM and interface slip effects into their analytical model, thereby enhancing the accuracy of predictions regarding the long-term performance of simply supported SCBs. Amadio and Fragiacomo [

9] proposed an improved approach that integrates AEMM with concrete aging factors to refine the evaluation of creep and shrinkage behaviors. Furthermore, Sakr and Sakla [

10] designed a finite element program aimed at analyzing the long-term performance of SCBs. This program incorporated a comprehensive assessment of the nonlinear displacement–slip behavior of shear connectors, concrete shrinkage and creep effects, as well as the cracking behavior of concrete slabs. Additional insights into the long-term performance of SCBs have been provided through experimental and numerical studies. Bradford and Gilbert [

11], Lou et al. [

12], and Wen et al. [

13] offered valuable contributions, enhancing the understanding of these effects and demonstrating the importance of capturing the complex interactions involved in long-term performance assessments.

While previous studies have laid a strong theoretical foundation for understanding the long-term performance of SCBs, the inherent complexity and variable force characteristics of these structures pose significant challenges for traditional theoretical modeling and finite element analysis (FEA) methods in practical applications. On the one hand, material properties, such as the elastic modulus and time-dependent behaviors of concrete, exhibit considerable uncertainty. On the other hand, accurately characterizing the interface slip phenomenon between steel and concrete remains a challenging issue that traditional analytical methods urgently need to address. These limitations contribute to notable discrepancies between theoretical predictions and actual structural performance, thereby undermining the reliability of long-term performance assessments.

With the rapid development of the scale and design of bridge and building projects, the limitations of field measurements have become increasingly apparent. To better study the response of structures, the combination of tests and FEA has proven to be an effective tool. For instance, Lantsoght et al. [

14] utilized load tests to optimize a finite element model for assessing an untestable span in a similar bridge, such as the Viaduct De Beek, thereby enabling a more thorough evaluation of the bridge’s performance. This combination of optimizations not only enhances the accuracy of the study but also has the potential to reduce the costs associated with field testing. Additionally, Domenico et al. [

15] investigated the actual operational response of the bridge under both static and dynamic loads. By integrating these observations with simulations, they proposed a methodology for assessing the quality control and load-carrying capacity of the bridge deck. This approach suggests that a more comprehensive understanding and assessment of bridge performance can be achieved through the synergy of finite element analysis and actual measurements. However, when structures are composed of multiple materials, uncertainties in the finite element model (FEM) increase significantly due to factors such as manufacturing imperfections, and variability in connections between components, and material inhomogeneities [

16]. These uncertainties can result in discrepancies between model predictions and actual structural performance, making it more difficult to reliably characterize the in-service behavior of the structure [

17,

18]. Consequently, it becomes necessary to update the FEM using measured data to ensure that the updated model reliably reflects the actual performance of the structure. This process is known as Finite Element Model Updating (FEMU).

According to the type of measurement data, FEMU methods are typically categorized into two main types: dynamic updating and static updating methods [

19]. Compared to static updating methods, dynamic model updating methods provide richer structural response information, such as frequency response function, natural frequencies, mode shapes, and mode strain energy. Additionally, dynamic methods do not require loading the structure and can be performed without disrupting the normal use of the structure. As a result, they have increasingly become a focal point of research in recent years [

19,

20,

21,

22]. FEMU is fundamentally a mathematical inverse problem, with the primary goal of inferring structural parameters based on observed response data. This process is typically formulated as a constrained optimization problem that minimizes the difference between the computational results of the model and the observed data. However, in practice, these optimization problems are often ill-posed, meaning that the inverse solution may not consistently exhibit assured uniqueness and stability, thereby compromising the robustness and practical applicability of FEMU methods. The Bayesian approach has proven effective in addressing the ill-posed nature of model updating inverse problems by incorporating a probabilistic framework into the parameter space [

23,

24,

25,

26]. For instance, Ching et al. [

25] introduced a Bayesian model updating (BMU) approach for linear elastic structures that accounts for parameter uncertainty and handles incomplete observed data through a Gibbs sampling algorithm. Applied to a three-dimensional frame structure and a shear structure, this method not only achieved model updating but also successfully identified the location and extent of structural damage. Furthermore, Christodoulou and Papadimitriou [

26] proposed a structural model updating method that integrates measured modal data with the minimization of weighted residuals within a Bayesian framework and demonstrated its effectiveness through a numerical example. Despite the success of these methods in engineering applications, significant challenges remain. Some approaches require repetitive finite element computations, which are very time-consuming, while others require solving ill-conditioned model updating equations, inevitably encountering ill-posed inverse problems, in multiple or unstable solutions [

17].

To address the issue of time-consuming computations, Chen et al. [

21] proposed a Bayesian Markov Chain Monte Carlo model updating method with a homotopy surrogate model. This approach efficiently approximates the vibration mode and frequency data of the structure, enabling the rapid updating of structural parameters. Its effectiveness and accuracy were demonstrated in an engineering case study involving a large cable-stayed bridge. In terms of mitigating the ill-posed nature of model updating, Chen et al. [

22] developed an FEMU algorithm that utilizes an improved cross-model cross-mode method to simultaneously update structural mass and stiffness. And the effectiveness of this method was confirmed through a modal test of a cantilever beam. Yuen, meanwhile, introduced a BMU method based on iterative optimization [

23,

24,

27,

28,

29]. This method calculates the partial derivatives of the fitting function and iteratively estimates the most likely values of the structural response and structural parameters. The Hessian matrix is then used to directly estimate the uncertainty of the modification coefficients. A key advantage of the approach is that it can avoid lengthy finite element computations and ill-posed inverse problems. This makes it particularly reliable for updating high-dimensional parameters.

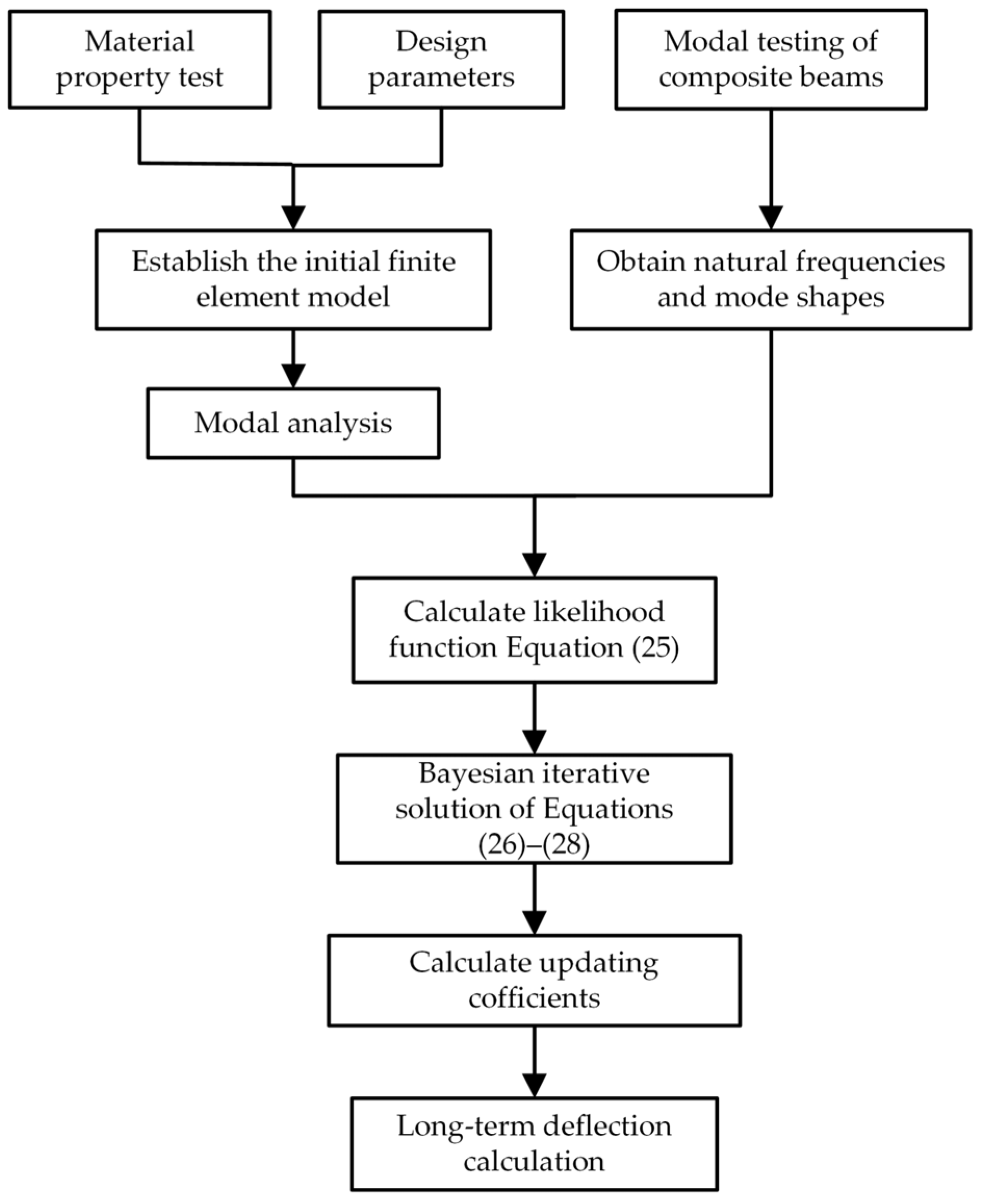

To improve the accuracy and reliability of predicting the long-term performance of SCBs, this study employs a BMU based on optimizing partial derivatives to update structural parameters. For SCBs, key factors, such as the slip characteristics at the interface and the elastic modulus of the materials, play a significant role in influencing their long-term deflection. Considering that only low-order frequency and modal data are available in the modal testing of SCBs, this study aims to update the FEM of SCBs using limited measurement data. Based on the updated models, the long-term performance of the SCBs is comprehensively analyzed.

The organization of this paper is as follows.

Section 2 reviews the underlying theory for the finite element analysis concerning the long-term behavior of SCBs.

Section 2 introduces the theoretical foundation pertaining to finite element analysis of the long-term behavior of SCBs.

Section 3 outlines the principles of the Bayesian method along with the model reduction approach used for updating SCBs.

Section 4 details the process of the proposed method and its associated workflow.

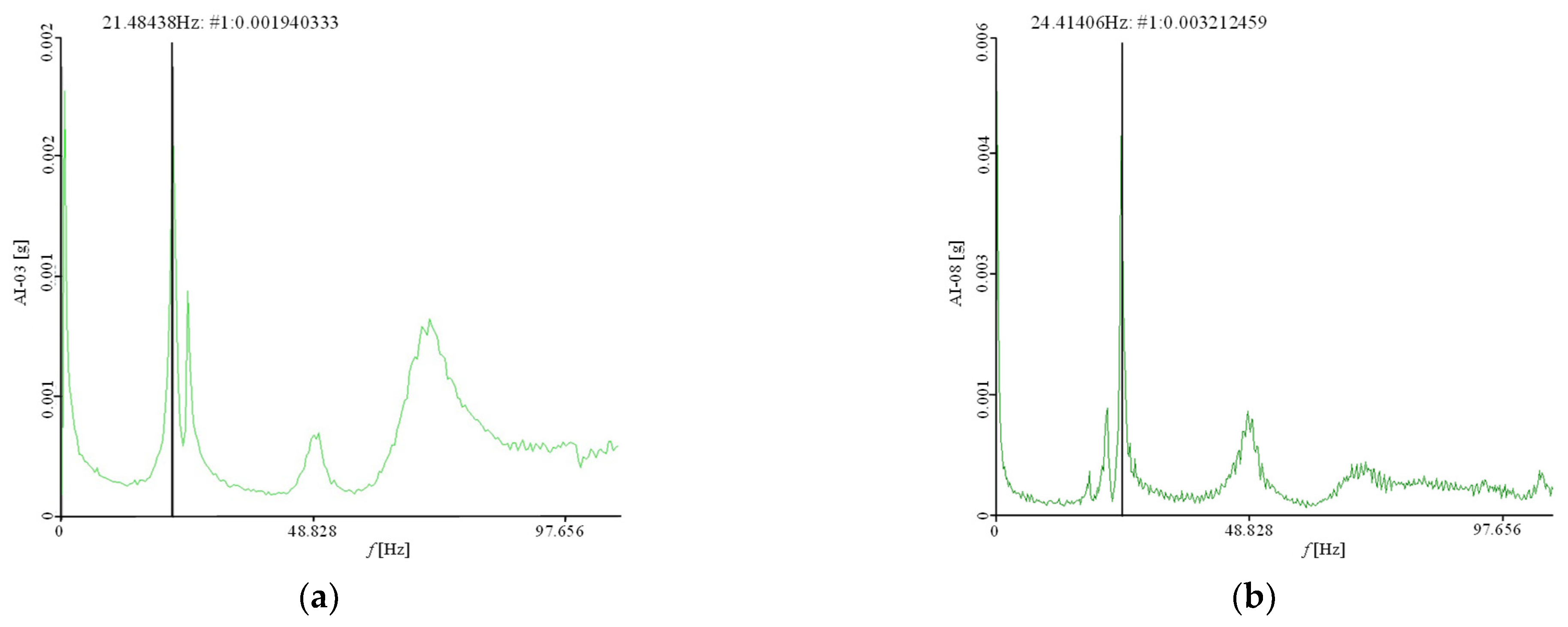

Section 5 presents the results of modal testing and FEMU for the SCBs.

Section 6 investigates the long-term performance based on the updated FEM of the SCBs. Finally,

Section 7 presents the main conclusions.

2. Finite Element Theory

2.1. Design of Specimens

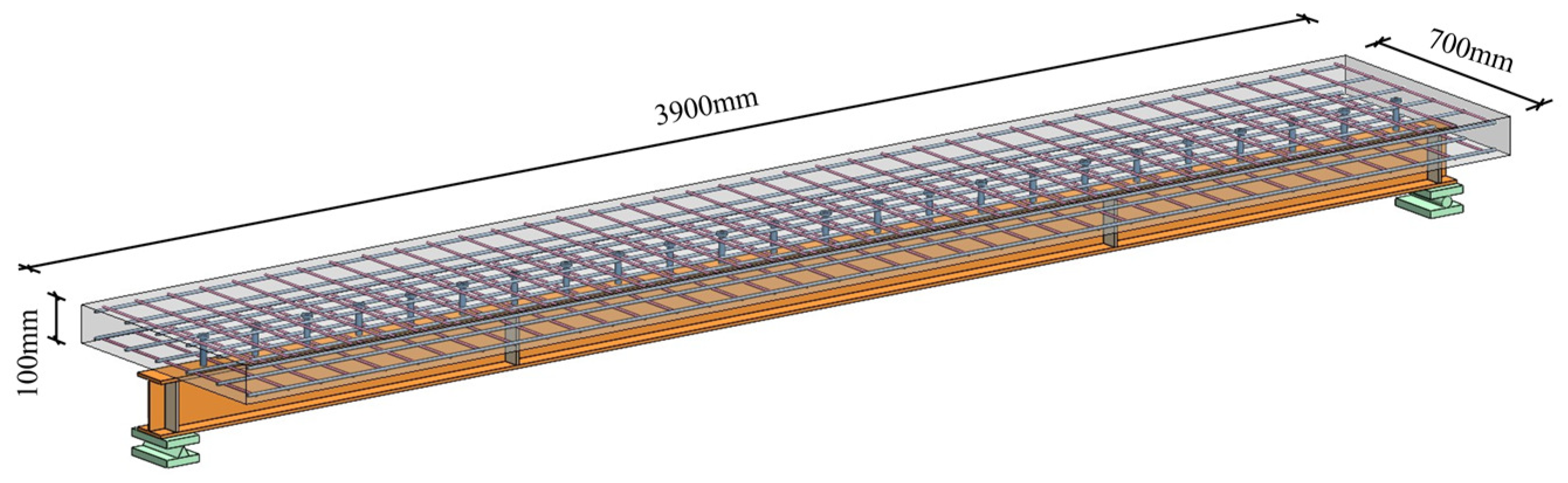

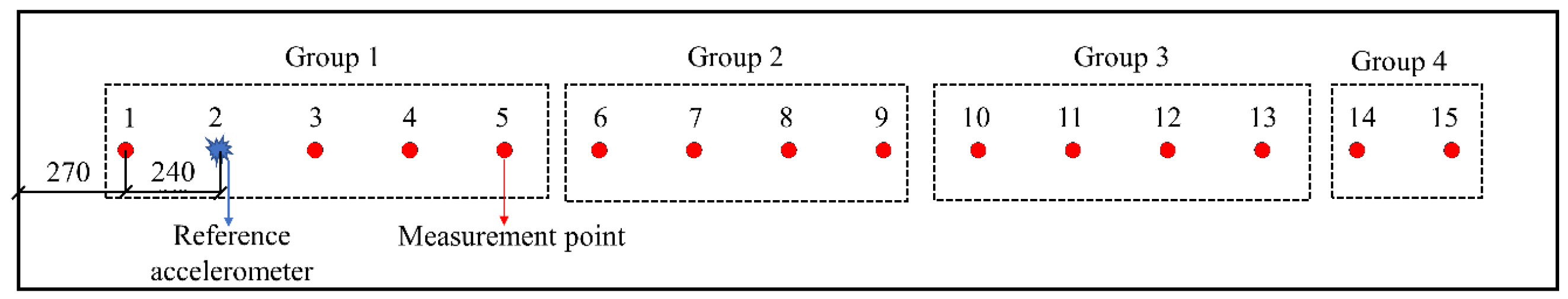

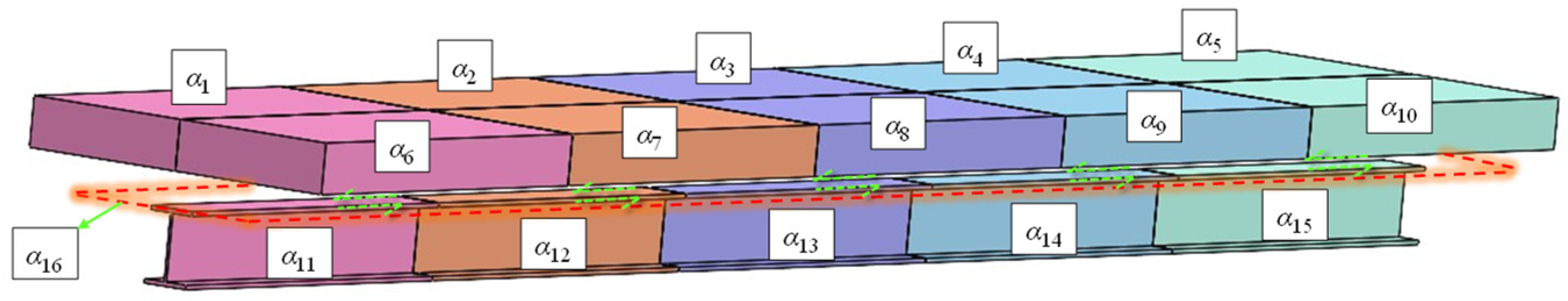

In this study, two SCBs with identical parameters were designed and fabricated, designated as SCB-1 and SCB-2. Both specimens were constructed with a full shear connection, achieving the synergistic interaction between the concrete slab and steel beam through the use of shear studs. This connection technique facilitates the coordinated transfer of forces between the two components. The overall structural configuration of the specimens is illustrated in

Figure 1.

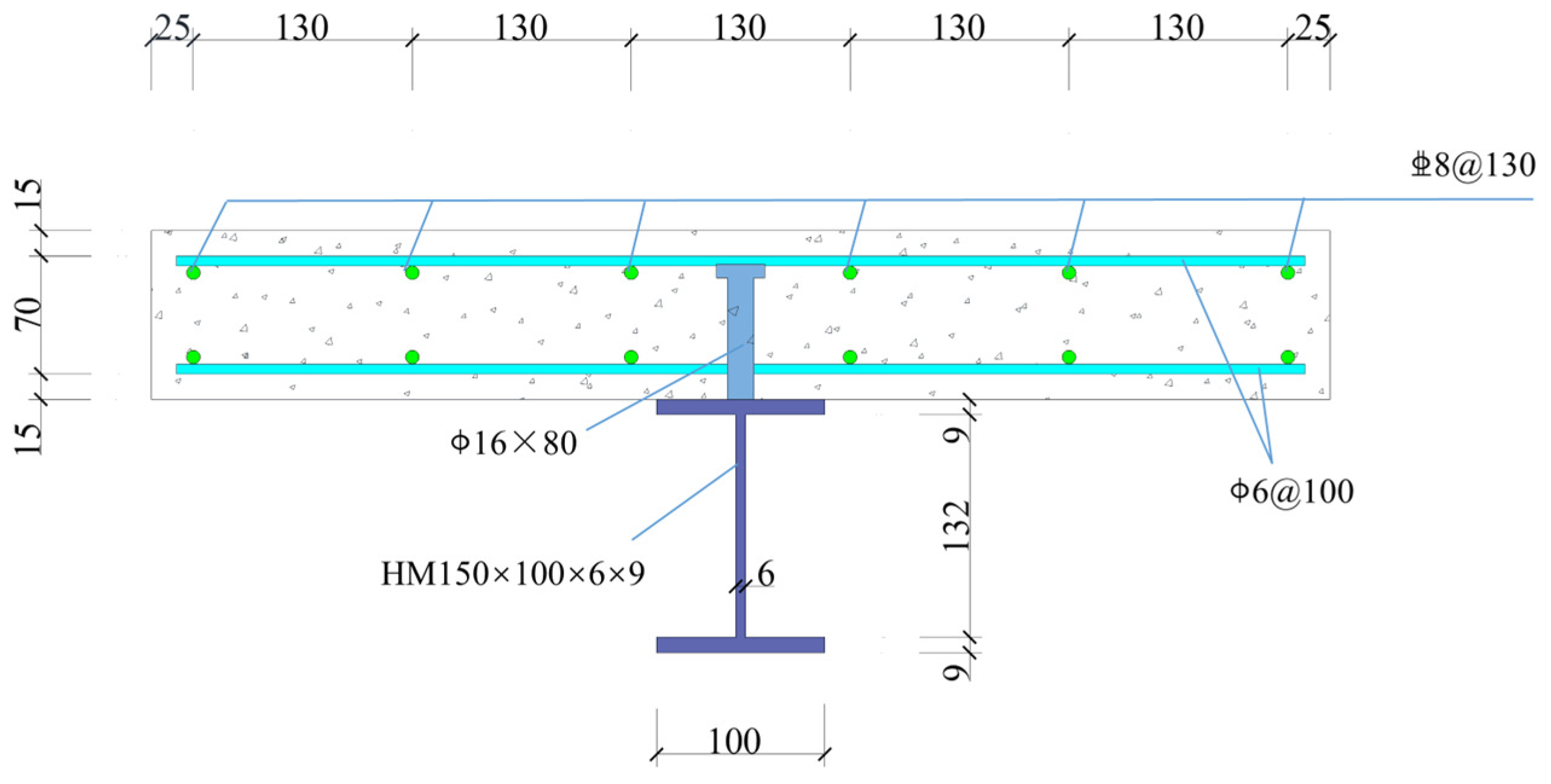

The main design parameters of the test specimens were as follows: the effective span of each test specimen was 3900 mm, with a total section height of 250 mm. The concrete flange plate was cast in place using C40 concrete, featuring a width of 700 mm and a thickness of 100 mm. Detailed dimensions and parameters for each component of the specimen are presented in

Figure 2. To ensure overall load-bearing performance and to prevent local instability, 8 mm thick Q235 steel stiffeners were welded at critical locations, including near the supports and at the mid-span.

Accurately selecting appropriate material models for steel and concrete is essential for ensuring the reliability of finite element analysis results when assessing the long-term performance of SCBs. This analysis was conducted using the nonlinear finite element software ABAQUS 2022/Standard 6.10, with appropriate parameters set to accurately describe the material properties and mechanical behavior of each component.

2.2. Cell Types and Meshing

In the finite element modeling process, appropriate element types are chosen for various structural components to accurately represent their mechanical properties. The concrete slab and shear connectors were modeled using eight-node linear solid elements (C3D8), while the steel beams were represented with four-node shell elements (S4). This approach enhances the computational efficiency while accurately capturing the mechanical behavior of thin-walled structures. The internal reinforcements were modeled with double-node truss elements (T3D2), which are particularly suitable for simulating axial force behavior.

A non-uniform grid strategy was employed during mesh generation to optimize the balance between computational accuracy and efficiency. The mesh sizes of each component were meticulously adjusted: 20 mm mesh sizes were applied to the steel beam and reinforcements, 50 mm mesh sizes were employed for the concrete slabs, and fine 5 mm mesh sizes were utilized for shear connectors to more accurately capture their intricate mechanical behavior.

2.3. Interaction and Boundary Conditions

The interaction among the various components of the SCBs is a key factor influencing its mechanical performance. To accurately capture the interface behavior within the numerical model, a detailed interface contact relationship was established. Furthermore, to simplify the model while accurately reflecting real-world conditions, the boundary conditions were carefully defined based on the actual constraints of the SCBs. The specific interface contact relationships and boundary condition configurations are presented in detail in

Figure 3.

2.4. Load

To accurately simulate the mechanical behavior of SCBs under real-world working conditions, a uniformly distributed load was applied across the entire span on the surface of the concrete slab. These loads were configured to simulate the cumulative effects of both dead and live loads, which are typical of the actual working conditions encountered by SCBs in structural applications.

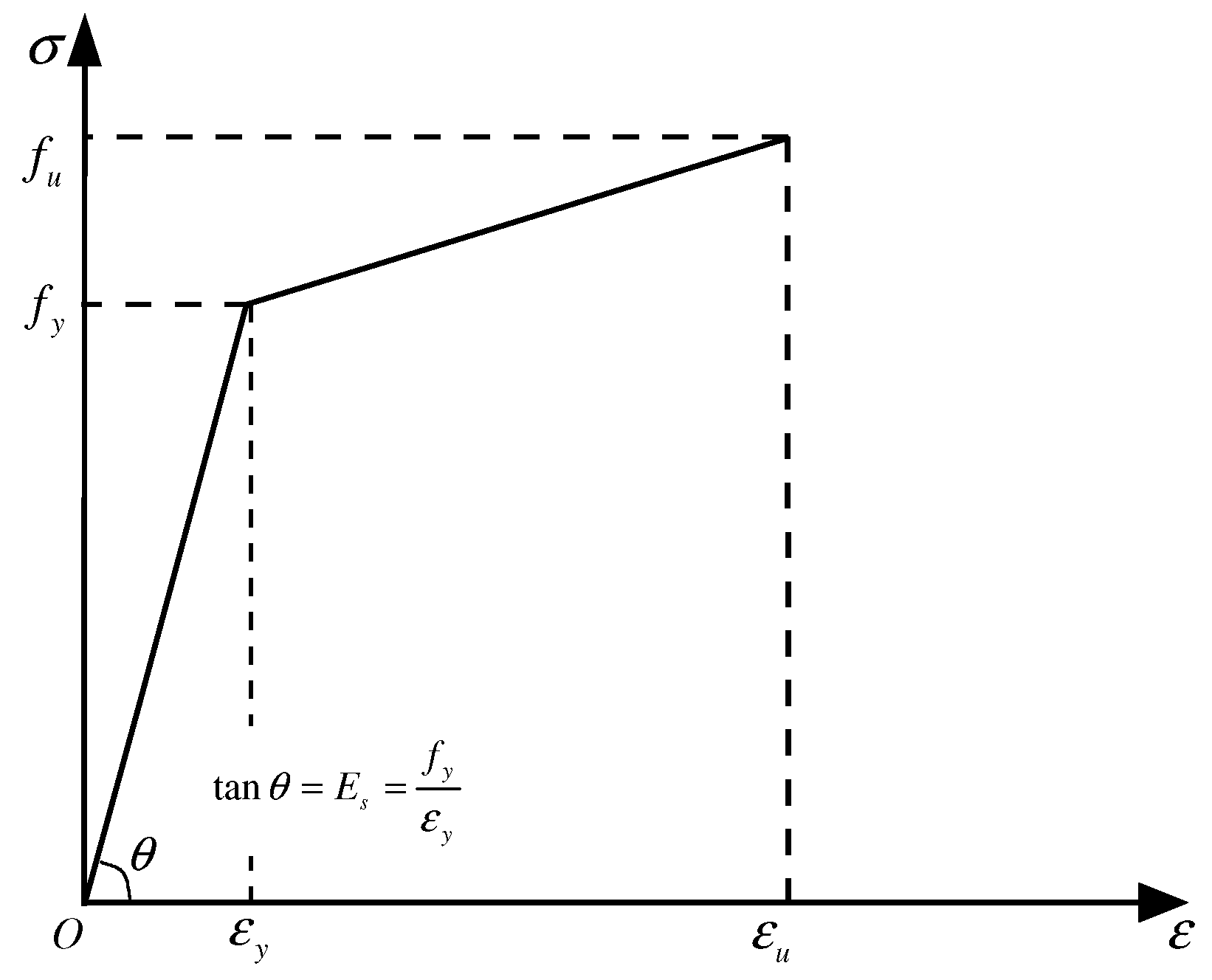

2.5. Steels

The steel components were modeled using a bilinear hardening principle, incorporating the Von Mises yield criterion to define the onset of plastic behavior. A tangent modulus of

Et = 0.01

Es was assigned to capture the material’s strain-hardening phase accurately. The detailed stress–strain relationship is illustrated in

Figure 4.

2.6. Concrete

To accurately simulate the complex mechanical behavior of concrete in SCBs, this study employed a multi-scale material simulation framework. The framework integrates the concrete damage plasticity (CDP) model and incorporates specialized FORTRAN subroutines to simulate the creep and shrinkage behavior of concrete. By coupling these subroutines with the plastic damage analysis module, the framework effectively captures the long-term performance of SCBs under sustained loads.

The uniaxial tensile and compressive behavior of concrete was modeled in accordance with GB50010-2010 [

30]. The primary parameters used for implementing the CDP model in ABAQUS are shown in

Table 1.

2.6.1. Creep Model

To achieve a more precise simulation of concrete creep behavior under long-term loading, this study employed the linear viscous transformation theory. According to the superposition principle and the assumption of a linear creep model, the total strain of concrete is divided into three components:

where

is the instantaneous elastic and plastic strain of concrete,

is the creep strain of concrete, and

is the shrinkage strain of concrete.

The creep behavior of concrete is commonly characterized by the creep coefficient

, which quantifies the gradual increase in strain over time under constant stress. As defined by the American ACI 209 model [

31], the creep strain of concrete can be expressed as:

where

is the stress value at the loading moment

.

In the analysis of the creep model, two key parameters are central to describing the time-dependent deformation of concrete: the creep degree function

and the creep function

. The relationship between these two parameters is expressed as follows:

The concrete creep behavior is governed by a range of factors, including intrinsic material properties, member dimensions, curing conditions, external environmental influences (e.g., temperature and humidity), and the stress history of the structure. These complexities make modeling and analyzing creep effects a challenging task. To address these intricacies, this study employed the step-by-step integration method for calculating creep effects in structures. This numerical approach divides the time domain into discrete intervals to incrementally evaluate the cumulative creep strain, accommodating changes in stress, environmental conditions, and time-dependent material properties. The process is illustrated in

Figure 5, providing a clear framework for assessing the long-term effects of creep in complex structural systems.

Throughout the duration of creep, the general expression for concrete creep strain is derived to represent the time-dependent deformation under sustained loading. This expression is conventionally defined as:

where [

A] is the transformation matrix that accounts for the effect of Poisson’s ratio:

The entire process of creep analysis can be segmented into a series of discrete time intervals (

), enabling the calculation of strain increments for each interval. The creep strain increment during a given time interval

is expressed as:

If the time interval is chosen to be sufficiently small such that the stress change remains constant within the time interval

, the integral expression in Equation (7) can be expressed as

where

is the stress increment.

The creep strain increment

of concrete from moment

n to moment

n + 1 can be calculated as

To improve computational efficiency, a step-by-step integral calculation approach based on the Dirichlet series was employed. In this method,

is expressed as a Dirichlet series [

32]:

In Equation (10), m = 4 is taken to improve the accuracy of the calculation, and is taken as 1, 0.1, 0.01, and 0.001; is the coefficient to be determined based on least-squares fitting.

It can be obtained from Equation (10):

Based on this expansion, the concrete creep strain increment

in Equation (9) can be re-expressed as

where the recurrence relation for the intermediate variable

is:

2.6.2. Shrinkage Model

In this study, the shrinkage deformation of concrete, which is less complex than creep due to its independence from applied stress, was estimated using the shrinkage model provided in JTG 3362-2018 [

33]. The corresponding shrinkage strain is expressed as:

where

In the above equation, and represent the age of the concrete at the time of calculation and the age of the concrete at the onset of shrinkage, respectively. is the shrinkage strain. is the nominal shrinkage coefficient. is the coefficient describing the development of shrinkage over time, is determined based on the type of cement used. and correspond to the average cylinder compressive strength and the standardized cubic compressive strength (MPa), respectively. represents the coefficient associated with the annual average relative humidity. refers to the annual average relative humidity (%) of the environment.

2.7. Calculation Program

To account for the long-term behavior of SCBs, this study leveraged the large-scale finite element software ABAQUS, incorporating three user-defined subroutines—USDFLD, GETVRM, and UEXPAN—for the customized development of material properties. Specifically, the USDFLD subroutine was employed to update the field variables at the integration points, dynamically capturing the time-dependent variations in the elastic modulus of concrete. The GETVRM subroutine enhanced the precision of the creep analysis by extracting stress and strain data at material points, enabling the effective coupling of stress states within the simulation. Meanwhile, the UEXPAN subroutine calculated the creep and shrinkage strain increments at each time step and integrates these effects into the main program, ensuring the robust modeling of time-dependent phenomena. Additionally, the CDP model was employed in the elasto-plastic analysis to capture the plastic damage behavior of concrete. Together, the main program and these subroutines constitute a comprehensive numerical simulation framework for analyzing the concrete shrinkage and creep behavior.

6. Long-Term Performance Analysis

The evolution of deformation in SCBs under long-term loading is influenced by various factors, including the elastic modulus, the creep and shrinkage characteristics of the concrete, the elastic behavior of the steel beam, and the bond slip mechanism at the steel–concrete interface.

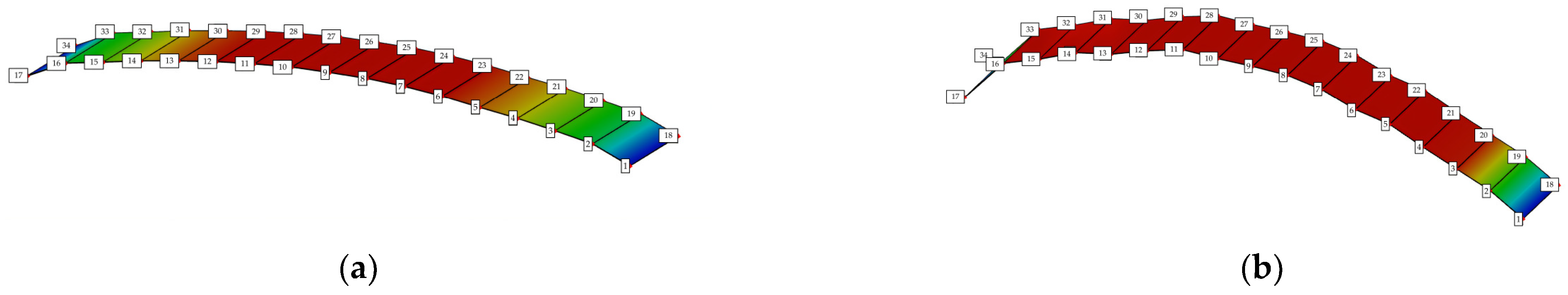

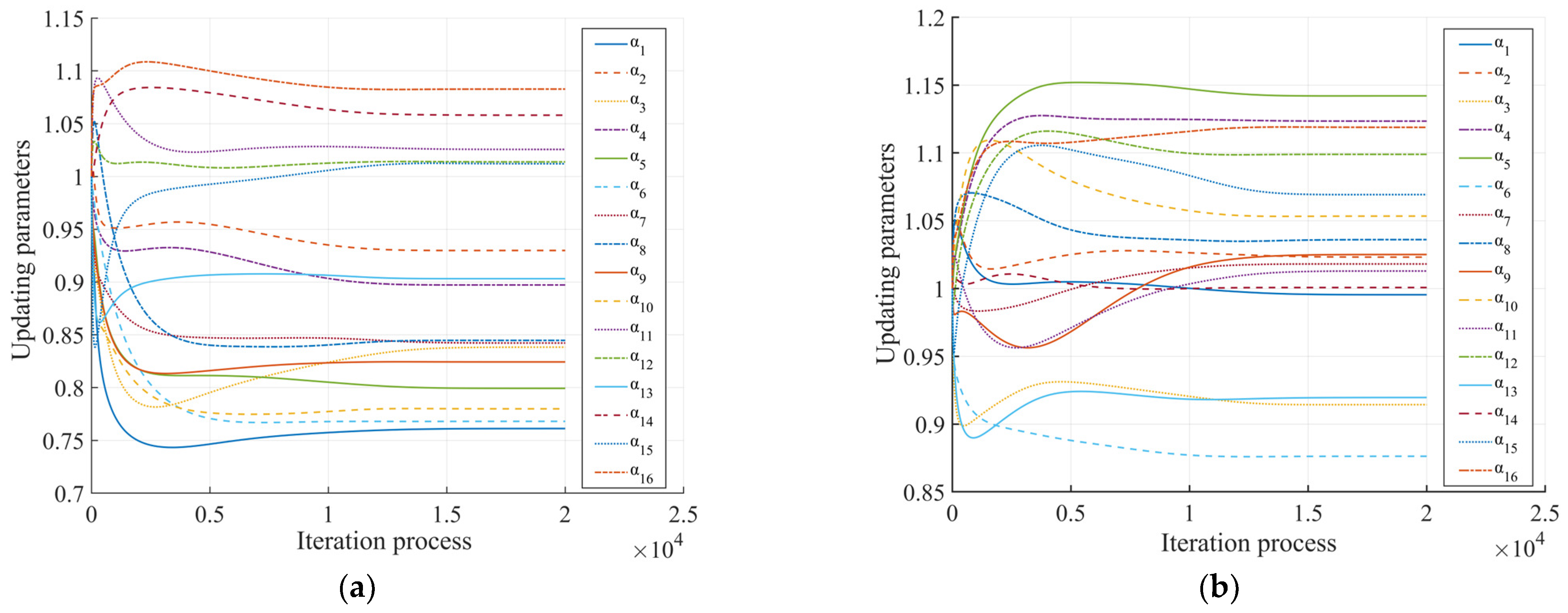

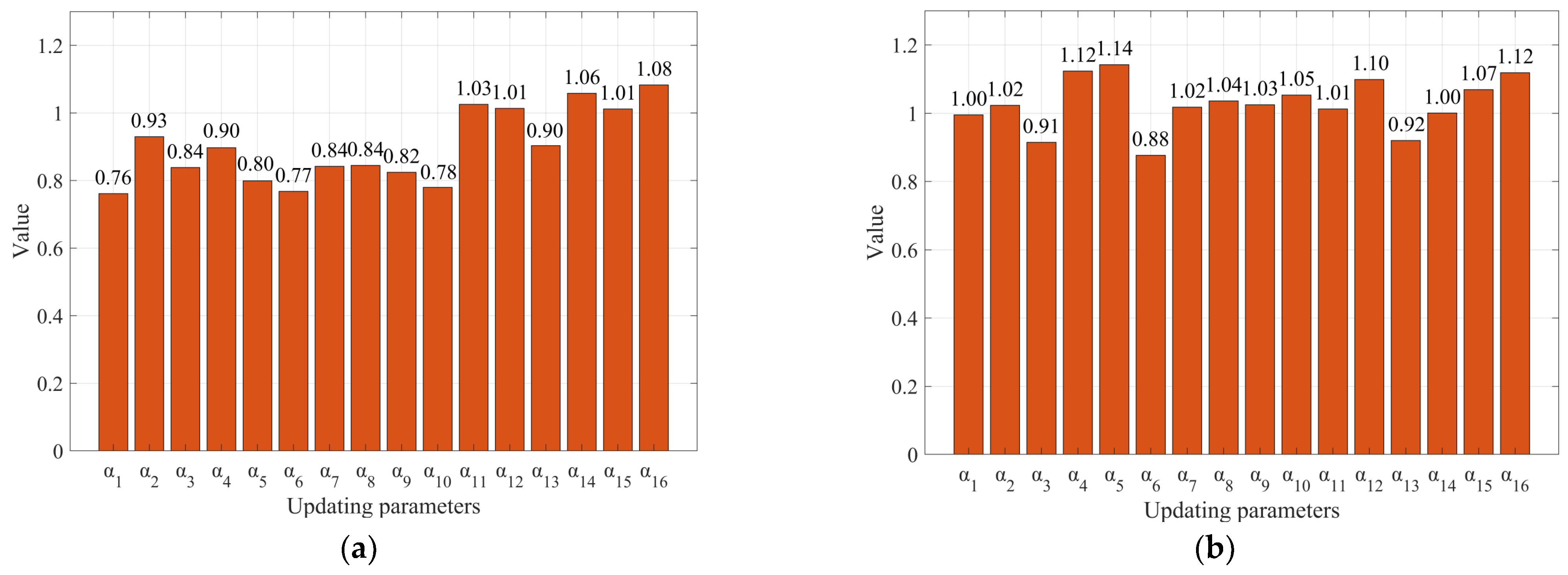

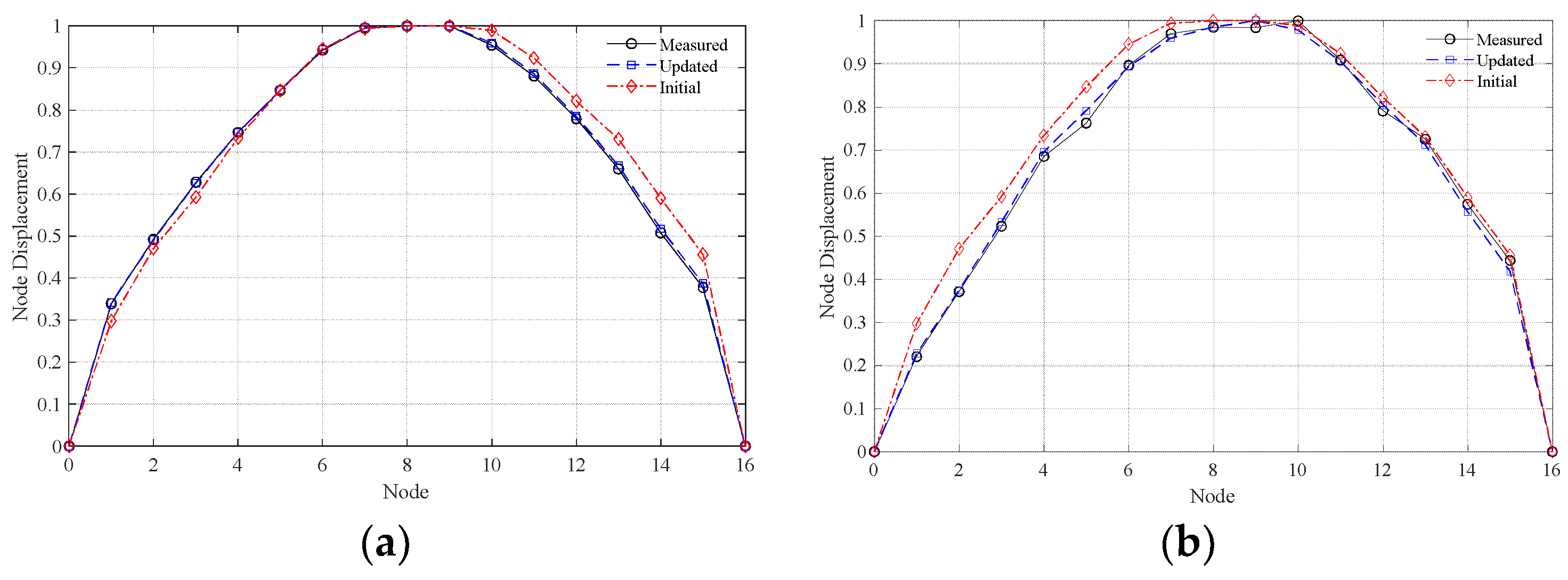

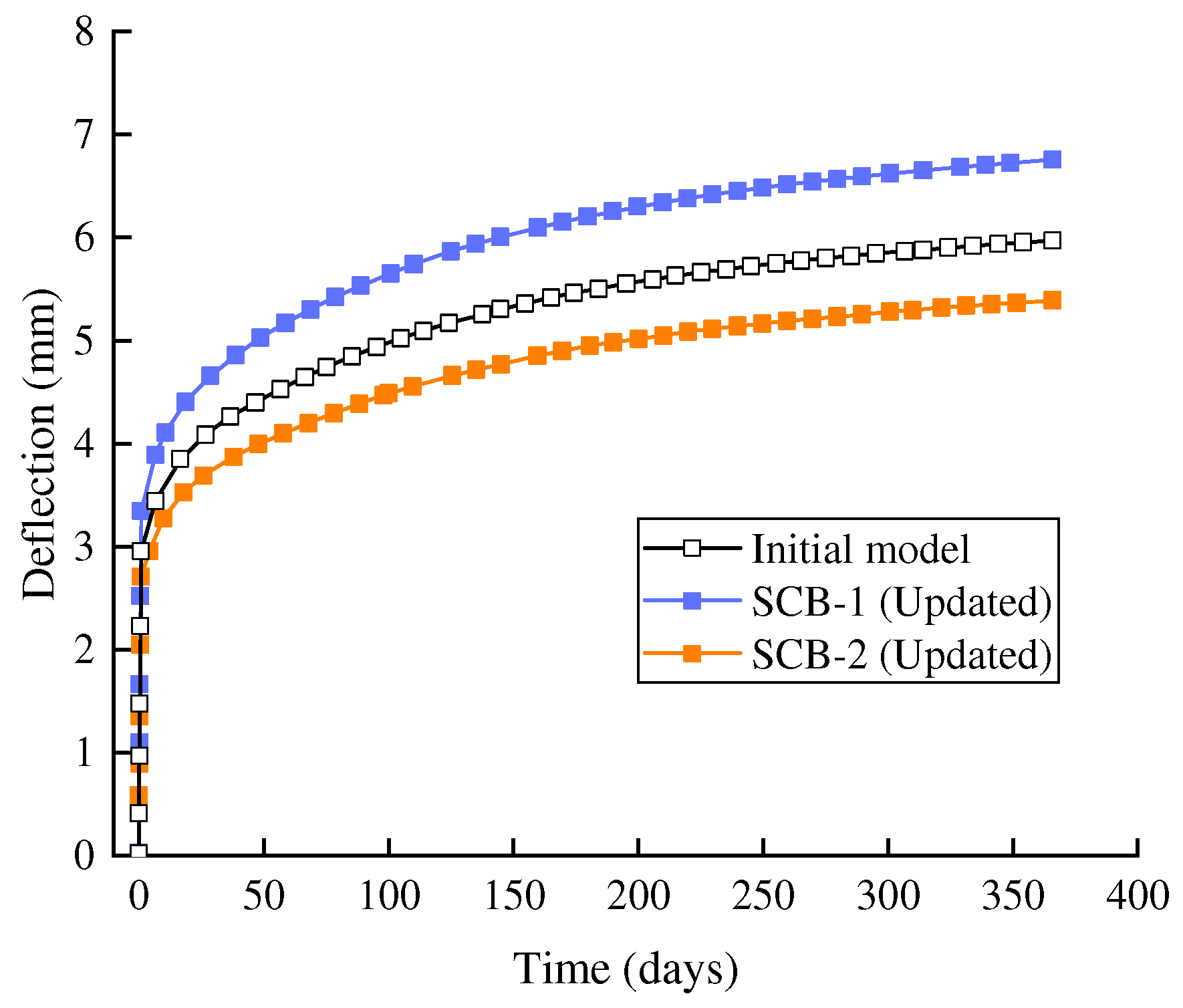

Figure 16 illustrates the predicted long-term deflection curves before and after the model update, highlighting the distinct “three-stage characteristic” of the long-term deflection evolution: the initial loading stage, the mid-term stable growth stage, and the long-term asymptotic stability stage.

The comparison of the long-term deflection curves derived from the initial model and the updated model (SCB-1 and SCB-2) reveals that the updated model offers a more accurate depiction of the long-term deflection behavior of SCBs, particularly in the middle and later stages. The rapid deflection growth observed in the early phase of long-term loading reflects the prompt response of the SCBs during the initial deformation phase. This phenomenon is primarily attributed to the shrinkage and creep of the early concrete, as well as the elastic compression of the steel beams. Additionally, the hydration reaction and stress redistribution within the concrete may further contribute to the initial-stage deflection. Over time, the rate of deflection growth gradually decreases, transitioning into the mid-term steady growth stage. During this stage, the creep effect of the concrete becomes the dominant factor influencing deflection, while the bond–slip properties at the steel–concrete interface begin to play a more pronounced role. The updated model more accurately captures the deformation behavior of SCBs at the current stage, especially in the mid-to-late phase, and the predicted results are closer to the actual situation than those obtained before the update. Under prolonged loading, the deflection curve progressively flattens, indicating a significant deceleration in the deformation growth rate of the SCBs. Eventually, the deflection increment converges, signifying that the internal stress and deformation distribution within the structure have stabilized, and the system reached equilibrium.

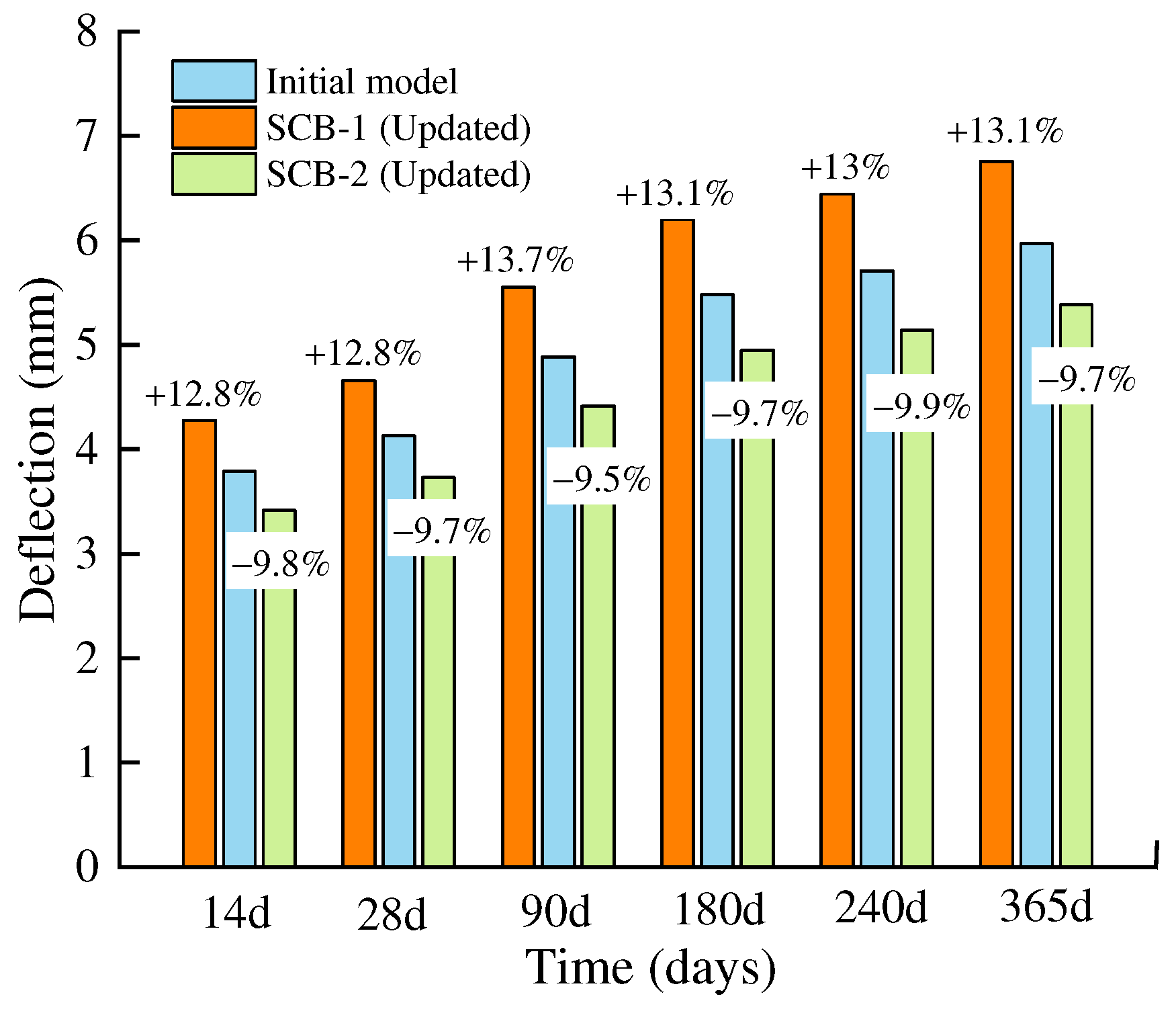

Figure 17 illustrates the deflection calculation results at various loading time points (14, 28, 90, 180, 240, and 365 days). From the figure, it is evident that the deflection calculations of the updated model exhibit significant optimization across all time points. Specifically, the deflection calculation results for SCB-1 improve by approximately 12.8% to 13.7% compared to the initial results at all time points. Conversely, the deflection calculation results for SCB-2 show a reduction of about 9.5% to 9.9%, highlighting the effectiveness of the model updates.