A Numerical Investigation of the Performance of Damaged Concrete Barriers Under Sequential Vehicular Impacts

Abstract

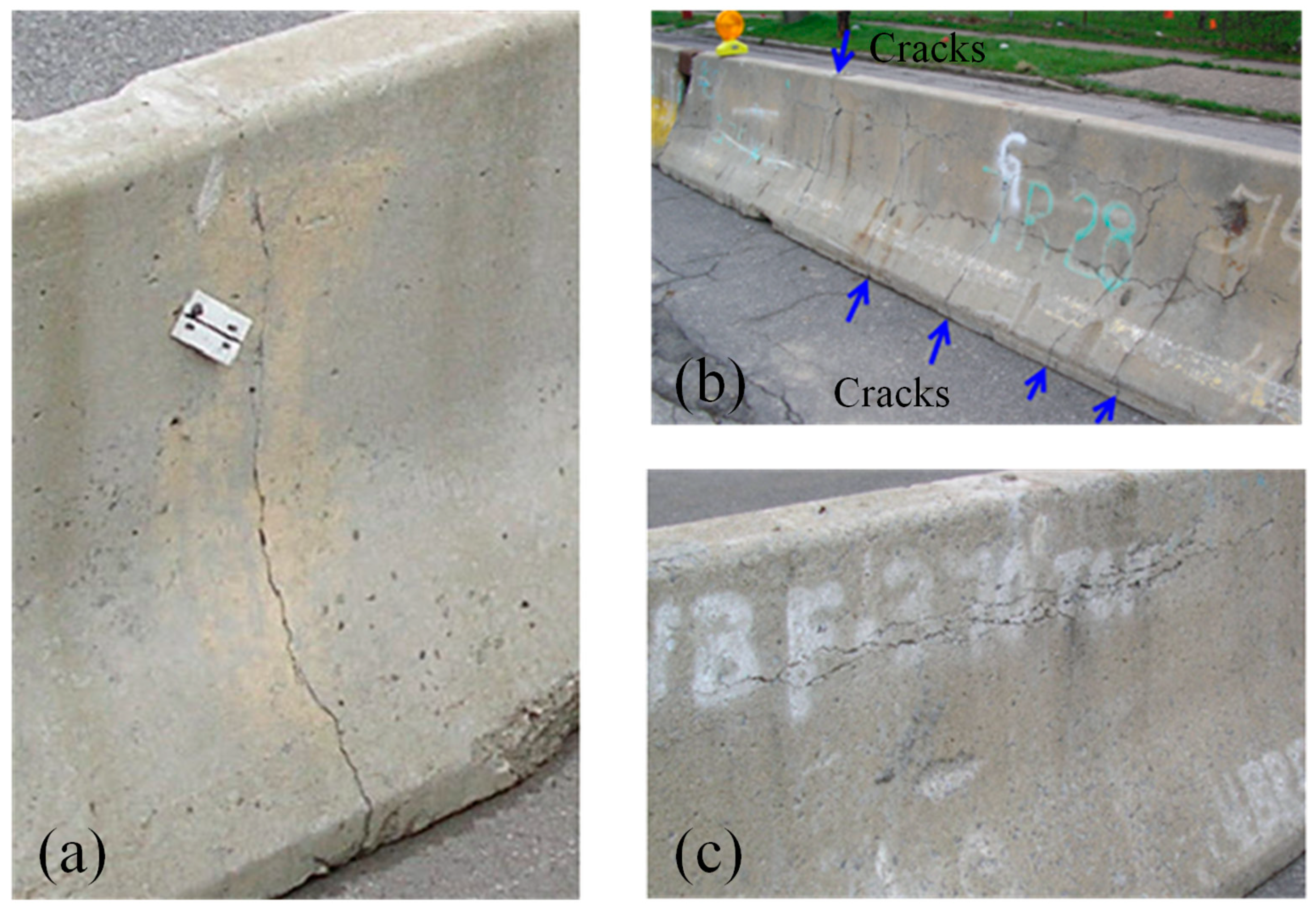

1. Introduction

2. Finite-Element Model Development and Validation

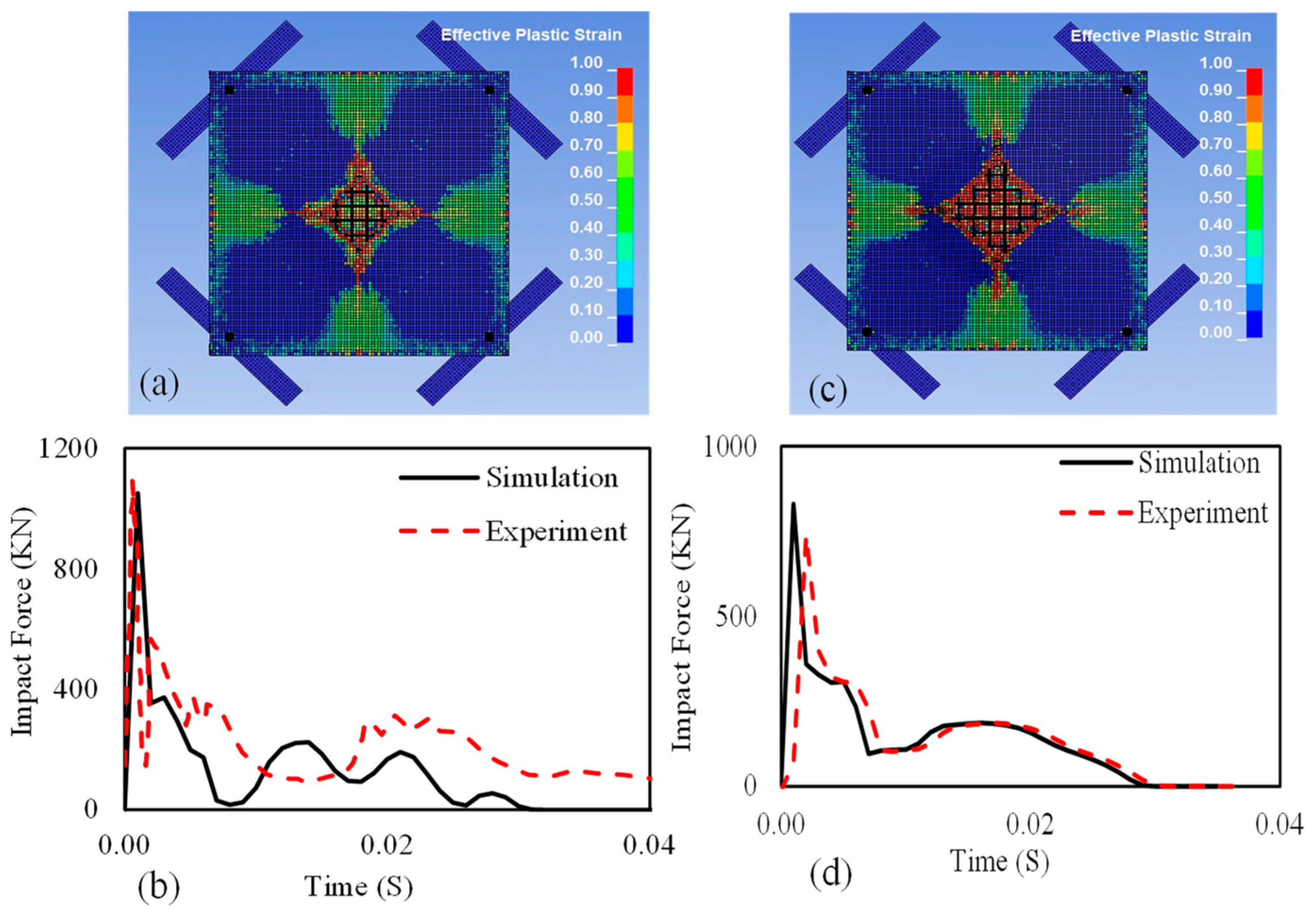

2.1. Tractor-Trailer Model Validation

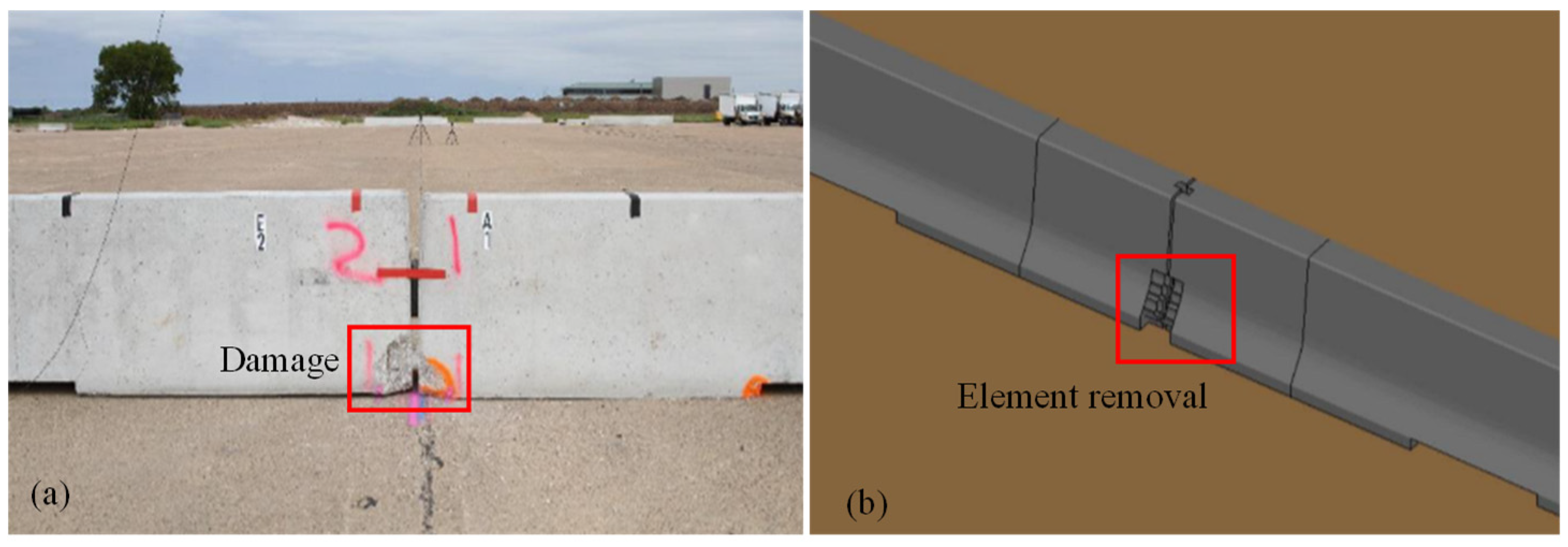

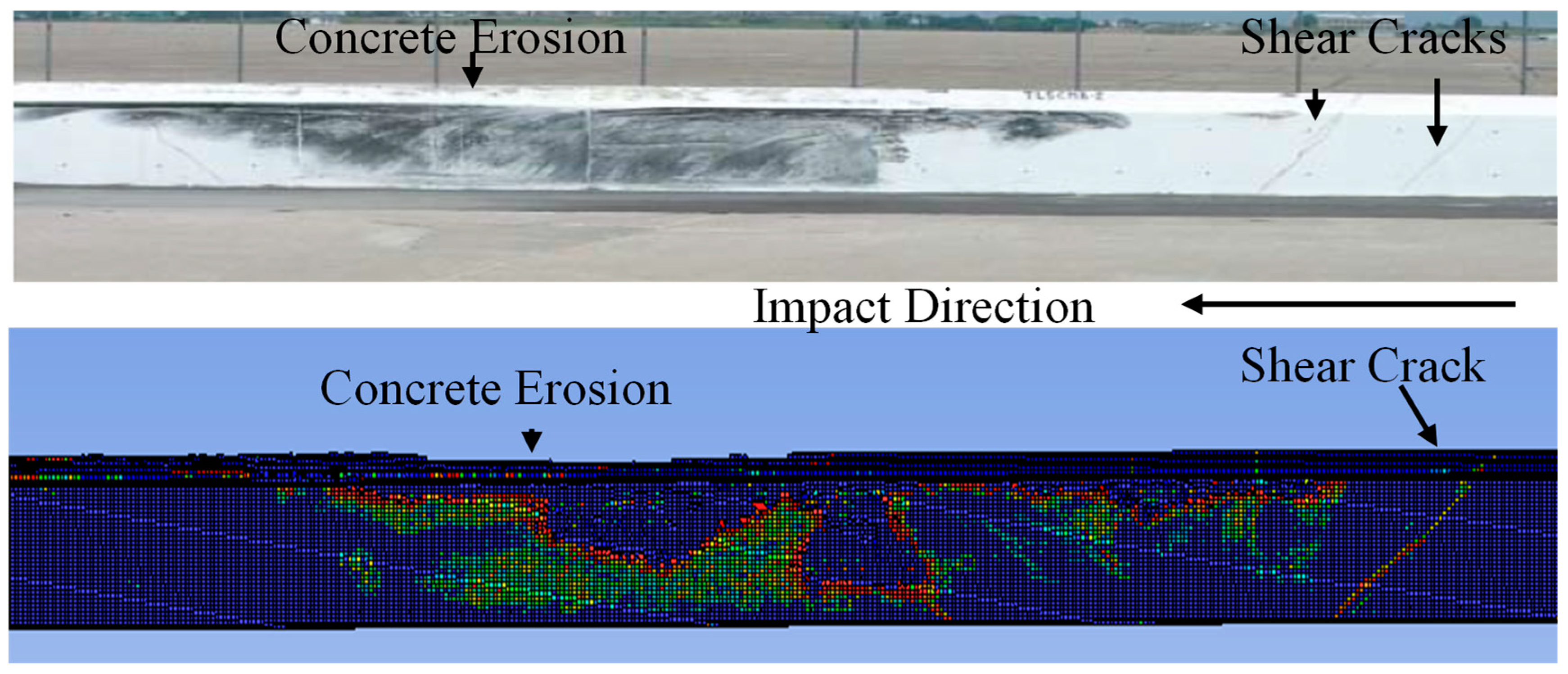

2.2. Reinforced Concrete Model Validation for Sequential Impact

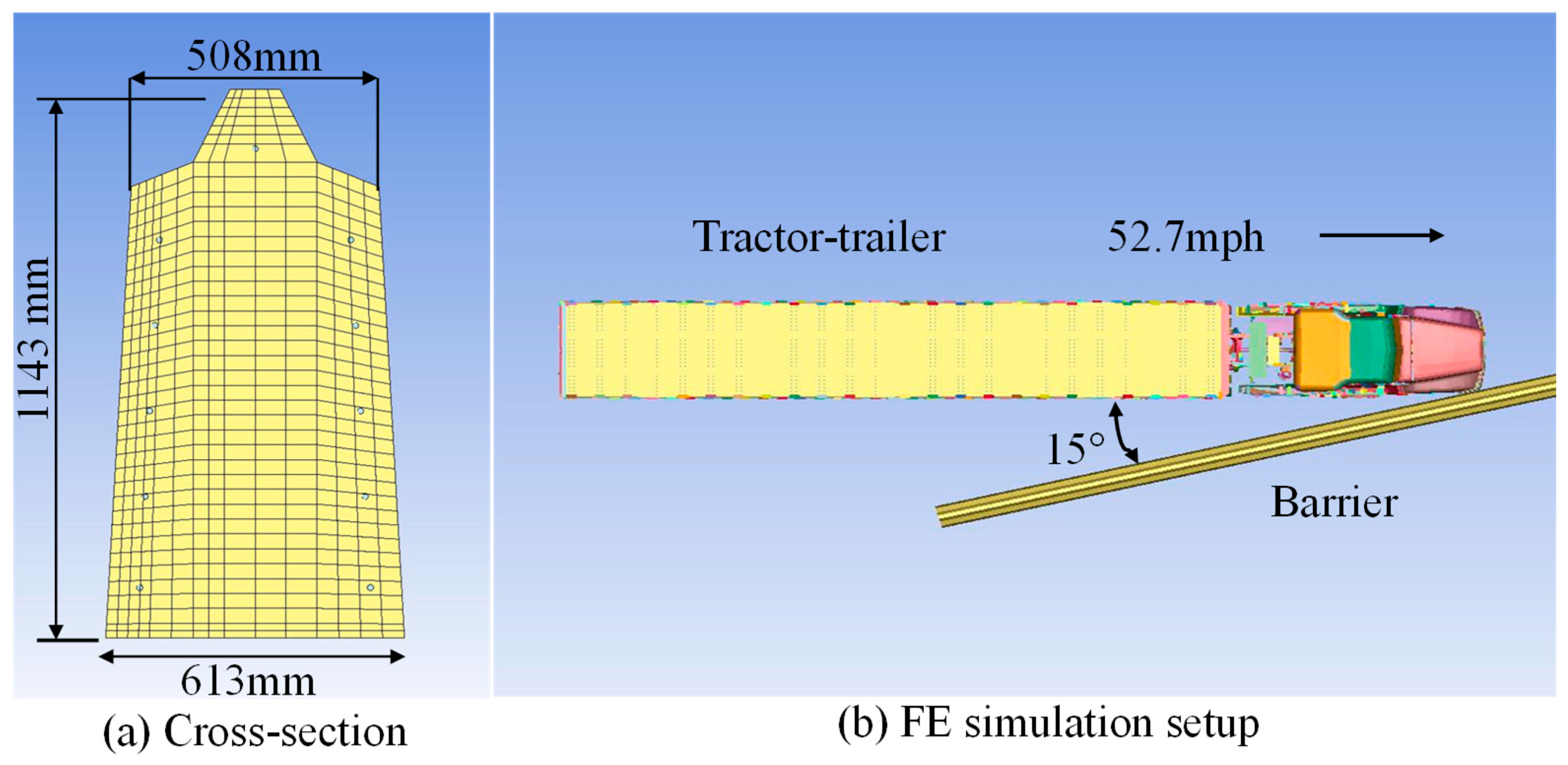

2.3. Modeling Tractor-Trailer Impact on Concrete Barrier

3. Parametric Analysis of Concrete Barrier Under Sequential Impact

3.1. Characterization of Impact Phases in Tractor-Trailer Collision Event

- Initial impact and deformation (Phase I): Rapid deceleration occurred when the tractor and the front edge of the trailer first contacted the barrier. Energy absorption occurred through the deformation of the tractor’s front and minor damage to the barrier. This phase spanned from 0.00 s to 0.50 s in the current analysis.

- Rebound and secondary contact (Phase II): Following the initial contact, the tractor’s rear axle and the front of the trailer struck the barrier, producing a second peak in the force measurement. The combination of vehicle rebound dynamics and the compact axle mass resulted in a sudden, high-magnitude force over a short duration. This phase occurred from 0.60 s to 0.88 s.

- Final interaction and exit (Phase III): In this stage, the spike in force was caused by the impact and rebound event due to the trailer’s rear axle. The impact due to the trailer’s rear axle occurred around the same region where the first two peaks were observed, indicating a consistent interaction area. This indicated significant energy transfer during the third impact phase, which happened between 0.88 s and 1.20 s in the performed simulations.

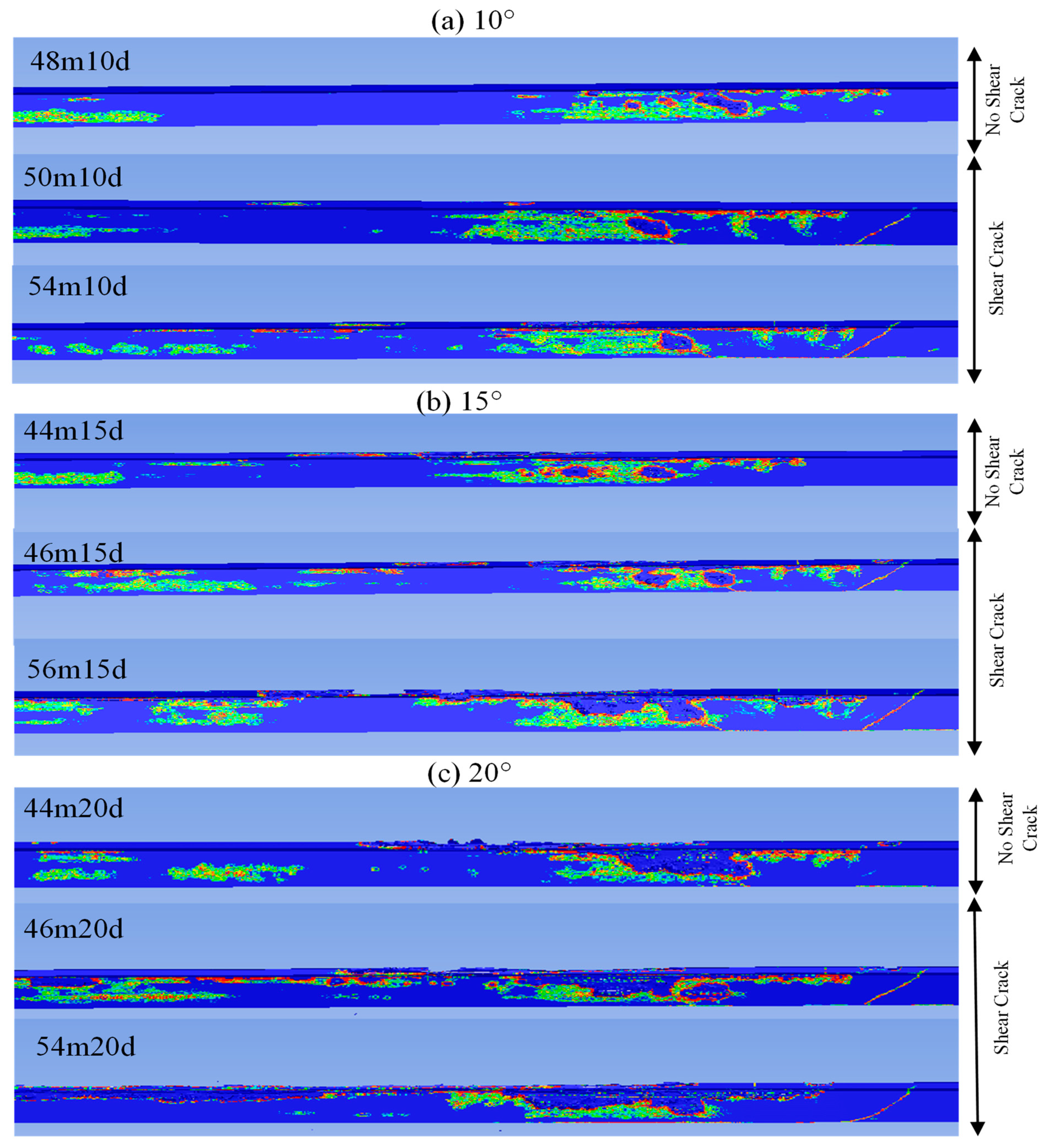

3.2. First Impact Sequence of TL-5 Barrier

3.3. Second Impact Sequence of TL-5 Barrier

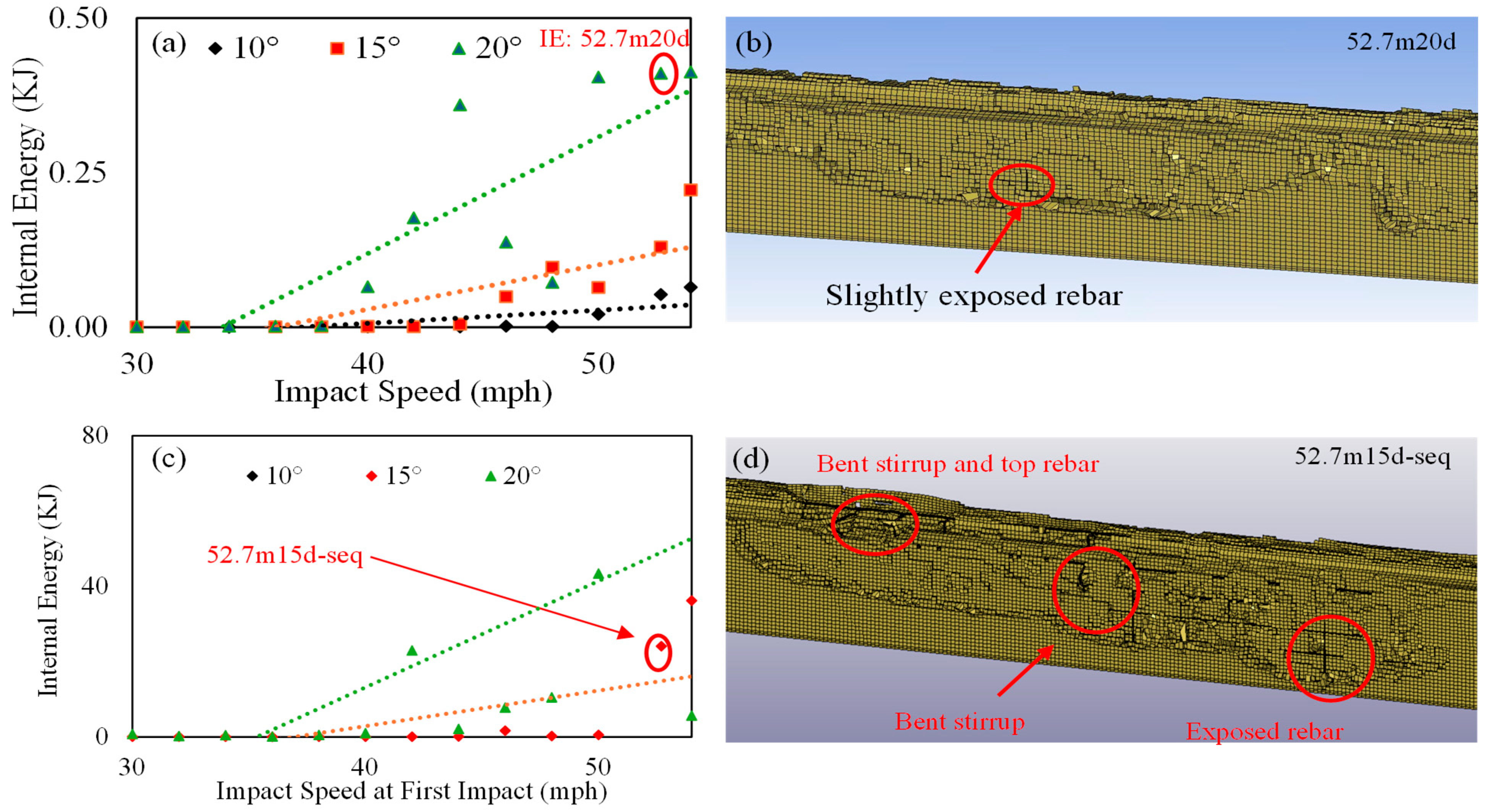

3.4. Internal Energy (IE)-Based Evaluation of Barrier Damage

3.4.1. First Impact

3.4.2. Second Impact

4. Conclusions

- The first sequence of impacts showed a clear correlation between the severity of barrier damage and the impact speed and angle. As the impact speed increased, the barrier sustained more significant damage, particularly at oblique angles of 15° and 20°, creating higher-stress concentrations than the lower angle of 10°. For example, the barriers experienced a shear crack at 50 mph (80.5 kmph) for the impact at 10°, whereas the same barrier showed shear crack at 46 mph (74 kmph) for 15° and 20° impact angles.

- For the second impact sequence, the pre-existing damage from the initial impact significantly affected the barrier’s response, leading to greater structural damage. The barriers that carried over shear cracks and damage, particularly for those impacted at 46 mph (74 kmph) and above for 15° and 20° angles during the first impact, exhibited severe damage such as the excessive fragmentation of concrete, reinforcement exposure, and bending.

- Barriers that developed shear cracks in the first impact demonstrated reduced peak impact forces in the second impact, particularly in the second and third phases of the crash (i.e., rebound and final interaction phases)

- Regression analysis showed a strong relationship between the peak impact force and an increasing velocity and angle during the first impact event, as indicated by high R-squared values (>70%), both overall and within each of the three phases.

- In the second impact, no significant relationship was observed between the first impact’s velocity and angle and the peak forces for the entire crash, as shown by a low R-squared value (i.e., 7%). However, a decreasing trend in the peak impact force was observed in the second (i.e., rebound) and third (i.e., final interaction) phases of the impact, with relatively higher R-squared values (26% and 39%, respectively)

- This reduction suggested that the barrier may have lost its capacity to satisfy the MASH TL-5 requirements after sustaining initial damage from loads close to the MASH TL-5 specifications, i.e., impacts at 50 mph (80.5 kmph) at 10° and 46 mph (74 kmph) at 15° and 20°.

- The energy-based evaluation of barrier damage concluded that during the first impact, concrete dominated the energy absorption, with its IE approximately 200 times higher than that of the reinforcement for higher-velocity and -impact cases, whereas the contribution from reinforcement for lower-velocity and -impact cases was negligible.

- In sequential impacts, the concrete’s ability to absorb energy diminished due to sustained damage, as evidenced by a decreasing IE trend at higher impact angles (15° and 20°). The IE of the reinforcement became significant at velocities equal to or higher than 38 mph (61 kmph) at 15° and equal to or higher than 36 mph (58 kmph) at 20°. As the trend shifted towards the reinforcement’s role in energy absorption, the energy absorption by the concrete decreased.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- NHTSA. FARS Encyclopedia. Available online: https://www-fars.nhtsa.dot.gov/Main/index.aspx (accessed on 15 February 2024).

- Manual for Assessing Safety Hardware, 2nd ed.; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2016.

- Bielenberg, R.W.; Faller, R.K.; Reid, J.D.; Schmidt, J.D.; Pajouh, M.A.; Emerson, E. Development of retrofit, low-deflection portable concrete barrier system. J. Transp. Saf. Secur. 2019, 11, 333–352. [Google Scholar] [CrossRef]

- Williams, W.F.; Sheikh, N.M.; Menges, W.L.; Kuhn, D.L.; Bligh, R.P. Crash Test and Evaluation of Restrained Safety-Shape Concrete Barriers on Concrete Bridge Deck; Texas A&M Transportation Institute: College Station, TX, USA, 2018; Available online: http://tti.tamu.edu/documents/9-1002-15-3.pdf (accessed on 1 December 2024).

- Bielenberg, B.W.; Faller, R.K.; Rohde, J.R.; Reid, J.D.; Sicking, D.L.; Holloway, J.H. Development of Tie-Down and Transition Systems for Temporary Concrete Barrier on Asphalt Road; Transportation Research Board: Washington, DC, USA, 2007. [Google Scholar]

- Bielenberg, B.W.; Faller, R.K.; Reid, J.D.; Rohde, J.R.; Sicking, D.L. Design and Testing of Tie-down Systems for Temporary Barriers. Transp. Res. Rec. 2003, 1851, 83–94. [Google Scholar] [CrossRef]

- Bligh, R.P.; Sheikh, N.M.; Alberson, D.C.; Abu-Odeh, A.Y. Low-deflection portable concrete barrier. Transp. Res. Rec. 2006, 1984, 47–55. [Google Scholar] [CrossRef]

- Bielenberg, R.W.M.E.; Asselin, N.M.; Faller, R.K. Mash TL-3 Evaluation of Concrete and Asphalt Tied-Down Anchorage for Portable Concrete Barrier; Midwest Roadside Safety Facility: Lincon, NE, USA, 2019. [Google Scholar]

- Sheikh, N.M.; Kovar, J.C.; Cakalli, S.; Menges, W.L.; Schroeder, G.E.; Kuhn, D.L. Analysis of 54-Inch Tall Single-Slope Concrete Barrier on a Structurally Independent Foundation; Texas A&M Transportation Institute: College Station, TX, USA, 2019. [Google Scholar]

- AS/NZS 3845.1:2015; Road Safety Barrier Systems. Standards Australia: Sydney, Australia, 2015.

- Karim, H.; Moudud, A.; Magnusson, R. Road Barrier Repair Costs and Influencing Factors. J. Transp. Eng. 2011, 137, 349–359. [Google Scholar] [CrossRef]

- Sheikh, N.M.; Bligh, R.P.; Menges, W.L. Determination of Minimum Height and Lateral Design Load for Mash Test Level 4 Bridge Rails; Texas A&M Transportation Institute: College Station, TX, USA, 2011. Available online: http://www.ntis.gov (accessed on 1 December 2024).

- Mak, K.K.; Campise, W.L. Test and Evaluation of Ontatio ‘Tall Wall’ Barrier with an 80,000-Pound Tractor-Trailer; Texas A&M Transportation Institute: College Station, TX, USA, 1990. [Google Scholar]

- Bhutani, S. Development of the Preliminary Guidelines for the Evaluation and Repair of Portable Concrete Barriers. Master’s Thesis, Texas A&M University, College Station, TX, USA, 2021. [Google Scholar]

- NYDOT. Temporary Barrier Guidelines. Available online: https://www.dot.ny.gov/divisions/engineering/design/dqab/tcbacceptability (accessed on 12 March 2024).

- Silvestri-Dobrovolny, C.; Schroeder, W.J.L.; Kuhn, D.L. Develop Guidelines for Inspection, Repair, and Use of Portable Concrete Barriers—Volume 2: Crash Report; Texas A&M Transportation Institute: College Station, TX, USA, 2022; Available online: https://tti.tamu.edu/documents/0-7059-R1-Vol2.pdf (accessed on 1 December 2024).

- Dobrovolny, C.S.; Bhutani, S.; Zalani, A.; Bligh, R.P.; Hurlebaus, S.; Aldahlki, H.; Schroeder, W.; Kuhn, D.L. Development of Guidelines for Inspection, Repair, and Use of Portable Concrete Barriers—Volume 1: Technical Report; Texas A&M Transportation Institute: College Station, TX, USA, 2022. [Google Scholar]

- Adhikary, S.D.; Li, B.; Fujikake, K. Low Velocity Impact Response of Reinforced Concrete Beams: Experimental and Numerical Investigation. Int. J. Prot. Struct. 2015, 6, 81–111. [Google Scholar] [CrossRef]

- Yu, Y.; Lee, S.; Cho, J.Y. Deflection of reinforced concrete beam under low-velocity impact loads. Int. J. Impact Eng. 2021, 154, 103878. [Google Scholar] [CrossRef]

- Lyu, X.; Ran, H.; Elchalakani, M.; Wittek, A.; Hassan, G.M.; Ayough, P.; Pham, T.M. Dynamic responses of rubberised concrete: A study using short-length F-shape barriers subjected to pendulum impact. J. Build. Eng. 2024, 95, 110135. [Google Scholar] [CrossRef]

- Sharma, R.; Kasilingam, S. Performance of thin reinforced concrete slabs against low velocity repeated impact load. Eur. J. Environ. Civ. Eng. 2024, 28, 1415–1444. [Google Scholar] [CrossRef]

- Othman, H.; Marzouk, H. Finite-Element Analysis of Reinforced Concrete Plates Subjected to Repeated Impact Loads. J. Struct. Eng. 2017, 143, 04017120. [Google Scholar] [CrossRef]

- Wei, J.; Li, J.; Liu, Z.; Wu, C.; Liu, J. Behaviour of hybrid polypropylene and steel fibre reinforced ultra-high performance concrete beams against single and repeated impact loading. Structures 2023, 55, 324–337. [Google Scholar] [CrossRef]

- Huang, Z.; Zhao, X.; Zhang, W.; Ye, J. Repeated impact performance of stainless steel-lightweight high ductility cement composite beams. Thin-Walled Struct. 2023, 188, 110791. [Google Scholar] [CrossRef]

- Jones, N. Pseudo-shakedown phenomenon for the mass impact loading of plating. Int. J. Impact Eng. 2014, 65, 33–39. [Google Scholar] [CrossRef]

- Cai, W.; Zhu, L.; Qian, X. Dynamic responses of steel plates under repeated ice impacts. Int. J. Impact Eng. 2022, 162, 104129. [Google Scholar] [CrossRef]

- Shi, S.; Lam, N.; Cui, Y.; Lu, G.; Gad, E.; Zhang, L. Life-cycle performance of aluminium cladding panels in resisting hailstorms. Struct. Saf. 2024, 108, 102439. [Google Scholar] [CrossRef]

- Fang, C.; Rasmussen, J.D.; Bielenberg, R.W.; Lechtenberg, K.A.; Faller, R.K.; Linzell, D.G. Experimental and numerical investigation on deflection and behavior of portable construction barrier subjected to vehicle impacts. Eng. Struct. 2021, 235, 112071. [Google Scholar] [CrossRef]

- Rosenbaugh, S.K.; Sicking, D.L.; Faller, R.K. Development of a TL-5 Vertical Faced Concrete Median Barrier Incorporating Head Ejection Criteria; University of Nebraska: Lincon, NE, USA, 2007. [Google Scholar]

- Miele, C.R.; Plaxico, C.; Stephens, D.; Simunovic, S. U26: Enhanced Finite Element Analysis Crash Model of Tractor-Trailers (Phase C); No. Phase C; National Transportation Research Center: Knoxville, TN, USA, 2010; 276p.

- Buth, E.; Brackin, M.S.; Williams, W.F.; Fry, G.T. Collision Loads on Bridge Piers: Phase 2. Report of Guidelines for Designing Bridge Piers and Abutments for Vehicle Collisions. 2011. Available online: https://rosap.ntl.bts.gov/view/dot/18684 (accessed on 1 December 2024).

- Buth, C.E.; Williams, W.F.; Brackin, M.S.; Lord, D.; Geedipally, S.R.; Abu, A.Y. Analysis of Large Truck Collisions with Bridge Piers: Phase 1. Report of Guidelines for Designing Bridge Piers and Abutments for Vehicle Collisions; Texas A&M Transportation Institute: College Station, TX, USA, 2009. [Google Scholar]

- Cao, R.; Agrawal, A.K.; El-Tawil, S.; Xu, X.; Wong, W. Heavy Truck Collision with Bridge Piers: Computational Simulation Study. J. Bridge Eng. 2019, 24, 04019052. [Google Scholar] [CrossRef]

- Murray, Y. Users Manual for LS-DYNA Concrete Material Model 159; Federal Highway Administration: Washington, DC, USA, 2007; p. 77.

- Jones, C.A. Use of *INTERFACE_SPRINGBACK to Precondition Beams for Impact Analyses; DYANmore GmbH: Stuttgart, Germany, 2012. [Google Scholar]

- Schwer, L.E. Modeling Pre and Post Tensioned Concrete. In Proceedings of the 14th International LS-DYNA Conference, Detroit, MI, USA, 12–14 June 2016. [Google Scholar]

- Salahat, F.H.; Jones, C.A.; Rasheed, H.A. Assessment of Substandard Concrete Barriers as Protective Structures to Bridge Piers against Vehicular Collision Force. J. Bridge Eng. 2024, 29, 04024043. [Google Scholar] [CrossRef]

- Cao, R.; Agrawal, A.K.; El-Tawil, S.; Wong, W. Numerical Studies on Concrete Barriers Subject to MASH Truck Impact. J. Bridge Eng. 2020, 25, 04020035. [Google Scholar] [CrossRef]

- LS DYNA Support. Internal Energy—Welcome to the LS-DYNA Support Site. Available online: https://www.dynasupport.com/howtos/general/internal-energy (accessed on 23 November 2024).

| Impact Phase | R-Squared (%) | Velocity | Angle | |||||

|---|---|---|---|---|---|---|---|---|

| Coefficient | t-Stat | p-Value | Coefficient | t-Stat | p-Value | |||

| First | I | 87.21 | 25,596.51 | 13.28 | 1.94 × 10−15 | 29,702.95 | 8.32 | 6.58 × 10−10 |

| II | 69.52 | 46,796.31 | 8.92 | 1.19 × 10−10 | 15,353.89 | 1.58 | 1.23 × 10−01 | |

| III | 78.38 | 38,036.54 | 10.28 | 2.95 × 10−12 | 34,141.15 | 4.98 | 1.57 × 10−05 | |

| Full | 85.00 | 41,406.18 | 13.76 | 6.64 × 10−16 | 21,361.45 | 3.83 | 4.88 × 10−04 | |

| Second | I | 25.45 | 4425.21 | 1.98 | 5.51 × 10−02 | 11,947.18 | 2.89 | 6.47 × 10−03 |

| II | 26.09 | −7777.22 | −2.31 | 2.69 × 10−02 | −16,955.17 | −2.72 | 1.01 × 10−02 | |

| III | 38.89 | −11,651.76 | −3.61 | 9.25 × 10−04 | −18,780.97 | −3.14 | 3.34 × 10−03 | |

| Full | 7.71 | 1400.55 | 0.64 | 5.24 × 10−01 | −6491.94 | −1.61 | 1.16 × 10−01 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pokhrel, A.; Sorensen, A.D.; Zaker Esteghamati, M. A Numerical Investigation of the Performance of Damaged Concrete Barriers Under Sequential Vehicular Impacts. Buildings 2025, 15, 1271. https://doi.org/10.3390/buildings15081271

Pokhrel A, Sorensen AD, Zaker Esteghamati M. A Numerical Investigation of the Performance of Damaged Concrete Barriers Under Sequential Vehicular Impacts. Buildings. 2025; 15(8):1271. https://doi.org/10.3390/buildings15081271

Chicago/Turabian StylePokhrel, Ashesh, Andrew D. Sorensen, and Mohsen Zaker Esteghamati. 2025. "A Numerical Investigation of the Performance of Damaged Concrete Barriers Under Sequential Vehicular Impacts" Buildings 15, no. 8: 1271. https://doi.org/10.3390/buildings15081271

APA StylePokhrel, A., Sorensen, A. D., & Zaker Esteghamati, M. (2025). A Numerical Investigation of the Performance of Damaged Concrete Barriers Under Sequential Vehicular Impacts. Buildings, 15(8), 1271. https://doi.org/10.3390/buildings15081271