1. Introduction

Throughout the course of human civilization, the exploration of space has always accompanied the evolution of society. Whether it is the “Cloaca Maxima” drainage system in ancient Rome or the qanats of Persia, early underground space development was primarily aimed at survival and resource management. In the medieval period, the technology of constructing underground cities was vividly demonstrated in Cappadocia, Turkey, providing people with hidden shelters and food storage during times of war. With the advent of the Industrial Revolution, which spurred the rapid expansion of cities, the surface space gradually became overwhelmed. In 1863, London opened the world’s first subway tunnel, marking the birth of modern underground transportation networks. Over the course of history, underground infrastructure has continually expanded globally, from New York’s underground water supply system to Tokyo’s underground drainage system. The development of underground space has become increasingly diverse, encompassing fields such as the water supply, drainage, transportation, and storage. As urbanization progresses worldwide, city sizes continue to grow, and the demand for spatial resources increases. Underground space development has become one of the most important development targets for modern cities, as it can improve the land use efficiency, alleviate urban traffic pressure, optimize infrastructure layouts, and promote sustainability [

1,

2,

3,

4].

The excavation of deep foundation pits is a core step in underground space development. To meet the growing demand for underground space in urban areas, large-scale deep foundation pit excavations are widely used in the construction of underground parking lots, comprehensive utility tunnels, subway stations, and underground commercial centers. However, deep excavation projects in high-density urban areas and complex geological conditions are fraught with technical challenges. A typical technical challenge arises from excavations in soft soil regions, which are common in coastal and riverbank urban areas. Excavation in soft soil areas often leads to a series of complex deformation phenomena, including not only surface settlement, but also the lateral displacement of support structures, uplift at the bottom of the foundation pit, and the uneven settlement of surrounding buildings. These issues increase the uncertainty and risk of the project and pose potential threats to the safety and stability of the surrounding environment [

5,

6,

7].

In general, surface settlement and the deformation of support structures in foundation pit excavation projects are influenced by various factors, including the excavation depth, the stiffness of the support structure, changes in groundwater levels, and soil characteristics [

8,

9,

10]. Furthermore, these deformations exhibit significant time dependence and spatial variability, meaning that deformations change with the construction progress and variations in the surrounding environment [

11]. Therefore, accurately identifying and predicting the deformation patterns during the excavation process of deep foundation pits in soft soil areas is crucial for optimizing design parameters, reducing project risks, and developing effective support measures.

Systematically analyzing and summarizing the deformation patterns during the foundation pit excavation process in a specific region and soil conditions can provide a valuable reference experience for similar geological conditions. It can assist engineers in making more scientific and rational decisions during the design and construction phases, effectively reducing the long-term maintenance costs of deep foundation pit projects in soft soil areas. For instance, Hesami et al. [

12] investigated the ground surface settlement distribution in shallow gravel–sand strata induced by the New Austrian Tunneling Method during the construction of Karaj Metro Line 2, employing two-dimensional finite element numerical simulations. Their study compared the prediction accuracy of analytical methods including Peck’s empirical formula [

13], Limanov’s elastic theoretical solution [

14], and Mair’s volume loss approach [

15]. Compared to other methodological models, the numerical simulation results in the study exhibited the highest consistency with the field monitoring data, demonstrating that soil cohesion exerted the most significant sensitivity to settlement variations. The research underscored the critical importance of precise geotechnical parameter determination for reliable settlement prediction in urban tunneling projects. Jiang et al. [

16] investigated the impacts of deep excavation for Shenzhen Bay Super Headquarters Tower C on supporting structures and adjacent metro facilities using FLAC3D three-dimensional numerical simulations coupled with field monitoring. Their study revealed that lateral displacements of the supporting system exhibited a concave inward pattern, with diaphragm wall segments demonstrating significantly lower horizontal displacements compared to secant pile sections. Bending moments were predominantly concentrated in the mid-depth regions, while axial forces in struts maintained uniform distributions. Gui et al. [

17] evaluated deformation mechanisms induced by top-down construction on adjacent metro tunnels through integrated field monitoring and MIDAS/GTS numerical simulations for a rock-embedded deep excavation project in Kunming’s urban area. Their research revealed that rock-socketed diaphragm walls exhibited maximum lateral deformations ranging from 0.06% to 0.27% of the excavation depth

, significantly lower than those observed in soft soil excavations. Vertical strut differential settlements remained within Bjerrum’s allowable threshold [

18] (<1/500). Surface subsidence displayed characteristic trough-shaped patterns, with peak settlement observed at 2.7

from the excavation face and deformation influence zones extending to 3.8

. These findings provide essential guidance for deformation-predominant design optimization in analogous rock-socketed geological environments. Wang et al. [

19] investigated the anisotropic stability of columnar jointed rock mass tunnels in the Baihetan Hydropower Station through 3DEC-based numerical simulations and field validations. By reconstructing irregular columnar jointed rock mass geological models with dip angles ranging from 0° to 90° based on site-specific statistical parameters, their study revealed that stress and displacement distributions exhibited strong directional dependency, with sidewalls being most prone to stress-structure-controlled failure (maximum deformation: 33.92 mm at 45° dip).

To this end, this study selects and collects 10 case studies of deep foundation pit excavations for subway stations in the soft soil region of Ningbo, China. By analyzing the vertical surface deformation values, the locations of the maximum vertical surface deformation, excavation depth, and the ratio of the foundation pit length to width, this study evaluates and summarizes the impact of different excavation parameters on surface deformation and compares the findings with another piece of research. The deformation pattern of deep foundation pit excavation in Ningbo’s soft soil area is analyzed in this way to provide a reference for similar condition projects in the same area.

2. Methodology

This study adopts a comprehensive research framework that integrates a literature review, the collection and analysis of monitoring data, and comparative statistical methods. Our objective is to summarize and elucidate the principal factors influencing deformation in deep excavations for subway stations in the soft soil region of Ningbo and to identify the associated deformation patterns.

The study area is focus on the soft soil regions of Ningbo City, Zhejiang Province, China. Ten representative deep excavation projects for subway stations were selected based on the typicality of their soft soil distribution. Although these cases exhibit certain variations in their geological conditions, excavation scale (length, width, and depth), and support systems, all of them feature relatively thick soft soil layers and similar retaining and bracing designs. Consequently, they adequately reflect the characteristic deformation behaviors of deep excavations in Ningbo’s soft soil environment.

The collected data primarily include the maximum lateral displacement of the retaining structures and the depths at which these displacements occur, the maximum vertical ground deformation induced by excavation, geological conditions, pit parameters, supporting and retaining design parameters, and construction methods. In addition to the engineering data obtained directly from these ten projects, we have also consulted relevant domestic and international studies on deformation behaviors of deep excavations in soft soils (such as typical deformation benchmarks and measured statistical patterns in soft soil areas of urban settings). This body of the literature provides comparative references and context for interpreting our results.

To quantitatively assess the dominant factors affecting deformation and their relative importance, we perform linear fitting, regression analyses, and group comparisons of key influencing factors—such as the maximum excavation depth, retaining wall embedment ratio, stiffness of the support system, pit aspect ratio, and soft soil thickness—against corresponding deformation indicators. By plotting X–Y scatter diagrams with both linear and nonlinear trend lines, we evaluate how the maximum ground settlement and the retaining structure’s maximum lateral displacement correlate with changes in each individual factor. After obtaining the statistical results of deep excavation deformation in Ningbo’s soft soil regions, we compare these findings with empirical formulas and measured averages reported for Shanghai, Hangzhou, Beijing, and international contexts. This comparison elucidates the impact of regional soft soil characteristics on deformation control in deep excavation.

3. Construction Conditions and Characteristics

Ningbo is one of the cities in China with significant land subsidence. As a coastal and riverbank city, Ningbo is surrounded by mountains on three sides and sits on a coastal plain with a deep distribution of soft clay layers. It is a rift basin formed by northeast-trending tectonic faults in the late Cretaceous period. The soil base in the area mainly consists of continental clastic sedimentary rocks from the Lower Cretaceous period. Since the mid-Quaternary period, through multiple cycles of sea–land changes, a set of loose sediments, ranging from continental to marine–continental transitional, have been deposited. The soft soils in the Ningbo region primarily consist of silty clay and clayey silt, as shown in

Table 1. Previous studies have identified the characteristic physical and mechanical properties of these soils. In its natural state, the soft soil in Ningbo is thick and continuous, exhibiting high compressibility, a high water content, and high liquidity index [

20,

21]. In the soft clay of the Ningbo region, secondary clay minerals (such as illite and illite–montmorillonite mixed layers) account for 56–60% [

22]. These hydrophilic clay minerals possess a relatively large specific surface area and a high cation exchange capacity, which significantly enhances the soil’s ability to adsorb and bind water. In addition, due to the recent depositional environment, the loose structure of the soft soils in Ningbo leads to a high pore ratio and low permeability, which also implies the characteristics of a high water content and high compressibility [

20]. These characteristics directly result in weak shear strength and large deformations when disturbed [

23]. This means that the in situ stress state of the soft soil layer is prone to redistribution during deep foundation pit excavation, leading to increased lateral pressure on the support structure, especially when the soft soil layer is thick. The surrounding soil is more susceptible to significant deformation under such conditions.

For deep foundation pit support in soft soil areas, the appropriate support system is usually selected based on factors such as geological conditions, the excavation depth, and the surrounding environment. Common systems include Deep Soil Mixing Columns, Diaphragm Walls, Contiguous Pile Walls, Soil Nailing Walls, and Internal Bracing Systems using Ground Anchors, Concrete Struts, or Steel Struts. As shown in

Figure 1, the engineering cases studied in this research all involve diaphragm walls with internal support systems using concrete and steel braces. Deep foundation pit projects in Ningbo’s subway stations are typically located in densely built-up urban areas, where the strict control of settlement and lateral displacement is required. During construction, the combined internal support system with concrete and steel braces shares the load, which not only controls deformations caused by stress redistribution due to construction disturbances in the short term, but also ensures the long-term load-bearing capacity, effectively preventing the buckling of the support structures.

Common deep foundation pit excavation methods include the Open-Cut Excavation Method, Top-Down Excavation Method, Step Excavation Method, Block Excavation Method, Cover and Cut Method, and Full Face Excavation Method [

24,

25,

26]. In the soft soil region of Ningbo, the Open-Cut Excavation Method is widely used. Almost all of the foundation pit excavation cases analyzed in this study adopt this method (

Figure 2). The width of the foundation pits in the subway stations is mostly concentrated between 20 and 25 m, while their length is typically between 150 and 200 m, with the maximum excavation depth reaching up to 27.85 m. The Open-Cut Excavation Method, as a top-down layered excavation and support approach, implements support structures simultaneously with each excavation layer, providing stable lateral support to limit lateral soil displacement. This method prevents excessive settlement and uneven deformation caused by stress redistribution in the soil layers, making it suitable for construction projects in densely built urban areas [

24,

27,

28]. Through gradual supporting and layered implementation, the Open-Cut Excavation Method effectively reduces the risk of soil disturbance in soft soil layers, ensuring the stability of surrounding soils, controlling settlement and lateral displacement, and ensuring the overall safety of the foundation pit during construction.

4. Analysis of Surface Deformation Patterns

4.1. Maximum Surface Deformation

Surface deformation refers to the settlement and displacement of the ground surface caused by the redistribution of soil stresses during foundation pit excavation [

29]. Controlling surface deformation is one of the key tasks in foundation pit excavation projects, as surface subsidence around the pit may pose risks to nearby buildings and infrastructure. The soil characteristics in soft soil areas exacerbate soil deformation, making surface settlement and lateral displacement more pronounced, and thus more challenging to control [

30].

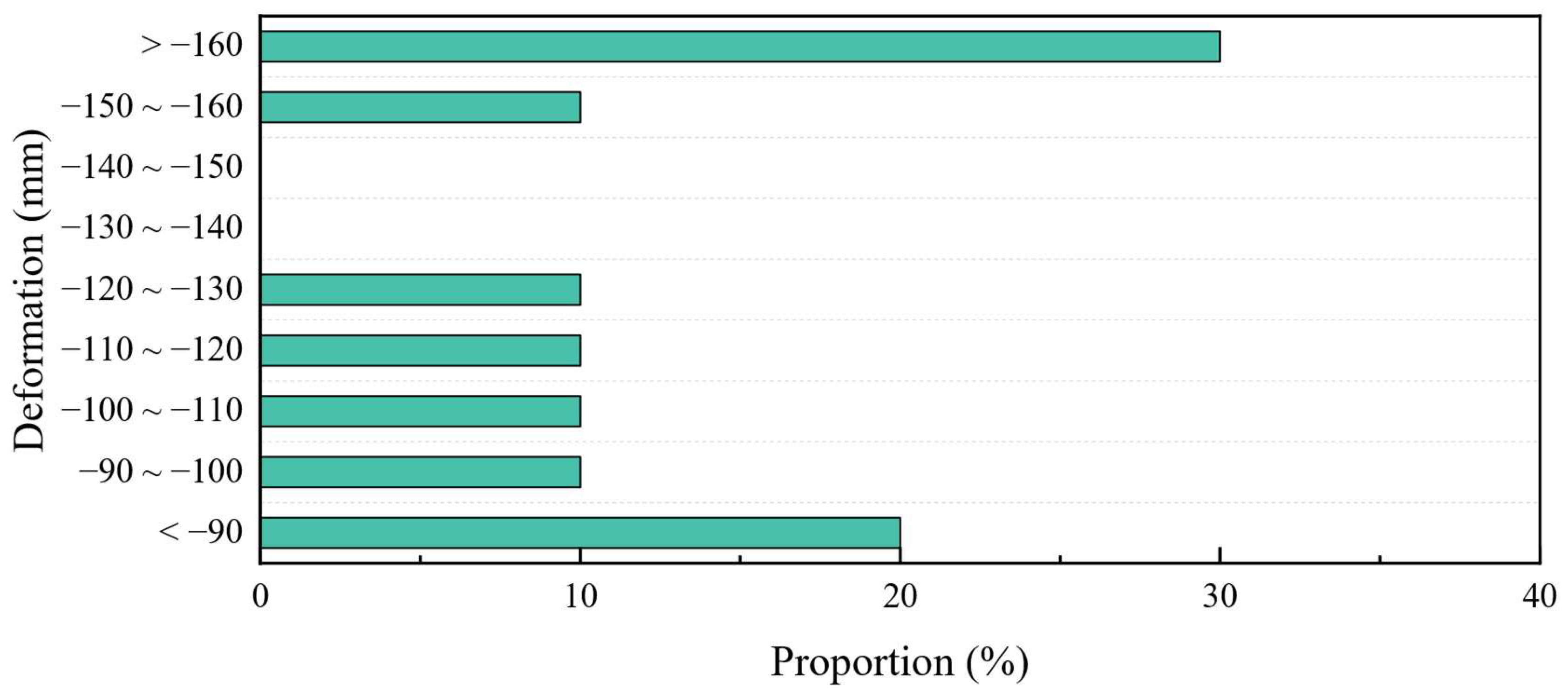

By summarizing and statistically analyzing the maximum excavation depths across all 10 foundation pit engineering cases examined in this study, the results presented in

Figure 3 were obtained. As shown in

Figure 3, the maximum vertical surface deformation caused by foundation pit excavation is downward settlement. The majority of maximum surface deformation values are distributed within the range of less than 130 mm, accounting for 30% of all intervals. Such low levels of settlement may be attributed to shallow excavation depths, high-strength support structures, or favorable geological conditions. Additionally, high settlement cases exceeding 150 mm are also observed. These higher settlements are typically associated with deeper excavations or more complex geological conditions, reflecting significant deformation in projects where support measures were inadequate or the geological conditions were unfavorable.

By quantifying and identifying the influence of various factors on the maximum vertical surface deformation caused by excavation in such projects, it can help more accurately predict the extent and magnitude of surface deformation in future similar projects in the same region. This will enable the reasonable layout of support structures and adjustment of excavation parameters during the design phase, ensuring the stability of the surrounding areas of the foundation pit.

4.2. Influence of Depth of Pit Excavation the Maximum Settlement of the Ground Surface Around the Pit

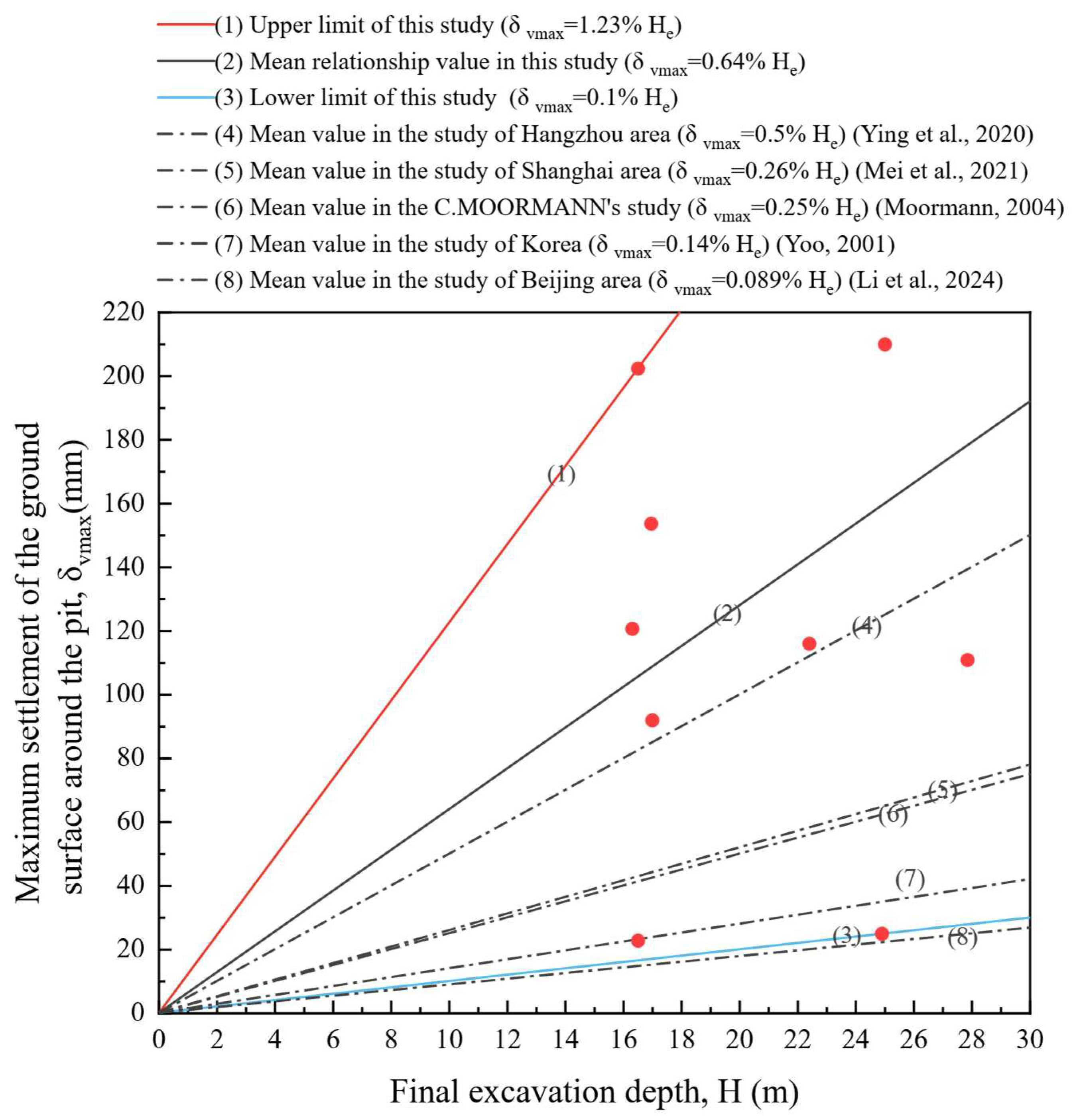

After identifying the overall deformation characteristics during the excavation process in soft soil layers, this section explores the relationship between the excavation depth and the maximum surface settlement around the foundation pit. As shown in

Figure 4, with the increase in the final excavation depth, the maximum surface settlement around the pit caused by excavation generally shows a clear increasing trend. The statistical results of this study are distributed within the range defined by the lower limit of

and the upper limit of

. The average relationship between the maximum surface settlement and the maximum excavation depth in this study,

, is higher than the average empirical formula derived from previous studies in Hangzhou (

[

31]), and is significantly higher than the average values from related studies in Shanghai and Beijing (

[

32] and

[

11], respectively). It is also much higher than the statistical average based on 530 foundation pit studies by C. MOORMANN and the study of 60 deep foundation pits by C.YOO in Korea (0.25%

[

33] and 0.14%

[

34], respectively). This indicates that Ningbo’s soft soil is more prone to significant surface settlement during deep foundation pit excavation. And the difference is closely related to the characteristics of Ningbo’s soft soil, such as high porosity, high compressibility, and the presence of a thick soft soil layer, which also confirms the important influence of regional geological conditions on foundation pit deformation control.

4.3. Influence of Diaphragm-Wall-Embedded Depth Ratio on the Maximum Settlement of the Ground Surface Around the Pit

The embedded depth ratio of a diaphragm wall is defined as the ratio of the height of the wall embedded below the bottom of the excavation pit to the total excavation depth of that pit [

35]. Some existing studies have shown that changes in this ratio are closely related to the lateral and vertical deformations of the diaphragm wall and the surrounding soil to varying degrees. According to Liu and Wang’s monograph [

36], under the condition that the retaining wall’s structural strength and stiffness sufficiently meet the required design criteria, increasing the embedment depth correspondingly enhances the basal uplift stability and effectively suppresses the wall’s lateral displacement deformation. Liu et al. [

37] validated this viewpoint by summarizing the empirical relationships derived from the field monitoring data of 26 deep foundation pits in metro stations in Changzhou, China. Li et al. [

11], in their analysis of 88 cases in the Beijing area, also reported a similar pattern, namely that the maximum ground settlement decreases with an increase in the embedment ratio, and that the rate of decrease gradually tapers off. However, Yuan et al. [

38], using statistical results from field measurements of 10 open-cut metro stations in Xi’an, identified a positive correlation between the pile embedment ratio and ground settlement, which deviates from the aforementioned general trend. Consequently, they concluded that the influence of the pile insertion ratio on ground settlement in deep excavations within collapsible loess regions is relatively weak.

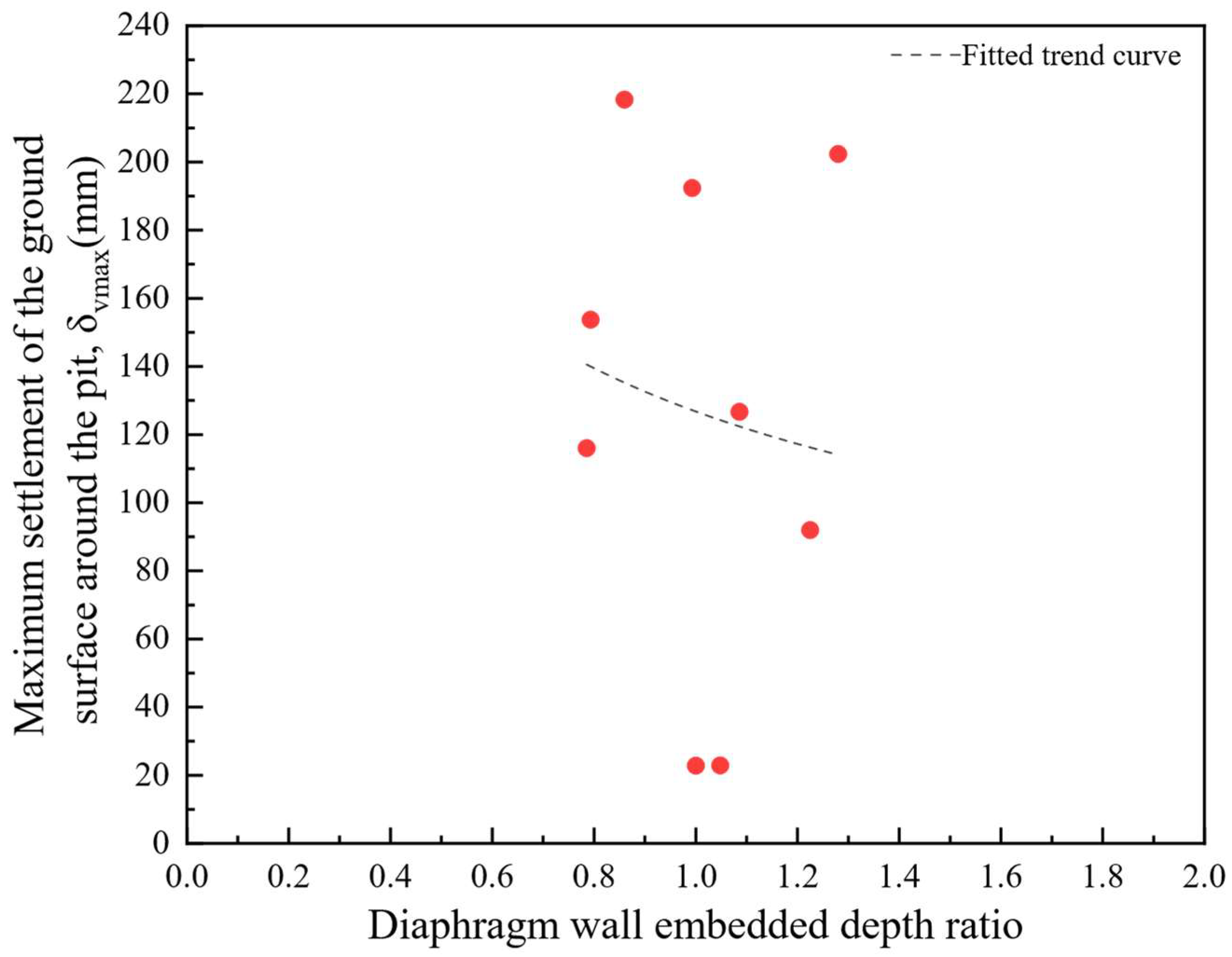

The relationship between the diaphragm-wall-embedded depth ratio and the maximum surface settlement, as recorded in this study, is shown in

Figure 5. As the embedded depth ratio increases, the maximum settlement around the foundation pit tends to decrease, which is consistent with the empirical trends found in previous studies. However, as the embedded depth ratio continues to increase, the rate of the decrease in the maximum surface settlement around the pit slows down. This indicates that while the deeper embedding of the diaphragm wall can continuously reduce the risk of surface settlement around the foundation pit, the marginal benefits gradually diminish.

But, it is worth noting that the scatter points in the figure still exhibit significant dispersion and the relationship between the two factors remains quite weak. One possible reason is that site-specific geological conditions, soil properties, and variations in construction methods may overshadow the effect of increasing the embedded depth ratio. These other factors introduce considerable variability, making a direct correlation with the maximum surface settlement less pronounced. Consequently, the embedded depth ratio of the diaphragm wall alone has a limited impact on the maximum surface settlement.

In foundation pit design and construction practice, the embedded depth of the diaphragm wall and its associated construction costs and deformation control objectives must be balanced by considering various factors based on the actual engineering conditions. This is especially important in deep excavations, where the cost-effectiveness diminishes with substantial increases in the embedment depth due to intensified design requirements and material consumption. Therefore, relying solely on a significant increase in the embedded depth ratio to limit vertical surface deformation is generally not cost-effective.

4.4. Influence of the Stiffness of the Support System on the Maximum Settlement of the Ground Surface Around the Pit

Based on the engineering cases studied in this paper, the foundation pit’s retaining structure mainly consists of diaphragm walls with different thicknesses (0.8 m, 1.0 m, and 1.2 m) and multiple internal supports. The configuration of the support system includes combinations of concrete and steel supports. Different projects typically use five to eight internal supports, and the concrete and steel supports are flexibly paired between adjacent support levels to meet the requirements of different foundation pit depths and surrounding environments.

Figure 6 shows the relationship between the stiffness of the support system and the maximum surface settlement around the foundation pit. The scatter points in different shapes and colors represent cases with five, six, seven, and eight internal supports, respectively.

As seen in

Figure 6, with the increase in the stiffness of the support system, the maximum surface settlement around the foundation pit generally decreases. This phenomenon aligns with theoretical expectations: the greater the stiffness of the support system, the more strictly the lateral displacement of the retaining wall is restricted, which reduces the transmission and superimposition effects of surface soil deformation, thus significantly decreasing surface settlement. However, when the stiffness of the support system reaches a certain level, the rate of reduction in the settlement decreases as the stiffness continues to increase, indicating diminishing marginal benefits in controlling settlement with further increases in stiffness. The differences observed with different numbers of supports further demonstrate that increasing the number of supports and optimizing the combination of support materials can achieve lower surface settlement at the same or higher stiffness levels.

Although the overall trend in

Figure 6 is clear, the dispersion of the scatter points should also be noted. Similar to the relationship between the diaphragm-wall-embedded depth ratio and surface settlement, the effect of support system stiffness on surface deformation is indirect. In actual engineering practice, relying solely on increasing support stiffness is not the only effective and economical method for controlling surface settlement. Instead, it should be combined with the characteristics of the foundation pit’s retaining system and other factors, with a comprehensive evaluation of design parameters to achieve a more economical and safe foundation pit support solution.

4.5. Relationship Between Soft Soil Thickness and Maximum Settlement of the Ground Surface Around the Pit

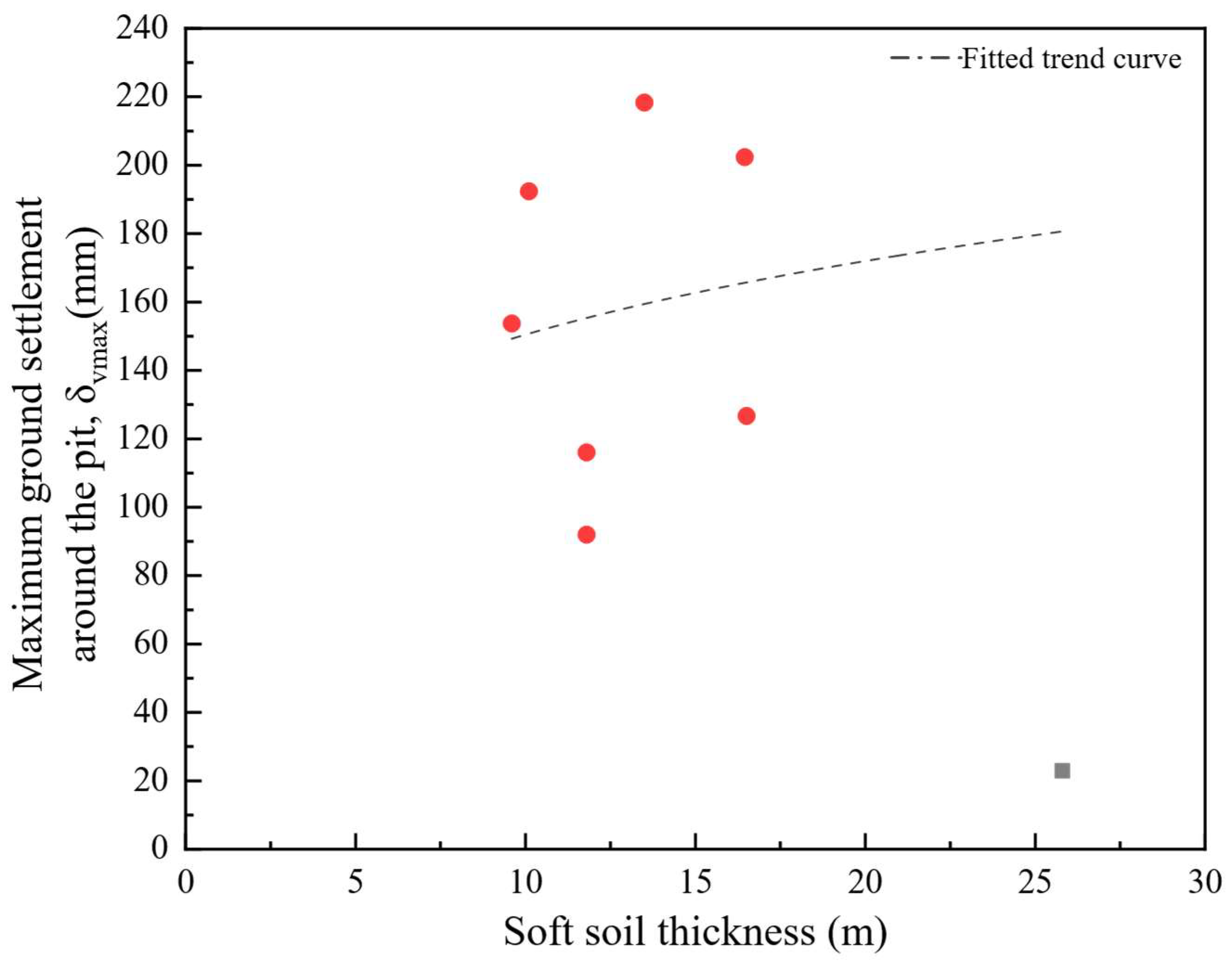

Figure 7 presents the relationship between the thickness of the soft soil layer and the maximum surface settlement around the excavated pit. The trend curve fitted to the data points shows a slight negative slope, indicating that, on average, as the thickness of the soft soil increases, the maximum surface settlement exhibits a small decreasing trend. However, the data points exhibit a broad distribution with significant dispersion, revealing a weak correlation. One possible reason for this weak correlation is that differences in the soil layer distribution, variations in groundwater levels, and the complexity of construction methods may overshadow the influence of the soft soil thickness itself. Additionally, the excavation depth, support system layout, and other engineering measures during construction may further mask any direct relationship.

Consequently, relying solely on the thickness of the soft soil layer to explain the maximum surface settlement is insufficient. More comprehensive studies that incorporate multiple factors—such as the mechanical characteristics of the soil layers, construction techniques, and environmental conditions—are essential for accurately predicting settlement. In practice, design and control measures should not be based on the soft soil thickness alone; rather, a holistic approach that accounts for these various parameters is recommended to balance cost, safety, and performance requirements.

4.6. Influence of the Aspect Ratio of Pit on the Maximum Settlement of the Ground Surface Around the Pit

Among the design parameters of foundation pits, past studies have shown that the dimensions of the pit affect the deformations and stability induced by excavation [

39,

40]. Different aspect ratio configurations lead to various settlement behaviors. This deformation is exacerbated in elongated tunnels, as their geometry leads to differential settlements and stress concentrations [

41]. Lv et al. [

42] found that at certain optimal aspect ratios, surface settlement can be minimized. Xiao et al. [

43], based on a statistical analysis of 92 large-width excavation projects in soft-soil foundations across China, and Li et al. [

11], in their study of 88 foundation pits in Beijing, both concluded that smaller length-to-width ratios correspond to relatively lower ground settlement values. Meanwhile, Yuan et al. [

38], drawing on field data from ten open-cut stations in the collapsible loess region of Xi’an, demonstrated that the excavation aspect ratio exerts a significant influence on foundation pit stability. Specifically, as the aspect ratio increases, the maximum ground-surface settlement decreases; when this ratio is below 10, the reduction in settlement is pronounced, whereas once it exceeds 10, the rate of the decrease becomes comparatively less pronounced.

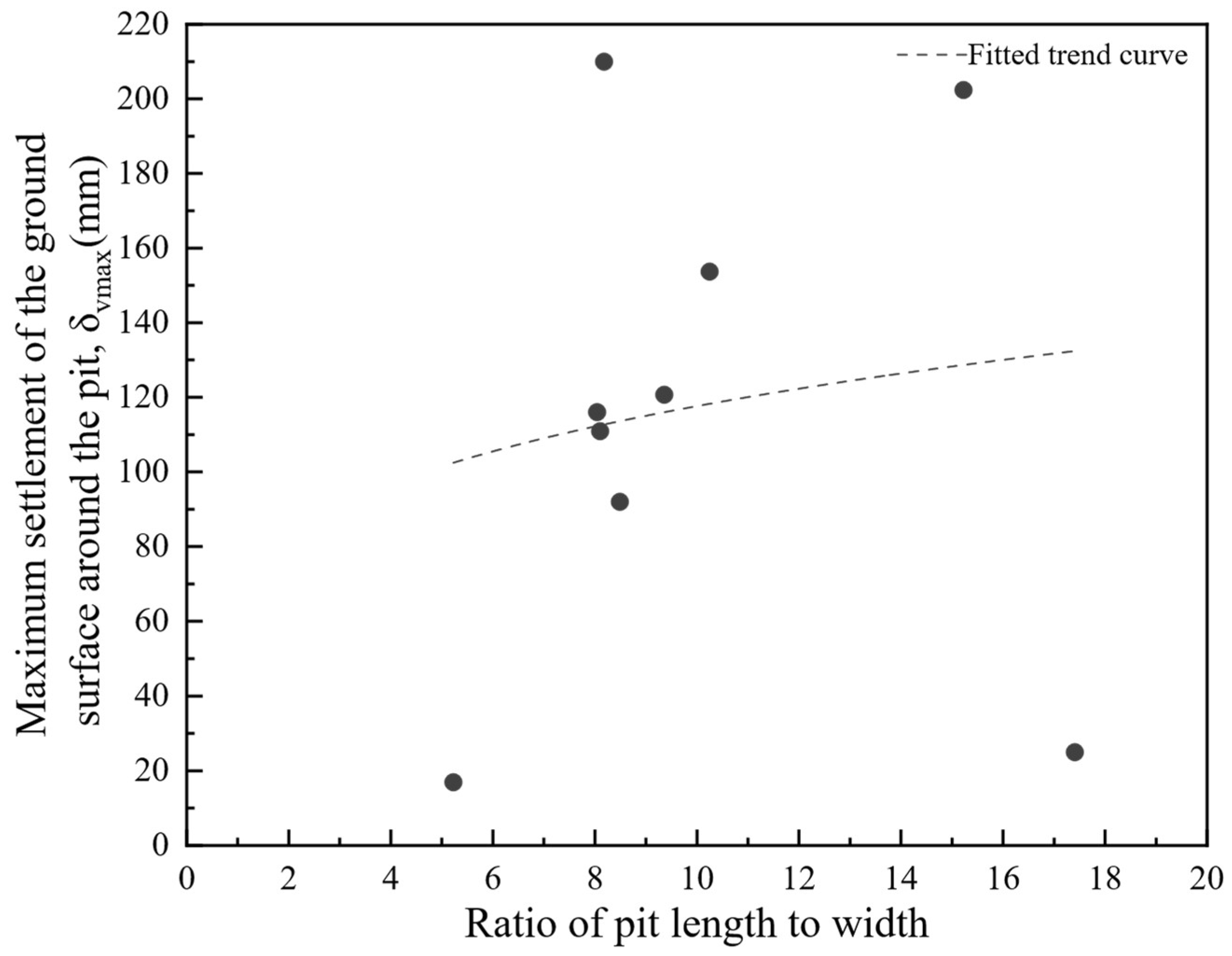

Figure 8 visualizes the distribution and fitting trend of the relationship between the pit’s length-to-width ratio and the maximum surface settlement in this study. Overall, as the pit’s length-to-width ratio increases, the maximum surface settlement rises correspondingly, demonstrating a positive correlation.

This phenomenon may be attributed to the fact that a larger length-to-width ratio implies a more elongated pit shape. Such pits typically experience a more uneven lateral pressure distribution during excavation, making the lateral pressure exerted by the surrounding soil more complex and difficult to predict [

44]. This result is consistent with previous studies that pointed out the significant impact of the length-to-width ratio on deformations induced by pit excavation [

11,

41].

However, the data points are scattered and the slope of this trend is relatively small, indicating that while a positive relationship is present, it is not pronounced. And, contrary conclusions exist under different regional or soil conditions. Research based on a case study of collapsible loess in Xi’an [

38] indicates that as the pit’s aspect ratio increases, the maximum ground surface settlement decreases. A possible explanation, akin to how the embedment ratio may influence the maximum ground settlement, is that project-specific factors—such as geological conditions, groundwater distribution, construction methods, and the support system design—can partially obscure the effect of the pit geometry. Consequently, the length-to-width shape of the foundation pit may not always directly translate into changes in the maximum ground surface settlement. Furthermore, the discrepancies between this and other studies suggest that, across all scenarios, the pit’s length-to-width ratio does not consistently or robustly exhibit a uniform correlation with settlement. The comprehensive consideration of geological conditions, support system characteristics, and construction processes remains essential. In addition, the coupled influence of the length-to-width ratio and other factors still warrants further investigation.

4.7. Observation of the Relationship Between the Distance from the Edge of the Pit to the Location of the Surface Deformation and the Maximum Surface Deformation

Surface deformation is typically most pronounced at a certain distance from the excavation edge. Studies have shown that deformation amplitudes decrease significantly with an increasing distance from the edge [

45].

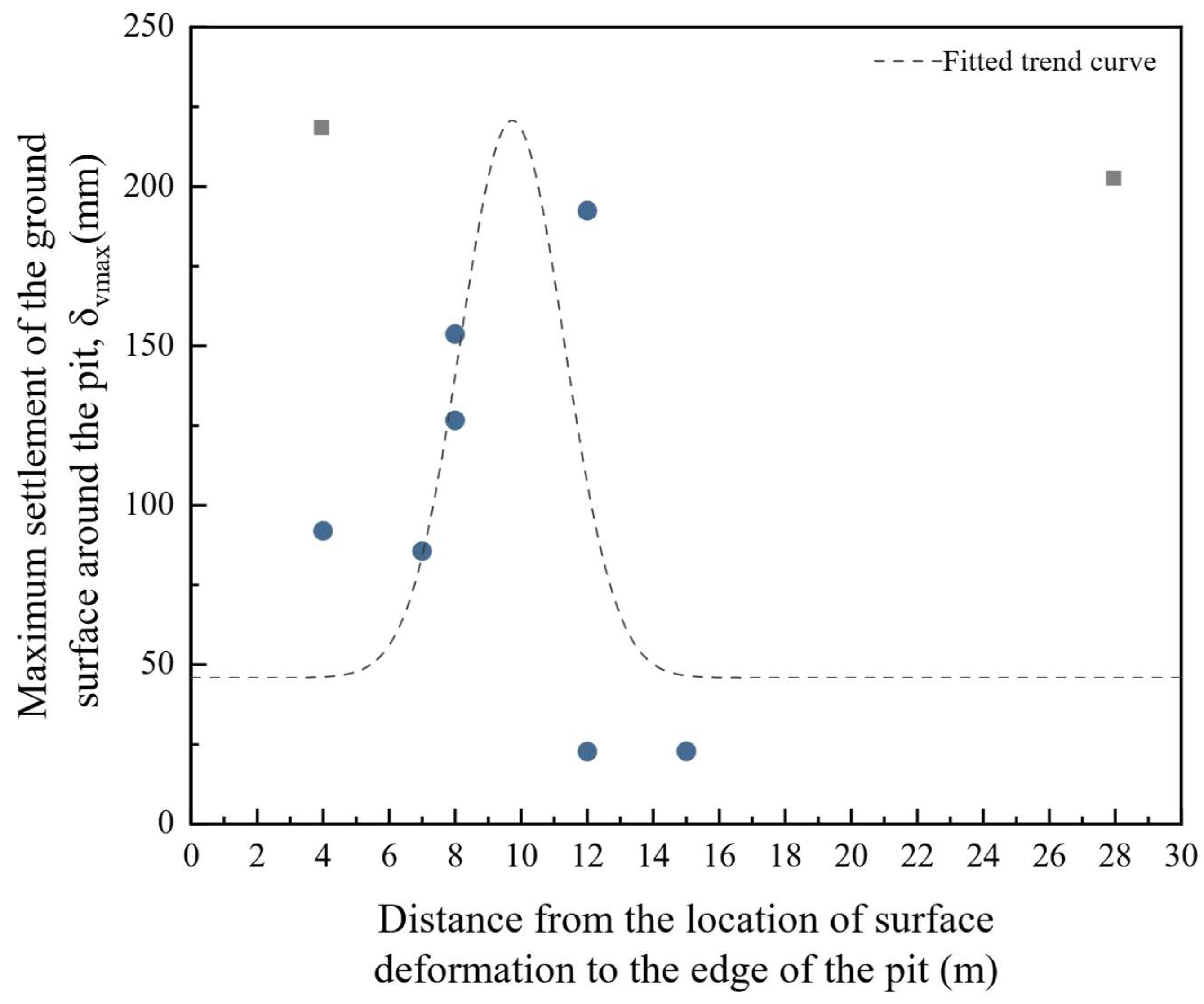

Figure 9 illustrates the relationship between the maximum ground surface settlement and the distance from the surface deformation location to the pit edge in the cases analyzed in this study.

The maximum ground surface settlement is frequently observed within a range of 4–12 m from the pit edge. As the distance from the pit edge increases, the maximum surface settlement generally exhibits a trend of first increasing and then decreasing, forming a curve-shaped distribution. Except for a special case at 30 m from the pit edge, the settlement–distance relationships at other observation points largely conform to this trend curve.

5. Deformation Characteristics of Pit Enclosure Structure

By visualizing the relationship between the maximum lateral deformation of the pit enclosure structure, the depth at which the maximum lateral deformation occurs, and the excavation depth, the deformation characteristics of deep foundation pits in Ningbo’s soft soil areas can be identified.

Figure 10 illustrates the relationship between the maximum lateral deformation of the pit enclosure structure (

) and the excavation depth (

). The maximum lateral deformation value (

) shows a positive correlation with

. The data points are enveloped by two characteristic boundary lines,

and

, with an average relationship of

= 0.37%

.

When compared with other studies, significant regional differences in the average ratio values become evident. In Hangzhou, the average value is approximately

[

31], which is close to the upper boundary line of this study (0.84%

) and significantly higher than the average value of this study. This suggests a higher tendency for lateral displacement in Hangzhou. Conversely, the results for Shanghai (0.26%

[

32]), C. Moormann’s study (0.20%

[

33]), South Korea (0.12%

[

34]), and Beijing (0.10%

[

46]) are all lower than the average value of this study and substantially lower than the average value for Hangzhou. Notably, the average value from C. Moormann’s research, based on multiple international cases (0.20%

[

33]), is close to the lower boundary line of this study (0.19%

).

These differences indicate that regional factors significantly influence the lateral deformation of diaphragm walls. Variations in geological conditions, groundwater levels, and construction and support technologies contribute to the uneven distribution of maximum lateral displacement values in pit enclosure structures.

Figure 11 demonstrates a positive correlation between the depth at which the maximum lateral deformation of the pit enclosure structure occurs (

) and the excavation depth (

). In the linear relationship established in this study, the upper boundary line is expressed as

, the average line as

, and the lower boundary line as

. These findings reveal that the depth of the maximum lateral displacement is distributed within a range slightly above and below the excavation depth.

Regional data exhibit distinct distribution characteristics. For instance, studies in Hangzhou indicate an average relationship of , which lies between the upper boundary and the average line of this study. This suggests that the point of maximum lateral displacement in Hangzhou tends to occur at a deeper position below the excavation bottom. In contrast, studies in Shanghai report a relationship of , indicating that the average depth of the maximum displacement point coincides with the excavation surface depth in this region.

By using the maximum lateral displacement of diaphragm walls as the y-axis and the maximum ground settlement as the x-axis,

Figure 12 visualizes the corresponding relationship. As shown in the figure, during deep foundation pit excavation, soil disturbances result in varying degrees of settlement in the surrounding ground. With an increase in the maximum settlement, the maximum lateral displacement of diaphragm walls exhibits a linear positive correlation.

In

Figure 12, the red, black, and blue lines represent the upper limit (

), mean value (

), and lower limit (

) relationships defined in this study, respectively. The observed relationships indicate that under adverse geological conditions or extreme scenarios, larger settlement around the excavation area poses significant challenges to the stability of the diaphragm walls.

Thus, the relationship between the maximum ground settlement and the lateral displacement of the diaphragm walls can serve as a key consideration in the design and construction. In cases where substantial ground settlement is observed near the excavation site, effective soil stabilization and structural reinforcement measures should be implemented to mitigate excessive displacement and prevent structural failure.

6. Discussion

This study systematically investigated the typical surface deformation characteristics and influencing factors during the construction of deep foundation pits in the Ningbo soft soil area. The analysis is based on statistical comparisons of ten subway station excavation projects in Ningbo. The results indicate that surface deformation patterns around deep foundation pits in soft soil regions are influenced by multiple coupled parameters, including, but not limited to, the maximum excavation depth, the diaphragm-wall-embedded depth ratio, the stiffness of the support system, and the pit’s aspect ratio.

In this study, most of the maximum ground settlement measurements remained within 130 mm; however, there were instances where the settlement exceeded 150 mm. This finding indicates that when the excavation is relatively deep, the geological conditions are complex, or support measures are inadequate, ground deformation becomes particularly pronounced.

In the Ningbo soft soil conditions, significant surface settlement was observed during deep foundation pit excavation. The average ratio of the maximum surface settlement to the excavation depth (

) in this study was 0.64%. Compared with values from other regions—such as Hangzhou (0.14–0.17%

[

47], average of 0.5

[

48]), Shanghai (average of 0.26%

[

32]), and specific soil conditions in Long et al.’s study (soft soil thickness >0.6

and overlying stiff soil at 0.5%

[

49])—Ningbo’s settlement ratio is significantly higher. It is also close to Singapore’s soft soil conditions with corresponding values of 0.5%

[

50]. This highlights the high compressibility and susceptibility to the significant deformation of Ningbo’s soft soils, emphasizing the critical role of regional geological characteristics in deformation control.

Increasing the embedded depth of the diaphragm walls effectively reduces surface settlement. However, the marginal benefit of further increasing the embedded depth diminishes beyond a certain threshold. Similarly, enhancing the stiffness of the support system can reduce settlement, but once stiffness reaches a certain level, the marginal reduction in settlement also decreases. In engineering practice, it is not advisable to pursue excessively high embedded depth ratios or substantial increases in support stiffness indiscriminately. Instead, it is essential to consider the coupled effects of multiple factors and balance construction costs against deformation control efficacy. An optimal design should involve a comprehensive evaluation of these factors to achieve a practical and efficient construction strategy.

Regarding the shape parameters of foundation pits, as the aspect ratio increases, the maximum ground settlement around the pit generally rises. This suggests that elongated pit shapes may exacerbate the uneven stress distribution, leading to greater deformation. However, opposing trends may occur under different regional and soil conditions. This indicates that the relationship between the aspect ratio and settlement is not universally consistent and requires the comprehensive consideration of factors such as geological characteristics, support systems, and construction techniques.

The study of the relationship between the maximum ground settlement and the distance from the measurement point to the pit edge reveals that the maximum settlement is most significant within a 4–12 m range from the edge. It follows a “first increasing, then decreasing” trend. This pattern provides quantitative references for determining risk control zones and monitoring areas around foundation pits. It shows that excavation impacts are primarily concentrated within a certain distance around the pit, with settlement values becoming smaller or stabilizing beyond 30 m.

Additionally, the deformation characteristics of the pit enclosure structure were analyzed in this study. The results demonstrate significant differences between this study’s findings and those of other regions due to geological, hydrogeological, and technical variations. The average statistical relationship between the maximum lateral deformation of the pit enclosure structure and the excavation depth in this study is , which is much lower than that of Hangzhou, but significantly higher than those of Shanghai, Beijing, and studies based on multiple cases in South Korea. The positive correlation between the depth of maximum lateral deformation and the excavation depth in this study indicates that the average distribution position of the maximum lateral deformation depth is slightly above the excavation depth, represented by .

There is also a notable positive correlation between the maximum ground settlement and the maximum lateral displacement of the diaphragm wall, characterized by an upper limit (), mean value (), and lower limit (). When substantial soil settlement occurs around the pit, the stability of the walls may face significant challenges.

7. Conclusions

In this study, monitoring data from 10 deep excavation projects for subway construction in Ningbo’s soft soil region were systematically analyzed to elucidate the typical characteristics of ground settlement and retaining structure deformation, as well as the complex coupling of multiple influencing factors. Compared with areas such as Shanghai and Beijing, the higher compressibility and greater thickness of soft soil in Ningbo lead to notably larger magnitudes of ground settlement and the lateral displacement of the diaphragm wall.

Within the context of this research, the maximum settlement recorded for the diaphragm wall, the maximum lateral deformation of the retaining structure, and the depth at which the maximum lateral displacement occurs all exhibit a positive correlation with the depth of excavation. Moreover, there is likewise a positive correlation between the maximum lateral displacement and the maximum ground settlement. Most cases in this study employ a combination of diaphragm walls and multiple internal supports as the retaining scheme. Another trend indicates that increasing the stiffness of the support system can effectively suppress the lateral displacement of the retaining structure and reduce ground settlement, albeit with diminishing marginal benefits as stiffness continues to rise. These findings are consistent with previously reported patterns in the literature.

Although factors such as the diaphragm wall’s embedded depth ratio, the stiffness of the support system, and the pit’s aspect ratio typically exhibit varying degrees of correlation, the impact of the embedded depth ratio of the diaphragm wall, soft soil thickness, and pit aspect ratio on the maximum ground settlement around the excavation proves to be indirect and not particularly evident. This is largely attributable to differing geological conditions and support designs in specific projects, highlighting the multifactor coupling effects that arise under various excavation approaches and geological settings. Furthermore, past research has produced inconsistent conclusions regarding the influence of the diaphragm wall’s embedded depth ratio and the pit’s aspect ratio on the maximum ground settlement, indicating that a further investigation of these parameters is warranted. Future studies should integrate long-term monitoring data and dynamic construction information to explore the underlying mechanisms of multifactor coupling effects. This effort will facilitate the development of more accurate regional empirical formulas and predictive models, providing robust scientific support for urban underground space development and informed decision making in planning.