A Comparative Investigation on Axial and Flexural Performance of Circularized Square RC Columns with Discontinuous and Continuous CFRP Confinement

Abstract

1. Introduction

2. Experimental Program

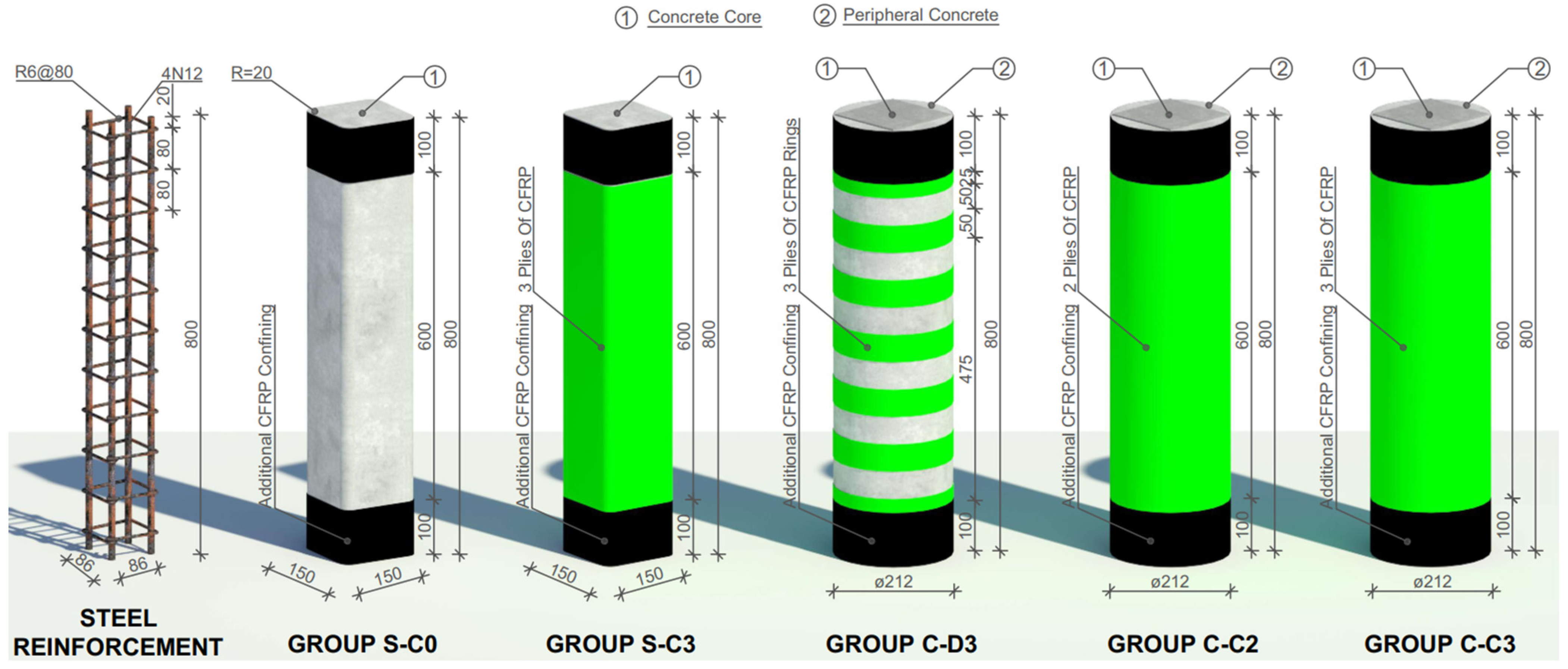

2.1. Test Specimens

2.2. Specimen Preparation and Preliminary Testing

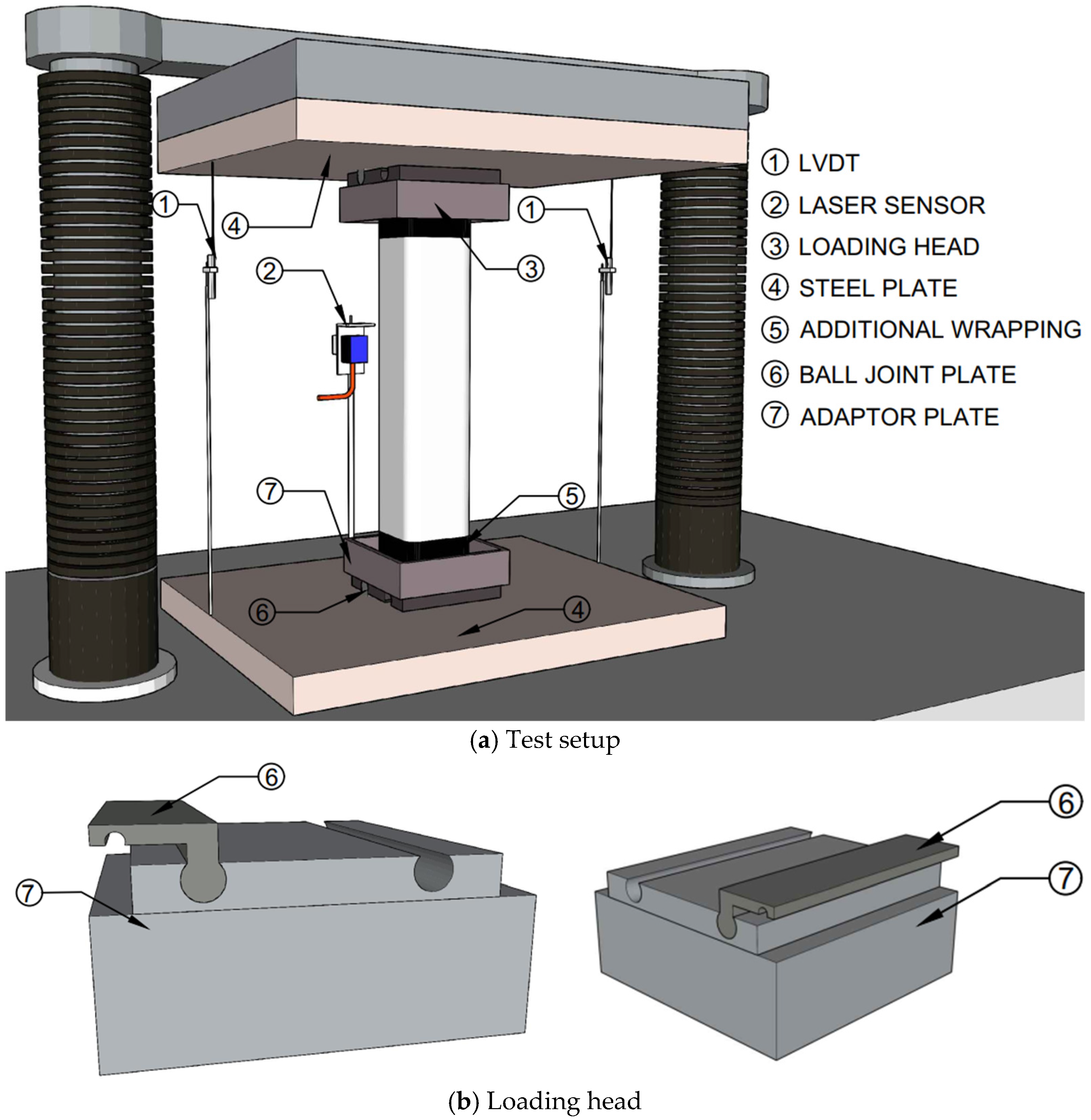

2.3. Test Setup and Instrumentation

3. Experimental Results and Discussion

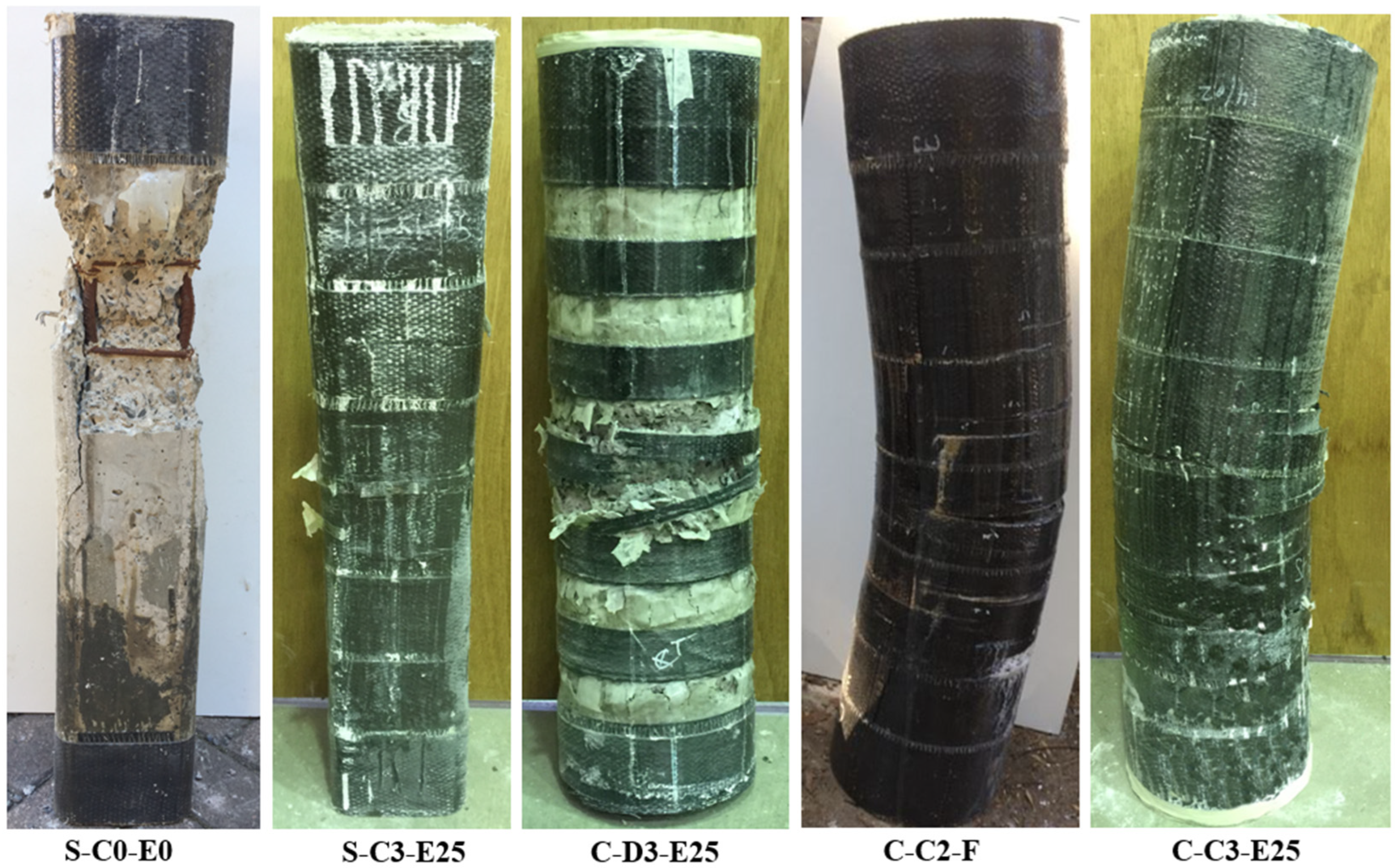

3.1. Failure Patterns

3.2. Load-Deformation Responses of Test Columns

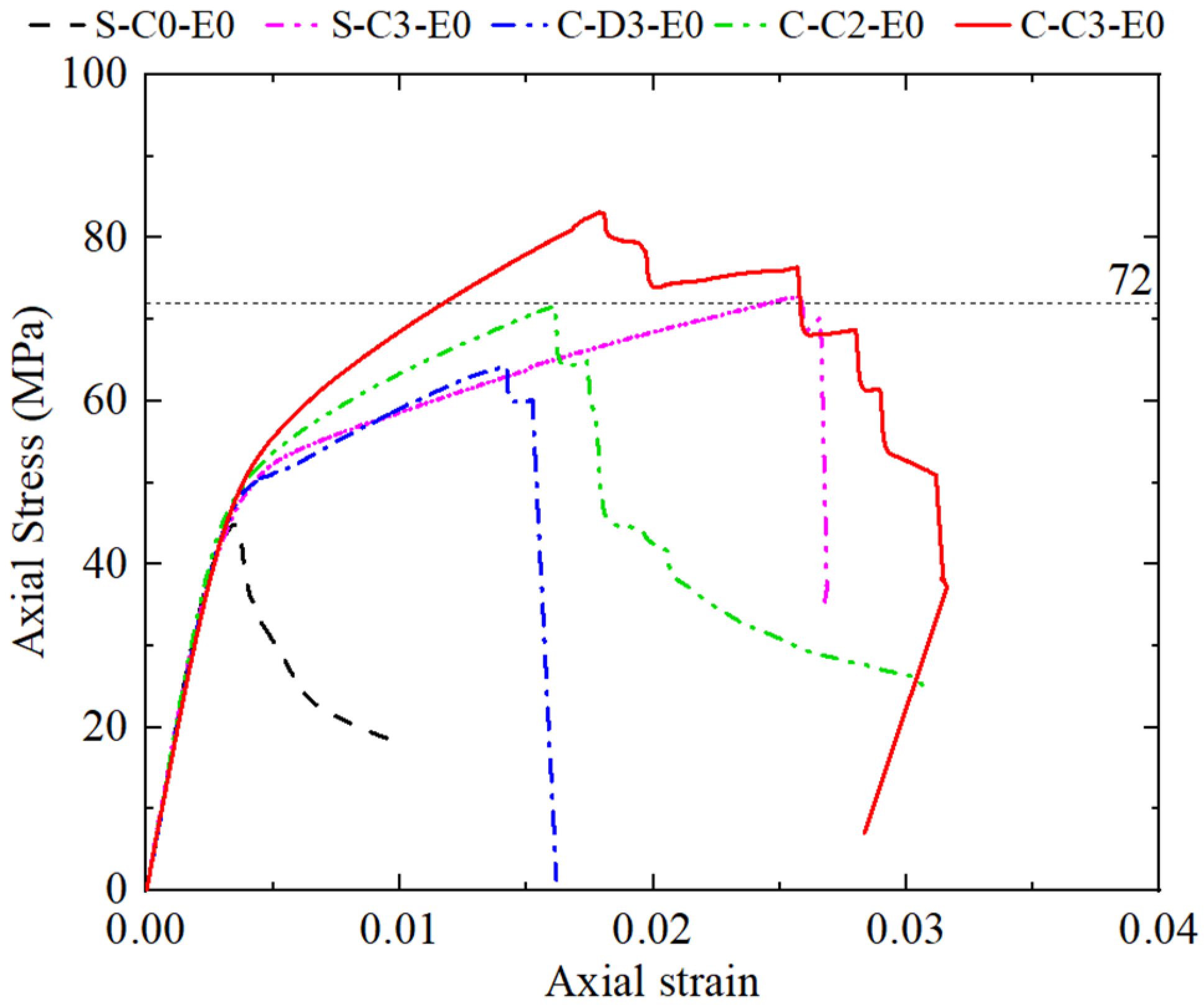

3.2.1. Behavior of Columns Under Concentric Axial Compression

3.2.2. Behavior of Columns Under Eccentric Axial Compression

3.2.3. Behavior of Columns Under Flexural Loading

3.3. Axial Stress-Axial Strain Response

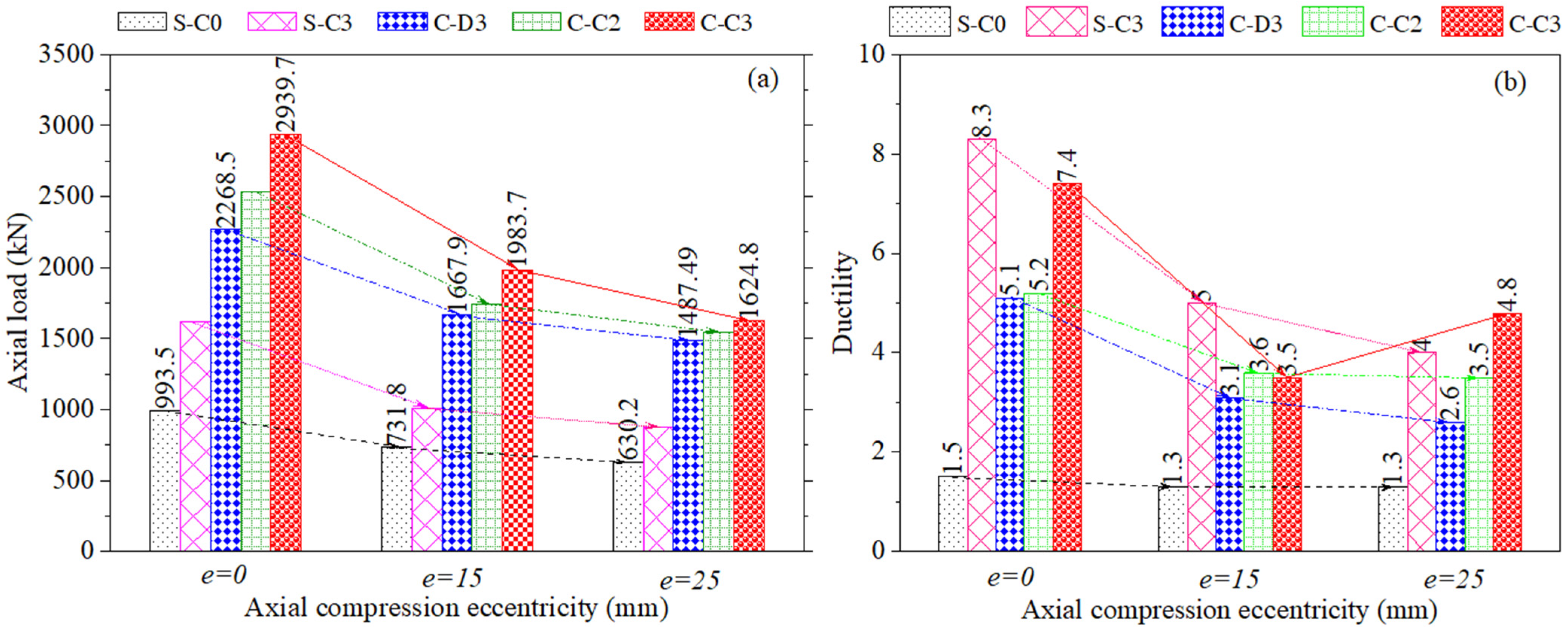

3.4. Effect of Axial Compression Eccentricity ()

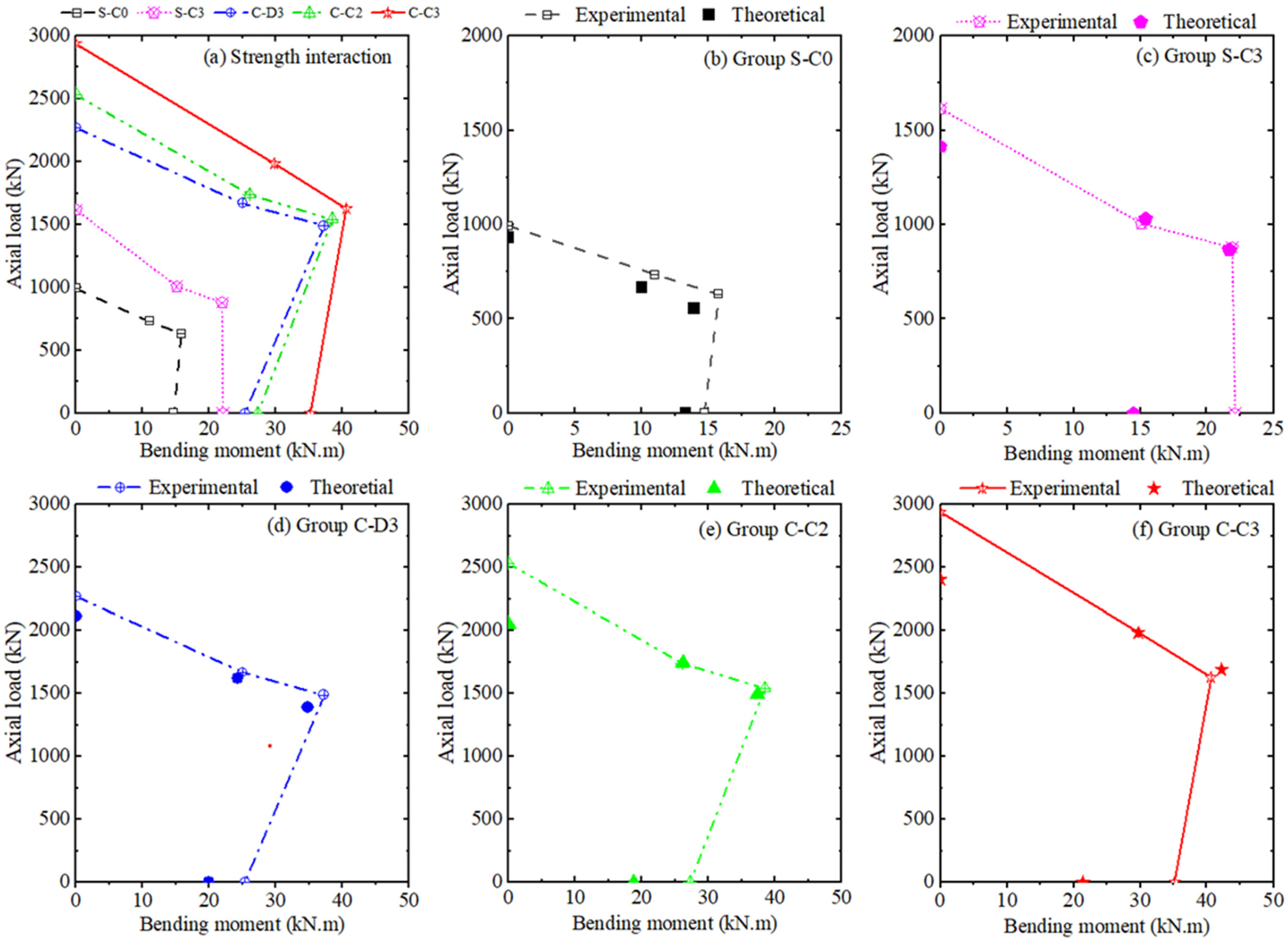

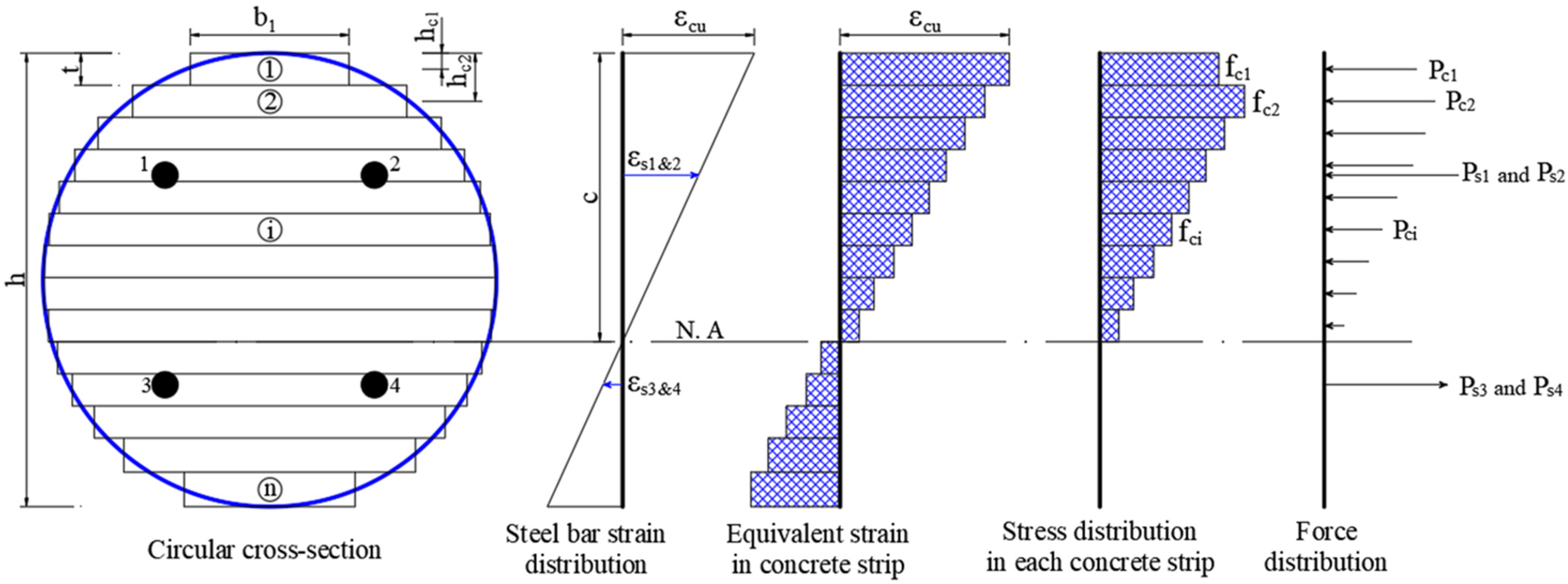

4. Strength Interaction Diagrams

5. Concluding Remarks

- The combination of the cross-section modification with CFRP confinement, whether discontinuous or continuous significantly improved the load-bearing capacity and ductility of the SRC columns. CSRC columns continuously confined with three CFRP plies obtained higher load-bearing capacity and ductility than their counterparts discontinuously confined with the same number of CFRP plies.

- Despite using a smaller amount of CFRP, CSRC columns with discontinuous confinement exhibited significantly higher load-bearing capacity than SRC columns with continuous CFRP confinement. However, their ductility was comparatively lower.

- For an equivalent amount of CFRP, CSRC columns with discontinuous confinement using three CFRP plies exhibited considerably lower load-bearing capacity and ductility compared to CSRC columns with continuous confinement using two CFRP plies.

- Both discontinuously and continuously CFRP-confined CSRC columns obtained significantly higher load-bearing capacity and bending moment compared to continuously CFRP-confined SRC columns. The highest strength interaction diagram was obtained by CSRC columns with continuous confinement using three CFRP plies, followed by those with two CFRP plies, and those with discontinuous confinement using three CFRP plies.

- The columns’ theoretical strength interaction diagrams developed based on the strip-by-strip method agreed well with their experimental strength interaction diagrams, confirming their reliability in estimating the load-bearing capacity and bending moment of FRP-confined CSRC and SRC columns. The confinement effect of discontinuous FRP confinement can be accurately captured by incorporating the confinement effectiveness coefficient into the lateral confining pressure.

- The findings in this paper on the effectiveness of the combined cross-section modification and discontinuous FRP confinement on the axial and flexural performance of SRC columns are drawn based on the test results of eight SRC and twelve CSRC columns. Thus, further investigations on environmental effects and different strengthening techniques on the short-term and long-term performance of discontinuously FRPC-CSRC columns are needed before the wide application of the combined cross-section modification and discontinuous FRP confinement.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aksoylu, C. Shear strengthening of reinforced concrete beams with minimum CFRP and GFRP strips using different wrapping technics without anchoring application. Steel Compos. Struct. 2022, 44, 845–965. [Google Scholar] [CrossRef]

- Mofidi, A.; Chaallal, O. Shear Strengthening of RC Beams with Externally Bonded FRP Composites: Effect of Strip-Width-to-Strip-Spacing Ratio. J. Compos. Constr. 2011, 15, 732–742. [Google Scholar] [CrossRef]

- Aksoylu, C.; Ozkilic, Y.O.; Şakir, Y.; Alsdudi, M.; Gemi, L.; Arslan, M.H. Numerical and analytical investigation of parameters influencing the behavior of shear beams strengthened by CFRP wrapping. Steel Compos. Struct. 2023, 47, 217–238. [Google Scholar] [CrossRef]

- Dong, S.; Shi, F.-W.; Deng, E.-F.; Chen, H.-T. Experimental Investigation on the Stress–Strain Behavior of Steel Fiber-Reinforced Rubberized Concrete Subjected to Cyclic Compressive Loading. Buildings 2025, 15, 584. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C. Axial compressive behavior of FRP-confined concrete: Experimental test database and a new design-oriented model. Compos. Part B Eng. 2013, 55, 607–634. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Lim, J.C.; Vincent, T. FRP-confined concrete in circular sections: Review and assessment of stress-strain models. Eng. Struct. 2013, 49, 1068–1088. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Analysis-oriented stress–strain models for FRP-confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- Lin, G.; Teng, J.G. Advanced stress-strain model for FRP-confined concrete in square columns. Compos. Part B Eng. 2020, 197, 108149. [Google Scholar] [CrossRef]

- Cao, Y.G.; Wu, Y.F.; Li, X.Q. Unified model for evaluating ultimate strain of FRP confined concrete based on energy method. Constr. Build. Mater. 2016, 103, 23–35. [Google Scholar] [CrossRef]

- Raza, A.; Rehman, A.U.; Masood, B.; Hussain, I. Finite element modelling and theoretical predictions of FRP-reinforced concrete columns confined with various FRP-tubes. Structures 2020, 26, 626–638. [Google Scholar] [CrossRef]

- Rasouli, M.; Broujerdian, V. 3D Finite Element Modeling of FRP-Confined Rectangular Short Columns Considering Variation of Poisson’s Ratio. Iran. J. Sci. Technol.-Trans. Civ. Eng. 2020, 44, 449–461. [Google Scholar] [CrossRef]

- Yu, T.; Teng, J.G.; Wong, Y.L.; Dong, S.L. Finite element modeling of confined concrete-I: Drucker-Prager type plasticity model. Eng. Struct. 2010, 32, 665–679. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Akin, E. Behavior of FRP-Confined Normal- and High-Strength Concrete under Cyclic Axial Compression. J. Compos. Constr. 2012, 16, 451–463. [Google Scholar] [CrossRef]

- Wang, W.; Wu, C.; Liu, Z.; Si, H. Compressive behavior of ultra-high performance fiber-reinforced concrete (UHPFRC) confined with FRP. Compos. Struct. 2018, 204, 419–437. [Google Scholar] [CrossRef]

- Wu, Y.-F.; Wei, Y.-Y. Effect of cross-sectional aspect ratio on the strength of CFRP-confined rectangular concrete columns. Eng. Struct. 2010, 32, 32–45. [Google Scholar] [CrossRef]

- Maaddawy, T.E.; Sayed, M.E.; Abdel-Magid, B. The effects of cross-sectional shape and loading condition on performance of reinforced concrete members confined with Carbon Fiber-Reinforced Polymers. Mater. Des. 2010, 31, 2330–2341. [Google Scholar] [CrossRef]

- Silva, M.A.G. Behavior of square and circular columns strengthened with aramidic or carbon fibers. Constr. Build. Mater. 2011, 25, 3222–3228. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Li, J. External reinforcement of high strength concrete columns. Compos. Struct. 2004, 65, 279–287. [Google Scholar] [CrossRef]

- Fallah Pour, A.; Gholampour, A.; Zheng, J.; Ozbakkaloglu, T. Behavior of FRP-confined high-strength concrete under eccentric compression: Tests on concrete-filled FRP tube columns. Compos. Struct. 2019, 220, 261–272. [Google Scholar] [CrossRef]

- Hadi, M.N.S. Comparative study of eccentrically loaded FRP wrapped columns. Compos. Struct. 2006, 74, 127–135. [Google Scholar] [CrossRef]

- Mai, A.D.; Sheikh, M.N.; Hadi, M.N.S. Investigation on the behaviour of partial wrapping in comparison with full wrapping of square RC columns under different loading conditions. Constr. Build. Mater. 2018, 168, 153–168. [Google Scholar] [CrossRef]

- Ismail, R.; Rashid, R.S.M.; Chan, W.C.; Jaafar, M.S.; Hejazi, F. Compressive behavior of concrete cylinder fully and partially confined by carbon fibre-reinforced polymer (CFRP). Constr. Build. Mater. 2019, 201, 196–206. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J. Ultimate Condition of Fiber Reinforced Polymer-Confined Concrete. J. Compos. Constr. 2004, 8, 539–548. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Zeng, J.-J.; Hadi, M.N.S. Ultimate strain prediction of partially FRP confined concrete considering strain localization. Constr. Build. Mater. 2022, 346, 128486. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wang, Z. Design-oriented axial stress–strain model for partially fiber-reinforced-polymer-confined normal-strength concrete. Adv. Struct. Eng. 2020, 23, 3481–3495. [Google Scholar] [CrossRef]

- Zeng, J.-J.; Duan, Z.-J.; Guo, Y.-C.; Xie, Z.-H.; Li, L.-J. Novel fiber-reinforced polymer cross wrapping strengthening technique: A comparative study. Adv. Struct. Eng. 2019, 23, 979–996. [Google Scholar] [CrossRef]

- Wang, W.; Al-Baali, A.Q.; Sheikh, M.N.; Hadi, M.N.S. Eccentrically Loaded FRP Confined Concrete with Different Wrapping Schemes. J. Compos. Constr. 2018, 22, 04018056. [Google Scholar] [CrossRef]

- Lin, G.; Zeng, J.J.; Teng, J.G.; Li, L.J. Behavior of large-scale FRP-confined rectangular RC columns under eccentric compression. Eng. Struct. 2020, 216, 110759. [Google Scholar] [CrossRef]

- Yuan, J.; Zhao, X.; Tian, L.; Hou, Z.; Pan, Y.; He, J. Experimental Study on Axial Compression Behavior of Molybdenum Tailings Concrete Column Confined by GFRP. Buildings 2024, 14, 3779. [Google Scholar] [CrossRef]

- Li, Y.-F.; Chen, B.-Y.; Syu, J.-Y.; Ramanathan, G.K.; Lee, W.-H.; Huang, C.-H.; Lok, M.-H. A Constitutive Model for Circular and Square Cross-Section Concrete Confined with Aramid FRP Laminates. Buildings 2023, 13, 2895. [Google Scholar] [CrossRef]

- Alkhattabi, L.; Ali, A.H.; Mohamed, H.M.; Gouda, A. Strain Behavior of Short Concrete Columns Reinforced with GFRP Spirals. Buildings 2024, 14, 2180. [Google Scholar] [CrossRef]

- Chaallal, O.; Shahawy, M.; Hassan, M. Performance of Axially Loaded Short Rectangular Columns Strengthened with Carbon Fiber-Reinforced Polymer Wrapping. J. Compos. Constr. 2003, 7, 200–208. [Google Scholar] [CrossRef]

- D’Amato, M.; Braga, F.; Gigliotti, R.; Kunnath, S.; Laterza, M. A numerical general-purpose confinement model for non-linear analysis of R/C members. Comput. Struct. 2012, 102–103, 64–75. [Google Scholar] [CrossRef]

- Teng, J.G.; Lam, L. Compressive behavior of carbon fiber reinforced polymer-confined concrete in elliptical columns. J. Struct. Eng. 2002, 128, 1535–1543. [Google Scholar] [CrossRef]

- Mai, A.D.; Sheikh, M.N.; Yamakado, K.; Hadi, M.N.S. Nonuniform CFRP Wrapping to Prevent Sudden Failure of FRP Confined Square RC Columns. J. Compos. Constr. 2020, 24, 04020063. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Xie, T. Geopolymer concrete-filled FRP tubes: Behavior of circular and square columns under axial compression. Compos. Part B Eng. 2016, 96, 215–230. [Google Scholar] [CrossRef]

- Wang, L.M.; Wu, Y.F. Effect of corner radius on the performance of CFRP-confined square concrete columns: Test. Eng. Struct. 2008, 30, 493–505. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Moshiri, N.; Mortazavi, N. Effect of corner radius and aspect ratio on compressive behavior of rectangular concrete columns confined with CFRP. Mater. Struct. 2015, 48, 107–122. [Google Scholar] [CrossRef]

- Pham, T.M.; Hadi, M.N.S. Stress prediction model for FRP confined rectangular concrete columns with rounded corners. J. Compos. Constr. 2014, 18, 04013019. [Google Scholar] [CrossRef]

- Wang, D.Y.; Wang, Z.Y.; Smith, S.T.; Yu, T. Size effect on axial stress-strain behavior of CFRP-confined square concrete columns. Constr. Build. Mater. 2016, 118, 116–126. [Google Scholar] [CrossRef]

- Saljoughian, A.; Mostofinejad, D. Corner Strip-Batten Technique for FRP-Confinement of Square RC Columns under Eccentric Loading. J. Compos. Constr. 2016, 20, 04015077. [Google Scholar] [CrossRef]

- Mai, A.D.; Sheikh, M.N.; Hadi, M.N.S. Performance evaluation of intermittently CFRP wrapped square and circularised square reinforced concrete columns under different loading conditions. Struct. Infrastruct. Eng. 2019, 15, 696–710. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Gao, W.Y.; Li, J.Z.; Xie, J.H. Behavior of partially and fully FRP-confined circularized square columns under axial compression. Constr. Build. Mater. 2017, 152, 319–332. [Google Scholar] [CrossRef]

- Park, T.W.; Na, U.J.; Chung, L.; Feng, M.Q. Compressive behavior of concrete cylinders confined by narrow strips of CFRP with spacing. Compos. Part B Eng. 2008, 39, 1093–1103. [Google Scholar] [CrossRef]

- Zeng, J.; Guo, Y.; Li, L.; Chen, W. Behavior and Three-Dimensional Finite Element Modeling of Circular Concrete Columns Partially Wrapped with FRP Strips. Polymers 2018, 10, 253. [Google Scholar] [CrossRef]

- Zeng, J.J.; Guo, Y.C.; Gao, W.Y.; Chen, W.P.; Li, L.J. Stress-strain behavior of concrete in circular concrete columns partially wrapped with FRP strips. Compos. Struct. 2018, 200, 810–828. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Al-Baali, A.Q.; Hadi, M.N.S. Compressive behaviour of partially FRP confined concrete: Experimental observations and assessment of the stress-strain models. Constr. Build. Mater. 2018, 192, 785–797. [Google Scholar] [CrossRef]

- Mai, A.D.; Sheikh, M.N.; Hadi, M.N.S. Influence of the location of CFRP strips on the behaviour of partially wrapped square reinforced concrete columns under axial compression. Structures 2018, 15, 131–137. [Google Scholar] [CrossRef]

- Abbasnia, R.; Hosseinpour, F.; Rostamian, M.; Ziaadiny, H. Effect of corner radius on stress-strain behavior of FRP confined prisms under axial cyclic compression. Eng. Struct. 2012, 40, 529–535. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Jameel, M.T.; Sheikh, M.N. Behavior of Circularized Hollow RC Columns under Different Loading Conditions. J. Compos. Constr. 2017, 21, 04017025. [Google Scholar] [CrossRef]

- Saljoughian, A.; Mostofinejad, D. Axial-flexural interaction in square RC columns confined by intermittent CFRP wraps. Compos. Part B Eng. 2016, 89, 85–95. [Google Scholar] [CrossRef]

- Triantafyllou, G.G.; Rousakis, T.C.; Karabinis, A.I. Axially Loaded Reinforced Concrete Columns with a Square Section Partially Confined by Light GFRP Straps. J. Compos. Constr. 2015, 19, 04014035. [Google Scholar] [CrossRef]

- Pham, T.M.; Hadi, M.N.S.; Youssef, J. Optimized FRP Wrapping Schemes for Circular Concrete Columns Under Axial Compression. J. Compos. Constr. 2015, 19, 04015015. [Google Scholar] [CrossRef]

- Yang, J.; Lu, S.; Wang, J.; Wang, Z. Behavior of CFRP partially wrapped square seawater sea-sand concrete columns under axial compression. Eng. Struct. 2020, 222, 111119. [Google Scholar] [CrossRef]

- CNR-DT 200 R1/2013; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Sructures. Italian National Research Council: Rome, Italy, 2013.

- Mai, A.D.; Sheikh, M.N.; Hadi, M.N.S. Experimental and analytical investigations on the effectiveness of non-uniform CFRP wrapping on circularised RC columns. Struct. Infrastruct. Eng. 2020, 17, 1125–1140. [Google Scholar] [CrossRef]

- AS 1391-2007; Methods of Testing Concrete: Method 9: Compressive Strength Tests-Concrete, Mortar and Grout Specimens. Australian Standard: Sydney, Australia, 2014.

- AS 1391-2007; Metallic Materials—Tensile Testing at Ambient Temperature. Australian Standard: Sydney, Australia, 2007.

- ASTM D3039; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Hadi, M.N.S.; Widiarsa, I.B.R. Axial and flexural performance of square RC columns wrapped with CFRP under eccentric loading. J. Compos. Constr. 2012, 16, 640–649. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M. Behavior of concrete columns confined by fiber composites. J. Struct. Eng. 1997, 123, 583–590. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Pham, T.M.; Lei, X. New Method of Strengthening Reinforced Concrete Square Columns by Circularizing and Wrapping with Fiber-Reinforced Polymer or Steel Straps. J. Compos. Constr. 2013, 17, 229–238. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Lam, L.; Teng, J.G. Design-oriented stress–strain model for FRP-confined concrete. Constr. Build. Mater. 2003, 17, 471–489. [Google Scholar] [CrossRef]

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. American Concrete Institute: Farmington Hills, MI, USA, 2017.

| Group | Column | Cross-Sectional Shape | Type of Confinement | Number of CFRP Plies (mm) | Amount of CFRP * (mm2) | (mm) |

|---|---|---|---|---|---|---|

| S-C0 | S-C0-E0 | Square | None | - | 0 | |

| S-C0-E15 | ||||||

| S-C0-E25 | ||||||

| S-C0-F | ||||||

| S-C3 | S-C3-E0 | Square | Continuous | 3 | 1,437,592 | |

| S-C3-E15 | ||||||

| S-C3-E25 | ||||||

| S-C3-F | ||||||

| C-D3 | C-D3-E0 | Circular | Discontinuous | 3 | 1,154,614 | |

| C-D3-E15 | ||||||

| C-D3-E25 | ||||||

| C-D3-F | ||||||

| C-C2 | C-C2-E0 | Circular | Continuous | 2 | 1,146,292 | |

| C-C2-E15 | ||||||

| C-C2-E25 | ||||||

| C-C2-F | ||||||

| C-C3 | C-C3-E0 | Circular | Continuous | 3 | 1,679,438 | |

| C-C3-E15 | ||||||

| C-C3-E25 | ||||||

| C-C3-F |

| Bar | Type of Reinforcement | (mm) | (mm) | (MPa) | (%) | (GPa) | |

|---|---|---|---|---|---|---|---|

| N12 | Longitudinal | 12 | 3 | 500 | 568 | 0.327 | 173 |

| R6 | Transverse | 6 | 3 | 500 | 517 | 0.284 | 182 |

| Material | (mm) | (mm) | (mm) | (MPa) | (%) | (GPa) | |

|---|---|---|---|---|---|---|---|

| Carbon fibers | 1 | 0.167 | 22.75 | 250 | 3726 | 1.55 | 240.43 |

| Column | (mm) | (kN) | (mm) | (kN) | (mm) | (mm) | (mm) | |

|---|---|---|---|---|---|---|---|---|

| S-C0-E0 | 0 | 890.5 | 2.1 | 993.5 | 2.8 | - | 3.2 | 1.5 |

| S-C3-E0 | 993.0 | 2.6 | 1614.5 | 20.7 | - | 21.3 | 8.3 | |

| C-D3-E0 | 1535.6 | 2.4 | 2268.5 | 11.2 | - | 12.2 | 5.1 | |

| C-C2-E0 | 1623.7 | 2.5 | 2534.1 | 12.9 | - | 20.6 | 5.2 | |

| C-C3-E0 | 1698.7 | 2.8 | 2939.7 | 14.3 | - | 20.6 | 7.4 | |

| S-C0-E15 | 15 | 687.0 | 1.9 | 731.8 | 2.2 | 2.5 | 2.4 | 1.3 |

| S-C3-E15 | 900.0 | 2.6 | 1006.2 | 4.5 | 7.8 | 13.1 | 5.0 | |

| C-D3-E15 | 1432.1 | 2.6 | 1667.9 | 6.2 | 8.8 | 8.0 | 3.1 | |

| C-C2-E15 | 1385.9 | 2.4 | 1739.1 | 7.4 | 6.7 | 8.7 | 3.6 | |

| C-C3-E15 | 1577.9 | 3.0 | 1983.7 | 9.5 | 8.0 | 10.6 | 3.5 | |

| S-C0-E25 | 25 | 595.4 | 1.9 | 630.2 | 2.2 | 2.5 | 2.5 | 1.3 |

| S-C3-E25 | 791.6 | 2.7 | 876.6 | 4.3 | 5.8 | 11.3 | 4.0 | |

| C-D3-E25 | 1303.2 | 2.9 | 1487.5 | 5.1 | 8.8 | 16.1 | 2.6 | |

| C-C2-E25 | 1234.0 | 2.6 | 1540.9 | 8.9 | 7.2 | 9.1 | 3.5 | |

| C-C3-E25 | 1302.1 | 2.9 | 1624.8 | 10.0 | 8.7 | 13.9 | 4.8 |

| Column | (kN) | (mm) | (kN) | (mm) | (mm) | |

|---|---|---|---|---|---|---|

| S-C0-F | 111.1 | 3.5 | 126.1 | 6.1 | 56.4 | 16.1 |

| S-C3-F | 117.5 | 3.3 | 189.3 | 34.8 | 43.1 | 13.1 |

| C-D3-F | 147.7 | 2.9 | 218.1 | 27.9 | 37.0 | 12.8 |

| C-C2-F | 145.5 | 3.2 | 234.5 | 30.1 | 34.2 | 10.7 |

| C-C3-F | 186.1 | 3.8 | 301.8 | 38.3 | 41.3 | 11.0 |

| Column | (kN) | (kN.m) | ||||

|---|---|---|---|---|---|---|

| (%) | (%) | |||||

| S-C0-E0 | 930.4 | 993.5 | 93.6 | 0 | 0.0 | - |

| S-C0-E15 | 665.4 | 731.8 | 90.1 | 10.0 | 11 | 90.1 |

| S-C0-E25 | 556.0 | 630.2 | 88.2 | 13.9 | 15.8 | 88.2 |

| S-C0-F | 0 | 0 | - | 13.3 | 14.7 | 90.5 |

| S-C3-E0 | 1413.6 | 1614.5 | 87.6 | 0 | 0.0 | - |

| S-C3-E15 | 1028.6 | 1006.2 | 102.2 | 15.4 | 15.1 | 102.2 |

| S-C3-E25 | 867.6 | 876.6 | 99.0 | 21.7 | 21.9 | 99.0 |

| S-C3-F | 0 | 189.3 | - | 14.5 | 22.1 | 65.6 |

| C-D3-E0 | 2112.8 | 2268.5 | 93.1 | 0 | 0 | - |

| C-D3-E15 | 1618.0 | 1667.9 | 97.0 | 24.3 | 25 | 97.0 |

| C-D3-E25 | 1390.4 | 1487.5 | 93.5 | 34.8 | 37.2 | 93.5 |

| C-D3-F | 0 | 0 | 20.0 | 25.4 | 78.7 | |

| C-C2-E0 | 2051.9 | 2534.1 | 81.0 | 0 | 0 | - |

| C-C2-E15 | 1746.3 | 1739.1 | 100.4 | 26.2 | 26.1 | 100.4 |

| C-C2-E25 | 1494.8 | 1540.9 | 97.0 | 37.4 | 38.5 | 97.0 |

| C-C2-F | 0 | 234.5 | - | 18.8 | 27.3 | 68.9 |

| C-C3-E0 | 2402.2 | 2939.7 | 81.7 | 0 | 0.0 | - |

| C-C3-E15 | 1979.7 | 1983.7 | 99.8 | 29.7 | 29.8 | 99.8 |

| C-C3-E25 | 1688.3 | 1624.8 | 103.9 | 42.2 | 40.6 | 103.9 |

| C-C3-F | 0 | 0 | - | 21.4 | 35.2 | 60.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mai, A.D.; Phan, H.N.; Truong, Q.C.; Nguyen, C.L.; Nguyen, Q.T. A Comparative Investigation on Axial and Flexural Performance of Circularized Square RC Columns with Discontinuous and Continuous CFRP Confinement. Buildings 2025, 15, 1228. https://doi.org/10.3390/buildings15081228

Mai AD, Phan HN, Truong QC, Nguyen CL, Nguyen QT. A Comparative Investigation on Axial and Flexural Performance of Circularized Square RC Columns with Discontinuous and Continuous CFRP Confinement. Buildings. 2025; 15(8):1228. https://doi.org/10.3390/buildings15081228

Chicago/Turabian StyleMai, Anh Duc, Hoang Nam Phan, Quynh Chau Truong, Cong Luyen Nguyen, and Quang Trung Nguyen. 2025. "A Comparative Investigation on Axial and Flexural Performance of Circularized Square RC Columns with Discontinuous and Continuous CFRP Confinement" Buildings 15, no. 8: 1228. https://doi.org/10.3390/buildings15081228

APA StyleMai, A. D., Phan, H. N., Truong, Q. C., Nguyen, C. L., & Nguyen, Q. T. (2025). A Comparative Investigation on Axial and Flexural Performance of Circularized Square RC Columns with Discontinuous and Continuous CFRP Confinement. Buildings, 15(8), 1228. https://doi.org/10.3390/buildings15081228