Study of Different Recycling Approaches for Gypsum-Based Composites with Recycled Rubber Aggregates

Abstract

1. Introduction

- Pinto et al. conducted a study involving different amounts of recycled rubber (5, 10, and 15 wt%) with particle sizes smaller than 0.60 mm and 1.20 mm [10]. Remarkable results were obtained in terms of decreased water absorption, with greater lightness being observed in the composites made with the smaller-size rubber because of the greater porosity of these mixtures, which was analysed by scanning electron microscopy (SEM) techniques. This study highlights that the main application of these composites could relate to the hygrothermal regulation of built spaces.

- Lozano-Diez et al. tried to improve the mechanical behaviour of gypsum composites with rubber aggregates by incorporating synthetic reinforcing fibres [11]. Thus, they for a water/gypsum ratio of 0.6 by mass and additions of 1.5% by mass of carbon fibre of 12 mm in length, they obtained gypsum composites with sufficient mechanical resistance to bending and compression stresses to develop prefabricated constructions of large dimensions in plate or panel format.

- Ferrández et al. developed composites in which gypsum material was partially replaced with recycled rubber aggregates (up to 30% by volume) [12]. A decrease in mechanical properties was observed, although in all cases, the threshold of 1 MPa in bending and 2 MPa in compression was exceeded. The main improvement obtained using these composites was a decrease in thermal conductivity of about 35% compared to traditional gypsum materials.

- Meddah et al., in alignment with the previous work, developed gypsum composites with high thermal performance for application in Mediterranean climates [13]. In contrast to other studies, these authors used dune sand as an additional aggregate to improve compressive strength, thus creating gypsum mortars more suitable for coating or for forming prefabricated blocks.

- Castellón et al. studied the fire performance of a gypsum coating made using tyre rubber waste [14]. The incorporation of these residues in percentages of 14.50% and 46.60% by volume significantly reduced the mechanical resistance, while the fire tests caused notable damage to the samples containing rubber, reducing the effectiveness of the gypsum coatings as a protective element in case of fire.

- Zaragoza-Benzal et al. developed a new gypsum composite that included recycled rubber waste with a diameter of less than 0.80 mm in combination with dissolved expanded polystyrene [15]. These composites showed excellent thermal insulation properties, up to 26.5% lower than those of conventional gypsum material, as well as excellent moisture resistance, which, together with their acceptable mechanical properties, made them widely applicable for use in damp rooms within dwellings.

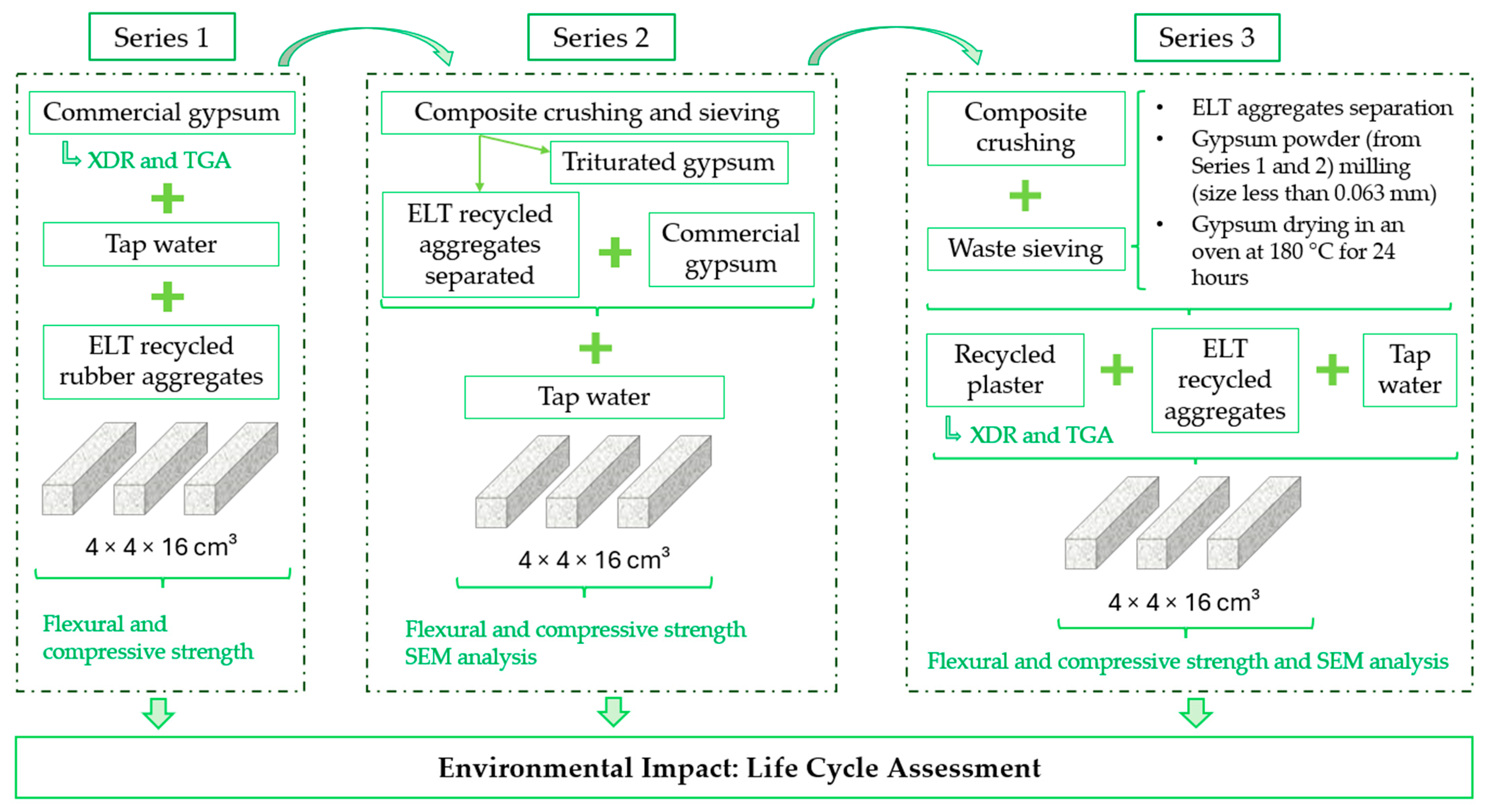

2. Materials and Methods

2.1. Materials

2.2. Gypsum-Based Composites Preparation

2.3. Test Procedures

2.3.1. Physicochemical Characterisation

2.3.2. Mechanical Characterisation

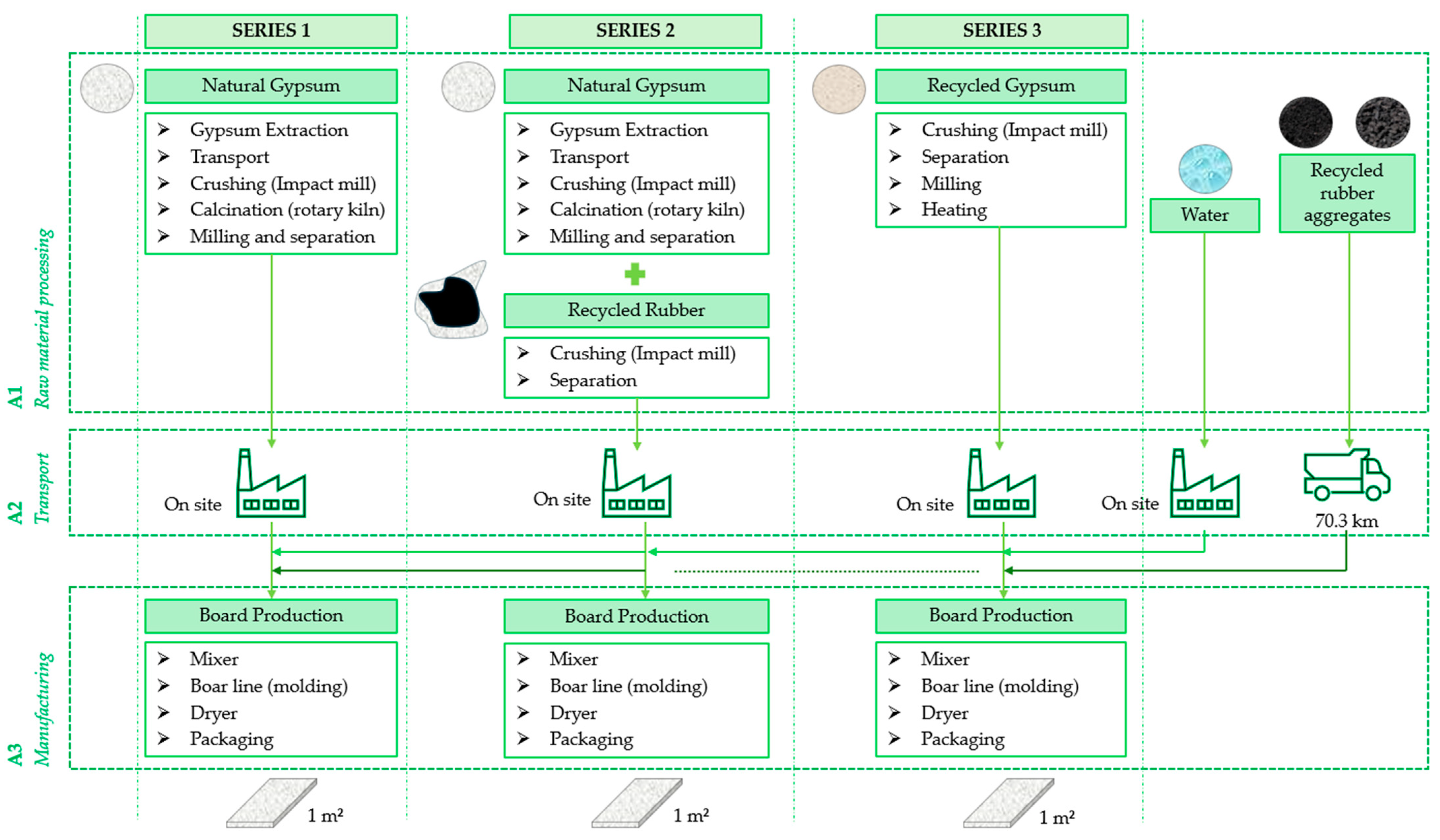

2.4. Environmental Performance Assessment

2.4.1. Declared Unit and System Boundaries

2.4.2. Inventory Analysis

2.4.3. Impact Assessment

3. Results and Discussion

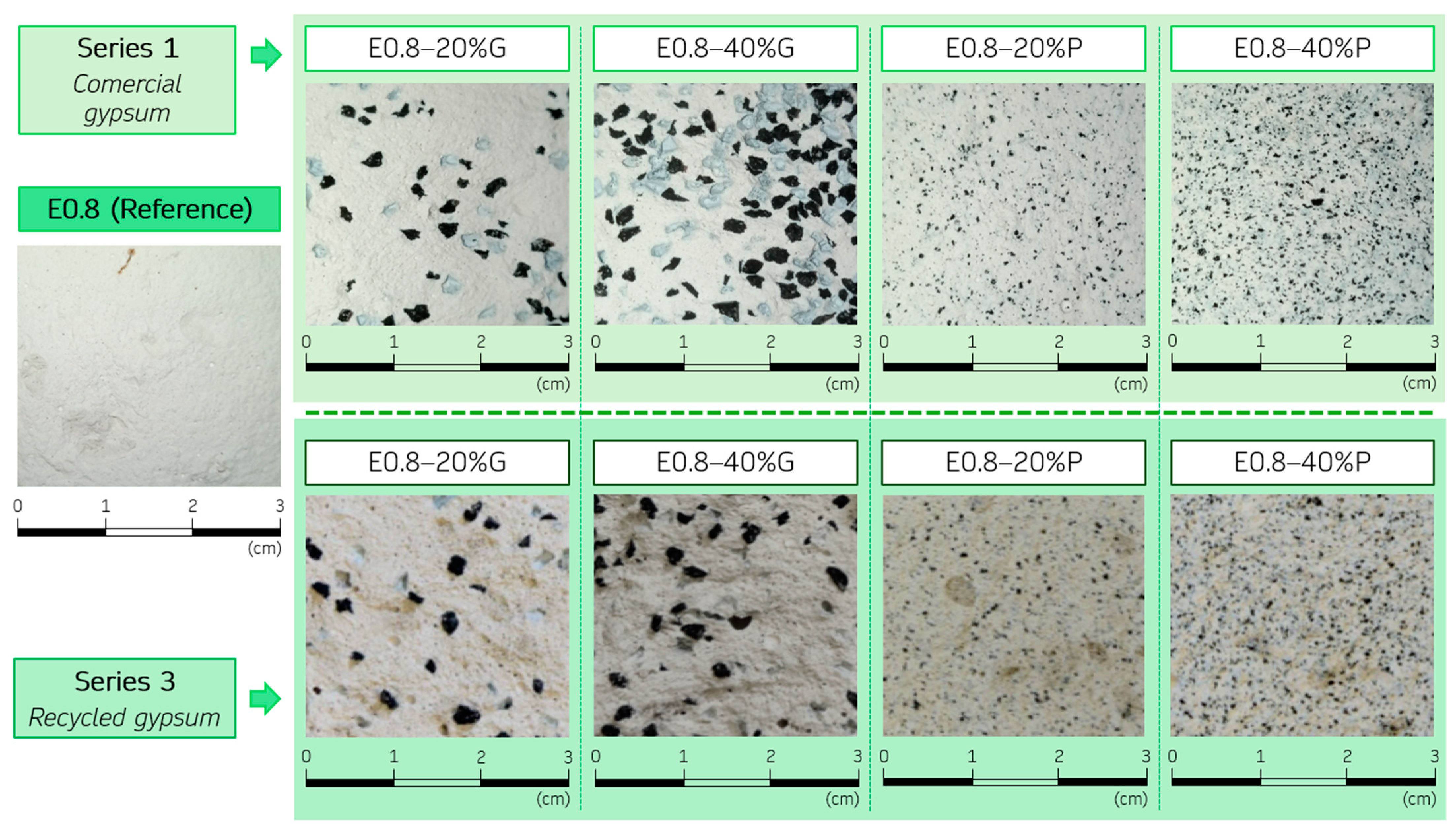

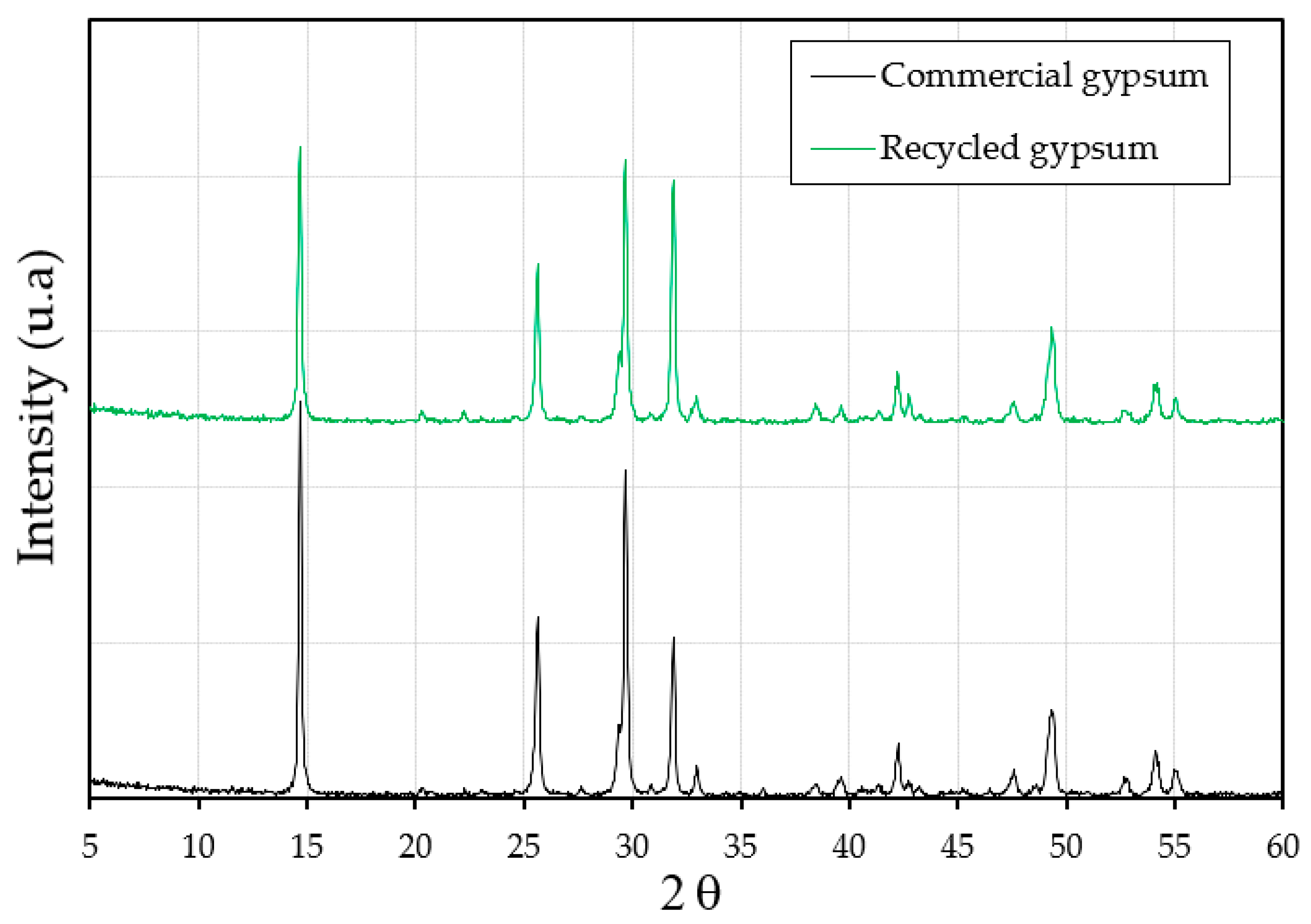

3.1. Physicochemical Characterisation

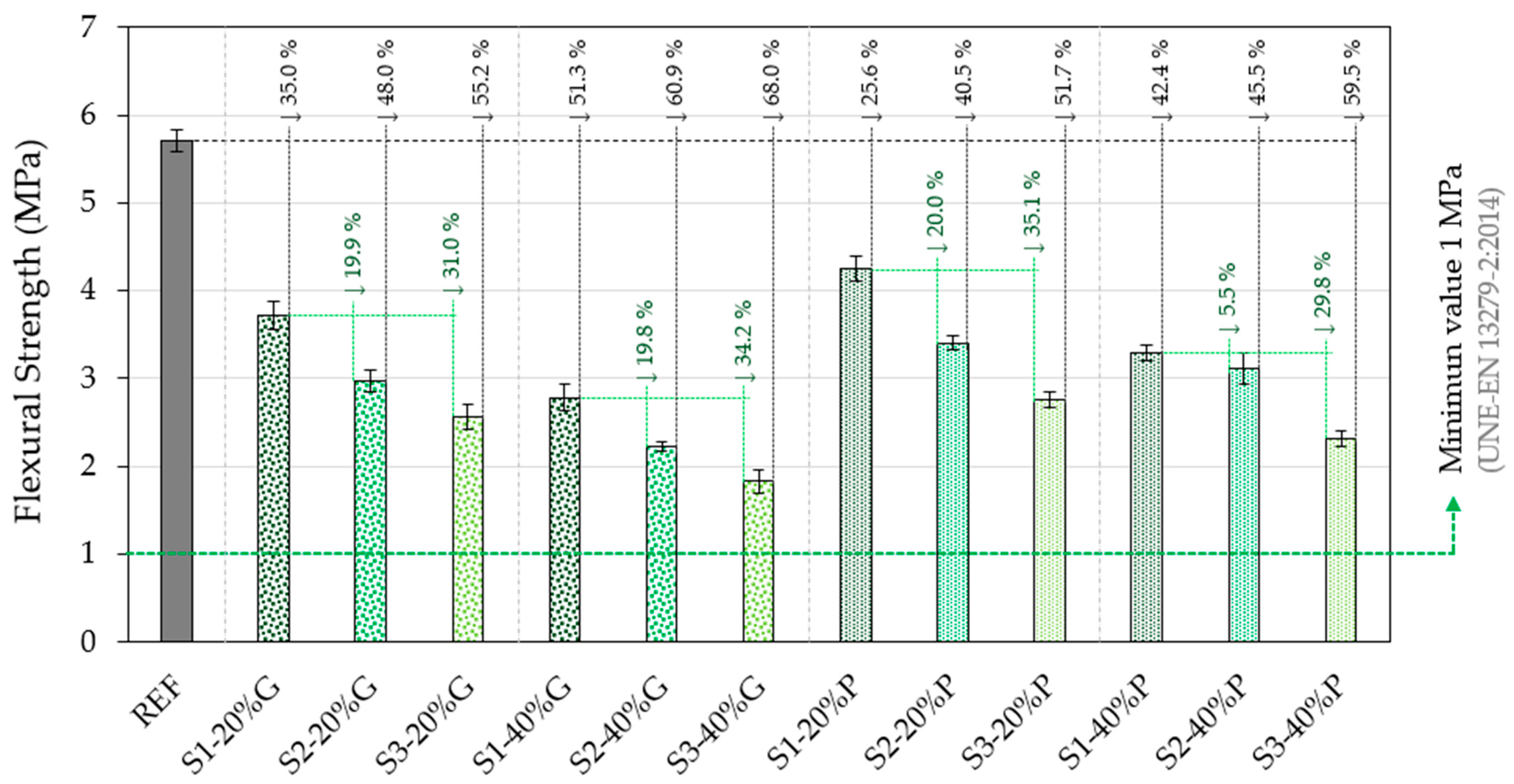

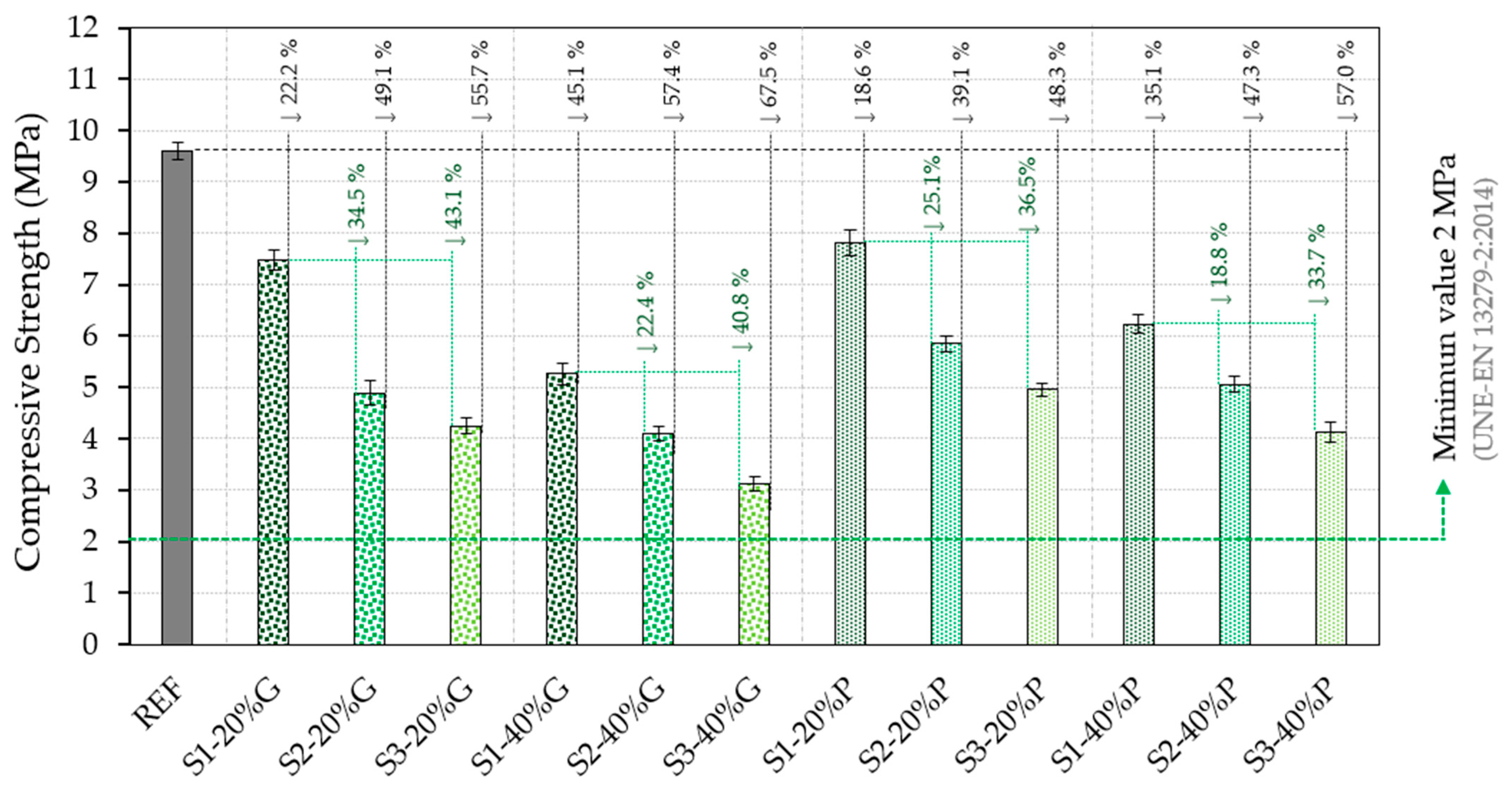

3.2. Mechanical Characterisation

3.3. Environmental Impact Analysis

4. Conclusions

- The recycling process of the gypsum material used (180 °C for 24 h) has proved to be effective for transforming the dihydrate into new hemihydrate to form the composites produced in Series 3. However, in the diffractogram of both raw materials, a lower crystalline intensity can be observed in the recycled composite compared to the commercial gypsum.

- All the composites produced, regardless of the recycled rubber content and the series analysed, exceeded the minimum flexural strength (1 MPa) recommended by the standard UNE-EN 13279-2. However, the resistance decreased progressively in the compounds of Series 2 and 3 with respect to Series 1, which was made with commercial gypsum. In fact, the composites of Series 3 showed flexural strengths which were, on average, 30% lower than their Series 1 counterparts. This means the composites which contained a greater proportion of recycled rubber aggregates (40% substitution by volume) had lower strength than the reference sample, which contained about 60%.

- Similar behaviour was observed for the same composites after the compression test; nevertheless, all of the composites exceeded the minimum value established in the standard guidelines, which was 2 MPa.

- Regarding SEM analysis of the compounds of Series 2 and 3 that underwent recycling as part of their manufacturing process, good integration of the residue in the matrix was observed with the formation of dihydrate crystals around the ELT aggregates. However, higher porosity was also observed in the samples, especially in the compounds of Series 3. This higher porosity could explain their lower mechanical strength.

- LCA has revealed the environmental benefit derived from these recycling processes. For all the environmental impact indicators, a decrease in emissions was achieved with respect to the reference plaster, reaching up to 60% in the case of S3-40%P in terms of CO2 release. Only for the ADP_FF indicator was a worse environmental performance obtained for the composites made with recycled material, as these require a greater amount of non-renewable energy during their manufacturing process, which can be attributed to the process of obtaining the rubber aggregates. However, in any case, the results obtained are encouraging and demonstrate the need to focus on recycled raw materials when developing building materials.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abbas-Abadi, M.S.; Kusenberg, M.; Shirazi, H.M.; Goshayeshi, B.; Van Geem, K.M. Towards full recyclability of end-of-life tires: Challenges and opportunities. J. Clean. Prod. 2022, 374, 134036. [Google Scholar] [CrossRef]

- Arulrajah, A.; Mohammadinia, A.; Maghool, F.; Horpibulsuk, S. Tire derived aggregates as a supplementary material with recycled demolition concrete for pavement applications. J. Clean. Prod. 2019, 230, 129–136. [Google Scholar] [CrossRef]

- Tafreshi, S.N.M.; Amiri, A.; Dawson, A.R. Sustainable use of End-of-Life-Tires (ELTs) in a vibration isolation system. Constr. Build. Mater. 2023, 405, 133316. [Google Scholar] [CrossRef]

- Dziejarski, B.; Hernández-Barreto, D.F.; Moreno-Piraján, J.C.; Giraldo, L.; Serafin, J.; Knutsson, P.; Andersson, K.; Krzyżyńska, R. Upgrading recovered carbon black (rCB) from industrial-scale end-of-life tires (ELTs) pyrolysis to activated carbons: Material characterization and CO2 capture abilities. Environ. Res. 2024, 247, 118169. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Barrios, A.M.; Morón, C. Water Resistance Analysis of New Lightweight Gypsum-Based Composites Incorporating Municipal Solid Waste. J. Compos. Sci. 2024, 8, 393. [Google Scholar] [CrossRef]

- Zabaniotou, A.; Antoniou, N.; Bruton, G. Analysis of good practices, barriers and drivers for ELTs pyrolysis industrial application. Waste Manag. 2014, 34, 2335–2345. [Google Scholar] [CrossRef]

- Al-Salem, S.M. Valorisation of End of Life Tyres (ELTs) in a Newly Developed Pyrolysis Fixed-Bed Batch Process. Process Saf. Environ. Prot. 2020, 138, 167–175. [Google Scholar] [CrossRef]

- Lavagna, L.; Colucci, G.; Pavese, M. Effect of oxidation of end-of-life tire rubber as aggregate substitute in cement mortars. Results Mater. 2024, 24, 100642. [Google Scholar] [CrossRef]

- Basik, A.A.; Sanglier, J.-J.; Yeo, C.T.; Sudesh, K. Microbial Degradation of Rubber: Actinobacteria. Polymers 2021, 13, 1989. [Google Scholar] [CrossRef]

- Pinto, N.; Fioriti, C.; Akasaki, J.; Acunha, T.; Okimoto, F. Performance of plaster composites incorporating rubber tire particles. Rev. Ing. Construcción 2020, 35, 216–232. [Google Scholar] [CrossRef]

- Lozano-Díez, R.V.; López-Zaldívar, Ó.; Herrero-del-Cura, S.; Mayor-Lobo, P.L.; Hernández-Olivares, F. Mechanical Behaviour of Plaster Composites Based on Rubber Particles from End-of-Life Tires Reinforced with Carbon Fibres. Materials 2021, 14, 3979. [Google Scholar] [CrossRef] [PubMed]

- Ferrández, D.; Álvarez, M.; Zaragoza-Benzal, A.; Santos, P. Eco-Design and Characterization of Sustainable Lightweight Gypsum Composites for Panel Manufacturing including End-of-Life Tyre Wastes. Materials 2024, 17, 635. [Google Scholar] [CrossRef]

- Meddah, A.; Laoubi, H.; Bederina, M. Effectiveness of using rubber waste as aggregates for improving thermal performance of plaster-based composites. Innov. Infrastruct. Solut. 2020, 5, 61. [Google Scholar] [CrossRef]

- Castellón, F.; Ayala, M.; Lanzón, M. Influence of tire rubber waste on the fire behaviour of gypsum coatings of construction and structural elements. Mater. Construcción 2022, 72, e275. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Santos, P.; Atanes-Sánchez, E. Development and characterization of new lightweight waste-based plaster composites for building applications. J. Build. Eng. 2024, 96, 110525. [Google Scholar] [CrossRef]

- Charai, M.; Oualid Mghazli, M.; Channouf, S.; El hammouti, A.; Jagadesh, P.; Moga, L.; Mezrhab, A. Lightweight waste-based gypsum composites for building temperature and moisture control using coal fly ash and plant fibres. Constr. Build. Mater. 2023, 393, 132092. [Google Scholar] [CrossRef]

- Rodrigo-Bravo, A.; Calderón, V.; Alameda, L.; Arroyo, R.; Gutiérrez-González, S. Eco-efficiency and economic assessment of gypsum-based precast with polymeric waste: A case study. Case Stud. Constr. Mater. 2024, 20, e03052. [Google Scholar] [CrossRef]

- Aguilera-Benito, P.; Morales-Segura, M.; Caballol, D.; Porras-Amores, C. Thermal and acoustic properties of new plasterboard composites with additions of cigarette butt waste. Constr. Build. Mater. 2023, 402, 133050. [Google Scholar] [CrossRef]

- Doleželová, M.; Krejsová, J.; Scheinherrová, L.; Keppert, M.; Vimmrová, A. Investigation of environmentally friendly gypsum based composites with improved water resistance. J. Clean. Prod. 2022, 370, 133278. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Diaz-Velilla, J.P.; Zúñiga-Vicente, J.A. Manufacture and characterisation of a new lightweight plaster for application in wet rooms under circular economy criteria. Case Stud. Constr. Mater. 2023, 19, e02380. [Google Scholar] [CrossRef]

- Ferrández, D.; Zaragoza-Benzal, A.; Barrak, E.; Santos, P.; Rodrigues, C. Upcycling expanded polyethylene waste for novel composite materials: Physico-mechanical, hygrothermal and life cycle assessment. Results Eng. 2024, 24, 103535. [Google Scholar] [CrossRef]

- Tèebwaoga Sina, A.; Ait Brahim, J.; Ben Ali, B.; Achiou, B.; Haneklaus, N.; Beniazza, R. Securing gypsum demand in cement industry by gypsum by-products: Current challenges and prospects. Mater. Today Sustain. 2024, 28, 101034. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; de Brito, J.; Flores-Colen, I.; Pereira, M.F.C.; Rubio de Hita, P. Influence of gypsum wastes on the workability of plasters: Heating process and microstructural analysis. J. Build. Eng. 2020, 29, 101143. [Google Scholar] [CrossRef]

- Erbs, A.; Nagalli, A.; Querne de Carvalho, K.; Mymrin, V.; Hermes Passig, F.; Mazer, W. Properties of recycled gypsum from gypsum plasterboards and commercial gypsum throughout recycling cycles. J. Clean. Prod. 2018, 183, 1314–1322. [Google Scholar] [CrossRef]

- Erbs, A.; Nagalli, A.; de Carvalho, K.Q.; Mazer, W.; Erbs, M.d.M.; Paz, D.H.; Lafayette, K.P. Development of plasterboard sheets exclusively from waste. J. Build. Eng. 2021, 44, 102524. [Google Scholar] [CrossRef]

- Puerto, J.D.; Uribe, S.; Ayala, L.; Padilla, A.; Rodriguez, A. Reliability of Reusing Gypsum Flat Board Grinded Waste as a Conventional Plaster Replacement for Buildings. Sustainability 2024, 16, 7889. [Google Scholar] [CrossRef]

- Li, Z.; Xu, K.; Peng, J.; Wang, J.; Zhang, J.; Li, Q. Influence of the Heating Temperature and Fineness on the Hydration and Mechanical Property of Recycled Gypsum Plaster. Adv. Mater. Sci. Eng. 2021, 2021, 7520378. [Google Scholar] [CrossRef]

- Weimann, K.; Adam, C.; Buchert, M.; Sutter, J. Environmental Evaluation of Gypsum Plasterboard Recycling. Minerals 2021, 11, 101. [Google Scholar] [CrossRef]

- Santos, T.; Wulani Luijten, N.; Santos Silva, A.; Dinis Silvestre, J.; Faria, P. Earthen plasters hygrothermal and mechanical performance: Effect of adding recycled gypsum from plasterboards and raw hemihydrate. J. Build. Eng. 2024, 98, 111407. [Google Scholar] [CrossRef]

- Jafari, A.; Sadghian, P. Influence of biochar and recycled gypsum on the strength and microstructure of conventional and sustainable cementitious composites. Constr. Build. Mater. 2023, 408, 133715. [Google Scholar] [CrossRef]

- European Council. European Green Deal. Available online: https://www.consilium.europa.eu/es/policies/green-deal/ (accessed on 26 December 2024).

- Merino, M.d.R.; Moreira, C.G.; Sáez, P.V. Mechanical behaviour of a gypsum material with additions of recycled waste from absorbent hygienic products. Constr. Build. Mater. 2023, 367, 130247. [Google Scholar] [CrossRef]

- Saint-Gobain Placo Ibérica, S.A. IBERYOLA E35. Available online: https://www.placomat.com/ficha-tecnica/PL114.pdf (accessed on 12 November 2024).

- Reglamento (UE) nº 305/2011 del Parlamento Europeo y del Consejo. Available online: https://www.boe.es/buscar/doc.php?id=DOUE-L-2011-80721 (accessed on 12 November 2024).

- UNE-EN 13279-1:2009; Gypsum Binders and Gypsum Plasters—Part 1: Definitions and Requirements. Asociacion Espanola de Normalizacion: Madrid, Spain, 2009.

- SIGNUS ECOVALOR, S.L. Available online: https://www.signus.es/esquema-reciclaje/ (accessed on 13 November 2024).

- Herrero, S.; Mayor, P.; Hernández-Olivares, F. Influence of proportion and particle size gradation of rubber from end-of-life tires on mechanical, thermal and acoustic properties of plaster–rubber mortars. Mater. Des. 2013, 47, 633–642. [Google Scholar] [CrossRef]

- López-Zaldívar, O.; Lozano-Díez, R.; Herrero del Cura, S.; Mayor-Lobo, P.; Hernández- Olivares, F. Effects of water absorption on the microstructure of plaster with end-of-life tire rubber mortars. Constr. Build. Mater. 2017, 150, 558–567. [Google Scholar] [CrossRef]

- Morón, A.; Ferrández, D.; Saiz, P.; Vega, G.; Morón, C. Influence of Recycled Aggregates on the Mechanical Properties of Synthetic Fibres-Reinforced Masonry Mortars. Infrastructures 2021, 6, 84. [Google Scholar] [CrossRef]

- Canal de Isabel II. Available online: https://www.canaldeisabelsegunda.es/calidad-del-agua (accessed on 12 November 2024).

- UNE-EN 13279-2:2014; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. Asociacion Espanola de Normalizacion: Madrid, Spain, 2014.

- Yi, P.; Du, H.; Chai, C.; Li, Y.; Hu, Y.; Sun, X.; Liu, W.; Xing, F. Potential of desulfurized gypsum as a sulfate alternative in preparing solid waste-based limestone calcined clay cement (LC3) and its effects on early properties. J. Build. Eng. 2024, 98, 111335. [Google Scholar] [CrossRef]

- Gordon, A.M.; Barrio, M.I.P.; Escamilla, A.C.; Matilla, A.L. From waste to resource: Exploring the recyclability and performance of gypsum-graphene nanofibre composites. Resour. Conserv. Recycl. Adv. 2024, 23, 200222. [Google Scholar] [CrossRef]

- Feng, H.; Zhao, J.; Holberg, A.; Habert, G. Where to focus? Developing a LCA impact category selection tool for manufacturers of building materials. J. Clean. Prod. 2023, 405, 136936. [Google Scholar] [CrossRef]

- Paula Junior, A.C.; Jacinto, C.; Oliveira, T.M.; Polisseni, A.E.; Brum, F.M.; Teixeira, E.R.; Mateus, R. Characterisation and Life Cycle Assessment of Pervious Concrete with Recycled Concrete Aggregates. Crystals 2021, 11, 209. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Mateus, R.; Camões, A.; Branco, F.G. Quality and durability properties and life-cycle assessment of high volume biomass fly ash mortar. Constr. Build. Mater. 2019, 197, 195–207. [Google Scholar] [CrossRef]

- Pedreño-Rojas, M.A.; Fořt, J.; Černý, R.; Rubio-de-Hita, P. Life cycle assessment of natural and recycled gypsum production in the Spanish context. J. Clean. Prod. 2020, 253, 120056. [Google Scholar] [CrossRef]

- Romero-Gómez, M.I.; Silva, R.V.; de Brito, J.; Flores-Colen, I. Prototype of alveolar gypsum blocks with plastic waste addition for partition walls: Physico-mechanical, water-resistance and life cycle assessment. J. Clean. Prod. 2023, 432, 139810. [Google Scholar] [CrossRef]

- Zaragoza-Benzal, A.; Ferrández, D.; Santos, P.; Morón, C. Recovery of End-of-Life Tyres and Mineral Wool Waste: A Case Study with Gypsum Composite Materials Applying Circular Economy Criteria. Materials 2023, 16, 243. [Google Scholar] [CrossRef] [PubMed]

- Villanueva, L.; García Santos, A. Manual Del Yeso; CIE Inversiones Editoriales Dossat-2000, S.L.: Madrid, Spain, 2001. [Google Scholar]

- Strydom, C.A.; Potgieter, J.H. Dehydration behaviour of a natural gypsum and a phosphogypsum during milling. Thermochem. Acta 1999, 332, 89–96. [Google Scholar] [CrossRef]

- Fleck, W.E.P.; Jones, M.H.; Kuntze, R.A.; McAdie, H.G. The differential thermal analysis of natural and synthetic hidrates of calcium sulphate. Can. J. Chem. 1960, 38, 936–943. [Google Scholar] [CrossRef]

- Serna, A.; del Río, M.; Palomo, J.G.; González, M. Improvement of gypsum plaster strain capacity by the addition of rubber particles from recycled tyres. Constr. Build. Mater. 2012, 35, 633–641. [Google Scholar] [CrossRef]

- Álvarez-Dorado, M.; Ferrández, D.; Guijarro-Miragaya, P.; Zaragoza-Benzal, A. Fire behaviour of plaster composite materials lightened with perlite and superabsorbent polymers. DYNA 2022, 98, 197–201. [Google Scholar] [CrossRef] [PubMed]

- Barroso, L.d.S.; Cherene, M.G.P.; Xavier, G.d.C.; de Azevedo, A.R.G.; Vieira, C.M.F. Bibliometric study of the application of gypsum residues and by-products in Portland cement and mortar. Constr. Build. Mater. 2023, 409, 134072. [Google Scholar] [CrossRef]

- Valentini, F.; Pegoretti, A. End-of-life options of tyres. A review. Adv. Ind. Eng. Polym. Res. 2022, 5, 203–213. [Google Scholar] [CrossRef]

- Zhu, C.; Zhang, J.; Yi, W.; Cao, W.; Peng, J.; Liu, J. Research on degradation mechanisms of recycled building gypsum. Constr. Build. Mater. 2018, 173, 540–549. [Google Scholar] [CrossRef]

- Ardebili, A.A.; Sáez, P.V.; Cortina, M.G.; Cruz, D.M.T.; Sáiz, Á.R.; Atanes-Sánchez, E. Mechanical characterization of gypsum mortars with waste from the automotive sector. Constr. Build. Mater. 2023, 370, 130675. [Google Scholar] [CrossRef]

- Zerin, N.H.; Rasul, M.G.; Jahirul, M.I.; Sayem, A.S.M. End-of-life tyre conversion to energy: A review on pyrolysis and activated carbon production processes and their challenges. Sci. Total Environ. 2023, 905, 166981. [Google Scholar] [CrossRef] [PubMed]

- Tamizhdurai, P.; Arthi, P.; Mangesh, V.; Krishnan, P.S.; Kumar, N.S.; Saravanan, P.; Subramani, A.; Sasikumar, P.; Alotibi, M.F.; Alreshaidan, S.B.; et al. Clean energy technology: Hydro-processing of waste tyre pyrolysis oil (WTPO) to diesel fuel in a continuous reactor using Co/SBA-15 catalyst. Appl. Energy Combust. Sci. 2025, 21, 100305. [Google Scholar] [CrossRef]

- SIGNUS Ecovalor, S.L. Aplicaciones de Los Neumáticos Reciclados. Available online: https://www.signus.es/aplicaciones-neumaticos-reciclados/ (accessed on 24 December 2024).

- Caro, D.; Lodato, C.; Damgaard, A.; Cristóbal, J.; Foster, G.; Flachenecker, F.; Tonini, D. Environmental and socio-economic effects of construction and demolition waste recycling in the European Unión. Sci. Total Environ. 2024, 908, 168295. [Google Scholar] [CrossRef] [PubMed]

- Jiménez Rivero, A.; Sathre, R.; García Navarro, J. Life cycle energy and material flow implications of gypsum plasterboard recycling in the European Unión. Resour. Conserv. Recycl. 2016, 108, 171–181. [Google Scholar] [CrossRef]

| Purity (%) | >92 | Water vapour diffusion (µ) | 6 |

| Granulometry (mm) | 0–0.2 | Flexural strength (MPa) | >3 |

| pH | 6 | Fire reaction | Euroclass A1 (Regulation (UE) n° 305/2011 [34]) |

| λ (W/m·K) | 0.30 | Classification | Tipo A (According to UNE-EN 13279-1:2009 [35]) |

| Physical Properties | Chemical Properties [38] | ||

|---|---|---|---|

| Density (kg/m3) | 1250 | Ketone extract (%) | 10–20 |

| Grain morphology | Angular | Polymers (%) | 40–55 |

| Humidity | <0.75% by mass | Natural rubber (%) | 21–42 |

| Textile content (%) | <0.50% by mass | Carbon black (%) | 30–38 |

| Steel content (%) | <0.25% by mass | Ashes (%) | 3–7 |

| Designation | Gypsum (g) | Water (g) | ELT Rubber Aggregates | |||

|---|---|---|---|---|---|---|

| Series 1 | Series 2 | Series 3 | Granulate (g) | Powder (g) | ||

| REF | ― | ― | 1000 | 800 | ― | ― |

| S1-20%G | S2-20%G | S3-20%G | 800 | 640 | 40 | ― |

| S1-40%G | S2-40%G | S3-40%G | 600 | 480 | 80 | ― |

| S1-20%P | S2-20%P | S3-20%P | 800 | 640 | ― | 75 |

| S1-40%P | S2-40%P | S3-40%P | 600 | 480 | ― | 150 |

| Designation | Gypsum (t) | Water (t) | ELT Rubber Aggregates | ||||

|---|---|---|---|---|---|---|---|

| Series 1 | Series 2 | Series 3 | Granulate (t) | Powder (t) | Transport (km) | ||

| REF | ― | ― | 0.01627604 | 0.01302083 | ― | ― | ― |

| S1-20%G | S2-20%G | S3-20%G | 0.01302083 | 0.01041667 | 0.000651042 | ― | 70.3 |

| S1-40%G | S2-40%G | S3-40%G | 0.00976563 | 0.00781250 | 0.001302083 | ― | 70.3 |

| S1-20%P | S2-20%P | S3-20%P | 0.01302083 | 0.01041667 | ― | 0.00122070 | 70.3 |

| S1-40%P | S2-40%P | S3-40%P | 0.00976563 | 0.00781250 | ― | 0.00244141 | 70.3 |

| Environmental Indicators | Units |

|---|---|

| Global Warming Potential (GWP) | (kg CO2 eq) |

| Ozone Layer Depletion (ODP) | (kg CFC-11 eq) |

| Acidification Potential (AP) | (kg SO2 eq) |

| Eutrophication Potential (EP) | (kg PO4 eq) |

| Formation Potential of Tropospheric Ozone (POCP) | (kg C2H4 eq) |

| Abiotic Depletion Potential of Fossil Resources (ADP_FF) | (MJ eq) |

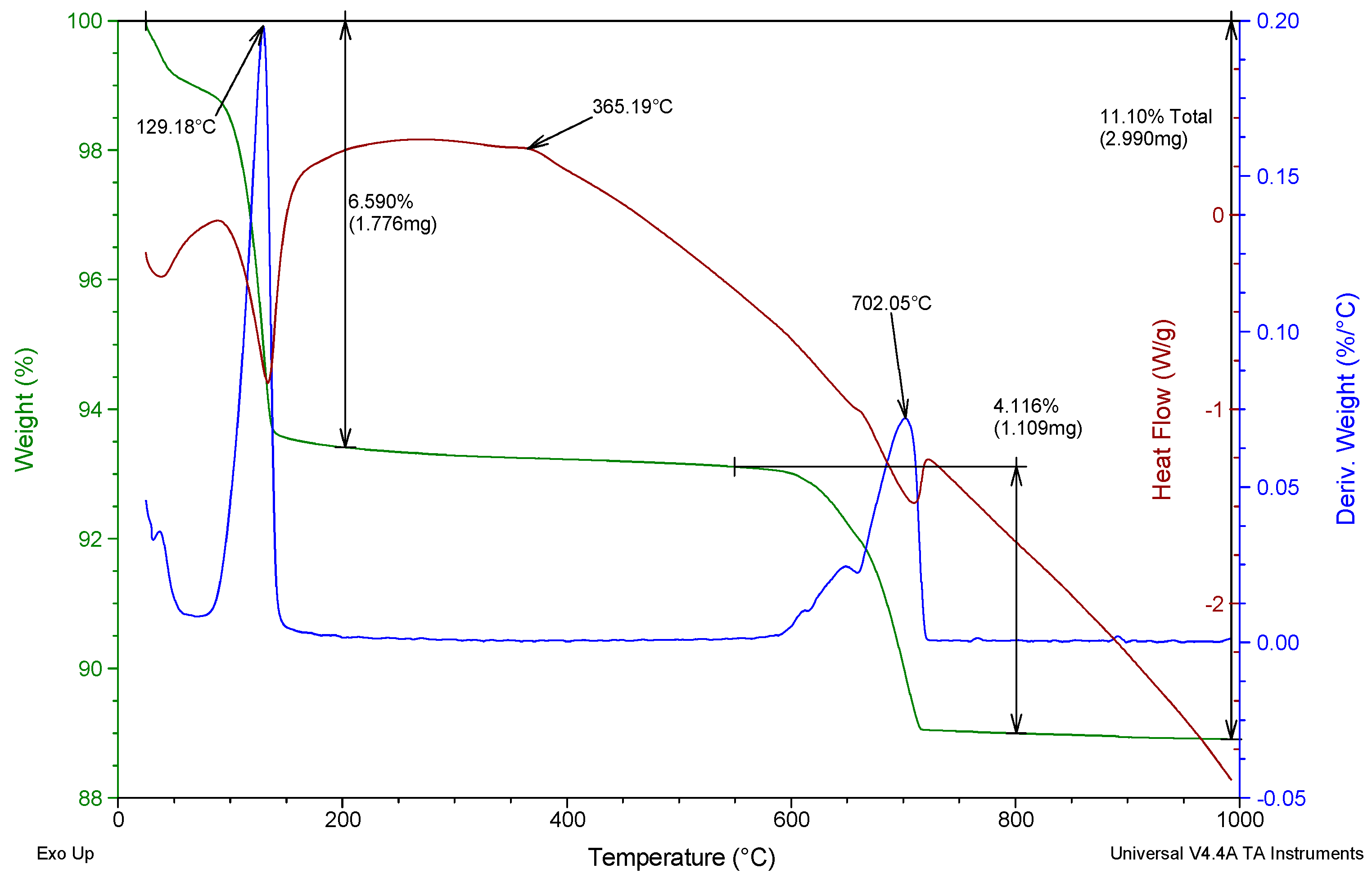

| Sample | Total Mass Loss (%) | Interval (°C) | Maximum Temperature (°C) | Partial Mass Loss (%) | Associated Thermal Effects | Comments (*) |

|---|---|---|---|---|---|---|

| Commercial gypsum | 11.100 | <200 | 129.18 | 6.590 | Endothermic | HH to anhydrite |

| 200–550 | 365.19 | - | Exothermic | Phase transition of anhydrite | ||

| 550–800 | 702.05 | 4.116 | Endothermic | CaCO3 to CaO | ||

| Recycled gypsum | 9.651 | <200 | 125.14 | 6.177 | Endothermic | HH to anhydrite |

| 200–550 | 365.86 | - | Exothermic | Phase transition of anhydrite | ||

| 550–800 | 681.88 | 2.832 | Endothermic | CaCO3 to CaO |

| Reference | Rubber Aggregate Size (mm) | Addition | Other Additions | Flexural Strength (MPa) | Compression Strength (MPa) |

|---|---|---|---|---|---|

| [53] | 0.60–2.50 | 5% wt. | — | 2.56 | 3.97 |

| [37] | 0.00–0.60 | 34% wt. | — | 0.78 | 0.55 |

| [38] | 2.50–4.00 | 50% wt. | — | 1.50 | 1.56 |

| [11] | 0.06–0.80 | 5% wt. | Carbon fibre | 5.92 | 7.77 |

| [54] | 2.50–10.00 | 20% vol. | — | 3.55 | 5.68 |

| [20] | 0.00–0.60 | 1% wt. | — | 4.96 | 7.36 |

| [10] | 0.60–1.20 | 15% wt. | — | 0.89 | 4.98 |

| [13] | 0.00–1.00 | 50% vol. | Dune sand | 1.30 | 2.10 |

| Values obtained in this research: | |||||

| Series 1 | 1.0–2.5 | 40% vol. | — | 2.78 | 5.27 |

| 0.0–0.8 | 40% vol. | — | 3.25 | 6.23 | |

| Series 2 | 1.0–2.5 | 40% vol. | — | 2.23 | 4.09 |

| 0.0–0.8 | 40% vol. | — | 3.11 | 5.06 | |

| Series 3 | 1.0–2.5 | 40% vol. | — | 1.83 | 3.12 |

| 0.0–0.8 | 40% vol. | — | 2.31 | 4.13 | |

| Series | GWP (kg CO2 eq) | ODP (kg CFC-11 eq) | AP (kg SO2 eq) | POCP (kg C2H4 eq) | EP (kg PO4 eq) | ADP_FF (MJ) |

|---|---|---|---|---|---|---|

| REF | 5.28 | 1.50 × 10−7 | 2.32 × 10−2 | 1.14 × 10−3 | 9.97 × 10−3 | 5.42 × 10 |

| S1-20%G | 4.56 | 1.26 × 10−7 | 1.94 × 10−2 | 9.64 × 10−4 | 8.19 × 10−3 | 6.48 × 10 |

| S1-40%G | 3.85 | 1.02 × 10−7 | 1.56 × 10−2 | 7.89 × 10−4 | 6.41 × 10−3 | 7.55 × 10 |

| S1-20%P | 4.59 | 1.26 × 10−7 | 1.95 × 10−2 | 9.67 × 10−4 | 8.20 × 10−3 | 7.95 × 10 |

| S1-40%P | 3.89 | 1.03 × 10−7 | 1.57 × 10−2 | 7.96 × 10−4 | 6.43 × 10−3 | 1.05 × 102 |

| S2-20%G | 4.68 | 1.28 × 10−7 | 2.00 × 10−2 | 9.86 × 10−4 | 8.32 × 10−3 | 6.81 × 10 |

| S2-40%G | 3.97 | 1.04 × 10−7 | 1.62 × 10−2 | 8.11 × 10−4 | 6.53 × 10−3 | 7.87 × 10 |

| S2-20%P | 4.17 | 9.49 × 10−8 | 1.80 × 10−2 | 8.82 × 10−4 | 7.87 × 10−3 | 5.88 × 10 |

| S2-40%P | 3.93 | 8.55 × 10−8 | 1.57 × 10−2 | 7.89 × 10−4 | 6.44 × 10−3 | 9.50 × 10 |

| S3-20%G | 2.74 | 8.04 × 10−8 | 1.45 × 10−2 | 6.66 × 10−4 | 6.97 × 10−3 | 2.97 × 10 |

| S3-40%G | 2.08 | 6.08 × 10−8 | 1.10 × 10−2 | 5.04 × 10−4 | 5.24 × 10−3 | 4.31 × 10 |

| S3-20%P | 2.45 | 6.42 × 10−8 | 1.35 × 10−2 | 6.10 × 10−4 | 6.73 × 10−3 | 3.13 × 10 |

| S3-40%P | 2.13 | 6.15 × 10−8 | 1.11 × 10−2 | 5.10 × 10−4 | 5.26 × 10−3 | 7.24 × 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ferrández, D.; Zaragoza-Benzal, A.; Atanes-Sánchez, E.; Merillas, B.; Mateus, R.; Santos, P. Study of Different Recycling Approaches for Gypsum-Based Composites with Recycled Rubber Aggregates. Buildings 2025, 15, 577. https://doi.org/10.3390/buildings15040577

Ferrández D, Zaragoza-Benzal A, Atanes-Sánchez E, Merillas B, Mateus R, Santos P. Study of Different Recycling Approaches for Gypsum-Based Composites with Recycled Rubber Aggregates. Buildings. 2025; 15(4):577. https://doi.org/10.3390/buildings15040577

Chicago/Turabian StyleFerrández, Daniel, Alicia Zaragoza-Benzal, Evangelina Atanes-Sánchez, Beatriz Merillas, Ricardo Mateus, and Paulo Santos. 2025. "Study of Different Recycling Approaches for Gypsum-Based Composites with Recycled Rubber Aggregates" Buildings 15, no. 4: 577. https://doi.org/10.3390/buildings15040577

APA StyleFerrández, D., Zaragoza-Benzal, A., Atanes-Sánchez, E., Merillas, B., Mateus, R., & Santos, P. (2025). Study of Different Recycling Approaches for Gypsum-Based Composites with Recycled Rubber Aggregates. Buildings, 15(4), 577. https://doi.org/10.3390/buildings15040577