Development and Performance of Coconut Fibre Gypsum Composites for Sustainable Building Materials

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Binder

2.1.2. Water

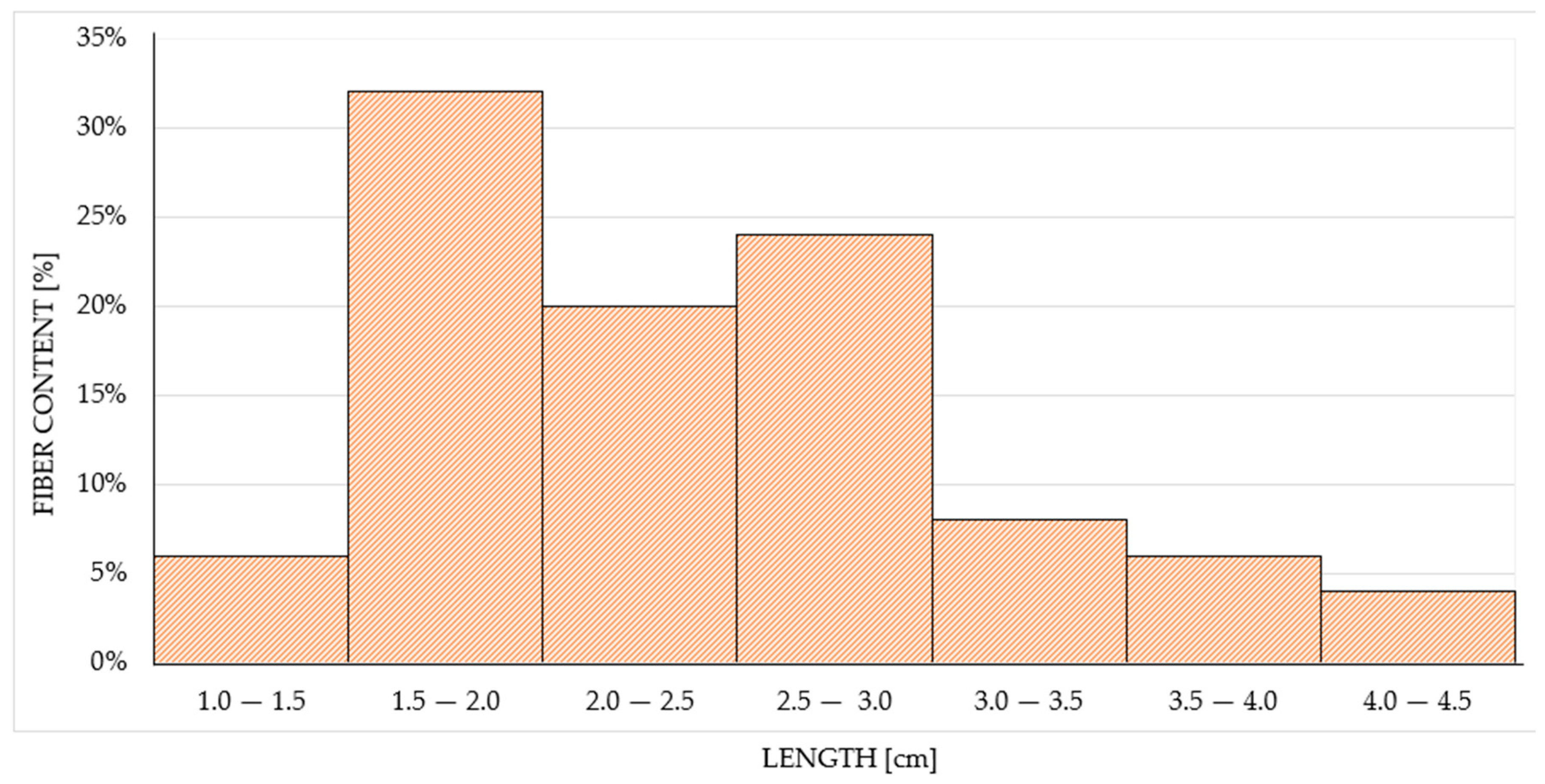

2.1.3. Coconut Fibre

2.1.4. Kraft Paper

2.1.5. Expanded Cork Agglomerate

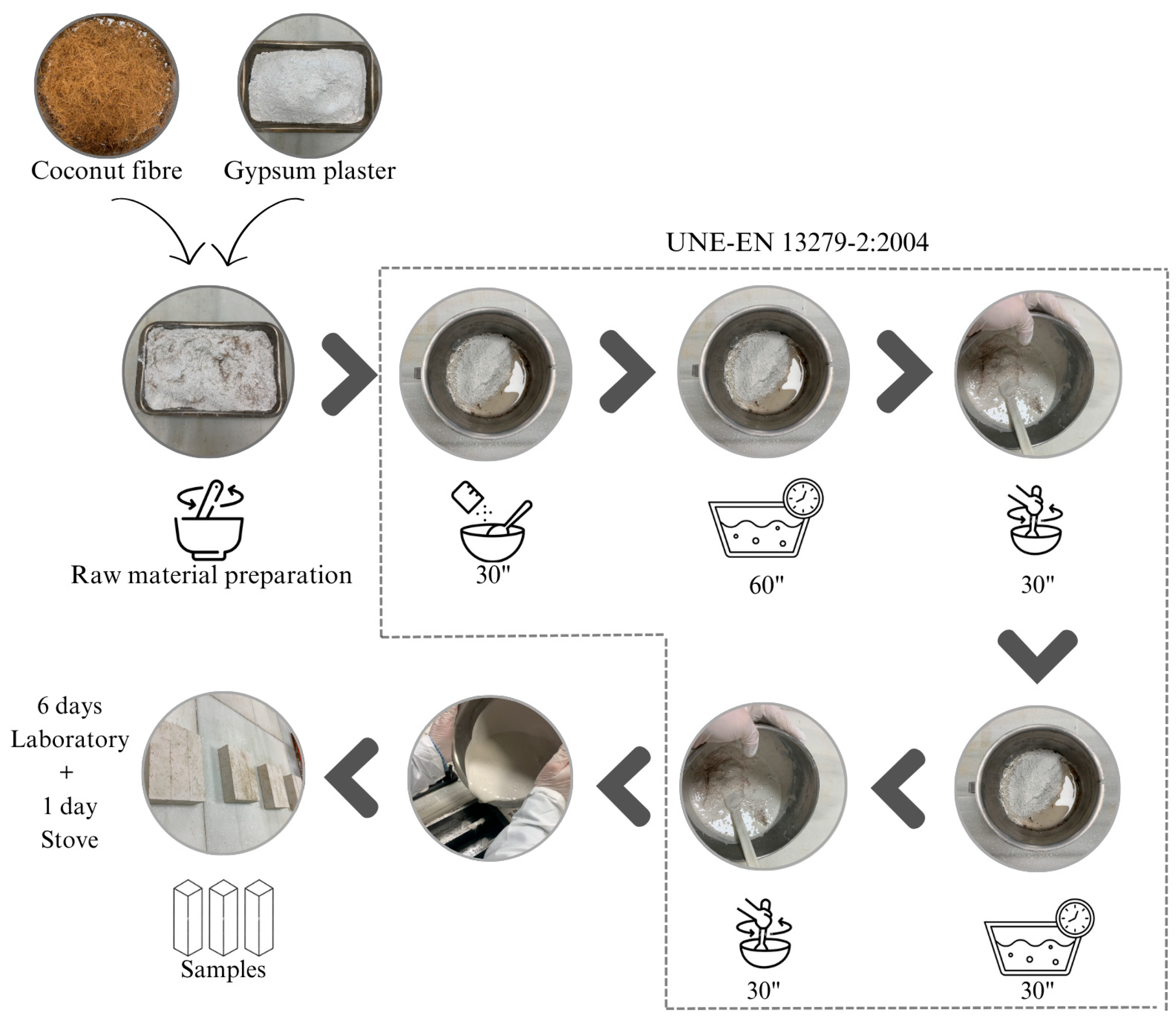

2.2. Sample Preparation

2.3. Experimental Programme

2.3.1. Physical Characterisation

2.3.2. Mechanical Characterisation

2.3.3. Water Properties

2.3.4. Physical and Mechanical Properties of Panels

3. Results and Discussion

3.1. Physical and Mechanical Characterisation

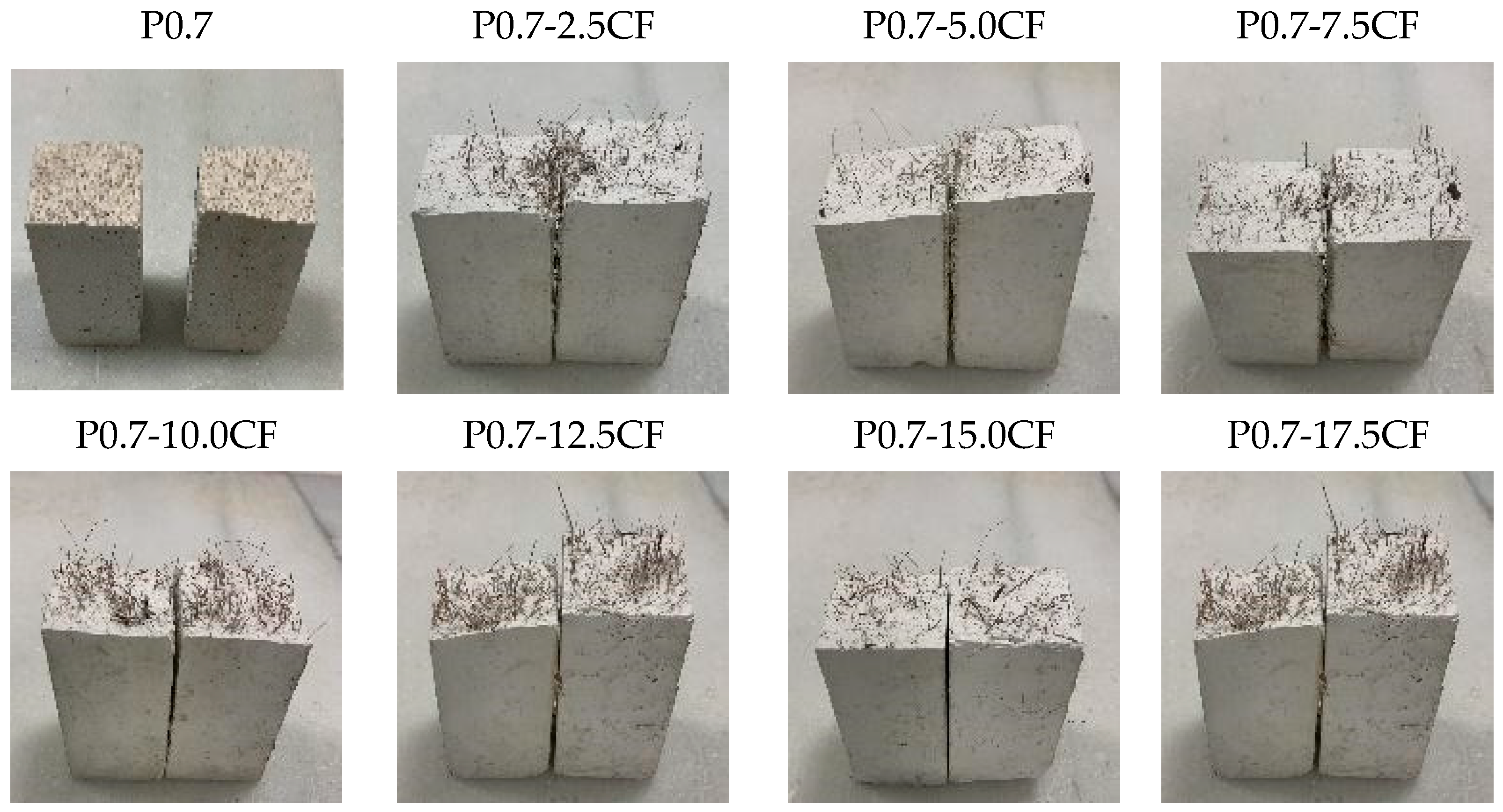

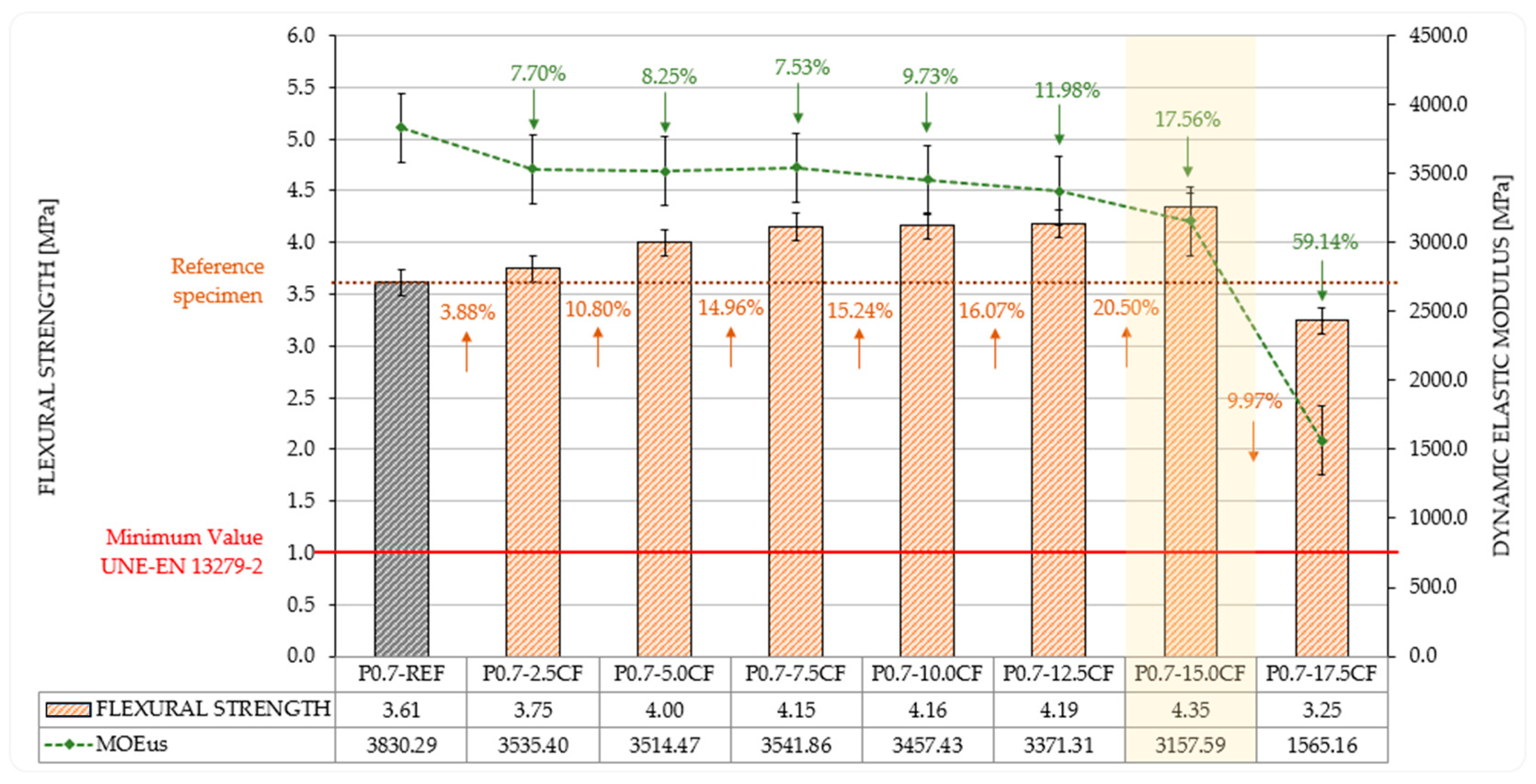

3.1.1. Flexural Strength and Dynamic Elastic Modulus (MOEus)

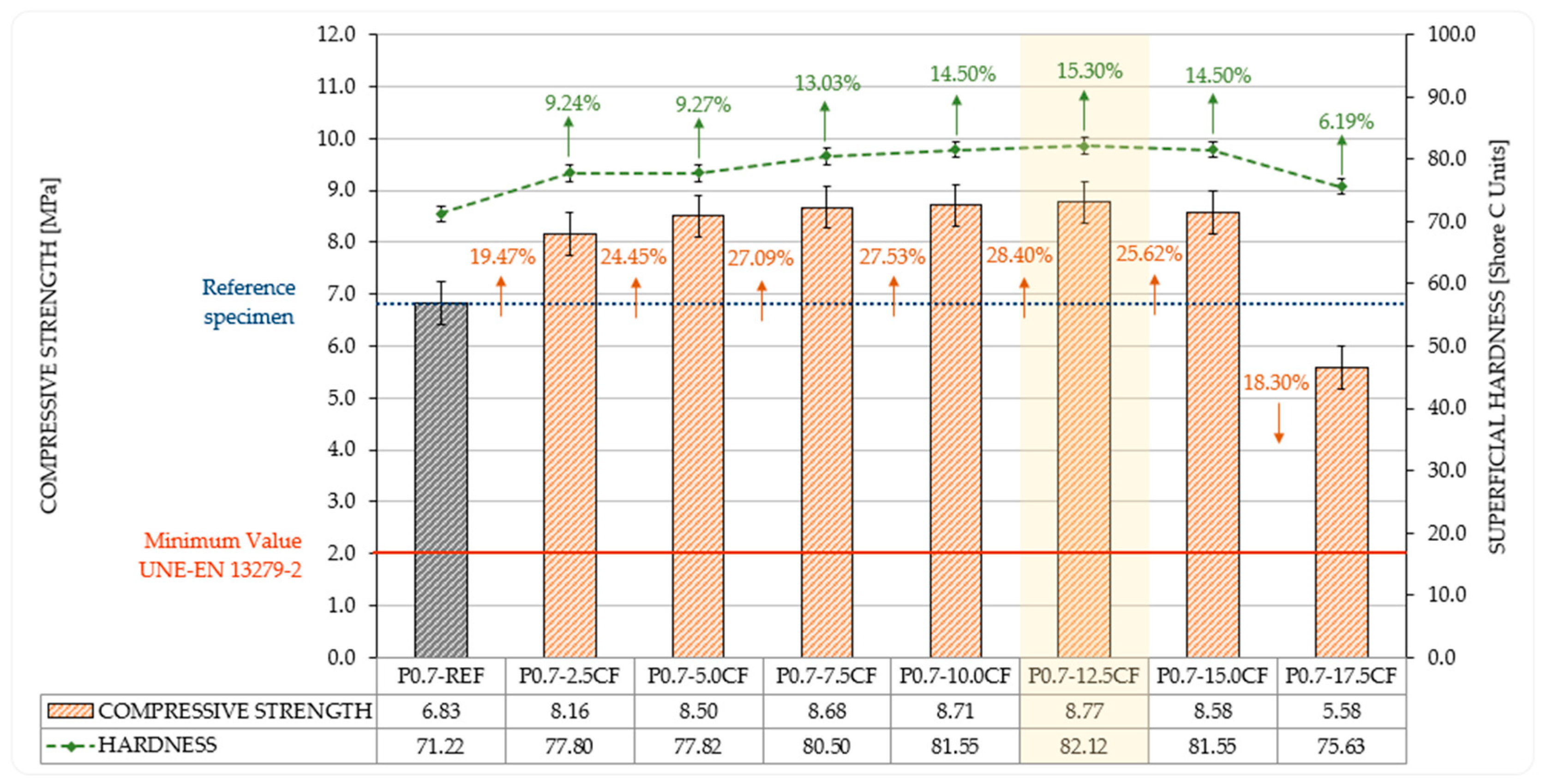

3.1.2. Compressive Strength and Superficial Hardness

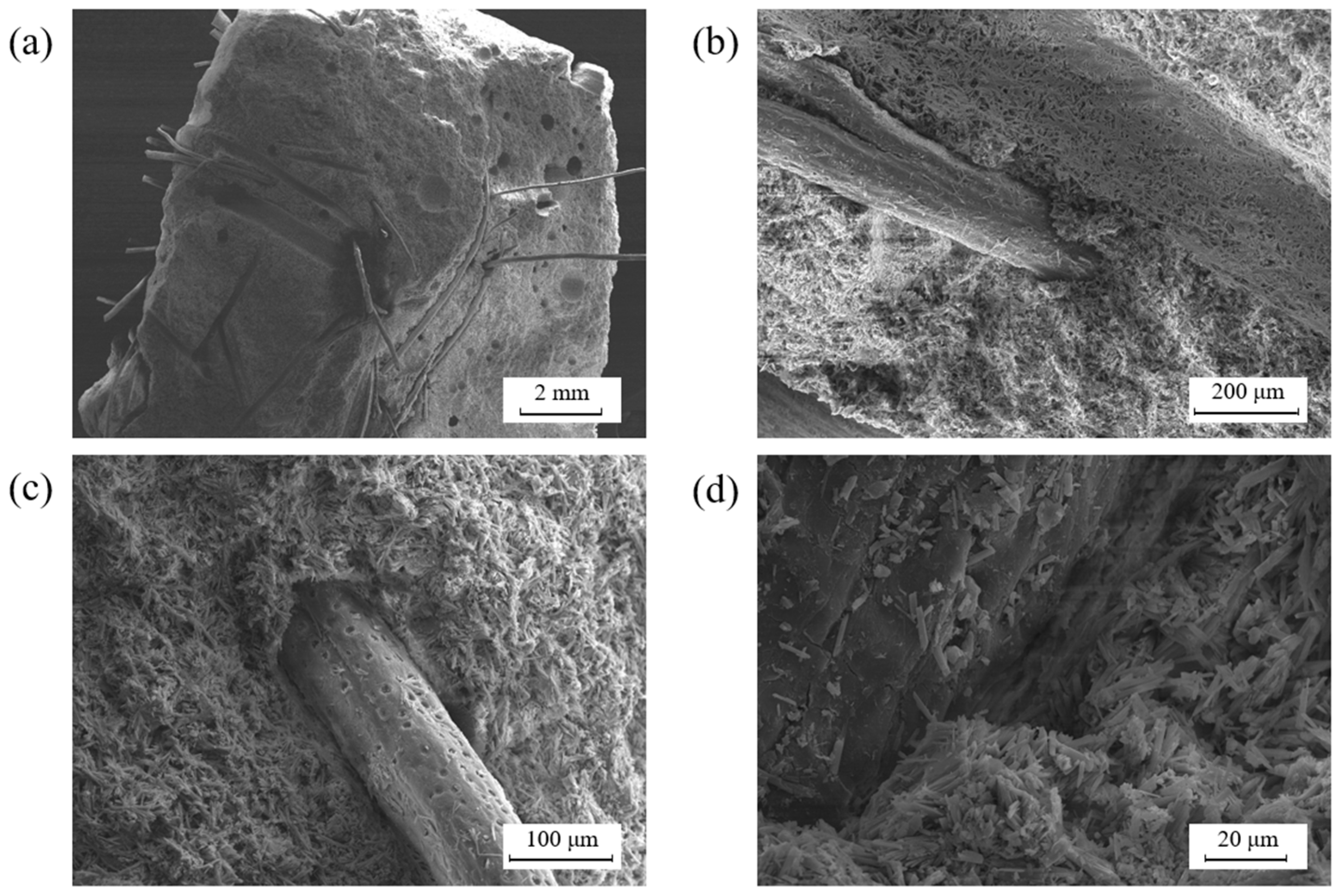

3.1.3. SEM Analysis

3.2. Water Properties

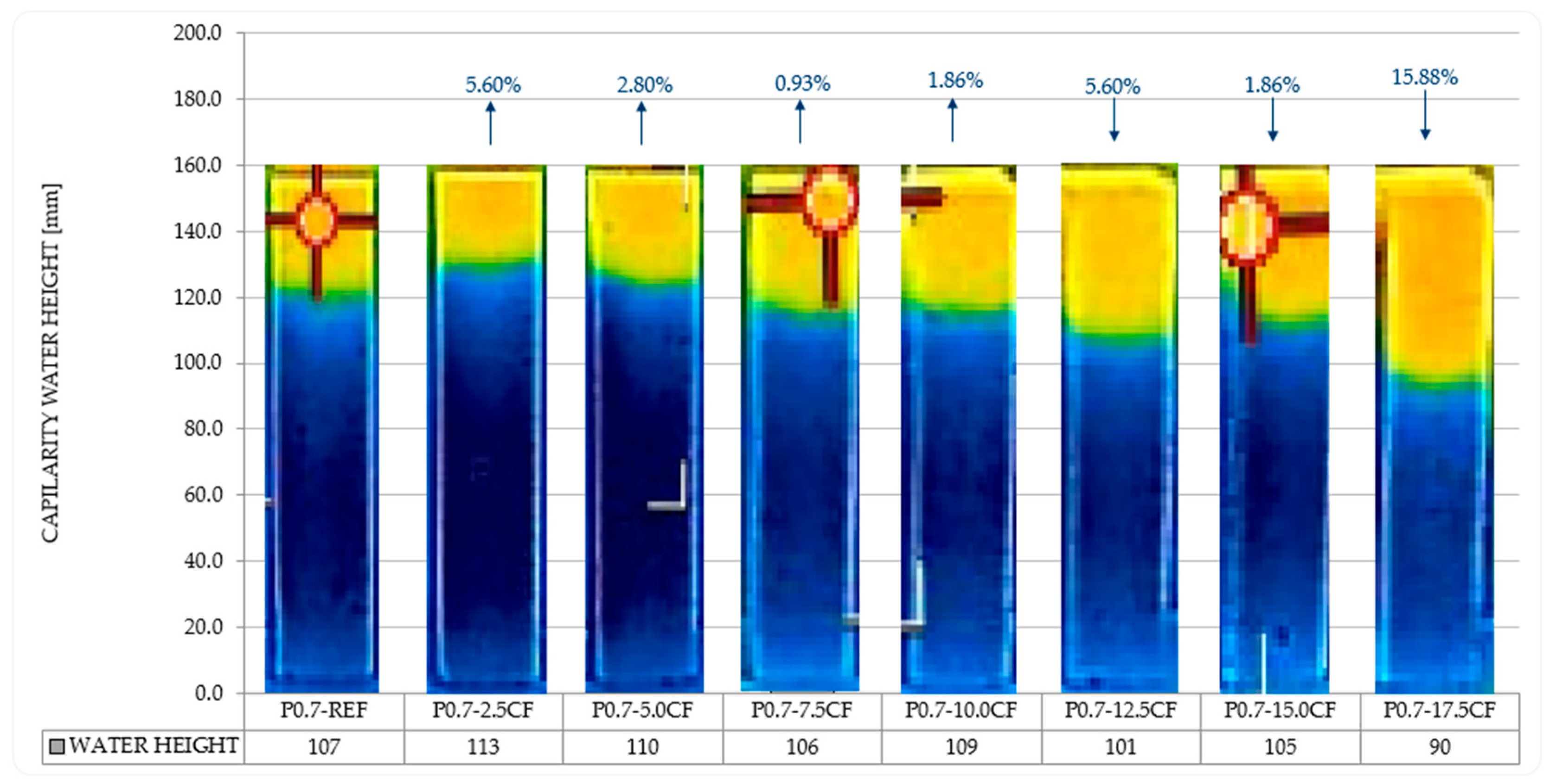

3.2.1. Capillary Water Absorption and Capillary Water Height

3.2.2. Total Water Absorption and Open Porosity

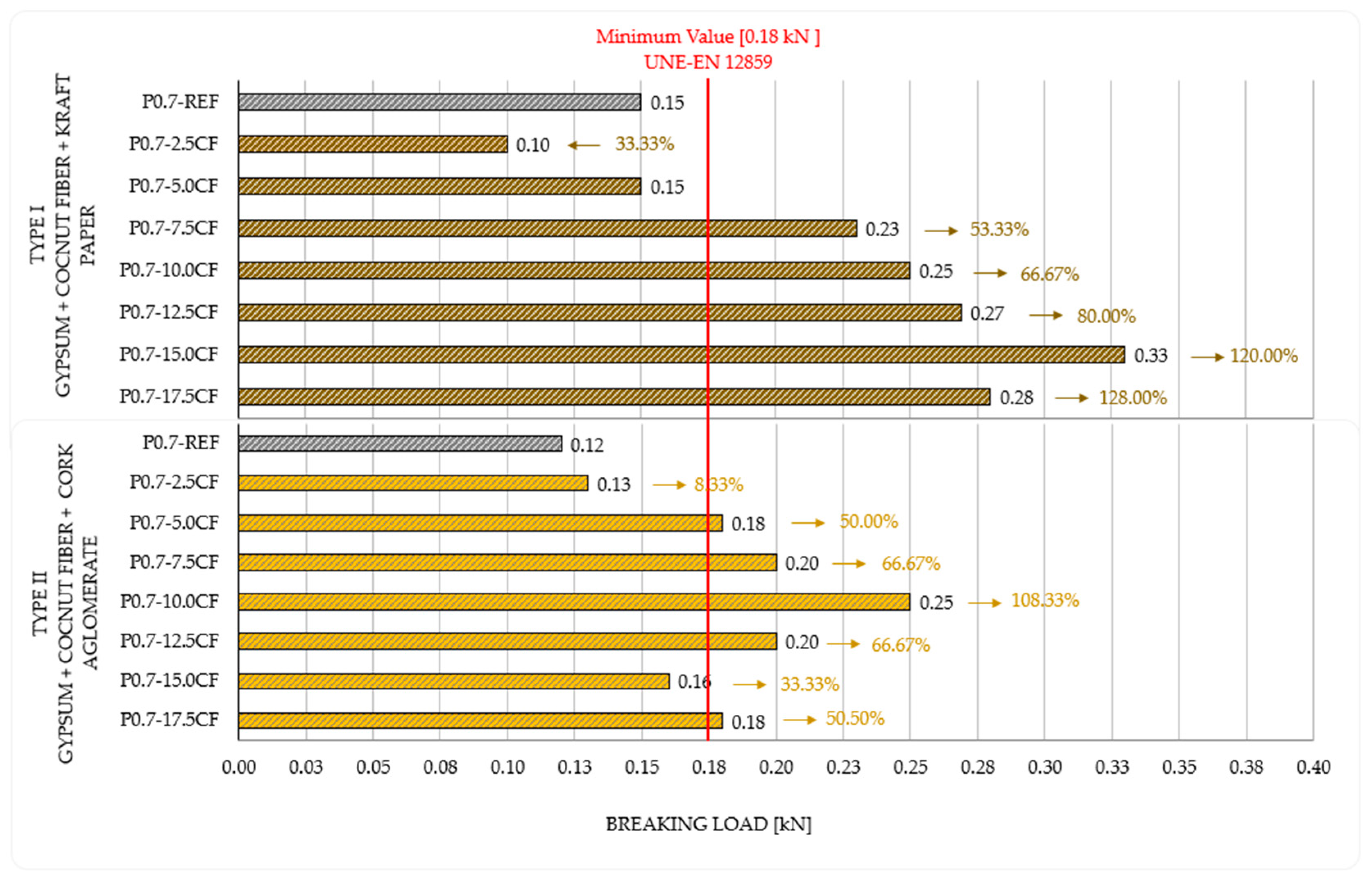

3.3. Application in Precast

3.3.1. Flexural Strength and Impact Hardness

3.3.2. Thermal Conductivity and Bulk Density

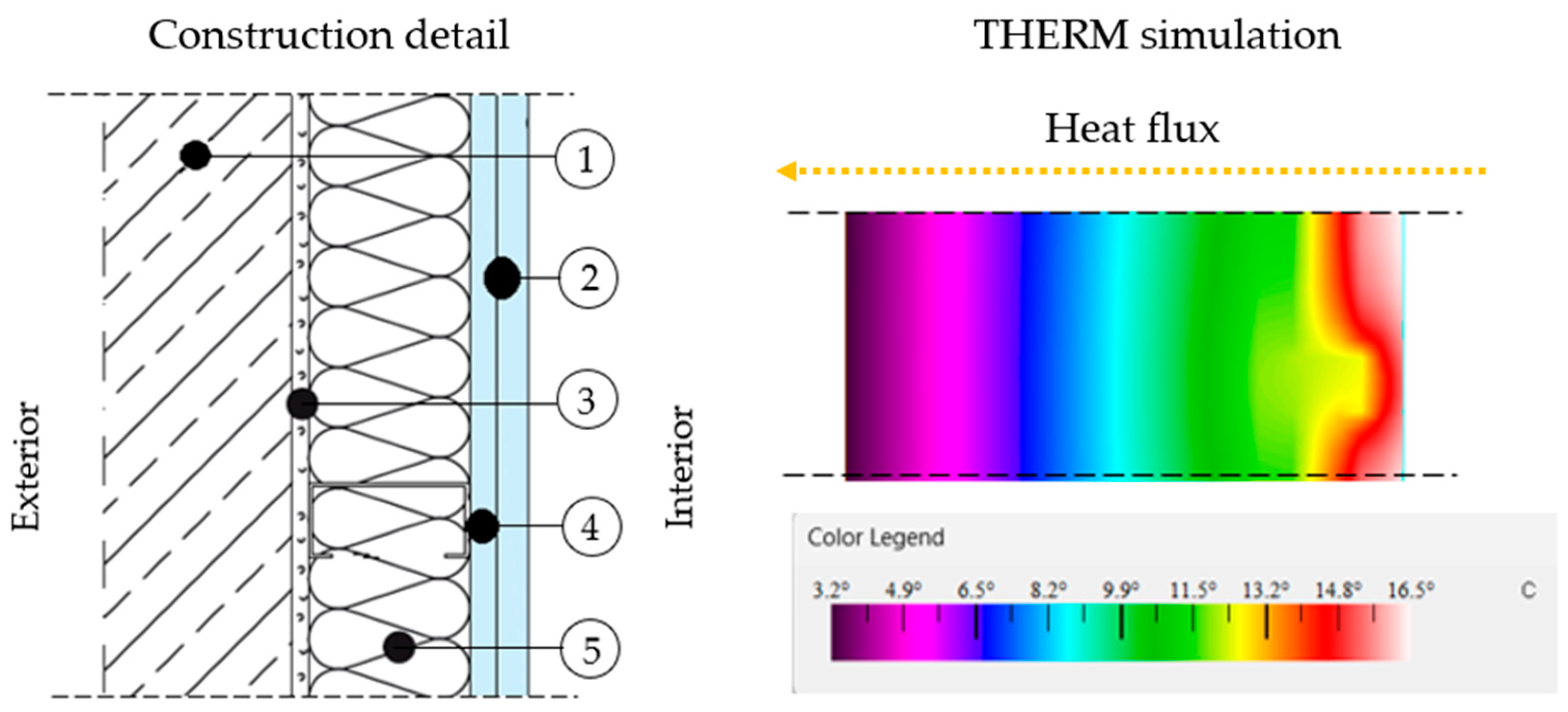

3.3.3. Thermal Performance Simulation

3.4. Critical Reflection and Implications for Industry

4. Conclusions

- The increase in fibre content led to a reduction in bulk density. The P0.7-17.5CF specimen, with higher fibre content, presented a 9.46% lower density than the reference sample, evidencing the fibres’ effectiveness in decreasing the composite’s total weight.

- Simultaneously with the increase in fibre, the surface hardness increased; however, an excessive addition of fibre, as in specimen P0.7-17.5CF, decreased surface hardness, attributed to increased porosity in the composite material.

- A progressive decrease in the dynamic modulus of elasticity was observed with increasing fibre content; in particular, the P0.7-17.5CF specimen presented the most significant difference (33.94%) compared to the reference specimen.

- Fibre reinforcement in the composites improved the flexural strength, reaching a maximum of 4.35 MPa with a 20.50% improvement over the reference specimen, specimen P0.7-15.0CF. However, as in specimen P0.7-17.5CF, excessive fibre content reduced the load-carrying capacity.

- A progressive increase in compressive strength was achieved, reaching a maximum of 8.77 MPa in sample P0.7-12.5CF; however, when the fibre content exceeded the optimum level, as in sample P0.7-17.5CF, the compressive strength decreased by 18.30%, which is attributed to increased porosity and inhomogeneous fibre distribution.

- SEM images showed good mechanical bonding between the fibre and matrix, with strong adhesion preventing fibre slippage and reducing the possibility of brittle breakage. In addition, the formation of dihydrate crystals (CaSO4·2H2O) was observed at the fibre–matrix interface, confirming its good anchorage and integration. No damage was evidenced on the surface of the fibres, indicating that the kneading process does not affect their structural integrity.

- The incorporation of coconut fibre reduced the capillarity of the composite. In particular, adding 17.50% coconut fibre in the plaster matrix decreased the capillary height by 15.88% compared to the reference material. This reduction in water infiltration is attributed to the ability of the fibres to limit capillary spaces within the matrix, thus improving the hydrophobic properties of the material and its moisture resistance. In addition, increasing the coconut fibre content in the plaster matrix influences the composite’s water absorption and open porosity. Although total water absorption varies, it tends to stabilise at higher fibre levels, while open porosity decreases progressively with increasing fibre content, reaching its minimum value at composite P0.7-17.5CF. This reduction in pore volume suggests lower pore connectivity, which limits water accessibility and improves the hydrophobic properties of the material, making it less permeable.

- The incorporation of coconut fibre in the plaster panels significantly reduced their density, which in turn decreased the thermal conductivity and improved the insulating capacity of the material. In particular, the P0.7-15.0CF composite presented a 4.96% reduction in density compared to the reference, translating into a decreased thermal conductivity of 51.33%. In addition, coconut fibre in plaster improves the thermal efficiency of the rendering, with a reduction in the U-Factor and an increase in the R-value. The best option is the P0.7-17.5CF dosage since it has the lowest U-Factor and the highest thermal resistance. Although the thermal improvement is not drastic, this combination of properties could generate significant energy savings in heating.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations Environment Programme. Global Status Report for Buildings and Construction: Beyond foundations: Mainstreaming Sustainable Solutions to Cut Emissions from the Buildings Sector; United Nations Environment Programme: Nairobi, Kenya, 2024. [Google Scholar] [CrossRef]

- Santos, P.; Lopes, P.; Abrantes, D. Thermal Performance of Load-Bearing, Lightweight, Steel-Framed Partition Walls Using Thermal Break Strips: A Parametric Study. Energies 2022, 15, 9271. [Google Scholar] [CrossRef]

- IEA. The Energy Efficiency Policy Package: Key Catalyst for Building Decarbonisation and Climate Action; IEA: Paris, France, 2023.

- World Green Building Council. Advancing Net Zero Status Report 2023; World Green Building Council: London, UK, 2023. [Google Scholar]

- Green Building Council España. Descarbonizar la Edificación en Todo su Ciclo de Vida—Guía Paso a Paso para Ciudades. 2023. Available online: https://gbce.es/wp-content/uploads/2024/05/roadmap-final_guia-paso-a-paso-para-ciudades-2.pdf (accessed on 26 May 2025).

- Könnölä, K.; Kangas, K.; Seppälä, K.; Mäkelä, M.; Lehtonen, T. Considering sustainability in cruise vessel design and construction based on existing sustainability certification systems. J. Clean. Prod. 2020, 259, 120763. [Google Scholar] [CrossRef]

- IEA Publications International Energy Agency. Energy Technology Perspectives 2023; IEA: Paris, France, 2023.

- Mordor Intelligence. Green Building Materials Market Size & Share Analysis. Growth Trends & Forecast (2025–2030). Green Building Materials—Market Size & Report. Available online: https://www.mordorintelligence.com/industry-reports/green-building-materials-market (accessed on 26 May 2025).

- United Nations Environment Programme. Building Materials and the Climate: Constructing a New Future; United Nations Environment Programme: Nairobi, Kenya, 2023. [Google Scholar] [CrossRef]

- Doleželová, M.; Scheinherrová, L.; Krejsová, J.; Keppert, M.; Černý, R.; Vimmrová, A. Investigation of gypsum composites with different lightweight fillers. Constr. Build. Mater. 2021, 297, 123791. [Google Scholar] [CrossRef]

- Global Gypsum. Global Gypsum Supply Top 10—2023. 2023. Available online: https://www.globalgypsum.com/magazine/articles/804-global-gypsum-supply-top-10-2023 (accessed on 26 May 2025).

- Mucha, M.; Mróz, P.; Kocemba, A. Polymer composites based on gypsum matrix. In Proceedings of the VIII International Conference on “Times of Polymers and Composites”, Naples, Italy, 19–23 June 2016; American Institute of Physics: College Park, MD, USA, 2016. [Google Scholar]

- Yu, Q.; Brouwers, H.J. Microstructure and mechanical properties of b-hemihydrate produced gypsum: An insight from its hydration process. Constr. Build. Mater. 2011, 25, 3149–3157. [Google Scholar] [CrossRef]

- Yıldızel, S.A.; Çarbaş, S. Mechanical performance comparison of glass and mono fibres added gypsum composites. Chall. J. Struct. Mech. 2018, 4, 9. [Google Scholar] [CrossRef]

- Al-Ridha, A.S.D.; Abbood, A.A.; Hussein, F.M.; Dheyab, L.S.; Abdullah, E.L.N.; Ali, E.H.Z.; Mohialdeen, E.M.S.; Abdulhussein, E.A.A. Effect of Chopped Sisal fibre (CSF) on enhancing the compressive strength of Local Plaster of Paris (LPOP). Mater. Today Proc. 2021, 47, 2575–2579. [Google Scholar] [CrossRef]

- Rivero, L. Fabricación de productos de base yeso y sus aplicaciones industriales. Bol. Soc. Esp. Cerám. Vidr. 1997, 36, 591–598. [Google Scholar]

- Iucolano, F.; Liguori, B.; Aprea, P.; Caputo, D. Thermo-mechanical behaviour of hemp fibres-reinforced gypsum plasters. Constr. Build. Mater. 2018, 185, 256–263. [Google Scholar] [CrossRef]

- del Río-Merino, M.; Vidales-Barriguete, A.; Piña-Ramírez, C.; Vitiello, V.; Santa Cruz-Astorqui, J.; Castelluccio, R. A review of the research about gypsum mortars with waste aggregates. J. Build. Eng. 2022, 45, 103338. [Google Scholar] [CrossRef]

- Sheng, D.D.C.V.; Ramegowda, N.S.; Guna, V.; Reddy, N. Groundnut shell and coir reinforced hybrid bio composites as alternative to gypsum ceiling tiles. J. Build. Eng. 2022, 57, 104892. [Google Scholar] [CrossRef]

- Aramwit, P.; Daniel Chin Vui Sheng, D.; Krishna Moorthy, G.; Guna, V.; Reddy, N. Rice husk and coir fibres as sustainable and green reinforcements for high performance gypsum composites. Constr. Build. Mater. 2023, 393, 132065. [Google Scholar] [CrossRef]

- Guna, V.; Yadav, C.; Maithri, B.R.; Ilangovan, M.; Touchaleaume, F.; Saulnier, B.; Grohens, Y.; Reddy, N. Wool and coir fibre reinforced gypsum ceiling tiles with enhanced stability and acoustic and thermal resistance. J. Build. Eng. 2021, 41, 102433. [Google Scholar] [CrossRef]

- Braiek, A.; Karkri, M.; Adili, A.; Ibos, L.; ben Nasrallah, S. Estimation of the thermophysical properties of date palm fibres/gypsum composite for use as insulating materials in building. Energy Build. 2017, 140, 268–279. [Google Scholar] [CrossRef]

- Désiré Omgba Betené, A.; Martoïa, F.; Dumont, P.J.J.; Ebanda Betené, F.; Ateba, A. Gypsum plaster composites reinforced with tropical fibre bundles extracted from Rhecktophyllum camerunense and Ananas comosus plants: Microstructure and mechanical performance. Constr. Build. Mater. 2023, 392, 131815. [Google Scholar] [CrossRef]

- Kuqo, A.; Mai, C. Mechanical properties of lightweight gypsum composites comprised of seagrass Posidonia oceanica and pine (Pinus sylvestris) wood fibres. Constr. Build. Mater. 2021, 282, 122714. [Google Scholar] [CrossRef]

- Iucolano, F.; Caputo, D.; Leboffe, F.; Liguori, B. Mechanical behavior of plaster reinforced with abaca fibres. Constr. Build. Mater. 2015, 99, 184–191. [Google Scholar] [CrossRef]

- Zidi, S.; Miraoui, I. Mechanical and morphological analysis of cellulose extracted from sisal fibres and their effect on bio-based composites mechanical properties. Funct. Compos. Struct. 2024, 6, 015008. [Google Scholar] [CrossRef]

- Alcaraz, J.S.; Belda, I.M.; Sanchis, E.J.; Gadea Borrell, J.M. Mechanical properties of plaster reinforced with yute fabrics. Compos. Part B Eng. 2019, 178, 107390. [Google Scholar] [CrossRef]

- Belayachi, N.; Hoxha, D.; Slaimia, M. Impact of accelerated climatic aging on the behavior of gypsum plaster-straw material for building thermal insulation. Constr. Build. Mater. 2016, 125, 912–918. [Google Scholar] [CrossRef]

- Ferrández, D.; Álvarez, M.; Zaragoza-Benzal, A.; Cobo-González, Á.; Santos, P. Development and Characterization of Innovative Hemp–Gypsum Composites for Application in the Building Industry. Appl. Sci. 2024, 14, 2229. [Google Scholar] [CrossRef]

- Wolfgang, S.; Narendra, R.; Soren, B.; Anand, R. Coir from Coconut Processing Waste as a Raw Material for Applications Beyond Traditional Uses. BioResources 2023, 18, 2187–2212. [Google Scholar] [CrossRef]

- IBERYOLA®. Iberyola® E-30/E35. Technical Sheet. 2023. Available online: https://www.placo.es/documents/fichas-tecnicas/ft-iberyola-es.pdf (accessed on 26 May 2025).

- UNE-EN 13279-1:2009; Gypsum Binders and Gypsum Plasters—Part 1: Definitions and Requirements. Asociación Española de Normalización: Madrid, Spain, 2009.

- Subdirección de Calidad de las Aguas. Características de Calidad de las Aguas. Análisis Completo; Canal de Isabel II: Madrid, Spain, 2023. [Google Scholar]

- TOPCIMENT. Fibratop. Technical Sheet. Available online: https://www.topciment.com/sheets/Fibras_Vidrio_es.pdf (accessed on 26 May 2025).

- TOPCIMENT. Fibratop PP. Technical Sheet. Available online: https://www.topciment.com/sheets/Fibras_Polipropileno_es.pdf (accessed on 26 May 2025).

- Sanou, I.; Bamogo, H.; Sory, N.; Gansoré, A.; Millogo, Y. Effect of the coconut fibres and cement on the physico-mechanical and thermal properties of adobe blocks. Heliyon 2024, 10, e38752. [Google Scholar] [CrossRef] [PubMed]

- ABRIGA NATURE. Fibra de Coco Natural. Technical Sheet. Available online: https://www.abriganature.com/galeria/articulos/ficha-t%C3%A9cnica---fibra-de-coco_12_1.pdf (accessed on 26 May 2025).

- Van Dam, J.E.G.; van den Oever, M.J.A.; Keijsers, E.R.P.; van der Putten, J.C.; Anayron, C.; Josol, F.; Peralta, A. Process for production of high density/high performance binderless boards from whole coconut husk. Part 2: Coconut husk morphology, composition and properties. Ind. Crops Prod. 2006, 24, 96–104. [Google Scholar] [CrossRef]

- Corgrap, S.A. Papel Kraft Natural 75 gr. Technical Sheet. 2019. Available online: https://embaling.com/productos/relleno-proteccion/22-p-apel-embalaje-carton/papel-kraft-75-gramos (accessed on 26 May 2025).

- Amorim Cork Solutions. Agglomerated Cork Resilient Layer for Impact Noise Insulation of Floating Screed. Technical Sheet. Available online: https://amorimcorksolutions.com/media/7705/mds_acousticork_u32_en.pdf (accessed on 26 May 2025).

- UNE-EN 13279-2:2014; Gypsum Binders and Gypsum Plasters—Part 2: Test Methods. Asociación Española de Estandarización: Madrid, Spain, 2014.

- UNE 102042:2023; Gypsum Plasters. Other Test Methods. Spanish Association for Standardization: Madrid, Spain, 2023.

- UNE-EN ISO 12680-1:2007; Methods of Test for Refractory Products—Part 1: Determination of Dynamic Young’s Modulus (MOE) by Impulse Excitation of Vibration (ISO 12680-1:2005). Spanish Association for Standardization: Madrid, Spain, 2007.

- UNE-EN 1925:1999; Natural Stone Test Methods—Determination of Water Absorption Coefficient by Capillarity. Spanish Association for Standardization: Madrid, Spain, 1999.

- UNE-EN 14617-1:2013; Agglomerated Stone—Test Methods—Part 1: Determination of Apparent Density and Water Absorption. Spanish Association for Standardization: Madrid, Spain, 2013.

- UNE-EN 1936:2007; Natural Stone Test Methods—Determination of Real Density and Apparent Density, and of Total and Open Porosity. Spanish Association for Standardization: Madrid, Spain, 2007.

- UNE-EN 12859:2012; Gypsum Blocks—Definitions, Requirements and Test Methods. Spanish Association for Standardization: Madrid, Spain, 2012.

- UNE-EN 14246:2007; Gypsum Elements for Suspended Ceilings—Definitions, Requirements and Test Methods. Spanish Association for Standardization: Madrid, Spain, 2007.

- UNE-EN 520:2005+A1:2010; Gypsum Plasterboards—Definitions, Requirements and Test Methods. Spanish Association for Standardization: Madrid, Spain, 2010.

- UNE-EN ISO 8990:1997; Thermal Insulation. Determination of Steady-State Thermal Transmission Properties. Calibrated and Guarded Hot Box (ISO 8990:1994). Spanish Association for Standardization: Madrid, Spain, 1997.

- Ministerio de Vivienda y Agenda Urbana. Documento Básico HE Ahorro de Energía. 14 June 2022. Available online: https://www.codigotecnico.org/pdf/Documentos/HE/DBHE.pdf (accessed on 26 May 2025).

- Rosell, J.R.; Cantalapiedra, I.R. Simple method of dynamic Young’s modulus determination in lime and cement mortars. Mater. Construcción 2011, 61, 39–48. [Google Scholar] [CrossRef]

- Ferrández, D.; Zaragoza-Benzal, A.; Barrak, E.; Santos, P.; Rodrigues, C. Upcycling expanded polyethylene waste for novel composite materials: Physico-mechanical, hygrothermal and life cycle assessment. Results Eng. 2024, 24, 103535. [Google Scholar] [CrossRef]

- Romero-Gómez, M.I.; Silva, R.V.; Costa-Pereira, M.F.; Flores-Colen, I. Thermal and mechanical performance of gypsum composites with waste cellulose acetate fibres. Constr. Build. Mater. 2022, 356, 129308. [Google Scholar] [CrossRef]

- Xu, R.; Lu, S.; Miao, J.; Tang, C.; Yu, J. Fibre-reinforced gypsum composites with ultra high ductility: Investigation of physical and mechanical properties. Constr. Build. Mater. 2024, 457, 139285. [Google Scholar] [CrossRef]

- Sahraoui, A.; Djoudi, T.; Hecini, M. Investigating the impact of date palm fibre waste on the properties of a novel gypsum-based bio-composite. Constr. Build. Mater. 2024, 457, 139419. [Google Scholar] [CrossRef]

- Abir, N.; Siddique, A.B.; Begum, H.A.; Gafur, M.A.; Khan, A.N.; Mahmud, M.A. Effect of fibre loading on mechanical properties of jute fibre bundle reinforced gypsum composites. Heliyon 2023, 9, e18147. [Google Scholar] [CrossRef]

- KNAUF. W61.es Knauf Trasdosados Directos. Technical Sheet. 2019. Available online: https://knauf.com/es-ES/knauf/soluciones/aplicaciones/trasdosados (accessed on 26 May 2025).

- Aurea Consulting. eCondensa2 (Software). 2012. Available online: https://ecoeficiente.es/econdensa2/ (accessed on 26 May 2025).

- TECNI-GYPSUM. Perfiles Livianos de Acero Galvanizado STUD Conocido Como Poste. Technical Sheet. 2023. Available online: https://tecnigypsum.com/wp-content/uploads/2023/02/Fichas-Tecnicas-TG-PERFILES-STUD.pdf (accessed on 26 May 2025).

- KNAUF. Placa Knauf wolplac LR (Tipo MW). Technical Sheet. 2023. Available online: https://escayolasbedmar.com/wp-content/uploads/2024/04/Ficha-tecnica-Placa-Woolplac-LR.pdf (accessed on 26 May 2025).

- Le, D.L.; Salomone, R.; Nguyen, Q.T. Circular bio-based building materials: A literature review of case studies and sustainability assessment methods. Build. Environ. 2023, 244, 110774. [Google Scholar] [CrossRef]

- Le, D.L.; Salomone, R.; Nguyen, Q.T.; Versele, A.; Piccardo, C. Status and barriers to circular bio-based building material adoption in developed economies: The case of Flanders, Belgium. J. Environ. Manag. 2024, 367, 121965. [Google Scholar] [CrossRef] [PubMed]

| Reference | Fibre | Addition Percentage | Fibre Length | Properties Analysed (*) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | E | F | G | H | I | J | K | L | M | N | ||||

| [19] | Coir | 10–20–30% WT | 5–10 mm | ● | ● | ● | ● | ● | |||||||||

| [15] | Sisal | 1–2% (1 mm long) WT; 1–2% (3 mm long) WT | 1–3 mm | ● | |||||||||||||

| [20] | Coir | 10–20–30% WT | 5–10 mm | ● | ● | ● | ● | ● | |||||||||

| [21] | Coir | 10–20–30–40% WT | 5 mm | ● | ● | ● | ● | ● | ● | ● | |||||||

| [22] | Date palm | 5–10–15–20% WT | - | ● | ● | ● | |||||||||||

| [24] | Pine Wood | 1–2–4–6% WT | 0.7 mm | ● | ● | ● | ● | ● | ● | ● | |||||||

| [25] | Abaca | 1–2–3% WT | 10 mm | ● | ● | ||||||||||||

| [27] | Jute | 0.1–0.2% WT | Jute netting 22 × 22 holes/dm2 | ● | ● | ● | ● | ||||||||||

| [28] | Straw | 0.2–0.3–0.4–0.6% WT | Original fibre length in straw bales | ● | ● | ● | ● | ||||||||||

| [29] | Hemp | 15–30% WT | 0–0.2 mm 2–12 mm | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||

| Features | Value | Features | Value |

|---|---|---|---|

| Water vapour diffusion factor (μ): | 6 | Purity index (%): | >80 |

| Compressive strength: | ≥2 N/mm2 | Granulometry: | (SN) 0–0.2 mm |

| Water/powder ratio: | 1–1.5 L/kg | Fire reaction: | A1 |

| Flexural strength: | ≥1 N/mm2 | pH: | >6 |

| pH [u] | Total Hardness [mg/L CO3Ca] | Chloride [mg/L] | Total Organic Carbon [mg/L] | Lead [µg/L] | Cadmium [µg/L] | Escherichia coli [CFU/100 mL] | Turbidity [NTU] |

|---|---|---|---|---|---|---|---|

| 7.1–8.9 | 10–50 | 10–21 | 1.6–2.5 | <2.5 | <2.5 | 0.0 | 0.3 |

| Mechanical Properties [30] | Physical Properties | Organic Composition [30] |

|---|---|---|

| Tensile strength: 165–222 MPa | Density: 100–140 kg/m3 | Cellulose: 27–36 wt% |

| Young’s modulus: ≈3.8 GPa | Thermal conductivity: 0.043–0.045 W/m°C [37] | Hemicellulose: 17–23 wt% |

| Elongation break: ≈40% | Long fibre length: 19.5–22.0 cm (avg. 21.0 cm)1 [38] | Lignin: 37–42 wt% |

| Short fibre length: 8.2–10.3 cm (avg. 9.2 cm)1 [38] | ||

| Fibre diameter (long fibres): 220–870 µm (avg. 0.34 mm) [38] | ||

| Fibre diameter (short fibres): 130–390 µm (avg. 0.21 mm) [38] | ||

| Aspect ratio long fibre (l/d): ≈618 | ||

| Aspect ratio short fibre (l/d): ≈438 |

| Property | Value | Property | Value |

|---|---|---|---|

| Weight [g/m2]: | 75 | Tensile index ST [N·m/g]: | 45 |

| Humidity [%]: | 6.80% ± 0.20% | Burst index [kPa·m2/g]: | 4.4 |

| SM tensile index [N·m/g]: | 100 | Breaking strength [kPa] | 355 |

| Thickness: | 0.10 mm | Cobb-60″ [g/m2]: | 27 |

| Thermal Properties [41] | Physical and Mechanical Properties [41] | ||

|---|---|---|---|

| Thermal Conductivity: | 0.04 W/mK | Specific Weight: | 150–220 kg/m3 |

| Tensile Strength: | >200 kPa | ||

| Recovery after 0.7 MPa: | >70.00% | ||

| Sample | Gypsum Plaster [g] | Water [g] | Coconut Fibre [g] |

|---|---|---|---|

| P0.7-REF | 1000 | 700.0 | – |

| P0.7-2.5CF | 975 | 682.5 | 2.8 |

| P0.7-5.0CF | 950 | 665.0 | 5.6 |

| P0.7-7.5CF | 925 | 647.5 | 8.3 |

| P0.7-10.0CF | 900 | 630.0 | 11.1 |

| P0.7-12.5CF | 875 | 612.5 | 13.9 |

| P0.7-15.0CF | 850 | 595.0 | 16.7 |

| P0.7-17.5CF | 825 | 577.5 | 19.4 |

| Experimental Programme and Application Regulations | |||

|---|---|---|---|

| STAGE I | 16 × 16 × 4 cm | Bulk density UNE-EN 102042:2023 [42] | SEM analysis - |

| Superficial hardness UNE-EN 102042:2023 [42] | Flexural strength UNE-EN 13279-2:2014 [41] | ||

| Dynamic elastic modulus (MOEus) UNE-EN ISO 12680-1:2007 [43] | Compressive strength UNE-EN 13279-2:2014 [41] | ||

16 × 16 × 4 cm | Capillarity water absorption EN 1925:1999 [44] | Total water absorption UNE-EN 14617-1:2013 [45] | |

| Capillarity height - | Open porosity UNE-EN 1936:2007 [46] | ||

| STAGE II | 40 × 30 × 1.5 cm | Bulk density UNE-EN 102042:2023 [42] UNE-EN 12859:2012 [47] | Flexural strength UNE-EN 12859:2012 [47] UNE-EN 14246:2007 [48] UNE-EN 520:2005 + A1:2010 [49] |

24 × 24 × 2 cm | Thermal conductivity UNE-EN ISO 8990:1997 [50] | Simulation THERM DBHE [51] | |

| Class Density [kg/m3] | Class Density [kg/m3] | Class Density [kg/m3] |

|---|---|---|

| High 1 100 ≤ ρ ≤ 1 500 | Medium 800 ≤ ρ < 1 100 | Low 600 ≤ ρ < 800 |

| Fibre | 2.00% | 2.50% | 5.00% | 6.00% | 7.50% | 10.00% | 12.50% | 15.00% | 17.50% | 20.00% | 30.00% |

|---|---|---|---|---|---|---|---|---|---|---|---|

| P-CF | - | 3.75 | 4.00 | - | 4.15 | 4.16 | 4.19 | 4.35 | 3.25 | - | - |

| Coir [20] | - | - | - | - | - | 3.10 | - | - | - | 4.30 | 5.60 |

| Coir [21] | - | - | - | - | - | 1.175 | - | - | - | 1.30 | 1.375 |

| Pine Wood [24] | 1.38 | - | - | 0.72 | - | - | - | - | - | - | - |

| Abaca [25] | 2.73 ± 0.19 | - | - | - | - | - | - | - | - | - | - |

| Hemp [29] | - | - | - | - | - | - | - | 4.80 | - | - | 4.10 |

| Series | P0.7 | P0.7-2.5CF | P0.7-5.0CF | P0.7-7.5CF | P0.7-10.0CF | P0.7-12.5CF | P0.7-15.0CF | P0.7-17.5CF |

|---|---|---|---|---|---|---|---|---|

| Total Water Absorption [%] | 40.64 | 41.29 | 41.08 | 41.12 | 40.76 | 40.79 | 41.68 | 40.85 |

| Open Porosity [%] | 54.98 | 55.70 | 55.23 | 53.55 | 54.23 | 53.88 | 54.09 | 53.18 |

| Fibre | 2.00% | 2.50% | 5.00% | 7.50% | 10.00% | 12.50% | 15.00% | 17.50% | 20.00% | 30.00% |

|---|---|---|---|---|---|---|---|---|---|---|

| P-CF | - | 1055.03 | 1044.64 | 1041.18 | 1038.26 | 1037.85 | 1036.91 | 987.83 | - | - |

| Coir [20] | - | - | - | - | 1183.59 | - | - | - | 1175.78 | 1164.06 |

| Date Palm [22] | - | - | 1226.24 | - | 1084.48 | - | 861.86 | - | 736.31 | - |

| Pine Wood [24] | 894 ± 17 | - | - | - | - | - | - | - | - | - |

| Hemp [29] | - | - | - | - | - | - | 575.00 | - | - | 470.00 |

| Sample | Bulk Density [kg/m3] | Density Class [49] | Thermal Conductivity [W/m·K] | Thermal Resistance [m2·K/W] |

|---|---|---|---|---|

| P0.7-REF | 1094.01 ± 62.24 (—) | Media | 0.30 | 0.067 |

| P0.7-2.5CF | 1055.03 ± 49.84 (↓ 3.30%) | Media | 0.165 | 0.121 |

| P0.7-5.0CF | 1044.64 ± 30.90 (↓ 4.25%) | Media | 0.163 | 0.123 |

| P0.7-7.5CF | 1041.18 ± 36.52 (↓ 4.57%) | Media | 0.159 | 0.126 |

| P0.7-10.0CF | 1038.26 ± 35.88 (↓ 4.83%) | Media | 0.165 | 0.121 |

| P0.7-12.5CF | 1037.85 ± 11.10 (↓ 4.87%) | Media | 0.157 | 0.127 |

| P0.7-15.0CF | 1036.91 ± 31.58 (↓ 4.86%) | Media | 0.146 | 0.137 |

| P0.7-17.5CF | 987.83 ± 33.97 (↓ 9.46%) | Media | 0.131 | 0.153 |

| Fibre | Property | 5.00% | 10.00% | 15.00% |

|---|---|---|---|---|

| P-CF | Density (kg/m3) | 1044.64 ± 30.90 | 1038.26 ± 35.88 | 1036.91 ± 31.58 |

| Thermal Conductivity (W/m·K) | 0.163 | 0.165 | 0.146 | |

| Coir [21] | Density (kg/m3) | - | 840 | - |

| Thermal Conductivity (W/m·K) | - | - | ||

| Date Palm [22] | Density (kg/m3) | 1226.24 | 1084.48 | 861.86 |

| Thermal Conductivity Flash Method (W/m·K) | 0.398 ± 0.02 | 0.297 ± 0.007 | 0.242 ± 0.018 | |

| Hemp [29] | Density (kg/m3) | - | - | 575 |

| Thermal Conductivity (W/m·K) | - | - | 0.17 |

| Material | Thickness (mm) | Density. (kg/m3) | Thermal Conductivity W/(m·K) | Thermal Resistance (m2·K)/W | Emissivity |

|---|---|---|---|---|---|

| Aerated concrete block [DIN 4165] [58] | 250.00 | 500.00 | 0.16 | 1.56 | 0.90 |

| Mansory cement mortar [59] | 20.00 | 2000.00 | 1.80 | 0.01 | 0.90 |

| Galvanised iron “C” profile [60] | 0.50 | 7850.00 | 85.00 | 5.88 × 10−6 | 0.35 |

| Rock wool [61] | 40.00 | 90.00 | 0.035 | 1.15 | 0.90 |

| Gypsum board [61] | 12.50 | 728.00 | 0.25 | 0.05 | 0.90 |

| Plaster and coconut fibreboards | 12.50 | See Table 13 | - | ||

| Madrid—Zone D3—Winter | |||

|---|---|---|---|

| Area | Feature | Unit | Value |

| Exterior | Temperature | °C | 3 and 6 |

| Relative humidity | % | 70.00 | |

| Rse | - | 0.04 | |

| Interior | Temperature | °C | 17 and 20 |

| Relative humidity | % | 55.00 | |

| Rsi | - | 0.13 | |

| Series | Outdoor Temperature [°C] | R-Value Wall [m2·K/W] | U-Factor Wall W/[m2·K] | Indoor Temperature [°C] |

|---|---|---|---|---|

| P0.7-REF | 3.2 | 2.4865 (—) | 0.4022 (—) | 16.4 |

| P0.7-2.5CF | 3.2 | 2.6150 (↑ 5.17%) | 0.3824 (↓ 4.92%) | 16.5 |

| P0.7-5.0CF | 3.2 | 2.6181 (↑ 5.29%) | 0.3820 (↓ 5.02%) | 16.5 |

| P0.7-7.5CF | 3.2 | 2.6246 (↑ 5.55%) | 0.3810 (↓ 5.27%) | 16.5 |

| P0.7-10.0CF | 3.2 | 2.6150 (↑ 5.17%) | 0.3824 (↓ 4.92%) | 16.5 |

| P0.7-12.5CF | 3.2 | 2.6280 (↑ 5.69%) | 0.3805 (↓ 5.40%) | 16.5 |

| P0.7-15.0CF | 3.2 | 2.6478 (↑ 6.49%) | 0.3777 (↓ 6.09%) | 16.5 |

| P0.7-17.5CF | 3.2 | 2.6791 (↑ 7.75%) | 0.3733 (↓ 7.19%) | 16.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Robalino, M.F.; Ferrández, D.; Verdú-Vázquez, A.; Zaragoza-Benzal, A. Development and Performance of Coconut Fibre Gypsum Composites for Sustainable Building Materials. Buildings 2025, 15, 1899. https://doi.org/10.3390/buildings15111899

Rodríguez-Robalino MF, Ferrández D, Verdú-Vázquez A, Zaragoza-Benzal A. Development and Performance of Coconut Fibre Gypsum Composites for Sustainable Building Materials. Buildings. 2025; 15(11):1899. https://doi.org/10.3390/buildings15111899

Chicago/Turabian StyleRodríguez-Robalino, María Fernanda, Daniel Ferrández, Amparo Verdú-Vázquez, and Alicia Zaragoza-Benzal. 2025. "Development and Performance of Coconut Fibre Gypsum Composites for Sustainable Building Materials" Buildings 15, no. 11: 1899. https://doi.org/10.3390/buildings15111899

APA StyleRodríguez-Robalino, M. F., Ferrández, D., Verdú-Vázquez, A., & Zaragoza-Benzal, A. (2025). Development and Performance of Coconut Fibre Gypsum Composites for Sustainable Building Materials. Buildings, 15(11), 1899. https://doi.org/10.3390/buildings15111899