Numerical Response of Advance Support Structures in TBM Tunneling Through Altered Zones: A Case Study

Abstract

1. Introduction

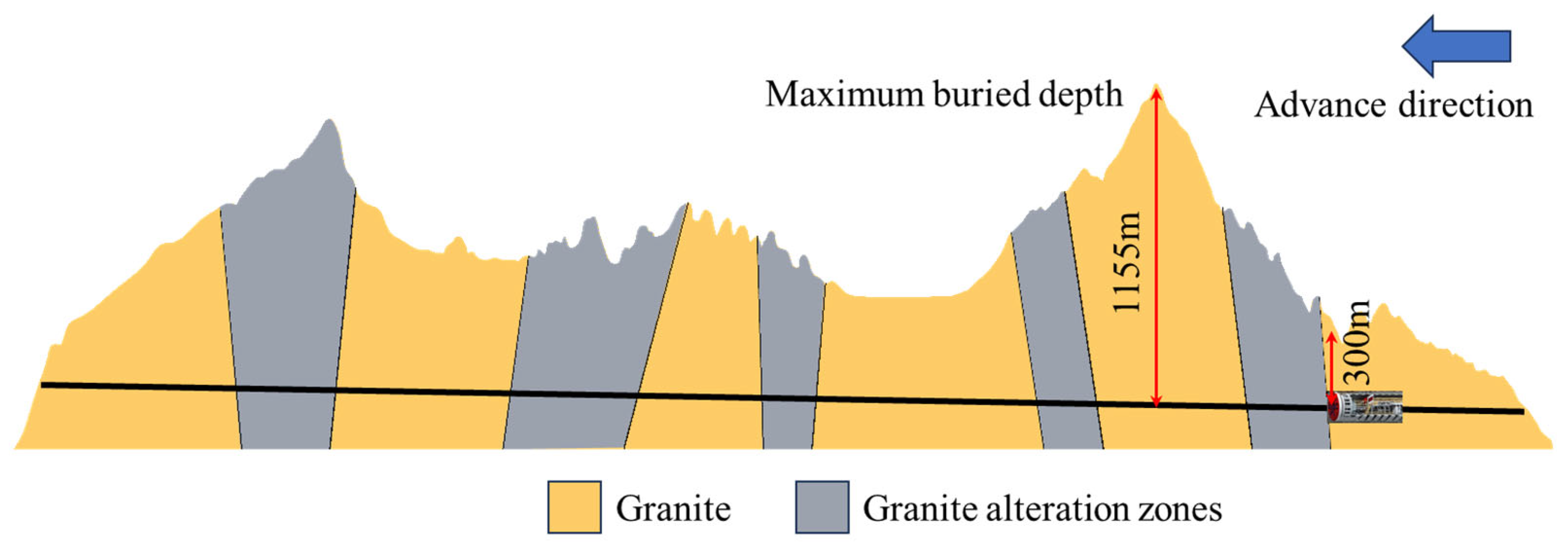

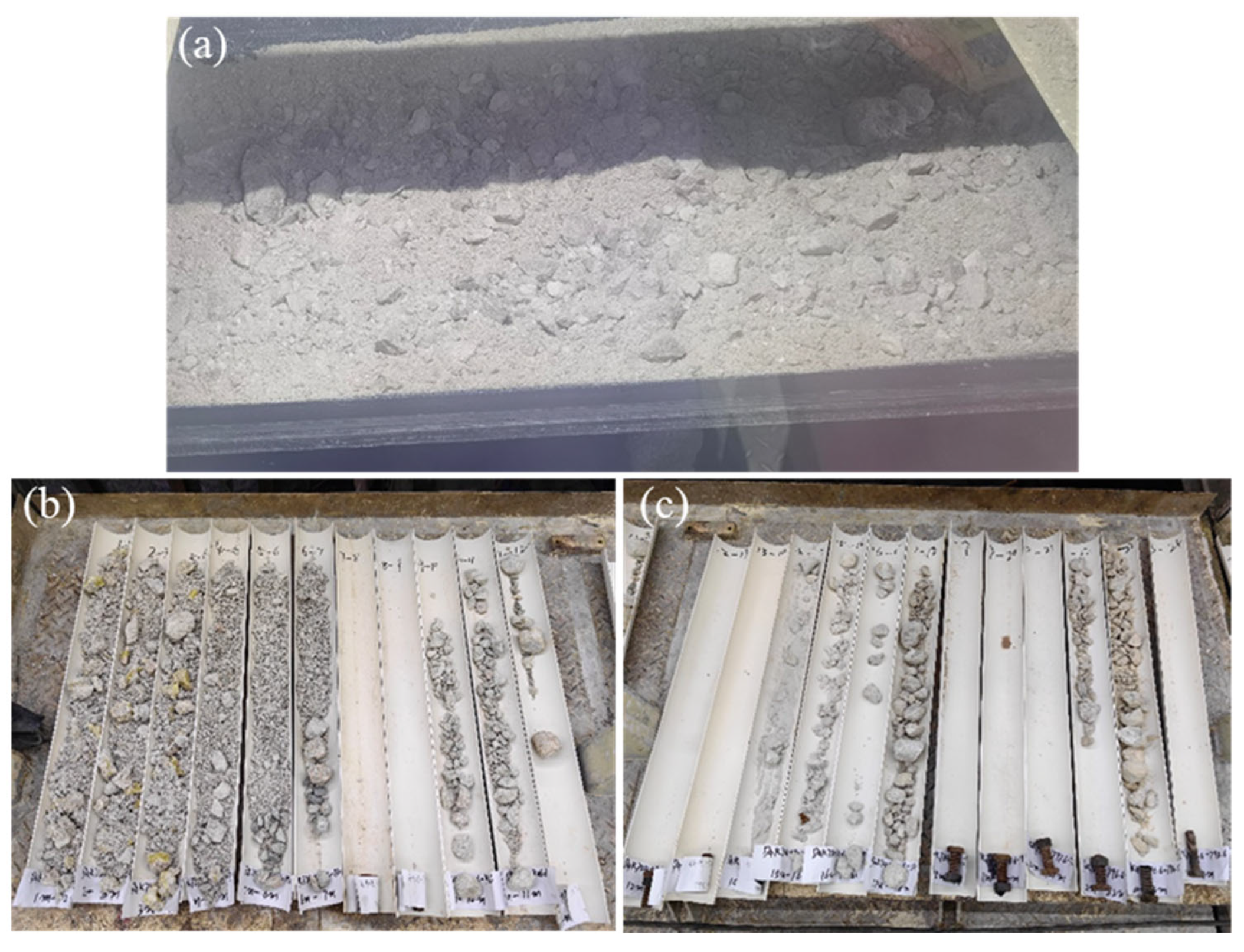

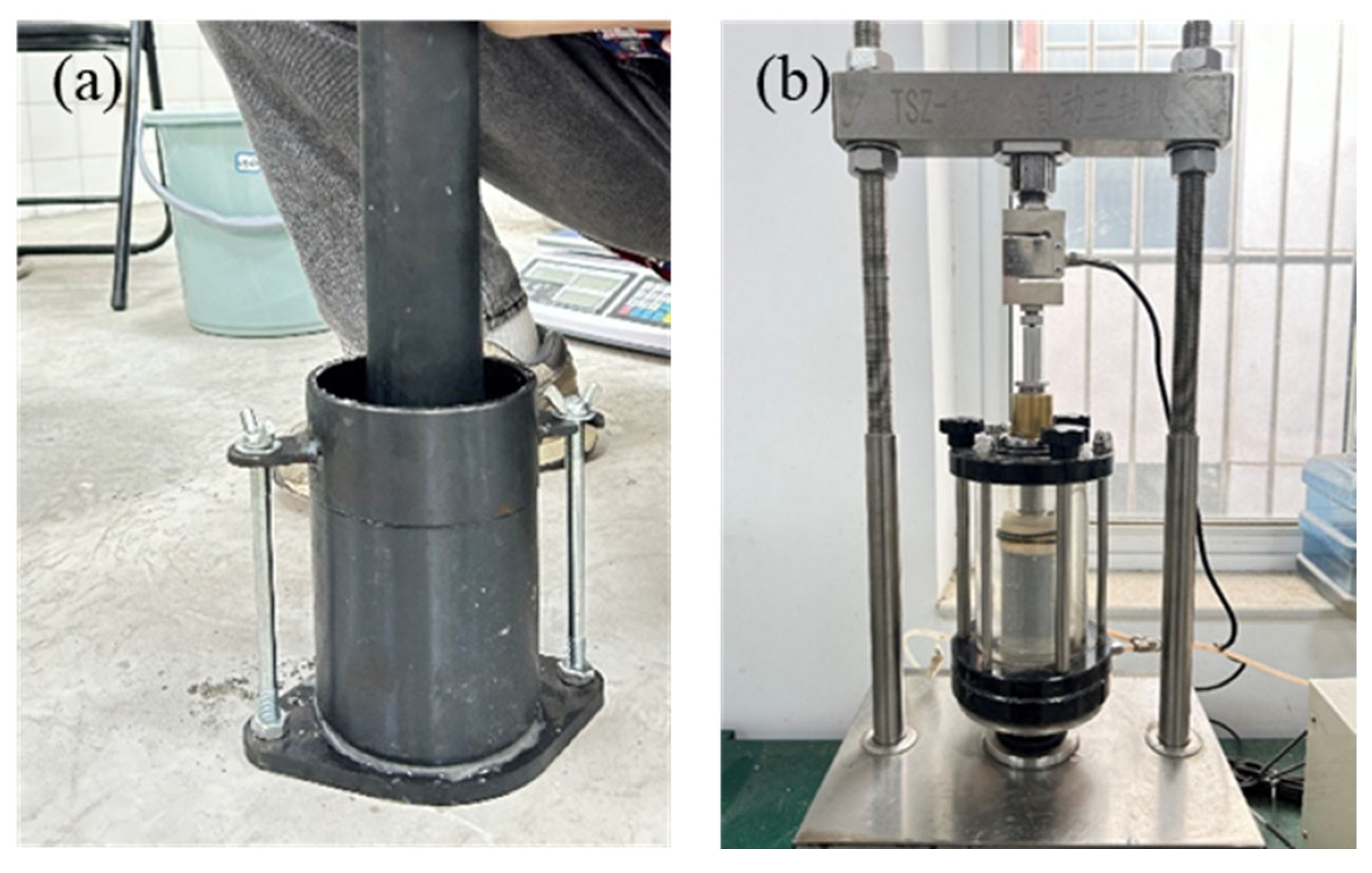

2. Engineering Background

3. Numerical Simulation

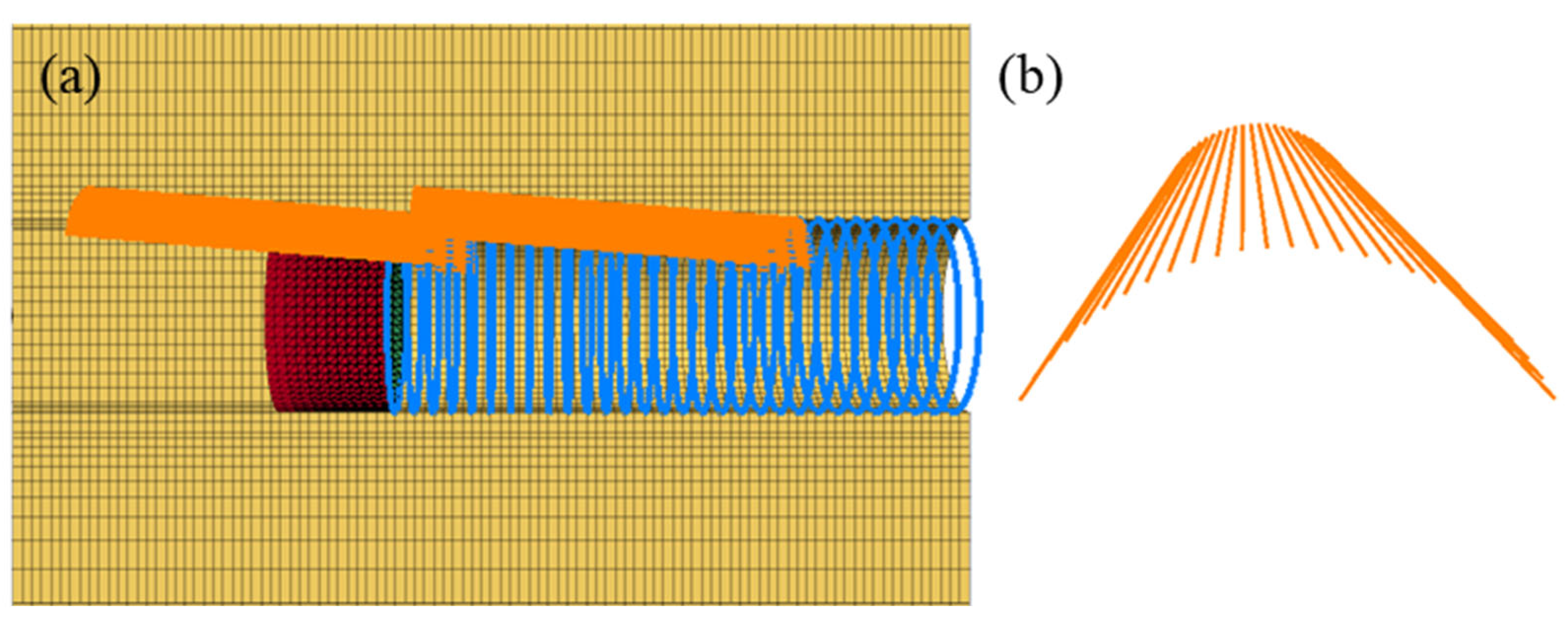

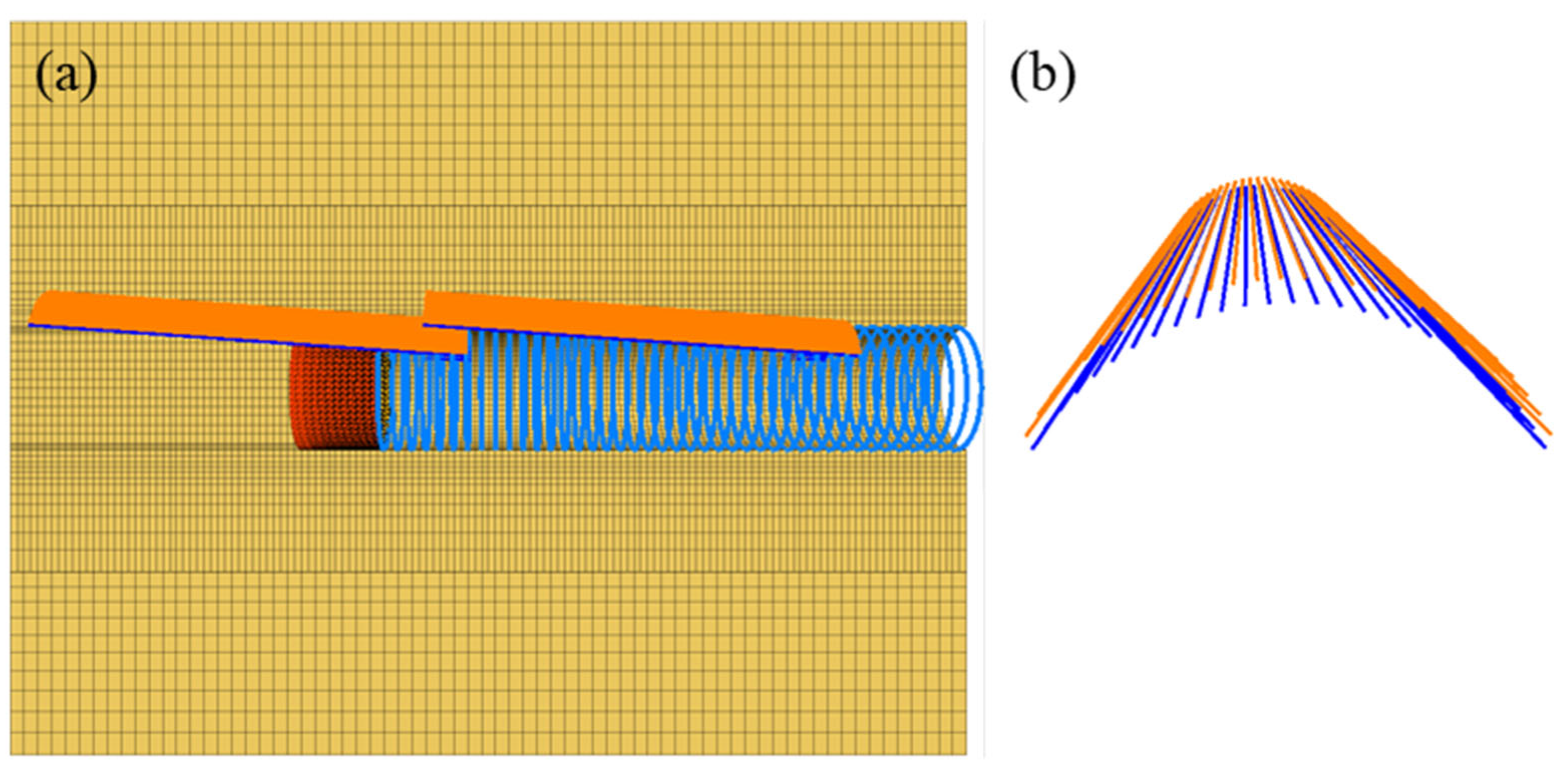

3.1. Numerical Modeling

3.2. Simulation Process

3.2.1. Single-Layer Pipe-Roof Support Simulation Method

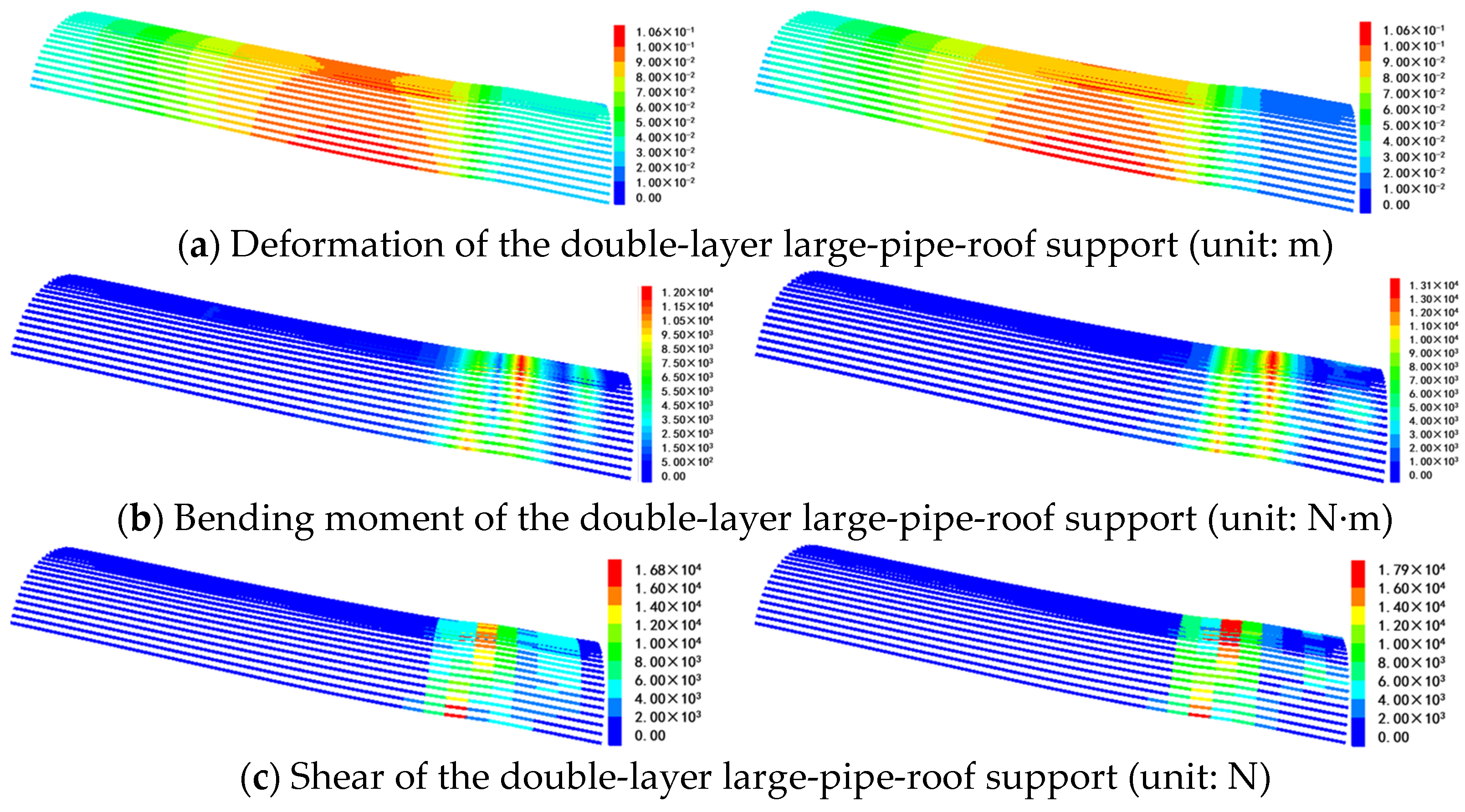

3.2.2. Double-Layer Large-Pipe-Roof Support Simulation Method

4. Numerical Experiment Results

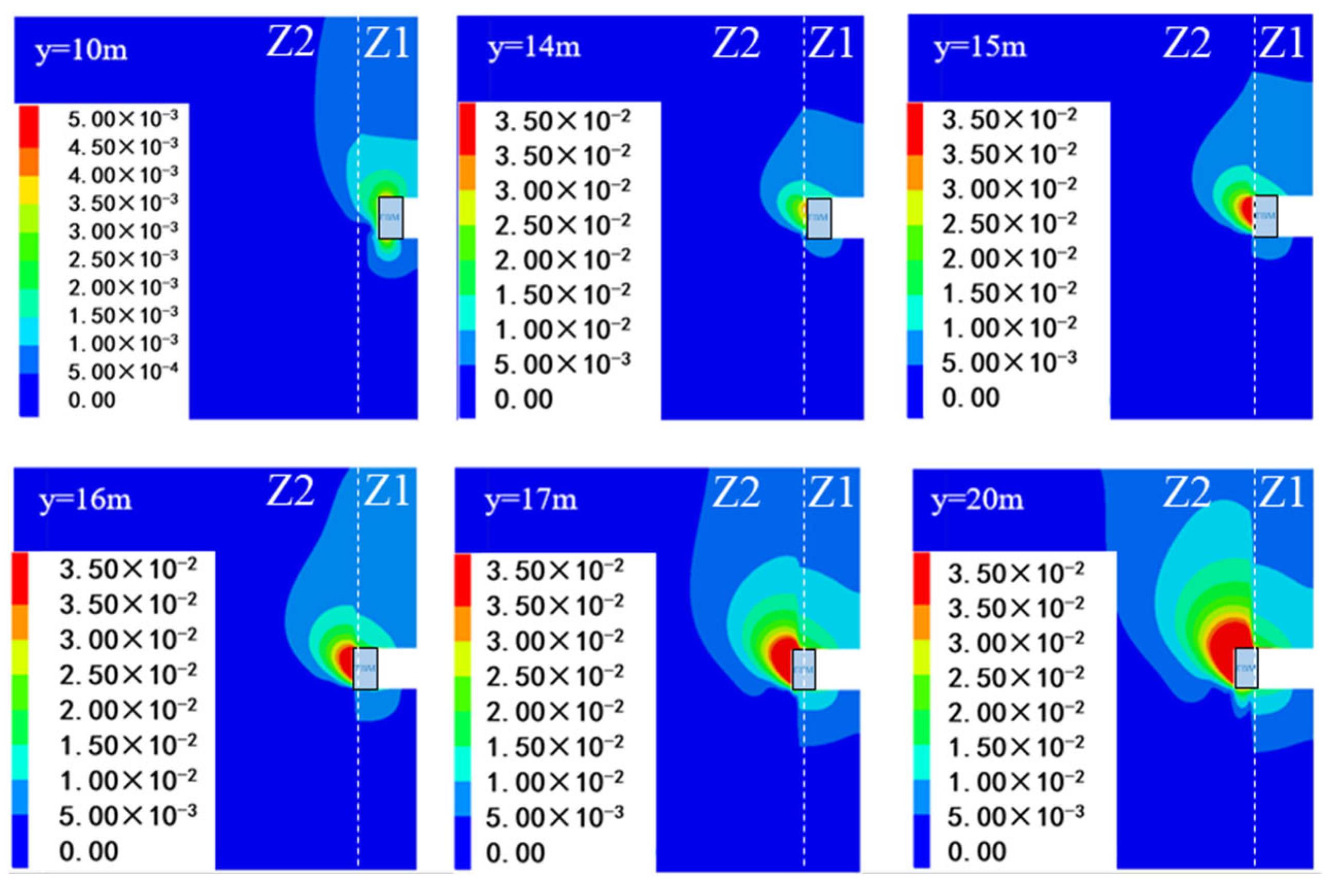

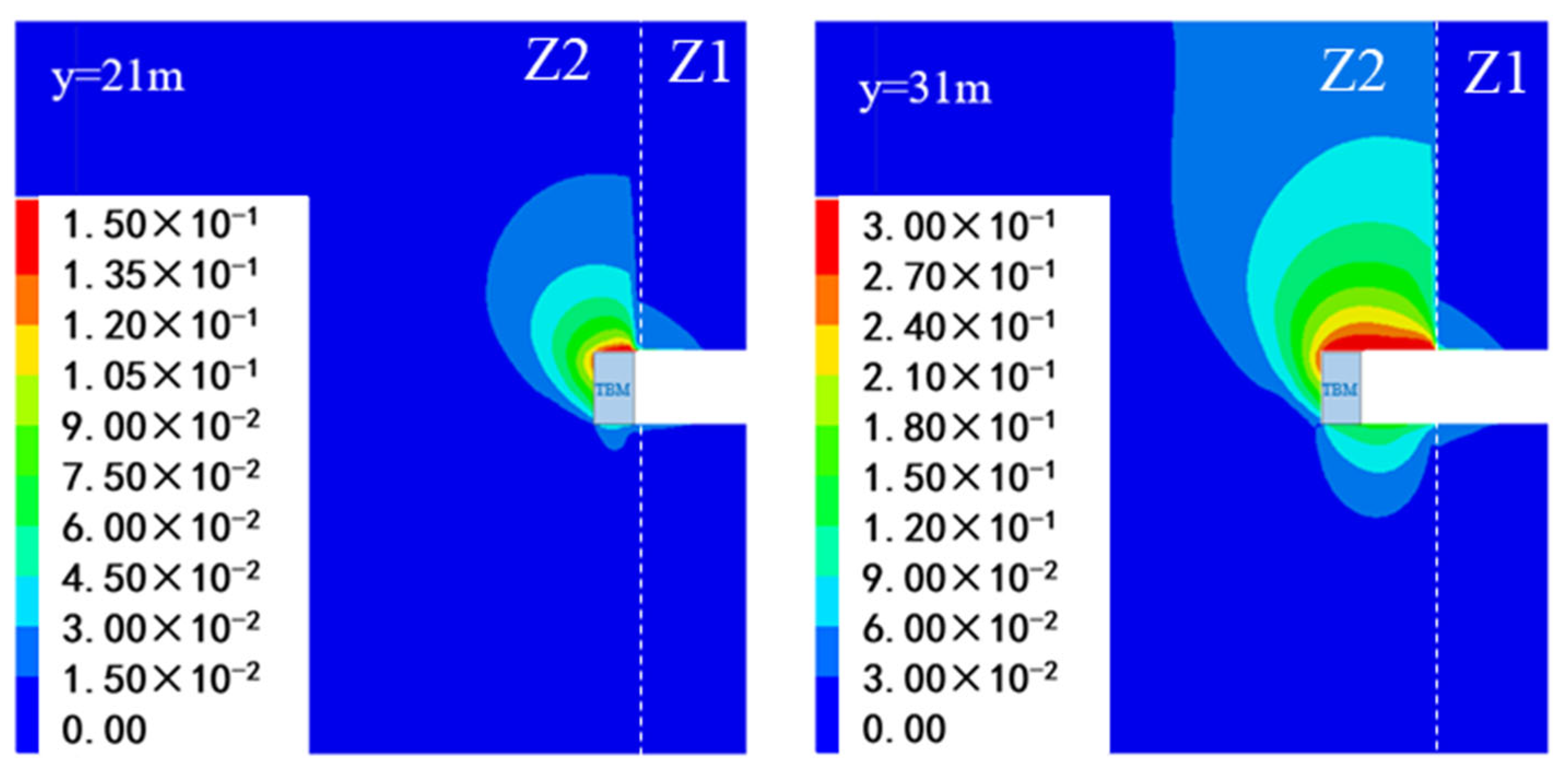

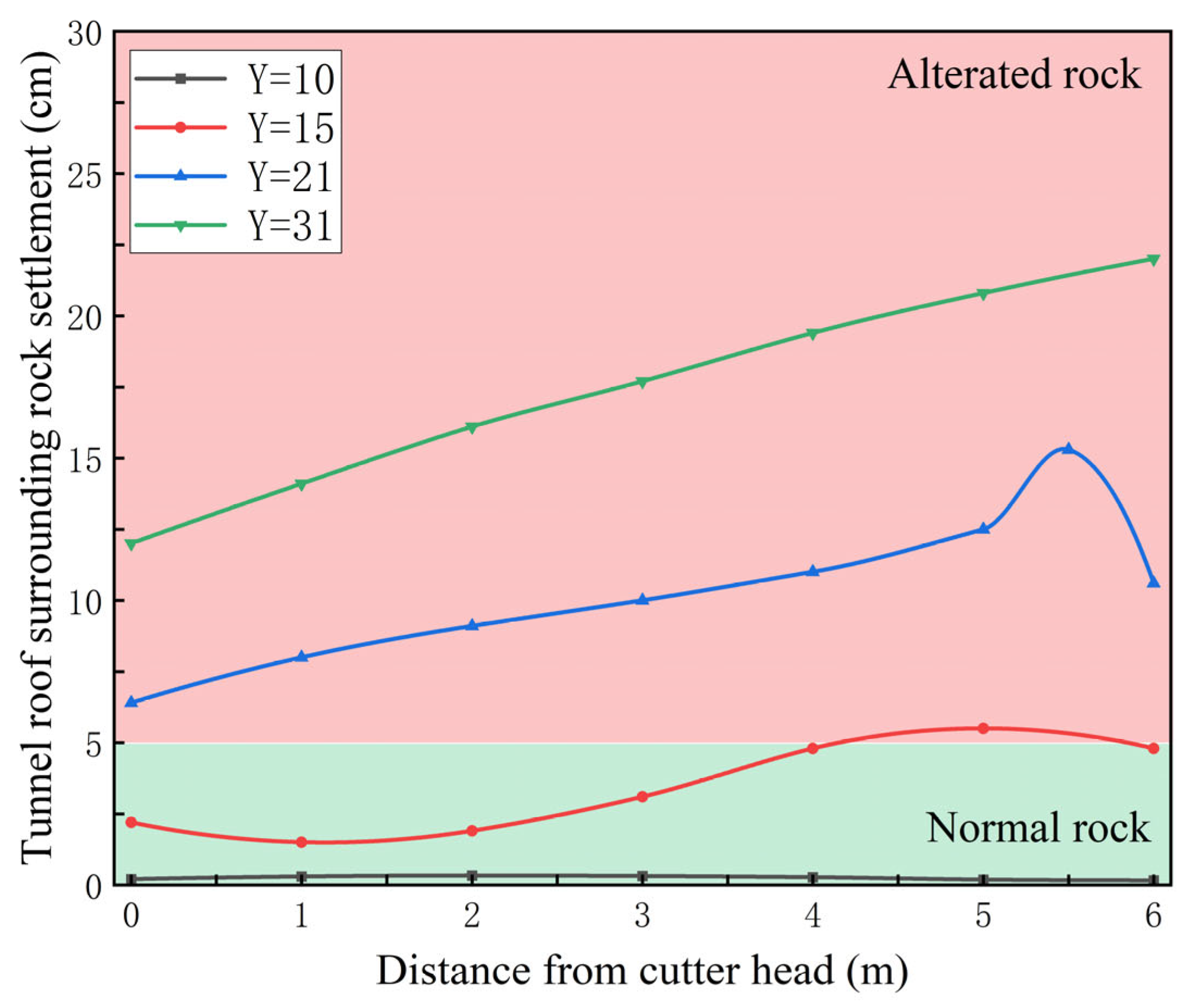

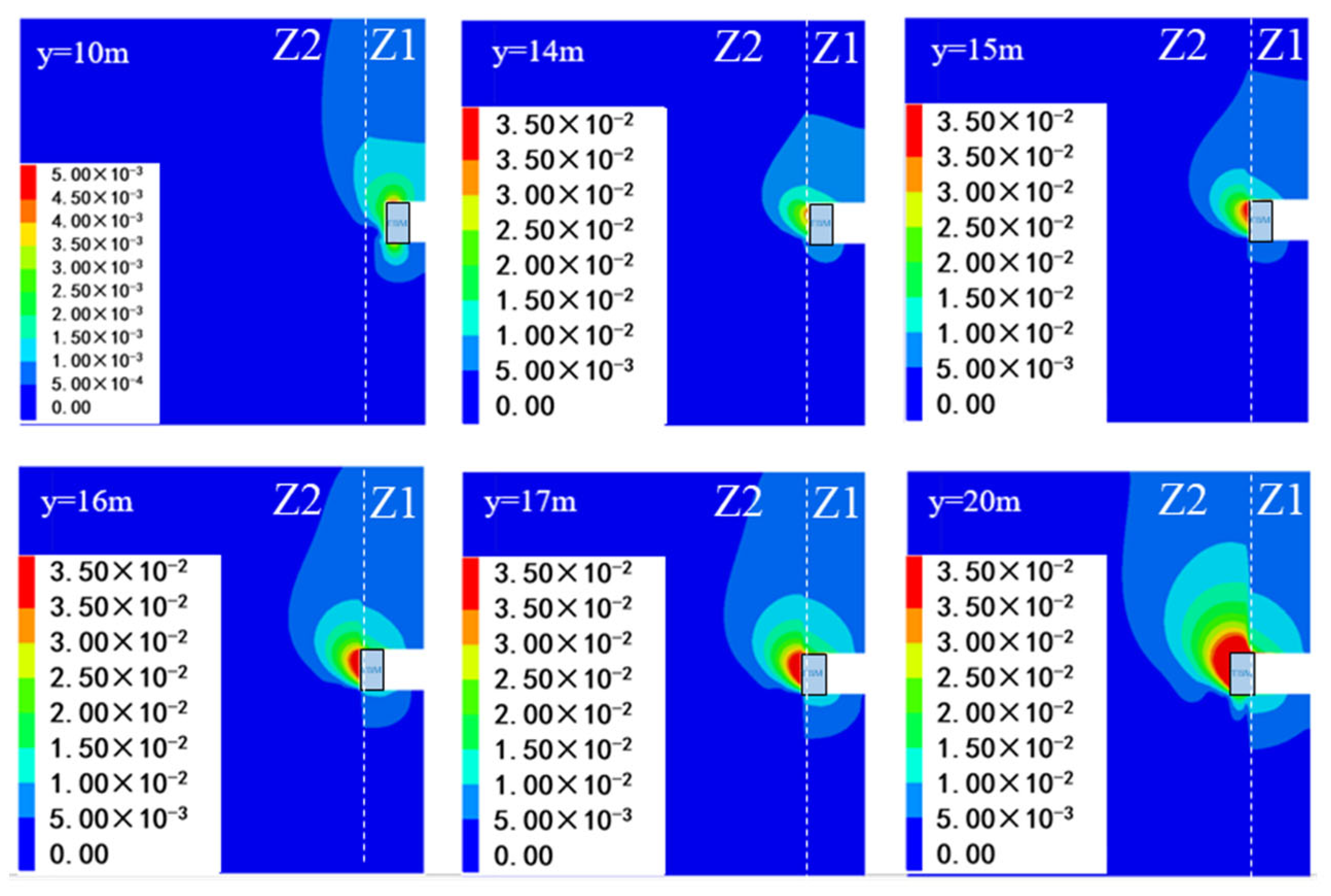

4.1. No Advance Support Effect

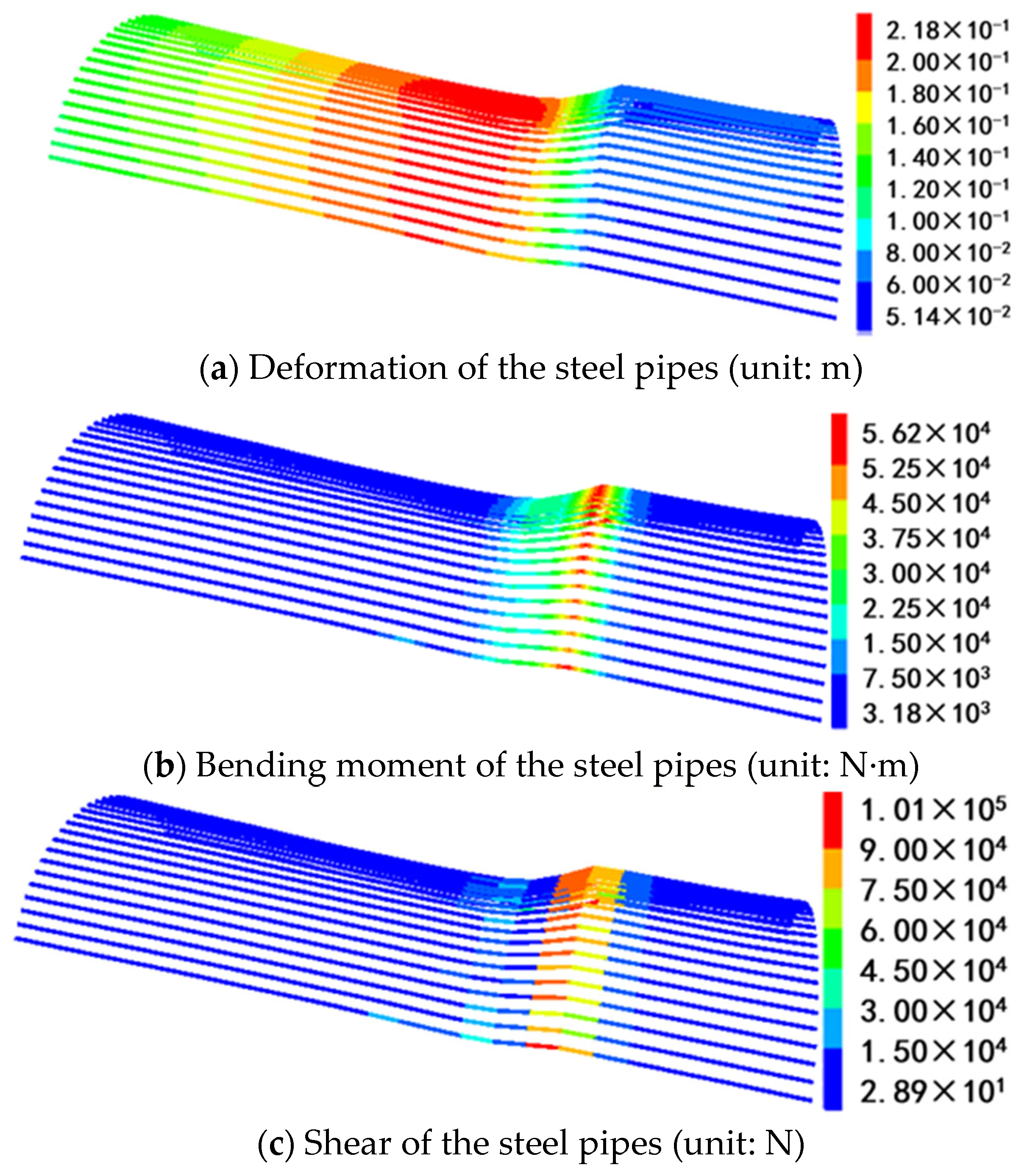

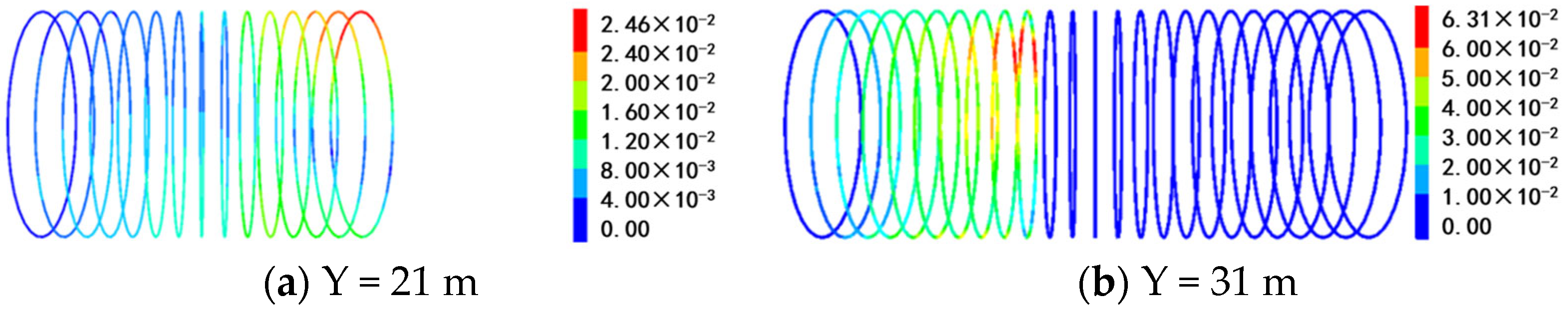

4.2. Support Effect of Single-Layer Pipe-Roof Support

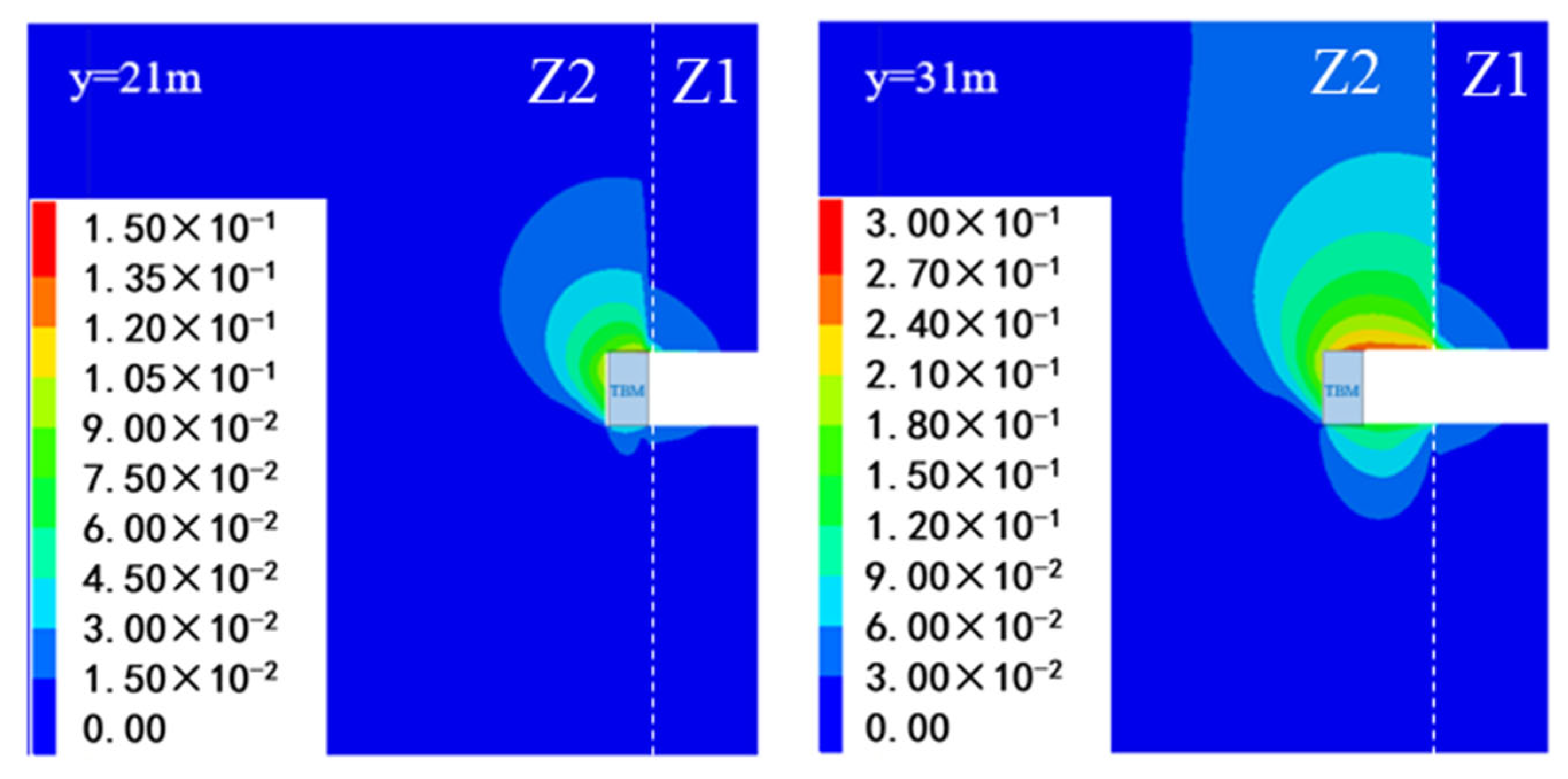

4.3. Supporting Effect of Double-Layer Large-Pipe-Roof Support

5. Discussion

6. Conclusions

- (1)

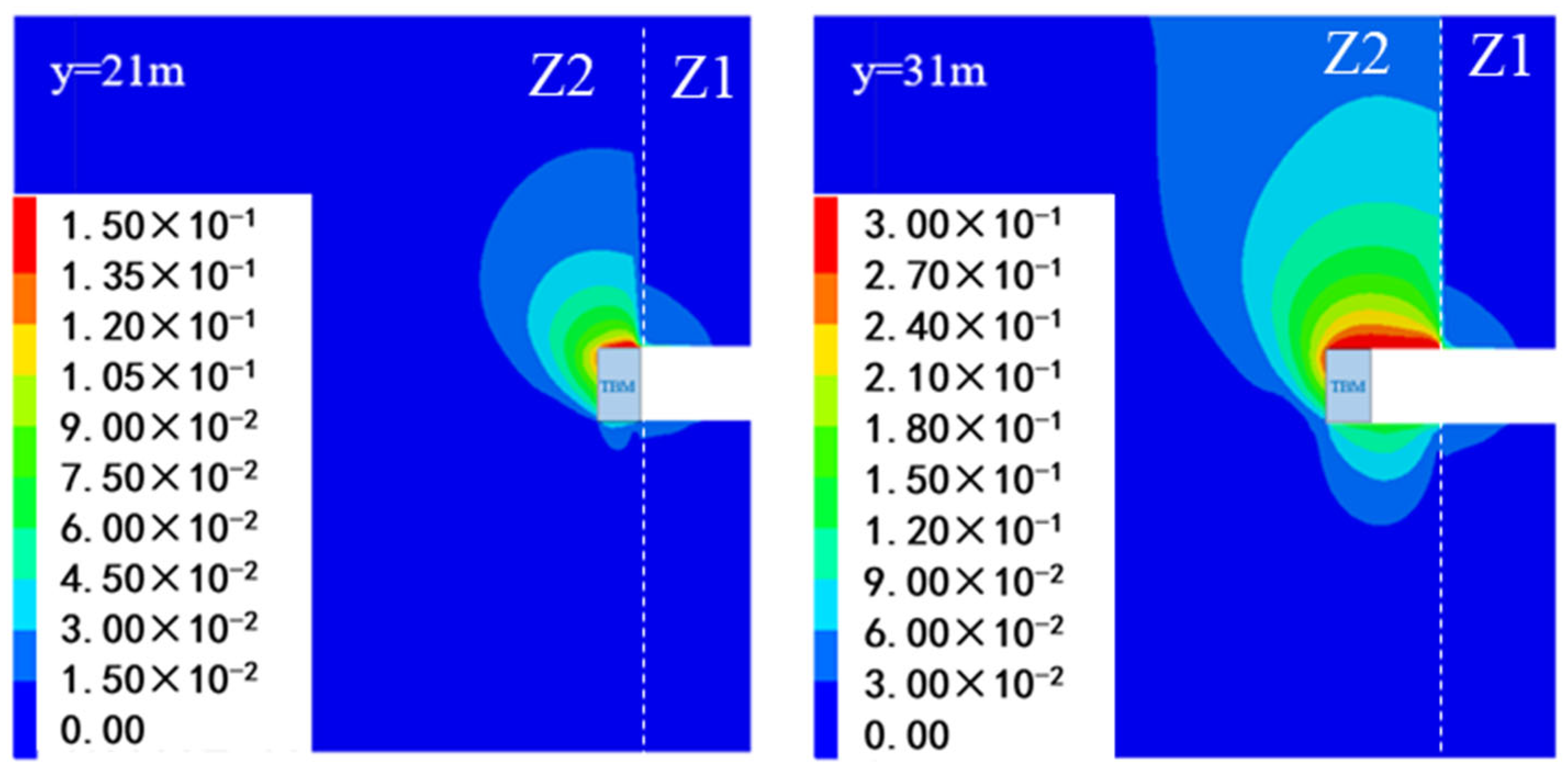

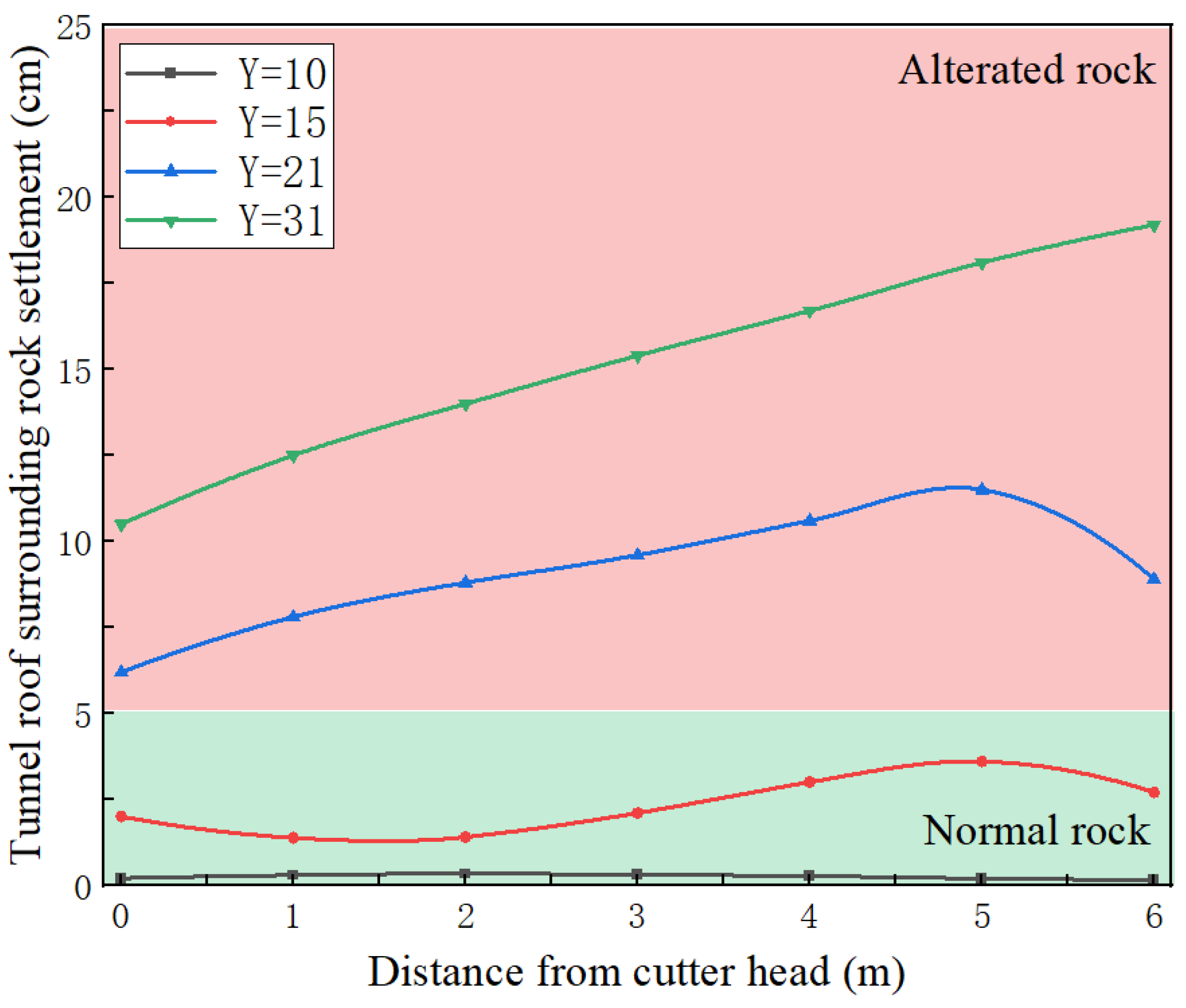

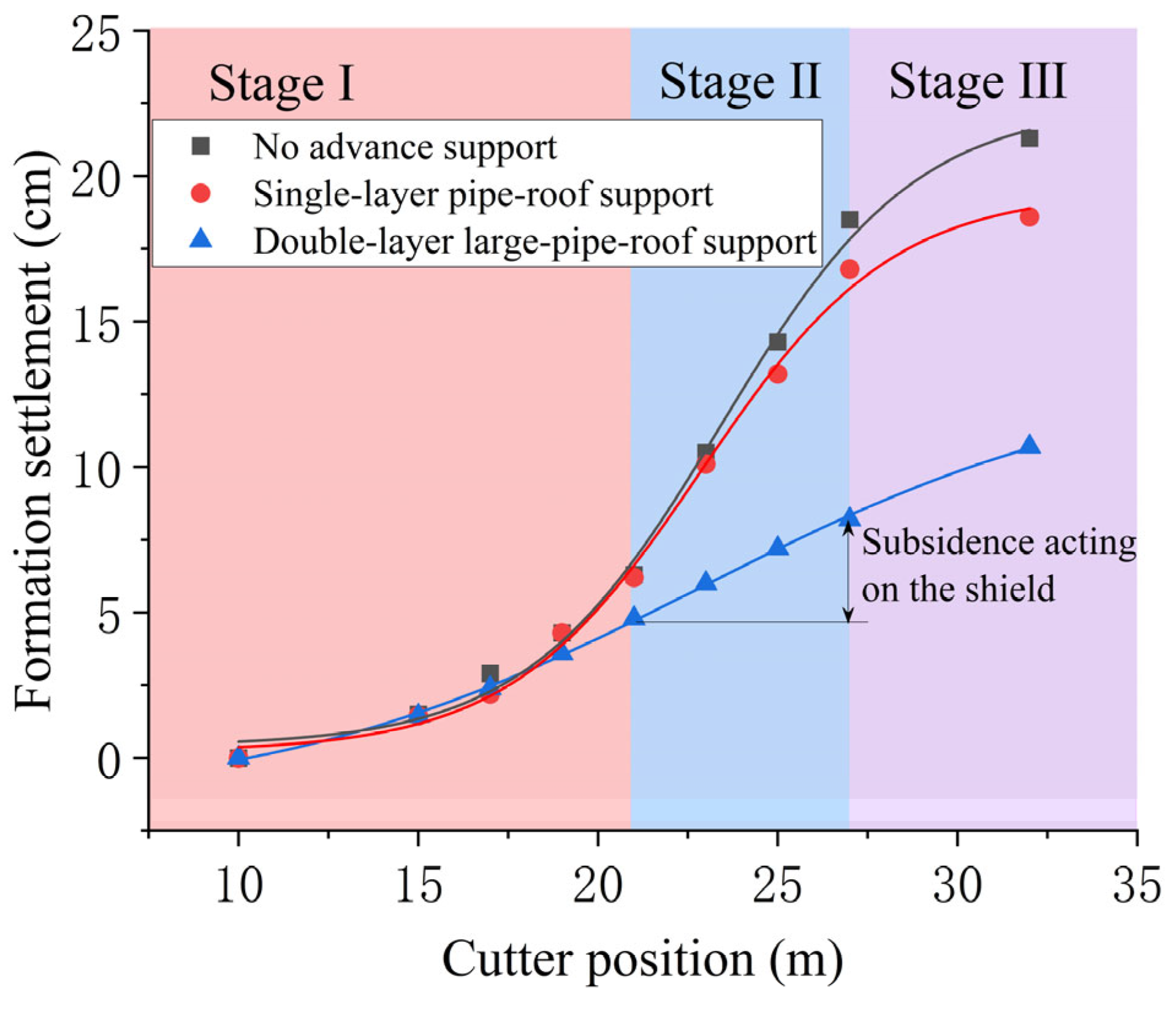

- When the TBM transitions from normal surrounding rock to altered rock, the excavation’s stability decreases due to the poorer physical and mechanical properties of the altered rock. The deformation of the surrounding rock around the tunnel occurs in three stages: deformation in front of the cutter head, gradual expansion of the deformation zone to the tunnel crown, and settlement and deformation above the TBM shield.

- (2)

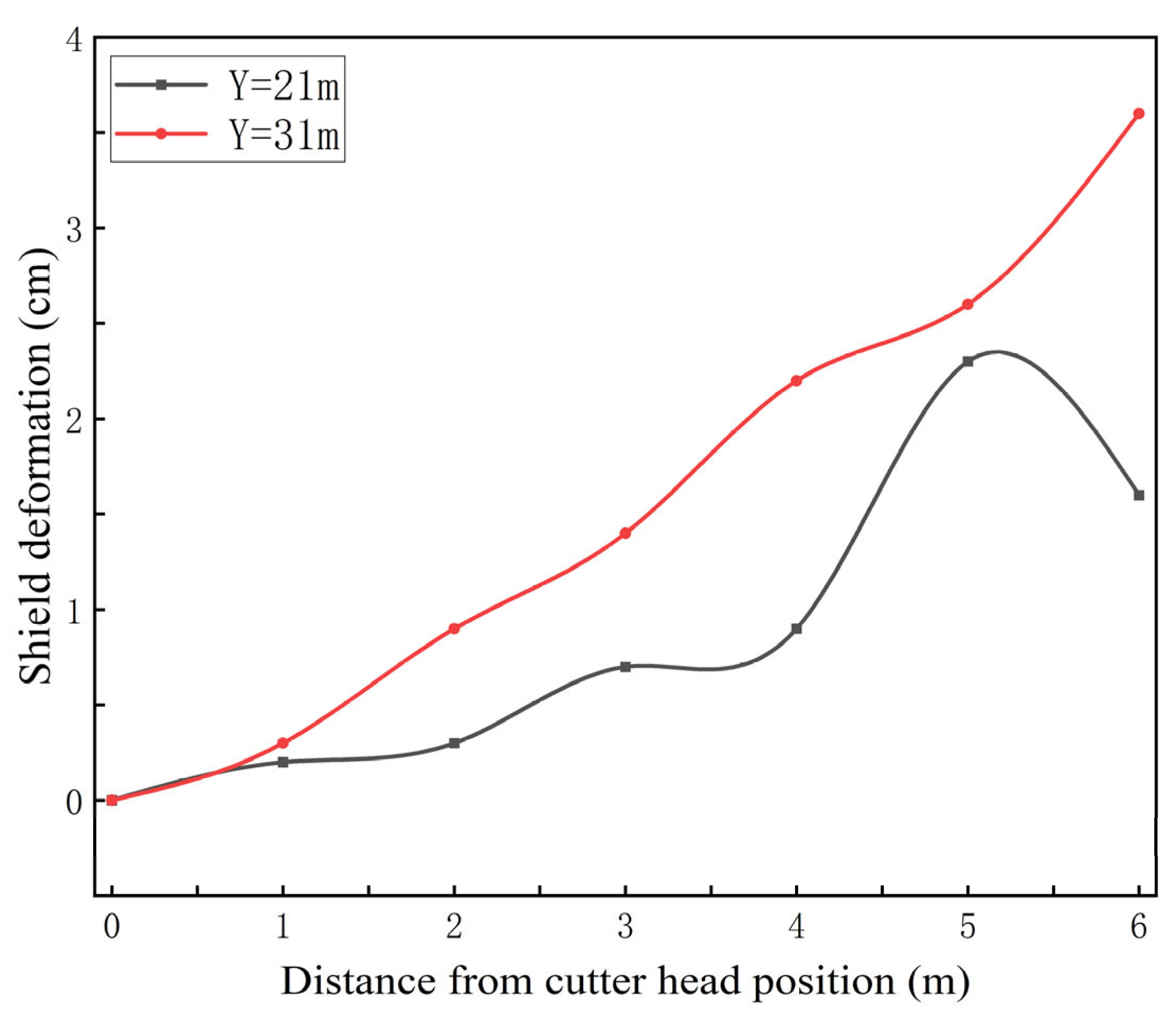

- Without advance support, TBM driving in altered rock can cause a maximum displacement of 20.8 cm, with shield deformation exceeding 3.5 cm. This indicates that in such conditions, the surrounding rock may completely lock the TBM shield, leading to jamming.

- (3)

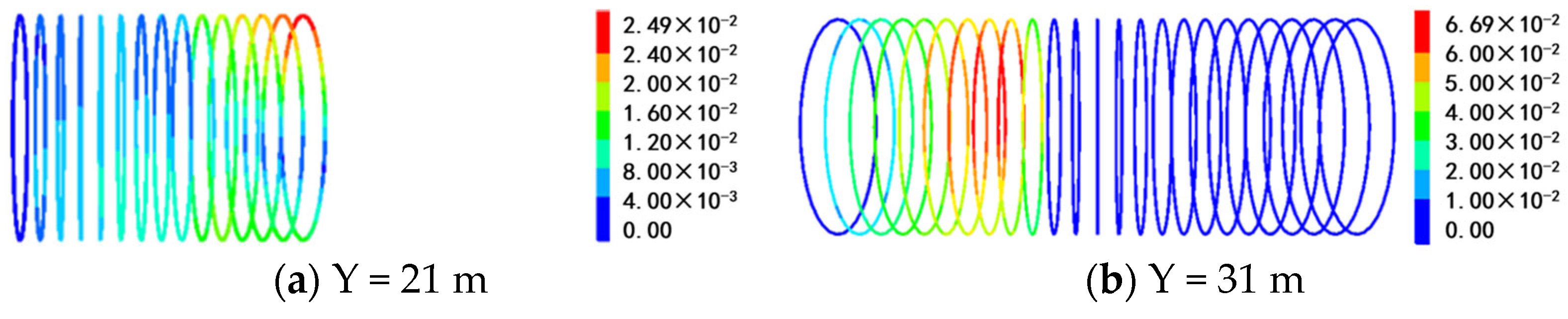

- Although a single-layer steel pipe offers some support, its limited flexural rigidity means that TBM tunneling in altered rock still results in significant displacement, up to 19.2 cm, with steel arch deformation reaching 6.3 cm. This suggests a high risk of large deformation and potential jamming in such conditions.

- (4)

- In contrast, a double-layer large-pipe-roof support, with its superior bending stiffness, effectively controls settlement and deformation, reducing maximum roof displacement to 9.7 cm—a 53.4% reduction compared to tunneling without advance support.

- (5)

- Overall, the single-layer pipe-roof support has little impact on the displacement evolution or maximum settlement, while double-layer large pipe sheds significantly reduce settlement and shield displacement. Therefore, the double-layer large-pipe-roof support provides better support in these formations and mitigates the risk of TBM jamming.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zheng, Y.L.; Zhang, Q.B.; Zhao, J. Challenges and Opportunities of Using Tunnel Boring Machines in Mining. Tunn. Undergr. Space Technol. 2016, 57, 287–299. [Google Scholar] [CrossRef]

- Fan, S.; Song, Z.; Zhang, Y.; Liu, N. Case Study of the Effect of Rainfall Infiltration on a Tunnel Underlying the Roadbed Slope with Weak Inter-Layer. KSCE J. Civ. Eng. 2020, 24, 1607–1619. [Google Scholar] [CrossRef]

- Fan, S.; Song, Z.; Xu, T.; Wang, K.; Zhang, Y. Tunnel Deformation and Stress Response under the Bilateral Foundation Pit Construction: A Case Study. Arch. Civ. Mech. Eng. 2021, 21, 109. [Google Scholar] [CrossRef]

- Karahan, S.; Yilmaz, O.; Karsli, Y.; Gokceoglu, C. A TBM Application in Shallow and Weak Ground Conditions (Ankara-Izmir High-Speed Railway Construction Project, Türkiye). In Proceedings of the 57th U.S. Rock Mechanics/Geomechanics Symposium, Atlanta, GA, USA, 25–28 June 2023. [Google Scholar] [CrossRef]

- Strappler, G.; Vigl, A.; Scheutz, R. Two-layer Lining for ÖBB Railway Tunnel Projects with TBM/Ein-und Zweischalige Auskleidung Bei Tunnelbauprojekten Der ÖBB Mit Kontinuierlichem Vortrieb. Geomech. Tunn. 2012, 5, 72–88. [Google Scholar] [CrossRef]

- Lu, Z.; Wang, X.; Zhou, G.; Feng, L.; Jiang, Y. Investigation on Vibration Influence Law of Double-Shield TBM Tunnel Construction. Appl. Sci. 2022, 12, 7727. [Google Scholar] [CrossRef]

- Scolari, F. Open-Face Borers in Italian Alps. In World Tunnelling and Subsurface Excavation; The Mining Journal Ltd.: London, UK, 1995; Volume 8, pp. 361, 363–366. [Google Scholar]

- Tang, B.; Chen, X.; Sun, C.; Cheng, S.; Tang, Y.; Wang, C. A Case Study on Control Technology of Surrounding Rocks of TBM Assembly Chamber in Underground Coal Mines. Arab. J. Geosci. 2022, 15, 450. [Google Scholar] [CrossRef]

- Marchionni, M.; Selleri, A.; Stahl, F.; Messina, L. Intensive Application of the TBM Data Management System for the Work Supervisor of the Largest Worldwide TBM-EPB Project. In Proceedings of the World Tunnel Congress WTC 2013, Geneva, Switzerland, 31 May–5 June 2013; pp. 1312–1319. [Google Scholar]

- Fang, Y.; Cui, J.; Wanatowski, D.; Nikitas, N.; Yuan, R.; He, Y. Subsurface Settlements of Shield Tunneling Predicted by 2D and 3D Constitutive Models Considering Non-Coaxiality and Soil Anisotropy: A Case Study. Can. Geotech. J. 2022, 59, 424–440. [Google Scholar] [CrossRef]

- Dong, L.; Song, D.; Liu, G. Seismic Wave Propagation Characteristics and Their Effects on the Dynamic Response of Layered Rock Sites. Appl. Sci. 2022, 12, 758. [Google Scholar] [CrossRef]

- Tian, X.; Song, Z.; Zhang, Y. Monitoring and Reinforcement of Landslide Induced by Tunnel Excavation: A Case Study from Xiamaixi Tunnel. Tunn. Undergr. Space Technol. 2021, 110, 103796. [Google Scholar] [CrossRef]

- Tian, X.; Song, Z.; Wang, H.; Zhang, Y.; Wang, J. Evolution Characteristics of the Surrounding Rock Pressure and Construction Techniques: A Case Study from Taoshuping Tunnel. Tunn. Undergr. Space Technol. 2022, 125, 104522. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Liu, F.; Xia, H. Mechanism and Sensitivity Analysis of Collapse in Large Section Mountain Neighborhood Tunnels. Front. Earth Sci. 2022, 10, 904655. [Google Scholar] [CrossRef]

- Zhao, M.; Cheng, Y.; Song, Z.; Wang, T.; Zhang, Y.; Gong, Y.; Song, Y. Stability Analysis of TBM Tunnel Undercrossing Existing High-Speed Railway Tunnel: A Case Study from Yangtaishan Tunnel of Shenzhen Metro Line 6. Adv. Civ. Eng. 2021, 2021, 6674862. [Google Scholar] [CrossRef]

- Xiaoli, L.I.U.; Huan, S.U.N.; Qinxi, D.; Xiong, Y.; Kumar, N.; Yan, S.U.; Jianjun, Z. Extremely Hard Rock Mass Excavation Using Rock Breakdown Methods to Assist TBM in a Deep, Long Diversion Tunnel in the Qinling Mountains. J. Tsinghua Univ. (Sci. Technol.) 2022, 62, 1292–1301. [Google Scholar]

- Bayati, M.; Hamidi, J.K. A Case Study on TBM Tunnelling in Fault Zones and Lessons Learned from Ground Improvement. Tunn. Undergr. Space Technol. 2017, 63, 162–170. [Google Scholar] [CrossRef]

- Acun, S.; Bilgin, N.; Erboylu, U. Contribution on the Understanding of EPB-TBM Drives in Complex Geologic Structures. Tunn. Undergr. Space Technol. 2021, 107, 103646. [Google Scholar] [CrossRef]

- Vibert, C.; Gupta, S.C.; Felix, Y.; Binquet, J.; Robert, F. Dul Hasti Hydroelectric Project (India): Experience Gained from Back Analysis of the Excavation of the Head Race Tunnel. In Proceedings of the Geoline 2005 International Symposium, Lyon, France, 23–25 May 2005; p. 154. [Google Scholar]

- Shang, Y.J.; Yang, Z.F.; Zeng, Q.L.; Sun, Y.C.; Shi, Y.Y.; Yuan, G.X. Retrospective Analysis of TBM Accidents from Its Poor Flexibility to Complicated Geological Conditions. Chin. J. Rock Mech. Eng. 2007, 26, 2404–2411. [Google Scholar]

- Hao, J.; Yin, Q.; Yong, L.I.; Liu, J.-F. Measures and Adaptability of Constructing Tunnel Crossing Compacted Granite under High Geostress. J. Chang. River Sci. Res. Inst. 2022, 39, 141. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Ren, S.; Wu, R.; Bi, J. Development Characteristics of Clayey Altered Rocks in the Sichuan-Tibet Traffic Corridor and Their Promotion to Large-Scale Landslides. Earth Sci. 2022, 47, 1945–1956. [Google Scholar]

- Li, J.; Zhang, Y.; Ren, S.; Bi, J. Catastrophic Mechanical Behavior of Clay-Altered Rock in the Baige Landslide Upstream of the Jinsha River. Adv. Eng. Sci. 2024, 56, 72–82. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, T.; Yan, X.; Dong, J.; Shi, S. Study on the Influence of Granite Alteration Degree on Tunnel Stability. J. North China Univ. Water Resour. Electr. Power (Nat. Sci. Ed.). Available online: https://link.cnki.net/urlid/41.1432.TV.20240325.1752.004 (accessed on 2 February 2025).

- Hoek, E. Big Tunnels in Bad Rock. J. Geotech. Geoenviron. Eng. 2001, 127, 726–740. [Google Scholar] [CrossRef]

- Ma, B.; Wu, S.; Chen, Q.; Liang, E.; Li, X. The Influence of Existing Piles on Station Settlement during the Construction of a Tunnel Undercrossing under Existing Stations. Sci. Rep. 2024, 14, 14024. [Google Scholar] [CrossRef] [PubMed]

- Rong, Y.; Du, W.; Sun, Y.; Xiong, F.; Liu, L.; Yu, S.; Jie, G. Study on Stress Deformation of Pipe Shed in Shallow Buried Tunnel Considering Micro-Arch Effect. Adv. Civ. Eng. 2024, 2024, 6651993. [Google Scholar] [CrossRef]

- Ou, X.; Ouyang, L.; Zhang, X.; Zhang, Y.; Tian, J. Floor Heave Mechanism and Prevention Countermeasures for High-Pressure Water-Rich Karst Tunnels-All Databases. Available online: https://webofscience.clarivate.cn/wos/alldb/full-record/CSCD:7621011 (accessed on 15 January 2025).

- Ding, W.; Huang, X.; Dai, Z.; Wang, C.; Wang, Z.; Yu, W. Analysis of the Collapse Mechanism and Stabilization Optimization of the Composite Stratum at the Boundary between Prereinforced and Unreinforced Areas near a Shield Launching Area. Int. J. Geomech. 2023, 23, 5023002. [Google Scholar] [CrossRef]

- Fang, Y.; Yao, Z.; Xu, W.; Tian, Q.; He, C.; Liu, S. The Performance of TBM Disc Cutter in Soft Strata: A Numerical Simulation Using the Three-Dimensional RBD-DEM Coupled Method. Eng. Fail. Anal. 2021, 119, 104996. [Google Scholar] [CrossRef]

- Huang, F.; Zhu, H.; Jiang, S.; Liang, B. Excavation-Damaged Zone around Tunnel Surface under Different Release Ratios of Displacement. Int. J. Geomech. 2017, 17, 04016094. [Google Scholar] [CrossRef]

- Tian, M.; Gao, X.; Zhang, A.; Han, L.; Xiao, H. Study on the Deformation Failure Mechanism and Coupling Support Technology of Soft Rock Roadways in Strong Wind Oxidation Zones. Eng. Fail. Anal. 2024, 156, 107840. [Google Scholar] [CrossRef]

- Xu, X.; Wu, Z.; Liu, Q. An Improved Numerical Manifold Method for Investigating the Mechanism of Tunnel Supports to Prevent Large Squeezing Deformation Hazards in Deep Tunnels. Comput. Geotech. 2022, 151, 104941. [Google Scholar] [CrossRef]

- He, B.-G.; Lin, B.; Li, H.-P.; Zhu, S.-Q. Suggested Method of Utilizing Soil Arching for Optimizing the Design of Strutted Excavations. Tunn. Undergr. Space Technol. 2024, 143, 105450. [Google Scholar] [CrossRef]

- Qin, Y.; Shang, C.; Li, X.; Lai, J.; Shi, X.; Liu, T. Failure Mechanism and Countermeasures of Rainfall-Induced Collapsed Shallow Loess Tunnels under Bad Terrain: A Case Study. Eng. Fail. Anal. 2023, 152, 107477. [Google Scholar] [CrossRef]

- Forsat, M.; Taghipoor, M.; Palassi, M. 3D FEM Model on the Parameters’ Influence of EPB-TBM on Settlements of Single and Twin Metro Tunnels during Construction. Int. J. Pavement Res. Technol. 2022, 15, 525–538. [Google Scholar] [CrossRef]

- Fang, X.; Yang, J.; Zhang, X.; Zhang, C.; Wang, S.; Xie, Y. Numerical Modeling of Open TBM Tunneling in Stratified Rock Masses Using a Coupled FDM-DEM Method. Comput. Geotech. 2023, 156, 105251. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, L.; Gu, S.; Zhang, X.; Li, W. Study on Rockburst Mechanism of TBM Excavation for Deep Tunnel Based on Energy Principle. J. Min. Saf. Eng. 2017, 34, 1103. [Google Scholar]

- Mikaeil, R.; Bakhshinezhad, H.; Haghshenas, S.S.; Ataei, M. Stability Analysis of Tunnel Support Systems Using Numerical and Intelligent Simulations (Case Study: Kouhin Tunnel of Qazvin-Rasht Railway). Rud.-Geološko-Naft. Zb. 2019, 34, 11. [Google Scholar] [CrossRef]

| Category | Volume-Weight (kN/m3) | Elasticity Modulus (MPa) | Poisson’s Ratio | Cohesion (kPa) | Internal Friction Angle (°) |

|---|---|---|---|---|---|

| Granite alteration zone | 18.03 | 816.49 | 0.39 | 39.7 | 22.4 |

| Intact granite | 27.0 | 15,000 | 0.28 | 1000 | 45 |

| Pre-Support System | Length/m | Vertical Spacing of Steel Pipe/m | Simulation Unit | ρ/(kg/m3) | E/GPa | ν | I/m4 | Cross-Sectional Area/ m2 |

|---|---|---|---|---|---|---|---|---|

| Single-layer pipe-roof support | 25 | - | Pile | 7850 | 200 | 0.3 | 111.95 × 10−8 | 4.53 × 10−3 |

| Double-layer large-pipe-roof support | 30 | 0.4 | 250.9 × 10−8 | 9.16 × 10−3 |

| Case | Deformation as a Percentage of Total Deformation | ||

|---|---|---|---|

| Stage I | Stage II | Stage III | |

| No advance support | 29.6% | 57.3% | 13.1% |

| Single-layer pipe-roof support | 33.3% | 57% | 9.7% |

| Double-layer large-pipe-roof support | 44.9% | 31.8% | 23.3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Yao, Z.; He, J.; Fan, L.; Fang, Y.; Fang, K.; Yang, Z.; Yan, J. Numerical Response of Advance Support Structures in TBM Tunneling Through Altered Zones: A Case Study. Buildings 2025, 15, 509. https://doi.org/10.3390/buildings15040509

Wang J, Yao Z, He J, Fan L, Fang Y, Fang K, Yang Z, Yan J. Numerical Response of Advance Support Structures in TBM Tunneling Through Altered Zones: A Case Study. Buildings. 2025; 15(4):509. https://doi.org/10.3390/buildings15040509

Chicago/Turabian StyleWang, Jianfeng, Zhigang Yao, Junyang He, Lei Fan, Yong Fang, Kejun Fang, Zhiyong Yang, and Jiabin Yan. 2025. "Numerical Response of Advance Support Structures in TBM Tunneling Through Altered Zones: A Case Study" Buildings 15, no. 4: 509. https://doi.org/10.3390/buildings15040509

APA StyleWang, J., Yao, Z., He, J., Fan, L., Fang, Y., Fang, K., Yang, Z., & Yan, J. (2025). Numerical Response of Advance Support Structures in TBM Tunneling Through Altered Zones: A Case Study. Buildings, 15(4), 509. https://doi.org/10.3390/buildings15040509