Analysis of the Influence of Excavated Soil Sand Characteristics on the Rheological and Mechanical Properties of Hydraulic Mortars

Abstract

1. Introduction

| References | Material | Problems in Raw Materials | Treatment Methods | Behavior in | Fresh Properties | Strength Properties | Durability Properties |

|---|---|---|---|---|---|---|---|

| Huang et al. [28] | Excavated soil recycled fine aggregates (ESRFA) | Fine content, less roundness and less uniform particle size distribution than river sand | Sediment separation and sieving | Mortar | River sand mortar exhibited superior flowability to ESRFA mortar | The flexural and compressive strength of mortar increased at 30% of replacement and then decreased upon increasing the ESRFA content | Porosity, water absorption, and dry shrinkage increased at 30% of replacement then decreased for higher replacement |

| Wu et Zhang [26] | Sand from weathered residual soil of granite (RS) and recycled concrete coarse aggregates (RCA) | Lower fineness modulus, more porous and higher water absorption than natural sand for RS; lower packing density and higher crushing index and water absorption for RCA | Wet sieving or grinding and dry sieving to produce recycled sand (RS) from soil | Concrete | - | Faster increase in compressive strength of concrete containing RS than the concrete with NS, the compressive and flexural strength at 90 days were not lower than the concrete with NS; the 7 d, 28 d, and 90 d compressive strength generally decreased with the utilization of 50% RCAs | - |

| Wu et Xiong [20] | Manufactured sandstone (MSS) of excavated waste from underground construction | The sandstone specimen contained a significantly smaller proportion of quartz and a higher proportion of illite (non-expansive clay mineral) | Raw material crushing; dry sieving or washing for removing stone powder | Mortar | The workability of fresh mortar is dominated by the stone powder content of MSS, while the effect of surface roughness of MSS on the workability of mortar is negligible | The compressive strength of mortar group with 30% replacement of NS by MSS was similar to the control group without MSS, a loss of 20% is obtained with 50% MSS replacement | - |

| Priyadharshini et al. [22] | Excavation soil | Presence of clay and fines | Granulometry to improve granular skeleton. Wet sieving to remove clay and fines | Concrete | Up to 40% clay could be used for laterized concrete though lower percentages are preferable. Less W/C ratio results in poor compaction | Compressive strength reduced with increasing percentage of excavation soil. | Raw earth-based materials present high shrinkage and tendency to crack during drying. |

| Guan et al. [23] | Abandoned excavated soil that taken from a foundation pit | High moisture content, inorganic soil of low plasticity. About 95% of the soil mass has a particle size of less than 1 mm, and particles smaller than 75 m account for 64% of the total mass | Natural air-drying, then crushing, and passing through a 2 mm sieve | Foamed concrete | When the soil content was adjusted from 25% to 50%, the workability was reduced of 15.79% | A reduction of 80.73% (from 1.09 MPa to 0.21 MPa) when the soil content enlarged from 25% to 50% | - |

2. Materials and Methods

2.1. Materials

2.1.1. Cement, Filler and Admixtures

2.1.2. Sand

2.2. Physico-Chemical Characterization of Sand

2.3. Composition of Mortar Mixtures

2.3.1. Fresh State Mortar Properties

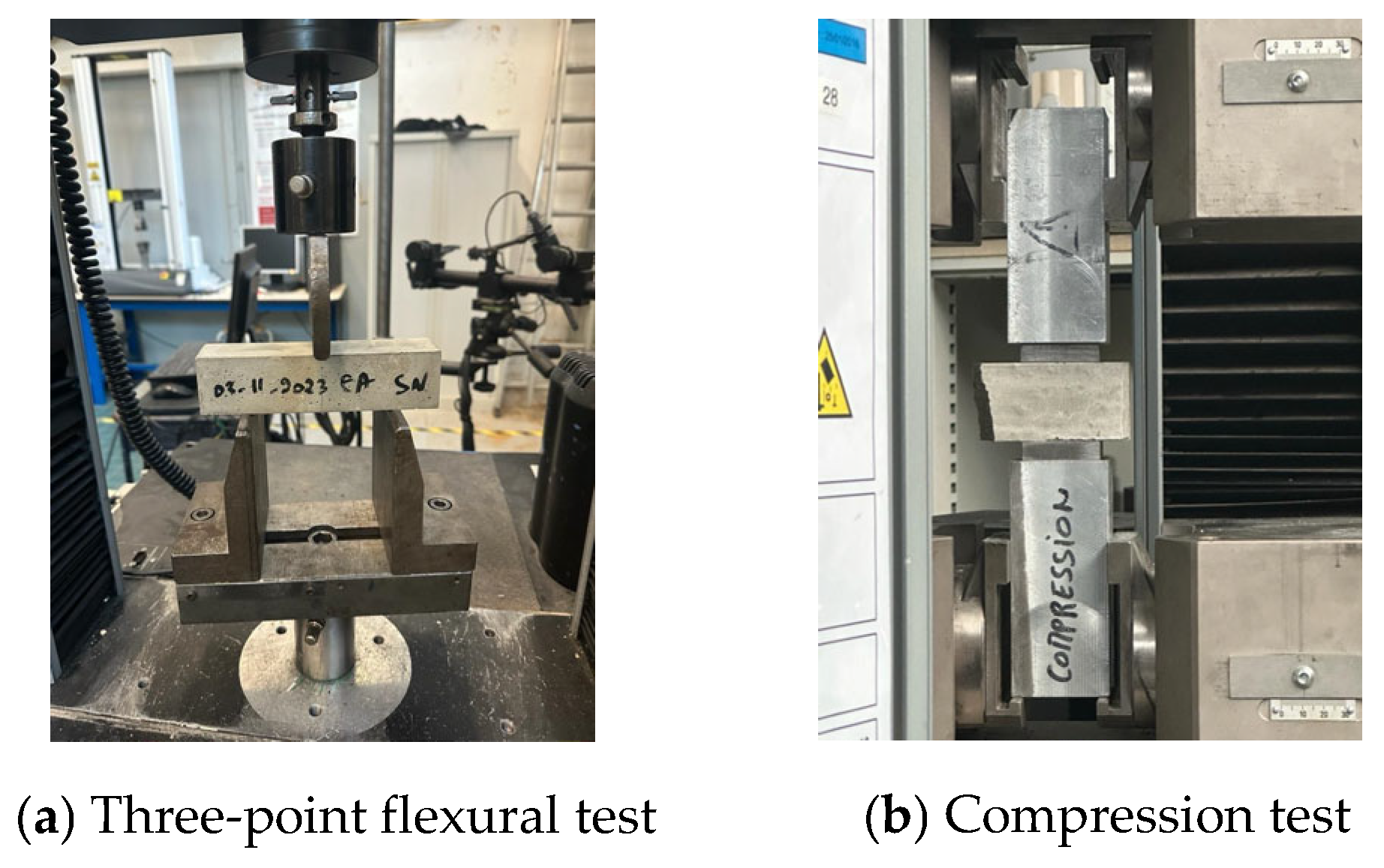

2.3.2. Properties of Hardened State Mortar

3. Results and Discussion

3.1. Properties of Sand

| Property | NS | ESS-SP | ESS-LT | ESS-SG | ESS-LB |

|---|---|---|---|---|---|

| Real density in SSD condition (kg/m3)—NF EN 1097-6 [30] | 2600 | 2106 ± 21 | 2535 ± 3 | 2348 ± 56 | 2093 ± 98 |

| Packing density (kg/m3)—NF EN 1097-3 [44] | 1650 | 1398 ± 11.13 | 1513 ± 9.6 | 1468 ± 14.7 | 1382 ± 18.5 |

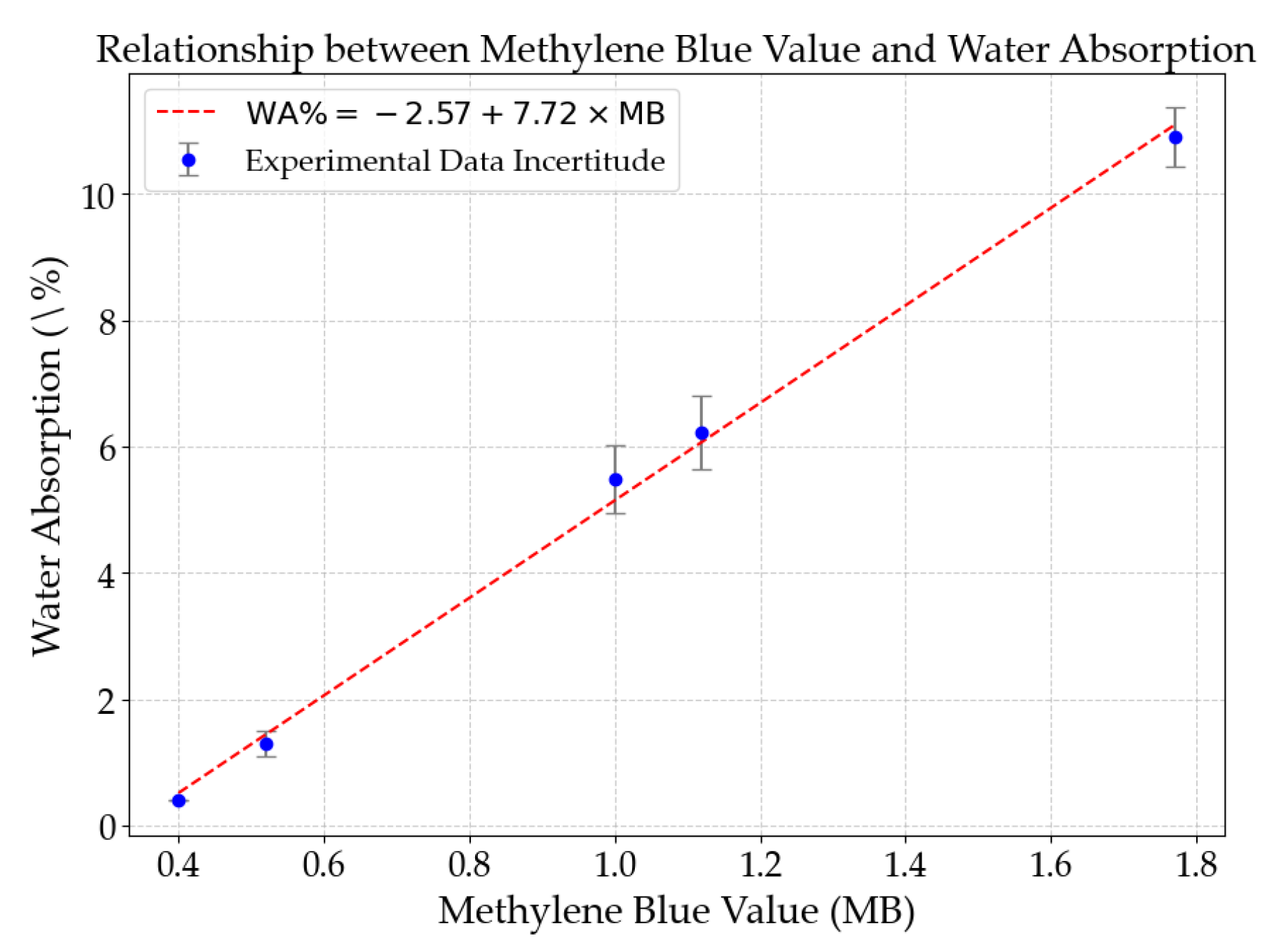

| Water absorption (%)—NF EN 1097-6 [30] | 0.4 | 5.49 ± 0.53 | 1.31 ± 0.2 | 6.22 ± 0.58 | 10.9 ± 0.47 |

| Fineness modulus—NF EN 933-1 [33] | 2.73 | 2.74 | 2.27 | 3 | 3.32 |

| Percentage of fines (%) ≤ 63 µm—NF EN 933-1 [33] | 1.17 | 3.6 | 1.31 | 1.66 | 6.84 |

| Sand equivalent value (%)—NF EN 933-8 [35] | 80 | 72.64 ± 2.94 | 88.16 ± 2.03 | 82.12 ± 1.71 | 63.17 ± 1.54 |

| Methylene blue test value—NF EN 933-9 [36] | 0.4 | 1 | 0.52 | 1.12 | 1.77 |

| Sulfates (%)—NF EN 1744-1 [37] | <0.036 | 0.048 | 0.08 | 0.052 | 0.096 |

| Chlorides (%)—NF EN 1744-1 [37] | 0.0011 | 0.0012 | 0.002 | 0.0007 | 0.0007 |

| Active alkalis (% Na2O + 0.658x% K2O)—NF P 18-454 [38] | 0.003 | 0.0067 | 0.0029 | 0.0047 | 0.0032 |

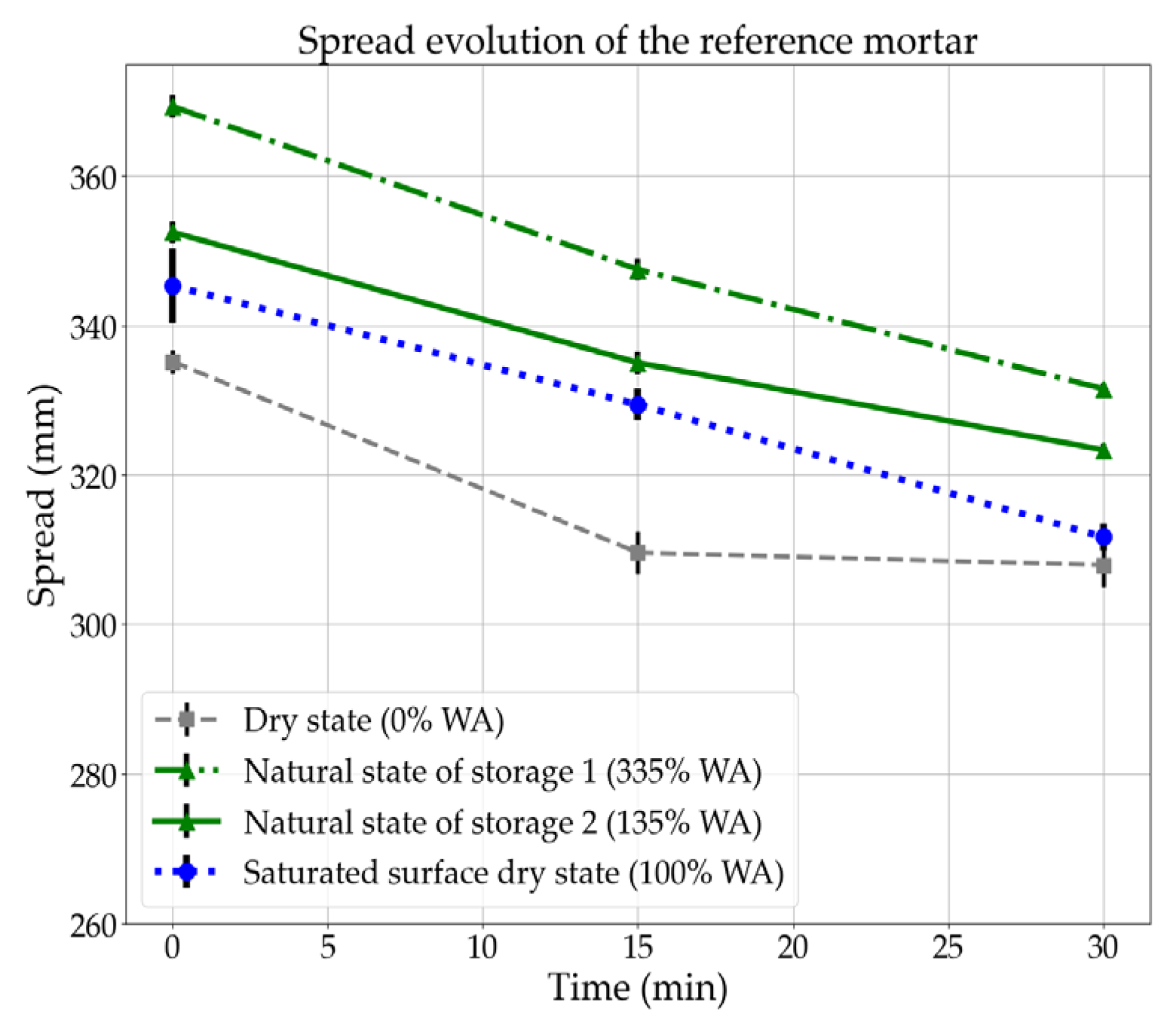

3.2. Results of Fresh Mortar

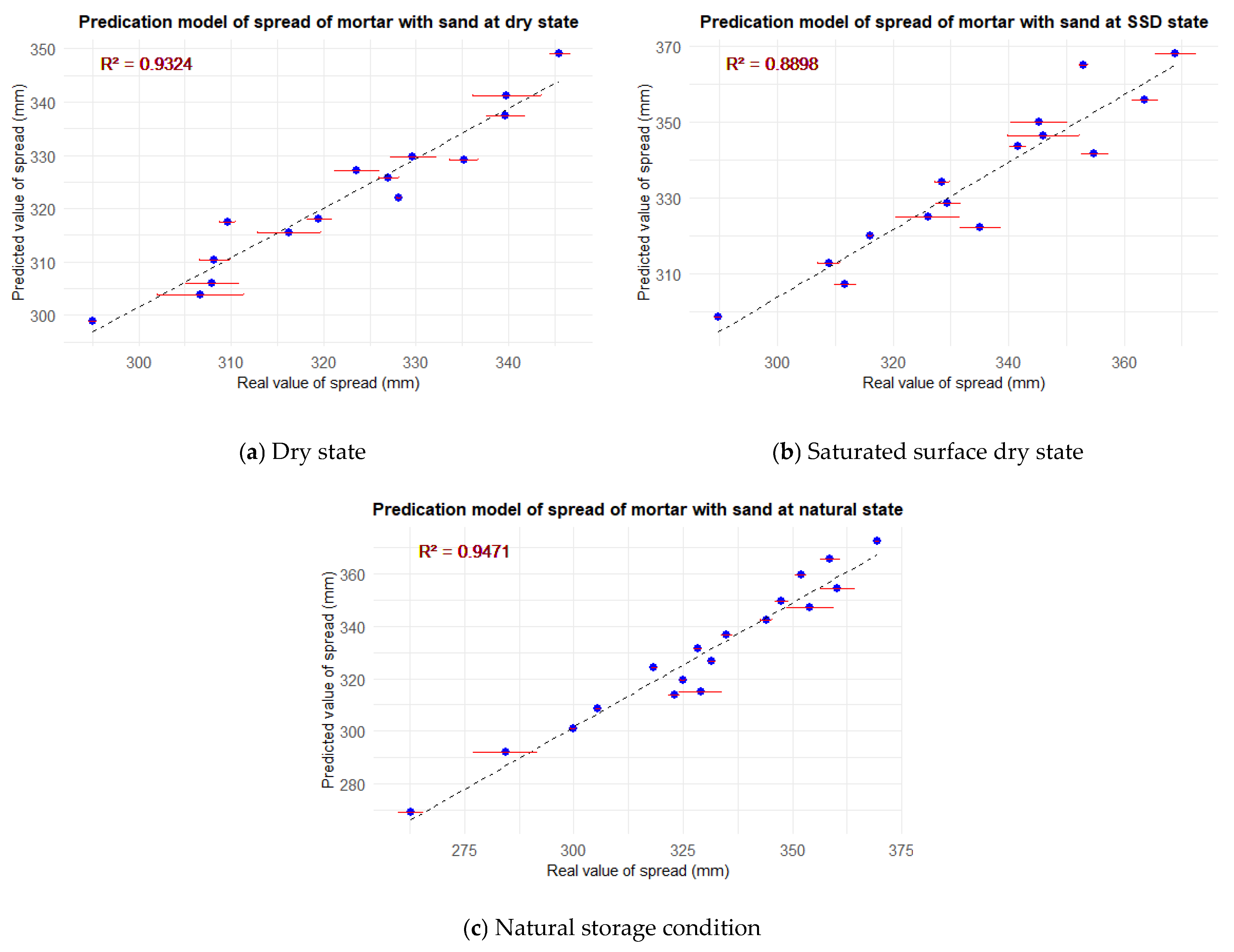

Statistical Study of Fresh State Results

3.3. Hardened State Mortar Results

3.3.1. Compressive Strength

3.3.2. Flexural Strength

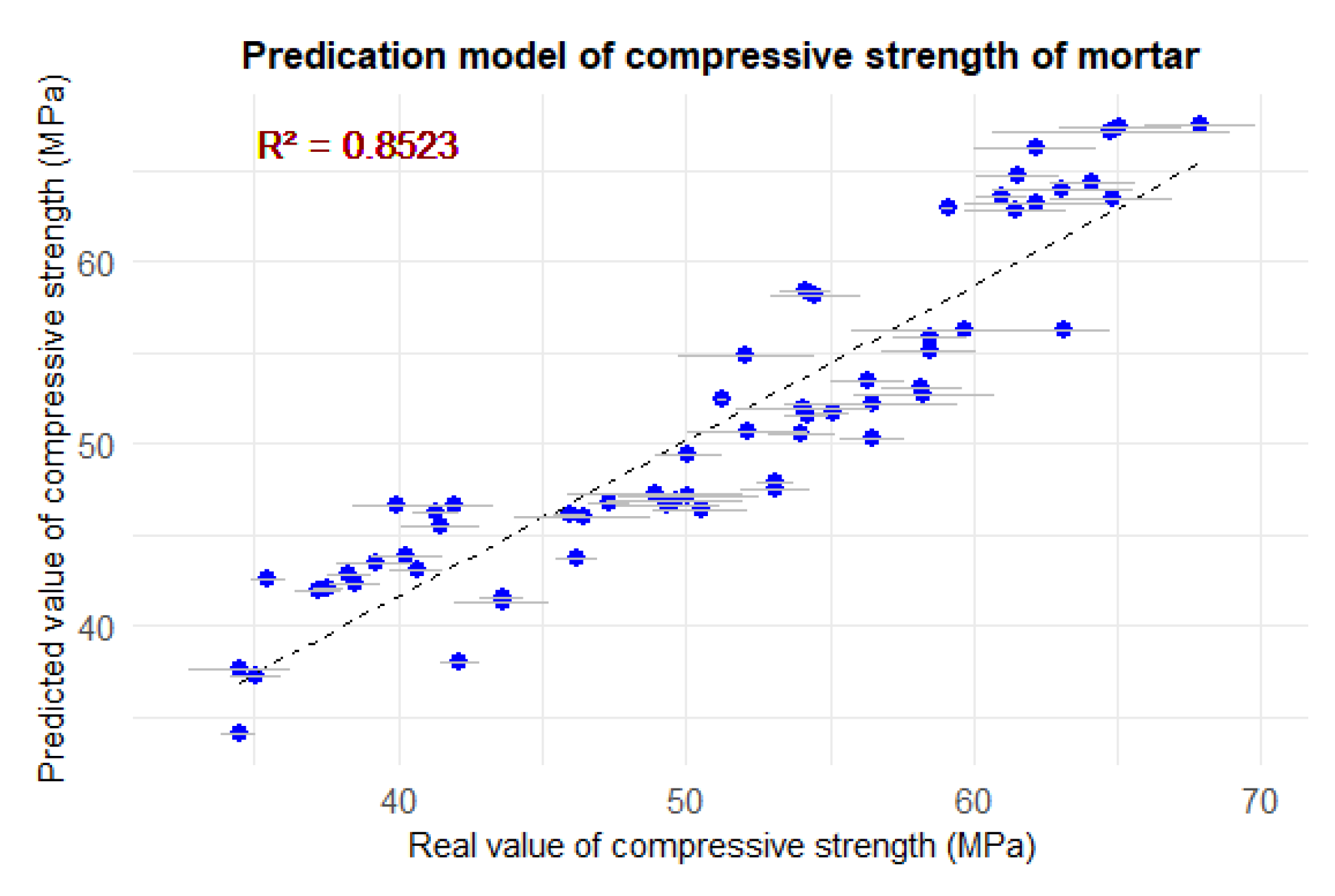

3.3.3. Statistical Study of Hardened State of Mortar

4. Conclusions

- The physicochemical properties of excavated soil sand, including its particle size distribution, fineness modulus (2.27–3.32), fines content (up to 6.84%), and water absorption (up to 10.9%), exhibited significant variability. Higher fines and clay content correlate with increased water absorption, with a methylene blue value of 1.77 corresponding to the highest absorption rate.

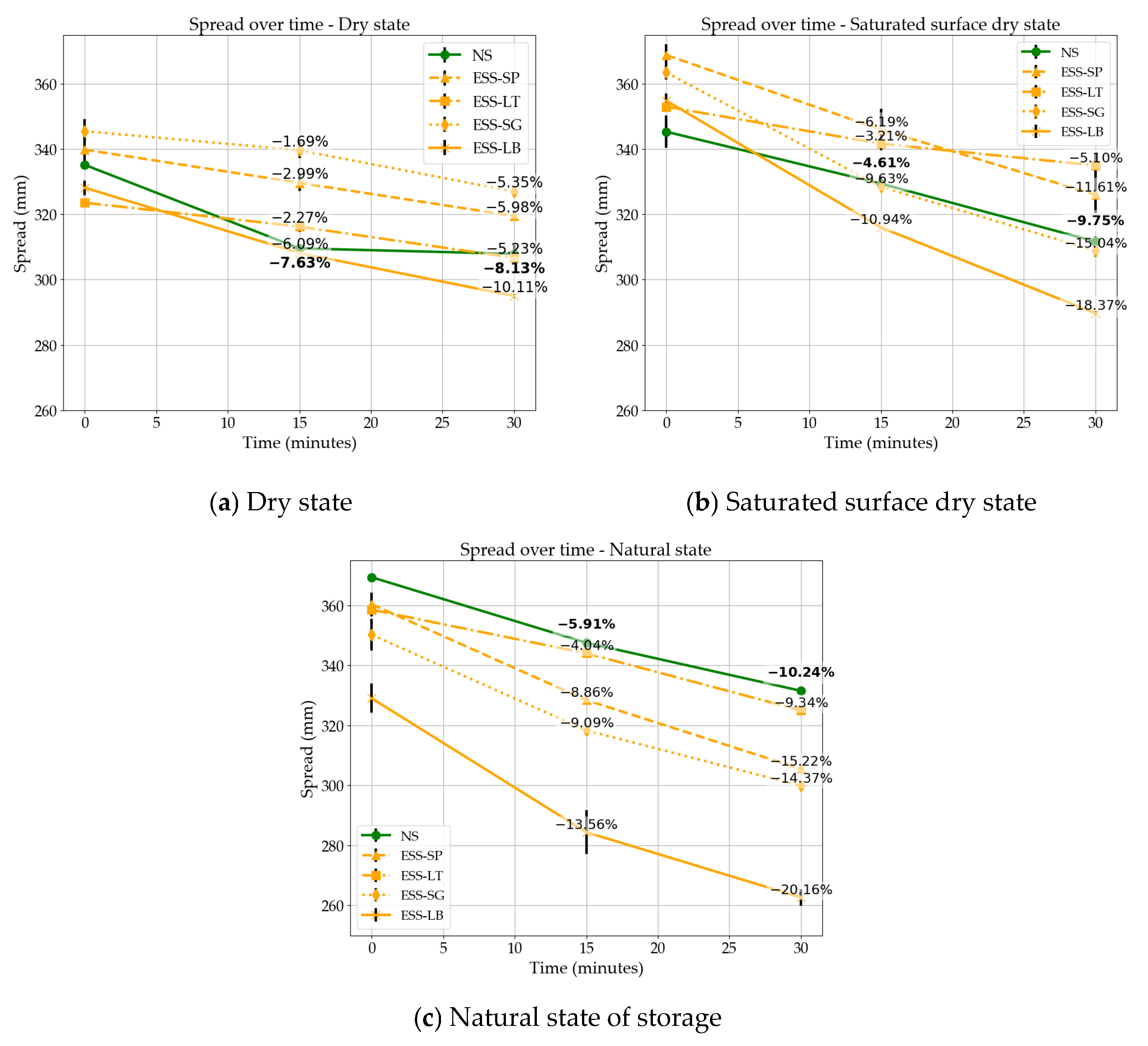

- The rheological properties of mortar were significantly influenced by the moisture state of the sand. Mortars prepared with sand in the saturated surface dry (SSD) state exhibited better flowability compared to those with sand in the dry or natural storage state. The spreading behavior was strongly affected by the sand’s absorption capacity and fines content.

- Compressive strength tests revealed that mortars with 30% excavated soil sand replacement maintained stability across different moisture states. However, for ESS_LB sand, a 20% reduction in compressive strength was observed.

- Flexural strength results showed improvements of 20% to 50% when using excavated soil sand at a 30% replacement rate in the SSD state, demonstrating the potential for enhanced performance in structural applications.

- Statistical modeling revealed a strong relationship (R2 = 85%) between the sand’s properties, particularly fineness modulus and methylene blue value, and the rheological and mechanical performance of the mortar. This predictive model provides valuable insights for optimizing mortar formulations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Eurostat. Vue D’ensemble—Déchets. Available online: https://ec.europa.eu/eurostat/fr/web/waste (accessed on 15 May 2023).

- La Librairie ADEME. Chiffres-Clés Déchets Édition 2023—L’infographie; La Librairie ADEME: Angers, France, 2023. [Google Scholar]

- Cellule Economique de Rhône-Alpes. Etude sur les Volumes et les Flux de Déchets et Matériaux Recyclés du BTP; Cellule Economique de Rhône-Alpes: Villeurbanne, France, 2013. [Google Scholar]

- Prabhu, P.S.; Nishaant, H.A.; Anand, T. Behaviour of Self-Compacting Concrete with Cement Replacement Materials. Int. J. Chem. Environ. Biol. Sci. 2019, 2, 151–156. [Google Scholar]

- Neville, A.M. Properties of Concrete; Pearson: London, UK, 2011. [Google Scholar]

- Sivamani, J.; Renganathan, N.T. Effect of fine recycled aggregate on the strength and durability properties of concrete modified through two-stage mixing approach. Environ. Sci. Pollut. Res. 2021, 29, 85869–85882. [Google Scholar] [CrossRef] [PubMed]

- Topçu, İ.B.; Şengel, S. Properties of concretes produced with waste concrete aggregate. Cem. Concr. Res. 2004, 34, 1307–1312. [Google Scholar] [CrossRef]

- Matias, D.; de Brito, J.; Rosa, A.; Pedro, D. Mechanical properties of concrete produced with recycled coarse aggregates—Influence of the use of superplasticizers. Constr. Build. Mater. 2013, 44, 101–109. [Google Scholar] [CrossRef]

- Nováková, I.; Mikulica, K. Properties of Concrete with Partial Replacement of Natural Aggregate by Recycled Concrete Aggregates from Precast Production. Procedia Eng. 2016, 151, 360–367. [Google Scholar] [CrossRef]

- Señas, L.; Priano, C.; Marfil, S. Influence of recycled aggregates on properties of self-consolidating concretes. Constr. Build. Mater. 2016, 113, 498–505. [Google Scholar] [CrossRef]

- Tahar, Z.E.A.; Kadri, E.-H.; Ngo, T.-T.; Bouvet, A.; Kaci, A.; Aggoun, S. Etude de l’influence des granulats recyclés sur le comportement des MBE. Rencontres Univ. Génie Civ. 2015, 9, 2–8. [Google Scholar]

- Chakradhara Rao, M.; Bhattacharyya, S.K.; Barai, S.V. Influence of field recycled coarse aggregate on properties of concrete. Mater. Struct. 2011, 44, 205–220. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of fine recycled concrete aggregates in concrete: A critical review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M.; Wang, Y. Optimization on proportion for recycled aggregate in concrete using two-stage mixing approach. Constr. Build. Mater. 2007, 21, 1928–1939. [Google Scholar] [CrossRef]

- Al-Bayati, H.K.A.; Das, P.K.; Tighe, S.L.; Baaj, H. Evaluation of various treatment methods for enhancing the physical and morphological properties of coarse recycled concrete aggregate. Constr. Build. Mater. 2016, 112, 284–298. [Google Scholar] [CrossRef]

- Le, T.; Rémond, S.; Le Saout, G.; Garcia-Diaz, E. Fresh behavior of mortar based on recycled sand—Influence of moisture condition. Constr. Build. Mater. 2016, 106, 35–42. [Google Scholar] [CrossRef]

- NF EN 206+A2; Béton—Spécification, Performances, Production et Conformité. AFNOR (Association Française de Normalisation): Paris, France, 2021.

- Xiong, W.; Zhu, H.; Xu, J.; Ma, J.; Luo, C. Experimental investigation on physical and mechanical properties of excavated soil- and fine recycled concrete aggregate-based unfired clay bricks containing compound additives. Case Stud. Constr. Mater. 2023, 18, e02057. [Google Scholar] [CrossRef]

- Wu, B.; Xiong, Y. Influence of sandstone sand manufactured by excavated waste on properties of cement mortar. Case Stud. Constr. Mater. 2024, 20, e02777. [Google Scholar] [CrossRef]

- Priyadharshini, P.; Ramamurthy, K.; Robinson, R.G. Excavated soil waste as fine aggregate in fly ash based geopolymer mortar. Appl. Clay Sci. 2017, 146, 81–91. [Google Scholar] [CrossRef]

- Priyadharshini, P.; Ramamurthy, K.; Robinson, R.G. Sustainable reuse of excavation soil in cementitious composites. J. Clean. Prod. 2018, 176, 999–1011. [Google Scholar] [CrossRef]

- Guan, L.; Chen, Y.; Ye, W.; Wu, D.; Deng, Y. Foamed concrete utilizing excavated soil and fly ash for urban underground space backfilling: Physical properties, mechanical properties, and microstructure. Tunn. Undergr. Space Technol. 2023, 134, 104995. [Google Scholar] [CrossRef]

- Ghorbel, E.; Nouali, M. Characterization of tunnel excavated earth-based mortars for rammed earth repair. E3S Web Conf. 2022, 353, 01001. [Google Scholar] [CrossRef]

- Wu, B.; Cao, H.X.; Lin, L.; Zhang, T.; Zhang, H.T. Experimental study on mechanical behaviors of cement mortar containing excavated soil. J. South China Univ. Technol. 2020, 48, 1–8. [Google Scholar]

- Wu, B.; Zhang, T. Preparation of recycled sand from WRSG and compressive and flexural behavior of recycled aggregate concrete. Constr. Build. Mater. 2024, 414, 134944. [Google Scholar] [CrossRef]

- Wu, B.; Wang, Z.; Chen, Z. Shrinkage behavior of recycled lump/aggregate concrete containing recycled sand from weathered residual soil of granite. Constr. Build. Mater. 2023, 394, 132146. [Google Scholar] [CrossRef]

- Xu, R.; Huang, T. Comparison of the Use of Excavated Soil Recycled Fine Aggregate as a Substitute for River Sand in Mortar Mixing. Buildings 2024, 14, 1917. [Google Scholar] [CrossRef]

- Cyr, M.; Mouret, M.; Cassagnabere, F.; Nguyen, V. Evolution de la Rhéologie du Béton Frais en Fonction du Pourcentage et de L’état de Présaturation des Granulats Recyclés, et en Fonction du Malaxage. Recybéton, Projet National de Recherche et de développement—Thème 2. Available online: https://www.pnrecybeton.fr/wp-content/uploads/2021/12/R14RECY012-Theme-2-Evolution-de-la-rheologie-du-beton-frais-LMDC-LC12RECY11.pdf (accessed on 2 June 2024).

- NF EN 1097-6:2014; Tests for Mechanical and Physical Properties of Aggregates—Part 6: Determination of Particle Density and Water Absorption. AFNOR (Association Française de Normalisation): Paris, France, 2014.

- Traitement des Déchets et Recyclage en Vendée|Alain TP. Available online: https://www.alaintp.fr/gestion-dechets-saint-prouant (accessed on 2 June 2024).

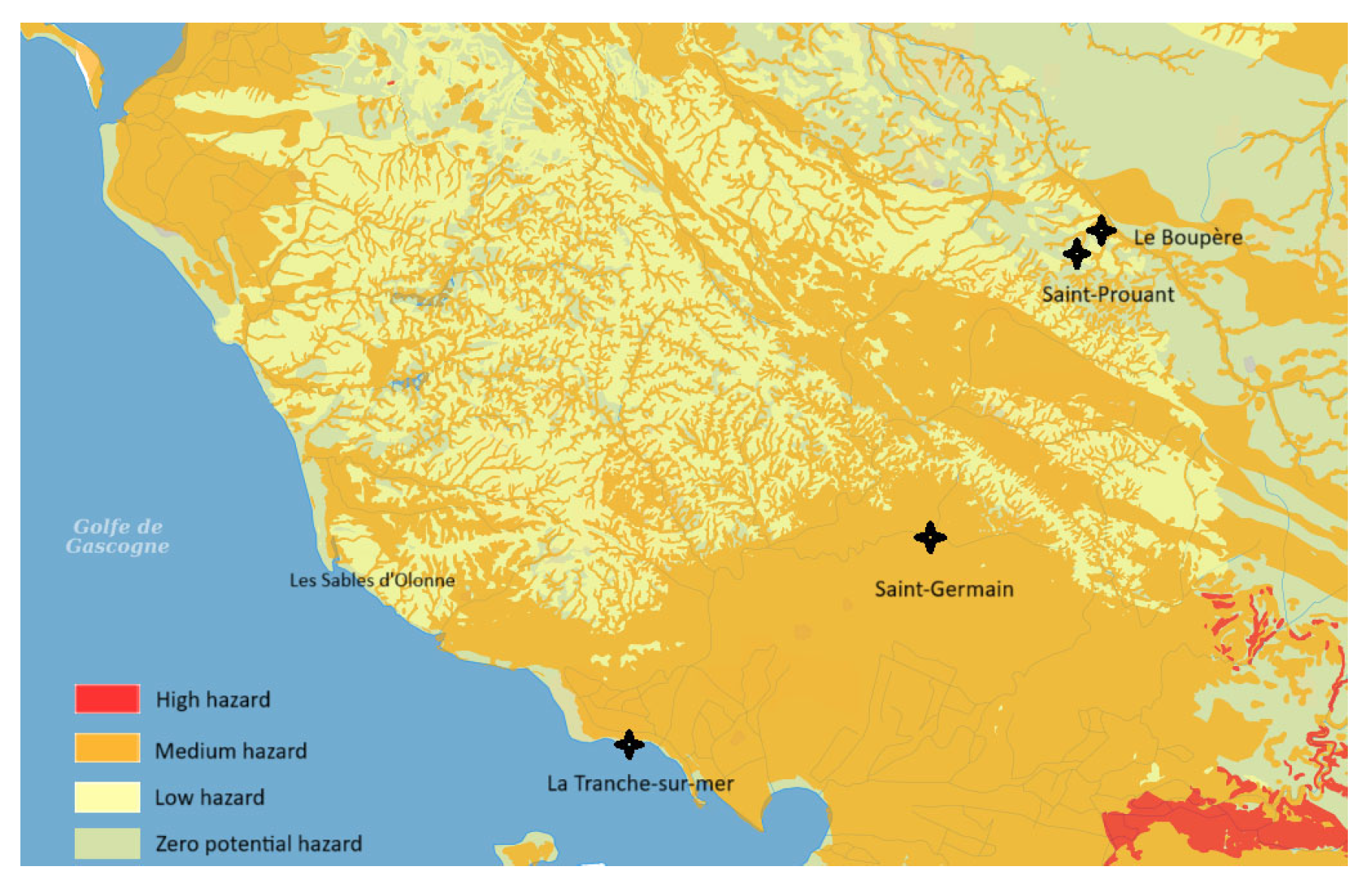

- Risques et Aménagement du Territoire: Retrait-Gonflement des Argiles|BRGM. Available online: https://infoterre.brgm.fr/viewer/MainTileForward.do (accessed on 2 June 2024).

- NF EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. AFNOR (Association Française de Normalisation): Paris, France, 2012.

- NF EN 13139:2003; Aggregates for Mortar. AFNOR (Association Française de Normalisation): Paris, France, 2003.

- NF EN 933-8:2012+A1:2015; Tests for Geometrical Properties of Aggregates—Part 8: Assessment of Fines—Sand Equivalent Test. AFNOR (Association Française de Normalisation): Paris, France, 2015.

- NF EN 933-9+A1; Tests for Determining the Geometrical Properties of Aggregates—Part 9: Assessment of Fines—Methylene Blue Test. AFNOR (Association Française de Normalisation): Paris, France, 2013.

- NF EN 1744-1+A1; Tests for Chemical Properties of Aggregates—Part 1: Chemical Analysis. AFNOR (Association Française de Normalisation): Paris, France, 2014.

- NF P18-454; Contrete—Reactivity of a Concrete Formula with Regard to the Alkali-Aggregate Reaction—Performance Test. AFNOR (Association Française de Normalisation): Paris, France, 2004.

- Schwartzentruberet, A.; Catherine, C. La Méthode du Mortier de Béton Équivalent (MBE)—Un nouvel outil d’aide à la formulation des bétons adjuvantés. Mater. Struct. 2000, 33, 475. [Google Scholar] [CrossRef]

- NF EN 12350-8; Testing Fresh Concrete–Part 8: Self-Compacting Concrete—Slump-Flow Test. AFNOR (Association Française de Normalisation): Paris, France, 2019.

- NF EN 1015-11; Methods of Test for Mortar for Masonry—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. AFNOR (Association Française de Normalisation): Paris, France, 2019.

- NF P18-545; Granulats–Élément de Définition, Conformité et Codification. AFNOR (Association Française de Normalisation): Paris, France, 2021.

- FD P18-456; Béton–Réactivité D’une Formule de Béton vis-à-vis de L’alcali-Réaction—Critères D’interprétation des Résultats de L’essai de Performance. AFNOR (Association Française de Normalisation): Paris, France, 2004.

- NF EN 1097-3; Tests for Mechanical and Physical Properties of Aggregates—Part 3: Determination of Loose Bulk Density and Voids. AFNOR (Association Française de Normalisation): Paris, France, 1998.

- Houria, M.; Nourredine, A. Les granulats recyclés humidifiés: Comportements des bétons frais et durcis. In Proceedings of the XXIXe Rencontres Universitaires de Gènie Civil, Tlemcen, Algeria, 29–31 May 2011; pp. 401–410. [Google Scholar]

- Choudhary, H.; Siddiqui, M.A.; Saha, D. Effect of Clay Fines on Strength and Workability of Concrete. In Proceedings of the International Conference on Architecture, Civil and Environmental Engineering (ACEE2019), Jawaharlal Nehru University, New Delhi, India, 21–23 September 2019; Volume 6. [Google Scholar]

- Hung; Bui, P.T.; Lai, T.L.K. Influence of moisture states of recycled sand from construction sites on mechanical strengths of cement-based mortar. J. Mater. Constr. 2023, 13, 4–9. [Google Scholar] [CrossRef]

- Benabed, B.; Azzouz, L.; Belaidi, A.S.E.; Kadri, E.H.; Kenai, S.; Boukhelkhal, A. Influence de Type du Sable sur les Proprietes Rheologiques et Mecaniques des Betons Autoplaçants. In Proceedings of the 3ème Séminaire International Innovation et Valorisation en Génie Civil et Matériaux de Construction, Alger, Algérie, 17–18 November 2014; p. 7. [Google Scholar]

- Ju, S.; Feng, T.; Wang, L.; Jiang, J. Effect of Fine Aggregate on Rheological Properties of Ultra-High Performance Concrete (UHPC). In Proceedings of the 4th International RILEM Conference on Microstructure Related Durability of Cementitious Composites (Microdurability2020), Online, 29 April–25 May 2021. [Google Scholar]

- Ahn, N. An Experimental Study on the Guidelines for Using Higher Contents of Aggregate Micro Fines in Portland Cement Concrete. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2001. [Google Scholar]

- Norvell, J.K.; Stewart, J.G.; Juenger, M.C.; Fowler, D.W. Influence of Clays and Clay-Sized Particles on Concrete Performance. J. Mater. Civ. Eng. 2007, 19, 1053–1059. [Google Scholar] [CrossRef]

- Topçu, İ.B.; Demir, A. Relationship between methylene blue values of concrete aggregate fines and some concrete properties. Can. J. Civ. Eng. 2008, 35, 379–383. [Google Scholar] [CrossRef]

- Léger, C. La Valeur-P Sous Surveillance; Association Mathématique du Québec: Montreal, QC, Canada, 2016; pp. 77–85. [Google Scholar]

- Almeida Filho, F.M.; Barragán, B.E.; Casas, J.R.; El Debs, A.L.H.C. Hardened properties of self-compacting concrete—A statistical approach. Constr. Build. Mater. 2010, 24, 1608–1615. [Google Scholar] [CrossRef]

- Le, T.; Le Saout, G.; Garcia-Diaz, E.; Betrancourt, D.; Rémond, S. Hardened behavior of mortar based on recycled aggregate: Influence of saturation state at macro- and microscopic scales. Constr. Build. Mater. 2017, 141, 479–490. [Google Scholar] [CrossRef]

- Xiao, J.-Z.; Li, J.-B.; Zhang, C. On relationships between the mechanical properties of recycled aggregate concrete: An overview. Mater. Struct. 2007, 39, 655–664. [Google Scholar] [CrossRef]

- Souche, J.-C.; Salgues, M.; Devilliers, P.; Eric, G.-D. Influence du degré de saturation initial des granulats recyclés sur les caractéristiques de la pâte cimentaire à l’état frais: Conséquences sur les propriétés du béton recyclé. In Proceedings of the Conférence Internationale Francophone NoMaD 2015, Douai, France, 5–6 November 2015. [Google Scholar]

- Ji, T.; Chen, C.-Y.; Chen, Y.-Y.; Zhuang, Y.-Z.; Chen, J.-F.; Lin, X. Effect of moisture state of recycled fine aggregate on the cracking resistibility of concrete. Constr. Build. Mater. 2013, 44, 726–733. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, X.; Liu, W.; Zhao, B.; Wang, Q. Influence of the moisture states of aggregate recycled from waste concrete on the performance of the prepared recycled aggregate concrete (RAC)—A review. Constr. Build. Mater. 2022, 326, 126891. [Google Scholar] [CrossRef]

| Abbreviation | Particle Class (mm) | Type | Origin |

|---|---|---|---|

| NS | 0/4 | Alluvial | Pays de La Loire |

| ESS-SP | 0/4 | Excavation | Saint-Prouant |

| ESS-LB | 0/4 | Excavation | Le Boupère |

| ESS-SG | 0/4 | Excavation | Saint-Germain |

| ESS-LT | 0/4 | Excavation | La Trance |

| Constituents | M-NS | M-ESS-SP-30 | M-ESS-LT-30 | M-ESS-SG-30 | M-ESS-B-30 |

|---|---|---|---|---|---|

| 0.56 | 0.56 | 0.56 | 0.56 | 0.56 | |

| 0.335 | 0.335 | 0.335 | 0.335 | 0.335 | |

| S/C | 2.74 | 2.55 | 2.71 | 2.65 | 2.51 |

| Model | Residuals (mm) | Min (mm) | Max (mm) |

|---|---|---|---|

| Dry state | −7.973 to 6.106 | −7.973 | 6.106 |

| Saturated surface dry state | −11.9786 to 13.355 | −11.9786 | 13.355 |

| Natural state of storage | −7.639 to 14.005 | −7.639 | 14.005 |

| Metric | Value |

|---|---|

| Multiple R2 | 0.8449 |

| Residual standard error | 9.799 mm |

| p-value | 1.692 × 10−13 |

| Metric | Value |

|---|---|

| Multiple R2 | 0.8523 |

| Residual standard error | 3.914 |

| p-value | <2.2 × 10−16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saad, L.; Nouri, M.; Tahlaiti, M.; Khelidj, A.; Fruchet, J.; Suraneni, P. Analysis of the Influence of Excavated Soil Sand Characteristics on the Rheological and Mechanical Properties of Hydraulic Mortars. Buildings 2025, 15, 353. https://doi.org/10.3390/buildings15030353

Saad L, Nouri M, Tahlaiti M, Khelidj A, Fruchet J, Suraneni P. Analysis of the Influence of Excavated Soil Sand Characteristics on the Rheological and Mechanical Properties of Hydraulic Mortars. Buildings. 2025; 15(3):353. https://doi.org/10.3390/buildings15030353

Chicago/Turabian StyleSaad, Lara, Mustapha Nouri, Mahfoud Tahlaiti, Abdelhafid Khelidj, Julien Fruchet, and Prannoy Suraneni. 2025. "Analysis of the Influence of Excavated Soil Sand Characteristics on the Rheological and Mechanical Properties of Hydraulic Mortars" Buildings 15, no. 3: 353. https://doi.org/10.3390/buildings15030353

APA StyleSaad, L., Nouri, M., Tahlaiti, M., Khelidj, A., Fruchet, J., & Suraneni, P. (2025). Analysis of the Influence of Excavated Soil Sand Characteristics on the Rheological and Mechanical Properties of Hydraulic Mortars. Buildings, 15(3), 353. https://doi.org/10.3390/buildings15030353