Macro and Microstructural Evaluation of Air-Cured Cement-Based Materials Enhanced by Marble Powder for Infrastructure Subject to Sulfuric Acid Attack

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Sample Preparation and Curing Conditions

2.2.2. Determination of Macro Properties

2.2.3. Microstructural Characterization

- X-Ray Diffraction (XRD): Powder XRD was employed for mineralogical analysis of hardened cement-based materials containing MP at different levels. Prior to analysis, a cross-section from the middle portion of each prism was extracted (40 × 40 × 8 ± 2 mm), dried in silica gel at a temperature of 20 °C, crushed, and then sieved to a particle size of <50 µm to reduce the effect of rehydration. XRD patterns were obtained from a diffractometer with a radiation source (λ = 1.54056 Å), and a to 70° (2θ) scan area, and a step of 0.002°.

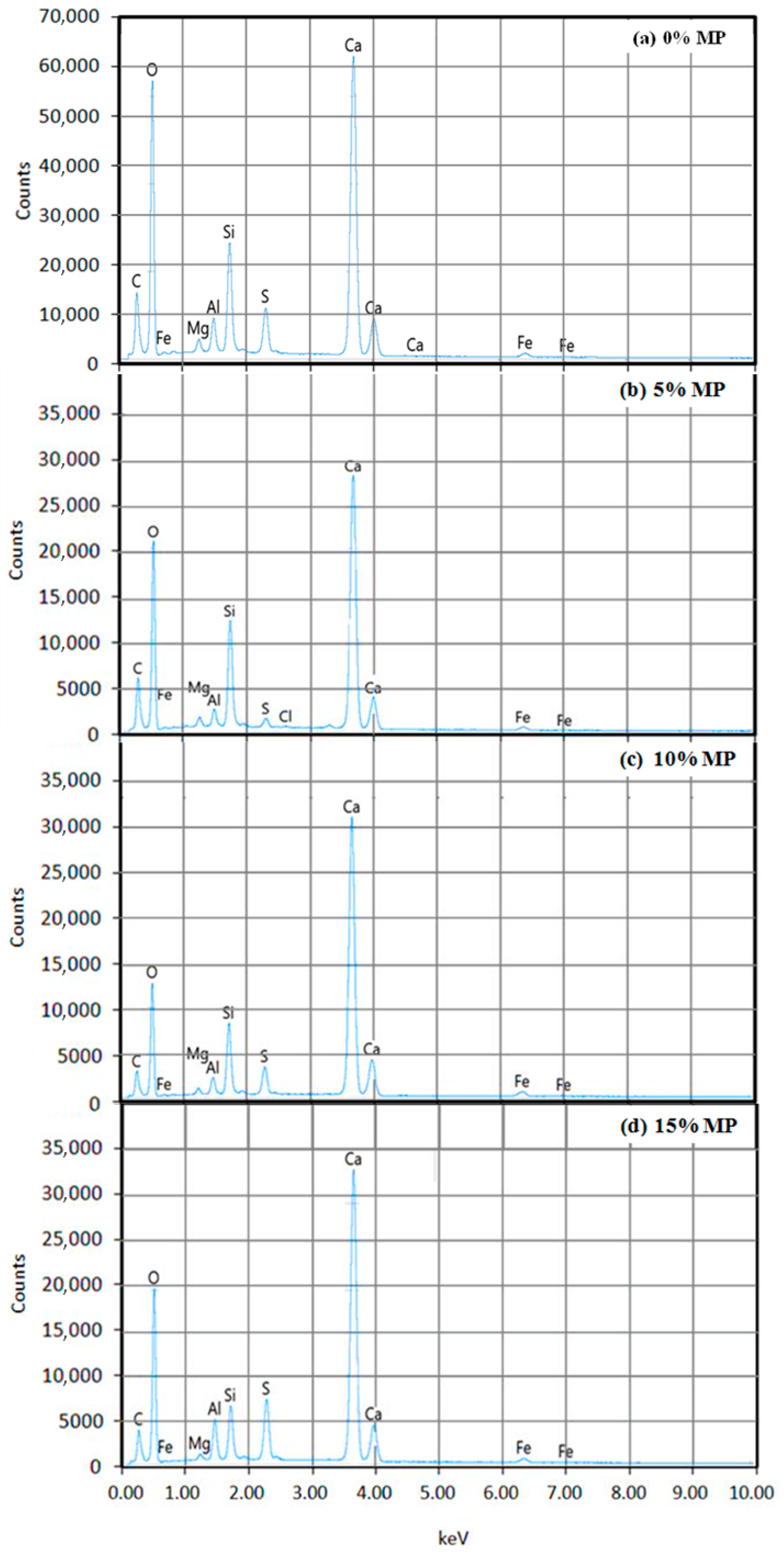

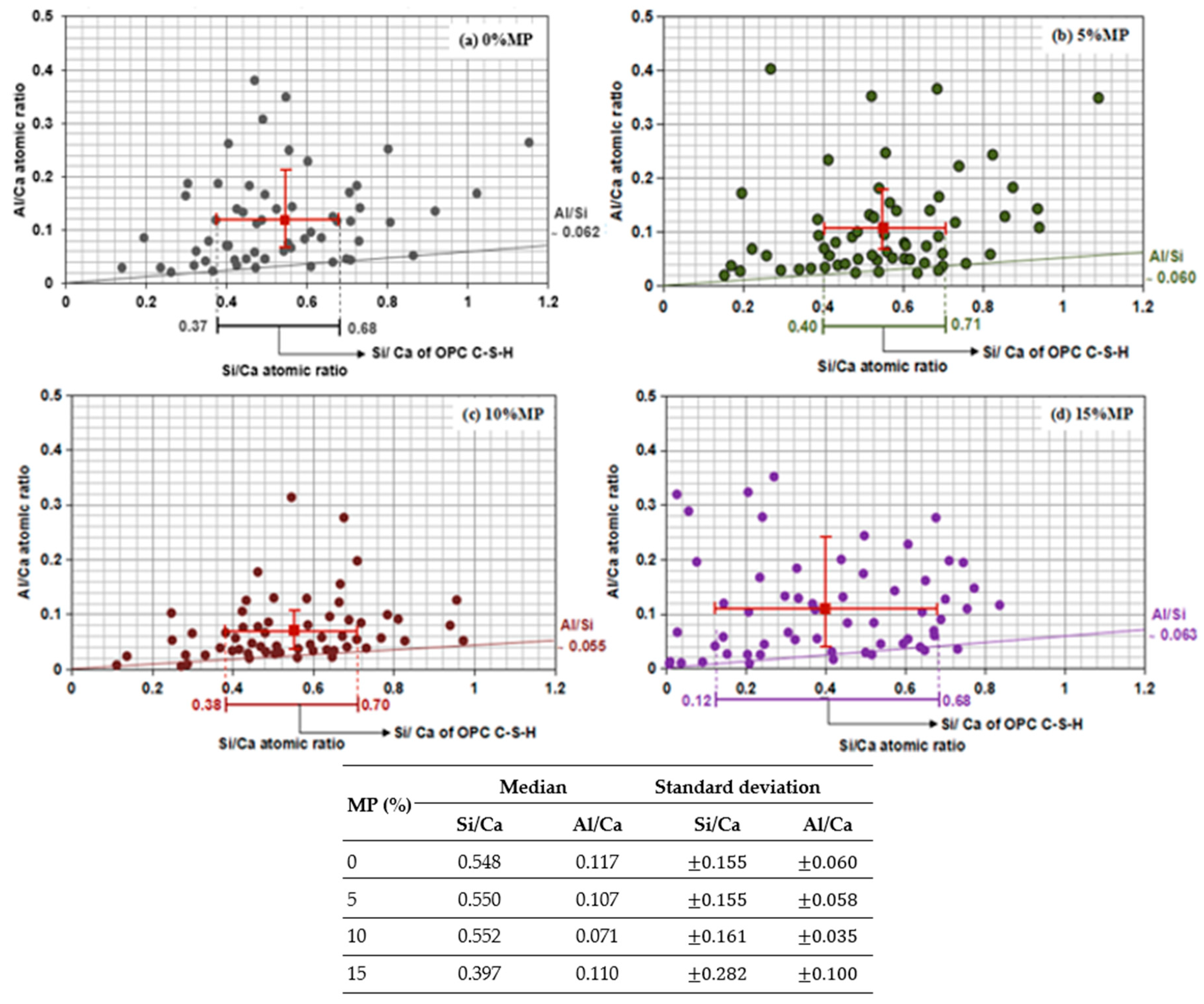

- Scanning Electron Microscopy (SEM) and Energy-Dispersive X-ray Spectroscopy (EDS): SEM-EDS analysis was performed on the cross-sectional surfaces of air-cured cement paste specimens exposed to sulfuric acid attack. For the purposes of this study, the SEM and EDS were concerned solely with examining microstructural phase changes and elemental distributions (Si, Ca, Al) without concern for cracks, voids, or general morphology. To support the XRD/Rietveld results, elemental mapping and Si/Ca ratios were generated to confirm proposed changes to the C-S-H gel and other cementitious phases, as a function of MP substitution and acid attack.

3. Results

3.1. Macro Properties

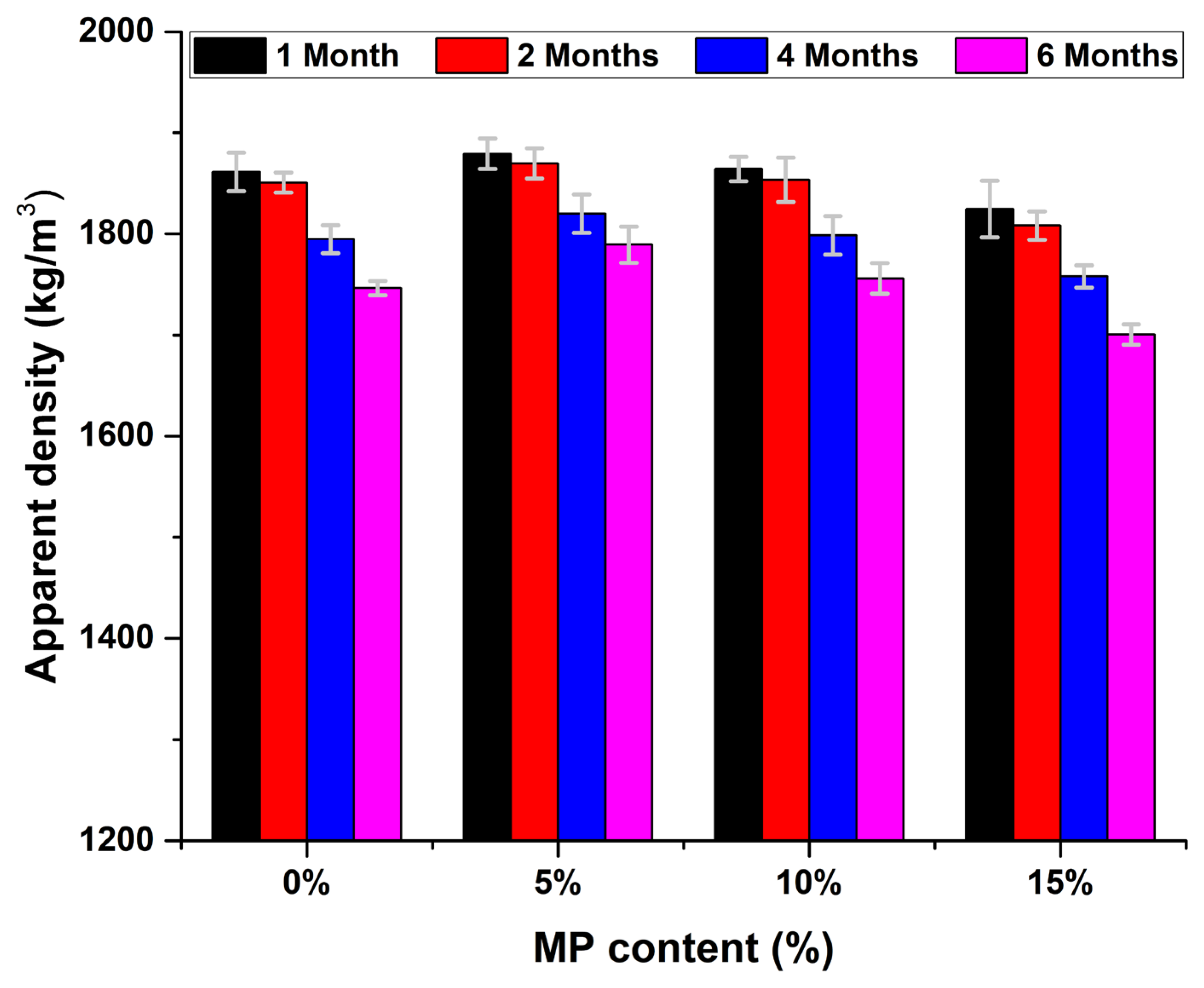

3.1.1. Apparent Density

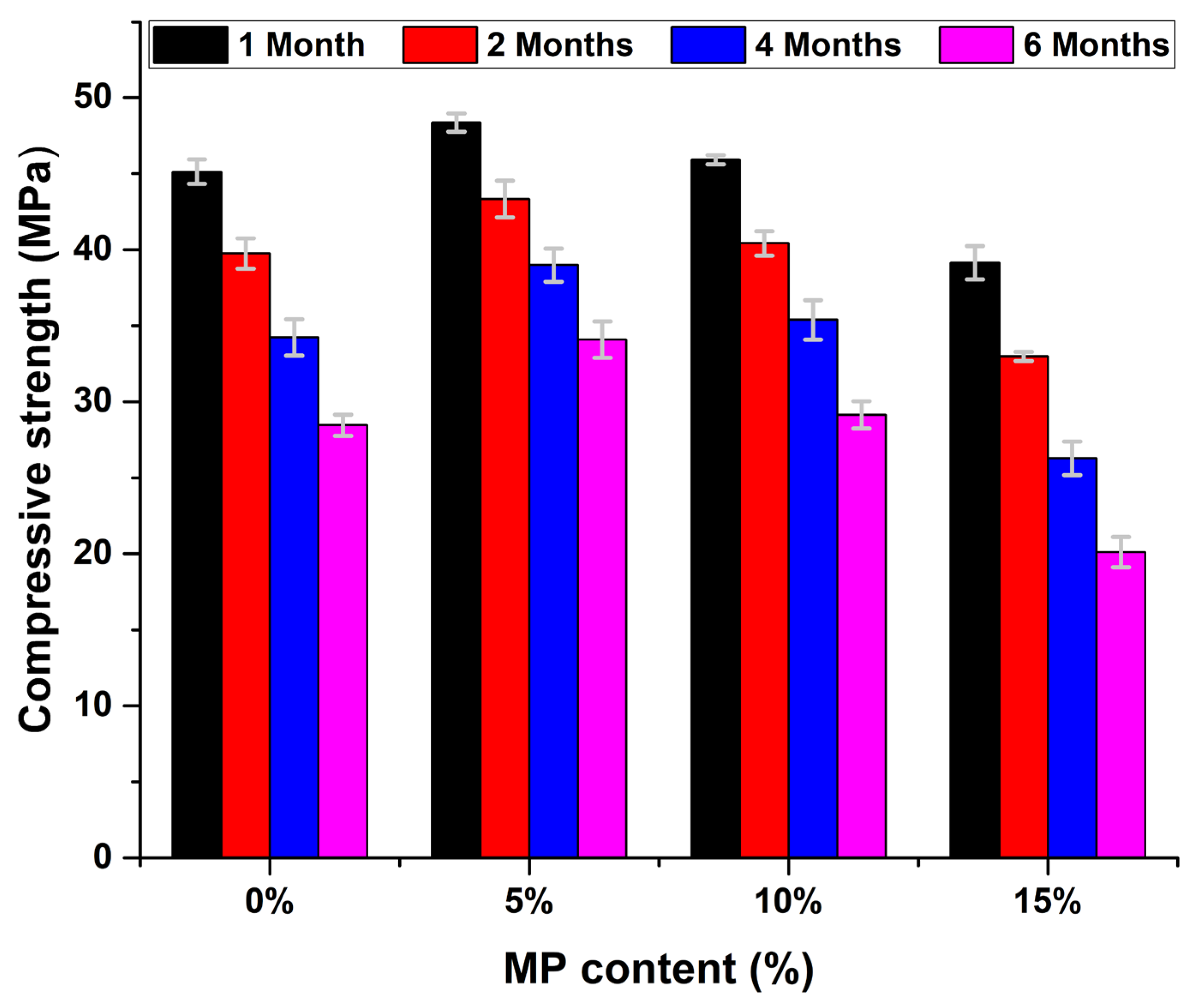

3.1.2. Compressive Strength

3.2. Microstructural Results

3.2.1. X-Ray Diffraction and Rietveld Analysis

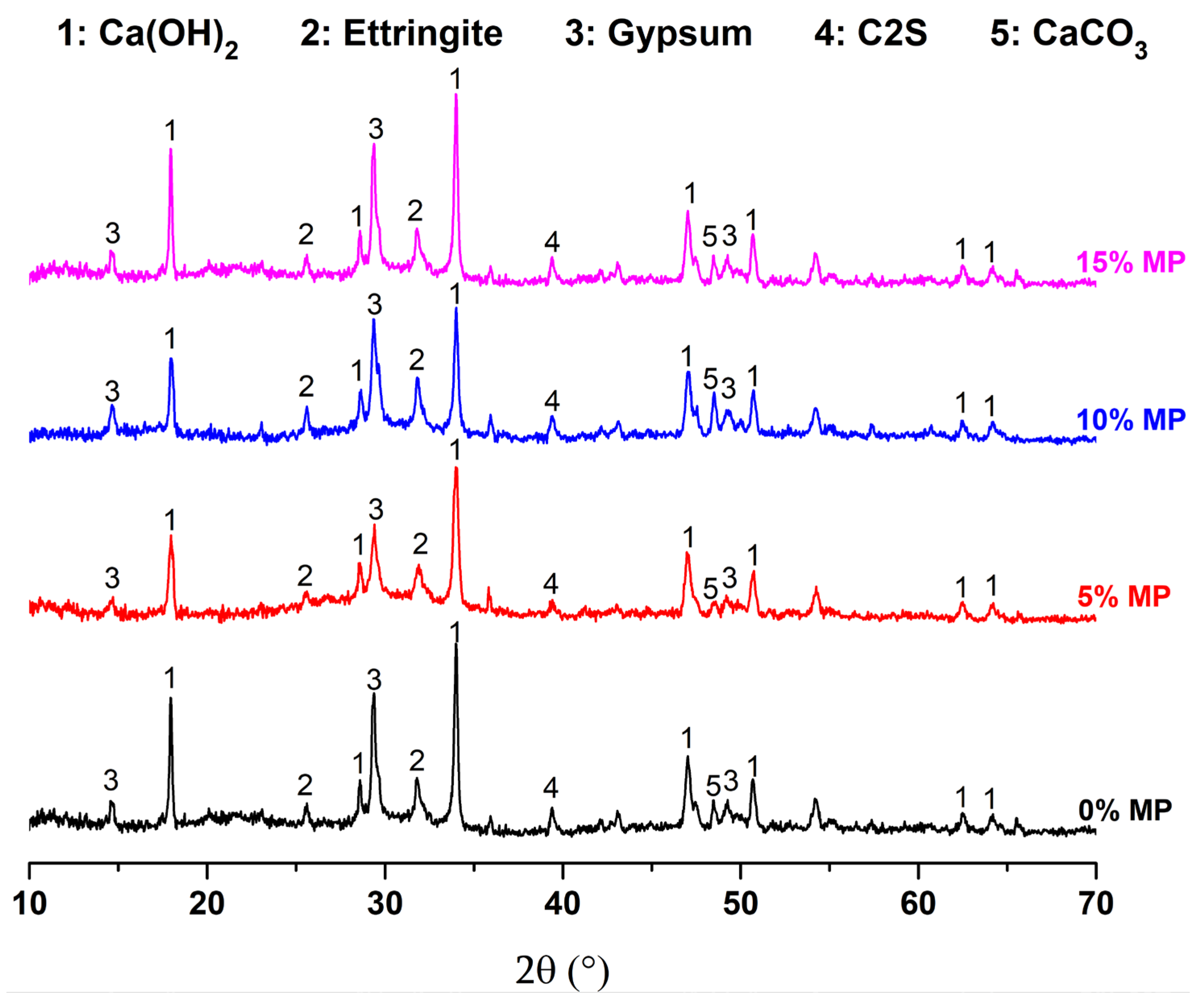

3.2.2. Qualitative Phase Identification

3.2.3. Effect of MP on Phase Intensity and Acid Resistance

3.2.4. Rietveld Refinement Applied to Quantitative Phase Analysis

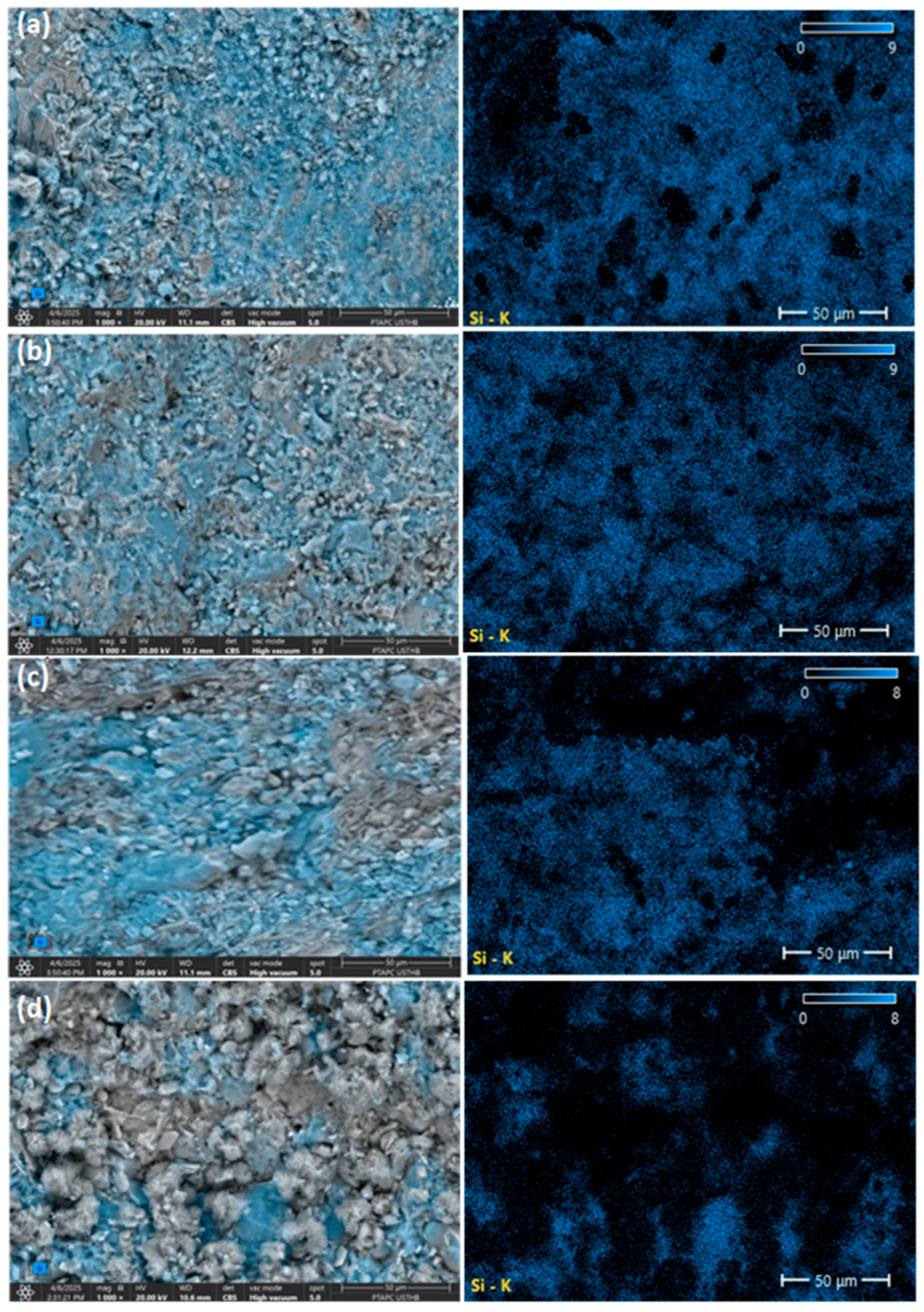

3.3. Microstructural and Elemental Characterization via SEM-EDS

C-S-H Phase Characterization by Elemental Ratios

4. Conclusions

- Partial replacement of OPC with 5% MP improved both macro- and microstructural properties, including apparent density and compressive strength, due to the filler effect and reduced matrix permeability, enhancing resistance to acid attack.

- X-ray Diffraction and Rietveld analysis revealed that MP significantly altered the phase composition. MP increased calcite content, preserved C-S-H phases, and promoted gypsum formation. Ettringite remained stable, with only a minor increase at 15% MP. Low MP contents (5–10%) effectively enhanced acid durability by retaining C-S-H and improving density.

- SEM-EDS analysis confirmed that incorporating up to 5% MP increased Ca and Si content, enhanced hydration, and improved particle packing, leading to better acid resistance.

- The Al/Ca vs. Si/Ca ratio analysis showed that 10% MP maintains C-S-H preservation and reduces leaching of aluminum-containing phases under acid attack, demonstrating acceptable durability.

- At 10% MP replacement, performance was comparable to the control, indicating no detrimental effect on durability.

- At 15% MP, reductions in all performance metrics were observed, likely due to dilution effects and increased silica leaching under sulfuric acid exposure.

- Optimizing MP particle size and chemical composition to further enhance acid resistance.

- Investigating long-term performance and durability under varying environmental conditions.

- Exploring the synergistic effects of MP with other supplementary cementitious materials to improve mechanical and chemical resistance.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, S.; Wang, Z. Effect of Limestone Powder on Acid Attack Characteristics of Cement Pastes. Mater. Sci. 2014, 20, 503–508. [Google Scholar] [CrossRef]

- Jahani, F.; Devinny, J.; Mansfeld, F.; Rosen, I.G.; Sun, Z.; Wang, C. Investigations of sulfuric acid corrosion of concrete. I: Modeling and chemical observations. J. Environ. Eng. 2001, 127, 572–579. [Google Scholar] [CrossRef]

- Shi, X.; Xie, N.; Fortune, K.; Gong, J. Durability of steel reinforced concrete in chloride environments: An overview. Constr. Build. Mater. 2012, 30, 125–138. [Google Scholar] [CrossRef]

- Riyahi, A.; Jebter, A.A.; Hejazi, F. Investigation on durability of concrete exposed to chloride, sulfate attack and steel corrosion. IOP Conf. Ser. Earth Environ. Sci. 2019, 357, 12011. [Google Scholar] [CrossRef]

- Chang, H.; Wang, P.; Jin, Z.; Li, G.; Feng, P.; Ye, S.; Liu, J. Durability and Aesthetics of Architectural Concrete under Chloride Attack or Carbonation. Materials 2020, 13, 839. [Google Scholar] [CrossRef]

- Bassuoni, M.T.; Nehdi, M.L. Resistance of self-consolidating concrete to sulfuric acid attack with consecutive pH reduction. Cem. Concr. Res. 2007, 37, 1070–1084. [Google Scholar]

- Naseer, A.; Tantray, M.A. Sulfuric acid’s effects on the characteristics of regular Portland cement concrete under various environmental circumstances. Libr. Prog. Int. 2024, 44, 19096–19103. [Google Scholar]

- Irico, S.; De Meyst, L.; Qvaeschning, D.; Alonso, M.C.; Villar, K.; De Belie, N. Severe Sulfuric Acid Attack on Self-Compacting Concrete with Granulometrically Optimized Blast-Furnace Slag-Comparison of Different Test Methods. Materials 2020, 13, 1431. [Google Scholar]

- Al-Sodani, K.A.A.; Adewumi, A.A.; Mohd Ariffin, M.A.; Salami, B.A.; Yusuf, M.O.; Ibrahim, M.; AlAteah, A.H.; Al-Tholaia, M.M.H.; Shamsah, S.M.I.; Ismail, M. Acid Resistance of Alkali-Activated Natural Pozzolan and Limestone Powder Mortar. Sustainability 2022, 14, 14451. [Google Scholar] [CrossRef]

- Zivica, V.; Bajza, A. Acidic attack of cement based materials—A review: Part 1. Principle of acidic attack. Constr. Build. Mater. 2001, 15, 331–340. [Google Scholar] [CrossRef]

- Selim, F.A.; Hashem, F.S.; Amin, M.S. Mechanical, microstructural and acid resistance aspects of improved hardened Portland cement pastes incorporating marble dust and fine kaolinite sand. Constr. Build. Mater. 2020, 251, 118992. [Google Scholar] [CrossRef]

- Shi, C.; Stegemann, J.A. Acid corrosion resistance of different cementing materials. Cem. Concr. Res. 2000, 30, 803–808. [Google Scholar] [CrossRef]

- Beddoe, R.E.; Dorner, H.W. Modelling acid attack on concrete: Part I. The essential mechanisms. Cem. Concr. Res. 2005, 35, 2333–2339. [Google Scholar] [CrossRef]

- Andrew, R.M. Global CO2 emissions from cement production, 1928–2018. Earth Syst. Sci. Data 2019, 11, 1675–1710. [Google Scholar] [CrossRef]

- Sengul, O.; Tasdemir, M.A. Compressive strength and rapid chloride permeability of concretes with ground fly ash and slag. J. Mater. Civ. Eng. 2009, 21, 494–501. [Google Scholar] [CrossRef]

- Abbas, Y.; Djebien, R.; Toubal Seghir, N.; Benaimeche, O. Enhancing mechanical behaviour and durability of high performance concrete with silica fume, ground blast furnace slag, and marble powder. J. Appl. Eng. Sci. 2023, 13, 137–146. [Google Scholar] [CrossRef]

- Madandoust, R.; Ranjbar, M.M.; Moghadam, H.A.; Mousavi, S.Y. Mechanical properties and durability assessment of rice husk ash concrete. Biosyst. Eng. 2011, 110, 144–152. [Google Scholar] [CrossRef]

- Yang, K.H.; Jung, Y.B.; Cho, M.S.; Tae, S.H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Boutlikht, M.; Douadi, A.; Khitas, N.E.H.; Messai, A.; Hebbache, K.; Belebchouche, C.; Smarzewski, P.; Tawfik, T.A. Optimizing of Self-Compacting Concrete (SCC): Synergistic Impact of Marble and Limestone Powders—A Technical and Statistical Analysis. Buildings 2025, 15, 1043. [Google Scholar]

- Arel, H.Ş. Recyclability of Waste Marble in Concrete Production. J. Clean. Prod. 2016, 131, 179–188. [Google Scholar] [CrossRef]

- Chakkor, O. Durability and Microstructural Evaluation of Geopolymer Mortars Exposed to Sulphuric Acid Using Industrial By-Product Fillers. Polymers 2025, 17, 2310. [Google Scholar] [CrossRef]

- Boukhelkhal, A.; Benguit, A.; Lakhdar, A. Study of the Durability Against Acid Sulfuric Attack and Accelerated Carbonation of Eco-Efficient Self-Compacting Concrete Blended with Marble Powder. Int. J. Integr. Eng. 2025, 17, 241–255. [Google Scholar]

- Wang, Q.; Kunther, W.; Li, Y.; Visalakshi, T.; Gomasa, R.; Amroun, S.; De Souza, D.J.; Kasaniya, M.; Tole, I.; Li, X.; et al. Sulfate Attack Testing Approaches from Concrete to Cement Paste: A Review by RILEM TC 298-EBD. Mater. Struct. 2025, 58, 232. [Google Scholar] [CrossRef]

- Liu, S.H.; Wang, Z.G.; Kong, Y.N.; Li, L.H.; Rao, M.J. Acid Attack on Cement Paste Containing Limestone Powder. Adv. Mater. Res. 2013, 724, 1589–1592. [Google Scholar] [CrossRef]

- Kore, S.D.; Vyas, A.K.; Syed Ahmed Kabeer, K.I. A brief review on sustainable utilisation of marble waste in concrete. Int. J. Sustain. Eng. 2020, 13, 264–279. [Google Scholar] [CrossRef]

- Atabey, İ.İ.; Çelikten, S.; Canbaz, M. Chemical resistance of hardened mortar containing andesite and marble industry waste powder. Chall. J. Concr. Res. Lett. 2023, 14, 31–38. [Google Scholar] [CrossRef]

- Chahour, K.; Safi, B. Mechanical behavior and chemical durability of marble-based mortar: Application to panels subjected to punching. Constr. Build. Mater. 2020, 232, 117245. [Google Scholar] [CrossRef]

- Benguit, A.; Azzouz, L.; Boukhelkhal, A. Durabilité des bétons autoplaçants à base de poudre de marbre vis-à-vis des attaques sulfates, acides et carbonatation accélérée. In Proceedings of the 1st International Congress on Advances in Geotechnical Engineering and Construction Management ICAGECM’19, Skikda, Algeria, 9–10 December 2019; Volume I, pp. 66–72. [Google Scholar]

- Messaoudene, I.; Jauberthie, R. Marble Filler: Does It Retard the Dissolution of Cement Constituents? Int. Sch. Res. Not. 2011, 2011, 695123. [Google Scholar] [CrossRef]

- Toubal Seghir, N.; Mellas, M.; Sadowski, Ł.; Żak, A. Effects of marble powder on the properties of the air-cured blended cement paste. J. Clean. Prod. 2018, 183, 858–868. [Google Scholar] [CrossRef]

- Toubal Seghir, N.; Benaimeche, O.; Krzywiński, K.; Sadowski, Ł. Ultrasonic Evaluation of Cement-Based Building Materials Modified Using Marble Powder Sourced from Industrial Wastes. Buildings 2020, 10, 38. [Google Scholar] [CrossRef]

- Toubal Seghir, N.; Mellas, M.; Sadowski, Ł.; Krolicka, A.; Zak, A. The Utilization of Waste Marble Dust as a Cement Replacement in Air-Cured Mortar. Sustainability 2019, 11, 2215. [Google Scholar] [CrossRef]

- Toubal Seghir, N.; Mellas, M.; Sadowski, Ł.; Krolicka, A.; Zak, A. The Effect of Curing Conditions on the Properties of Cement- Based Composites Blended with Waste Marble Dust. JOM-J. Miner. Met. Mater. Soc. 2019, 71, 1002–1015. [Google Scholar]

- Taylor, H.F.W. Cement Chemistry; Thomas Telford: London, UK, 1997. [Google Scholar]

- Hewlett, P.; Liska, M. (Eds.) Lea’s Chemistry of Cement and Concrete; Butterworth-Heinemann: Oxford, UK, 2019. [Google Scholar]

- ASTM C109/C109 M-99; Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens). Annual Book of ASTM Standards 4; ASTM International: West Conshohocken, PA, USA, 1999.

- Panchal, V.C.; Vesmawala, G.R. Durability Performance of Binary and Ternary Blend Self-Compacting Concrete Using Waste Marble Powder and Lime Powder. Int. J. Eng. Adv. Technol. 2020, 9, 3381–3387. [Google Scholar]

- Amar, B.; Boukhelkhal, A.; Lakhdar, A. Durability self-compacting mortar under external chemical attacks based on composite binder. Cem.-Wapno-Beton = Cem. Lime Concr. 2024, 29, 71–81. [Google Scholar] [CrossRef]

- Kirgiz, M.S. Advancements in mechanical and physical properties for marble powder-cement composites strengthened by nanostructured graphite particles. Mech. Mater. 2016, 92, 223–234. [Google Scholar] [CrossRef]

- Kashyap, V.S.; Sancheti, G.; Yadav, J.S. Durability and microstructural behavior of Nano silica-marble dust concrete. Clean. Mater. 2023, 7, 100165. [Google Scholar]

- Abbas, M.M.; Muntean, R. Marble Powder as a Sustainable Cement Replacement: A Review of Mechanical Properties. Sustainability 2025, 17, 736. [Google Scholar] [CrossRef]

- SAli, S.; Ahmad, S.; Ullah, I. Discover Civil Engineering Utilization of waste marble dust as cement and sand replacement in concrete. Discov. Civ. Eng. 2024, 1, 15. [Google Scholar]

- Hashem, F.S.; Amin, M.S.; El-Gamal, S.M.A. Improvement of acid resistance of Portland cement pastes using rice husk ash and cement kiln dust as additives. J. Therm. Anal. Calorim. 2013, 111, 1391–1398. [Google Scholar]

- Zhang, Q.; Ye, G. Quantitative analysis of phase transition of heated Portland cement paste. J. Therm. Anal. Calorim. 2013, 112, 629–636. [Google Scholar]

- Jennings, H.M. A model for the microstructure of calcium silicate hydrate in cement paste. Cem. Concr. Res. 2000, 30, 101–116. [Google Scholar] [CrossRef]

- Jennings, H.M. Refinements to colloid model of C-S-H in cement: CM-II. Cem. Concr. Res. 2008, 38, 275–289. [Google Scholar] [CrossRef]

- Scrivener, K.L.; Füllmann, T.; Gallucci, E.; Walenta, G.; Bermejo, E. Quantitative study of Portland cement hydration by X-ray diffraction/Rietveld analysis and independent methods. Cem. Concr. Res. 2004, 34, 1541–1547. [Google Scholar] [CrossRef]

- Mirmoghtadaei, R.; Shen, L.; Hargraves, J. A New Method to Predict Final Products of Red Mud-Slag-Based Alkali-Activated Materials Using Complete Phase Analysis of Precursors. Sustainability 2023, 15, 3473. [Google Scholar] [CrossRef]

- Asghari-Kaljahi, E.; Mansouri, H.; Hoseinzadeh, Z. Experimental study on the stabilization of fine grained soils by steel furnace slag and lime for using as subbase material. Int. J. Pavement Res. Technol. 2024, 1–15. [Google Scholar] [CrossRef]

- Huo, G.; Jiang, X.; Sun, X.; Li, H.; Shi, H. Performance of high-belite calcium sulfoaluminate cement subjected to hydrochloric acid and sulfuric acid. Front. Mater. 2024, 10, 1282919. [Google Scholar] [CrossRef]

- Aliabdo, A.A.; Abd-Elmoaty, A.E.M.; Hassan, H.H. Utilization of crushed clay brick in concrete industry. Alex. Eng. J. 2014, 53, 151–168. [Google Scholar] [CrossRef]

- Singh, L.P.; Karade, S.R.; Bhattacharyya, S.K.; Yousuf, M.M.; Ahalawat, S. Beneficial role of nanosilica in cement based materials—A review. Constr. Build. Mater. 2013, 47, 1069–1077. [Google Scholar] [CrossRef]

- Berger, F.; Bogner, A.; Hirsch, A.; Ukrainczyk, N.; Dehn, F.; Koenders, E. Thermodynamic Modeling and Experimental Validation of Acetic Acid Attack on Hardened Cement Paste: Effect of Silica Fume. Materials 2022, 15, 8355. [Google Scholar] [CrossRef]

- Ergün, A. Effects of the usage of diatomite and waste marble powder as partial replacement of cement on the mechanical properties of concrete. Constr. Build. Mater. 2011, 25, 806–812. [Google Scholar] [CrossRef]

- Ulubeyli, G.C.; Artir, R. Properties of Hardened Concrete Produced by Waste Marble Powder. Procedia-Soc. Behav. Sci. 2015, 195, 2181–2190. [Google Scholar] [CrossRef]

- Makhloufi, Z.; Bederina, M.; Bouhicha, M.; Kadri, E.H. Effect of mineral admixtures on resistance to sulfuric acid solution of mortars with quaternary binders. Phys. Procedia 2014, 55, 329–335. [Google Scholar] [CrossRef]

- Ercikdi, B.; Külekci, G.; Yilmaz, T. Utilization of granulated marble wastes and waste bricks as mineral admixture in cemented paste backfill of sulphide-rich tailings. Constr. Build. Mater. 2015, 93, 573–583. [Google Scholar] [CrossRef]

- Sadek, D.M.; El-Attar, M.M.; Ali, H.A. Reusing of Marble and Granite Powders in Self-Compacting Concrete for Sustainable Development. J. Clean. Prod. 2016, 121, 19–32. [Google Scholar] [CrossRef]

- Chavez Panduro, E.A.; Torsæter, M.; Gawel, K.; Bjørge, R.; Gibaud, A.; Bonnin, A.; Schlepütz, C.M.; Breiby, D.W. Computed X-ray Tomography Study of Carbonate Precipitation in Large Portland Cement Pores. Cryst. Growth Des. 2019, 19, 5850–5857. [Google Scholar] [CrossRef]

- Scrivener, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Kurdowski, W. Cement and Concrete Chemistry; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Attigobe, E.K.; Rizkalla, S.H. Response of Concrete to Sulfuric Acid. ACI Mater. J. 1988, 85, 481–488. [Google Scholar] [CrossRef]

- Monteny, J.; De Belie, N.; Taerwe, L. Resistance of Different Types of Concrete Mixtures to Sulfuric Acid. Mater. Struct. 2003, 36, 242–249. [Google Scholar] [CrossRef]

- Dillard, R.J.; Murray, C.D.; Deschenes, R.A. Belitic calcium sulfoaluminate cement subjected to sulfate attack and sulfuric acid. Constr. Build. Mater. 2022, 343, 128089. [Google Scholar] [CrossRef]

- Tsubone, K.; Yamaguchi, Y.; Ogawa, Y.; Kawai, K. Deterioration of Concrete Immersed in Sulfuric Acid for a Long Term. Key Eng. Mater. 2016, 711, 659–664. [Google Scholar] [CrossRef]

- Monteny, J.; Vincke, E.; Beeldens, A.; De Belie, N.; Taerwe, L.; Van Gemert, D.; Verstraete, W. Chemical, microbiological, and in situ test methods for biogenic sulfuric acid corrosion of concrete. Cem. Concr. Res. 2000, 30, 623–634. [Google Scholar] [CrossRef]

- von Greve-Dierfeld, S.; Lothenbach, B.; Vollpracht, A.; Wu, B.; Huet, B.; Andrade, C.; Medina, C.; Thiel, C.; Gruyaert, E.; Vanoutrive, H.; et al. Understanding the carbonation of concrete with supplementary cementitious materials: A critical review by RILEM TC 281-CCC. Mater. Struct. 2020, 53, 136. [Google Scholar] [CrossRef]

- Wang, T.; Yang, W.; Zhang, J. Experimental Studies on Mechanical Properties and Microscopic Mechanism of Marble Waste Powder Cement Cementitious Materials. Crystals 2022, 12, 868. [Google Scholar] [CrossRef]

- Abbas, Y.; Djebien, R.; Toubal Seghir, N. Utilization of marble waste as fine aggregate in the composition of high-performance concrete containing mineral additions. Can. J. Civ. Eng. 2024, 52, 45–59. [Google Scholar] [CrossRef]

- Ingram, K.D.; Daugherty, K.E. A Review of Limestone Additions to Portland Cement and Concrete. Cem. Concr. Compos. 1991, 13, 165–170. [Google Scholar] [CrossRef]

- Deschner, F.; Winnefeld, F.; Lothenbach, B.; Seufert, S.; Schwesig, P.; Dittrich, S.; Goetz-neunhoeffer, F.; Neubauer, J. Hydration of Portland cement with high replacement by siliceous fly ash. Cem. Concr. Res. 2012, 42, 1389–1400. [Google Scholar] [CrossRef]

- Richardson, I.G. The Calcium Silicate Hydrates. Cem. Concr. Res. 2008, 38, 137–158. [Google Scholar] [CrossRef]

- Carde, C.; François, R. Effect of the Leaching of Calcium Hydroxide from Cement Paste on Mechanical and Physical Properties. Cem. Concr. Res. 1997, 27, 539–550. [Google Scholar] [CrossRef]

- Liu, X.; Feng, P.; Yu, X.; Huang, J. Decalcification of Calcium Silicate Hydrate (C-S-H) under Aggressive Solution Attack. Constr. Build. Mater. 2022, 342, 127988. [Google Scholar] [CrossRef]

- Das, K.K.; Wu, X.; Noh, G.; Lee, J.H.; Jang, J.G. Effect of acid attack coupled with elevated temperatures on carbonation-cured calcium sulfoaluminate and ordinary Portland cement paste. Case Stud. Constr. Mater. 2025, 23, e05150. [Google Scholar] [CrossRef]

- Kovalčíková, M.; Eštoková, A. Leaching of calcium and silicon from cement composites in the aggressive. Pollack Period. 2014, 9, 123–130. [Google Scholar] [CrossRef]

| Oxide Content (%) | OPC | WMP | |

| Compound Name | Formula | ||

| Calcium oxide | CaO | 62.91 | 56.94 |

| Silicon dioxide | SiO2 | 20.83 | 0.05 |

| Iron oxide | Fe2O3 | 5.58 | 0.02 |

| Aluminum oxide | Al2O3 | 4.13 | 0.05 |

| Sulfur trioxide | SO3 | 2.3 | 0.32 |

| Magnesium oxide | MgO | 1.42 | 0.92 |

| Potassium oxide | K2O | 0.38 | 0.009 |

| Chlorine | Cl | 0.028 | 0.001 |

| Loss on ignition (L.O.I) | 2.04 | 41.63 | |

| Insoluble Residue (I.R) | 0.382 | 0.06 | |

| Mineralogical Composition | |||

| Mineral Name | Formula | ||

| Tricalcium silicate (C3S) | 3CaO·SiO2 | 62.03% | - |

| Dicalcium silicate (C2S) | 2CaO·SiO2 | 13% | - |

| Tricalcium aluminate (C3A) | 3CaO·Al2O3 | 1.5% | - |

| Tetracalcium aluminoferrite (C4AF) | 4CaO·Al2O3·Fe2O3 | 16.98% | - |

| Physical Properties | |||

| True density (g/cm3) | 3.15 | 2.74 | |

| Bulk density (g/cm3) | 0.98 | 0.98 | |

| Blaine Specific Surface Area (m2/kg) | 357.18 | 386.95 | |

| Crystalline Phases | Element Content (% Weight) | ||||

|---|---|---|---|---|---|

| Phase Name | Symbol | Air-Cured Cement-Based Materials After Acid Immersion (MP Content) | |||

| 0 | 5 | 10 | 15 | ||

| Alite | C3S | 1.47 | 1.33 | 1.21 | 0.96 |

| Belite | C2S | 4.30 | 3.82 | 2.95 | 2.78 |

| Aluminate | C3A | 2.86 | 2.67 | 2.35 | 1.82 |

| Ferrite | C4AF | - | - | - | - |

| Portlandite | CH | 5.73 | 4.3 | 4.11 | 4.89 |

| Ettringite | AFt | 10.21 | 9.94 | 9.82 | 10.97 |

| Gypsum | CŜH2 | 8.84 | 9.23 | 9.73 | 10.48 |

| Calcite | CaCO3 | 3.51 | 6.56 | 9.07 | 12.58 |

| Total of Crystalline phases | 36.92 | 37.85 | 39.24 | 44.48 | |

| Amorphous phase | |||||

| Calcium silicate hydrate | C-S-H | 43.57 | 49.23 | 44.09 | 35.28 |

| Unquantified loss | 19.51 | 12.92 | 16.67 | 20.24 | |

| Total | 100 | 100 | 100 | 100 | |

| Chemical Element | Element Content (% Weight) | ||||

|---|---|---|---|---|---|

| Element Name | Symbol | Air-Cured Cement Paste After Acid Immersion (MP Content) | |||

| 0 | 5 | 10 | 15 | ||

| Oxygen | O | 51.7 | 49.2 | 42.6 | 47.8 |

| Calcium | Ca | 28 | 31.9 | 40.9 | 34.3 |

| Silicon | Si | 5.1 | 6.5 | 5 | 3.1 |

| Iron | Fe | 1 | 1.2 | 1.4 | 1.2 |

| Aluminum | Al | 1.7 | 1.1 | 1.3 | 2.6 |

| Magnesium | Mg | 0.8 | 0.7 | 0.6 | 0.4 |

| Sulfur | S | 2.8 | 0.8 | 2.7 | 4.6 |

| Carbon | C | 8.9 | 8.6 | 5.5 | 6 |

| Total | 100 | 100 | 100 | 100 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benykhlef, A.; Seghir, N.T.; Sadoudi, L.; Abbas, Y.; Boutlikht, M.; Hebbache, K.; Belebchouche, C.; Tang, Y. Macro and Microstructural Evaluation of Air-Cured Cement-Based Materials Enhanced by Marble Powder for Infrastructure Subject to Sulfuric Acid Attack. Buildings 2025, 15, 4541. https://doi.org/10.3390/buildings15244541

Benykhlef A, Seghir NT, Sadoudi L, Abbas Y, Boutlikht M, Hebbache K, Belebchouche C, Tang Y. Macro and Microstructural Evaluation of Air-Cured Cement-Based Materials Enhanced by Marble Powder for Infrastructure Subject to Sulfuric Acid Attack. Buildings. 2025; 15(24):4541. https://doi.org/10.3390/buildings15244541

Chicago/Turabian StyleBenykhlef, Aissa, Nadhir Toubal Seghir, Lyacia Sadoudi, Yassine Abbas, Mourad Boutlikht, Kamel Hebbache, Cherif Belebchouche, and Yunchao Tang. 2025. "Macro and Microstructural Evaluation of Air-Cured Cement-Based Materials Enhanced by Marble Powder for Infrastructure Subject to Sulfuric Acid Attack" Buildings 15, no. 24: 4541. https://doi.org/10.3390/buildings15244541

APA StyleBenykhlef, A., Seghir, N. T., Sadoudi, L., Abbas, Y., Boutlikht, M., Hebbache, K., Belebchouche, C., & Tang, Y. (2025). Macro and Microstructural Evaluation of Air-Cured Cement-Based Materials Enhanced by Marble Powder for Infrastructure Subject to Sulfuric Acid Attack. Buildings, 15(24), 4541. https://doi.org/10.3390/buildings15244541