1. Introduction

With the rapid advancement of urbanization and infrastructure construction, the number of large and complex projects such as high-rise buildings and extra-large bridges is increasing. These projects have strict requirements for the bearing capacity and stability of pile foundations to meet the demands of special engineering and complex geological conditions [

1,

2,

3,

4,

5,

6,

7,

8]. Large-diameter and ultra-long piles, which can effectively penetrate weak soil layers and transfer the load of the superstructure to deep stable soil or rock layers, have become one of the key technologies to solve such engineering problems. However, due to the high difficulty in design and construction, accurately assessing their bearing performance is particularly crucial. Among them, the “vertical compressive static load test of pile foundation” is the most direct and reliable method for evaluating the bearing capacity of pile foundations, playing an irreplaceable role in ensuring the scientific design of pile foundations, the qualification of construction quality, and the long-term safe operation of structures [

9,

10,

11,

12,

13].

Research on the bearing capacity of ultra-long, large-diameter piles has been limited both domestically and internationally due to high costs and lengthy testing cycles. Li Tiantian et al. [

14] employed a large-diameter, ultra-long cast-in-place pile with a diameter of 1 m and a pile tip burial depth of 94 m to validate bearing capacity values and pile construction feasibility through field testing. Liu Xiujun et al. [

15] combined static load tests to reveal certain characteristics of the bearing mechanism for large-diameter, extra-long cast-in-place piles in reclaimed land areas. Wang Zemin et al. [

16] conducted a detailed analysis of the test plan and data from a large-diameter, extra-long rock-embedded pile static load test project in Nanjing. They also employed numerical simulation to investigate the variation of axial force within the pile body with depth under different load levels.

Xiao Li et al. [

17] analyzed and summarized the strain distribution, Poisson’s ratio variation, axial force transfer, lateral resistance performance, and compression deformation patterns of large-diameter ultra-long piles based on the Ningbo LNG project. They concluded that ultra-long rock-embedded piles exhibit a bearing characteristic of “lateral resistance dominance with delayed end resistance,” quantitatively revealing the nonlinear relationship between pile-side friction resistance and relative pile–soil displacement. Duan Chang et al. [

18] established a relationship between the uniaxial compressive strength of intact coral reef limestone and the ultimate lateral friction resistance and end resistance of piles. Based on field static load tests and core drilling tests of post-grouted rock-embedded cast-in-place piles, they proposed a calculation method for the bearing capacity design of such piles in coral reef limestone formations. Jin Ruibao et al. [

19] investigated the effects of grouting methods and volumes on the vertical bearing capacity of large-diameter, extra-long piles in clayey soils based on static load tests. Results indicated that post-grouting significantly enhanced the ultimate bearing capacity of model piles while reducing pile-head settlement. He et al. [

20] established a numerical model for extra-long piles based on Green–Lagrange strain theory, validated through field tests. They systematically investigated bearing characteristics under uniaxial and combined loads, revealing a complex sequence of failure modes. Tan et al. [

21] proposed a novel machine learning (ML) approach coupling the extreme gradient boosting (XGBoost) algorithm with the state-of-the-art student-based optimization method (SPBO) to predict pile resistance. Results demonstrated that the proposed SPBO-XGBoost model outperformed all other models in prediction accuracy and reliability. Hu et al. [

22] conducted in situ static load tests on three ultra-high-rise, large-diameter, extra-long rock-anchor bored cast-in-place piles (LSRBP). They analyzed the effects of composite excavation and combined grouting on pile response, along with the optimization benefits of combined grouting. Results indicated that composite excavation enhances construction efficiency but compromises borehole quality and reduces LSRBP bearing capacity, while combined grouting compensates for this deficiency. Elsawwaf A et al. [

23] proposed a hybrid method combining three-dimensional finite element (FE) modeling with evolutionary polynomial regression (EPR) based on a multi-objective genetic algorithm (MOGA) to predict the lateral bearing capacity of short straight piles and stepped conical piles in non-cohesive soils. Gao et al. [

24] evaluated the effects of different additives (sodium carbonate, carboxymethyl cellulose, polyacrylamide, and barite powder) on modified mud properties and microstructure, determining optimal additive ratios. SEM tests revealed these additives produced denser mud cake structures, enhancing wall protection and filtration/loss reduction effects. Based on Randolph’s research on pile resistance in homogeneous soils, Xiao et al. [

25] proposed a novel, scientifically accurate three-stage analytical method for predicting pile settlement. Xu et al. [

26] discovered through centrifuge model tests and finite element simulations that the unit external friction force propagates downward along the pile shaft and varies linearly with depth, while the unit internal friction force activates within a five-diameter (5D) zone above the pile tip and exhibits an exponential distribution with depth. They subsequently proposed a correction method to determine the unit internal sliding friction coefficient for open-ended single pile foundations, enabling precise assessment of their axial ultimate bearing capacity. Yuan et al. [

27] conducted a series of centrifugal vibration table tests on large-diameter monopiles at scour locations, revealing that scour exerts a more pronounced influence on the higher-order modal frequencies of OWT systems. He Wentao et al. [

28] investigated the seismic response of OWTs supported by single piles using advanced soil models. Results indicate that contributions from higher vibration modes become increasingly significant for large wind turbines, with soil–structure interaction playing a crucial role in dynamic response. Mozaffari N et al. [

29] proposed a novel design model for large-diameter single piles, capable of accurately predicting pile behavior under lateral loads. Atroush A M et al. [

30] rigorously evaluated machine learning (ML) and deep learning (DL) techniques. They found that while ML methods outperform traditional approaches in predicting pile lateral behavior, their “black-box” nature and reliance on data-driven insights yield results reflecting statistical robustness rather than clear geotechnical insights. Wan H Z et al. [

31] investigated the effect of combined end-side grouting on the bearing capacity of large-diameter rock-bearing bored piles in highly weathered rock formations. Results demonstrated that combined grouting significantly enhanced the lateral and end resistance of bored piles, substantially increased bearing capacity, and effectively controlled settlement.

Numerous scholars have conducted extensive research on special engineering geological conditions, such as loess regions, karst areas, and water-saturated sand layers. Xue Zhennian et al. [

32] investigated the influence of slenderness ratio on the lateral friction resistance of bored cast-in-place piles in loess regions through model tests and laboratory loading experiments. To address the impact of pile cap settlement in thick collapsible loess areas, Kui Jiangang et al. [

33] analyzed the load–settlement relationship for piles of varying lengths under identical loading conditions through field load tests. Liu Sisi et al. [

34] proposed a bearing capacity calculation method based on the minimum potential energy principle for ultra-long piles penetrating karst formations with complex strata such as karst gullies and caves. Hu Changming et al. [

35] analyzed the bearing characteristics of ultra-long foundation piles in water-rich sand layers using field tests and numerical simulations. Zhang Zhiguo [

36] examined the load transfer patterns and bearing deformation characteristics of extra-long piles in deep volcanic ash deposits. Kang Zhenxing [

37] conducted dual-load box self-balancing tests to investigate the bearing capacity of extra-long, large-diameter piles in deep sandy soils, obtaining characteristic values for single-pile bearing capacity and the distribution of lateral resistance with depth. Jiang Zhaowei [

38] simulated settlement changes and stress distributions in pile foundations and surrounding soil layers to investigate settlement issues of extra-long pile foundations under varying soil conditions. Liang Huayan et al. [

39] analyzed the bearing mechanism of large-diameter extra-long piles in deep soft soils based on PLAXIS 3D numerical simulations and field test results from the Fuzhou Metro Garden project. Boelter et al. [

40] identified multiple factors influencing the physical and mechanical properties of peat soils. Chen Yuntao et al. [

41] employed static loading and pile stress testing methods to determine pile tip bearing capacity and lateral friction resistance. Fu Lijun et al. [

42] analyzed the vertical bearing characteristics of two pile foundation types based on a foundation project in Qingdao’s coastal area.

Among these, research on the bearing capacity of ultra-long piles within complex, thick lacustrine deposits remains scarce, particularly concerning the distinctive peat soils found therein. Gui Yue et al. [

43,

44,

45,

46] conducted shear strength tests on peat soils from the Dianchi and Erhai regions, revealing that as axial stress increases, the internal density of the soil exhibits a synchronous upward trend. Creep tests reveal an S-shaped e-lgt curve for this soil type, exhibiting subconsolidation characteristics. Furthermore, permeability consolidation tests indicate that the permeability coefficient is influenced by consolidation stress, loading duration, and the vector of consolidation. Using peat soils from Wisconsin, USA as a case study, Edil et al. [

47] conducted triaxial and consolidation tests. They compared relevant data between American and other countries’ peat soils while discussing how fiber composition and content influence the mechanical properties of these American peat soils. Peat soils, unique to the Kunming region, are abundantly present around Dianchi Lake. As a soft foundation soil with higher moisture content than other foundation soils, peat poses significant challenges for pile foundation selection. Consequently, to mitigate risks, most high-rise buildings in this area adopt pile foundation systems [

48,

49,

50]. Consequently, investigating the bearing capacity of large-diameter, extra-long piles in lacustrine peat soils holds significant practical engineering value.

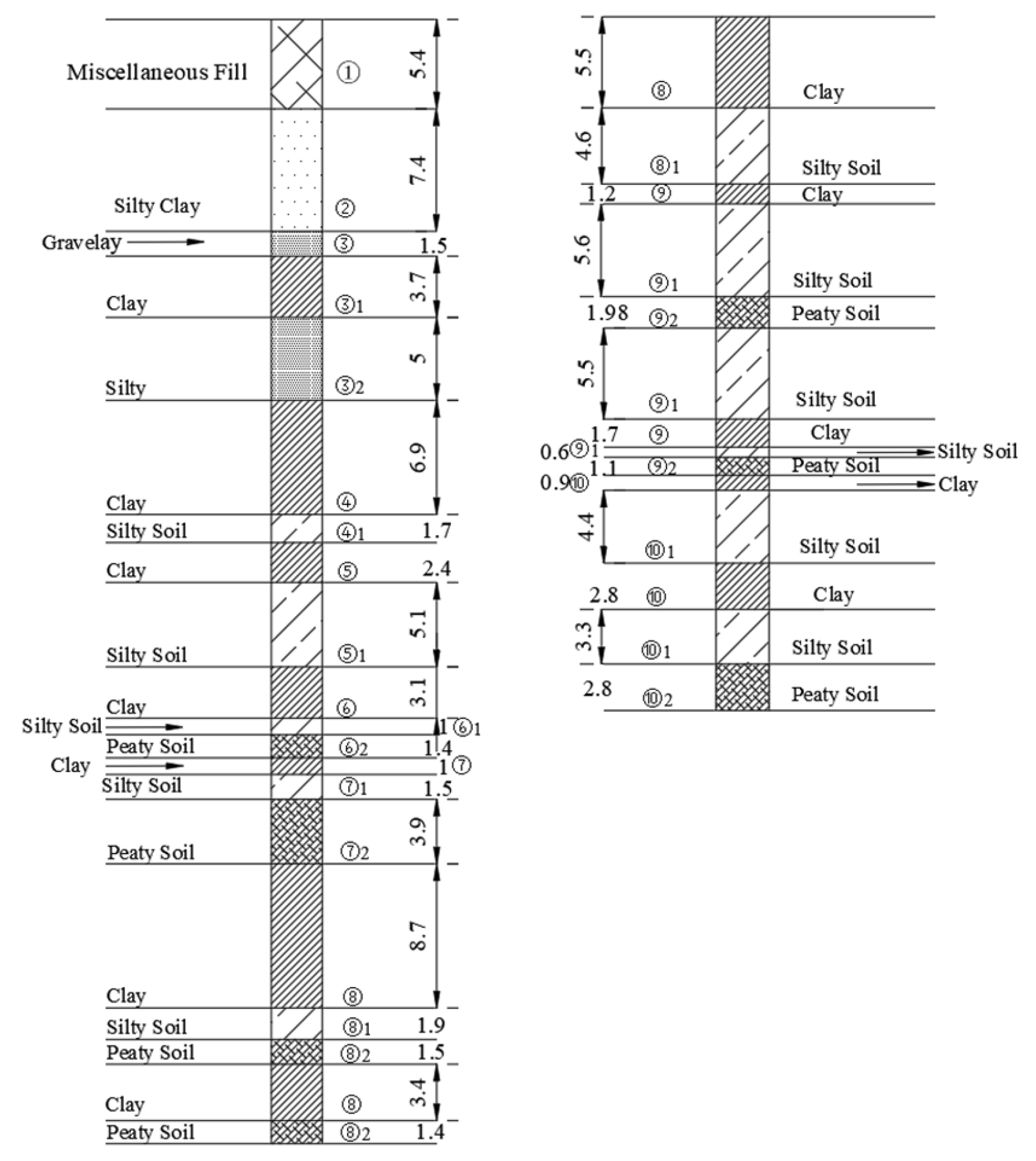

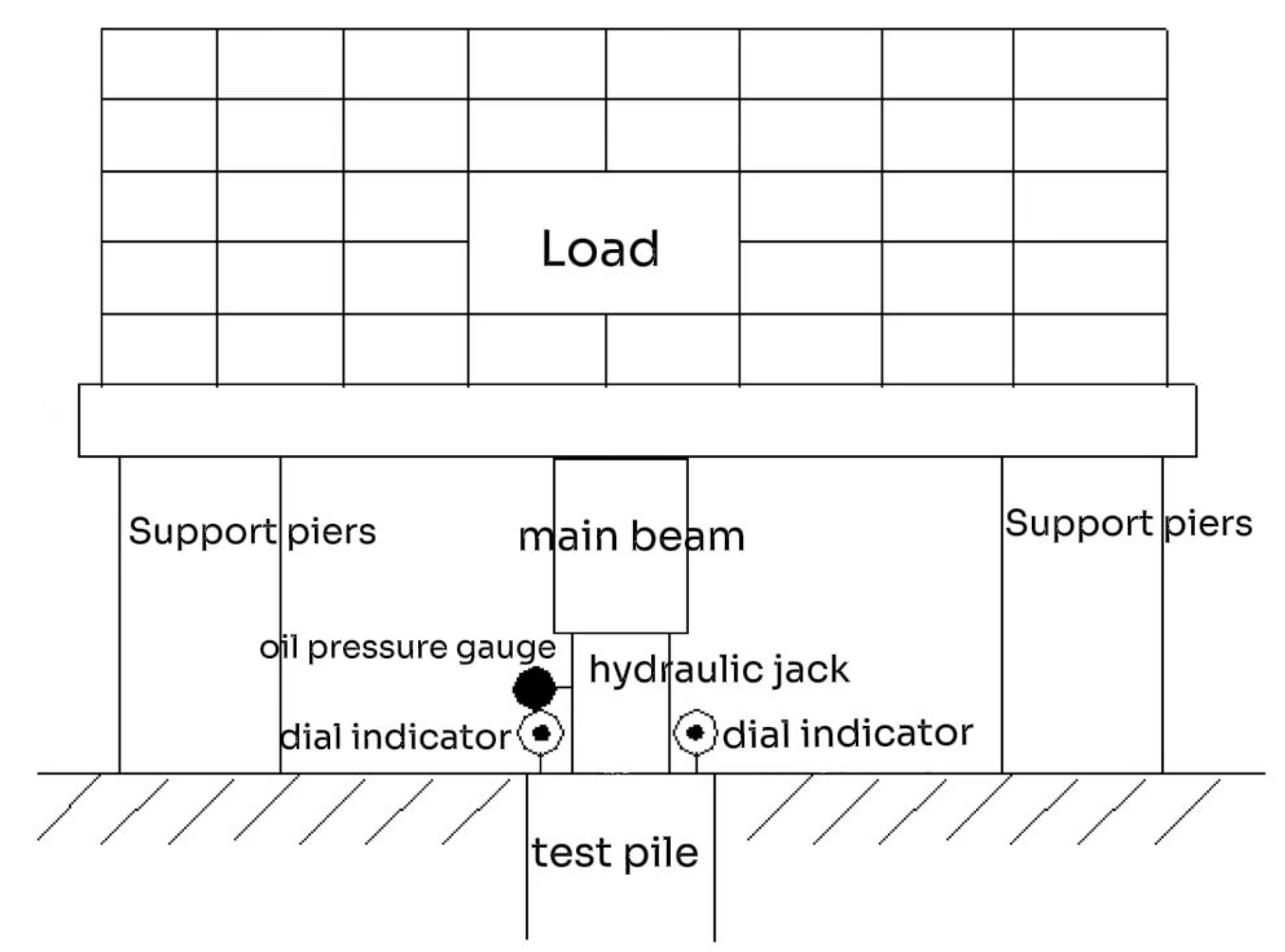

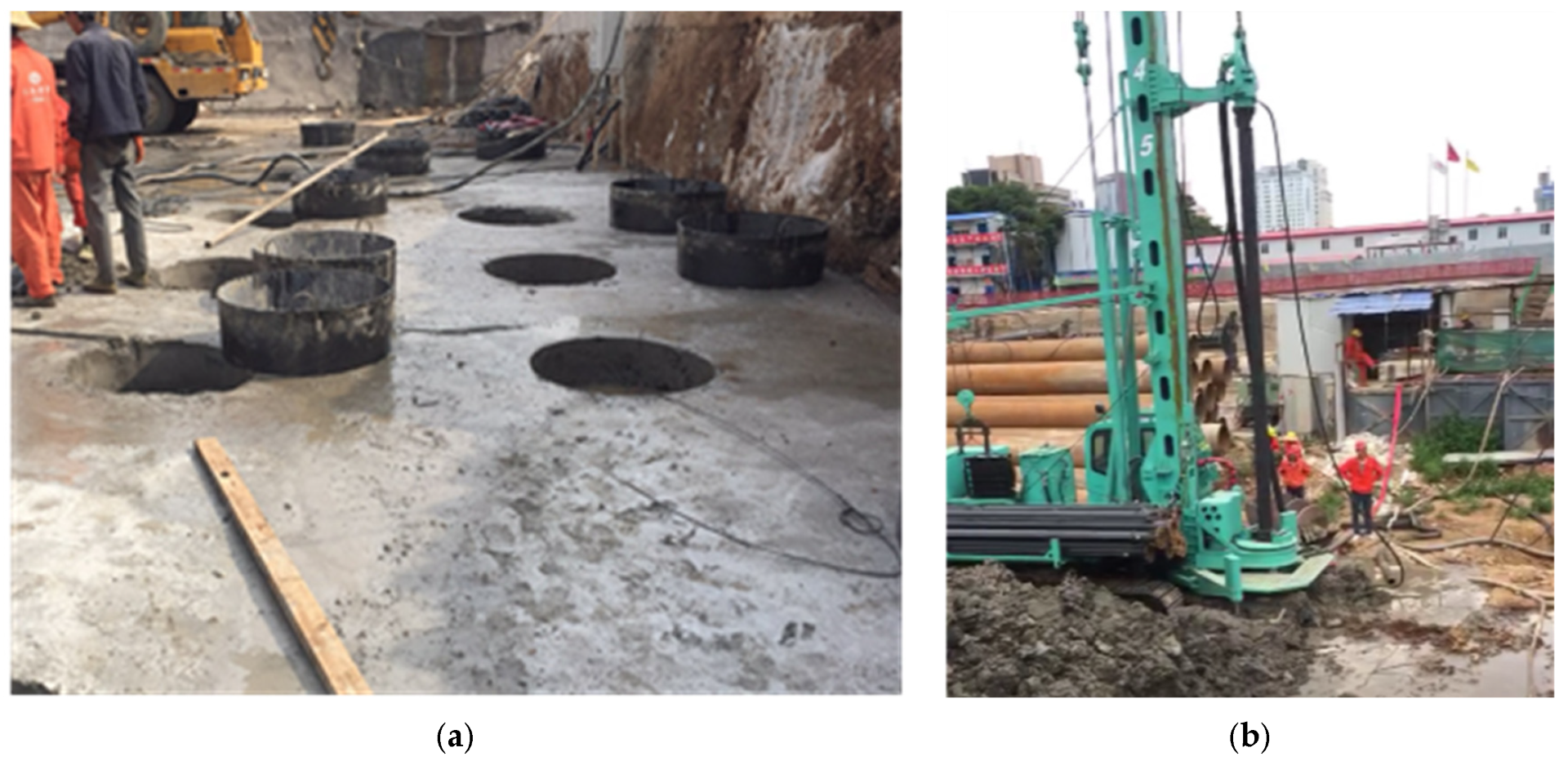

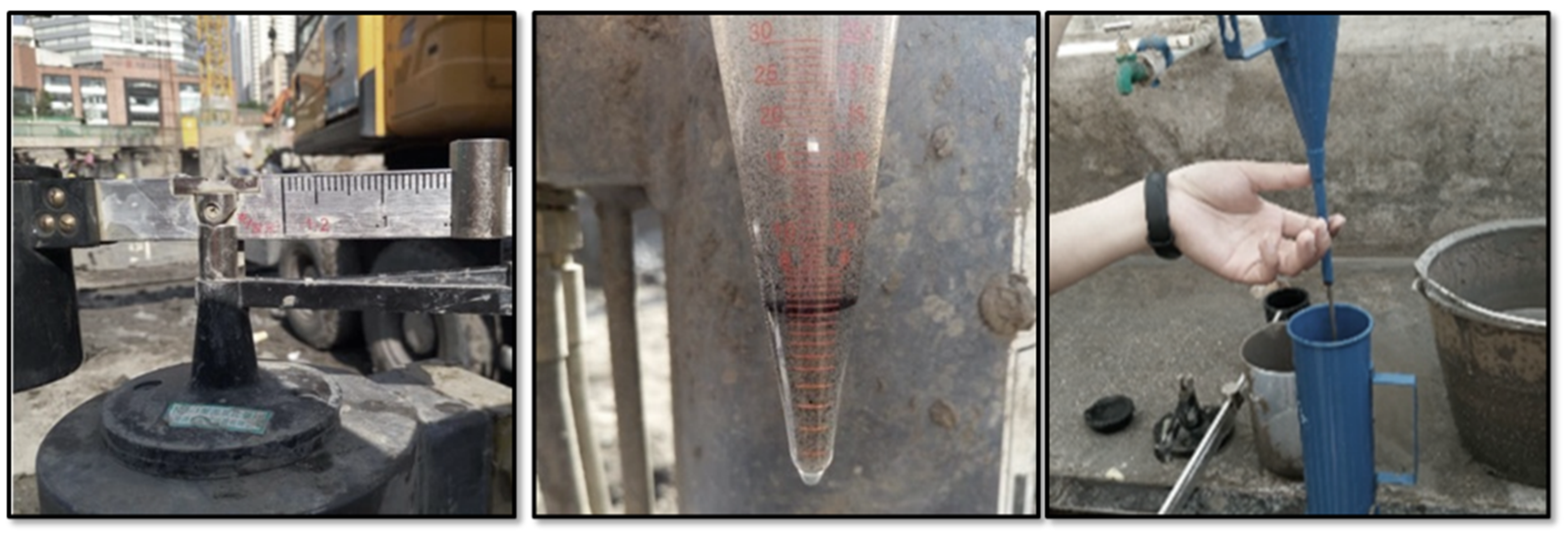

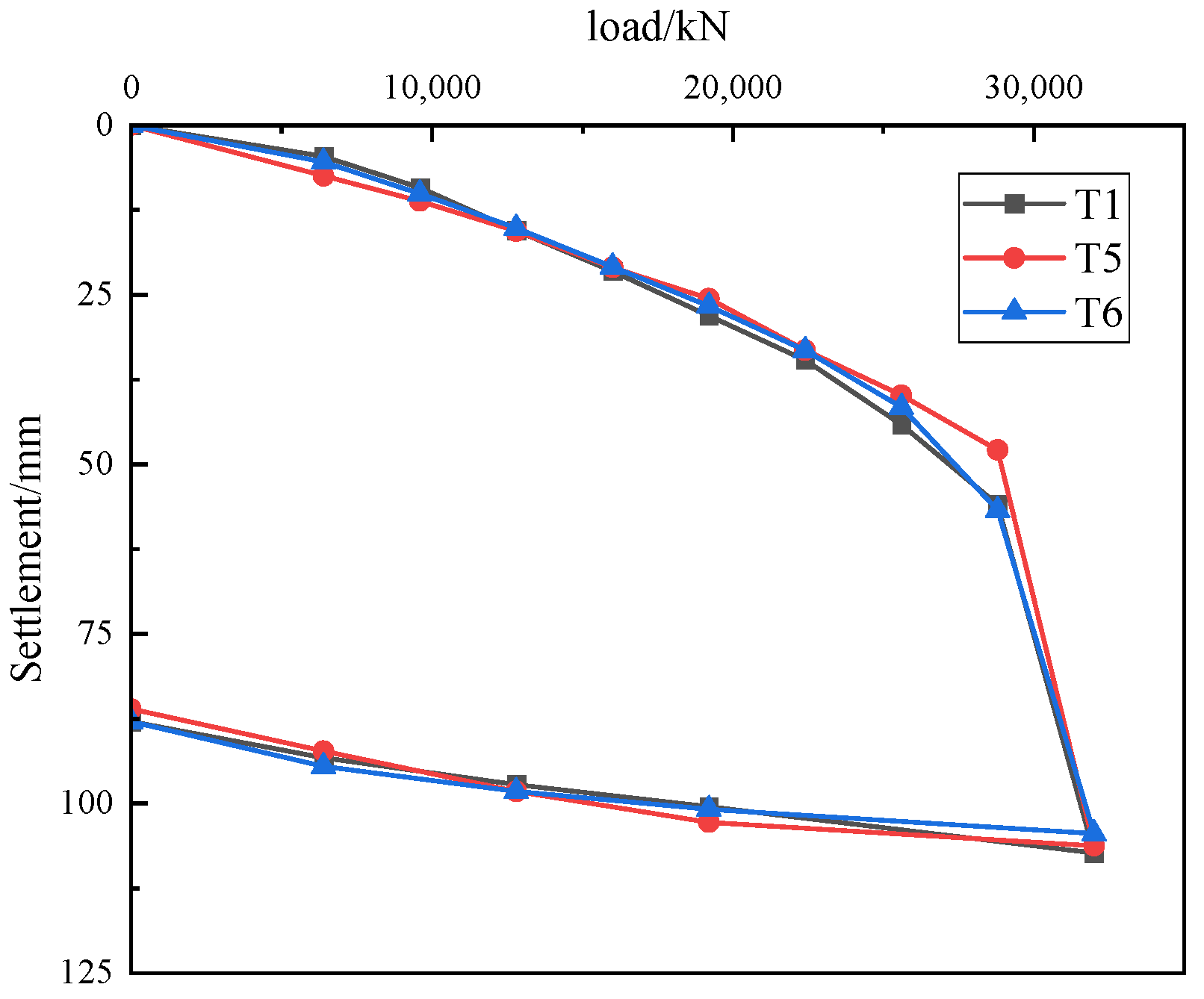

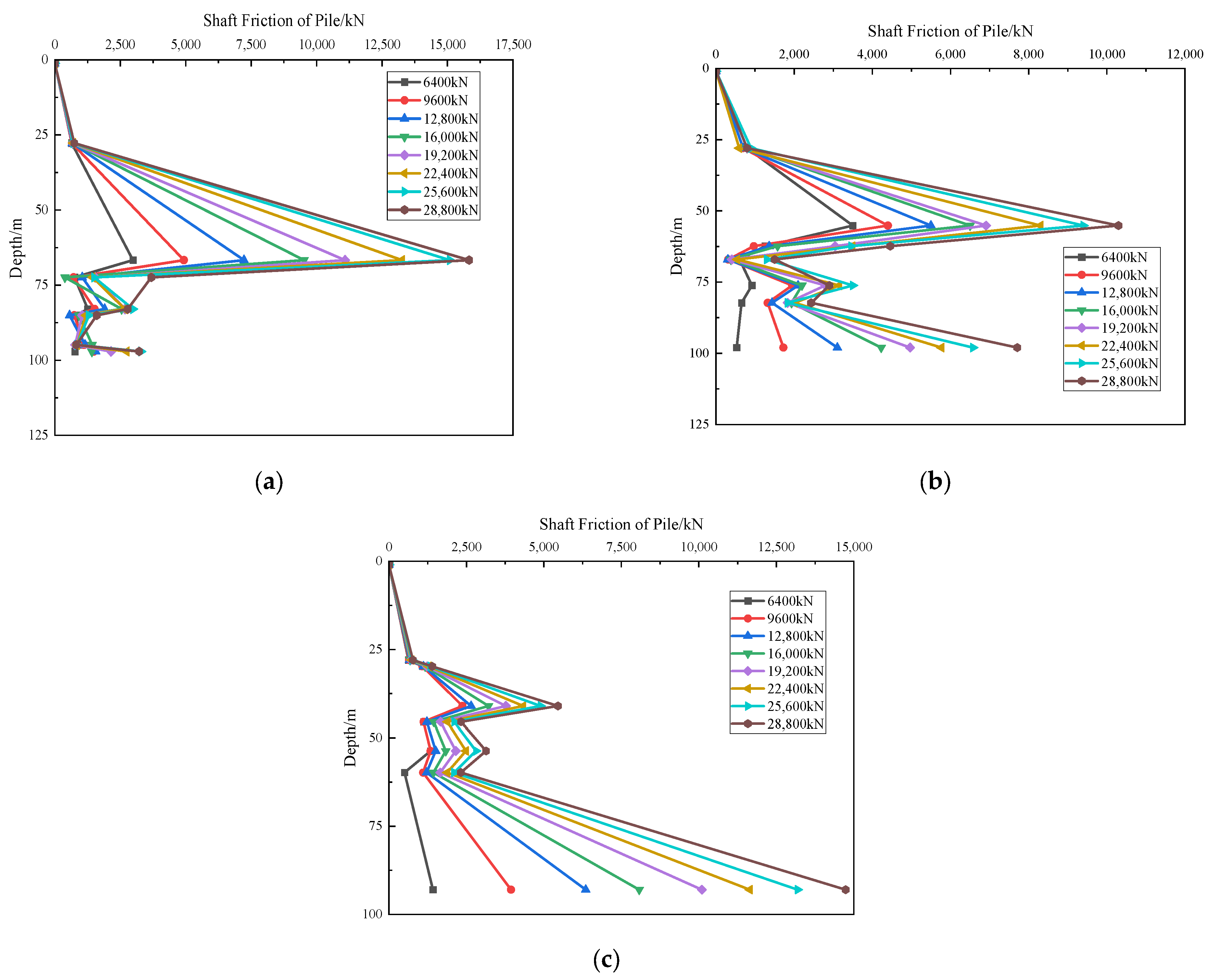

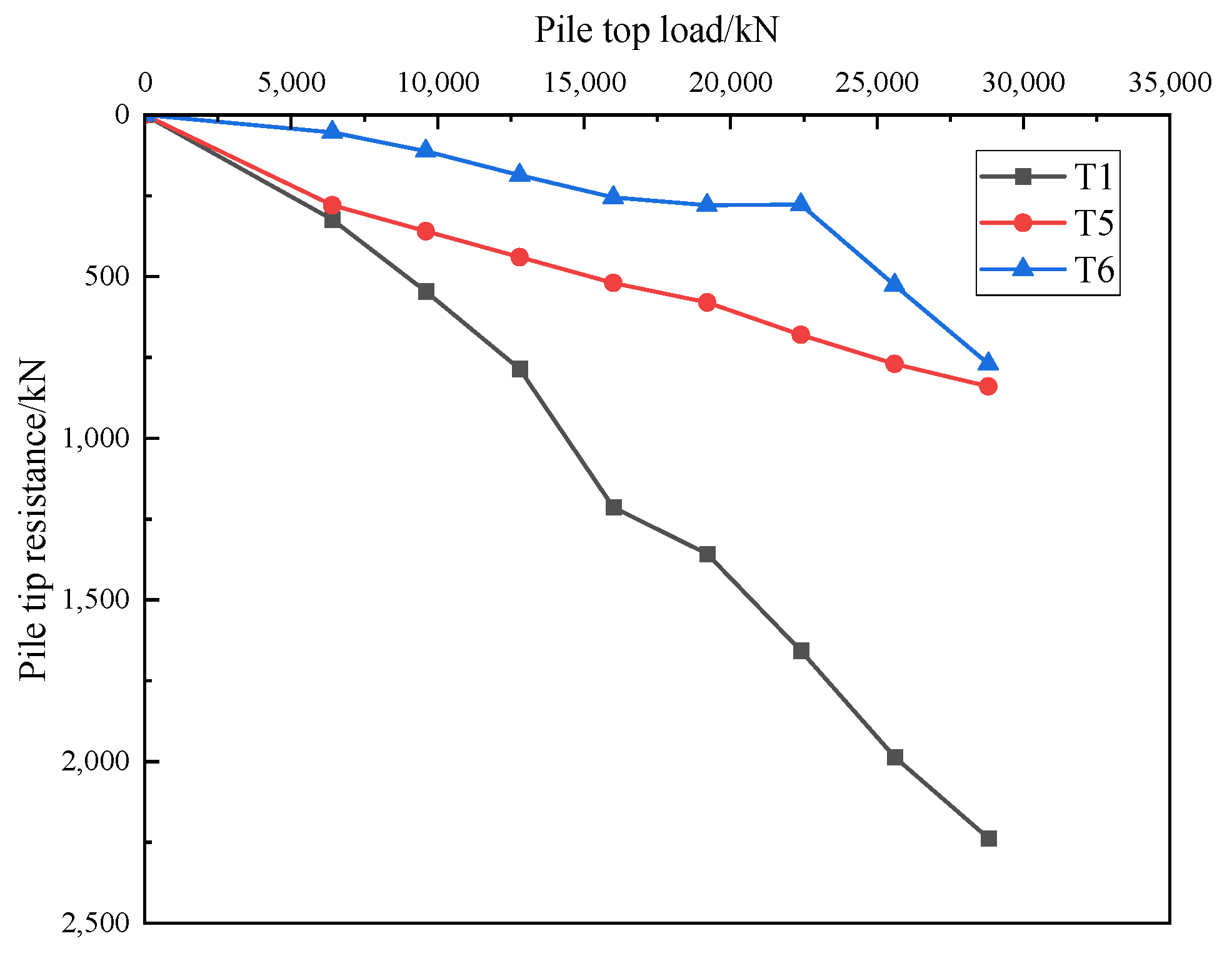

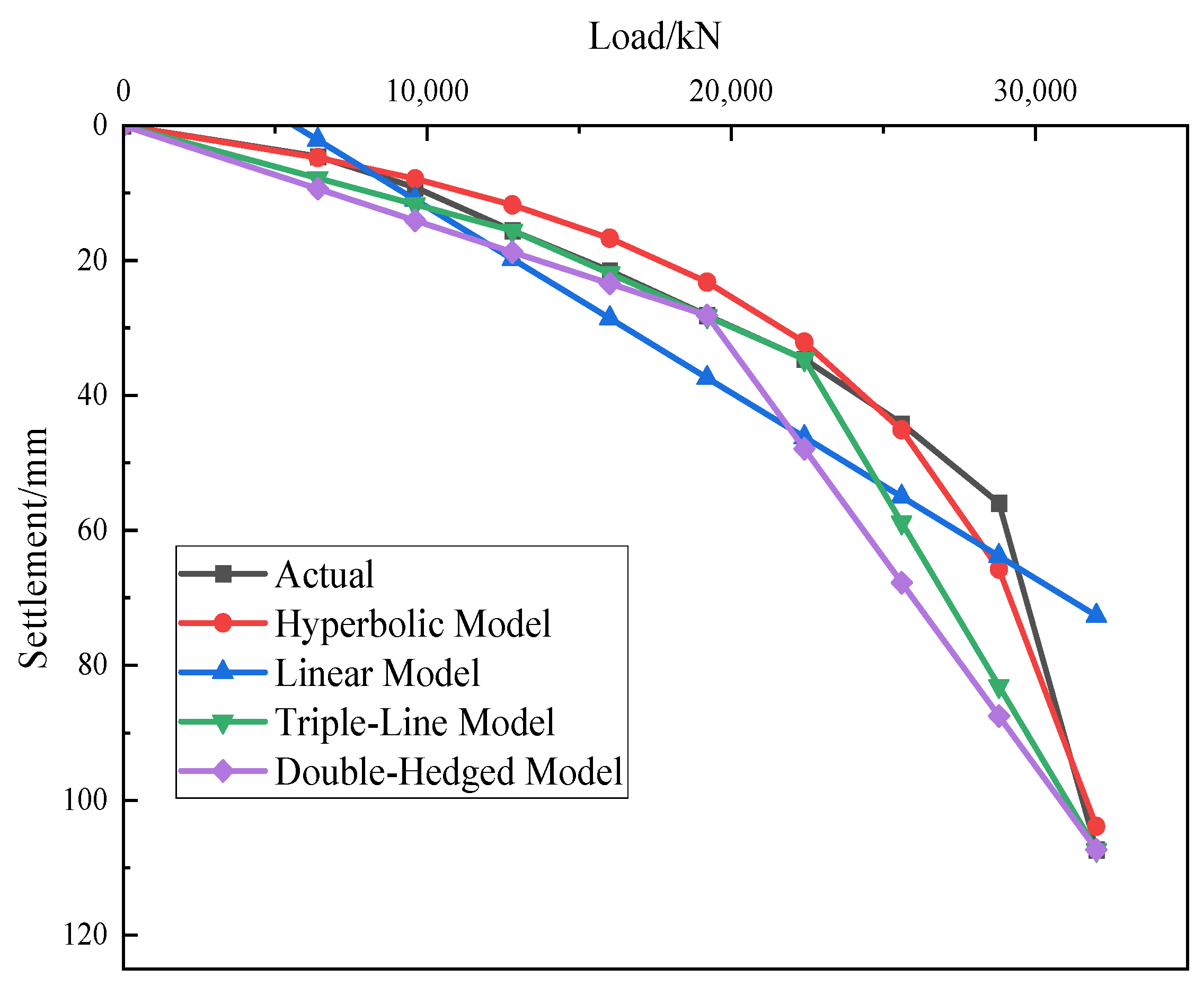

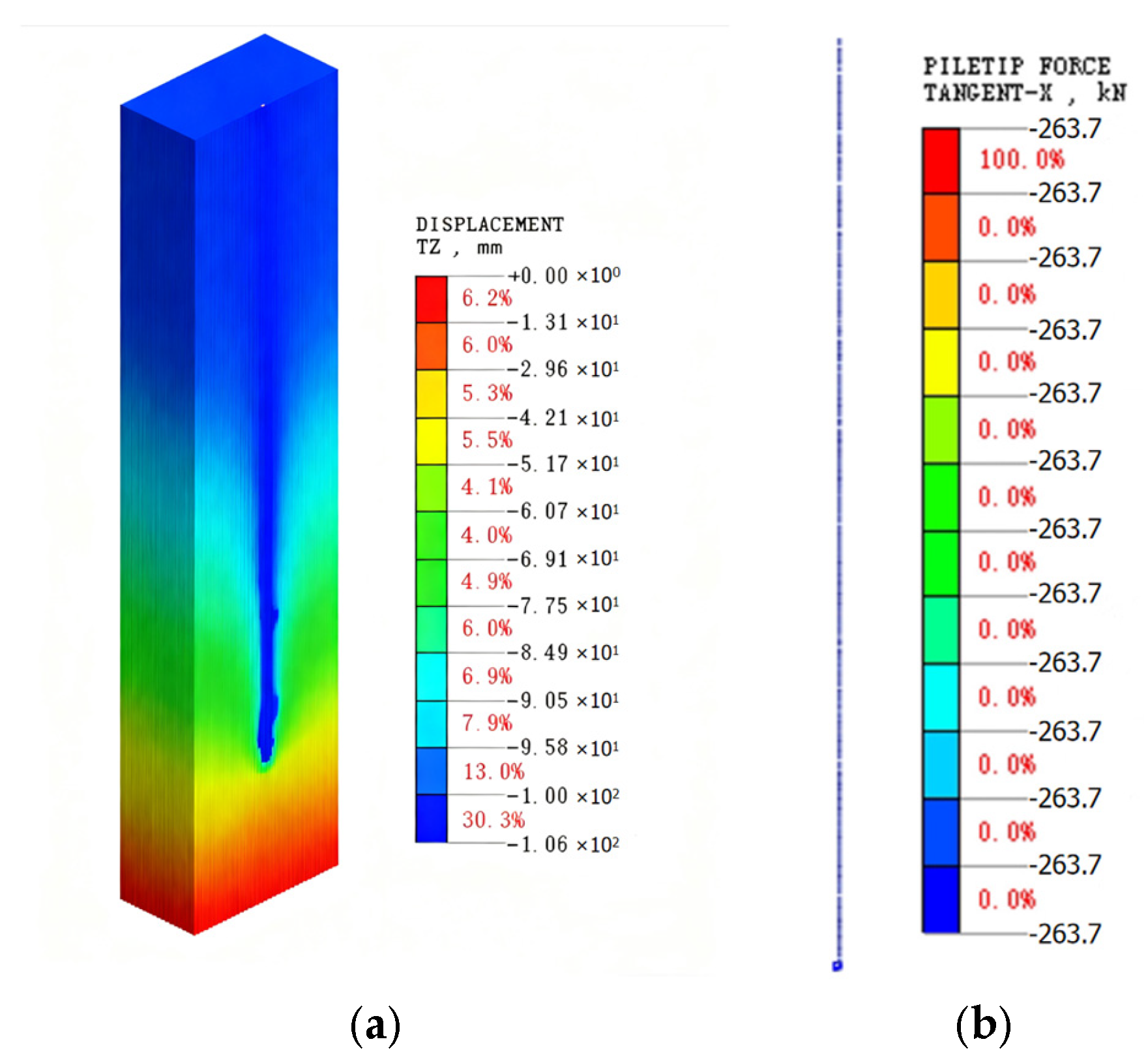

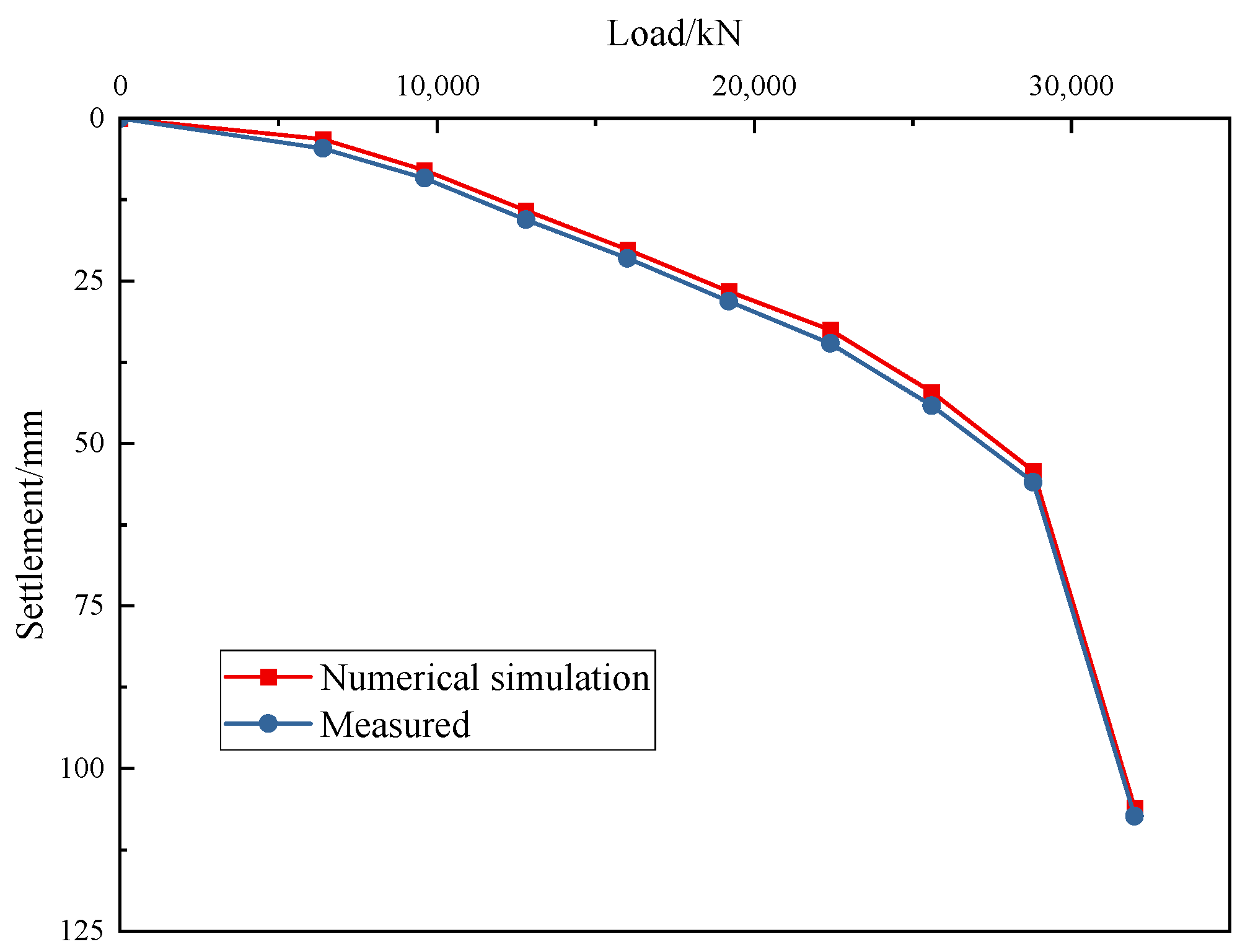

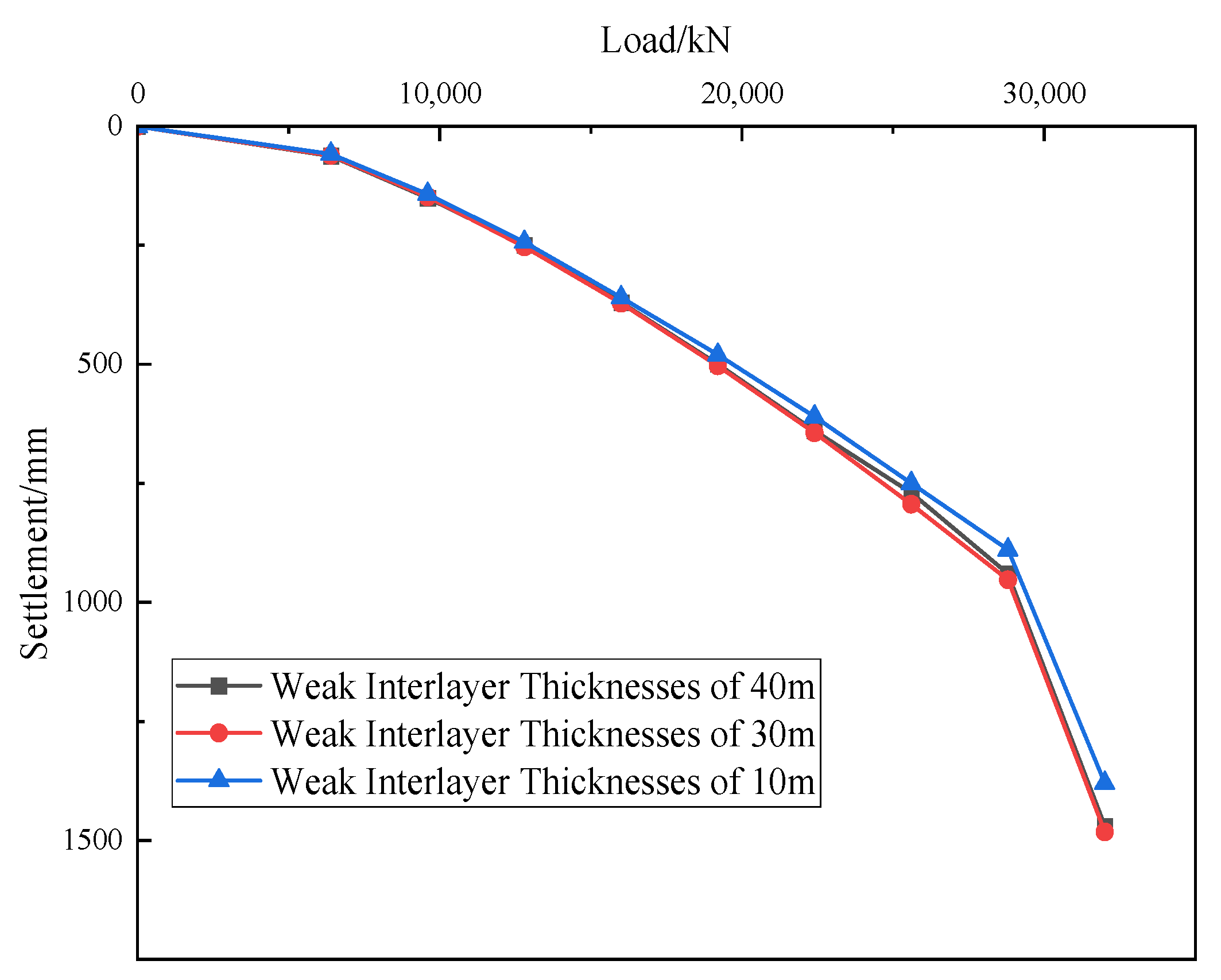

Therefore, this study investigates the load transfer mechanism and bearing deformation characteristics of extra-long piles in complex, thick lacustrine sediment layers by conducting internal force tests on pile foundations through single-pile static load tests at Juhou Lake in Kunming. A numerical model of the pile foundation static load test is established using finite element software. The model’s validity is verified by comparing simulation results with actual test data. By analyzing parameters such as weak layer thickness, pile length, and pile diameter, the study investigates the influence of peat-like soil layers on the bearing capacity of extra-long piles, providing guidance for controlling settlement in Kunming’s soft soil foundations.

5. Discussion

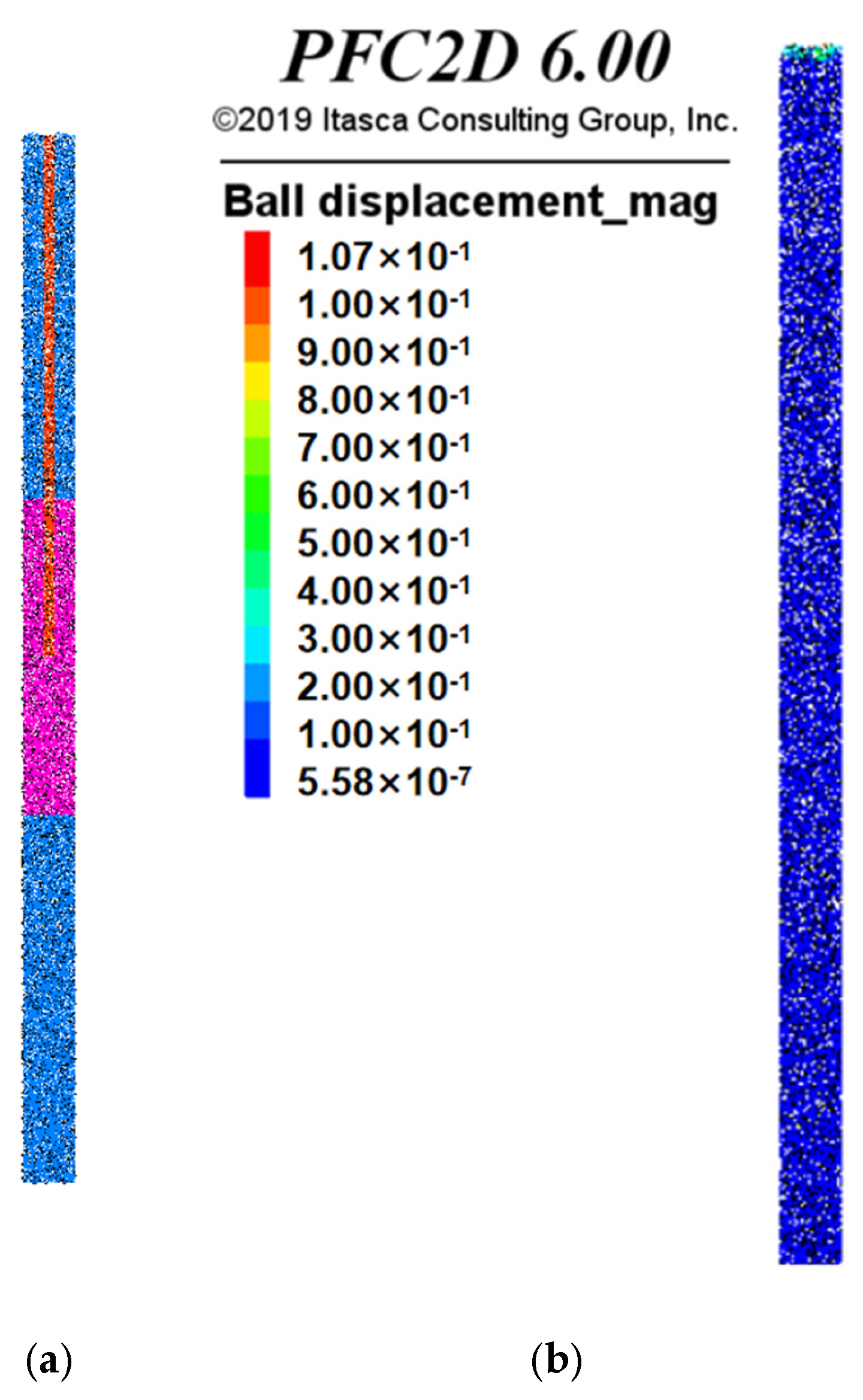

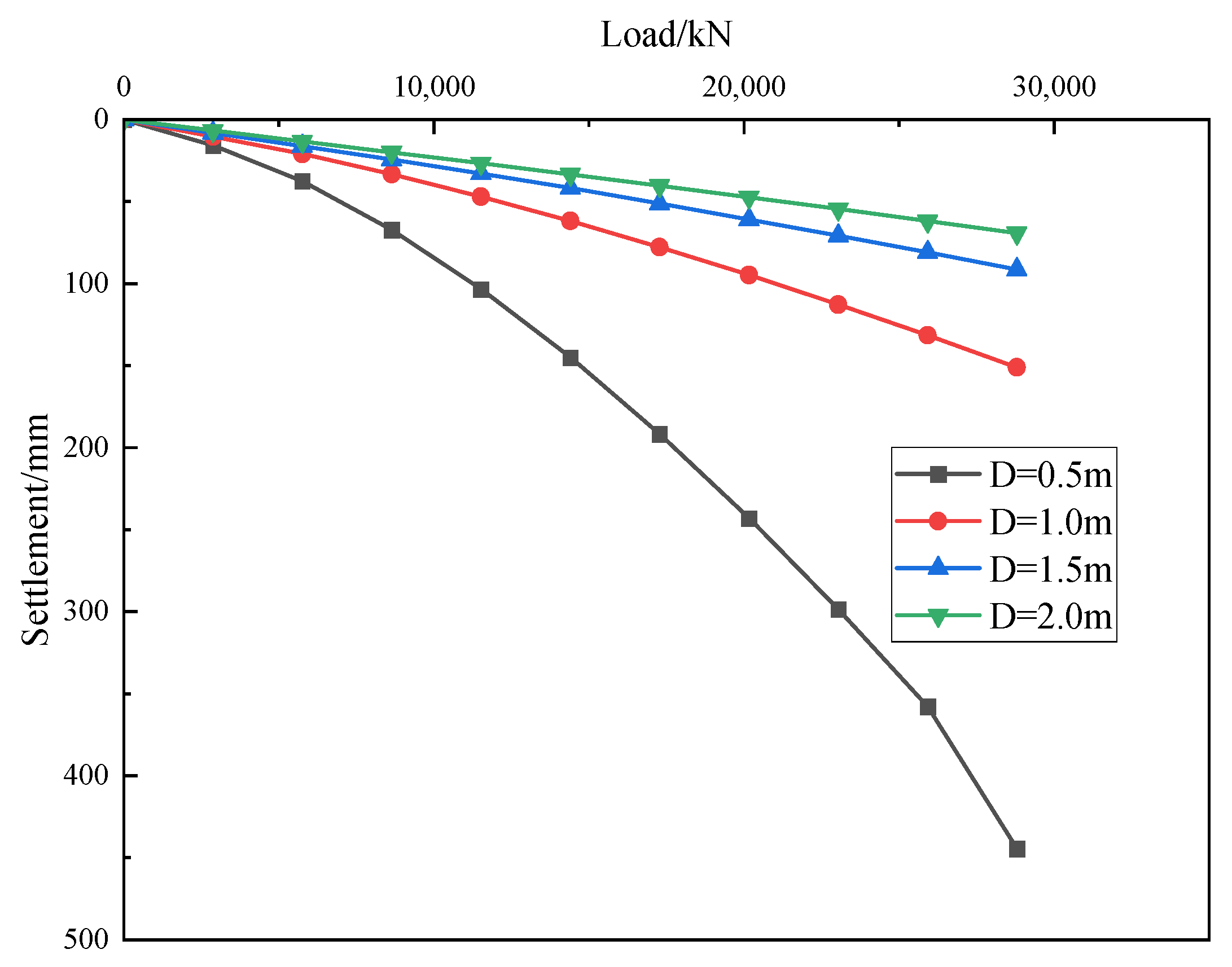

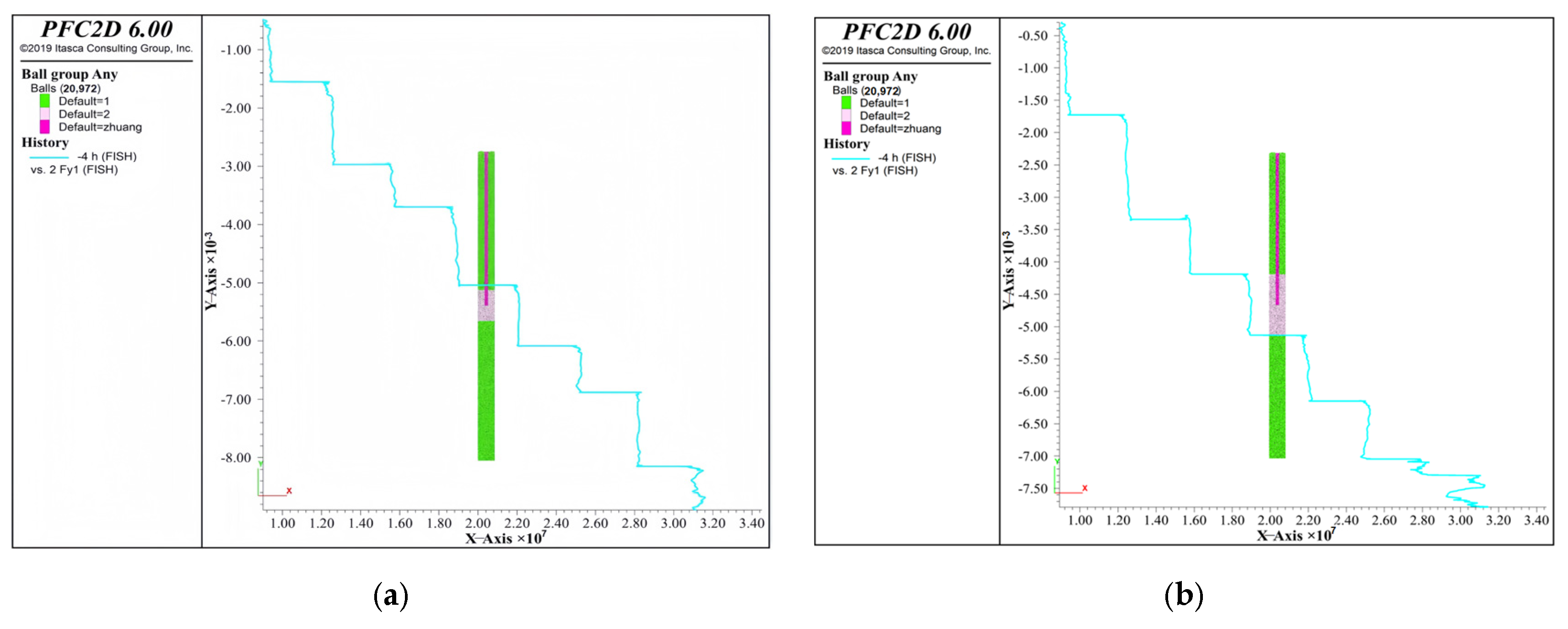

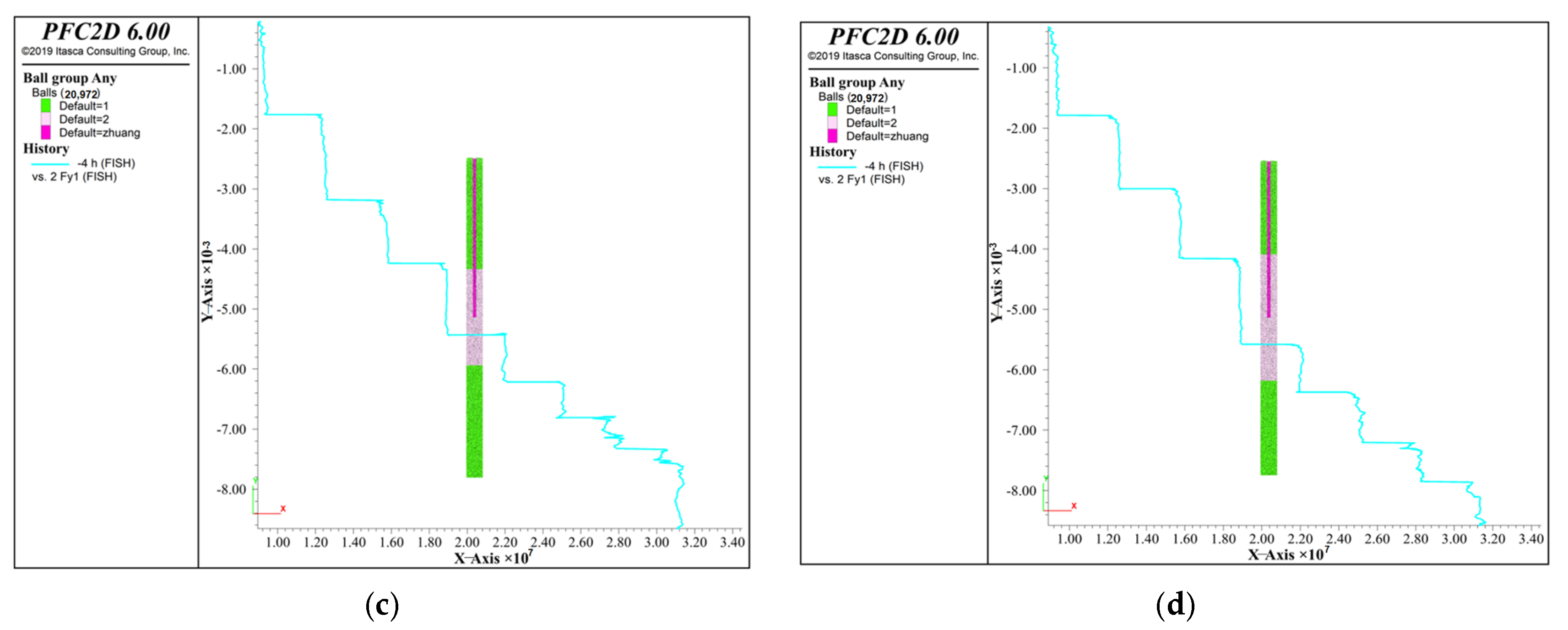

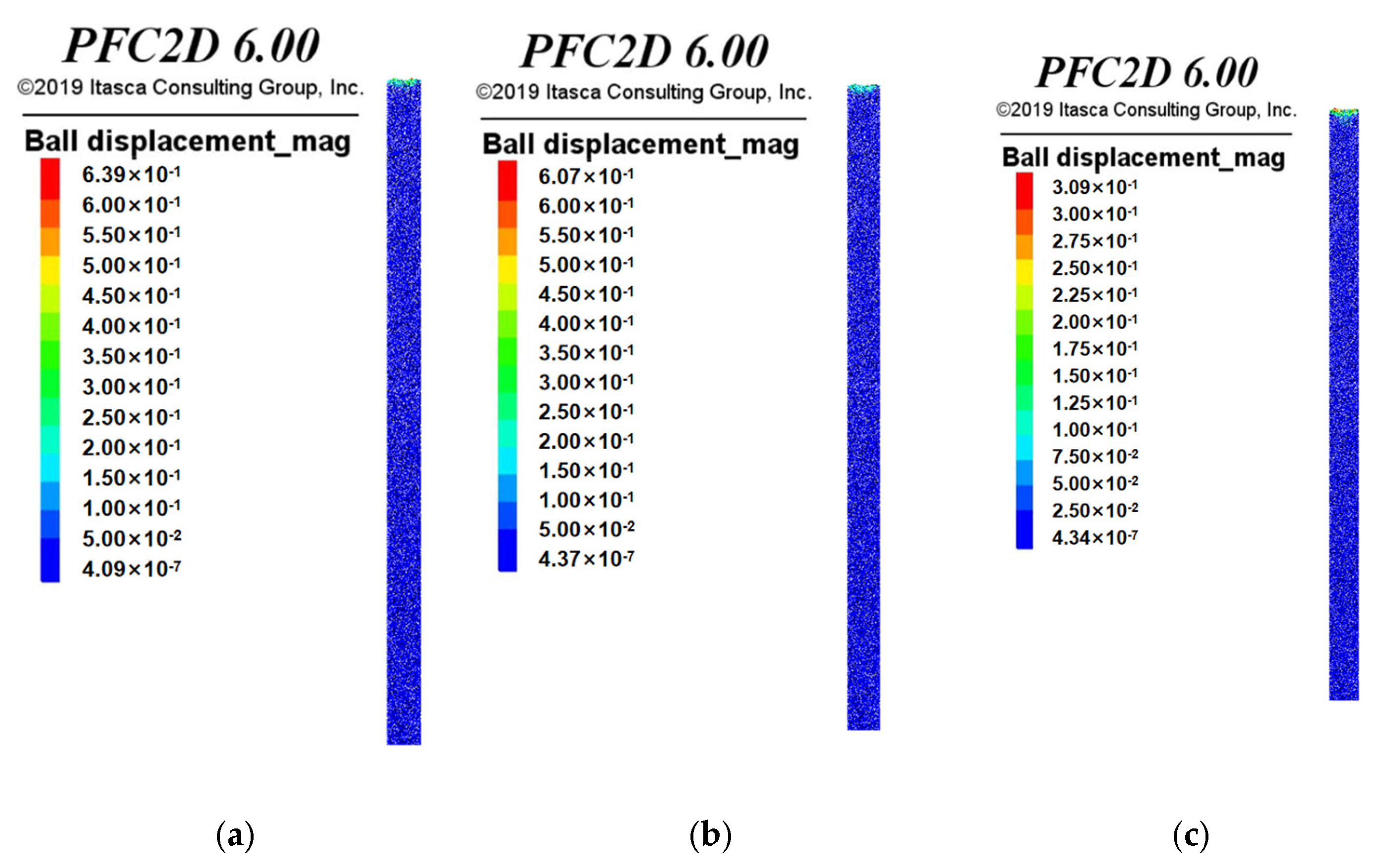

This study combines finite element modeling (FEM) with discrete element modeling (DEM) to analyze the bearing characteristics of ultra-long, large-diameter piles in complex geological formations. Key findings reveal that finite element simulations demonstrate increased pile bearing capacity with larger pile diameters and greater pile lengths. while discrete element modeling further reveals that soil particle displacement around the pile exhibits a “superficial dispersion and deep aggregation” pattern as pile diameter and length increase. The results from both simulation methods corroborate each other, quantifying the influence of pile diameter from a macromechanical perspective while elucidating the underlying mechanisms at the microscopic particle level. This provides multidimensional support for related engineering design and theoretical research.

Regarding the complementarity of simulation methods: Finite element simulation, leveraging its efficiency in modeling continuous media, precisely captures the macro-mechanical response between pile foundations and soil. As pile diameter increases, both pile stiffness and bearing area grow synchronously, leading to more uniform stress distribution within the pile and surrounding soil while mitigating stress concentration—consistent with predictions from soil mechanics’ continuous medium theory. Discrete element simulation, however, overcomes the limitations of the continuous medium assumption by clearly revealing the microscopic movement patterns of soil particles: at small pile diameters (<800 mm), the compaction effect of pile penetration on surrounding particles is concentrated near the surface, leading to high particle dispersion and disordered displacement; when the pile diameter increases to 1000 mm, the squeezing stress propagates deeper, forming an ordered stress system among particles with a significantly reduced displacement range. This microscopic mechanism also provides a rational explanation for the macroscopic phenomenon of the “critical bearing capacity threshold” observed in finite element simulations. The combination of these two methods achieves dual verification through “macroscopic mechanical quantification + microscopic mechanism analysis,” avoiding the potential limitations of a single simulation approach.

The limitations of this study must be objectively stated: the simulation process did not account for the nonlinear rheological properties of the soil or damage effects during pile construction, and the particle model in the discrete element simulation simplified the complex composition of actual soil. Furthermore, the simulation was limited to a single soil type (peaty soil) and did not address composite soils or special geological conditions. Future research should incorporate soil rheological constitutive models, optimize discrete element particle parameters, and extend simulations to diverse geological scenarios. Integrating field prototype experiments to validate results will further enhance the accuracy of this simulation method in pile foundation engineering.

In summary, this study employs a synergistic analysis of finite element and discrete element simulations to clarify the influence patterns of pile length, pile diameter, and soft layer thickness on macro- and micro-scale mechanical responses of pile foundations. The findings not only provide multidimensional data support for optimizing pile diameter design but also establish a reference paradigm for applying the “finite element-discrete element coupled simulation method” in similar engineering problems. This holds significant theoretical value and practical significance for enhancing the scientific rigor and safety of pile foundation engineering design.