Performance Study of Nano-Enhanced PCM in Building-Integrated Semi-Transparent Photovoltaic Modules

Abstract

1. Introduction

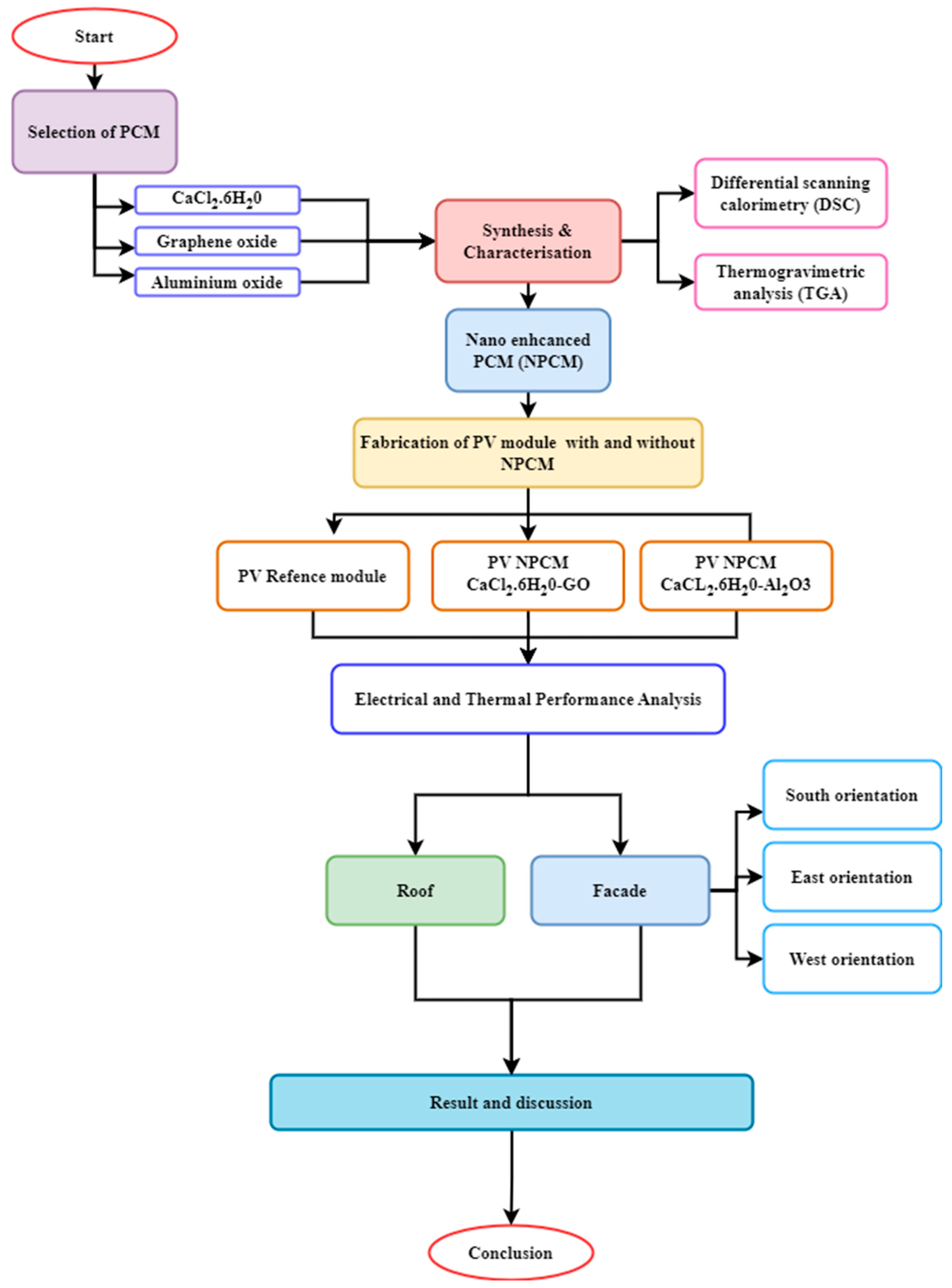

2. Materials and Methods

2.1. Objectives

2.2. Materials

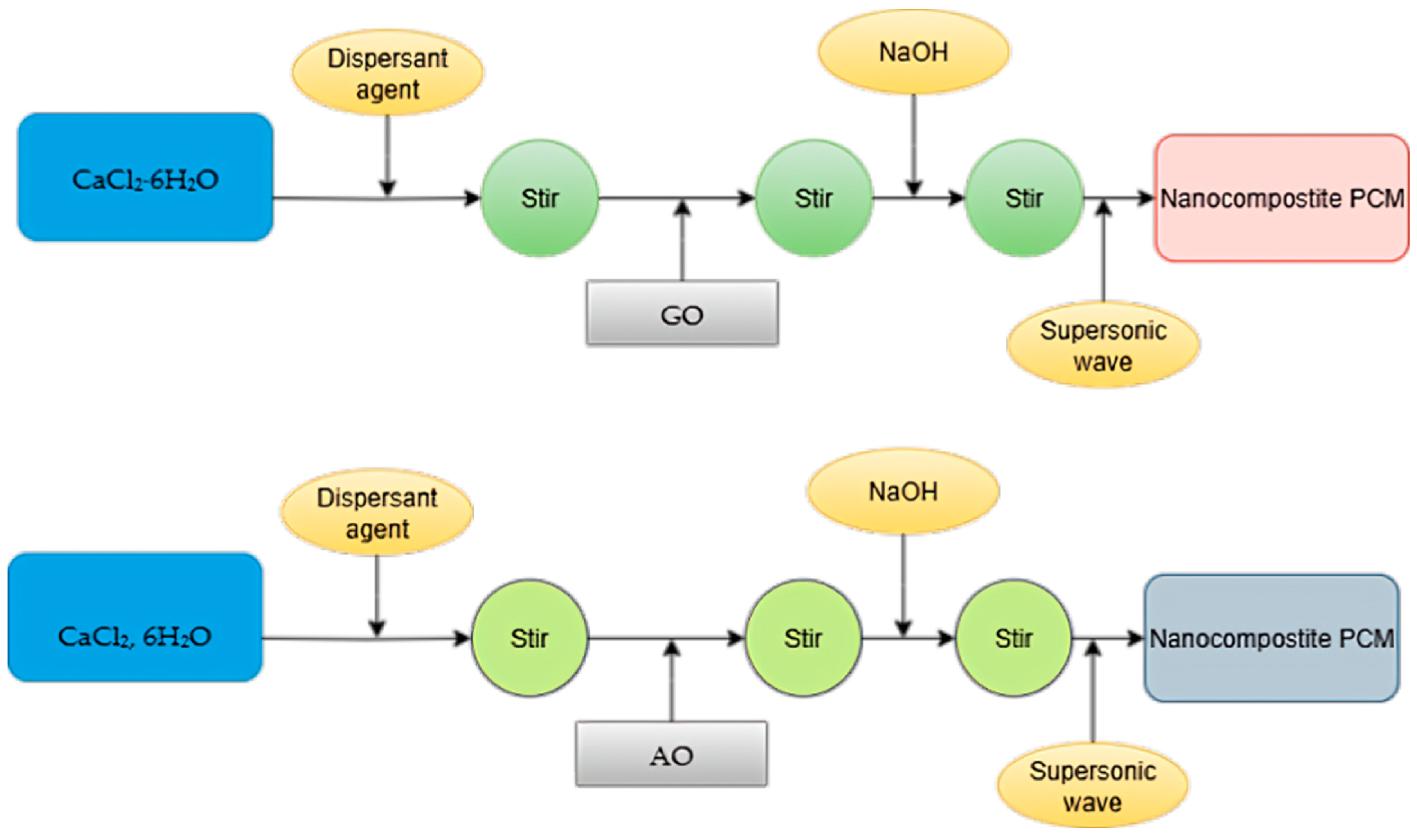

2.2.1. Preparation of the PCM

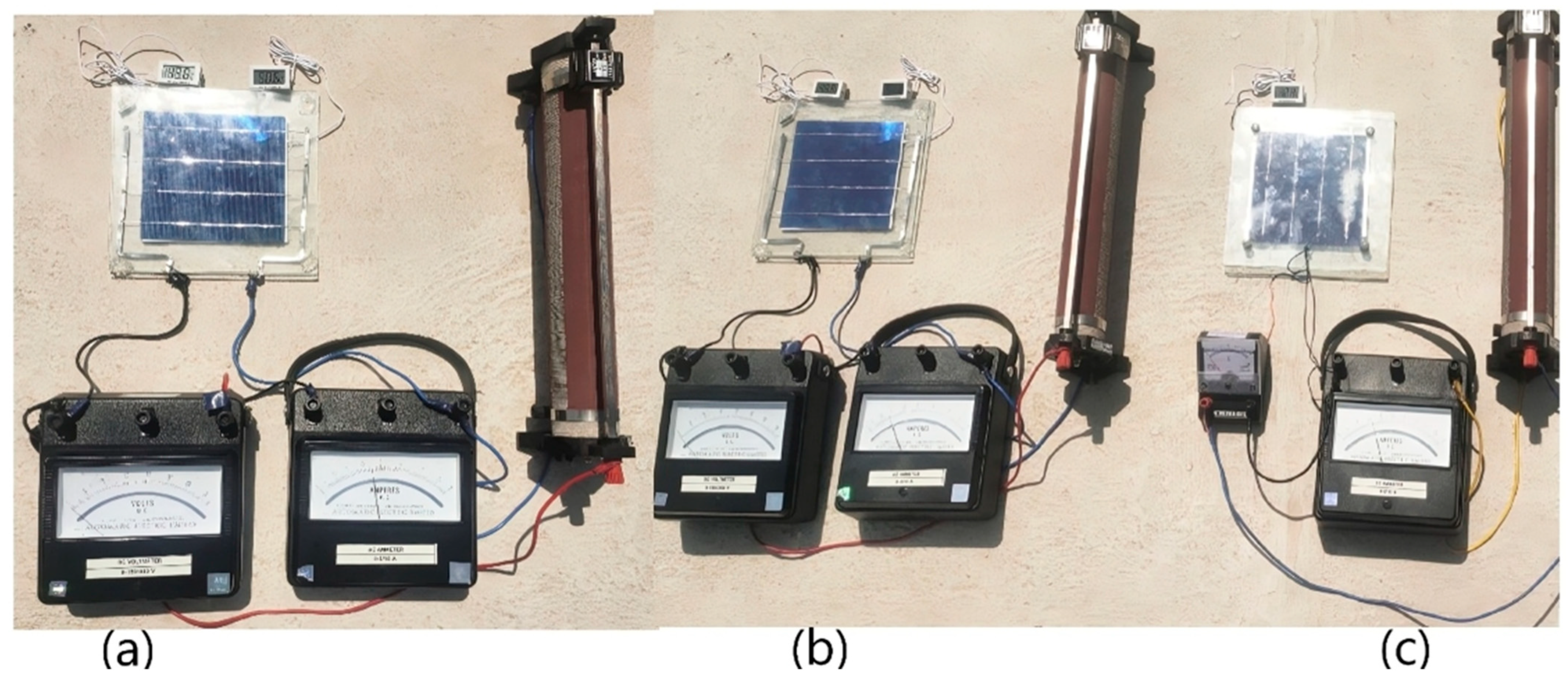

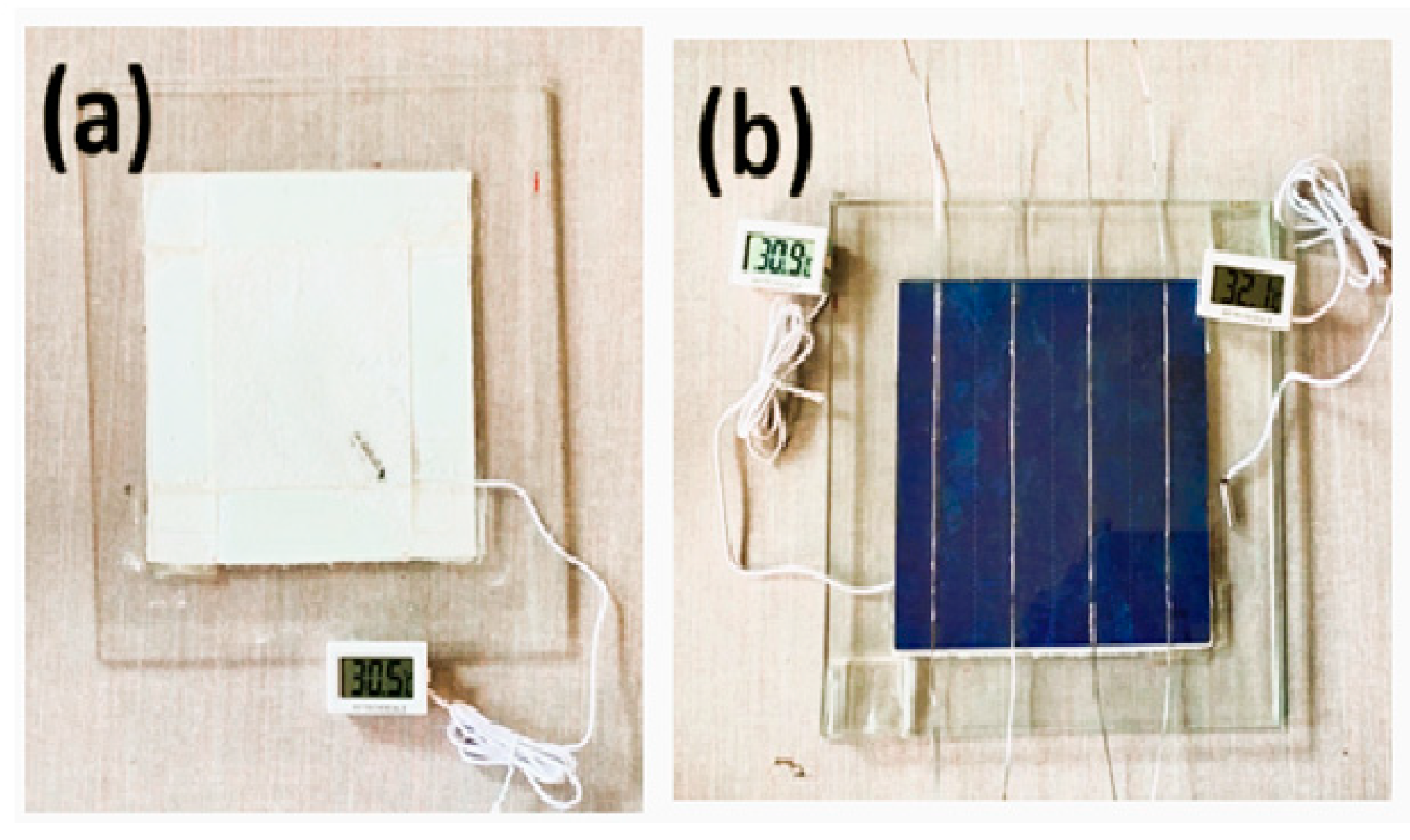

2.2.2. Fabrication of STPV Module

- , : mass of PV layer and PCM

- , : specific heat capacities

- : latent heat of fusion of PCM

- : liquid fraction (0–1)

- : exposed area of module

- , : convective heat transfer coefficients

- : absorbed solar flux

- : instantaneous electrical conversion efficiency

- : conductive heat flow between the PV layer and the PCM interface

2.3. Analyzing Experimental Uncertainty

3. Results and Discussion

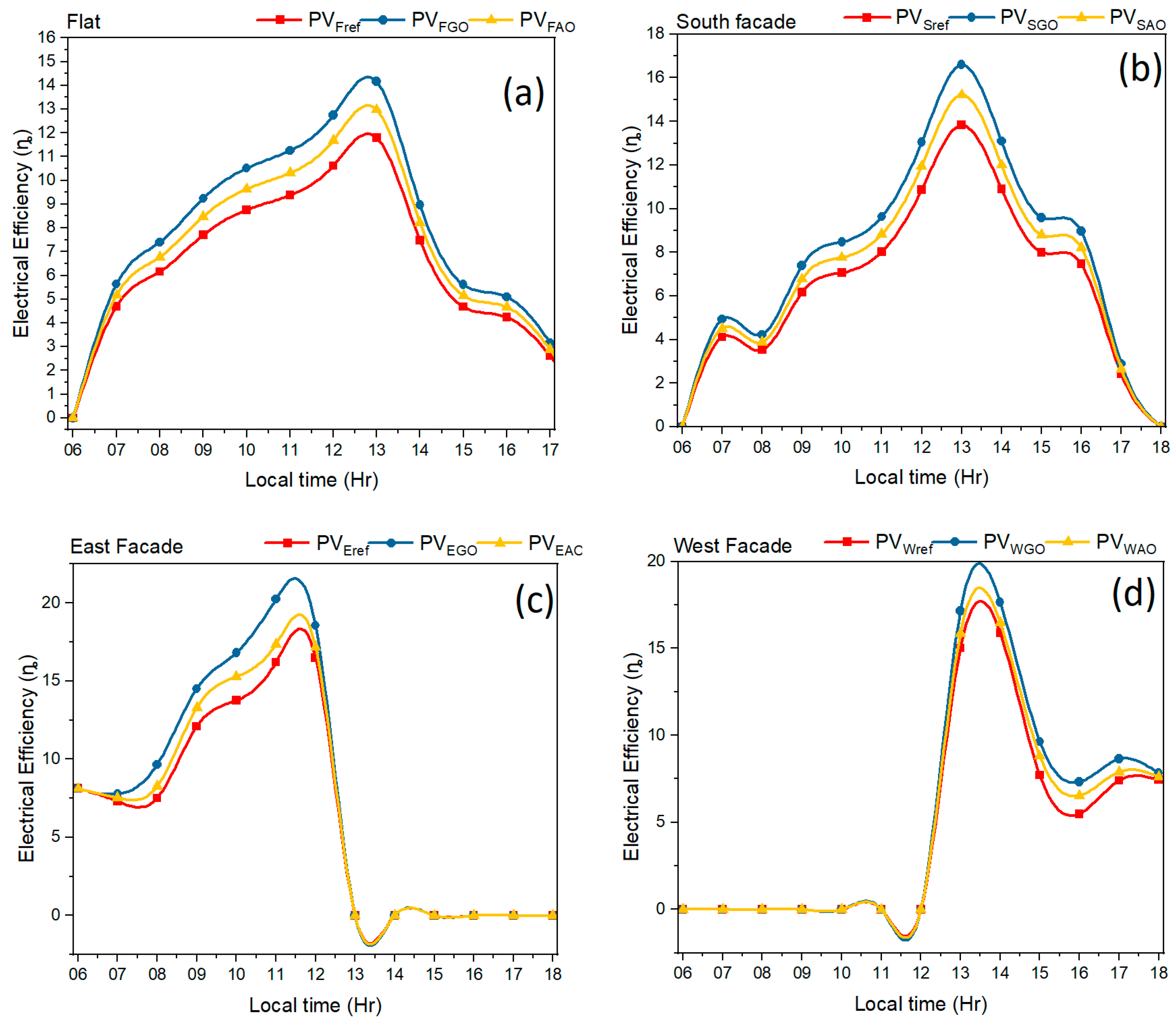

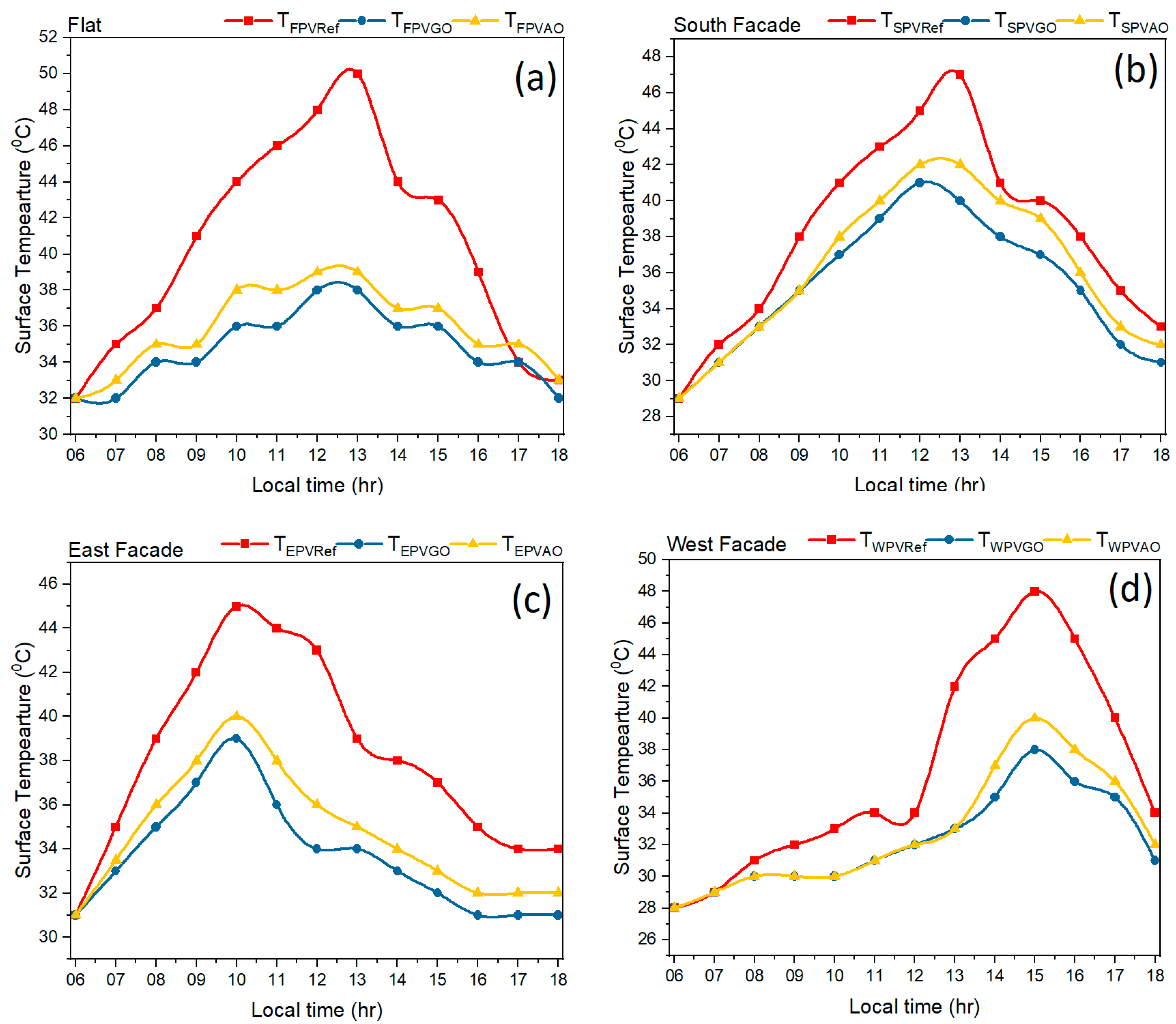

Environmental and Economic Benefits

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PCM | Phase change material |

| STPV | Semi-transparent photovoltaic |

| GO | Graphene oxide |

| Al2O3 | Aluminum oxide |

| TGA | Thermogravimetric analysis |

| DSC | Differential scanning calorimetry |

| PV | Photovoltaic |

References

- Zhang, Z.; Wang, J.; Xia, Y.; Wei, D.; Niu, Y. Solar-Mixer: An Efficient End-to-End Model for Long-Sequence Photovoltaic Power Generation Time Series Forecasting. IEEE Trans. Sustain. Energy 2023, 14, 1979–1991. [Google Scholar] [CrossRef]

- Hossen, M.D.; Islam, M.F.; Ishraque, M.F.; Shezan, S.A.; Arifuzzaman, S.M. Design and Implementation of a Hybrid Solar-Wind-Biomass Renewable Energy System Considering Meteorological Conditions with the Power System Performances. Int. J. Photoenergy 2022, 2022, 8792732. [Google Scholar] [CrossRef]

- Aruna, M.; Nagabhooshanam, N.; Parihar, P.S.; Kedia, N.; Jemmy Christy, H.; Satya, G.; Barik, D.; Thirugnanasambandham, T.; Sathiyamurthy, S. Enhancement of Solar Thermal Performance and Reduction of Thermal Loss Behaviour of Solar Thermal Collector Featured with Polyaniline and Paraffin. Appl. Therm. Eng. 2025, 278, 127273. [Google Scholar] [CrossRef]

- Maneechot, P.; Klungsida, N.; Kueathaweekun, T.; Butploy, N.; Somnugpong, S.; Khiewwan, K.; Thongchai, J.; Tantisantisom, K.; Ramachandran, T.; Kuppusamy, M.; et al. A Portable Hybrid Photovoltaic Thermal Application: Shape-Stabilised Phase-Change Material with Metal Flakes for Enhanced Heat Transfer. Energies 2025, 18, 452. [Google Scholar] [CrossRef]

- Rajamony, R.K.; Pandey, A.K.; Sofiah, A.G.N.; Wadaan, M.A.; Siaw Paw, J.K.; Suraparaju, S.K.; Baabbad, A.; Samykano, M.; Paranthaman, V. Energy, Exergy, Economic and Environmental (4E) Analysis of Serpentine Tube Absorber Photovoltaic Thermal System Using Nano Enhanced Phase Change Material. Energy 2025, 319, 135032. [Google Scholar] [CrossRef]

- Bouzidi, M.; Aljibori, H.S.S.; Raizah, Z.; Ali, M.H.; Saidani, T.; Alresheedi, F.; Elhassanein, A.; Sabour, M.; Ghalambaz, M. Simulation of Conjugate Free Convection Heat Transfer of NEPCM/Al2O3-Kerosene Non-Newtonian Hybrid Nanoliquid between a Double-Pipe Space. Case Stud. Therm. Eng. 2025, 71, 106143. [Google Scholar] [CrossRef]

- Anand, A.; Shukla, A.; Panchal, H.; Sharma, A. Thermal Regulation of Photovoltaic System for Enhanced Power Production: A Review. J. Energy Storage 2021, 35, 102236. [Google Scholar] [CrossRef]

- Chandel, S.S.; Agarwal, T. Review of Cooling Techniques Using Phase Change Materials for Enhancing Efficiency of Photovoltaic Power Systems. Renew. Sustain. Energy Rev. 2017, 73, 1342–1351. [Google Scholar] [CrossRef]

- Jayaprakash, V.; Ganesan, S.; Beemkumar, N.; Sunil Kumar, M.; Kamakshi Priya, K. Enhancing Thermal Energy Storage Efficiency: Synthesis and Analysis of Hybrid Nano-PCMs. Results Eng. 2025, 26, 104899. [Google Scholar] [CrossRef]

- Venkatesh, R.; Logesh, K.; Vinayagam, M.; Prabagaran, S.; Chaturvedi, R.; Hossain, I.; Soudagar, M.E.M.; Salmen, S.H.; Al Obaid, S. Hybrid Photovoltaic Solar System Performance Enriched by Adaptation of Silicon Carbide Made Porous Medium. Electr. Eng. 2025, 107, 3271–3283. [Google Scholar] [CrossRef]

- Sathish, T.; Giri, J.; Saravanan, R.; Said, Z.; Al-lehaibi, M. MWCNT/SiO2 Hybrid Nano-PCM for Ultrafast Solar Cookers: An Experimental Study. Eng. Rep. 2025, 7, e13102. [Google Scholar] [CrossRef]

- Ashok, R.; Sakthivel, T.G. A Complete Review of Augmenting Solar Desalination Efficiency with PCMs. Results Eng. 2025, 25, 104421. [Google Scholar] [CrossRef]

- Hasan, A.; Sarwar, J.; Alnoman, H.; Abdelbaqi, S. Yearly Energy Performance of a Photovoltaic-Phase Change Material (PV-PCM) System in Hot Climate. Sol. Energy 2017, 146, 417–429. [Google Scholar] [CrossRef]

- Waqas, A.; Ji, J. Thermal Management of Conventional PV Panel Using PCM with Movable Shutters—A Numerical Study. Sol. Energy 2017, 158, 797–807. [Google Scholar] [CrossRef]

- Sharma, S.; Micheli, L.; Chang, W.; Tahir, A.A.; Reddy, K.S.; Mallick, T.K. Nano-Enhanced Phase Change Material for Thermal Management of BICPV. Appl. Energy 2017, 208, 719–733. [Google Scholar] [CrossRef]

- Hasan, A.; McCormack, S.J.; Huang, M.J.; Sarwar, J.; Norton, B. Increased Photovoltaic Performance through Temperature Regulation by Phase Change Materials: Materials Comparison in Different Climates. Sol. Energy 2015, 115, 264–276. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Al-Sulaiman, F.A.; Saidur, R. Numerical Investigation of the Effects of the Nano-Enhanced Phase Change Materials on the Thermal and Electrical Performance of Hybrid PV/Thermal Systems. Energy Convers. Manag. 2020, 205, 112449. [Google Scholar] [CrossRef]

- Sivashankar, M.; Selvam, C.; Manikandan, S.; Harish, S. Performance Improvement in Concentrated Photovoltaics Using Nano-Enhanced Phase Change Material with Graphene Nanoplatelets. Energy 2020, 208, 118408. [Google Scholar] [CrossRef]

- Abdollahi, N.; Rahimi, M. Potential of Water Natural Circulation Coupled with Nano-Enhanced PCM for PV Module Cooling. Renew. Energy 2020, 147, 302–309. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, X. Thermal Properties of a New Type of Calcium Chloride Hexahydrate-Magnesium Chloride Hexahydrate/Expanded Graphite Composite Phase Change Material and Its Application in Photovoltaic Heat Dissipation. Sol. Energy 2020, 204, 683–695. [Google Scholar] [CrossRef]

- Abdelrazik, A.S.; Saidur, R.; Al-Sulaiman, F.A. Thermal Regulation and Performance Assessment of a Hybrid Photovoltaic/Thermal System Using Different Combinations of Nano-Enhanced Phase Change Materials. Sol. Energy Mater. Sol. Cells 2020, 215, 110645. [Google Scholar] [CrossRef]

- Emam, M.; Ookawara, S.; Ahmed, M. Performance Study and Analysis of an Inclined Concentrated Photovoltaic-Phase Change Material System. Sol. Energy 2017, 150, 229–245. [Google Scholar] [CrossRef]

- Foteinis, S.; Savvakis, N.; Tsoutsos, T. Energy and Environmental Performance of Photovoltaic Cooling Using Phase Change Materials under the Mediterranean Climate. Energy 2023, 265, 126355. [Google Scholar] [CrossRef]

- Xu, Z.; Kong, Q.; Qu, H.; Wang, C. Cooling Characteristics of Solar Photovoltaic Panels Based on Phase Change Materials. Case Stud. Therm. Eng. 2023, 41, 102667. [Google Scholar] [CrossRef]

- Velmurugan, K.; Karthikeyan, V.; Korukonda, T.B.; Madhan, K.; Emsaeng, K.; Sukchai, S.; Sirisamphanwong, C.; Wongwuttanasatian, T.; Elavarasan, R.M.; Alhelou, H.H. Experimental Studies on PV Module Cooling with Radiation Source PCM Matrix. IEEE Access 2020, 8, 145936–145949. [Google Scholar] [CrossRef]

- Badi, N.; Alghamdi, S.A.; El-Hageen, H.M.; Albalawi, H. Onsite Enhancement of REEEC Solar Photovoltaic Performance through PCM Cooling Technique. PLoS ONE 2023, 18, e0281391. [Google Scholar] [CrossRef]

- Bria, A.; Raillani, B.; Chaatouf, D.; Salhi, M.; Amraqui, S.; Mezrhab, A. Effect of PCM Thickness on the Performance of the Finned PV/PCM System. Mater. Today Proc. 2023, 72, 3617–3625. [Google Scholar] [CrossRef]

- Devarajan, M.M.; Kumaraguruparan, G. Thermal Analysis of Solar Panel with Phase Change Material: Experimental and Numerical Study. J. Braz. Soc. Mech. Sci. Eng. 2024, 46, 222. [Google Scholar] [CrossRef]

- Refaey, H.A.; Abdo, S.; Saidani-Scott, H.; El-Shekeil, Y.A.; Bendoukha, S.; Barhoumi, N.; Abdelrahman, M.A. Thermal Regulation of Photovoltaic Panels Using PCM with Multiple Fins Configuration: Experimental Study with Analysis. Therm. Sci. Eng. Prog. 2024, 49, 102457. [Google Scholar] [CrossRef]

- Karthick, A.; Kalidasa Murugavel, K.; Sudalaiyandi, K.; Muthu Manokar, A. Building Integrated Photovoltaic Modules and the Integration of Phase Change Materials for Equatorial Applications. Build. Serv. Eng. Res. Technol. 2020, 41, 634–652. [Google Scholar] [CrossRef]

- Kline, S.J. Describing Uncertainties in Single-Sample Experiments. Mech. Eng. 1963, 75, 3–8. [Google Scholar]

- Kirkup, L.; Frenkel, R.B. An Introduction to Uncertainty in Measurement: Using the GUM (Guide to the Expression of Uncertainty in Measurement); Cambridge University Press: Cambridge, UK, 2006; ISBN 1139454900. [Google Scholar]

- Stritih, U. Increasing the Efficiency of PV Panel with the Use of PCM. Renew. Energy 2016, 97, 671–679. [Google Scholar] [CrossRef]

- Kumar, K.S.; Revanth, S.; Sanjeev, D.; Kumar, P.S.; Surya, P. Experimental Investigation of Improving the Energy Conversion Efficiency of PV Cell by Integrating with PCM. Mater. Today Proc. 2021, 37, 712–716. [Google Scholar] [CrossRef]

- Kibria, M.G.; Mohtasim, M.S.; Paul, U.K.; Das, B.K.; Saidur, R. Impact of Hybrid Nano PCM (Paraffin Wax with Al2O3 and ZnO Nanoparticles) on Photovoltaic Thermal System: Energy, Exergy, Exergoeconomic and Enviroeconomic Analysis. J. Clean. Prod. 2024, 436, 140577. [Google Scholar] [CrossRef]

- Hassan, E.A.; Tony, M.A.; Awad, M.M. Thermal Energy Storage Using Hybrid Nanofluid Phase Change Material (PCM) Based on Waste Sludge Incorp Rated ZnO/α-Fe2O3. Nanomaterials 2024, 14, 604. [Google Scholar] [CrossRef]

- Kalidasan, B.; Pandey, A.K.; Rahman, S.; Yadav, A.; Samykano, M.; Tyagi, V. V Graphene–Silver Hybrid Nanoparticle Based Organic Phase Change Materials for Enhanced Thermal Energy Storage. Sustainability 2022, 14, 13240. [Google Scholar] [CrossRef]

| Parameter | Specification | ||

|---|---|---|---|

| STPV (PVRef) | STPV PCM1 (PVGO) | STPV PCM2 (PVAO) | |

| Type of solar cell | Polycrystalline silicon cell | ||

| Nominal power (Wp) | 4.33 W | 4.33 W | 4.33 W |

| Current at maximum power (Imp) (A) | 8.22 A | 8.22 A | 8.22 A |

| Voltage at maximum power (Vmp) (V) | 0.53 V | 0.53 V | 0.53 V |

| Short circuit current (Isc) (A) | 8.7 A | 8.7 A | 8.7 A |

| Open circuit voltage (VOC) (V) | 0.631 V | 0.631 V | 0.631 V |

| Conversion efficiency % | 17.8 | 17.8 | 17.8 |

| Cooling method | - | Passive | Passive |

| Type of cooling | - | PCM—CaCl2·6H2O | PCM—CaCl2·6H2O |

| Nano Material | - | Graphene oxide | Aluminum oxide |

| Dimension | 56 mm × 156 mm ± 0.5 mm | ||

| Thickness | 200 µm ± 30 µm (Wafer thickness) | ||

| Front | Silver bus bars; silicon nitride antireflection coating | ||

| Back | Silver bus bars; Full-surface | ||

| Property | Value/Description | ||

|---|---|---|---|

| Chemical Formula | CaCl2·6H2O | CxOyHz | Al2O3 |

| Molar Mass | 219.08 g/mol | ~60–80 g/mol per C atom unit | 101.96 g/mol |

| Appearance | Colorless to white crystalline solid | Brown to yellow-brown powder | White crystalline solid |

| Density | 1.71 g/cm3 (at 20 °C) | 1.8–2.2 g/cm3 | 3.95–4.1 g/cm3 |

| Thermal Conductivity | ~0.5–0.6 W/m·K (estimated for solid form) | 5–10 W/m·K | 20–38.5 W/m·K |

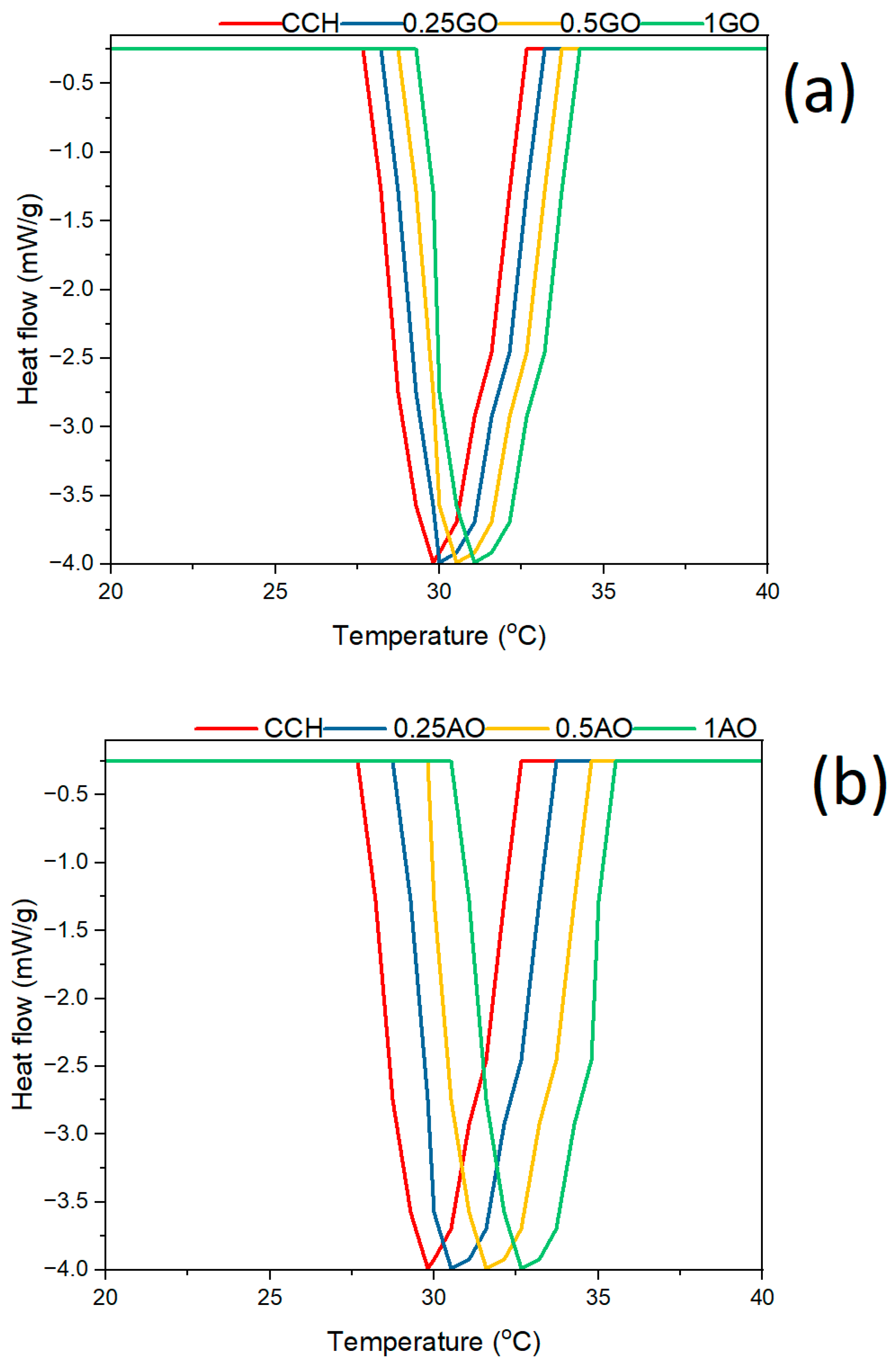

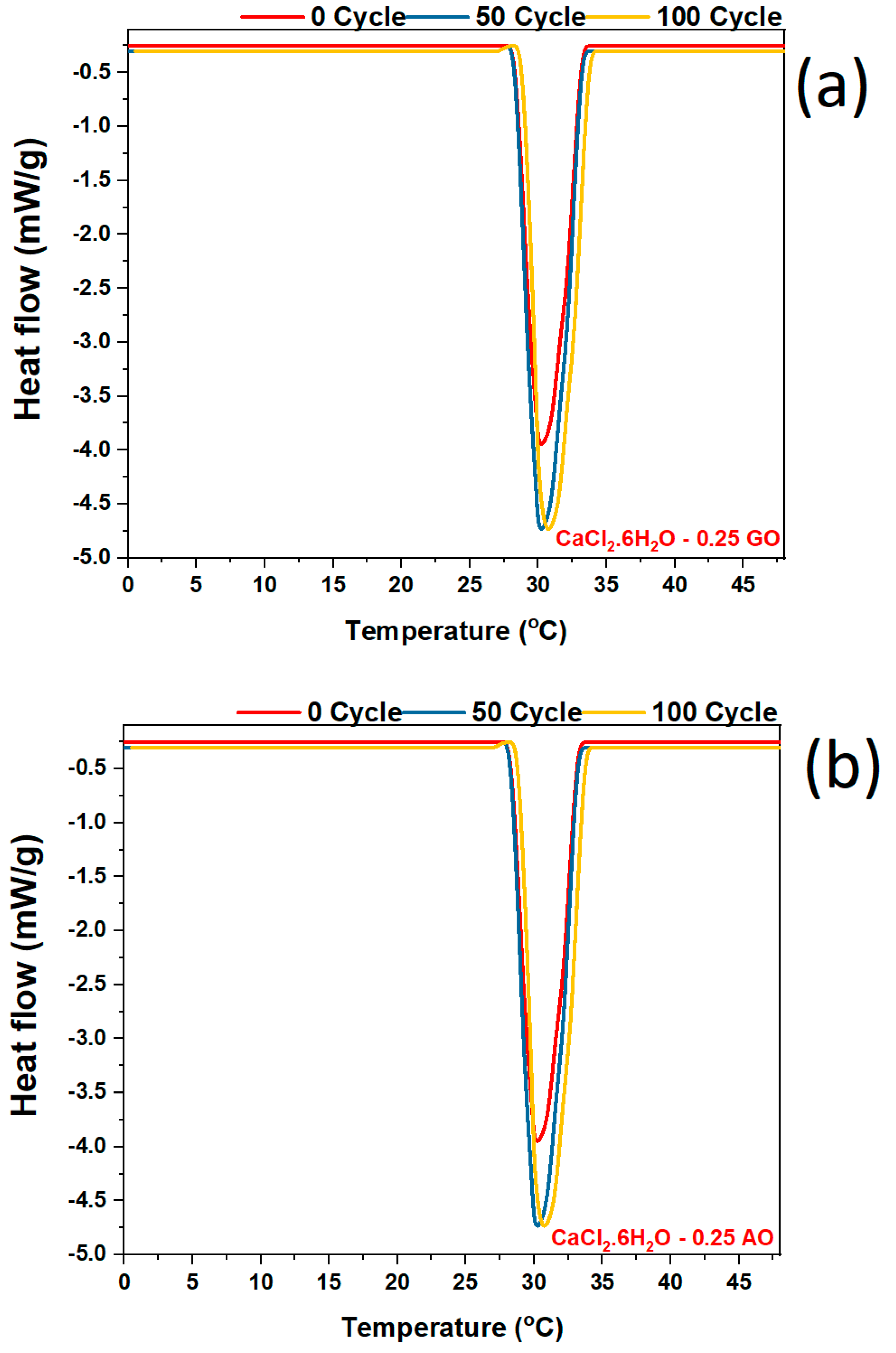

| Sample Code | Sample Name | CaCl2·6H2O (%) | Concentration (%)Wt | Thermal Conductivity (W/mK) | Latent Heat (kJ/kg) |

|---|---|---|---|---|---|

| CaCl2·6H2O | Calcium chloride hexahydrate | 100 | 0 | 0.58 | 160 |

| 0.25GO | Nanocomposite PCM | 99.75 | 0.25 | 0.78 | 172 |

| 0.5GO | NCP | 99.5 | 0.5 | 0.72 | 165 |

| 1GO | NCP | 99 | 1 | 0.7 | 158 |

| 0.25 AO | NCP | 99.75 | 0.25 | 0.68 | 155 |

| 0.5AO | NCP | 99.5 | 0.5 | 0.65 | 152 |

| 1AO | NCP | 99 | 1 | 0.62 | 148 |

| Instrument | Range | Accuracy |

|---|---|---|

| Pyranometer | 0–2000 W/m2 | ±1 W/m2 |

| Temperature sensor | 0–200 °C | ±1 °C |

| Analog Ammeter (A) | 0–5 A | ±0.1 A |

| Analog Voltmeter (V) | 75 V | ±1 V |

| Loading Rheostat (ohm) | 90 ohm, 4 A | ±0.1% |

| Thermocouple sensor | K-type 220 °C | ±5 °C |

| Thermal conductivity | ||

| Sensor Interface | DB-15 connector | ±5 C |

| 0.00–50.00 °C | ||

| Conductivity | 0.02–2.00 W/(m K) | ±0.01 W/(m K) |

| Resistivity | 50–5000 °Ccm/W | ±10 C |

| PCM | Findings | Location | References |

|---|---|---|---|

| CaCl2·6H2O-capric and palmitic acids | CaCl2⋅6H2O performed best in both climates, lowering temperatures and improving overall performance, with particularly notable gains in the hot environment of Vehari. | Dublin, Ireland | [26] |

| PCM RT28HC | Increased yearly power output by 7.3%; surface temperature decreased on panels of up to 35.6% | City of Ljubljana | [32] |

| Copper, silicon carbide, paraffin wax | Analyzing the impact of PV cell combinations between and without PCM | Coimbatore India | [33] |

| PCM-RT27 | A drop in temperature occurs. Boosts electrical production by nearly 9.4% | Greece | [23] |

| PCM-OM37P | Keep the temperature at or near the ambient level. The increase in power output could reach 3%. | Tabuk | [34] |

| Hybrid nanoparticles (2.0 wt% ZnO and 2.0 wt% Al2O3) used in the PCM | As the rate of heat transmission increases, the temperature drops. The electrical efficiency was around 35% higher than that of the standard PV panel. | Bangladesh | [35] |

| AS-ZnO/α-Fe2O3 nanocrystals added to PCM | As the rate of heat transmission increases, the temperature drops. A 93% improvement in thermal storage performance was possible with 1.0 wt% hybrid nanoparticles in PCM. | Saudi Arabia | [36] |

| Gr, Ag nano-powder is distributed at 0.8 wt% in RT50 | As the rate of heat transmission increases, the temperature drops. A 93% improvement in thermal storage performance was possible with 1.0 wt% hybrid nanoparticle in PCM. | Malaysia | [37] |

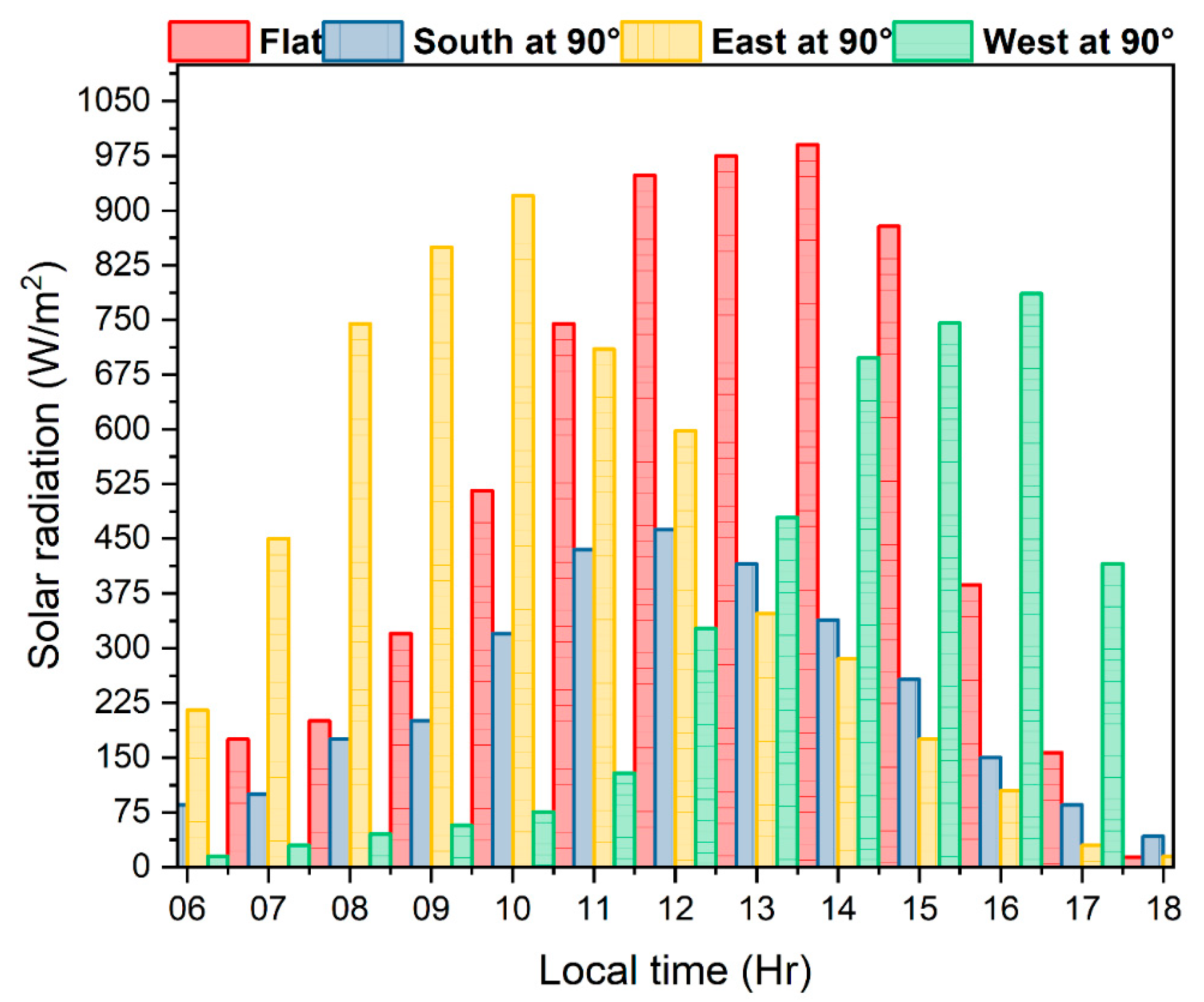

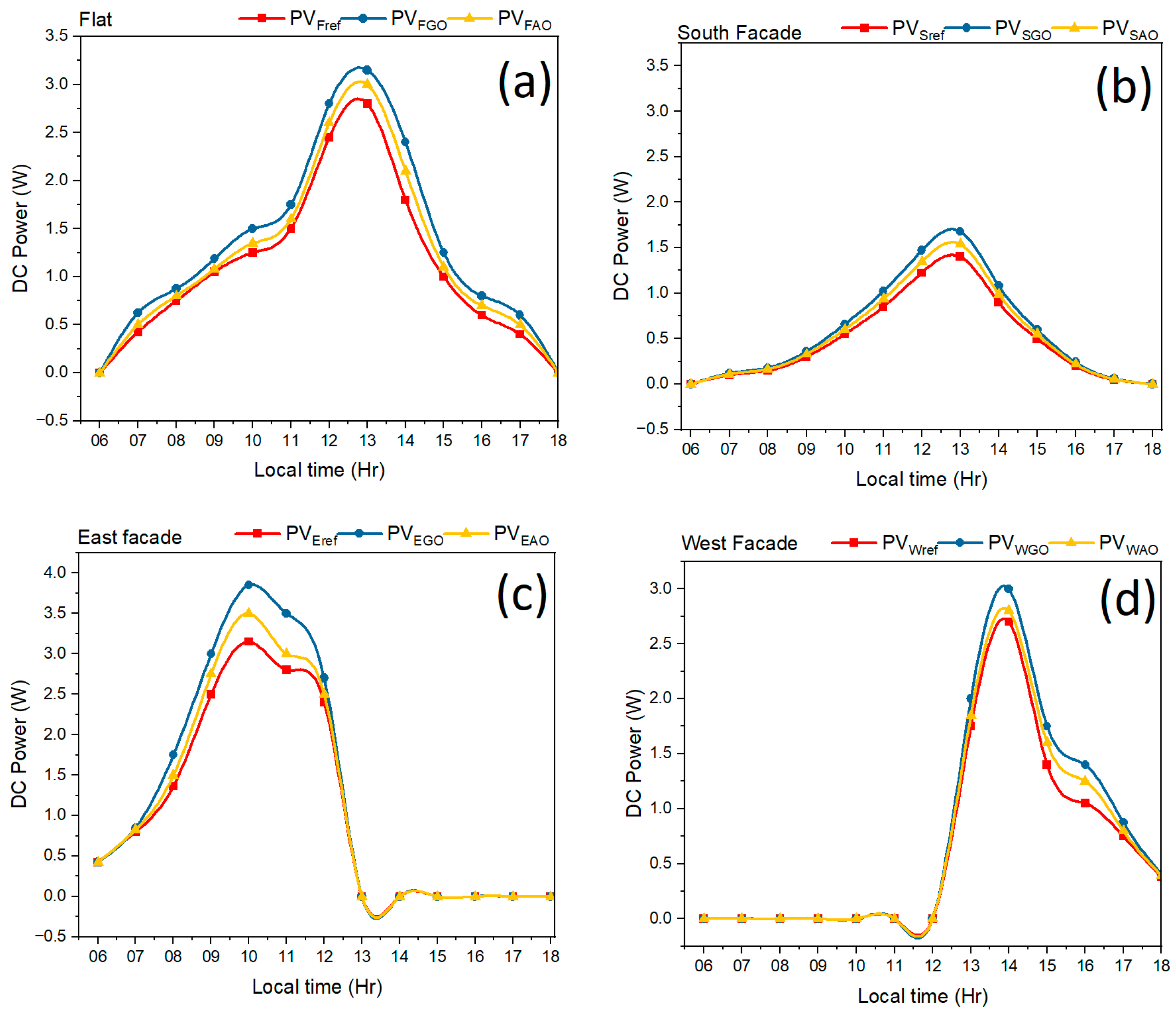

| Cacl2·6H2O mixture of Aluminium oxide and graphene oxide | Temperature reduction of a maximum of 12 °C in the façade during peak hours | Coimbatore India | Present study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alrasheedi, N.H.; Karthick, A.; Kumar, P.M.; Rajendran, V. Performance Study of Nano-Enhanced PCM in Building-Integrated Semi-Transparent Photovoltaic Modules. Buildings 2025, 15, 4236. https://doi.org/10.3390/buildings15234236

Alrasheedi NH, Karthick A, Kumar PM, Rajendran V. Performance Study of Nano-Enhanced PCM in Building-Integrated Semi-Transparent Photovoltaic Modules. Buildings. 2025; 15(23):4236. https://doi.org/10.3390/buildings15234236

Chicago/Turabian StyleAlrasheedi, Nashmi H., Alagar Karthick, P. Manoj Kumar, and Vijayakumar Rajendran. 2025. "Performance Study of Nano-Enhanced PCM in Building-Integrated Semi-Transparent Photovoltaic Modules" Buildings 15, no. 23: 4236. https://doi.org/10.3390/buildings15234236

APA StyleAlrasheedi, N. H., Karthick, A., Kumar, P. M., & Rajendran, V. (2025). Performance Study of Nano-Enhanced PCM in Building-Integrated Semi-Transparent Photovoltaic Modules. Buildings, 15(23), 4236. https://doi.org/10.3390/buildings15234236