Functional Strut-and-Tie Model of Filament Pipes in Extradosed Cable-Stayed Bridges Under Mechanical Loading

Abstract

1. Introduction

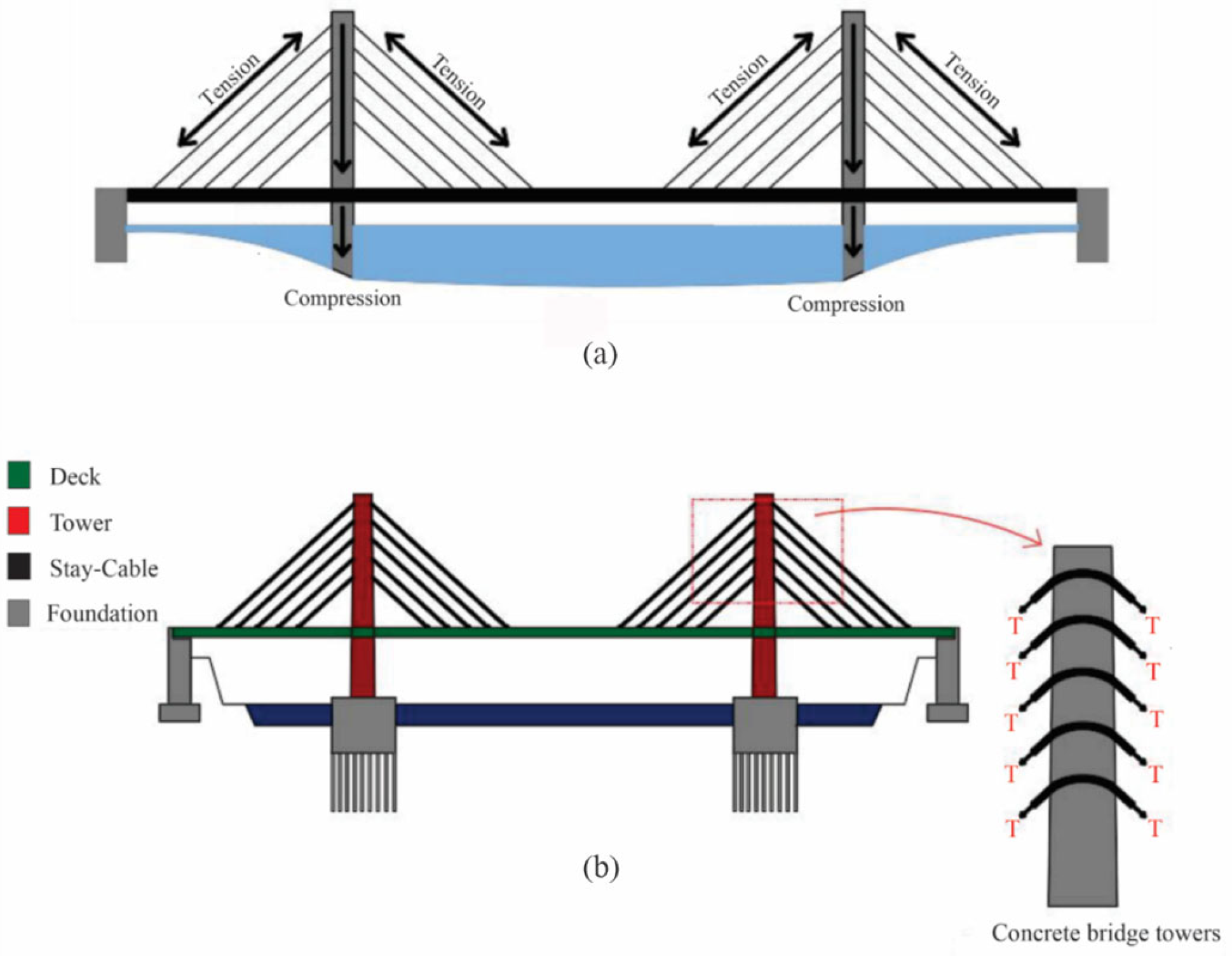

2. Cable-Stayed Bridges

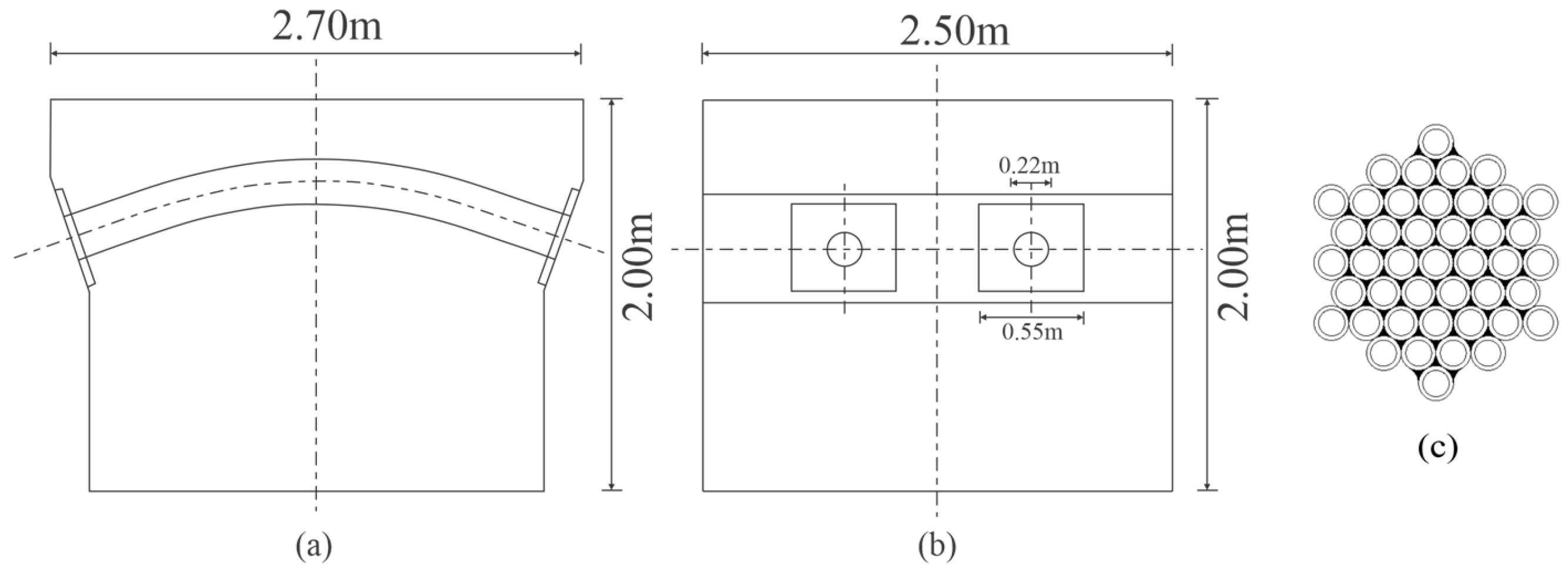

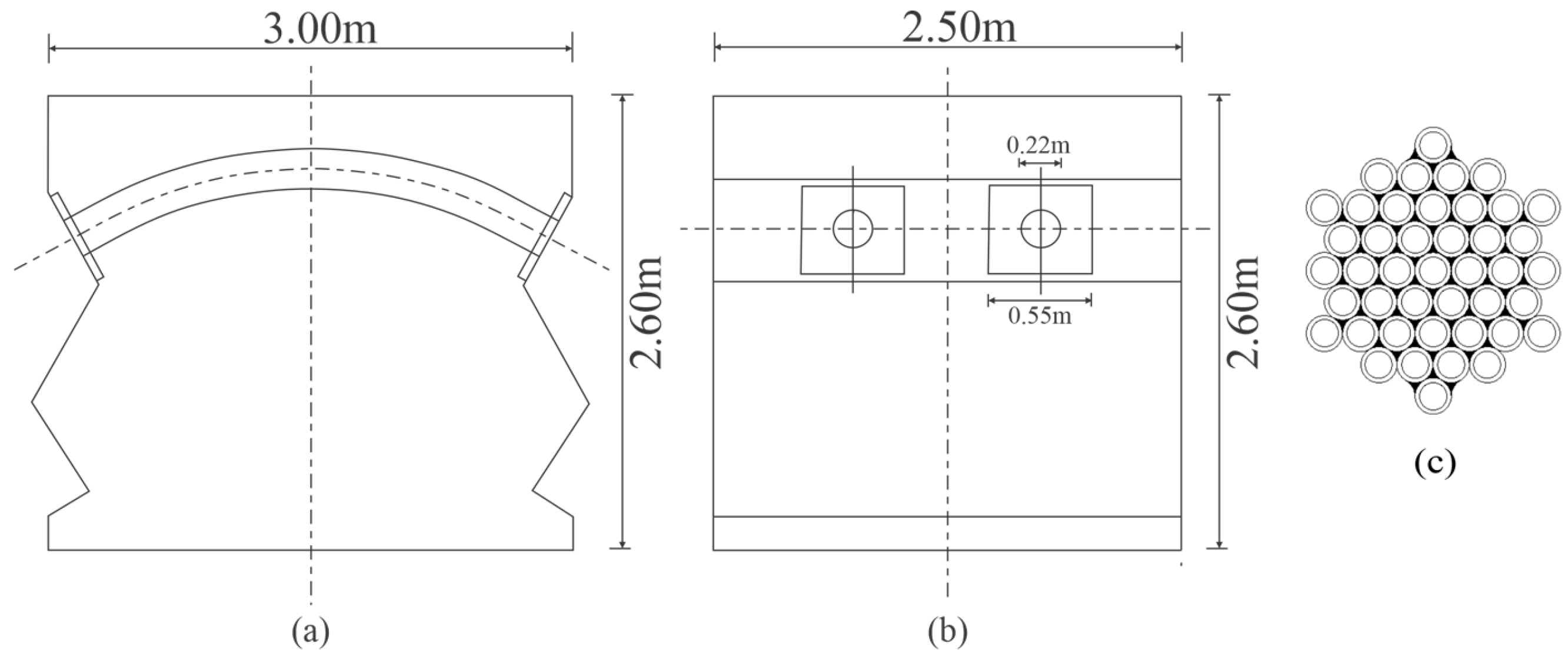

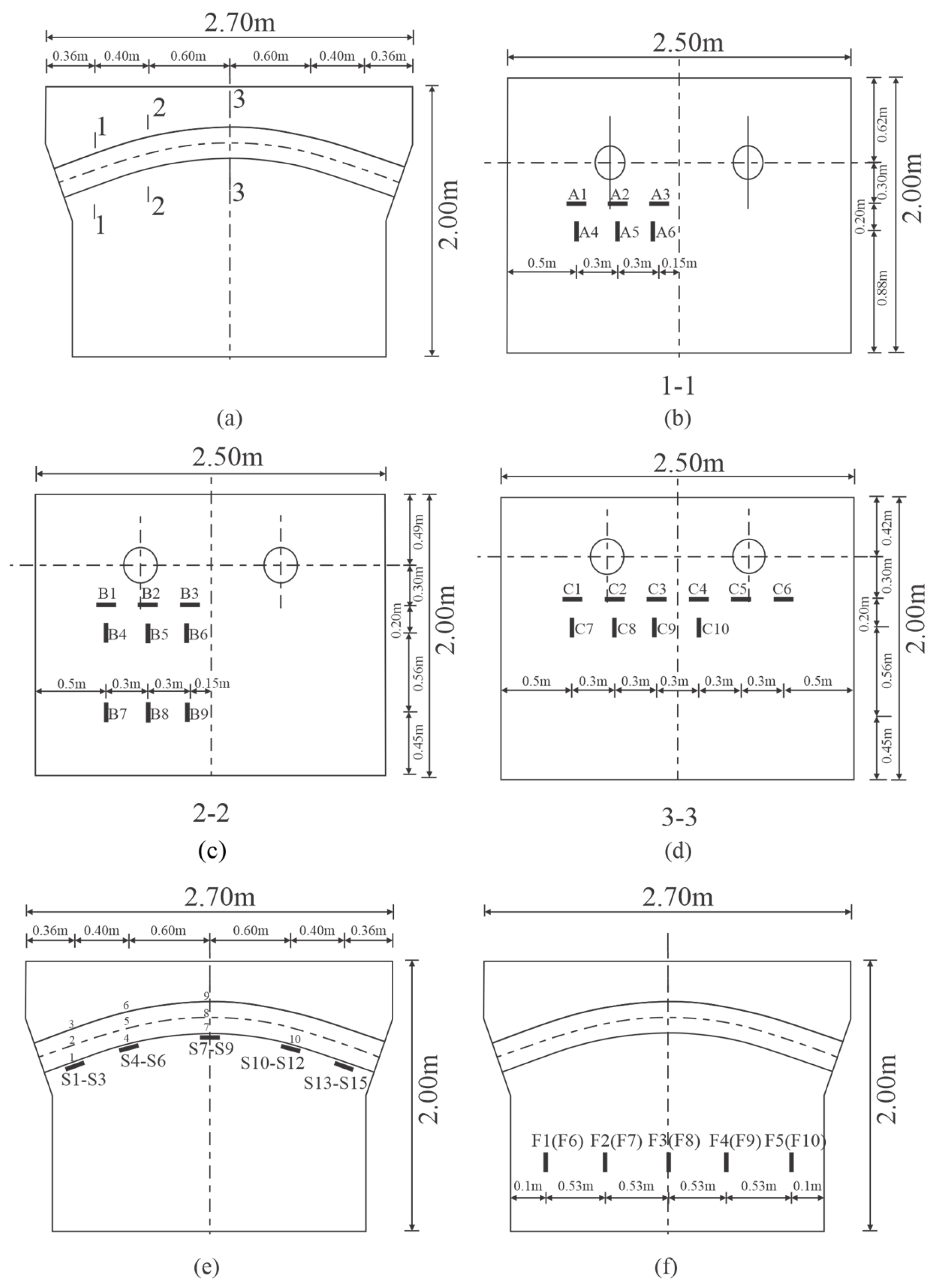

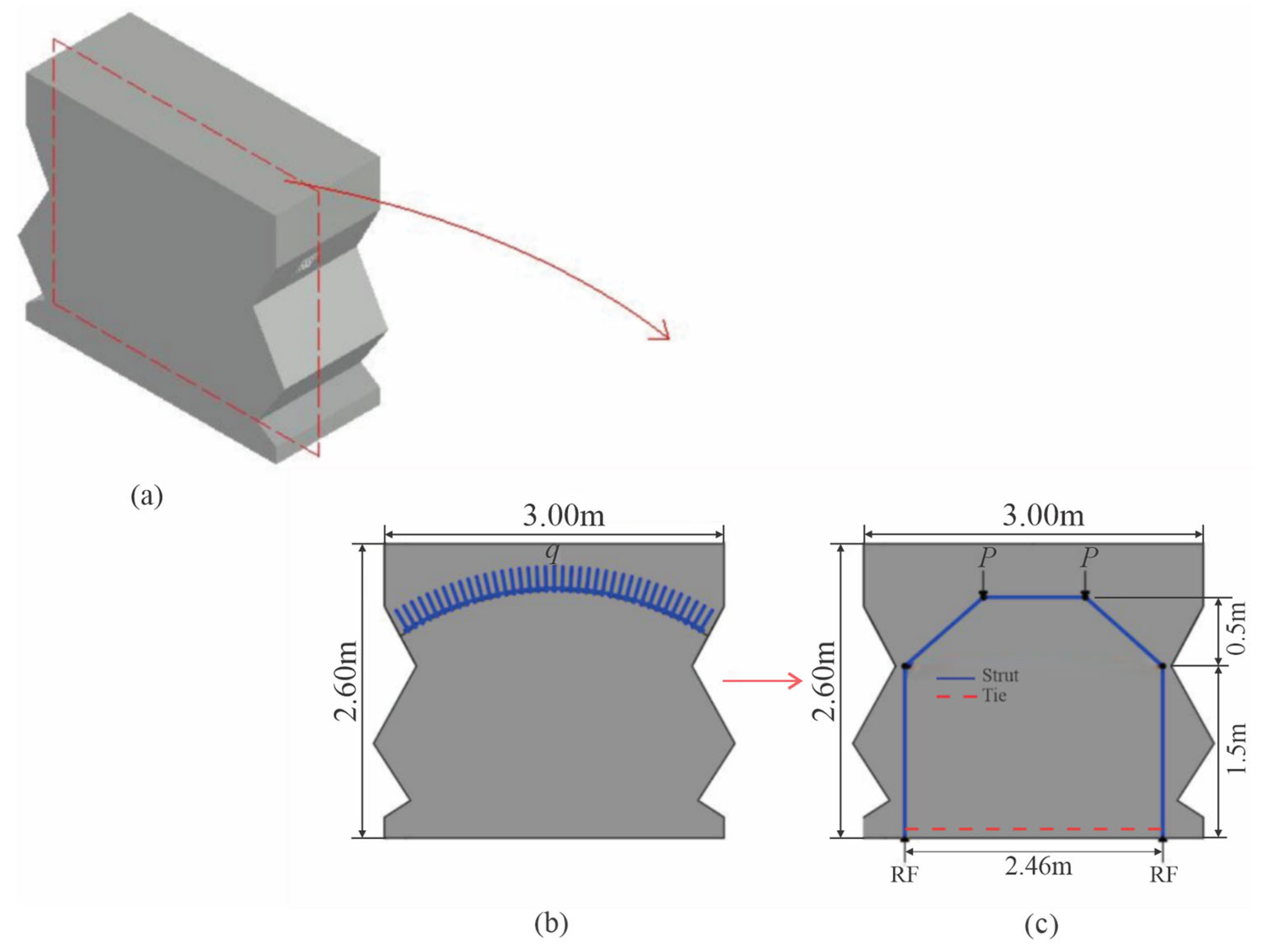

2.1. Model Geometry

2.2. Finite Element Analysis of Filament Pipe Anchorage Zone and Tower

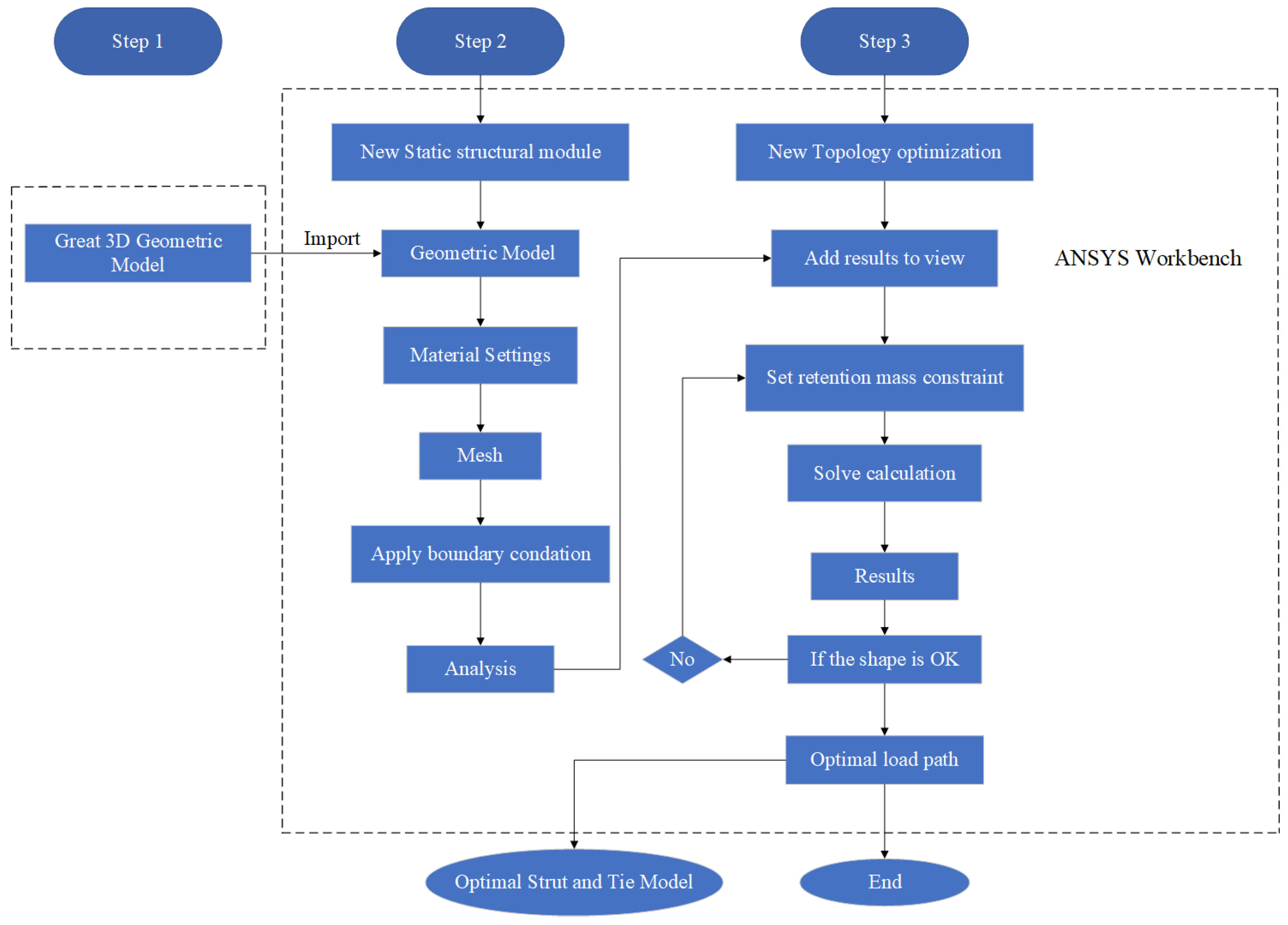

3. Topology Optimization Method

4. Parameter Selection

5. Results and Discussion

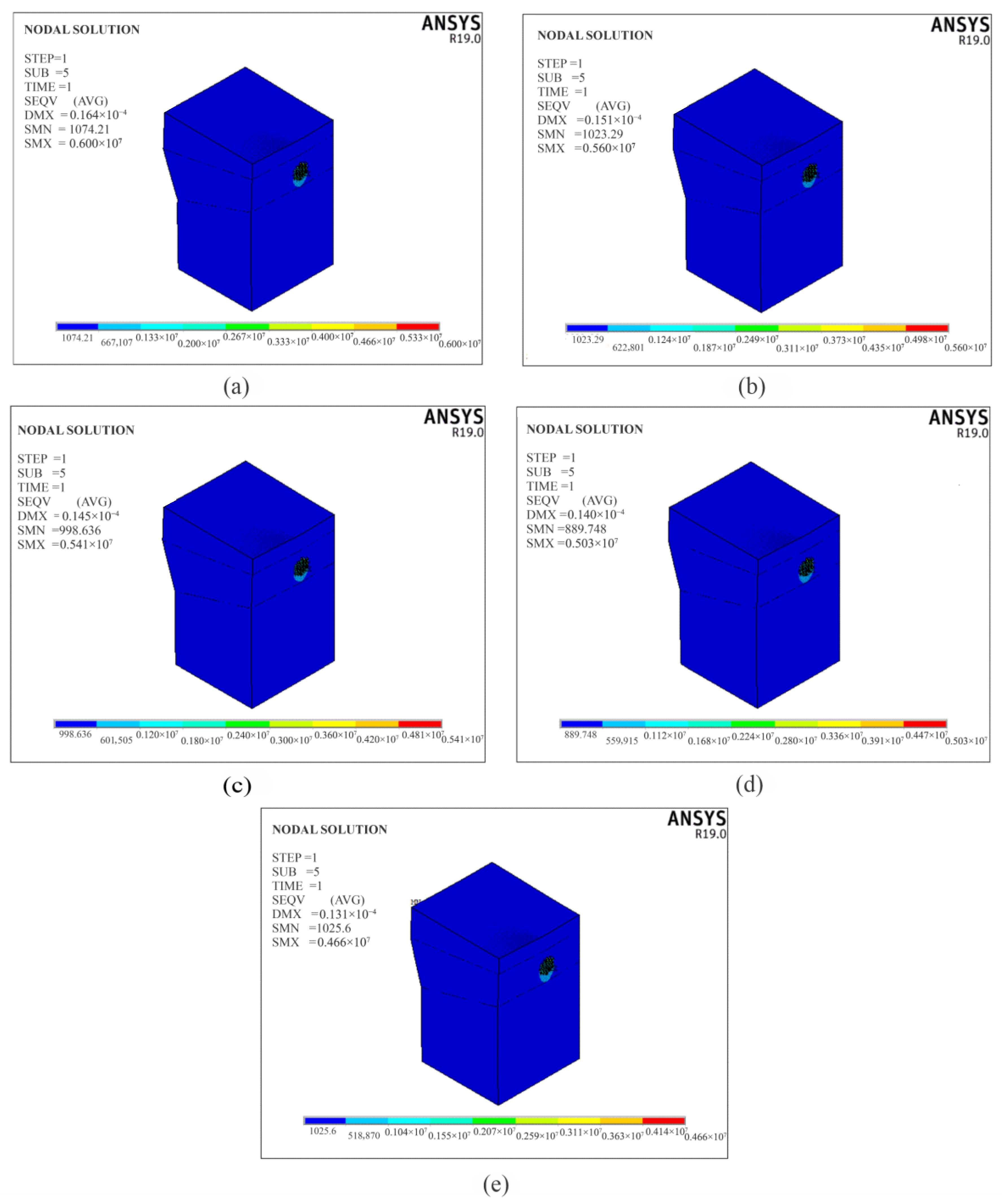

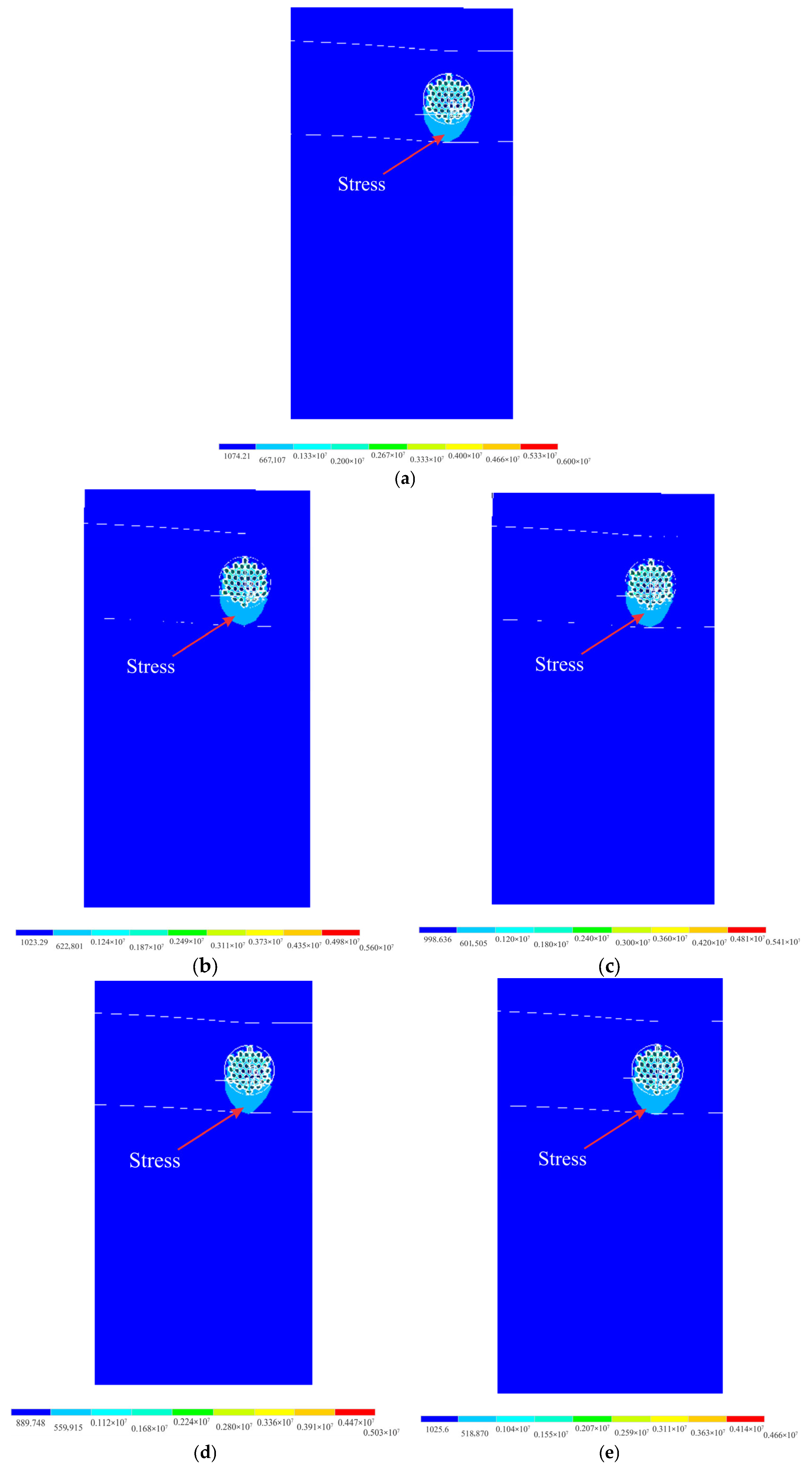

5.1. Von Mises Stress

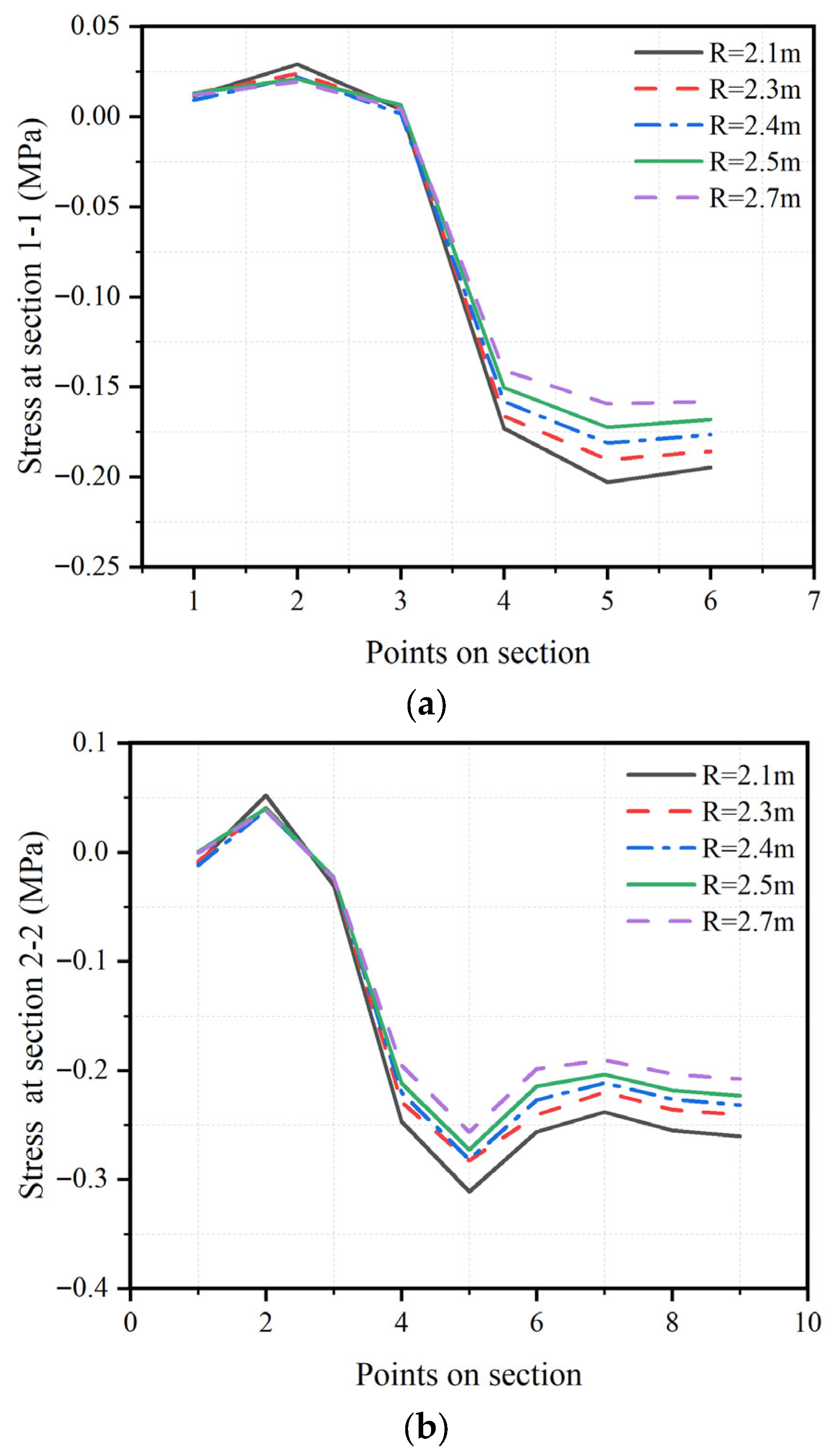

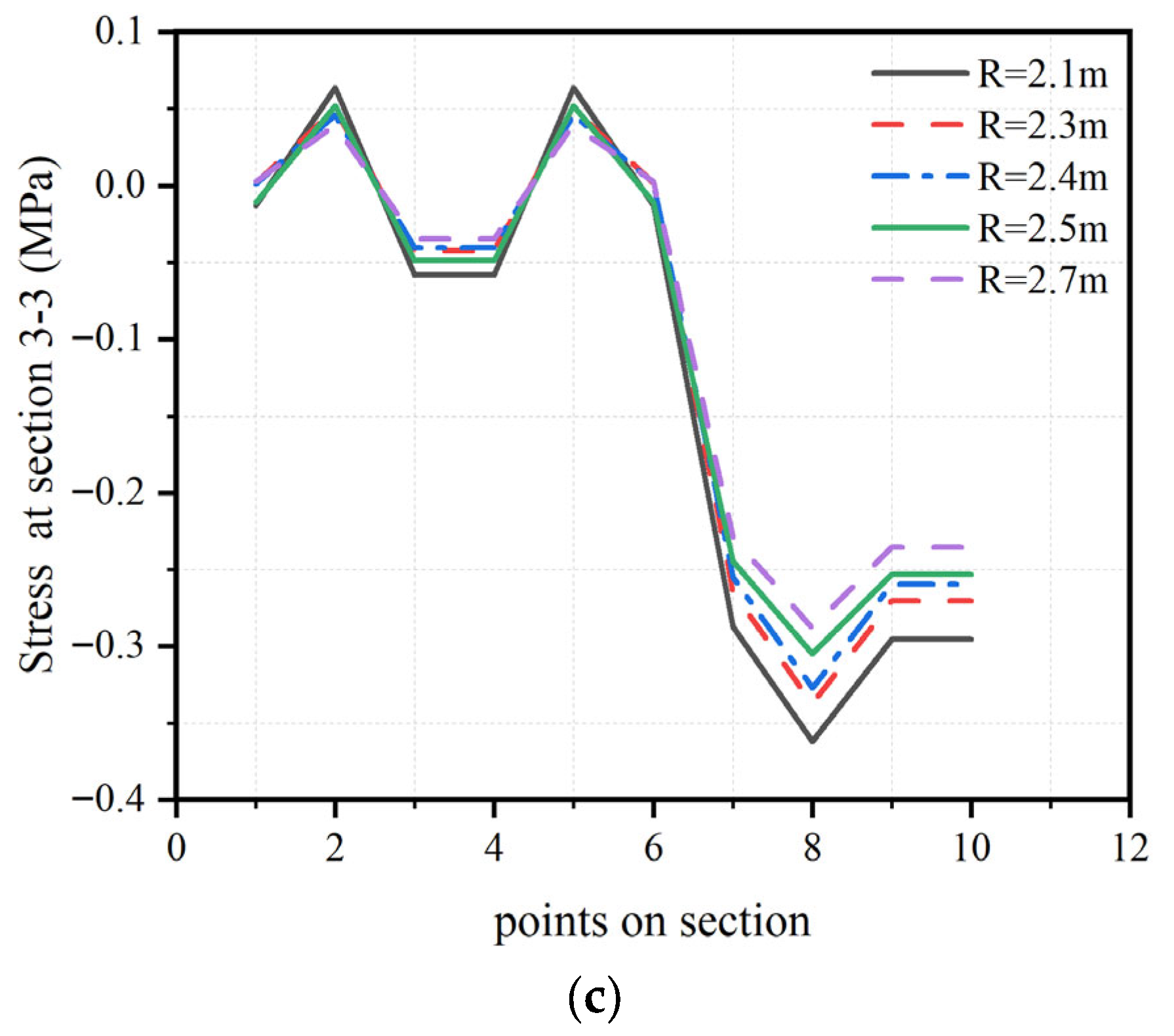

5.1.1. Stresses on Sections 1-1, 2-2, and 3-3

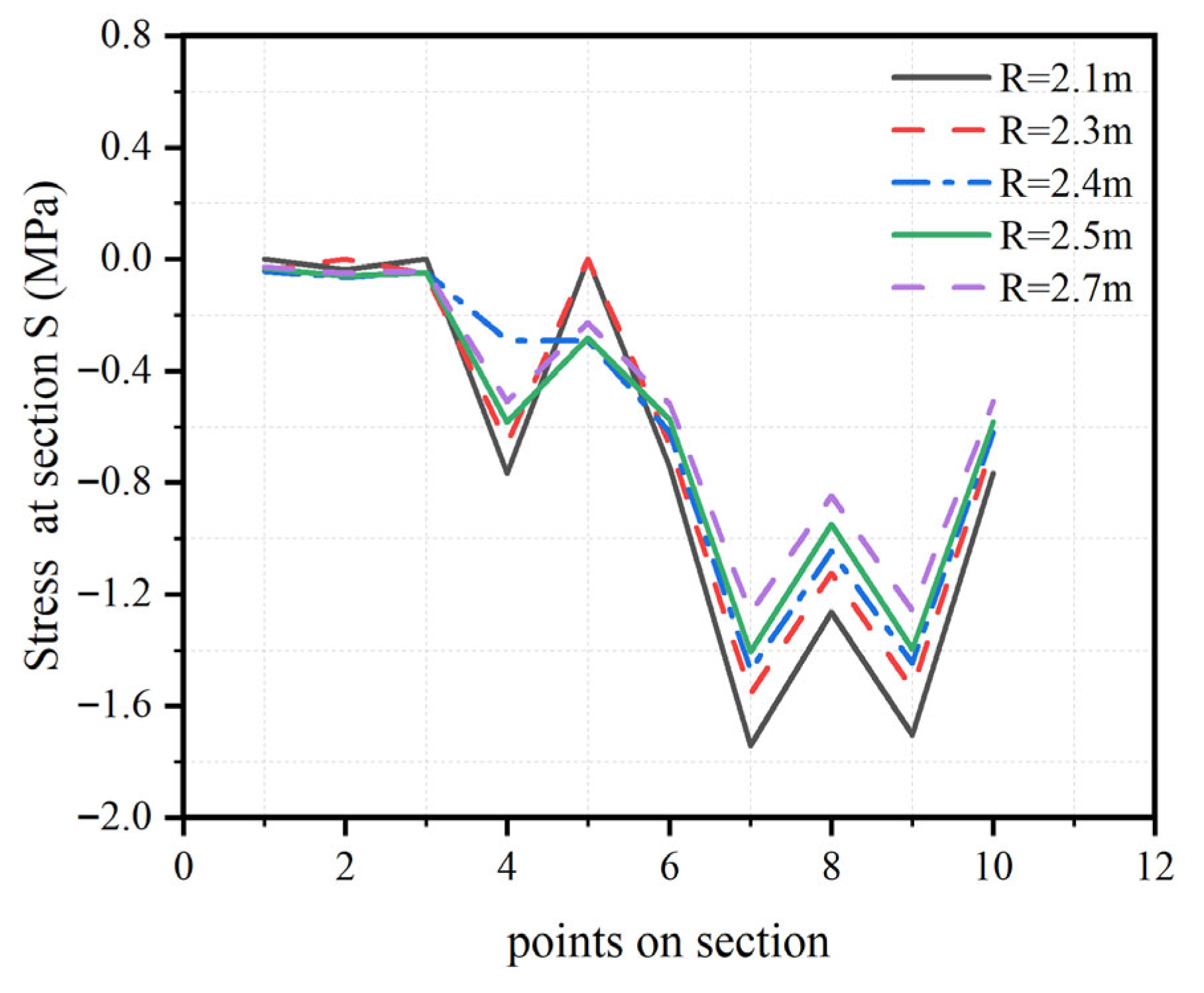

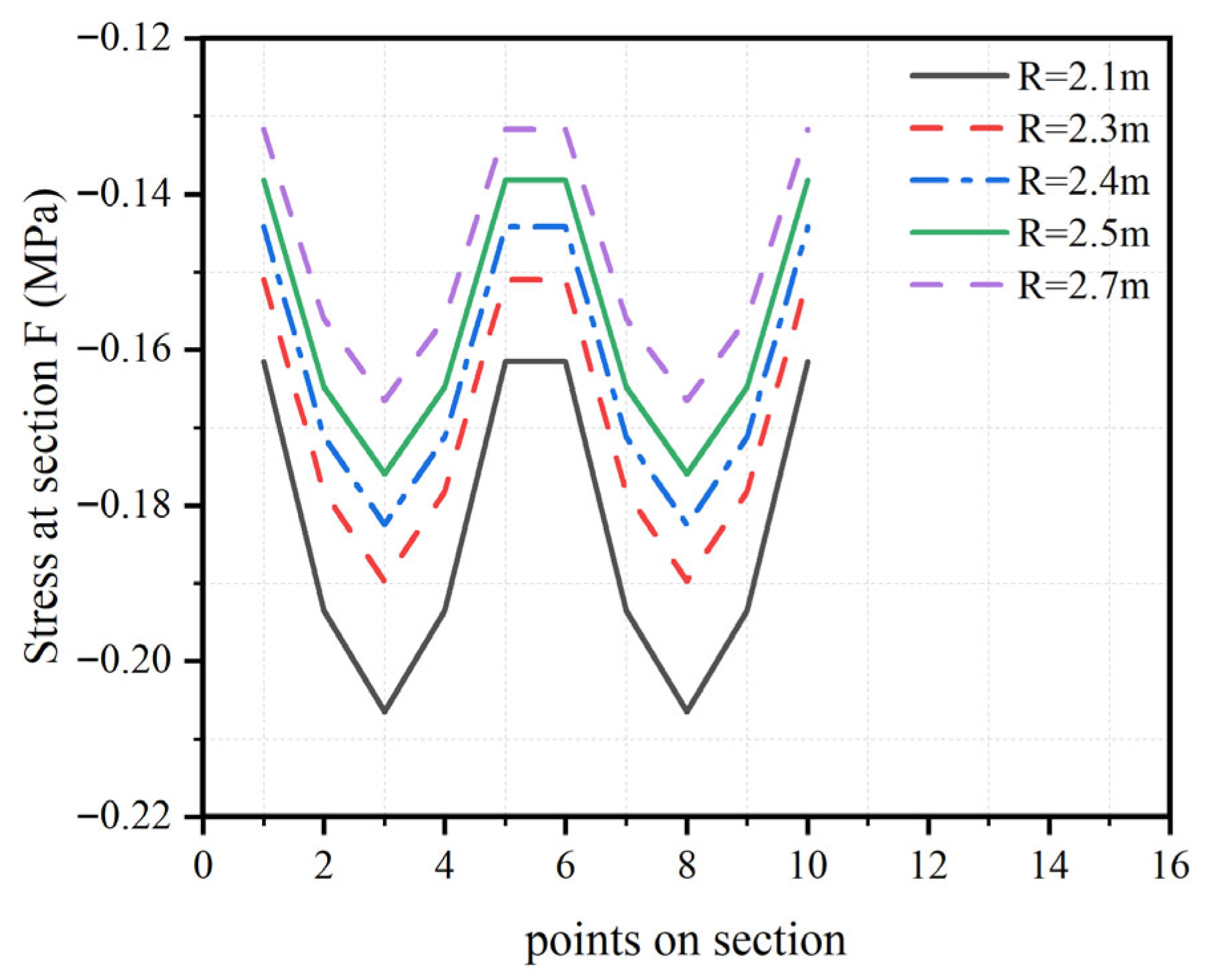

5.1.2. Stresses on Sections S and F

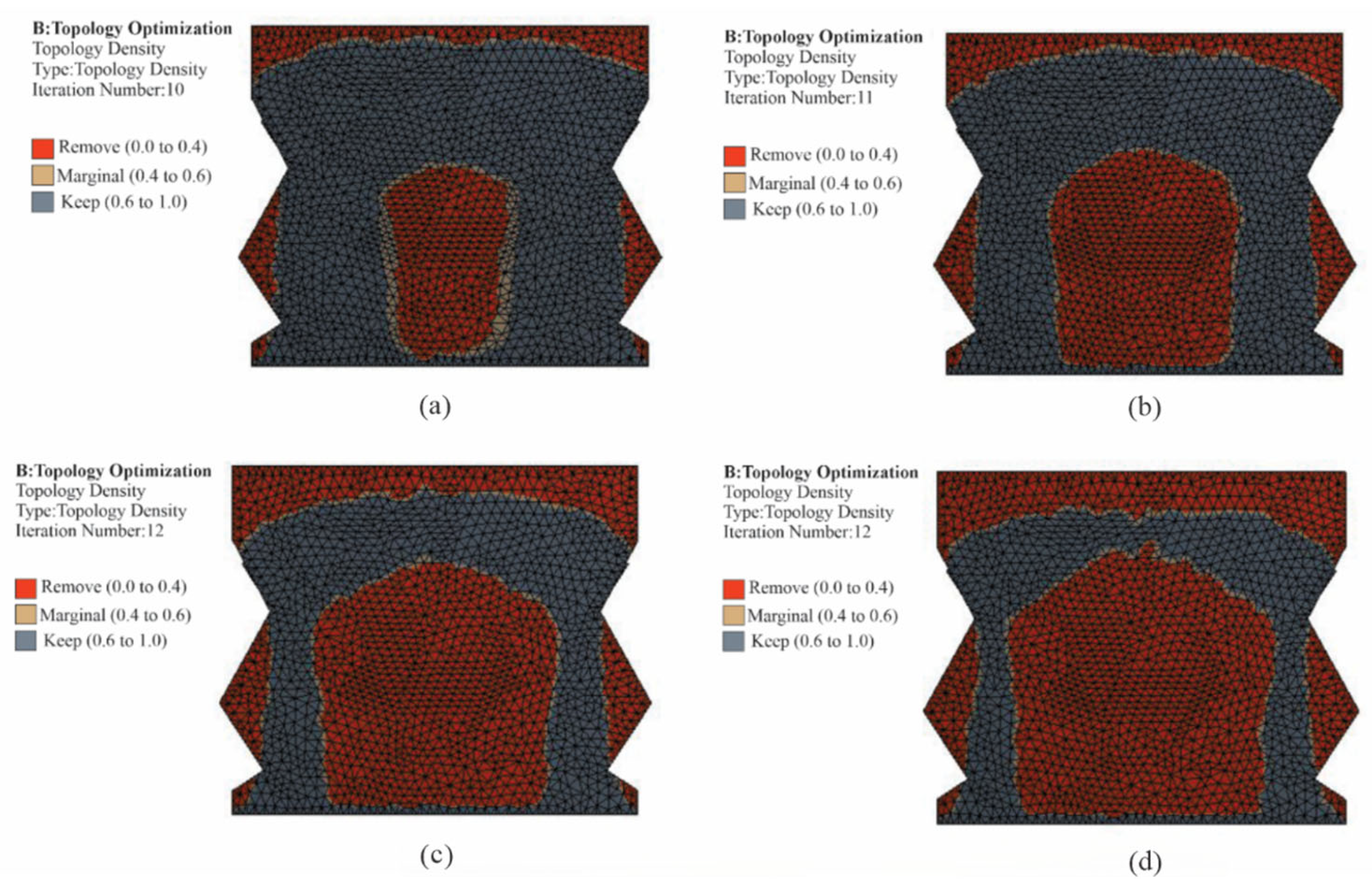

5.2. Topology Optimization

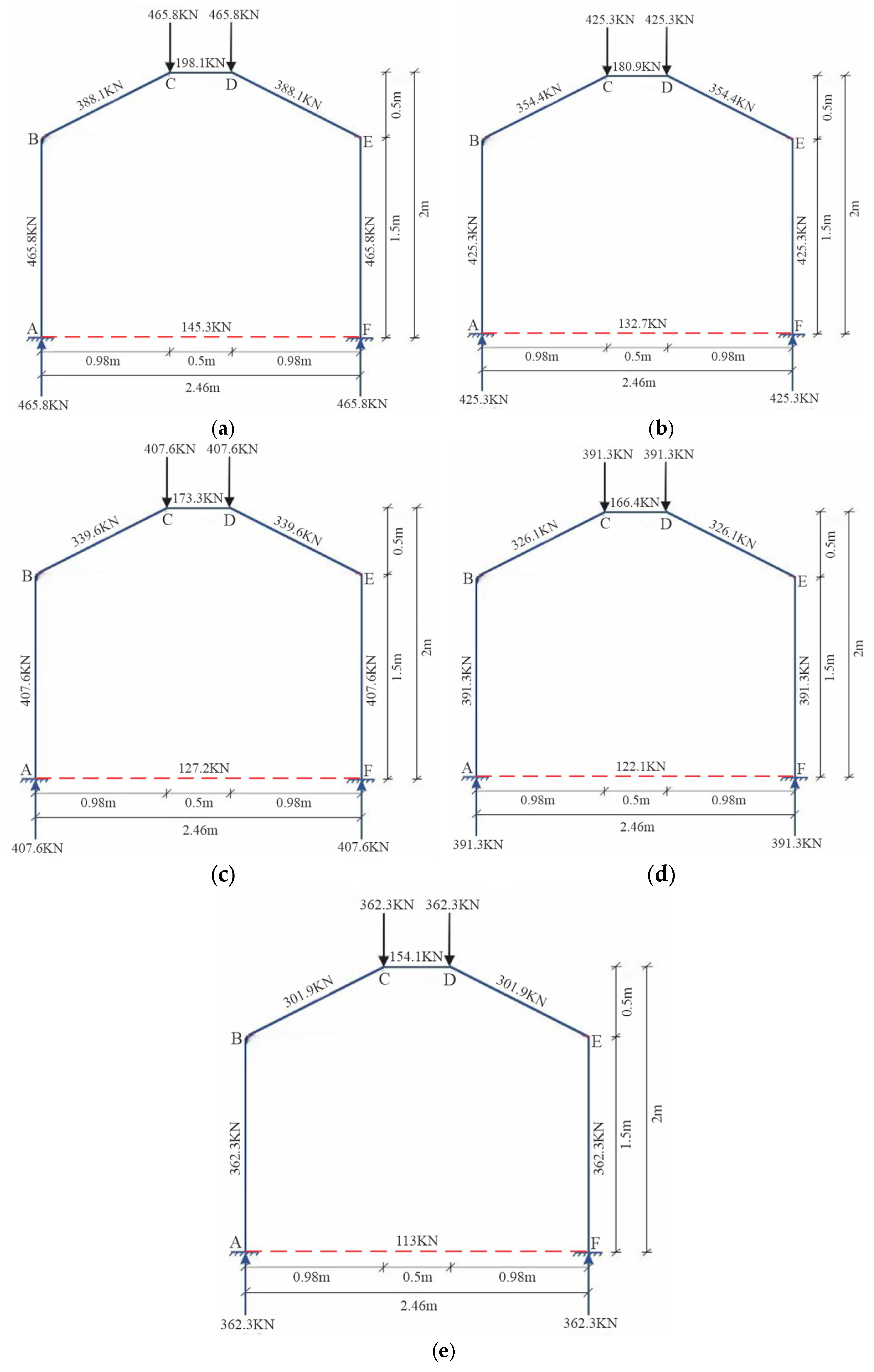

5.3. Optimal Strut-and-Tie Model

6. Conclusions

- The results indicated that vertical stress predominated in Section A, with a minor presence of horizontal stress. Consequently, the horizontal stress component was minimal. Furthermore, the vertical stress in the concrete increased the closer the point is to the center of the tower.

- Stress levels were notably high in sections with smaller radius of curvature. In Section B, the stress was highest at point B5, and in Section C, it was highest at point C8.

- In Section S, only horizontal forces were considered, as this section is located directly beneath the cable along the tower curvature. The stress distribution indicated an increase from the edge of the tower to its center.

- The stress analysis revealed that sections farther from the center of the tower experienced lower stress levels. The highest stress concentration occurred directly beneath the cable along the curvature, as evidenced in the distribution at Section S.

- In Section F, only the vertical force-induced stress was analyzed. The stress levels increased near the center of the tower and then decreased toward the edge.

- The model with the smaller radius of curvature exhibited higher stress levels. This indicates an inverse relationship between the stress in the concrete and the radius of curvature of the cable saddle (R), whereby increasing the radius reduces the stress, and vice versa.

- The STM was generated using the topology optimization method. The optimal mass was determined to be 45%.

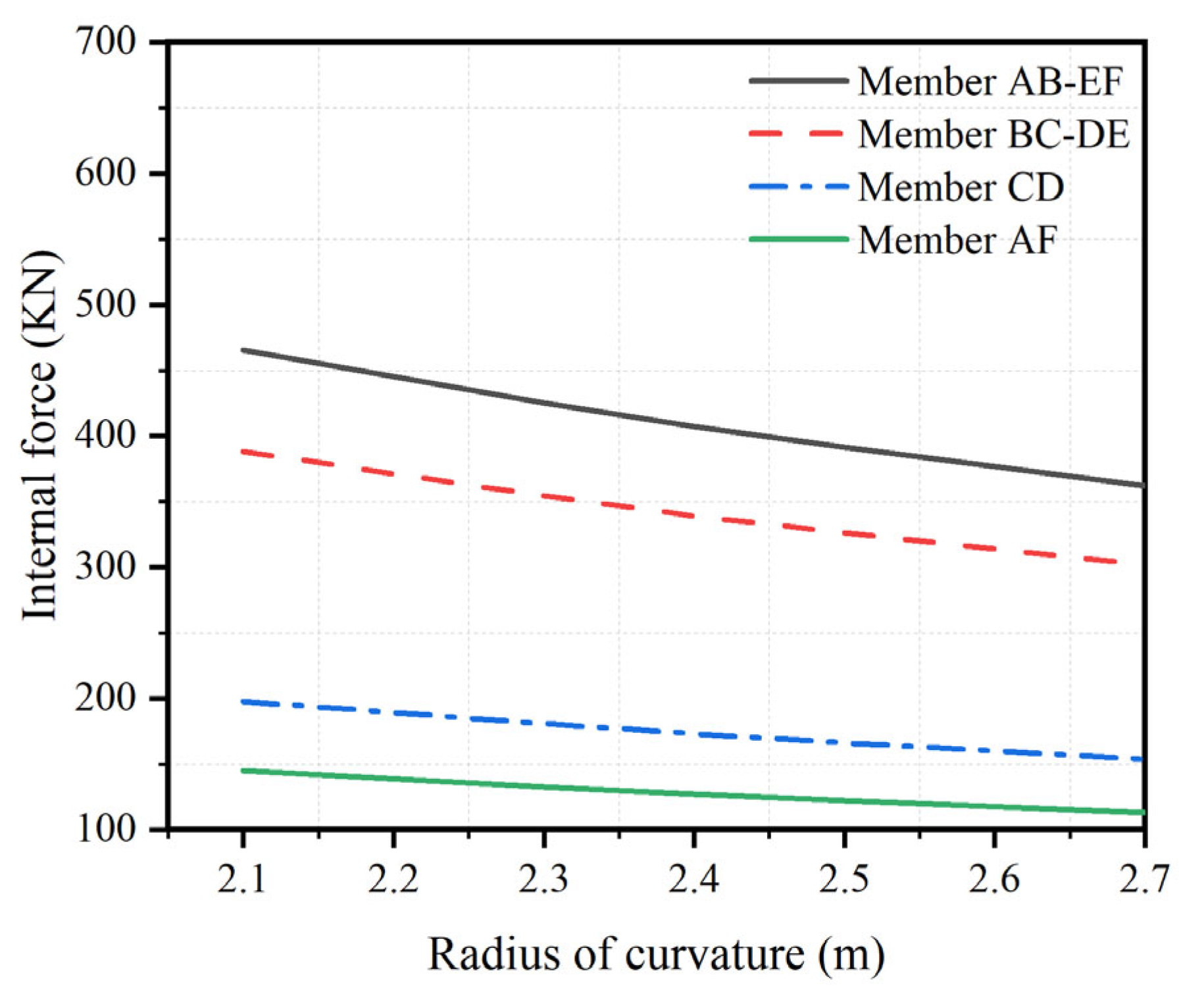

- The internal force distribution evolves with changes in the radius of curvature (R), which plays a crucial role in optimizing STM designs by ensuring adequate load transfer and preventing overstressing in the concrete tower.

- Specifically, the results show that as the cable-saddle curvature radius increased from 2.1 m (Model A) to 2.7 m (Model E), the maximum von Mises stress within the concrete tower decreased from approximately 6.00 MPa to 4.66 MPa, representing a reduction of about 22%. This addition clarifies the magnitude of the stress improvement achieved through the optimization process and enhances the quantitative insight of the study’s conclusions.

- The present STM formulation was derived for a single-plane, box-section tower segment subjected to symmetrical loading. However, the underlying topology optimization-based framework is general and can be extended to three-dimensional geometries. For towers with asymmetrical cross-sections or multiple cable planes, the same process—finite-element stress analysis followed by topology-based STM extraction—can be used to determine the corresponding optimal load paths. The resulting STM geometry naturally adapts to different boundary and loading conditions. In such cases, the struts represent compressive force flow lines (which can be enhanced through concrete confinement or compressive reinforcement), while the ties indicate tension trajectories (to be aligned with primary reinforcement bars or tendon ducts). This adaptability enables the STM to guide reinforcement orientation and anchorage detailing even in complex D-regions. Nonetheless, the broader application of this framework is presently constrained by the assumptions of linear elasticity and the absence of experimental validation. Future work will extend the method to incorporate dynamic loading effects and nonlinear material behavior, enhancing its applicability to diverse bridge tower configurations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Sun, S.; Zhang, J. Stay Cable Vibration Mitigation: A Review. Adv. Struct. Eng. 2022, 25, 1573–1588. [Google Scholar] [CrossRef]

- Li, M.; Ou, J. The State of the Art in Structural Health Monitoring of Cable-Stayed Bridges. J. Civ. Struct. Health Monit. 2015, 5, 297–307. [Google Scholar] [CrossRef]

- Wang, X.L.; Liang, T.; Qi, T.D. Study on Cable Force Optimization for Extradosed Cable-Stayed Bridge under the Rational Completion Stage. Appl. Mech. Mater. 2014, 501, 1170–1173. [Google Scholar] [CrossRef]

- Lamesgin, A.; Golla, A.; Rasool, G.; Jemanenh, W. Optimization of extradosed bridge and analysis of parameters’ sensitiveness: A case study on Abay Bridge. Ce/papers 2023, 6, 1144–1152. [Google Scholar] [CrossRef]

- Yan, L.; Guo, W.; Yang, N.; Dong, C.; Liu, M.; Cai, Y.J.; Zhang, Z.Z. Research progress of intelligent operation and maintenance of high-speed railway bridges. Intell. Transp. Infrastruct. 2022, 1, 015. [Google Scholar] [CrossRef]

- Zhou, X.; Lu, D.C.; Du, X.L.; Wang, G.S.; Meng, F.P. A 3D non-orthogonal plastic damage model for concrete. Comput. Methods Appl. Mech. Eng. 2020, 360, 112716. [Google Scholar] [CrossRef]

- Lu, D.C.; Meng, F.P.; Zhou, X.; Zhuo, Y.H.; Gao, Z.W.; Du, X.L. A dynamic elastoplastic model of concrete based on a modeling method with environmental factors as constitutive variables. J. Eng. Mech. 2023, 149, 04023102. [Google Scholar] [CrossRef]

- Ritter, W. Die Bauweise Hennebique. Schweiz. Bauztg. 1899, 33, 49–50. [Google Scholar]

- Mörsch, E. Concrete-Steel Construction (Der Eisenbetonbau); The Engineering News Publishing Company: New York, NY, USA, 1909. [Google Scholar]

- Schlaich, J.; Schäfer, K.; Jennewein, M. Toward a consistent design of structural concrete. PCI J. 1987, 32, 74–150. [Google Scholar] [CrossRef]

- Schlaich, J.; Schäfer, K. Design and detailing of structural concrete using strut-and-tie models. Struct. Eng. 1991, 69, 113–125. [Google Scholar]

- Panjehpour, M.; Ali, A.A.; Mohammed Parvez, A.; Aznieta, F.N.; Voo, Y.L. An overview of strut-and-tie model and its common challenges. Int. J. Eng. Res. Afr. 2012, 8, 37–45. [Google Scholar] [CrossRef]

- Gong, H.J.; Su, M. Introduction of the application of strut-and-tie model in concrete deep beams. Adv. Mater. Res. 2013, 671, 704–708. [Google Scholar] [CrossRef]

- Hou, D.W.; Zhao, J.L.; Shen, J.S.; Chen, J. Investigation and improvement of strut-and-tie model for design of end anchorage zone in post-tensioned concrete structures. Constr. Build. Mater. 2017, 136, 482–494. [Google Scholar] [CrossRef]

- Lu, D.C.; Wang, G.S.; Du, X.L.; Wang, Y. A nonlinear dynamic uniaxial strength criterion that considers the ultimate dynamic strength of concrete. Int. J. Impact Eng. 2017, 103, 124–137. [Google Scholar] [CrossRef]

- Dawood, A.A.; Abdul-Razzaq, K.S. Shear friction and strut-and-tie modeling verification for pier caps. J. Bridge Eng. 2021, 26, 04021059. [Google Scholar] [CrossRef]

- Tian, Y.D.; Zhang, J.H.; Lyu, Y.F.; Zhang, J. Comprehensive review of noncontact sensing technologies for bridge condition monitoring and assessment. Intell. Transp. Infrastruct. 2024, 3, 012. [Google Scholar] [CrossRef]

- Cui, N.; Huang, S. On the optimal strut-and-tie models and design approach for the cable-pylon anchorage zone. J. Civ. Eng. Manag. 2019, 25, 576–586. [Google Scholar] [CrossRef]

- Li, S.; Hong, Y.; Huang, S.; Pu, Q. Investigation of the strut-and-tie model of a two-plane cable-stayed bridge tower under vertical component of the cable force. Struct. Concr. 2021, 22, 3288–3303. [Google Scholar] [CrossRef]

- Vinayak, H.K.; Nak, S.S.; Tv, P.K. Direct strut-and-tie model for reinforced concrete bridge pier cap. Math. Model. Civ. Eng. 2016, 12, 1–8. [Google Scholar]

- Byun, N.; Lee, J.; Won, J.Y.; Kang, Y.J. Structural response estimation of cable-stayed bridge from limited number of multi-response data. Sensors 2022, 22, 3745. [Google Scholar]

- Asgari, B.; Osman, S.A.; Adnan, A. Sensitivity analysis of the influence of structural parameters on dynamic behaviour of highly redundant cable-stayed bridges. Adv. Civ. Eng. 2013, 2013, 426932. [Google Scholar] [CrossRef]

- Wu, W.H.; Chen, C.C.; Lin, S.L.; Lai, G.L. Automatic anomaly detection and processing for long-term tension monitoring of stay cables based on vibration measurements. Intell. Transp. Infrastruct. 2022, 1, liac002. [Google Scholar] [CrossRef]

- Li, S.; Hong, Y.; Chen, L.; Pu, Q. Investigation of the strut-and-tie model of a single-plane cable-stayed bridge tower under vertical component of the cable force. Struct. Concr. 2023, 24, 4515–4529.20. [Google Scholar] [CrossRef]

- Zhang, Q.; Kang, J.; Bao, Y.; Cheng, Z.; Jia, D.; Bu, Y. Numerical study on cable-saddle frictional resistance of multi-span suspension bridges. J. Constr. Steel Res. 2018, 150, 51–59. [Google Scholar] [CrossRef]

- Wang, L.; Shen, R.; Zhang, S.; Bai, L.; Zhen, X.; Wang, R. Strand-element analysis method for interaction between cable and saddle in suspension bridges. Eng. Struct. 2021, 242, 112283. [Google Scholar] [CrossRef]

- Cheng, Z.; Zhang, Q.; Bao, Y.; Jia, D.; Bu, Y.; Li, Q. Analytical models of frictional resistance between cable and saddle equipped with friction plates for multispan suspension bridges. J. Bridge Eng. 2018, 23, 04017118. [Google Scholar] [CrossRef]

- Zhang, Q.; Cheng, Z.; Cui, C.; Bao, Y.; He, J.; Li, Q. Analytical model for frictional resistance between cable and saddle of suspension bridges equipped with vertical friction plates. J. Bridge Eng. 2017, 22, 04016103. [Google Scholar] [CrossRef]

- Liang, Q.Q.; Xie, Y.M.; Steven, G.P. Topology optimization of strut-and-tie models in reinforced-concrete structures using an evolutionary procedure. Struct. J. 2000, 97, 322–330. [Google Scholar]

- Kwak, H.G.; Noh, S.H. Determination of strut-and-tie models using evolutionary structural optimization. Eng. Struct. 2006, 28, 1440–1449. [Google Scholar] [CrossRef]

- He, Z.Q.; Liu, Z. Optimal three-dimensional strut-and-tie models for anchorage diaphragms in externally prestressed bridges. Eng. Struct. 2010, 32, 2057–2064. [Google Scholar] [CrossRef]

- Jewett, J.L.; Carstensen, J.V. Experimental investigation of strut-and-tie layouts in deep RC beams designed with hybrid bi-linear topology optimization. Eng. Struct. 2019, 197, 109322. [Google Scholar] [CrossRef]

- Ma, C.; Lu, D.C.; Du, X.L.; Qi, C.Z.; Zhang, X.Y. Structural components functionalities and failure mechanism of rectangular underground structures during earthquakes. Soil Dyn. Earthq. Eng. 2019, 119, 265–280. [Google Scholar] [CrossRef]

- Li, S.; Lim, E.; Shen, L.; Hong, Y.; Pu, Q. Strut-and-Tie Model-Based Prestress Design for the Cable–Pylon Anchorage Zone of Cable-Stayed Bridges. J. Bridge Eng. 2021, 26, 04021069. [Google Scholar] [CrossRef]

- Zhu, J.; Wang, M.; Li, Y.; Cui, N.; Xun, J. Research on topology optimization strut-and-tie model and prestress construction for cable-pylon anchorage zone of Fengshuba Bridge. Structures 2024, 68, 107146. [Google Scholar] [CrossRef]

- Li, S.; Lim, E.; Chen, Z.; Hong, Y.; Pu, Q. Simplified method for predicting the internal forces in strut-and-tie model of cable-pylon anchorage zone in a cable-stayed bridge. Struct. Concr. 2024, 25, 4134–4149. [Google Scholar] [CrossRef]

- Wang, P.G.; Xu, H.R.; Shen, Y.M.; Qu, Y.; Du, X.L. Dynamic response analysis of a floating bridge structure under combined actions from seismic loading and waves at different incident angles. Intell. Transp. Infrastruct. 2024, 3, 016. [Google Scholar] [CrossRef]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture &. Building Press: Beijing, China, 2010.

- GB/T 700-2006; Carbon Structural Steels. Standards Press of China: Beijing, China, 2006.

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications, 9th ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2020. [Google Scholar]

| Property | Value | Unit |

|---|---|---|

| Density | 2600 | Kg/m3 |

| Young’s Modulus | 3.45 × 1010 | pa |

| Poisson’s Ratio | 0.2 |

| Property | Value | Unit |

|---|---|---|

| Density | 7850 | Kg/m3 |

| Young’s Modulus | 2.0 × 1011 | pa |

| Poisson’s Ratio | 0.3 |

| Property | Radius of Curvature of Cable Saddle (m) |

|---|---|

| Model A | 2.1 |

| Model B | 2.3 |

| Model C | 2.4 |

| Model D | 2.5 |

| Model E | 2.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frah, M.A.; Ye, J.; Wan, C.; Abusogi, M.A.; Idris, T.; Alkhatatneh, O.A.; Wu, W. Functional Strut-and-Tie Model of Filament Pipes in Extradosed Cable-Stayed Bridges Under Mechanical Loading. Buildings 2025, 15, 4235. https://doi.org/10.3390/buildings15234235

Frah MA, Ye J, Wan C, Abusogi MA, Idris T, Alkhatatneh OA, Wu W. Functional Strut-and-Tie Model of Filament Pipes in Extradosed Cable-Stayed Bridges Under Mechanical Loading. Buildings. 2025; 15(23):4235. https://doi.org/10.3390/buildings15234235

Chicago/Turabian StyleFrah, Mohamed A., Jingliang Ye, Chunbin Wan, Maha A. Abusogi, Tasneem Idris, Omar A. Alkhatatneh, and Wenbing Wu. 2025. "Functional Strut-and-Tie Model of Filament Pipes in Extradosed Cable-Stayed Bridges Under Mechanical Loading" Buildings 15, no. 23: 4235. https://doi.org/10.3390/buildings15234235

APA StyleFrah, M. A., Ye, J., Wan, C., Abusogi, M. A., Idris, T., Alkhatatneh, O. A., & Wu, W. (2025). Functional Strut-and-Tie Model of Filament Pipes in Extradosed Cable-Stayed Bridges Under Mechanical Loading. Buildings, 15(23), 4235. https://doi.org/10.3390/buildings15234235