Seismic Performance Analysis and Structural Optimization Design of a Science and Innovation Building in a Certain University

Abstract

1. Introduction

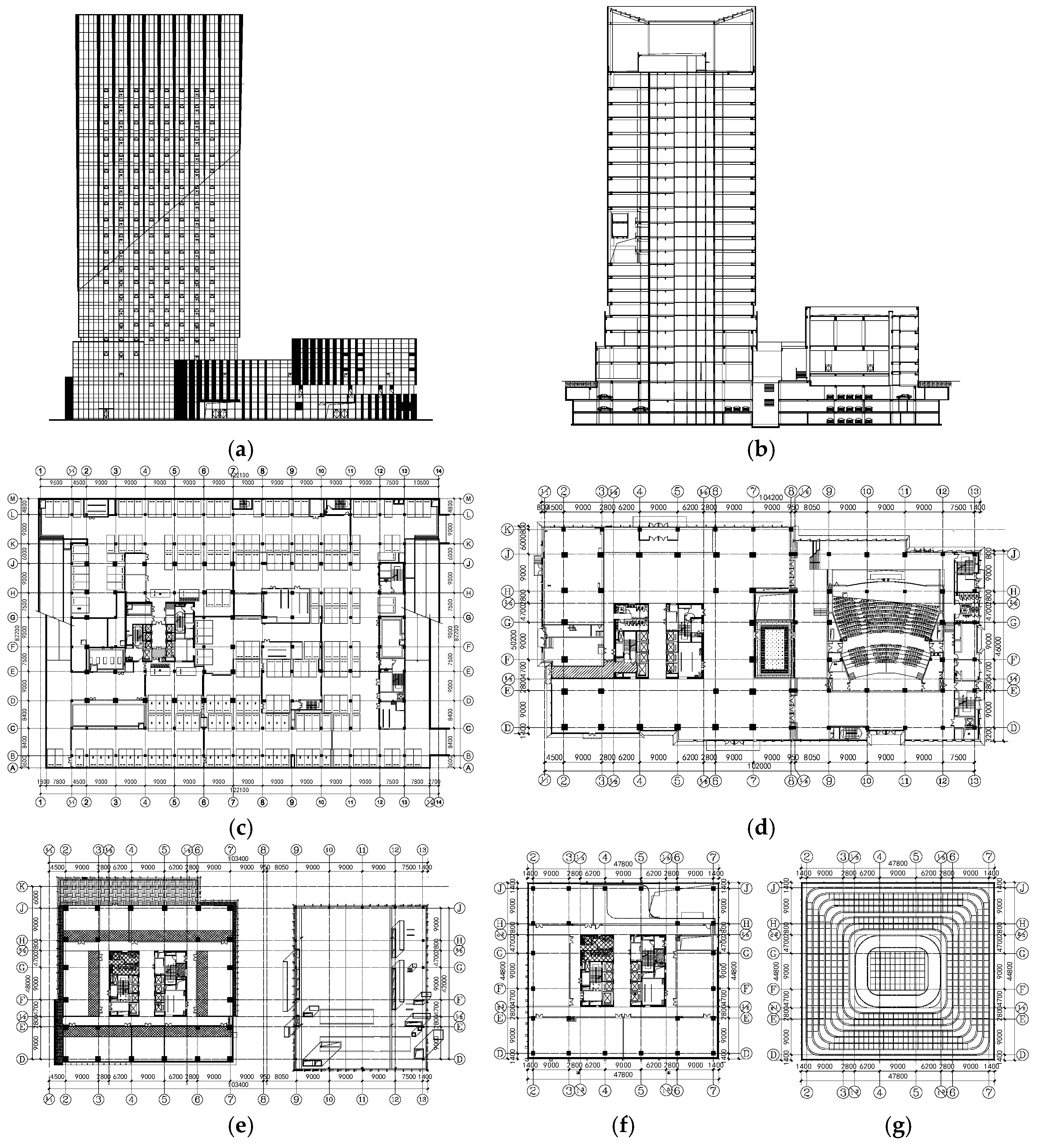

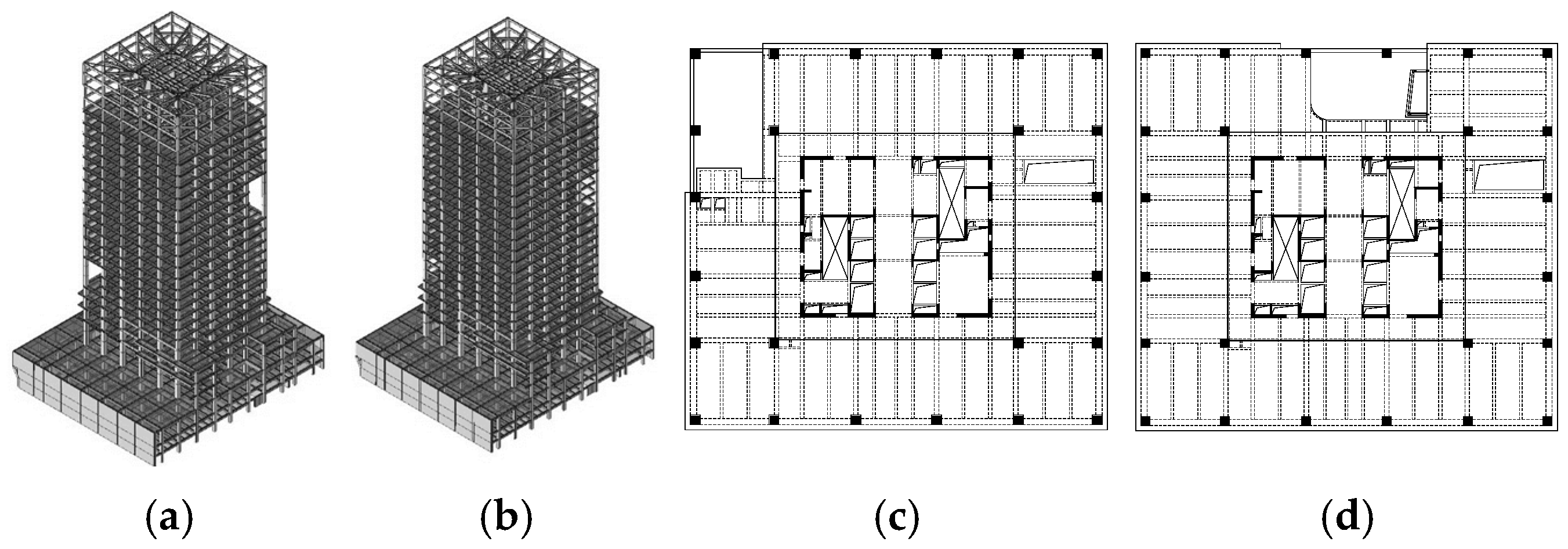

2. Project Overview

2.1. General Description

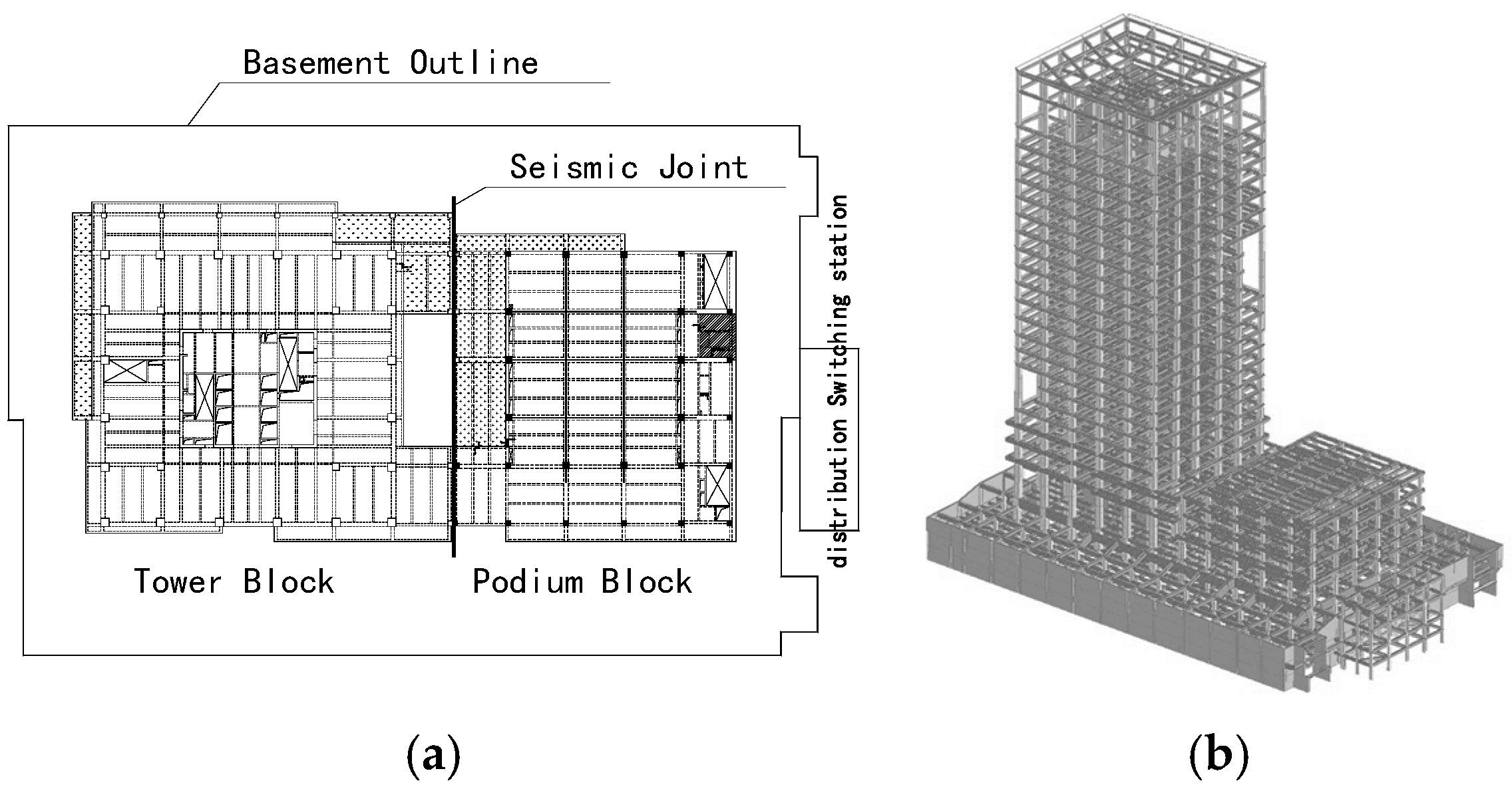

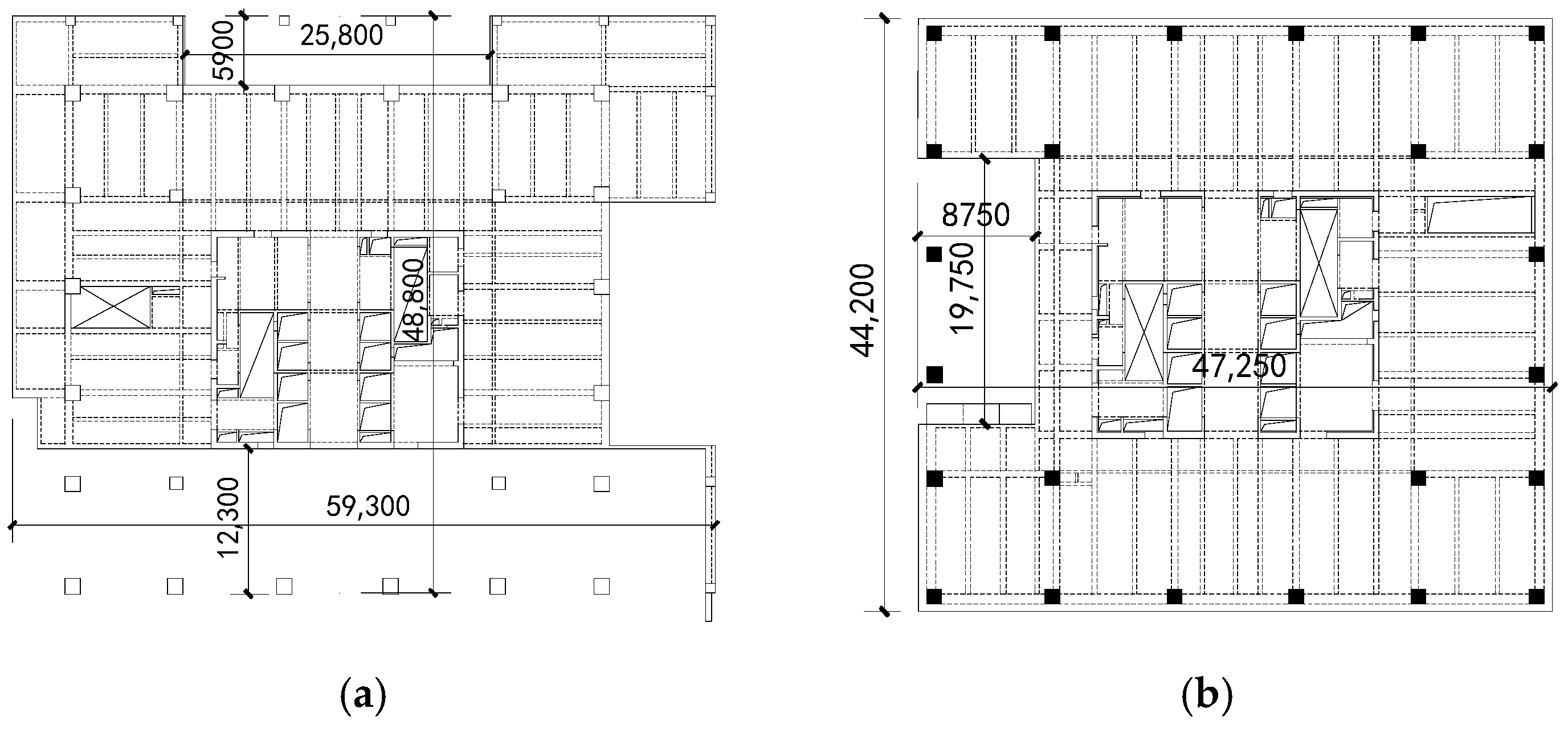

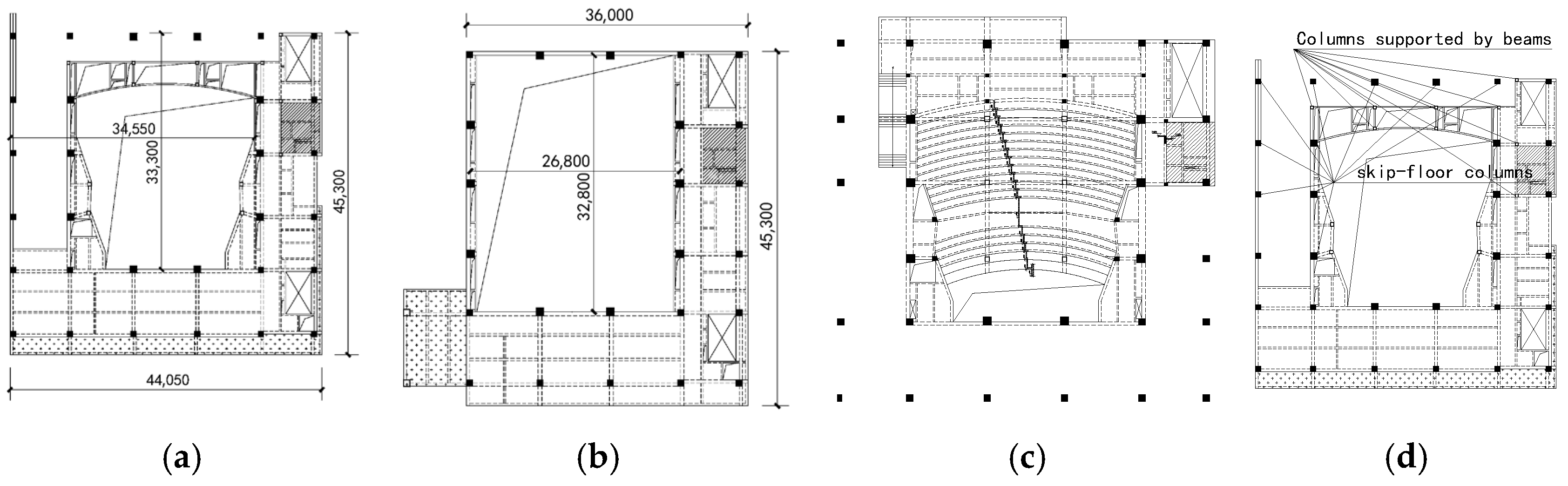

2.2. Functional Layout and Dimensions

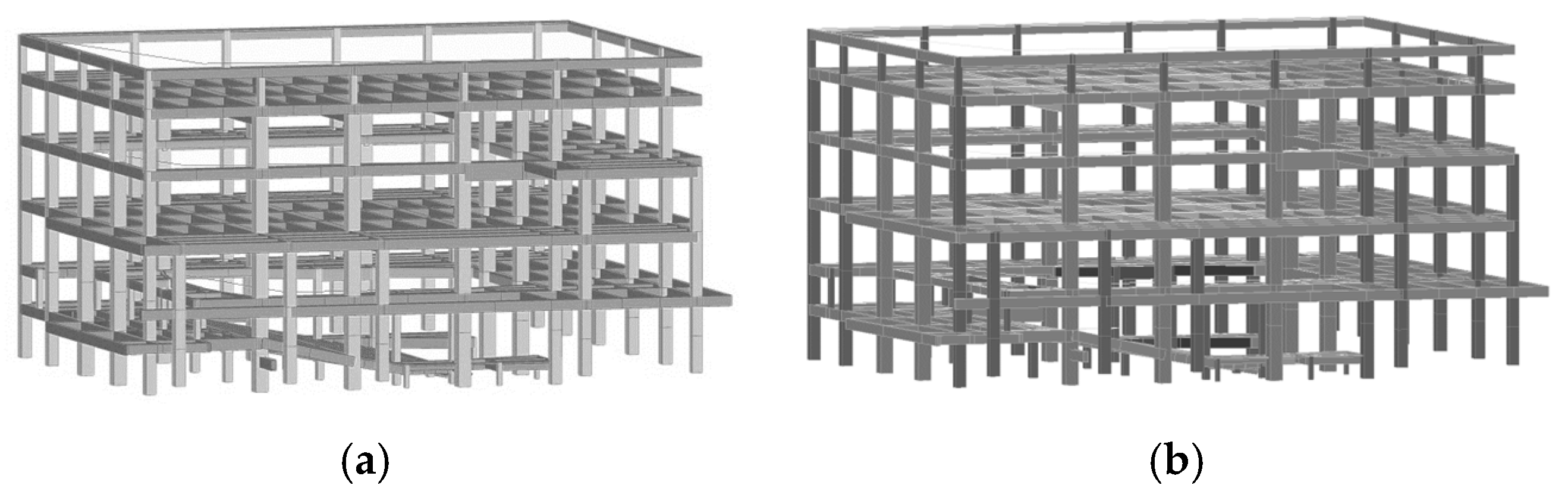

2.3. Structural System Configuration

2.4. Material Grades and Member Dimensions

2.5. Seismic Design Parameters and Joint Arrangement

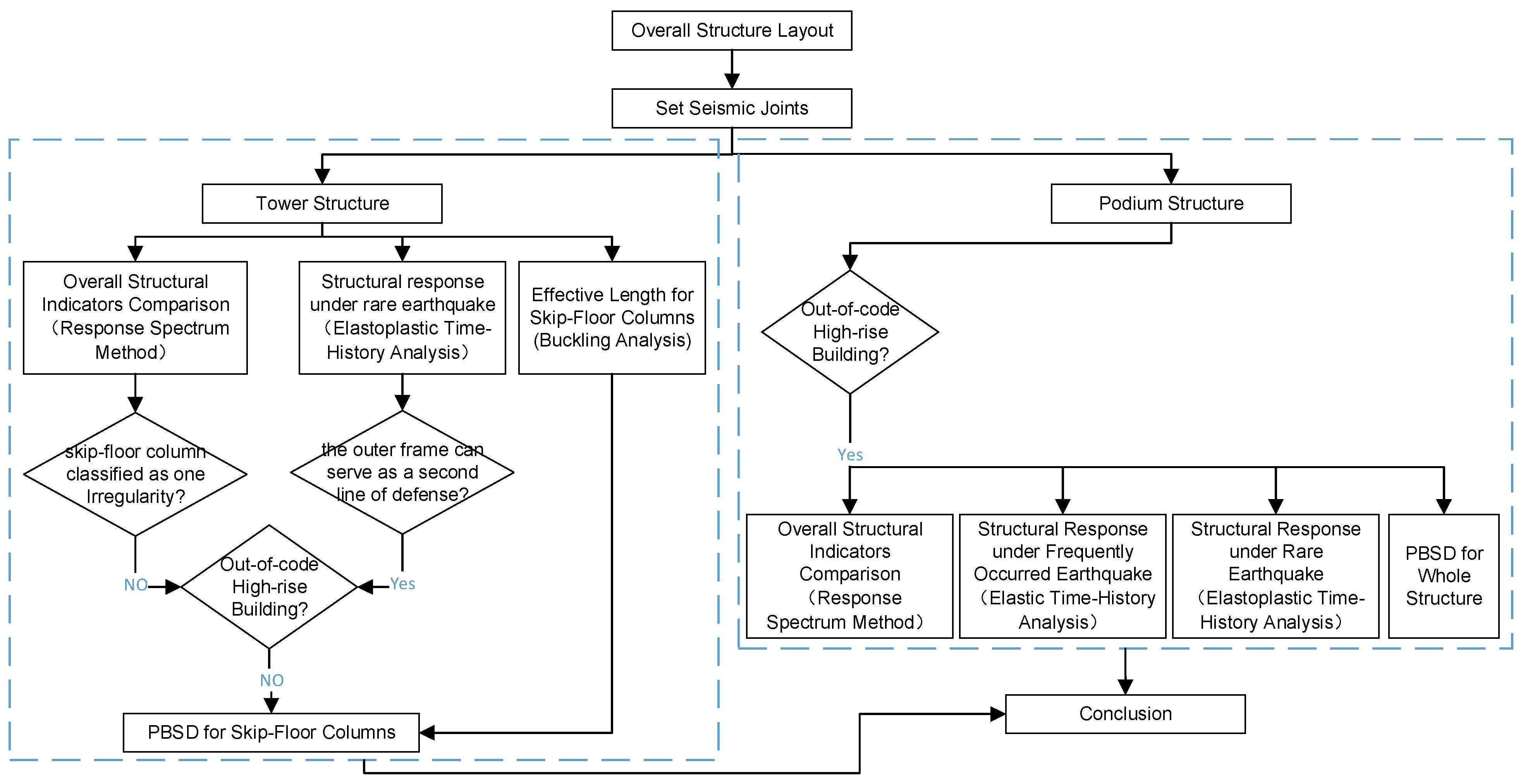

3. PBSD Modeling Framework

3.1. Framework Concept and Methodology

3.2. Model Development and Analysis Process

- (1)

- Material Modeling: Concrete and steel were modeled using constitutive relationships capable of reflecting cyclic behavior, stiffness degradation, and strength reduction. Steel was represented by a bilinear kinematic hardening model with a tensile-to-yield strength ratio of 1.2, accounting for the Bauschinger effect. Concrete followed a uniaxial nonlinear constitutive model, incorporating tensile and compressive damage parameters (dt, dc) to describe stiffness and strength degradation.

- (2)

- Component Modeling: Beam-column elements adopted the fiber-bundle model, enabling interaction between axial force and bending. Shear walls and slabs were simulated using layered shell elements with distributed reinforcement layers, allowing elastic–plastic damage representation.

- (3)

- Global Model Assembly: The overall model was generated by connecting all elements into a three-dimensional system. To account for cracking and flexibility of floors, the rigid-floor assumption was omitted, and slabs were discretized into shell elements.

- (4)

- Damping Model: A quasi-modal damping system was adopted, providing more accurate energy-dissipation representation than the conventional Rayleigh model.

- (5)

- Seismic Input: Three pairs of horizontal acceleration time histories—two natural and one artificial—were selected in accordance with GB 50011-2010. Each pair was applied in orthogonal X and Y directions, scaled to meet the statistical consistency between the average and design response spectra.

3.3. Performance Objectives and Verification Principles

4. Skip-Floor Column Irregularity-Classification and Seismic Performance

4.1. Identification and Modeling of Skip-Floor Column Irregularities

- (1)

- Comparative Modeling and Analysis

- (2)

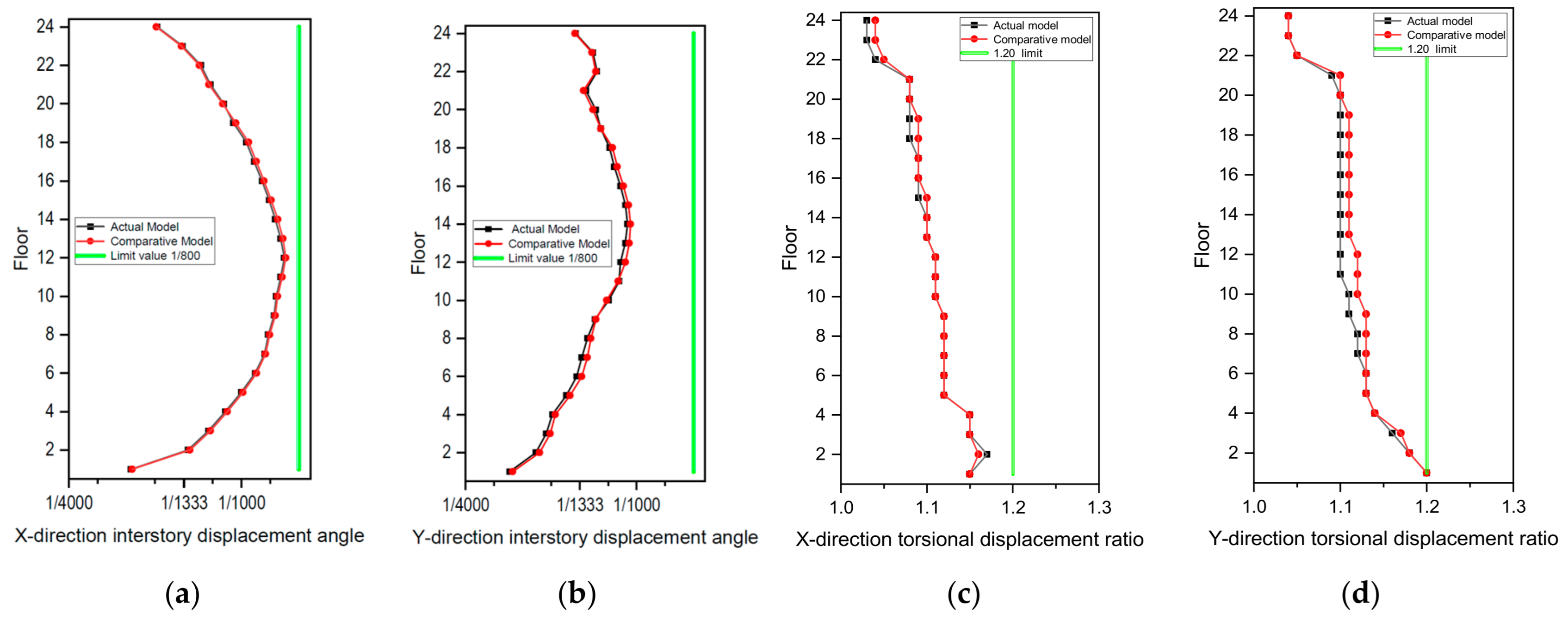

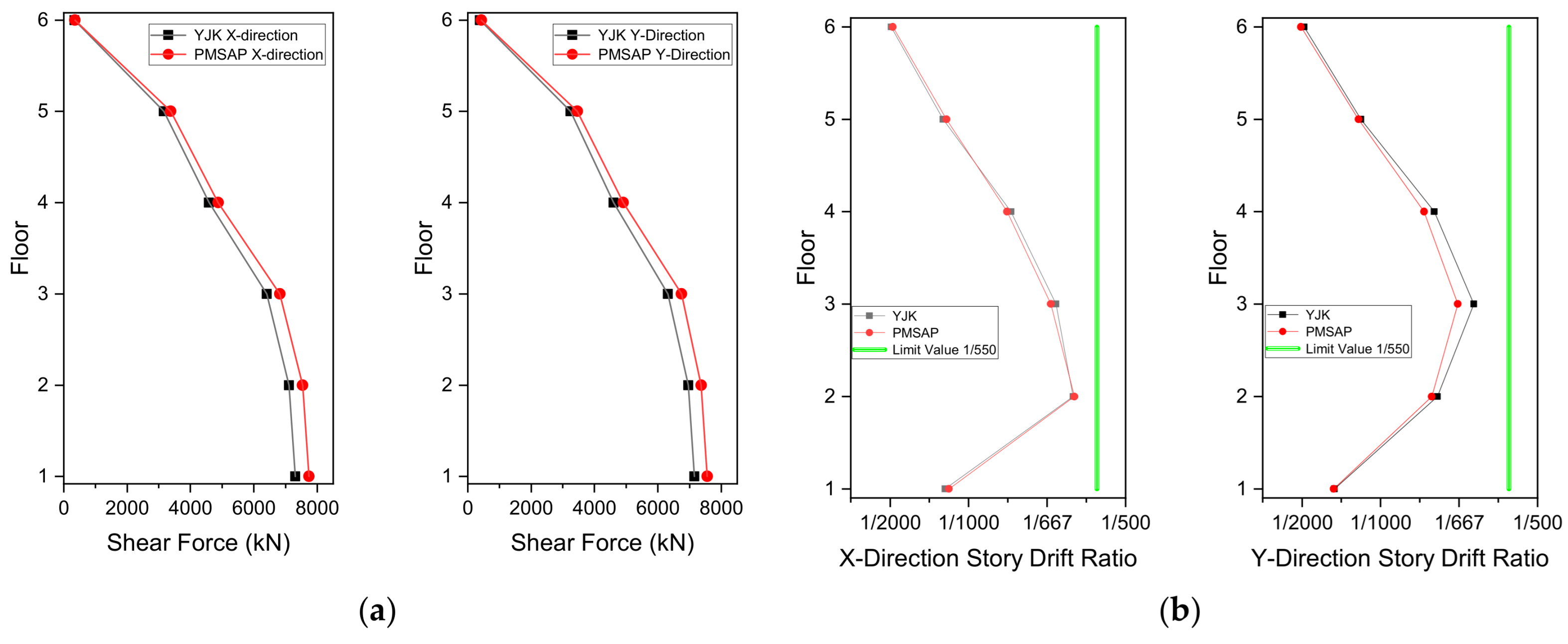

- Story Drift and Torsional Response

- (3)

- Shear Distribution and Structural Classification

4.2. Seismic Performance Evaluation Under Rare Earthquakes

- (1)

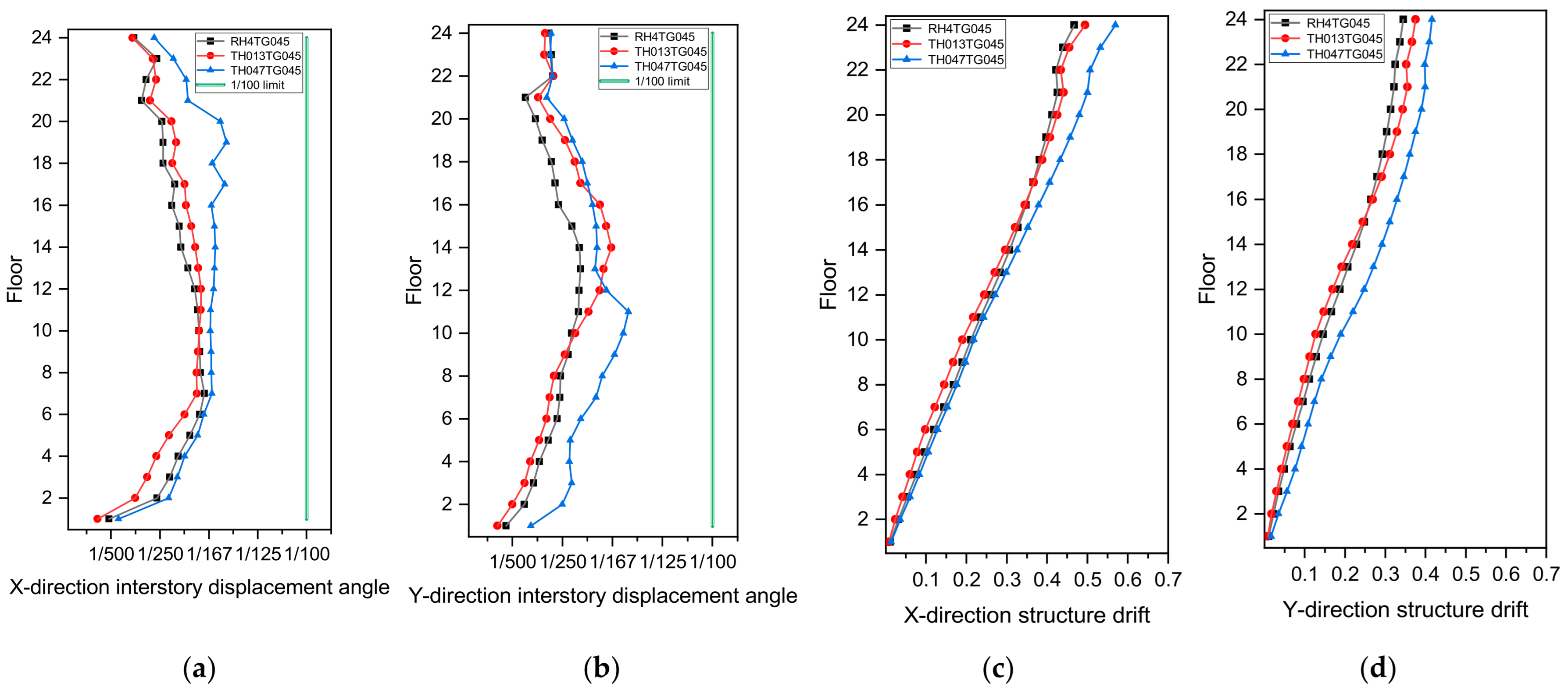

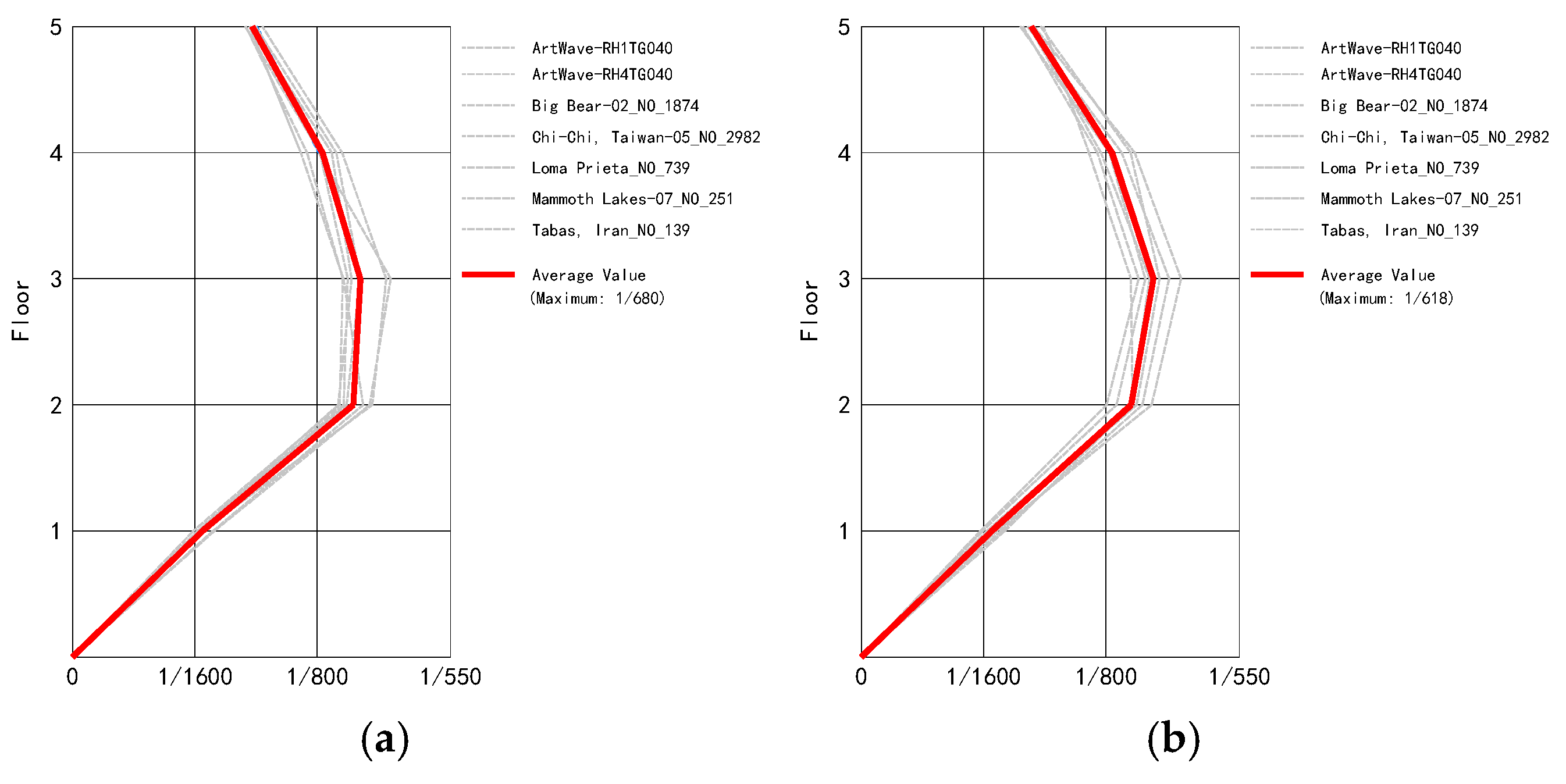

- Global Displacement and Interstory Drift

- (2)

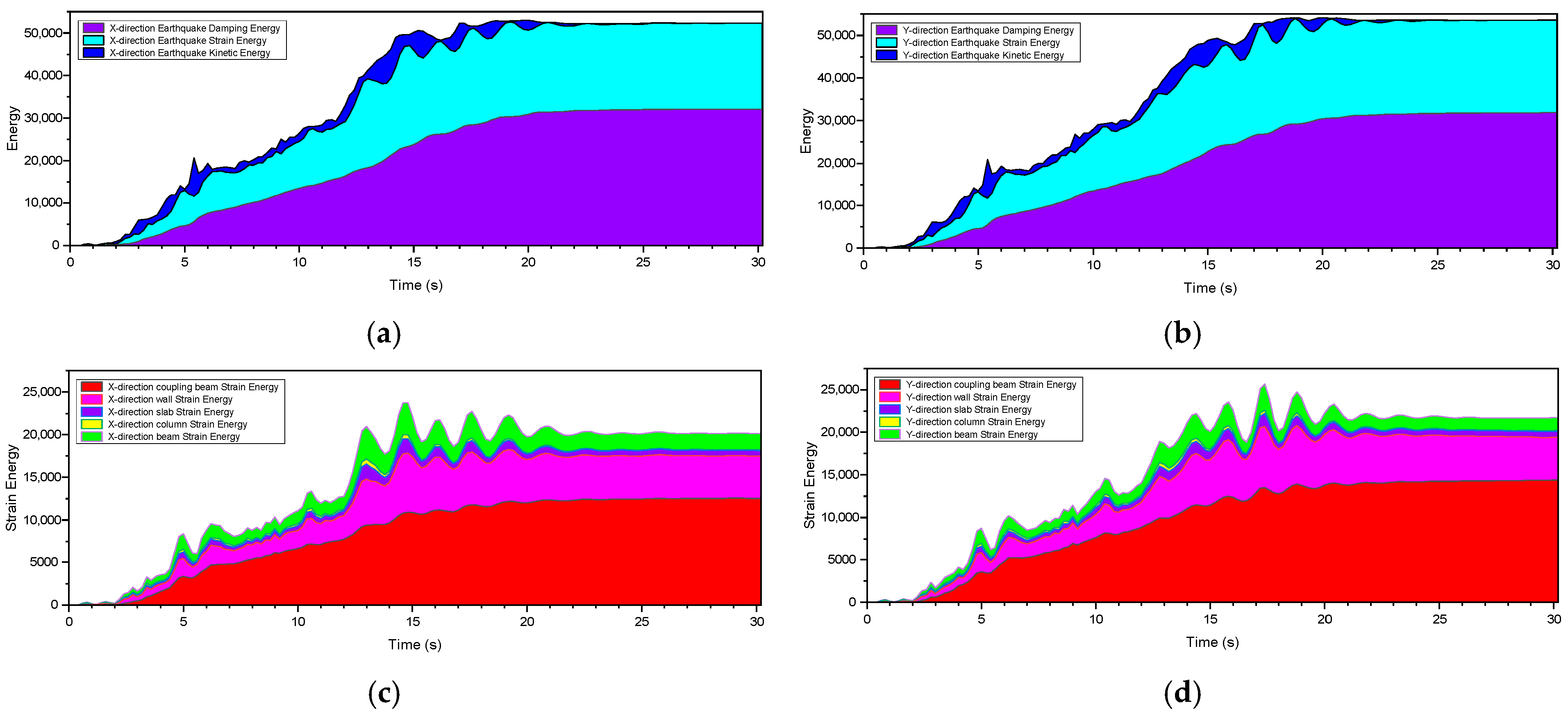

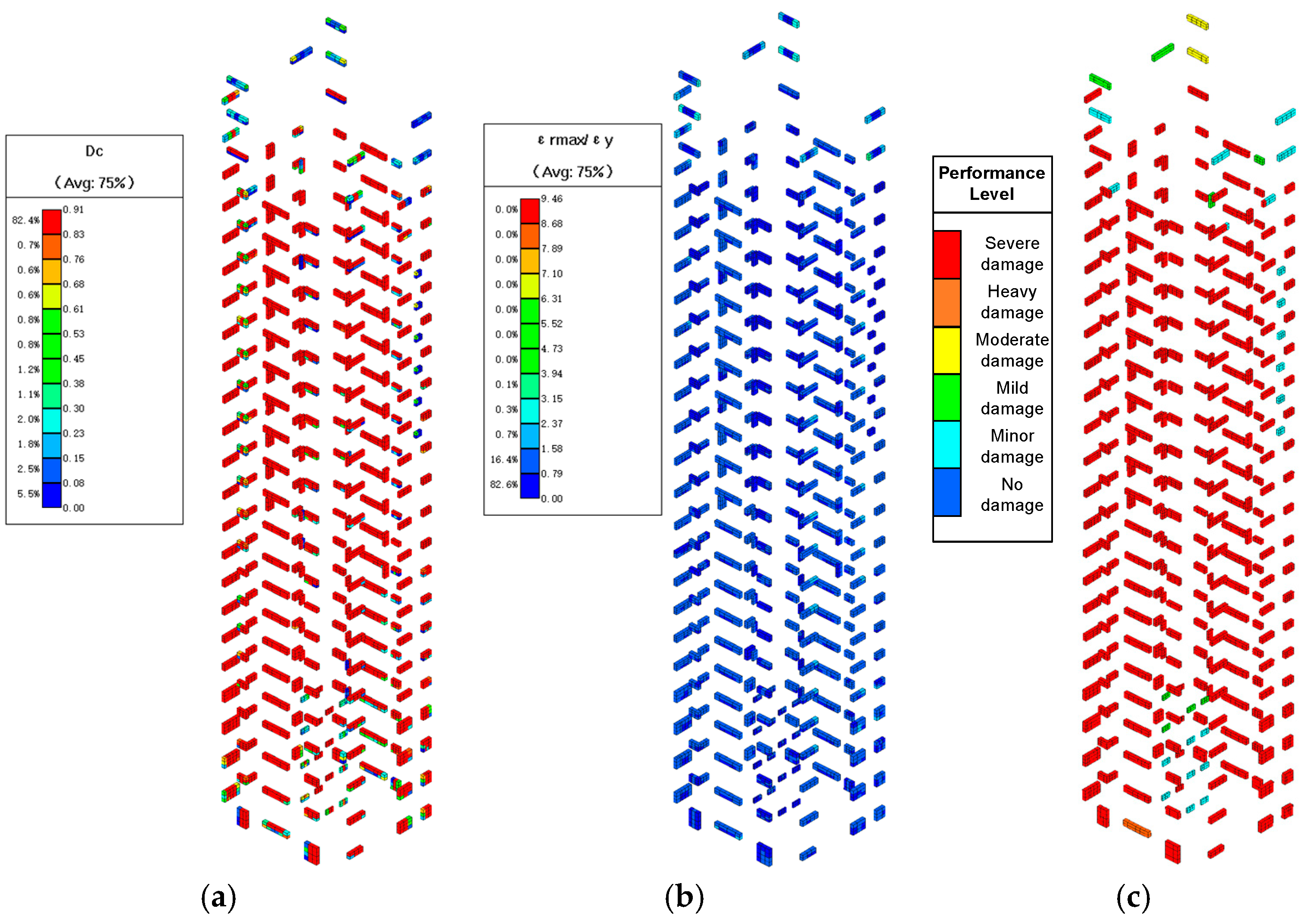

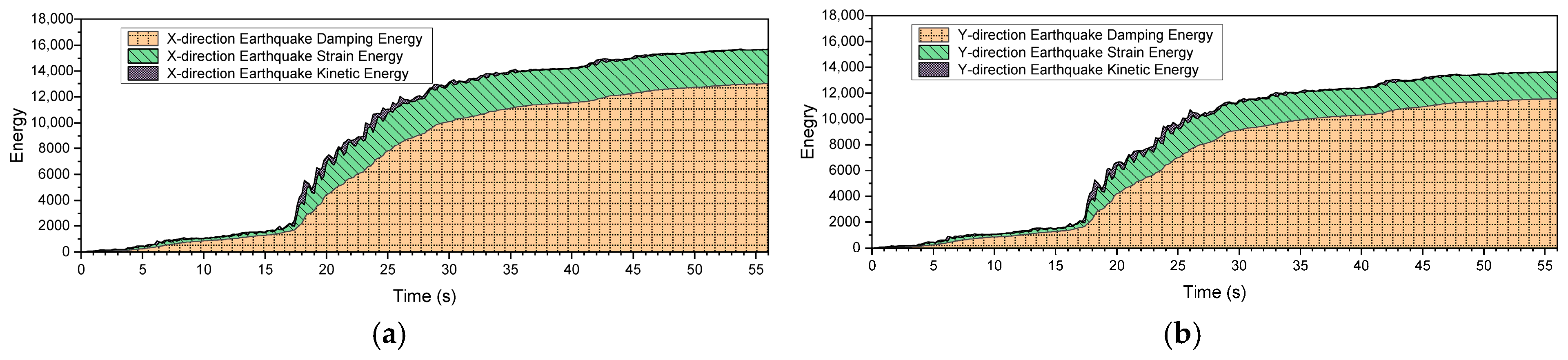

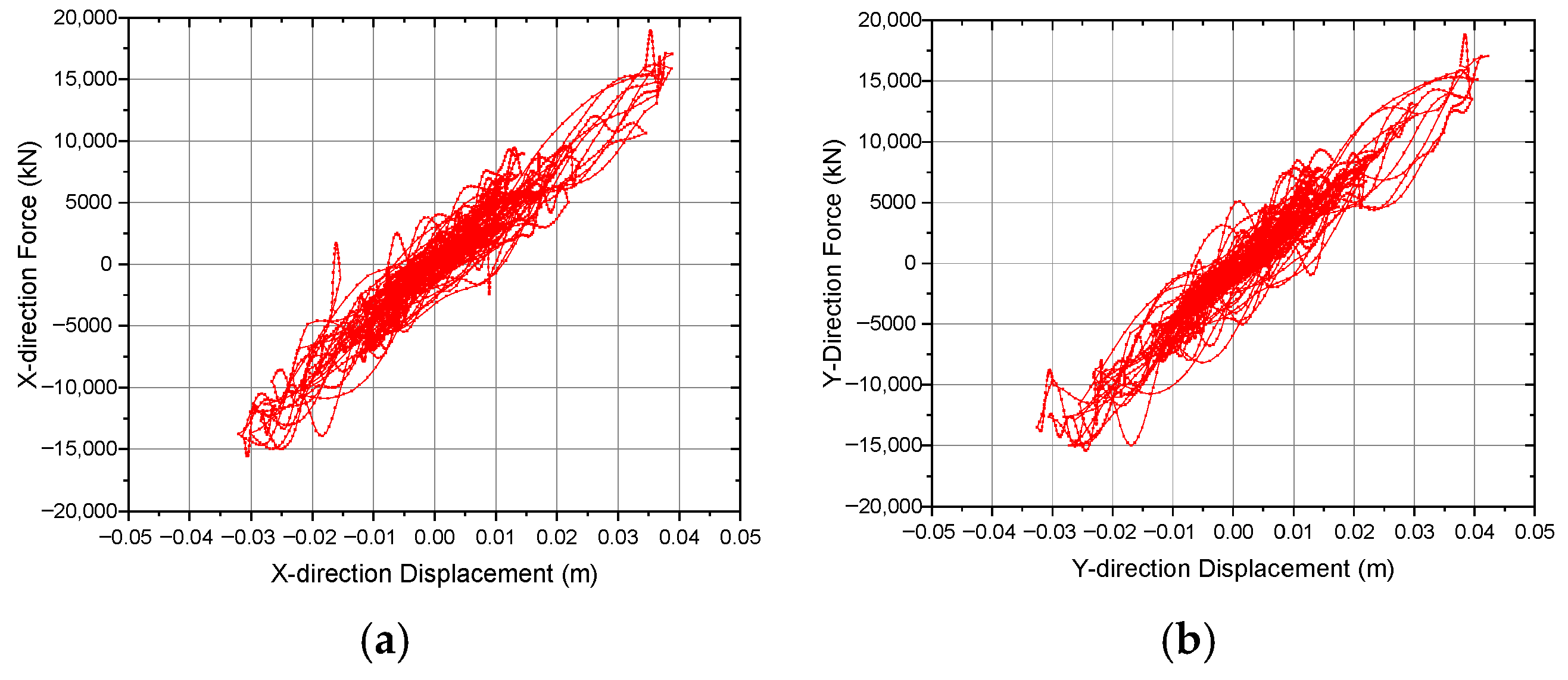

- Energy Dissipation Characteristics

- (3)

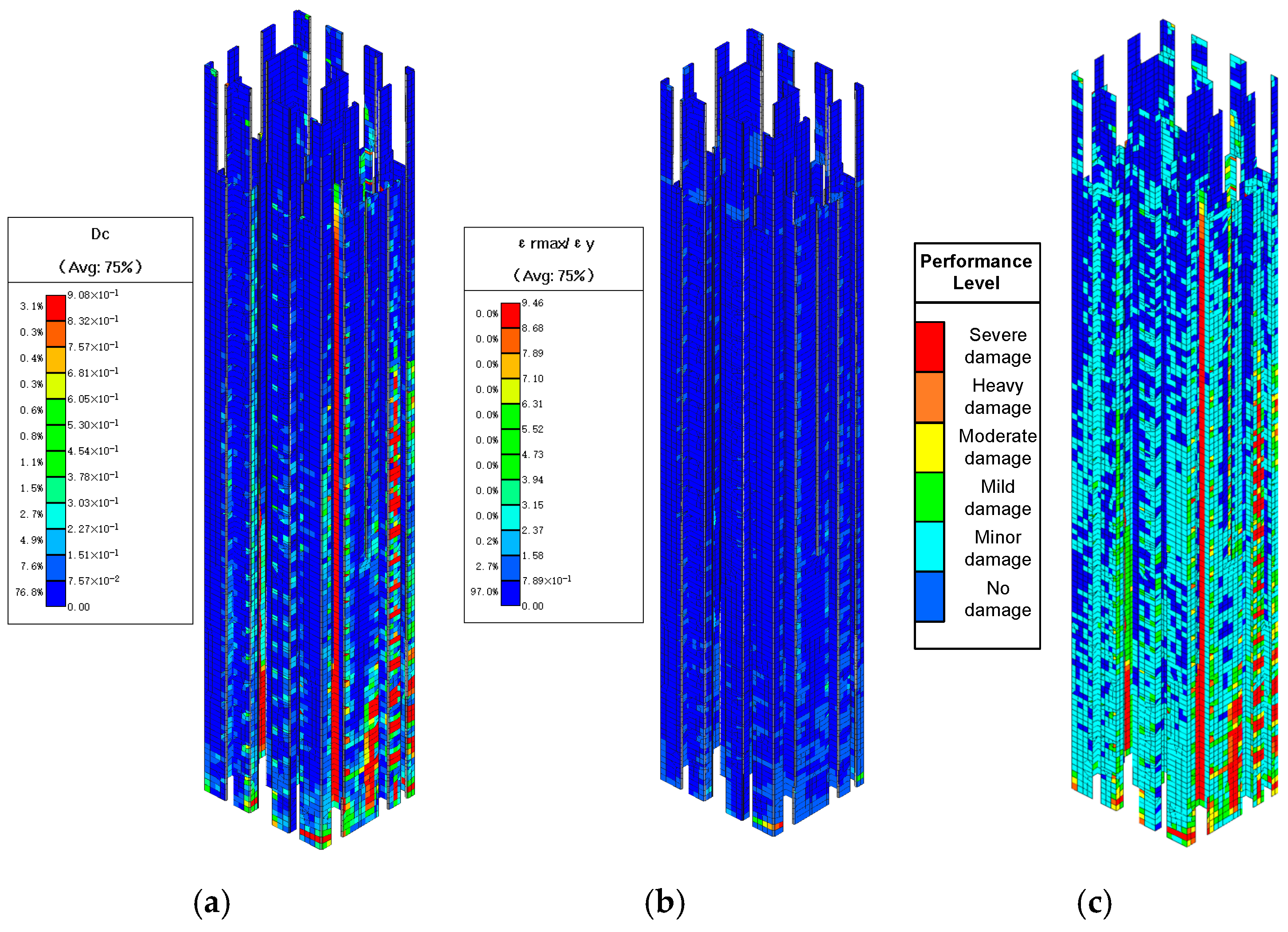

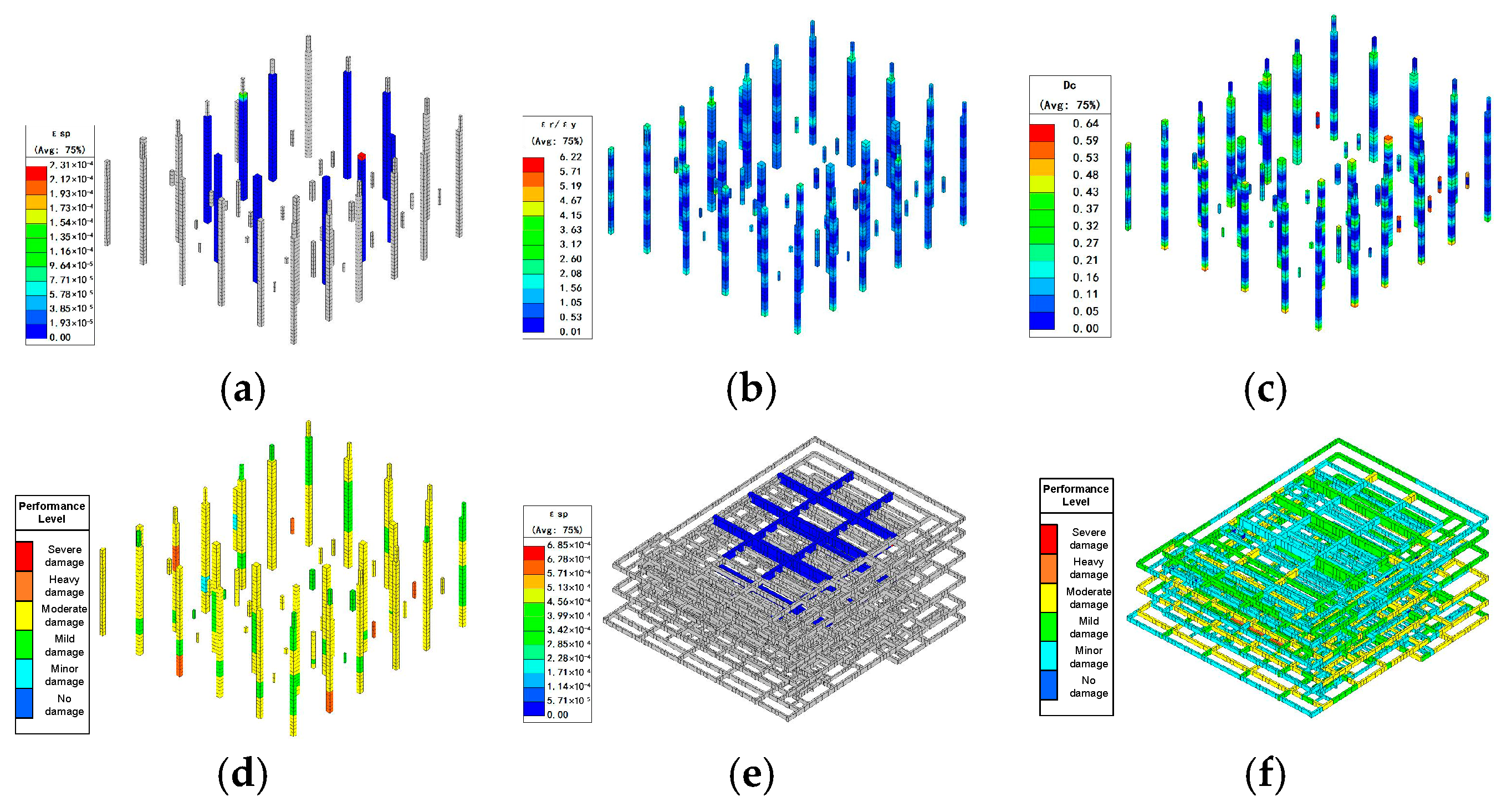

- Damage Distribution of Key Components

4.3. Performance Verification and Design Implications

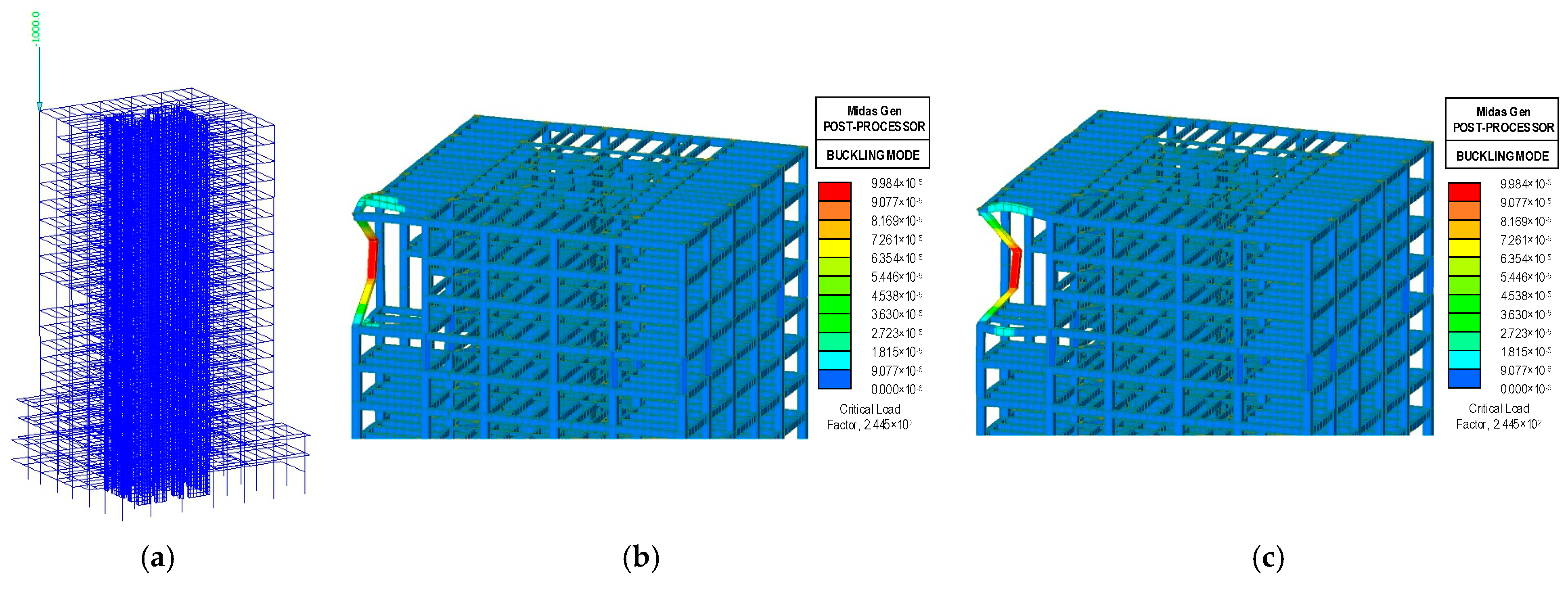

- (1)

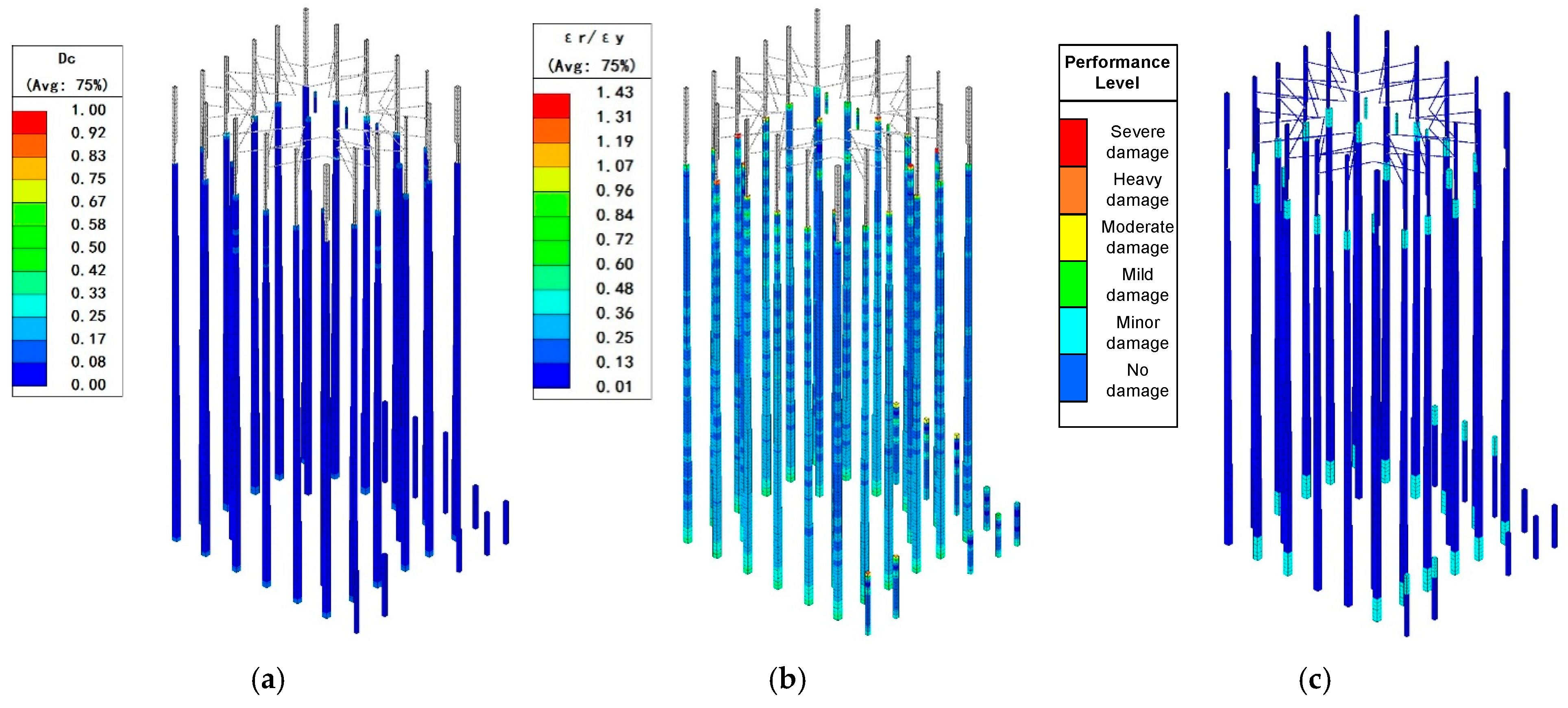

- Effective Length of Skip-Floor Columns

- (2)

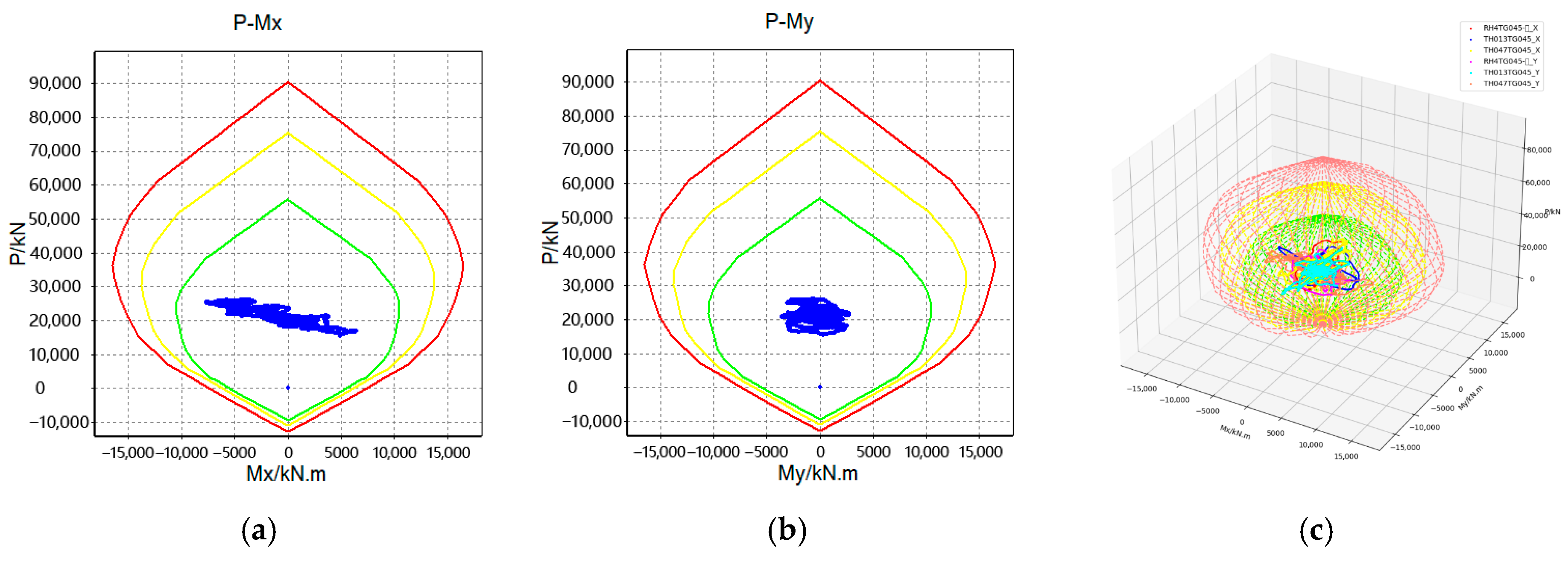

- Performance Verification Based on PBSD

- (3)

- Design Implications

5. Vertical Irregularities in the Podium-Response and Energy Dissipation Mechanism

5.1. Structural Characteristics and Elastic Analysis

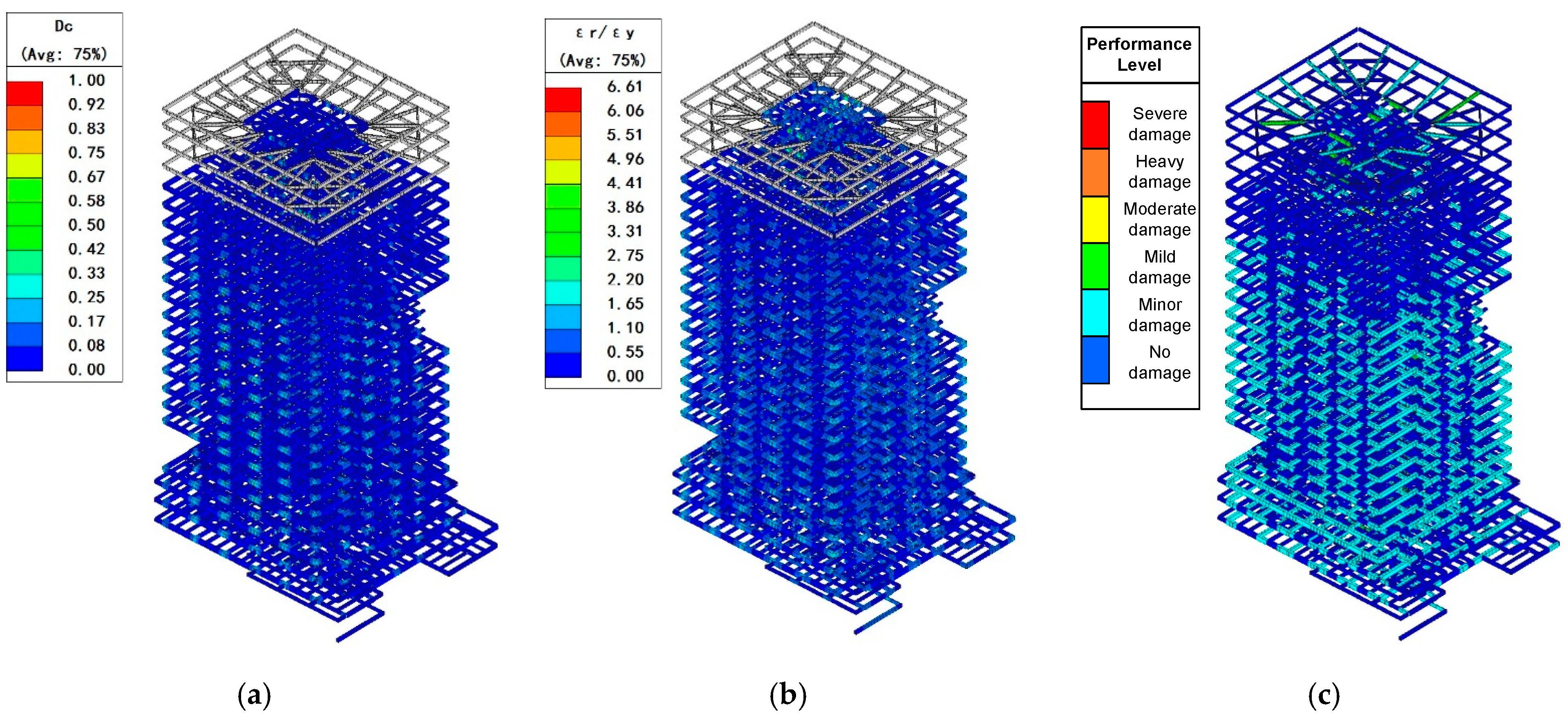

5.2. Performance-Based Seismic Design of the Podium

5.3. Nonlinear Response and Energy Dissipation Mechanism

6. Recommended Construction Sequence and Implementation Plan

7. Conclusions

- (1)

- Influence of Skip-Floor Columns. Comparative analysis between the actual and modified models showed that vibration periods, interstory drift, and shear distribution differed by less than 5%. Skip-floor columns have limited influence on global stiffness and do not require separate classification as irregularities; thus, the tower can be regarded as a generally irregular high-rise structure.

- (2)

- Seismic Behavior of the Tower. Elastoplastic time-history analysis indicated that the tower remained upright under rare earthquakes, with maximum interstory drift ratios of 1/149 and 1/150 in the X and Y directions, respectively. Energy analysis revealed that damping and strain energies accounted for 50% and 40% of total input energy. The core tube remained mostly elastic, coupling beams experienced shear-dominant failure, and the outer frame showed only minor damage, forming a dual seismic defense of “core-tube dissipation and frame protection.”

- (3)

- Performance of Skip-Floor Columns. Buckling analysis yielded an effective length coefficient of μ = 0.589, confirming that physical height can be used as the design length. PBSD verification showed that column internal forces remained within the elastic P–M envelope under rare earthquakes, meeting the target of elastic behavior under extreme conditions.

- (4)

- Podium Seismic Response. The podium exhibited significant vertical irregularities but maintained stable performance. The YJK and PMSAP models produced consistent results under frequent earthquakes. Under rare earthquakes, maximum interstory drifts were 1/103 (X) and 1/89 (Y), with more than 80% of total energy dissipated by material hysteresis, satisfying PBSD requirements for “no collapse under rare earthquakes.”

- (5)

- Engineering Implications. The integrated PBSD and nonlinear analysis framework provides a practical reference for irregular high-rise buildings with discontinuous vertical systems. It achieves a rational balance between safety, economy, and functionality, offering guidance for the seismic design of complex scientific research facilities. In addition, a practical construction sequence based on the recommended design is proposed, which demonstrates the feasibility of applying the PBSD approach to real projects and enhances its engineering applicability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Bhasker, R.; Menon, A. Torsional irregularity indices for the seismic demand assessment of RC moment resisting frame buildings. Structures 2020, 26, 888–900. [Google Scholar] [CrossRef]

- Rooshenas, A. Comparing pushover methods for irregular high-rise structures, partially infilled with masonry panels. Structures 2020, 28, 337–353. [Google Scholar] [CrossRef]

- Leelataviwat, S.; Goel, S.C.; Stojadinovic, B. Energy-Based Seismic Design of Structures using Yield Mechanism and Target Drift. J. Struct. Eng. 2002, 128, 1046–1054. [Google Scholar] [CrossRef]

- Sarkisian, M.; Long, E.; Hassan, W. Performance-Based Engineering of Core Wall Tall Buildings. Structures Congress 2013, Pittsburgh, Pennsylvania, United States. Available online: https://ascelibrary.org/doi/abs/10.1061/9780784412848.097 (accessed on 11 November 2025).

- Da, G.; Wang, B.; Wenhao, X.; Dan, L. Study on the influence of additional deformation of deepfoundation pit construction in sensitive environment. Eng. Constr. 2021, 53, 52–57. (In Chinese) [Google Scholar]

- Brunesi, E.; Nascimbene, R.; Casagrande, L. Seismic analysis of high-rise mega-braced frame-core buildings. Eng. Struct. 2016, 115, 1–17. [Google Scholar] [CrossRef]

- Gan, X.; Xiaoqin, W.; Qun, Z. Shared Mega-Form: A Preliminary Study on the Design of Major National Scientific and Technological Infrastructure. Time + Archit. 2024, 110–117. (In Chinese) [Google Scholar]

- Sun, X.; Li, J.; Qian, Y.; Chai, H. Structural design of Zhengzhou International Cultural Exchange Center. Build. Struct. 2023, 53, 1–7. [Google Scholar]

- Gao, L.; Jia, J.; Cui, Z.; Wei, X. Seismic Performance Analysis of Zhengzhou Science Museum Structure. Build. Struct. 2018, 48, 45–49. [Google Scholar]

- JGJ 3-2010; Technical Specification for Concrete Structures of Tall Buildings. China Architecture & Building Press: Beijing, China, 2011.

- Ellingwood, B.R.; Kinali, K. Quantifying and communicating uncertainty in seismic risk assessment. Struct. Saf. 2009, 31, 179–187. [Google Scholar] [CrossRef]

- Lu, X.; Cui, Y.; Liu, J.; Gao, W. Shaking table test and numerical simulation of a 1/2-scale self-centering reinforced concrete frame. Earthq. Eng. Struct. Dyn. 2015, 44, 1899–1917. [Google Scholar] [CrossRef]

- Nielsen, G.M.; Almufti, I.; Mahin, S.A.; Willford, M.R. Performance of rocking core walls in tall buildings under severe seismic motions. In Proceedings of the 9th US National and 10th Canadian Conference on Earthquake Engineering, Ottawa, ON, Canada, 25–29 July 2010; Paper No 483. Canadian Association for Earthquake Engineering: Vancouver, BC, Canada, 2010. [Google Scholar]

- BS EN 1998-3:2005; Eurocode 8: Design of Structures for Earthquake Resistance—Part 3: Assessment and Retrofitting of Buildings. British Standards Institution: Brussels, Belgium, 2005.

- Lu, X.; Gong, Z.; Weng, D.; Ren, X. The application of a new structural control concept for tall building with large podium structure. Eng. Struct. 2007, 29, 1833–1844. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, Y.; Deng, F.; Zhang, L.; Li, J. Structural Design and Analysis of Zhengzhou Museum New Building. Build. Struct. 2018, 48, 56–59. [Google Scholar]

- Lu, J.; Li, Z.; Teng, J. Two-Stage Seismic Resilience Enhancement for Frame–Core Tube Structures Based on Performance Loss and Repair Paths in Complex Networks. Struct. Des. Tall Spec. Build. 2025, 34, e70067. [Google Scholar] [CrossRef]

- Regulations on Seismic Management of Construction Projects. State Council Decree No.744, effective 1 September 2021. Available online: https://www.gov.cn/gongbao/content/2021/content_5631815.htm (accessed on 11 November 2025).

- Yuan, Z.; Su, F.; Mao, X.; Wang, G.; Li, X.; Wang, J.; Gao, M.; Li, G. Seismic Design of Out-of-Code Complex Structure for Zhengzhou Grand Theater. Build. Struct. 2018, 48, 50–55. [Google Scholar]

| Floor Number | Core Tube | Outer Frame Column (mm × mm) | Outer Frame Beam (mm × mm) | Slab (mm) | ||

|---|---|---|---|---|---|---|

| Exterior Wall (mm) | Inner Wall (mm) | Coupling Beam (mm × mm) | ||||

| 1~5 | 500 | 200 and 300 | 500 × 800~500 × 1500 | 1300 × 1300 | 700 × 900~700 × 1100 | 150 in Core tube area, others 120 |

| 6~9 | 500 | 500 × 600~500 × 900 | 1200 × 1200 | 700 × 900 | ||

| 10~13 | 400 | 400 × 800 and 400 × 1000 | 1100 × 1100 | |||

| 14~18 | 400 | 400 × 800 and 400 × 1000 | 1000 × 1000 | |||

| 19~RF | 400 | 400 × 800 and 400 × 1000 | 900 × 900 | |||

| Vibration Mode | Actual Model Period | Comparison Model Period | Difference |

|---|---|---|---|

| 1 | 2.9713 | 2.9467 | 0.828% |

| 2 | 2.6268 | 2.6104 | 0.624% |

| 3 | 2.4780 | 2.4334 | 1.800% |

| 4 | 0.9506 | 0.9496 | 0.105% |

| 5 | 0.8965 | 0.8857 | 1.205% |

| 6 | 0.8335 | 0.8317 | 0.216% |

| Max | 1.800% |

| Load Case | Comparison Item | Actual Model | Comparison Model |

|---|---|---|---|

| X earthquake | Maximum interstory displacement angle | 1/843 | 1/838 |

| Floor number | 12 | 12 | |

| Y earthquake | Maximum interstory displacement angle | 1/1042 | 1/1027 |

| Floor number | 14 | 14 |

| Main Direction | Base Shear Force for Frequently Occurring Earthquakes (kN) | Rare Earthquake Elastoplastic Load Case | Base Shear Force for Elastoplastic Load Cases (kN) | Base Shear Ratio of Elastoplastic/Elastic Cases |

|---|---|---|---|---|

| X | 18,345.10 | RH4TG045_X | 68,453.4 | 3.73 |

| TH013TG045_X | 60,754.0 | 3.31 | ||

| TH047TG045_X | 84,963.4 | 4.63 | ||

| Y | 19,369.26 | RH4TG045_Y | 67,467.7 | 3.48 |

| TH013TG045_Y | 61,595.8 | 3.18 | ||

| TH047TG045_Y | 82,512.0 | 4.26 |

| Proportion of Energy Consumption | |||||

|---|---|---|---|---|---|

| Seismic Wave | Beam | Column | Slab | Wall | Coupling Beam |

| RH4TG045 | 9.4% | 0.4% | 3.3% | 24.6% | 62.3% |

| TH013TG045 | 7.0% | 0.5% | 3.3% | 23.0% | 66.2% |

| TH047TG045 | 7.9% | 0.2% | 3.2% | 34.4% | 54.2% |

| Seismic Level | Frequently Occurring Earthquakes | Fortification Against Earthquakes | Rare Earthquakes |

|---|---|---|---|

| skip-floor columns | Elasticity | Flexural and shear elasticity | Flexural and shear unyielding |

| common columns | Elasticity | Flexural and shear unyielding | Partly moderate damage, satisfying the shear section control conditions |

| Comparison Term | YJK (t) | PMSAP (t) | Difference |

|---|---|---|---|

| Constant load | 11,816 | 11,852 | +0.30% |

| Live load | 1302 | 1292 | −0.77% |

| total mass | 13,118 | 13,144 | +0.20% |

| Periodicity | YJK (t) | PMSAP (t) | Difference r |

|---|---|---|---|

| T1 | 0.9953 | 0.9511 | −4.44% |

| T2 | 0.9601 | 0.9147 | −4.73% |

| T3 | 0.8618 | 0.8372 | −2.85% |

| T3/T1 | 0.866 | 0.880 |

| Working Condition | YJK (KN·m) | PMSAP (KN·m) | Difference |

|---|---|---|---|

| X-quake | 124,000 | 128,000 | +3.23% |

| Y Earthquake | 121,200 | 126,000 | +3.96% |

| X Winds | 19,180 | 18,505 | −3.52% |

| Y Wind | 16,640 | 15,890 | −4.50% |

| Seismic Level | Frequently Occurring Earthquakes | Fortification Against Earthquakes | Rare Earthquakes | |

|---|---|---|---|---|

| Qualitative description of performance levels | intact | Moderately damaged | Avoid serious damage | |

| The angular limit of interstory displacement | 1/550 | 1/180 | 1/60 | |

| Key building blocks | Large-span-bearing columns, transition beam columns | Elasticity | Flexural and shear elasticity | Flexural and shear unyielding |

| General vertical members and important horizontal members | Large-span frame beams | Elasticity | Flexural unyielding and shear elasticity | Shear unyielding |

| General columns | Elasticity | Flexural and shear unyielding | Satisfying the shear section control conditions | |

| Weak parts of the floor slab | Elasticity | Shear unyielding | Satisfying the shear section control conditions | |

| Energy-consuming components | General beams | Elasticity | Partly moderate damage | Partly severe damage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, J.; Li, K.; Yang, Z. Seismic Performance Analysis and Structural Optimization Design of a Science and Innovation Building in a Certain University. Buildings 2025, 15, 4171. https://doi.org/10.3390/buildings15224171

Jiang J, Li K, Yang Z. Seismic Performance Analysis and Structural Optimization Design of a Science and Innovation Building in a Certain University. Buildings. 2025; 15(22):4171. https://doi.org/10.3390/buildings15224171

Chicago/Turabian StyleJiang, Junqing, Ke Li, and Zhenfang Yang. 2025. "Seismic Performance Analysis and Structural Optimization Design of a Science and Innovation Building in a Certain University" Buildings 15, no. 22: 4171. https://doi.org/10.3390/buildings15224171

APA StyleJiang, J., Li, K., & Yang, Z. (2025). Seismic Performance Analysis and Structural Optimization Design of a Science and Innovation Building in a Certain University. Buildings, 15(22), 4171. https://doi.org/10.3390/buildings15224171