A Closed-Loop Scheduling Framework for Prefabricated Bridge Girders: Bayesian Regression and TCTO-Based Optimization

Abstract

1. Introduction

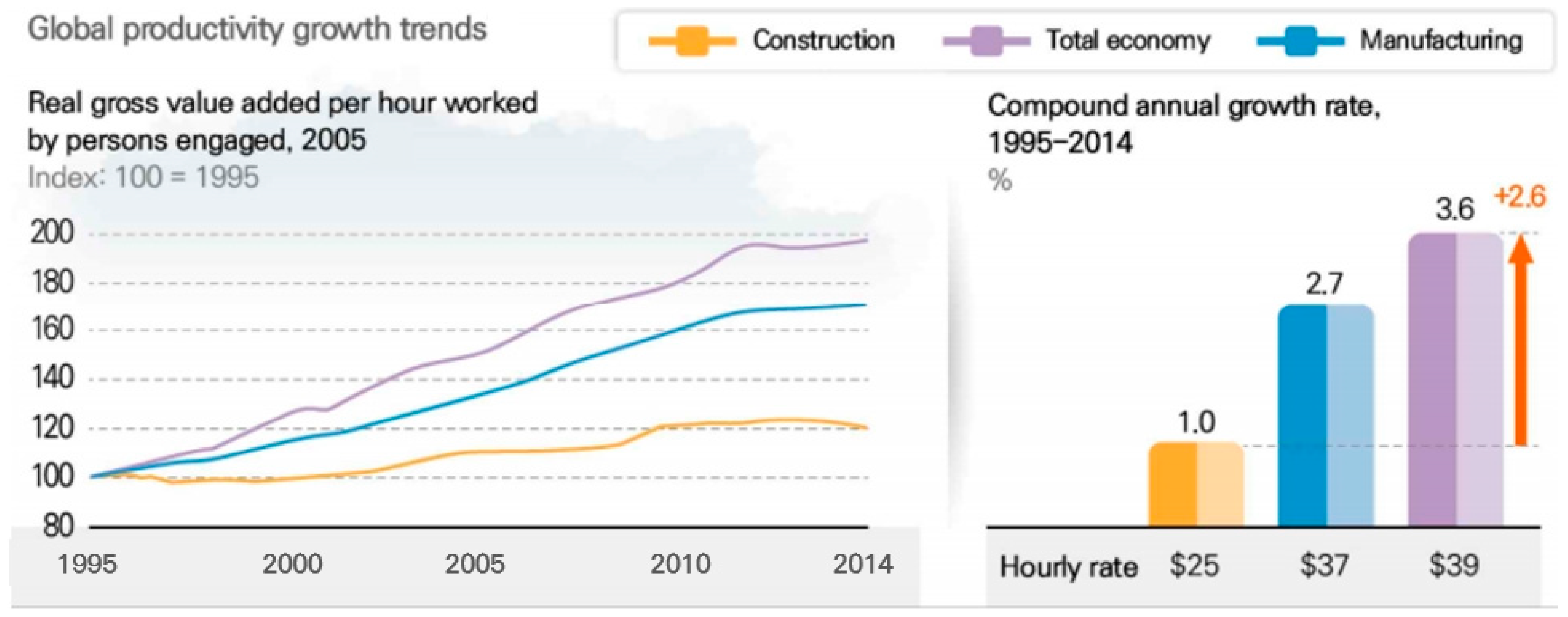

1.1. Research Background

1.2. Literautre Review on Scheduling Prefabricated Construction

1.2.1. Prefabrication and Factory Site Synchronization

1.2.2. Standard Time (ST): Dynamics and Learning

1.2.3. TCTO with Uncertainty Durations

1.2.4. Performance Analytics and Missing Feedback Loop

1.2.5. Synthesis: Toward an Operational Closed-Loop

1.3. Purpose of This Study

2. Research Framework and Methodology

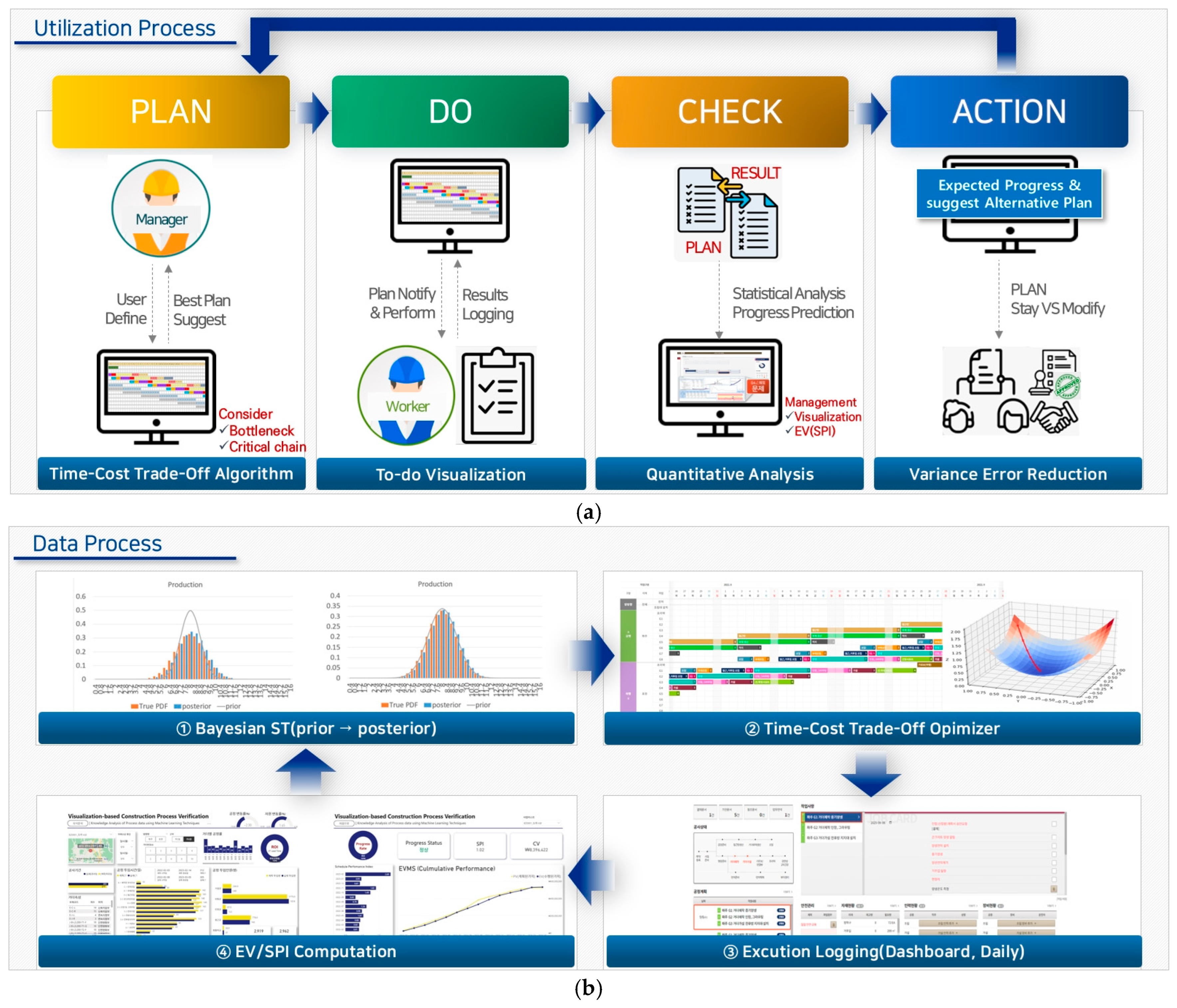

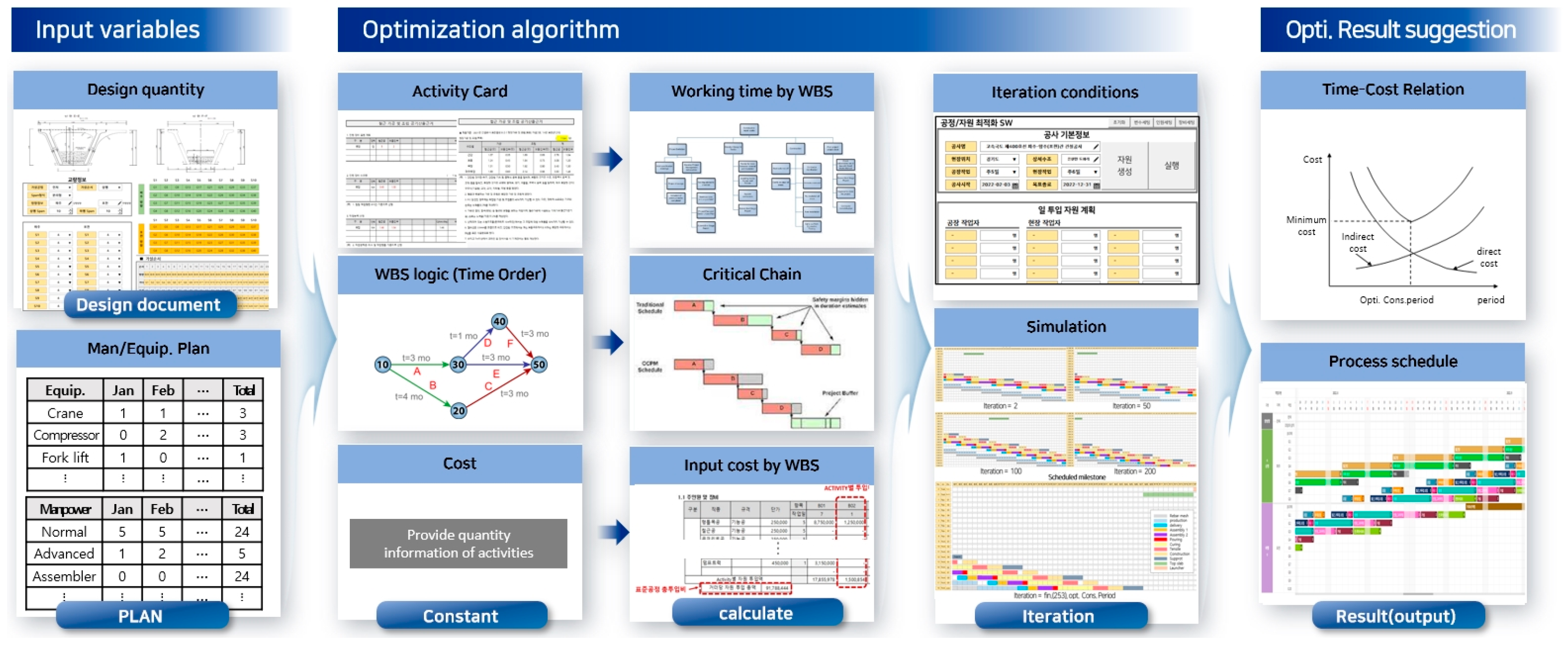

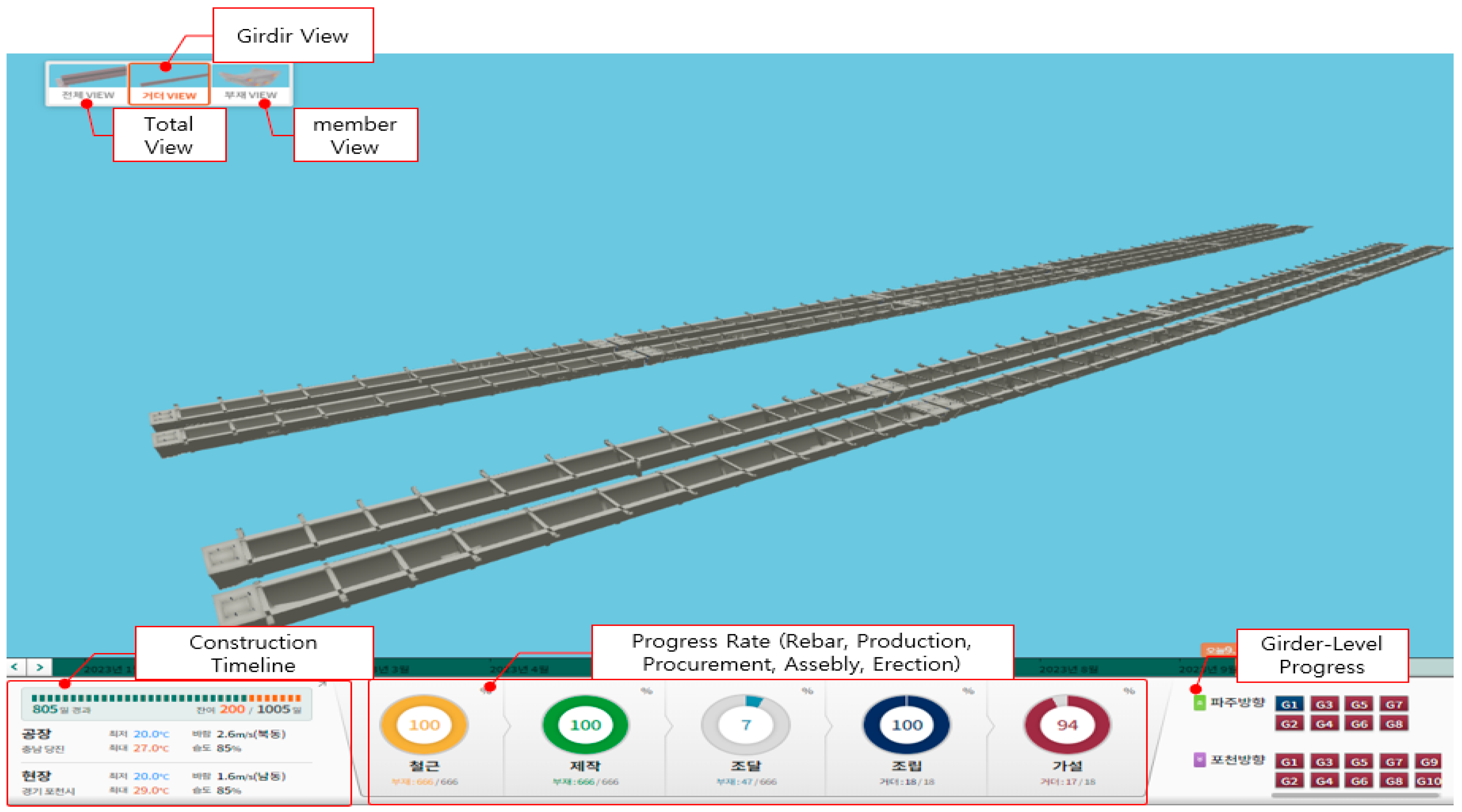

2.1. Overall Closed-Loop Framework

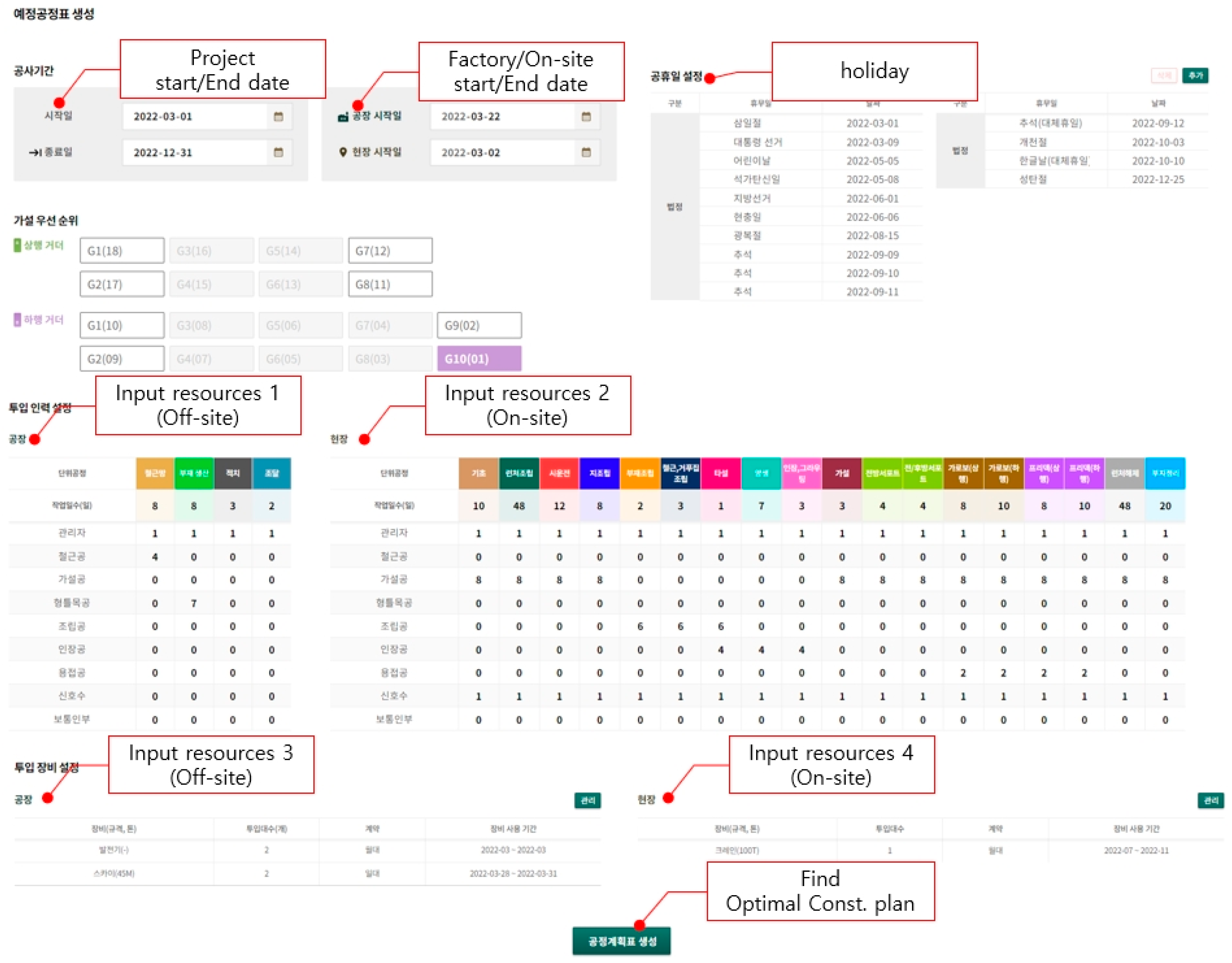

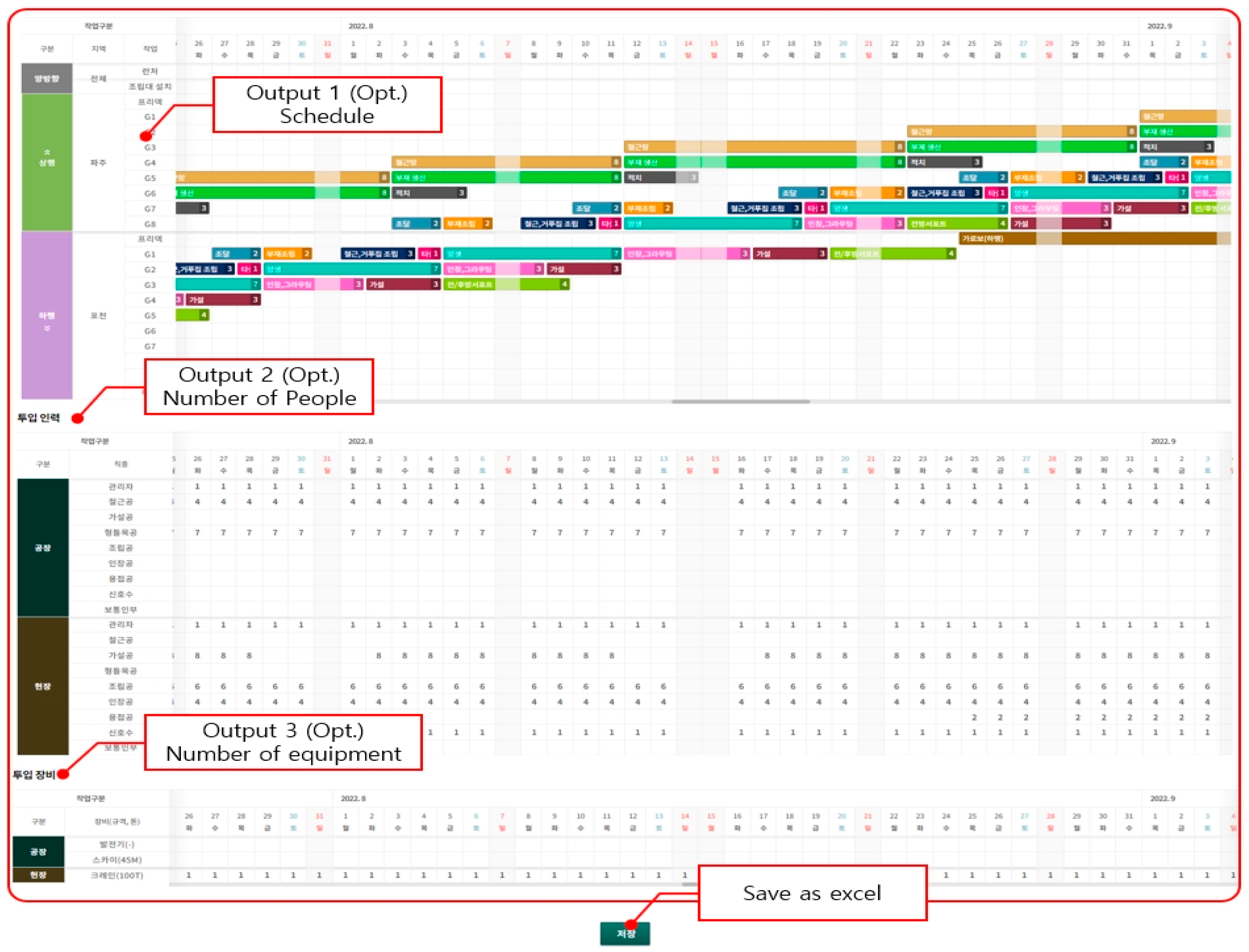

- Plan phase: A project schedule is generated using the TCTO (Time–Cost Trade-Off) algorithm, with Bayesian regression-based ST estimates serving as key inputs. This ensures that the schedule accounts for resource constraints while satisfying target duration and cost conditions.

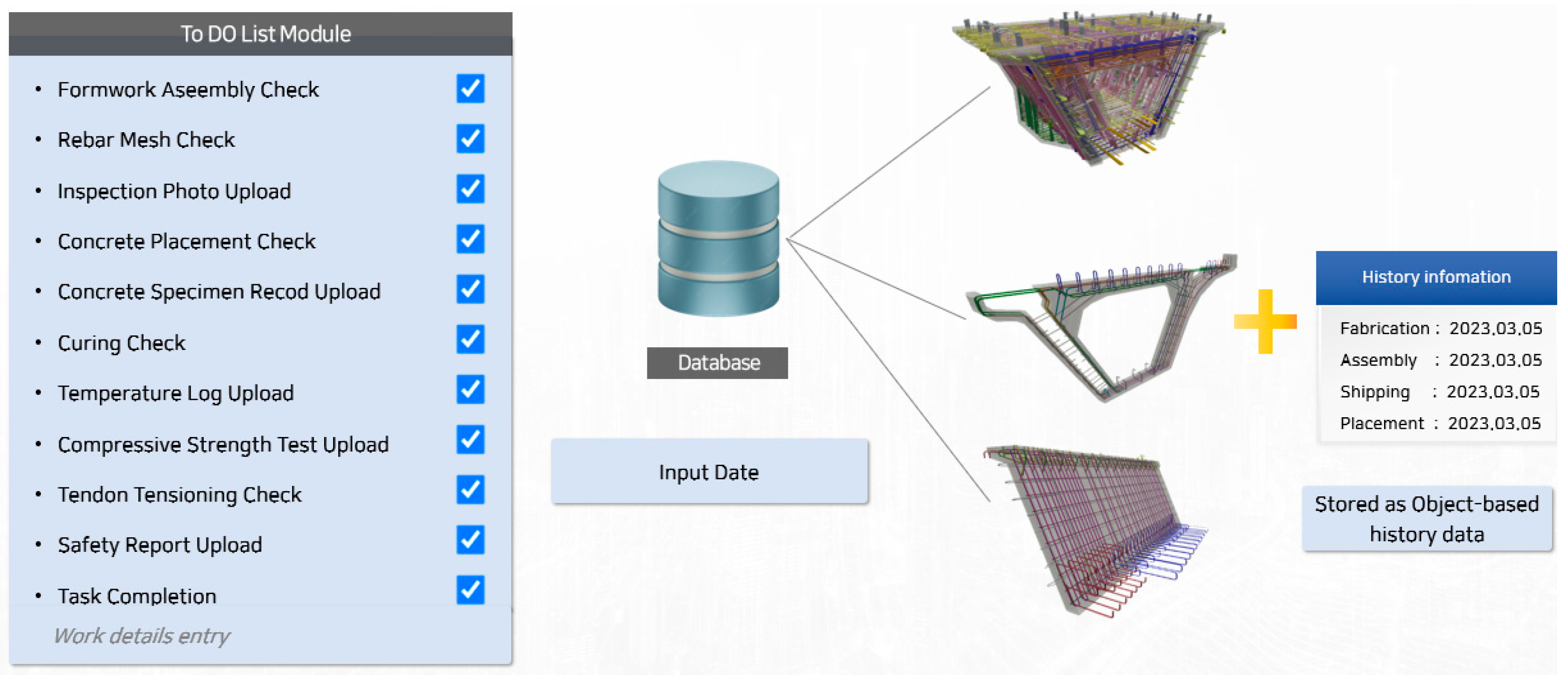

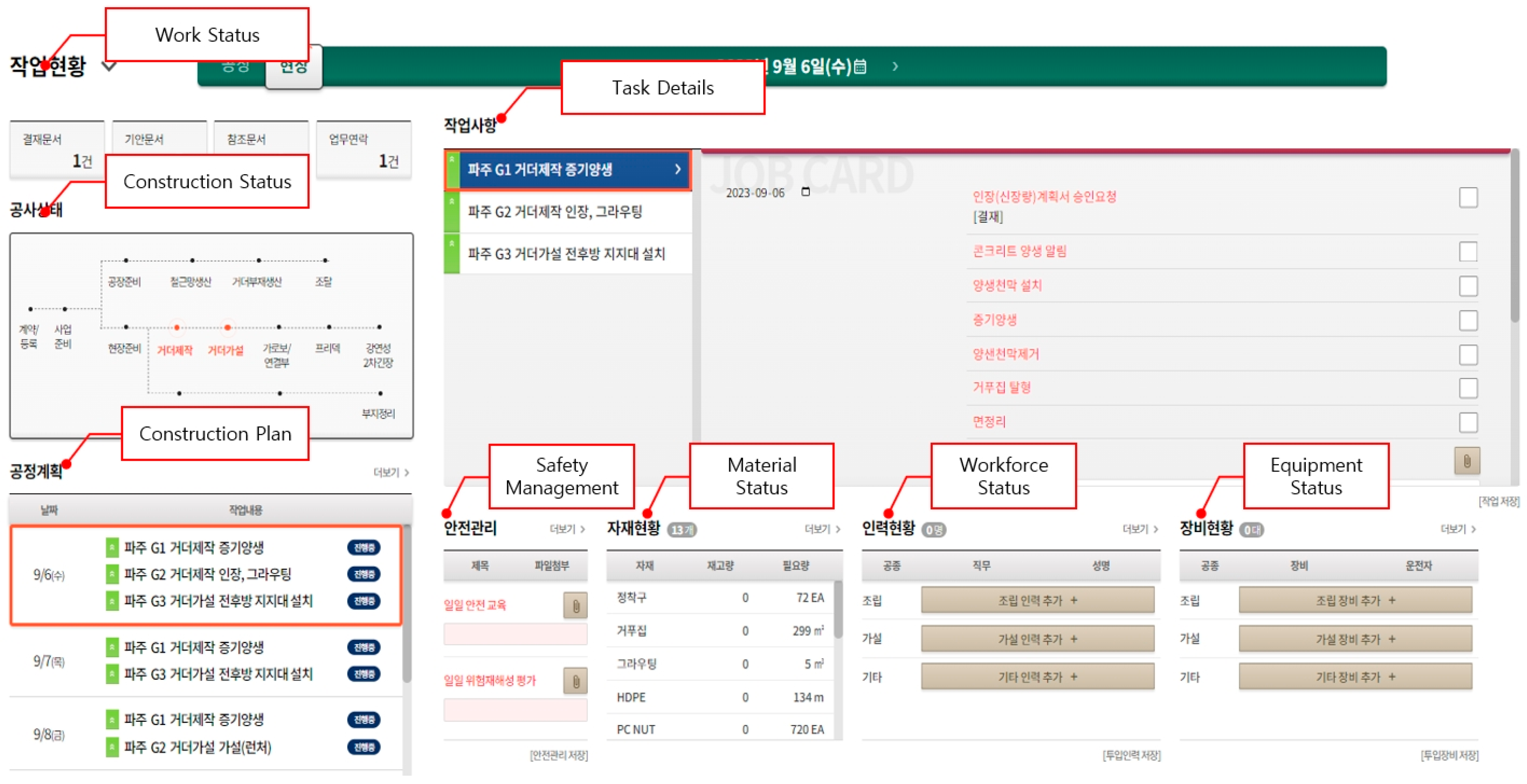

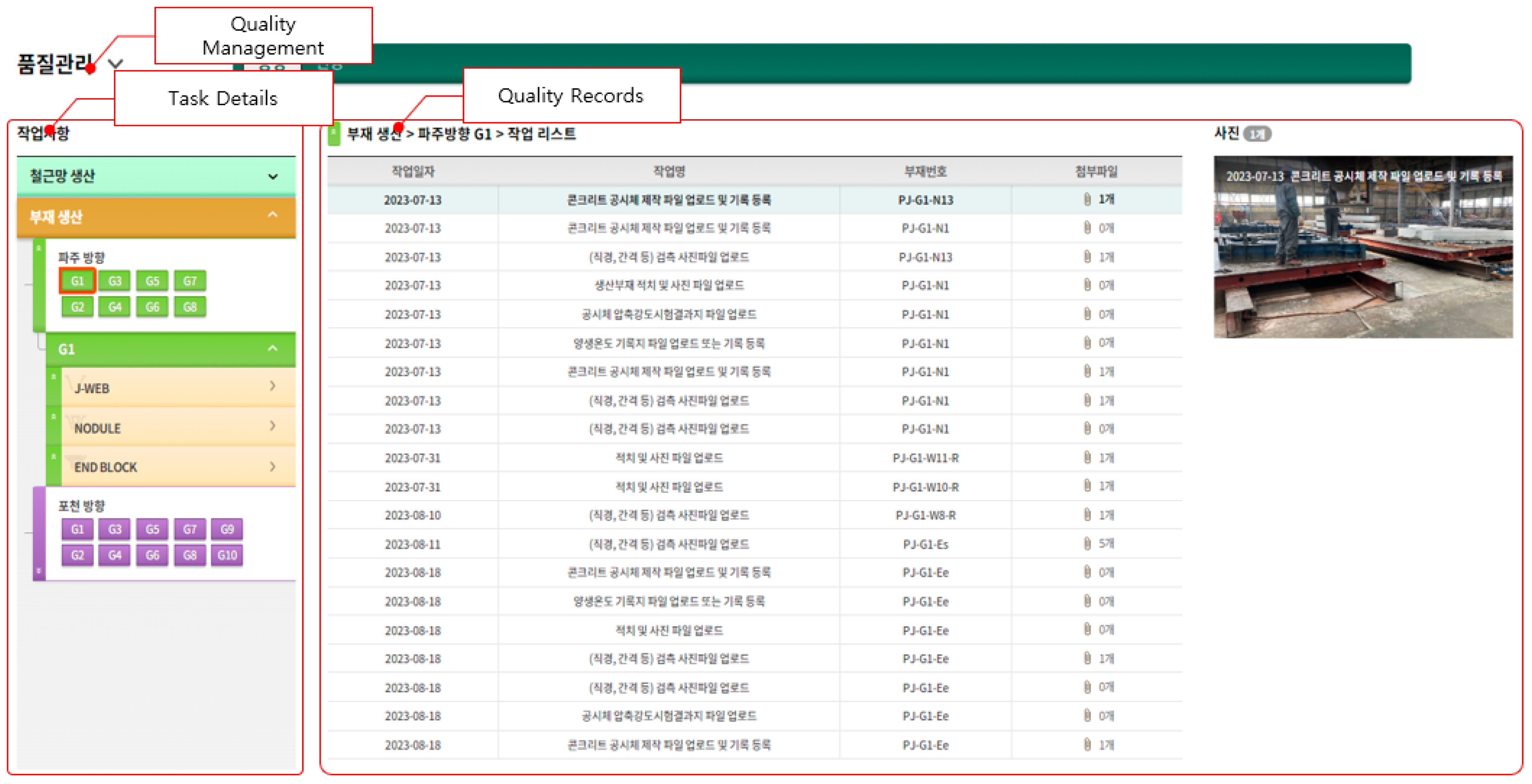

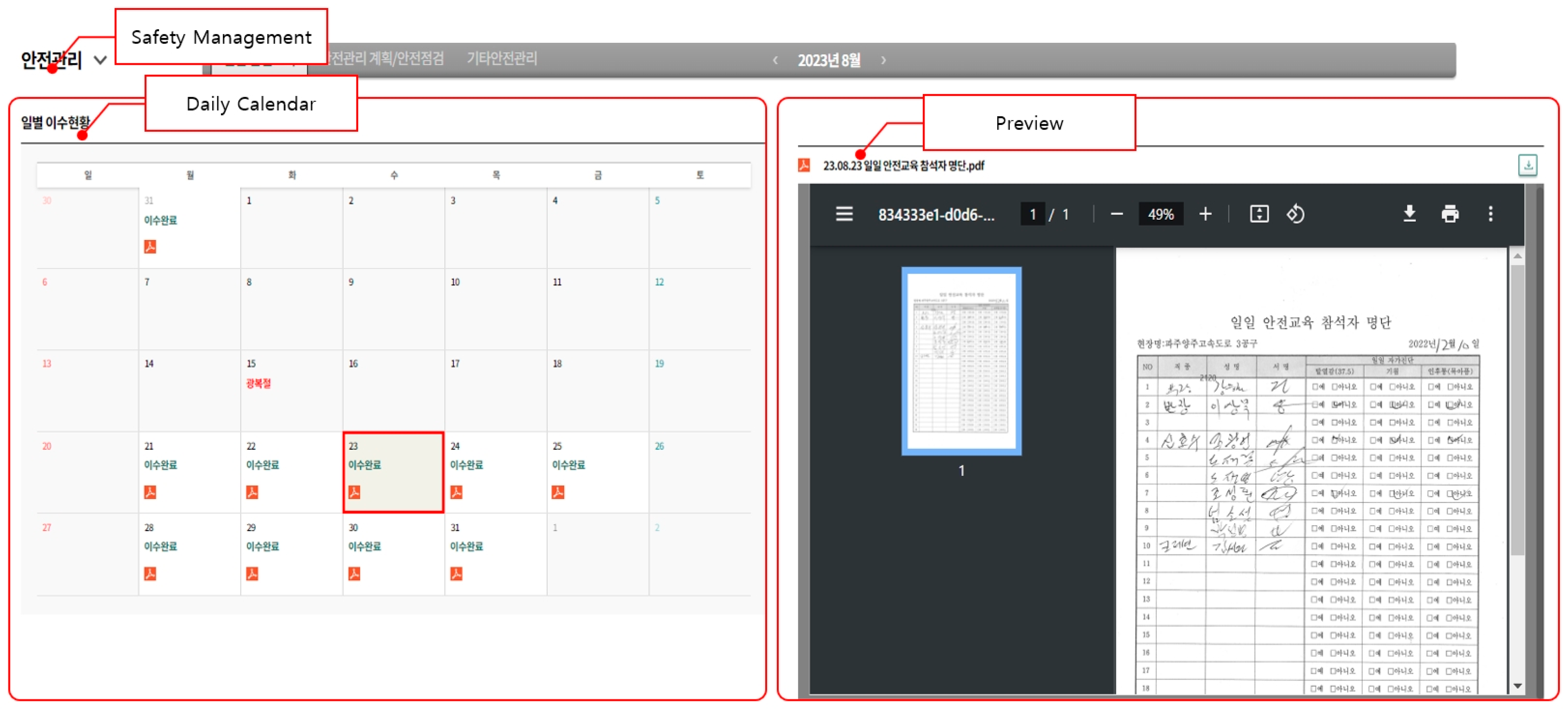

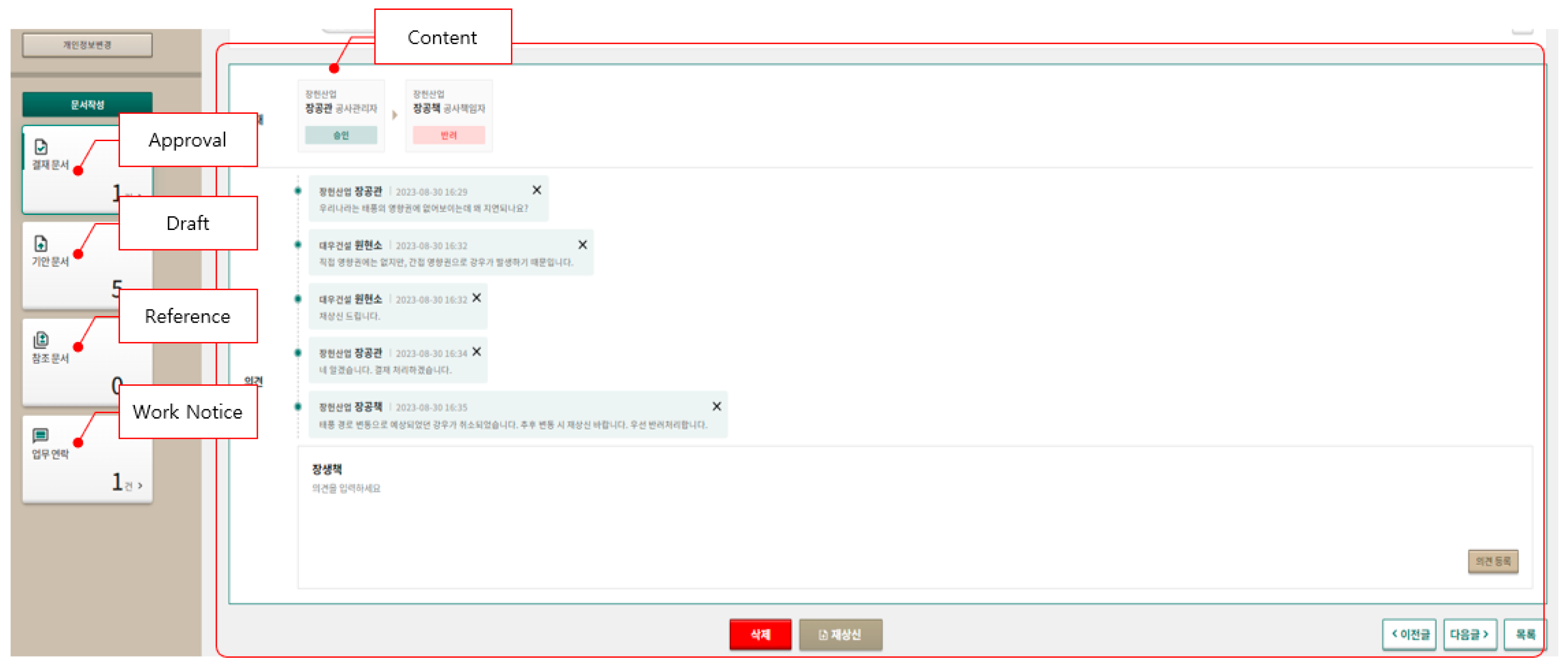

- Do phase: The schedule is communicated to site workers, and task execution is digitally recorded through a task visualization interface, enabling systematic logging of actual progress.

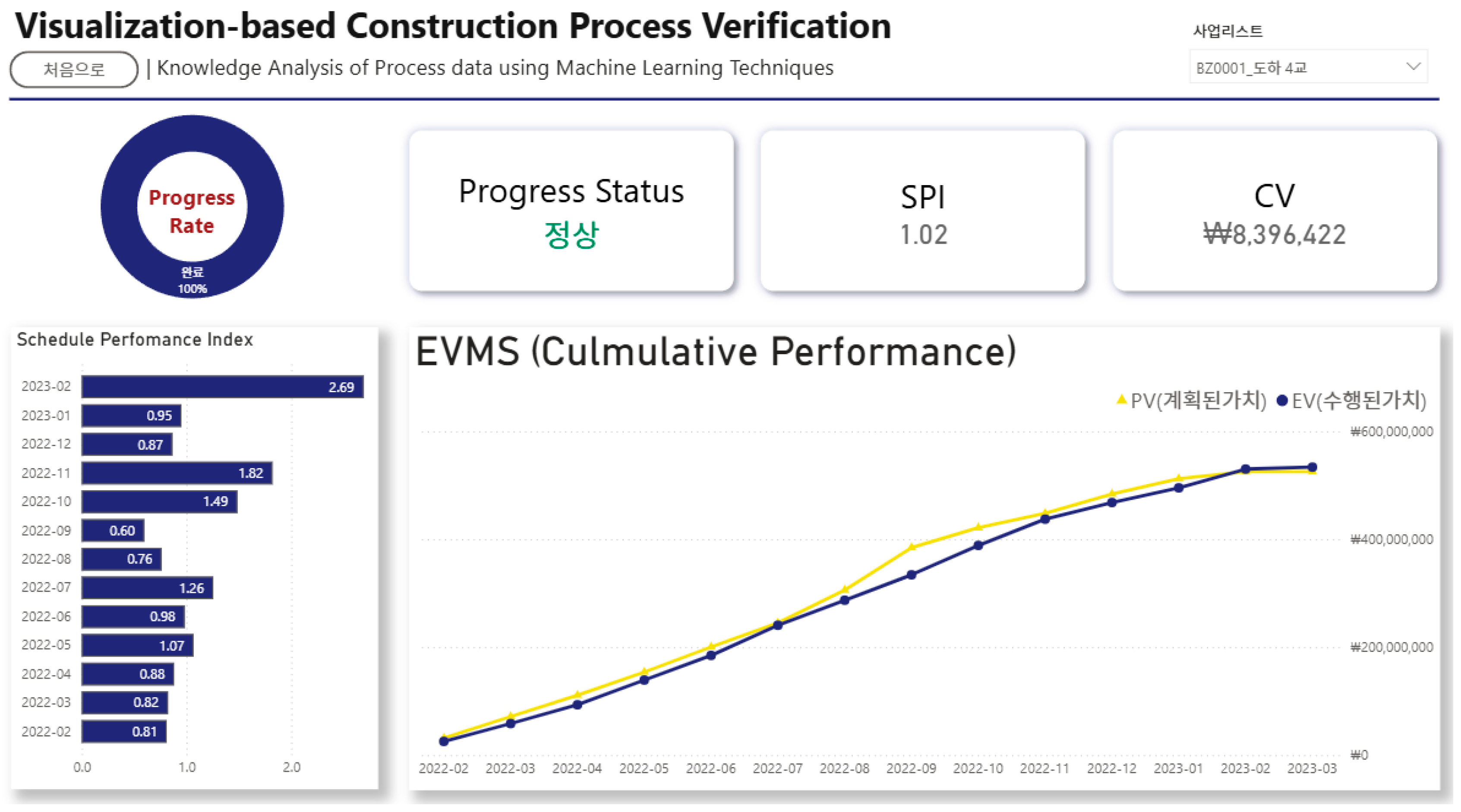

- Check phase: Logged data are transformed into Earned Value Management (EVM) metrics, such as Planned Value (PV) and Earned Value (EV), to calculate performance indicators including the Schedule Performance Index (SPI). This enables quantitative analysis of deviations between planned and actual progress.

- Action phase: Based on the performance analysis, corrective measures and alternative plans are proposed, feeding into the next planning cycle to minimize deviations and improve alignment between plan and execution.

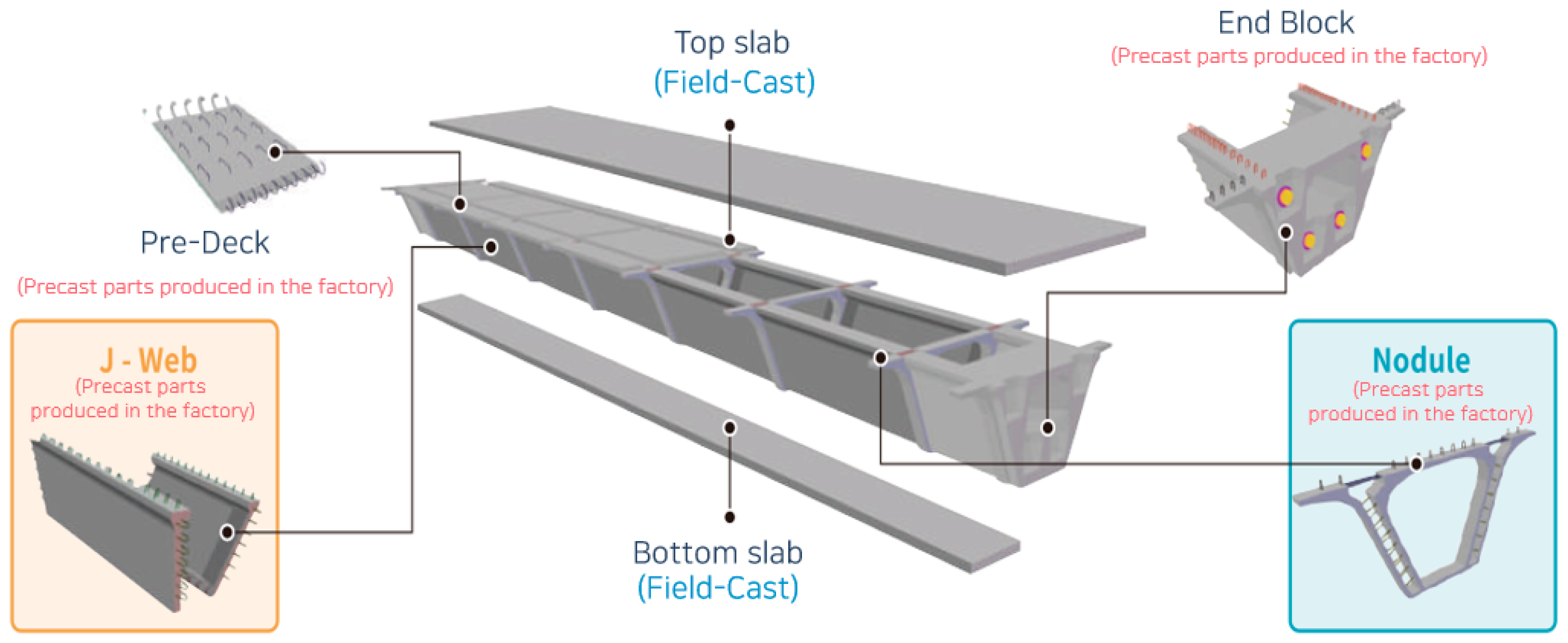

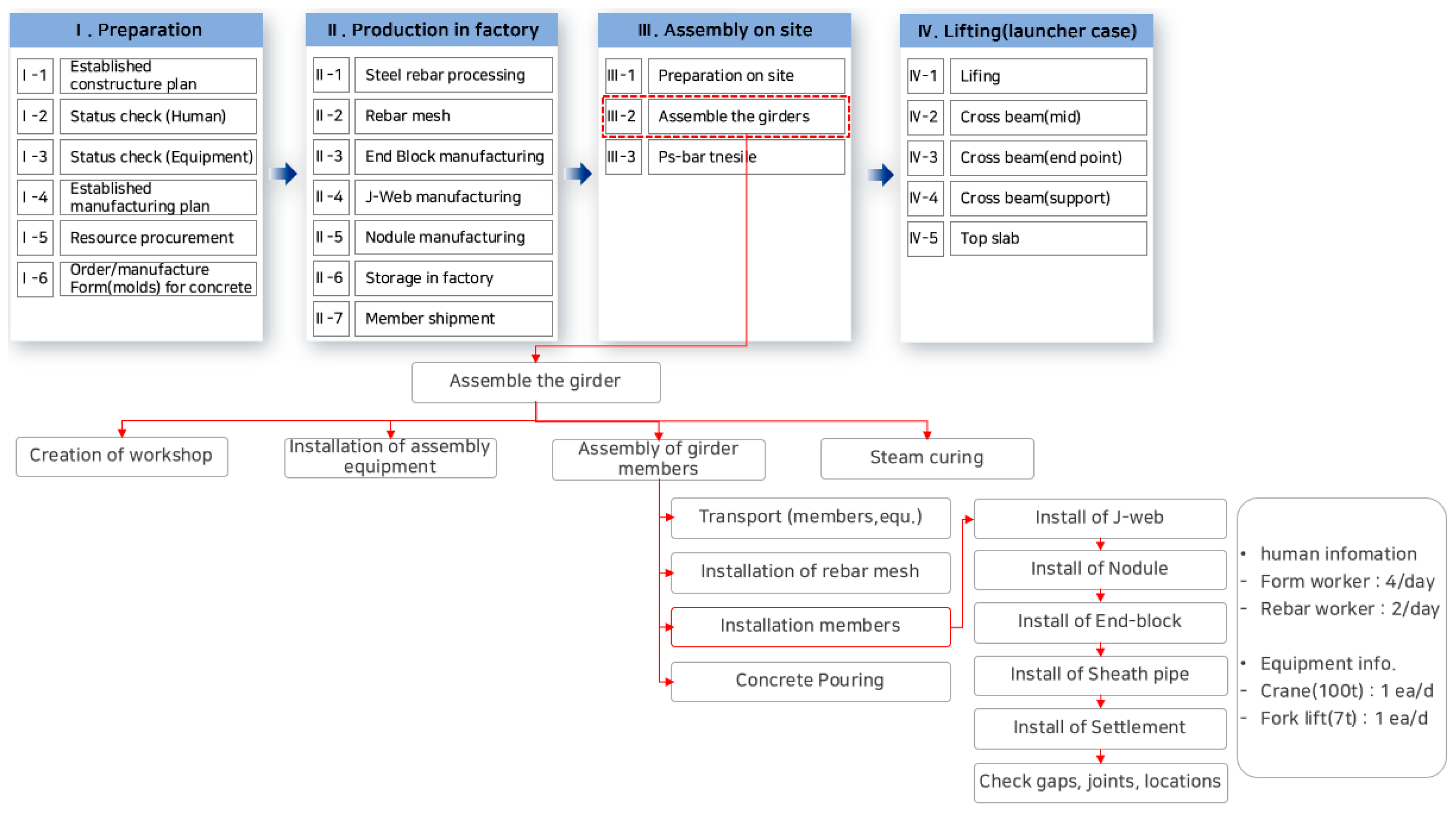

2.2. Standardizing Key Construction Processes and Data

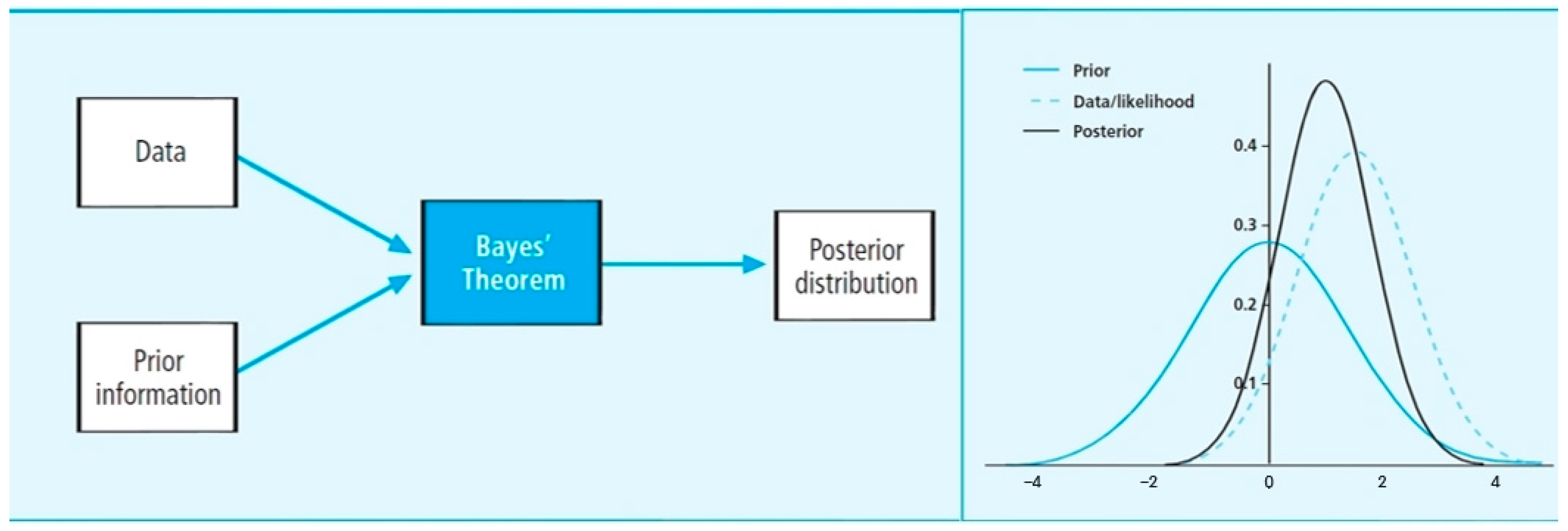

2.3. Bayesian Regression-Based Estimation of Standard Time (ST)

- : average task duration for project

- : explanatory variables (e.g., number of girders, crew size, and other resources);

- : intercept term, representing the baseline task duration when all explanatory variables are zero;

- : regression coefficients estimated via Bayesian inference.

- : normally distributed error term with variance

2.4. Time–Cost Trade-Off (TCTO) Algorithm with Bayesian ST Integration

2.5. Object-Based Logging and SPI Performance Analysis

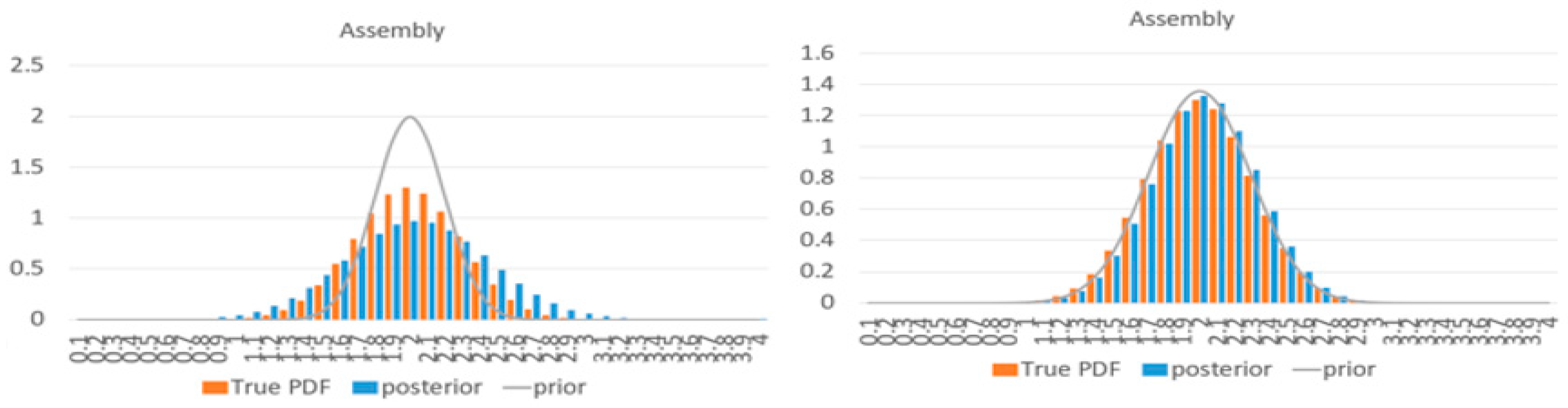

2.6. Bayesian Updating and Self-Correcting Mechanism

3. Application and Validation of the Proposed Framework

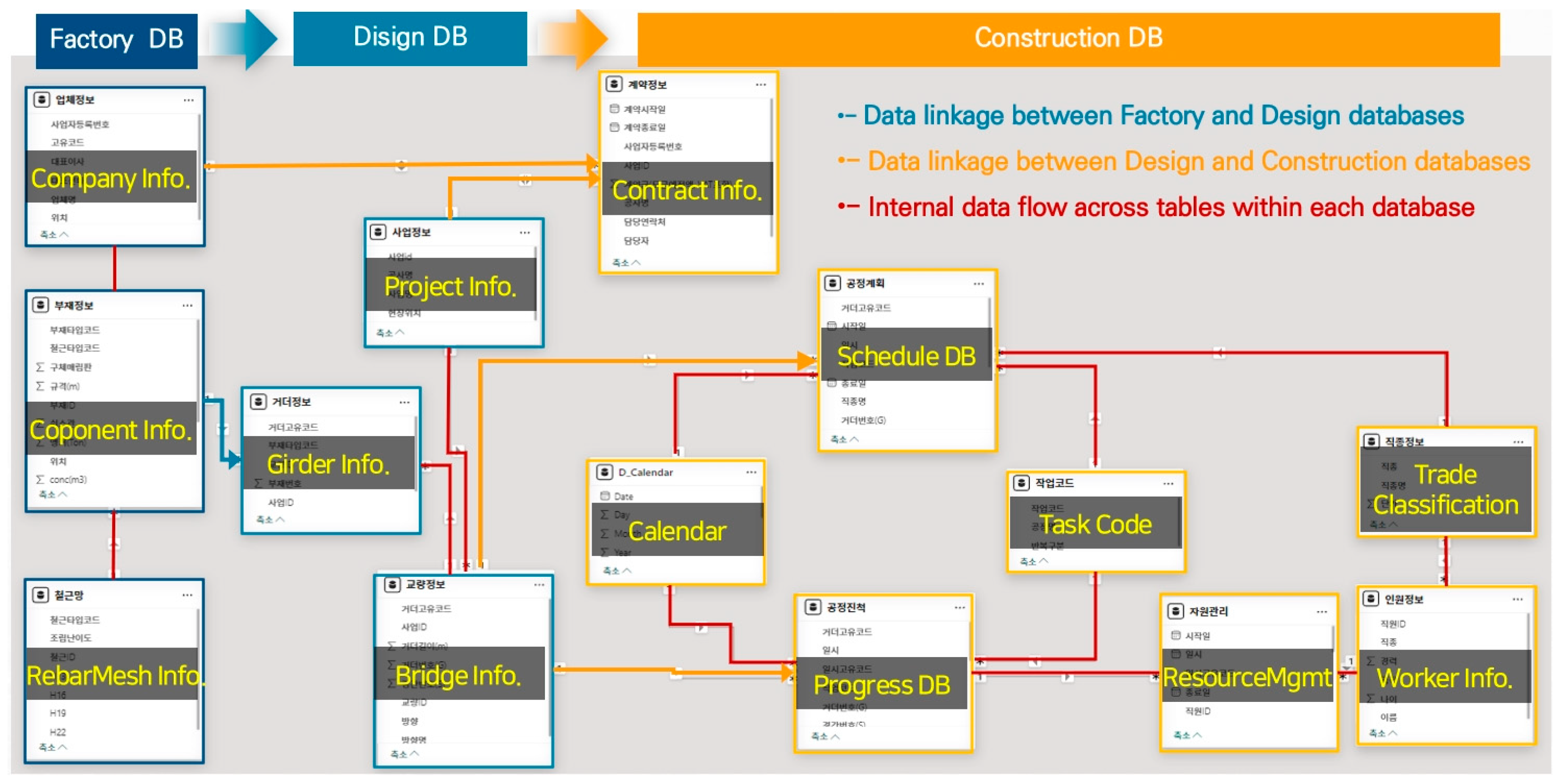

3.1. Construction Object-Oriented Information Classification System

3.2. Training and Verification Data for Bayesian Regression

3.3. Information Classification System of Construction Objects

- : Planned schedule duration;

- : Actual schedule duration;

- : Planned resource usage;

- : Actual resource usage.

3.4. Information Classification System of Activities

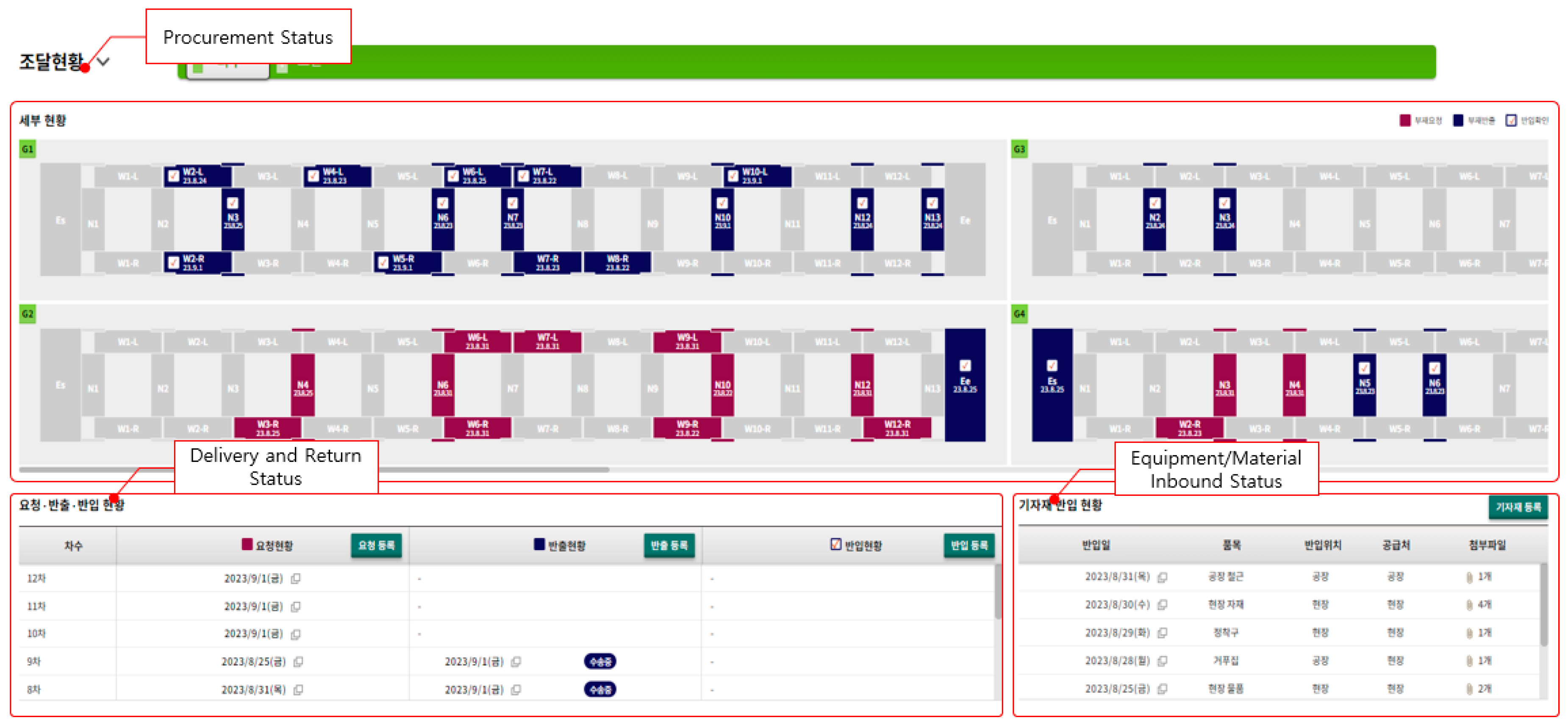

3.5. Applications of the Smart Delivery System for Prefabricated Bridge Projects

4. Results and Discussion

4.1. Bayesian Updating of Standard Time (ST)

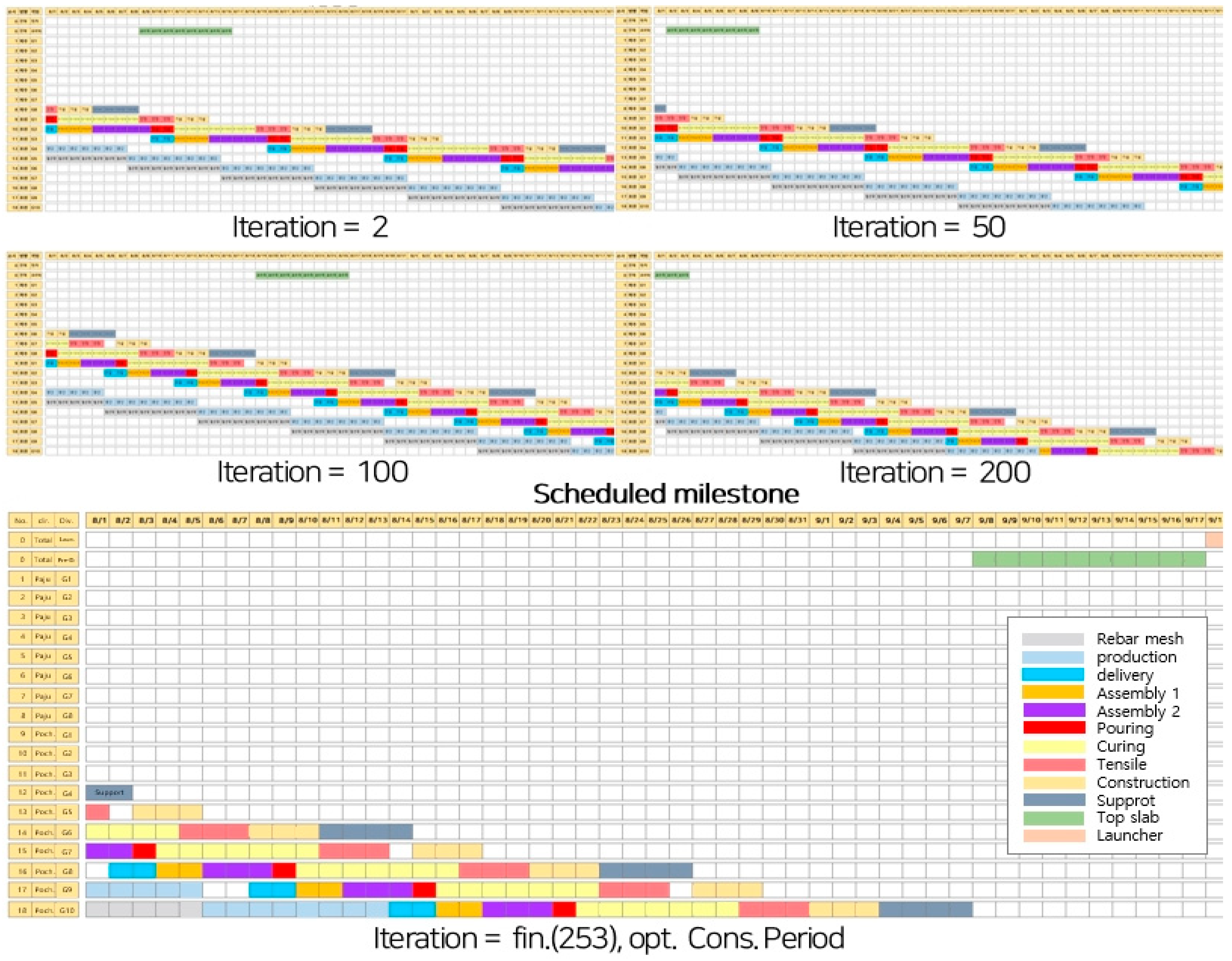

4.2. Comparative Verification of TCTO Optimization

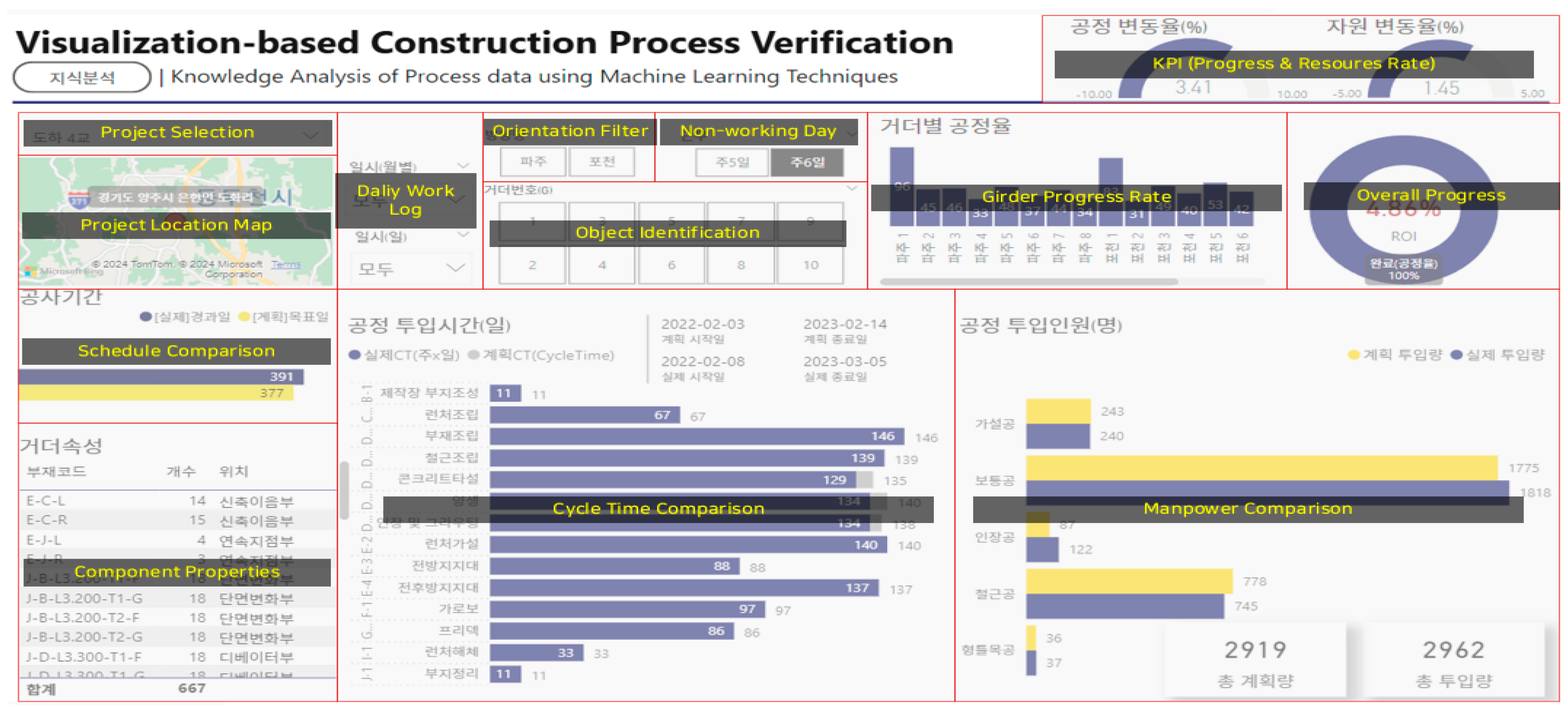

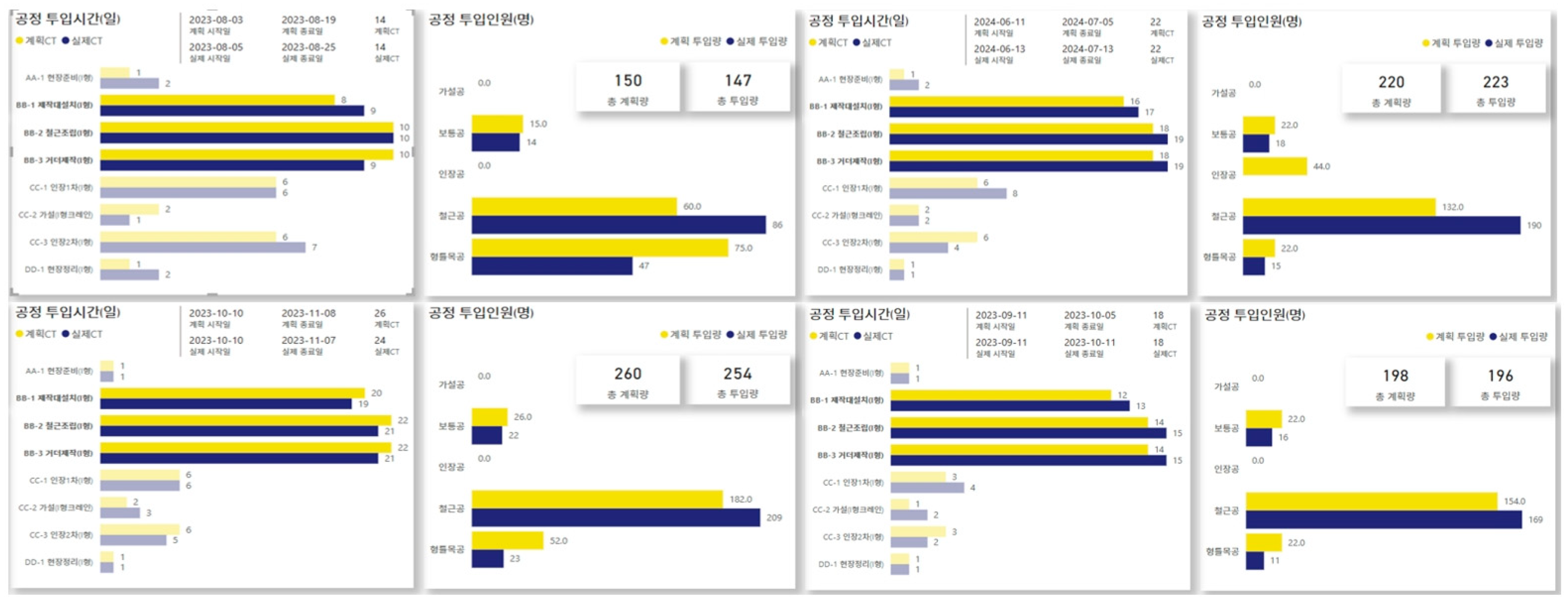

4.3. Case Study: Doha No.4 Bridge Results

4.4. Performance Analysis Using SPI

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ST | Standard Time |

| TCTO | Time–Cost Trade–Off |

| OSC | Off-Site Construction |

| EVMS | Earned Value Management System |

| SPI | Schedule Performance Index |

| PV | Planned Value |

| EV | Earned Value |

| AC | Actual Cost |

References

- McKinsey Global Institute. Reinventing Construction: A Route to Higher Productivity; McKinsey & Company: New York, NY, USA, 2017. [Google Scholar]

- Chan, D.W.M.; Kumaraswamy, M.M. A Comparative Study of Causes of Time Overruns in Hong Kong Construction Projects. Int. J. Proj. Manag. 1997, 15, 55–63. [Google Scholar] [CrossRef]

- Flyvbjerg, B.; Holm, M.S.; Buhl, S. Underestimating Costs in Public Works Projects: Error or Lie? J. Am. Plan. Assoc. 2007, 68, 279–295. [Google Scholar] [CrossRef]

- Love, P.E.D.; Edwards, D.J.; Irani, Z.; Walker, D.H.T. Project Pathogen: The Anatomy of Project Cost Overruns. IEEE Trans. Eng. Manag. 2009, 56, 548–561. [Google Scholar] [CrossRef]

- Hwang, B.G.; Ng, W.J. Project Management Knowledge and Skills for Green Construction: Overcoming Challenges. Int. J. Proj. Manag. 2013, 31, 272–284. [Google Scholar] [CrossRef]

- Cynthia, O.U. Implementation of Project Evaluation and Review Technique (PERT) and Critical Path Method (CPM): A Comparative Study. Int. J. Ind. Oper. Res. 2020, 3, 4. [Google Scholar] [CrossRef]

- Nasirian, A.; Arashpour, M.; Assasi, B. Multiskilled Human Resource Problem in Off-Site Construction. In Proceedings of the International Symposium on Automation and Robotics in Construction, Berlin, Germany, 20–25 July 2018; pp. 1017–1021. [Google Scholar] [CrossRef]

- Barkokebas, B.; Brown, R.; Altaf, M.S.; Hamzeh, F. Evaluation of Multi-Skilled Labor in an Off-Site Construction Facility using Computer Simulation Hybrid Approach. In Proceedings of the 37th CIB W78 Information Technology for Construction Conference, Sao Paulo, Brazil, 2–4 June 2020. [Google Scholar]

- Durdyev, S.; Ismail, S. Offsite Manufacturing in the Construction Industry for Productivity Improvement. Eng. Manag. J. 2019, 31, 62–76. [Google Scholar] [CrossRef]

- Yan, X.; Zhang, H.; Zhang, W. Intelligent Monitoring and Evaluation for the Prefabricated Construction Schedule. Comput. Aided Civ. Infrastruct. Eng. 2023, 38, 391–407. [Google Scholar] [CrossRef]

- Li, Y.; Wu, J.; Hao, Y.; Gao, Y.; Chai, R.; Zhang, B. Process Scheduling for Prefabricated Construction Based on Multi-Objective Optimization Algorithm. Autom. Constr. 2024, 168, 105809. [Google Scholar] [CrossRef]

- Lyons, J.S. Critical Success Factors for Prefabricated Construction Firms. Master’s Thesis, Oregon State University, Corvallis, OR, USA, 2024. [Google Scholar]

- Bortolini, R.; Formoso, C.T.; Viana, D.D. Site Logistics Planning and Control for Engineer-to-Order Prefabricated Building Systems Using BIM 4D Modeling. Autom. Constr. 2019, 98, 248–264. [Google Scholar] [CrossRef]

- Wang, Q.; Shen, C.; Guo, Z.; Zhu, K.; Zhang, J.; Huang, M. Research on the Barriers and Strategies to Promote Prefabricated Buildings in China. Buildings 2023, 13, 1200. [Google Scholar] [CrossRef]

- Wu, H.; Qian, Q.K.; Straub, A.; Visscher, H. Exploring Transaction Costs in the Prefabricated Housing Supply Chain in China. J. Clean. Prod. 2019, 226, 550–563. [Google Scholar] [CrossRef]

- Luo, L.; Jin, X.; Shen, G.Q.; Wang, Y.; Liang, X. Supply Chain Management for Prefabricated Building Projects in Hong Kong. J. Manag. Eng. 2020, 36, 05020007. [Google Scholar] [CrossRef]

- Li, C.Z.; Hong, J.; Xue, F.; Shen, G.Q.; Xu, X.; Luo, L. SWOT Analysis and Internet of Things-Enabled Platform for Prefabrication Housing Production in Hong Kong. Habitat Int. 2016, 57, 187–196. [Google Scholar] [CrossRef]

- Cheng, S.; Zhou, X.; Zhang, Y.; Duan, M.; Gao, J. Study on Resilience Factors and Enhancement Strategies in Prefabricated Building Supply Chains. Buildings 2024, 14, 195. [Google Scholar] [CrossRef]

- Leach, L.P. Critical Chain Project Management; Artech House: Boston, MA, USA, 2005. [Google Scholar]

- Williams, T. Assessing Extension of Time Delays on Major Projects. Int. J. Proj. Manag. 2003, 21, 19–26. [Google Scholar] [CrossRef]

- Shin, N.R.; Kim, Y.S.; Han, S.W.; Yeom, D.J. Development of a Decision Support System for Production Scheduling of Precast Concrete Members. J. Archit. Inst. Korea Struct. Constr. 2016, 32, 31–40. [Google Scholar] [CrossRef]

- Koo, B.; Fischer, M. Feasibility Study of 4D CAD in Commercial Construction. J. Constr. Eng. Manag. 2000, 126, 251–260. [Google Scholar] [CrossRef]

- Feng, C.W.; Liu, L.; Burns, S.A. Stochastic Construction Time-Cost Trade-Off Analysis. J. Comput. Civ. Eng. 1997, 11, 45–52. [Google Scholar] [CrossRef]

- De, P.; Dunne, E.J.; Ghosh, J.B. Complexity of the Discrete Time–Cost Tradeoff Problem for Project Networks. Oper. Res. 1997, 45, 302–306. [Google Scholar] [CrossRef]

- Sobieraj, J.; Metelski, D. Project Risk in Construction Schedules: Monte Carlo & Time-at-Risk Approach. Appl. Sci. 2022, 12, 1044. [Google Scholar] [CrossRef]

- Ezeldin, A.S.; Soliman, A. Hybrid Time–Cost Optimization of Nonserial Repetitive Construction Projects. J. Constr. Eng. Manag. 2009, 135, 42–55. [Google Scholar] [CrossRef]

- Lipke, W. Schedule Is Different. Meas. News 2003, 31, 31–34. [Google Scholar]

- Vanhoucke, M. Using Activity Sensitivity and Network Topology Information to Monitor Project Time Performance. Omega 2010, 38, 359–370. [Google Scholar] [CrossRef]

- Narbaev, T.; De Marco, A. Combination of Growth Model and Earned Schedule to Forecast Project Cost at Completion. J. Constr. Eng. Manag. 2014, 140, 04013039. [Google Scholar] [CrossRef]

- Namazian, A.; Haji Yakhchali, S.; Yousefi, V.; Tamošaitienė, J. Combining Monte Carlo Simulation and Bayesian Networks Methods for Assessing Completion Time of Projects under Risk. Int. J. Environ. Res. Public Health 2019, 16, 5024. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lu, Q.; Han, D. A Bayesian-Driven Monte Carlo Approach for Managing Construction Schedule Risks of Infrastructures under Uncertainty. Expert Syst. Appl. 2023, 212, 118810. [Google Scholar] [CrossRef]

- Wu, W.; Lu, Z.; Sun, Y.; Ang, M.H., Jr. Dynamic Task Assignment of Multiple Heterogeneous Unmanned Aerial Vehicles Based on Consensus with Uncertainties. IEEE Aerosp. Electron. Syst. Mag. 2024, 40, 48–60. [Google Scholar] [CrossRef]

- Szwarcfiter, C.; Herer, Y.T.; Shtub, A. Balancing Project Schedule, Cost, and Value under Uncertainty: A Reinforcement Learning Approach. Algorithms 2023, 16, 395. [Google Scholar] [CrossRef]

- Kostrzewa-Demczuk, P. Construction Schedule versus Various Constraints and Risks. Appl. Sci. 2024, 14, 196. [Google Scholar] [CrossRef]

- Lu, Y.; Liu, C.; Wang, K.I.-K.; Huang, H.; Xu, X. Digital Twin-Driven Smart Manufacturing: Connotation, Reference Model, Applications and Research Issues. Robot. Comput. Integr. Manuf. 2020, 61, 101837. [Google Scholar] [CrossRef]

- Wang, Y.; Liao, S.; Gong, Z.; Deng, F.; Yin, S. Enhancing Construction Management Digital Twins through Process Mining of Progress Logs. Sustainability 2024, 16, 10064. [Google Scholar] [CrossRef]

- Hwang, B.G.; Shan, M.; Looi, K.Y. Knowledge-Based Decision Support System for Prefabricated Volumetric Construction. Autom. Constr. 2018, 94, 246–254. [Google Scholar] [CrossRef]

- Kim, D.-Y.; Chung, T.; Kim, R.-G. Development of Time-Cost Trade-Off Algorithm for JIT System of Prefabricated Girder Bridges (Nodular Girder). J. Korean Soc. Civ. Eng. Constr. Manag. 2023, 24, 12–19. [Google Scholar]

- Jordan, M.; Kleinberg, M.; Schӧlkopf, B. Information Science and Statistics: Its benefits and implementation. In Bayesian Probabilities; Springer Science: New York, NY, USA, 2006; pp. 24–28. [Google Scholar]

- Nam, J.Y.; Kim, M.J. A study on the Development of BIM Property Classification System in Road and River Field. J. Korea Acad. Ind. Coop. Soc. 2019, 20, 773–784. [Google Scholar]

- Xie, L.; Chen, Y.; Chang, R. Scheduling Optimization of Prefabricated Construction Projects by Genetic Algorithm. Appl. Sci. 2021, 11, 5531. [Google Scholar] [CrossRef]

| No | Project | Contract Date | Girder | Resources | Period |

|---|---|---|---|---|---|

| 1 | Onjikcheon | 2022 | 24 | 496 | 33 |

| 2 | Guyongcheon | 2022 | 16 | 276 | 21 |

| 3 | KTX No. 1 | 2023 | 18 | 233 | 29 |

| 4 | KTX No. 2 | 2023 | 15 | 148 | 20 |

| 5 | Jeonhwa No. 1 | 2023 | 12 | 184 | 20 |

| 6 | Jeonhwa No. 2 | 2023 | 12 | 144 | 23 |

| No | Project | Contract Date | Girder | Resources | Period |

|---|---|---|---|---|---|

| 1 | Jangdong | 2023 | 8 | 147 | 14 |

| 2 | Jeonggok | 2023 | 16 | 223 | 22 |

| 3 | Jukjang | 2023 | 20 | 254 | 24 |

| 4 | Ip-am | 2023 | 12 | 196 | 18 |

| No | Project | Duration Plan | Duration Actual | Resource Plan | Resource Actual | Duration Deviation | Resource Deviation |

|---|---|---|---|---|---|---|---|

| 1 | Jangdong | 14 | 14 | 150 | 147 | 0.00 | −2.04 |

| 2 | Jeonggok | 22 | 22 | 220 | 223 | 0.00 | 1.35 |

| 3 | Jukjang | 26 | 24 | 260 | 254 | 8.33 | −2.36 |

| 4 | Ip-am | 18 | 18 | 198 | 196 | 0.00 | −1.02 |

| No | Activities | Duration Plan | Duration Actual | Resource Plan | Resource Actual | Duration Deviation | Resource Deviation |

|---|---|---|---|---|---|---|---|

| 1 | Site Preparation | 68 | 70 | 562 | 542 | 2.94 | 3.56 |

| 2 | Assembly | 157 | 156 | 1434 | 1414 | 0.64 | 1.39 |

| 3 | Installation | 144 | 146 | 78 | 349 | 1.39 | 347.44 |

| 4 | Cross Beam | 106 | 104 | 570 | 487 | 1.89 | 14.56 |

| 5 | Site Demobilization | 44 | 41 | 275 | 170 | 6.82 | 38.18 |

| 6 | Total Duration | 377 | 391 | 2919 | 2962 | 3.71 | 1.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, D.Y.; Kim, R.G.; Kwak, H.S. A Closed-Loop Scheduling Framework for Prefabricated Bridge Girders: Bayesian Regression and TCTO-Based Optimization. Buildings 2025, 15, 4168. https://doi.org/10.3390/buildings15224168

Kim DY, Kim RG, Kwak HS. A Closed-Loop Scheduling Framework for Prefabricated Bridge Girders: Bayesian Regression and TCTO-Based Optimization. Buildings. 2025; 15(22):4168. https://doi.org/10.3390/buildings15224168

Chicago/Turabian StyleKim, Dae Young, Ryang Gyun Kim, and Hyun Seok Kwak. 2025. "A Closed-Loop Scheduling Framework for Prefabricated Bridge Girders: Bayesian Regression and TCTO-Based Optimization" Buildings 15, no. 22: 4168. https://doi.org/10.3390/buildings15224168

APA StyleKim, D. Y., Kim, R. G., & Kwak, H. S. (2025). A Closed-Loop Scheduling Framework for Prefabricated Bridge Girders: Bayesian Regression and TCTO-Based Optimization. Buildings, 15(22), 4168. https://doi.org/10.3390/buildings15224168