Evaluation of the Mechanical and Durability Properties of Marble Waste-Modified Rigid Pavement Material

Abstract

1. Introduction

2. Materials and Methods

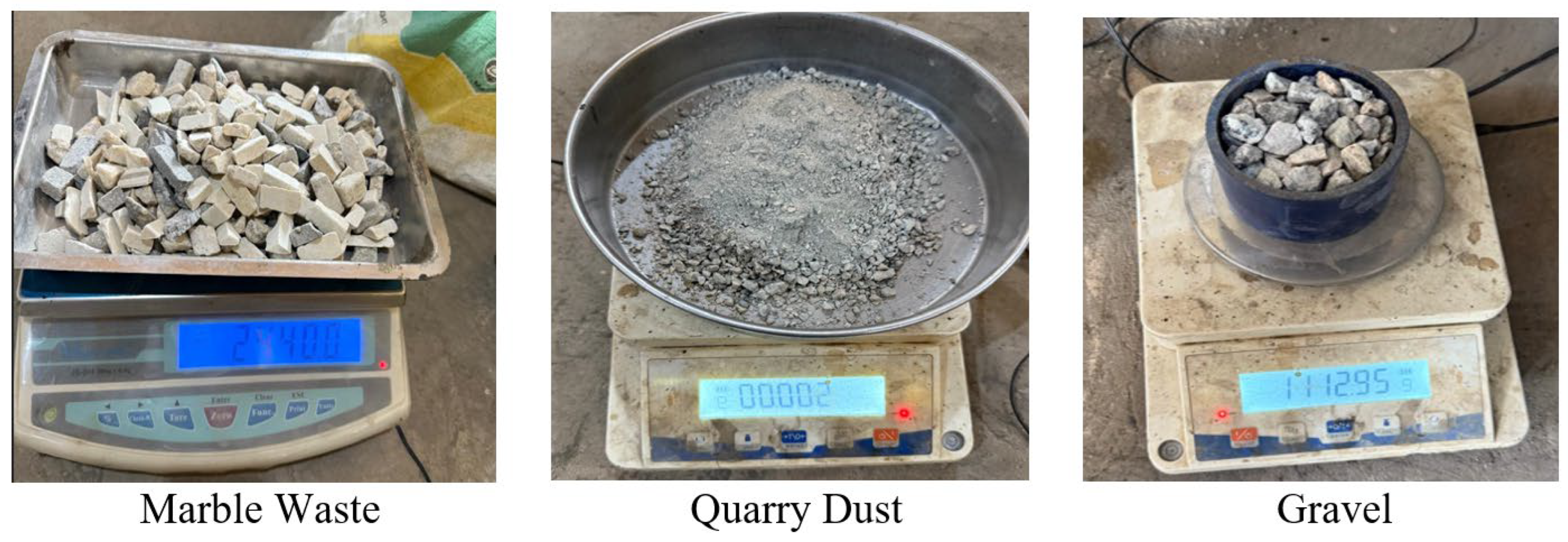

2.1. Research Materials

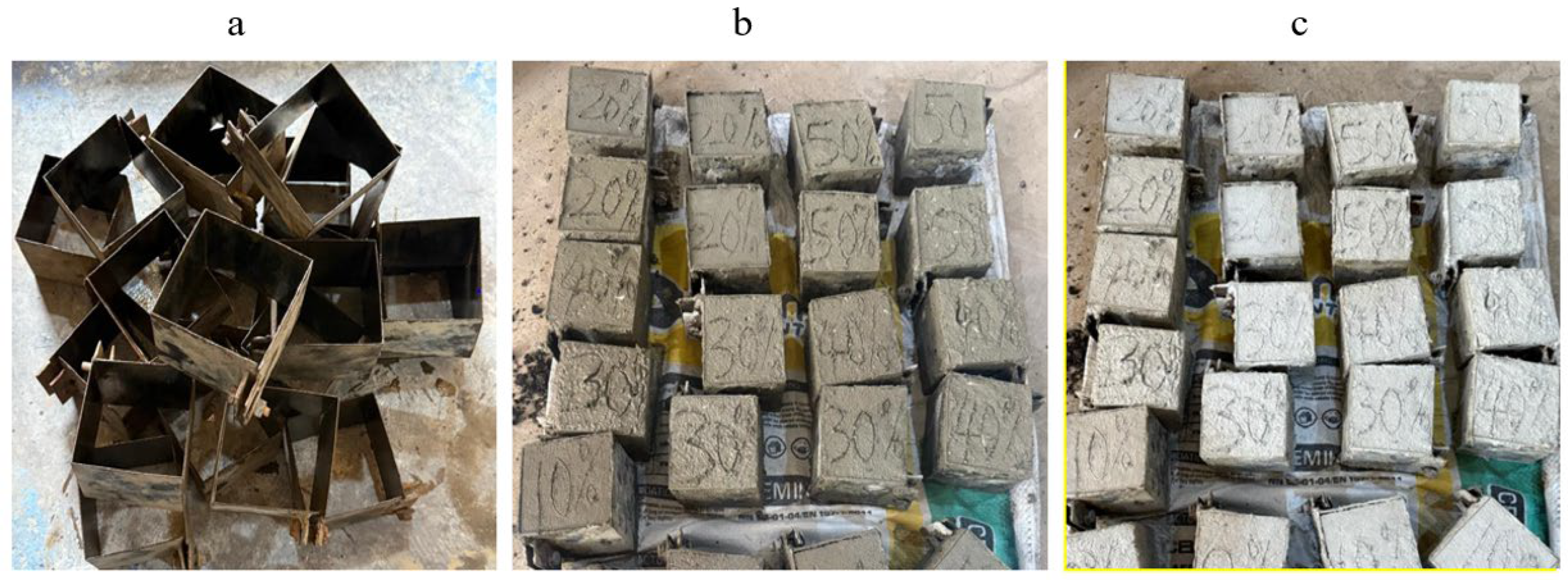

2.2. Research Design

2.3. Preliminary Analysis

2.4. Mechanical and Durability Tests

3. Results

3.1. Preliminary Test Results

3.1.1. Coarse Aggregate (Gravel) Impact Value Test Results

3.1.2. Coarse Aggregate (Marble Waste) Impact Test Results

3.1.3. Specific Gravity for Coarse Aggregates Test Results

3.1.4. Abrasion Test Results

3.1.5. Sieve Analysis Test Results

3.1.6. Slump Test Results

3.2. Mechanical Test Results

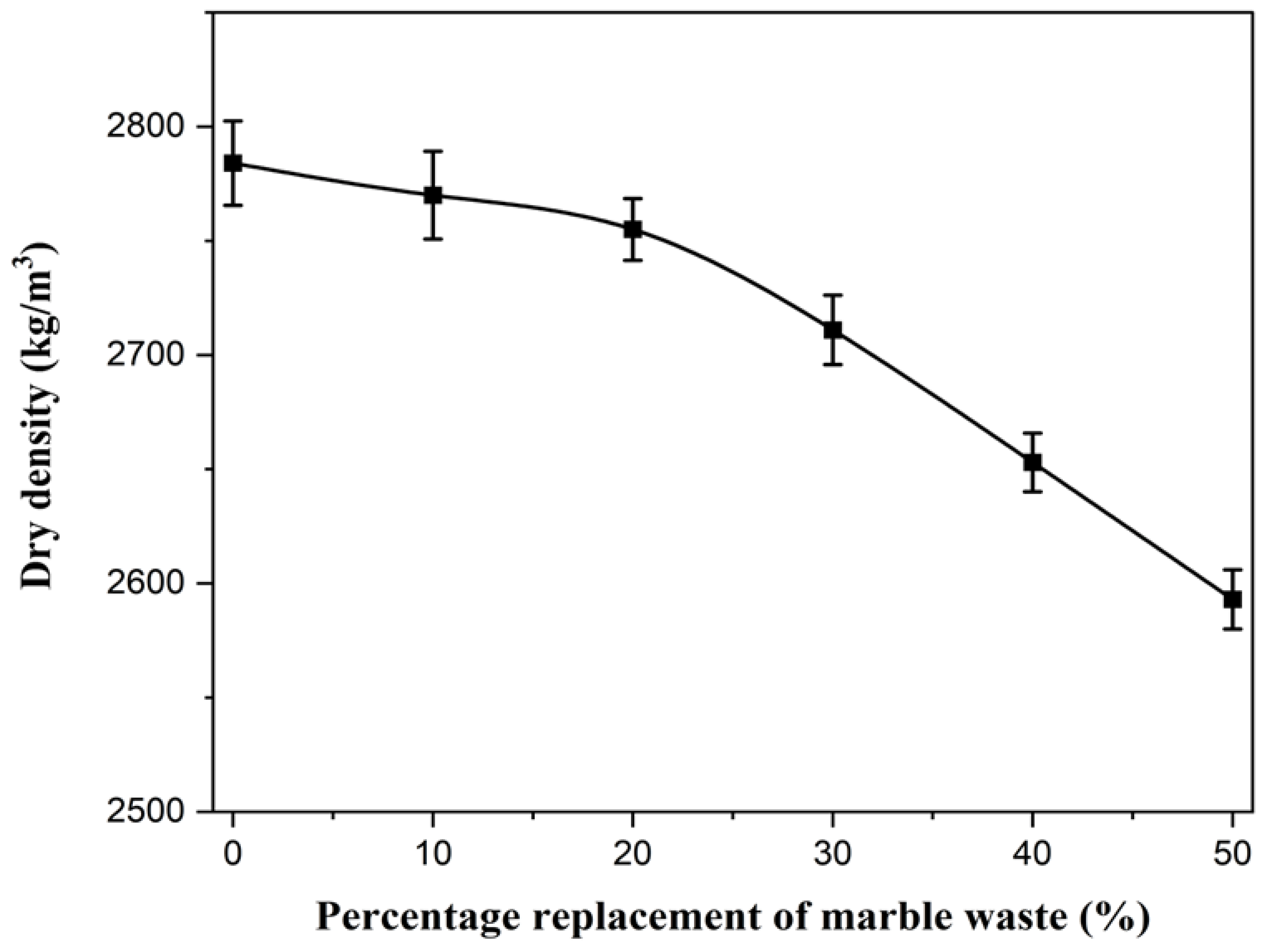

3.2.1. Dry Density Test Results

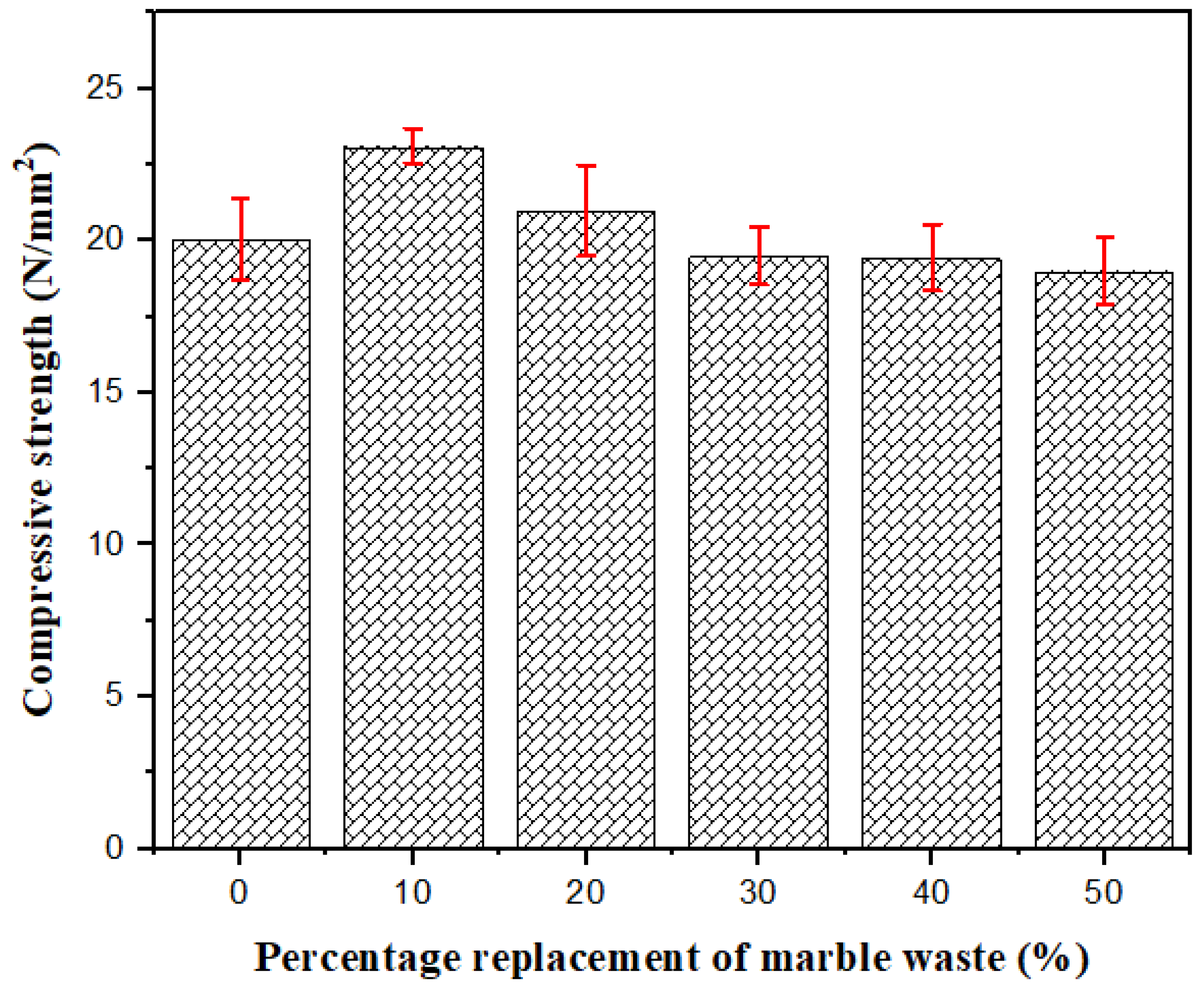

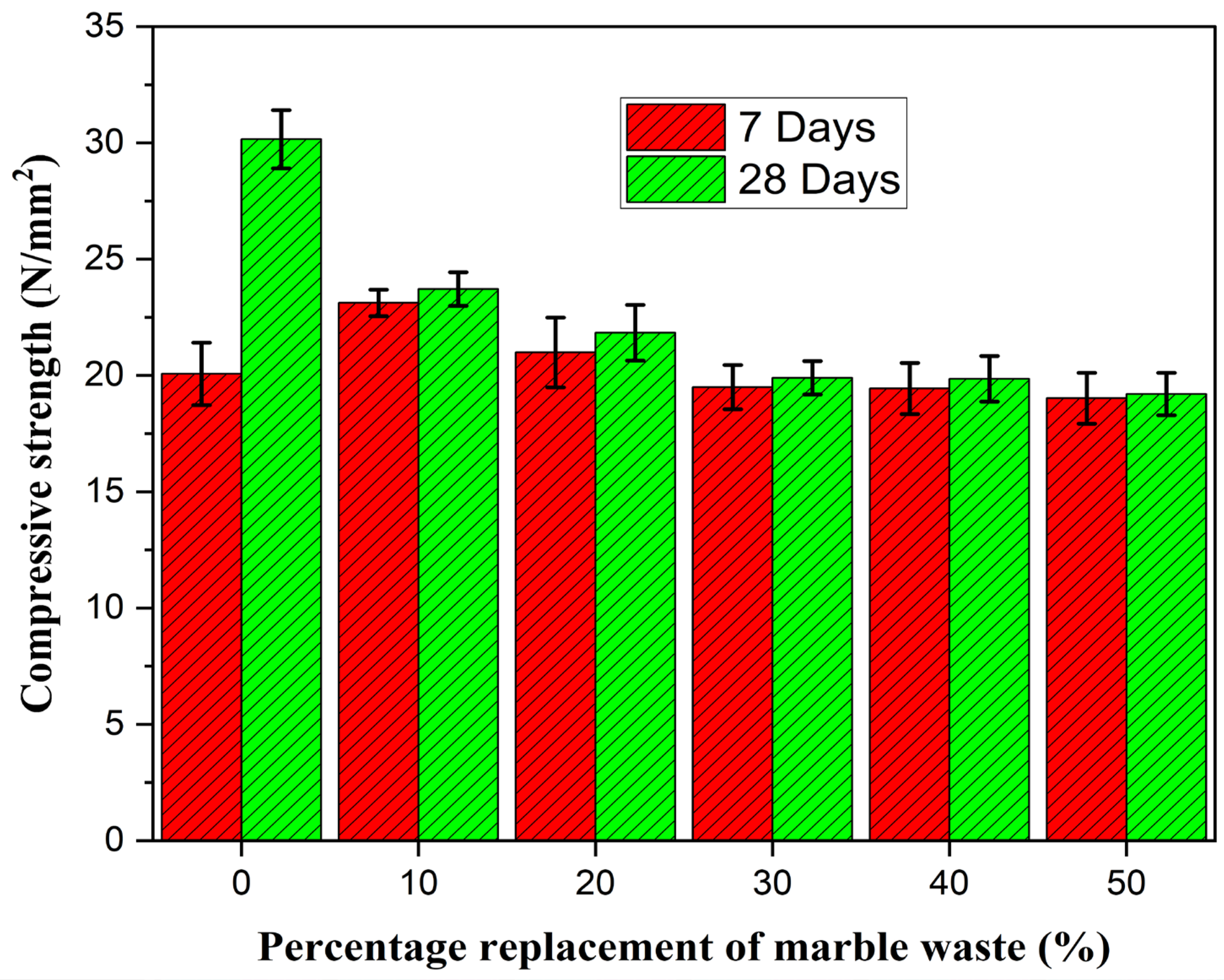

3.2.2. Compressive Test Results

3.3. Durability Test Results

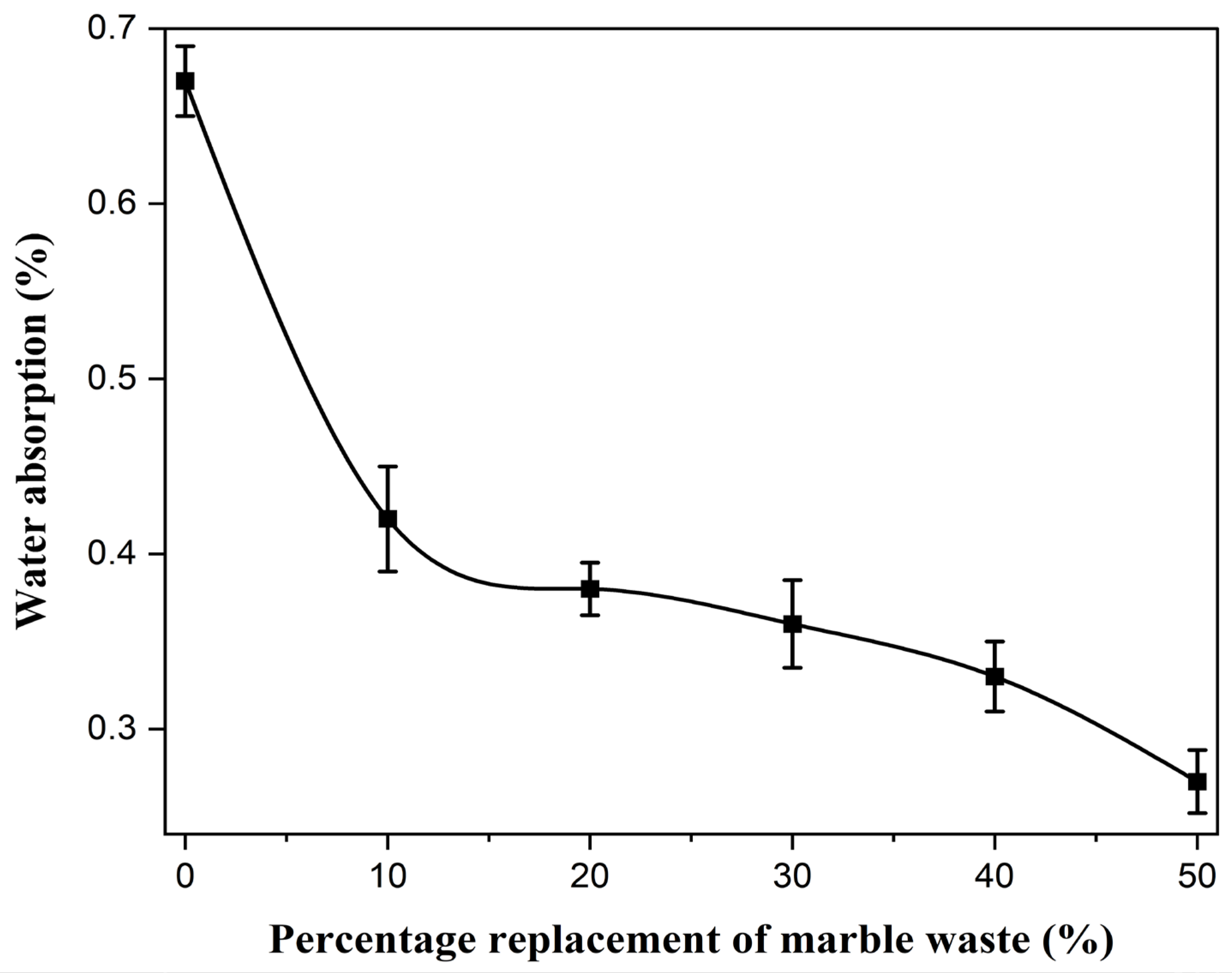

Water Absorption Test

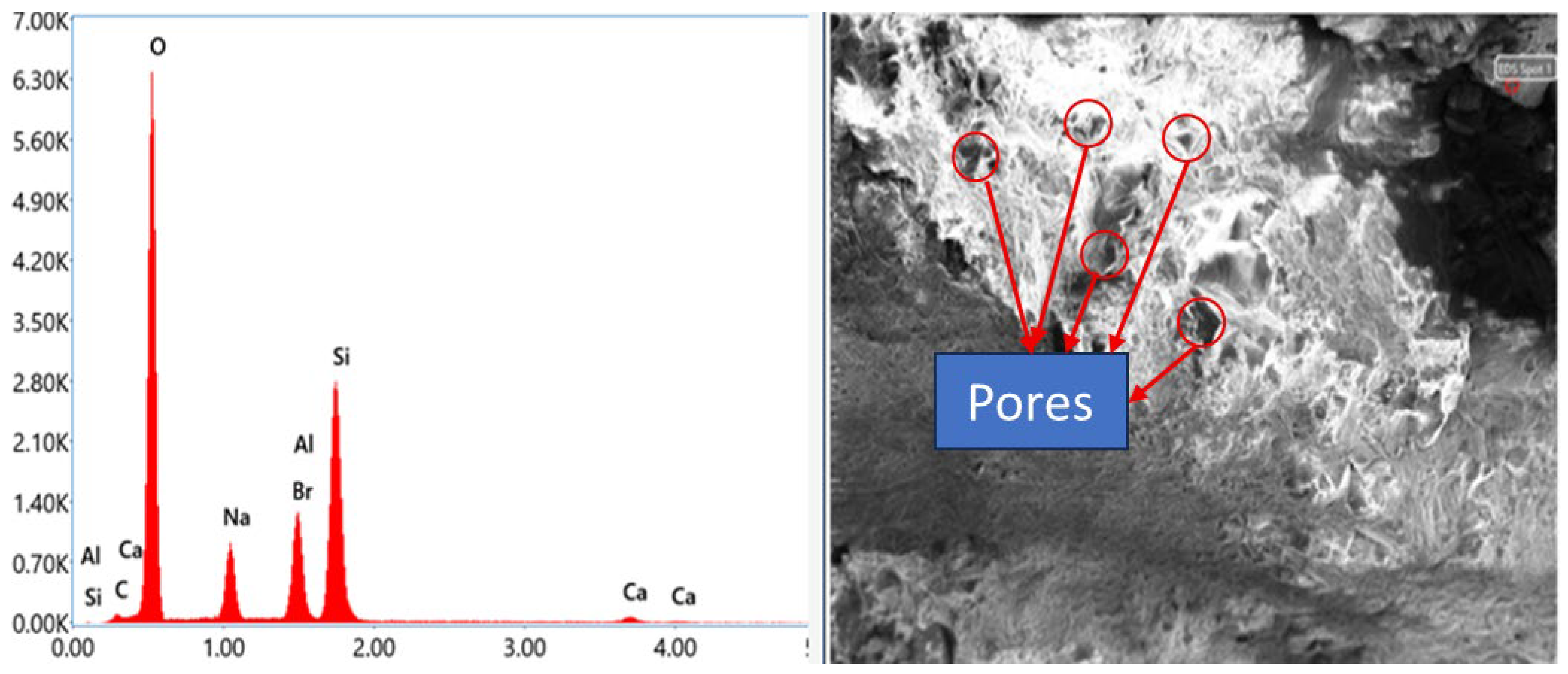

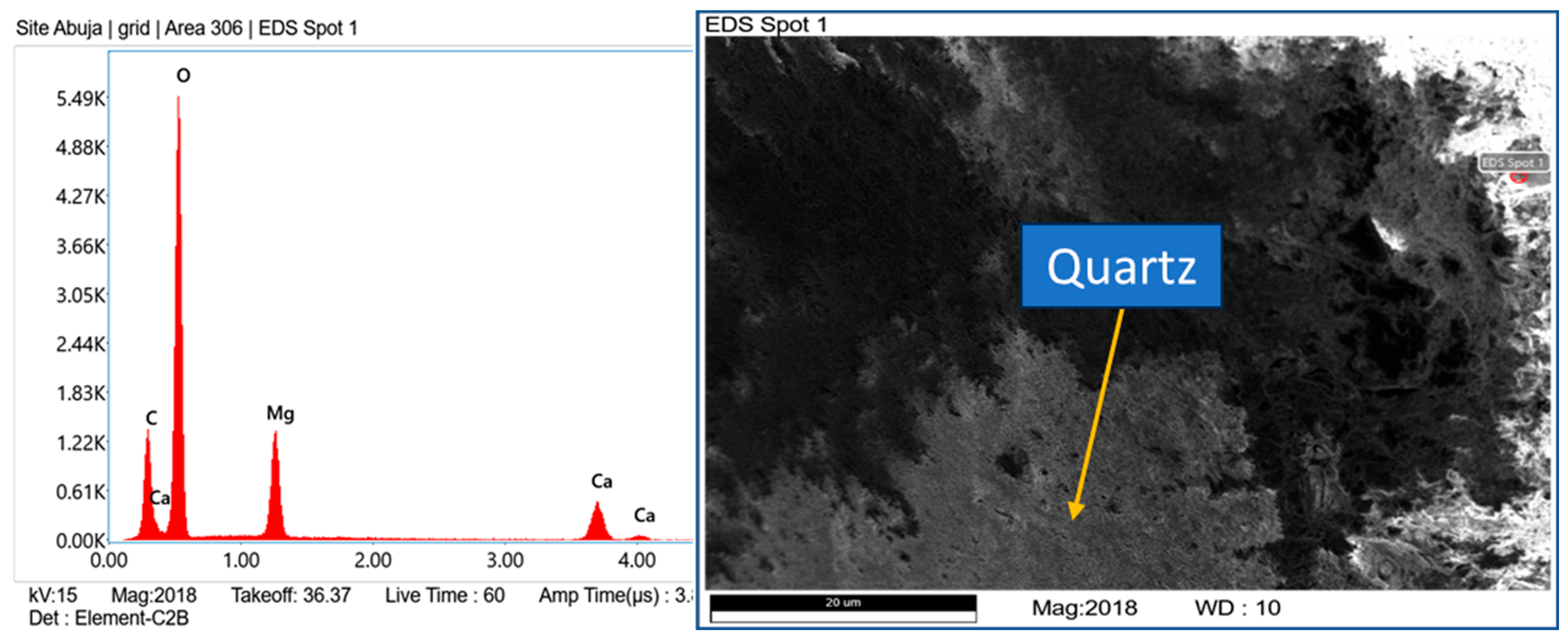

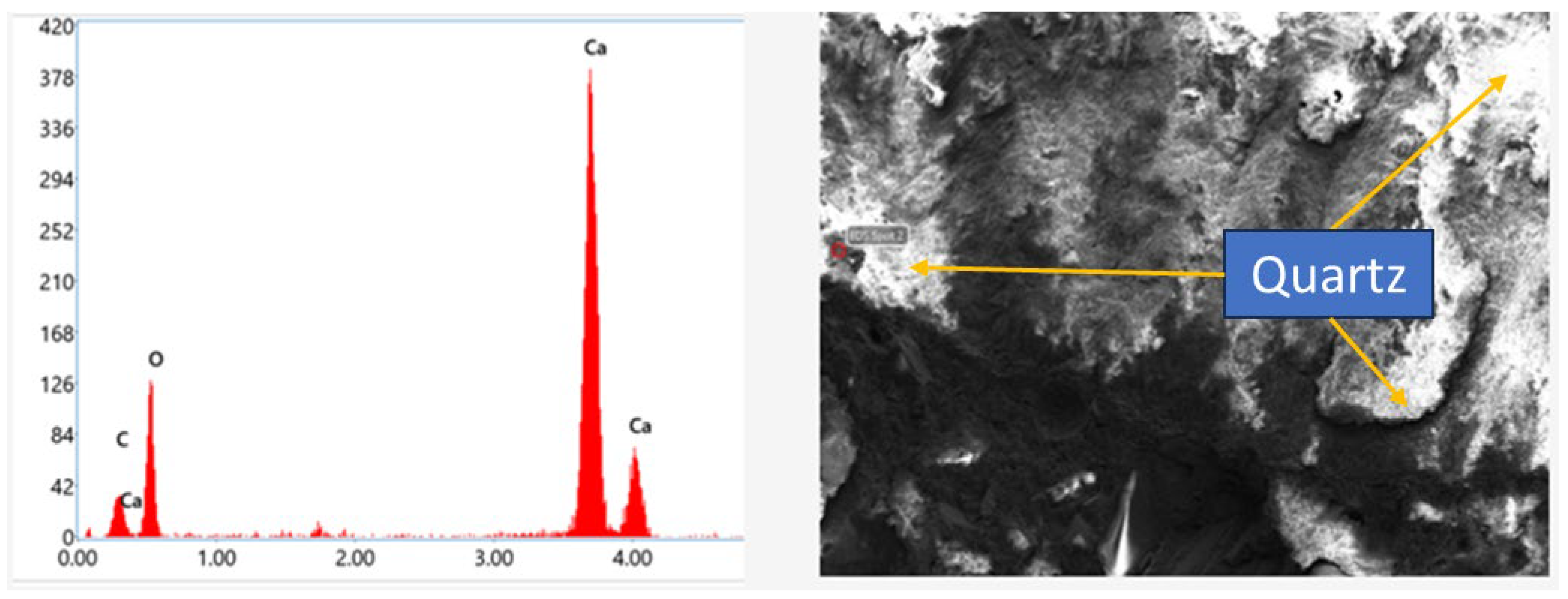

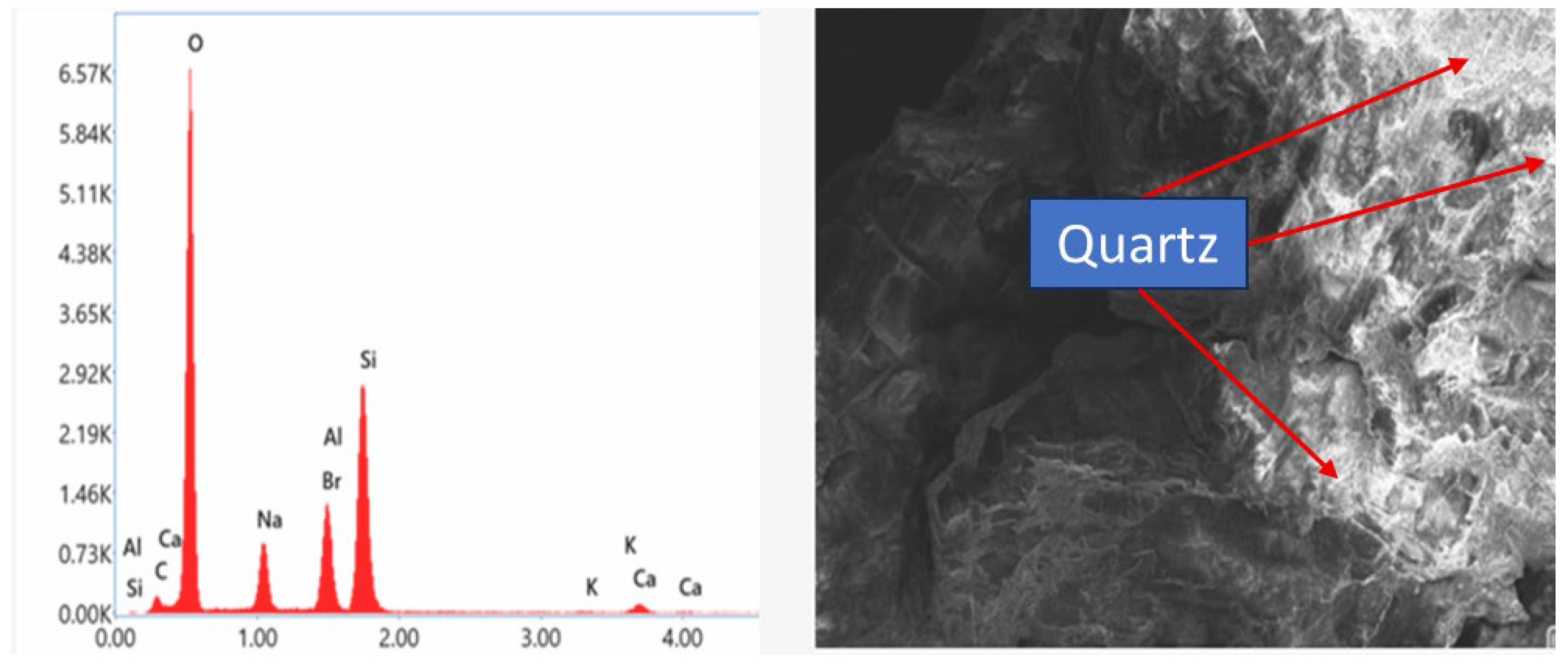

3.4. Scanning Electron Microscopy/Energy Dispersive X-Ray Spectroscopy Results

4. Discussion

5. Conclusions

- i.

- The specific gravity of gravel (2.66) and marble waste (2.65) is similar, making marble waste a promising replacement for gravel.

- ii.

- The impact value of 24.48% and 11.92% obtained for gravel and marble waste, respectively, falls within acceptable limits. The impact value results indicate that marble waste has higher resistance to impact compared to the gravel, with an impact value of 24.48%. This implies that producing rigid pavement materials with marble waste will result in higher durability of the constructed road pavement.

- iii.

- As the percentage of marble waste increases, the water absorption reduces. Conventional concrete samples have higher water absorption compared to the concrete samples produced with marble waste. This implies that rigid pavement produced using marble waste will be more durable.

- iv.

- There is an increase in the 7-day compressive strength on the addition of 10% marble waste, but the strength decreases on further addition of marble waste due to decreased workability.

- v.

- Early strength gain was observed for the sample with 10% replacement at 7 days due to the ability of the marble waste to serve as filler in the concrete mix.

- vi.

- As the percentage replacement of marble waste increases, the 28-day compressive strength decreases. The observed decrease in the compressive strength is due to the reduced workability of the concrete resulting from the smoothness of the marble waste aggregates. The smoothness of the marble waste aggregates results in decreased cohesion (binding) of the concrete mix, leading to a reduction in compressive strength.

- vii.

- Higher calcium content observed in the EDS of MW10 is responsible for the cementation/hydration process. It supports the higher compressive strength result obtained for the same sample at 28 days of curing.

- viii.

- Comparison of the 7-day and 28-day compressive strength indicates that replacing the gravel with marble waste resulted in early strength gain, making them suitable for use in conditions that require early strength gain.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Thakur, A.K.; Pappu, A.; Thakur, V.K. Resource Efficiency Impact on Marble Waste Recycling towards Sustainable Green Construction Materials. Curr. Opin. Green Sustain. Chem. 2018, 13, 91–101. [Google Scholar] [CrossRef]

- Mehta, D.; Mondal, P.; George, S. Utilization of Marble Waste Powder as a Novel Adsorbent for Removal of Fluoride Ions from Aqueous Solution. J. Environ. Chem. Eng. 2016, 4, 932–942. [Google Scholar] [CrossRef]

- Singh, M.; Choudhary, K.; Srivastava, A.; Singh Sangwan, K.; Bhunia, D. A Study on Environmental and Economic Impacts of Using Waste Marble Powder in Concrete. J. Build. Eng. 2017, 13, 87–95. [Google Scholar] [CrossRef]

- Abdel-Shafy, H.I.; Mansour, M.S.M. Solid Waste Issue: Sources, Composition, Disposal, Recycling, and Valorization. Egypt. J. Pet. 2018, 27, 1275–1290. [Google Scholar] [CrossRef]

- Chen, L.; Ranzi, G.; Jiang, S.; Tahmasebinia, F.; Li, G. An Experimental Study on the Behaviour and Design of Shear Connectors Embedded in Solid Slabs at Elevated Temperatures. J. Constr. Steel Res. 2015, 106, 57–66. [Google Scholar] [CrossRef]

- Benjeddou, O.; Alyousef, R.; Mohammadhosseini, H.; Soussi, C.; Khadimallah, M.A.; Alabduljabbar, H.; Tahir, M.M. Utilisation of Waste Marble Powder as Low-Cost Cementing Materials in the Production of Mortar. J. Build. Eng. 2020, 32, 101642. [Google Scholar] [CrossRef]

- Ali, S.; Ahmad, S.; Ullah, I. Utilization of Waste Marble Dust as Cement and Sand Replacement in Concrete. Discov. Civ. Eng. 2024, 1, 15. [Google Scholar] [CrossRef]

- Korochkin, A. Impact of Rigid Pavements with the Asphalt-Concrete Wearing Course on Road Performance and Traffic Safety. In Proceedings of the Transportation Research Procedia; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 36, pp. 315–319. [Google Scholar]

- Kočí, J.; Fořt, J.; Kočí, V.; Hager, I. Assessment of Environmental Impact of Coarse Aggregates Substitution by Crushed Pavements in Concrete Mixtures. MATEC Web Conf. 2020, 322, 01036. [Google Scholar] [CrossRef]

- Maurya, S.; Ushendra Kumar, M. Utilization of Waste Materials in the Construction of Rigid Pavement: A Review. Int. Res. J. Eng. Technol. (IRJET) 2024, 11, 6. Available online: https://www.irjet.net/archives/V11/i6/IRJET-V11I6145.pdf (accessed on 15 November 2025).

- Islam, R.; Nazifa, T.H.; Yuniarto, A.; Shanawaz Uddin, A.S.M.; Salmiati, S.; Shahid, S. An Empirical Study of Construction and Demolition Waste Generation and Implication of Recycling. Waste Manag. 2019, 95, 10–21. [Google Scholar] [CrossRef]

- Abedin Khan, Z.; Balunaini, U.; Costa, S. Environmental Feasibility and Implications in Using Recycled Construction and Demolition Waste Aggregates in Road Construction Based on Leaching and Life Cycle Assessment—A State-of-the-Art Review. Clean. Mater. 2024, 12, 100239. [Google Scholar] [CrossRef]

- Busari, A.; Adeyanju, E.; Loto, T.; Ademola, D. Recycled Aggregate in Pavement Construction: Review of Literatures. In Proceedings of the Journal of Physics: Conference Series; Institute of Physics Publishing: Bristol, UK, 2019; Volume 1378. [Google Scholar]

- Hoy, M.; Horpibulsuk, S.; Chinkulkijniwat, A.; Suddeepong, A.; Buritatum, A.; Yaowarat, T.; Choenklang, P.; Udomchai, A.; Kantatham, K. Innovations in Recycled Construction Materials: Paving the Way towards Sustainable Road Infrastructure. Front. Built Environ. 2024, 10, 1449970. [Google Scholar] [CrossRef]

- Xuan, D.; Poon, C.S.; Zheng, W. Management and Sustainable Utilization of Processing Wastes from Ready-Mixed Concrete Plants in Construction: A Review. Resour. Conserv. Recycl. 2018, 136, 238–247. [Google Scholar] [CrossRef]

- Sánchez, A.R.; Ramos, V.C.; Polo, M.S.; Ramón, M.V.L.; Utrilla, J. Life Cycle Assessment of Cement Production with Marble Waste Sludges. Int. J. Environ. Res. Public Health 2021, 18, 10968. [Google Scholar] [CrossRef] [PubMed]

- Hebhoub, H.; Aoun, H.; Belachia, M.; Houari, H.; Ghorbel, E. Use of Waste Marble Aggregates in Concrete. Constr. Build. Mater. 2011, 25, 1167–1171. [Google Scholar] [CrossRef]

- Kore, S.D.; Vyas, A.K.; Syed, S.A. A Brief Review on Sustainable Utilisation of Marble Waste in Concrete. Int. J. Sustain. Eng. 2020, 13, 264–279. [Google Scholar] [CrossRef]

- Buyuksagis, I.S.; Uygunoglu, T.; Tatar, E. Investigation on the Usage of Waste Marble Powder in Cement-Based Adhesive Mortar. Constr. Build. Mater. 2017, 154, 734–742. [Google Scholar] [CrossRef]

- Mahmoud, A.A.; El-Sayed, A.A.; Aboraya, A.M.; Fathy, I.N.; Abouelnour, M.A.; Nabil, I.M. Influence of Sustainable Waste Granite, Marble and Nano-Alumina Additives on Ordinary Concretes: A Physical, Structural, and Radiological Study. Sci. Rep. 2024, 14, 22011. [Google Scholar] [CrossRef]

- Bastidas-Martínez, J.G.; Reyes-Lizcano, F.A.; Rondón-Quintana, H.A. Use of Recycled Concrete Aggregates in Asphalt Mixtures for Pavements: A Review. J. Traffic Transp. Eng. (Engl. Ed.) 2022, 9, 725–741. [Google Scholar] [CrossRef]

- Singh, T.S. Management of Construction Waste Materials: A Review. Int. J. Geol. Agric. Environ. Sci. 2015, 3, 23–28. [Google Scholar]

- Fournier, J.M.; Acosta Álvarez, D.; Aenlle, A.A.; Tenza-Abril, A.J.; Ivorra, S. Combining Reclaimed Asphalt Pavement (RAP) and Recycled Concrete Aggregate (RCA) from Cuba to Obtain a Coarse Aggregate Fraction. Sustainability 2020, 12, 5356. [Google Scholar] [CrossRef]

- Liu, Z.; Yu, S.; Huang, Y.; Liu, L.; Pan, Y. A Systematic Review of Rigid-Flexible Composite Pavement. J. Road Eng. 2024, 4, 203–223. [Google Scholar] [CrossRef]

- Kelechi, S.E.; Adamu, M.; Mohammed, A.; Ibrahim, Y.E.; Obianyo, I.I. Durability Performance of Self-Compacting Concrete Containing Crumb Rubber, Fly Ash and Calcium Carbide Waste. Materials 2022, 15, 488. [Google Scholar] [CrossRef] [PubMed]

- Pranav, S.; Aggarwal, S.; Yang, E.H.; Kumar Sarkar, A.; Pratap Singh, A.; Lahoti, M. Alternative Materials for Wearing Course of Concrete Pavements: A Critical Review. Constr. Build. Mater. 2020, 236, 117609. [Google Scholar] [CrossRef]

- Abbas, M.M. Recycling Waste Materials in Construction: Mechanical Properties and Predictive Modeling of Waste-Derived Cement Substitutes. Waste Manag. Bull. 2025, 3, 168–192. [Google Scholar] [CrossRef]

- Basaran, B.; Kalkan, I.; Aksoylu, C.; Özkılıç, Y.O.; Sabri, M.M.S. Effects of Waste Powder, Fine and Coarse Marble Aggregates on Concrete Compressive Strength. Sustainability 2022, 14, 14388. [Google Scholar] [CrossRef]

- Karaşahin, M.; Terzi, S. Evaluation of Marble Waste Dust in the Mixture of Asphaltic Concrete. Constr. Build. Mater. 2007, 21, 616–620. [Google Scholar] [CrossRef]

- Ohm, B.; Lee, S.Y.; Le, T.H.M. Utilizing Crushed Recycled Marble Stone Powder as a Sustainable Filler in SBS-Modified Asphalt Containing Recycled Tire Rubber. Polymers 2025, 17, 70. [Google Scholar] [CrossRef]

- Purnawan; Utami, S. The Influence of Base Course Types on Rigid Pavement Concrete Strength. In Proceedings of the IOP Conference Series: Materials Science and Engineering; Institute of Physics Publishing: Bristol, UK, 2018; Volume 288. [Google Scholar]

- Obianyo, I.I.; Mahamat, A.A.; Anosike-Francis, E.N.; Stanislas, T.T.; Geng, Y.; Onyelowe, K.C.; Odusanya, S.; Onwualu, A.P.; Soboyejo, A.B.O. Performance of Lateritic Soil Stabilized with Combination of Bone and Palm Bunch Ash for Sustainable Building Applications. Cogent Eng. 2021, 8, 1921673. [Google Scholar] [CrossRef]

- El-Sayed, H.A.; Farag, A.B.; Kandeel, A.M.; Younes, A.A.; Yousef, M.M. Characteristics of the Marble Processing Powder Waste at Shaq El-Thoaban Industrial Area, Egypt, and Its Suitability for Cement Manufacture. HBRC J. 2018, 14, 171–179. [Google Scholar] [CrossRef]

- Obianyo, I.I.; Anosike-Francis, E.N.; Ihekweme, G.O.; Geng, Y.; Jin, R.; Onwualu, A.P.; Soboyejo, A.B.O. Multivariate Regression Models for Predicting the Compressive Strength of Bone Ash Stabilized Lateritic Soil for Sustainable Building. Constr. Build. Mater. 2020, 263, 120677. [Google Scholar] [CrossRef]

- Elayouty, E.E.; Ragheb, S.R.; Youssef, A.M.; El-Bany, M.E.S.; Agwa, I.S. Enhancing the performance of rigid pavement slabs using sugarcane bagasse ash and macro synthetic fibers. Innov. Infrastruct. Solut. 2025, 10, 77. [Google Scholar] [CrossRef]

- Styer, J.; Tunstall, L.; Landis, A.; Grenfell, J. Innovations in pavement design and engineering: A 2023 sustainability review. Heliyon 2024, 10, e33602. [Google Scholar] [CrossRef] [PubMed]

- Nagy, N. Use of marble’s waste in asphalt mixtures. In Proceedings of the 8th ICCAE-8 Conference, Cairo, Egypt, 25–27 May 2010; Available online: https://ssrn.com/abstract=5266581 (accessed on 4 August 2025).

- Cahyaningru, K.; Siswanto, H. Utilization of marble waste as a filler in asphalt-sand sheet in road pavement. AIP Conf. Proc. 2024, 2991, 040017. [Google Scholar] [CrossRef]

- Saputro, M.Y.E.; Hasanuddin, A.; Nurtanto, D. The Use of Marble Waste as a Coarse Aggregate in Rigid Pavement Concrete Mixture Using Rice Husk Ash as an Admixture. Reka Buana J. Ilm. Tek. Sipil Dan Tek. 2022, 7, 93–103. [Google Scholar] [CrossRef]

- Benjeddou, O.; Mashaan, N. Experimental Study of the Usability of Recycling Marble Waste as Aggregate for Road Construction. Sustainability 2022, 14, 3195. [Google Scholar] [CrossRef]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C138/C138M-17a; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM C127-88; Standard Test Method for Specific Gravity and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 1988.

- ASTM C131/C131M-20; Standard Test Method for Resistance to Degradation of Small-Size Coarse Aggregate by Abrasion and Impact in the Los Angeles Machine. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM C136/C136M-19; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM C143/C143M-20; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

| Sample Names | % Replacement | Cement (kg/m3) | Marble Waste (kg/m3) | Gravel (kg/m3) | Quarry Dust (kg/m3) |

|---|---|---|---|---|---|

| MW0 | 0 | 343.17 | 0.00 | 1372.68 | 686.34 |

| MW10 | 10 | 343.17 | 137.27 | 1235.41 | 686.34 |

| MW20 | 20 | 343.17 | 274.54 | 1098.14 | 686.34 |

| MW30 | 30 | 343.17 | 411.80 | 960.88 | 686.34 |

| MW40 | 40 | 343.17 | 549.07 | 823.61 | 686.34 |

| MW50 | 50 | 343.17 | 686.34 | 686.34 | 686.34 |

| Test 1 | Test 2 | |

|---|---|---|

| Empty Impact Pot Weight (g) | 788.68 | 788.68 |

| Empty Pan Weight (g) | 329.88 | 329.88 |

| Empty Sieve Weight (g) | 394.41 | 394.41 |

| Aggregate with Impact Pot Weight (g) | 1112.95 | 1110.00 |

| Aggregate Weight (g) | 324.30 | 321.32 |

| Retained + Sieve (g) | 636.54 | 638.71 |

| Passing + Pan (g) | 411.59 | 406.24 |

| Weight of Retained (g) | 242.13 | 244.30 |

| Weight of Passing (g) | 81.71 | 76.36 |

| Impact value (%) | 25.20 | 23.76 |

| Average Impact value (%) | 24.48 | |

| Parameters Measured | Test 1 | Test 2 |

|---|---|---|

| Empty Pot Impact Weight (g) | 787.50 | 787.50 |

| Empty Pan Weight (g) | 226.00 | 226.00 |

| Empty Sieve Weight (g) | 393.00 | 393.00 |

| Aggregate with Impact Pot Weight (g) | 1142.00 | 1142.00 |

| Marble Waste Weight (g) | 354.50 | 354.50 |

| Weight of Retained (g) | 317.50 | 311.50 |

| Retained + Sieve (g) | 710.50 | 704.50 |

| Passing + Pan (g) | 262.50 | 274.10 |

| Weight of Passing (g) | 36.50 | 48.10 |

| Impact value (%) | 10.30 | 13.57 |

| Average Impact value (%) | 11.92 | |

| Parameters Measured | Gravel | Marble Waste |

|---|---|---|

| Aggregate weight (g) | 2000.00 | 2000.00 |

| Aggregate Weight with pan (g) | 1978.00 | 1978.00 |

| Weight of pan (g) | 583.50 | 444.50 |

| Weight of Aggregate + Bucket in Water (A1) (g) | 2059.00 | 2456.00 |

| Weight of Bucket Suspended in Water (A2) (g) | 566.50 | 566.50 |

| Weight of Saturated Aggregate in Water (A) = (A1 − A2) (g) | 1452.50 | 1489.50 |

| Weight of Saturated Surface Dry Aggregate (B) (g) | 1965.00 | 2004.00 |

| Weight of Oven-Dry Aggregate (C) (g) | 1364.50 | 1361.50 |

| Specific gravity = C/B − A | 2.66 | 2.65 |

| Measurements | Gravel | Marble Waste |

|---|---|---|

| Sample weight (g) | 5000 | 5000 |

| Weight retained in sieve after abrasion (g) | 2898.00 | 2846.00 |

| Weight of passing after abrasion (g) | 2102.00 | 2154.00 |

| Abrasion value (%) | 27.47 | 24.31 |

| Percentage Marble Waste Replacement (%) | Slump Value (mm) |

|---|---|

| 0 | 83 |

| 10 | 22 |

| 20 | 13 |

| 30 | 9 |

| 40 | 5 |

| 50 | 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Obianyo, I.I.; Nwaforcha, M.S.; Yusuf, K.; Sanusi, A.; Dayyabu, A.; Kolo, M.U.; Onwualu, A.P. Evaluation of the Mechanical and Durability Properties of Marble Waste-Modified Rigid Pavement Material. Buildings 2025, 15, 4159. https://doi.org/10.3390/buildings15224159

Obianyo II, Nwaforcha MS, Yusuf K, Sanusi A, Dayyabu A, Kolo MU, Onwualu AP. Evaluation of the Mechanical and Durability Properties of Marble Waste-Modified Rigid Pavement Material. Buildings. 2025; 15(22):4159. https://doi.org/10.3390/buildings15224159

Chicago/Turabian StyleObianyo, Ifeyinwa Ijeoma, Maurice Simon Nwaforcha, Kudu Yusuf, Abdulganiyu Sanusi, Abubakar Dayyabu, Musa Umar Kolo, and Azikiwe Peter Onwualu. 2025. "Evaluation of the Mechanical and Durability Properties of Marble Waste-Modified Rigid Pavement Material" Buildings 15, no. 22: 4159. https://doi.org/10.3390/buildings15224159

APA StyleObianyo, I. I., Nwaforcha, M. S., Yusuf, K., Sanusi, A., Dayyabu, A., Kolo, M. U., & Onwualu, A. P. (2025). Evaluation of the Mechanical and Durability Properties of Marble Waste-Modified Rigid Pavement Material. Buildings, 15(22), 4159. https://doi.org/10.3390/buildings15224159