Properties of Concrete Influenced by Plastic Materials

Abstract

1. Introduction

2. Experimental Program

2.1. Materials and Test Specimens

2.2. Test Procedures

3. Results and Discussion

3.1. Effect on Mixture Properties

3.2. Effect on Strength Properties

3.3. Effect on Durability

4. Conclusions

- 1.

- The workability of PCC containing plastic waste decreased with the increase in plastic waste content mainly due to sharp edges or the irregular shape of plastic materials (Figure 1). The slump decreased by 10% when PCC included 10% of plastic, which is not a significant reduction, and by 23% for the PCC with 20% plastic waste.

- 2.

- The density of PCC with plastic waste decreased with the increase in plastic waste level. The maximum decrease in density was 6.2% for the mixture with 20% plastic waste content.

- 3.

- The air content of PCC with plastic waste increased with increasing plastic waste amounts. The air content increased by 39% and 78% for the mixtures with 10% and 20% plastic waste content, respectively.

- 4.

- The absorption of concrete increased as the amount of plastic waste increased. The maximum percentage of water absorption was 29% for the PCC mixture containing a 20% plastic waste level.

- 5.

- The mechanical properties (compressive and splitting strength) decreased with the increase in the plastic waste substitution level. The decrease in the compressive strength after 7 and 28 days of moist curing were 26% and 23%, respectively, for the mixture with 20% plastic replacement. Moreover, the maximum decrease in the splitting strength after 7 and 28 days of moist curing were 30% and 31%, respectively, for the same mixture. The compressive strength reduction was only 11% when the PCC included 10% plastic waste, indicating that an addition of 10% plastic waste in concrete can be practical.

- 6.

- The electrical charge passing through PCC specimens using the rapid chloride permeability test increased with an increasing amount of plastic waste. The maximum increase in the electrical charge was 24% for the mixture with 20% plastic waste.

- 7.

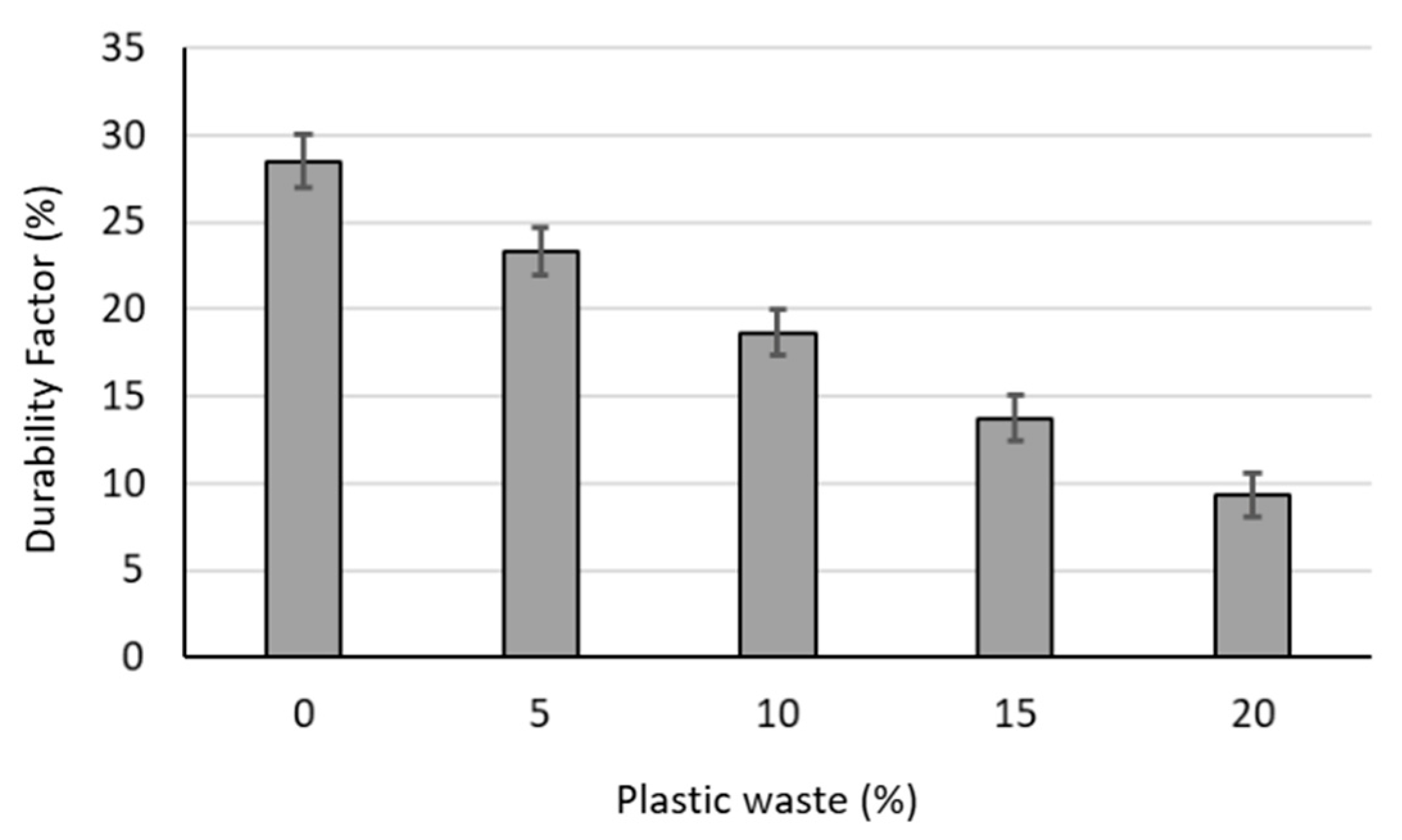

- The durability of PCC under freeze–thaw cycles decreased as the plastic waste content increased. The durability factor decreased from 29% for the control mixture without plastic waste to 9% for the mixture with a 20% plastic waste level.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| PCC | Portland Cement Concrete |

| ASTM | American Standards for Testing and Materials |

| RDM | Relative Dynamic Modulus |

| N | Number of Freeze–Thaw Cycles |

| TFn | Transverse Frequency After n Cycles of Freeze–Thaw |

| TF0 | Transverse Frequency Before Freeze-Thaw |

| DF | Durability Factor |

References

- Guerra, E.; Lima, E. Handbook of Polymer Synthesis, Characterization, and Processing, 1st ed.; 222 Rosewood Drive: Danvers, MA, USA, 2013. [Google Scholar]

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef]

- Singh, P.; Sharma, V. Integrated plastic waste management: Environmental and improved health approaches. Procedia Environ. Sci. 2016, 35, 692–700. [Google Scholar] [CrossRef]

- Siddiqua, A.; Hahladakis, J.; Al-Attiya, W. An overview of the environmental pollution and health effects associated with waste landfilling and open dumping. Environ. Sci. Pollut. Res. 2022, 29, 58514–58536. [Google Scholar] [CrossRef]

- Cudjoe, D.; Zhu, B. Gasification of medical plastic waste into hydrogen: Energy potential, environmental benefits and economic feasibility. Fuel 2024, 371, 132150. [Google Scholar] [CrossRef]

- Babaremu, K.; Oladijo, O.; Akinlabi, E. Biopolymers: A suitable replacement for plastics in product packaging. Adv. Ind. Eng. Polym. Res. 2023, 6, 333–340. [Google Scholar] [CrossRef]

- Awoyera, P.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Choudhary, A.; Shah, V.; Bishnoi, S. Effect of Low-Cost Fillers on Cement Hydration. Constr. Build. Mater. 2016, 124, 533–543. [Google Scholar] [CrossRef]

- Tejaswini, M.; Pathak, P.; Gupta, D. Sustainable approach for valorization of solid wastes as a secondary resource through urban mining. J. Environ. Manag. 2022, 319, 115727. [Google Scholar] [CrossRef]

- Lin, R.; Wang, X.; Zhang, G. Effects of Quartz Powder on the Microstructure and Key Properties of Cement Paste. Sustainability 2018, 10, 3369. [Google Scholar] [CrossRef]

- Akbar, M.; Hussain, Z.; Imran, M.; Bhatti, S.; Anees, M. Concrete matrix based on marble powder, waste glass sludge, and crumb rubber: Pathways towards sustainable concrete. Front. Mater. 2024, 10, 1329386. [Google Scholar] [CrossRef]

- Hamada, H.M.; Al-Attar, A.; Abed, F.; Beddu, S.; Humada, A.M.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Enhancing sustainability in concrete construction: A comprehensive review of plastic waste as an aggregate material. Sustain. Mater. Technol. 2024, 40, e00877. [Google Scholar] [CrossRef]

- Li, X.; Ling, T.; Mo, K. Functions and Impacts of Plastic/Rubber Wastes as Eco-Friendly Aggregate in Concrete: A Review. Constr. Build. Mater. 2020, 240, 117869. [Google Scholar] [CrossRef]

- Cordoba, L.; Barrera, G.; Diaz, C.; Nunez, F.; Yanez, A. Effects on Mechanical Properties of Recycled PET in Cement-Based Composite. Int. J. Polym. Sci. 2013, 2013, 763–776. [Google Scholar] [CrossRef]

- Dawood, A.; Al-khazrahi, H.; Falih, R. Physical and Mechanical Properties of Concrete Containing PET Wastes as a Partial Replacement for Fine Aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Islam, M.; Meherier, M.; Islam, A. Effects of Waste PET as Coarse Aggregate on the Fresh and Harden Properties of Concrete. Constr. Build. Mater. 2016, 125, 946–951. [Google Scholar] [CrossRef]

- Iucolano, F.; Liguori, B.; Caputo, D.; Colangelo, F.; Cioffi, R. Recycled plastic aggregate in mortars composition: Effect on physical and Mechanical Properties. Mater. Des. 2013, 52, 916–922. [Google Scholar] [CrossRef]

- Jacob-Vaillancourt, C.; Sorelli, L. Characterization of concrete composites with recycled plastic aggregates from postconsumer material streams. Constr. Build. Mater. 2018, 182, 561–572. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.; Allahyari, H.; Nikbin, I. On the Mechanical Properties of Concrete Containing Waste PET Particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Saikia, N.; Brito, J. Use of plastic Waste as Aggregate in Cement Mortar and Concrete Preparation: A Review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Yang, S.; Yue, Z.; Liu, X.; Tong, Y. Properties of Self-Compacting Lightweight Concrete Containing Recycled Plastic Particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- Zulkernain, N.; Gani, P.; Chuan, N.; Uvarajan, T. Utilization of Plastic Waste as Aggregate in Construction Materials: A Review. Constr. Build. Mater. 2021, 296, 123669. [Google Scholar] [CrossRef]

- Abduallah, R.; Burris, L.; Castro, J.; Sezen, H. Utilization of Different Types of Plastics in Concrete Mixtures. Constr. Mater. 2025, 5, 39. [Google Scholar] [CrossRef]

- Ammari, M.; Sezen, H.; Castro, J. Effect of Different Plastics on Mechanical Properties of Concrete. Constr. Mater. 2025, 5, 60. [Google Scholar] [CrossRef]

- ASTM Standard C127; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Coarse Aggregate. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM Standard C128; Standard Test Method for Relative Density (Specific Gravity) and Absorption of Fine Aggregate. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM Standard C29; Standard Test Method for Bulk Density (Unit Weight) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2023.

- ASTM Standard C136; Standard Test Method for Sieve Analysis of Fine and Coarse Aggregates. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM Standard C138; Standard Test Method for Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM Standard C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM Standard C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM Standard C496; Standard Test Method for Splitting Tensile Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM Standard C642; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM Standard C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM Standard C666; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing. ASTM International: West Conshohocken, PA, USA, 1997.

- ASTM Standard C215; Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 1997.

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

| Property | Value |

|---|---|

| Color | Dark |

| Absorption (%) | 0.1 |

| Average particle Size (mm) | 0.3 |

| Specific gravity | 0.95 |

| Mixture | PW (%) | w/c | Cement (kg) | Water (kg) | CA (kg) | FA (kg) | PW (kg) | SP (%) |

|---|---|---|---|---|---|---|---|---|

| P0 | 0 | 0.5 | 400 | 200 | 980 | 710 | 0 | 0.7 |

| P5 | 5 | 0.5 | 400 | 200 | 980 | 675 | 14 | 0.7 |

| P10 | 10 | 0.5 | 400 | 200 | 980 | 639 | 28 | 0.7 |

| P15 | 15 | 0.5 | 400 | 200 | 980 | 604 | 42 | 0.7 |

| P20 | 20 | 0.5 | 400 | 200 | 980 | 568 | 56 | 0.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Akhras, N.; Sezen, H. Properties of Concrete Influenced by Plastic Materials. Buildings 2025, 15, 4061. https://doi.org/10.3390/buildings15224061

Al-Akhras N, Sezen H. Properties of Concrete Influenced by Plastic Materials. Buildings. 2025; 15(22):4061. https://doi.org/10.3390/buildings15224061

Chicago/Turabian StyleAl-Akhras, Nabil, and Halil Sezen. 2025. "Properties of Concrete Influenced by Plastic Materials" Buildings 15, no. 22: 4061. https://doi.org/10.3390/buildings15224061

APA StyleAl-Akhras, N., & Sezen, H. (2025). Properties of Concrete Influenced by Plastic Materials. Buildings, 15(22), 4061. https://doi.org/10.3390/buildings15224061