A Novel Simulation Method for the Spatiotemporal Variation in Relative Humidity in Early Age of Polypropylene Fibers Reinforced Concrete

Abstract

1. Introduction

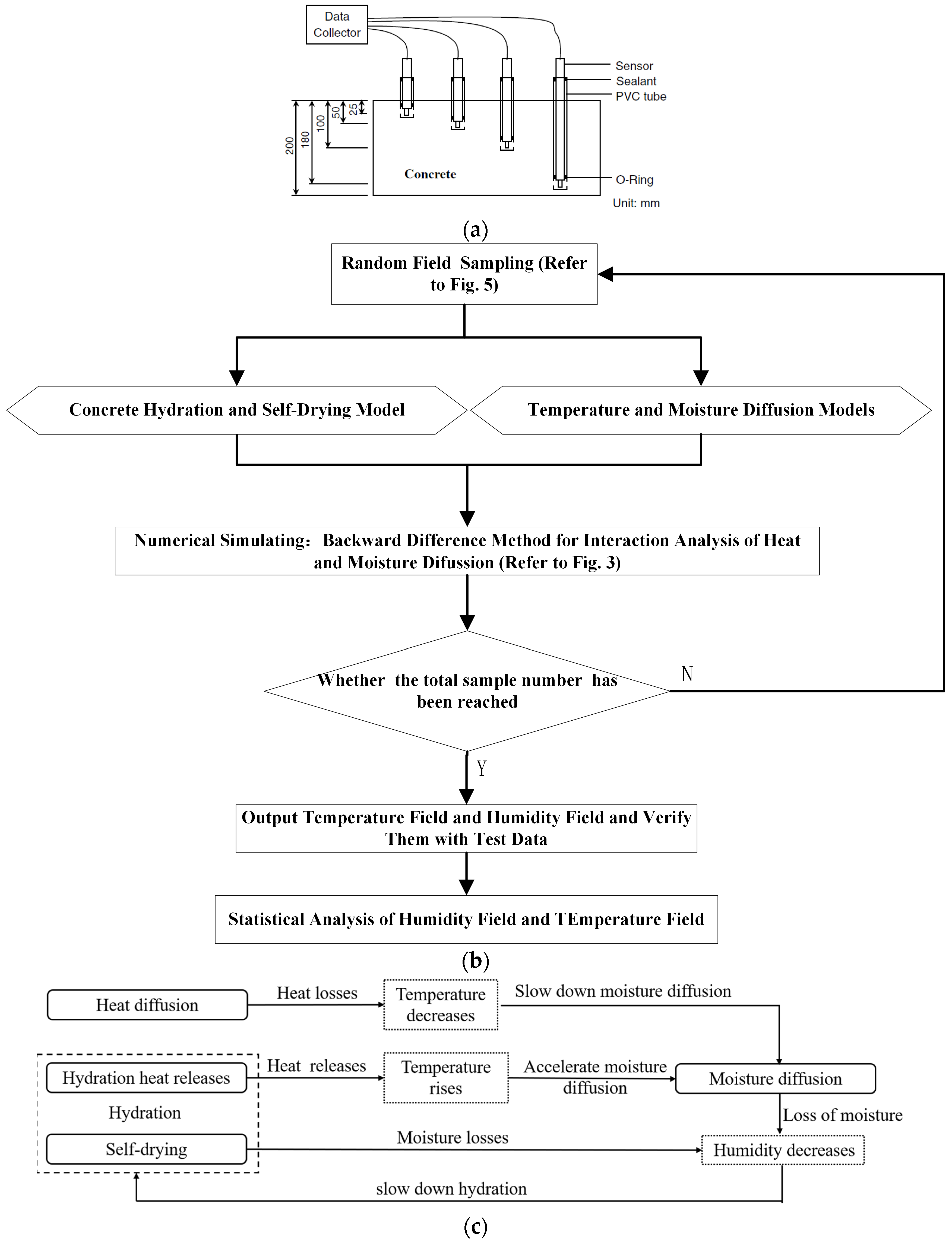

2. Materials and Methods

2.1. Mixing Ratio and Production of Concrete in the Literature

2.2. Physical and Chemical Models of the Hydration and Diffusion Processes

2.2.1. Concrete Hydration and Self-Drying Model

2.2.2. Temperature and Moisture Diffusion Models

2.2.3. Correction of Diffusion Factors Based on the Coupling Effect

2.3. Numerical Simulation Method for Temperature and Relative Humidity

2.3.1. Backward Difference Method for Diffusion Simulation

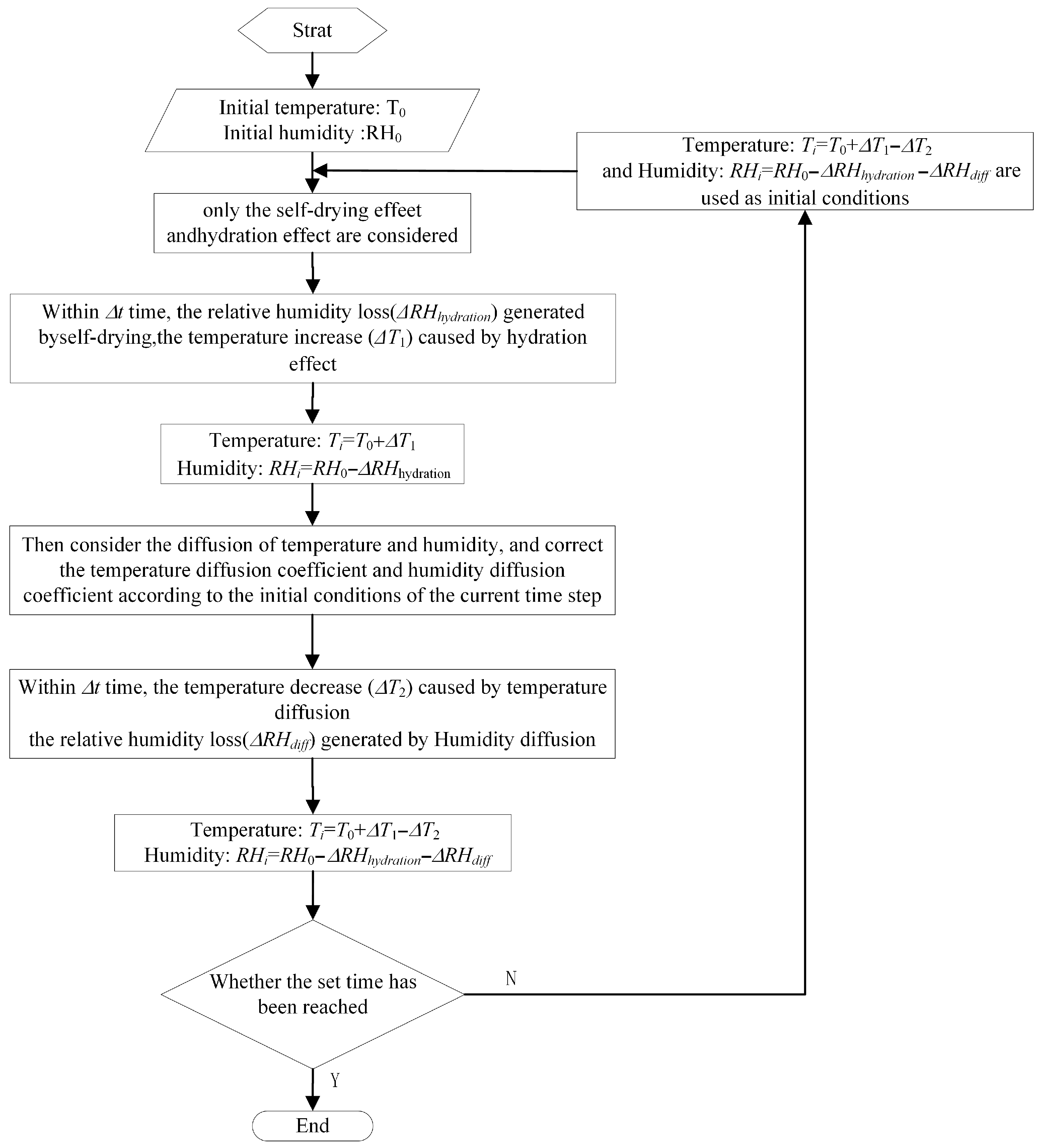

2.3.2. Analysis Process Considering Interaction Between Temperature and Humidity

- (1)

- Firstly, the analyzed concrete specimens are divided into grid models. Set up time step and boundary conditions. Initialize the temperature, , relative humidity, , temperature diffusion factor, DT0, and relative humidity diffusion factor, DH0.

- (2)

- At time step , update the temperature diffusion factor, , and humidity diffusion factor, , using Equations (13) and (14), respectively, based on the temperature Tt and the relative humidity RHt at the end of the previous time step, t. Then, simulate the current temperature and relative humidity through the following two sub-stages.

- (i).

- Sub-stage one: Internal processes with hydration and self-drying. Based on the current hydration degree, (using Equation (5)), calculate the temperature increment, , due to hydration (using Equation (6)), and the relative humidity increment, , caused by self-drying (using Equations (7) and (8)). Subsequently, update the current temperature to and the relative humidity to .

- (ii).

- Sub-stage two: Diffusion process with environment. Using the updated temperature and relative humidity from sub-stage one, predict the temperature increment, , and the relative humidity increment, , due to diffusion by the application of the backward difference method, as shown in Equation (15).

- (iii).

- Final revision: Superimpose the increments of temperature and relative humidity from both stages to obtain the final temperature, , and the final relative humidity, , at the end of the current time step.

- (3)

- Iterate Step 2 to obtain the spatiotemporal distribution of the temperature and relative humidity within the early-age concrete until the desired time point is achieved.

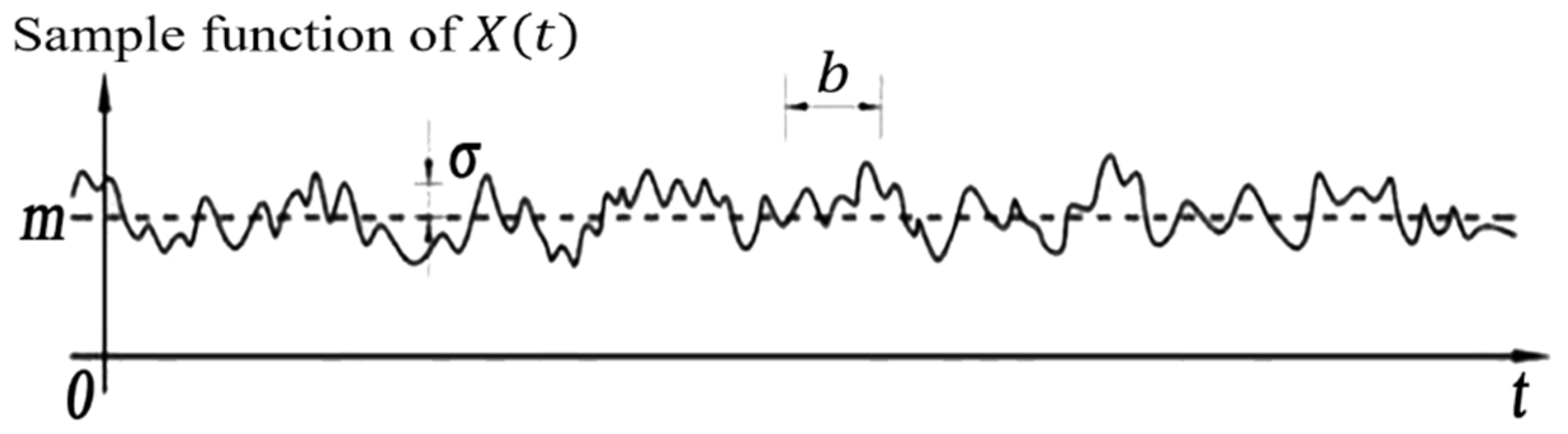

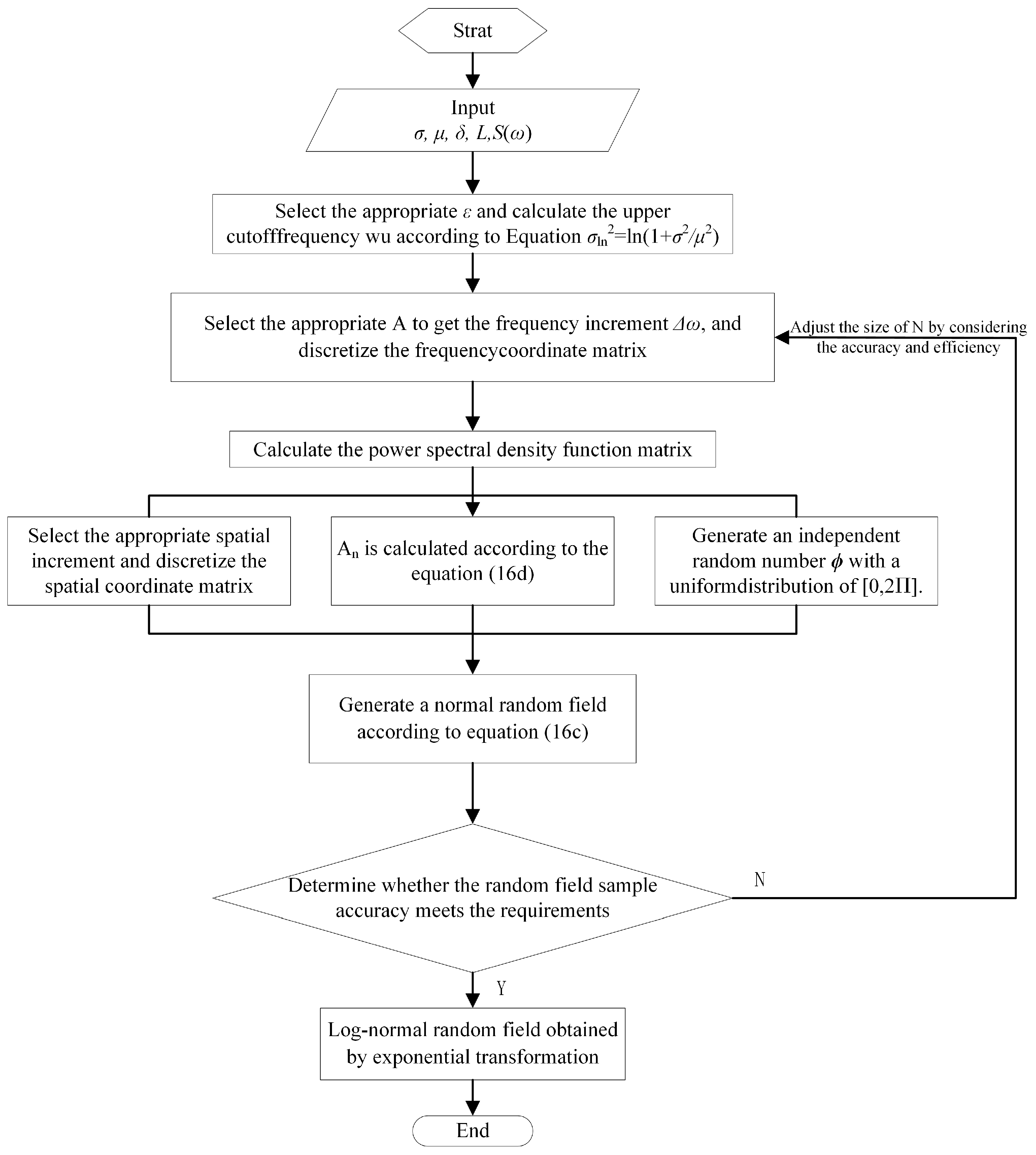

2.4. Random Field Model of Diffusion Factor Considering Spatial Uncertainty

3. Results and Discussion

3.1. Numerical Simulations

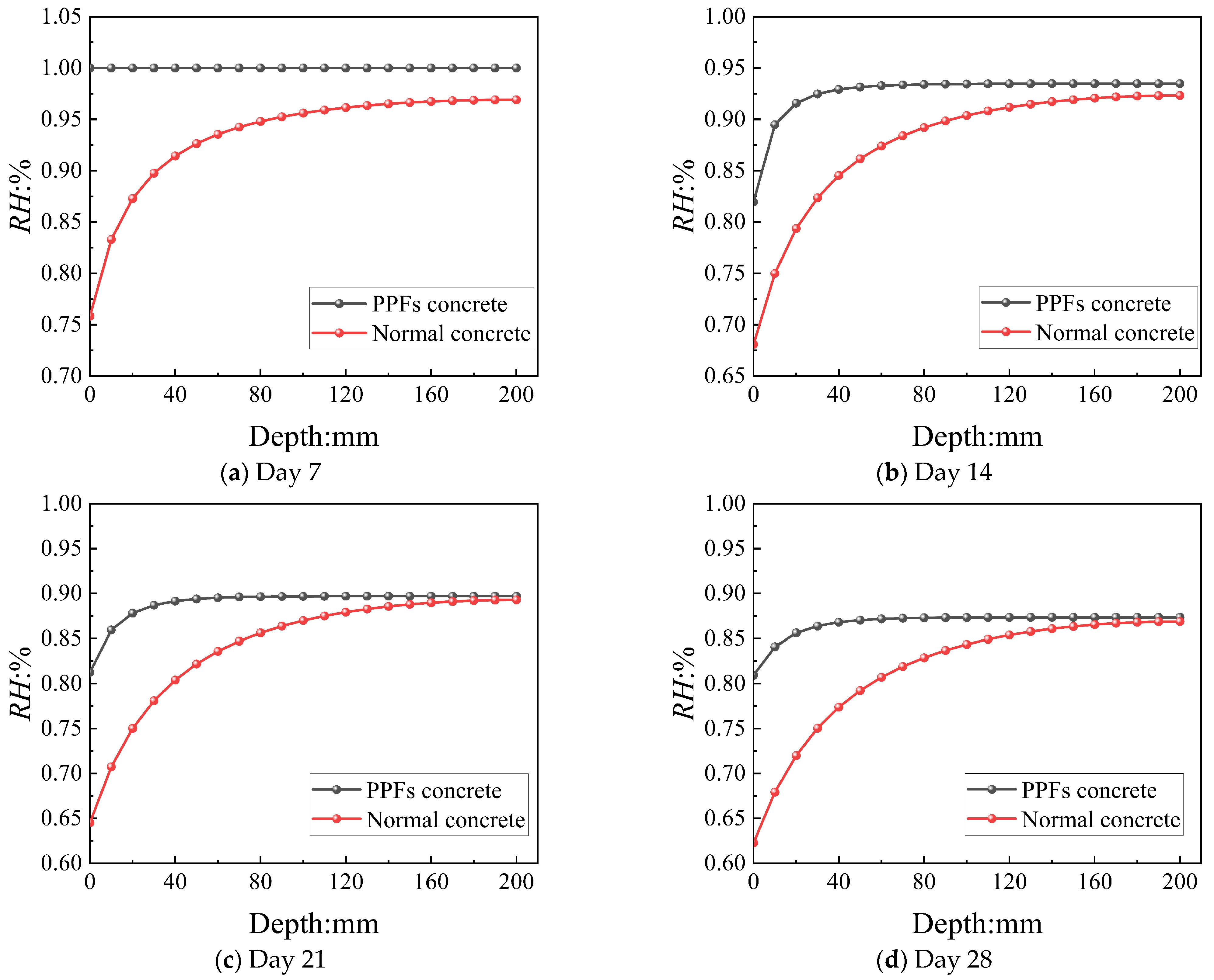

3.2. The Spatiotemporal Distribution of the Humidity of the PPF Concrete

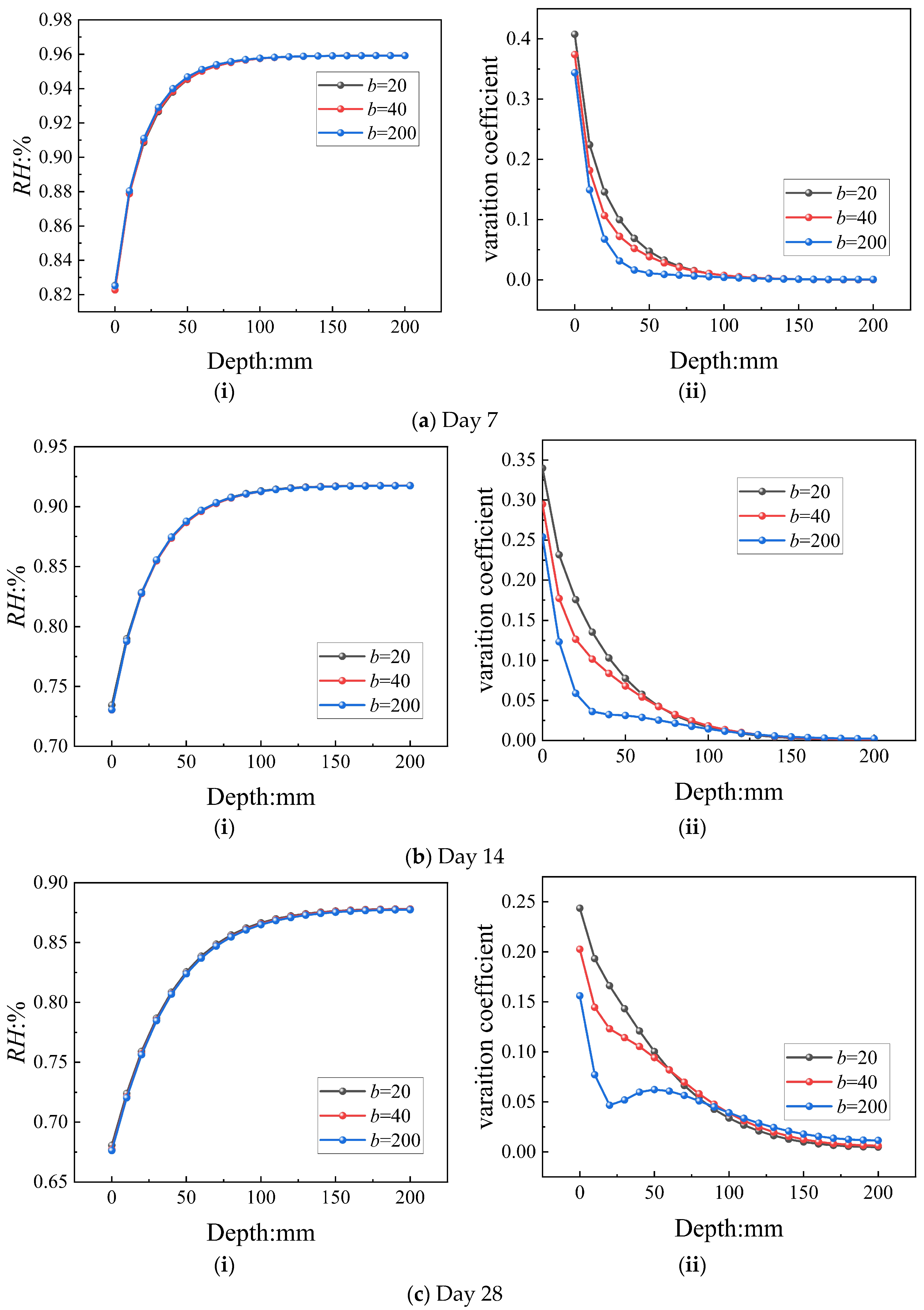

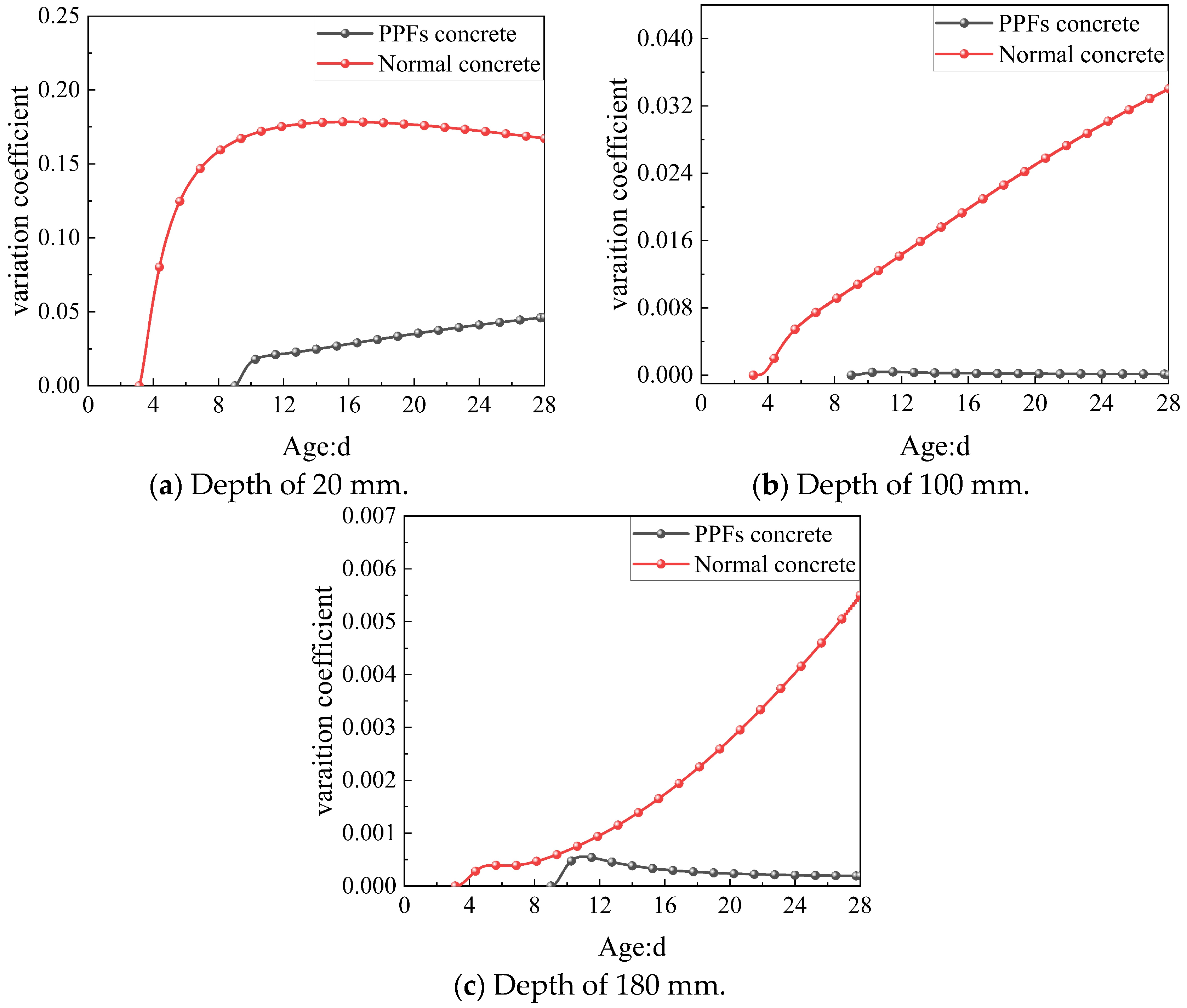

3.3. The Influence on the Humidity of Spatial Variability of Diffusion Factor

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| Notation | |||

, v | Empirical constant | Critical value of relative humidity | |

| Heat of hydration [kJ/kg] | Relative humidity of concrete surface | ||

| Total heat of complete hydration [kJ/kg] | Environment humidity | ||

| Hydration degree | Final thermal conductivity of concrete [W/(m2·K)] | ||

| Relative humidity | Coefficient of humidity diffusion with 100% RH | ||

| Equivalent age [day] | Number of the nodes | ||

| Real-time degree of hydration | Iteration time steps of the nodes | ||

| Ultimate degree of hydration | Time period of concern | ||

| κ | Comprehensive hydration rate constant | Time step [day] | |

| Water–cement ratio | Mesh size [mm] | ||

| Activation energy of cement hydration at a reference temperature of 20 °C [J/mol] | Length of the concrete specimen [mm] | ||

| Activation energy of cement hydration at the actual temperature [J/mol] | A parameter related to the difference step size and the grid scale | ||

| R | Constant | Standard deviation of item i | |

| T | Temperature [°C] | Frequency of item i | |

| t | Time [day] | Frequency increment | |

| Heat capacity of concrete [J/(kg·K)] | The power spectral density function corresponding to the autocorrelation function | ||

| Density of concrete [kg/m3] | Related upper cut-off frequency | ||

| The relative humidity caused by self-drying with the degree of hydration | Coordinate [mm] | ||

| The relative humidity caused by self-drying with the degree of hydration | An independent random phase angle | ||

| Concrete surface temperature [°C] | Logarithmic mean value of the diffusion factor | ||

| Environment temperature [°C] | Standard deviation of the diffusion factor | ||

| Diffusion factor of temperature [W·m/J] | Autocorrelation coefficient of the two consideration points | ||

| Heat transfer coefficient [W/(m2·K)] | Interval between the points | ||

| Convective heat transfer coefficient between concrete and air [W/(m2·K)] | Correlation length [mm] | ||

| Diffusion factor of relative humidity | Surface humidity exchange coefficient |

References

- Hou, D.W.; Zhang, J.; Yang, S.Q. Effect of polypropylene fiber on crack resistance of early age concrete. In Proceedings of the 12th National Fiber Concrete Academic Conference, Beijing China, 29–31 October 2008. (In Chinese). [Google Scholar]

- Fang, B.; Hu, Z.; Shi, T.; Liu, Y.; Wang, X.; Yang, D.; Zhu, K.; Zhao, X.; Zhao, Z. Research progress on the properties and applications of magnesium phosphate cement. Ceram. Int. 2023, 49, 4001–4016. [Google Scholar] [CrossRef]

- Xiang, Y.; Zhao, H.; Liu, J.; Hu, D.; Hu, Z.; Xu, W.; Hu, N. Shrinkage cracking law and anti-crack inverse design in early-age concrete: A novel perspective on the development of crack resistance properties. Eng. Fract. Mech. 2024, 310, 110395. [Google Scholar] [CrossRef]

- Maruyama, I.; Lura, P. Properties of early-age concrete relevant to cracking in massive concrete. Cem. Concr. Res. 2019, 123, 105770. [Google Scholar] [CrossRef]

- Zhou, W.; Qi, T.; Liu, X.; Feng, C.; Yang, S. A hygro-thermo-chemical analysis of concrete at an early age and beyond under dry-wet conditions based on a fixed model. Int. J. Heat. Mass. Tran. 2017, 115, 488–499. [Google Scholar] [CrossRef]

- Zhao, H.; Jiang, K.; Yang, R.; Tang, Y.; Liu, J. Experimental and theoretical analysis on coupled effect of hydration, temperature and humidity in early-age cement-based materials. Int. J. Heat. Mass. Tran. 2020, 146, 118784. [Google Scholar] [CrossRef]

- Miao, Y.; Lu, Z.; Wang, F.; Wang, H.; Li, Y.; Lin, J.; Jiang, J. Shrinkage cracking evolvement in concrete cured under low relative humidity and its relationship with mechanical development. J. Build. Eng. 2023, 72, 106670. [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Ma, C.; Cai, C.; Wang, J. Effect of surface curing condition on the humidity field and humidity transfer in concrete. Constr. Build. Mater. 2024, 411, 134701. [Google Scholar] [CrossRef]

- Ding, X.; Zhang, J.; Wang, J. Wang, Integrative modeling on self-desiccation and humidity diffusion in concrete based on variation of water content. Cem. Concr. Compos. 2019, 97, 322–340. [Google Scholar] [CrossRef]

- Min, H.; Zhang, W.; Gu, X. Effects of load damage on humidity transport and relative humidity response in concrete. Constr. Build. Mater. 2018, 169, 59–68. [Google Scholar] [CrossRef]

- Shen, D.; Liu, C.; Li, C.; Zhao, X.; Jiang, G. Influence of Barchip fiber length on early-age behavior and cracking resistance of concrete internally cured with super absorbent polymers. Constr. Build. Mater. 2019, 214, 219–231. [Google Scholar] [CrossRef]

- Zhao, C.; Zhou, W.; Chen, X.; Wu, Q.; Ma, G.; Wang, Q. Mesoscopic analysis of heat and humidity coupled transfer in concrete considering phase change under frost action. J. Build. Eng. 2022, 57, 104888. [Google Scholar] [CrossRef]

- Bouziadi, F.; Boulekbache, B.; Tahenni, T.; Haddi, A.; Hamrat, M.; Amziane, S. Finite element analysis of steady-state uniaxial basic creep of high-performance concrete. J. Build. Eng. 2022, 52, 104500. [Google Scholar] [CrossRef]

- Puatatsananon, W.; Saouma, V.E. Nonlinear coupling of carbonation and chloride diffusion in concrete. J. Mater. Civil. Eng. 2005, 17, 264–275. [Google Scholar] [CrossRef]

- Brugger, A.; Gamnitzer, P.; Hofstetter, G. Multiphase modeling of the effect of external loading on the shrinkage of concrete and its consequences for modeling tensile creep. Cem. Concr. Compos. 2022, 130, 104499. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, J.; Guo, Y.; Wang, C. Early shrinkage experiment of concrete and the development law of its temperature and humidity field in natural environment. J. Build. Eng. 2023, 63, 105528. [Google Scholar] [CrossRef]

- Zhang, W.; Kang, S.; Liu, X.; Lin, B.; Huang, Y. Experimental study of a composite beam externally bonded with a carbon fiber-reinforced plastic plate. J. Build. Eng. 2023, 71, 106522. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.; Zhang, C.; Yang, Z.; Li, C.; Qiao, P. Experimental investigation on the bond performance of sea sand coral concrete with FRP bar reinforcement for marine environments. Adv. Struct. Eng. 2023, 26, 533–546. [Google Scholar] [CrossRef]

- Latifi, M.R.; Biricik, Ö.; Mardani Aghabaglou, A. Effect of the addition of polypropylene fiber on concrete properties. J. Adhes. Sci. Technol. 2022, 36, 345–369. [Google Scholar] [CrossRef]

- Bayat Pour, M. From experimental studies to predictive machine learning modelling: Polypropylene fibre reinforced concrete. Results Mater. 2025, 28, 100777. [Google Scholar] [CrossRef]

- Wongprachum, W.; Sappakittipakorn, M.; Sukontasukkul, P.; Chindaprasirt, P.; Banthia, N. Resistance to sulfate attack and underwater abrasion of fiber reinforced cement mortar. Constr. Build. Mater. 2018, 189, 686–694. [Google Scholar] [CrossRef]

- Leong, G.W.; Mo, K.H.; Loh, Z.P.; Ibrahim, Z. Mechanical properties and drying shrinkage of lightweight cementitious composite incorporating perlite microspheres and polypropylene fibers. Constr. Build. Mater. 2020, 246, 118410. [Google Scholar] [CrossRef]

- Nguyen, H.; Kinnunen, P.; Carvelli, V.; Illikainen, M. Durability of ettringite-based composite reinforced with polypropylene fibers under combined chemical and physical attack. Cem. Concr. Compos. 2019, 102, 157–168. [Google Scholar] [CrossRef]

- Madhavi, T.C.; Raju, L.S.; Mathur, D. Polypropylene fiber reinforced concrete—A review. Int. J. Emerg. Technol. Adv. Eng. 2014, 4, 114–118. [Google Scholar] [CrossRef]

- Aulia, T.B. Effects of Polypropylene Fibers on the Properties of High-Strength Concretes; Institutes for Massivbau and Baustoffechnologi, University Leipzig: Leipzig, Germany, 2002. [Google Scholar]

- Song, P.S.; Hwang, S.; Sheu, B.C. Strength properties of nylon-and polypropylene-fiber-reinforced concretes. Cem. Concr. Res. 2005, 35, 1546–1550. [Google Scholar] [CrossRef]

- Dirikgil, T. Experimental Research of the Influence of High Temperature on Some of the Physical and Mechanical Properties of Concrete Reinforced with Polypropylene. Master’s Thesis, Erciyes University Institute of Science and Technology, Kayseri, Turkey, 2009. (In Turkish). [Google Scholar]

- Mehta, P.K.; Monteiro, P. Concrete: Micro-Structure, Properties, and Materials, 4th ed.; McGraw-Hill: Englewood Cliffs, NJ, USA, 2014. [Google Scholar]

- Wang, J.; Li, M.; Chen, J.; Zhao, Z.; Zhao, H.; Zhang, L.; Ren, J. Investigation on shrinkage characteristics of polyester-fiber-reinforced cement-stabilized concrete considering fiber length and content. Buildings 2023, 13, 1027. [Google Scholar] [CrossRef]

- Xu, F.; Zhou, M.; Chen, J.; Ruan, S. Mechanical performance evaluation of polyester fiber and SBR latex compound-modified cement concrete road overlay material. Constr. Build. Mater. 2014, 63, 142–149. [Google Scholar] [CrossRef]

- Yang, Y.; Deng, Y. Mechanical properties of hybrid short fibers reinforced oil well cement by polyester fiber and calcium carbonate whisker. Constr. Build. Mater. 2018, 182, 258–272. [Google Scholar] [CrossRef]

- Zhang, G.; Chen, C.; Sun, J.; Li, K.; Xiao, F.; Wang, Y.; Chen, M.; Huang, J.; Wang, X. Mixture optimisation for cement-soil mixtures with embedded GFRP tendons. J. Mater. Res. Technol. 2022, 18, 611–628. [Google Scholar] [CrossRef]

- Jia, Y.; Zhu, J.; Zhao, E.; Zhang, J.; Li, S.; Jiang, Y.; Zhang, T.; Liu, L. Study on the performance of polyester fibers modification system for low-carbon magnesium silicate-based cementitious materials. Cem. Concr. Compos. 2025, 157, 105948. [Google Scholar] [CrossRef]

- Rostami, R.; Zarrebini, M.; Mandegari, M.; Mostofinejad, D.; Abtahi, S.M. A review on performance of polyester fibers in alkaline and cementitious composite environments. Constr. Build. Mater. 2020, 241, 117998. [Google Scholar] [CrossRef]

- Gupta, S.; Rao, V.V.L.K.; Sengupta, J. Evaluation of polyester fiber reinforced concrete for use in cement concrete pavement works. Road Mater. Pavement Des. 2008, 9, 441–461. [Google Scholar] [CrossRef]

- Christopher, C.G.; Gopal, R.; Sadasivam, S.; Devi Keerthika Esakki, A.K.; Dinesh Kumar, P. Experimental toughness and durability evaluation of FRC composite reinforced with steel–polyester fiber combination. Int. J. Concr. Struct. Mater. 2023, 17, 39. [Google Scholar] [CrossRef]

- Siddique, R.; Kapoor, K.; Kadri, E.; Bennacer, R. Effect of polyester fibres on the compressive strength and abrasion resistance of HVFA concrete. Constr. Build. Mater. 2012, 29, 270–278. [Google Scholar] [CrossRef]

- Guo, J.; Wang, K.; Qi, C. Determining the mineral admixture and fiber on mechanics and fracture properties of concrete under sulfate attack. J. Mar. Sci. Eng. 2021, 9, 251. [Google Scholar] [CrossRef]

- Ma, L.; Zhang, Q.; Lombois-Burger, H.; Jia, Z.; Zhang, Z.; Niu, G.; Zhang, Y. Pore structure, internal relative humidity, and fiber orientation of 3D printed concrete with polypropylene fiber and their relation with shrinkage. J. Build. Eng. 2022, 61, 105250. [Google Scholar] [CrossRef]

- Xu, Y.; Xing, G.; Zhao, J.; Zhang, Y. The effect of polypropylene fiber with different length and dosage on the performance of alkali-activated slag mortar. Constr. Build. Mater. 2021, 307, 124978. [Google Scholar] [CrossRef]

- Abusogi, M.A.; Che Muda, Z.; Hafez, M.A.; Bakri, M. Effect of polypropylene fibre on cementitious mortar early shrinkage cracking using the eccentric-ring test. Front. Mater. 2023, 9, 1052870. [Google Scholar] [CrossRef]

- Lu, S.; Liu, J.; Tian, Z.; Lu, Y.; Liang, G.; Zhang, L.; Bian, H. Deterioration mechanisms and strength prediction of hybrid fiber-reinforced concrete under coupled sulfate attack and dry–wet cycles. Constr. Build. Mater. 2025, 493, 143243. [Google Scholar] [CrossRef]

- Cao, H.; Li, J.; Chen, T.; Ren, H.; Qiao, Z. Active polypropylene fibers for controlling shrinkage cracks in cement-stabilized materials. Crystals 2024, 14, 1033. [Google Scholar] [CrossRef]

- John, S.K.; Cascardi, A.; Verre, S.; Nadir, Y. RC-columns subjected to lateral cyclic force with different FRCM-strengthening schemes: Experimental and numerical investigation. Bull. Earthq. Eng. 2025, 23, 1561–1590. [Google Scholar] [CrossRef]

- Feng, J.; Su, Y.; Qian, C. Coupled effect of PP fiber, PVA fiber and bacteria on self-healing efficiency of early-age cracks in concrete. Constr. Build. Mater. 2019, 228, 116810. [Google Scholar] [CrossRef]

- Aslani, F.; Hou, L.; Nejadi, S.; Sun, J.; Abbasi, S. Experimental analysis of fiber-reinforced recycled aggregate self-compacting concrete using waste recycled concrete aggregates, polypropylene, and steel fibers. Struct. Concr. 2019, 20, 1670–1683. [Google Scholar] [CrossRef]

- Aslani, F.; Sun, J.; Bromley, D.; Ma, G. Fiber-reinforced lightweight self-compacting concrete incorporating scoria aggregates at elevated temperatures. Struct. Concr. 2019, 20, 1022–1035. [Google Scholar] [CrossRef]

- Kakooei, S.; Akil, H.M.; Jamshidi, M.; Rouhi, J. The effects of polypropylene fibers on the properties of reinforced concrete structures. Constr. Build. Mater. 2012, 27, 73–77. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, G.; Wu, B.; Kong, X. A study on mechanical properties and permeability of steam-cured mortar with iron-copper tailings. Constr. Build. Mater. 2023, 383, 131372. [Google Scholar] [CrossRef]

- Bažant, Z.P.; Cusatis, G.; Cedolin, L. Temperature effect on concrete creep modeled by microprestress-solidification theory. J. Eng. Mech. 2004, 130, 691–699. [Google Scholar] [CrossRef]

- Rastrup, E. Heat of hydration in concrete. Mag. Concr. Res. 1954, 6, 79–92. [Google Scholar] [CrossRef]

- Pane, I.; Hansen, W. Concrete hydration and mechanical properties under nonisothermal conditions. ACI Mater. J. 2002, 99, 534–542. [Google Scholar] [CrossRef]

- Zhang, J.; Hou, D.W.; Gao, Y. Calculation of Shrinkage Stress in Early-Age Concrete Pavements. I: Calculation of Shrinkage Strain. J. Transp. Eng. 2013, 139, 961–970. [Google Scholar] [CrossRef]

- Schindler, A.K.; Folliard, K.J. Heat of hydration models for cementitious materials. ACI Mater. J. 2005, 102, 24. [Google Scholar] [CrossRef]

- Mi, Z.; Hu, Y.; Li, Q.; Gao, X.; Yin, T. Maturity model for fracture properties of concrete considering coupling effect of curing temperature and humidity. Constr. Build. Mater. 2019, 196, 1–13. [Google Scholar] [CrossRef]

- Vanmarcke, E.H. Random Fields: Analysis and Synthesis; MIT Press: Cambridge, MA, USA, 1983; ISBN 0262220261. [Google Scholar]

- Hou, D.; Zhang, J.; Chen, H.; Liu, W. Development of strength and elastic modulus of concrete under moisture and drying curing conditions. J. Hydraul. Eng. 2012, 43, 198–208. [Google Scholar] [CrossRef]

| Label | Strength | Cement | Water | Sand | Coarse Aggregate | Fly Ash | Superplasticizer | Polypropylene |

|---|---|---|---|---|---|---|---|---|

| C30-0 | C30 | 288 (P.O.32.5) | 180 | 750 | 1100 | 72 | 0.65% | 0 |

| C30-C-0.9 | C30 | 288 (P.O.32.5) | 180 | 750 | 1100 | 72 | 0.65% | 0.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Shen, L.; Gerong, W.; He, F.; Zhao, H.; Sun, J. A Novel Simulation Method for the Spatiotemporal Variation in Relative Humidity in Early Age of Polypropylene Fibers Reinforced Concrete. Buildings 2025, 15, 4032. https://doi.org/10.3390/buildings15224032

Chen Z, Shen L, Gerong W, He F, Zhao H, Sun J. A Novel Simulation Method for the Spatiotemporal Variation in Relative Humidity in Early Age of Polypropylene Fibers Reinforced Concrete. Buildings. 2025; 15(22):4032. https://doi.org/10.3390/buildings15224032

Chicago/Turabian StyleChen, Zhaohui, Linsong Shen, Wangdui Gerong, Fengyou He, Hongyu Zhao, and Junbo Sun. 2025. "A Novel Simulation Method for the Spatiotemporal Variation in Relative Humidity in Early Age of Polypropylene Fibers Reinforced Concrete" Buildings 15, no. 22: 4032. https://doi.org/10.3390/buildings15224032

APA StyleChen, Z., Shen, L., Gerong, W., He, F., Zhao, H., & Sun, J. (2025). A Novel Simulation Method for the Spatiotemporal Variation in Relative Humidity in Early Age of Polypropylene Fibers Reinforced Concrete. Buildings, 15(22), 4032. https://doi.org/10.3390/buildings15224032