Abstract

In an era in which more than half of the world’s population resides in urban centers, cultivating food within cities, close to consumers, is increasingly crucial. Given the limited availability of arable land in urban centers, food can be cultivated on a large scale within residential buildings equipped with balconies, in both current and future Mediterranean cities. This research defines the term “edible balconies” as a subtype of Zfarming and urban agriculture, indicating that the floors, walls, edges, and overhead spaces of edible balconies offer horizontal and vertical surfaces suitable for cultivating edible plants. The primary objective of this article is to propose a series of design guidelines for architects interested in designing edible balconies. It also highlights major obstacles that architects may encounter during the design process. To identify key design guidelines, determine significant obstacles, and develop design proposals, a comprehensive literature review was conducted on urban agriculture, horticulture, building-integrated agriculture, and Zfarming. By considering these suggested guidelines, architects can incorporate edible balconies into residential buildings. Such a design approach aims to develop a multifunctional housing typology that not only provides habitat but also promotes food cultivation.

1. Introduction

According to UN projections, the global population is expected to reach 8.5 billion by 2030, increase to 9.7 billion by 2050, and fall within the range of 10.2 to 10.4 billion by 2100. The global population has surpassed 8 billion, which is three times larger than in the mid-20th century [1,2]. More than half of the world’s population now lives in cities, compared to only about 30% in 1950. By 2050, around two-thirds of the global population is expected to reside in urban areas. In many regions, cities are expected to continue growing [3].

Rapid urbanization leads to new development occurring on prime agricultural land, leading to the loss of arable land [4,5,6,7]. For countries with large populations to feed, losing high-quality arable land to urban expansion is a significant concern [4,8]. Arable land within urban peripheries is estimated to account for approximately one-quarter of the world’s total arable land [4,9]. In regions such as Asia and Africa, arable land in peri-urban areas is vital for ensuring food security. The loss of such land in these regions could threaten food security [4,5].

The impact of climate change on current and future global agricultural production is another vital issue [10,11,12,13]. Agriculture is an economic activity vulnerable to climate change [12,14]. Extreme weather events related to climate change—such as heat waves, droughts, floods, soil degradation and erosion, changes in growing seasons, desertification, and rising sea levels—can reduce both existing and future arable land and crop yields [10,12,13,14]. Climate change has decreased the production of potatoes, rice, wheat, maize, and vegetables, and it is expected to continue declining globally by 2050 [15,16]. In the Mediterranean region, crop yields are also predicted to decrease due to climate change [17,18,19]. Agriculture is the primary source of income for developing nations. Millions depend on it for their livelihood and employment. It is projected that climate change will lead to reduced crop yields in developing countries, impacting low-income farmers [11,12,13,14]. By 2080, between 5 million and 170 million people are expected to be at risk of starvation due to climate change [17,20].

Currently, cities depend on importing food from faraway places [21]. A city with 10 million or more residents needs to bring in over 6000 tons of food each day [22]. This heavy reliance on external food sources makes urban areas vulnerable during crises. Urban food security can be at risk if city supply lines are disrupted [21,23]. Events such as the food crises in Cuba, the 2007–2008 food riots, and the Ukraine crisis have highlighted the vulnerability of cities in terms of food security.

The food crisis in Cuba: The fall of the Soviet Union in 1989 negatively affected food production, distribution, and imports in Cuba. Urban residents suffered food shortages because cities mainly relied on supplies from rural areas and abroad [24,25,26]. The 2007–2008 food riots: Rising prices for basic foods such as wheat, soy, rice, dairy, and other staples in 2007–2008 triggered food riots in major cities across the globe. These price spikes reduced the purchasing power of low-income populations [27,28,29]. The Ukraine crisis: The global food security situation is under severe stress due to the ongoing war in Ukraine, which disrupts both local and international food and energy markets [30,31,32,33]. Many developing countries in East Africa, North Africa, and the Middle East (MENA) depend heavily on wheat and cereal imports from Ukraine. Disruptions in supply chains and rising global prices for agricultural commodities pose a serious threat to the food security of low-income urban dwellers in these regions [31,32,34]. Individuals with limited income often cannot afford nutritious food rich in vital micro- and macronutrients [35].

As is evident, the agricultural sector will face multiple challenges in the 21st century. To meet the food demands of a growing population, it must adjust to climate change, increase food production, and adopt more sustainable and efficient farming techniques [36]. Specifically, urban population growth is driving the need to reconsider how future city residents will be fed [37,38]. Urban agriculture can serve as a promising solution [7,21,29,39,40]. Growing food on a large scale within cities can help alleviate the current and future pressures on rural agriculture. It can complement rural production and significantly contribute to the urban food system [29,39,41].

1.1. Urban Agriculture’s Correlation with Urban Sustainability

Urban agriculture can be regarded as an industry located within urban or peri-urban areas. It encompasses the cultivation, raising, processing, and distribution of a variety of food and non-food items to urban centers. Typically, it makes use of labor, resources, products, and services available within and surrounding the city, thereby supplying the urban area with goods and services [42]. Urban agriculture can be incorporated into urban land and buildings to maximize urban space [43]. According to the Food and Agriculture Organization, approximately 100 million individuals engage in urban agriculture, with a portion of their income dependent on it [44].

Urban agriculture fulfills economic, social, and environmental roles that contribute to urban sustainability [37,45]. Regarding the economic sustainability of cities, some low-income urban residents, particularly in developing countries, depend on urban agriculture as a source of employment and income, and a means to offset food expenses [37,45,46]. It can enhance both the quantity and quality of food accessible to low-income urban dwellers while supplementing their nutritional requirements [37,45,47]. Concerning the social sustainability of cities, urban agriculture serves as a platform for education, youth development, and learning opportunities [45,48]. It can also provide a basis for social interaction [37]. Urban agriculture also offers environmental advantages. Expanding green spaces within the urban fabric can assist in reducing air and surface temperatures [49,50]. Furthermore, gardens embedded within urban fabric can help mitigate urban stormwater impacts [37,49,51].

1.2. Zero-Acreage Farming (Zfarming)

Vacant land constitutes a valuable resource in most urban areas [39,41]. The projected increase in city populations is expected to amplify the demand for urban land [45]. Numerous cities are witnessing escalating property prices and the conversion of public green spaces and agricultural land near urban centers for alternative uses [23]. Urbanization appears inevitable; therefore, new approaches should be considered to ensure the delivery of fresh, nutritious food to urban areas [52]. Zero-Acreage Farming (Zfarming) has emerged as an innovative method of food production and may serve as a viable solution to land scarcity and the provision of fresh, nutritious food in metropolitan regions.

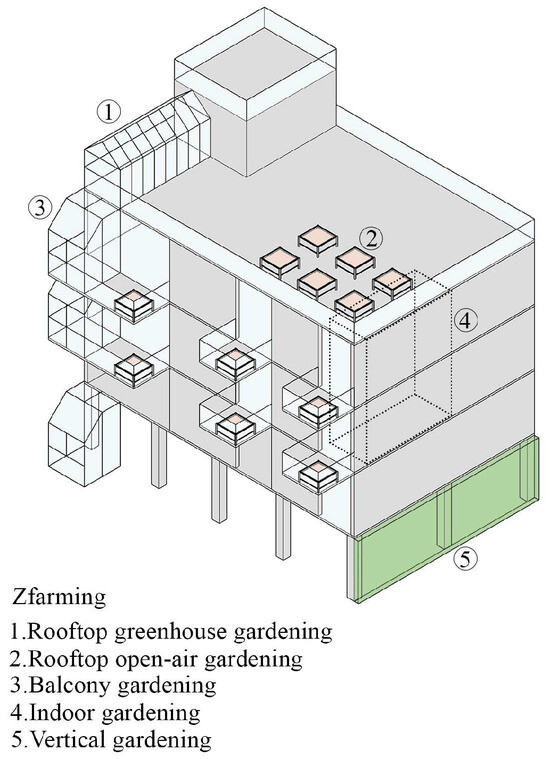

Zfarming constitutes a distinctive form of food cultivation that does not require land. The principal aim of Zfarming is to integrate architecture with food production in order to cultivate food in large quantities in and on buildings in cities. It is generally incorporated into existing mixed-use buildings. Zfarming includes all possible methods of cultivating food, such as soil-based and soilless methods. The focus is on the cultivation of fruits and vegetables. The approach also aims to utilize and recycle the waste resources generated by buildings, such as waste heat, wastewater, and organic waste. It can be regarded as a subtype of urban agriculture and serves as a supplementary method to traditional ground-based agricultural production [38,41] (Figure 1).

Figure 1.

Zfarming can be considered a subtype of urban agriculture (developed by the author, 2025).

Food can be cultivated in available spaces in and on buildings within dense urban areas. Underutilized spaces such as balconies, rooftops, south-facing walls, windowsills, external staircases, interior spaces, transitional spaces, and gardens at the front and back of buildings can be effectively used to produce food [21,53]. The potential production of fruit and vegetable crops exceeds that of other food crops, such as grains. Growing vegetables and fruits on just 1 m2 can yield up to 50 kg annually, depending on the species and technologies used. Additionally, many species have short growth cycles and can be harvested 60 to 90 days after planting [22,29,39,54]. Considering this potential yield and short cycle, it is essential to utilize available vacant space in and on buildings in order to ease the pressure on rural agriculture [22]. This research advocates for the idea that food can be cultivated on a large scale in and on buildings in both present and future cities. It integrates architecture with innovative food cultivation methods to enhance food production and reimagine cities as places for agriculture. In this concept, urban residents participate in food production alongside their roles as consumers.

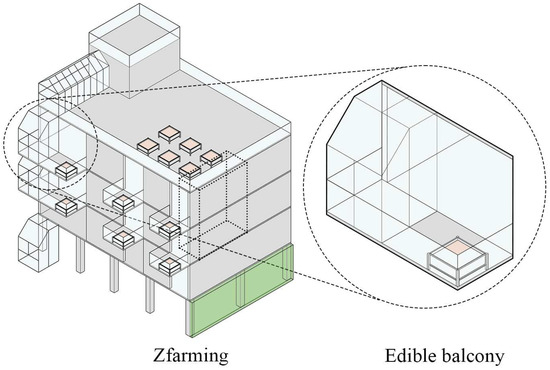

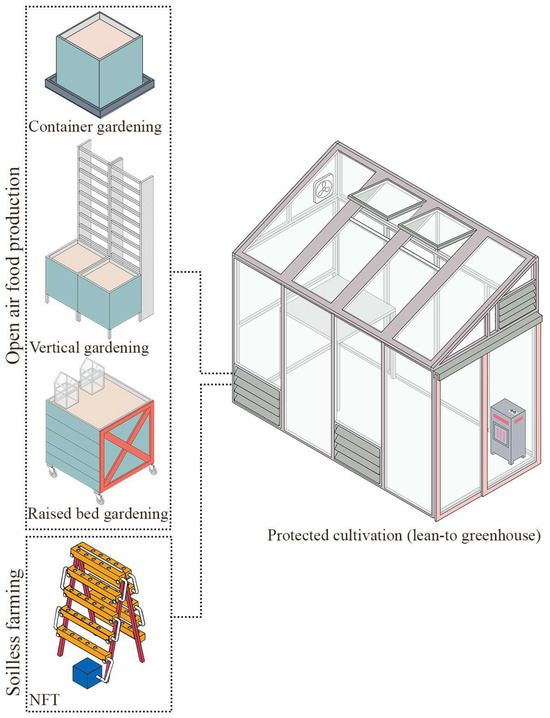

The term “edible balcony” describes growing fruits, vegetables, herbs, and medicinal plants on balconies. It focuses on cultivating short-term, highly perishable crops rather than long-cycle crops. It is usually practiced on private balconies with limited space in dense urban areas. It utilizes various space-efficient growing methods, including container gardening, raised beds, vertical gardening, greenhouse cultivation, and innovative techniques such as soilless farming. These small-scale or mini gardens are typically operated by families, and the harvest is mainly used for personal consumption rather than for sale. Adding edible balconies to residential buildings creates a multifunctional housing type that offers both living space and productivity. An edible balcony can be considered a subtype of Zfarming and urban agriculture (Figure 2).

Figure 2.

Edible balcony as a subtype of Zfarming (developed by the author, 2025).

1.3. Balconies in the Mediterranean Region

The Mediterranean climate is typically characterized by hot, dry summers and mild, wet winters. It generally occurs between 30° north and 45° south of the equator. Most regions within this climatic zone experience moderate winter temperatures and warm summer conditions. Irregular precipitation patterns are common, with the majority of rainfall occurring during the winter months. Temperature variations can be considerable across different areas within this zone. The Mediterranean climate supports agriculture [55]. The vernacular urban fabric often fosters urban farming, with small to medium-sized plots situated within cities or on the outskirts, cultivating fresh produce such as vegetables, fruits, and herbs [56]. Balconies, rooftops, and flat or vertical surfaces on residential buildings that receive sufficient sunlight are suitable for food cultivation.

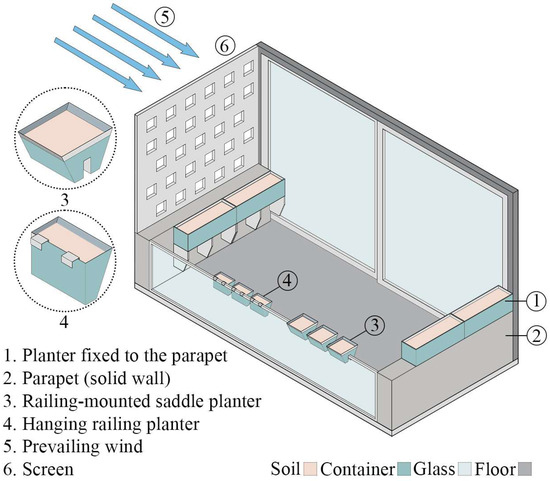

In the Mediterranean region, balconies are often used to incorporate green elements, either for decorative purposes or to cultivate fresh vegetables and herbs. Typically, balcony floors, walls, and edges serve as the main growing areas. A variety of containers, including hanging railing planters and railing-mounted saddle planters, are employed. To make efficient use of vertical space, these planters are either attached directly to walls or arranged on shelves. Low-tech gardening techniques are widely practiced in open-air spaces such as balconies (Figure 3).

Figure 3.

Use of balcony floors, railings, and vertical spaces for plant cultivation in the Mediterranean region (developed by the author, 2025).

This research highlights open-air cultivation as one way to grow food on balconies. It also suggests that, to grow food year-round, protected cultivation should be considered. Additionally, it proposes innovative methods such as soilless farming. Overall, this study outlines three distinct cultivation methods for edible balconies in the Mediterranean region: (1) open-air food production, (2) protected cultivation, and (3) soilless farming.

1.4. Purpose of the Research

To design edible balconies in residential buildings, a series of design guidelines must be considered. Architects should incorporate these guidelines throughout the design process to ensure the necessary infrastructure for food production is in place. This research aims to (1) review the existing literature on urban agriculture, horticulture, building-integrated agriculture, and Zfarming; (2) identify and extract key design guidelines; (3) propose a comprehensive set of design guidelines; (4) identify major obstacles to designing edible balconies; and (5) suggest design proposals.

1.5. Research Gap

The literature lacks a comprehensive set of design guidelines for architects to follow when designing edible balconies in residential apartment buildings in Mediterranean climates. It also does not identify major obstacles that architects might encounter during the design process. Although balcony gardening has been discussed in broader contexts within urban agriculture, horticulture, and building-integrated agriculture research, there remains a dearth of comprehensive studies on balcony food production in the Mediterranean region. To our knowledge, this study is among the first to compile and organize the key design guidelines and obstacles specific to the Mediterranean region.

1.6. Research Questions

This research investigates the following two key questions:

- (1)

- What key design guidelines should architects follow when designing edible balconies for residential apartment buildings in Mediterranean climates?

- (2)

- What are the main obstacles to designing edible balconies for residential apartment buildings within Mediterranean climates?

1.7. Research Contribution

The main contribution of this research to the existing literature is as follows: It consolidates the scattered data on balcony gardening and presents a comprehensive set of architectural design guidelines. It also identifies the main obstacles that architects might encounter during the design process. Neither the design guidelines nor the main obstacles have been systematically addressed in previous studies. This research aims to expand the current understanding of urban agriculture, horticulture, and building-integrated agriculture by proposing a region-specific framework for edible balconies in the Mediterranean context.

1.8. Research Limitations

This research is solely focused on balconies as potential spaces for food cultivation. In terms of building typology, it is limited to residential apartment buildings. The focus is on the Mediterranean climate.

2. Materials and Methods

A literature review was conducted to identify key design guidelines, recognize major obstacles, and develop corresponding design proposals. Google Scholar was used to collect secondary data by reviewing relevant literature on urban agriculture, horticulture, building-integrated agriculture, and Zfarming. The reviewed documents included articles, book chapters, books, and fact sheets.

Articles, book chapters, and fact sheets: The search strategy for articles, book chapters, and fact sheets began with defining keywords relevant to the research themes. General keywords included “balcony gardening,” “cultivating food in small spaces,” and “building-integrated agriculture.” To capture low-tech open-air production methods on balconies, the keywords “container gardening,” “vertical gardening,” and “raised bed gardening” were used. For protected environments, including small lean-to and mini greenhouses that can be installed on balconies, the keyword “low-tech greenhouses” was applied. Finally, to address innovative soilless techniques, keywords such as “soilless farming,” “soilless farming review,” and “hydroponic systems review” were included.

The following inclusion and exclusion criteria were applied: (1) The selected material was mainly drawn from recent publications, with a focus on works from the past 10–15 years, although earlier influential studies were also considered when highly relevant. (2) Publications were required to be in English and peer-reviewed by experts in the field. (3) The content needed to be directly relevant to urban agriculture, horticulture, building-integrated agriculture, or Zfarming. Titles and abstracts were screened prior to a full review. In total, 80 articles, 8 book chapters, and 8 fact sheets were included.

Books: Google Books was used to review published books on urban agriculture and horticulture. For general topics, the keywords “balcony gardening” and “cultivating food in small spaces” were applied. To identify books on low-tech open-air food production, the keywords “container gardening,” “raised bed gardening,” and “vertical gardening” were used. Finally, the keyword “greenhouse gardening” was applied to capture books on protected cultivation.

The following inclusion and exclusion criteria were established: (1) Priority was given to recently published works, generally within the last 10–15 years, while earlier influential titles were considered when highly relevant. (2) Books had to be published in English and by reputable publishers, defined as established academic or professional publishing houses. Self-published books were excluded. A total of 61 books were included. In total, 157 documents (80 articles, 8 book chapters, 8 fact sheets, and 61 books) were included in the final review.

The selected texts were read thoroughly to identify and extract the relevant information. A qualitative content analysis method was used to evaluate the data collected. The relevant data in each text were identified, summarized, and noted rather than coded. Each summary captures the main ideas of the document. All summarized texts and notes were placed into separate Word files and organized by themes and keywords. During the summarization process, an effort was made to ensure the data’s original meaning was preserved.

Finally, all summarized data were synthesized, interlinked, and paraphrased. By following this process, a concise and well-structured synthesis of the relevant literature was compiled. In the next phase, a set of design guidelines was developed using the summarized data from the literature review. Additionally, the main obstacles were identified. Based on the summarized data, three design proposals were developed.

3. Results

3.1. Edible Balconies: Design Considerations

Given the scarcity of available land in densely populated urban areas, spaces in and on buildings—such as rooftops, balconies, windowsills, south-facing walls, external staircases, and transitional spaces—can be used for food cultivation [22,53,57,58,59,60]. Apartment buildings in urban environments usually have balconies, which provide horizontal and vertical surfaces such as floors, walls, edges, and overhead spaces suitable for growing edible plants [60,61,62]. Cultivating food on balconies transforms underused areas into productive spaces for food production [61].

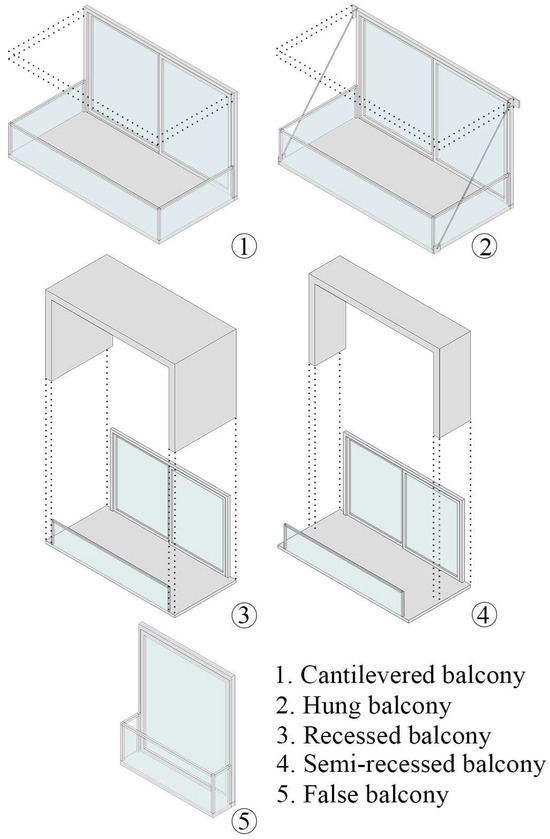

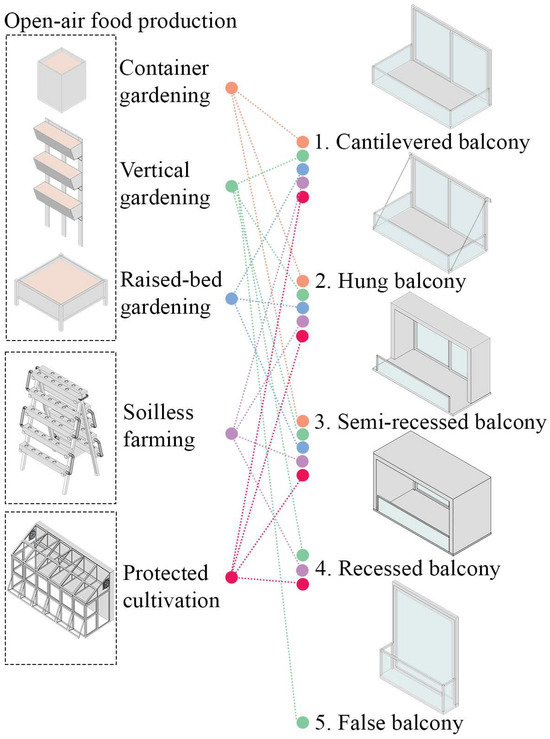

Apartment balconies can be classified as follows: (1) cantilevered balconies, (2) hung balconies, (3) semi-recessed balconies, (4) fully recessed balconies, and (5) Juliet or false balconies (Figure 4). Based on the literature review on urban agriculture, horticulture, building-integrated agriculture, and Zfarming, the following three distinct cultivation methods can be applied on balconies: (1) open-air food production, including container gardening, vertical gardening, and raised bed gardening; (2) protected cultivation using lean-to or mini greenhouses; and (3) soilless farming techniques such as hydroponics.

Figure 4.

Classification of apartment balconies (developed by the author, 2025).

Open-air food production, protected cultivation (in lean-to or mini greenhouses), and soilless farming methods are suitable for cantilevered balconies, hung balconies, and semi-recessed balconies. Juliet balconies, or false balconies, lack sufficient space; therefore, they are appropriate for vertical gardening techniques. Fully recessed balconies typically lack adequate sunlight; thus, the installation of grow lights is recommended. Vertical gardening with grow lights, lean-to or mini greenhouses equipped with grow lights, and soilless farming methods incorporating grow lights can be effectively implemented in such settings (Figure 5).

Figure 5.

Integration of open-air food production, soilless farming, and protected cultivation methods within different types of balconies (developed by the author, 2025).

3.1.1. Open-Air Food Production

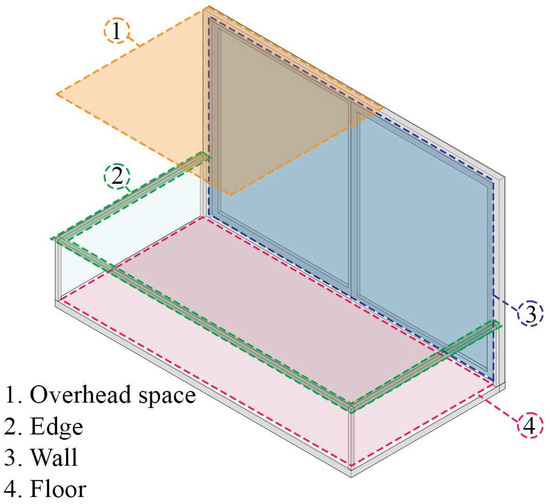

Balconies serve as suitable locations for cultivating edible crops such as vegetables, fruits, and herbs, given their typical exposure to sufficient sunlight [57,60,63]. Moreover, balconies generally feature floors, walls, overhead surfaces, and edges that may be utilized for food cultivation [62] (Figure 6).

Figure 6.

Food cultivation can be implemented on balcony floors, walls, overhead surfaces, and edges (developed by the author, 2025).

Container Gardening

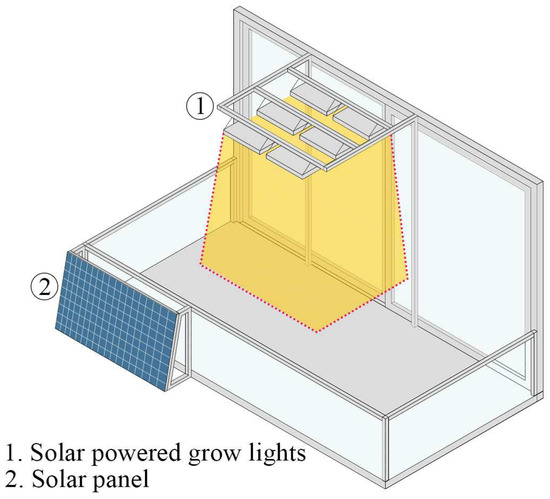

Container gardening can serve as a viable solution to address the limited availability of ground-level space [64,65]. In densely populated urban environments where surfaces are predominantly covered with hard materials, it offers an alternative gardening method [64]. This form of gardening is well-suited for cultivating plants in constrained spaces such as balconies [62,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79]. Edible plants can be cultivated in potting soil within containers of various sizes and shapes, including ovals, circles, squares, and rectangles [60,80]. Sunlight is essential for optimal plant growth [59]. Typically, vegetables, fruits, and herbs require at least six to eight hours of daily sunlight [58,61,65,67,68,69,71,72,75,78,80,81,82,83,84,85,86,87,88,89]. Containers should be placed where they are exposed to adequate direct sunlight [61,62,67,68,90]. South- and southeast-facing balconies generally receive the maximum sunlight during the day, rendering them suitable locations for cultivating edible plants [62,71,80,91,92]. In urban areas, neighboring structures such as buildings, trees, solid railings, and overhanging roof eaves can cast shadows on balconies, thereby posing a potential challenge for food cultivation [76,80,90,91,92,93]. If the balcony does not receive sufficient natural light per day, grow lights can be installed on the balcony [76] (Figure 7).

Figure 7.

Grow lights and solar panels can be installed on balconies (developed by the author, 2025).

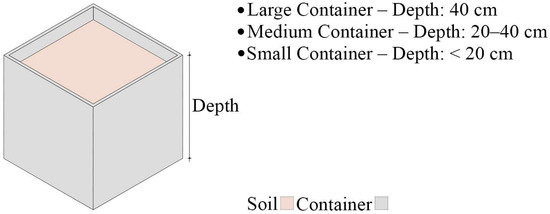

The dimensions of the container must be taken into account; it should be sufficiently deep and wide to provide edible plants with sufficient room for root growth [61,62,65,66,68,73,75,79,83,88,90,92,94,95]. Large containers generally possess a minimum depth of 40 cm [16 in.], medium containers range from 20 to 40 cm [8 to 16 in.] in depth, and small containers are less than 20 cm [8 in.] deep [83] (Figure 8). Plants with shallow root systems can thrive in small containers, hanging baskets, or hanging planters [61,91]. Conversely, plants with deep root systems require medium or large containers [68,70,91,96]. Furthermore, it is essential to consider the ultimate size of the plant during planning; vining plants, in particular, may outgrow their allocated space and extend across both horizontal and vertical surfaces within the balcony [61].

Figure 8.

Containers with varying depths (developed by the author, 2025).

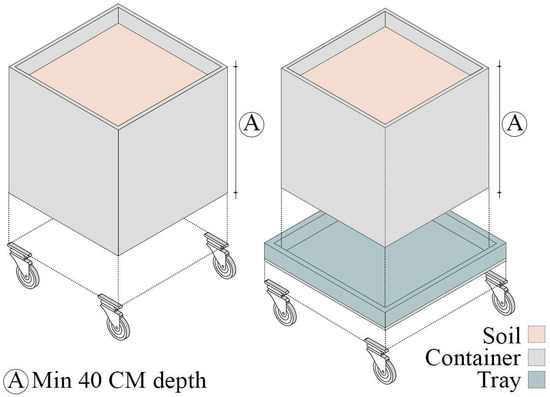

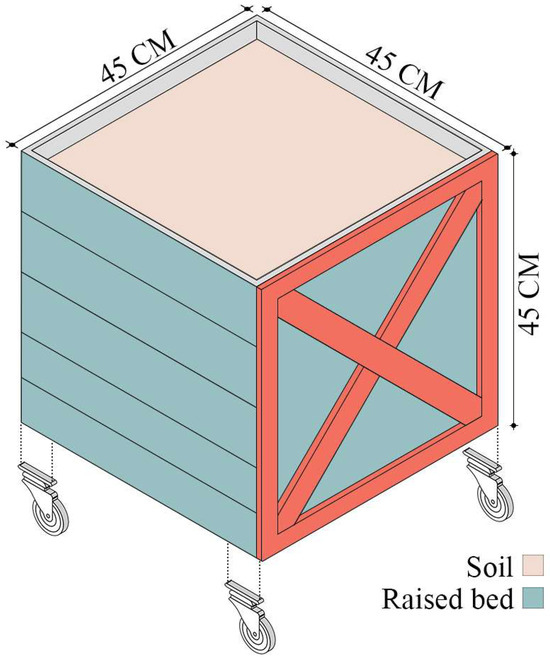

Large containers, once filled with potting soil and watered, are heavy to move. They become a fixture on the balcony [61,68,80,85,92]. In order to be able to move large containers, casters can be attached to the bottom of the containers. Large containers can also be placed on trays with casters or plant caddies [57,68,78,80,97] (Figure 9). To reduce the container’s weight, lightweight materials such as plastic, fiberglass, fiber clay, or fabric can be considered for large containers [60,61]. Terracotta or glazed ceramic containers are usually heavier than containers made from lightweight materials [61].

Figure 9.

Mobile containers with casters (developed by the author, 2025).

Containers can be fabricated from a range of materials, including terracotta clay, terrazzo, ceramic, plastic, wood, glazed stoneware, metal, concrete, stone, fiberstone, fiberglass, wicker, fabric, and grow bags [57,62,64,67,70,75,76,79,80,81,82,83,90,92,98,99,100,101,102]. Additionally, containers may be produced from recycled materials. Examples include used cans, baskets, metal crates, file drawers, wine boxes, gallon-sized buckets, polyethylene buckets, or wooden boxes that can be repurposed into containers [61,62,64,68,70,71,81,83,84,86,89,90,93,100,103,104]. It is essential that the items selected are capable of retaining soil, possess sufficient depth, and facilitate proper drainage [61,88,92,94]. Adequate drainage is vital. If water does not drain well from the container, it creates a soggy soil that can kill the plant’s roots [62,65,67,68,71,74,75,76,78,79,80,82,84,86,88,89,90,92,93,103].

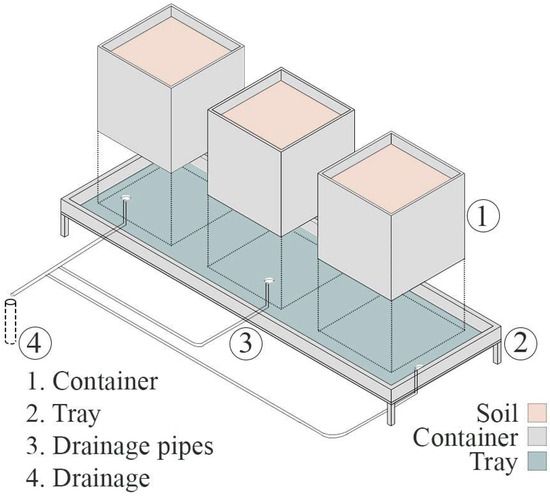

The balcony should be equipped with an appropriate drainage system. Absent this, runoff water from containers may seep onto the balcony below, potentially causing damage to the flooring materials and structural elements, as well as disturbance to neighboring residents [62,65,78,92,97]. To mitigate runoff water, containers may be positioned on a tray elevated above ground level. The tray can be supported by several legs, with a drainage pipe attached to it. This drainage pipe should be connected to the balcony’s existing drainage system. The tray must be waterproof and strong enough to handle the container’s weight (Figure 10).

Figure 10.

Containers on a tray with integrated drainage pipes (developed by the author, 2025).

Plants in containers require regular watering, as they tend to dry out more rapidly than those in the ground due to the limited volume of growing medium [61,65,66,67,70,71,73,74,75,78,79,80,84,88,89,90,91,92,96,100,103,105]. Larger containers contain greater quantities of potting soil, thereby allowing them to retain more moisture and consequently reducing the frequency of watering compared to smaller containers [57,62,67,69,70,80,84,91,95,100]. Watering may be performed manually using buckets or with a garden hose or drip irrigation system [68,72,74,75,90,91,97,98,106]. The proximity of the edible garden to the irrigation water source is of critical importance [67,71,82,83,86,87,95]. For irrigation purposes, it is advisable to have one or more spigots installed on the balcony [70,84,91,92,96,106,107].

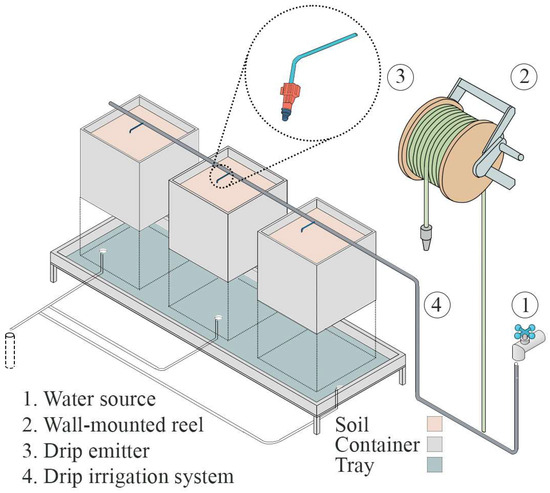

A garden hose can serve as a primary tool for irrigation. Owing to their lightweight and flexible nature, garden hoses are easy to handle and store; they can also be conveniently coiled for winter storage [91,106]. Furthermore, a wall-mounted reel equipped with an automatic mechanism for winding the hose may be installed to facilitate storage [70]. Moreover, a drip irrigation system can be incorporated on the balcony; this system comprises tubes and emitters designed to dispense water in drops directly at the plant roots [68,72,92,96,97,106,108,109]. To enhance automation, an automatic timer can be integrated into the drip irrigation setup [69,90,92,96,98,109]. It is important to note that automatic drip irrigation systems require outdoor water sources, such as spigots [91]. Such systems are advantageous in delivering water directly to the root zone of plants, thereby conserving water by reducing evaporation, preventing misapplication, and eliminating the need to soak the entire cultivated surface [67,97,98] (Figure 11).

Figure 11.

Irrigation system components (spigot, wall-mounted reel, and drip irrigation system) suitable for balcony installation (developed by the author, 2025).

During the summer months, small containers may require watering twice daily [67,71,80,81,83,90,92,97,107]. During such periods, plants in containers can wilt if the growing medium is unable to retain moisture. Applying a layer of mulch or compost atop the container can assist in maintaining the moisture level of the growing medium [61,62,71,98]. Typically, containers composed of non-porous materials lose less moisture compared to those made from porous materials such as unglazed clay or moss-lined containers [67,90]. Metal containers should be positioned carefully on balconies exposed to direct sunlight, as they are susceptible to overheating; under such conditions, the roots of the plants may be burned [61,71,84].

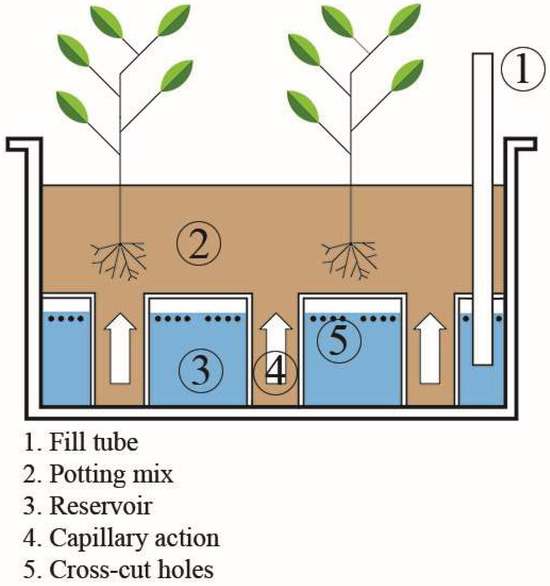

Edible plants can be cultivated within a self-watering container or subirrigated planter, which incorporates a water reservoir situated at the base of the container. This reservoir may be filled up through a tube. The growing medium positioned above the reservoir wicks water to maintain appropriate moisture levels. As edible plants absorb moisture through their roots, water from the reservoir is drawn upward into the growing medium, ensuring optimal soil moisture. The problem of overwatering is resolved as the growing medium absorbs only the necessary amount of water through capillary action, corresponding to the requirements of the edible plants [57,58,62,67,68,70,92] (Figure 12).

Figure 12.

Self-watering container (developed by the author, 2025).

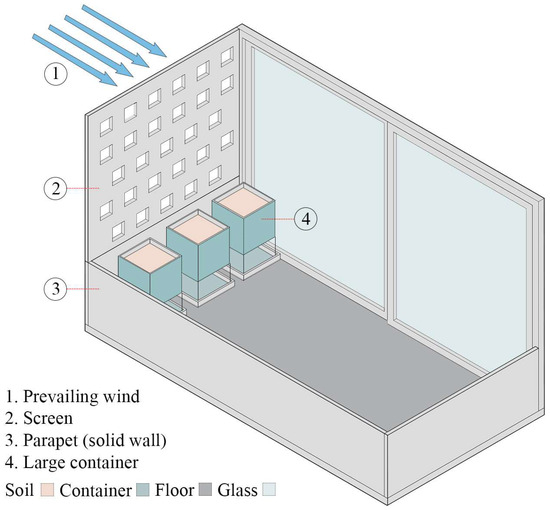

The prevailing wind direction must be considered carefully during the design phase. Similarly to rooftops, high-floor balconies are generally exposed to strong winds, which can cause damage to plants by dislodging their fruits and by tearing and battering their leaves [61,69,81,82,91,92,93,96]. It is advisable to utilize large containers rather than small, lightweight ones on high-floor balconies [57,69,81,88]. Strong winds have the potential to displace or topple small, lightweight containers [57,71,81,88]. Edible plants can be protected by vertical barriers, such as screens or walls, designed to deflect prevailing winds [57,62,69,74,82,84,92,96,97,107]. These screens should be securely attached to the balcony walls, floors, or railings; failure to do so may result in them being blown over [90,92] (Figure 13). Additionally, wind can accelerate moisture loss within the growing medium in containers [69,71,91,92,96]. The application of a mulch or compost layer atop the growing medium may help reduce moisture loss [91,92,96].

Figure 13.

A vertical barrier, such as a screen, can be used to protect an edible balcony (developed by the author, 2025).

The balcony structure represents another vital aspect. It must possess adequate load-bearing capacity. After watering, the containers add supplementary weight, which must be taken into account. The load burden can be alleviated by selecting lightweight containers such as plastic, resin, or fiberglass [62,71,82,92]. To achieve an even distribution of weight, containers should be strategically positioned across the balcony rather than concentrated in a single corner [62,82,92].

Vertical Gardening

Traditional gardening methods usually require a lot of land, which is limited in densely populated urban environments [94]. Urban horticulturists may have greater access to vertical surfaces than horizontal ones for the cultivation of edible plants [58,60,72]. Creating gardens on the balconies of apartment buildings—where conventional gardening space is absent—requires innovative techniques such as vertical gardening [61,66,76,91,94]. Edible plants can be cultivated vertically where horizontal surfaces are limited, such as on balconies [58,66,69,74,81,82,91,94,96,97,98,101,108,110,111]. Vertical gardening conserves space by enabling plants to grow upward and above the ground, thereby reducing their footprint [62,68,81,87,94,97,98]. This method optimizes the utilization of vertical space for food production, leading to an expansion in cultivation area [69,77,81,112].

By cultivating edible plants vertically, more edible plants can be grown [91,108,110,111,112]. Typically, apartment buildings feature south-facing walls that receive adequate daily sunlight, which can be utilized for plant cultivation [62,96]. These vertical surfaces are suitable for supporting climbing and trailing crops [74]. Presently, the market offers waterproof membranes, irrigation systems, and lightweight growing mediums that facilitate the cultivation of plants on vertical surfaces [96].

To facilitate the vertical cultivation of edible plants, manufacturers have designed hanging wall units that can be directly affixed to balcony walls. These units are fabricated from materials such as plastic, metal, ceramic, or terracotta [61,80,98] (Figure 14). Hanging wall planters generally feature shallow soil pockets that tend to dry out frequently; therefore, they require regular watering. To safeguard the balcony wall against potential damage or staining, hanging wall planters should be equipped with an appropriate drainage system and a built-in moisture barrier [61].

Figure 14.

Hanging wall units (developed by the author, 2025).

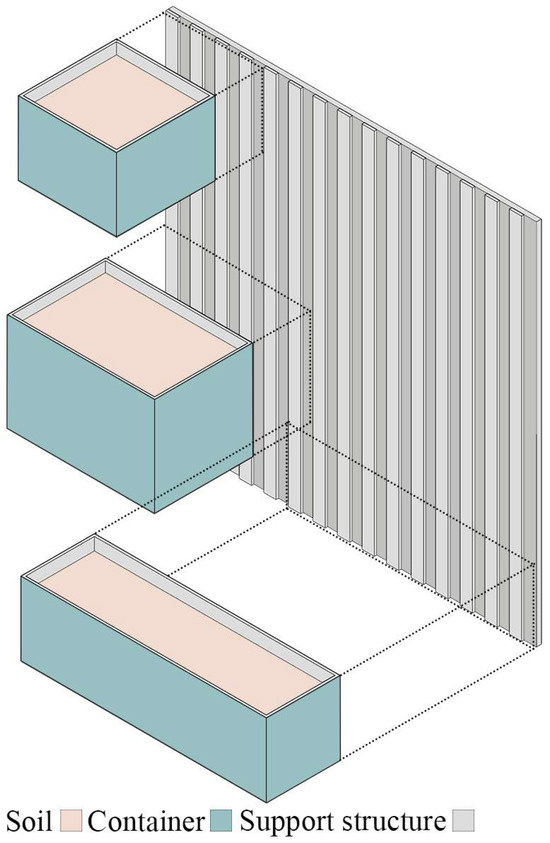

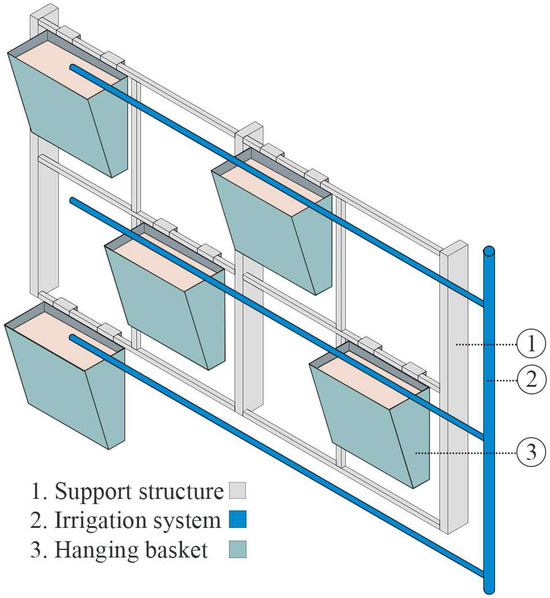

Designing a living wall unit for a balcony wall is another option. A living wall can be affixed to a balcony wall and comprises a structural support directly attached to the wall, as well as modular planters of various sizes and materials. These planters contain edible plants and potting soil and are securely attached to the support structure [91,111,113] (Figure 15). Additionally, containers, hanging baskets, suspended grow bags, and modular fabric bags can serve as planters and are commercially available [96]. Support structures are typically constructed from wood or metal [61]. It is essential that the support structure possesses adequate strength to bear the weight of the planters, growing medium, and mature plants, including fruits [91] (Figure 16).

Figure 15.

A living wall unit (developed by the author, 2025).

Figure 16.

Living wall unit with hanging baskets (developed by the author, 2025).

A drip irrigation system is suitable for irrigating a series of planters within a living wall [91]. This system can be affixed to the supporting structure to facilitate the watering of the planters [91,106,110,111]. Market-available living wall products feature integrated self-watering systems designed to automate the irrigation process [96,111]. The water requirements for irrigating a living wall are influenced by factors such as climate conditions, plant species, planter types, and wall location [91]. Similarly to container gardening, the growing medium in a living wall system should be replaced on an annual basis. An appropriately installed living wall unit should be positioned to receive a minimum of six to eight hours of sunlight each day. Furthermore, regular maintenance activities such as weeding, pruning, and trimming are necessary [111].

A living wall can be assembled by stacking containers vertically [66,96,108,111]. Each container measuring 17 cm by 60 cm (7 by 24 in.) offers a cultivable surface area of 102 cm2 (1.17 ft2). When five such containers are stacked and affixed to a support structure on a wall, the cumulative cultivating surface area amounts to 510 cm2 (0.54 ft2). This method allows for efficient utilization of a small balcony wall space, thereby transforming a narrow section or the entirety of a balcony wall into a living wall [111].

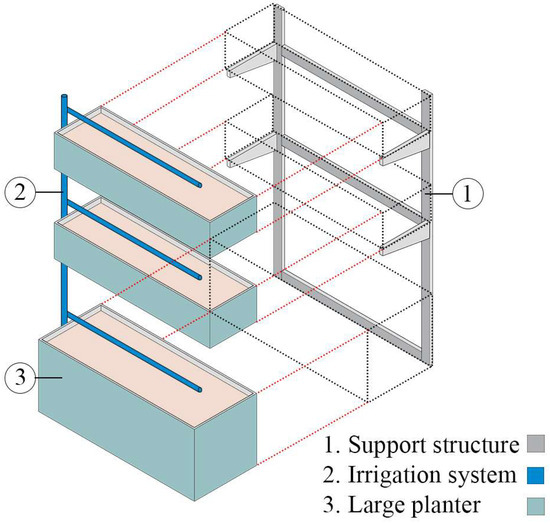

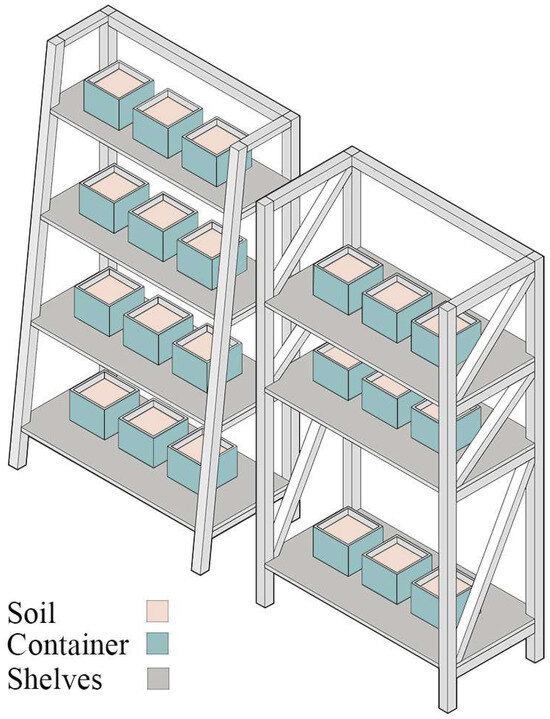

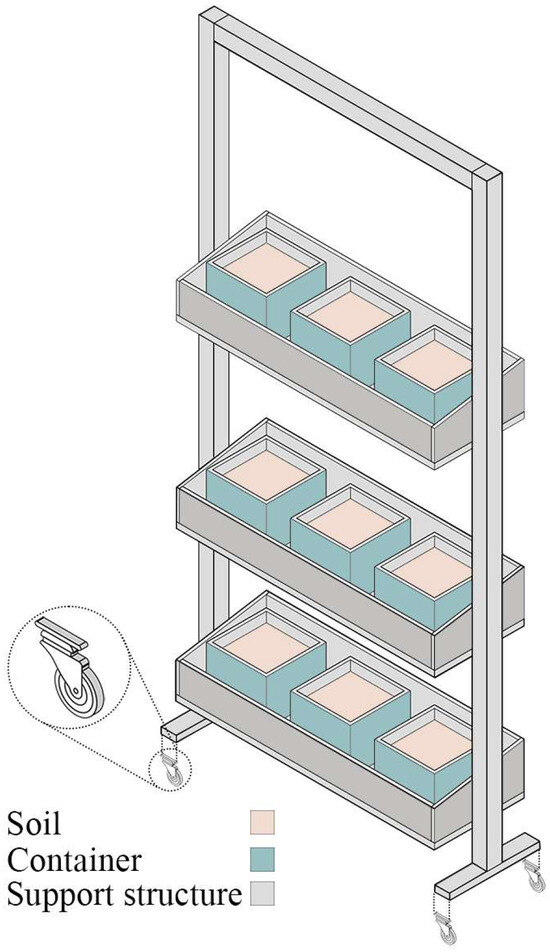

Typically, containers occupy a small footprint. Square or rectangular containers optimize space utilization near building edges with straight lines more effectively than round containers [70]. Such containers can be organized at the base of a south-facing balcony wall, adjacent to a vertical support structure such as a trellis or wire mesh. Edible plants may be cultivated within these containers and trained to grow vertically [67,70,91,96,108] (Figure 17). A living wall can be designed as a standalone structure that is made of wood or metal. Shelves are attached to a wooden or metal structure. Containers of various sizes and shapes can be positioned on the shelves [98,111] (Figure 18). Casters may be affixed to the base of the support structure to facilitate the mobility of the entire living wall system [111]. Additionally, a shelving unit or utility rack may be positioned adjacent to a south-facing wall, with containers of various sizes and shapes arranged within the structure [66,84]. Both the shelving unit and utility rack should be strong enough to handle the weight of the containers, which includes a moist growing medium and mature plants [66,77]. Lastly, attaching casters to the bottom of these units makes them mobile [77] (Figure 19).

Figure 17.

Containers placed at the base of a support structure (developed by the author, 2025).

Figure 18.

A living wall designed as a standalone structure (developed by the author, 2025).

Figure 19.

A freestanding mobile shelving unit (developed by the author, 2025).

The balcony walls must be constructed from suitable materials to ensure they can bear the weight of the attached living wall [61,96,111]. A living wall comprises a moist growing medium, mature plants, containers, and a supporting structure. The entire system’s weight is supported by the wall [61,72,94,96]. Planters chosen for a living wall should be able to hold water so, over time, the moist growing medium does not damage the wall structure due to prolonged moisture exposure [111].

Balcony edges typically receive the maximum amount of direct sunlight each day; therefore, they constitute an ideal location for the cultivation of food products [61,62,92]. Balcony railings can support railing planters. Railings may be constructed from either opaque materials, such as concrete, brick, or cement blocks; or transparent or translucent materials, such as glass with metal frames [61,80]. Railing planters can be either hung from the balcony railings or placed atop the railings [61,62,80]. Hanging railing planters can be attached to the railings using hooks or brackets [62,84,90]. If the balcony railing is wide enough, then planters can be positioned on top of the railing. If the balcony is exposed to wind, then the planter should be adequately secured to the railing [62,96]. Some railing planters are saddle-shaped and are placed on both sides of the railings [80,84] (Figure 20). Similarly to small containers, railing planters tend to dry out quickly due to the maximum direct sunlight received by balcony railings; consequently, they require consistent watering [96].

Figure 20.

An edible balcony with railing planters (developed by the author, 2025).

Edible plants with shallow roots can be grown in hanging baskets [58,62,72,74,91]. Hanging baskets should be installed where they can be easily reached [91]. They can be secured under the overhanging roof eaves of a balcony or on walls or columns [84,91,98,108]. Baskets can be made from wire, wood, or plastic. Wire baskets are typically lined with fiber or moss to hold the potting soil. Since edible plants in hanging baskets tend to dry out quickly, they need regular watering [101,108]. Additionally, hanging baskets should be sheltered from the prevailing wind [91].

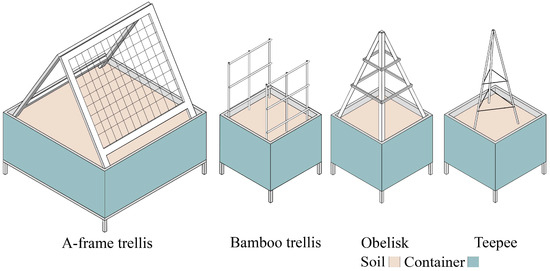

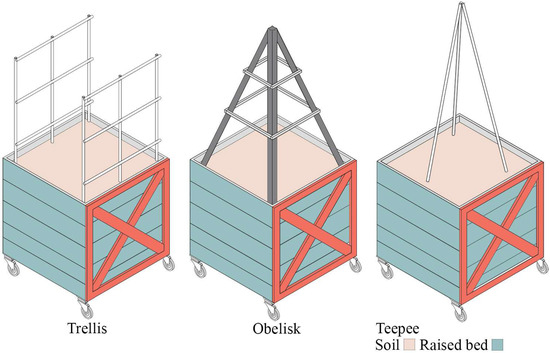

Edible plants can be trained to grow vertically using trellises, obelisks, teepees, or pergolas. These support structures provide vertical space for growing edible plants [58,70,75,77,91,92,96,110,112]. Trellises, obelisks, or teepees can be attached to containers or raised beds. Support structures can be made from wood, metal, plastic, or bamboo. They should be strong enough to hold the weight of mature vines [61,75,77,91,94,110] (Figure 21). Strong winds can damage support structures, so they should be designed to withstand prevailing winds. Screens and walls can protect both the plants and the support structures [91,92].

Figure 21.

Trellises, obelisks, or teepees can be added to containers or raised beds (developed by the author, 2025).

By installing a pergola on a balcony, the underutilized overhead space can be utilized to support edible plants such as vines [110]. Large containers or raised beds can be placed at the pergola’s base, enabling cultivation of edible vining plants [91] (Figure 22). A pergola can help large vining crops climb, creating a shady green roof over the balcony [91,108]. In the Mediterranean, pergolas are typically used to support grapes [91]. To support vines with heavy fruits, hammocks should be attached to the pergola [69,77,91]. Pergolas are usually made from wood or steel [75]. Compared to plants that grow on the ground, vertically trained plants generally have more space to grow, higher yields of edible crops per square meter of soil, increased sunlight exposure to leaves and fruit, easier monitoring and harvesting, and better air circulation around the foliage and fruit [66,69,77,92,96,98,99,108,109].

Figure 22.

Edible balcony featuring raised beds, railing planters, and a pergola (developed by the author, 2025).

Raised Bed Gardening

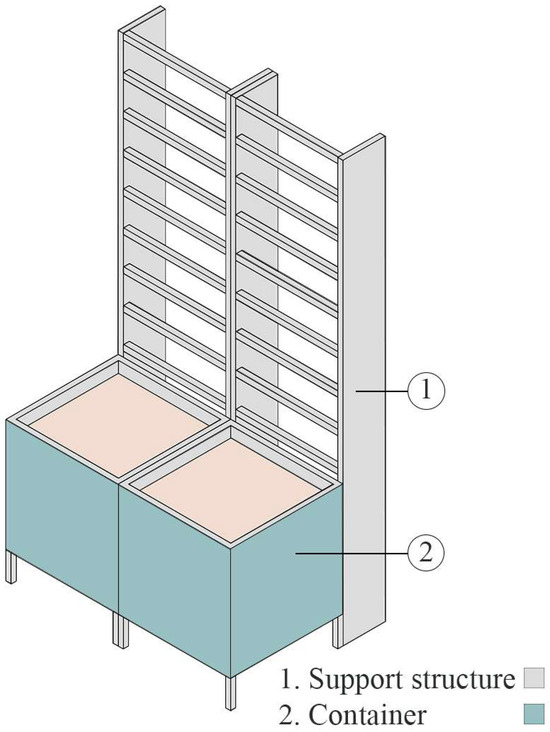

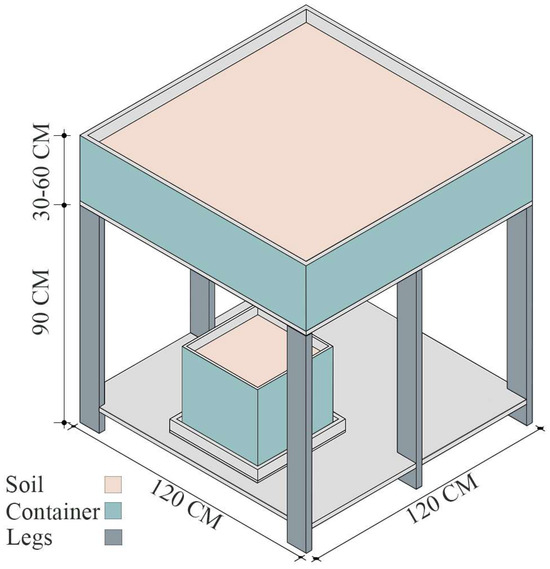

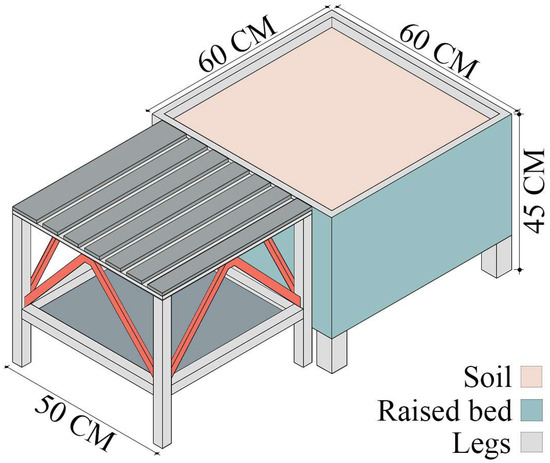

Raised beds can be added to balconies where traditional gardening space is unavailable [63,84,97,109,114,115]. Raised beds, in line with container gardening, can be considered a low-tech way to cultivate edible plants in the small spaces available in densely populated urban areas [96,97,99,116,117]. A small patch of balcony that receives sufficient sunlight is suitable for setting up a raised bed garden [97,109]. Similarly to container gardening, growing edible plants in raised beds requires at least six to eight hours of sunlight daily [63,97,109,114,118]. To maximize sunlight, a raised bed should face north–south [62,116,119]. Raised beds should be located where they can be easily accessed for watering and maintenance [109]. They can be placed directly on the ground or raised on legs. A shelf can be installed beneath the raised bed to hold containers [96] (Figure 23).

Figure 23.

A raised bed with a shelf (developed by the author, 2025).

Raised beds can be a range of sizes and shapes, including triangles, circles, squares, and rectangles [97]. A standard rectangular raised bed typically measures 90 cm [3 ft] wide and 180 cm [6 ft] long, with a height of 30 cm [12 in.] [63,114]. The center of the raised bed should be accessible from all sides, so the width should be limited to 100 cm to 120 cm [3 to 4 ft] [63,71,84,85,102,107,119]. The length, width, and height of a raised bed can be adjusted to fit the available balcony space [109,114,118]. Raised beds can be built from wooden boards, landscape ties, plastic, concrete blocks, bricks, stones, metal, fabric, or recycled materials [62,63,69,74,75,82,97,98,108,109,114,116,118,119].

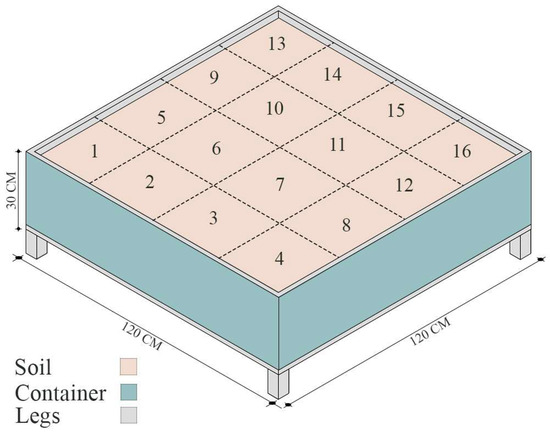

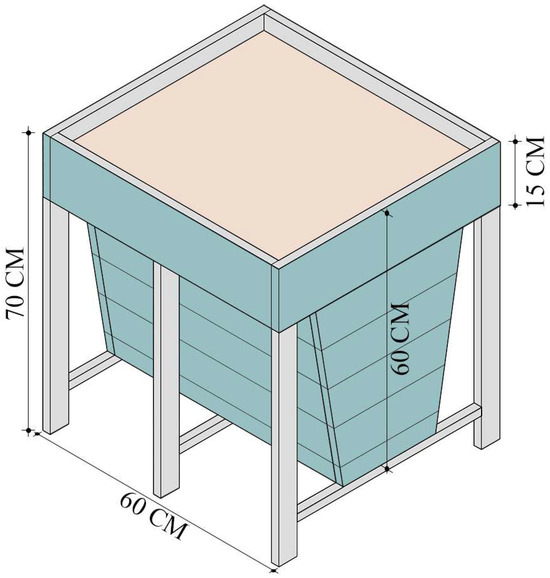

A single raised bed measuring 120 cm by 120 cm [4 by 4 ft] can be divided into 16 squares using strings. Each square is used to plant one type of vegetable. After harvesting, the crops can be rotated, allowing a variety of vegetables to be grown in the squares (Figure 24). Instead of designing one large raised bed, it is better to create smaller ones measuring 120 cm by 120 cm [4 by 4 ft], with 90 cm [3 ft] of space between them [109]. To access the beds, there needs to be enough space between them [97,107,116,119]. A small balcony can hold raised beds that are 60 cm by 60 cm [2 by 2 ft], stacked at different heights. In this way, the vertical space is used efficiently [109]. Balconies with limited space can accommodate raised troughs. The depth of the growing medium in the center of a raised trough can reach up to 60 cm [2 feet]; therefore, deep-rooted edible plants can be cultivated in the center. Shallow-rooted edible plants can be grown near the edges [116] (Figure 25).

Figure 24.

A single raised bed subdivided into 16 squares (developed by the author, 2025).

Figure 25.

A raised trough (developed by the author, 2025).

The height of the raised beds can be adjusted to the desired level [62,96,98,109,114,118,119]. Raised beds can be elevated on four legs, with the height adjustable up to 75 cm. This design makes it easier for people with limited mobility to access the beds more comfortably [62,96,98,109,114,119]. If the height of the raised beds is set between 40 cm and 50 cm [16 to 20 in.], benches can be integrated into the raised beds, thereby incorporating seating areas into the balcony space [97,114] (Figure 26).

Figure 26.

Raised bed with an attached seating element (developed by the author, 2025).

Similarly to container gardening, edible plants grown in raised beds need regular watering. Watering edible plants during summer is crucial, as they can wilt quickly [74,116]. In summer, the soil in the raised bed can lose its moisture; therefore, a layer of mulch can be added on top of the raised bed [97,114,116]. Like a large container, a raised bed, once filled with potting soil and watered, becomes heavy to move. Casters can be added to the bottom of the raised bed so it can be relocated easily [114] (Figure 27).

Figure 27.

A mobile raised bed equipped with casters (developed by the author, 2025).

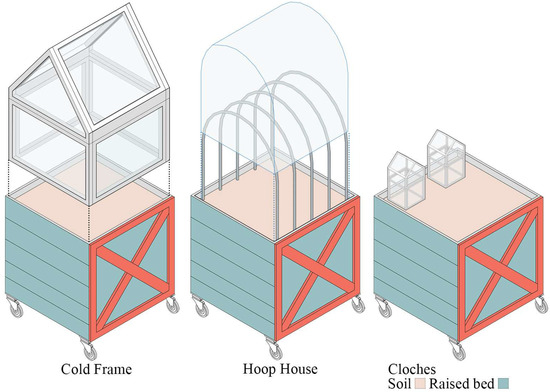

It is possible to extend the growing season by adding a cold frame, hoop house, or cloches to a raised bed [97,98,114,116] (Figure 28). Cold frames, hoop houses, and cloches can protect plants from cold weather [74,84,97,98]. They can also trap heat while shielding edible plants from frost, snow, hail, or sudden temperature changes [63,82,84,97,98]. These structures help create ideal microclimates for edible plants [71,82,98]. A cold frame can be built using wooden frames with glass, twin-wall plastic, or PVC panels attached [71,93,97,102,107,116]. Hinges can be added to the top of the frame, allowing it to be propped open or closed to control airflow [93]. An automatic window opener with a built-in sensor can be installed on a cold frame. It responds to temperature fluctuations by opening the frame for ventilation and automatically closes when the temperature drops to the preset level [97]. PVC pipes covered with row cover can be placed on top of a raised bed to convert it into a hoop house [97,99,114,118]. During summer, row cover can be replaced with horticultural fleece or netting to protect plants from pests, or with shade cloth to shield plants from excessive sunlight [96,118]. Individual plants can be covered with dome cloches, which are usually made of glass or rigid plastic [63,74,82,93,97,98,107,116].

Figure 28.

Extending the growing season by adding a cold frame, hoop house, or cloches to a raised bed (developed by the author, 2025).

Adding an obelisk, teepee, or trellis to a raised bed allows for efficient use of vertical space for cultivation (Figure 29). These support structures offer a climbing pathway for vines and other edible plants [63,75,94,98,109,118,119]. An obelisk is a pyramid-shaped support with four sides, usually made from wood, plastic, or metal [77,98,99]. Similarly to obelisks, teepees are stand-alone structures that support edible plants such as peas and pole beans, often made from garden stakes tied together at the top [77,98].

Figure 29.

Raised bed with a trellis, obelisk, or teepee to utilize vertical space (developed by the author, 2025).

A trellis can be used as either a freestanding or wall-mounted support structure [69,75,77,81,91,108]. It can be attached to a wall [57,75,77], installed on a container or raised bed [66,99,109,118], or attached to one, two, or three sides of a raised bed. Two trellises can be connected to form an A-frame trellis and added to a raised bed. An A-frame trellis provides ample space for edible vining plants to grow on both sides [91,99]. A trellis should be placed on the north side of a raised bed so vertical-growing edible plants do not cast shadows on other edible plants [109].

Trellises can be constructed from materials such as wood, bamboo, plastic (for instance, PVC pipe), or metal, including wire mesh or galvanized steel [58,66,91,98,99,108]. A metal trellis, such as wire mesh, is appropriate for supporting the weight of heavy, vine-bearing fruits such as melons, squash, and grapes [67,108]. Small hammocks or slings may be affixed to the trellis to support growing fruits such as pumpkins, squashes, or melons [91,98].

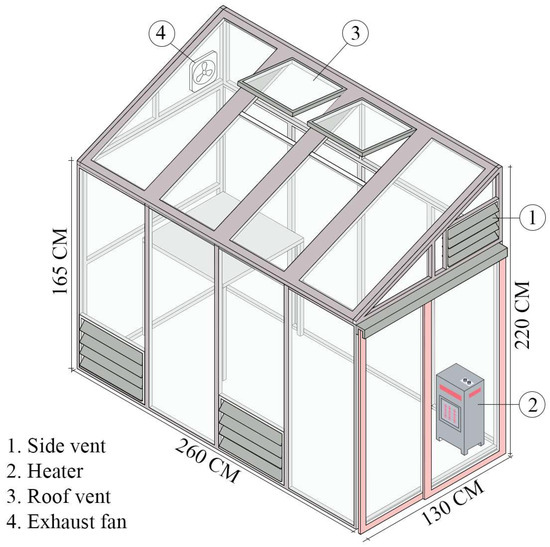

3.1.2. Protected Cultivation (Lean-To and Mini Greenhouses)

A greenhouse is a structure that enables crops to be grown year-round [120]. It can protect edible plants from rain, wind, and snow [120,121,122]. An unheated greenhouse, such as a lean-to or mini greenhouse, will keep the interior 2 °C to 4 °C [5–8° F] warmer than the outside temperature [122]. It creates an ideal environment for edible plants [120,121]. To grow edible crops in a greenhouse, the optimal temperature range is between 18.5 °C and 26.5 °C [120]. The principal components of a greenhouse are the structure, glazing, vents, and shading.

The greenhouse structure can be made from either aluminum or wood. An aluminum structure is generally durable and lightweight, resisting corrosion and rust. However, it tends to lose more heat through the frame compared to wood-framed structures. Installing thermal breaks that act as insulating barriers in the aluminum frame can help reduce heat loss [121,122,123,124]. Glazing, which serves as the greenhouse’s exterior surface that allows natural light in, is usually the most expensive feature. It can be made from glass or strong polymers such as polycarbonate, polyethylene, or fiberglass-reinforced plastics [120,121,122,123,124,125,126]. To improve the greenhouse’s energy efficiency, it is advisable to use double- or triple-thick insulated glass or plastic sheets instead of single-pane glass or plastic sheets [121,122].

When selecting greenhouse glazing, the following considerations should be taken into account: (1) Fire resistance: Plastic sheets are highly flammable; therefore, they should be avoided. Local building codes may prohibit the use of flammable materials on balconies. (2) Resistance to rain, hail, and wind: The glazing must be capable of withstanding rain, hail, and wind. (3) Light transmittance: Adding more layers to the glazing reduces the amount of light that passes through. The minimum light transmission should be 75% [121].

Optimal ventilation is essential to prevent the greenhouse from overheating. To ensure proper airflow, it is necessary to install both roof and side vents. Cold air enters through the side vents, while hot air exits from the roof vents, creating effective ventilation. Vents can be opened either manually or automatically with automatic vent openers [121,122,123,124,127]. Proper ventilation is especially important during the summer months. Installing exhaust fans helps remove hot air and improve airflow, ensuring effective ventilation [121,122,127]. Additionally, placing an electric cooling fan inside the greenhouse can further enhance airflow [121,122]. The exhaust fan and cooling fan can be controlled by a thermostat that monitors the greenhouse’s internal temperature [122]. During summer, providing shade is necessary. Shading helps lower the temperature within the greenhouse [120,123,124,127]. The following shading systems can be used: (1) netting, (2) roller blinds (internal shading systems), (3) external shade cloths, (4) whitewash, (5) reflective shade screens, and (6) slatted blinds [123,127].

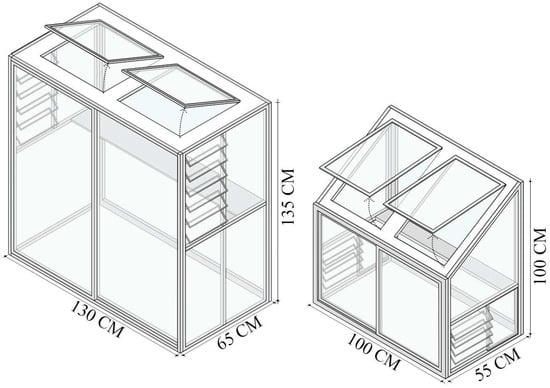

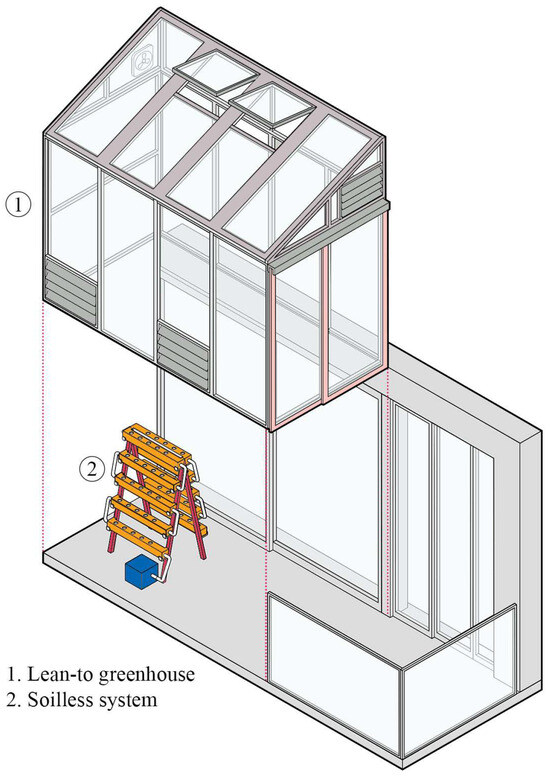

Both prefabricated lean-to and mini greenhouses are available on the market and are suitable for balconies with limited space (Figure 30 and Figure 31). Both open-air food production methods (container gardening, vertical gardening, and raised bed gardening) and soilless farming methods can be used within a lean-to greenhouse structure (Figure 32). A well-managed 1.3 m by 2.6 m [4.2 by 8.5 ft] lean-to greenhouse will provide ample growing space for edible plants. Both lean-tos and mini greenhouses are typically unheated and feature shelves that provide space for containers. Both models can be attached to a balcony wall. Ideally, the longer side of either model should be attached to a south-facing balcony wall (east–west orientation) to maximize sunlight exposure [121,122,123,124]. It is preferable to orient both models east–west, as this decreases heating requirements by about 20% compared to a north–south orientation [120,128]. Providing direct access from the living room to a lean-to greenhouse helps it serve as an extension of indoor space [122]. As previously mentioned, balconies can be exposed to wind, which may cause heat loss; therefore, both models should be sheltered from the wind [124]. Additionally, supplying water and electricity to both models is essential [122,123].

Figure 30.

Two mini greenhouses with dimensions indicated (developed by the author, 2025).

Figure 31.

A lean-to greenhouse (developed by the author, 2025).

Figure 32.

A lean-to greenhouse can accommodate both open-air food production and soilless farming methods (developed by the author, 2025).

Lean-to greenhouses are usually unheated. To grow edible crops year-round, supplemental heating systems and grow lights should be added to the greenhouse [121,122,123,124,127]. Supplemental heaters can operate on electricity, natural gas, or propane (LP) gas. Proper ventilation is crucial for gas-fired heaters, as combusted gases need to be vented outside [121,123]. The heater chosen should have thermostatic controls to turn on and off automatically, maintaining the desired greenhouse temperature [123]. Keeping the greenhouse temperature toward the lower end of the target range, while preventing frost damage to edible plants, can help lower heating costs [122].

During the winter months, to compensate for low light levels, lengthen the day (photoperiod), and increase photosynthesis (daily illumination), grow lights should be installed [120,122,123]. Both LED (light-emitting diode) and HPS (high-pressure sodium) grow lights are available on the market. LEDs are becoming popular as a light source for plants. Their extended lifespan, compact size, low heat emission, ability to control spectral composition, and low energy consumption are some of their benefits [21,22,129].

During the winter months, the greenhouse can be insulated by attaching plastic greenhouse bubble wrap to the structure. Bubble wrap acts as an insulating barrier, helping to prevent heat loss from the interior of the greenhouse to the outside [122,124]. When all openings are sealed during winter, fungal growth such as mold and mildew may develop. To prevent this, continuous internal air circulation should be maintained by installing fans [122]. A greenhouse can be automated through the integration of various sensors and actuators, thereby reducing the need for human intervention [120].

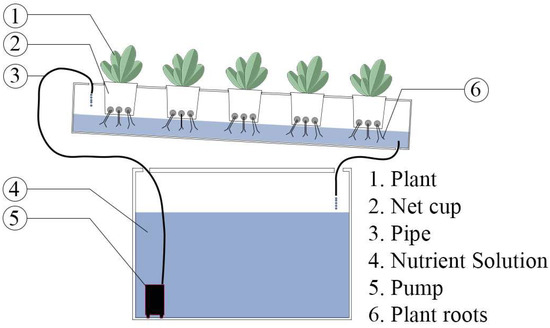

3.1.3. Soilless Farming

Urban centers typically lack adequate arable land suitable for traditional soil-based farming [130,131]. Soilless cultivation presents an alternative or supplementary approach by enabling vertical crop production within urban environments [131,132,133]. Spaces in and on buildings, including balconies, may serve as venues for innovative cultivation techniques, such as small-scale soilless farming. Implementing these methods can facilitate access to fresh and nutritious foods, including vegetables, fruits, and herbs, for urban residents in densely populated current and future cities [134,135,136]. Soilless farming facilitates continuous year-round cultivation, increases yields, permits multiple harvest cycles annually, supports the cultivation of numerous plants within a limited space, improves water efficiency, provides enhanced control over nutrients, water, and aeration, and diminishes dependency on weather conditions [130,131,132,133,137,138,139,140,141,142]. It also permits crop growth in areas lacking arable land, such as building rooftops in urban areas, deserts, mountainous regions, infertile land, or contaminated soils [130,131,132,140].

Hydroponics is a soil-free crop production method where the roots of edible plants are immersed in nutrient-rich water. In hydroponic systems, the appropriate amount of nutrient solution and water is supplied from the reservoir to the plant roots to promote healthy growth [129,130,131,132,133,136,137,138,139,140,141,142,143]. Water and nutrients can be recycled in hydroponics, as the drained solution is reusable [130]. Various inert media such as peat moss, gravel, coco peat, rock wool, charcoal, perlite, and coconut coir are used in hydroponic systems to provide physical support for root growth [129,133,136,137,138,141]. Vegetables, herbs, and medicinal plants have been successfully cultivated using hydroponic techniques [130,131,133,137,138,142,143].

The various hydroponic systems that may be employed include: (1) Wick System, (2) Deep Water Culture (DWC), (3) Nutrient Film Technique (NFT), (4) Drip Irrigation System, (5) Ebb and Flow (Flood and Drain), (6) Aeroponics, and (7) Aquaponics [129,130,136,137,139]. In the Nutrient Film Technique (NFT), plants grow in V-shaped channels known as gullies, where a thin layer of nutrient-rich water continually circulates around the roots. This constant flow keeps the roots moist and nourished. Ideally, the bottom of the roots should remain in contact with the nutrient-rich water [130,131,133,136,137,143]. A submerged automated motor pump inside a reservoir supplies a steady flow of nutrient-rich water to the gullies [130,138] (Figure 33). By stacking the gullies vertically, the amount of produce grown per square meter can be increased. The Nutrient Film Technique (NFT) is well suited for balconies as it utilizes available vertical space. Short-cycle crops such as leafy greens and herbs are suitable for NFT systems [130,131,139,143]. In this system, no growing medium or soil is required; therefore, edible crops can be grown cleanly, eliminating the need for washing [130].

Figure 33.

Nutrient Film Technique (NFT) (developed by the author, 2025).

Hydroponic systems can be installed inside greenhouses (Figure 34). Hydroponic greenhouse methods can also be implemented in and on buildings in dense urban environments where arable land is limited. This concept is known as building-integrated agriculture. Its goal is to shift from ground-based farming to a vertical, multi-layer, soilless system. It is based on the idea of growing food within the built environment while utilizing local, renewable energy and water sources. This method allows for year-round cultivation of vegetables, herbs, and fruits. Additionally, inside greenhouses, crops can be grown vertically with hydroponic systems, leading to higher yields [7,21,41,144].

Figure 34.

Soilless systems, such as hydroponics (Nutrient Film Technique), can be installed in a lean-to greenhouse (developed by the author, 2025).

The principal challenges that may hinder the implementation of soilless farming are as follows: (1) substantial initial setup costs, (2) the need for skilled laborers possessing adequate technical knowledge, (3) high energy consumption, (4) the requirement for effective nutrient management and disease control, (5) the need for regular maintenance, and (6) the demand for a reliable and continuous power source in NFT systems, as plant roots can dry out rapidly if the pumps fail [130,131,132,134,136,137,139,140].

3.2. Design Guidelines and Major Obstacles

This section presents a series of key design guidelines derived from the existing literature on urban agriculture, horticulture, building-integrated agriculture, and ZFarming. The following guidelines should be considered during the design process of edible balconies: (1) Orientation of the balcony: Balconies facing south and southeast receive the maximum amount of sunlight per day; therefore, they are suitable for cultivating food. (2) Sun exposure: Typically, vegetables, fruits, and herbs require a minimum of six to eight hours of daily sunlight; hence, balconies should be oriented towards the south or southeast. (3) Artificial lighting: If the balcony does not receive adequate natural light during the day, grow lights may be installed. (4) Sufficient space: Balconies should provide enough space to accommodate an edible garden. Mature plants cultivated in horizontal, vertical, overhead, or edge arrangements also require adequate growing space. (5) Access pathways: Principal access pathways should be clearly defined for the balcony. Garden elements positioned on horizontal, vertical, or overhead planes should not obstruct access routes. (6) Balcony structure: The balcony structure should have sufficient load-bearing capacity. When assessing loads, the total weight of containers and raised beds at full saturation (after drainage) must be taken into account. This weight depends on the medium type; for instance, the wet bulk density of a peat–perlite mix is approximately 865 kg/m3 (54 lb/ft3), while that of a peat–vermiculite mix is about 995 kg/m3 (62 lb/ft3) [145]. Table 1 presents the estimated saturated weights of peat–perlite and peat–vermiculite in small and large containers as well as in two raised bed sizes. The weight of the container structure should also be added: approximately 1–2 kg for plastic pots and 10–40 kg for raised beds, depending on the material. A structural engineer should be consulted before designing the balcony.

Table 1.

Estimated saturated weights of peat–perlite and peat–vermiculite media in different container and raised bed sizes (developed by author, 2025).

(7) Considering prevailing wind direction: Balconies are generally exposed to strong winds, which may cause damage to plants by tearing their leaves. Plants can be safeguarded by vertical barriers such as screens. (8) Accessibility: Balconies should be accessible via stairs or an elevator. External staircases may also provide access. It is essential to consider methods for transporting containers, soil, and other materials to the balcony. (9) Placement of gardening elements: Containers, wall planters, and other gardening features should be positioned where they receive at least six to eight hours of daily sunlight. (10) Utilizing available surfaces: Floors, walls, overhead surfaces, and edges can support food production. (11) Utilizing south-facing walls: Many apartment buildings have south-facing walls that receive sufficient sunlight each day, which can be used for growing plants. (12) Appropriate wall structure: The wall should be capable of supporting the weight of the attached vertical garden. (13) Staining of the balcony floor and walls: Runoff water from the planters might stain the balcony floor or walls. Runoff water should be effectively directed to the balcony drainage system by placing containers on trays and connecting drainage pipes to the trays. (14) Movable containers and raised beds: Casters can be added to the bottom of large containers and raised beds so they can be moved during the season. (15) Irrigation system: One or several spigots should be installed on the balcony. Watering can be performed manually, with a garden hose, or through a drip irrigation system. (16) Drainage: Balconies should have proper drainage to allow runoff water from containers to flow out. Without proper drainage, runoff water from containers or raised beds might drip from the balcony to the balconies below, which could eventually damage the floor materials and structure, as well as disturb neighbors. (17) Appropriate greenhouse types: Both prefabricated lean-to and mini greenhouses are available on the market and are ideal for balconies with limited space. (18) Greenhouse placement: A greenhouse should be located where it receives the maximum amount of sunlight each day. A south-facing balcony wall can provide sufficient sunlight for lean-to or mini greenhouses. (19) Greenhouse size: The size of the balcony determines the dimensions of the lean-to or mini greenhouses (Table 2).

Table 2.

Proposed key design guidelines (developed by author, 2025).

This section outlines several significant obstacles identified within the existing literature on urban agriculture, horticulture, building-integrated agriculture, and ZFarming. The key challenges in designing edible balconies include the following: (1) Casting shadows: Nearby structures, such as neighboring buildings, trees, and overhanging roof eaves, may cast shadows on the balcony, potentially hindering food cultivation. (2) Natural light obstruction: Positioning a vertical garden in front of a balcony window that covers half of or the entire window surface might block the natural light reaching into the interior space. (3) Building regulations: Existing regulations established by homeowners’ associations may prohibit the installation of edible gardens on balconies. (4) Zoning laws: Existing zoning regulations may pose challenges to the integration of urban agriculture within the balconies of apartment buildings. (5) Greenhouse permits: The installation of a greenhouse on a balcony might necessitate obtaining permits from homeowners’ associations or the relevant local authorities. (6) Soilless farming challenges: These include high initial setup costs, the need for skilled labor with proper technical knowledge, high energy consumption, the importance of effective nutrient management and disease control, regular maintenance, and the need for a reliable, steady power source in NFT systems, as plant roots can dry out quickly if pumps fail. (7) Maintenance: Edible balconies require regular maintenance. Edible plants require consistent watering, fertilization, pruning, weeding, trimming, and other essential activities. Support structures and irrigation systems also demand regular maintenance. Residents should be prepared to contribute time and effort to the upkeep of the edible balcony. (8) Time and skill: Edible balconies are managed by residents, who need to be competent gardeners and demonstrate a willingness to devote adequate time to their management (Table 3).

Table 3.

Major obstacles (developed by author, 2025).

3.3. Potential Food Yield and Approximate Cost

The potential food yield and approximate cost of small-scale cultivation systems—such as container gardening, raised beds, vertical gardens, and soilless hydroponic systems—are compared in this section. Such comparisons help assess the financial feasibility of edible balcony designs.

Regarding potential yield, a single tomato plant can produce approximately 4.5–7 kg (10–15 lb) of fruit per growing season when provided with adequate sunlight, irrigation, and nutrients. Tomatoes are suitable for container cultivation, and typically one plant is grown per container [146,147]. Raised-bed systems typically provide more soil volume and root development than containers, which results in larger yields per unit area. Raised beds typically provide higher yields than containers [148]. Leafy greens such as lettuce and chicory grown in raised beds in urban areas can produce approximately 2.7 kg per m2 per harvest cycle of around 20–30 days [149]. Under favorable conditions, a total yield of about 9 kg per m2 can be achieved over three cycles during a growing season.

Vertical gardening is a cultivation method that produces yields while utilizing minimal horizontal space, making it suitable for residential buildings with limited area. Regarding vertical garden yields in dense urban areas, up to approximately 6.8 kg per m2 per harvest cycle can be achieved for leafy greens such as lettuce and chicory under controlled conditions [149]. Another study reported total yields of about 24 kg per m2 per year for vegetables and fruits grown using vertical gardening methods (a hydroponics system) at an urban, family scale [150]. Regarding the cultivation of leafy greens such as lettuce using hydroponic NFT systems in non-heated greenhouses, yields of approximately 2.8 kg per m2 per harvest cycle are achievable [151]. In highly optimized greenhouse NFT systems, yields can reach up to 14 kg per m2 per harvest cycle [152].

Regarding the financial costs and benefits of container gardening, a study reported the following findings: Roma tomatoes were cultivated in 5-gallon containers, with a material cost of USD 13.85 per container. The average yield was approximately 285 g of tomatoes per container. In the first year, when both material and labor costs were included, no positive net benefit was observed. However, in the second year, when material costs were excluded, a positive net value was expected [153]. Likewise, excluding labor costs made container gardening financially beneficial [153,154]. In general, home vegetable gardens can be profitable if the cost of labor required to maintain the garden is excluded from the total expenses [154].

Regarding the financial costs and benefits of raised beds, it is noted that constructing a wooden raised bed with dimensions of 122 × 244 × 31 cm costs approximately USD 190 when using untreated wood and about USD 215 when using treated wood. For a cinder block raised bed of similar size, the estimated cost is around USD 155, while a metal raised bed of comparable dimensions costs approximately USD 180 [155]. Although the initial purchase and setup require a higher upfront investment, these costs can be recovered after several harvesting cycles.

The costs and benefits of vertical farming using soilless cultivation methods, such as hydroponics, can be summarized as follows: for a simple hydroponic system installed on south-facing balconies or windows, an annual yield of approximately 112–147 kg of vegetables and fruits can be achieved. The yield per unit area is about 24 kg m−2, with an estimated installation cost of GBP 70 m−2. The projected annual profit ranges between GBP 100 and GBP 130, while the annual operating cost is estimated at GBP 24–32. To maximize economic returns, it is recommended to select vegetables with a high market value [150].

Overall, container gardening is the most accessible system; however, it offers the lowest yield per unit area. The cost of raised beds is higher than that of containers but remains moderate compared to vertical gardens and soilless systems such as NFT hydroponics. Raised beds provide greater yields than container gardening, while vertical gardens and NFT hydroponic systems achieve the highest yields but require higher initial investments (Table 4).

Table 4.

Comparative summary of potential yield and cost for small-scale cultivation systems (developed by author, 2025).

3.4. Edible Balconies and Rooftop Gardens: Similarities and Differences

The principal similarities between edible balconies and rooftop gardens can be summarized as follows: (1) Cultivation methods: Open-air cultivation methods such as container gardening, vertical gardening, and raised-bed gardening, as well as protected cultivation in lean-to or mini greenhouses and soilless farming, are possible in both balconies and rooftops in Mediterranean climates. (2) Sun exposure: Both balconies and rooftops should receive a minimum of six to eight hours of direct sunlight per day. (3) Prevailing wind direction: For both balconies and rooftops, the prevailing wind direction should be identified, and appropriate barriers should be installed. (4) Casting shadows: Shade from neighboring buildings or trees may pose an obstacle for both balconies and rooftops. (5) Irrigation system and electricity: Both edible balconies and rooftop gardens require an appropriate irrigation system and access to electrical outlets. (6) Structural capacity: Both balcony and rooftop structures should have sufficient load-bearing capacity. (7) Building regulations and zoning laws: Existing building regulations and zoning laws may pose challenges to integrating urban agriculture into balconies and rooftops of apartment buildings. (8) Access pathways: Principal access pathways should be clearly defined for both balconies and rooftops. (9) Drainage: Both balconies and rooftops should have adequate drainage to allow runoff water from containers to flow out safely. (10) Greenhouse permits: Installing a greenhouse on balconies or rooftops may require permits from local authorities. (11) Maintenance: Both edible balconies and rooftop gardens require regular maintenance. (12) Time and skill: Edible balconies and rooftop gardens should be managed by individuals or families who possess basic gardening skills. (13) Movable containers and raised beds: It is possible to use movable containers and raised beds in both edible balconies and rooftop gardens. (14) Utilizing available surfaces: Floors, walls, overhead surfaces, and edges can all be used to support food production in both balconies and rooftops.

The principal differences between edible balconies and rooftop gardens are as follows: (1) Available space: The space available for cultivation—whether horizontal, vertical, overhead, or along the edges—is generally more limited on balconies than on rooftops. (2) Appropriate cultivation methods: Because of the limited space available, applying green roof cultivation methods on edible balconies is challenging. (3) Appropriate greenhouse types: Due to restricted space, freestanding greenhouses cannot be installed on edible balconies, whereas their installation on rooftops is feasible. Lean-to and mini greenhouses are therefore more suitable for balconies. (4) Accessibility: Balconies are typically limited to individual apartment units and are accessible only from within each dwelling. In contrast, rooftops can often accommodate multiple users and are generally accessible to residents for maintenance and harvesting.

Both edible balconies and rooftop gardens can be considered extensions of urban agriculture, enabling residents to cultivate food within apartment buildings. They are similar in terms of cultivation methods, sunlight requirements, and structural considerations. The primary difference between edible balconies and rooftop gardens is the amount of suitable space available. Balconies offer a limited cultivation area, making them less suitable for large-scale farming, whereas rooftops provide more space, allowing for broader cultivation options.

3.5. Design Proposals

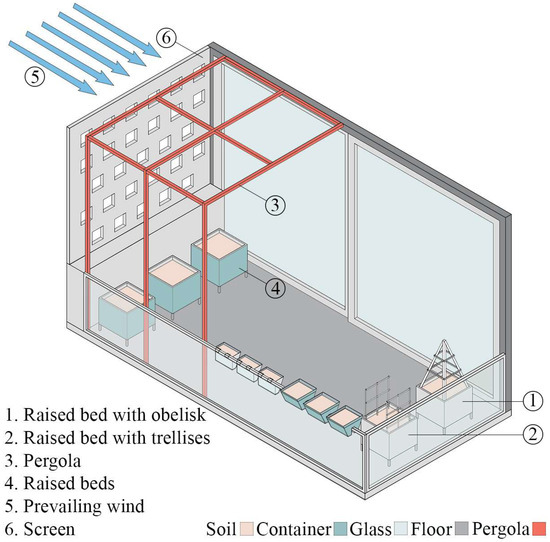

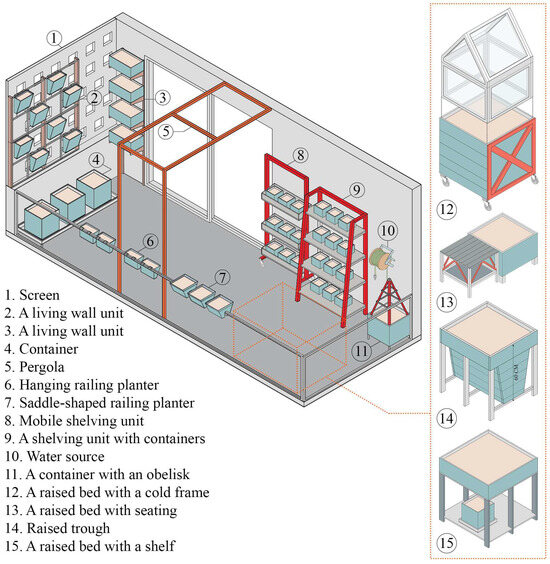

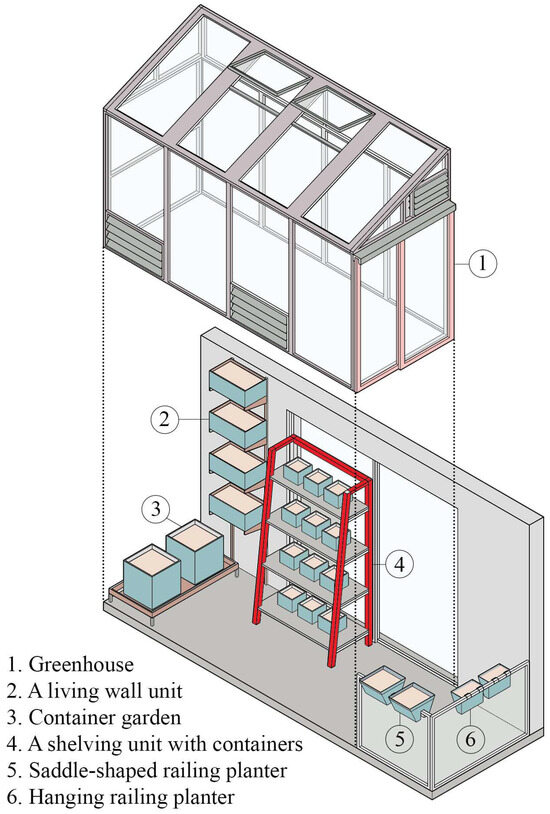

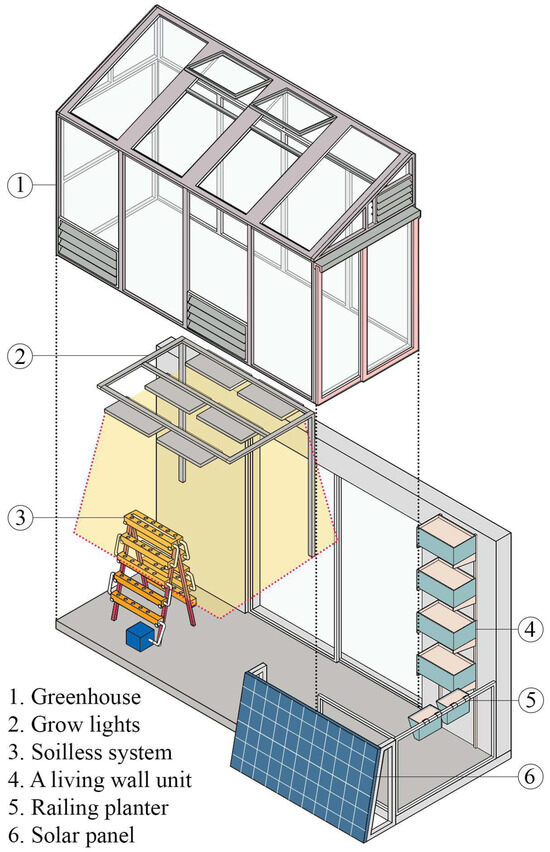

The following three design proposals are established based on the reviewed literature. The first design proposal employs soil-based techniques, utilizing containers, vertical gardens, and raised beds on the balcony. To maximize wall surface utilization, living wall units have been installed. Both hanging railing planters and saddle-shaped railing planters are incorporated. Shelving units with containers are arranged along the south-facing wall. Additionally, a pergola has been installed to optimize overhead space (Figure 35). The second design proposal features the installation of a lean-to greenhouse on the balcony, which contains containers, a shelving unit, and a living wall system. To make the most of the balcony edge, saddle-shaped railing planters and hanging railing planters are considered (Figure 36). Design proposal three integrates both soil-based and soilless cultivation techniques. The soilless system, supplemented by solar-powered grow lights, is placed within a lean-to greenhouse. Additionally, a solar panel is affixed to the balcony railing. The design also incorporates a living wall unit in conjunction with hanging railing planters (Figure 37).

Figure 35.

Design proposal number one (developed by the author, 2025).

Figure 36.

Design proposal number two (developed by the author, 2025).

Figure 37.

Design proposal number three (developed by the author, 2025).

4. Discussion

At a time when more than half of the global population resides in urban centers, cultivating food within cities, in close proximity to consumers, has become critical. Given the scarcity of ground-based arable land in urban areas, it is essential to utilize all available space in and on buildings to produce substantial quantities of food for urban populations [21,41,156]. South-facing balconies, which typically receive ample sunlight, are particularly suitable for cultivating edible crops. The floors, walls, overhead structures, and edges of balconies can be effectively adapted for food cultivation.

This research defines the term “edible balcony,” which is founded on the principle that food cultivation can be integrated with architectural design. Edible balconies, as an innovative strategy for food production, may be incorporated into residential buildings within densely populated urban environments. Nonetheless, it is essential to recognize that edible balconies alone are insufficient to meet urban food requirements. As a subtype of urban agriculture and Zfarming, however, this approach has the potential to improve household access to fresh and nutritious vegetables and fruits. When implemented on a large scale, it can also play a role in alleviating the pressure on traditional rural agriculture.

This study demonstrates that food cultivation on balconies can be achieved through various methods, including (1) open-air food production: container gardening, vertical gardening, and raised bed gardening; (2) protected cultivation utilizing lean-to or mini greenhouses; and (3) soilless farming techniques. Additionally, the study indicates that food can be cultivated on specific types of balconies, such as (1) cantilevered balconies, (2) hung balconies, (3) semi-recessed balconies, (4) fully recessed balconies, and (5) Juliet balconies or false balconies.

4.1. Response to Research Questions