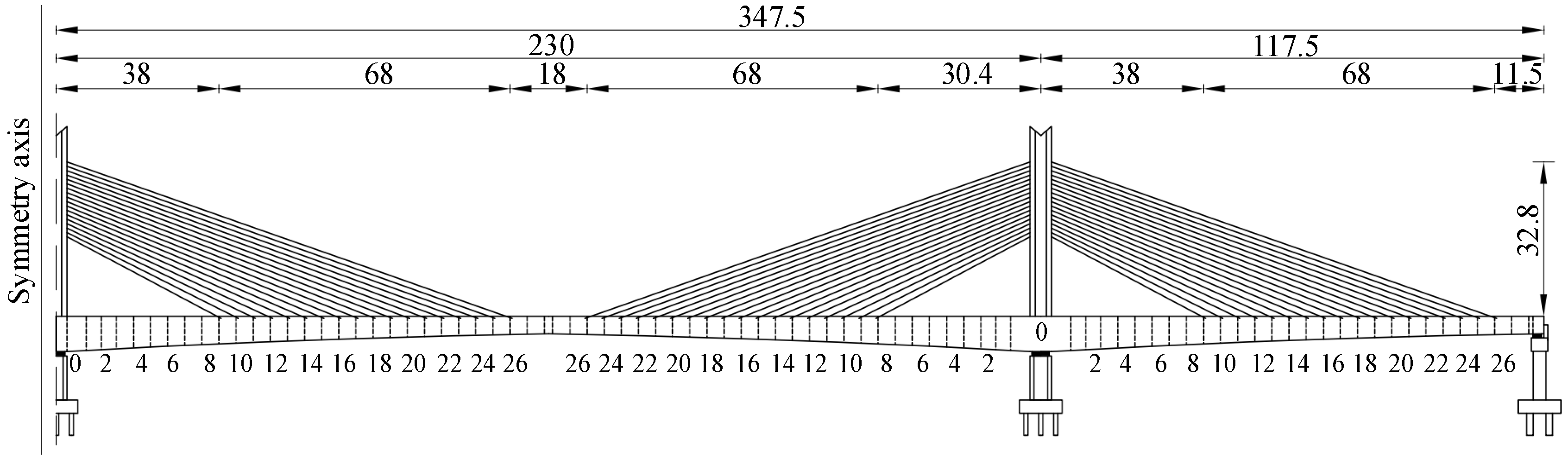

Figure 1.

Front view of the case bridge (dimension in m).

Figure 1.

Front view of the case bridge (dimension in m).

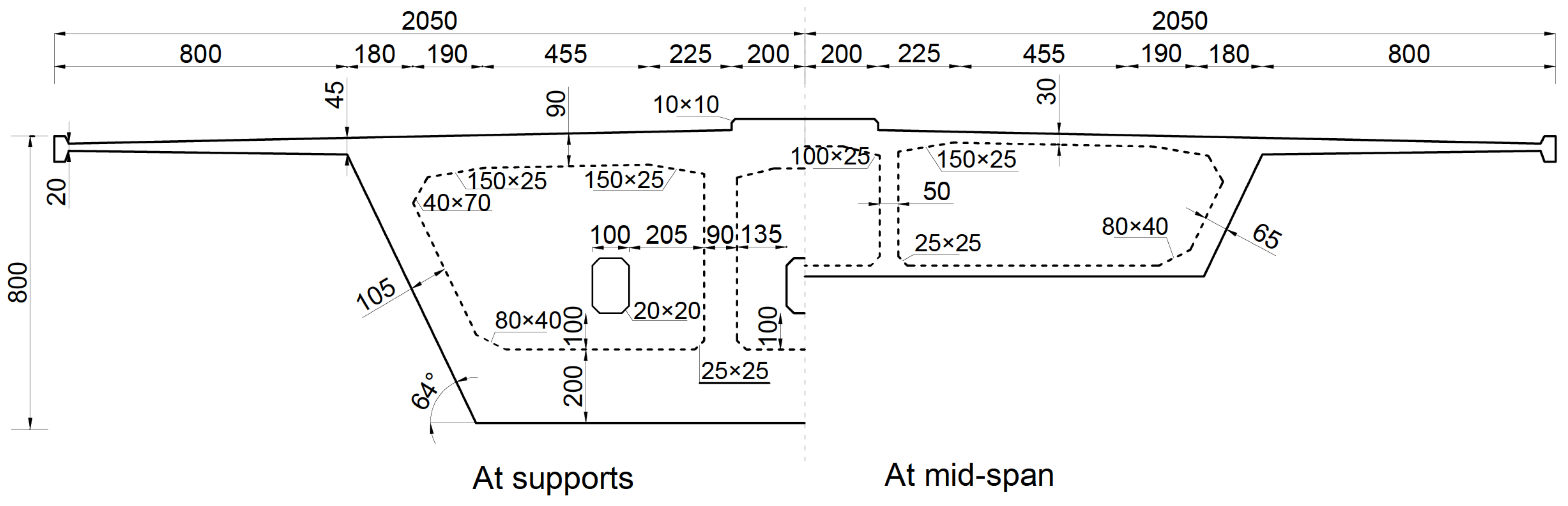

Figure 2.

Cross-section of the main girder (dimension in cm).

Figure 2.

Cross-section of the main girder (dimension in cm).

Figure 3.

Cross-section of the pylon (dimension in cm).

Figure 3.

Cross-section of the pylon (dimension in cm).

Figure 4.

Geometric model of a bridge using the beam element.

Figure 4.

Geometric model of a bridge using the beam element.

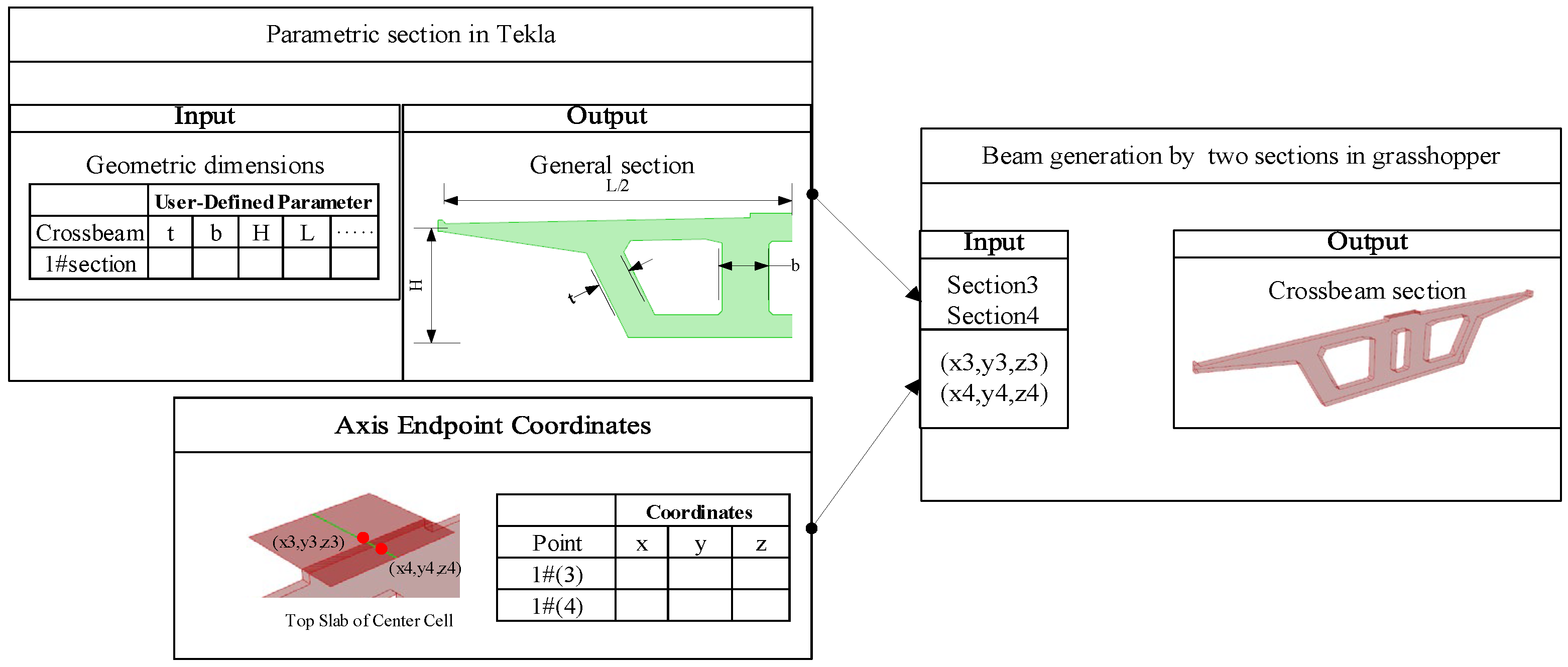

Figure 5.

Parametric modeling of girder segment with varying Cross-Sections using Tekla and Grasshopper.

Figure 5.

Parametric modeling of girder segment with varying Cross-Sections using Tekla and Grasshopper.

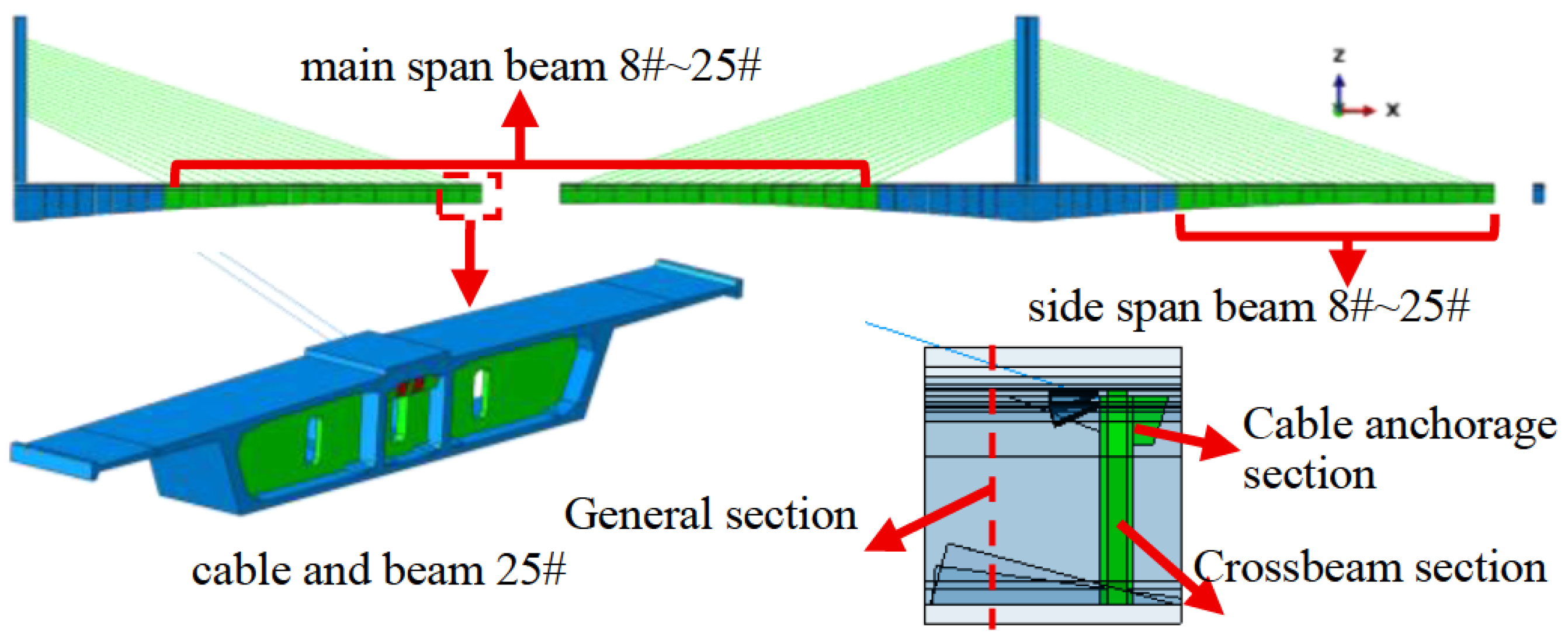

Figure 6.

Solid bridge model of the case bridge during cantilever construction.

Figure 6.

Solid bridge model of the case bridge during cantilever construction.

Figure 7.

Stress Paths in Inclined Web for comparing different meshing.

Figure 7.

Stress Paths in Inclined Web for comparing different meshing.

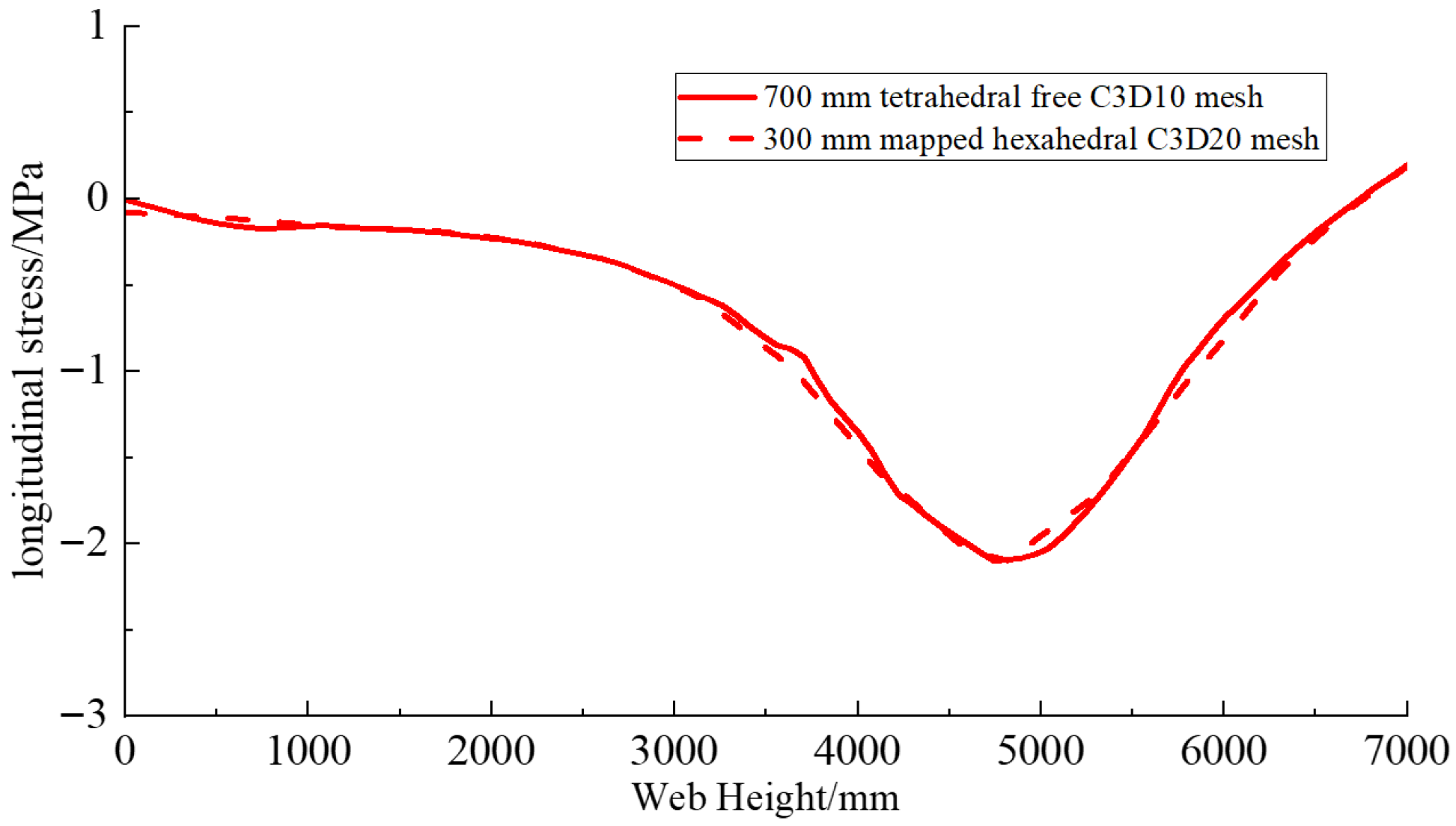

Figure 8.

Compare of normal stress produced by different meshing.

Figure 8.

Compare of normal stress produced by different meshing.

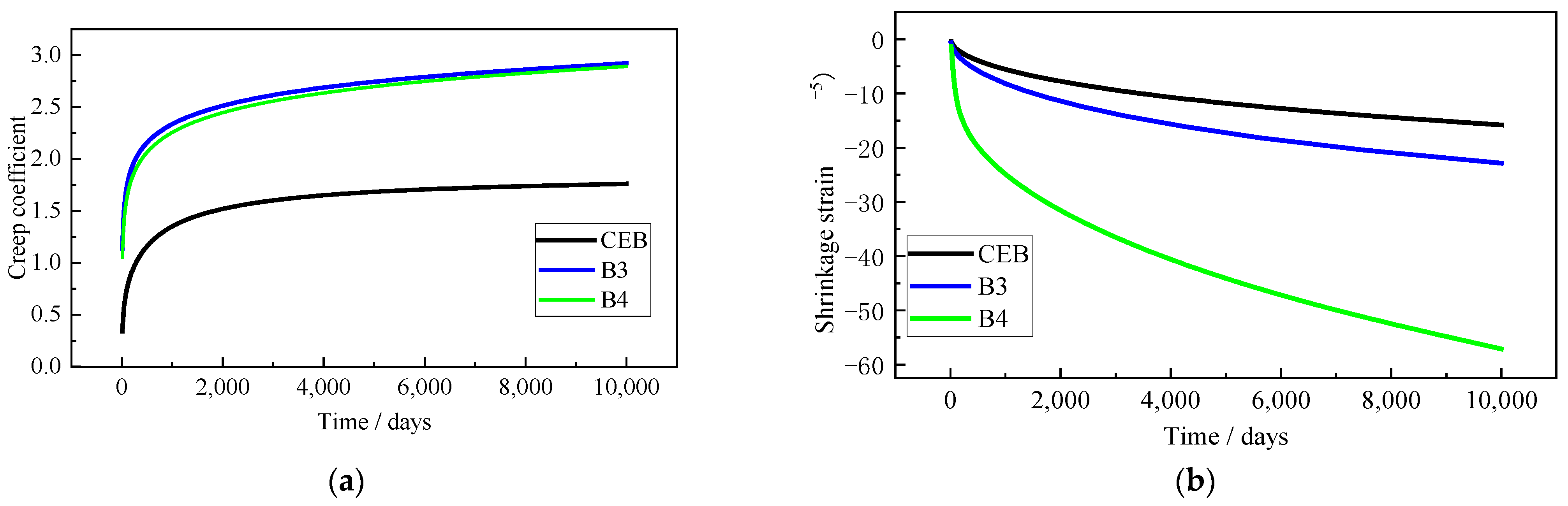

Figure 9.

Evolution of (a) creep coefficient (a,b) shrinkage strain over time.

Figure 9.

Evolution of (a) creep coefficient (a,b) shrinkage strain over time.

Figure 10.

Comparison of mean long-term mid-span deflection: beam vs. solid analysis.

Figure 10.

Comparison of mean long-term mid-span deflection: beam vs. solid analysis.

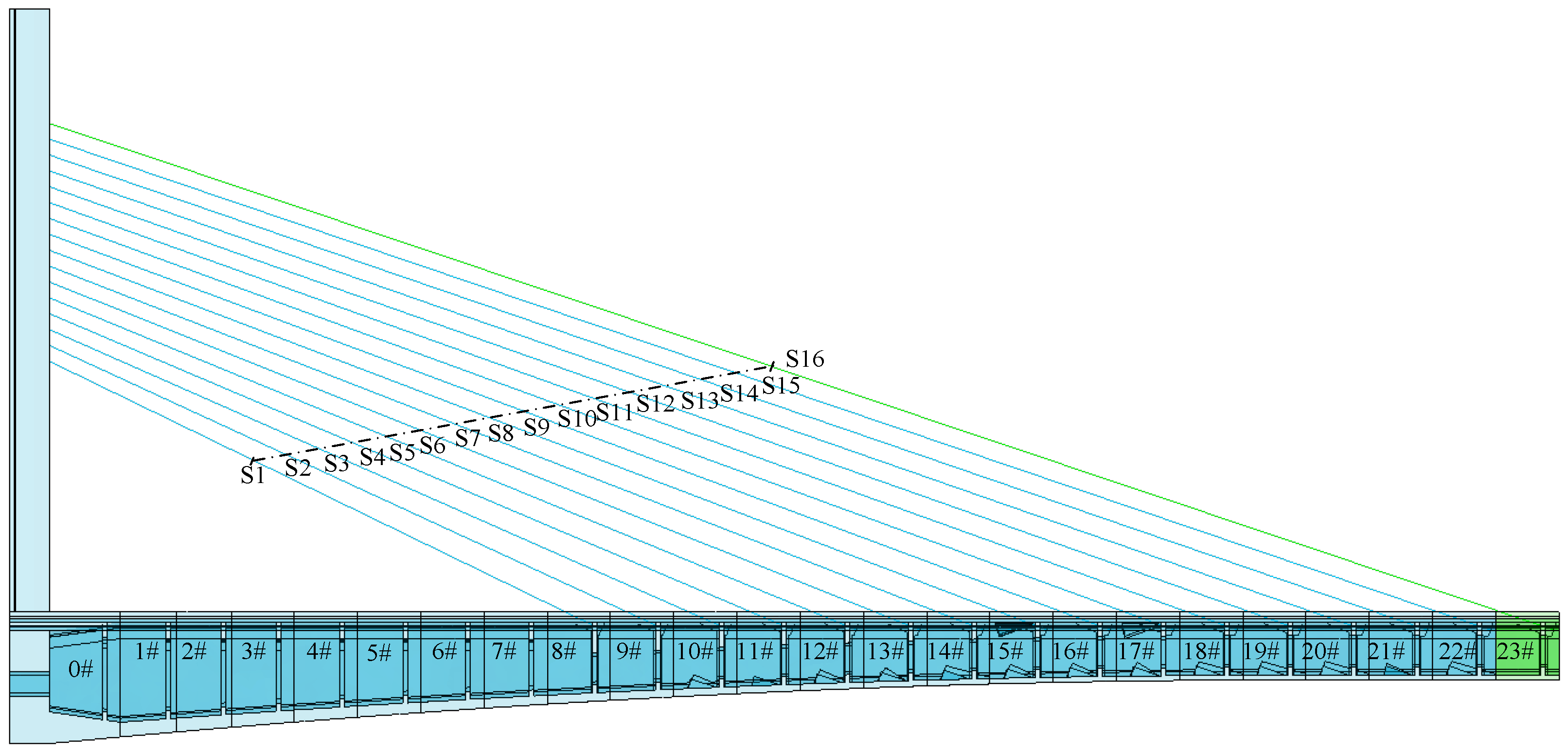

Figure 11.

Half of the cantilever structure after tensioning cable S16. S1–S16: Cable numbers. 0#–23# Beam segment numbers. The cross-section of the beam segment marked in green is shown in

Figure 12.

Figure 11.

Half of the cantilever structure after tensioning cable S16. S1–S16: Cable numbers. 0#–23# Beam segment numbers. The cross-section of the beam segment marked in green is shown in

Figure 12.

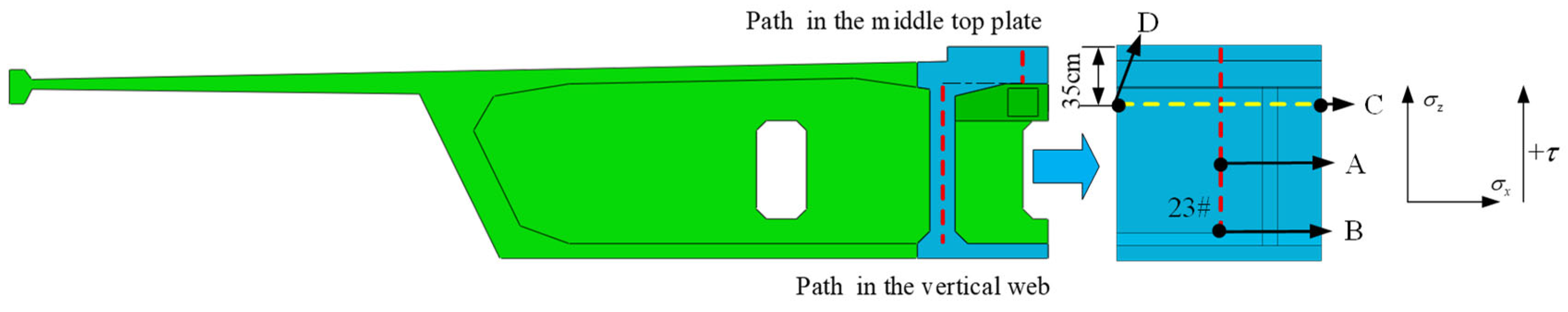

Figure 12.

Stress observation path on the inner web.

Figure 12.

Stress observation path on the inner web.

Figure 13.

Inner web stress comparison: solid element vs. beam analysis (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

Figure 13.

Inner web stress comparison: solid element vs. beam analysis (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

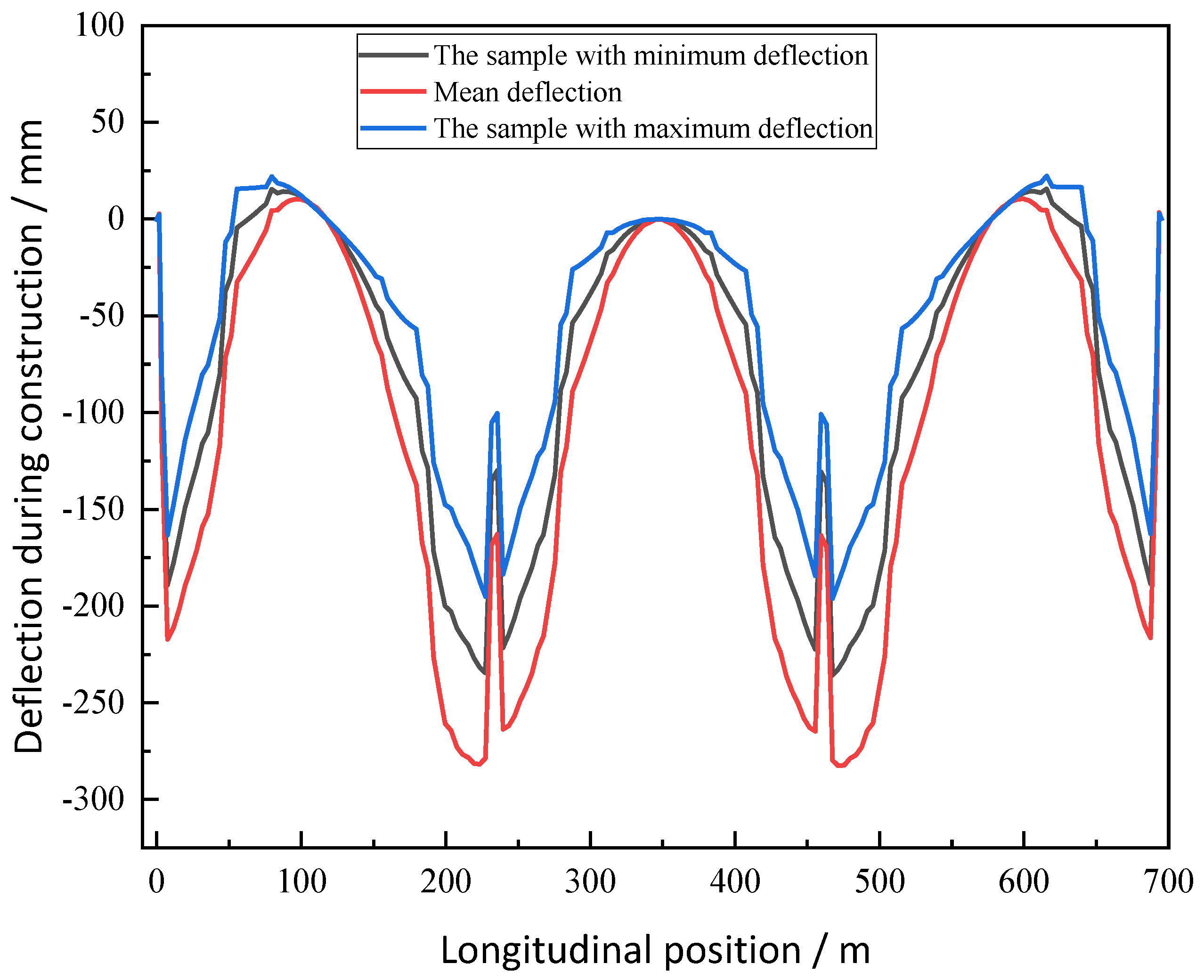

Figure 14.

Girder deflection during construction: mean, maximum, and minimum sample values (the beam element model).

Figure 14.

Girder deflection during construction: mean, maximum, and minimum sample values (the beam element model).

Figure 15.

Effect of the variation in bridge parameters on the maximum deflection during construction.

Figure 15.

Effect of the variation in bridge parameters on the maximum deflection during construction.

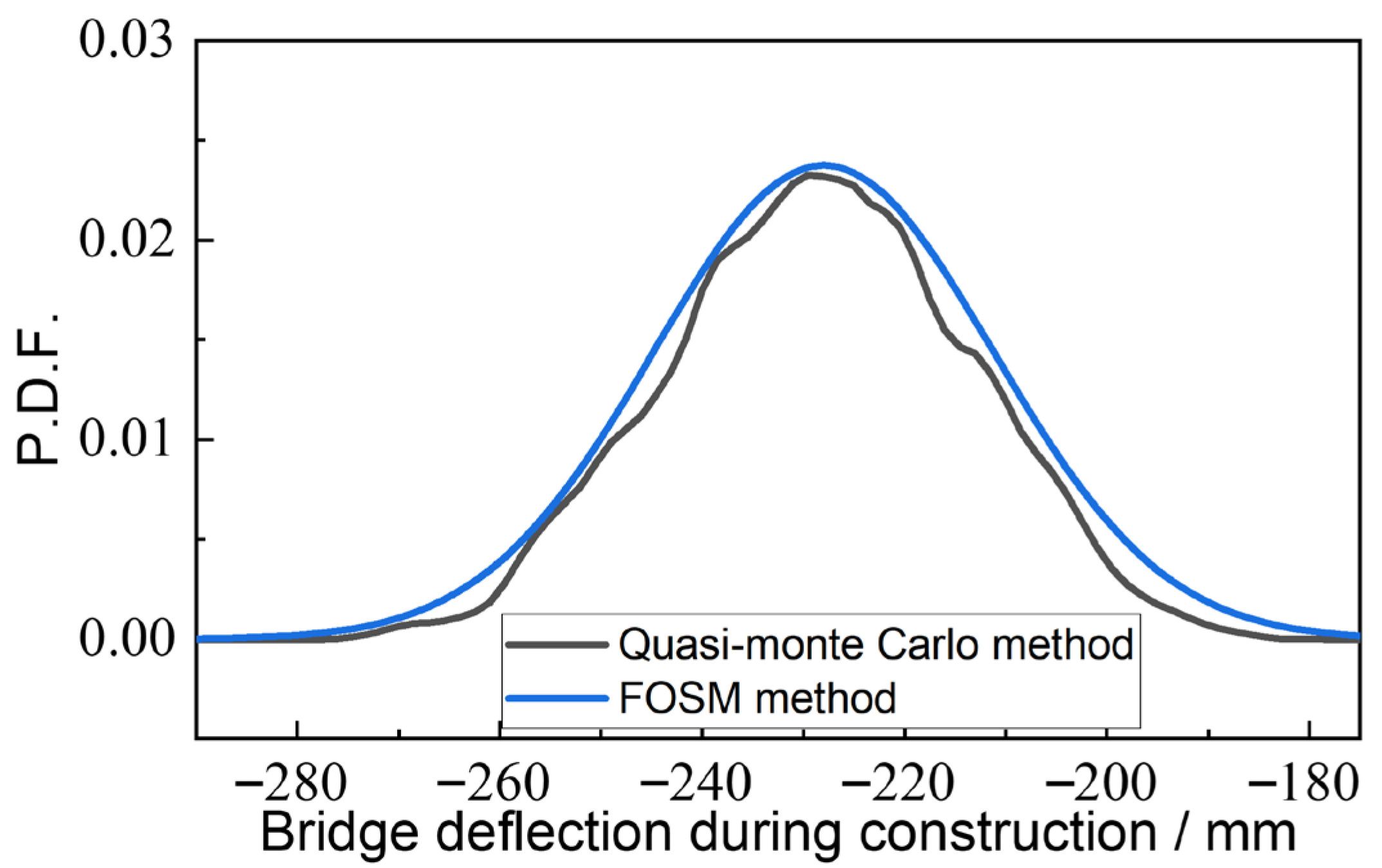

Figure 16.

Comparison of probability densities for bridge deflection during construction: two probabilistic analysis methods (beam element model).

Figure 16.

Comparison of probability densities for bridge deflection during construction: two probabilistic analysis methods (beam element model).

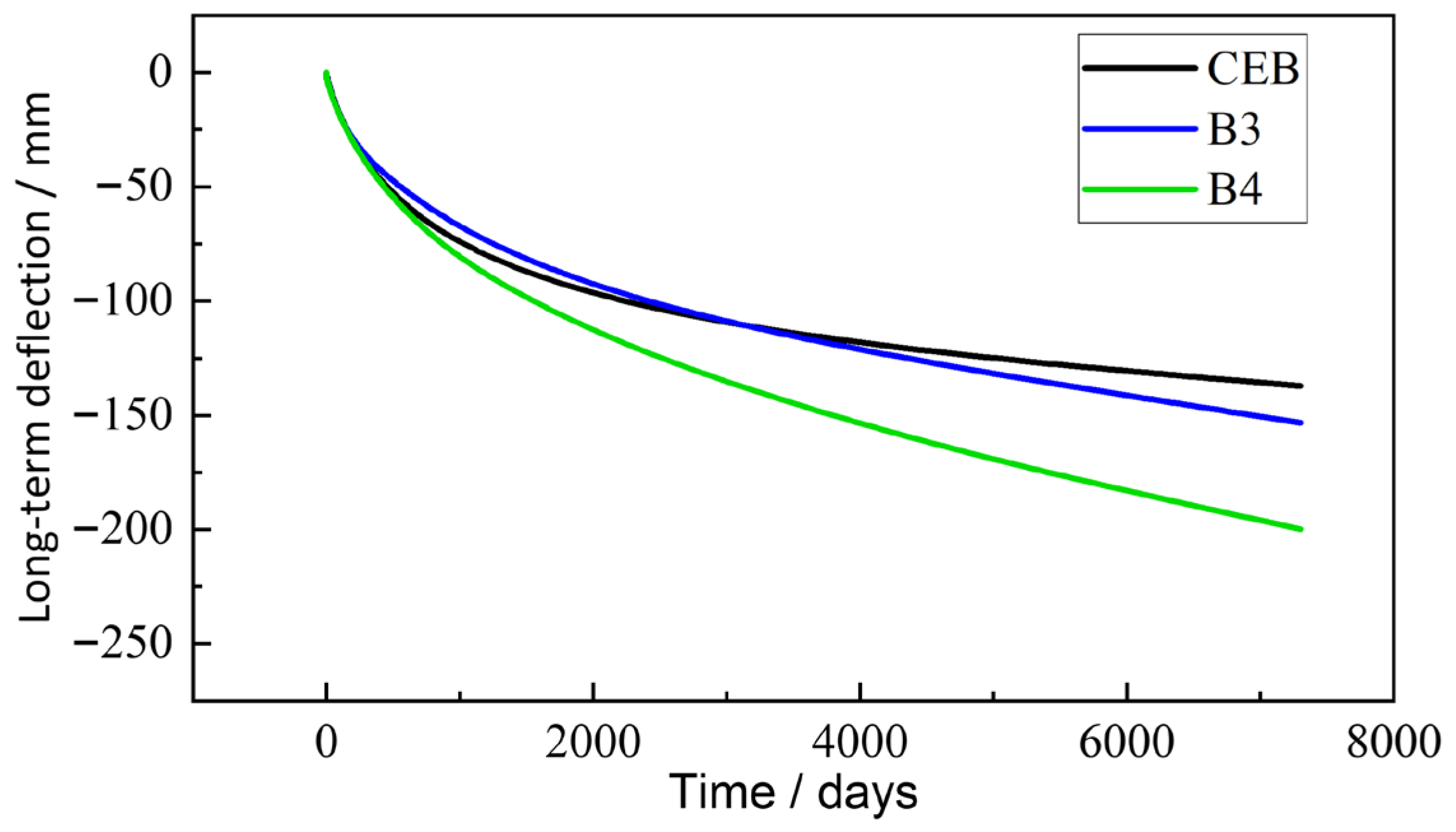

Figure 17.

Evolution of the mean values of the long-term deformation obtained from the three shrinkage-creep models.

Figure 17.

Evolution of the mean values of the long-term deformation obtained from the three shrinkage-creep models.

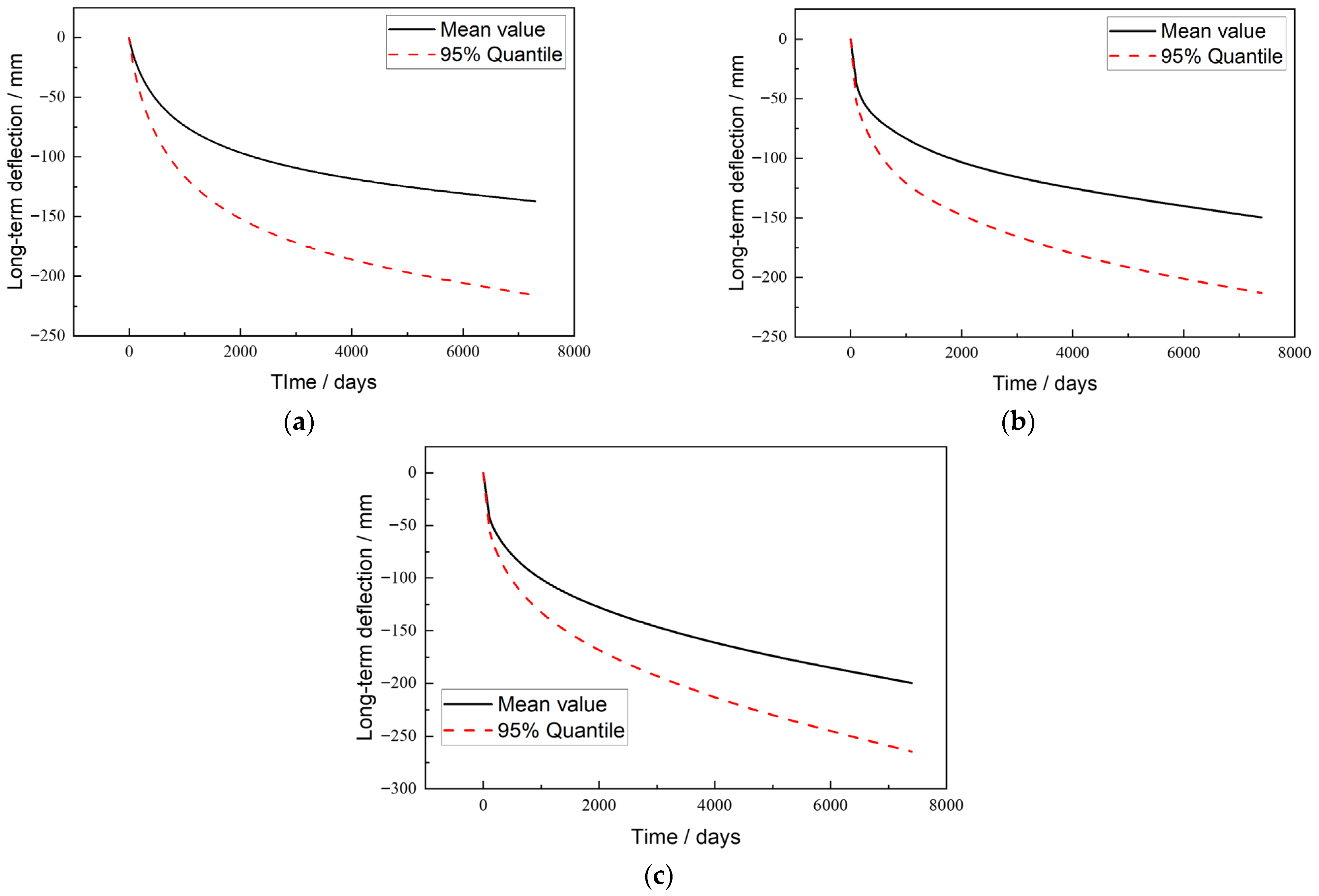

Figure 18.

95% Confidence Interval for Long-term Deflection of Based on Solid Element Analysis (3 Creep-Shrinkage Models), (a) CEB Model, (b) B3 Model, (c) B4 Model.

Figure 18.

95% Confidence Interval for Long-term Deflection of Based on Solid Element Analysis (3 Creep-Shrinkage Models), (a) CEB Model, (b) B3 Model, (c) B4 Model.

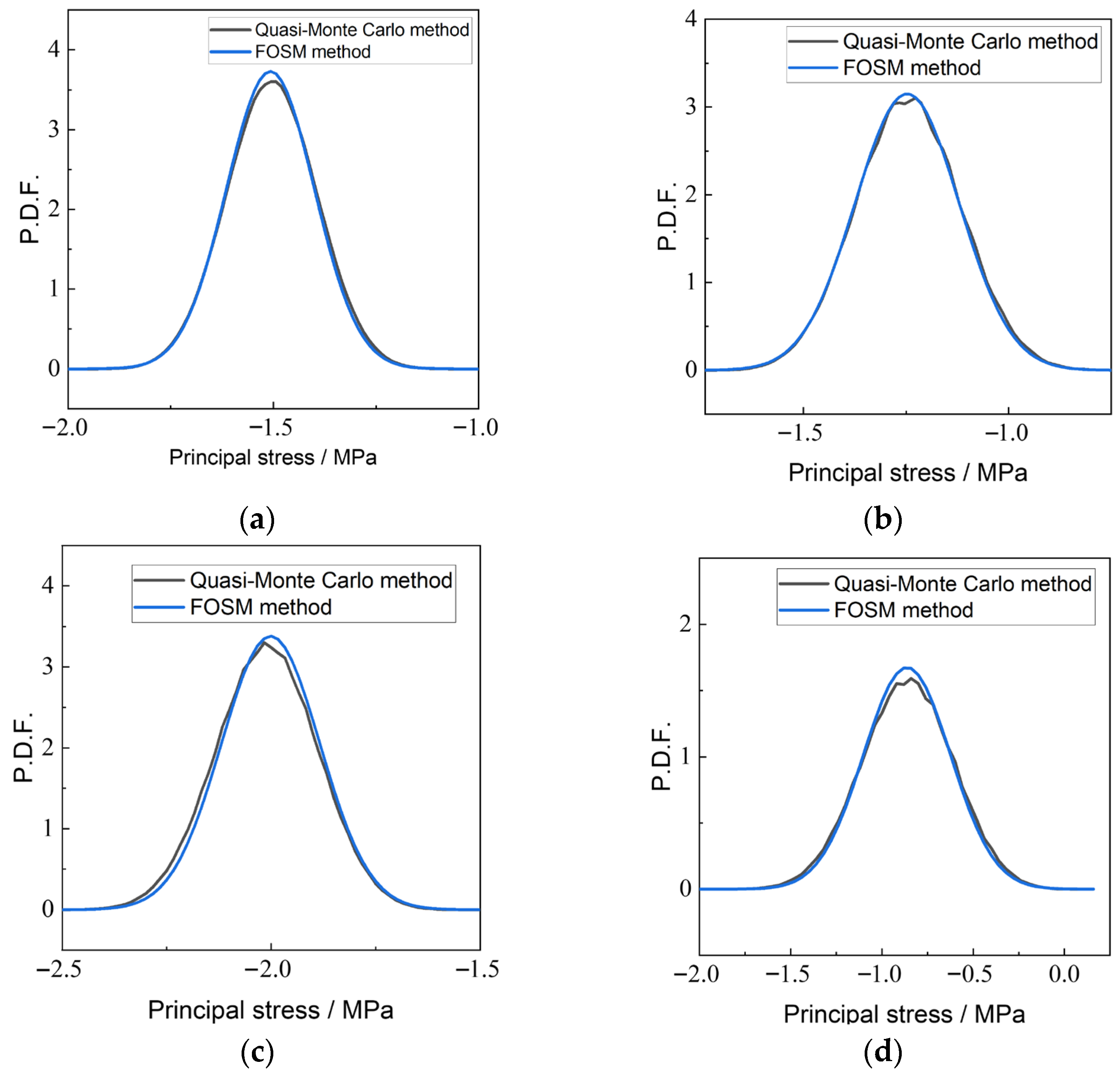

Figure 19.

Comparison of Principal Stress Probability Densities from Two Analysis Methods: (a) Point A, (b) Point B, (c) Point C, (d) Point D.

Figure 19.

Comparison of Principal Stress Probability Densities from Two Analysis Methods: (a) Point A, (b) Point B, (c) Point C, (d) Point D.

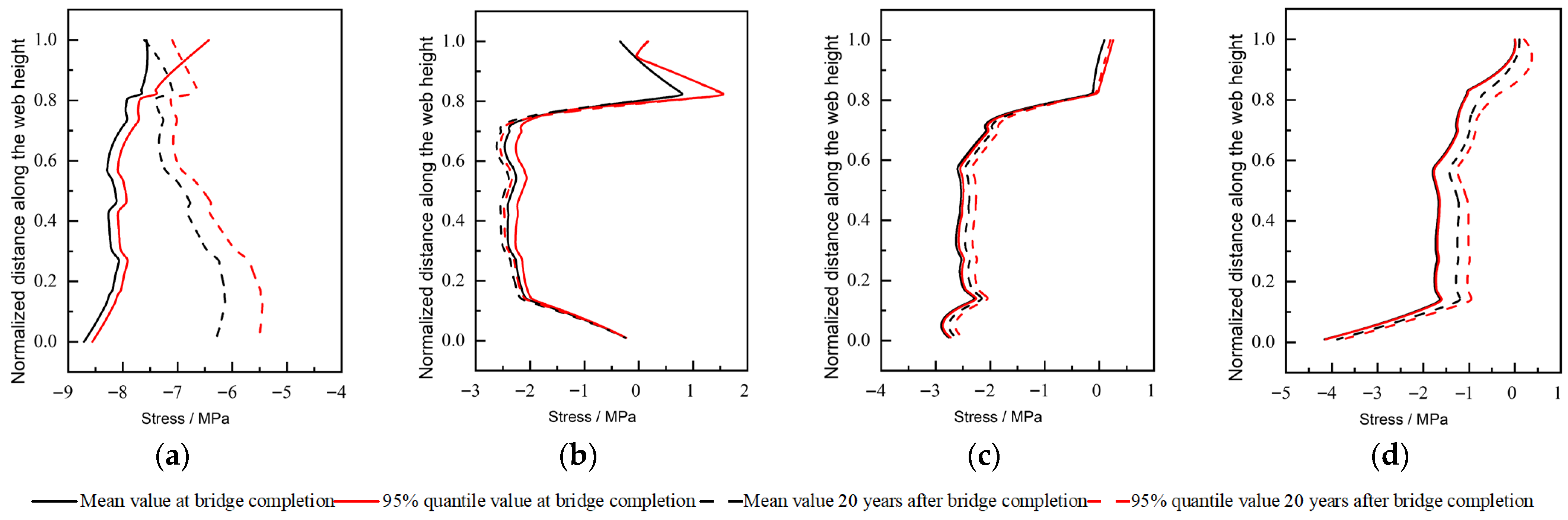

Figure 20.

Mean and 95% quantile stress on the web at bridge completion and after 20 years of bridge completion obtained from the CEB and B4 model: (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

Figure 20.

Mean and 95% quantile stress on the web at bridge completion and after 20 years of bridge completion obtained from the CEB and B4 model: (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

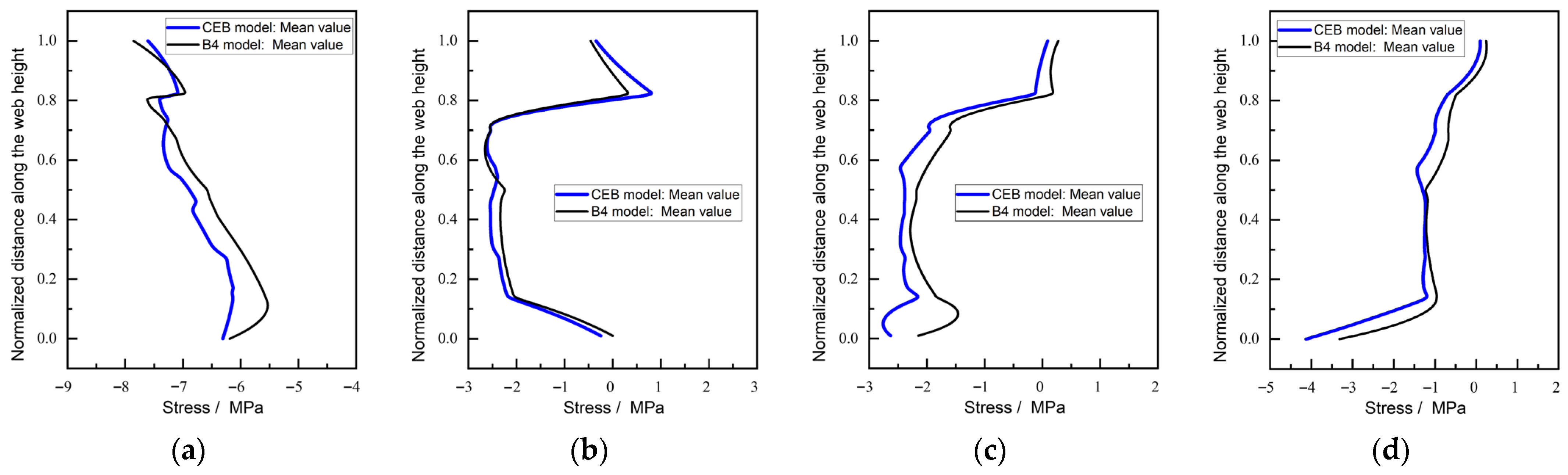

Figure 21.

Mean stress on the web under two creep-shrinkage models after 20 years of bridge completion: (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

Figure 21.

Mean stress on the web under two creep-shrinkage models after 20 years of bridge completion: (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

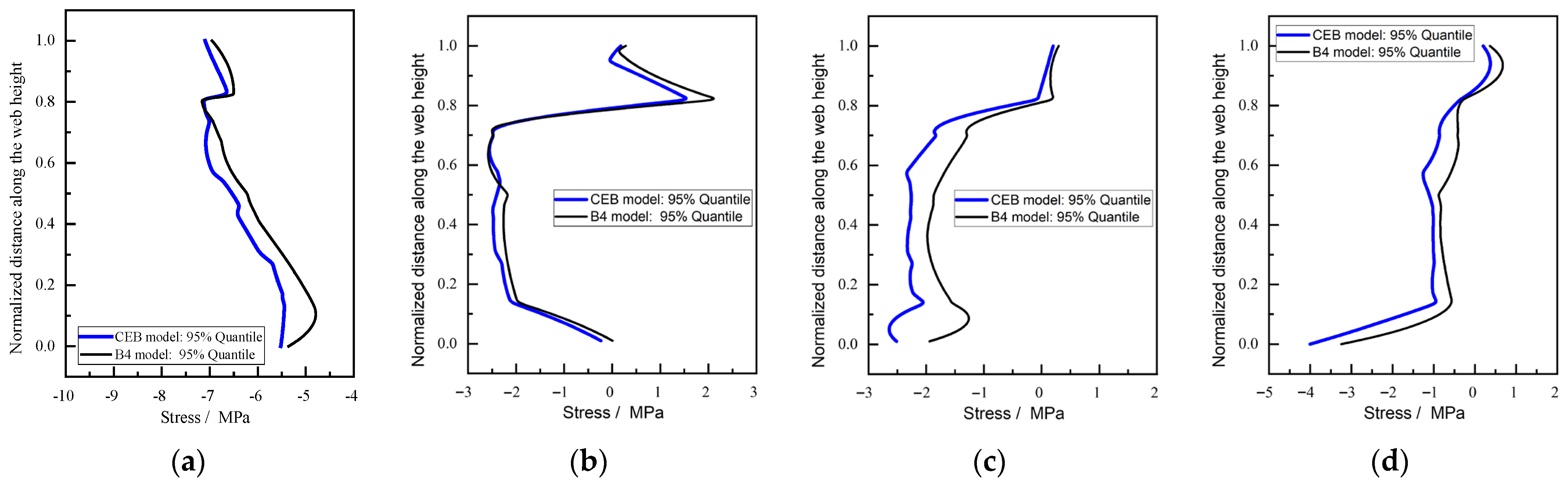

Figure 22.

95% quantile stress on the web under two creep-shrinkage models after 20 years of bridge completion: (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

Figure 22.

95% quantile stress on the web under two creep-shrinkage models after 20 years of bridge completion: (a) longitudinal normal stress, (b) shear stress, (c) vertical normal stress, (d) principal stress.

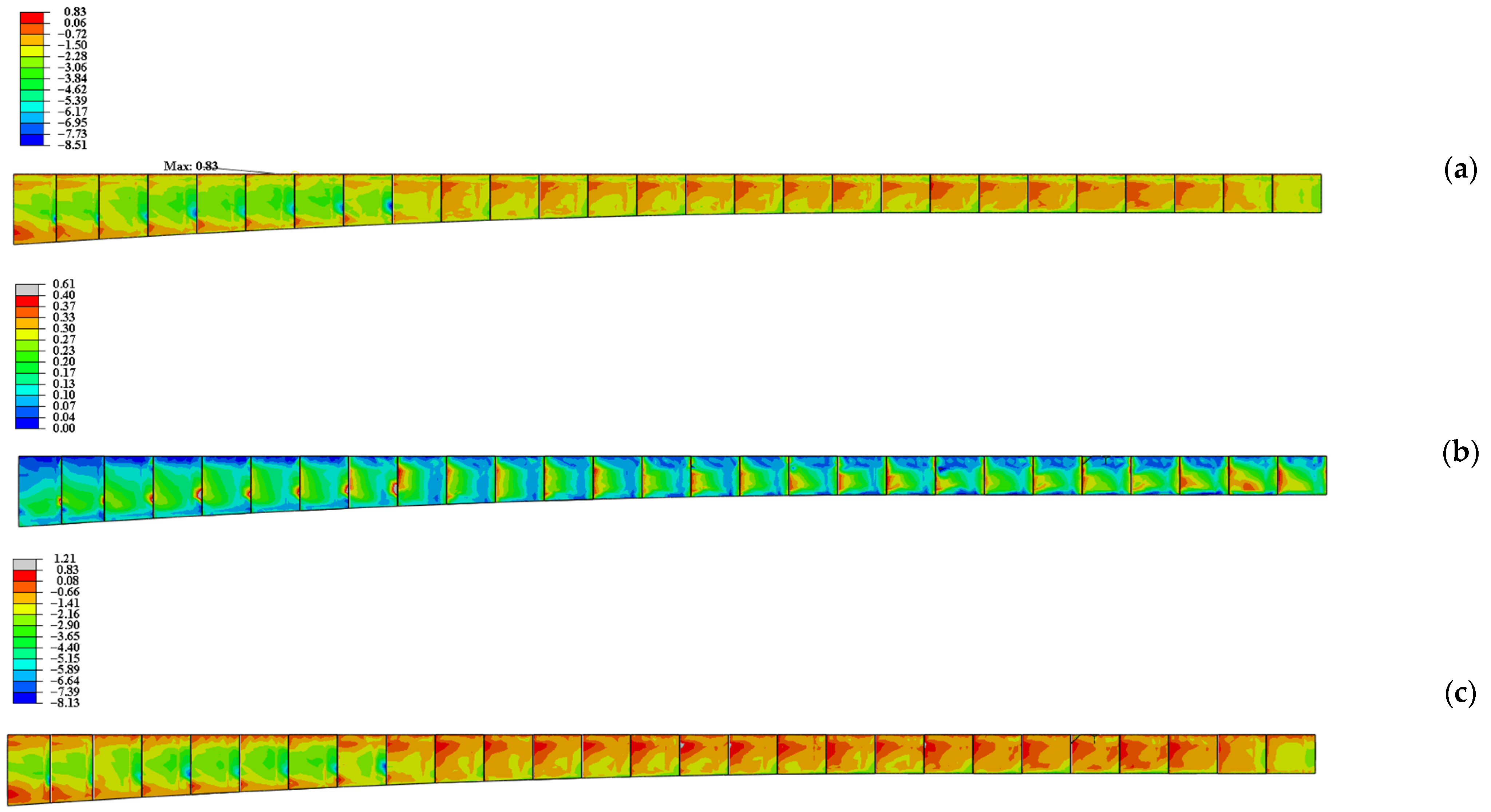

Figure 23.

Contour of the principal stress in the web considering uncertain creep and shrinkage from the B4 model (After 20 Years of bridge completion): (a) mean value (b) standard derivation (c) 95% quantile value.

Figure 23.

Contour of the principal stress in the web considering uncertain creep and shrinkage from the B4 model (After 20 Years of bridge completion): (a) mean value (b) standard derivation (c) 95% quantile value.

Table 1.

Cross-section of the girder.

Table 1.

Cross-section of the girder.

| Section ID | 0 | 2 | 4 | 6 | 8 | 10 | 12 |

|---|

| Distance from the mid-span/m | 7 | 14 | 22 | 30 | 38 | 46 | 54 |

| Area/m2 | 60.21 | 52.91 | 48.45 | 44.51 | 41.08 | 38.15 | 35.73 |

| Moment of inertia/m4 | 481.7 | 333.75 | 258.46 | 200.78 | 157.19 | 124.81 | 101.4 |

| Section ID | 14 | 16 | 18 | 20 | 22 | 24 | 26 |

| Distance from the mid-span/m | 62 | 70 | 78 | 86 | 94 | 102 | 110 |

| Area/m2 | 33.82 | 32.45 | 31.81 | 31.68 | 31.68 | 31.68 | 31.68 |

| Moment of inertia/m4 | 85.6 | 78.3 | 72.8 | 71.4 | 71.4 | 71.4 | 71.4 |

Table 2.

Material properties of the cables, tendons, and concrete.

Table 2.

Material properties of the cables, tendons, and concrete.

| Material | Modulus of Elasticity

/(N/m2) | Mass Density

/(kg/m3) | Compressive Strength/(N/m2) | Strength of Steel Strand/(N/m2) | Poisson’s Ratio |

|---|

| Girder, pylon | 3.60 × 1010 | 2.60 × 103 | 5.6 × 107 | - | 0.2 |

| Cable | 1.95 × 1011 | 2.45 × 103 | - | 1.86 × 109 | 0.3 |

| Tendon | 1.95 × 1011 | 8.00 × 103 | - | 1.86 × 109 | 0.3 |

Table 3.

Construction Sequence of the case bridge.

Table 3.

Construction Sequence of the case bridge.

| Construction Stage | Stage Name | Construction Description | Duration (Days) |

|---|

| 1 | Pier | Construct of All Pier | 10 |

| 2 | Girder Segment 0# | Construct Girder Segment 0#, Temporary Fixation at Girder Bottom | 10 |

| Tensioning Prestressing Tendons for Segment 0# | 3 |

| 3 | Main Tower Construction | Construct Main Tower | 3 |

| 4~18 | Cable-Free Zone: Girder Segments 1#–7# | Construct Girder Segment 1# | 5 |

| Tensioning Prestressing Tendons for Segment 1# | 3 |

| 19~53 | Cable-Supported Zone: Girder Segments 8#–25# | Construct Girder Segment 8# | 5 |

| Tensioning Prestressing Tendons for Segment 8# | 3 |

| Tensioning Stay Cables for Segment 8# | 3 |

| 54~58 | Cable-Free Zone: Girder Segments 26#–27# | Construct Girder Segment 26# | 5 |

| Tensioning Prestressing Tendons for Segment 26# | 3 |

| 59~60 | Side Span Closure Segment | Construct Side Span Closure Segment | 5 |

| Tensioning Closure Segment Tendons | 3 |

| 61~62 | Mid-Span Closure Segment | Construct Mid-Span Closure Segment | 5 |

| Tensioning Closure Segment Tendons | 3 |

| 63 | Bridge Deck Paving | Apply Secondary Dead Load | 5 |

| 64 | Bridge in Service | Long-Term Creep | 7400 |

Table 4.

Coefficients of variation (C.o.V.) for creep and shrinkage [

33].

Table 4.

Coefficients of variation (C.o.V.) for creep and shrinkage [

33].

| Model | Creep Coefficient of Variation | Shrinkage Coefficient of Variation |

|---|

| CEB | 0.470 | 0.415 |

| B3 | 0.366 | 0.410 |

| B4 | 0.273 | 0.316 |

Table 5.

Sensitivity Coefficients of the 20-Year Long-Term Deflection .

Table 5.

Sensitivity Coefficients of the 20-Year Long-Term Deflection .

| Random Variable | BEAM Element Analysis | SOLID Element Analysis | Solid/Beam Ratio |

|---|

| Creep Coefficient | −0.281 | −0.376 | 1.340 |

| Shrinkage Coefficient | −0.173 | −0.250 | 1.444 |

Table 6.

Probabilistic characteristics of the Random Variables.

Table 6.

Probabilistic characteristics of the Random Variables.

| Random Variable | Probability Distribution | Mean | Coefficient of Variation |

|---|

| Concrete Density [34] | Normal | 25 kN/m3 | 0.03 |

| Concrete Elastic Modulus E [35] | Normal | 35,500 MPa | 0.04 |

| Tendon Stress [36] | Normal | 1395/1300 MPa | 0.088 |

| Cable Stress [36] | Normal | Design Value | 0.06 |

| Creep Coefficient φ [32] | Normal | 1.85 | 0.470 |

| Shrinkage Coefficient [32] | Normal | 3.36 × 10−4 | 0.415 |

Table 7.

Sensitivity coefficient of bridge deflection during construction based on the beam analysis.

Table 7.

Sensitivity coefficient of bridge deflection during construction based on the beam analysis.

| Random Variable | (mm) | Random Variable | (mm) |

|---|

| Concrete Density | −7.57 | Cable stress | 2.3 |

| Concrete Elastic Modulus | 2.9 | Creep Coefficient | −12.84 |

| Tendon stress | 6.8 | Shrinkage Coefficient | 0.33 |

Table 8.

Statistics of long-term deflection at 20 years from bridge completion based on solid element analysis.

Table 8.

Statistics of long-term deflection at 20 years from bridge completion based on solid element analysis.

| Creep-Shrinkage Model | Coefficient of Variation for Parameters | Long-Term Deflection Sensitivity Coefficient (mm) | Statistical Values of Long-Term Deflection (mm) |

|---|

| Creep | Shrinkage | Creep | Shrinkage | Mean Value | Standard Deviation | 95% Confidence Value |

|---|

| CEB | 0.47 | 0.415 | −39.86 | −26.47 | −137.19 | 49.16 | −218.058 |

| B3 | 0.366 | 0.41 | −35.59 | −14.72 | −149.6 | 40.2 | −215.729 |

| B4 | 0.273 | 0.316 | −30.88 | −24.62 | −199.62 | 41.14 | −267.295 |

Table 9.

Effect of Creep and Shrinkage Parameters on Stress Components at Points A to D (20 years after completion) (MPa).

Table 9.

Effect of Creep and Shrinkage Parameters on Stress Components at Points A to D (20 years after completion) (MPa).

| Point ID | Stress State | | | | | | |

|---|

| A | | −6.936 | 0.131 | −2.427 | 0.100 | −2.244 | −0.053 |

| −6.752 | 0.130 | −2.412 | 0.100 | −2.267 | −0.052 |

| −6.904 | 0.130 | −2.349 | 0.101 | −2.272 | −0.053 |

| B | | −6.591 | 0.004 | −2.359 | 0.123 | −2.439 | 0.039 |

| −6.372 | 0.004 | −2.340 | 0.123 | −2.463 | 0.039 |

| −6.487 | 0.005 | −2.285 | 0.124 | −2.472 | 0.040 |

| C | | −7.189 | −0.225 | −2.451 | 0.134 | −1.549 | −0.162 |

| −7.082 | −0.185 | −2.355 | 0.166 | −1.558 | −0.131 |

| −7.345 | −0.363 | −2.488 | 0.137 | −1.561 | −0.208 |

| D | | −7.021 | 0.148 | −1.258 | 0.180 | −1.564 | −0.042 |

| −6.907 | 0.106 | −1.367 | 0.217 | −1.549 | −0.050 |

| −7.145 | 0.274 | −1.045 | 0.161 | −1.607 | −0.004 |

Table 10.

Effect of Creep and Shrinkage Parameters on Principal Stresses at Points A to D (20 years after completion) (MPa).

Table 10.

Effect of Creep and Shrinkage Parameters on Principal Stresses at Points A to D (20 years after completion) (MPa).

| Point ID | Stress State | The 2nd Principal Stress | Direction of the Principal Stress | Cosine with Mean Direction |

|---|

| X | Y | Z |

|---|

| A | | −1.507 | 0.381 | −0.053 | −0.923 | / |

| −1.450 | 0.392 | −0.055 | −0.919 | 0.999 |

| −1.416 | 0.381 | −0.056 | −0.923 | 0.999 |

| B | | −1.248 | 0.415 | −0.013 | −0.910 | / |

| −1.175 | 0.428 | −0.015 | −0.904 | 0.997 |

| −1.144 | 0.419 | −0.014 | −0.908 | 0.999 |

| C | | −2.001 | 0.282 | −0.108 | −0.953 | / |

| −1.896 | 0.284 | −0.100 | −0.954 | 0.999 |

| −2.055 | 0.277 | −0.139 | −0.951 | 0.999 |

| D | | −0.863 | 0.243 | −0.083 | −0.966 | / |

| −0.966 | 0.248 | −0.094 | −0.964 | 0.999 |

| −0.648 | 0.239 | −0.046 | −0.970 | 0.999 |

Table 11.

Comparison of the Probabilistic values of the Principal Stress Using Two Methods.

Table 11.

Comparison of the Probabilistic values of the Principal Stress Using Two Methods.

| Point ID | PDEM Mean (MPa) | FOSM Mean (MPa) | Error (%) | PDEM Standard Deviation (MPa) | FOSM Standard Deviation (MPa) | Error (%) |

|---|

| A | −1.504 | −1.507 | 0.20 | 0.105 | 0.107 | 1.87 |

| B | −1.245 | −1.248 | 0.24 | 0.124 | 0.127 | 2.36 |

| C | −2.012 | −2.00 | 0.60 | 0.115 | 0.118 | 2.54 |

| D | −0.863 | −0.869 | 0.69 | 0.239 | 0.238 | 0.42 |