Advancements Toward a Standard System for Intelligent Operation and Maintenance of Buildings and Municipal Facilities

Abstract

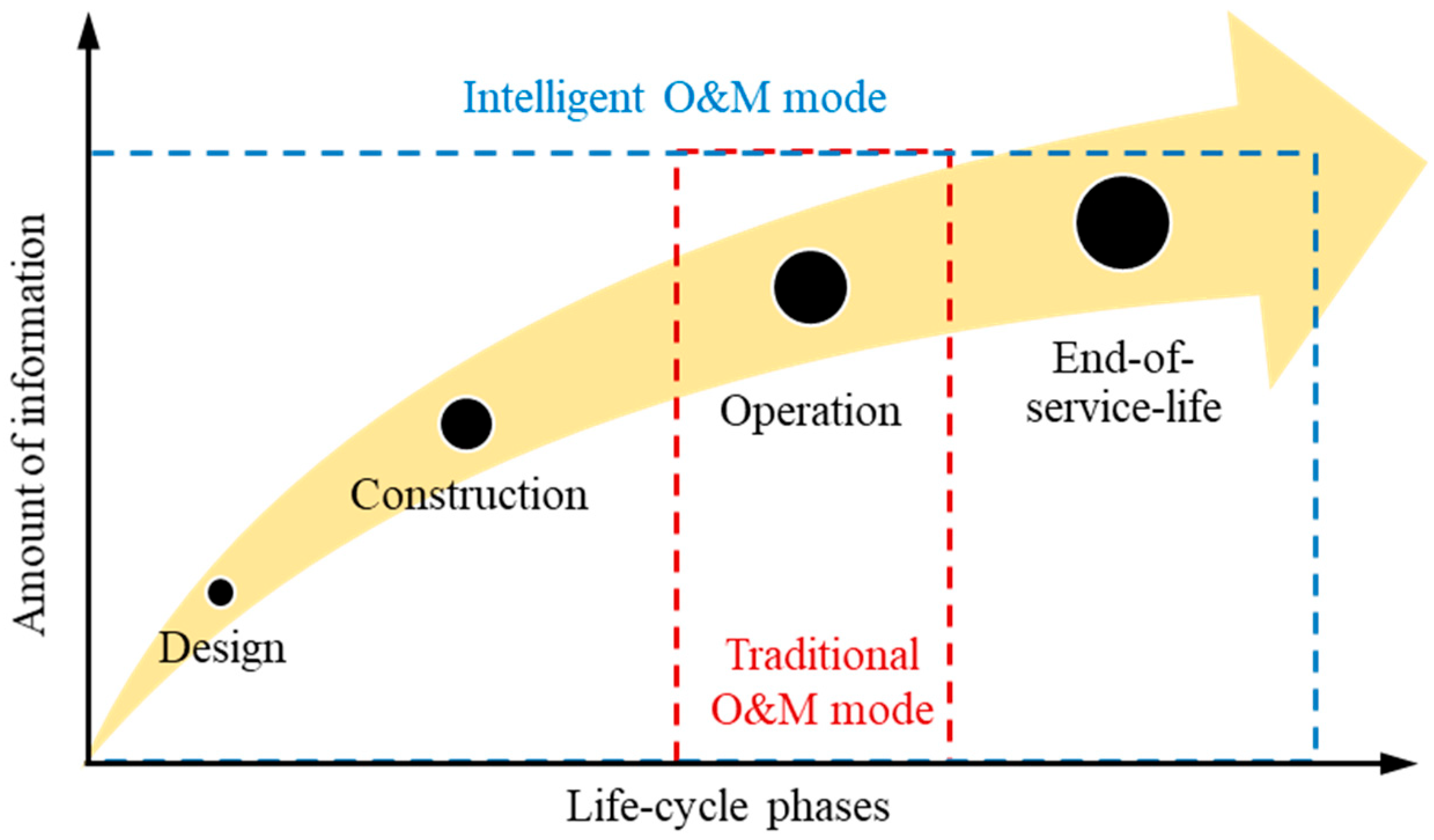

1. Introduction

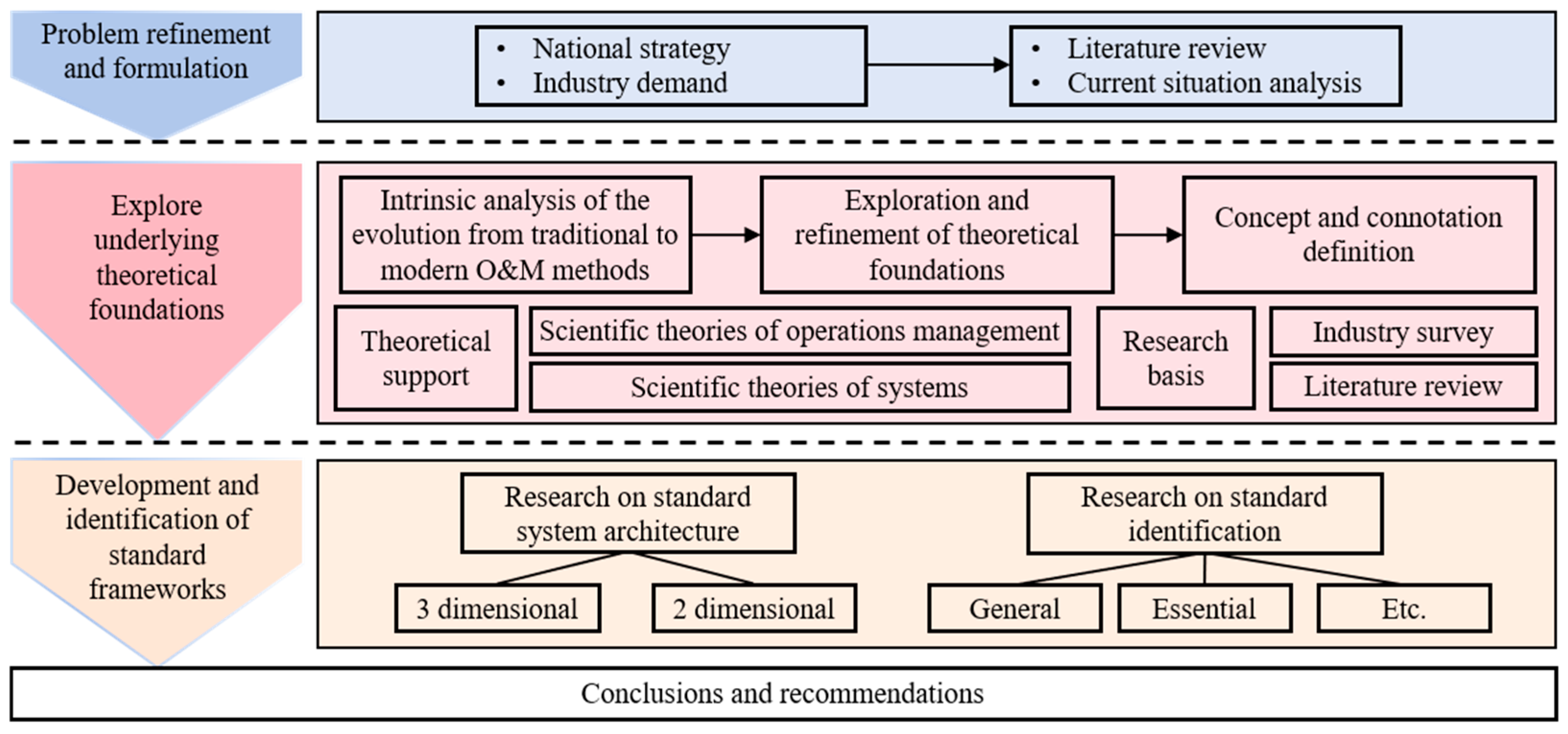

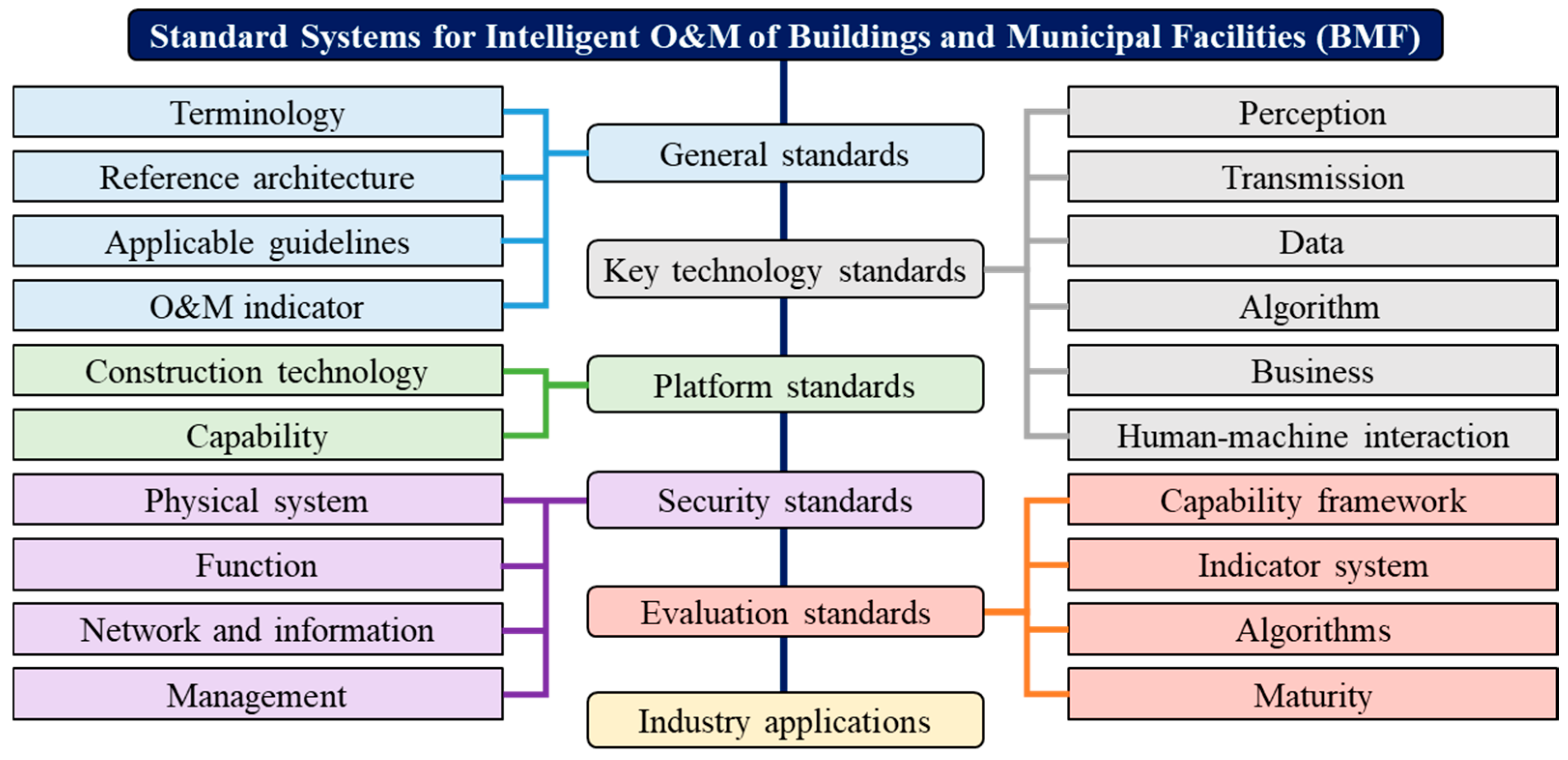

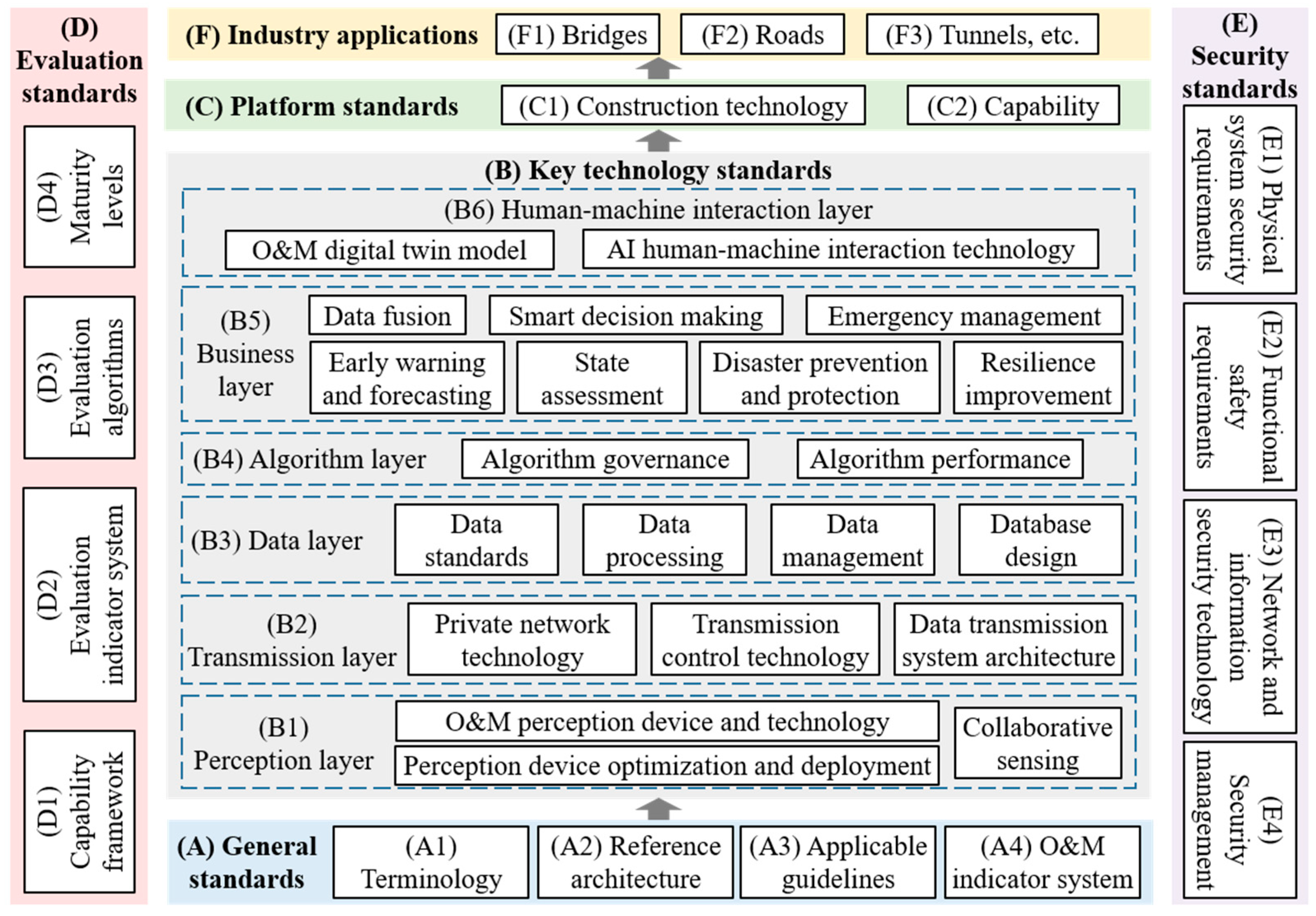

2. Architecture of Intelligent O&M Standard Systems

2.1. Objectives

2.2. Basic Principles

2.3. O&M Standard System Deconstruction

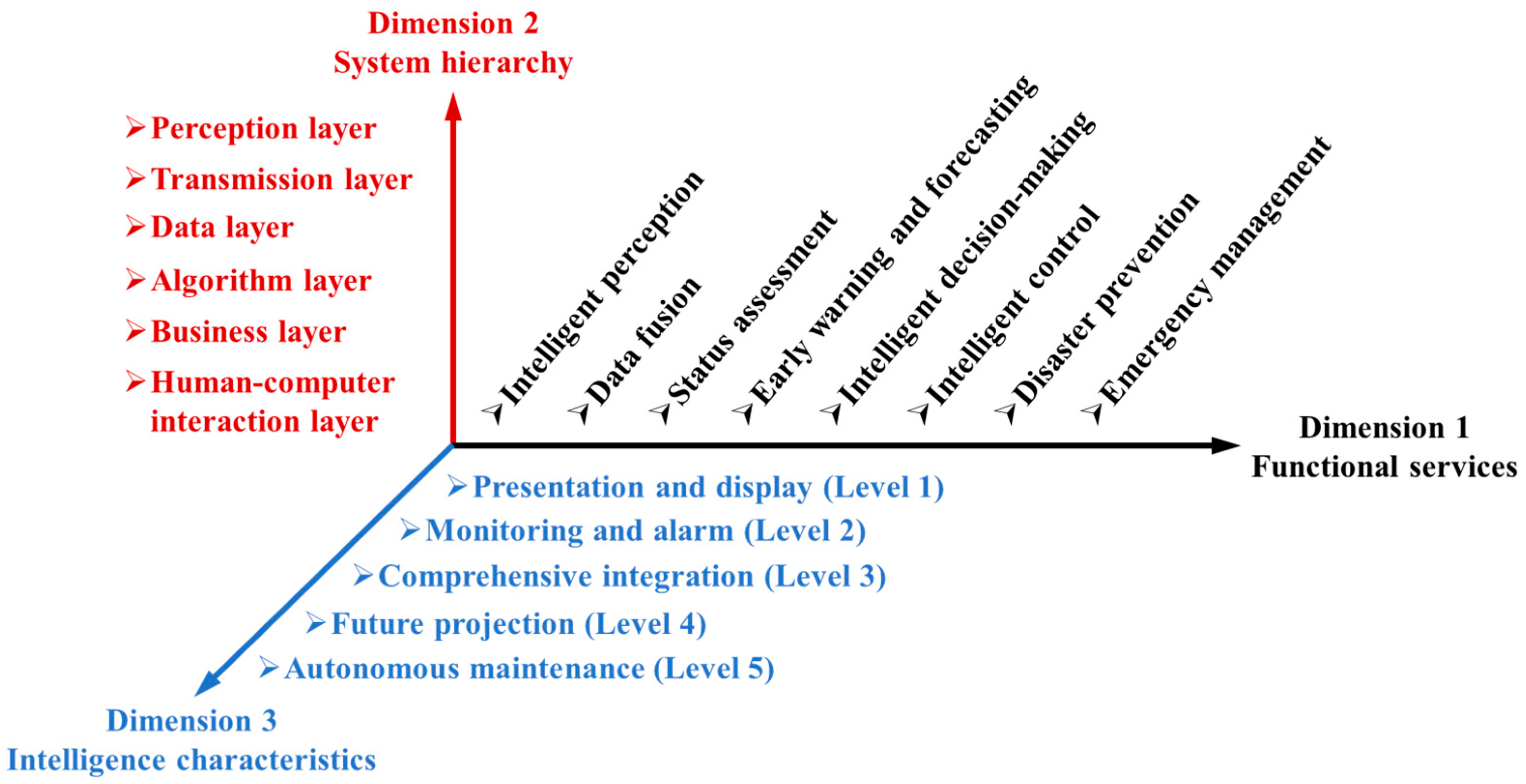

2.3.1. Functional Services (Dimension 1)

- 1.

- Intelligent perception: Employing sensing methods such as sound, light, electricity, magnetism, and heat combined with intelligent sensors, an Internet of Everything is formed. Data on functional performance, durability, safety, and energy consumption is collected through online monitoring, inspections, and routine patrols.

- 2.

- Data fusion: Collected data are modeled and analyzed to understand changes in facility status and service functions caused by loads, environmental factors, or disasters.

- 3.

- Status assessment: Real-time data, physical knowledge, and AI techniques (e.g., machine learning, large models like ChatGPT-4o and DeepSeek-R1) are used to build models for status recognition, evaluation, and risk identification, forming an “O&M brain” that is updated regularly or post disaster.

- 4.

- Early warning and forecasting: Big data and machine learning algorithms process information to detect risks and issue timely warnings and forecasts.

- 5.

- Intelligent decision-making: Status assessments, combined with knowledge bases and AI techniques, generate decision models to recommend maintenance and repair actions.

- 6.

- Intelligent control: Robotics, VR/AR, drones, and other intelligent technologies detect and respond to maintenance needs and emergencies.

- 7.

- Disaster prevention: “Intelligent monitoring + intelligent equipment” technologies mitigate significant hazards such as floods, freezing, earthquakes, mudslides, snow accumulation, fires, and rockfalls.

- 8.

- Emergency management: A self-circulating closed-loop system coordinates pre-event warnings, event response through rapid resource scheduling, and post-event optimization for resilience and improved emergency management.

2.3.2. System Hierarchy (Dimension 2)

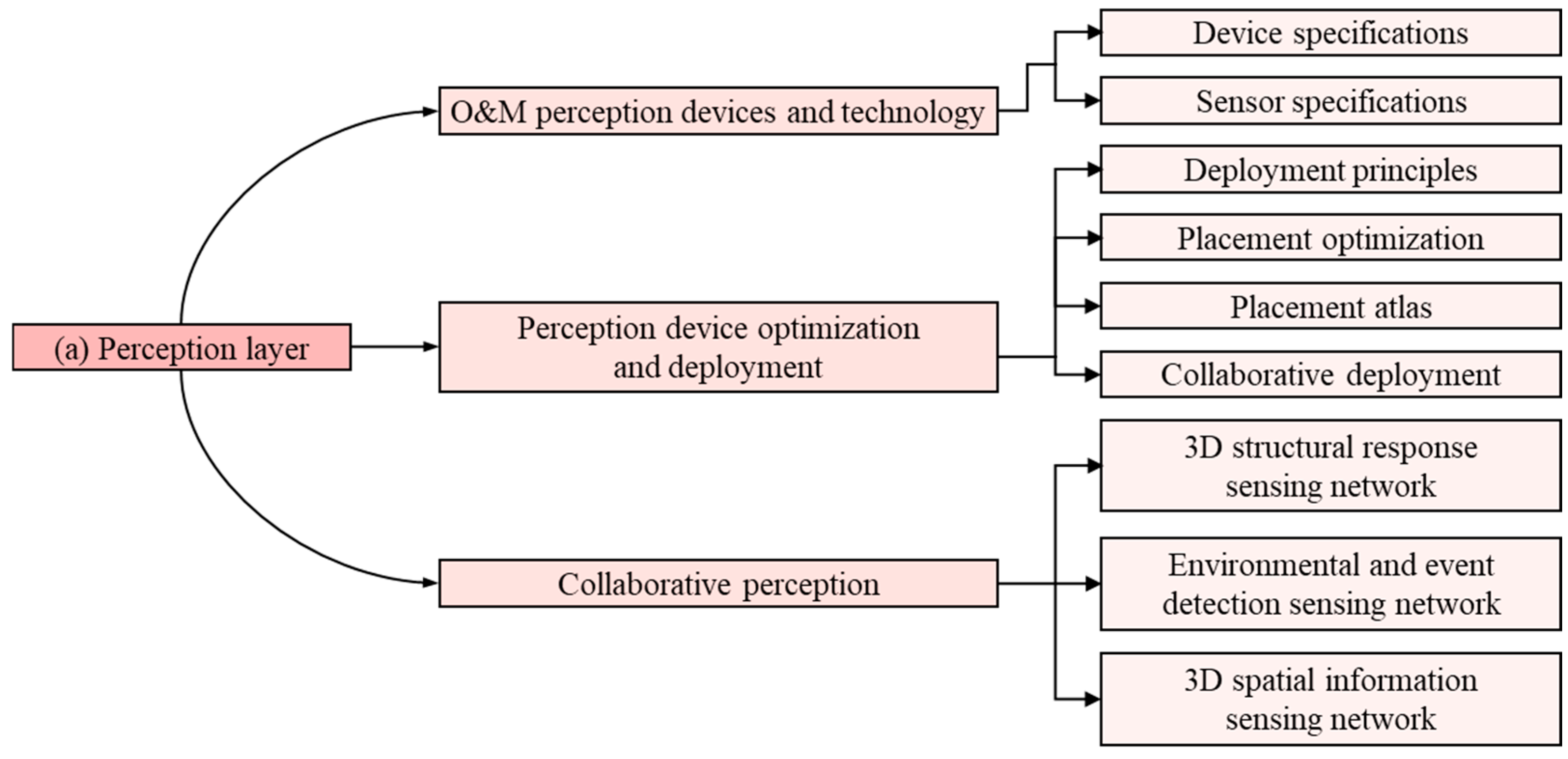

- Perception layer: Senses environmental and infrastructure changes, collecting O&M information.

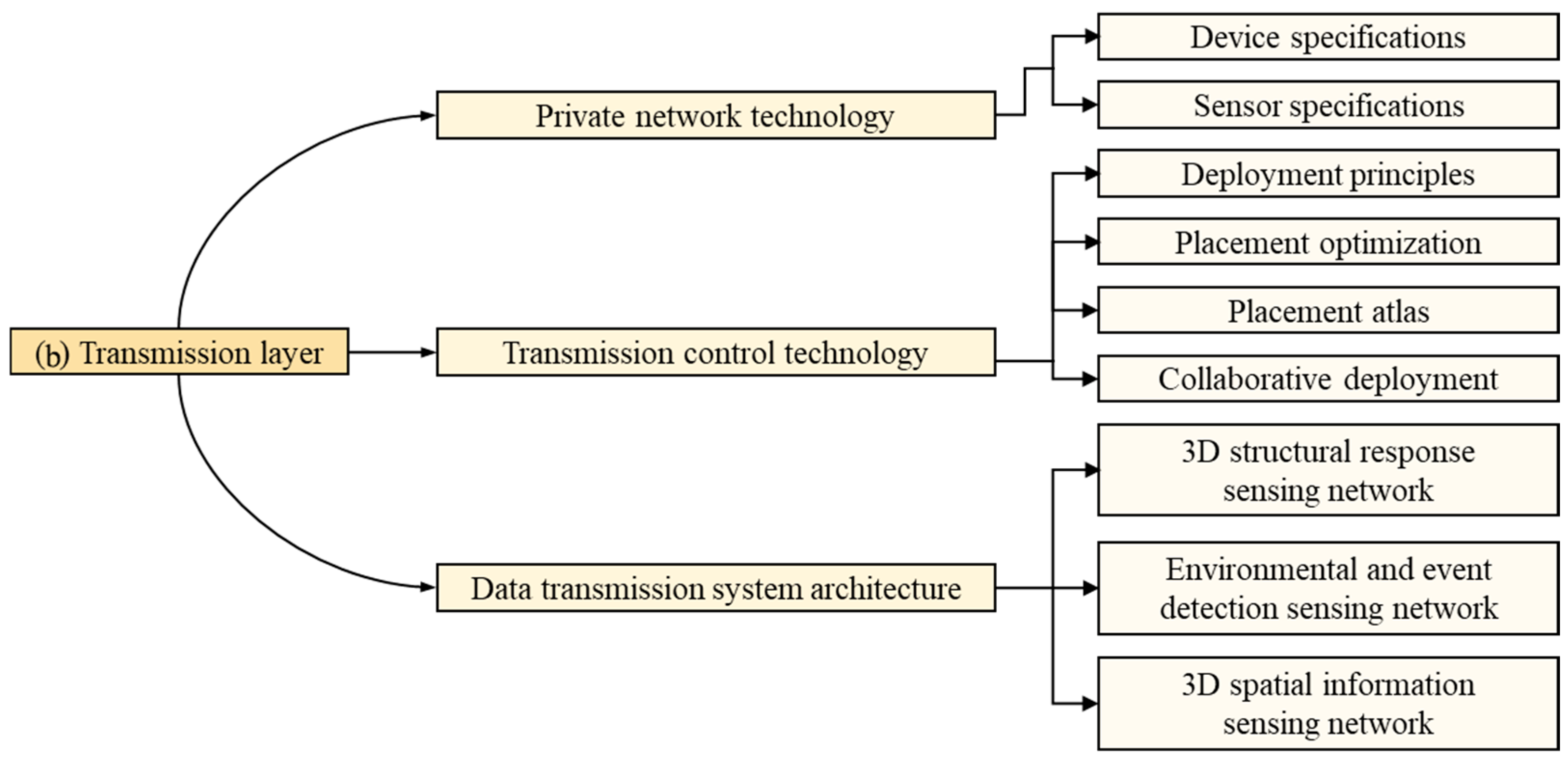

- Transmission layer: Enables real-time interaction between physical and information spaces through wired/wireless media, cloud–edge–terminal networks, and high-capacity, low-latency transmission technologies.

- Data layer: Aggregates collected, generated, and fused data, forming the foundation for platform operations.

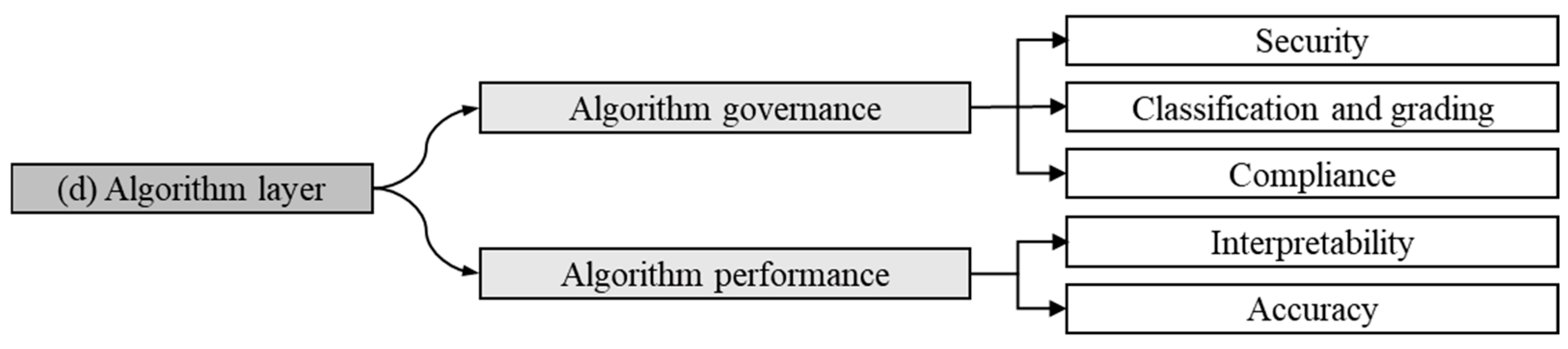

- Algorithm layer: The core driver of intelligent O&M is analyzing high-quality data to make decisions, generate insights, and control automated O&M operations.

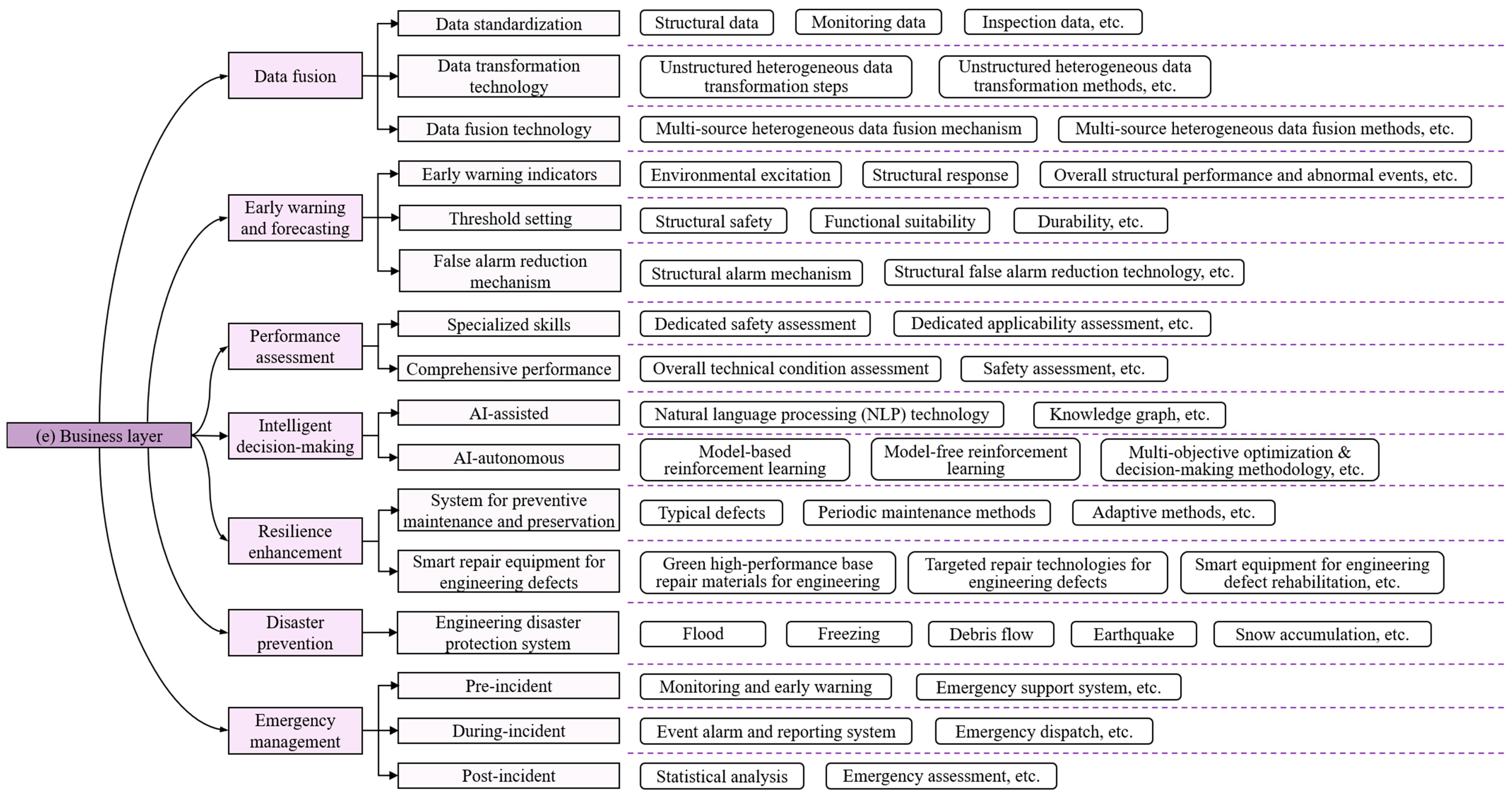

- Business layer: Provides essential services—including limit alarms, status assessment, and emergency control—based on algorithm outputs, representing the system’s functional core.

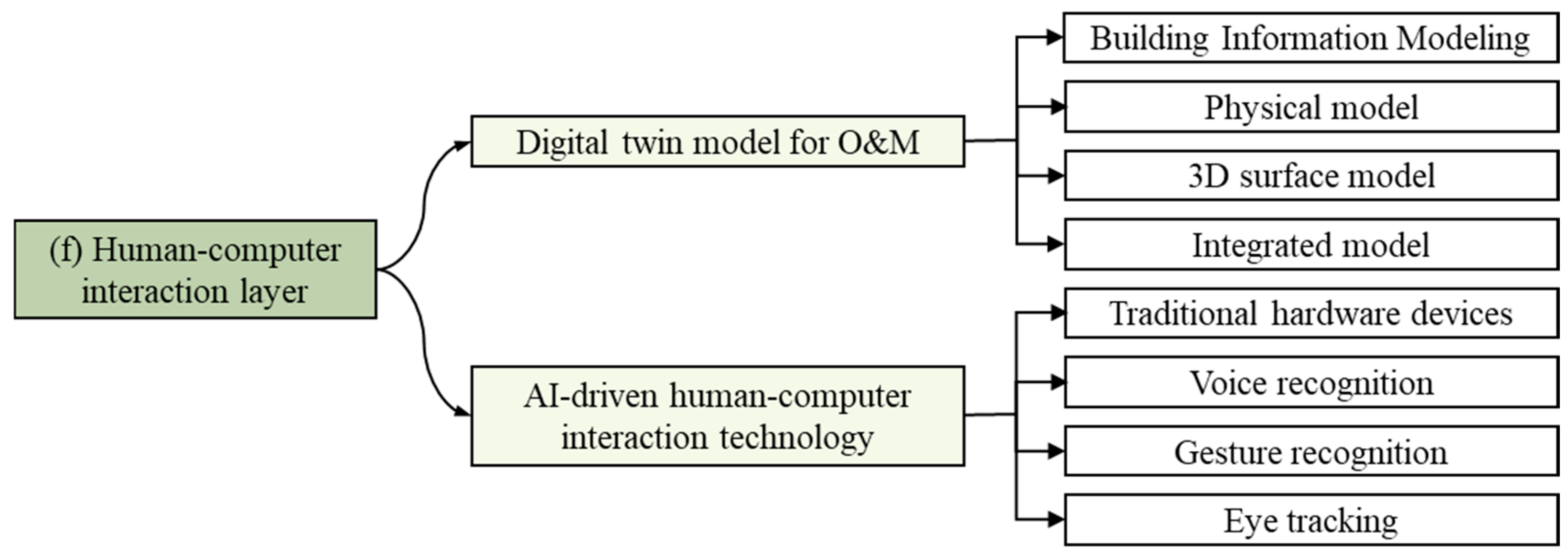

- Human–computer interaction layer: Supports data visualization, digital twin models, AI interfaces, intelligent alerts, and automated work orders for various infrastructures and O&M scenarios.

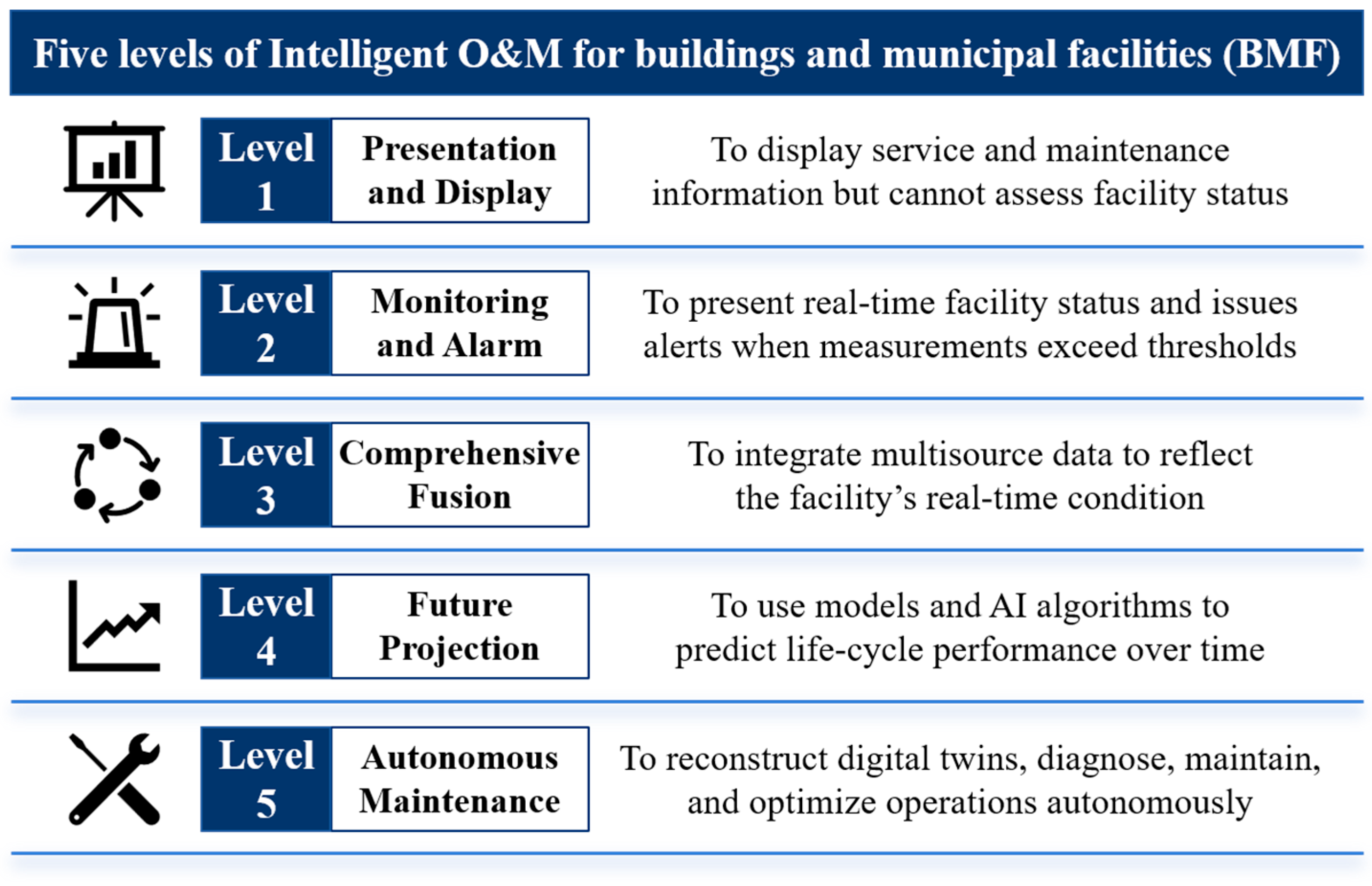

2.3.3. Intelligence Characteristics (Dimension 3)

- Presentation and display (Level 1): Displays infrastructure service and maintenance information but cannot assess facility status, relying mainly on expert intervention. For example, bridge technicians may monitor vehicle operations using video and weighing systems, ensuring some structural safety; however, the system cannot assess structural integrity.

- Monitoring and alarm (Level 2): Presents real-time facility status and issues alerts when measurements exceed thresholds, prompting personnel intervention. For instance, sensors on a bridge collect data on deflection and stress, triggering alarms if abnormal readings are detected.

- Comprehensive fusion (Level 3): Integrates multisource data to reflect the facility’s real-time condition, laying the foundation for predictive analysis. In bridges, sensors and algorithms monitor vehicle, wind, temperature, and structural responses, while digital twins enable the real-time fusion of data and evaluation of service status.

- Future projection (Level 4): Uses models and AI algorithms to predict infrastructure performance over time, enabling proactive maintenance. Time-variant material models combined with dynamic fusion data forecast future bridge service states, transforming sudden issues into predictable events.

- Autonomous maintenance (Level 5): The system continuously adapts through long-term interaction with infrastructure, reconstructing digital twins, diagnosing, maintaining, and optimizing operations autonomously. Bridges benefit from dynamic perception, prediction, decision-making, and the automated deployment of maintenance robots, enabling sustainable, low-cost, high-quality intelligent O&M.

2.4. Framework of Standard System

3. Content of Intelligent O&M Standard System

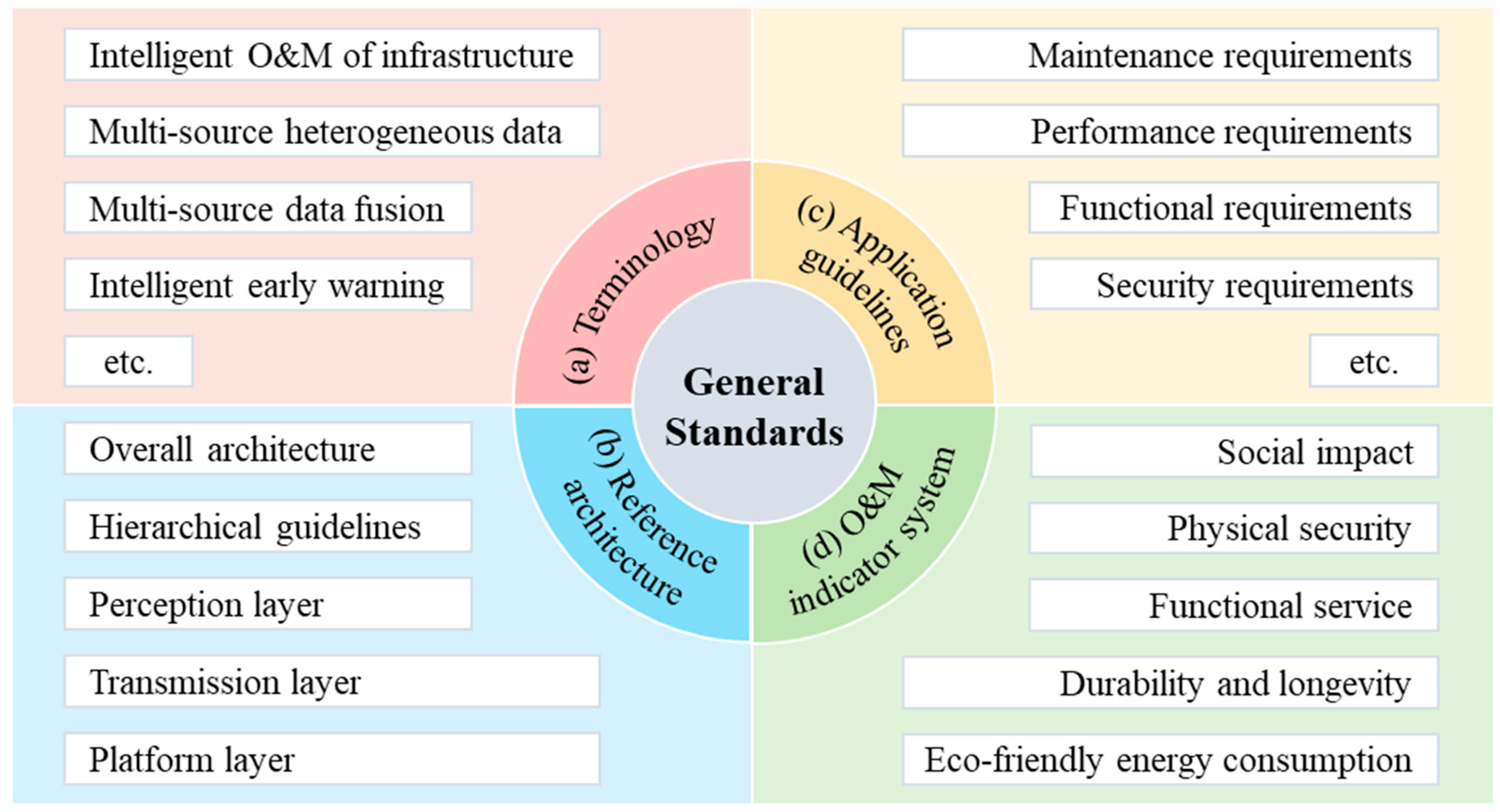

3.1. General Standards

3.1.1. Terminology

3.1.2. Reference Architecture

3.1.3. Application Guidelines

3.1.4. O&M Indicator System

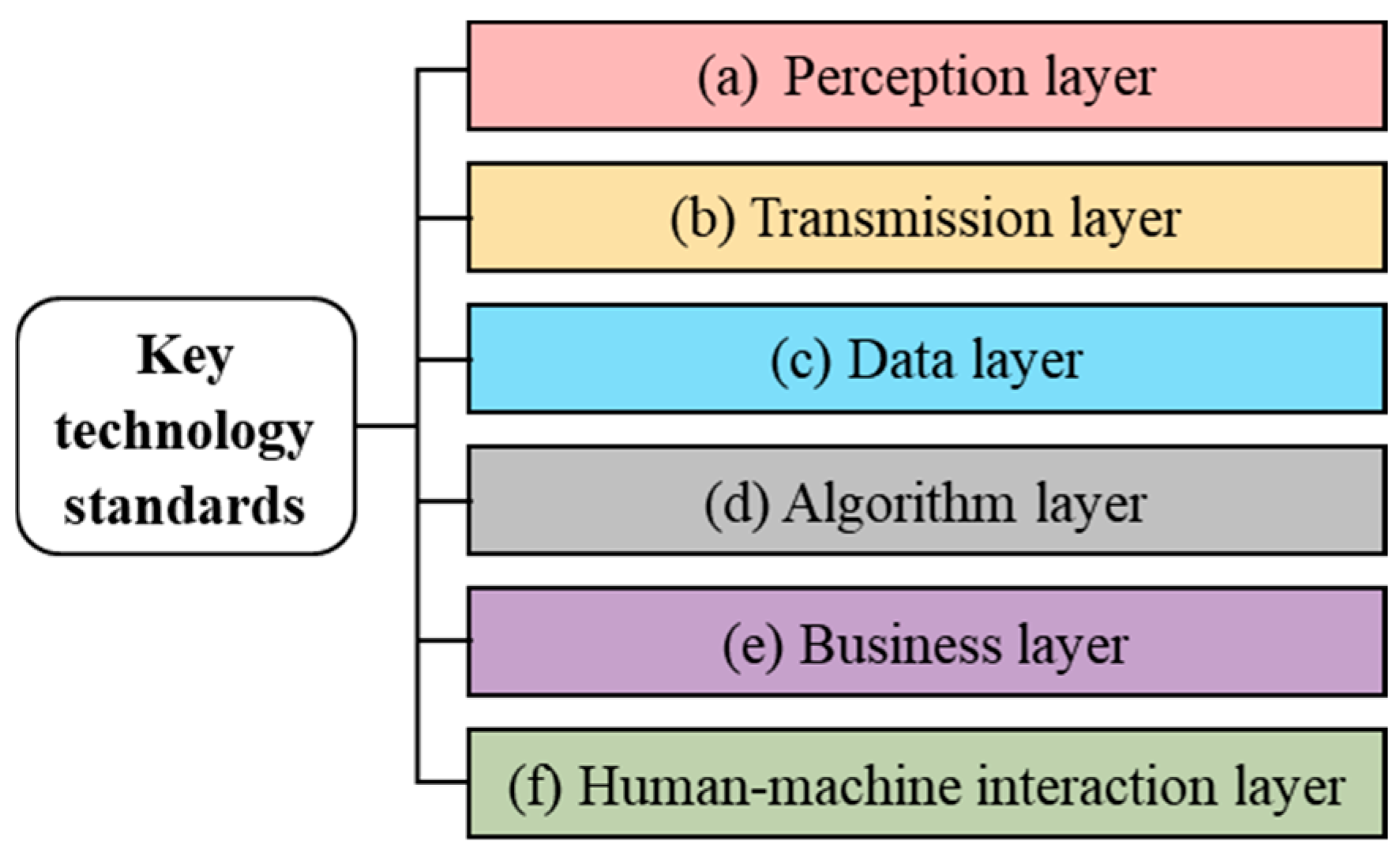

3.2. Key Technology Standards

3.2.1. Perception Layer

- O&M perception devices and technology: These standards establish technical requirements for intelligent sensor performance, data output, installation testing, and protection during O&M information collection. They regulate the specifications and usage rules for sensors and detection equipment integrated into intelligent O&M systems, thereby enhancing the reliability, compatibility, and operability of perception devices.

- Perception device optimization and deployment: Sensors represent the primary cost component in constructing intelligent O&M systems and serve as the primary data source. Optimizing the spatial placement of sensors and perception networks is essential for a scientifically and efficiently built system. Standards should provide guidelines for monitoring point deployment, optimization calculation methods, typical structural sensor placement atlases, and strategies for cooperative perception deployment, ensuring practical and rational sensor layouts.

- Collaborative perception: These standards define requirements and interaction rules for the collaborative operation of multi-source heterogeneous devices (e.g., structural response sensors, environmental detectors, space–sky–ground–sea–vehicle platforms). They cover 3D perception networks for structural response, ecological and sudden-change detection, and spatial information acquisition systems, with clear identification and interconnection criteria to enable integrated collaboration and system modeling.

3.2.2. Transmission Layer

- Private network technology: These standards define information exchange and communication technologies across heterogeneous network platforms. By interconnecting sensing devices through different media, data transmission and information exchange are enabled. Key technologies include the Internet of Things (IoT), Wireless Sensor Networks (WSNs), and next-generation Internet technologies. For example, IoT technologies are regulated by international ISO 18000 security standards [49] and LAN IEEE 802 transmission protocol standards [50]. WSNs follow standards such as Zigbee [51] and ISA100 [52]. Next-generation Internet technologies, including IPv6 and 5G, offer enhanced connectivity, scalability, and transmission capacity.

- Transmission control technology: These standards regulate the formats, conversion, and control mechanisms that data must follow during transmission. They cover real-time access, multi-source aggregation, and trusted, controllable, and manageable network technologies. Widely adopted protocols include TCP/IP and the Real-Time Control Protocol (RTCP). Additionally, control technology standards promote interoperability by facilitating the conversion of diverse device control protocols, including network transmission protocols, control protocols, and device addressing schemes.

- Data transmission system architecture: Large-scale and complex infrastructure O&M systems must process massive and rapidly growing data streams. Edge computing is a critical technology for ensuring efficient data transmission and interaction. A well-structured cloud–edge–end collaborative architecture is required to achieve low-latency, high-reliability transmission. This includes standards for local data collection at end devices, transmission to the edge or cloud, and edge computing capabilities for real-time preprocessing and regional data management. Big data processing, intelligent analysis, and long-term storage architectures are standardized at the cloud side to support decision-making and system optimization.

3.2.3. Data Layer

- Data standards regulate the formats and interface requirements for diverse data types within the intelligent O&M system. They cover structured data, device data from intelligent O&M systems, online monitoring data, offline inspection data, intelligent inspection data, feature data, and data interaction protocols, ensuring consistency and interoperability across all data types.

- Data processing technology: These standards specify the technical processes for analyzing and processing data, including massive data storage, urban data mining, large-scale data cleaning, dynamic modeling of correlated data, and trend prediction. Since different fields often adopt symbols, charts, and notations, unified standards are critical for effective transmission and utilization. International Organization for Standardization (ISO) standards provide a basis for the systematic analysis, organization, calculation, and editing of raw data.

- Data management: These standards address integrating isolated data and restoring correlations to overcome data utilization barriers. They cover data description and cognition, maintenance and management, association and growth, as well as active security and privacy protection. These standards promote dynamic, integrated, and secure data sharing and exchange by establishing clear rules for data identification, association, and governance.

- Database design: Given the wide variety of data involved in the O&M of BMF, rational classification and structuring of databases are essential. Standards in this area regulate database types, partitioning rules, functional requirements, and interaction mechanisms. Examples include structural information databases, static and dynamic response databases, data feature libraries, and O&M information libraries, all of which provide critical support for the intelligent O&M system.

3.2.4. Algorithm Layer

- Algorithm governance ensures that intelligent O&M algorithms are secure, ethical, and systematically managed. It consists of three dimensions:

- Security: Security is the prerequisite for algorithm adoption in O&M. Standards for security evaluation cover aspects such as the safety of objective functions, resistance to algorithmic attacks, reliability of dependent libraries, traceability, and internal control. These provide requirements, evaluation methods, and criteria to ensure secure implementation.

- Compliance: It defines the ethical and legal boundaries of algorithm use. Standards are needed to promote the industrial growth of intelligent O&M algorithms and prevent malicious or unlawful applications by ensuring accountability and legal enforcement.

- Classification and Grading: Just as data governance requires data classification and grading, algorithms must also be categorized and graded to build a systematic governance framework.

- Algorithm performance: It is essential to support intelligent O&M at scale, which includes two critical aspects:

- Explainability: It determines the transparency of an algorithm’s internal logic, technical pathways, decision-making processes, and intended objectives. Algorithms with higher explainability are easier to understand, validate, and manage, facilitating broader adoption. Evaluation criteria focus on the modeling preparation, process, and application stages.

- Accuracy and efficiency: Accuracy and efficiency are the primary indicators of an algorithm’s effectiveness. High accuracy ensures reliable outputs, while efficiency determines the applicability of solutions in real-time O&M scenarios. Performance evaluation emphasizes requirements, methods, and criteria across the modeling and application stages to ensure dependable results.

3.2.5. Business Layer

- 1.

- Data fusion

- 2.

- Early warning and forecasting

- 3.

- Performance assessment

- 4.

- Intelligent decision-making

- 5.

- Resilience improvement

- 6.

- Disaster prevention

- 7.

- Emergency management

3.2.6. Human–Computer Interaction Layer

- O&M digital twin model

- 2.

- AI-driven human–computer interaction technology

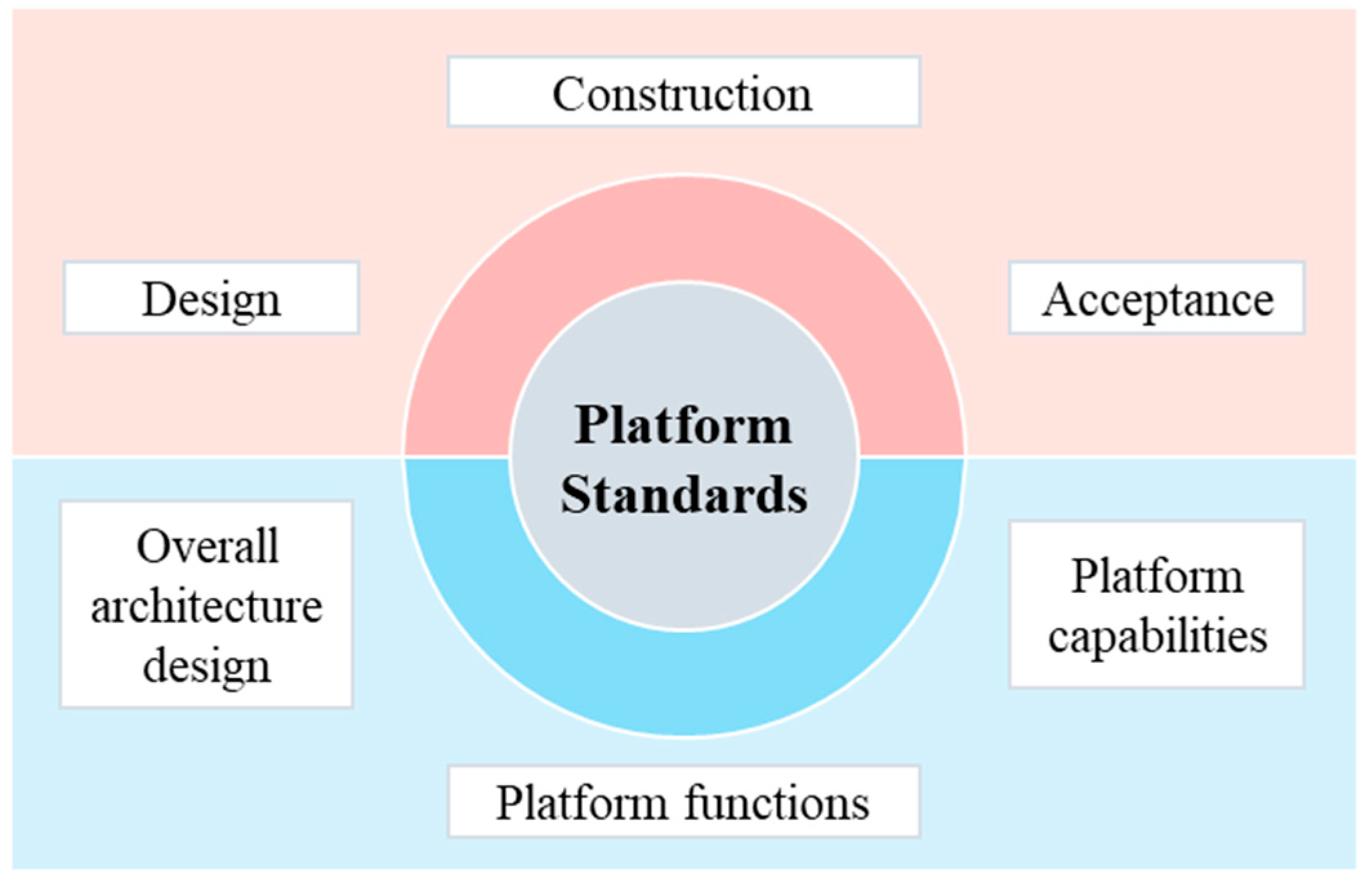

3.3. Platform Standards

3.3.1. Construction Technology

3.3.2. Capability

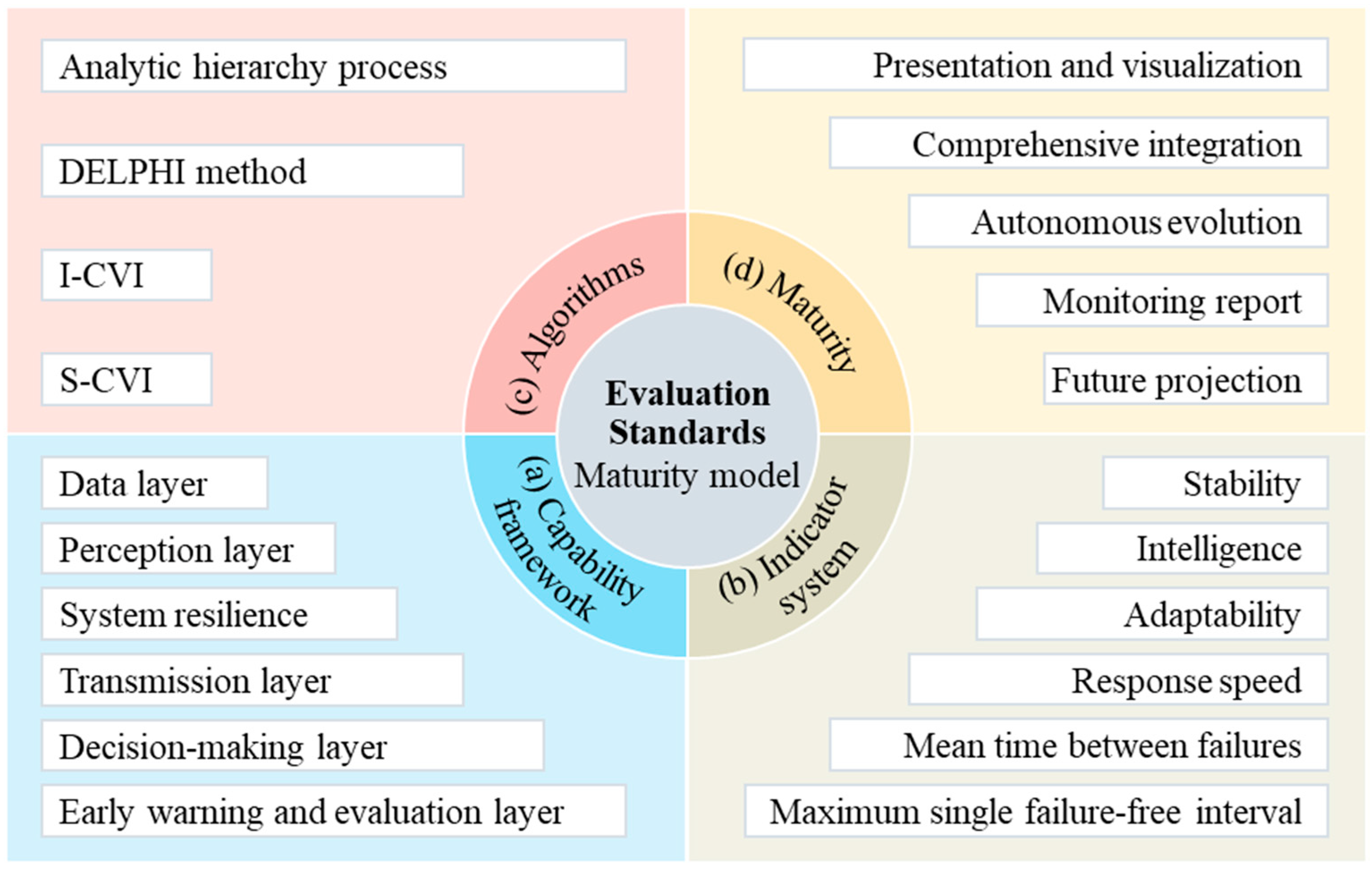

3.4. Evaluation Standards

3.4.1. Capability Framework

3.4.2. Indicator System

3.4.3. Algorithms

3.4.4. Maturity Levels

3.5. Security Standards

3.5.1. Physical System Security Requirements

3.5.2. Functional Safety Requirements

3.5.3. Information Security Technology

3.5.4. Information Security Management

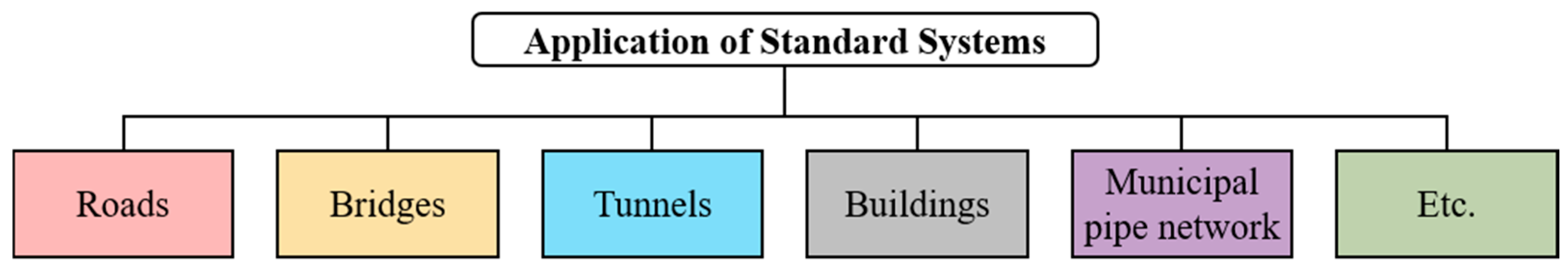

3.6. Industry Applications

4. Discussion

- 1.

- Intelligent O&M for BMFs refers to a management approach that leverages new-generation intelligent technologies and equipment, such as IoT, robotics, big data, and artificial intelligence, to achieve a comprehensive perception of service conditions, deep fusion analysis, intelligent interaction, and scientific decision-making. Its core lies in real-time monitoring and analyzing BMF’s various O&M data. It integrates periodic inspections and routine patrol information to detect abnormal conditions, fault risks, and performance degradation, providing timely safety warnings and supporting maintenance decision-making.

- 2.

- Intelligent O&M systems deliver seven key services: perception, data fusion, status assessment, early warning and forecasting, decision-making, intelligent control, disaster prevention, and emergency management. These functions are structured across hierarchical layers, from perception to human–computer interaction, and their intelligence maturity progresses through five levels, from basic presentation and monitoring to dynamic fusion, performance projection, and autonomous maintenance. This framework highlights the comprehensive and multi-layered nature of intelligent O&M, providing a clear path for advancing system capabilities.

- 3.

- The intelligent O&M standard system framework for BMFs mainly comprises six parts: general standards (A), key technical standards (B), intelligent O&M platform standards (C), intelligent O&M evaluation standards (D), intelligent O&M security standards (E), and industry application standards (F). According to their differing attributes, their subordinate standards and main technical contents also vary accordingly.

- 4.

- Beyond the technical and managerial dimensions, the successful implementation of the proposed framework is inherently influenced by the surrounding socio-economic and policy environment. The economic feasibility, including factors such as initial investment and maintenance expenditure, is achieved through data-driven decision-making and plays a pivotal role in determining the adoption and scalability of the framework. At the policy level, supportive regulations, institutional coordination, and incentive mechanisms are essential for promoting the standardization, interoperability, and large-scale integration of O&M systems across different agencies and regions. Furthermore, stakeholder alignment, which involves government authorities, private operators, and end-users, has a significant impact on implementation efficiency and sustainability. Incorporating these socio-economic and policy perspectives enables a more comprehensive and realistic understanding of how the proposed framework can be effectively deployed, institutionalized, and maintained in real-world practice.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| BMF | Buildings and Municipal Facility |

| O&M | Operation and Maintenance |

| ITSS | Information Technology Service Standard |

| IoT | Internet of Things |

| WSN | Wireless Sensor Network |

| RTCP | Real-Time Control Protocol |

| ISO | International Organization for Standardization |

| AI | Artificial Intelligence |

| BIM | Building Information Modeling |

References

- Ministry of Transport of the People’s Republic of China. 2023 Statistical Bulletin on the Development of the Transportation Industry. China Transportation News. Available online: https://xxgk.mot.gov.cn/2020/jigou/zhghs/202406/t20240614_4142419.html (accessed on 5 August 2025).

- Xin, J.; Frangopol, D.M.; Akiyama, M.; Zhang, L.; Pei, J. Life-cycle performance, design, maintenance, optimization, and decision-making of asphalt pavement under uncertainty: A review. Struct. Infrastruct. Eng. 2025, 1–29. [Google Scholar] [CrossRef]

- Lei, S.; Zou, C.; Ding, Z. Reflections on intelligent construction of land transportation buildings and municipal public facilities in China. Railw. Constr. Technol. 2023, 1, 17–19. [Google Scholar]

- Su, D. Research on long-cycle O&M management mode for transportation buildings and municipal public facilities. Transp. Manag. World 2022, 15, 50–52. [Google Scholar]

- Xin, J.; Zhang, L.; Frangopol, D.M.; Akiyama, M.; Pei, J. Probabilistic life-cycle performance, design, maintenance, optimization, and decision-making in asphalt pavements. In Proceedings of the 14th International Symposium on Structural Safety and Reliability (ICOSSAR 2025), Los Angeles, CA, USA, 1–6 June 2025; pp. 1–6. [Google Scholar]

- Wang, Y. Research on Standardization of Emergency Management for Production Safety in China. Ph.D. Thesis, Harbin Engineering University, Harbin, China, 2011. [Google Scholar]

- Notaro, P.; Cardoso, J.; Gerndt, M. A systematic mapping study in AIOps. In Proceedings of the 2020 International Conference on Service-Oriented Computing, Dubai, United Arab Emirates, 14–17 December 2020. [Google Scholar]

- Reiter, L.; Wedel, F.H. Seminar Paper, AIOps—A Systematic Literature Review, FH Wedel, Germany, Winter 2021. Available online: https://www.fh-wedel.de/fileadmin/Mitarbeiter/Records/Reiter_2021_-_AIOps_-_A_Systematic_Literature_Review.pdf (accessed on 28 October 2025).

- Xin, J.; Frangopol, D.M.; Akiyama, M. Probabilistic time-variant functionality-based analysis of transportation networks incorporating asphalt pavements and bridges under multiple hazards. J. Bridge Eng. 2024, 29, 04024095. [Google Scholar] [CrossRef]

- Xin, J.; Frangopol, D.M.; Akiyama, M.; Han, X. Probabilistic life-cycle connectivity assessment of transportation network using deep learning. J. Bridge Eng. 2023, 28, 04023066. [Google Scholar] [CrossRef]

- Wang, G.; Pang, Y.; Ren, H.; Zhan, K.; Du, M.; Zhang, Y.; Cheng, J.; Du, Y.; Zhang, J.; Gong, S.; et al. Research and practice on system engineering and key technologies of smart mines. J. China Coal Soc. 2024, 49, 181–202. [Google Scholar]

- Cai, Y.; Yue, Z.; Shan, H.; Leng, K.; Wang, Z.; Liu, Y. Construction and exploration of standardized O&M service system under the ITSS framework in large hospitals. China Digit. Med. 2020, 15, 28–30. [Google Scholar]

- Xu, D. Study on the construction path of smart hospitals. Med. Inf. 2021, 34, 21–28. [Google Scholar]

- Fu, Q.; Liu, X.; Su, W. Data cognition and intelligence in bank O&M work. China Financ. Comput. 2019, 26, 40–44. [Google Scholar]

- Hu, H.; Zhu, J. Research on smart agriculture systems. China Natl. Cond. Strength 2017, 11, 48–50. [Google Scholar]

- Yang, J.; Li, B.; Hu, S.; Long, G.; Li, Y.; Cheng, Y. Practice and suggestions on smart agriculture standardization. China Stand. 2021, 22, 60–63. [Google Scholar]

- Zhang, B. Design and Implementation of Wind Turbine Intelligent O&M System Based on Cloud Platform. Master’s Thesis, Beijing University of Posts and Telecommunications, Beijing, China, 2021. [Google Scholar]

- Pattison, D.; Garcia, M.S.; Xie, W.; Quail, F.; Revie, M.; Whitfield, R.I.; Irvine, I. Intelligent integrated maintenance for wind power generation. Wind Energy 2016, 19, 547–562. [Google Scholar] [CrossRef]

- Zhu, H.; Ding, W.; Qiao, Y.; Wang, X.; Han, C.; Zhang, D.; Li, X. Analysis of problems and challenges in the development and utilization of urban underground space in China. Earth Sci. Front. 2019, 26, 22–31. [Google Scholar] [CrossRef]

- Wang, J.; Xie, Q.; Liu, J.; Koizumi, A. Current situation of railway tunnel defects and O&M in Japan and suggestions for China. Tunn. Constr. Chin. Engl. 2020, 40, 1824–1833. [Google Scholar]

- Li, X.; Chang, Q.; Wang, H.; Li, H.; Gao, F.; Li, W.; Wang, Y. Architecture design of Chinese digital highway standard system. In Proceedings of the Seventh International Conference on Traffic Engineering and Transportation System (ICTETS 2023), Dalian, China, 22–24 September 2023. [Google Scholar]

- Liu, H.; Zhang, R. Research on the construction of smart highway standard system. Transp. Sci. Technol. Manag. 2023, 4, 17–19. [Google Scholar]

- Jing, Q.; Zheng, S.; Liang, P. Intelligent O&M technologies and engineering practices of the Hong Kong-Zhuhai-Macao Bridge. China J. Highw. Transp. 2023, 36, 143–156. [Google Scholar]

- Jiao, P.; Fan, H.; Yang, C.; Zheng, L. Research on standards for smart utility tunnel construction. Technol. Mark. 2019, 26, 34–36. [Google Scholar]

- Yang, J.; Li, D.; Yue, Q.; Zeng, B.; Liu, X.; Fan, J. Key Scientific Issues and State-of-art in Whole-lifecycle Intelligentization of Buildings and Infrastructures. Bull. Natl. Nat. Sci. Found. China 2021, 35, 620–626. [Google Scholar]

- Wang, D.; Fu, J.; Zhou, T.; Chen, X. Research on the design and key technologies of regional monitoring systems for clusters of transportation infrastructures. Highw. Transp. Sci. Technol. 2022, 39, 124–135. [Google Scholar]

- Zhang, J.; Zhu, S.; Xu, Y.; Chen, Z. SHM-based correlation study of Trainload-induced response in Tsing Ma Bridge. In Proceedings of the 14th Asia Pacific Vibration Conference on Dynamics for Sustainable Engineering, Hong Kong, China, 5–8 December 2011; pp. 113–122. [Google Scholar]

- Wong, K. Design of a structural health monitoring system for long-span bridges. Struct. Infrastruct. Eng. 2007, 3, 169–185. [Google Scholar] [CrossRef]

- Soman, R.; Kyriakides, M.; Onoufriou, T.; Ostachowicz, W. Numerical evaluation of multi-metric data fusion based structural health monitoring of long span bridge structures. Struct. Infrastruct. Eng. 2018, 14, 673–684. [Google Scholar] [CrossRef]

- Fujino, Y.; Murata, M.; Okano, S.; Takeguchi, M. Monitoring system of the Akashi Kaikyo Bridge and displacement measurement using GPS. In Proceedings of the SPIE’s 5th Annual International Symposium on Nondestructive Evaluation and Health Monitoring of Aging Infrastructure, Newport Beach, CA, USA, 16–18 October 2000. [Google Scholar]

- Livingston, R.; Jin, S. Application of a maximum entropy method to estimate the probability density function of Nonlinear or chaotic behavior in structural health monitoring data. In Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 7–10 March 2005; pp. 749–757. [Google Scholar]

- Ren, G.; Song, G. Preliminary Study on the Standard System for Smart City Construction. Stand. Sci. 2014, 21, 14–17. [Google Scholar]

- Liu, X. Study on the standardization of smart cities. China Stand. 2018, 7, 52–55. [Google Scholar]

- Dai, J.; Tian, L.; Guo, C. Research on the demand and content of the new smart city standardization system: A case study of Fuzhou. China Stand. 2022, 11, 58–63. [Google Scholar]

- Silva, B.N.; Khan, M.; Han, K. Towards sustainable smart cities: A review of trends, architectures, components, and open challenges in smart cities. Sustain. Cities Soc. 2018, 38, 697–713. [Google Scholar] [CrossRef]

- Folmer, E.; Jakobs, K. Standards development for smart systems—A potential way forward. IEEE Trans. Eng. Manag. 2020, 68, 75–86. [Google Scholar] [CrossRef]

- Trivedi, Y. Smart CitieS: StandardS Will enSure SuCCeSS. IEEE Commun. Mag. 2016, 5, 5–11. [Google Scholar] [CrossRef]

- Caragliu, A.; Del Bo, C.; Nijkamp, P. Smart cities in Europe. In Creating Smart-er Cities; Routledge: London, UK, 2013; pp. 65–82. [Google Scholar]

- Rita, J.; Salvado, J.; Rocha, H.D.; Espírito-Santo, A. A Comprehensive Review of IoT Standards: The Role of IEEE 1451 in Smart Cities and Smart Buildings. Smart Cities 2025, 8, 108. [Google Scholar] [CrossRef]

- Fahmideh, M.; Zowghi, D. IoT smart city architectures: An analytical evaluation. In Proceedings of the 2018 IEEE 9th Annual Information Technology, Electronics and Mobile Communication Conference (IEMCON), Vancouver, BC, Canada, 1–3 November 2018; pp. 709–715. [Google Scholar]

- Lenk, U. Smart cities and MBSE: Comparison of concepts. In Proceedings of the 2020 IEEE 15th International Conference of System of Systems Engineering (SoSE), Budapest, Hungary, 2–4 June 2020; pp. 169–174. [Google Scholar]

- Chiang, T.Y.; Lin, I.L.; Huang, C.J. Analysis of Smart Building System: Risks, Threats, and Standards. In Proceedings of the 2023 IEEE 6th International Conference on Knowledge Innovation and Invention (ICKII), Sapporo, Japan, 11–13 August 2023; pp. 203–205. [Google Scholar]

- Zhang, X. Research on the Elements, Structure, and Models of Smart City Systems. Ph.D. Thesis, South China University of Technology, Guangzhou, China, 2015. [Google Scholar]

- Bogatinoska, D.C.; Malekian, R.; Trengoska, J.; Nyako, W.A. Advanced sensing and internet of things in smart cities. In Proceedings of the 39th International Convention on Information and Communication Technology, Electronics and Microelectronics, Opatija, Croatia, 30 May–3 June 2016. [Google Scholar]

- Yang, C. AIOps: From digitalized O&M to intelligent O&M and smart operation. China Financ. Comput. 2022, 29, 87–89. [Google Scholar]

- Yin, L.; Shi, L.C.; Zhao, J.Y.; Du, S.-Y.; Xie, W.-B.; Yuan, F.; Chen, D.-B. Heterogeneous information network model for equipment-standard system. Phys. A Stat. Mech. Its Appl. 2018, 490, 935–943. [Google Scholar] [CrossRef]

- Qi, Y.; Quddus, A.U.; Imran, M.A.; Tafazolli, R. Semi-persistent RRC protocol for machine-type communication devices in LTE networks. IEEE Access 2015, 3, 864–874. [Google Scholar] [CrossRef]

- Unsworth, H.; Wolfram, V.; Dillon, B.; Salmon, M.; Greaves, F.; Liu, X.; MacDonald, T.; Denniston, A.K.; Sounderajah, V.; Ashrafian, H.; et al. Building an evidence standards framework for artificial intelligence-enabled digital health technologies. Lancet Digit. Health 2022, 4, e216–e217. [Google Scholar] [CrossRef]

- ISO/IEC 18000-63:2021; Information Technology-Radio Frequency Identification for Item Management. International Organization for Standardization: Geneva, Switzerland, 2021.

- IEEE 802; IEEE Standard for Local and Metropolitan Area Networks: Overview and Architecture. Institute of Electrical and Electronics Engineers: New York, NY, USA, 2014.

- IEEE 802.15.4; IEEE Standard for Low-Rate Wireless Networks. Institute of Electrical and Electronics Engineers: New York, NY, USA, 2020.

- ISA-100.11a; Wireless Systems for Industrial Automation: Process Control and Related Applications. International Society of Automation: Research Triangle Park, NC, USA, 2011.

- Yu, G.; Wang, Y.; Hu, M.; Shi, L.; Mao, Z.; Sugumaran, V. RIOMS: An intelligent system for operation and maintenance of urban roads using spatio-temporal data in smart cities. Future Gener. Comput. Syst. 2021, 115, 583–609. [Google Scholar] [CrossRef]

- Habibzadeh, H.; Kaptan, C.; Soyata, T.; Kantarci, B.; Boukerche, A. Smart city system design: A comprehensive study of the application and data planes. ACM Comput. Surv. (CSUR) 2019, 52, 1–38. [Google Scholar] [CrossRef]

- Huang, Y.; Fu, J. Review on application of artificial intelligence in civil engineering. Comput. Model. Eng. Sci. 2019, 121, 845–875. [Google Scholar] [CrossRef]

- Zhang, X.; Liang, Y.; Deng, L.; Wang, L. Design and implementation of an O&M data visualization platform. Meteorol. Res. Appl. 2019, 40, 84–87. [Google Scholar]

- Dong, H.; Zhang, P.; Wang, Y. Top-level design architecture of new smart cities. Intell. Build. Smart Cities 2019, 26, 21–24. [Google Scholar]

- Lin, P.C.; Gu, J.C.; Yang, M.T. An intelligent maintenance model to assess the condition-based maintenance of circuit breakers. Int. Trans. Electr. Energy Syst. 2015, 25, 2376–2393. [Google Scholar] [CrossRef]

- Amaizu, G.C.; Lee, J.M.; Kim, D.S. Machine learning based security for smart cities. In Proceedings of the 27th Asia Pacific Conference on Communications (APCC), Jeju Island, Republic of Korea, 19–21 October 2022. [Google Scholar]

- Wright, M.; Chizari, H.; Viana, T. A systematic review of smart city infrastructure threat modelling methodologies: A Bayesian focused review. Sustainability 2022, 14, 10368. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). The Manual for Bridge Evaluation; American Association of State Highway and Transportation Officials: Washington, DC, USA, 2011. [Google Scholar]

- Frangopol, D.; Strauss, A.; Kim, S. Bridge reliability assessment based on monitoring. J. Bridge Eng. 2008, 13, 258–270. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, L.; Hou, Y.; Deng, K.; Xin, J. Advancements Toward a Standard System for Intelligent Operation and Maintenance of Buildings and Municipal Facilities. Buildings 2025, 15, 3965. https://doi.org/10.3390/buildings15213965

Zhang L, Hou Y, Deng K, Xin J. Advancements Toward a Standard System for Intelligent Operation and Maintenance of Buildings and Municipal Facilities. Buildings. 2025; 15(21):3965. https://doi.org/10.3390/buildings15213965

Chicago/Turabian StyleZhang, Lianzhen, Yang Hou, Kaizhong Deng, and Jiyu Xin. 2025. "Advancements Toward a Standard System for Intelligent Operation and Maintenance of Buildings and Municipal Facilities" Buildings 15, no. 21: 3965. https://doi.org/10.3390/buildings15213965

APA StyleZhang, L., Hou, Y., Deng, K., & Xin, J. (2025). Advancements Toward a Standard System for Intelligent Operation and Maintenance of Buildings and Municipal Facilities. Buildings, 15(21), 3965. https://doi.org/10.3390/buildings15213965