Performance Optimization of Expanded Polystyrene Lightweight Concrete Using a Multi-Objective Physically Interpretable Algorithm with Random Forest

Abstract

1. Introduction

2. Data Basis and Characterization Analysis for Model Establishment

2.1. Preparation of Specimens

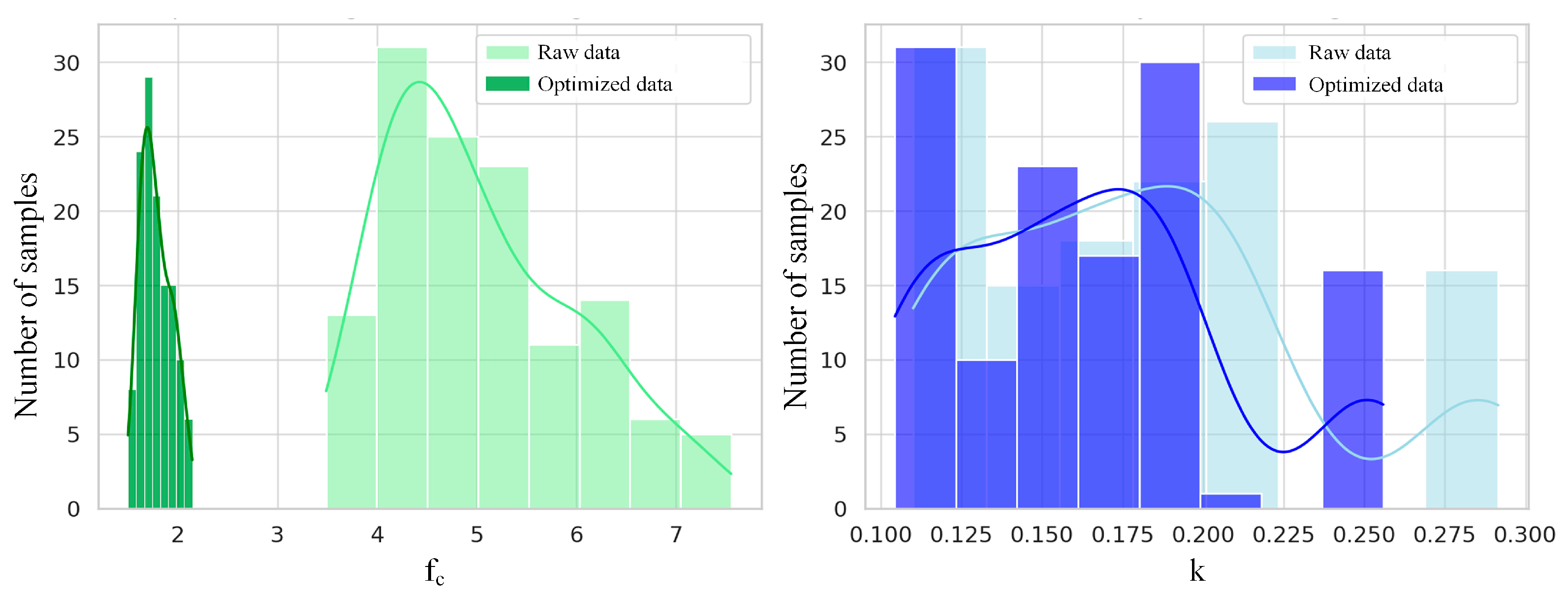

2.2. Distribution Characteristics and Preprocessing of EPS Concrete Experimental Data

2.3. Influencing Factors and Correlation Analysis of EPS Concrete Performance

3. Machine Learning Algorithms and Model Optimization

3.1. Random Forest Baseline Model for Predicting EPS Concrete Performance

3.2. Physics-Informed Approach (PIA) and Its Application in the Prediction Model

| Algorithm 1: Physics-Informed Random Forest (PIA-RA), concise version |

| Input: dataset , monotonic priors , weight , step . |

| Output: trained RF , best hyperparams . |

| Split train 70%/test 30%; apply preprocessing fitted on train. |

| Use 5-fold CV on train; for each hyperparam set : |

| Fit RF with on CV-train; predict on CV-val → . |

| For each feature with prior, compute finite diff . |

| Penalty . |

| Fold loss ; pick . |

| Retrain RF on full train with ; evaluate on test (R2, RMSE) + violation rate. |

| Return , , metrics. |

3.3. Global Hyperparameter Optimization of Random Forest Based on the Firefly Algorithm

3.4. Evaluation Metrics for Compressive Strength and Thermal Performance of EPS Concrete Prediction Model

4. Verification and Interpretability Analysis of the EPS Concrete Performance Prediction Model

4.1. Accuracy Evaluation and Stability Analysis of the EPS Concrete Performance Prediction Model

4.2. Interpretability Analysis of the EPS Concrete Performance Prediction Model

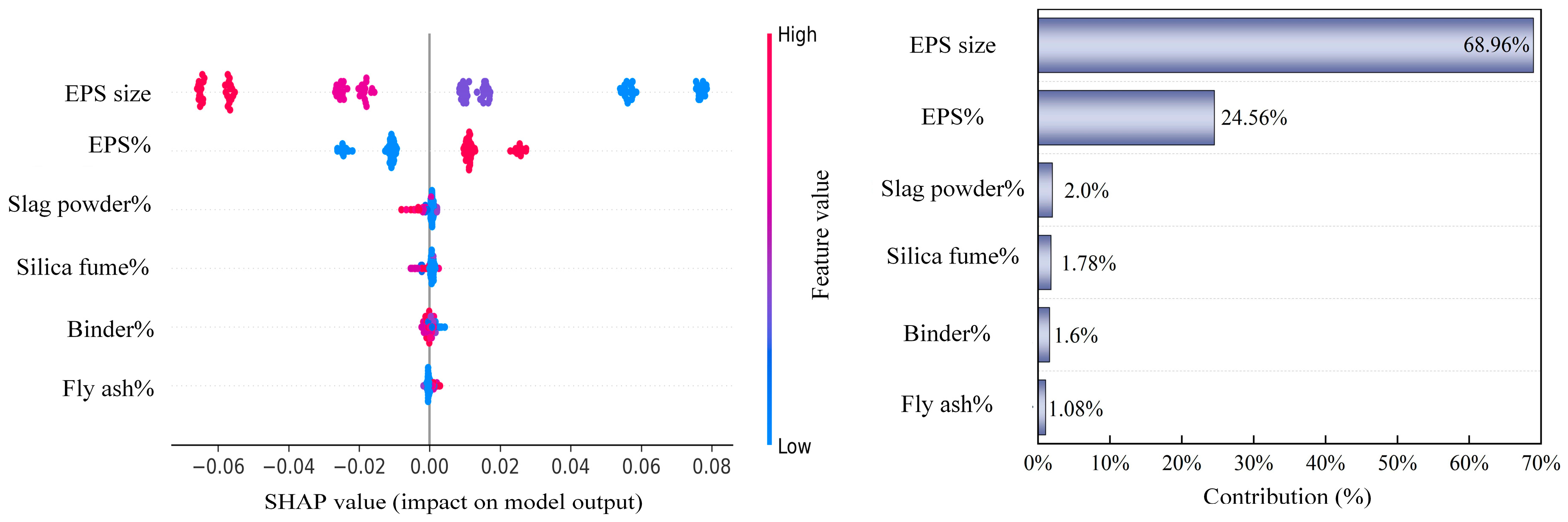

4.2.1. Feature Importance Analysis Based on SHAP

4.2.2. Feature Dependence Analysis Based on SHAP

5. Mix Proportion Design and Optimization of EPS Concrete

5.1. Establishment of the MOPIA-RA Model

5.1.1. Definition of Objective Functions and Material Cost Modeling

5.1.2. Constraint Setting and Feasible Domain Definition

- (1)

- Volume closure constraint

- (2)

- Proportion and Mutual Exclusivity Constraints

- (3)

- Value Range Constraints

5.1.3. Weighted-Sum-Based Multi-Objective Optimization

5.2. Multi-Objective Decision-Making Method and Scheme Selection

5.3. Analysis of Mix Proportion Optimization Results Based on the MOPIA-RA Model

5.4. Comparative Analysis and Advantages of the Proposed Framework

6. Conclusions

- (1)

- By introducing physical constraints (PIA) and firefly algorithm (FA)-based hyperparameter optimization, the predictive accuracy and robustness of the surrogate model were significantly improved. The enhanced PIA-RA model achieved coefficients of determination (R2) of 0.98 and 0.95 for predicting thermal conductivity and compressive strength, respectively, representing an improvement of approximately 8–12% compared with the baseline RA model.

- (2)

- According to the SHAP-based interpretability analysis, EPS particle size was identified as the key factor simultaneously governing both compressive strength and thermal performance, contributing over 40% to the overall model output. EPS content also played a significant regulatory role, contributing approximately 15–20%. Regarding cementitious material replacement, the use of slag powder and fly ash at appropriate replacement ratios improved compressive strength by about 5–10%, while their enhancement of thermal performance was limited (<3%).

- (3)

- The established MOPIA-RA multi-objective optimization model effectively characterized the trade-offs among strength, thermal conductivity, and cost. The Pareto front analysis indicated that pursuing high strength alone often leads to higher cost and poorer thermal performance. The representative optimal mix (Point A), selected using the TOPSIS method, achieved a reasonable balance among the three performance indicators.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- El Gamal, S.; Al-Jardani, Y.; Meddah, M.S.; Sohel, K.A.; Al-Saidy, A. Mechanical and thermal properties of lightweight concrete with recycled expanded polystyrene beads. Eur. J. Environ. Civ. Eng. 2024, 28, 80–94. [Google Scholar] [CrossRef]

- Abdellatief, M.; Ahmed, Y.M.; Taman, M.; Elfadaly, E.; Tang, Y.; Abadel, A.A. Physico-mechanical, thermal insulation properties, and microstructure of geopolymer foam concrete containing sawdust ash and eggshell. J. Build. Eng. 2024, 90, 109374. [Google Scholar] [CrossRef]

- Shree, V.; Dwivedi, A.; Saxena, A.; Pathak, S.K.; Agrawal, N.; Tripathi, B.M.; Shukla, S.K.; Kumar, R.; Goel, V. A comprehensive review of harnessing the potential of phase change materials (PCMs) in energy-efficient building envelopes. J. Build. Eng. 2025, 101, 111841. [Google Scholar] [CrossRef]

- Wei, L.; Chen, S.; Wang, J.; Wu, Z.; She, W. Lightweight EPS cementitious composites via hot-pressing strategy: Toward mechanical, thermal, and acoustic properties. J. Build. Eng. 2025, 112, 113794. [Google Scholar] [CrossRef]

- Mohamed, A.M.; Tayeh, B.A.; Majeed, S.S.; Aisheh, Y.I.A.; Salih, M.N.A. Ultra-light foamed concrete mechanical properties and thermal insulation perspective: A comprehensive review. J. CO2 Util. 2024, 83, 102827. [Google Scholar] [CrossRef]

- Prasittisopin, L.; Termkhajornkit, P.; Kim, Y.H. Review of concrete with expanded polystyrene (EPS): Performance and environmental aspects. J. Clean. Prod. 2022, 366, 132919. [Google Scholar] [CrossRef]

- El-Mir, A.; Fayad, E.; Assaad, J.J.; El-Hassan, H. Multi-Response Optimization of Semi-Lightweight Concrete Incorporating Expanded Polystyrene Beads. Sustainability 2023, 15, 8757. [Google Scholar] [CrossRef]

- Li, Z.; Lu, D.; Gao, X. Optimization of mixture proportions by statistical experimental design using response surface method—A review. J. Build. Eng. 2021, 36, 102101. [Google Scholar] [CrossRef]

- Feng, J.; Yin, G.; Tuo, H.; Niu, Z. Parameter optimization and regression analysis for multi-index of hybrid fiber-reinforced recycled coarse aggregate concrete using orthogonal experimental design. Constr. Build. Mater. 2021, 267, 121013. [Google Scholar] [CrossRef]

- Kadam, S.S.; Karjinni, V.V. Prediction of mechanical properties of high strength steel fiber reinforced concrete with multiple regression technique. IOP Conf. Mater. Sci. Eng. 2020, 814, 012043. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, W.; Tang, Y.; Jian, Y.; Lai, Y. Orthogonal Experimental Study on Concrete Properties of Machine-Made Tuff Sand. Materials 2022, 15, 3516. [Google Scholar] [CrossRef]

- Lam, M.N.-T.; Le, D.-H.; Nguyen, D.-L. Reuse of clay brick and ceramic waste in concrete: A study on compressive strength and durability using the Taguchi and Box–Behnken design method. Constr. Build. Mater. 2023, 373, 130801. [Google Scholar] [CrossRef]

- George, E.S.; Hari, R.; Madhavan, M.K. Performance assessment of blended self-compacting concrete with ferrochrome slag as fine aggregate using functional ANOVA. J. Build. Eng. 2024, 89, 109390. [Google Scholar] [CrossRef]

- Pan, P.; Yang, W.; Zhang, Y.; Li, P.-P. Optimized strength modelling of foamed concrete using principal component analysis featurized regressors. Structures 2023, 48, 1730–1745. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, X.; Wang, H. Pavement crack instance segmentation using YOLOv7-WMF with connected feature fusion. Autom. Constr. 2024, 160, 105123. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Chen, W. Adaptive feature expansion and fusion model for precast component segmentation. Autom. Constr. 2024, 164, 105456. [Google Scholar] [CrossRef]

- Zhou, M.; Ye, G.; Yuen, K.-V.; Yu, W.; Jin, Q. A graph attention reasoning model for prefabricated component detection. Comput. Aided Civ. Infrastruct. Eng. 2025, 40, 1606–1626. [Google Scholar] [CrossRef]

- Onyelowe, K.C.; Ibe, A.S.; Ezeokonkwo, F.C.; Brito, N.A.E.; Velasco, N.; Buñay, J.; Muhodir, S.H.; Imran, H.; Hanandeh, S. Estimating the compressive strength of lightweight foamed concrete using different machine-learning-based symbolic regression techniques. Front. Built Environ. 2024, 10, 1446597. [Google Scholar] [CrossRef]

- Kumar, A.; Singh, P.; Gupta, R. Artificial Neural Network predictions for properties of concrete with expanded polystyrene (EPS). SSRG Int. J. Civ. Eng. 2025, 12, 25–34. [Google Scholar]

- Hussain, F.; Ali, M.; Ahmad, R.; Khan, A. Modeling compressive strength of EPS lightweight concrete using regression, neural network and ANFIS. Sustainability 2022, 15, 641. [Google Scholar] [CrossRef]

- Mahmoud, S.; El-Sayed, M.; Abdel-Latif, T. Harnessing expanded polystyrene waste for sustainable self-compacting concrete: A hybrid ML technique for predicting strength and durability. Int. J. Pavement Eng. 2025; in press. [Google Scholar]

- Yang, D.; Xu, P.; Zaman, A.; Alomayri, T.; Houda, M.; Alaskar, A.; Javed, M.F. Compressive strength prediction of concrete blended with carbon nanotubes using gene expression programming and random forest: Hyper-tuning and optimization. J. Mater. Res. Technol. 2023, 24, 7198–7218. [Google Scholar] [CrossRef]

- Zhang, W.; Liu, D.; Cao, K. Prediction of concrete compressive strength using support vector machine regression and non-destructive testing. Case Stud. Constr. Mater. 2024, 21, e03416. [Google Scholar] [CrossRef]

- Akber, M.Z.; Anwar, G.A.; Chan, W.-K.; Lee, H.-H. TPE-xgboost for explainable predictions of concrete compressive strength considering compositions, and mechanical and microstructure properties of testing samples. Constr. Build. Mater. 2024, 457, 139398. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, W.; Lei, J.; Sun, L.; Mi, Y.; Chen, Y. Predicting the compressive strength of high-performance concrete via the DR-CatBoost model. Case Stud. Constr. Mater. 2024, 21, e03990. [Google Scholar] [CrossRef]

- Sun, B.; Wang, P.; Guo, J.; Zheng, Y.; Zhang, P.; Wang, J.; Tan, J. Intelligent mix design of steel fiber reinforced concrete using a particle swarm algorithm based on a multi-objective optimization model. J. Build. Eng. 2024, 96, 110653. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, X.; Ding, X.; Chen, T.; Deng, R.; Li, J.; Jiang, J. Multi objective optimization and evaluation approach of prefabricated component combination solutions using NSGA-II and simulated annealing optimized projection pursuit method. Sci. Rep. 2024, 14, 16688. [Google Scholar] [CrossRef]

- Zheng, W.; Shui, Z.; Xu, Z.; Gao, X.; Zhang, S. Multi-objective optimization of concrete mix design based on machine learning. J. Build. Eng. 2023, 76, 107396. [Google Scholar] [CrossRef]

- Chen, B.; Wang, L.; Feng, Z.; Liu, Y.; Wu, X.; Qin, Y.; Xia, L. Optimization of high-performance concrete mix ratio design using machine learning. Eng. Appl. Artif. Intell. 2023, 122, 106047. [Google Scholar] [CrossRef]

- Fan, M.; Li, Y.; Shen, J.; Jin, K.; Shi, J. Multi-objective optimization design of recycled aggregate concrete mixture proportions based on machine learning and NSGA-II algorithm. Adv. Eng. Softw. 2024, 192, 103631. [Google Scholar] [CrossRef]

- da Silva, I.M.; Alves, É.C.; Calenzani, A.F.G. Multiobjective optimization of steel and concrete composite slabs via MOPSO algorithm. Structures 2025, 80, 109722. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Zhang, J. Intelligent optimisation of ultra-high-performance concrete mixture design based on particle swarm optimization. Int. J. Pavement Eng. 2023, 24, 2130919. [Google Scholar] [CrossRef]

- Dai, J.; Zhang, Z.; Dong, X.; He, J.; Yang, X.; Wang, Q. Prediction of frost resistance and multiobjective optimisation of low-carbon concrete on the basis of machine learning. Mater. Today Commun. 2024, 40, 109525. [Google Scholar] [CrossRef]

- Zhang, Q.; Chen, L.; Liu, Y.; Zhou, X. Mix design and performance prediction of EPS lightweight structural concrete based on orthogonal experimentation. Sci. Rep. 2025, 15, 21420. [Google Scholar] [CrossRef]

- Dabi, G.M.; Kozhakhmetov, H.; Akmetov, M.; Nauryzbayev, A. Stochastic optimization of expanded polystyrene size and proportion in concrete using machine learning. Mech. Technol. Sci. J. 2025, 3, 286–295. [Google Scholar]

- JG/T 266-2011; Application of Foamed Concrete. China Architecture & Building Press: Beijing, China, 2011. (In Chinese)

- GB/T 50081-2019; Standard for Test Methods of Physical and Mechanical Properties of Concrete. China Architecture & Building Press: Beijing, China, 2019. (In Chinese)

- GB/T 10294-2008; Test Method for Steady-State Thermal Resistance and Related Properties of Thermal Insulation Materials. Standards Press of China: Beijing, China, 2008. (In Chinese)

- Beyer, H. Tukey, John W.: Exploratory Data Analysis. Addison-Wesley Publishing Company Reading, Mass.—Menlo Park, Cal., London, Amsterdam, Don Mills, Ontario, Sydney 1977, XVI, 688 S. (n.d.). Biom. J. 1981, 23, 413–414. [Google Scholar] [CrossRef]

- Pearson, K. Notes on regression and inheritance in the case of two parents. Proc. R. Soc. Lond. 1895, 58, 240–242. [Google Scholar] [CrossRef]

- Breiman, L. Random forests. Mach. Learn. 2001, 45, 5–32. [Google Scholar] [CrossRef]

- Raissi, M.; Perdikaris, P.; Karniadakis, G.E. Physics-informed neural networks: A deep learning framework for solving forward and inverse problems involving nonlinear partial differential equations. J. Comput. Phys. 2019, 378, 686–707. [Google Scholar] [CrossRef]

- Yang, X.-S. Firefly algorithms for multimodal optimization, in: Stochastic Algorithms: Foundations and Applications. In Lecture Notes in Computer Science; Springer: Berlin, Germany, 2009; Volume 5792, pp. 169–178. [Google Scholar] [CrossRef]

- Kvålseth, T.O. Cautionary Note about R2. Am. Stat. 1985, 39, 279–285. [Google Scholar] [CrossRef]

- Chai, J.; Draxler, R. Root means square error (RMSE) or mean absolute error (MAE)–Arguments against avoiding RMSE in the literature. Geosci. Model Dev. 2014, 7, 1247–1250. [Google Scholar] [CrossRef]

- Willmott, W.G. Some comments on the evaluation of model performance. Bull. Am. Meteorol. Soc. 1982, 63, 1309–1313. [Google Scholar] [CrossRef]

- Kohavi, R. A study of cross-validation and bootstrap for accuracy estimation and model selection. In Proceedings of the 14th International Joint Conference on Artificial Intelligence (IJCAI), San Francisco, CA, USA, 20–25 August 1995; pp. 1137–1143. [Google Scholar]

- Lundberg, S.M.; Erion, G.; Lee, S.-I. Explainable AI for trees: From local explanations to global understanding. Nat. Mach. Intell. 2020, 2, 252–260. [Google Scholar] [CrossRef]

- Deb, K. Multi-Objective Optimization Using Evolutionary Algorithms; Wiley: Hoboken, NJ, USA, 2001. [Google Scholar]

- Miettinen, K. Nonlinear multiobjective optimization. In International Series in Operations Research & Management Science; Springer: Boston, MA, USA, 1999. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making: Methods and Applications; Springer: Berlin, Germany, 1981. [Google Scholar] [CrossRef]

| Index | Density (g/cm3) | Soundness | Setting Time (min) | Compressive Strength (MPa) | Flexural Strength (MPa) | |||

|---|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 3 d | 28 d | 3 d | 28 d | |||

| Value | 3.12 | Qualified | 147 | 208 | 21.2 | 45.2 | 4.5 | 7.3 |

| Type of Cementitious Material | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | Loss on Ignition (%) |

|---|---|---|---|---|

| Silica fume | 90–93 | 0.19 | 0.12 | 3.92 |

| Fly ash | 45.1 | 24.2 | 3 | 2.8 |

| Slag powder | 27.85 | 12.93 | 0.31 | 2.3 |

| Cement by Mass of Total Binder | Coal Ash/Silica Fume /Mineral Powder by Mass of Total Binder | EPS Particle Size Range | Polystyrene Granule by Volume of Concrete |

|---|---|---|---|

| 100% | 0% | 6.3–4.75 mm; 2.36–1.18mm | 85%; 80%; 75%; 70% |

| 95% | 5% | 6.3–4.75 mm; 2.36–1.18mm | 85%; 80%; 75%; 70% |

| 90% | 10% | 6.3–4.75 mm; 2.36–1.18mm | 85%; 80%; 75%; 70% |

| 85% | 15% | 6.3–4.75 mm; 2.36–1.18mm | 85%; 80%; 75%; 70% |

| 80% | 20% | 6.3–4.75 mm; 2.36–1.18mm | 85%; 80%; 75%; 70% |

| 75% | 25% | 6.3–4.75 mm; 2.36–1.18mm | 85%; 80%; 75%; 70% |

| Fold | 1 | 2 | 3 | 4 | 5 | Mean | Std |

|---|---|---|---|---|---|---|---|

| R2 | 0.95 | 0.94 | 0.96 | 0.95 | 0.95 | 0.95 | 0.01 |

| RMSE | 0.236 | 0.228 | 0.242 | 0.230 | 0.233 | 0.234 | 0.006 |

| MAE | 0.182 | 0.180 | 0.184 | 0.185 | 0.184 | 0.183 | 0.002 |

| Fold | 1 | 2 | 3 | 4 | 5 | Mean | Std |

|---|---|---|---|---|---|---|---|

| R2 | 0.98 | 0.97 | 0.98 | 0.97 | 0.98 | 0.98 | 0.01 |

| RMSE | 0.0061 | 0.0057 | 0.0059 | 0.0058 | 0.0060 | 0.0059 | 0.0002 |

| MAE | 0.0049 | 0.0043 | 0.0047 | 0.0048 | 0.0046 | 0.0047 | 0.0002 |

| Model | R2 (Compressive Strength) | R2 (Thermal Conductivity) | RMSE (Compressive Strength) | RMSE (Thermal Conductivity) | MAE (Compressive Strength) | MAE (Thermal Conductivity) |

|---|---|---|---|---|---|---|

| SVR | 0.89 | 0.91 | 0.186 | 0.0048 | 0.176 | 0.0039 |

| XGBoost | 0.91 | 0.93 | 0.198 | 0.0050 | 0.177 | 0.0041 |

| CatBoost | 0.92 | 0.94 | 0.212 | 0.0053 | 0.180 | 0.0045 |

| PIA-RA | 0.95 | 0.98 | 0.234 | 0.0059 | 0.183 | 0.0049 |

| Material | Symbol | Unit Weight (kg/m3) | Unit Price |

|---|---|---|---|

| Cement | 3060 | 395 (CNY/ton) | |

| Slag powder | 2860 | 266 (CNY/ton) | |

| Fly ash | 2370 | 120 (CNY/ton) | |

| Silica fume | 2210 | 5800 (CNY/ton) | |

| Polystyrene beads (large size) | 32 | 638 (CNY/ton) | |

| Polystyrene beads (small size) | 10.6 | 772 (CNY/ton) |

| Material | Symbol | Range |

|---|---|---|

| EPS volume fraction (%) | 70–85 | |

| EPS particle size (mm) | 6.3–4.75 mm; 2.36–1.18 mm | |

| Fly ash replacement (% binder) | 0–25 | |

| Slag powder replacement (% binder) | 0–25 | |

| Silica fume replacement (% binder) | 0–25 |

| Study | Prediction Target | R2 (Compressive Strength) | Main Advantages and Limitations |

|---|---|---|---|

| Hussain et al. [20] | Compressive Strength | 0.88 | Advantages: The model has a simple structure and high computational efficiency. Limitations: The study primarily focused on compressive strength estimation, without addressing thermal or economic factors, which limits its applicability to holistic mix design. |

| Kumar et al. [19] | Density and Strength | 0.89 | Advantages: Accurate prediction of mechanical properties with stable training performance. Limitations: The work mainly concentrated on mechanical behavior, while thermal insulation and cost considerations were not incorporated into the modeling framework. |

| Zhang et al. [34] | Compressive Strength and Thermal Conductivity | 0.96 | Advantages: High prediction accuracy; the orthogonal design reduces experimental workload and can be used for preliminary mix proportion optimization. Limitations: The approach emphasized data-driven optimization but did not integrate physical constraints or multi-objective coupling, leaving the interaction between performance indicators unexplored. |

| Dabi et al. [35] | Compressive Strength | 0.92 | Advantages: Capable of achieving multi-objective stochastic optimization and revealing the sensitivity of EPS parameters to performance. Limitations: The model mainly targeted parameter optimization, and its interpretability and generalization under varying data domains were not the central focus of the study. |

| This Study | Compressive Strength, Thermal Conductivity, Material Cost | 0.95 | Advantages: Simultaneously achieves physical consistency, interpretability, and multi-objective optimization; demonstrates high prediction accuracy and strong engineering applicability. Limitations: The cost model and dataset size still need to be expanded, and additional performance indicators should be incorporated. |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Hu, D.; Yu, F.; Jin, Q.; Li, Z. Performance Optimization of Expanded Polystyrene Lightweight Concrete Using a Multi-Objective Physically Interpretable Algorithm with Random Forest. Buildings 2025, 15, 3944. https://doi.org/10.3390/buildings15213944

Li S, Hu D, Yu F, Jin Q, Li Z. Performance Optimization of Expanded Polystyrene Lightweight Concrete Using a Multi-Objective Physically Interpretable Algorithm with Random Forest. Buildings. 2025; 15(21):3944. https://doi.org/10.3390/buildings15213944

Chicago/Turabian StyleLi, Sen, Di Hu, Fei Yu, Qiang Jin, and Zihua Li. 2025. "Performance Optimization of Expanded Polystyrene Lightweight Concrete Using a Multi-Objective Physically Interpretable Algorithm with Random Forest" Buildings 15, no. 21: 3944. https://doi.org/10.3390/buildings15213944

APA StyleLi, S., Hu, D., Yu, F., Jin, Q., & Li, Z. (2025). Performance Optimization of Expanded Polystyrene Lightweight Concrete Using a Multi-Objective Physically Interpretable Algorithm with Random Forest. Buildings, 15(21), 3944. https://doi.org/10.3390/buildings15213944