Case Study on Ultra-High-Performance-Concrete-Reinforced Autoclaved Lightweight Concrete: Multi-Scale Optimization of Autogenous Shrinkage, Interface, and Structure

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Cementitious Materials

2.1.2. Fine Aggregate

2.1.3. Chemical Admixtures

2.1.4. Interface Agents

2.2. Specimen Preparation

2.3. UHPC Performance Test

2.4. Methods for Enhancing Interfacial Bonding Performance of UHPC-ALC

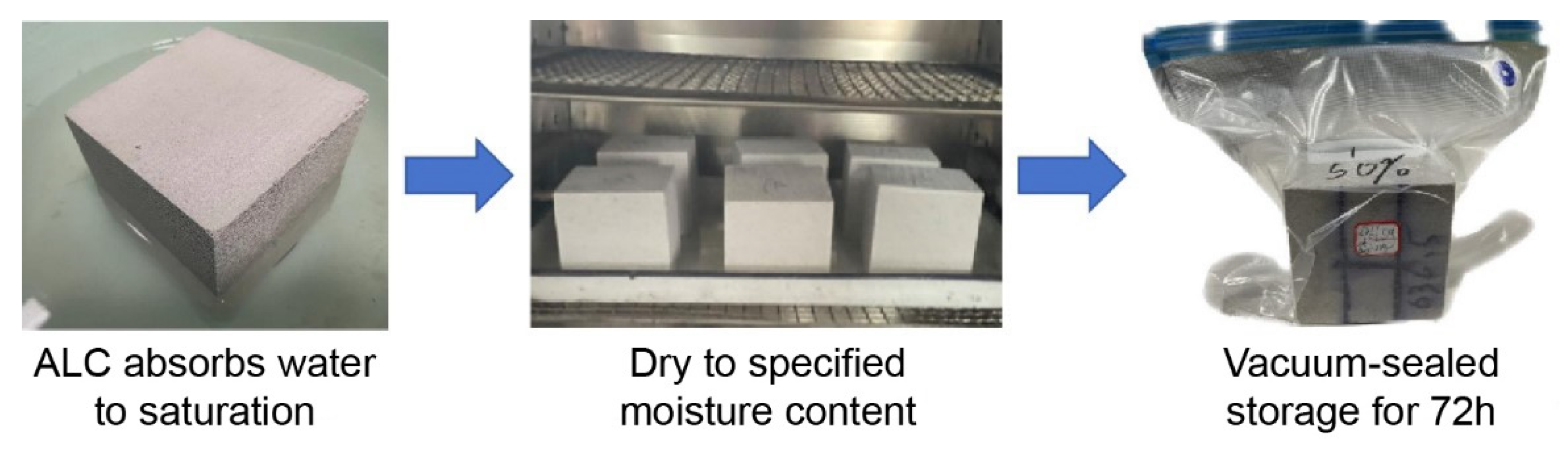

2.4.1. Pretreatment of ALC

2.4.2. ALC Surface Water Absorption Test Method

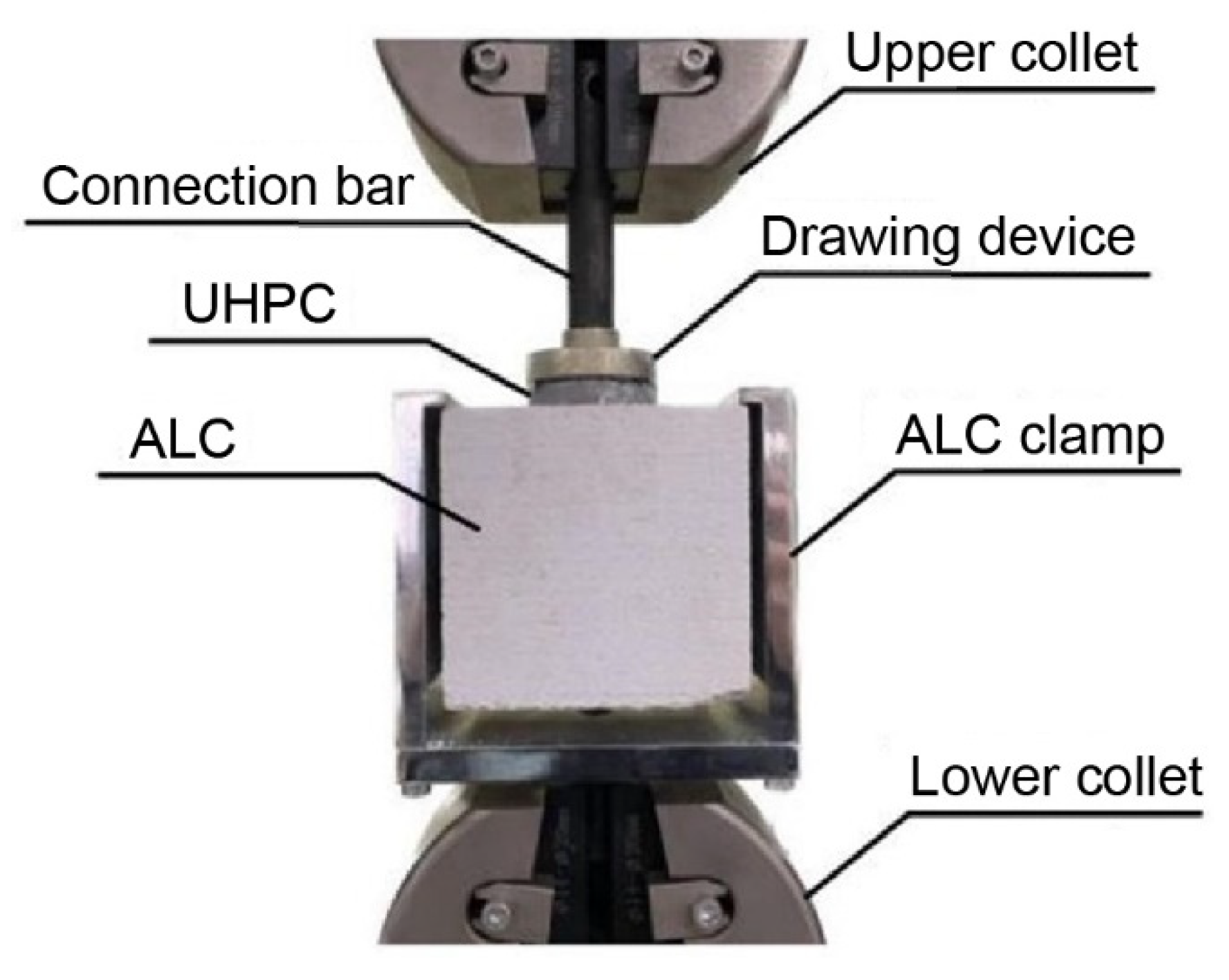

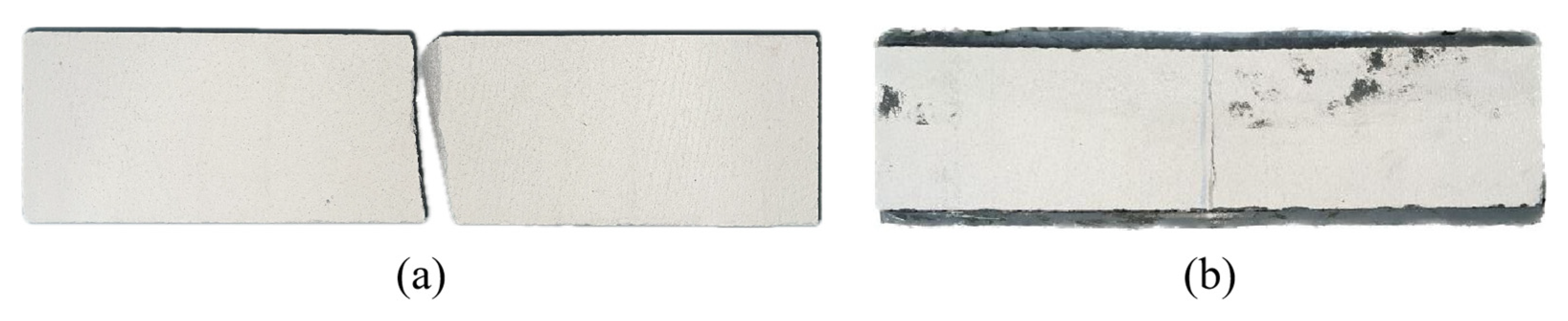

2.4.3. Test Method for Bond Strength of Interfaces

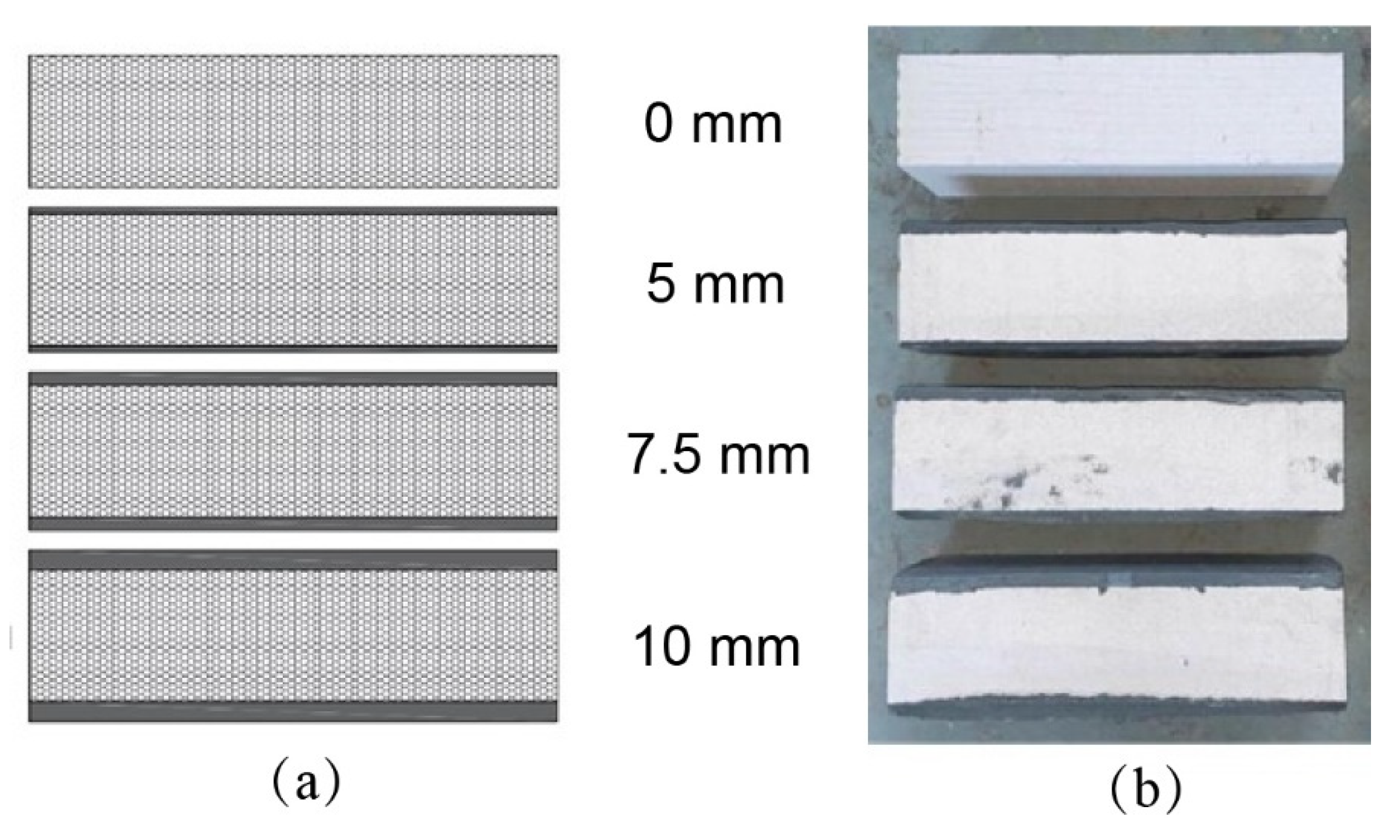

2.5. Simulation and Validation of UHPC-ALC Composite Wall

2.5.1. Finite Element Modeling of Composite Wall

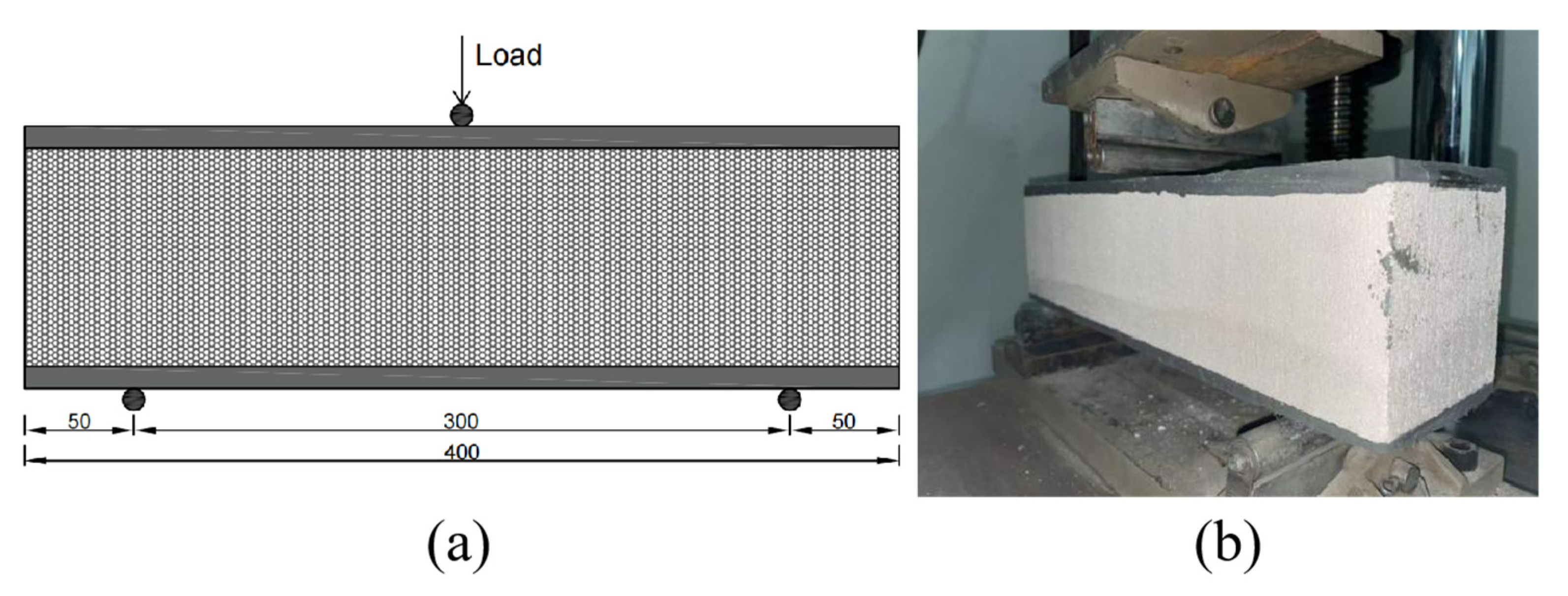

2.5.2. Test Method for Mechanical Properties of Composite Wall Material

3. Results and Discussion

3.1. Effect of SRA and EA on UHPC Properties

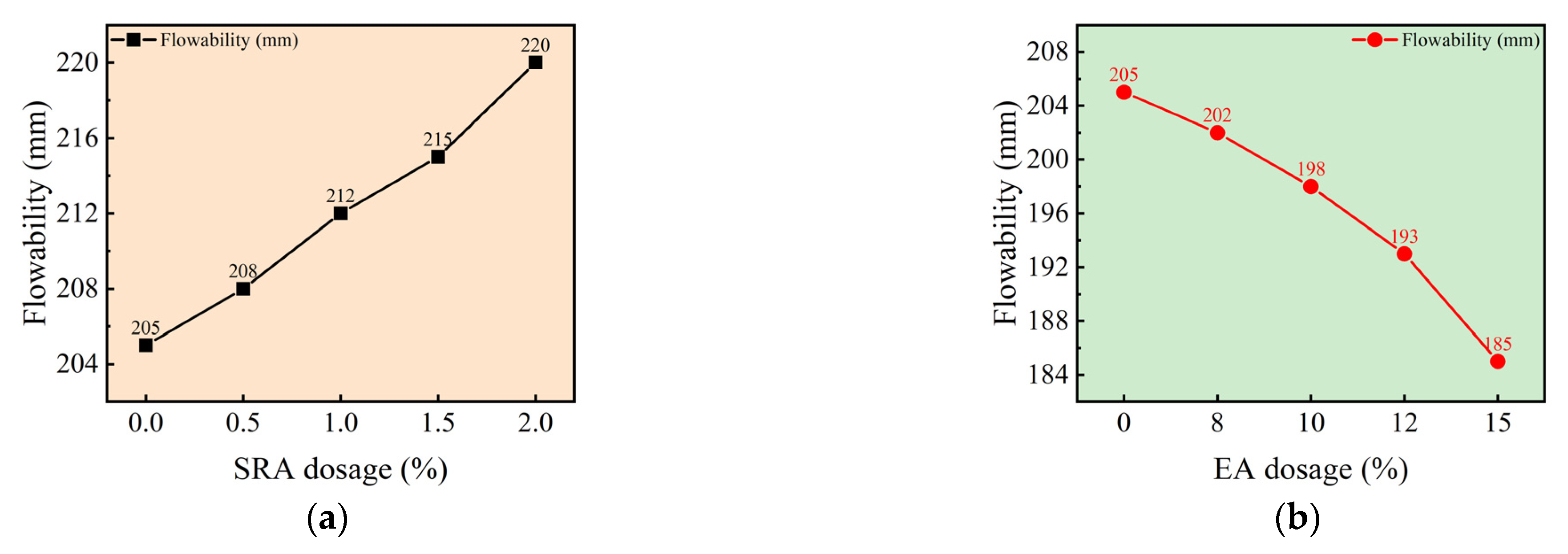

3.1.1. Effect of SRA and EA on UHPC Flowability

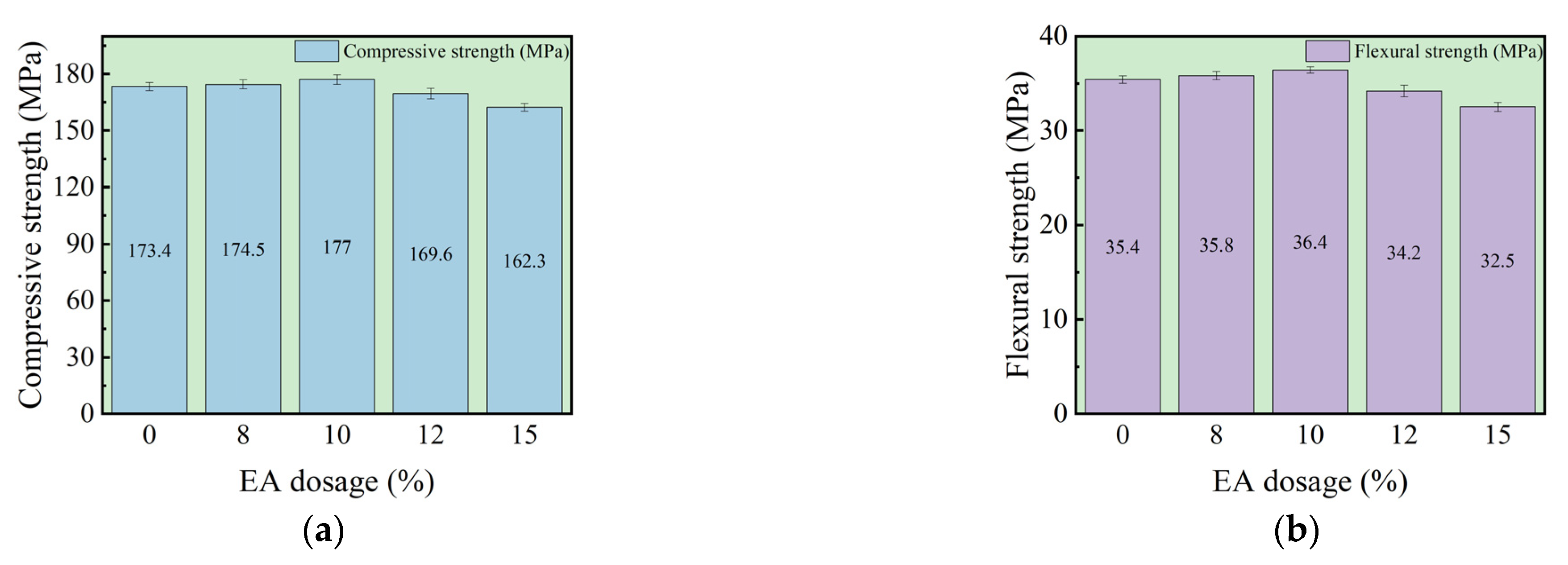

3.1.2. Effect of SRA and EA on Mechanical Properties of UHPC

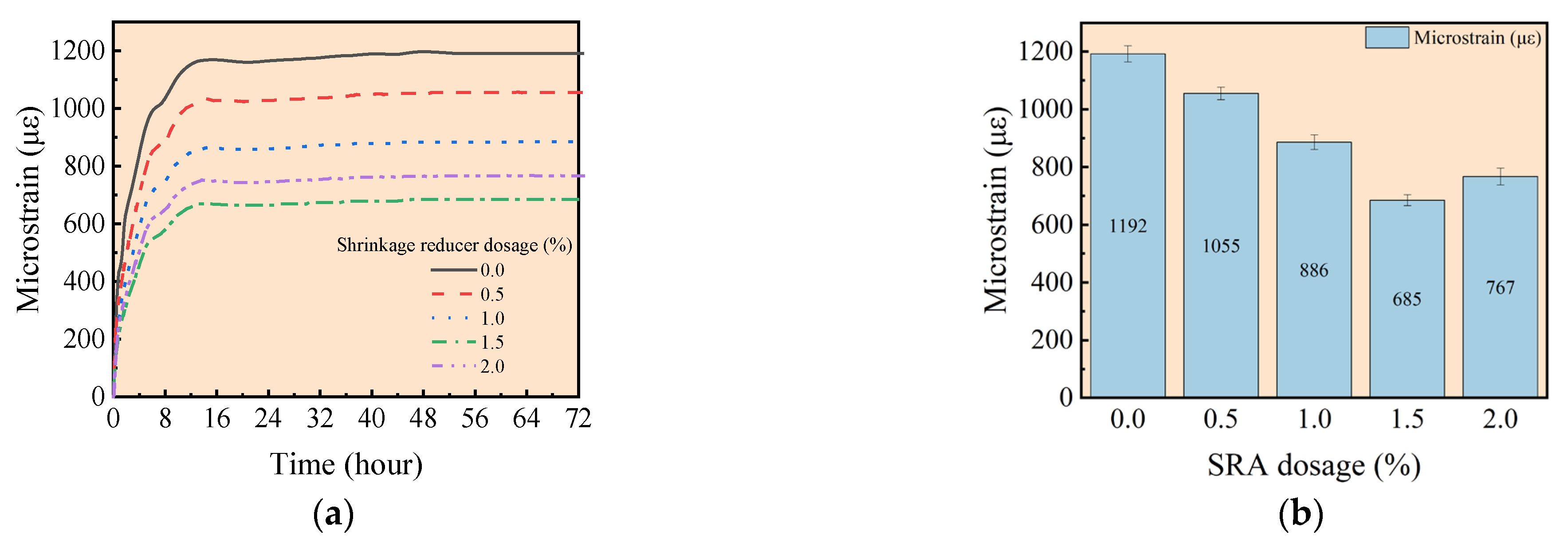

3.1.3. Effect of SRA and EA on Early Self-Shrinkage of UHPC

3.2. Effect of ALC Treatment on Bond Strength

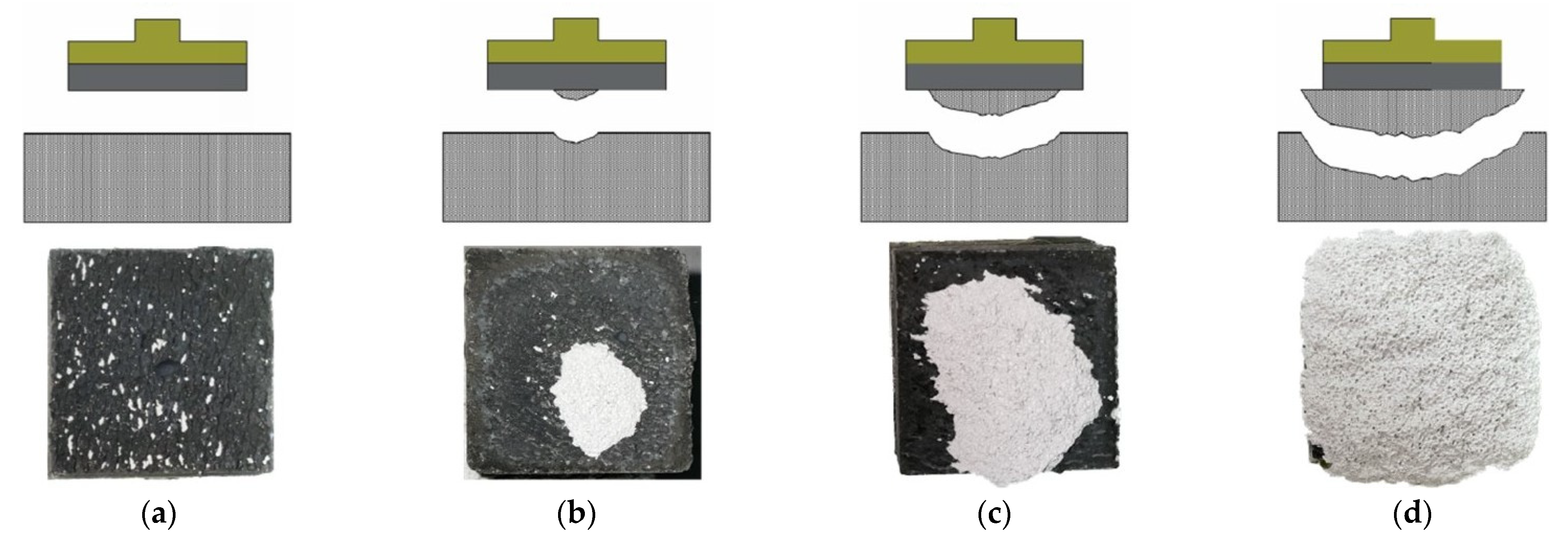

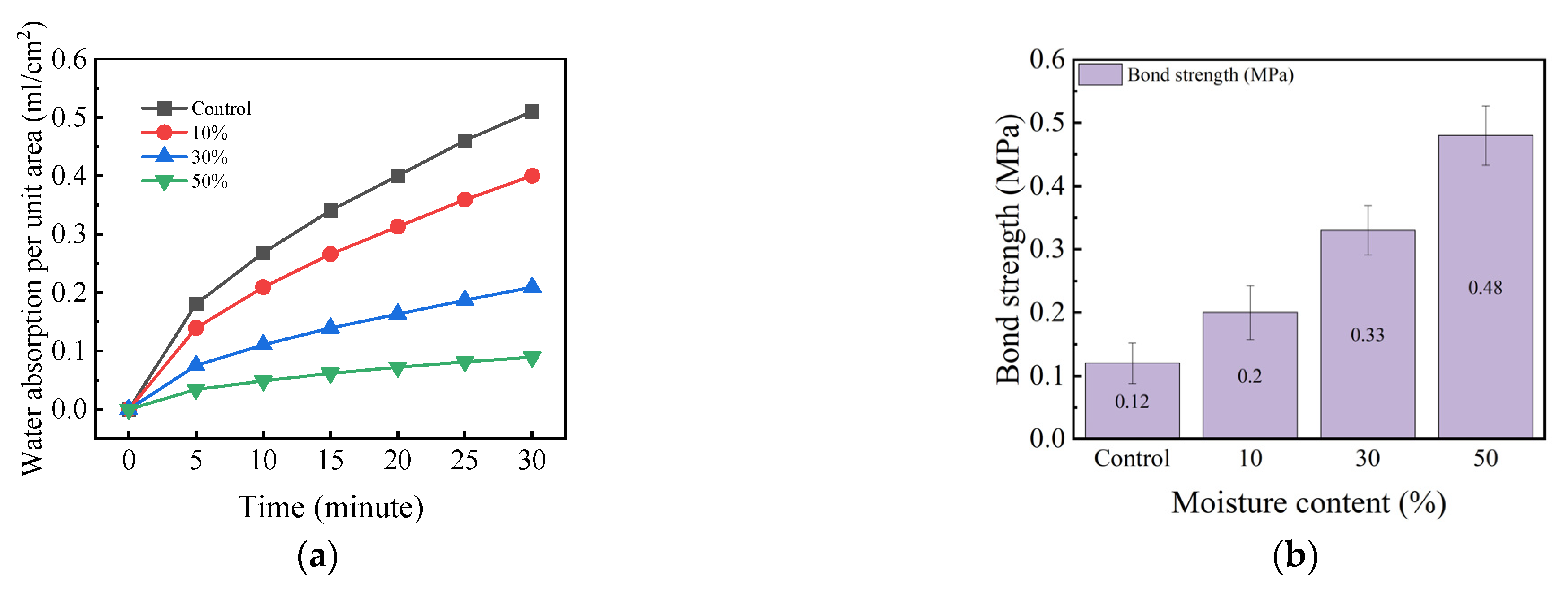

3.2.1. Effect of ALC Water Content on Interfacial Bond Strength

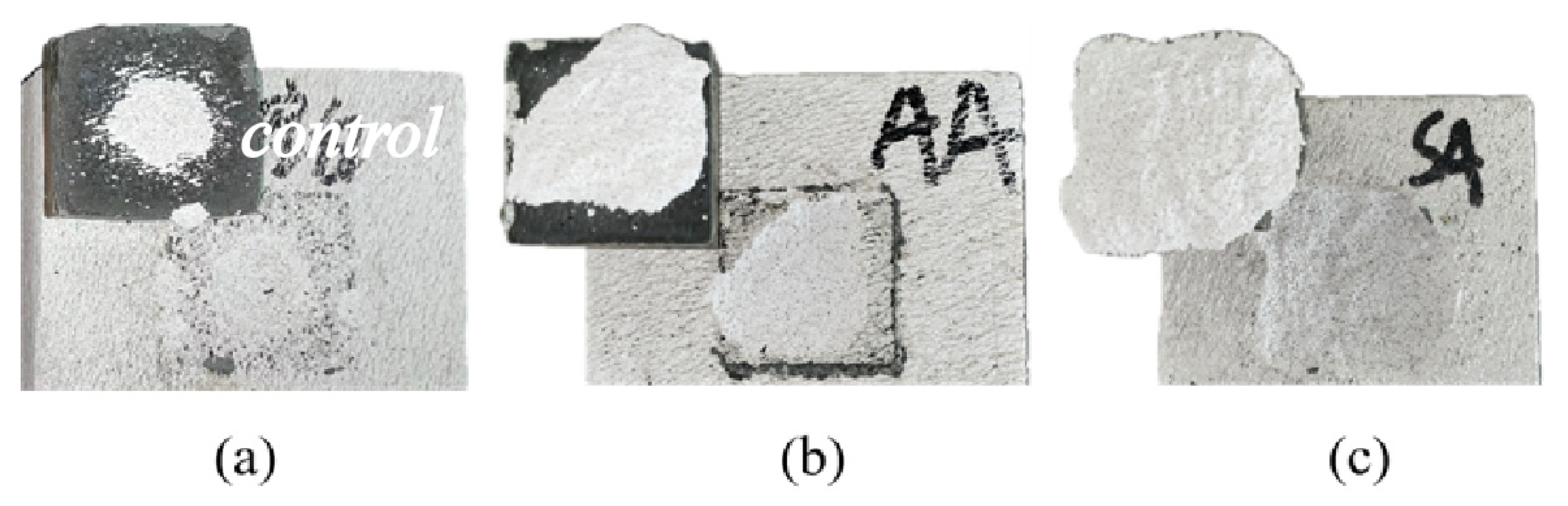

3.2.2. Effect of Interfacial Agents on Bond Strength

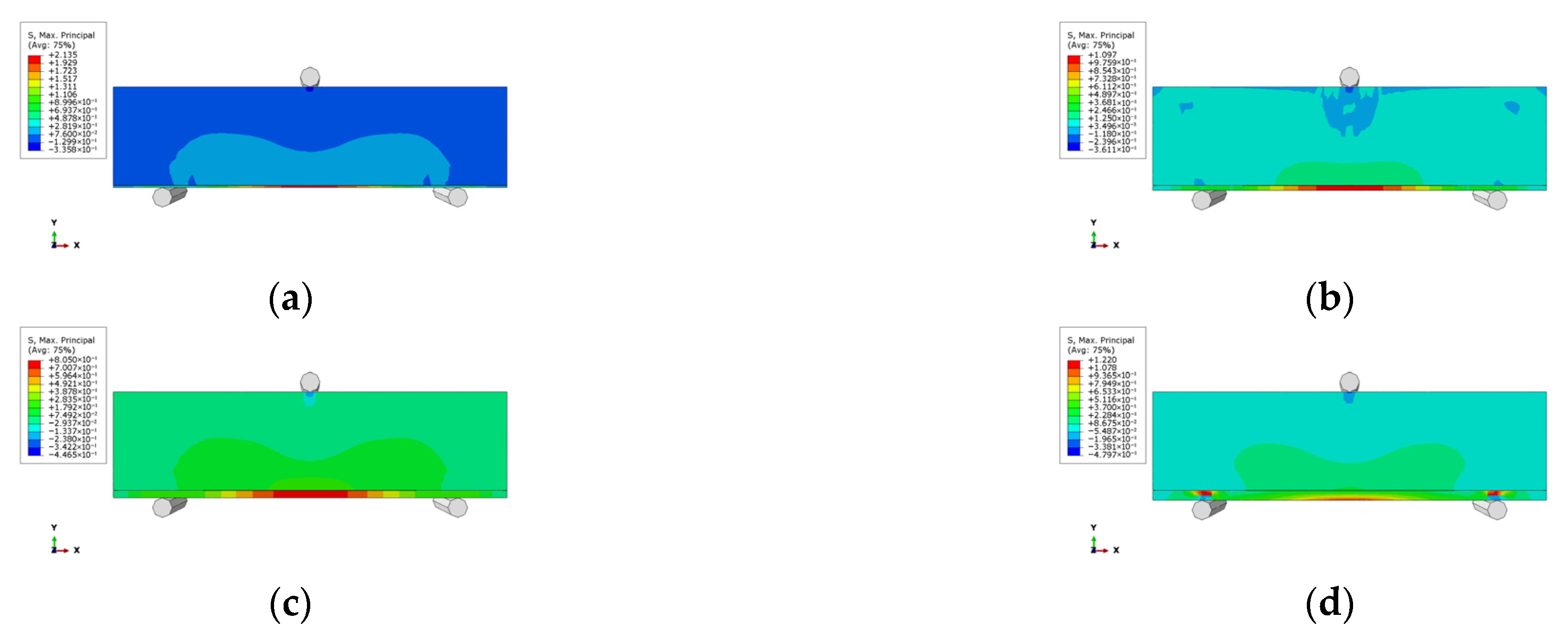

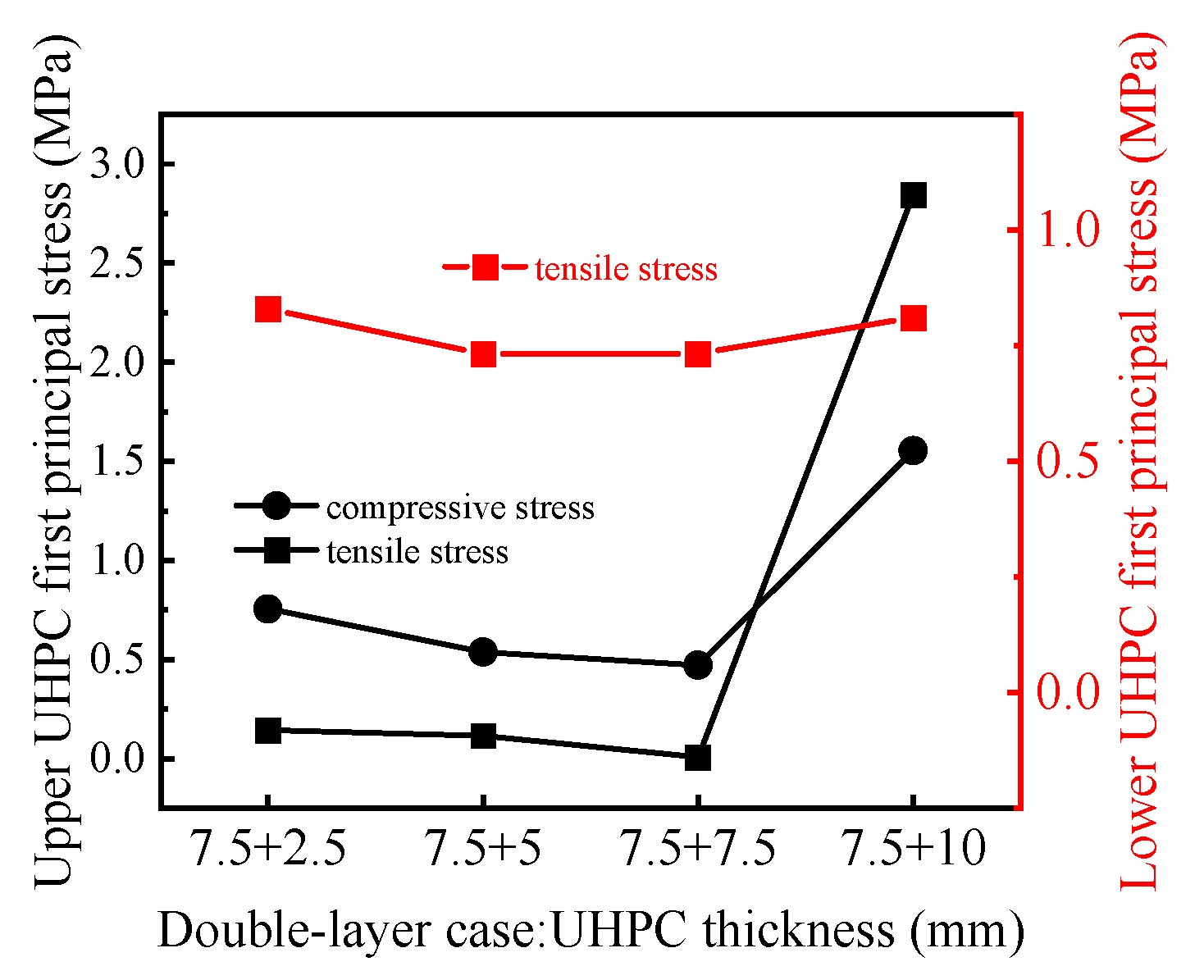

3.3. Finite Element Simulation of Composite Wall

3.3.1. Loading the First Principal Stress at the Same Time

3.3.2. Analysis of Damage Patterns

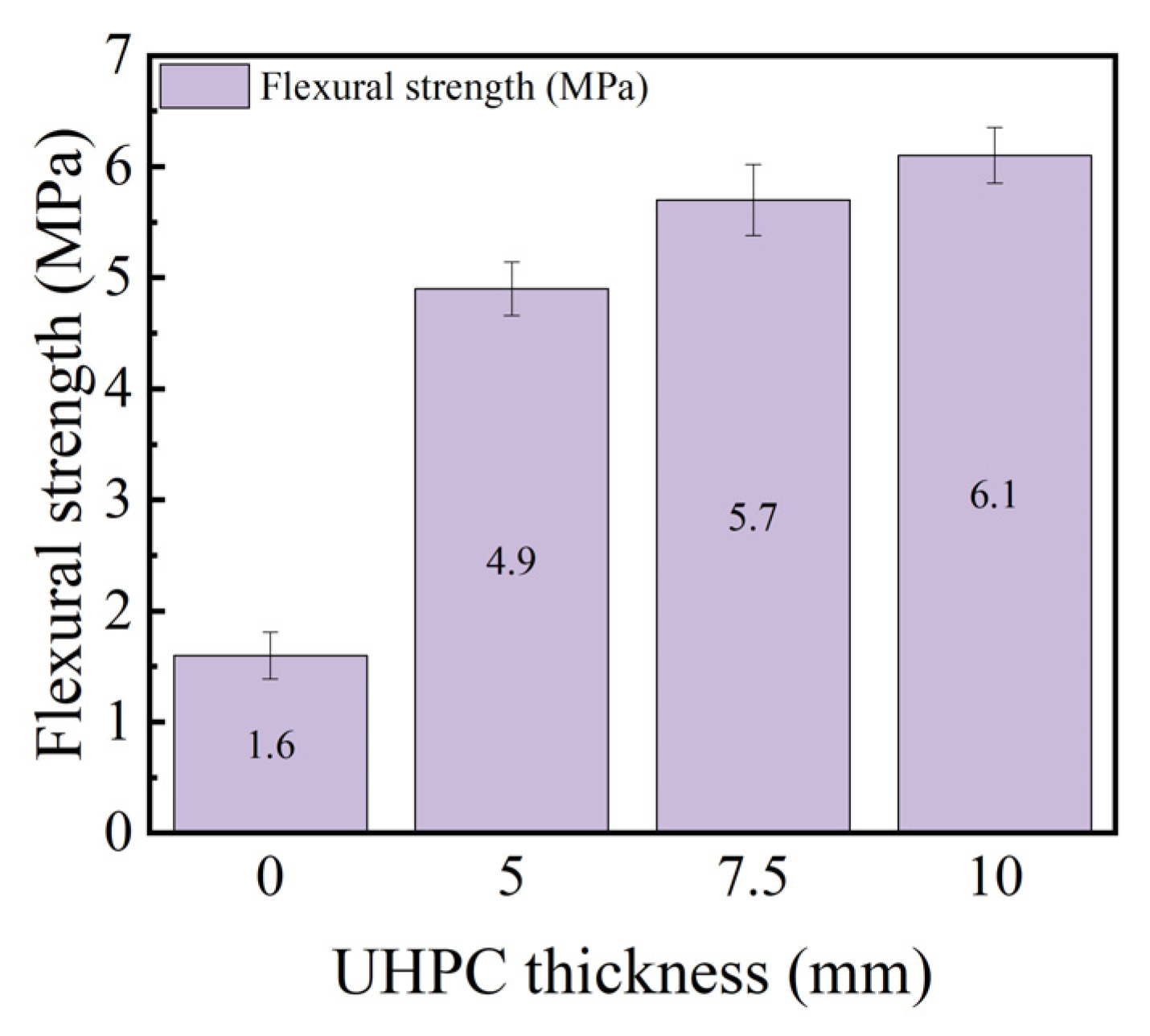

3.4. Strength Testing of Composite Wall Material

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| ALC | Autoclaved lightweight concrete |

| UHPC | Ultra-high-performance concrete |

| SRA | shrinkage-reducing agent |

| EA | expansive agent |

| NC | normal concrete |

| AAC | autoclaved aerated concrete |

| NSC | normal strength concrete |

| CDP | concrete damage plasticity |

References

- Jiang, J.; Cai, Q.; Ma, B.; Hu, Y.Y.; Qian, B.B.; Ma, F.; Shao, Z.Y.; Xu, Z.F.; Wang, L.M. Effect of ZSM-5 waste dosage on the properties of autoclaved aerated concrete. Constr. Build. Mater. 2021, 278, 122114. [Google Scholar] [CrossRef]

- Schreiner, J.; Jansen, D.; Ectors, D.; Goetz-Neunhoeffer, F.; Neubauer, J.; Volkmann, S. New analytical possibilities for monitoring the phase development during the production of autoclaved aerated concrete. Cem. Concr. Res. 2018, 107, 247–252. [Google Scholar] [CrossRef]

- Luo, Y.; Ma, B.; Liang, F.Y.; Xue, Z.Y.; Qian, B.B.; Wang, J.Q.; Zhou, L.Z.; Zang, J.; Liang, R.H.; Li, Y.B. Use of untreated phosphogypsum as a raw material for autoclaved aerated concrete preparation. J. Build. Eng. 2023, 64, 105607. [Google Scholar] [CrossRef]

- Karim, G.W.; Hugi, E.; Karvonen, L.; Schnewlin, P.; Winnefeld, F. Thermal behaviour of autoclaved aerated concrete exposed to fire. Cem. Concr. Compos. 2015, 62, 52–58. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J. Properties of lightweight pedestrian paving blocks incorporating wheat straw: Micro-to macroscale investigation. Results Eng. 2022, 16, 100758. [Google Scholar] [CrossRef]

- Jing, R.; Liu, Y.; Yan, P. Uncovering the effect of fly ash cenospheres on the macroscopic properties and microstructure of ultra high-performance concrete (UHPC). Constr. Build. Mater. 2021, 286, 122977.1–122977.9. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, P.; Sha, F.; Yu, Z.W.; He, S.S.; Xu, W.; Lv, M.F. Effects of Type and Content of Fibers, Water-to-Cement Ratio, and Cementitious Materials on the Shrinkage and Creep of Ultra-High Performance Concrete. Polymers 2022, 14, 1956. [Google Scholar] [CrossRef]

- Ren, G.S.; Yao, B.; Ren, M.; Gao, X.J. Utilization of natural sisal fibers to manufacture eco-friendly ultra-high performance concrete with low autogenous shrinkage. J. Clean. Prod. 2022, 332, 130105. [Google Scholar] [CrossRef]

- Lim, J.L.G.; Raman, S.N.; Safiuddin, M.; Zain, M.F.M.; Hamid, R. Autogenous Shrinkage, Microstructure, and Strength of Ultra-High Per-formance Concrete Incorporating Carbon Nanofibers. Materials 2019, 12, 320. [Google Scholar] [CrossRef]

- Liu, K.Z.; Yu, R.; Shui, Z.H.; Yi, S.Q.; Li, X.S.; Ling, G.; He, Y.J. Influence of external water introduced by coral sand on autogenous shrinkage and mi-crostructure development of Ultra-High Strength Concrete (UHSC). Constr. Build. Mater. 2020, 252, 119111. [Google Scholar] [CrossRef]

- Feng, H.C.; Zhang, Y.Y.; Xin, H.H.; Zhao, J.R.; Shah, S.Y. Restrained Shrinkage in Ultra-High-Performance Concrete (UHPC)-Normal strength concrete interface. J. Build. Eng. 2025, 111, 113293. [Google Scholar] [CrossRef]

- Shen, P.L.; Lu, L.N.; He, Y.J.; Rao, M.J.; Fu, Z.D.; Wang, F.Z.; Hu, S.G. Experimental investigation on the autogenous shrinkage of steam cured ultra-high performance concrete. Constr. Build. Mater. 2018, 162, 512–522. [Google Scholar] [CrossRef]

- Huang, H.; Ye, G. Examining the “time-zero” of autogenous shrinkage in high/ultra-high performance cement pastes. Cem. Concr. Res. 2017, 97, 107–114. [Google Scholar] [CrossRef]

- Xie, T.; Fang, C.; Ali, M.S.M.; Visintin, P. Characterizations of autogenous and drying shrinkage of ultra-high performance concrete (UHPC): An experimental study. Cem. Concr. Compos. 2018, 91, 156–173. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Li, S.K.; Chen, P.; Liu, X.Y.; Wang, J.Y. Mitigating shrinkage in ultra-high performance concrete using MgO expansive agents with different activity levels. Front. Mater. 2022, 9, 1033467. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Huang, Z.Y.; Wu, Y.Y. Solving shrinkage problem of ultra-high-performance concrete by a combined use of expansive agent, super absorbent polymer, and shrinkage-reducing agent. Compos. Part B 2022, 230, 109503. [Google Scholar] [CrossRef]

- De la Varga, I.; Muñoz, J.F.; Bentz, D.P.; Spragg, R.P.; Stutzman, P.E.; Graybeal, B.A. Grout-concrete interface bond performance: Effect of interface moisture on the tensile bond strength and grout microstructure. Constr. Build. Mater. 2018, 170, 747–756. [Google Scholar] [CrossRef]

- Kadhim, M.M.A.; Jawdhari, A.; Peiris, A. Development of hybrid UHPC-NC beams: A numerical study. Eng. Struct. 2021, 233, 111893. [Google Scholar] [CrossRef]

- Miccoli, L.; Fontana, P.; Qvaeschning, D.; Kreft, O.; Hoppe, J.; Meng, B. UHPC–AAC facade elements: Structural design, production technology, and mechanical behavior. Civ. Eng. Perform. Assess. 2018, 2, 483–488. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Pang, K.; Xu, L.H.; Zou, Y.; Yang, J.; Wang, C.B. The bond properties between UHPC and stone under different interface treatment methods. Constr. Build. Mater. 2023, 365, 130092. [Google Scholar] [CrossRef]

- Zhang, B.S.; Yu, J.J.; Chen, W.Z.; Liu, H.; Li, H. Multi-scale investigation on the interfacial behavior of between NC and UHPC in flexural members considering influence of the interface morphology. Compos. Struct. 2024, 345, 118388. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Qiao, P.Z.; Sun, J.; Chen, A. Multiscale characterization of bond performance of UHPC-NC with different interface agents. Constr. Build. Mater. 2025, 480, 141436. [Google Scholar] [CrossRef]

- Jin, D.L.; Yuan, Y.; Zheng, S.M.; Muciaccia, G.; Logo, J.; Zhang, J.L. Effects of UHPC age and interfacial treatment on structural behavior of post-cast UHPC joints in prefabricated wall-base slab assemblies. Eng. Struct. 2025, 344, 121324. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, C.Y.; Zhu, Y.P.; Cao, J.H.; Shao, X.D. An experimental study: Various influence factors affecting interfacial shear performance of UHPC-NSC. Constr. Build. Mater. 2020, 236, 117480. [Google Scholar] [CrossRef]

- ISO 13007-2:2013; Ceramic Tiles—Grouts and Adhesives—Part 2: Test Methods for Adhesives. International Organization for Standardization (ISO): Geneva, Switzerland, 2013.

- Wang, Z.; Wang, J.Q.; Liu, T.X.; Zhang, F. Modeling seismic performance of high-strength steel-ultra-high-performance concrete piers with modified Kent-Park model using fiber elements. Adv. Mech. Eng. 2016, 8, 168781401663341. [Google Scholar] [CrossRef]

- Tian, X.; Fang, Z.; Zhou, T.; Xiang, Y. Behavior and constitutive model of ultra-high-performance concreteunder monotonic and cyclic tensile loading. Constr. Build. Mater. 2023, 389, 131634. [Google Scholar] [CrossRef]

- Liu, X. Experimental Study on Mechanical Properties of Autoclaved Aerated Concrete Load-Bearing Masonry. Ph.D. Thesis, Tianjin University, Tianjin, China, 2005. [Google Scholar]

- GB/T 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- Valikhani, A.; Jahromi, A.J.; Mantawy, I.M.; Azizinamini, A. Numerical Modelling of Concrete-to-UHPC Bond Strength. Mater. 2020, 13, 1379. [Google Scholar] [CrossRef] [PubMed]

- Zhang, W.Y.; Xue, M.F.; Lin, H.X.; Duan, X.H.; Jin, Y.Z.; Su, F.Q. Effect of polyether shrinkage reducing admixture on the drying shrinkage properties of alkali-activated slag. Cem. Concr. Compos. 2023, 136, 104865. [Google Scholar] [CrossRef]

- Rahoui, H.; Maruyama, I.; Vandamme, M.; Pereira, J.M.; Mosquet, M. Impact of alkalis and shrinkage-reducing admixtures on hydration and pore structure of hardened cement pastes. Cem. Concr. Res. 2024, 184, 107620. [Google Scholar] [CrossRef]

- Wang, T.Y.; Gong, J.Q.; Chen, B.; Gong, X.; Luo, H.K.; Zhang, Y.; Qu, Z.G. Effects of Shrinkage Reducing Agent and Expanded Cement on UHPC Fluidity, Mechanical Properties, and Shrinkage Performance. Adv. Mater. Sci. Eng. 2021, 7, 9045754. [Google Scholar] [CrossRef]

- Du, J.; Tan, X.; Wang, Y.H.; Bao, Y.; Meng, W.N. Reducing the cracking potential of ultra-high-performance concrete (UHPC) with the prewet expansive agent. Constr. Build. Mater. 2024, 431, 136597. [Google Scholar] [CrossRef]

- Liu, L.; Chen, H.; He, Z.; Wang, P.; Cui, J.Y.; Cai, X.H.; Sun, Y.Q. Effect and mechanism of compound expansive agent on rheological, mechanical, and shrinkage properties of UHPC. Constr. Build. Mater. 2024, 444, 137730. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Feng, H.C.; Shah, S.Y.; Xin, H.H. Effect of shrinkage-mitigating additive and curing condition on flexural and fracture behavior of ultra-high-performance concrete (UHPC) unnotched beam. Constr. Build. Mater. 2024, 445, 137890. [Google Scholar] [CrossRef]

- Zhang, Y.Y.; Duan, L.; Xin, H.H.; Wang, C.S. Shrinkage behavior of ultra-high-performance concrete (UHPC) in cold winter conditions with shrinkage reducing agent (SRA) and expansive agent (EA). Constr. Build. Mater. 2024, 436, 136645. [Google Scholar] [CrossRef]

- Li, J.H.; Zhang, Z.T.; Asamoto, S.; Wang, Y. Bonding performance of low-shrinkage ultra-high-performance concrete–concrete interface under different stress conditions. Struct. Concr. 2025, 7, 70233. [Google Scholar] [CrossRef]

- Tan, W.B.; Xu, Y.; Zhou, T.; Qian, X.L.; Chen, P.Y.; Liu, Q.H.; Wang, J.L. Synergistic effect of expansive agent and internal curing on the performance of UHPC. Case Stud. Constr. Mater. 2025, 23, e05238. [Google Scholar] [CrossRef]

- Gao, J.; Geng, Y.J.; Li, S.C.; Chen, X.; Shi, D.D.; Zhou, P.J.; Zhou, Z.H.; Wu, Z.H. Effect of silane emulsion on waterproofing and anti-icing performance of foamed concrete. Constr. Build. Mater. 2021, 301, 124082. [Google Scholar] [CrossRef]

- Dong, Y.; Lai, L.P.; Xiao, X.D.; Zhang, L.; Zhao, Z.L.; Zhao, J. Water Consolidation Performance of Acrylic-Polymer-Modified Materials and Their Concrete Impermeability Repair Characteristics. Molecules 2023, 28, 8157. [Google Scholar]

- Ding, Y.; Qian, G.P.; Liu, J.W.; Yao, J.L. Application of Polymer Curing Agent in Ecological Protection Engineering of Weak Rock Slopes. J. Perform. Constr. Facil. 2020, 34, 04019068. [Google Scholar]

- Tian, Z.Y.; Ma, R.; Sun, D.S.; Zhang, W.; Wang, A.G. Finite element analysis of bonding property and flexural strength of WUHPC-NC gradient concrete. Materials 2023, 16, 3625. [Google Scholar] [CrossRef] [PubMed]

- El-Helou, R.; Graybeal, B. Flexural behavior and design of ultrahigh-performance concrete beams. J. Struct. Eng. 2022, 148, 04022016. [Google Scholar] [CrossRef]

- Zhang, Z.; Qin, H. Study on flexural performance of reinforced concrete beams strengthened with FRP grid–PCM composite reinforcement. Appl. Sci. 2024, 14, 9013. [Google Scholar] [CrossRef]

- Huang, H.; Lan, W.; Yin, L.T.; Wang, H.Z.; Cheng, Y.Y.; Zeng, J.T. Flexible mechanical properties of recycled ceramic aggregate concrete-filled double-skin square steel tubes. Structures 2025, 79, 109605. [Google Scholar] [CrossRef]

- Tang, X.Y.; Feng, C.Z.; Chang, J.; Ma, J.L.; Hu, X.S. Research on the flexural performance of steel pipe steel slag powder ultra-high-performance concrete components. Materials 2023, 16, 5960. [Google Scholar] [CrossRef] [PubMed]

- Song, L.T.; Duan, S.J.; Hou, J.; Tong, J.Z.; Li, Q.H.; Xu, S.L. Flexural performance evaluation on precast UHTCC-concrete composite slabs. Structures 2025, 81, 110284. [Google Scholar] [CrossRef]

- Zhu, Y.P.; Zhang, Y.; Li, X.L.; Chen, G.D. Finite element model to predict structural response of predamaged RC beams reinforced by toughness-improved UHPC under unloading status. Eng. Struct. 2021, 235, 112019. [Google Scholar] [CrossRef]

- Yuan, S.; Liu, Z.; Teng, T. Investigation of over-nonlocal damage and interface cohesive models for simulating structural behaviors of composite UHPC-NC members. Structures 2020, 28, 2617–2632. [Google Scholar] [CrossRef]

- Al-Saawani, M.A.; Al-Negheimish, A.I.; El-Sayed, A.K.; Alhozaimy, A.M. Finite element modeling of debonding failures in FRP-strengthened concrete beams using cohesive zone model. Polymers 2022, 14, 1889. [Google Scholar] [CrossRef]

- Chen, X.D.; Liu, Y.L.; Ma, Q.Y.; Zhou, P.; Liu, X.; Lin, J.J. Finite element analysis of flexural performance of reinforced truss hollow composite concrete slabs. Sci. Rep. 2025, 15, 7057. [Google Scholar] [CrossRef]

- Liu, P.; Xie, S.S.; Liu, L.; Luo, A.; Zhang, N.; He, S.S.; Wu, Y.Y.; Xu, W.; Chen, Y.; Yu, Z.W. Research on bending performance of concrete sandwich laminated floor slabs with integrated thermal and sound insulation. Coatings 2022, 12, 1075. [Google Scholar] [CrossRef]

| Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | K2O | Na2O | SO3 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 21.60 | 4.35 | 2.95 | 63.81 | 1.76 | 0.51 | 0.16 | 2.06 | 1.19 |

| Silica fume | 98.07 | - | 0.12 | 0.51 | 0.31 | 0.53 | 0.14 | 0.12 | 0.01 |

| Fly ash microbeads | 56.5 | 26.5 | 5.3 | 4.8 | 1.3 | 3.28 | 1.4 | 0.65 | 0.01 |

| Form | Density (g/cm3) | pH | Total Chloride Ions (%) | Alkali Content (%) |

|---|---|---|---|---|

| White powder | 0.5 | 10 | ≤0.1 | ≤3.0 |

| Name | Solid Content (%) | Density (g/cm3) | Form |

|---|---|---|---|

| SRA | 10 ± 1 | 1.0 ± 0.1 | Light yellow liquid |

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | LOI |

|---|---|---|---|---|---|---|

| 1.50 | 15.61 | 1.37 | 50.60 | 2.08 | 27.50 | 1.19 |

| C (%) | SF (%) | FA (%) | B/S | W/B | WR (%) | S (/vol%) | SRA (%) |

|---|---|---|---|---|---|---|---|

| 75 | 15 | 10 | 1.2 | 0.16 | 1 | 2 | 1.5 |

| Material | Expansion Angle | Eccentricity | Strength Ratio | K | Viscosity Factor | Density | Young’s Modulus | Poisson’s Ratio |

|---|---|---|---|---|---|---|---|---|

| UHPC | 30° | 0.1 | 1.16 | 0.6667 | 0.0005 | 2450 kg/m3 | 49.57 GPa | 0.2 |

| ALC | 30° | 0.1 | 1.16 | 0.6667 | 0.0005 | 625 kg/m3 | 2.88 GPa | 0.2 |

) | ) | ||

|---|---|---|---|

| 1000 | 10 | 0.5 | 2.8 |

| Moisture Content (%) | Bond Strength (MPa) | Forms of Interface Damage |

|---|---|---|

| Control | 0.12 | Interface main disconnect |

| 10 | 0.2 | Interface main disconnect |

| 30 | 0.33 | ALC main disconnect |

| 50 | 0.48 | ALC main disconnect |

| Interfacial Agent | Bond Strength (MPa) | Forms of Interface Damage |

|---|---|---|

| Control | 0.12 | Interface main disconnect |

| Acrylic emulsion | 0.74 | ALC main disconnect |

| Phenylpropylene emulsion | 0.93 | ALC fully disconnect |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Xie, D.; Su, Y.; Zhang, T.; Guan, Y. Case Study on Ultra-High-Performance-Concrete-Reinforced Autoclaved Lightweight Concrete: Multi-Scale Optimization of Autogenous Shrinkage, Interface, and Structure. Buildings 2025, 15, 3850. https://doi.org/10.3390/buildings15213850

Li J, Xie D, Su Y, Zhang T, Guan Y. Case Study on Ultra-High-Performance-Concrete-Reinforced Autoclaved Lightweight Concrete: Multi-Scale Optimization of Autogenous Shrinkage, Interface, and Structure. Buildings. 2025; 15(21):3850. https://doi.org/10.3390/buildings15213850

Chicago/Turabian StyleLi, Jianxin, Duochao Xie, Yilin Su, Tiezhi Zhang, and Yan Guan. 2025. "Case Study on Ultra-High-Performance-Concrete-Reinforced Autoclaved Lightweight Concrete: Multi-Scale Optimization of Autogenous Shrinkage, Interface, and Structure" Buildings 15, no. 21: 3850. https://doi.org/10.3390/buildings15213850

APA StyleLi, J., Xie, D., Su, Y., Zhang, T., & Guan, Y. (2025). Case Study on Ultra-High-Performance-Concrete-Reinforced Autoclaved Lightweight Concrete: Multi-Scale Optimization of Autogenous Shrinkage, Interface, and Structure. Buildings, 15(21), 3850. https://doi.org/10.3390/buildings15213850