Emerging Trends in the Use of Recycled Sand in Mortar: A Systematic Review

Abstract

1. Introduction

- How does the processing of construction and demolition waste (CDW) affect the properties of recycled sand?

- What recent technologies have been applied to CDW recycled sand for use in mortars?

- What are the impacts of using recycled sand on the properties of mortars, also considering its environmental and civil construction benefits?

2. Methodology

2.1. Bibliographic Analysis

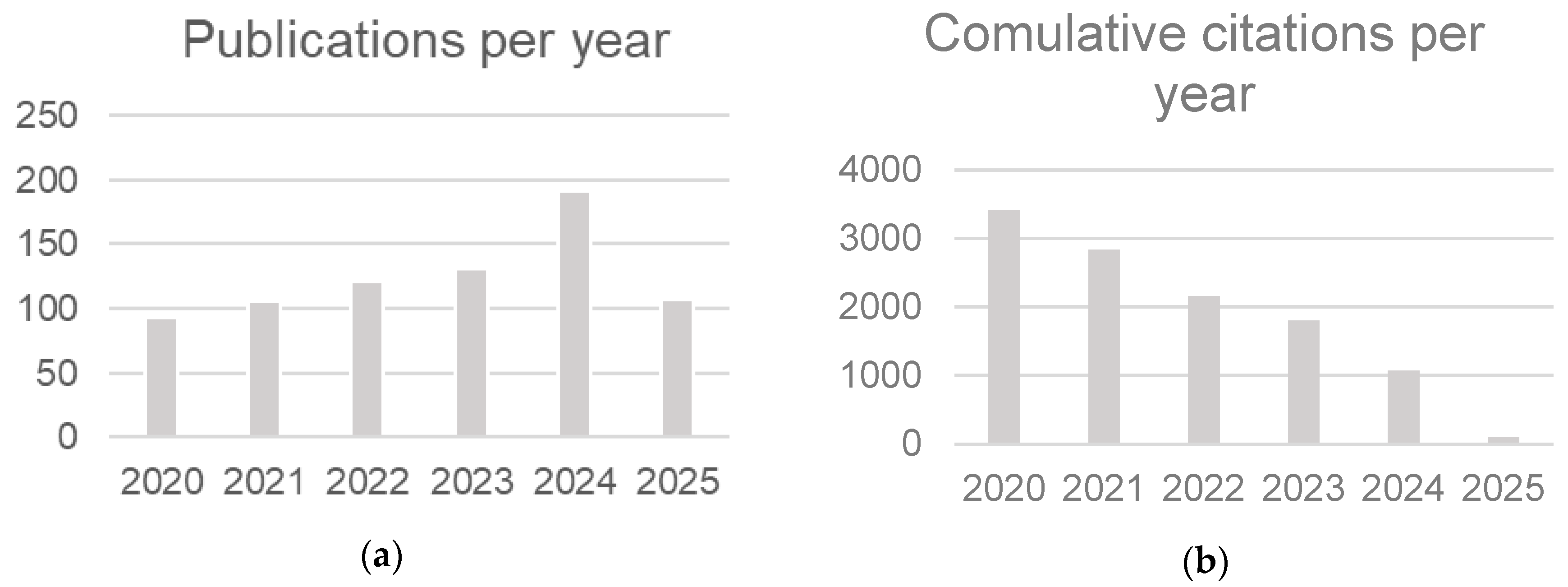

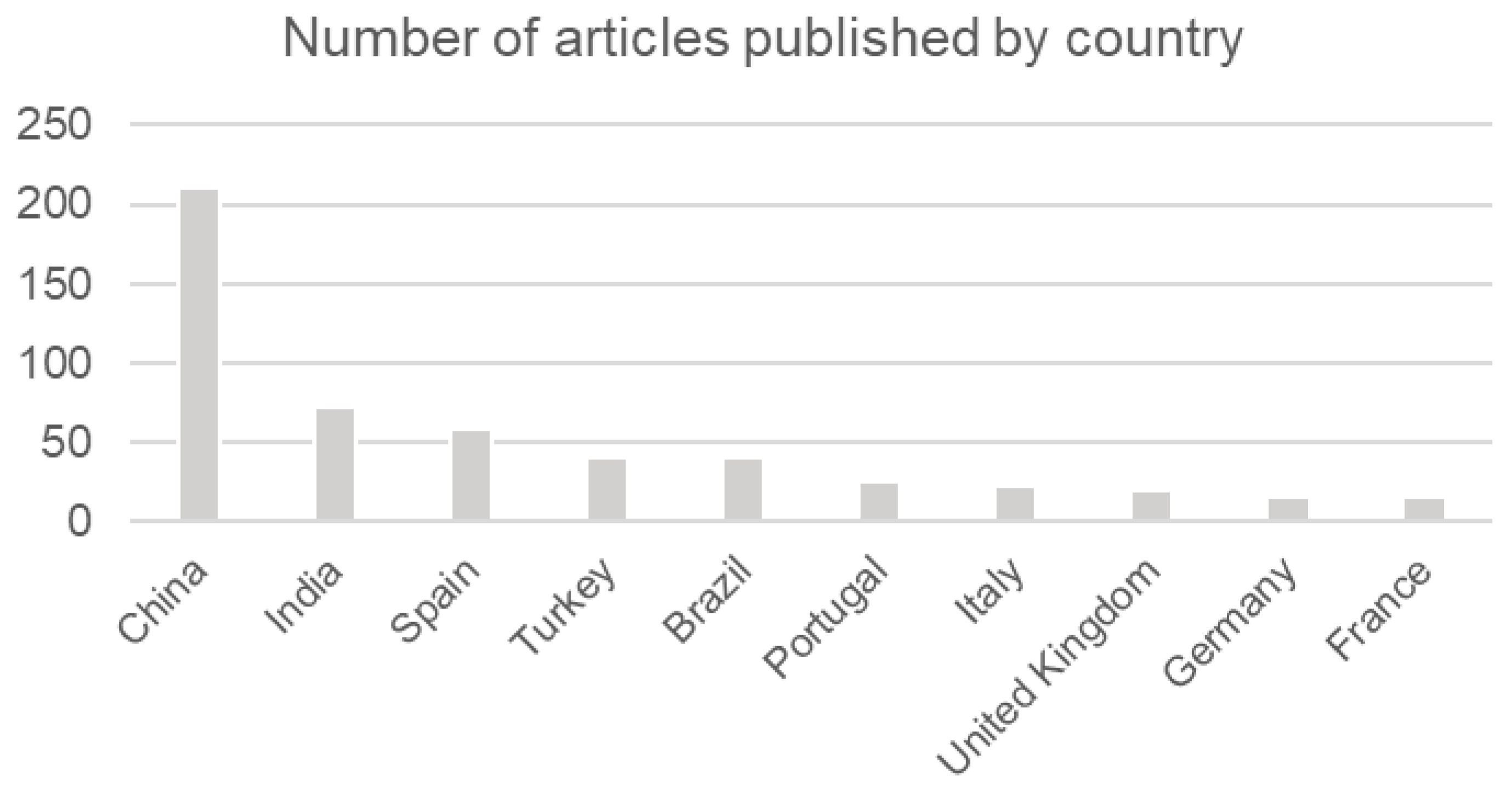

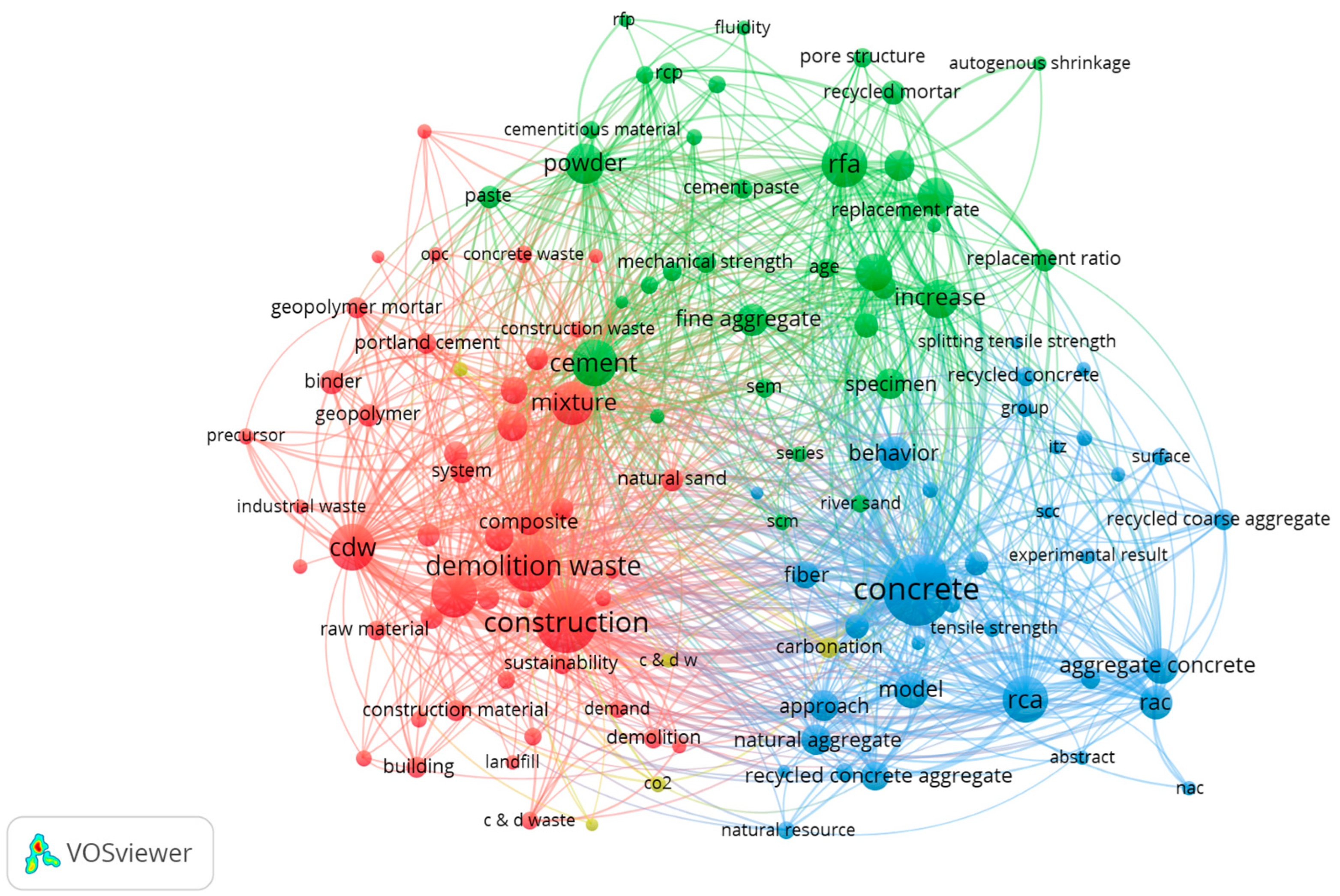

2.2. Bibliometric Analysis

3. General Discussion

3.1. Processing of CDW and Its Effects on the Properties of Recycled Sand

3.2. Experimental Assessment of Mortars with Recycled CDW Sand

3.3. Recent Technologies Applied to CDW Recycled Sand

3.4. Mechanical Properties of Mortars with Recycled Sand

3.5. Environmental Benefits of Recycled Sand

3.6. Critical Analysis of Limitations and Methodological Contradictions in the Literature

4. Practical Implications for Industry and Policy Makers

4.1. Recommendations for Material Producers and Suppliers

4.2. Guidelines for Construction Companies and Professionals

4.3. Recommendations for Policy Makers and Regulatory Agencies

4.4. Economic Feasibility Considerations

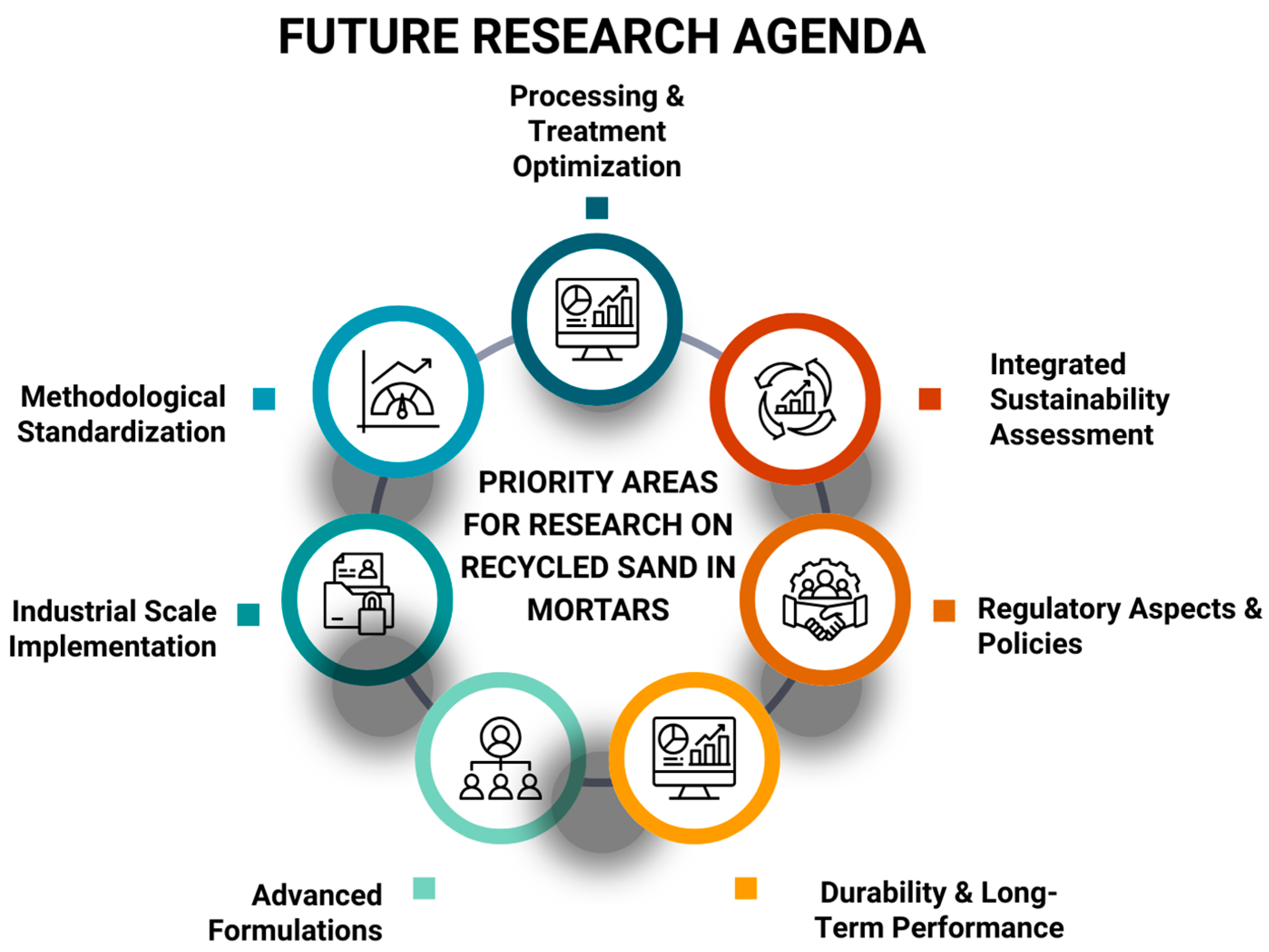

5. Future Research Directions

5.1. Priority Research Areas

5.2. Opportunities for Interdisciplinary Research

6. Summary and Conclusions

- High heterogeneity of CDW sources and compositions is the primary barrier to large-scale application of recycled sand in mortars, as variability in origin and mineralogy directly affects mechanical and durability outcomes.

- Lack of standardized methodologies for processing and testing recycled sand limits comparability across studies, preventing the consolidation of universally applicable guidelines.

- Optimal substitution ranges have been identified: up to 30–50% for cement-based mortars and up to 100% for geopolymer mortars, provided that advanced processing and treatment methods are applied.

- Technological solutions, including carbonation, polymeric coatings, and fiber reinforcement, show promise but require optimization to balance performance, cost, and environmental trade-offs.

- Environmental benefits are consistently observed across studies, with recycled sand contributing to resource conservation, waste reduction, and lower carbon footprint.

- Specific implications for stakeholders emerge from this synthesis, indicating that researchers should focus on harmonizing processing and testing protocols and expanding long-term durability studies; industry professionals can adopt partial replacement strategies supported by rigorous quality control to ensure reliable performance; and policymakers have a role to play in updating construction standards and promoting economic incentives that encourage the adoption of recycled aggregates.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ONU (United Nations). Global Status Report for Buildings and Construction: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector. United Nations Environment Programme 2020. Available online: https://wedocs.unep.org/20.500.11822/40507 (accessed on 2 May 2025).

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A Review of Recycled Aggregate in Concrete Applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste and Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Bonifazi, G.; Grosso, C.; Palmieri, R.; Serranti, S. Current trends and challenges in construction and demolition waste recycling. Curr. Opin. Green Sustain. Chem. 2025, 53, 101032. [Google Scholar] [CrossRef]

- Papamichael, I.; Voukkali, I.; Loizia, P.; Zorpas, A.A. Construction and demolition waste framework of circular economy: A mini review. Waste Manag. Res. 2023, 41, 1728–1740. [Google Scholar] [CrossRef]

- PNUMA (United Nations Environment Programme). Global Resources Outlook 2024: Challenges and Inequalities in the Use of Natural Resources. United Nations Environment Programme 2024. Available online: https://www.unep.org/pt-br/noticias-e-reportagens/comunicado-de-imprensa/paises-ricos-usam-seis-vezes-mais-recursos-naturais-e (accessed on 2 May 2025).

- Wu, J.; Ye, X.; Cui, H. Recycled Materials in Construction: Trends, Status, and Future of Research. Sustainability 2025, 17, 2636. [Google Scholar] [CrossRef]

- Boff, L. Sustainability: What It Is—What It Is Not; Editora Vozes: Petrópolis, Brazil, 2015. [Google Scholar]

- Alencar, L.H.; de Almeida, A.T.; Morais, D.C. A Multicriteria Group Decision Model Aggregating the Preferences of Decision-Makers Based on ELECTRE Methods. Pesqui. Oper. 2010, 30, 687–702. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. CONCRETop method: Optimization of concrete with various incorporation ratios of fly ash and recycled aggregates in terms of quality performance and life-cycle cost and environmental impacts. J. Clean. Prod. 2019, 226, 642–657. [Google Scholar] [CrossRef]

- Banias, G.F.; Karkanias, C.; Batsioula, M.; Melas, L.D.; Malamakis, A.E.; Geroliolios, D.; Skoutida, S.; Spiliotis, X. Environmental Assessment of Alternative Strategies for the Management of Construction and Demolition Waste: A Life Cycle Approach. Sustainability 2022, 14, 9674. [Google Scholar] [CrossRef]

- Trindade, E.L.G.d.; Lima, L.R.; Alencar, L.H.; Alencar, M.H. Identification of Obstacles to Implementing Sustainability in the Civil Construction Industry Using Bow-Tie Tool. Buildings 2020, 10, 165. [Google Scholar] [CrossRef]

- Barbosa Júnior, I.O.; Macêdo, A.N.; Martins, V.W.B. Construction Industry and Its Contributions to Achieving the SDGs Proposed by the UN: An Analysis of Sustainable Practices. Buildings 2023, 13, 1168. [Google Scholar] [CrossRef]

- Contreras, M.; Teixeira, S.R.; Lucas, M.C.; Lima, L.C.N.; Cardoso, D.S.L.; da Silva, G.A.C.; Gregório, G.C.; de Souza, A.E.; dos Santos, A. Recycling of construction and demolition waste for producing new construction material (Brazil case-study). Constr. Build. Mater. 2016, 123, 594–600. [Google Scholar] [CrossRef]

- Wang, L.; Chen, L.; Tsang, D.C.W.; Li, J.S.; Baek, K.; Poon, C.S.; Ding, S.; Hou, D. Recycling dredged sediment into fill materials, partition blocks, and paving blocks: Technical and economic assessment. J. Clean. Prod. 2018, 199, 69–76. [Google Scholar] [CrossRef]

- Joseph, H.S.; Pachiappan, T.; Avudaiappan, S.; Maureira-Carsalade, N.; Roco-Videla, Á.; Guindos, P.; Parra, P.F. A Comprehensive Review on Recycling of Construction Demolition Waste in Concrete. Sustainability 2023, 15, 4932. [Google Scholar] [CrossRef]

- PNUMA (United Nations Environment Programme). Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis; United Nations Environment Programme: Nairobi, Kenya, 2022; Available online: https://www.unep.org/pt-br/noticias-e-reportagens/comunicado-de-imprensa/nosso-uso-da-areia-esta-nos-colocando-contra-parede (accessed on 2 May 2025).

- Khater, D. Rethinking sand as earth material for a sustainable construction in Egypt. Front. Built Environ. 2025, 11, 1566515. [Google Scholar] [CrossRef]

- Bader, N.; Al-Jabri, K. Utilization of Recycled Sand from Excavation Waste for Sustainable Cement Mortar Production. Civ. Eng. J. 2024, 10, 1909–1921. [Google Scholar] [CrossRef]

- Jiang, H.; Wu, L.; Guan, L.; Liu, M.; Ju, X.; Xiang, Z.; Jiang, X.; Li, Y.; Long, J. Durability life evaluation of marine infrastructures built by using carbonated recycled coarse aggregate concrete due to the chloride corrosive environment. Front. Mar. Sci. 2024, 11, 1357186. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Durability performance of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2010, 32, 9–14. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. Br. Med. J. 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Wang, C.; Ding, T.; Akbarnezhad, A. A recycled aggregate concrete high-rise building: Structural performance and embodied carbon footprint. J. Clean. Prod. 2018, 199, 868–881. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Mandal, A.; Gupta, R. Exploring Mechanical Characteristics of Recycled Concrete Aggregates: A Comprehensive Review. J. Build. Mater. Struct. 2025, 12, 185. [Google Scholar] [CrossRef]

- Ning, Y.; Lv, X. Effect of Recycled Fine Aggregate on Properties of Mortar. Ceram. -Silik. 2023, 67, 468–476. [Google Scholar] [CrossRef]

- Rohit, P.R.; Guneswara Rao, T.D.; Chandrasekhar, M. Effect of Construction Demolition Waste as Fine Aggregate and NaOH Molarity on Strength and Fracture Parameters of Slag-Based Geopolymer Mortars. J. Eng. Appl. Sci. 2024, 71, 37. [Google Scholar] [CrossRef]

- Liu, S.; Liu, Z.; Takasu, K.; Koyamada, H.; Sugama, H. Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GBBS-Based Geopolymer Mortar. Materials 2023, 16, 7289. [Google Scholar] [CrossRef] [PubMed]

- Abouwda, E.; El-Hassan, H.; El-Maadawy, T. Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates. Sustainability 2023, 16, 8147. [Google Scholar] [CrossRef]

- Kruger, P.; Serpai, P.; Chinelatto, A.S.A.; Pereira, E.T. Influence of Particle Size Distribution of Conventional Fine Aggregate and Construction Demolition Waste Aggregate in Portland Cement Mortar. Cerâmica 2021, 67, 269–276. [Google Scholar] [CrossRef]

- Grabois, T.M.; Caldas, L.R.; Julião, M.R.; Filho, R.D.T. An Experimental and Environmental Evaluation of Mortars with Recycled Demolition Waste from a Hospital Implosion in Rio de Janeiro. Sustainability 2020, 12, 8945. [Google Scholar] [CrossRef]

- Martínez-García, R.; de Rojas, M.I.S.; Pozo, J.M.M.; Fraile-Fernández, F.J.; Juan-Valdés, A. Evaluation of Mechanical Characteristics of Cement Mortar with Fine Recycled Concrete Aggregates (FRCA). Sustainability 2021, 13, 414. [Google Scholar] [CrossRef]

- Galderisi, A.; Bravo, M.; Iezzi, G.; Cruciani, G.; Paris, E.; de Brito, J. Physico-Mechanical Performances of Mortars Prepared with Sorted Earthquake Rubble: The Role of CDW Type and Contained Crystalline Phases. Materials 2023, 16, 2855. [Google Scholar] [CrossRef]

- Manzi, S.; Baldazzi, L.; Saccani, A. Formulating Geopolymer Mortars through Construction and Demolition Waste (CDW) Recycling: A Comprehensive Case Study. Materials 2023, 16, 7304. [Google Scholar] [CrossRef]

- Fernández, D.; Zaragoza-Beneal, A.; Pastor Lamberto, R.; Santos, P.; Michalak, J. Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers. Appl. Sci. 2024, 14, 6226. [Google Scholar] [CrossRef]

- Grigorjevi, V.; Azenha, M.; de Belie, N. Towards Sustainable Masonry Construction through Natural Aggregate Replacement by Fine Recycled Aggregates in Cement–Lime Mortars. Sustainability 2025, 17, 1269. [Google Scholar] [CrossRef]

- Sodaliti, L.; Bacciocchi, M.; Tarantino, A.M. Mechanical Characterization of Sustainable Mortars with Recycled Aggregates from Construction and Demolition Wastes: An Experimental Investigation. Materials 2024, 17, 5409. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Jia, Z.; Li, N.; Luo, H. Impact of Recycled Fine Aggregate on Physical and Mechanical Properties of Green Mortar. Materials 2025, 18, 696. [Google Scholar] [CrossRef]

- Mahmood, A.; Nanos, N.; Begg, D. An Evaluation of the Strength for Recycled Fine Aggregate Replacement in Cementitious Mortars. Buildings 2024, 14, 470. [Google Scholar] [CrossRef]

- Vo, D.-H.; Hwang, C.-L.; Tran Thi, K.-D.; Liao, M.-C.; Yehualaw, M.D. Engineering performance of high-content MgO-Alkali-activated slag mortar incorporating fine recycled concrete aggregate and fly ash. J. Mater. Cycles Waste Manag. 2021, 23, 778–789. [Google Scholar] [CrossRef]

- Zhu, P.; Hua, M.; Liu, H.; Wang, X.; Chen, C. Interfacial evaluation of geopolymer mortar prepared with recycled geopolymer fine aggregates. Constr. Build. Mater. 2020, 259, 119849. [Google Scholar] [CrossRef]

- Hwalla, J.; El-Hassan, H.; Assaad, J.J.; El-Maaddawy, T. Fiber-reinforced geopolymers made with recycled aggregates for screed flooring and repair applications. Clean. Mater. 2025, 15, 100293. [Google Scholar] [CrossRef]

- Li, Z.; Liu, J.; Xiao, J.; Zhong, P. Internal curing effect of saturated recycled fine aggregates in early-age mortar. Cem. Concr. Compos. 2020, 108, 103444. [Google Scholar] [CrossRef]

- Kaplan, G.; Turkoglu, M.; Bodur, B.; Bayraktar, O.Y. Usage of recycled fine aggregates obtained from concretes with low w/c ratio in the production of masonry plaster and mortar. Environ. Dev. Sustain. 2022, 24, 2685–2714. [Google Scholar] [CrossRef]

- Deng, Q.; Zhuang, Y.; Nasr, A.; Liu, H.; Duan, Z. Assessing the effect of particle characteristics on the rheological properties of mortar with recycled fine aggregate. J. Build. Eng. 2025, 107, 112673. [Google Scholar] [CrossRef]

- Liu, Q.; Tang, H.; Chen, K.; Peng, B.; Sun, C.; Singh, A.; Li, J. Utilizing CO2 to improve plastic shrinkage and mechanical properties of 3D printed mortar made with recycled fine aggregates. Constr. Build. Mater. 2024, 433, 136546. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.M.; Martín-Pascual, J.; Martín-Morales, M.; Valverde-Palacios, I.; Zamorano, M. Effects of water to cement ratio, recycled fine aggregate and air entraining/plasticizer admixture on masonry mortar properties. Constr. Build. Mater. 2020, 230, 116929. [Google Scholar] [CrossRef]

- Borges, P.M.; Rother, L.A.; da Silva, S.R.; Possan, E.; Andrade, J.J.D.O. Environmental and technical assessment of mortars produced with recycled aggregate from construction and demolition waste. Constr. Build. Mater. 2025, 467, 140407. [Google Scholar] [CrossRef]

- Ilcan, H.; Sahin, O.; Kul, A.; Yildirim, G.; Sahmaran, M. Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing. Constr. Build. Mater. 2022, 328, 127114. [Google Scholar] [CrossRef]

- Ferrández, D.; Álvarez, M.; Saiz, P.; Zaragoza, A. Experimental Study with Plaster Mortars Made with Recycled Aggregate and Thermal Insulation Residues for Application in Building. Sustainability 2022, 14, 2386. [Google Scholar] [CrossRef]

- Ledesma, E.F.; Jiménez, J.R.; Ayuso, J.; Fernández, J.M.; de Brito, J. Maximum feasible use of recycled sand from construction and demolition waste for eco-mortar production—Part-I: Ceramic masonry waste. J. Clean. Prod. 2015, 87, 692–706. [Google Scholar] [CrossRef]

- Hubert, J.; Zhao, Z.; Michel, F.; Courard, L. Effect of Washing Process on the Performance of Coarse and Fine Recycled Aggregates. J. Miner. Mater. Charact. Eng. 2025, 13, 156–169. [Google Scholar] [CrossRef]

- Neno, C.; Brito, J.; Veiga, R. Using Fine Recycled Concrete Aggregate for Mortar Production. Mater. Res. 2014, 17, 168–177. [Google Scholar] [CrossRef]

- Cuenca-Moyano, G.; García-Alcántara, A.; De Brito, J. Influence of pre-soaked recycled fine aggregate on the properties of masonry mortar. Constr. Build. Mater. 2014, 68, 127–134. [Google Scholar] [CrossRef]

- Kępniak, M.; Kępniak, M.; Zawisza, M. Multicriteria Analysis of Cement Mortar with Recycled Sand. Sustainability 2024, 16, 1773. [Google Scholar] [CrossRef]

- Kilumile, M.; Veiga, R. Use of Recycled Aggregates in Lime Mortars for the Restoration of Historic Buildings. Heritage 2025, 5, 28. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, J. Editorial: Sustainable Building Materials from Recycled Waste: Current Status and Future Perspectives. Front. Built Environ. 2025, 11, 1573450. [Google Scholar] [CrossRef]

- Venugopal Reddy, P.; Nakkeeran, G.; Roy, D.; Alaneme, G.U. Evaluating the use of recycled fine aggregates in 3D printing: A systematic review. Discov. Appl. Sci. 2024, 6, 630. [Google Scholar] [CrossRef]

- D’Orazio, M.; Di Giuseppe, E.; Carosi, M. Life Cycle Assessment of Mortars with Fine Recycled Aggregates from Industrial Waste: Evaluation of Transports Impact in the Italian Context. Sustainability 2023, 15, 3221. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Mechanical performance of concrete made with aggregates from construction and demolition waste recycling plants. J. Clean. Prod. 2015, 99, 59–74. [Google Scholar] [CrossRef]

- Marinković, S.; Josa, I.; Braymand, S.; Delibasic, N.; Ilić, B.; Ignjatović, I.; Dragaš, J.; Ignjatović, D.; Tošić, N. Sustainability assessment of recycled aggregate concrete structures: A critical view on the current state-of-knowledge and practice. Struct. Concr. 2023, 24, 1956–1979. [Google Scholar] [CrossRef]

- Pitarch, Á.M.; Reig, L.; Tomás, A. Reuse of Recycled CDW Sand in Mortars, Paving Blocks and Precast Elements: Technical and Environmental Assessment. Appl. Sci. 2025, 15, 3652. [Google Scholar] [CrossRef]

- Olaiya, B.C.; Akinwumi, I.I.; Olofinnade, O.M. Development of Sustainable Sand Concrete Bricks Using Recycled Concrete Aggregates and Agricultural Waste Ashes. Sci. Rep. 2025, 15, 17202. [Google Scholar] [CrossRef]

- Gupta, S.; Kua, H.W.; Pang, S.D. Autonomous healing in concrete by bio-based healing agents—A review. Constr. Build. Mater. 2018, 146, 419–428. [Google Scholar] [CrossRef]

| Criterion | Details | Type |

|---|---|---|

| Publication period | 2020–2025 | Inclusion |

| Language | English | Inclusion |

| Document type | Full articles | Inclusion |

| Material studied | Mortars with substitution of natural sand by recycled sand from CDW | Inclusion |

| Concrete studies not addressing mortar separately | Excluded | Exclusion |

| Articles without PDF available | Excluded | Exclusion |

| Literature reviews | Excluded | Exclusion |

| Duplicates | Excluded | Exclusion |

| Out-of-scope articles (not about recycled sand from CDW in mortar) | Excluded | Exclusion |

| Nº | Author | Documents | Citations | Total Link Strength | Average Citation/Publication |

|---|---|---|---|---|---|

| 1 | Xiao, jianzhuang | 42 | 1951 | 3721 | 46.45- |

| 2 | Duan, zhenhua | 21 | 1288 | 2851 | 61.33- |

| 3 | Ma, zhiming | 14 | 794 | 1726 | 56.71- |

| 4 | Singh, amardeep | 12 | 720 | 1562 | 60.00 |

| 5 | Madina, c | 5 | 189 | 1490 | 37.80 |

| 6 | Sáez del bosque, i.f. | 4 | 82 | 1490 | 20.50 |

| 7 | Sánchez de rojas, m.i. | 5 | 98 | 1454 | 19.60 |

| 8 | Hou, shaodan | 8 | 714 | 1450 | 89.25 |

| 9 | Del angel-meraz, ebelia | 3 | 33 | 1426 | 11.00 |

| 10 | Díaz, sergio alberto | 3 | 33 | 1426 | 11.00 |

| 11 | Magaña-hernández, Francisco | 3 | 33 | 1426 | 11.00 |

| 12 | Mora-ortiz, rené sebastián | 3 | 33 | 1426 | 11.00 |

| 13 | Wu, huixia | 11 | 712 | 1362 | 64.73 |

| 14 | Wang, changqing | 7 | 336 | 1247 | 48.00 |

| 15 | Zou, shuai | 7 | 472 | 1229 | 67.43 |

| 16 | Li, long | 4 | 167 | 1142 | 41.75 |

| 17 | Deng, qi | 5 | 79 | 1086 | 15.80 |

| 18 | Liu, qiong | 8 | 316 | 1011 | 39.50 |

| 19 | De brito, Jorge | 13 | 263 | 451 | 20.23- |

| 20 | Mukherjee, abhijit | 3 | 36 | 296 | 12.00 |

| Nº | Source Title | Frequency |

|---|---|---|

| 1 | Construction and Building Materials | 117 |

| 2 | Structural Concrete | 68 |

| 3 | Journal of Building Engineering | 50 |

| 4 | Materials | 40 |

| 5 | Sustainability | 24 |

| 6 | Journal of Cleaner Production | 23 |

| 7 | Advances in Civil Engineering | 19 |

| 8 | Case Studies in Construction Materials | 19 |

| 9 | Advances in Materials Science and Engineering | 18 |

| 10 | Cement and Concrete Composites | 17 |

| 11 | Buildings | 15 |

| 12 | Journal of Materials in Civil Engineering | 14 |

| 13 | Applied Sciences | 13 |

| 14 | Bulletin of the Chinese Ceramic Society | 9 |

| 15 | Cleaner Materials | 7 |

| 16 | Infrastructures | 6 |

| 17 | Journal of Material Cycles and Waste Management | 6 |

| 18 | Journal of Materials Research and Technology | 6 |

| 19 | Chemie Ingenieur Technik | 5 |

| 20 | Heliyon | 5 |

| Nº | Term | Occurrences | Relevance |

|---|---|---|---|

| 1 | Concrete | 834 | 0.35 |

| 2 | Construction | 671 | 0.34 |

| 3 | Demolition Waste | 485 | 0.39 |

| 4 | CDW | 383 | 1.01 |

| 5 | Cement | 378 | 0.41 |

| 6 | RFA | 377 | 1.79 |

| 7 | RCA | 370 | 1.51 |

| 8 | Waste | 367 | 0.43 |

| 9 | Mixture | 316 | 0.40 |

| 10 | Powder | 278 | 1.40 |

| 11 | Increase | 255 | 0.43 |

| 12 | Recycled Fine Aggregate | 235 | 1.86 |

| 13 | Recycled Sand | 232 | 0.76 |

| 14 | Model | 224 | 1.01 |

| 15 | Aggregate Concrete | 213 | 2.60 |

| 16 | RAC | 203 | 3.48 |

| 17 | Behavior | 201 | 0.44 |

| 18 | Fine Aggregate | 185 | 0.50 |

| 19 | Treatment | 178 | 0.63 |

| 20 | Approach | 164 | 0.52 |

| 21 | Shrinkage | 160 | 1.77 |

| 22 | Natural Aggregate | 160 | 0.50 |

| 23 | Specimen | 159 | 0.42 |

| 24 | Brick | 156 | 0.44 |

| 25 | Recycled Concrete Aggregate | 145 | 0.81 |

| Title | Reference | Year | Citations | Purpose |

|---|---|---|---|---|

| Effect of Recycled Fine Aggregate on Properties of Mortar | [26] | 2023 | 0 | Evaluate the effect of different replacement rates of natural sand with RFA on the mechanical properties, durability, and microstructure of mortar. |

| Effect of Construction Demolition Waste as Fine Aggregate and NaOH Molarity on Strength and Fracture Parameters of Slag-Based Geopolymer Mortars | [27] | 2024 | 7 | Investigate the influence of NaOH molarity and RFA content from CDW on the mechanical and fracture properties of slag-based geopolymer mortar. |

| Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GBBS-Based Geopolymer Mortar | [28] | 2023 | 5 | Assess the effect of RFA quality and preprocessing on the fresh, mechanical, and shrinkage properties of FA/GGBS-based geopolymer mortar. |

| Characterization of Geopolymer Masonry Mortars Incorporating Recycled Fine Aggregates | [29] | 2024 | 2 | Evaluate the fresh, mechanical, physical, and durability properties of slag–fly ash geopolymer masonry mortars with up to 100% RFA. |

| Influence of Particle Size Distribution of Conventional Fine Aggregate and Construction Demolition Waste Aggregate in Portland Cement Mortar | [30] | 2021 | 8 | Compare the influence of particle size distribution of natural and CDW-derived fine aggregates on the physical and mechanical properties of mortars. |

| An Experimental and Environmental Evaluation of Mortars with Recycled Demolition Waste from a Hospital Implosion in Rio de Janeiro | [31] | 2020 | 10 | Assess the mechanical, rheological, and environmental performance of mortars with micrometer-scale recycled concrete aggregates from building demolition. |

| Evaluation of Mechanical Characteristics of Cement Mortar with Fine Recycled Concrete Aggregates (FRCA) | [32] | 2021 | 28 | Evaluate the optimal replacement level of natural fine aggregates with fine recycled concrete aggregates (FRCA) from urban C&DW in cement mortars. |

| Physico-Mechanical Performances of Mortars Prepared with Sorted Earthquake Rubble: The Role of CDW Type and Contained Crystalline Phases | [33] | 2023 | 7 | Evaluate how different types of recycled aggregates from earthquake CDW affect the mechanical performance of mortars, and the benefits of sorting RA by material type. |

| Formulating Geopolymer Mortars through Construction and Demolition Waste (CDW) Recycling: A Comprehensive Case Study | [34] | 2023 | 4 | Investigate the effects of recycled concrete aggregates on alkali-activated metakaolin mortars and their environmental potential as a low-impact building material. |

| Optimizing Masonry Mortar: Experimental Insights into Physico-Mechanical Properties Using Recycled Aggregates and Natural Fibers | [35] | 2024 | 5 | Analyze the physico-mechanical properties of cement mortars made with recycled concrete aggregates (RCA) and reinforced with natural fibers for sustainable construction. |

| Towards Sustainable Masonry Construction through Natural Aggregate Replacement by Fine Recycled Aggregates in Cement–Lime Mortars | [36] | 2025 | 1 | To evaluate the performance of mortars with natural sand replaced by fine recycled fractions from concrete and mixed waste. |

| Mechanical Characterization of Sustainable Mortars with Recycled Aggregates from Construction and Demolition Wastes: An Experimental Investigation | [37] | 2024 | 0 | Mechanically characterize sustainable mortars with partial or total replacement of natural sand by recycled sand from construction and demolition waste. |

| Impact of Recycled Fine Aggregate on Physical and Mechanical Properties of Green Mortar | [38] | 2025 | 1 | Evaluate the physical and mechanical properties of mortars with partial or total replacement of natural sand by recycled fine aggregate (RFA). |

| An Evaluation of the Strength for Recycled Fine Aggregate Replacement in Cementitious Mortars | [39] | 2024 | 0 | Evaluate the feasibility of recycled concrete aggregate (RCA) as a partial replacement for natural fine aggregates in mortars. |

| Engineering performance of high-content MgO-Alkali-activated slag mortar incorporating fine recycled concrete aggregate and fly ash | [40] | 2021 | 14 | To evaluate effects of fine recycled sand and fly ash in alkali-activated mortars. |

| Interfacial evaluation of geopolymer mortar prepared with recycled geopolymer fine aggregates | [41] | 2020 | 61 | To investigate feasibility and interfacial behavior of recycled geopolymer sand replacing natural river sand. |

| Fiber-reinforced geopolymers made with recycled aggregates for screed flooring and repair applications | [42] | 2025 | 1 | To evaluate fiber-reinforced geopolymer composites with recycled sand for flooring and repair applications. |

| Internal curing effect of saturated recycled fine aggregates in early-age mortar | [43] | 2020 | 74 | To investigate internal curing effects of saturated recycled sand on early-age mortar shrinkage. |

| Usage of recycled fine aggregates obtained from concretes with low w/c ratio in the production of masonry plaster and mortar | [44] | 2022 | 6 | To evaluate recycled sand from low w/c concretes for producing masonry plaster and mortar. |

| Assessing the effect of particle characteristics on the rheological properties of mortar with recycled fine aggregate | [45] | 2025 | 1 | To analyze influence of recycled sand particle characteristics on rheological properties of mortar mixtures. |

| Utilizing CO2 to improve plastic shrinkage and mechanical properties of 3D printed mortar made with recycled fine aggregates | [46] | 2024 | 5 | To investigate CO2 treatments improving shrinkage and mechanical properties of 3D-printed mortar with recycled sand. |

| Effects of water to cement ratio, recycled fine aggregate and air entraining/plasticizer admixture on masonry mortar properties | [47] | 2020 | 56 | To evaluate effects of w/c ratio, recycled sand, and admixtures on masonry mortar properties. |

| Environmental and technical assessment of mortars produced with recycled aggregate from construction and demolition waste | [48] | 2025 | 1 | To assess environmental and technical performance of mortars with recycled fine aggregates from CDW. |

| Rheological properties and compressive strength of construction and demolition waste-based geopolymer mortars for 3D-Printing | [49] | 2022 | 91 | To develop CDW-based geopolymer mortars with suitable rheology and strength for 3D-printing applications. |

| Reference | Processing Method | Affected Properties | Observed Effects |

|---|---|---|---|

| [30] | Crushing + Screening | Granulometry, density, absorption | Lower performance than crushed natural sand; particle size and mineralogical composition strongly affect mortar properties |

| [39] | Crushing + Screening (RCA) | Particle size, impurity removal | Up to 50% replacement maintains resistance close to natural; above that, significant performance drop |

| [50] | Crusher type (jaw, impact, cone) | Morphology and surface texture | Direct influence on workability and mechanical properties, via rheological behavior |

| [32] | Washing + Sieving | Absorption, particle size | Reduced absorption and better particle size distribution; performance similar to natural sand in partial replacements |

| [33] | Mineralogical classification of RCD (concrete, natural stone, ceramic, tiles) | Heterogeneity, porosity | Concrete/stone-rich RCD outperforms ceramic materials; mineralogical characterization is crucial |

| [51] | Contaminant control (gypsum, clay, organic matter) | Durability, resistance | The presence of contaminants impairs the properties of the mortar; quality control is essential |

| Factor | Description | Impact on Economic Feasibility |

|---|---|---|

| Cost of recycled sand production | Includes collection, transportation, processing, quality control, distribution | Higher production costs can reduce competitiveness if not offset by other factors |

| Price of natural sand | Local market price of natural sand | Higher natural sand prices improve competitiveness of recycled sand |

| Landfill taxes/disposal costs | Costs for disposing of construction waste | Higher taxes favor adoption of recycled materials |

| Market demand for sustainable materials | Interest from construction companies, public projects, and certifications | Higher demand increases economic attractiveness |

| Economies of scale | Size and efficiency of production facilities | Larger operations reduce unit costs, improving feasibility |

| Regional conditions | Labor costs, transport distances, infrastructure | Affects overall costs and competitiveness in different regions |

| Regulatory incentives | Tax benefits, mandates, or procurement policies | Incentives can make recycled sand more cost-effective |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sampaio, T.R.d.S.; Pierott, R.; Stolz, C.M.; Amario, M.; Haddad, A.N. Emerging Trends in the Use of Recycled Sand in Mortar: A Systematic Review. Buildings 2025, 15, 3841. https://doi.org/10.3390/buildings15213841

Sampaio TRdS, Pierott R, Stolz CM, Amario M, Haddad AN. Emerging Trends in the Use of Recycled Sand in Mortar: A Systematic Review. Buildings. 2025; 15(21):3841. https://doi.org/10.3390/buildings15213841

Chicago/Turabian StyleSampaio, Thaís Renata de S., Rodrigo Pierott, Carina Mariane Stolz, Mayara Amario, and Assed N. Haddad. 2025. "Emerging Trends in the Use of Recycled Sand in Mortar: A Systematic Review" Buildings 15, no. 21: 3841. https://doi.org/10.3390/buildings15213841

APA StyleSampaio, T. R. d. S., Pierott, R., Stolz, C. M., Amario, M., & Haddad, A. N. (2025). Emerging Trends in the Use of Recycled Sand in Mortar: A Systematic Review. Buildings, 15(21), 3841. https://doi.org/10.3390/buildings15213841