Research on Optimization of Grouting Parameters for the CRD Method in Tunnels in Upper-Soft and Lower-Hard Composite Strata Based on Finite Element Method

Abstract

1. Introduction

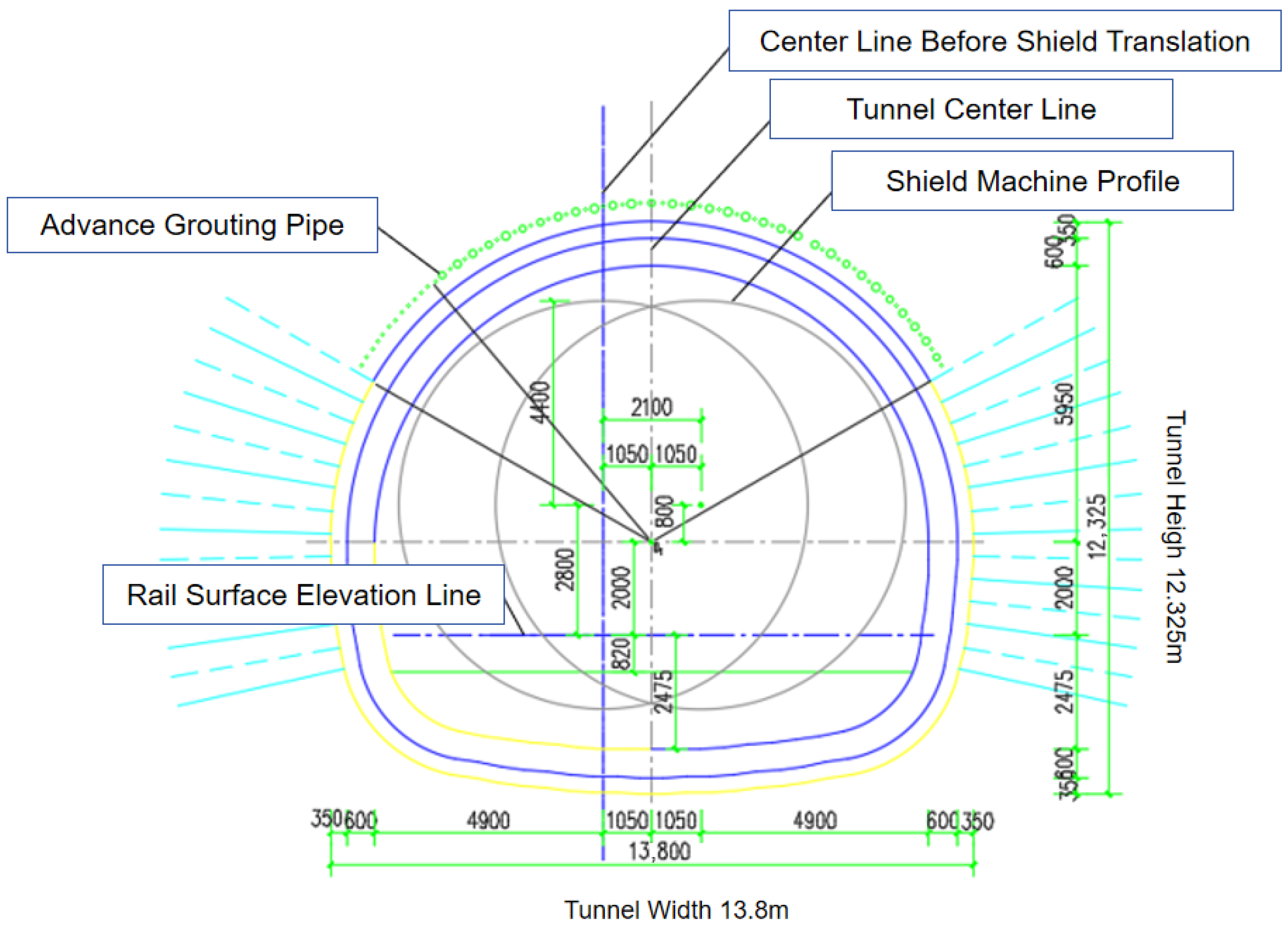

2. Project Overview

3. Establishment of the Numerical Model

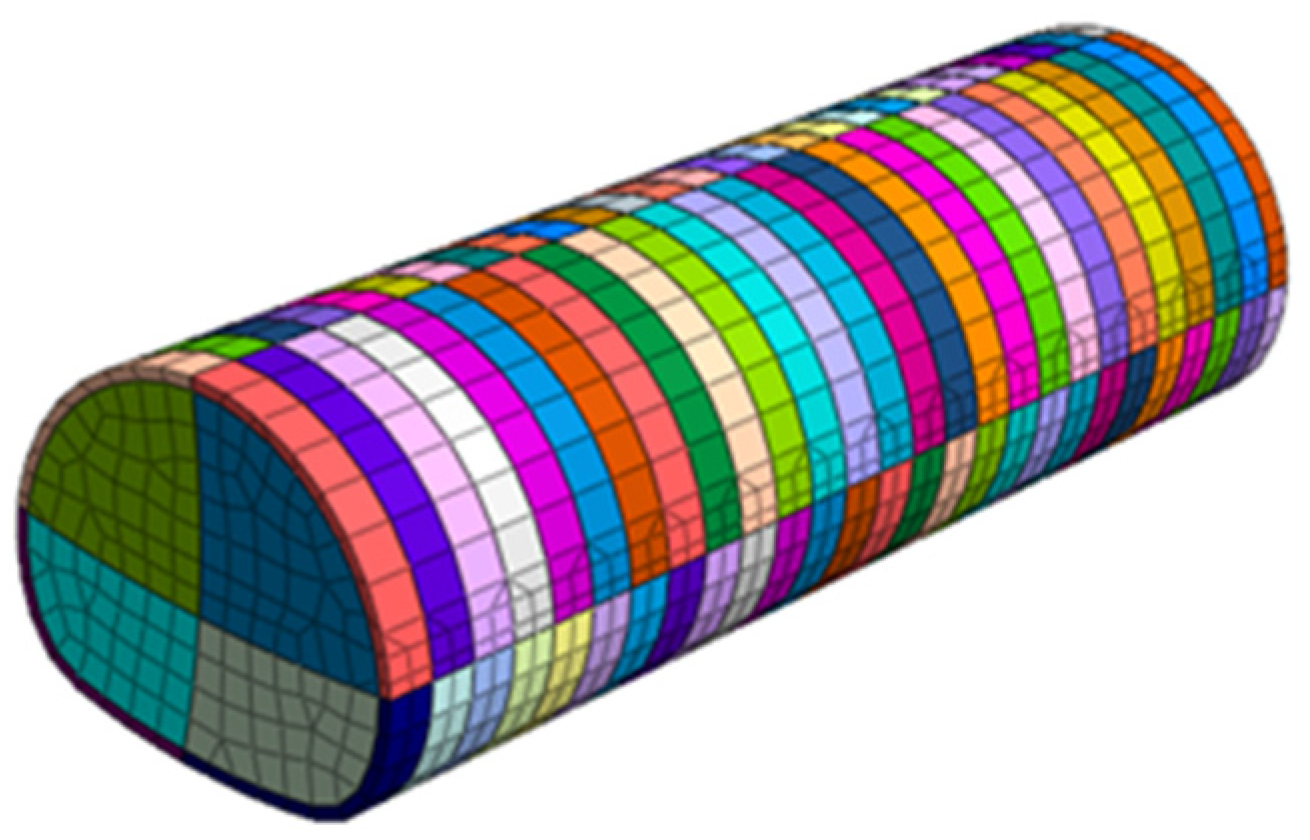

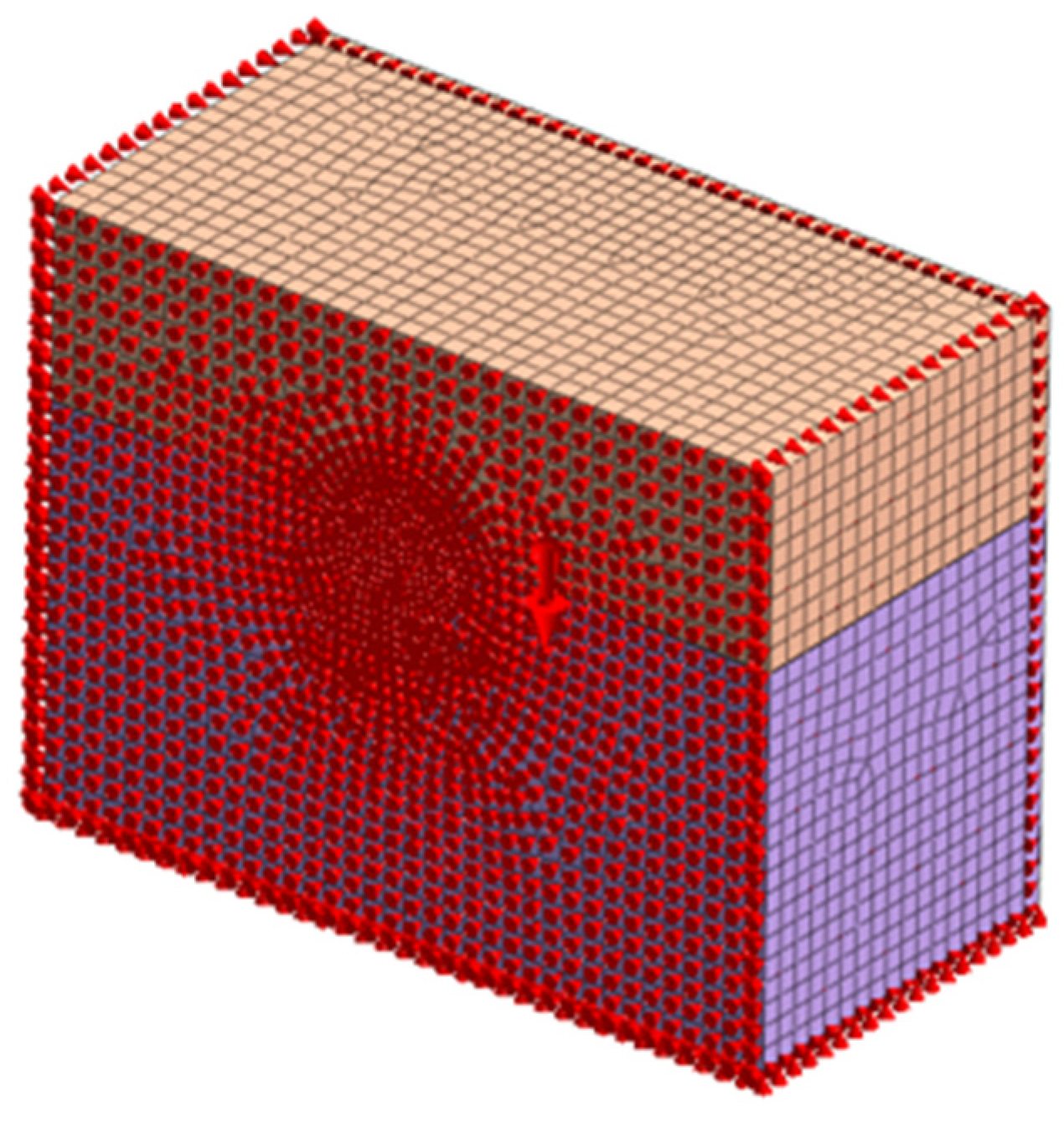

3.1. Numerical Model Construction and Material Properties

3.2. Boundary Conditions

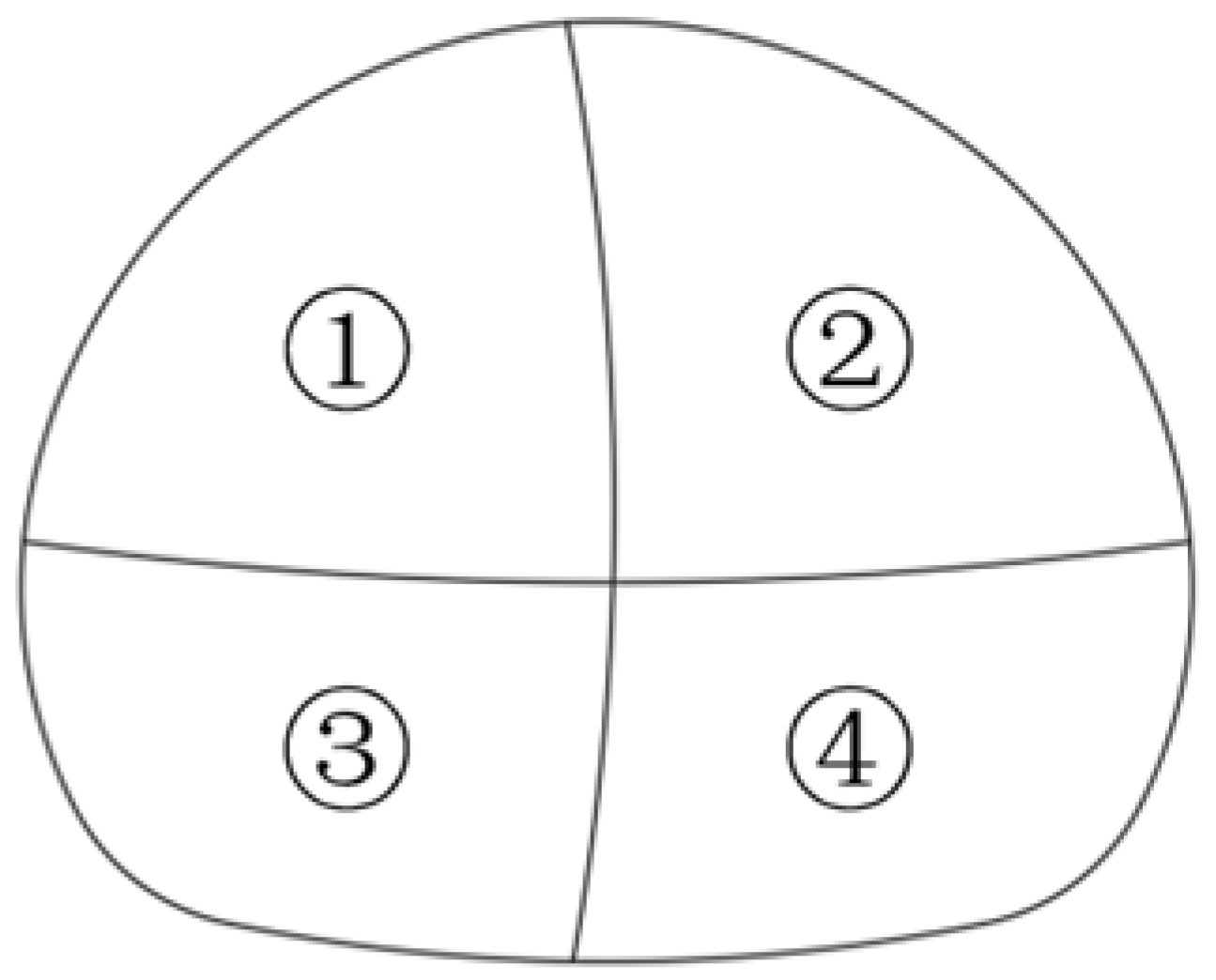

3.3. Setting of Construction Stages and Analysis Conditions

4. Analysis of Simulation Results

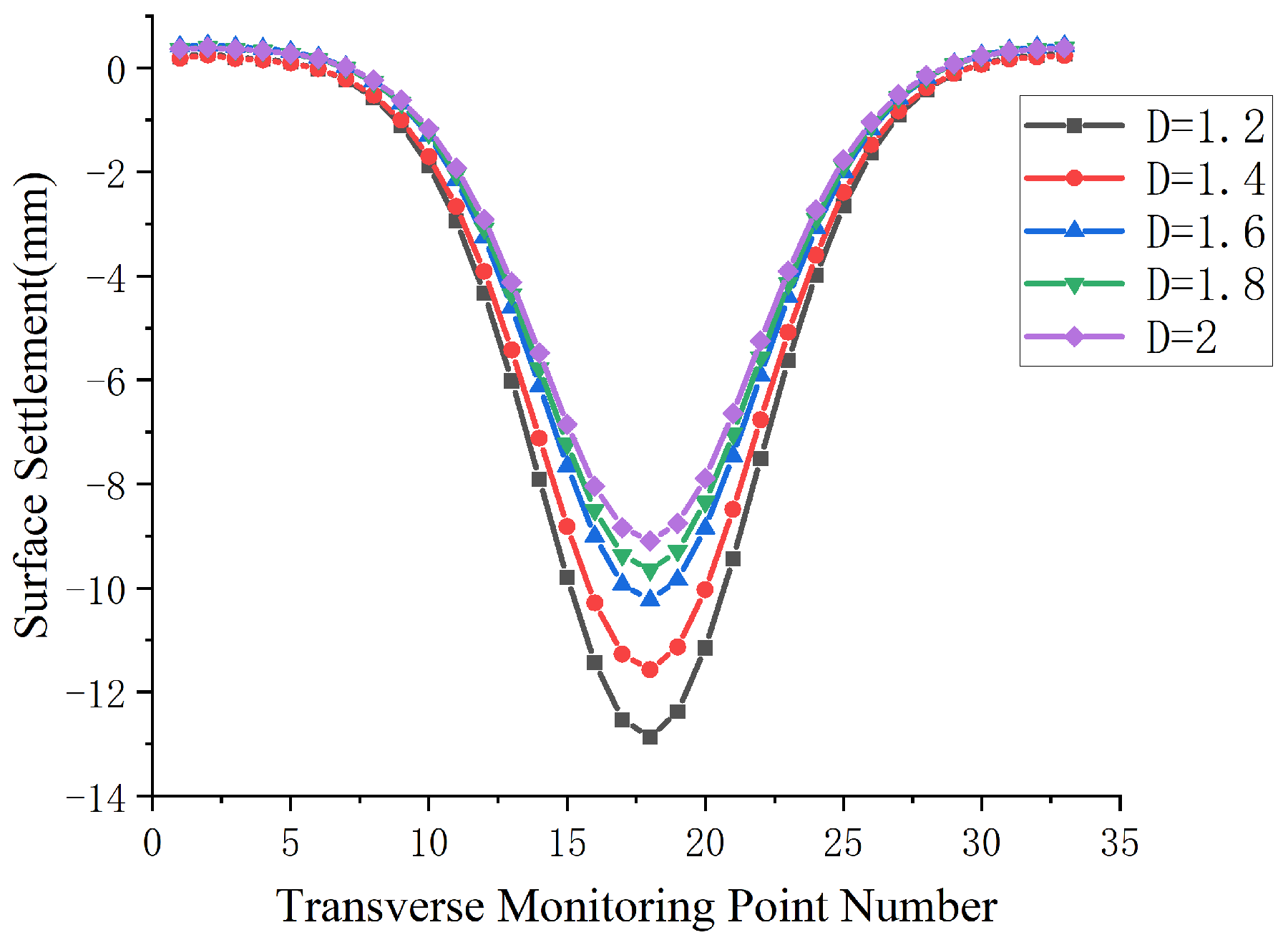

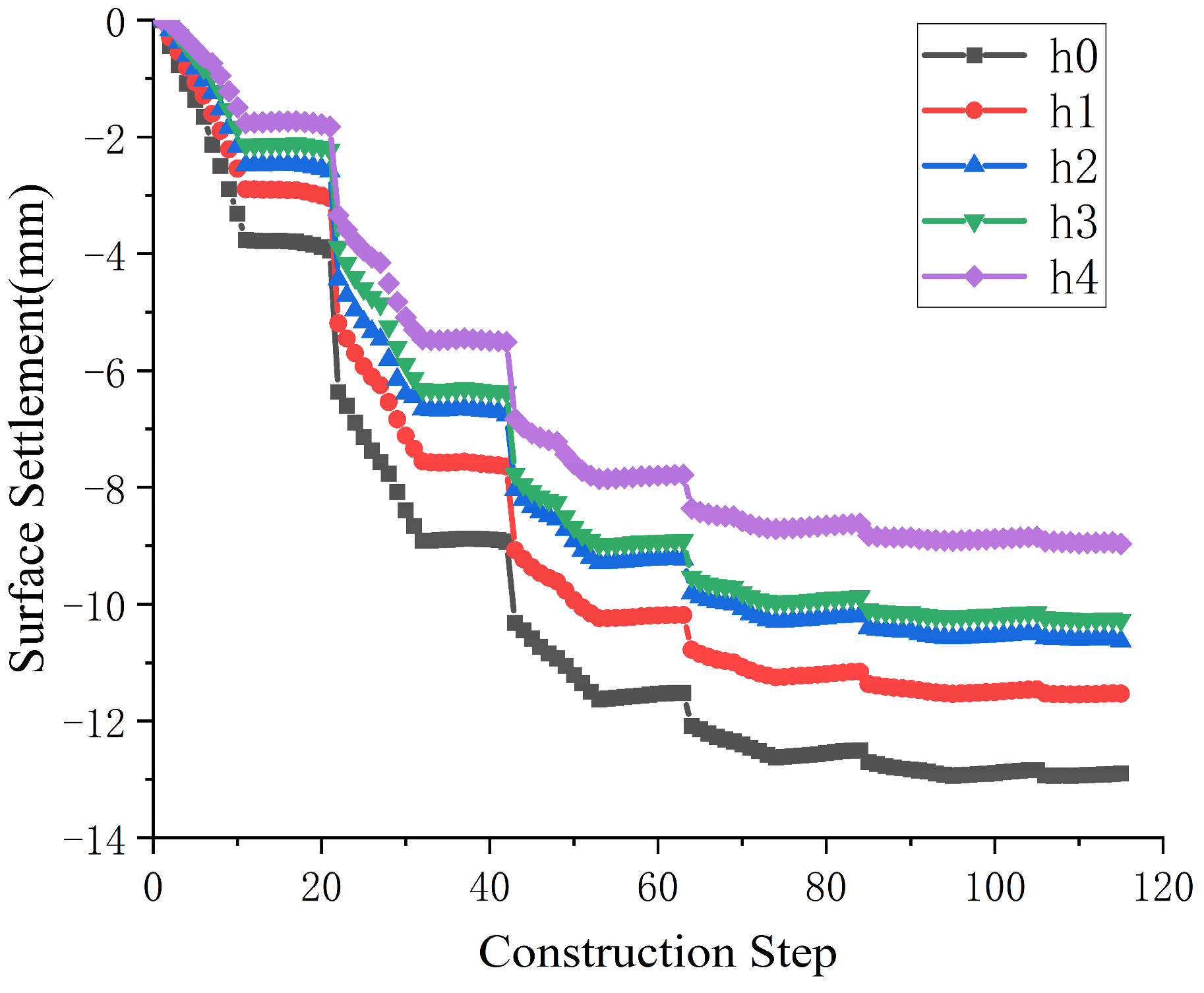

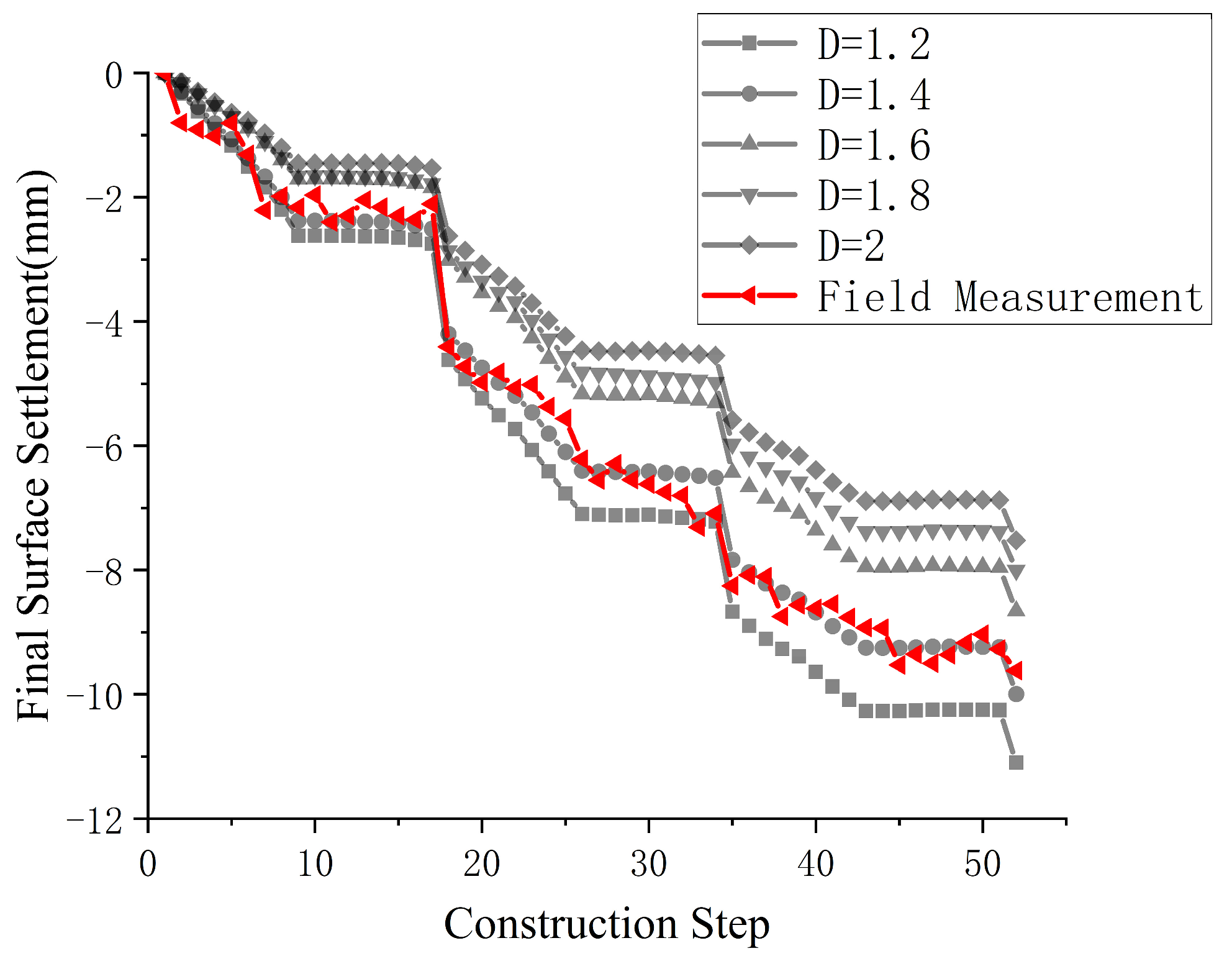

4.1. Analysis of Surface Settlement

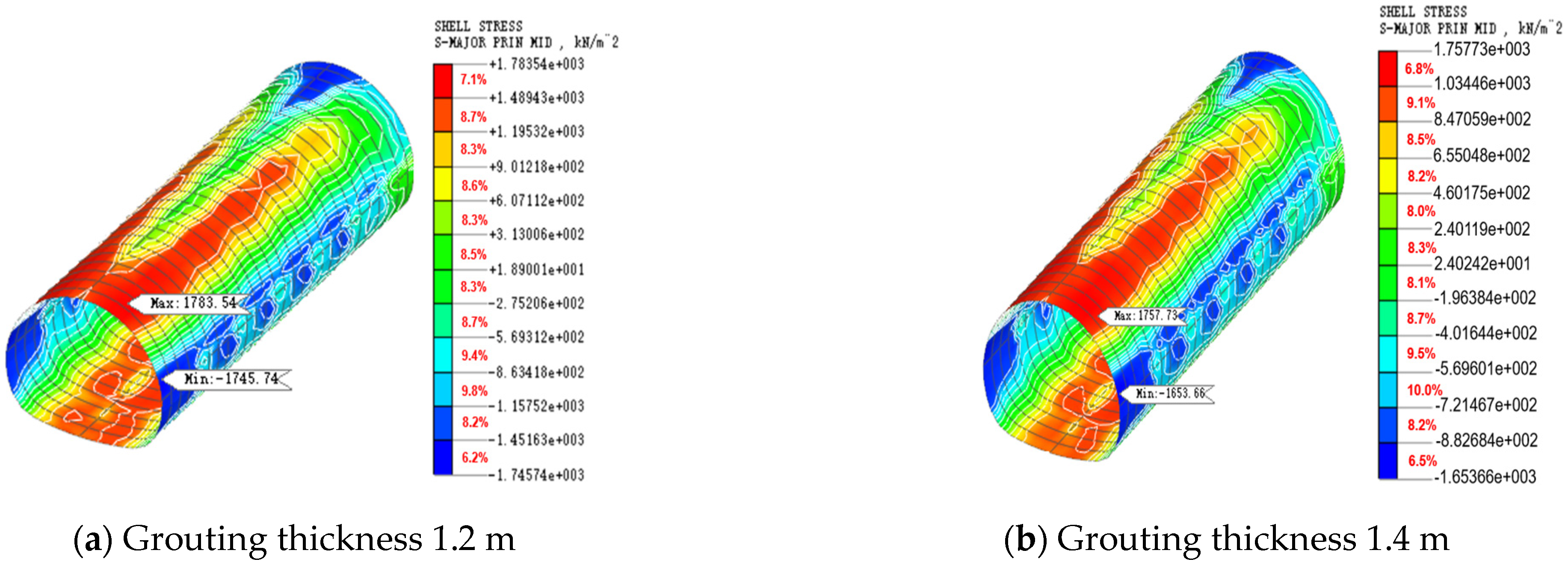

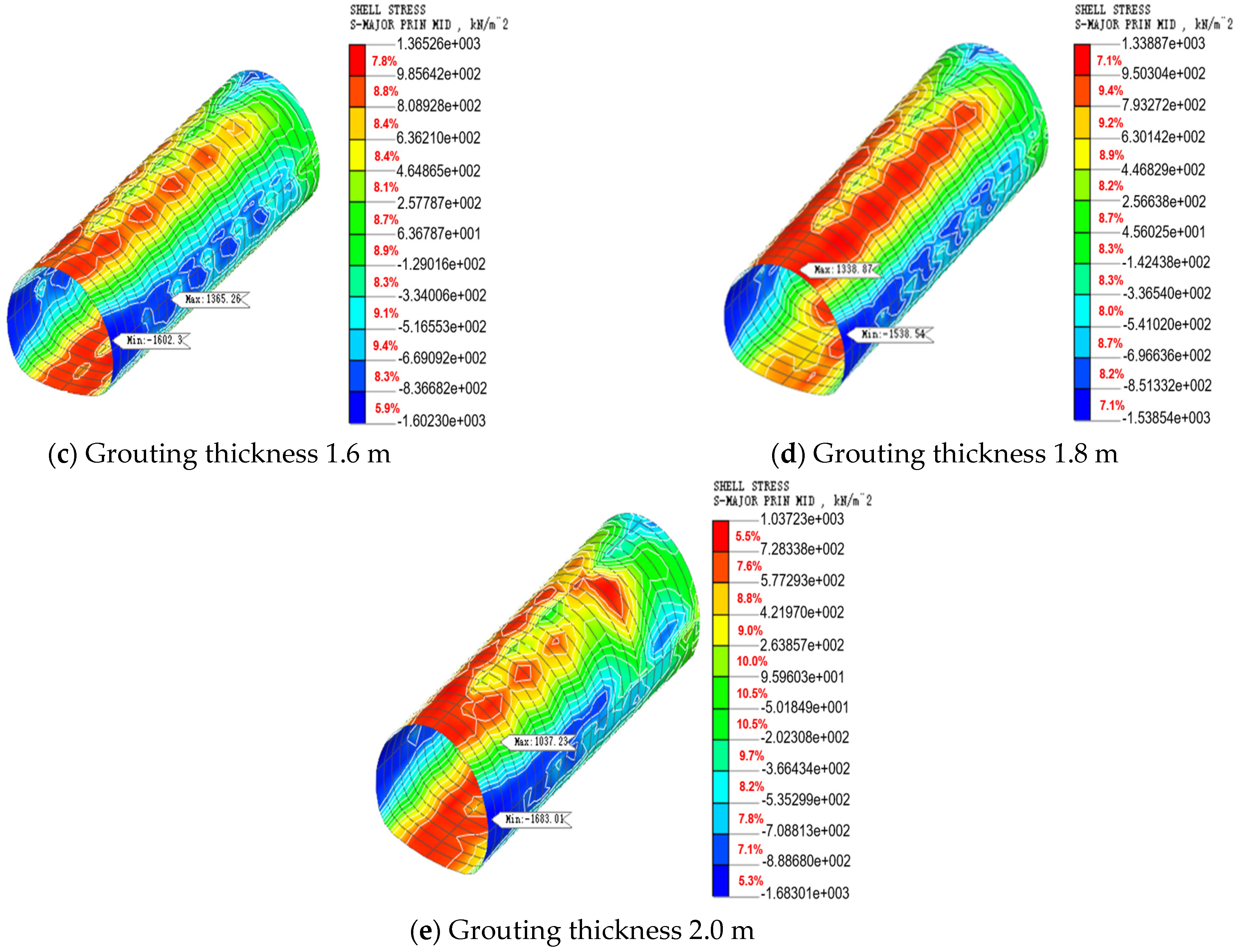

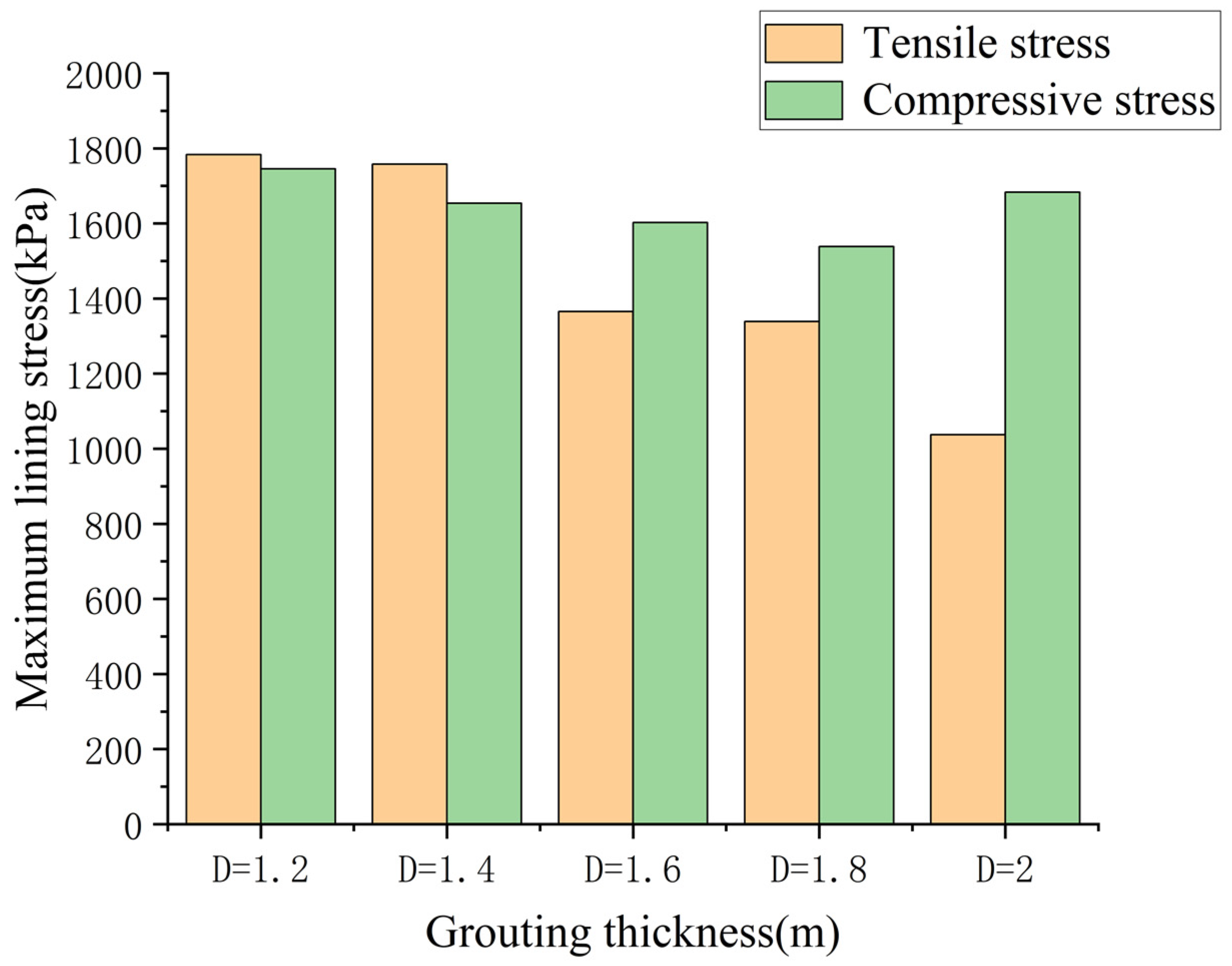

4.2. Analysis of Lining Stress

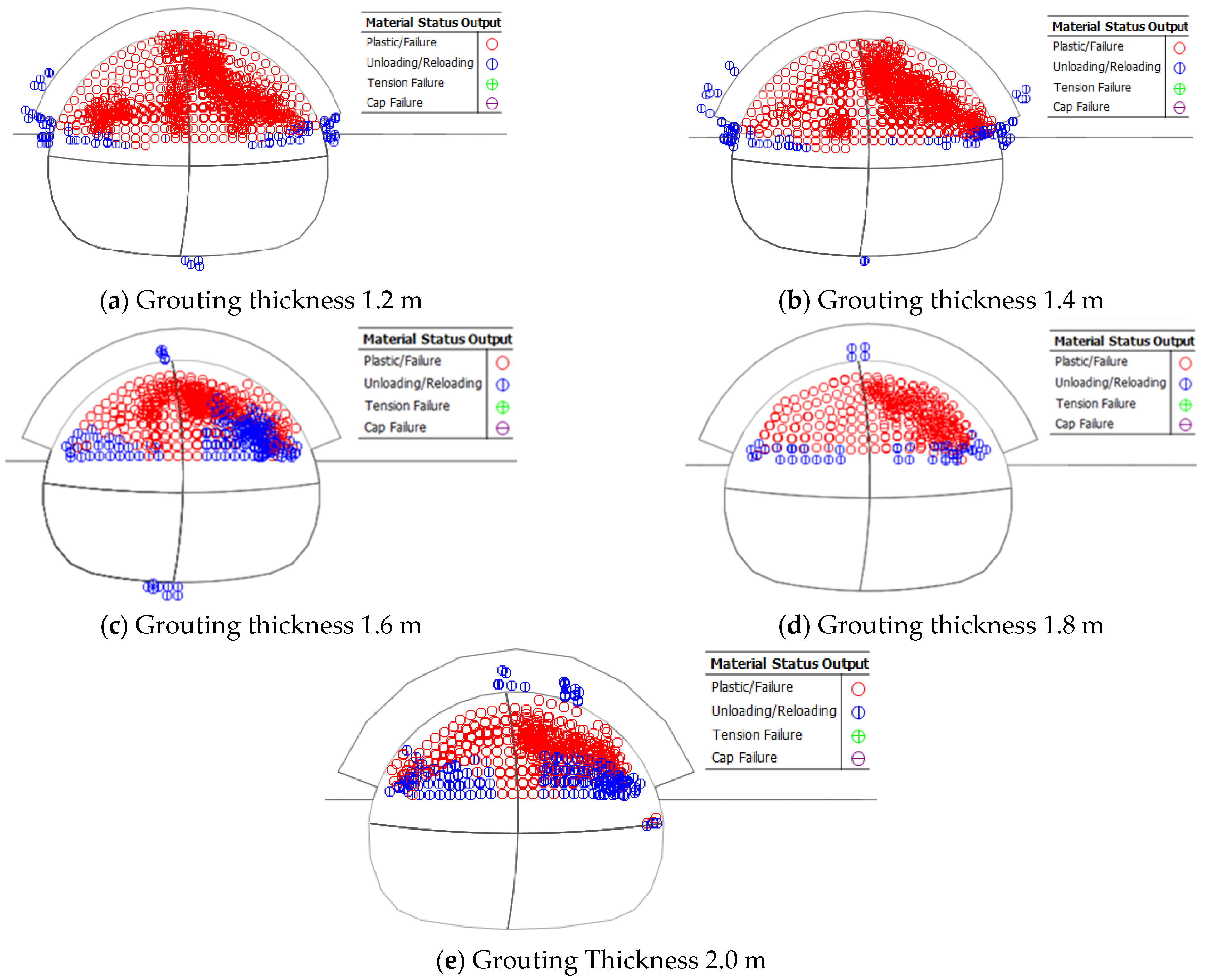

4.3. Comparative Analysis of Surrounding Rock Plastic Zones

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zacharias, J.; Tang, Y. Restructuring and Repositioning Shenzhen, China’s New Mega City. Prog. Plan. 2010, 73, 209–249. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, X.; Huang, Q.; Shiau, J.; Liang, J.; Zhang, B.; Zheng, J.; Fahimizadeh, M.; Sabri, M.M. Effects of Particle Size on Properties of Engineering Muck-Based Geopolymers: Optimization through Sieving Treatment. Constr. Build. Mater. 2025, 492, 142967. [Google Scholar] [CrossRef]

- Shi, J.; Wang, J.; Chen, Y.; Shi, C.; Lu, H.; Ma, S.; Fan, Y. Physical Modeling of the Influence of Tunnel Active Face Instability on Existing Pipelines. Tunn. Undergr. Space Technol. 2023, 140, 105281. [Google Scholar] [CrossRef]

- Feature Fusion Method for Rock Mass Classification Prediction and Interpretable Analysis Based on TBM Operating and Cutter Wear Data. Tunn. Undergr. Space Technol. 2025, 157, 106351. [CrossRef]

- Wang, J.; Huo, Q.; Song, Z.; Zhang, Y. Study on Adaptability of Primary Support Arch Cover Method for Large-Span Embedded Tunnels in the Upper-Soft Lower-Hard Stratum. Adv. Mech. Eng. 2019, 11, 1687814018825375. [Google Scholar] [CrossRef]

- Lv, J.; Lin, D.; Wu, W.; Huang, J.; Li, Z.; Fu, H.; Li, H. Mechanical Responses of Slurry Shield Underpassing Existing Bridge Piles in Upper-Soft and Lower-Hard Composite Strata. Buildings 2022, 12, 1000. [Google Scholar] [CrossRef]

- Shi, L.; Zhou, H.; Song, M.; Lu, J.; Liu, Z. Geomechanical Model Test for Analysis of Surrounding Rock Behaviours in Composite Strata. J. Rock Mech. Geotech. Eng. 2021, 13, 774–786. [Google Scholar] [CrossRef]

- Lu, D.; Liang, J.; Du, X.; Ma, C.; Gao, Z. Fractional Elastoplastic Constitutive Model for Soils Based on a Novel 3D Fractional Plastic Flow Rule. Comput. Geotech. 2019, 105, 277–290. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, S.; Zhang, D.; Zhang, K.; Wang, Z. Model Tests on Progressive Collapse Mechanism of a Shallow Subway Tunnel in Soft Upper and Hard Lower Composite Strata. Tunn. Undergr. Space Technol. 2023, 131, 104824. [Google Scholar] [CrossRef]

- Lv, J.; Li, X.; Fu, H.; Tang, Y.; Li, Z.; Zhao, H. Influence of Shield Tunnel Construction on Ground Surface Settlement under the Condition of Upper-Soft and Lower-Hard Composite Strata. J. Vibroeng. 2020, 22, 1126–1144. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, Q.; Xu, W.; Han, Z.; Luo, Q.; Chen, G.; Yuan, J.; Zhang, Q.; Sabri, S.M.M. Study on the Interaction between Pile and Soil under Lateral Load in Coral Sand. Geomech. Energy Environ. 2025, 42, 100674. [Google Scholar] [CrossRef]

- Zhang, X.; Song, Q.; Yao, Z.; Su, D.; Zhang, Y.; Li, Q. Limit Equilibrium Models for Tunnel Face Stability in Composite Soft-Hard Strata. Appl. Sci. 2023, 13, 10748. [Google Scholar] [CrossRef]

- Zhang, L.; Pan, Y.; Chen, K.; Zheng, G.; Gao, Y.; Chen, P.; Zhong, G.; Chen, P.; Xu, F.; Zhang, Y.; et al. The Effect of CRD Method and Auxiliary Construction on Surface Settlement in Shallow-Buried Tunnels. Front. Earth Sci. 2023, 10, 998717. [Google Scholar] [CrossRef]

- Han, Y.; Wei, C.; Cui, M.; Xie, H.; Ou, Y.; Zhu, H.; Liu, T. Ground Settlement of Deeply Buried Two-Lane Tunnels with Large Cross-Sections Using Different Construction Methods. Appl. Sci. 2022, 12, 11105. [Google Scholar] [CrossRef]

- Ren, Y.; Zhou, S.; Jia, J.; Yuan, Q.; Liu, M.; Song, S.; Zhou, Z.; Wang, Z. The Influence of Construction Methods on the Stability of Tunnels and Ground Structures in the Construction of Urban Intersection Tunnels. Sustainability 2023, 15, 14720. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Cao, M.; Wang, Z. Study on Excavation Sequence of Pilot Tunnels for a Rectangular Tunnel Using Numerical Simulation and Field Monitoring Method. Rock Mech. Rock Eng. 2022, 55, 3507–3523. [Google Scholar] [CrossRef]

- Liu, W.; Chen, J.; Chen, L.; Luo, Y.; Shang, Q.; Zhang, L.; Gao, S.; Jia, H. A Rational Construction Method and Deformation Control System of Tunnelling in Extremely Soft and Fractured Chlorite Schist Medium. Tunn. Undergr. Space Technol. 2024, 143, 105472. [Google Scholar] [CrossRef]

- Ren, Y.; Zhou, S.; Jia, J.; Yuan, Q.; Zhou, Z.; Liu, M.; He, H. Construction Stability Analysis of Intersection Tunnel in City under CRD Method. Front. Earth Sci. 2023, 11, 1264140. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, W.; Cai, Y.; Xu, B.; Fu, Y.; Wei, G. Analysis of Ground Surface Settlement Induced by the Construction of a Large-Diameter Shallow-Buried Twin-Tunnel in Soft Ground. Tunn. Undergr. Space Technol. 2019, 83, 520–532. [Google Scholar] [CrossRef]

- Shi, J.; Zhong, X.; Lu, H.; Ni, X.; Shi, C. Influence of Joint Stiffness on Three-Dimensional Deformation Mechanisms of Pipelines under Tunnel Active Face Instability. Can. Geotech. J. 2025, 62, 1–18. [Google Scholar] [CrossRef]

- Yuan, B.; Liang, J.; Zhang, B.; Chen, W.; Huang, X.; Huang, Q.; Li, Y.; Yuan, P. Optimized Reinforcement of Granite Residual Soil Using a Cement and Alkaline Solution: A Coupling Effect. J. Rock Mech. Geotech. Eng. 2025, 17, 509–523. [Google Scholar] [CrossRef]

- Lu, D.; Zhou, X.; Du, X.; Wang, G. A 3D Fractional Elastoplastic Constitutive Model for Concrete Material. Int. J. Solids Struct. 2019, 165, 160–175. [Google Scholar] [CrossRef]

- Yuan, B.; Huang, X.; Li, R.; Luo, Q.; Shiau, J.; Wang, Y.; Yuan, J.; Muayad Sabri, S.M.; Huang, S.; Liao, C. Dynamic Behavior and Deformation of Calcareous Sand under Cyclic Loading. Soil Dyn. Earthq. Eng. 2025, 199, 109730. [Google Scholar] [CrossRef]

- Lu, H.; Qiu, J.; Kong, X.; He, Z. Experimental Study on Temperature Characterization during Cement Grouting Reinforcement. Case Stud. Therm. Eng. 2023, 41, 102577. [Google Scholar] [CrossRef]

- Lou, P.; Huang, W.; Huang, X. Analysis of Shield Tunnels Undercrossing an Existing Building and Tunnel Reinforcement Measures. Appl. Sci. 2023, 13, 5729. [Google Scholar] [CrossRef]

- Wang, X.; Li, Z.; Li, W.; He, C.; Wang, Z. Analysis and Prediction of Dynamic Stress Concentration in Jointed Coal Using Boundary Element Method. Theor. Appl. Fract. Mech. 2025, 140, 105136. [Google Scholar] [CrossRef]

- Cheng, W.; Zhu, C.; Shi, G.; Liu, Z.; Liu, C.; Du, Y.; Chen, Y.; Zhuang, C.; Gu, H. Effect of Grouting, Concrete Cover, and Combined Reinforcement on Masonry Retaining Walls. Buildings 2025, 15, 309. [Google Scholar] [CrossRef]

- Hua, T.; Liu, S.; Zhang, X.; Meng, L.; Wang, P. Numerical Analysis of Grouting of Water-Enriched Karst Highway Tunnel Based on Critical Water-Enriched Height. Processes 2023, 11, 149. [Google Scholar] [CrossRef]

- Tabaroei, A.; Sarfarazi, V.; Moaveni, M.; Vakili, A.H.; Pham, T.A. Deep Excavation–Induced Stability Evaluation of a Triple Tunnel Using Discrete and Continuum Numerical Modeling. Int. J. Geomech. 2025, 25, 04024299. [Google Scholar] [CrossRef]

- Aghajari, M.; Dehghan, A.N.; Lajevardi, S.H. Optimizing Sequential Excavation Method for Ground Settlement Control in Tehran Subway Tunnel Line 6. Geotech. Geol. Eng. 2024, 42, 3595–3614. [Google Scholar] [CrossRef]

- Galli, G.; Grimaldi, A.; Leonardi, A. Three-Dimensional Modelling of Tunnel Excavation and Lining. Comput. Geotech. 2004, 31, 171–183. [Google Scholar] [CrossRef]

- Yun, J.; Kim, H.; Yoo, H. Three-Dimensional Modeling and Analysis of Ground Settlement Due to Twin Tunneling Using GIS. Sustainability 2024, 16, 5891. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, J.; Yang, J.; Zhao, L.; Zheng, X. Stability Analysis of Unlined Elliptical Tunnel Using Finite Element Upper-Bound Method with Rigid Translatory Moving Elements. Tunn. Undergr. Space Technol. 2015, 50, 13–22. [Google Scholar] [CrossRef]

- Jitchaijaroen, W.; Wipulanusat, W.; Keawsawasvong, S.; Chavda, J.T.; Ramjan, S.; Sunkpho, J. Stability Evaluation of Elliptical Tunnels in Natural Clays by Integrating FELA and ANN. Results Eng. 2023, 19, 101280. [Google Scholar] [CrossRef]

- Hu, J.; Xu, N. Numerical Analysis of Failure Mechanism of Tunnel under Different Confining Pressure. Procedia Eng. 2011, 26, 107–112. [Google Scholar] [CrossRef][Green Version]

- Chen, J.; Zhang, J.; Chen, B.; Lu, G. The Influence of the Underpassing Frozen Connecting Passage on the Deformation of the Existing Tunnel. Res. Cold Arid Reg. 2022, 14, 258–266. [Google Scholar] [CrossRef]

- Kitchah, F.; Benmebarek, S.; Djabri, M. Numerical Assessment of Tunnel Collapse: A Case Study of a Tunnel at the East–West Algerian Highway. Bull. Eng. Geol. Environ. 2021, 80, 6161–6176. [Google Scholar] [CrossRef]

- Yassaghi, A.; Salari-Rad, H. Squeezing Rock Conditions at an Igneous Contact Zone in the Taloun Tunnels, Tehran-Shomal Freeway, Iran: A Case Study. Int. J. Rock Mech. Min. Sci. 2005, 42, 95–108. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, W. Numerical Simulation of Dynamic Response Law of Intersecting Metro Tunnels in Upper and Lower Strata. Geotech. Geol. Eng. 2020, 38, 3773–3785. [Google Scholar] [CrossRef]

- Wang, Z.B.; Wei, J.X.; Fu, J.W.; Li, T.; Haeri, H.; Shangguan, L.J. Stress Analysis and Settlement Observations for a Case Study of Tunneling Interactions with Existing Structures Using Midas GTS NX Software. Strength Mater. 2025, 57, 373–387. [Google Scholar] [CrossRef]

- Wang, Z.; Jin, D.; Shi, C. Spatial Variability of Grouting Layer of Shield Tunnel and Its Effect on Ground Settlement. Appl. Sci. 2020, 10, 5002. [Google Scholar] [CrossRef]

- Wang, J.; Cao, A.; Wu, Z.; Wang, H.; Liu, X.; Li, H.; Sun, Y. Experiment and Numerical Simulation on Grouting Reinforcement Parameters of Ultra-Shallow Buried Double-Arch Tunnel. Appl. Sci. 2021, 11, 10491. [Google Scholar] [CrossRef]

- Chen, D.; Wang, L.; Versaillot, P.D.; Sun, C. Triaxial Creep Damage Characteristics of Sandstone under High Crustal Stress and Its Constitutive Model for Engineering Application. Deep Undergr. Sci. Eng. 2023, 2, 262–273. [Google Scholar] [CrossRef]

- Qi, Y.; Wei, G.; Xie, Y.; Wang, Q. Effect of Grouting Reinforcement on Settlement of Existing Tunnels: Case Study of a New Crossing Underpass. Symmetry 2021, 13, 482. [Google Scholar] [CrossRef]

- Lu, D.; Meng, F.; Zhou, X.; Zhuo, Y.; Gao, Z.; Du, X. A Dynamic Elastoplastic Model of Concrete Based on a Modeling Method with Environmental Factors as Constitutive Variables. J. Eng. Mech. 2023, 149, 04023102. [Google Scholar] [CrossRef]

- Zhang, Y.; Yin, Z.; Xu, Y. Analysis of Ground Deformation Induced by Shield Tunneling. J. Rock Mech. Eng. 2002, 21, 388–392. [Google Scholar]

| Material Name | Elastic Modulus /(MPa) | Unit Weight /(kN/m3) | Poisson’s Ratio | Cohesion /(kN/m2) | Internal Friction Angle /(°) |

|---|---|---|---|---|---|

| Moderately Weathered Argillaceous Siltstone | 958.0 | 22.5 | 0.34 | 124 | 30.21 |

| Slightly Weathered Siltstone | 2146.0 | 26.7 | 0.25 | 462 | 42.33 |

| Grouting Reinforcement Layer | 1245.4 | 24.0 | 0.2 | - | - |

| Initial Support | 2.55 × 104 | 22 | 0.2 | - | - |

| Temporary Support | 20.0 × 104 | 79 | 0.3 | - | - |

| Rock Bolt | 8.0 × 104 | 82.0 | 0.3 | - | - |

| Grouting Small Pipe | 15.0 × 104 | 78 | 0.2 | - | - |

| Construction Step | Construction Content |

|---|---|

| I.S | Initial State |

| S1-S4, S18-S21, S35-S38, S52-S55, S69-S72, S86-S89, S103-S105 | Construction of Upper-Left Pilot Tunnel |

| S5-S8, S22-S25, S39-S42, S56-S59, S73-S77, S90-S93, S106-S108 | Construction of Upper-Right Pilot Tunnel |

| S9-S12, S26-S29, S43-S46, S60-S63, S78-S80, S94-S97, S109-S111 | Construction of Lower-Left Pilot Tunnel |

| S13-S16, S30-S33, S47-S50, S64-S67, S81-S84, S98-S101, S112-S114 | Construction of Lower-Right Pilot Tunnel |

| S17, S34, S51, S68, S85, S102, S115 | Removal of Temporary Support |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, G.; Wan, L.; Zhang, D.; Li, J.; Li, R.; Long, Y.; Li, H.; Liu, H.; Yuan, B. Research on Optimization of Grouting Parameters for the CRD Method in Tunnels in Upper-Soft and Lower-Hard Composite Strata Based on Finite Element Method. Buildings 2025, 15, 3745. https://doi.org/10.3390/buildings15203745

Guo G, Wan L, Zhang D, Li J, Li R, Long Y, Li H, Liu H, Yuan B. Research on Optimization of Grouting Parameters for the CRD Method in Tunnels in Upper-Soft and Lower-Hard Composite Strata Based on Finite Element Method. Buildings. 2025; 15(20):3745. https://doi.org/10.3390/buildings15203745

Chicago/Turabian StyleGuo, Guixi, Lei Wan, Deming Zhang, Jin Li, Runcheng Li, Yaojian Long, Hongzhong Li, Huifen Liu, and Bingxiang Yuan. 2025. "Research on Optimization of Grouting Parameters for the CRD Method in Tunnels in Upper-Soft and Lower-Hard Composite Strata Based on Finite Element Method" Buildings 15, no. 20: 3745. https://doi.org/10.3390/buildings15203745

APA StyleGuo, G., Wan, L., Zhang, D., Li, J., Li, R., Long, Y., Li, H., Liu, H., & Yuan, B. (2025). Research on Optimization of Grouting Parameters for the CRD Method in Tunnels in Upper-Soft and Lower-Hard Composite Strata Based on Finite Element Method. Buildings, 15(20), 3745. https://doi.org/10.3390/buildings15203745