Mitigation of Expansive Soil Through Controlled Thermal Treatment: Geotechnical and Microstructural Assessment

Abstract

1. Introduction

2. Experimental Work

2.1. Collection of Expansive Soil Sample

2.2. Specimen Preparation and Experimental Methodology

3. Results and Discussion

3.1. Particle Size Distribution of Soil

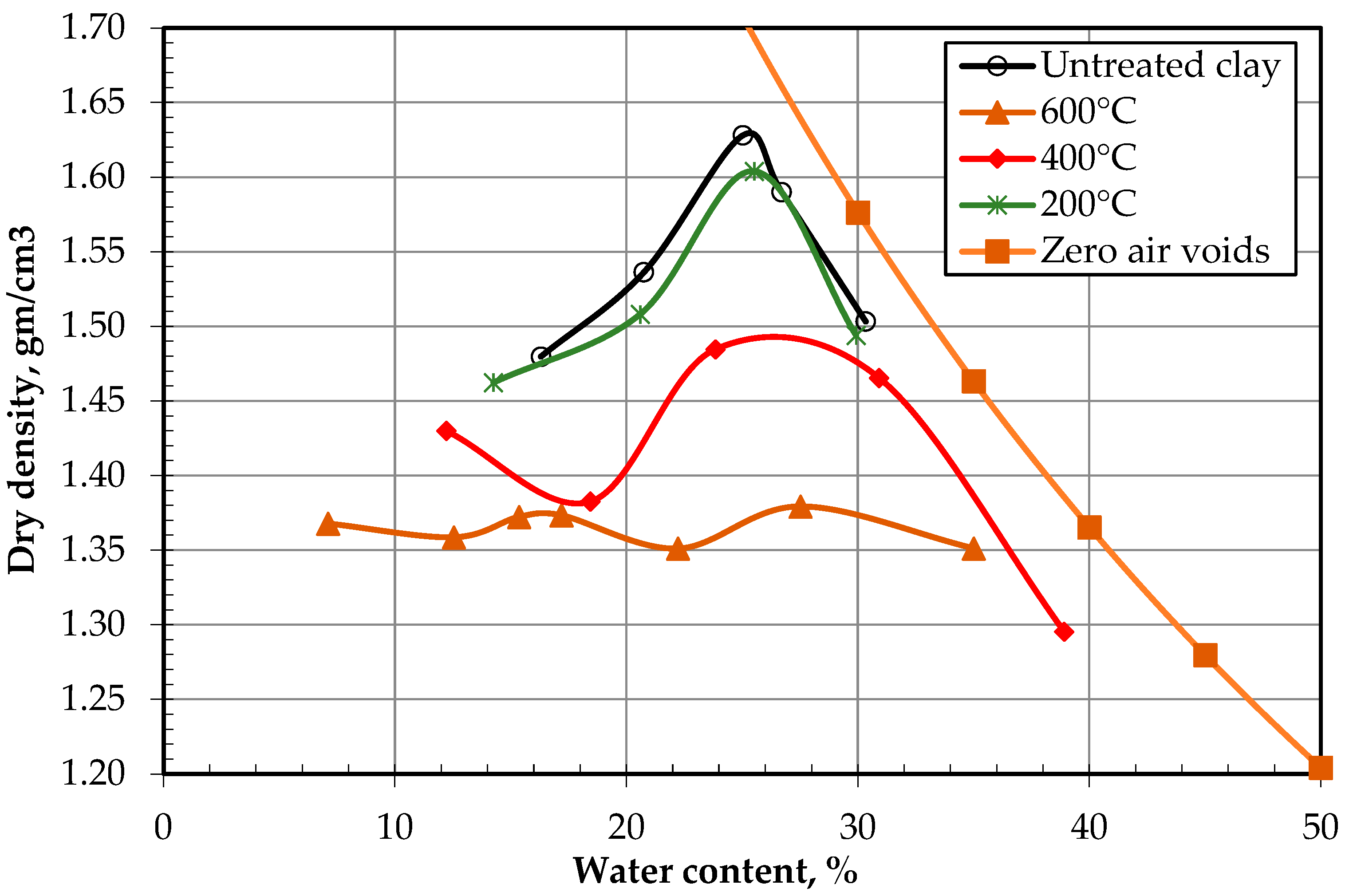

3.2. Compaction Characterestics

3.3. Effect of Thermal Treatment on Consistency Limits and Specific Gravity

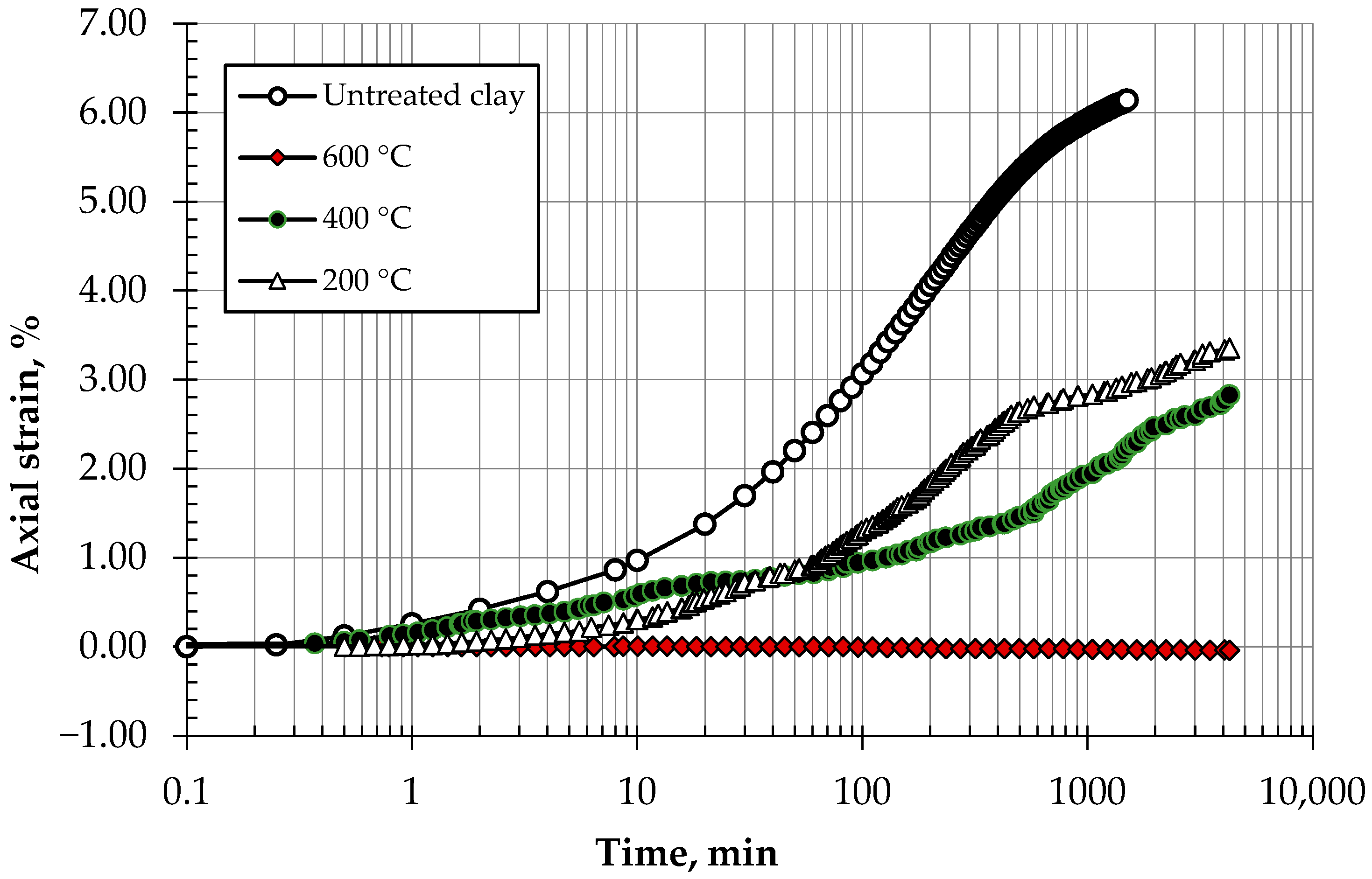

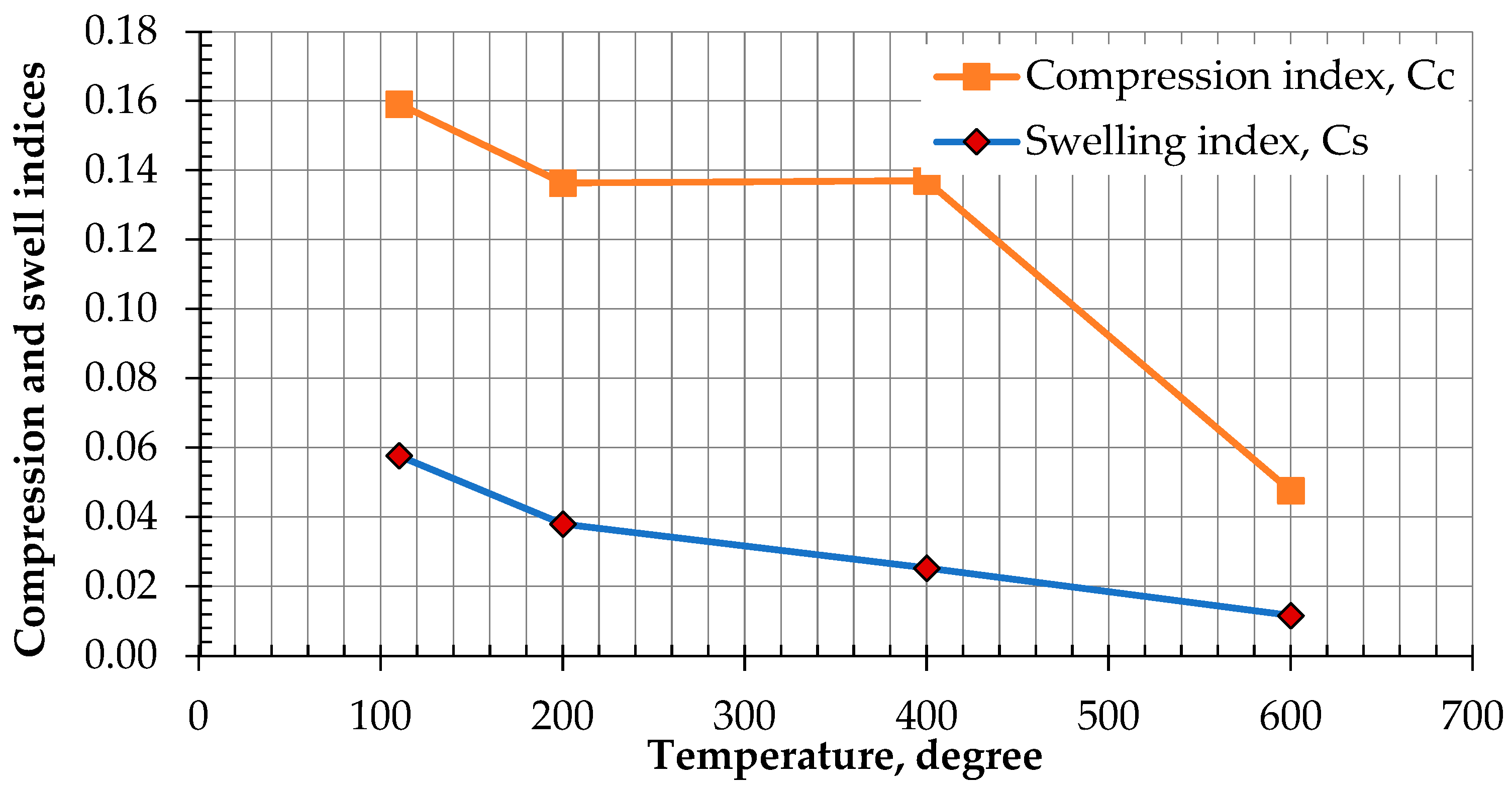

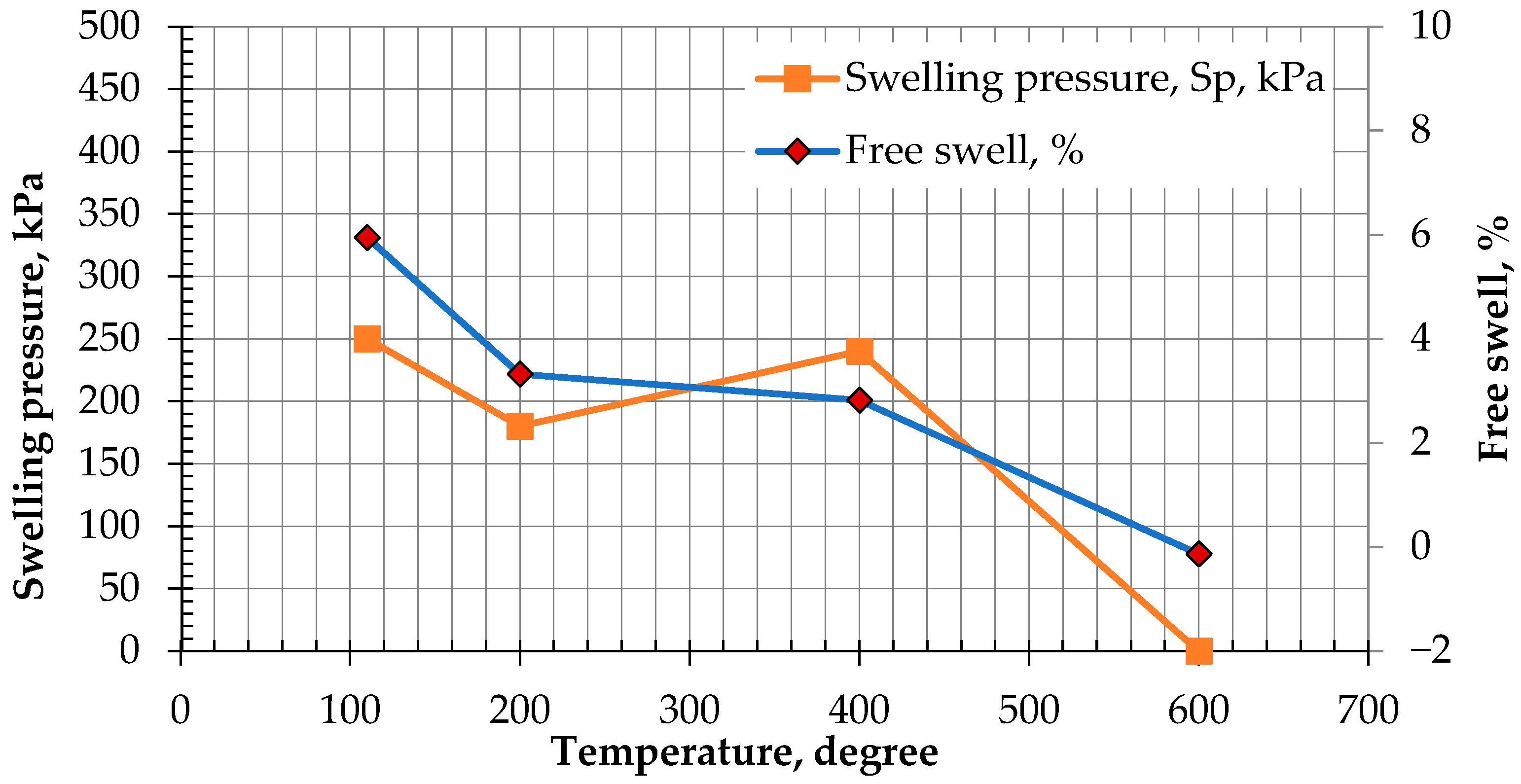

3.4. Swelling and Consolidation Characteristics

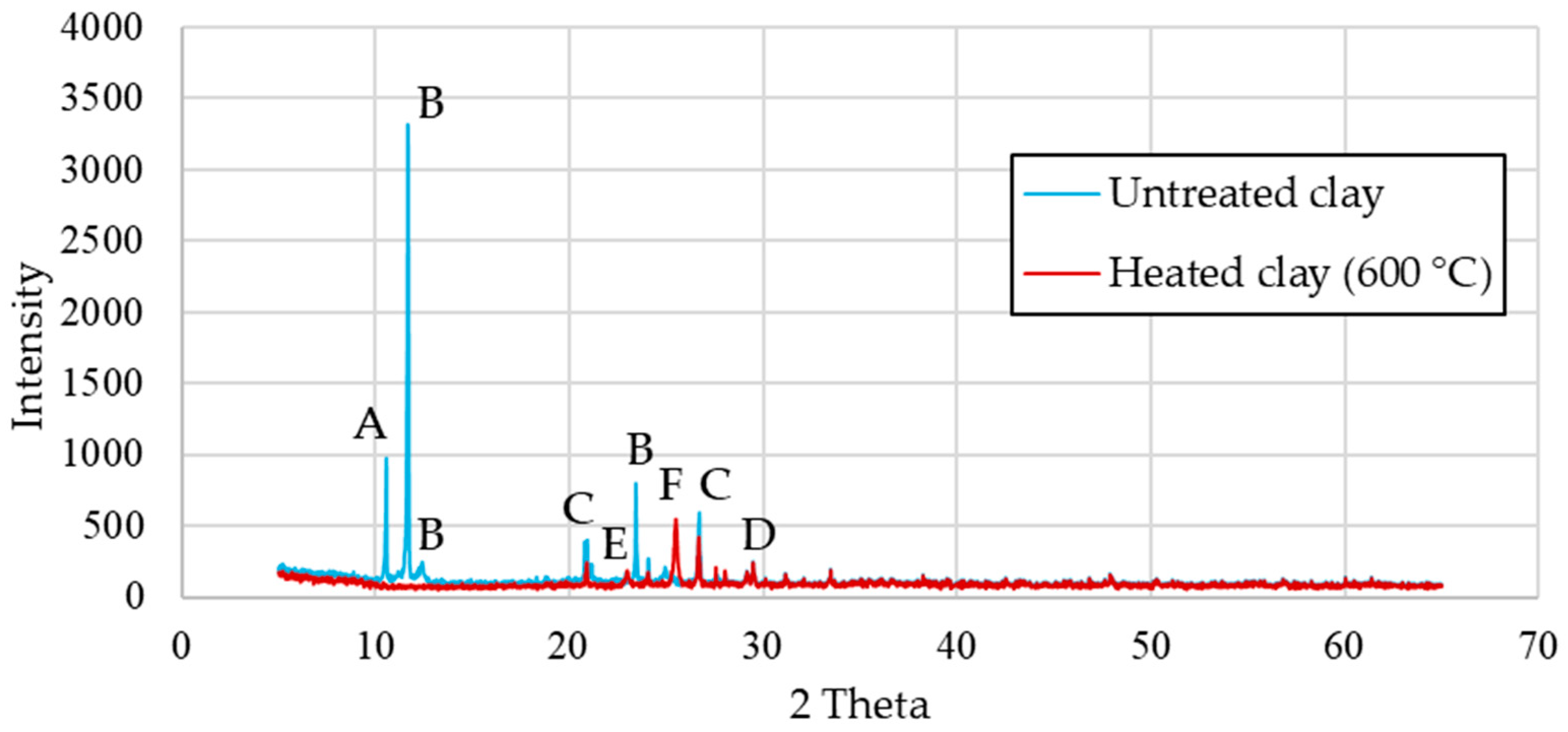

3.5. XRD Analyses

3.6. SEM Images

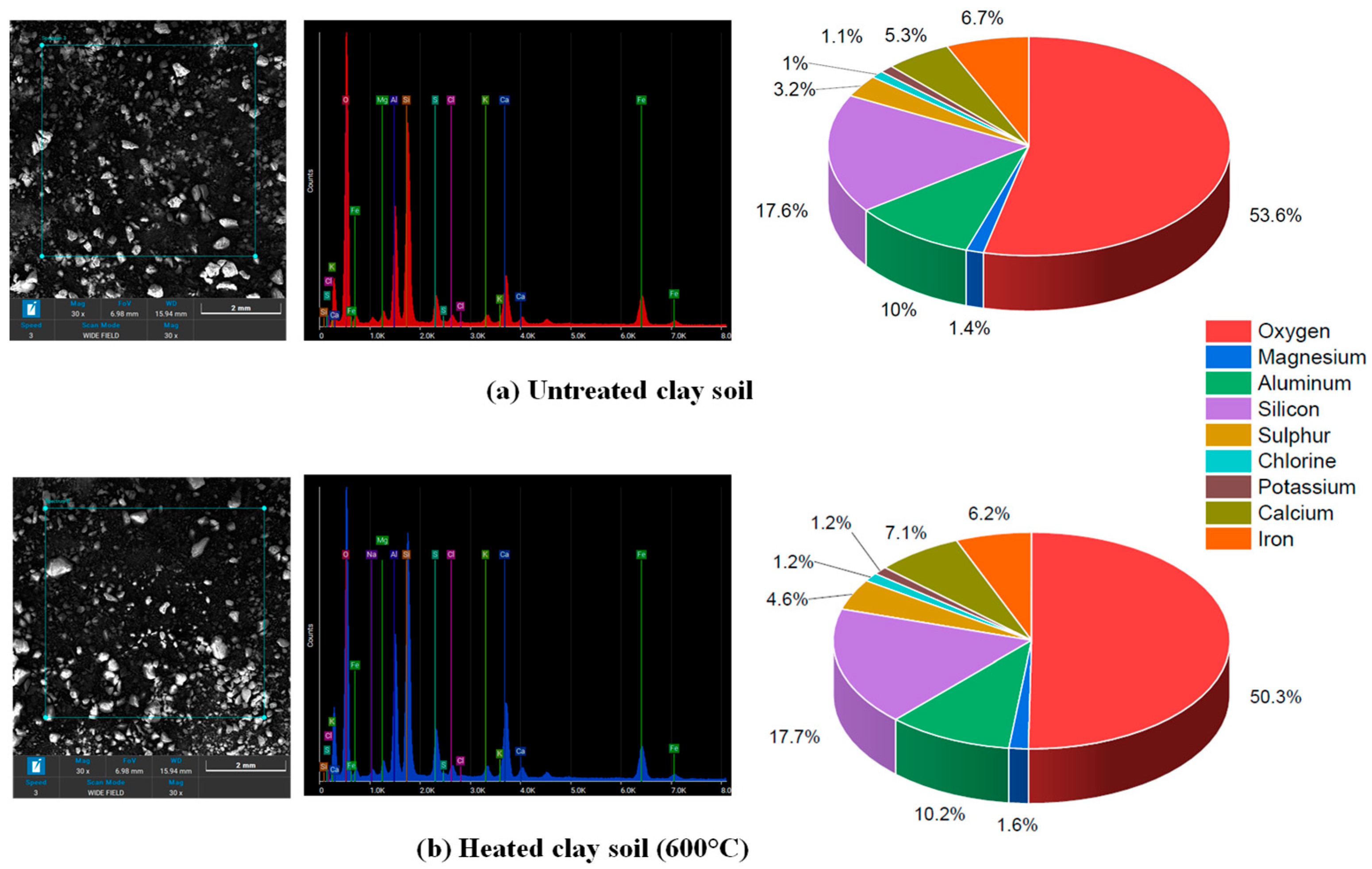

3.7. EDX Analysis

3.8. Linking Microstructural Changes to Geotechnical Improvements

3.9. Considerations for Field Application and Associated Risks

4. Conclusions

- Thermal treatment induced significant and favorable changes in the soil’s physical characteristics. The liquid limit decreased by approximately 42% when heated to 600 °C, while the plasticity index shows a dramatic reduction from 27.00 in the untreated state to just 2.94 at 600 °C. This transformed the soil from a high-plasticity clay to a material with significantly reduced swelling potential. Conversely, the MDD decreased as temperatures rose, particularly at 400 °C and 600 °C, indicating a degradation of the soil’s compactability due to structural changes.

- Heating the soil to 600 °C led to a significant coarsening of its texture, with the median particle size increasing from approximately 12 µm to 200 µm. SEM analysis confirmed this, revealing that the smooth, platy structure of the untreated clay was transformed into a more heterogeneous matrix characterized by particle fusion and aggregation.

- Oedometer tests provided conclusive evidence of the efficacy of the heat treatment. The free swell of the soil was progressively reduced with increasing temperature, decreasing from 6% in its natural state to being virtually eliminated at 600 °C. Similarly, the swelling pressure was reduced from 250 kPa to 0 kPa at 600 °C. Both the Cc and Cs also decreased, with the most significant reductions occurring above 400 °C.

- XRD analysis revealed the underlying cause of these behavioral changes. Treatment at 600 °C resulted in the thermal decomposition of the crystalline clay minerals, evidenced by the disappearance of kaolinite and illite peaks. This process, identified as the conversion of kaolinite to metakaolin, irreversibly destroys the layered mineral structure responsible for water adsorption and swelling. EDX analysis supported this by showing a decrease in oxygen content, consistent with dehydroxylation.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Devkota, B.; Karim, M.R.; Rahman, M.M.; Nguyen, H.B.K. Accounting for Expansive Soil Movement in Geotechnical Design—A State-of-the-Art Review. Sustainability 2022, 14, 15662. [Google Scholar] [CrossRef]

- Alsabhan, A.H.; Hamid, W. Innovative Thermal Stabilization Methods for Expansive Soils: Mechanisms, Applications, and Sustainable Solutions. Processes 2025, 13, 775. [Google Scholar] [CrossRef]

- Hamid, W.; Lemboye, K.; Dhowian, A. Characteristics and Treatment of Expansive Soil Using Biopolymer. Arab. J. Geosci. 2022, 15, 411. [Google Scholar] [CrossRef]

- Abden, A.; Al-Shamrani, M.; Dafalla, M.; Siddiqui, N. Assessment of the Performance of Spread Footings and Mat Foundations on Expansive Soils. Results Eng. 2024, 23, 102782. [Google Scholar] [CrossRef]

- Dafalla, M.A.; Shamrani, M.A. Road Damage Due to Expansive Soils: Survey of the Phenomenon and Measures for Improvement. In Design, Construction, Rehabilitation, and Maintenance of Bridges; ASCE Library: Reston, VA, USA; pp. 73–80.

- Jones, L. Expansive Soils. In Encyclopedia of Engineering Geology; Bobrowsky, P., Marker, B., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 1–7. ISBN 978-3-319-12127-7. [Google Scholar]

- Mutaz, E.; Dafalla, M. Utilizing Chemical Treatment in Improving Bearing Capacity of Highly Expansive Clays. In Characterization, Modeling, and Evaluation of Geotechnical Engineering Systems; ASCE Library: Reston, VA, USA, 2014; pp. 74–82. [Google Scholar]

- Rao, B.H.; Shukla, S.; Tahasildar, J. Mineralogical Compositions of Some Indian Expansive Soils and Their Influence on Swelling Properties. Int. J. Geosynth. Ground Eng. 2017, 3, 5. [Google Scholar] [CrossRef]

- Reddy, P.S.; Mohanty, B.; Rao, B.H.; Reddy, K. Combined Effect of Mineralogical and Chemical Parameters on Swelling Behaviour of Expansive Soils. Sci. Rep. 2021, 11, 16562. [Google Scholar] [CrossRef] [PubMed]

- Wu, J.; Dong, Y.; Zhang, H.; Zhang, C. Water Adsorption on Kaolinite Basal and Edge Surfaces. Langmuir ACS J. Surf. Colloids 2023, 39, 7539–7547. [Google Scholar] [CrossRef]

- Abbey, S.J.; Eyo, E.U.; Ng’ambi, S. Swell and Microstructural Characteristics of High-Plasticity Clay Blended with Cement. Bull. Eng. Geol. Environ. 2020, 79, 2119–2130. [Google Scholar] [CrossRef]

- Bouassida, M.; Manigniavy, S.A.; Tani, N.K.; Bouassida, Y. Expansive Soils: Is It a Hidden Problem in Civil Engineering? In Advances in Research in Geosciences, Geotechnical Engineering, and Environmental Science; Baba, K., Ouadif, L., Nounah, A., Bouassida, M., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 424–431. [Google Scholar]

- Khadka, S.; Jayawickrama, P.; Senadheera, S.; Šegvić, B. Stabilization of Highly Expansive Soils Containing Sulfate Using Metakaolin and Fly Ash Based Geopolymer Modified with Lime and Gypsum. Transp. Geotech. 2020, 23, 100327. [Google Scholar] [CrossRef]

- Uprety, B.; Uprety, B.; Panta, A. Influence of Egg Shell Powder, Bagasse Ash and Lime on Stability of Soil. J. Lumbini Eng. Coll. 2023, 5, 67–74. [Google Scholar] [CrossRef]

- Wei, J.; Wei, J.; Huang, Q.; Zainal Abidin, S.M.I.B.S.; Zou, Z. Mechanism and Engineering Characteristics of Expansive Soil Reinforced by Industrial Solid Waste: A Review. Buildings 2023, 13, 1001. [Google Scholar] [CrossRef]

- Wang, M.C.; Jao, M.; Ghazal, M.S. Heating Effect on Swelling Behaviour of Expansive Soils. Geomech. Geoengin. 2008, 3, 121–127. [Google Scholar] [CrossRef]

- Abu-Zreig, M.M.; Al-Akhras, N.M.; Attom, M.F. Influence of Heat Treatment on the Behavior of Clayey Soils. Appl. Clay Sci. 2001, 20, 129–135. [Google Scholar] [CrossRef]

- Geng, J.; Sun, Q. Effects of High Temperature Treatment on Physical-Thermal Properties of Clay. Thermochim. Acta 2018, 666, 148–155. [Google Scholar] [CrossRef]

- Li, J.; Wu, X.; Hou, L. Physical, Mineralogical, and Micromorphological Properities of Expansive Soil Treated at Different Temperature. J. Nanomater. 2014, 2014, 848740. [Google Scholar] [CrossRef]

- Kramarenko, V.V.; Nikitenkov, A.N.; Yu Molokov, V.; Shramok, A.V.; Pozdeeva, G.P. Application of Microwave Method for Moisture Determination of Organic and Organic-Mineral Soils. IOP Conf. Ser. Earth Environ. Sci. 2016, 33, 012040. [Google Scholar] [CrossRef]

- Kabubo, C.K.; Mwea, S.K.; Abuodha, S.O.; Gariy, Z.A. The Effect of Heat on the Properties of Expansive Clay Soil. Int. J. Sci. Res. IJSR 2017, 6, 464–469. [Google Scholar] [CrossRef]

- Singh, B.; Novais, R.F.; Melo, V.; Schaefer, C.; Fontes, M. Chemical and Mineralogical Properties of Kaolinite-Rich Brazilian Soils. Soil Sci. Soc. Am. J. 2001, 65, 1324–1333. [Google Scholar] [CrossRef]

- Vakili, A.; Falamaki, A.; Aryanpour, M. Effects of Elevated Temperature on Mineralogical/Microstructural Changes and Mechanical Responses of Clay Soil. Phys. Chem. Earth Parts ABC 2023, 132, 103493. [Google Scholar] [CrossRef]

- Tamiru, M.; Assefa, E.; Assefa, S.M.; Jilo, N.Z. Effect of Heat Treatment on Geotechnical and Microstructural Properties of Expansive Soils. Quat. Sci. Adv. 2025, 17, 100262. [Google Scholar] [CrossRef]

- Yao, H.; Lu, J.; Bian, H.; Zhang, Z. Influence of Microwave Heating on the Swelling Properties of Expansive Soil in Hefei. Case Stud. Therm. Eng. 2022, 39, 102466. [Google Scholar] [CrossRef]

- Yilmaz, G. The Effects of Temperature on the Characteristics of Kaolinite and Bentonite. Sci. Res. Essays 2011, 6, 1928–1939. [Google Scholar] [CrossRef]

- Zihms, S.; Switzer, C.; Tarantino, A. Understanding the Effects of High Temperature Processes on the Engineering Properties of Soils; University of Strathclyde: Glasgow, UK, 2013; pp. 3427–3430. [Google Scholar]

- Sridharan, A.; Sivapullaiah, P.V. Mini Compaction Test Apparatus for Fine Grained Soils. Geotech. Test. J. 2005, 28, 240–246. [Google Scholar] [CrossRef]

- ASTM D698-12e2; Standard Test Method for Laboratory Compaction Characteristics of Soil Using Standard Effort. ASTM: West Conshohocken, PA, USA, 2012.

- ASTM D4546-21; Standard Test Methods for One-Dimensional Swell or Collapse of Soils 2021. ASTM: West Conshohocken, PA, USA, 2021.

- Mac-Eteli, H.D.; Sopakirite, S. Experimental Analysis on the Effect of Calcination on the Index and Engineering Properties of Clay Soil. Saudi J. Civ. Eng. 2021, 5, 133–138. [Google Scholar]

- Al-Swaidani, A.M.; Hamood, I.; Meziab, A. Thermally Treated Clay as a Stabilizing Agent for Expansive Clayey Soil: Some Engineering Properties. Stud. Geotech. Mech. 2018, 40, 220–232. [Google Scholar] [CrossRef]

- Zeinali, S.M.; Ung, A.; Abdelaziz, S.L. Temperature Effects on Atterberg Limits. In Proceedings of the 2023 Symposium on Energy Geotechnics, Delft, The Netherlands, 3–5 October 2023. [Google Scholar] [CrossRef]

- Hwang, K.; Lee, S.-H.; Min, T.-K. The Effects on the Atterberg Limits of Clays with Heat Treatment. J. Korean Geotech. Soc. 2007, 23, 29–34. [Google Scholar]

- Chen, F.H. Foundations on Expansive Soils; American Elsevier Science Publishing: New York, NY, USA, 1988; Volume 12, ISBN 0-444-60166-X. [Google Scholar]

- Park, M.-C.; Im, E.-S.; Shin, B.-C.; Han, H.-S. Improvement of Shallow Soil Using Electric Heating Equipment. J. Korean Geotech. Soc. 2012, 28, 41–54. [Google Scholar] [CrossRef]

- Hu, Q.; Liu, Z.; He, L.; Gu, Y.; Zeng, J.; Li, M. Study on Microwave Heating In-Situ Treatment of Wasted Clayey Soil. J. Soils Sediments 2023, 23, 3345–3361. [Google Scholar] [CrossRef]

| Properties | Temperature, °C | |||

|---|---|---|---|---|

| Untreated | 200 | 400 | 600 | |

| Liquid Limit, LL, % | 60.00 | 57.64 | 45.61 | 34.96 |

| Plastic Limit, PL, % | 33.00 | 39.00 | 38.78 | 32.02 |

| Plasticity Index, PI | 27.00 | 18.64 | 6.83 | 2.94 |

| Shrinkage Limit, SL, % | 15.00 | 23.39 | 32.74 | 30.24 |

| Specific Gravity, Gs | 2.800 | 2.899 | 2.868 | 2.804 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alsabhan, A.; Hamid, W.; Al-Mahbashi, A.M.; Binyahya, A.S. Mitigation of Expansive Soil Through Controlled Thermal Treatment: Geotechnical and Microstructural Assessment. Buildings 2025, 15, 3678. https://doi.org/10.3390/buildings15203678

Alsabhan A, Hamid W, Al-Mahbashi AM, Binyahya AS. Mitigation of Expansive Soil Through Controlled Thermal Treatment: Geotechnical and Microstructural Assessment. Buildings. 2025; 15(20):3678. https://doi.org/10.3390/buildings15203678

Chicago/Turabian StyleAlsabhan, Abdullah, Wagdi Hamid, Ahmed M. Al-Mahbashi, and Abobaker Salem Binyahya. 2025. "Mitigation of Expansive Soil Through Controlled Thermal Treatment: Geotechnical and Microstructural Assessment" Buildings 15, no. 20: 3678. https://doi.org/10.3390/buildings15203678

APA StyleAlsabhan, A., Hamid, W., Al-Mahbashi, A. M., & Binyahya, A. S. (2025). Mitigation of Expansive Soil Through Controlled Thermal Treatment: Geotechnical and Microstructural Assessment. Buildings, 15(20), 3678. https://doi.org/10.3390/buildings15203678