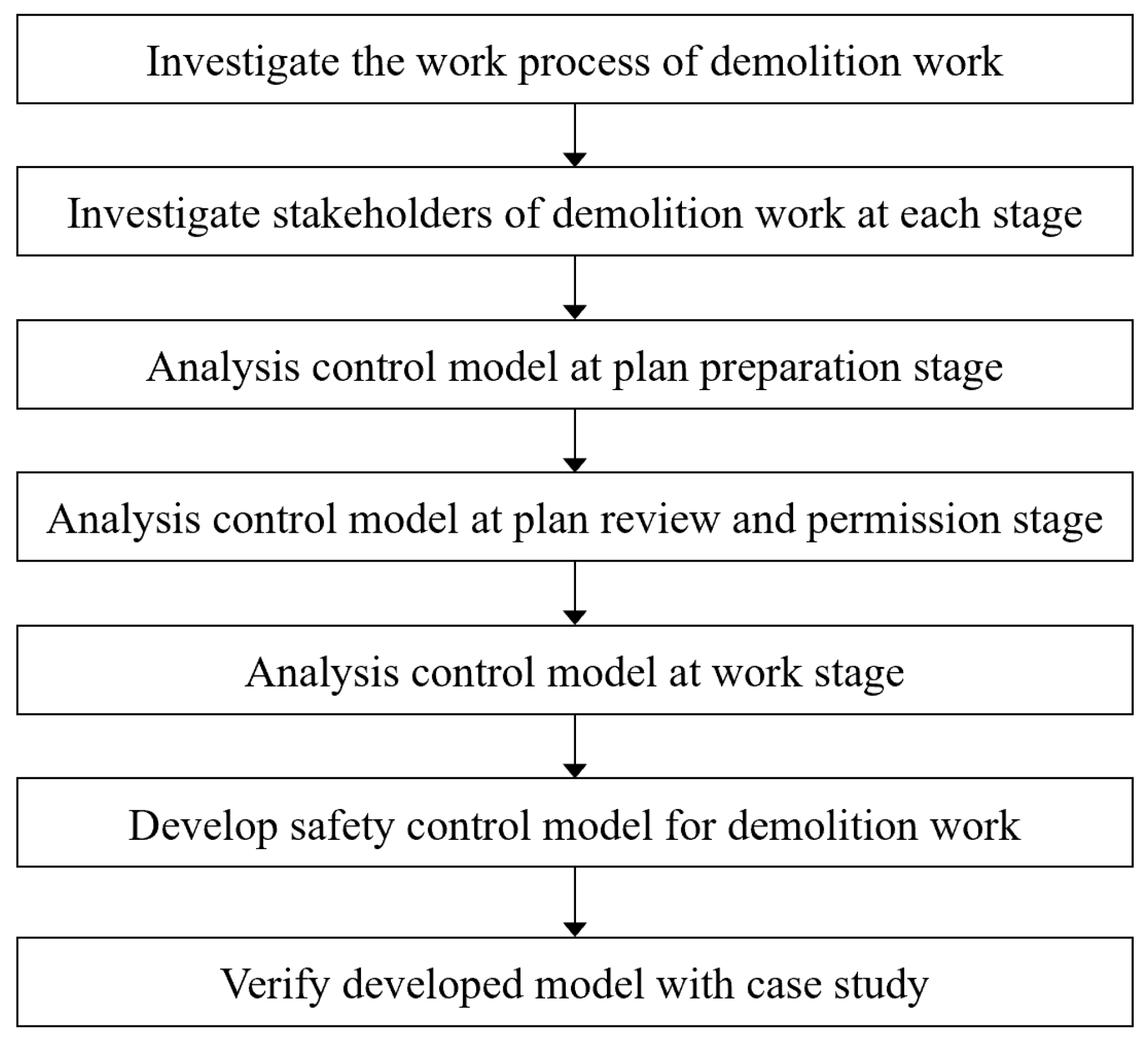

Proposed Safety Control Structure Model for Building Demolition Projects Based on STAMP Model in South Korea

Abstract

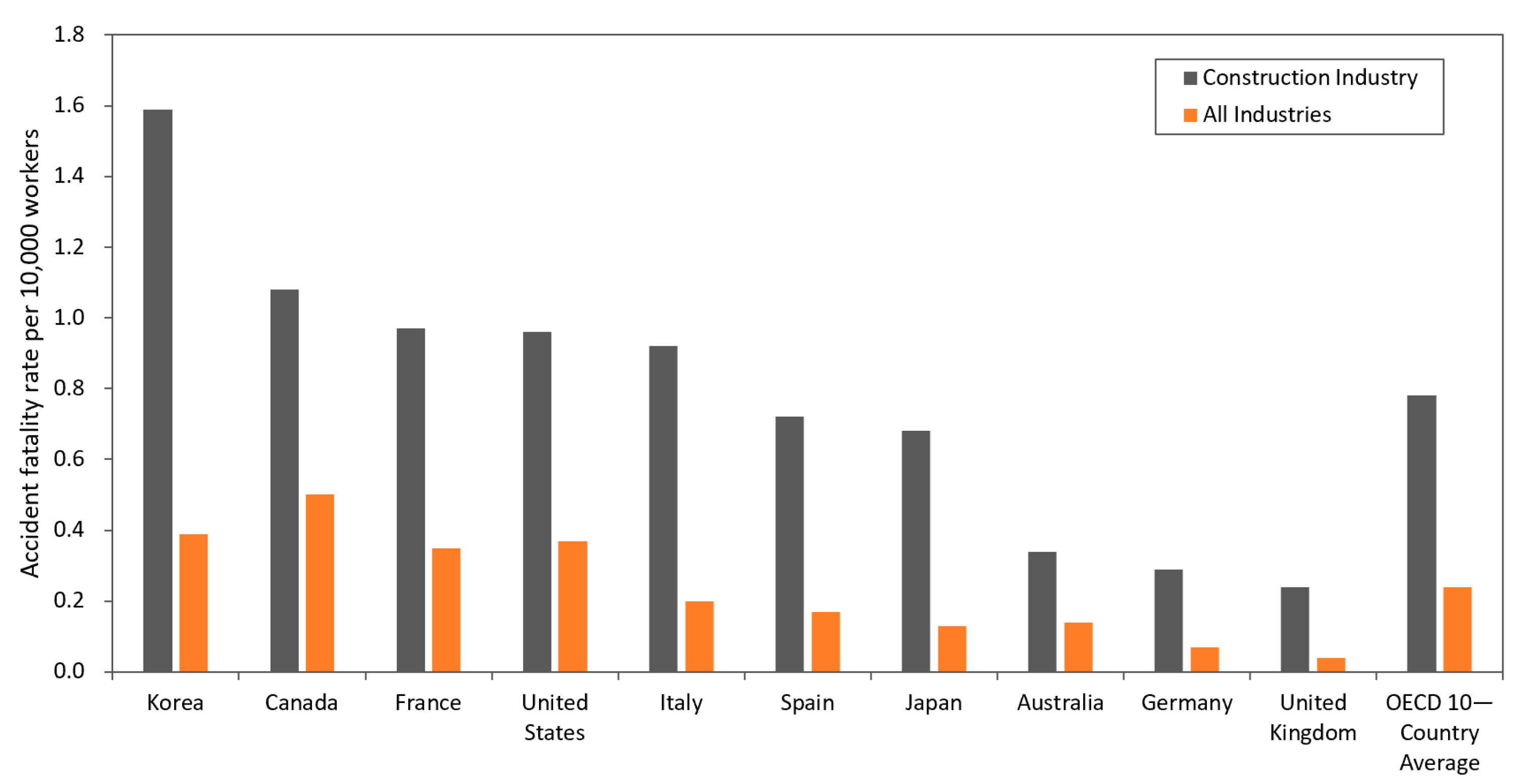

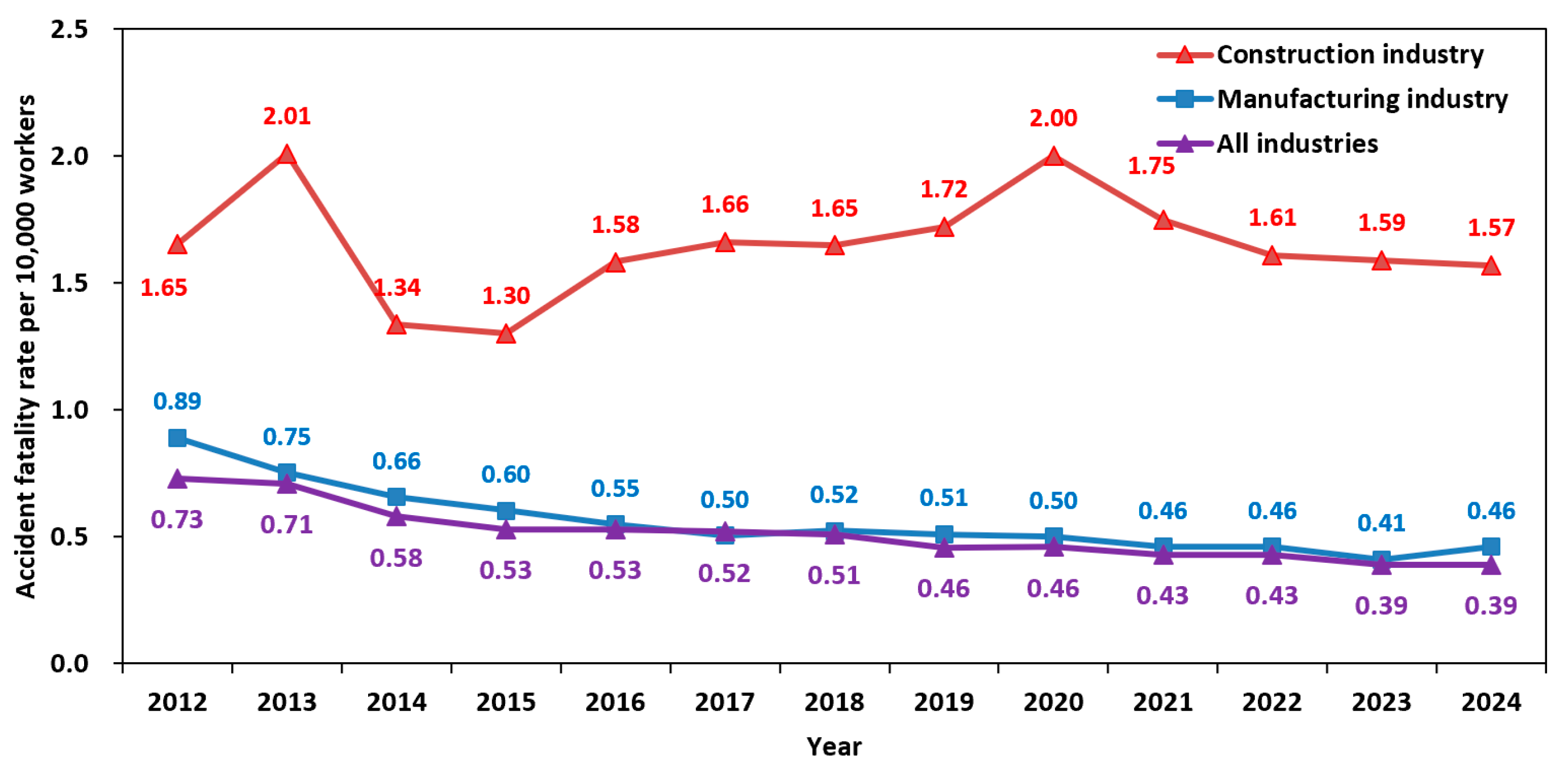

1. Introduction

2. Theoretical Background

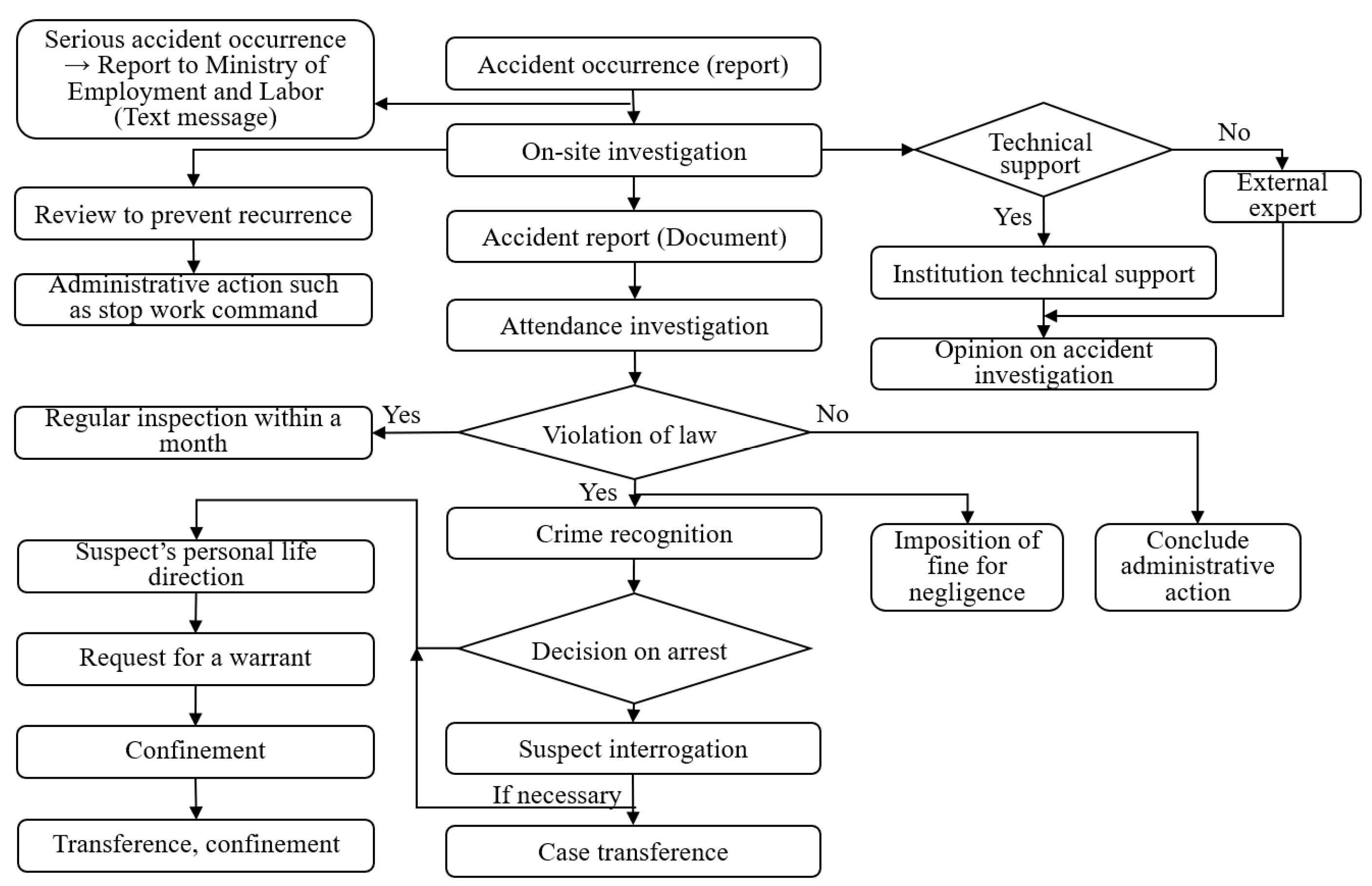

2.1. Limitations of Accident Investigation System

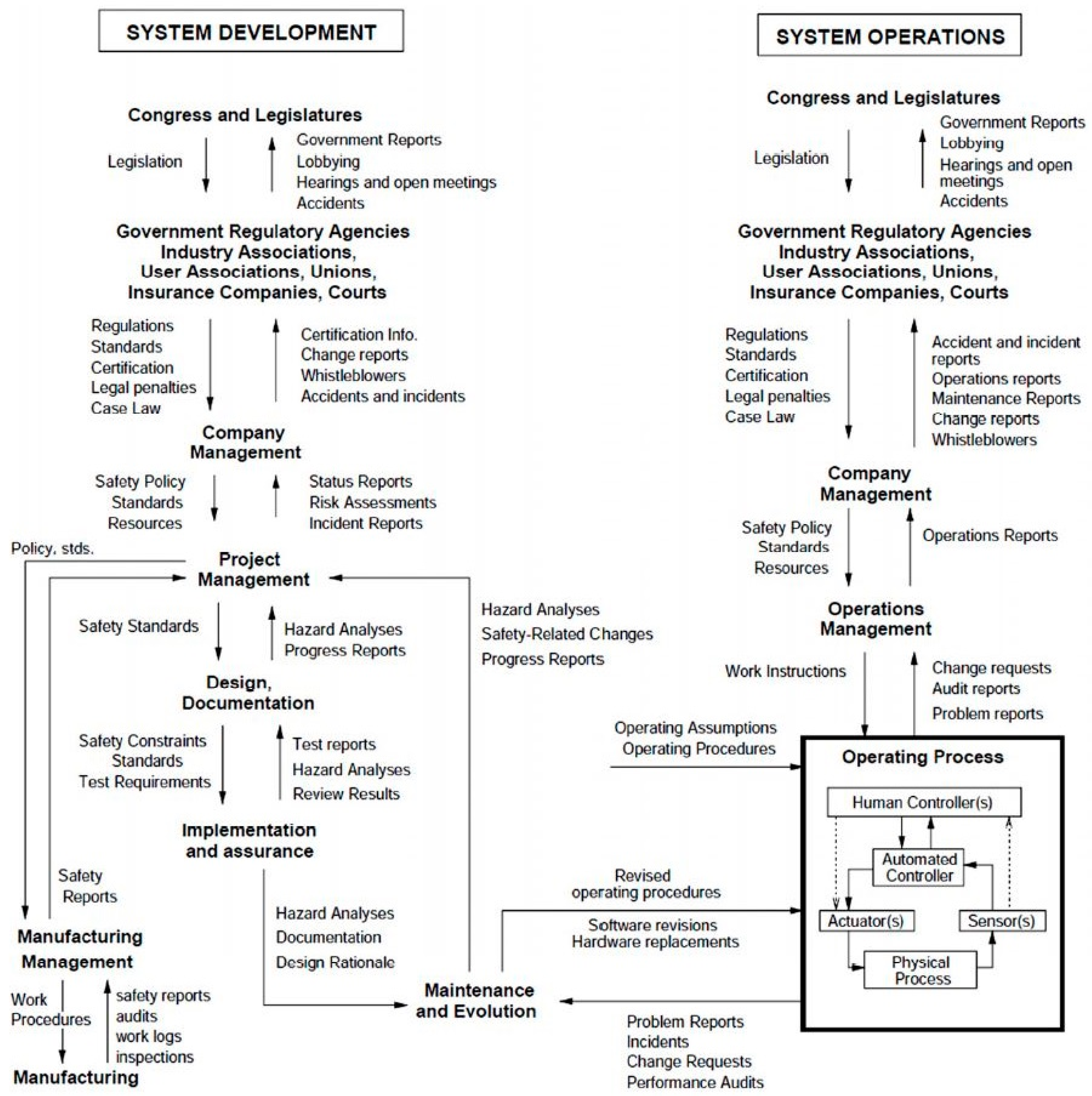

2.2. STAMP Model

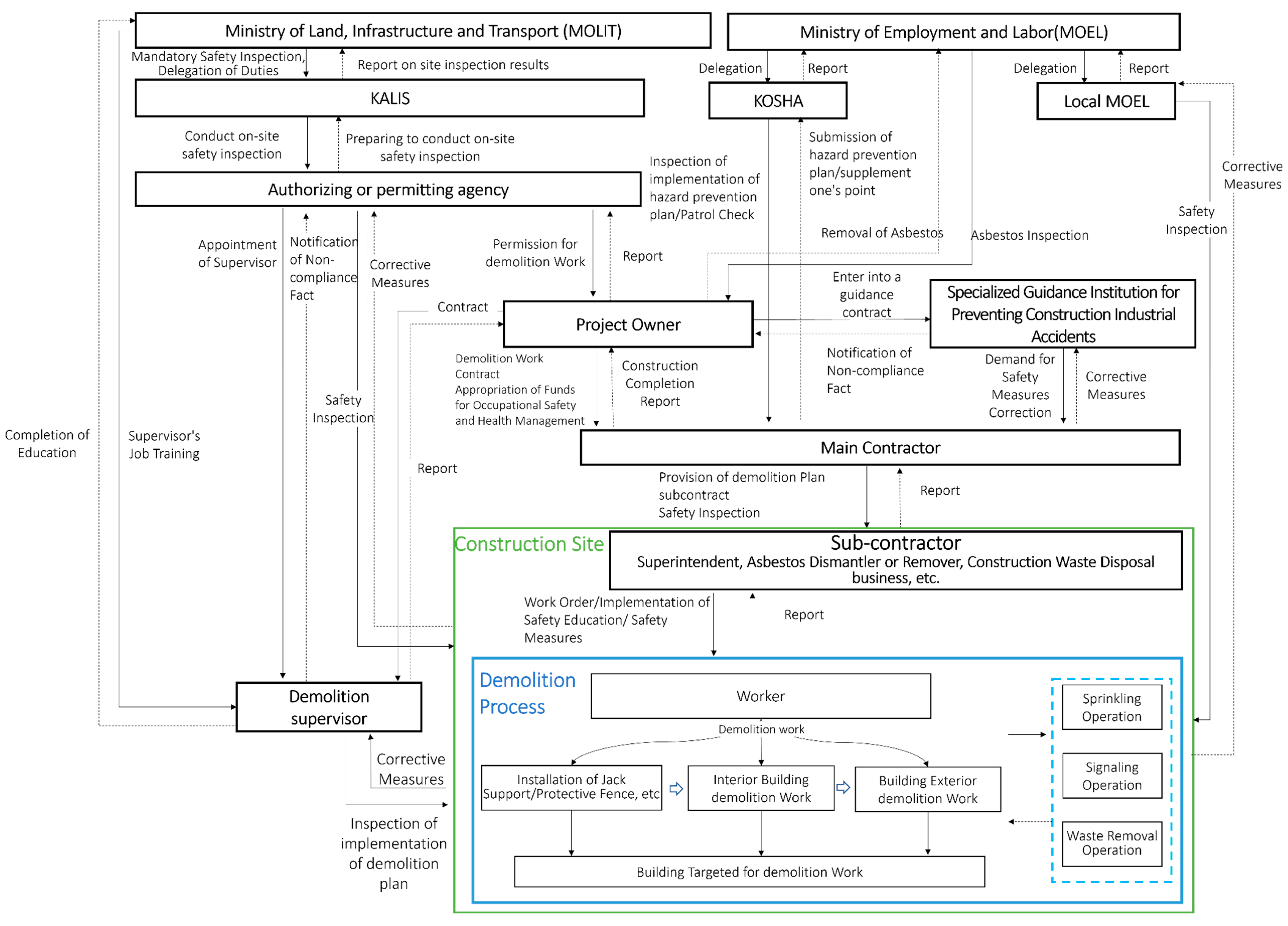

3. Work Process and Stakeholders of Demolition Work in South Korea

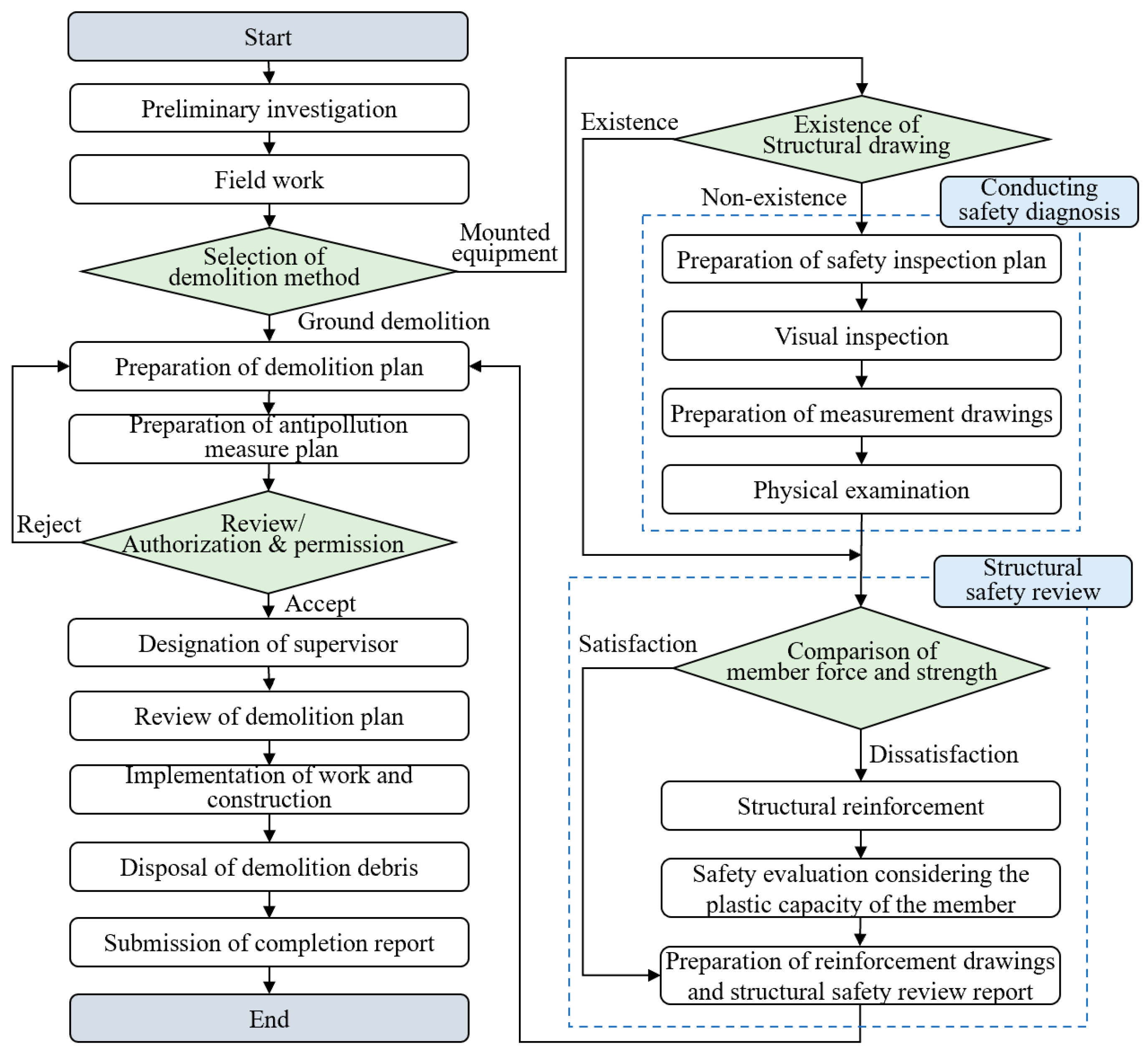

3.1. Demolition Process: Permitting Authority

3.2. Stakeholders According to Demolition Stage

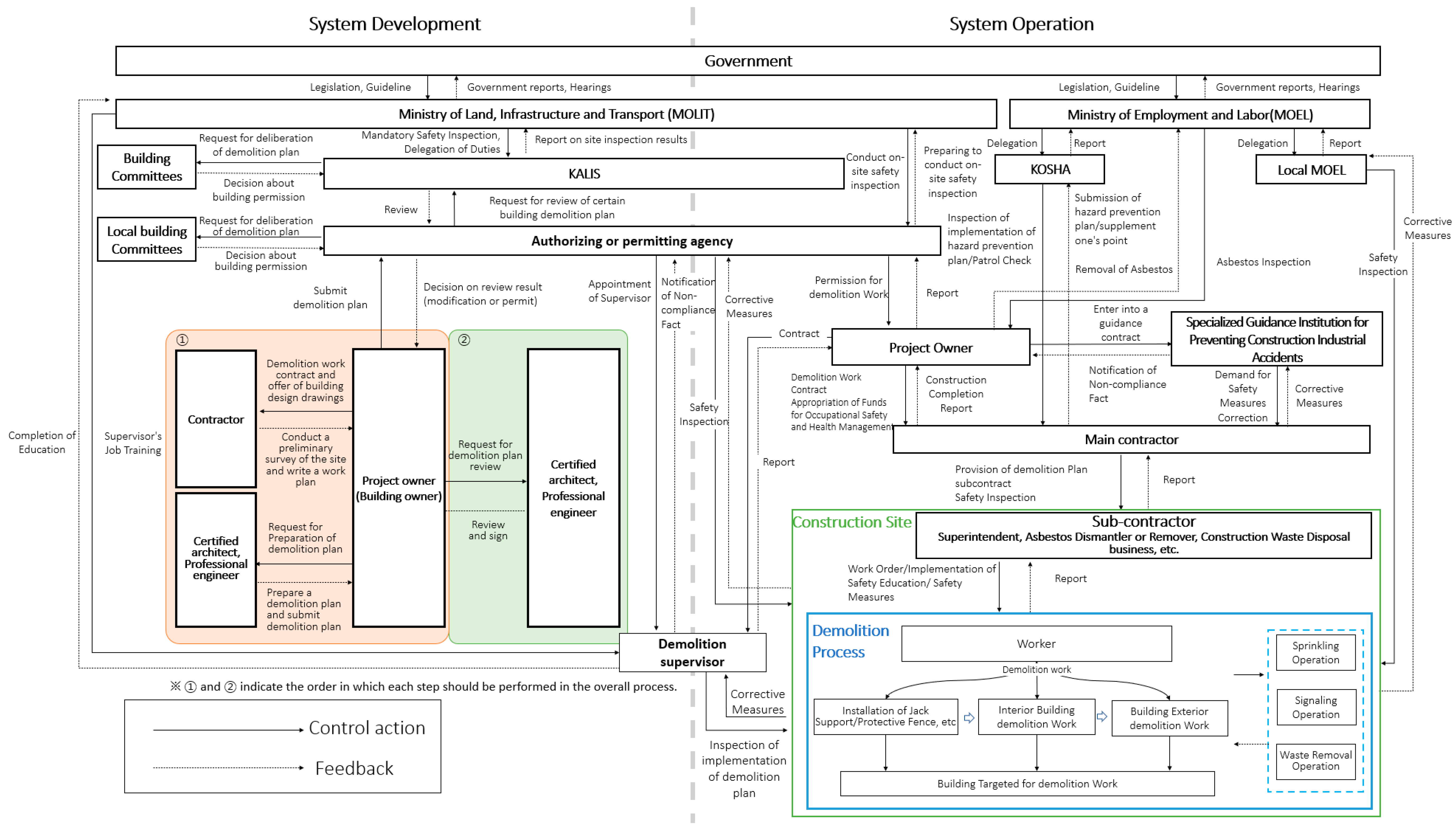

4. Model Development

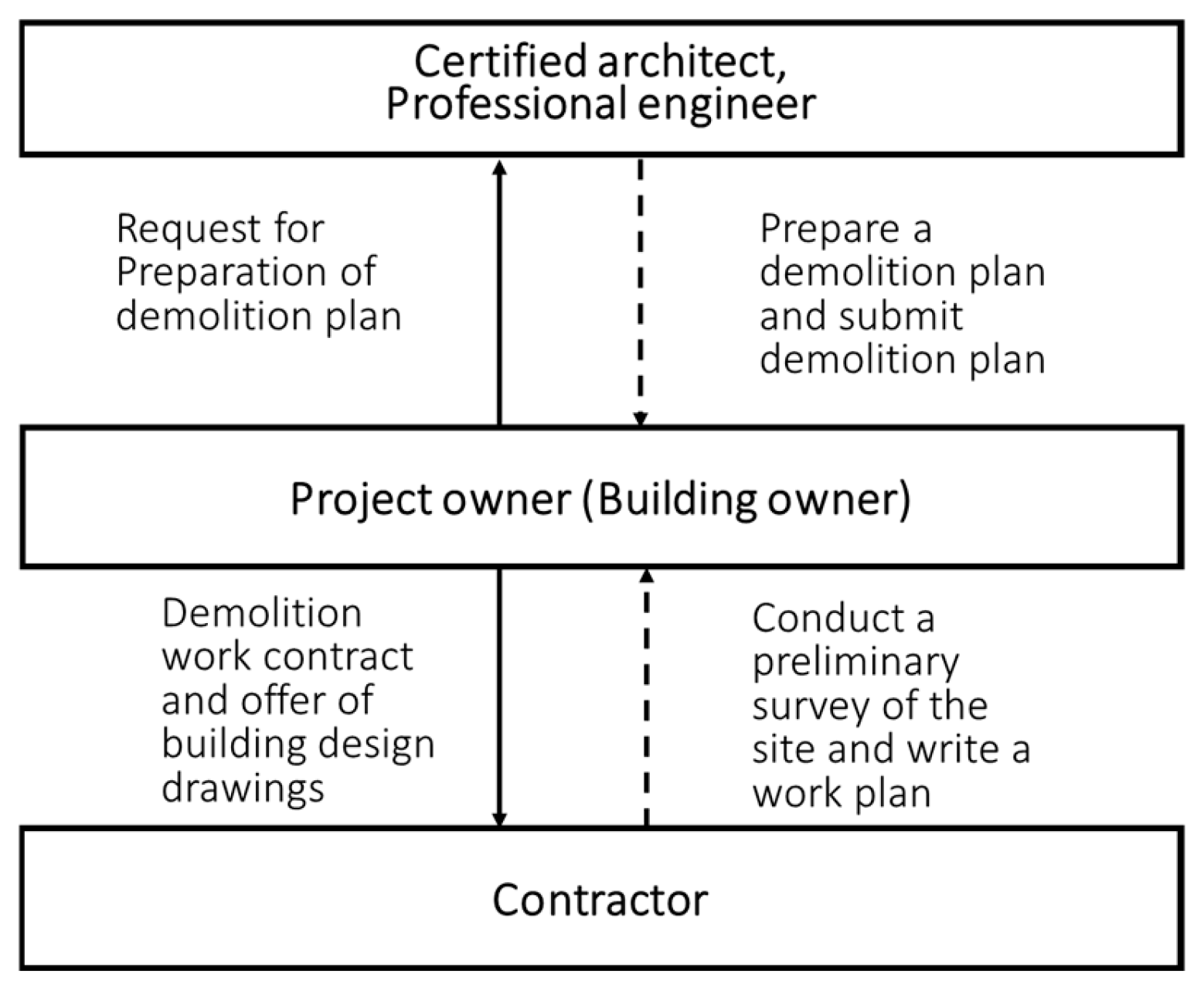

4.1. Control Model at the Demolition Plan Preparation Stage

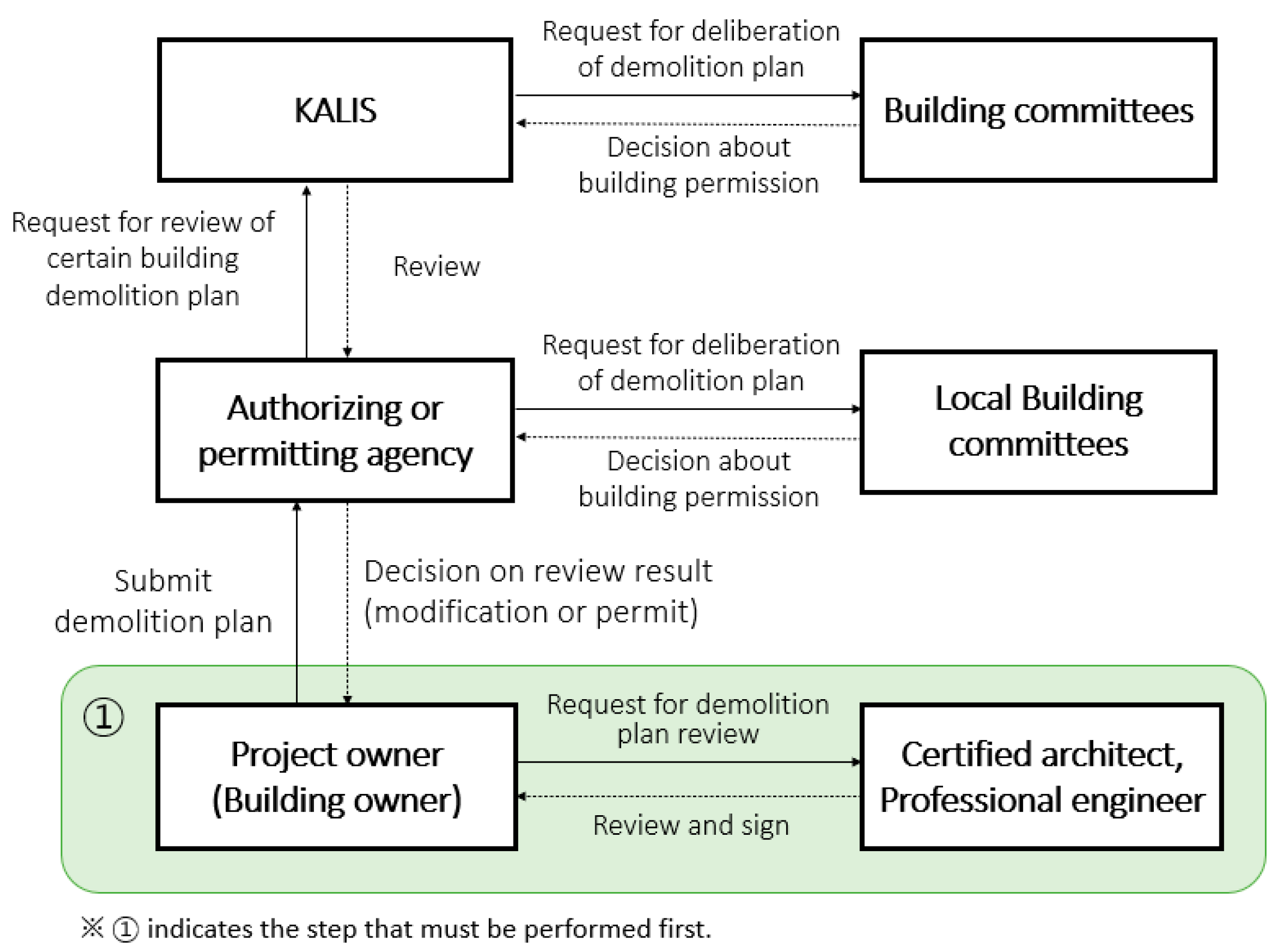

4.2. Control Model at the Demolition Plan Review and Building Permitting Stage

4.3. Control Model in the Demolition Work Stage

4.4. Development of Safety Control Model for Building Demolition System

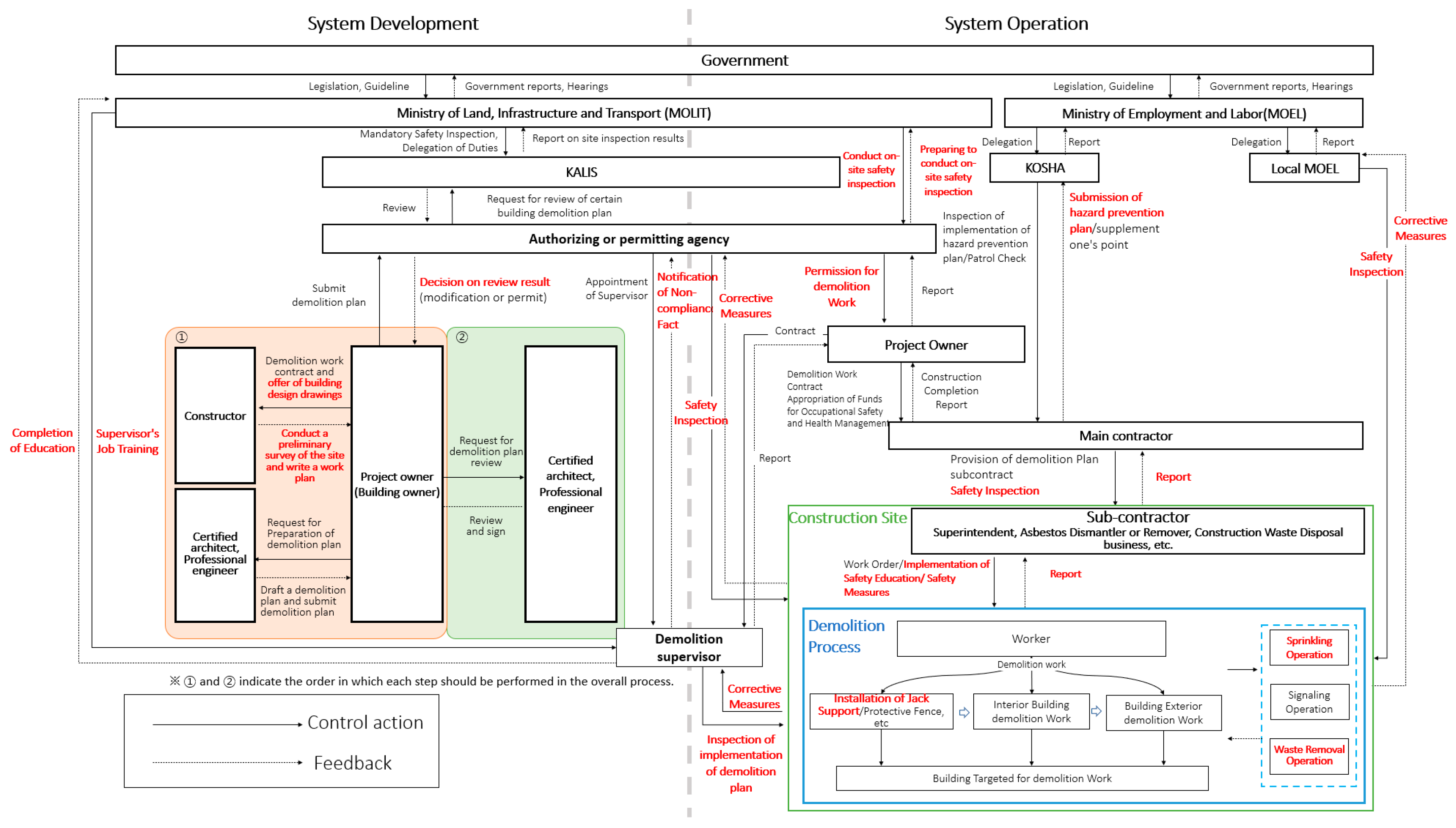

5. Case Study

5.1. Selection of Accident

- -

- Collapse of the first-floor slab owing to excessive load from the overburden caused by the soil inside the building.

- -

- Excessive watering operations reduced the internal friction angle of the soil, leading to a rapid impact load.

5.2. Accident Analysis Results Using the Developed Model

6. Conclusions

- Licensing agencies decisively influence the overall safety of demolition projects.

- Supervisors’ inspections and corrective actions directly impact on-site safety.

- Missing safety measures and weak enforcement highlight systemic and organizational deficiencies beyond technical issues.

- Strengthening training, qualification standards, and institutional authority for supervisors is essential.

- The proposed STAMP-based model provides a systematic framework to identify unimplemented safety measures and guide future policy improvements.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Shin, S.H.; Won, J.H.; Jeong, H.J.; Kang, M.G. Development of a site information classification model and a similar-site accident retrieval model for construction using the KLUE-BERT model. Buildings 2024, 14, 1797. [Google Scholar] [CrossRef]

- Omer, M.M.; Mohd-Ezazee, N.M.A.; Lee, Y.S.; Rajabi, M.S.; Rahman, R.A. Constructive and destructive leadership behaviors, skills, styles and traits in BIM-based construction projects. Buildings 2022, 12, 2068. [Google Scholar] [CrossRef]

- Wang, D.; Qin, Y.; He, Y. The effect of leader–follower psychological capital congruence on safety behavior. Buildings 2024, 14, 1. [Google Scholar] [CrossRef]

- Igwe, C.; Nasiri, F.; Hammad, A. Construction workspace management: Critical review and roadmap. Int. J. Constr. Manag. 2022, 22, 1960–1973. [Google Scholar] [CrossRef]

- Won, J.H.; Jeong, H.J.; Kim, W.; Kim, S.; Kang, S.Y.; Hwang, J.M. Mechanisms analysis for fatal accident types caused by multiple processes in the workplace: Based on accident case in South Korea. Int. J. Environ. Res. Public Health 2022, 19, 11430. [Google Scholar] [CrossRef]

- Moon, H.S.; Kim, H.S.; Kim, C.H.; Kang, L.S. Development of a schedule-workspace interference management system simultaneously considering the overlap level of parallel schedules and workspaces. Autom. Constr. 2013, 39, 93–105. [Google Scholar] [CrossRef]

- Gwak, H.S.; Shin, W.S.; Park, Y.J. Space-constrained scheduling optimization method for minimizing the effects of stacking of Trades. Appl. Sci. 2021, 11, 11047. [Google Scholar] [CrossRef]

- ILO (International Labour Organization), Statistic on Safety and Health at Work. Available online: https://ilostat.ilo.org/topics/safety-and-health-at-work/ (accessed on 17 August 2025).

- MOLIT Construction Safety Management Integrated Information. Construction Accident Information Report (2024 Construction Accidents). 2025. Available online: https://www.csi.go.kr/community/dataMain.do (accessed on 1 September 2025).

- Mitropoulos, P.; Abdelhamid, T.S.; Howell, G.A. Systems model of construction accident causation. J. Constr. Eng. Manag. 2005, 131, 816–825. [Google Scholar] [CrossRef]

- Ertas, H.; Erdogan, A.S. An analysis of occupational accidents in demolition work. Civ. Eng. Archit. 2017, 5, 37–51. [Google Scholar] [CrossRef]

- Takahashi, H. An investigation of fatal accidents in demolition work of buildings. In Proceedings of the International Structural Engineering and Construction Conference, Chicago, IL, USA, 20–25 May 2019. [Google Scholar] [CrossRef]

- Patel, D.J.; Patel, D.A. Identification of potential demolition hazard attributes: An exploratory factor analysis approach. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2023, 15, 04522061. [Google Scholar] [CrossRef]

- Patel, D.J.; Ponnana, S.A.; Patel, D.A.; Patel, M.B. Development of a framework for risk assessment in building demolition works. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2023, 15, 04523016. [Google Scholar] [CrossRef]

- Alipour-Bashary, M.; Ravanshadnia, M.; Abbasianjahromi, H.; Asnaashari, E. A hybrid fuzzy risk assessment framework for determining building demolition safety index. KSCE J. Civ. Eng. 2021, 25, 1144–1162. [Google Scholar] [CrossRef]

- Alipour-Bashary, M.; Ravanshadnia, M.; Abbasianjahromi, H.; Asnaashari, E. Building demolition risk assessment by applying a hybrid fuzzy FTA and fuzzy CRITIC-TOPSIS framework. Int. J. Build. Pathol. Adapt. 2022, 40, 134–159. [Google Scholar] [CrossRef]

- Fu, M.; Liang, Y.; Feng, Q.; Wu, B.; Tang, G. Research on the Application of Multi-Source Data Analysis for Bridge Safety Monitoring in the Reconstruction and Demolition Process. Buildings 2022, 12, 1195. [Google Scholar] [CrossRef]

- Mohammadi, M.; Mohammad, S.M.; Roshanbin, M.; Lomboy, G.R.; Abubakri, S. Advances in Concrete Demolition Technologies: A Review of Conventional and Emerging Methods for Sustainable Waste Management. Eng 2024, 5, 3174–3191. [Google Scholar] [CrossRef]

- Yuzbasi, J. Controlled Demolition: Novel Monitoring and Experimental Validation of Blast-Induced Full-Scale Existing High-Rise Building Implosion Using Numerical Finite Element Simulations. J. Civ. Struct. Health Monit. 2025, 15, 891–914. [Google Scholar] [CrossRef]

- Andruszko, J.; Derlukiewicz, D. Enhancing Demolition Works Safety: Integrating Numerical and Experimental Methods for Structural Failure Prevention in Remote-Controlled Demolition Robots. Eksploat. I Niezawodn.—Maint. Reliab. 2024, 26, 1–16. [Google Scholar] [CrossRef]

- Leveson, N. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Salmon, P.M.; Cornelissen, M.; Trotter, M.J. Systems-based accident analysis methods: A Comparison of Accimap, HFACS, and STAMP. Saf. Sci. 2012, 50, 1158–1170. [Google Scholar] [CrossRef]

- Suraji, A.; Duff, A.R.; Peckitt, S.J. Development of causal model of construction accident causation. J. Constr. Eng. Manag. 2001, 127, 337–344. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, W.; Xu, P.; Chen, N. Applicability of accident analysis methods to Chinese construction accidents. J. Saf. Res. 2019, 68, 187–196. [Google Scholar] [CrossRef]

- Woolley, M.J.; Goode, N.; Read, G.J.M.; Salmon, P.M. Have we reached the organisational ceiling? A review of applied accident causation models, methods and contributing factors in construction. Theor. Issues Ergon. Sci. 2019, 20, 533–555. [Google Scholar] [CrossRef]

- Yoon, H.K.; Kwon, Y.J.; Oh, B.H.; Gwon, Y.I.; Yoon, Y.G.; Oh, T.K. A Study on the improvement of safety management of plan/order, design, and construction business management. J. Korean Soc. Saf. 2020, 35, 56–63. [Google Scholar] [CrossRef]

- Yonhap News. ‘Gwangju Hakdong Collapse Disaster’ Only 3 People, Including the Subcontractor Manager and Supervisor, Were Sentenced to Prison (Comprehensive). 2021. Available online: https://www.yna.co.kr/view/AKR20220907065651054 (accessed on 1 September 2025).

- Kim, H.K.; Kim, T.H.; Cho, C.G. A Study on the Regulations and Standards for Structural Demolition Safety. Constr. Eng. Manag. 2022, 23, 8–12. Available online: https://scienceon.kisti.re.kr/commons/util/originalView.do?cn=JAKO202213841032554&oCn=JAKO202213841032554&dbt=JAKO&journal=NJOU00291654 (accessed on 1 September 2025).

- Lee, S.J.; Lee, H.G.; Shin, D.G. Analysis of the effectiveness and feasibility of accident analysis policy for construction safety from the perspective of system safety. J. Soc. Disaster Inf. 2023, 19, 146–160. [Google Scholar] [CrossRef]

- Shim, Y.K.; Jeong, J.W.; Lee, J.H.; Jeong, J.M. Necessity of improvements on code of practice at the demolition work considering building structure type: Based on demolition work of permission and registration. Korean J. Constr. Eng. Manag. 2020, 21, 66–74. [Google Scholar] [CrossRef]

- Primer, S. An STPA Primer. MIT Cambridge 2013. Available online: https://psas.scripts.mit.edu/home/wp-content/uploads/2013/10/An-STPA-Primer-version-0-4.pdf (accessed on 19 August 2025).

- Leveson, N.G. Applying systems thinking to analyze and learn from events. Saf. Sci. 2011, 49, 55–64. [Google Scholar] [CrossRef]

- Rising, J.M.; Leveson, N.G. Systems-theoretic process analysis of space launch vehicles. J. Space Saf. Eng. 2018, 5, 153–183. [Google Scholar] [CrossRef]

- Leveson, N.G. CAST Handbook: How to Learn More from Incidents and Accidents. 2019. Available online: http://sunnyday.mit.edu/CAST-Handbook.pdf (accessed on 19 August 2025).

- MOLIT and Korea Authority of Land & Infrastructure Safety. Building Demolition Plan Preparation and Review Manual. 2024. Available online: https://www.kalis.or.kr/www/brd/m_435/view.do?seq=191 (accessed on 1 September 2025).

- Central Building Accident Investigation Committee. Gwangju Building Demolition Collapse Accident Investigation Report. 2021. Available online: https://www.molit.go.kr/USR/policyData/m_34681/dtl.jsp?id=4559 (accessed on 1 September 2025).

| Stage | Stakeholders | |

|---|---|---|

| Demolition plan preparation | Project owner (building owner), contractor, certified architect, and professional engineer | |

| Demolition plan review and building permitting | Project owner, authorizing or permitting agency, Korea Authority of Land & Infrastructure Safety (KALIS), certified architect, and professional engineer | |

| Demolition work | Internal organization | Project owner, main contractor, subcontractor, supervisor |

| External organization | Authorizing or permitting agency Government

| |

| Control Action | Explanation | Feedback | Explanation |

|---|---|---|---|

| Project owner (building owner) | Provide demolition work contract and offer of building design drawings | Contractor | Conduct a preliminary survey of the site and write a work plan |

| Project owner | Request preparation of demolition plan | Certified architect, professional engineer | Prepare and submit demolition plan |

| Control Action | Explanation | Feedback | Explanation |

|---|---|---|---|

| Project owner | Request demolition plan review | Certified architect, professional engineer | Review and sign the demolition plan |

| Project owner | Submit demolition plan | Authorizing or permitting agency | Review the demolition plan |

| Authorizing or permitting agency | Request review of the demolition plan | KALIS | Review the demolition plan |

| KALIS | Request deliberation of demolition plan | Building committees | Make decision building permit |

| Authorizing or permitting agency | Issue demolition permit | Project owner | Receive demolition permit |

| Control Action | Explanation | Feedback | Explanation | |

|---|---|---|---|---|

| On-site internal organization | Project owner | Demolition work contract and appropriation of funds for occupational safety and health management | Main contractor | Construction completion report |

| Main contractor | Subcontract and offer demolition plan | Subcontractor | Construction completion report Follow demolition plan | |

| Main contractor | Safety inspection Safety education | Subcontractor | Safety measures | |

| Subcontractor | Work order Safety education | Construction site | Report work result | |

| Demolition supervisor | Check demolition plan is followed | Construction site | Corrective measures | |

| Project owner | Offer site information | Demolition supervisor | Inspection of implementation of demolition plan | |

| External organization | Authorizing or permitting agency | Safety inspection | Construction site | Corrective measures |

| Authorizing or permitting agency | Appointment of supervisor | Demolition supervisor | Notification of non-compliance | |

| Constructor | Submission of hazard prevention plan | KOSHA | Inspection of implementation of hazard prevention plan | |

| MOEL | Asbestos inspection | Project owner | Removal of asbestos | |

| Project owner | Covenant | Specialized guidance institution for preventing construction industrial accidents | Notification of non-compliance | |

| Specialized guidance institution for preventing construction industrial accidents | Demand for safety measure correction | Main contractor | Corrective measures | |

| MOIT | Mandatory safety inspection | Authorizing or permitting agency | Report on-site inspection results | |

| MOIT | Supervisor’s job training | Demolition supervisor | Completion of education | |

| KALIS | Conduct on-site safety inspection | Authorizing or permitting agency | Preparing to conduct on-site safety inspection | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeong, H.-J.; Won, J.-H. Proposed Safety Control Structure Model for Building Demolition Projects Based on STAMP Model in South Korea. Buildings 2025, 15, 3680. https://doi.org/10.3390/buildings15203680

Jeong H-J, Won J-H. Proposed Safety Control Structure Model for Building Demolition Projects Based on STAMP Model in South Korea. Buildings. 2025; 15(20):3680. https://doi.org/10.3390/buildings15203680

Chicago/Turabian StyleJeong, Hyeon-Ji, and Jeong-Hun Won. 2025. "Proposed Safety Control Structure Model for Building Demolition Projects Based on STAMP Model in South Korea" Buildings 15, no. 20: 3680. https://doi.org/10.3390/buildings15203680

APA StyleJeong, H.-J., & Won, J.-H. (2025). Proposed Safety Control Structure Model for Building Demolition Projects Based on STAMP Model in South Korea. Buildings, 15(20), 3680. https://doi.org/10.3390/buildings15203680