Analytical Investigation of CFRP- and Steel Plate-Strengthened RC Beams with Partially Unbonded Reinforcement

Abstract

1. Introduction

2. FEA Model

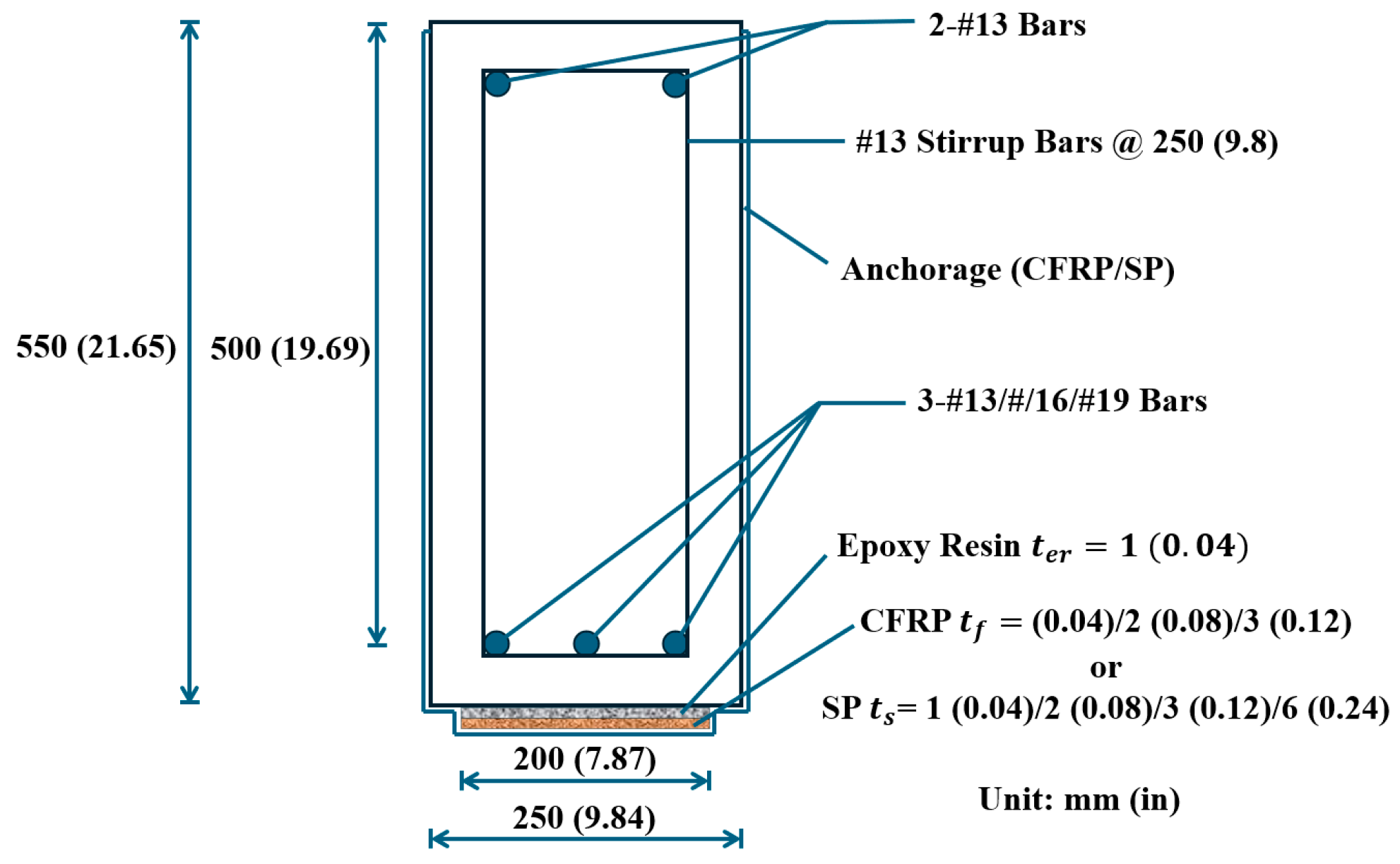

2.1. Cross-Section Design of Specimens

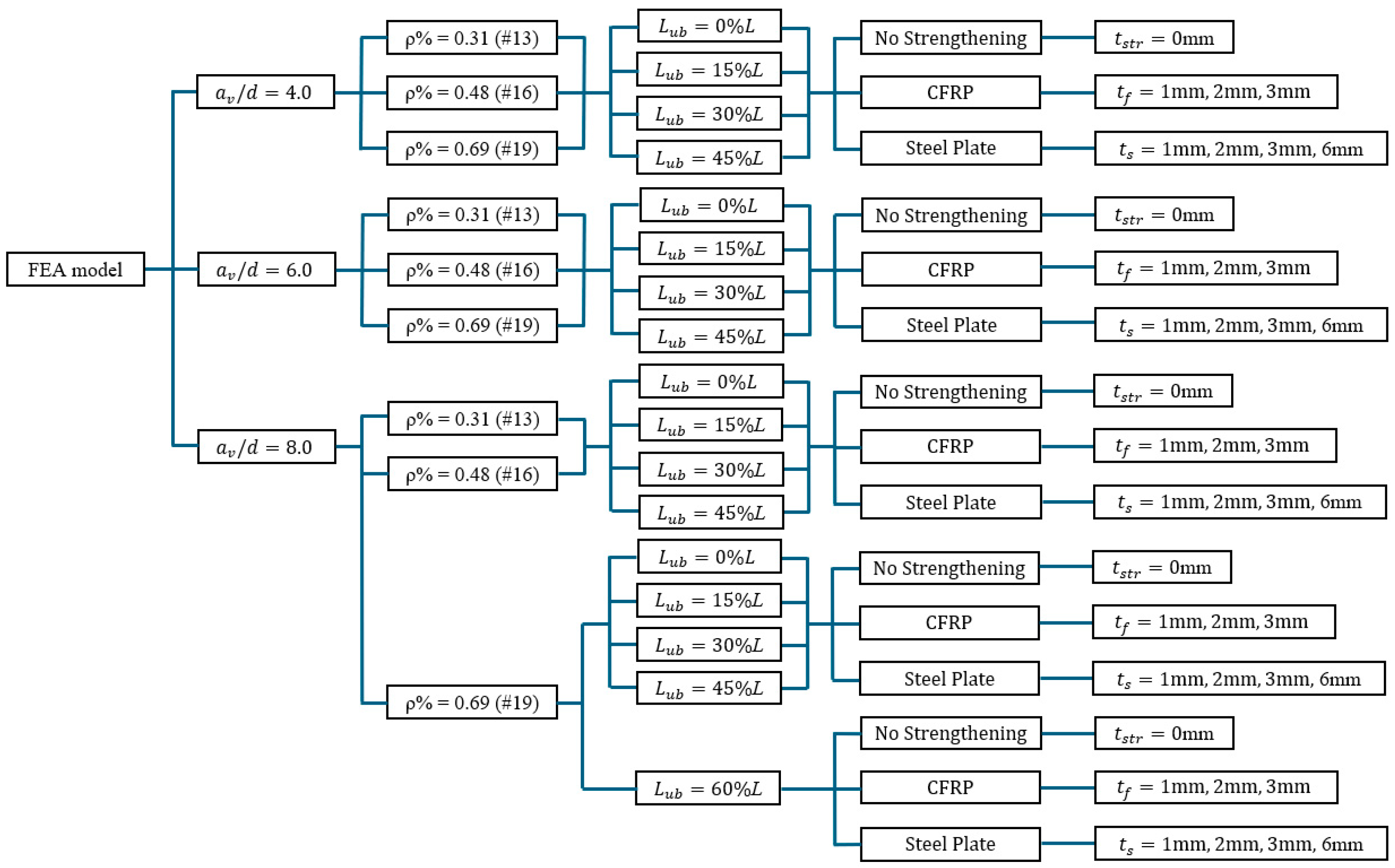

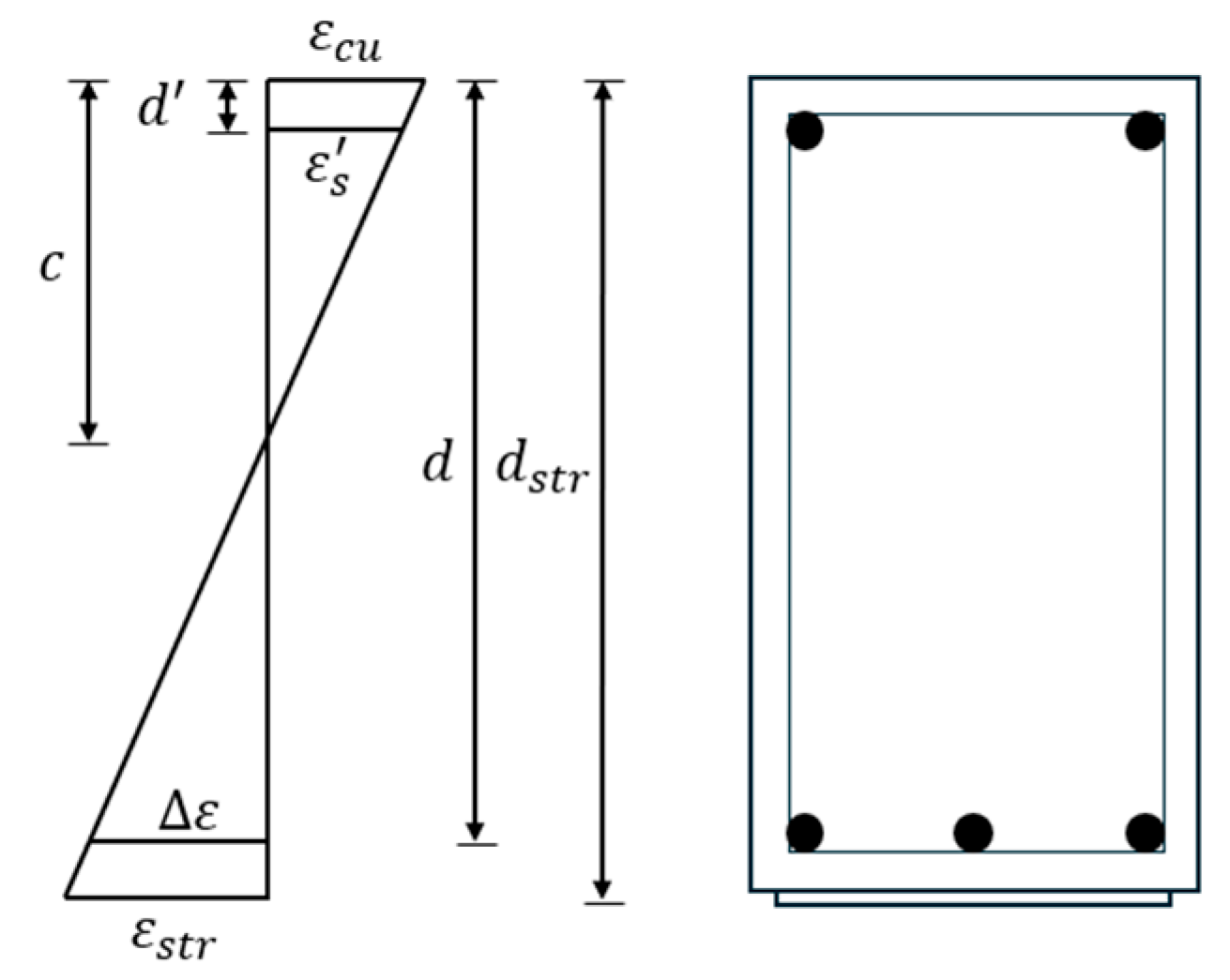

2.2. Parametric Framework

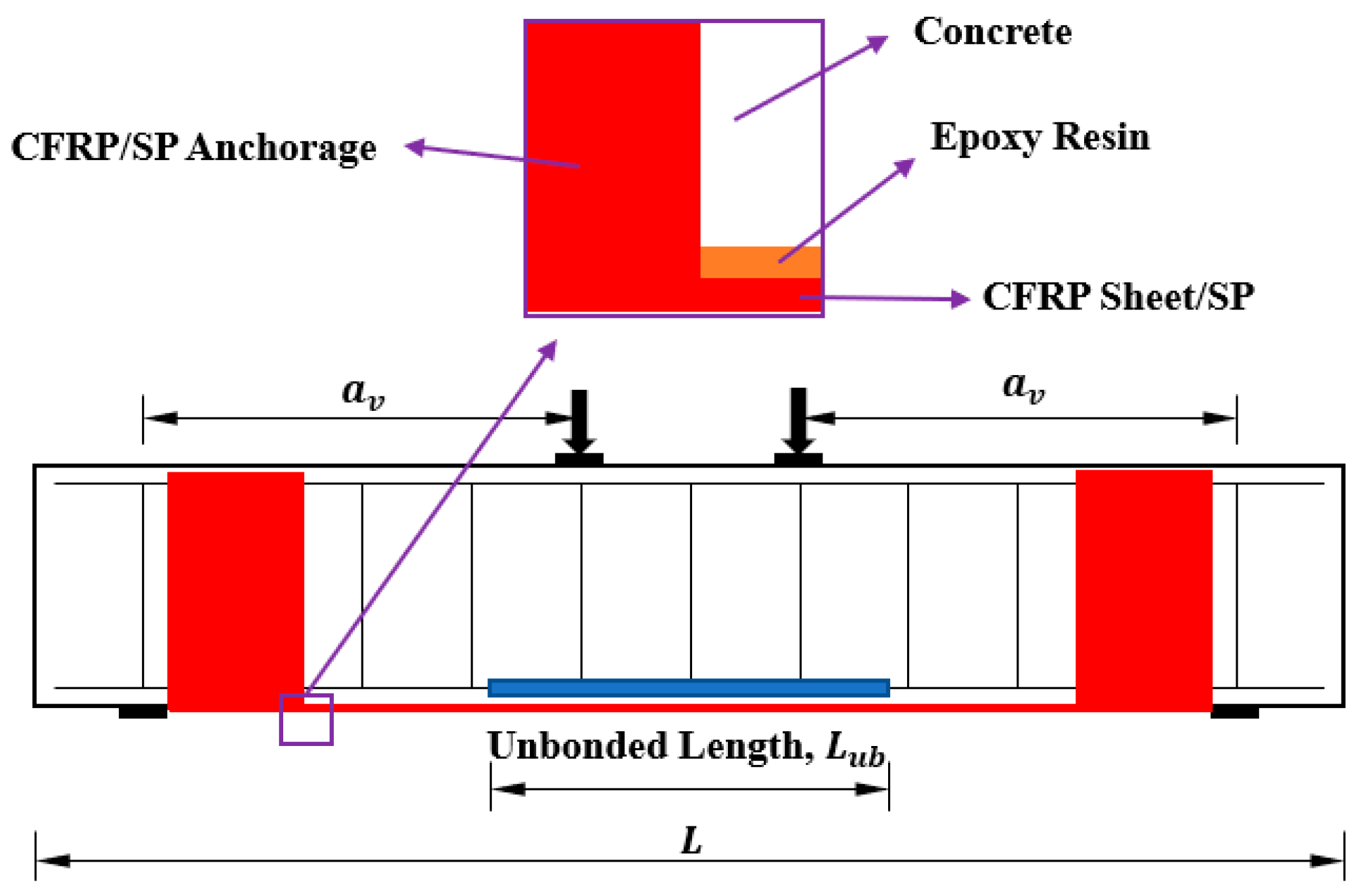

2.3. Strengthening Scheme

2.4. Materials

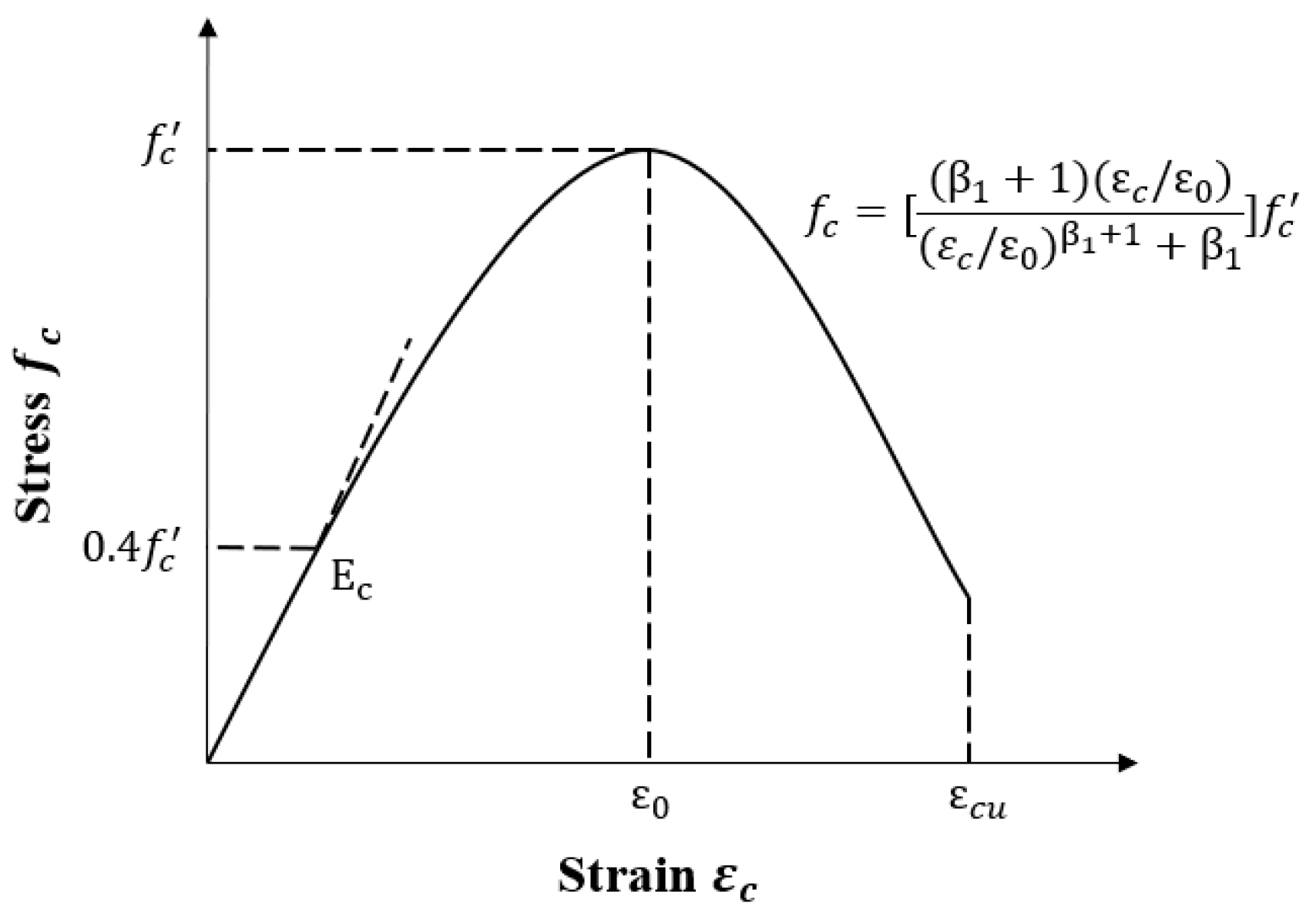

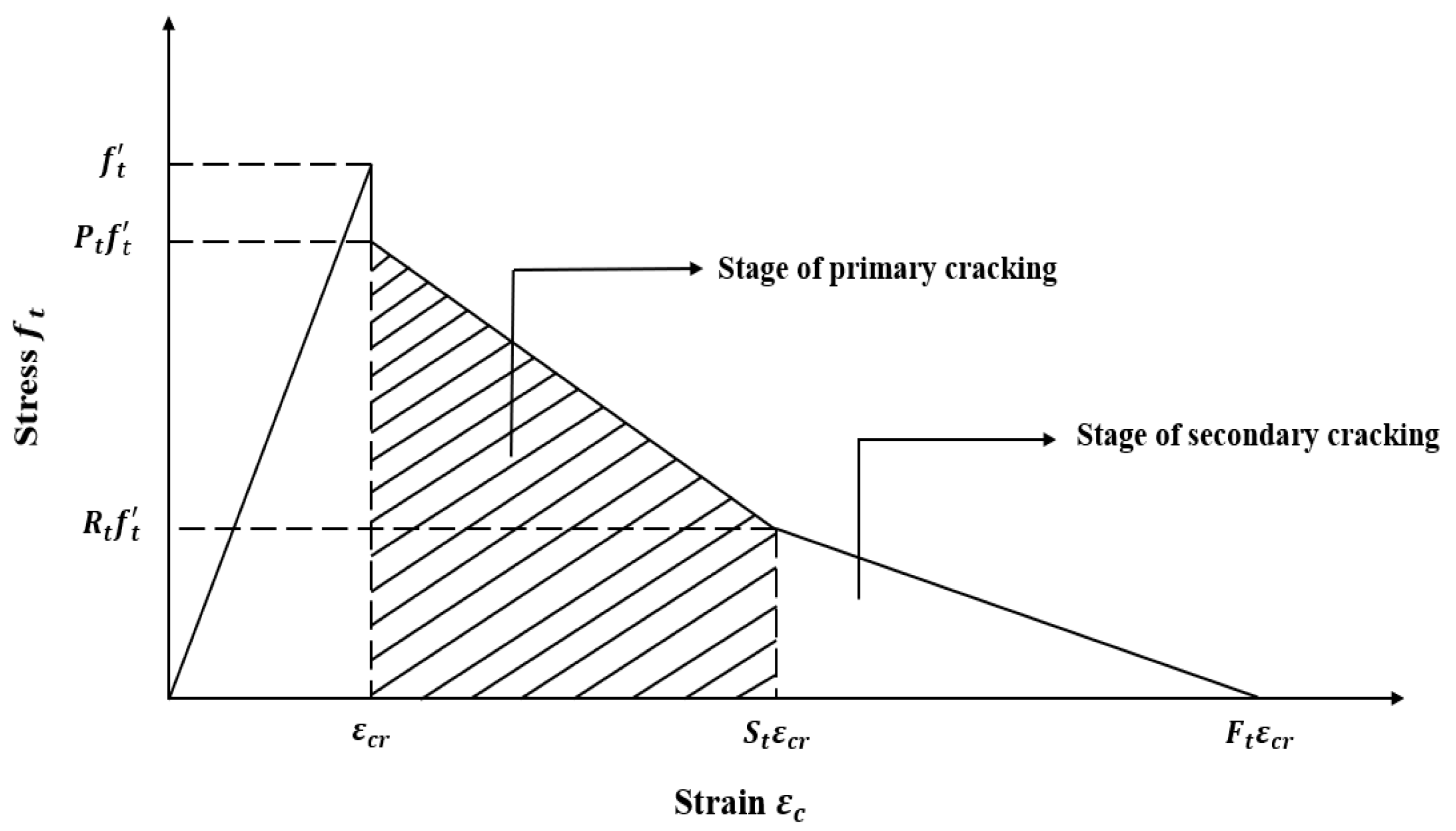

2.4.1. Concrete

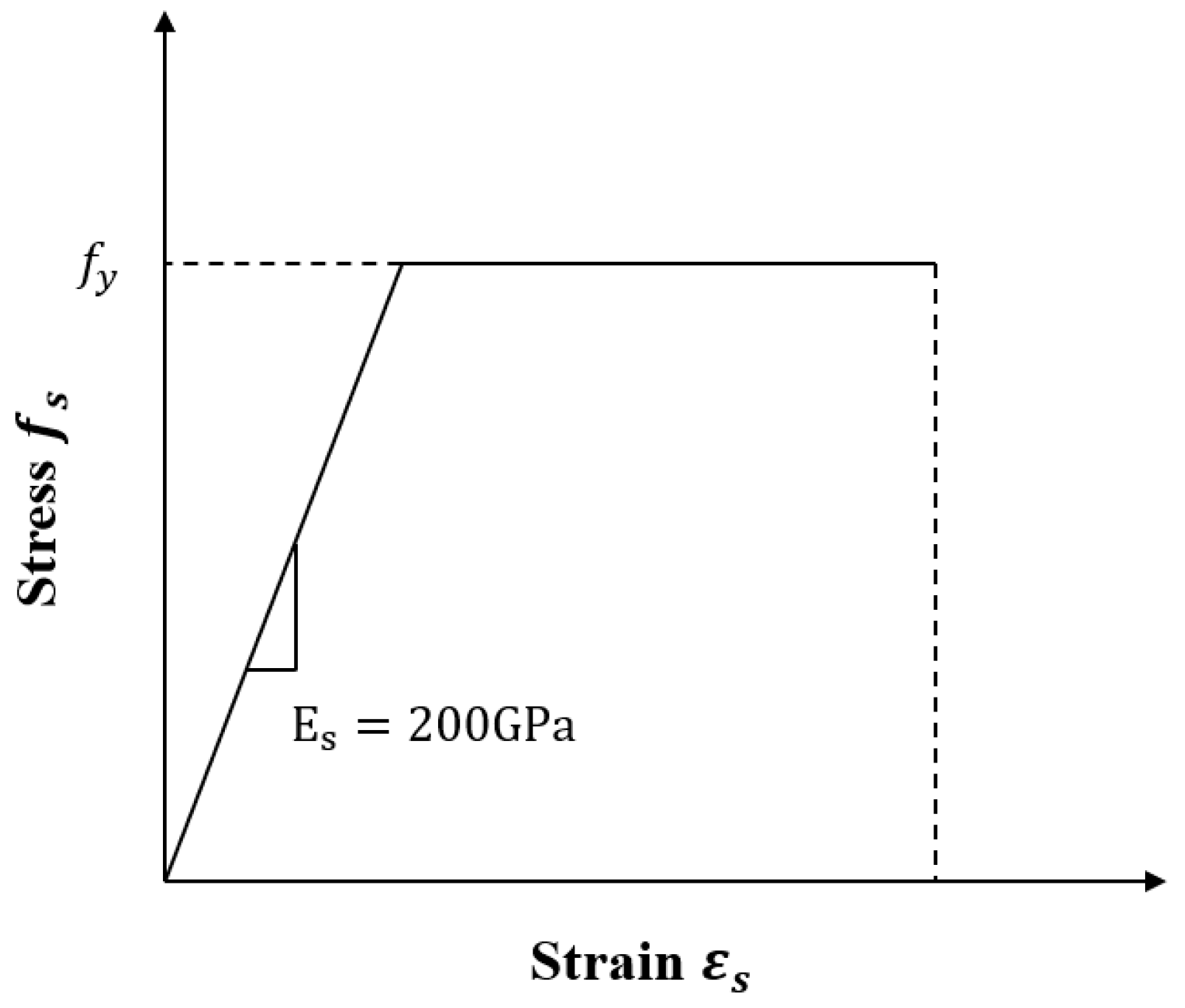

2.4.2. Steel

2.4.3. CFRP

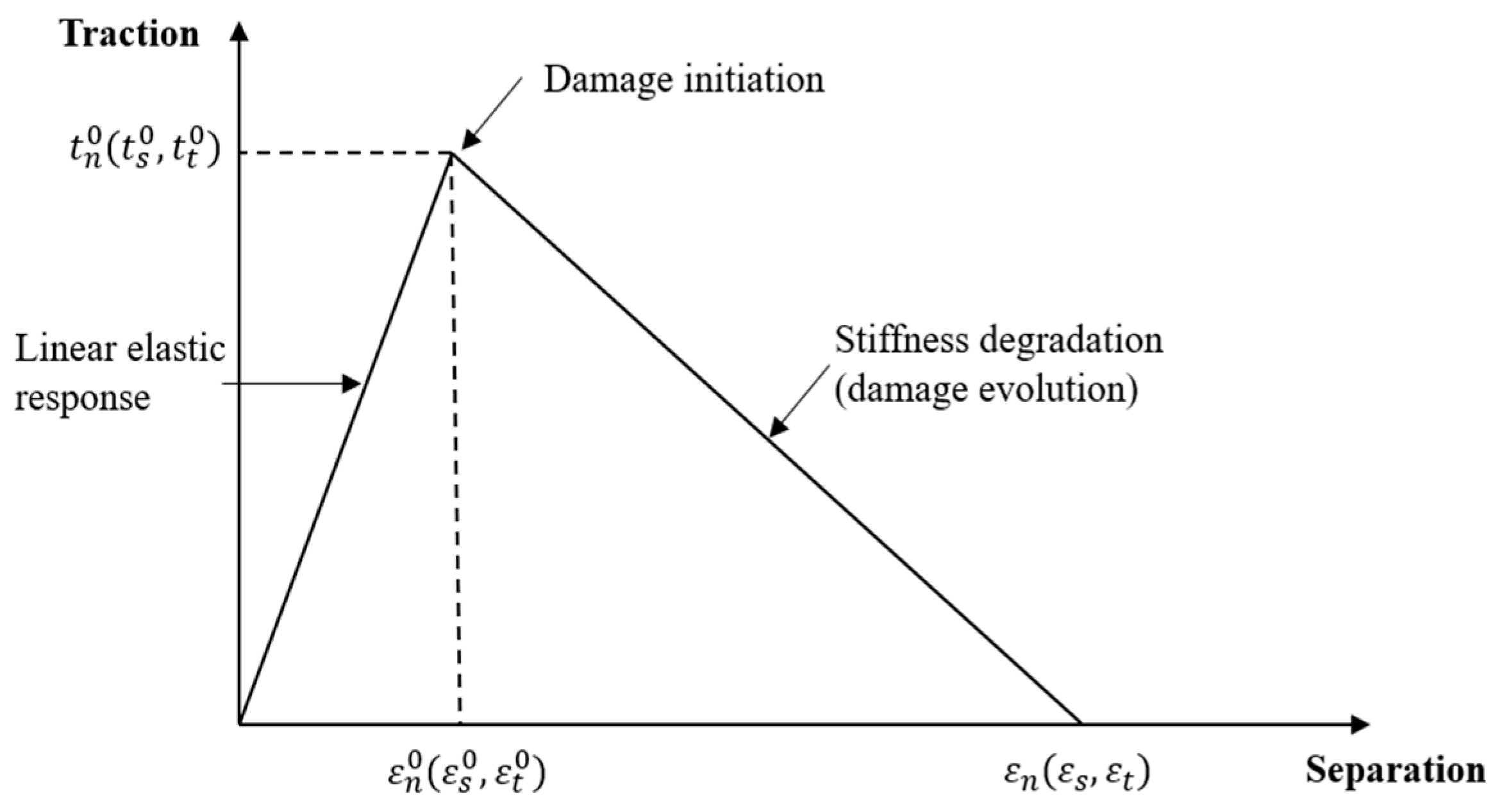

2.4.4. Cohesive Element Between Strengthened Materials and Concrete

2.5. Interaction Properties

- Supports and loading points: Rigid plates were introduced at supports and loading locations to ensure uniform load transfer and realistic boundary conditions, connected to the concrete through tie constraints.

- Stirrups and compressive reinforcement: These were embedded in the concrete using the Embedded constraint, assuming full bond and ensuring displacement compatibility while improving computational efficiency.

- Tensile reinforcement in unbonded regions: Modeled with Hard contact in the normal direction (compression transfer only) and frictionless tangential behavior, allowing free sliding without shear transfer.

- Tensile reinforcement in bonded regions: A Tie constraint was applied, with bond–slip and tension stiffening effects implicitly captured by the constitutive model, ensuring stable load transfer without explicit bond-slip definitions.

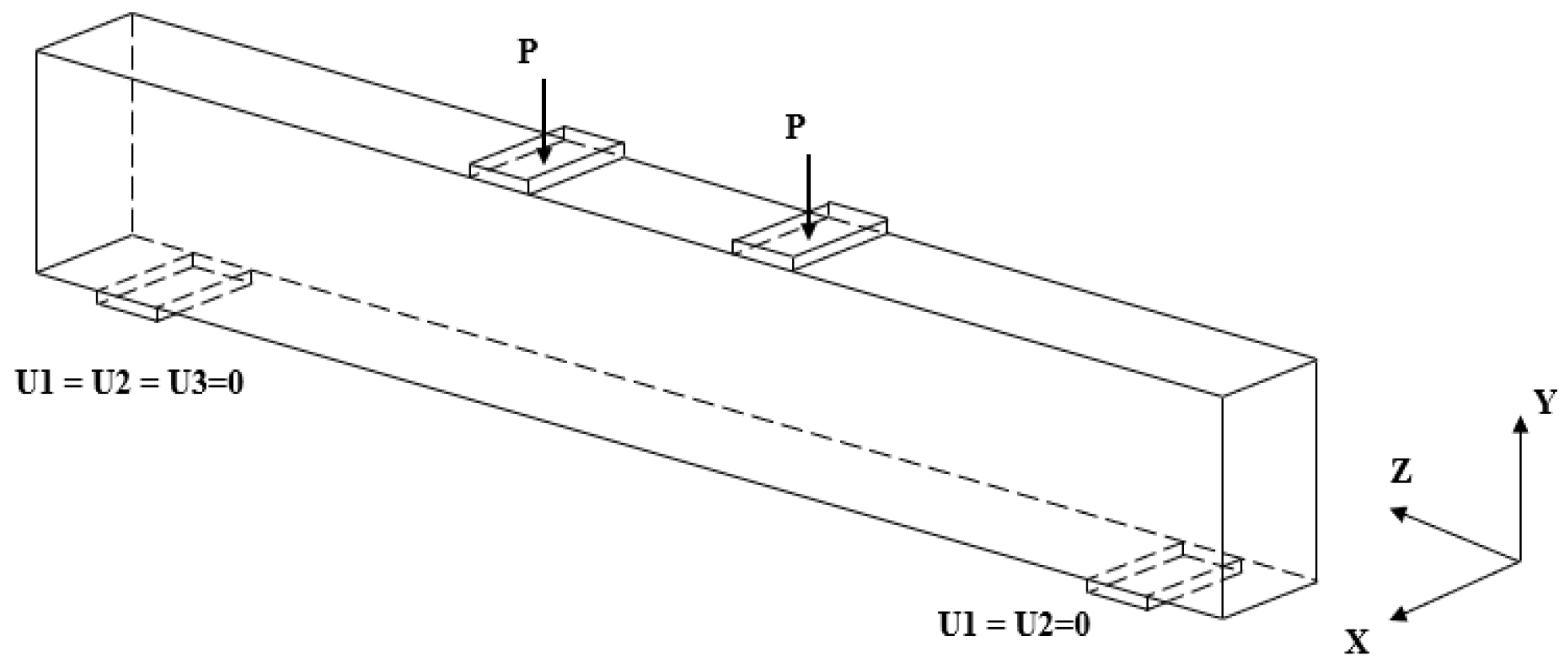

2.6. Boundary Conditions and Loading

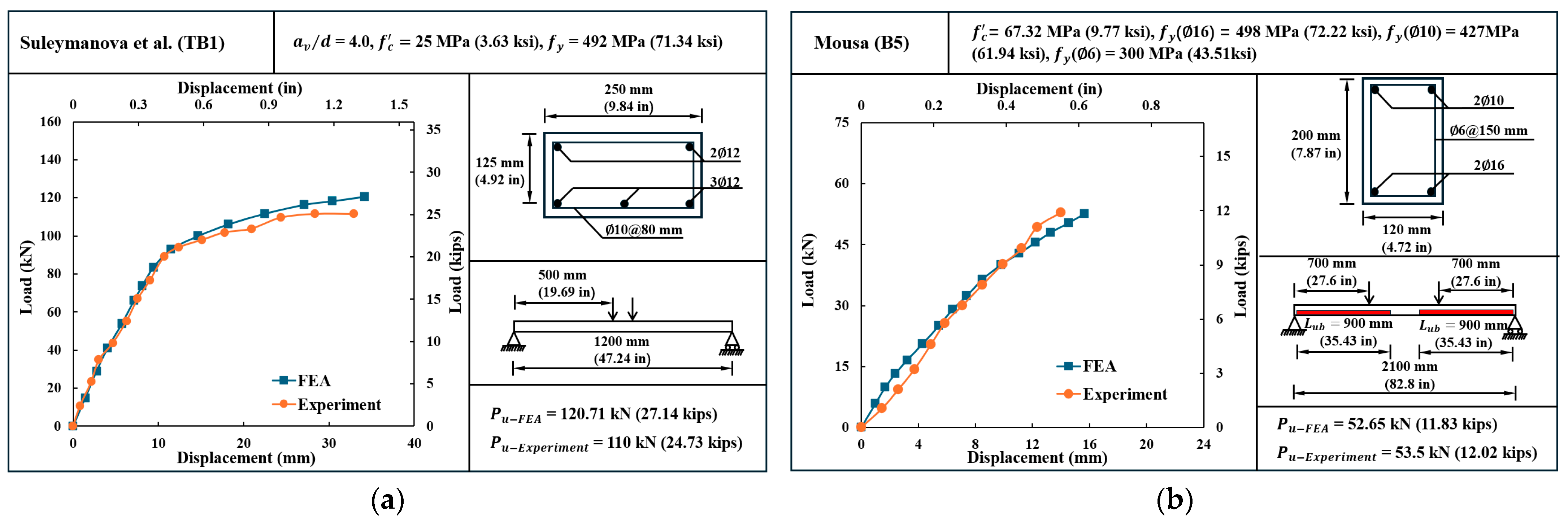

3. FEA Model Verification and Convergence Study

3.1. FEA Model Verification

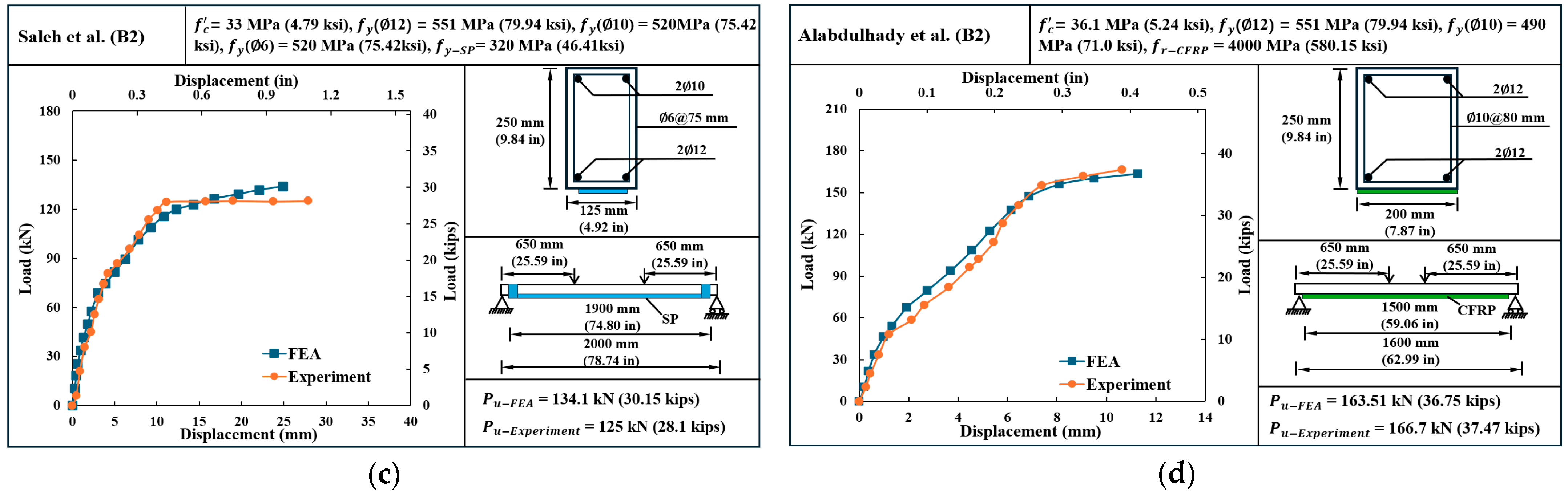

3.2. Sensitivity Analysis

4. Results and Discussion

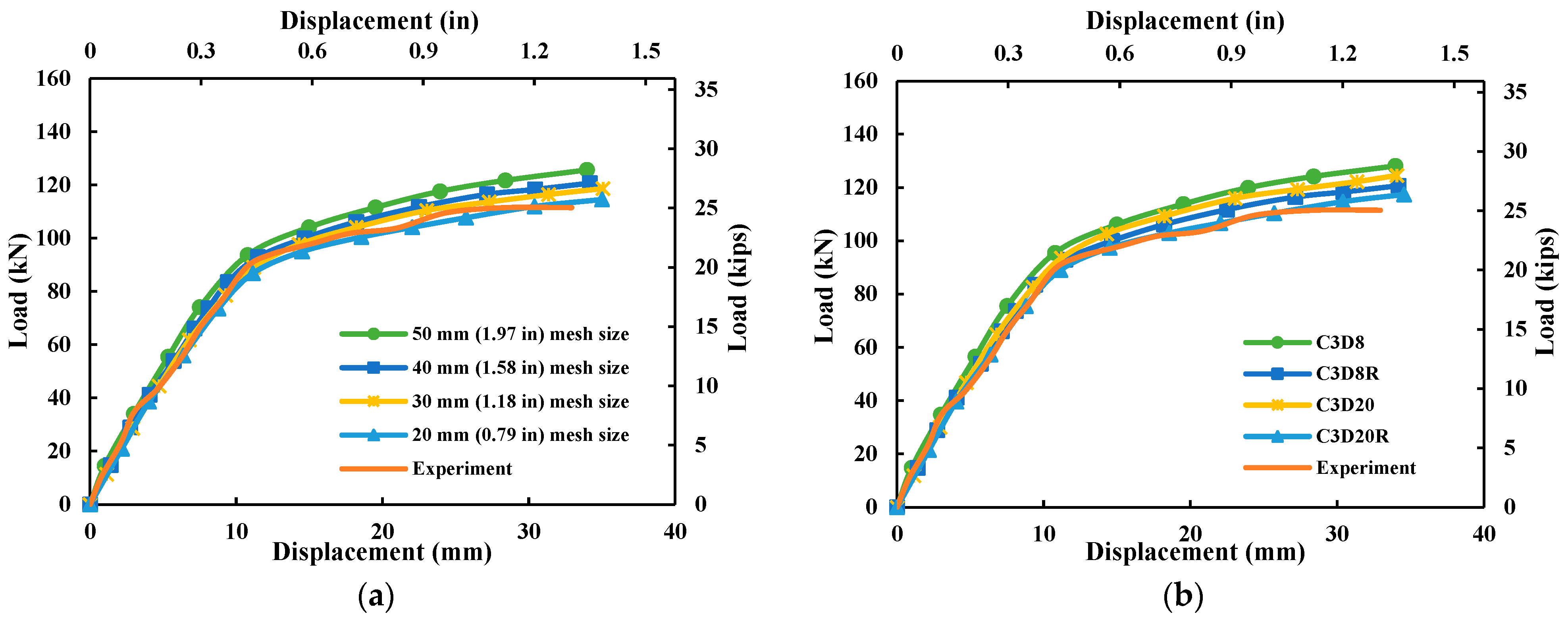

4.1. Unstrengthened Beams

4.1.1. Shear Span-to-Depth Ratio ()

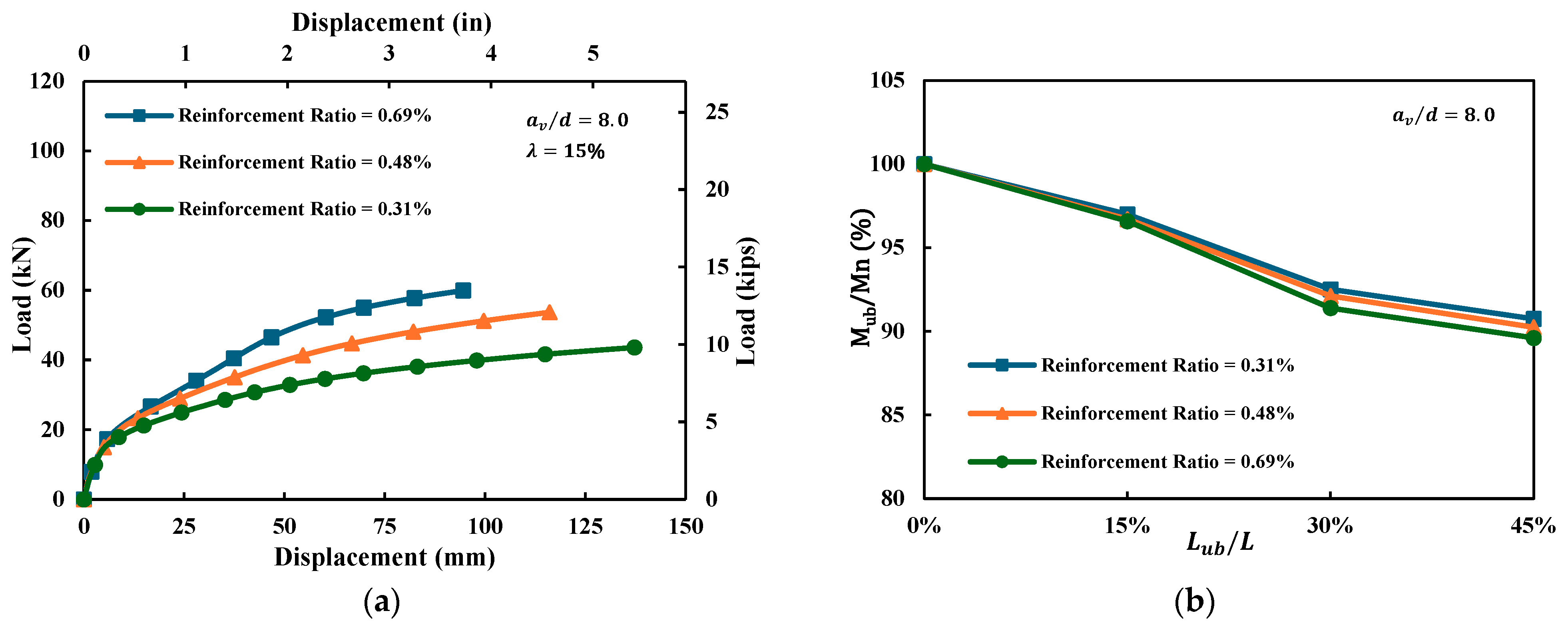

4.1.2. Reinforcement Ratio ()

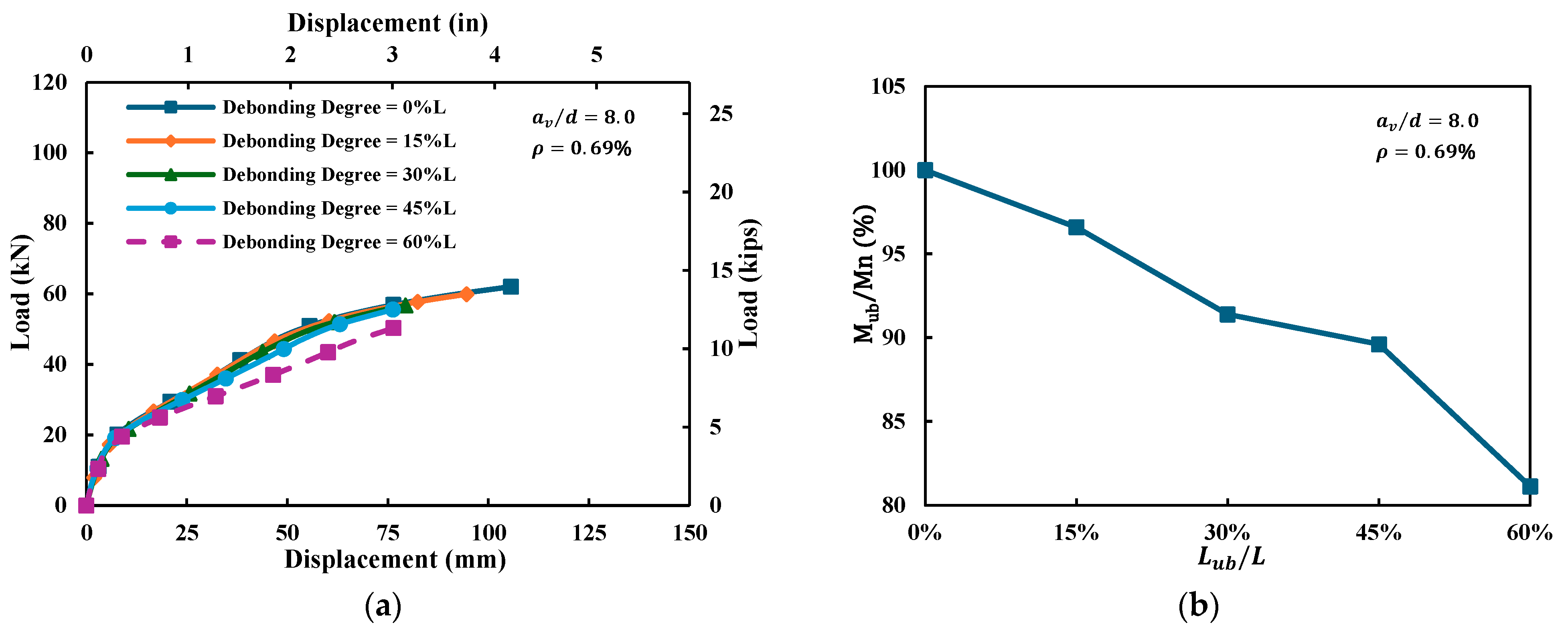

4.1.3. Debonding Degree ()

4.2. Strengthened Beams

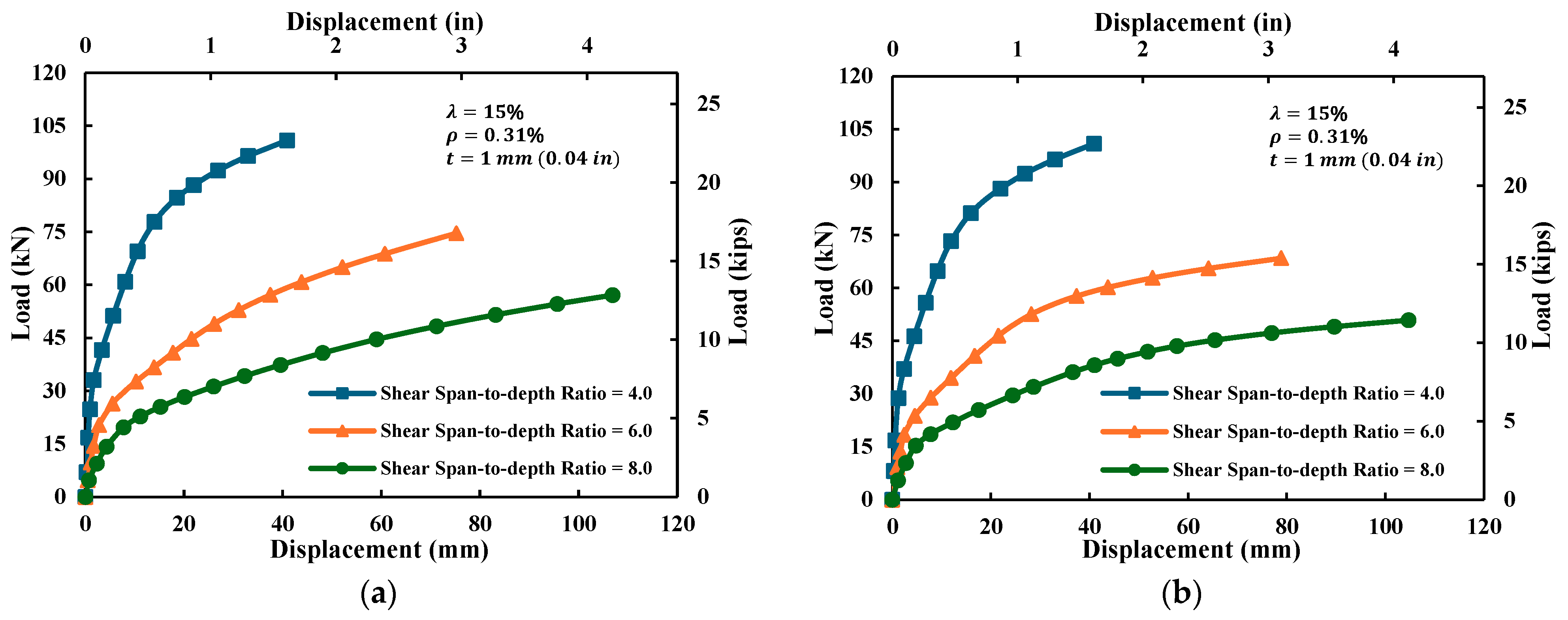

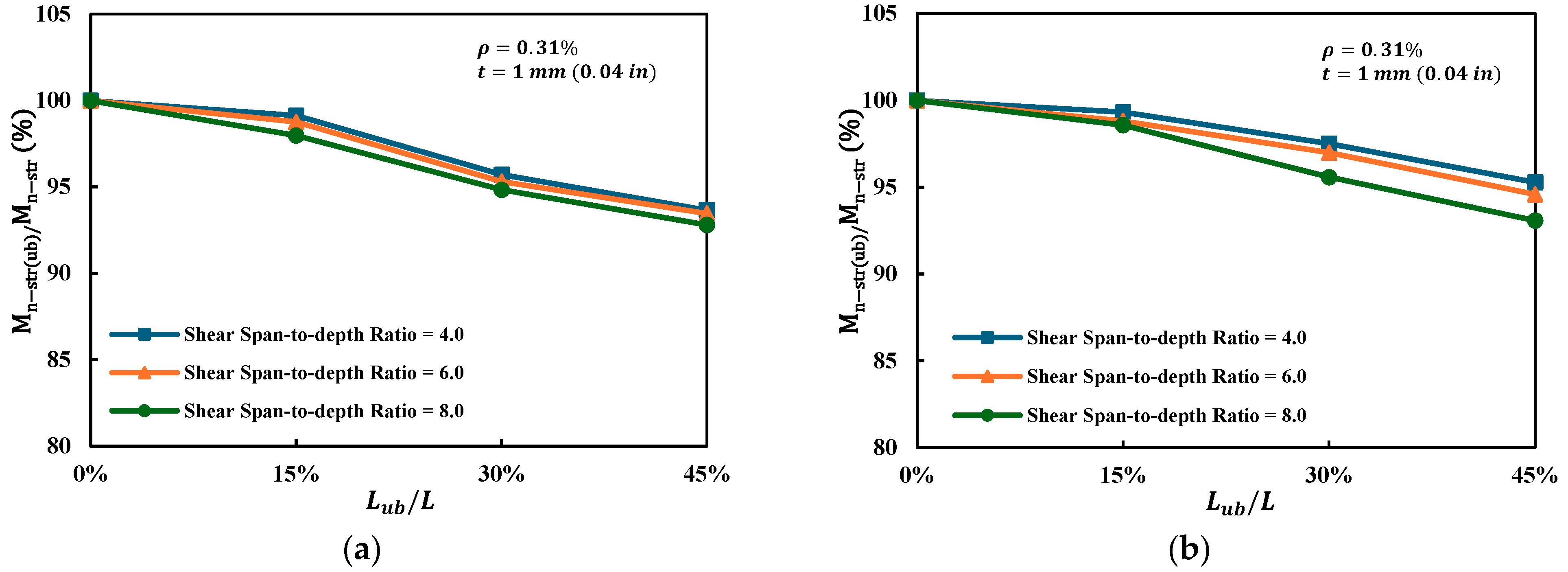

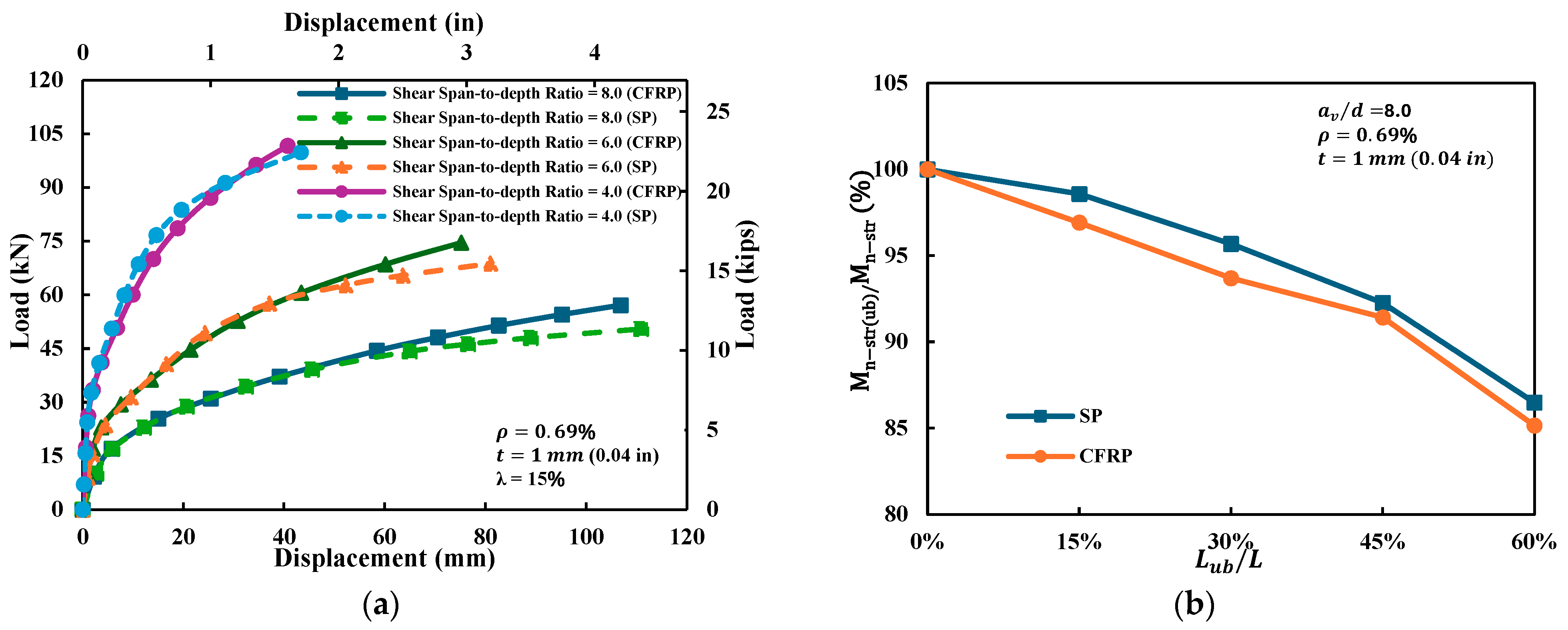

4.2.1. Shear Span-to-Depth Ratio ()

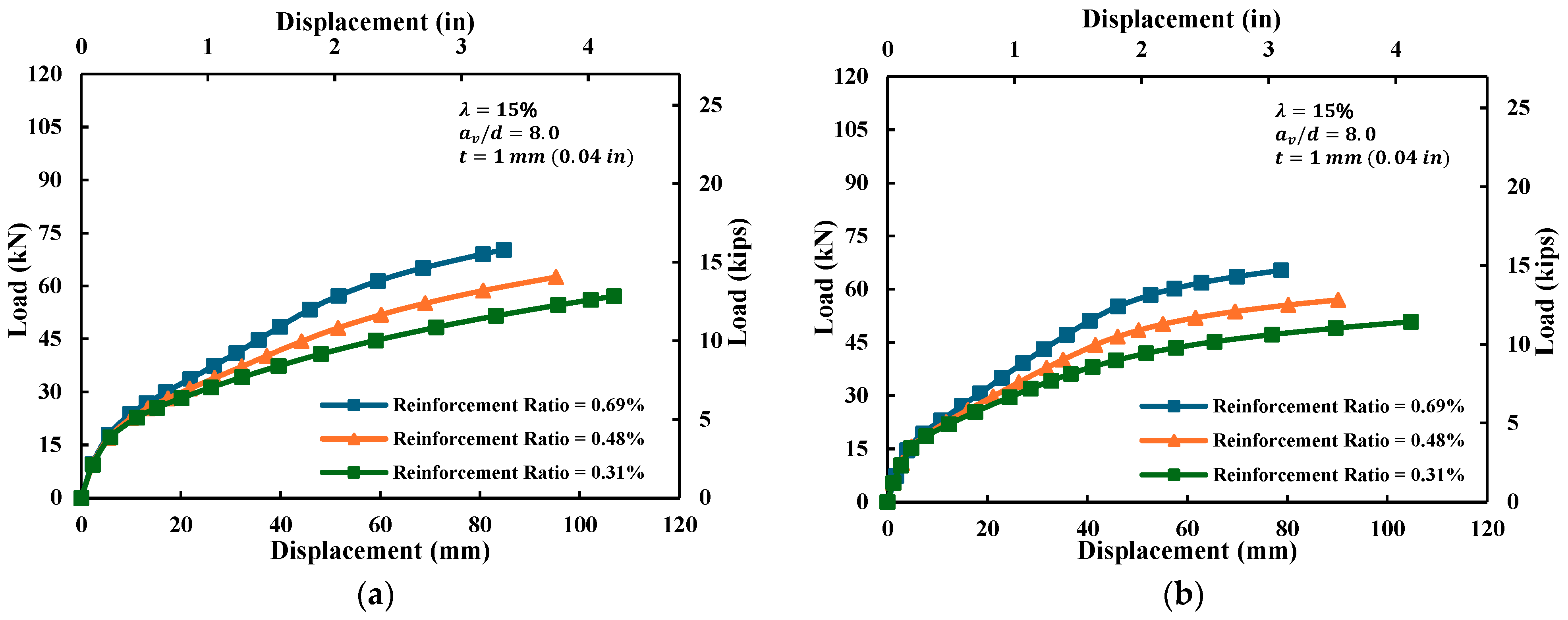

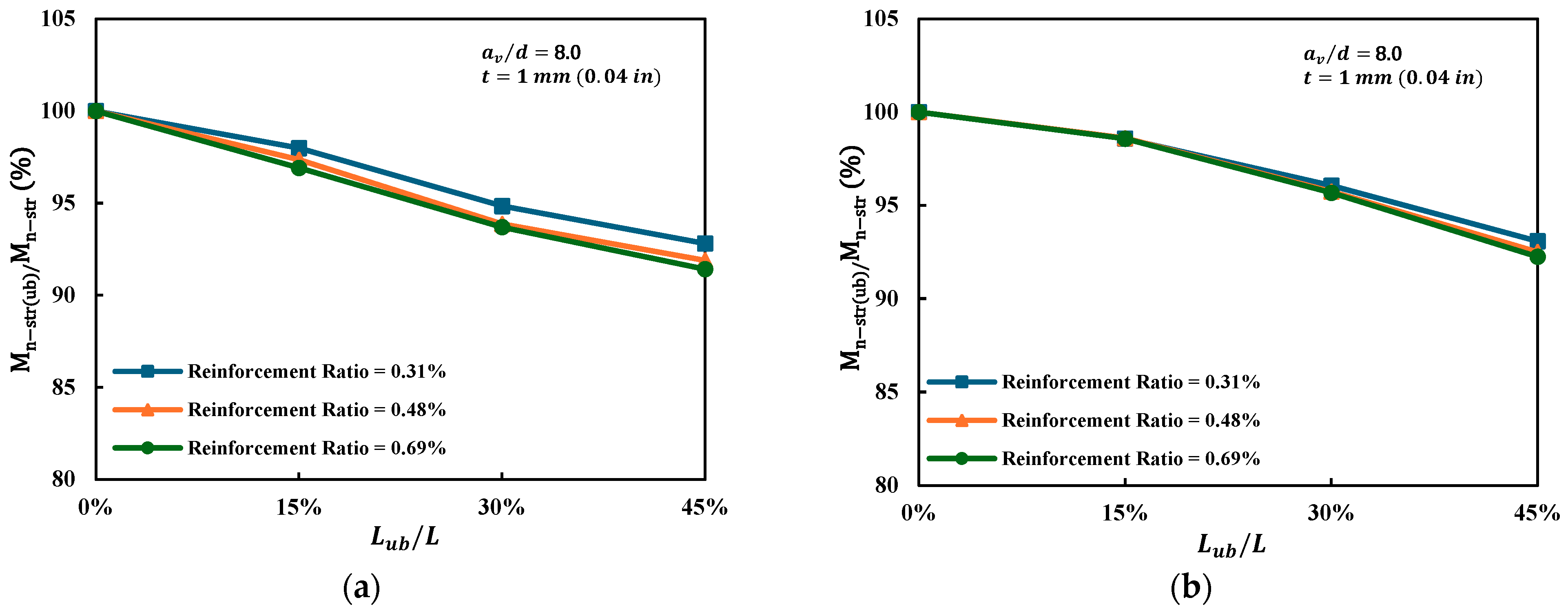

4.2.2. Reinforcement Ratio ()

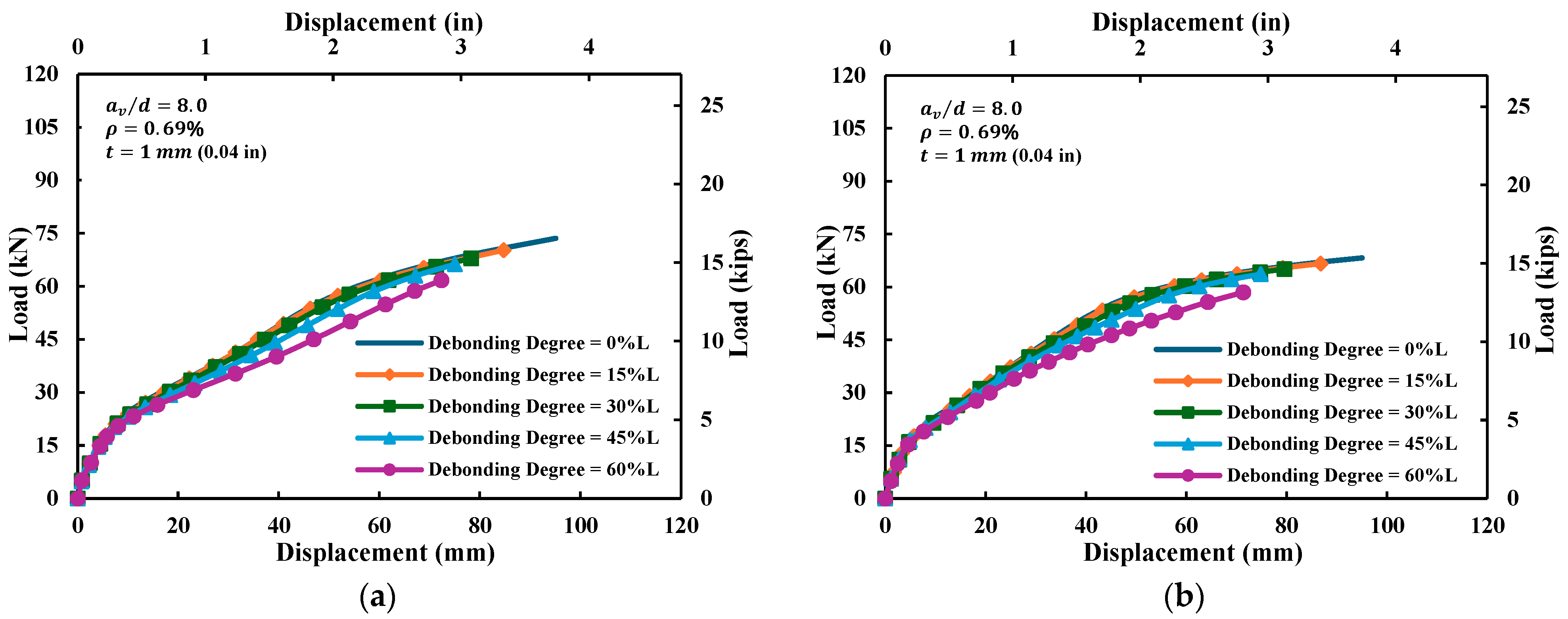

4.2.3. Debonding Degree ()

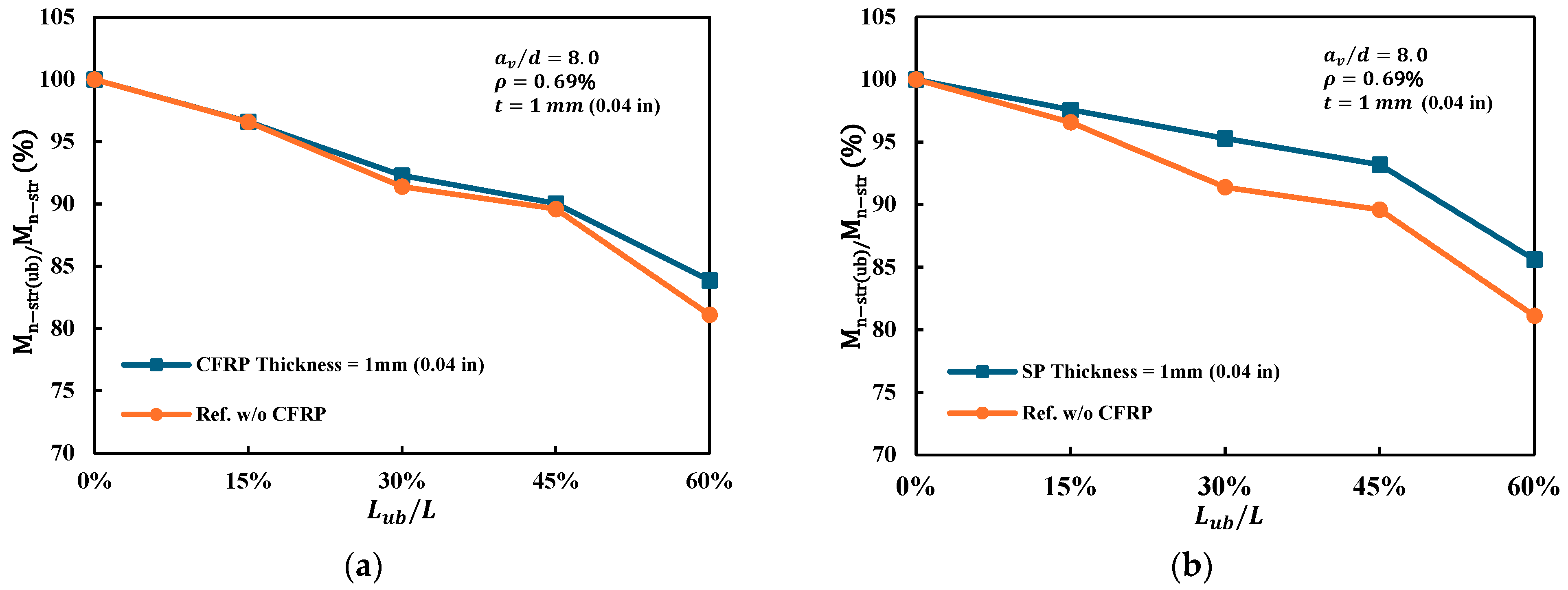

4.2.4. Type of Strengthening Materials (CFRP/SP)

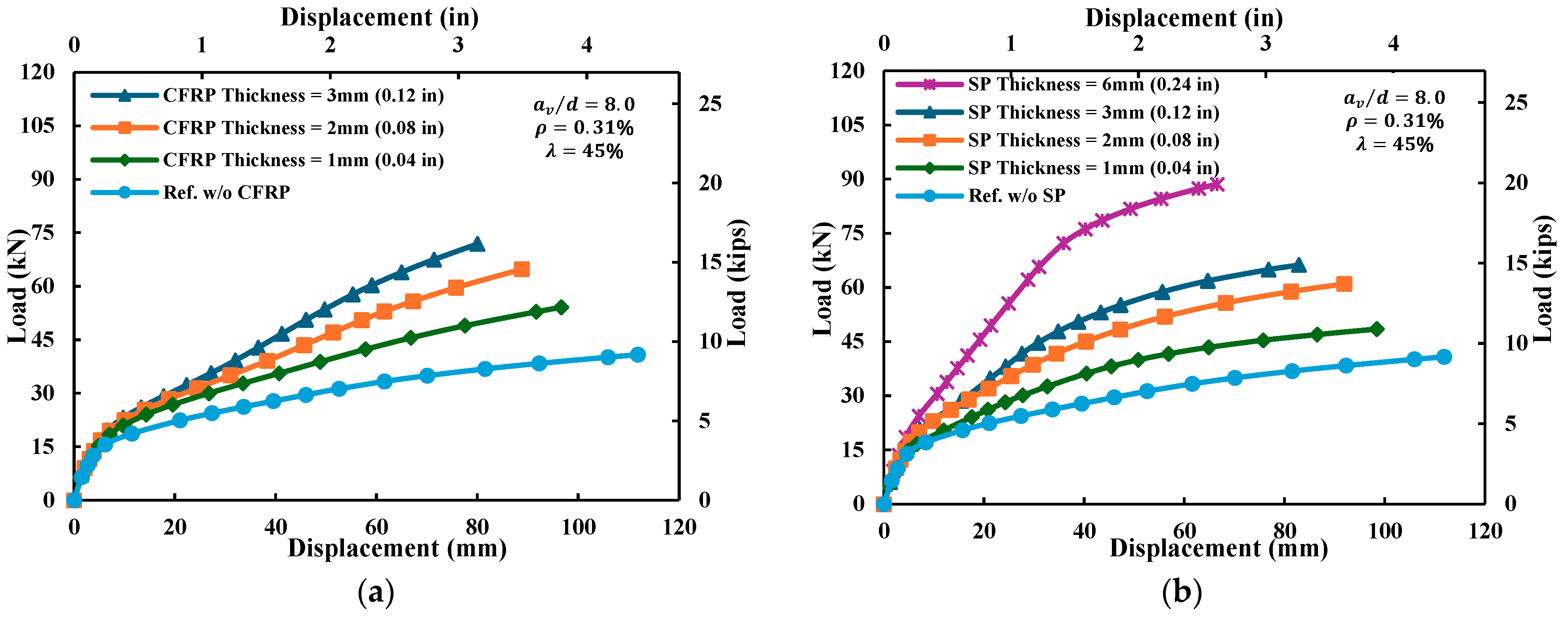

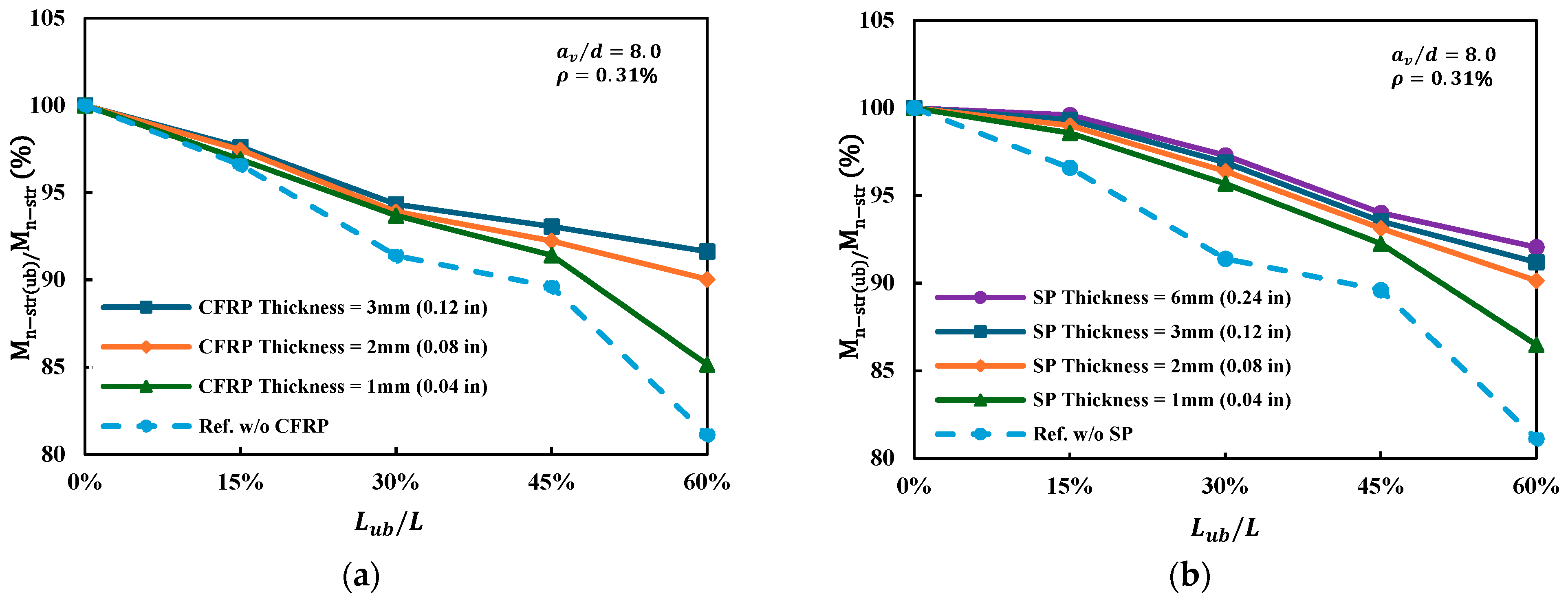

4.2.5. Thickness of Strengthening Materials ()

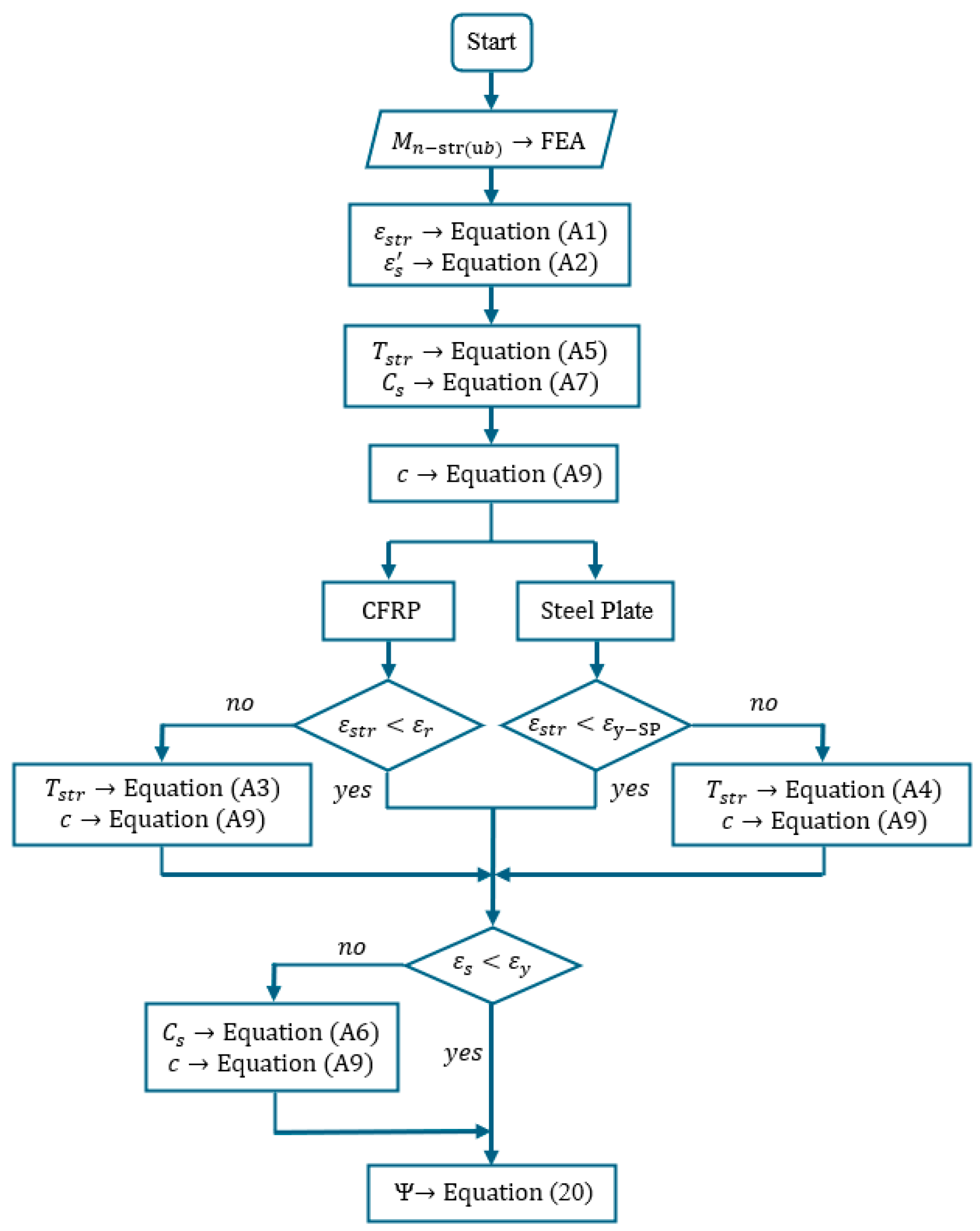

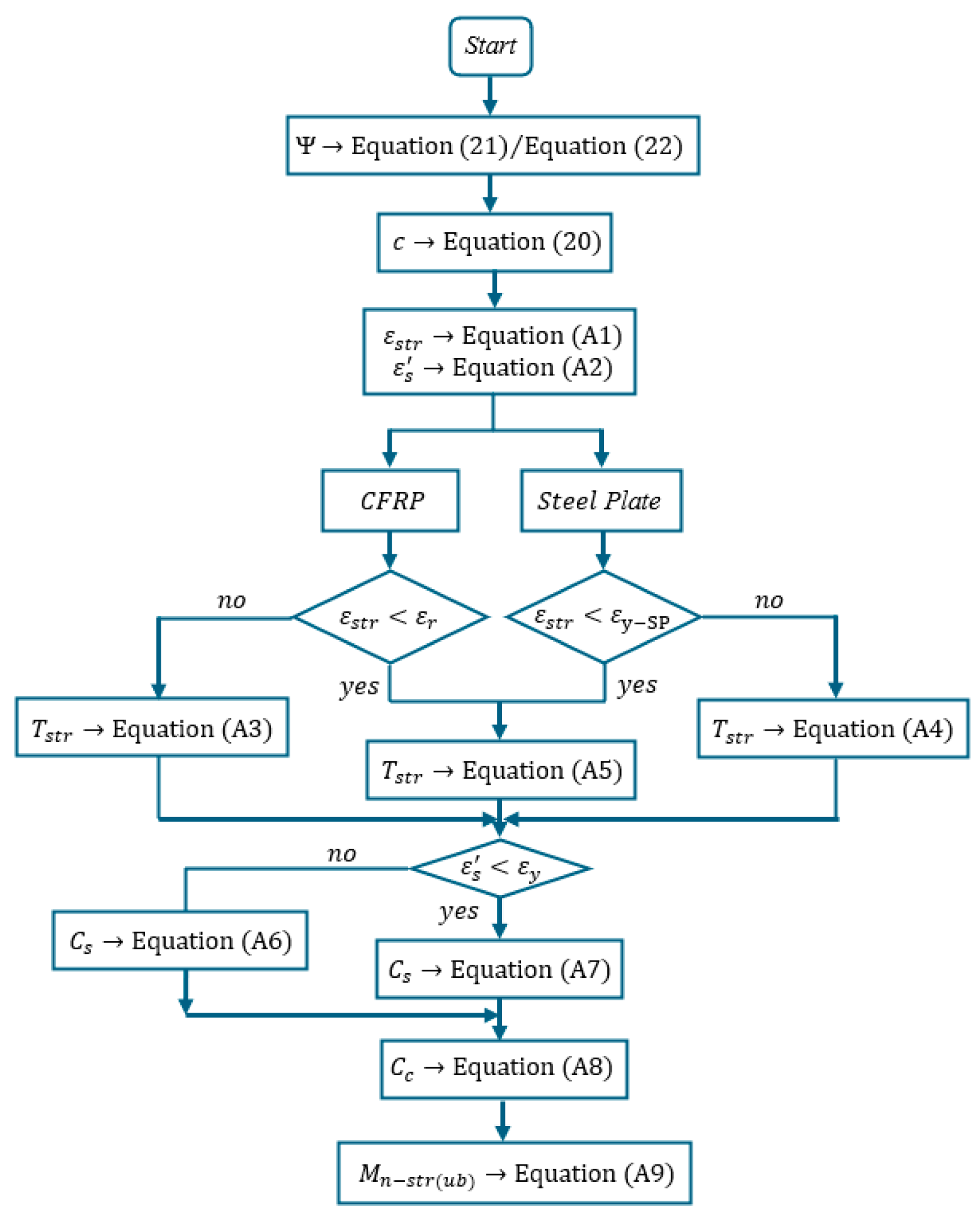

5. Analytical Models

6. Summary and Conclusions

- RC beams without strengthening

- Beams with larger shear span-to-depth ratios exhibited greater sensitivity to reinforcement–concrete bond loss; for example, when the ratio increased from 4.0 to 8.0, the debonding-induced moment reduction nearly doubled under comparable conditions, indicating that slender, flexure-dominated beams were more vulnerable to bond deterioration. In addition, increasing the shear span-to-depth ratio reduced global stiffness (larger deflections) and decreased the ultimate load capacity, while the apparent ductility increased, consistent with a longer flexural response region.

- Higher reinforcement ratios enhanced the overall flexural strength and stiffness but decreased ductility and offered only limited mitigation against debonding-induced moment loss. Within the studied range (0.31–0.69%), the increase in reinforcement ratio resulted in only minor changes in moment reduction, suggesting that debonding degree exerts a more dominant influence than reinforcement ratio.

- From 0% to about 45% debonding, the reductions in flexural capacity, stiffness, and apparent ductility were mild (generally ≤10%); however, once the debonding degree exceeded this 45% threshold, these performance measures deteriorated significantly. In representative cases, further increasing the debonding length to 60% resulted in moment losses approaching 19%, highlighting that excessive bond deterioration could severely compromise structural performance.

- CFRP/SP Strengthened RC beams

- Larger shear span-to-depth ratios led to lower stiffness and peak load but higher ductility and greater sensitivity to debonding. For strengthened beams, moment reduction increased only slightly (≤2%) when grew from 4.0 to 8.0, compared to nearly double losses in unstrengthened beams. This indicates that external strengthening effectively suppresses the detrimental influence of shear span-to-depth variation.

- Increasing the reinforcement ratio enhanced stiffness and peak load but slightly reduced apparent ductility within the response range up to the ultimate load. Although a higher reinforcement ratio tended to amplify debonding-induced capacity loss, the variation in moment reduction across the relatively low reinforcement range considered (0.31–0.69%) was less than 1%, indicating that for low reinforcement ratio beams (including up to 0.69%), reinforcement–concrete debonding had only a minor effect on flexural capacity.

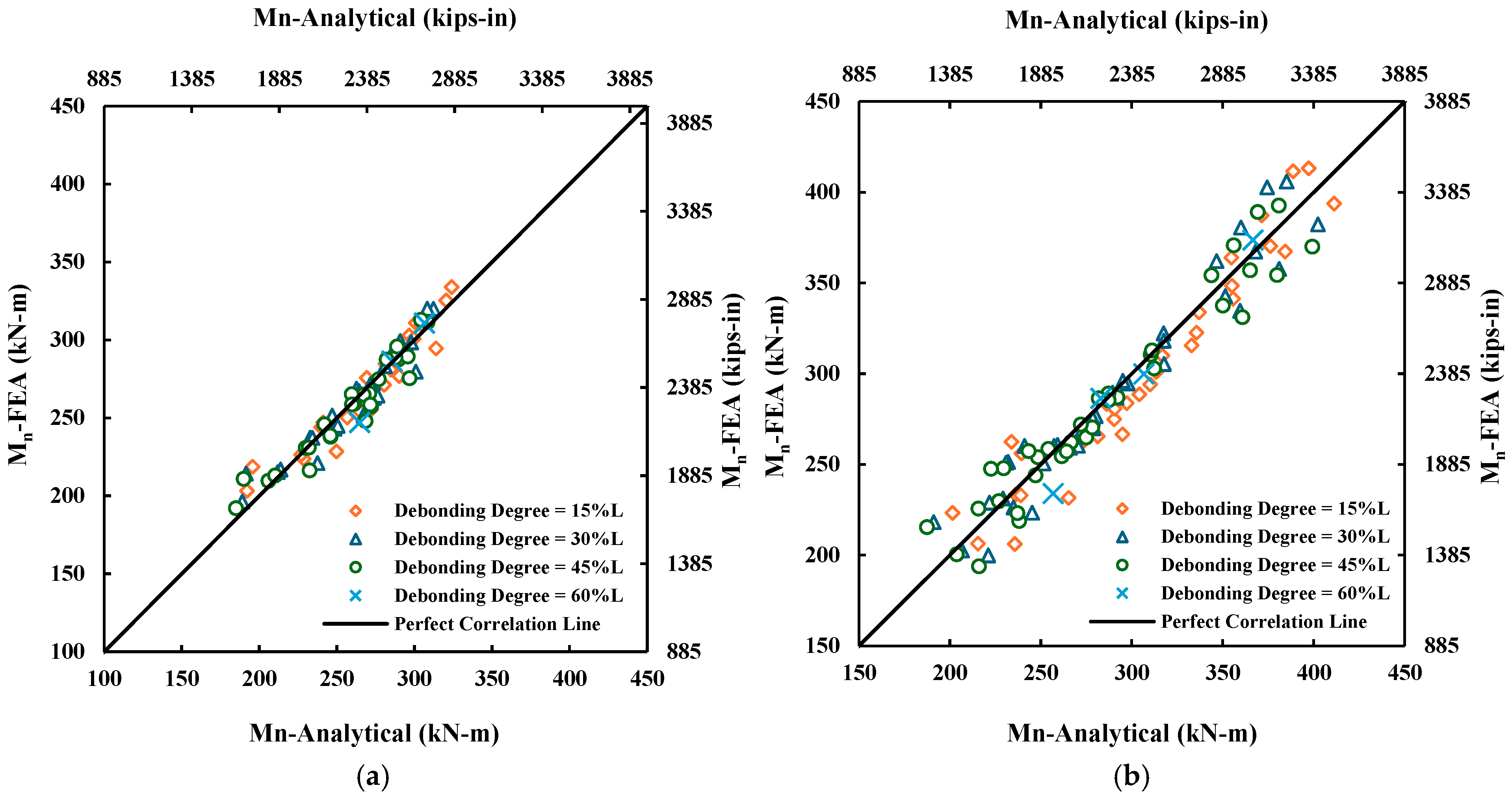

- Flexural capacity deteriorated progressively with increasing debonding, and a ratio of about 45% marked a critical threshold: below this level, capacity loss was moderate (≤10%), while beyond it, reductions became pronounced (>15%). In representative cases, 60% debonding caused moment losses up to 19%, highlighting the severe impact of excessive bond deterioration. In addition to strength reduction, debonding also decreased overall stiffness and ductility, indicating a comprehensive degradation of structural performance.

- CFRP provided higher strength and more sustained stiffness, while SP demonstrated superior ductility and slightly lower sensitivity to reinforcement–concrete debonding. From a practical standpoint, CFRP was preferable where strength and stiffness are prioritized, whereas SP was more suitable when ductility, energy absorption, and bond resilience are critical.

- Increasing CFRP thickness from 1 mm to 3 mm and SP thickness up to 6 mm markedly enhanced ultimate capacity (by approximately 76% and 117%, respectively) and reduced debonding-related losses. However, excessive thickness decreased ductility and could induce a brittle mode of failure, highlighting the importance of optimal thickness selection.

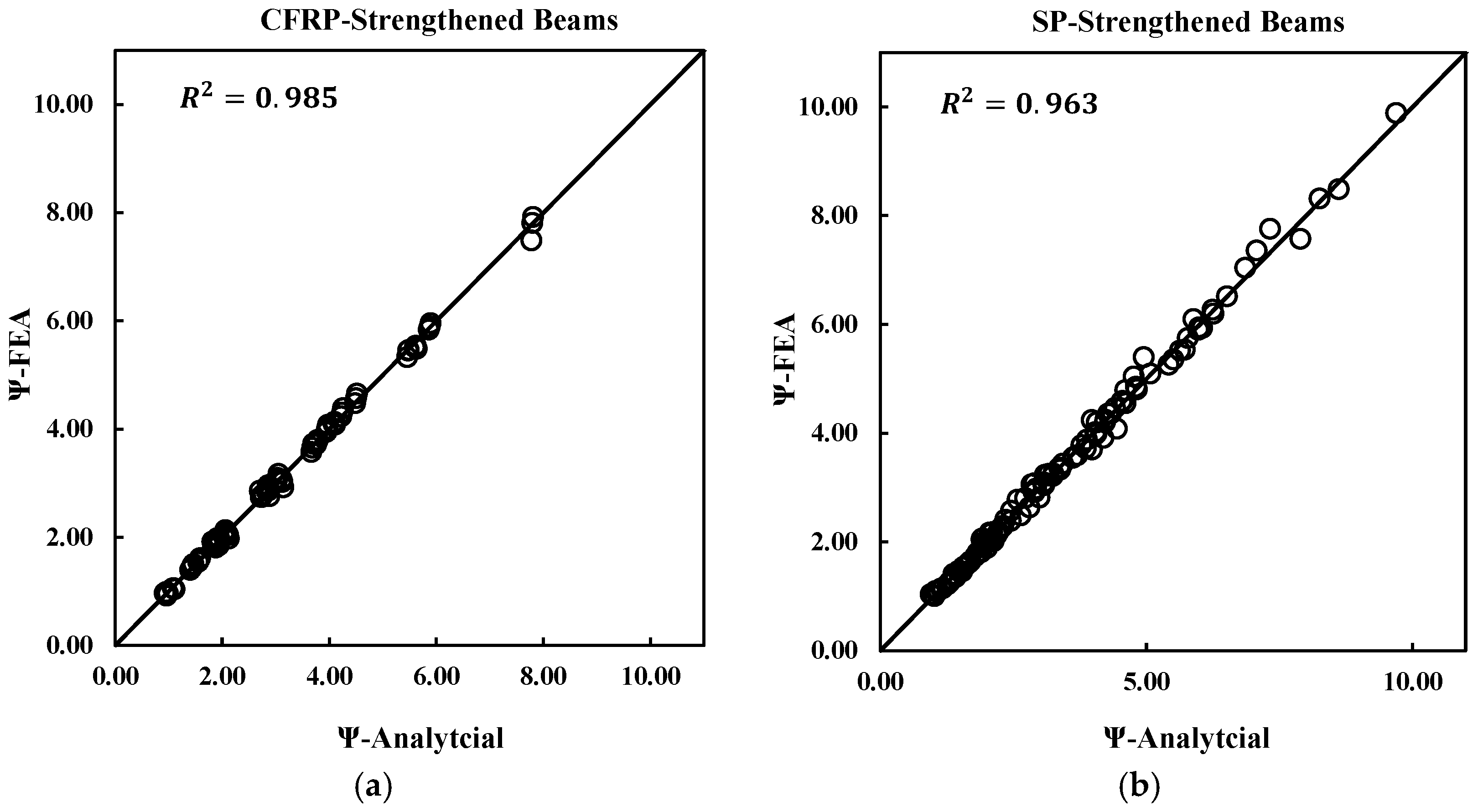

- Analytical models

- The proposed Ψ-based analytical models accurately reproduced the flexural strengths obtained from FEA. The mean analytical-to-FEA ratios were close to 1.00 with standard deviations below 0.06 for both CFRP- and SP-strengthened beams.

- Model accuracy was only marginally affected by partial bond deterioration. Even with debonding ratios up to 60%, predictions remained consistent with FEA results, confirming the robustness of the models under partially bonded reinforcement conditions.

- These models provided simple yet reliable closed-form tools for evaluating residual flexural strength, offering practical value for the design and assessment of RC beams where internal bond deterioration coexists with external strengthening.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

Appendix B

References

- Minkarah, I.; Ringo, B.C. Behavior and repair of deteriorated reinforced concrete beams. Transp. Res. Rec. 1981, 821, 73–79. [Google Scholar]

- Cairns, J.; Zhao, Z. Behavior of concrete beams with exposed reinforcement. Proc. Inst. Civ. Eng. Struct. Build. 1993, 99, 141–154. [Google Scholar] [CrossRef]

- Raoof, M.; Lin, Z. Structural characteristics of RC beams with exposed main steel. Proc. Inst. Civ. Eng. Struct. Build. 1997, 122, 35–51. [Google Scholar] [CrossRef]

- Jeppsson, J.; Thelandersson, S. Behavior of reinforced concrete beams with loss of bond at longitudinal reinforcement. J. Struct. Eng. 2003, 129, 1376–1383. [Google Scholar] [CrossRef]

- Jnaid, F.; Aboutaha, R.S. Residual flexural strength of reinforced concrete beams with unbonded reinforcement. ACI Struct. J. 2014, 111, 1419–1430. [Google Scholar] [CrossRef]

- Mousa, M.I. Effect of bond loss of tension reinforcement on the flexural behavior of reinforced concrete beams. HBRC J. 2016, 12, 235–241. [Google Scholar] [CrossRef]

- Yang, J.; Wang, L.; Yang, D.; Wang, Q. Influence of concrete and unbonded ratio on RC beams. Constr. Build. Mater. 2023, 403, 133086. [Google Scholar] [CrossRef]

- Shahawy, M.A.; Arockiasamy, M.; Beitelman, T.; Sowrirajan, R. Reinforced concrete rectangular beams strengthened with CFRP laminates. Compos. B Eng. 1996, 27, 225–233. [Google Scholar] [CrossRef]

- Fanning, P.J.; Kelly, O. Ultimate response of RC beams strengthened with CFRP plates. J. Compos. Constr. 2001, 5, 122–127. [Google Scholar] [CrossRef]

- Esfahani, M.R.; Kianoush, M.R.; Tajari, A.R. Flexural behavior of reinforced concrete beams strengthened by CFRP sheets. Eng. Struct. 2007, 29, 2428–2444. [Google Scholar] [CrossRef]

- Dong, J.; Wang, Q.; Guan, Z. Structural behavior of RC beams with external flexural and flexural–shear strengthening by FRP sheets. Compos. B Eng. 2013, 44, 604–612. [Google Scholar] [CrossRef]

- Abdulhady, M.Y.; Ojaimi, M.F.; Chkheiwer, A.H. The efficiency of CFRP strengthening and repair system on the flexural behavior of RC beams constructed with different concrete compressive strength. Results Eng. 2022, 16, 100763. [Google Scholar] [CrossRef]

- Tankut, T.; Arslan, M. Behavior of reinforced concrete beams strengthened by epoxy bonded steel plates. Tek. Derg. 1992, 3, 176–185. [Google Scholar]

- Oh, B.H.; Kim, E.S.; Yang, Y.S. Static and fatigue behavior of reinforced concrete beams strengthened with steel plates for flexure. KSCE J. Civ. Eng. 2003, 7, 657–666. [Google Scholar] [CrossRef]

- Saleh, M.A.A.; Galbat, M.A.K.; Nasr, M.A.K. Strengthened reinforced concrete beams in flexural using steel plate. Int. J. Eng. Adv. Technol. 2021, 10, 62–70. [Google Scholar]

- Sallam, H.E.M.; Khalil, H.S.; Saba, A.M.; Shehab El-Din, H. Flexural behavior of externally strengthened RC beams by bonded steel plate or by suspended steel bars. In Proceedings of the Eighth International Conference, Cairo, Egypt, 24–27 December 2004. [Google Scholar]

- Ozbek, E.; Bocek, M.; Aykac, S. Strengthening of RC beams with solid steel plates. Athens J. Technol. Eng. 2016, 3, 291–298. [Google Scholar] [CrossRef]

- Lei, D.; Chen, G.Y.; Chen, Y.Q.; Ren, Q.W. Experimental research and numerical simulation of RC beams strengthened with bonded steel plates. Sci. China Technol. Sci. 2012, 55, 3270–3277. [Google Scholar] [CrossRef]

- Kotynia, R.; Debaiky, A.S.; El-Salakawy, E.; Benmokrane, B. Flexural strengthening of RC beams with externally bonded CFRP systems: Test results and 3D nonlinear FE analysis. J. Compos. Constr. 2008, 12, 469–478. [Google Scholar] [CrossRef]

- Ibrahim, A.M.; Salman, W.D. Finite element analysis of reinforced concrete beams strengthened with CFRP in flexural. Diyala J. Eng. Sci. 2009, 2, 88–104. [Google Scholar] [CrossRef]

- Jankowiak, I. Analysis of RC beams strengthened by CFRP strips—Experimental and FEA study. Arch. Civ. Mech. Eng. 2012, 12, 376–388. [Google Scholar] [CrossRef]

- Hawileh, R.A.; Abdalla, J.A.; Fardmanesh, A.A.; Darwish, M.K.; Tamimi, A.K. Finite element simulation of reinforced concrete beams externally strengthened with short-length CFRP plates. Compos. B Eng. 2013, 45, 1365–1377. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, J.; Wang, X. Simulation study on CFRP-strengthened reinforced concrete beam under four-point bending. Eng. Struct. 2016, 127, 355–368. [Google Scholar] [CrossRef]

- Barour, S.; Taleb, A.; Boulekbache, B. Finite element modelling of RC beams strengthened with CFRP sheets. World J. Eng. 2020, 17, 675–682. [Google Scholar]

- Hong, X. Finite element analysis on reinforced concrete beams strengthened with CFRP. J. Struct. Eng. 2022, 148, 04022012. [Google Scholar] [CrossRef]

- Hamoush, S.A.; Ahmad, S.H. Debonding of steel plate-strengthened concrete beams. J. Struct. Eng. 1990, 116, 3569–3583. [Google Scholar] [CrossRef]

- American Concrete Institute (ACI). Building Code Requirements for Structural Concrete (ACI 318-22) and Commentary; ACI Committee 318, American Concrete Institute: Farmington Hills, MI, USA, 2022. [Google Scholar]

- Yang, K.H.; Mun, J.H.; Cho, M.S.; Kang, T.H.K. Stress-strain model for various unconfined concretes in compression. ACI Struct. J. 2014, 111, 819–826. [Google Scholar] [CrossRef]

- Nayal, R.; Rasheed, H.A. Tension stiffening model for concrete beams reinforced with steel and FRP bars. J. Mater. Civ. Eng. 2006, 18, 831–841. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). AASHTO LRFD Bridge Design Specifications, 10th ed.; AASHTO: Washington, DC, USA, 2024. [Google Scholar]

- Fédération Internationale du Béton (fib). Fib Model Code for Concrete Structures 2020, Version 1.2; fib: Lausanne, Switzerland, 2024. [Google Scholar]

- Dassault Systèmes Simulia Corp. Abaqus 2025 User’s Manual; Dassault Systèmes Simulia Corp.: Providence, RI, USA, 2024. [Google Scholar]

- Suleymanova, L.; Rimshin, V.; Ibrahim, A.; Hameed, A.A.; Obernikhin, D. The role of shear span to effective depth ratio (a/d) on the deflection in deep and normal reinforced concrete beams when this ratio is (1, 2, 3, and 4). IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012044. [Google Scholar] [CrossRef]

- Kazemi, F.; Asgarkhani, N.; Shafighfard, T.; Jankowski, R.; Yoo, D.-Y. Machine-learning methods for estimating performance of structural concrete members reinforced with fiber-reinforced polymers. Arch. Comput. Methods Eng. 2025, 32, 571–603. [Google Scholar] [CrossRef]

- Au, F.T.K.; Du, J.S. Prediction of ultimate stress in unbonded prestressed tendons. Mag. Concr. Res. 2004, 56, 1–11. [Google Scholar] [CrossRef]

| 165 Gpa (23,900 ksi) | 11 GPa (1595 ksi) | 5.3 GPa (769 ksi) | 3.9 GPa (566 ksi) | 0.26 | 0.5 |

| 2800 MPa (406 ksi) | 1654 MPa (240 ksi) | 110 MPa (16 ksi) | 240 MPa (35 ksi) | 115 MPa (16.6 ksi) | 40 MPa (5.8 ksi) |

| Elastic Properties | Damage Initiation | Damage Evolution | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

(GPa) | (GPa) | (GPa) | (m) | (kg/m3) | (MPa) | (MPa) | (MPa) | (J/m2) | (J/m2) | (J/m2) |

| 4.5 | 11.7 | 11.7 | 10−3 | 1650 | 24.8 | 16 | 16 | 355 | 280 | 280 |

| Variables | Experimental Coverage (From Validation) | Parametric Space (From This Study) | Status |

|---|---|---|---|

| Shear span-to-depth ratio () | 4.0, 4.5, 2.6, 3.0 | 4.0, 6.0, 8.0 | Covered: 4.0 Extrapolated: 6.0, 8.0 |

| Reinforcement Ratio () | 1.80%, 2.02%, 0.55%, 0.85% | 0.31%, 0.48%, 0.69% | Extrapolated |

| Debonding degree () | 85% | 0%, 15%, 30%, 45%, 60% | Extrapolated |

| Strengthening material | CFRP, SP | CFRP, SP | Covered |

| Strengthening thickness () | CFRP: 0.167 mm (0.01 in) SP: 2.76 mm (0.11 in) | CFRP: 1 mm (0.04 in), 2 mm (0.08 in), 3 mm (0.12 in) SP: 1 mm (0.04 in), 2 mm (0.08 in), 3 mm (0.12 in), 6 mm (0.24 in) | Extrapolated |

| Reinforcement strength () | 492 MPa (71.3 ksi), 498 MPa (72.2 ksi), 551 MPa (79.9 ksi) | 414.69 MPa (60 ksi) | Extrapolated |

| Concrete strength () | 25 MPa (3.63 ksi), 67.32 MPa (9.77 ksi), 33 MPa (4.79 ksi), 36.1 MPa (5.24 ksi) | 21 MPa (3 ksi) | Extrapolated |

| Reinforcement layout | Three/Two-bar tension layout with two compression bars | Three-bar tension layout with two compression bars | Partially covered |

| Loading scheme | Four-point bending | Four-point bending | Covered |

| Anchorage | CFRP: No anchorage SP: U-shaped end anchorage | CFRP: U-shaped end anchorage SP: U-shaped end anchorage | Covered: SP Extrapolated: CFRP |

| Adhesive type | CFRP: Sikadur®-330 (Sika AG, Zurich, Switzerland) SP: Sikadur®-30 (Sika AG, Zurich, Switzerland) | CFRP: Sikadur®-30 (Sika AG, Zurich, Switzerland) SP: Sikadur®-30 (Sika AG, Zurich, Switzerland) | Covered |

| Boundary conditions | One end fixed, one end pinned | One end fixed, one end pinned | Covered |

| Specimen ID | Peak Load Exp. (kN) | Peak Load FEA (kN) | Error (%) | Initial Stiffness Exp. (kN/mm) | Initial Stiffness FEA. (kN/mm) | Error (%) | RMSE (kN) | Bias (kN) |

|---|---|---|---|---|---|---|---|---|

| Suleymanova et al. (TB 1) [33] | 110 | 120.71 | 9.74 | 9.39 | 10.11 | 7.67 | 3.84 | 2.38 |

| Mousa (B5) [6] | 53.5 | 52.65 | −1.59 | 4.18 | 4.79 | 14.6 | 2.87 | 1.07 |

| Saleh et al. (B2) [12] | 125 | 134.1 | 7.28 | 16.35 | 18.92 | 15.76 | 6.90 | 1.59 |

| Alabdulhady et al. (B2) [15] | 166.7 | 163.51 | −1.91 | 21.13 | 23.76 | 12.43 | 7.17 | 3.63 |

| Parameter | Trend of Threshold Shift | Explanation |

|---|---|---|

| Concrete strength | Decrease with higher strength | Higher-strength concrete reduces ductility and bond reserve, so severe bond loss becomes critical earlier. |

| Reinforcement ratio/bar spacing | Decrease with higher ratio/closer spacing | Higher steel ratios increase bond demand in critical zones, lowering the tolerance to unbonded length. |

| Strengthening thickness/anchorage | Increase with thicker FRP/SP or stronger anchorage | Enhanced external reinforcement or end anchorage compensates for bond loss and delays severe capacity reduction. |

| Case | (kN) | (kN) | (mm) | (mm) | (kN·mm) | (kN·mm) | |||

|---|---|---|---|---|---|---|---|---|---|

| 4.0 | SP | 99.88 | 6.17 | 77.13 | 13.15 | 43.36 | 3.30 | 623.55 | 3381.28 |

| CFRP | 101.65 | 4.99 | 62.38 | 12.52 | 40.71 | 3.25 | 582.75 | 3037.85 | |

| 6.0 | SP | 68.79 | 2.03 | 42.29 | 24.66 | 80.95 | 3.28 | 641.25 | 4292.64 |

| CFRP | 74.59 | 1.71 | 35.63 | 23.66 | 75.22 | 3.18 | 630.91 | 3997.67 | |

| 8.0 | SP | 50.51 | 1.06 | 30.92 | 39.42 | 110.94 | 2.81 | 663.52 | 4256.13 |

| CFRP | 57.12 | 0.95 | 27.71 | 38.92 | 106.86 | 2.75 | 659.46 | 4249.21 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, R.; Aboutaha, R.S. Analytical Investigation of CFRP- and Steel Plate-Strengthened RC Beams with Partially Unbonded Reinforcement. Buildings 2025, 15, 3665. https://doi.org/10.3390/buildings15203665

Li R, Aboutaha RS. Analytical Investigation of CFRP- and Steel Plate-Strengthened RC Beams with Partially Unbonded Reinforcement. Buildings. 2025; 15(20):3665. https://doi.org/10.3390/buildings15203665

Chicago/Turabian StyleLi, Riliang, and Riyad S. Aboutaha. 2025. "Analytical Investigation of CFRP- and Steel Plate-Strengthened RC Beams with Partially Unbonded Reinforcement" Buildings 15, no. 20: 3665. https://doi.org/10.3390/buildings15203665

APA StyleLi, R., & Aboutaha, R. S. (2025). Analytical Investigation of CFRP- and Steel Plate-Strengthened RC Beams with Partially Unbonded Reinforcement. Buildings, 15(20), 3665. https://doi.org/10.3390/buildings15203665