Climatic Adaptation-Based Evaluation of Vernacular Anatolian Houses: A Comparative Analysis of Stone and Adobe Materials in Terms of Energy, Environment, and Thermal Comfort

Abstract

1. Introduction

2. Conceptual Framework

3. Scope, Limitations, and Method of the Study

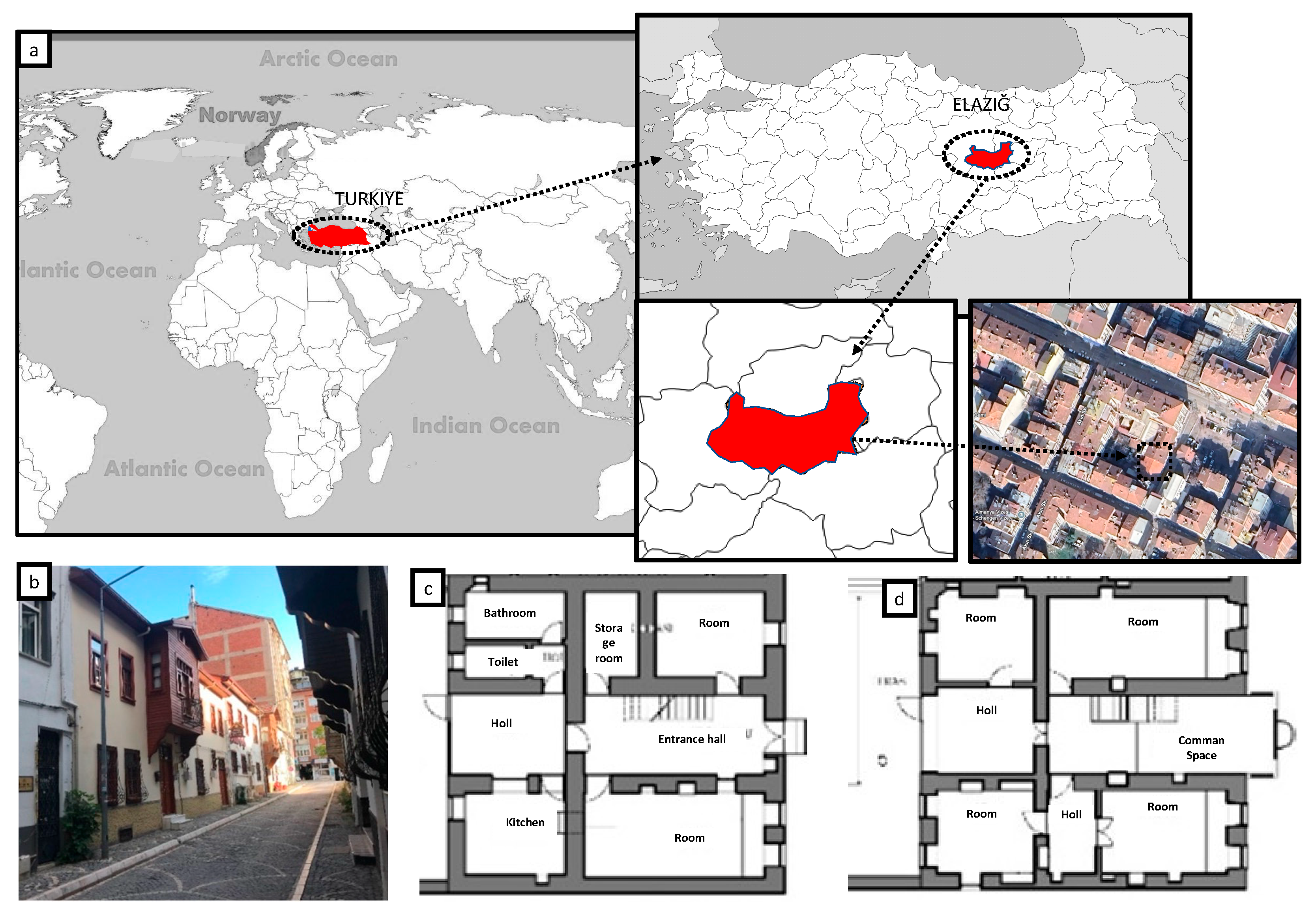

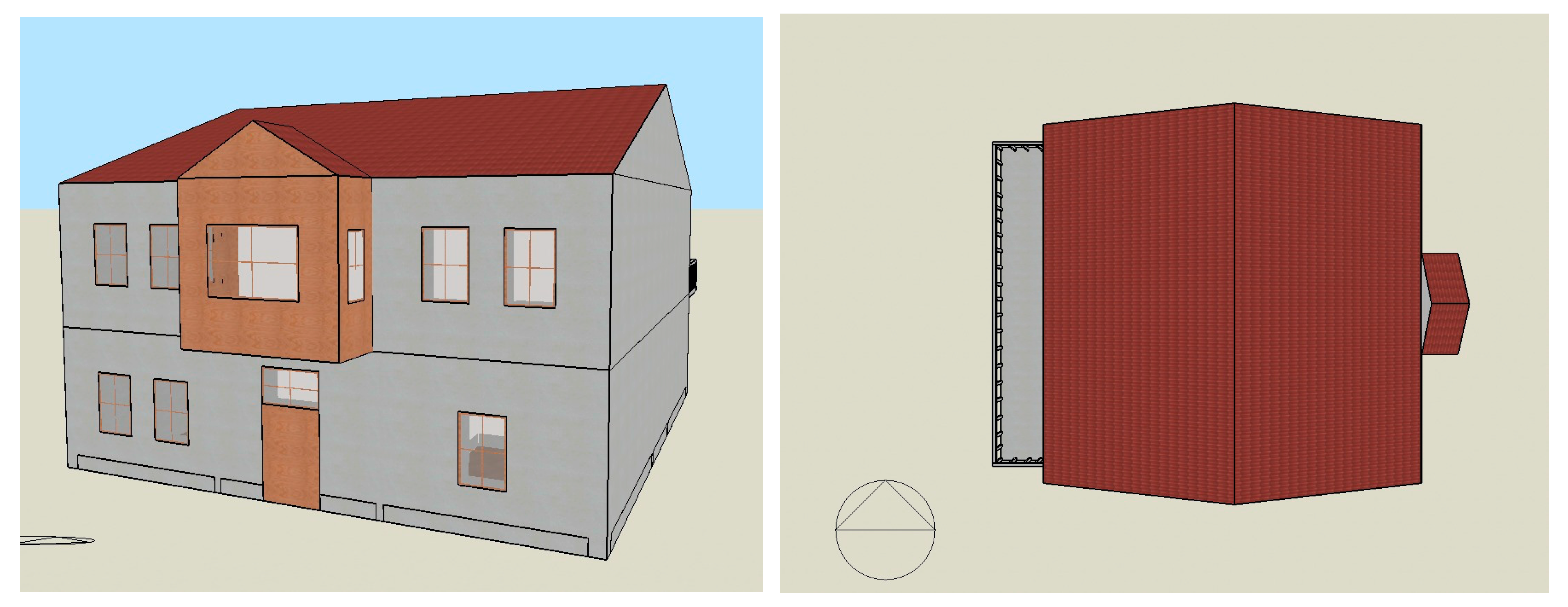

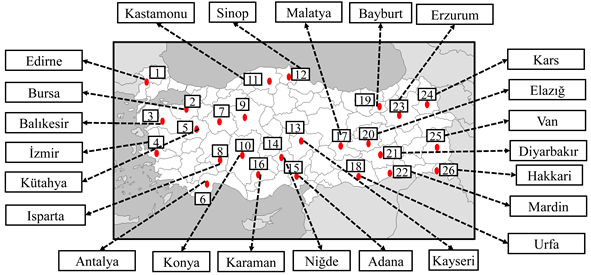

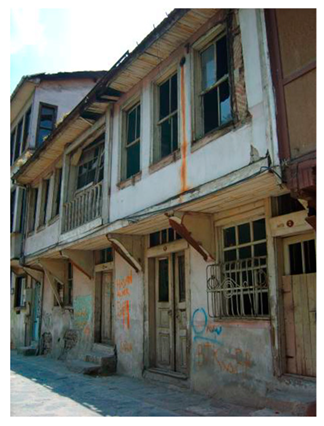

3.1. Case Study

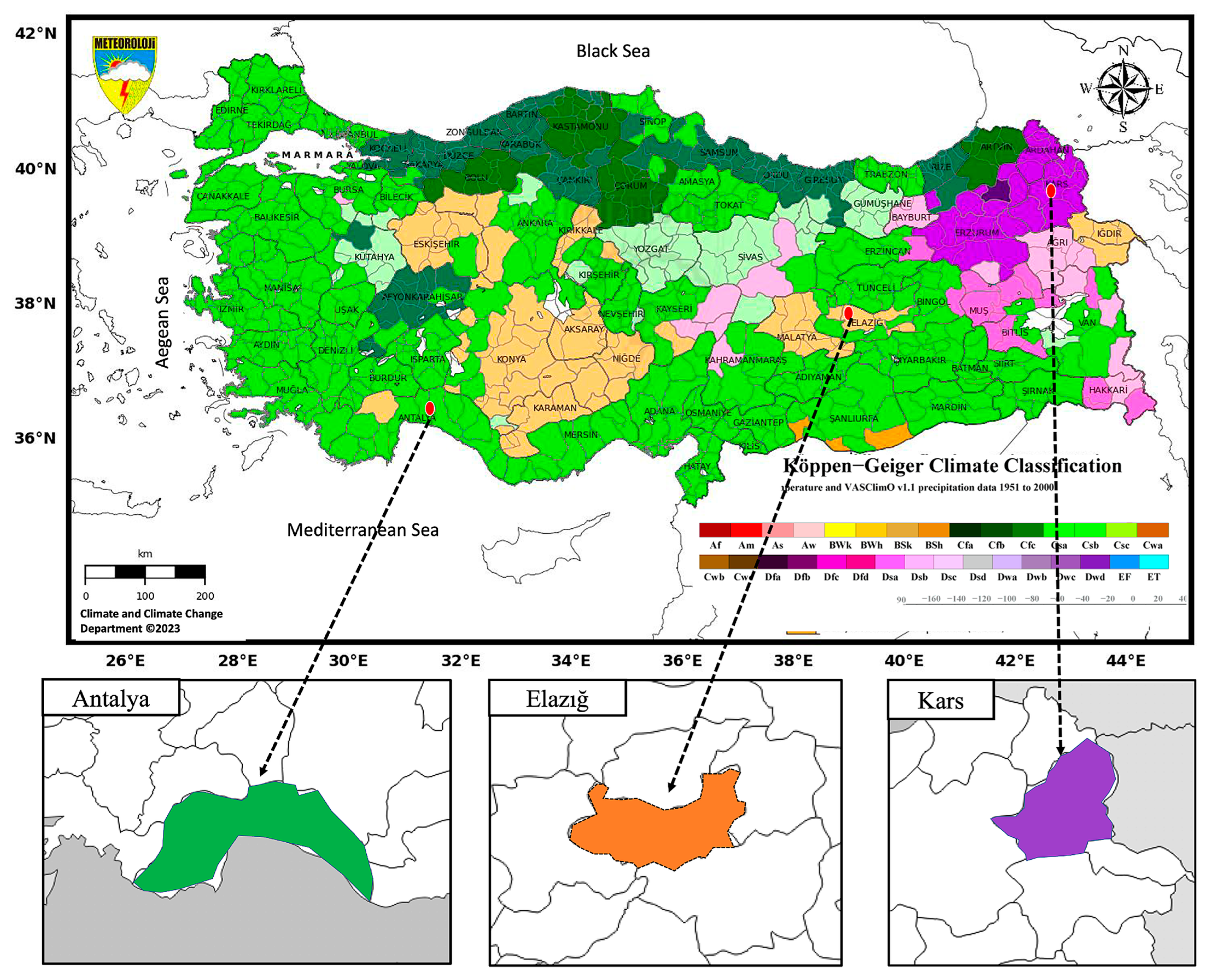

3.2. Climate Zone Selection

3.3. Numerical Modeling Parameters and Simulation Inputs

4. Comparative Analysis in Climatic and Material Contexts

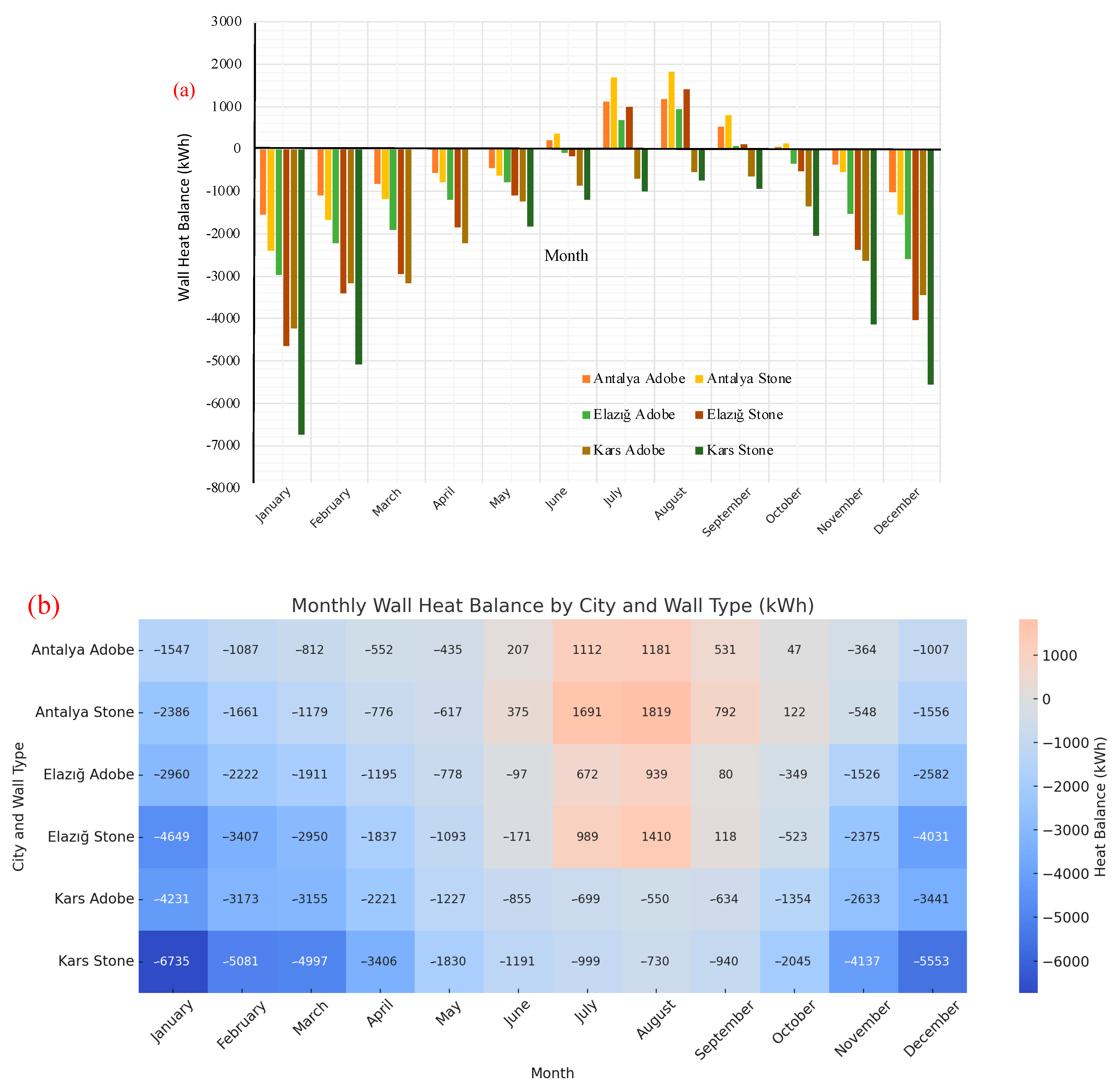

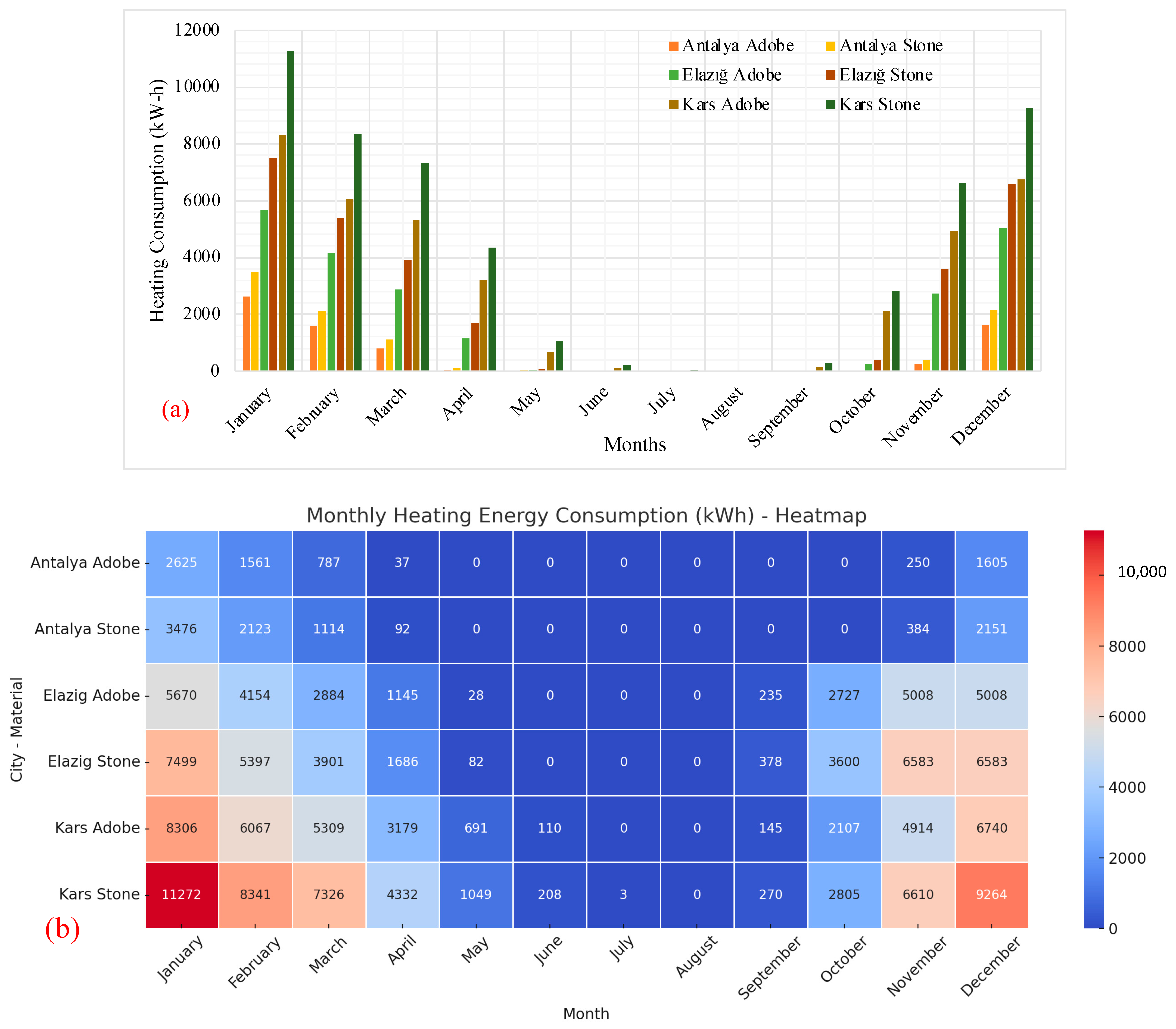

4.1. Analysis of Wall Heat Balance, Heating, Cooling, and Total Energy Consumption

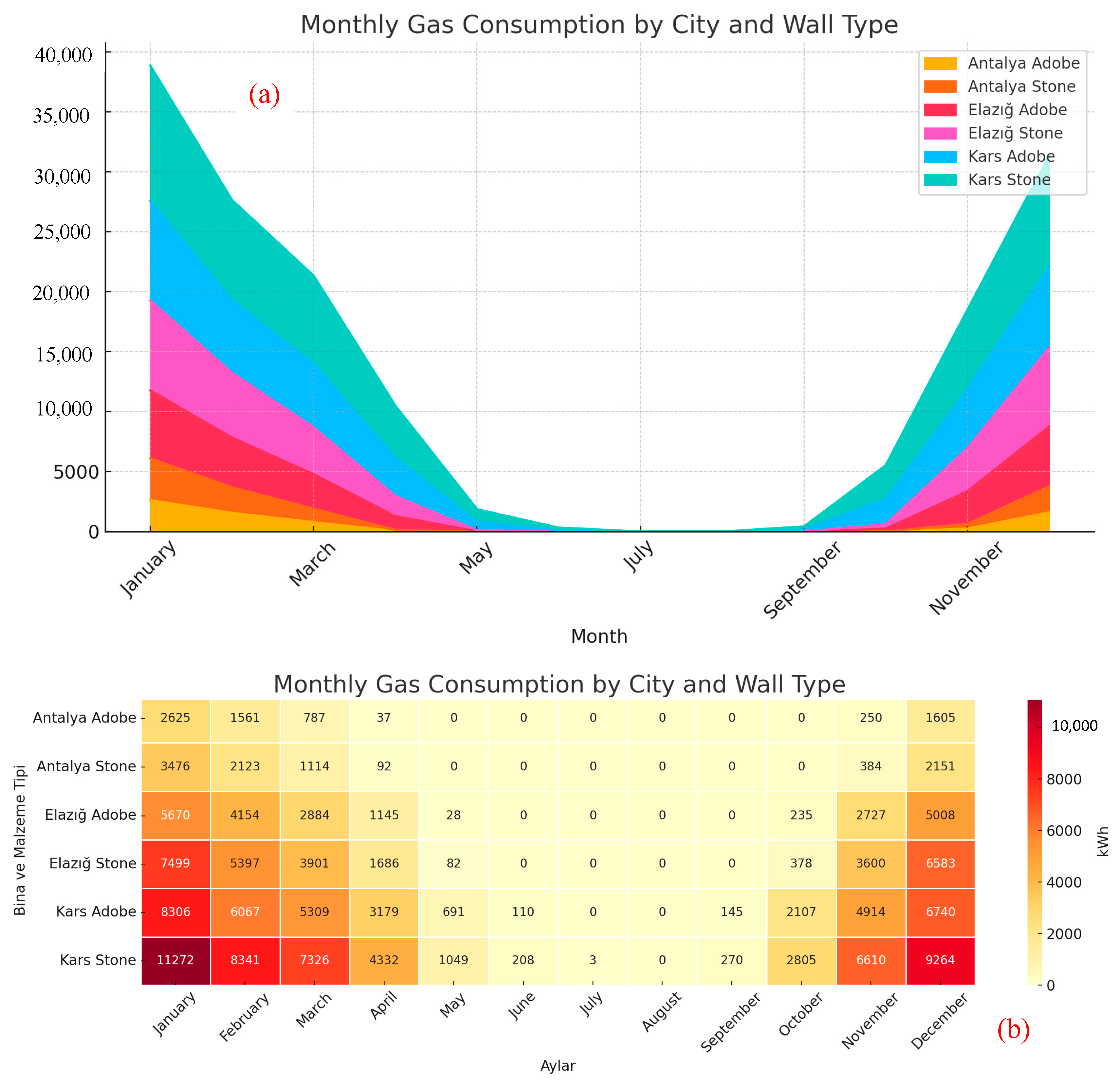

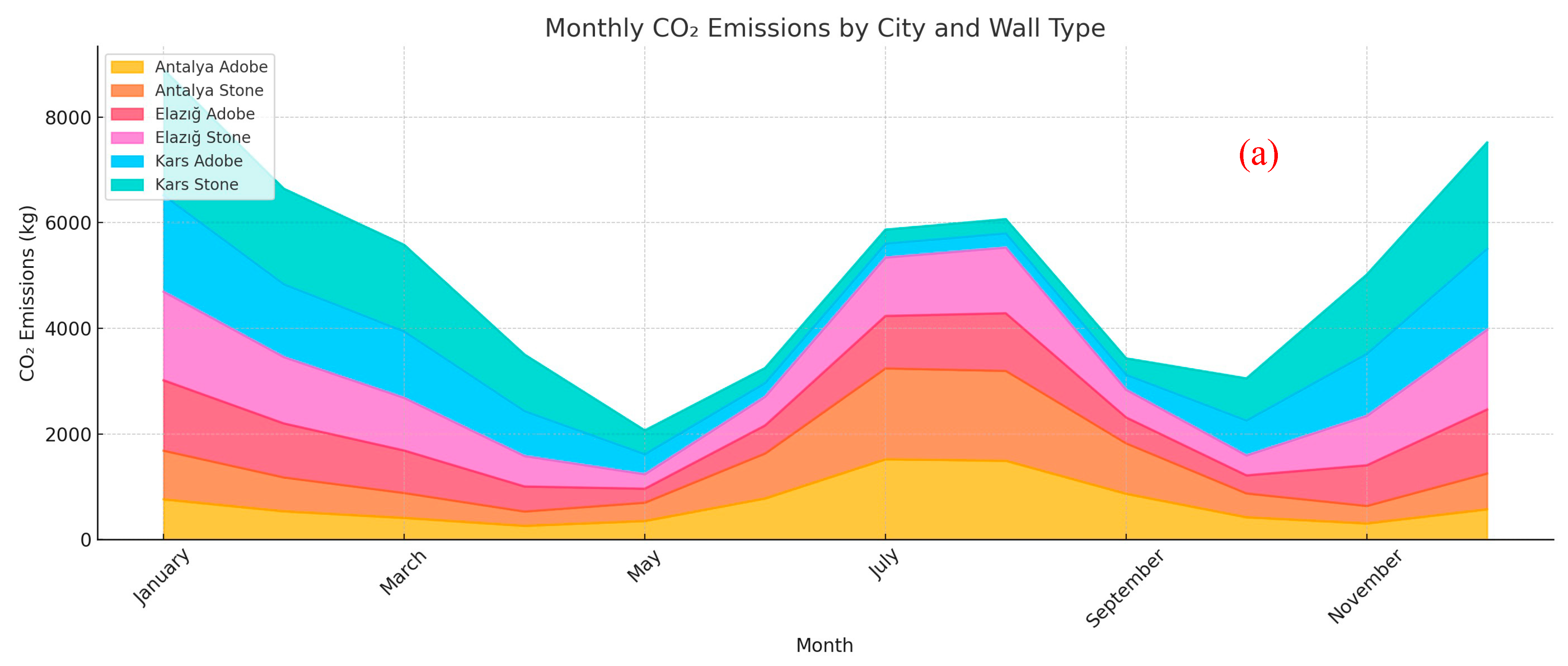

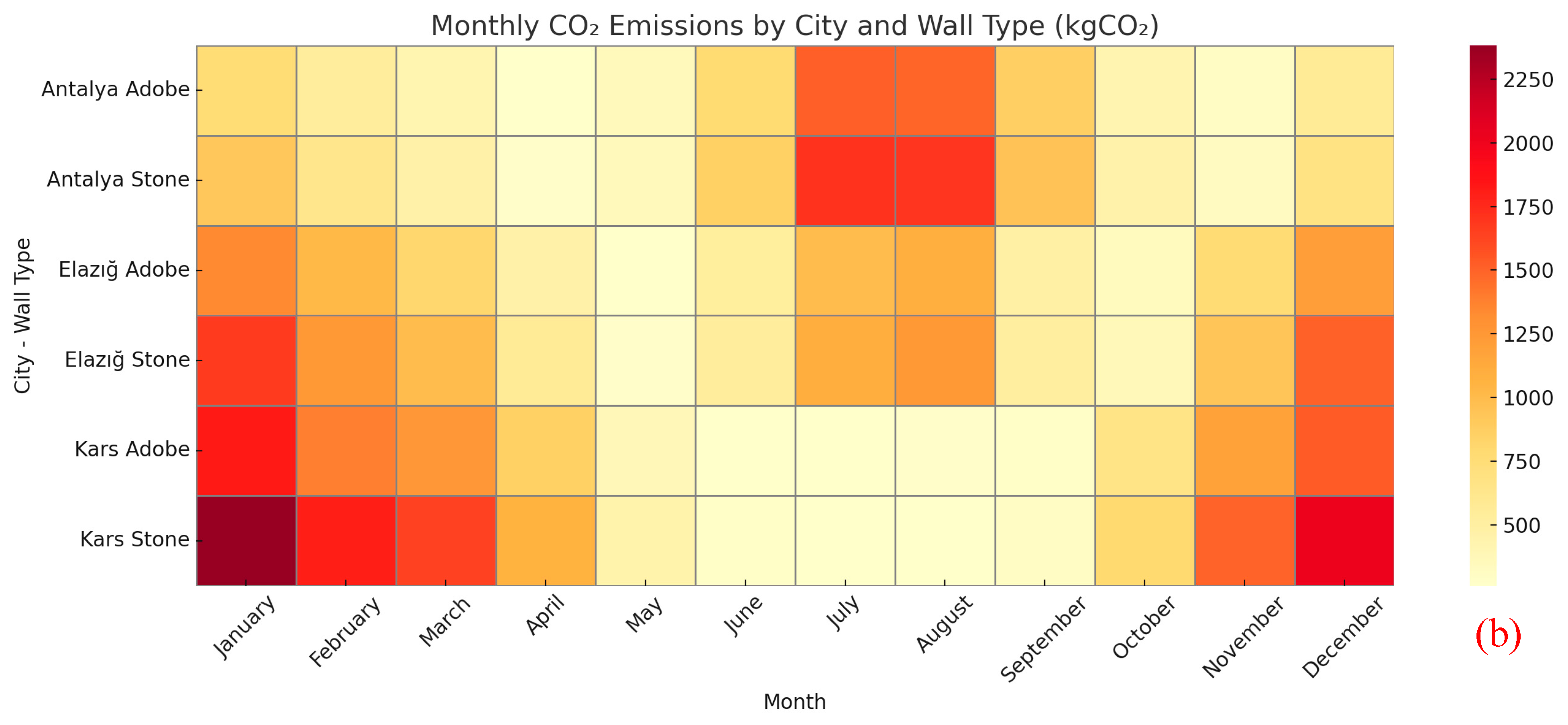

4.2. Analysis of Operational Energy Demand and Environmental Outcomes: Focus on Electricity, Gas, and Carbon Emissions

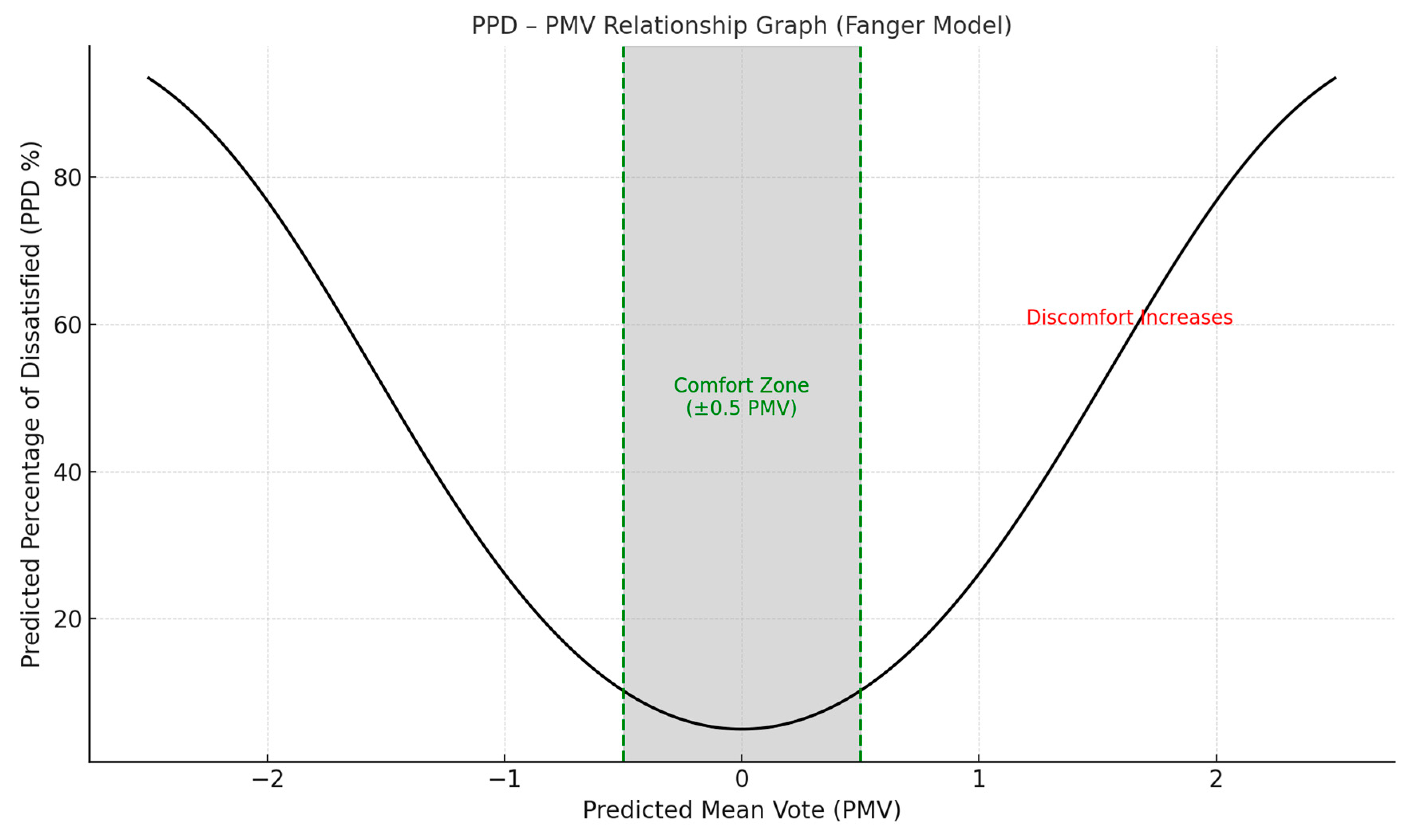

4.3. PMV–PPD Analysis of Adobe and Stone Buildings in Antalya, Elazığ, and Kars

5. Findings and Discussion

- In hot–dry climates, high thermal mass and low thermal conductivity damp summer peak loads and reduce cooling demand; synergy is expected with night ventilation and effective shading.

- In heating-dominated climates, layered/insulated stone envelopes can limit winter losses and narrow the performance gap; normalization against equal-U or code-minimum configurations should be tested in future work (EN ISO 13786; ASHRAE).

- When energy–carbon–comfort is considered together, the increase in hours within the comfort band tends to track the energy/CO2 ranking, indicating that material choice has concurrent effects on occupant well-being and operating costs.

6. Conclusions and Recommendations

- Wall heat balance analyses revealed that stone-walled buildings experience high heat losses throughout the year, especially in cold climates. In contrast, adobe walls provide net heat gains during summer months in hot regions, contributing to better thermal regulation.

- Heating energy demand significantly increased in stone-walled buildings, particularly in cold climates. Adobe walls, however, showed up to 27% lower consumption, indicating better insulation and energy efficiency.

- Cooling loads were higher in stone-walled buildings in hot and transitional climates. Adobe walls, with their high thermal mass and heat delay characteristics, reduced cooling needs by maintaining more stable indoor temperatures.

- Electricity and natural gas consumption was generally higher in stone wall scenarios throughout the year. This is attributed to the increased demand for both heating and cooling.

- Carbon emissions were found to be higher in stone-walled buildings across all climate zones. This confirms adobe’s potential as a more environmentally friendly building material due to its low embodied energy.

- PMV-PPD comfort analyses showed that adobe-walled buildings provided better user comfort in hot and transitional climates. However, in cold climates, neither material achieved thermal comfort levels, highlighting the need for additional insulation strategies.

- In summary, the adobe wall scenario reduced annual heating energy in all three cities. For cooling, a decrease was observed in Antalya, while Elazığ showed a modest increase. Electricity use declined in Antalya and Elazığ, and operational CO2 emissions fell across all three cities. In Kars, electricity consumption remained relatively low and stable throughout the year, with most thermal demand met by natural gas. Average PPD values decreased in all climates, and absolute PMV magnitudes were lower with adobe. The Kars results clearly indicate that, in cold continental climates, vernacular envelopes require supplementary insulation to meet comfort targets.

Recommendations

- Local vernacular building materials specific to Anatolia offer sustainable solutions with low carbon footprints and the ability to provide passive thermal comfort in alignment with regional climates. These materials should be given greater consideration in modern restoration and adaptive reuse projects.

- Materials such as adobe can be reconsidered and modernized to meet contemporary housing needs, particularly in hot and transitional climate zones, to develop energy-efficient residential typologies.

- In cold climate regions, the thermal insulation properties of adobe structures can be enhanced to improve energy performance. This would not only reduce energy consumption but also support the long-term sustainability of vernacular architecture.

- In conservation practices, thermal comfort and energy performance should be included among evaluation criteria, alongside aesthetic and cultural integrity.

- Integrating such simulation-based analyses into rural and cultural heritage policies can contribute to the development of climate-sensitive preservation approaches.

- Equal total thickness was used to isolate material effects. Code-minimum or equal-U layered/insulated assemblies may change outcomes in real buildings.

- Geometry, window-to-wall ratio, orientation, and occupancy schedules were standardized; no site-specific usage measurements were taken.

- HVAC was represented with the EnergyPlus Ideal Loads Air System; equipment types and efficiencies were not modeled. Mechanical humidification/dehumidification, natural/night ventilation, and neighboring-building shading were not included.

- Carbon accounting was limited to operational emissions using a fixed grid emission factor; embodied carbon, water, and circularity indicators were excluded.

- PMV/PPD was reported with fixed Met–Clo and indoor air speed (0.1 m/s) for occupied hours only; these assumptions influence absolute comfort magnitudes.

- Thermophysical properties of materials were taken from the literature; local material variability and coupled hygrothermal (heat–moisture) behavior were out of scope.

- Infiltration and internal gains followed template-consistent assumptions and were not calibrated to field measurements.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Masson-Delmotte, V.; Zhai, P.; Pirani, A.; Connors, S.L.; Péan, C.; Berger, S.; Caud, N.; Chen, Y.; Goldfarb, L.; Gomis, M.I. Climate Change 2021: The Physical Science Basis. In Contribution of Working Group I to the Sixth Assessment Report of the Intergovernmental Panel on Climate Change; Cambridge University Press: Cambridge, UK, 2023; Volume 2, p. 2391. [Google Scholar]

- Crawley, D.B.; Lawrie, L.K.; Winkelmann, F.C.; Buhl, W.F.; Huang, Y.J.; Pedersen, C.O.; Strand, R.K.; Liesen, R.J.; Fisher, D.E.; Witte, M.J. EnergyPlus: Creating a new-generation building energy simulation program. Energy Build. 2001, 33, 319–331. [Google Scholar] [CrossRef]

- Sayigh, A. Sustainable Vernacular Architecture: How the Past Can Enrich the Future; Springer: Berlin/Heidelberg, Germany, 2019. [Google Scholar]

- Oliver, P. Encyclopedia of Vernacular Architecture of the World; Cambridge University Press: Cambridge, UK, 1997. [Google Scholar]

- Asquith, L.; Vellinga, M. Vernacular Architecture in the 21st Century: Theory, Education and Practice; Taylor & Francis: London, UK, 2006. [Google Scholar]

- Manioğlu, G. Geleneksel mimaride iklimle uyumlu binalar: Mardin’de bir öğrenci atölyesi. In Proceedings of the VIII. Ulusal Tesisat Mühendisliği Kongresi, İzmir, Turkey, 25–28 October 2007; pp. 25–28. [Google Scholar]

- Turgutlugil, G.; Mıhlayanlar, E. Geleneksel konut binalarinda pasif tasarim stratejilerinin incelemesi: Tekirdağ ertuğrul mahallesi. Karesi J. Archit. 2024, 3, 1–24. [Google Scholar]

- Akyildiz, N.A. Evaluation of sustainable traditional buildings in the context of energy efficiency and conservation. Int. J. Res.–GRANTHAALAYAH 2020, 8, 200–215. [Google Scholar]

- Manioğlu, G.; Yılmaz, Z. Energy efficient design strategies in the hot dry area of Turkey. Build. Environ. 2008, 43, 1301–1309. [Google Scholar] [CrossRef]

- Yüksek, İ.; Esin, T. Analysis of traditional rural houses in Turkey in terms of energy efficiency. Int. J. Sustain. Energy 2013, 32, 643–658. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Choksiriwanna, J. The physical and thermal properties of adobe brick containing bagasse for earth construction. Int. J. Build. Urban Inter. Landsc. Technol. 2011, 1, 57–66. [Google Scholar] [CrossRef]

- Shukla, A.; Tiwari, G.; Sodha, M. Embodied energy analysis of adobe house. Renew. Energy 2009, 34, 755–761. [Google Scholar] [CrossRef]

- Bui, Q.-B.; Morel, J.-C.; Reddy, B.V.; Ghayad, W. Durability of rammed earth walls exposed for 20 years to natural weathering. Build. Environ. 2009, 44, 912–919. [Google Scholar] [CrossRef]

- Abanto, G.A.; Karkri, M.; Lefebvre, G.; Horn, M.; Solis, J.L.; Gómez, M.M. Thermal properties of adobe employed in peruvian rural areas: Experimental results and numerical simulation of a traditional bio-composite material. Case Stud. Constr. Mater. 2017, 6, 177–191. [Google Scholar] [CrossRef]

- Parra-Saldivar, M.L.; Batty, W. Thermal behaviour of adobe constructions. Build. Environ. 2006, 41, 1892–1904. [Google Scholar] [CrossRef]

- Chowdhury, D.; Neogi, S. Thermal performance evaluation of traditional walls and roof used in tropical climate using guarded hot box. Constr. Build. Mater. 2019, 218, 73–89. [Google Scholar] [CrossRef]

- Hofheinz, A.; Walker, R.; Purcell, C.E.; Kinnane, O. The hygrothermal properties of stone used in traditional construction: A Western European case study. Build. Environ. 2025, 276, 112855. [Google Scholar] [CrossRef]

- Ben-Alon, L.; Rempel, A.R. Thermal comfort and passive survivability in earthen buildings. Build. Environ. 2023, 238, 110339. [Google Scholar] [CrossRef]

- Costa-Carrapico, I.; González, J.N.; Raslan, R.; Sanchez-Guevara, C. Understanding the challenges of determining thermal comfort in vernacular dwellings: A meta-analysis. J. Cult. Herit. 2022, 58, 57–73. [Google Scholar] [CrossRef]

- Jalali, Z.; Noorzai, E.; Heidari, S. Design and optimization of form and facade of an office building using the genetic algorithm. Sci. Technol. Built Environ. 2020, 26, 128–140. [Google Scholar] [CrossRef]

- Wang, H.; Zhai, Z.J. Advances in building simulation and computational techniques: A review between 1987 and 2014. Energy Build. 2016, 128, 319–335. [Google Scholar] [CrossRef]

- Martinaitis, V.; Zavadskas, E.K.; Motuzienė, V.; Vilutienė, T. Importance of occupancy information when simulating energy demand of energy efficient house: A case study. Energy Build. 2015, 101, 64–75. [Google Scholar] [CrossRef]

- Çetinmakas, T.A.; Canıtez, T. Edirne/keşan çamlıca (grabuna) köyü’nde kırsal mimari ve koruma sorunları. Digit. Int. J. Archit. Art Herit. 2023, 2, 124–162. [Google Scholar]

- Perker, Z.S.; Akincitürk, N. Geleneksel Konutlarda Fiziksel Değişim: Bursa’da Üç Örnek Yapı. Available online: https://dergipark.org.tr/tr/pub/uumfd/issue/21674/233253 (accessed on 3 October 2025).

- Ergün, A.; Çavdar, E. Geleneksel balıkesir dursunbey evleri’nde yapım teknolojileri ve malzeme kullanımları. Balıkesir Üniversitesi Fen Bilim. Enstitüsü Derg. 2010, 12, 1–11. [Google Scholar]

- Aktuğ, E.C. Yok olmaya yüz tutmuş geleneksel mimari: Izmir-kiraz-yağlar evleri. Kahramanmaraş Sütçü İmam Üniv. Sos. Bilim. Derg. 2023, 20, 94–106. [Google Scholar] [CrossRef]

- Ürer, H. Geleneksel türk evi ölçeğinde eskigediz evlerinin cephe düzenlemeleri. Sanat Tarihi Derg. 2013, 22, 189–230. [Google Scholar]

- Bacak, F.N.; Yaldız, E. Akseki ilçesi emiraşıklar mahallesi geleneksel konut mimarisi tescilli yapıları üzerine bir çalışma. Konya Sanat 2023, 6, 1–24. [Google Scholar]

- Öztürk, D.; Halaç, H.H. Eskişehir laçin kirsalindaki geleneksel konutlarin mimari özellikleri. Türk. Bilim. Akad. Kültür Envant. Derg. 2024, 29, 39–62. [Google Scholar]

- Şenol, P.; Akan, A.E. Kırsal yaşam/kırsal konut: Bir yaşam biçimi olarak geleneksel kırsal konut kızılcık köyü örneği. Süleyman Demirel Üniv. Fen Edeb. Fak. Sos. Bilim. Derg. 2011, 2011, 143–160. [Google Scholar]

- Karacag, A. Geleneksel türk konut mimarisine ankara-ulus’ tan bir örnek. MANAS Sos. Araştırmalar Derg. 2017, 6, 353–375. [Google Scholar]

- Öztürk, D. Seydişehir Geleneksel Konut Mimarsi. Master’s Thesis, Selçuk University, Konya, Turkiye, 2011. [Google Scholar]

- Harputlugil, G.U.; Çetintürk, N. Geleneksel türk evi’nde isil konfor koşullarinin analizi: Safranbolu haci hüseyinler evi. Gazi Üniv. Mühendis. Mimar. Fak. Derg. 2005, 20, 77–84. [Google Scholar]

- Turan, H. Sinop’ta geleneksel bir türk evi: Tercümanoğlu konaği. Süleyman Demirel Üniv. Fen Edeb. Fak. Sos. Bilim. Derg. 2018, 1, 58–90. [Google Scholar]

- Görgülü, H.C.; Koman, İ. Kayseri kırsalı’ndaki yığma konutlar için duvar tipi önerisi. Tasarım+ Kuram 2013, 9, 56–70. [Google Scholar]

- Özbek, K. Geleneksel Niğde Evleri Mekânsal Araştırması ve Kale Bölgesi Örnek Alanında Konut Yerleşimi ve Tipoloji-Morfoloji Ilişkisi. Master’s Thesis, Mimar Sinan Güzel Sanatlar Üniversitesi, Fen Bilimleri Enstitüsü, İstanbul, Turkey, 2010. [Google Scholar]

- Burak, B. Adana tufanbeyli ilçesinde kirsal mimari: Muharrem öner evi. Türk Dünya. Araştırmaları 2024, 136, 389–406. [Google Scholar] [CrossRef]

- Kasap, T.L. Karaman’da bir geleneksel türk evi: Tartan konaği. Turk. Online J. Des. Art Commun. 2023, 13, 501–518. [Google Scholar] [CrossRef]

- Şahin, Y.D.; Çetintürk, E.N. Türk evi ölçeğinde geleneksel malatya evlerinin sosyo-kültürel sürdürebilirliğinin değerlendirilmesi. TÜBAV Bilim Dergisi 2020, 13, 50–67. [Google Scholar]

- Karaçizmeli, M. Urfa Ili Geleneksel Konut Yapılarının Malzeme ve Plan Tipi Farklılıklarının Iklimsel Performans Açısından Değerlendirilmesi. Master’s Thesis, Mimar Sinan Güzel Sanatlar Üniversitesi, Fen Bilimleri Enstitüsü, İstanbul, Turkey, 2011. [Google Scholar]

- Akgün, T.; Özen, H. Bayburt kırsal ev mimarisi. Mimar. Yaşam 2019, 4, 239–255. [Google Scholar] [CrossRef]

- Olğun, T.N. Geleneksel konutların korunmasına yönelik bir inceleme: Elazığ evleri örneği. İdealkent 2022, 13, 2330–2364. [Google Scholar] [CrossRef]

- Özer, G.; Oral, M. Sürdürülebilirlik bağlaminda; Geleneksel mimaride iklimle uyumlu yapılar: Elazığ-harput evleri üzerinde inceleme. Akad. Mühendislik Fen Bilim. Derg. 2017, 2, 83–91. [Google Scholar]

- Yariş, S. Geleneksel türk evi mimarisinde diyarbakır evlerinin yeri üzerine bir değerlendirme. J. Turk. Res. Inst. 2020, 68, 313–340. [Google Scholar] [CrossRef]

- Karakaş, B. Süryani Kırsal Mimarisi Üzerine bir Araştırma: Midyat-Haberli (Basibirn) Köyü Örneği. Master’s Thesis, Dicle University, Institute of Science and Technology, Diyarbakır, Turkey, 2011. [Google Scholar]

- Köşklü, Z.; Kındığılı, M.L. Geleneksel erzurum evlerine bir örnek: Yaşar ikizler evi. J. Turk. Res. Inst. 2018, 63, 685–704. [Google Scholar] [CrossRef]

- Orhan, H.N.; Çakıcı, F.Z. Kars karakurt geleneksel konutlarının tipolojik analizi. J. Humanit. Tour. Res. 2023, 13, 338–353. [Google Scholar]

- Uşma, G.; Urfalıoğlu, N. Geleneksel van evlerinin cephe özellikleri ve tipolojisi üzerine bir inceleme. Çukurova Üniv. Mühendis. Mimar. Fak. Derg. 2018, 33, 1–16. [Google Scholar]

- Mühürdaroğlu, K.; Direk, Y.S. Hakkâri yerel konutlarinin turizm açisindan irdelenmesi. Yüz. Yıl Üniv. Sos. Bilim. Enst. Derg. 2019, 3, 311–328. [Google Scholar]

- Yaman, G.Ö.; Coşkun, M. Tarihî çevrelerde sokak örneği: Elazığ kazım efendi sokak. In Mimarlik Alanindafarkli Yaklaşimlar; Çağlar, A., Ed.; Nobel: Ankara, Turkiye, 2021; Volume 1, pp. 1–20. [Google Scholar]

- Özdemir, S.; Ekici, B.B. Evaluation of the energy performance of traditional harput houses: Şefik gül house sample. Int. J. Innov. Eng. Appl. 2020, 4, 64–72. [Google Scholar] [CrossRef]

- Özer, G. Restorasyon Sonrası Yeniden Işlevlendirilmiş Geleneksel Harput Evlerinde Ekolojik Değerlendirme. Master’s Thesis, Selçuk Üniversitesi, Fen Bilimleri Enstitüsü, Konya, Türkiye, 2014. [Google Scholar]

- Müdürlüğü, M.G. Iklim Sınıflandırmaları. 2017. Available online: http://www.mgm.gov.tr/FILES/iklim/iklim_siniflandirmalari.pdf (accessed on 25 June 2025).

- Mıhlayanlar, E.; Umaroğulları, F. Kalker taş duvarlarda sıcaklık ve nem performansının incelenmesi. Çukurova Üniv. Mühendis.-Mimar. Fak. Derg. 2016, 31, 313–322. [Google Scholar] [CrossRef]

- Fanger, P.O. Thermal Comfort: Analysis and Applications in Environmental Engineering; Danish Technical Press: Copenhagen, Denmark, 1970. [Google Scholar]

- Sözer, O. Termal Konfor Ve Enerji Verimliliği Odaklı Akıllı Klima Kontrol Sistemi. Master’s Thesis, İstanbul Teknik Üniversitesi, Fen Bilimleri Enstitüsü, Istanbul, Turkiye, 2016. [Google Scholar]

- ISO 7730; Ergonomics of the Thermal Environment—Analytical Determination and Interpretation of Thermal Comfort Using Calculation of the PMV and PPD Indices and Local Thermal Comfort Criteria. International Organization for Standardization: Geneva, Switzerland, 2005.

- Pourshaghaghy, A.; Omidvari, M. Examination of thermal comfort in a hospital using PMV–PPD model. Appl. Ergon. 2012, 43, 1089–1095. [Google Scholar] [CrossRef] [PubMed]

- ASHRAE. Ashrae Handbook of Fundamentals; IP Edition–F09; American Society of Heating, Refrigerating and Air-Conditioning Engineers: Peachtree, GA, USA, 2017; ISBN 978-1-933742-54-0. Available online: https://shop.iccsafe.org/media/wysiwyg/material/8950P217-toc.pdf (accessed on 3 October 2025).

- Bergman, T.L. Fundamentals of Heat and Mass Transfer; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Givoni, B. Passive Low Energy Cooling of Buildings; John Wiley & Sons: New York, NY, USA, 1994. [Google Scholar]

| Location of the cities with vernacular houses examined in the scope of the study on the map of Turkey. |  | ||

| City and Reference and Structural Notes and Figure | City and Reference and Structural Notes and Figure | ||

| 1. Edirne [18]. Construction system/materials: The load-bearing structure is rubble-stone masonry. Exterior walls are 50–80 cm thick-typically thicker at the ground floor and reduced on the upper floors. Quoins are built with large, well-dressed stones, with smaller stones used as core/infill; no timber tie-beams (hatıl) are present in the exterior walls, and interior partitions are mostly adobe. In some cases, the buildings are oriented toward the south/east façades. |  | 2. Bursa [19]. From a structural standpoint, traditional houses typically have ground-floor exterior walls/plinths built as stone masonry reinforced with timber tie beams, whereas the upper stores are timber-frame (hımış/bağdadi) constructions infilled with adobe, stone, or brick. |  |

| 3. Balıkesir [20]. 2–3 storeys; foundation: rubble stone (30–100 cm); ground floor: stone masonry walls (50–80 cm); upper floors: timber frame with adobe infill (hımış), 8–12 cm timber ring beams; beam spacing ~60–150 cm; roof: gable/hipped with Turkish clay tiles; windows: timber; orientation: not specified. |  | 4. İzmir: [21]. 2 storeys; ground floor: rubble-stone masonry with timber ring beams; upper floor: timber frame (hımış/bağdadi) with adobe and/or stone infill; roof: hipped with Turkish clay tiles; openings: dense on upper floor, limited on ground floor; plan: open exterior sofa (gallery), mostly east-oriented; wall thickness: not specified. |  |

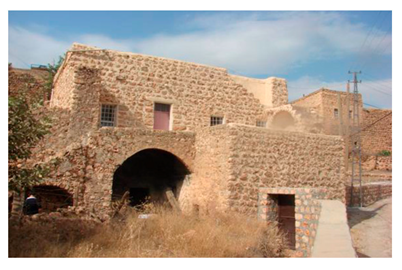

| 5. Kütahya: [22]. Ground floor: stone masonry; upper floors: timber frame (hımış/bağdadi) with stone/brick/adobe infill; plan: inner/central sofa (mostly central); storeys: 2–3; setting/orientation: attached (party-wall) fabric aligned to the street; orientation shaped by sun, views, and parcel geometry; wall thickness: not specified. |  | 6. Antalya: [23]. Akseki–Emiraşıklar “düğmeli” houses: stone walls with timber lacing/ring beams, dry-stone (timber ends visible on façades); siting: plot-attached with courtyard; ground floor: service/barn/storage; upper floor: living spaces; plan: inner and outer sofa (gallery) variants; openings: upper-floor windows aspect ≈ 1:2, smaller openings on ground floor; storeys: 1–2 (predominantly 2). |  |

| 7. Eskişehir: [24]; hımış system (timber frame with adobe infill); finishes: earthen/adobe plaster (interior/exterior); roof: Turkish clay tiles; storeys: predominantly ground + 1 (~82%), single-storey ~14%, ground + 2 ~4%; siting: compact slope settlement with dwellings and ancillary/work units co-located; orientation governed by topography and plot geometry; external wall thickness: not specified; infill unit size: adobe ≈ 8 × 30 cm. |  | 8. Isparta: [25]. Ground floor of stone masonry (rubble/cut stone); upper floor timber frame (hımış/bağdadi) with adobe infill; finishes: earthen and/or lime plaster; floors: timber joists; façades/garden walls: stone; siting: compact slope settlement along both sides of the valley following the stream; orientation and opening pattern governed by topography and plot geometry; storeys: not specified. |  |

| 9. Ankara: [26]. Sloped plot; levels: basement + ground + first + attic; basement: rubble-stone masonry; ground: rubble stone + handmade brick; first floor: timber frame (bağdadi/hımış) with adobe/brick/stone infill; roof: hipped on timber structure, Marseille tiles; plan: similar to inner-sofa type; orientation: main façade/parcel to NE; topography allows external access to different floors; wall thickness: not specified, oriel (projecting bay) and balconies. |  | 10. Konya: [27]. Rubble-stone masonry; double-wythe stone with small-stone core (“helik”); surfaces finished with mud plaster; timber ring beams at intervals; floors: timber joists; roof: hipped on timber structure; wall thickness: basement ~80 cm, ground/upper 70–80 cm; plan: inner sofa (upper floor main living, lower floors service/storage); storey arrangement: mostly two storeys; façade finishes: cement-mortared joints/cladding or mud plaster; orientation: not specified. |  |

| 11. Kastamonu: [28]. Basement and/or ground floor in rubble/cut-stone masonry; 1–2 upper floors in timber frame (hımış/bağdadi) with adobe infill; exterior finished with fibred/adobe plaster; joinery: timber frames with single glazing; roof: hipped on timber structure, clay tiles; wall thickness: stone outer ~50 cm, adobe infill ~25 cm; plan: inner sofa (lower floors service/storage, upper floors living); siting on valley slopes; orientation governed by topography and plot geometry. |  | 12. Sinop: [29]. Basement in rubble-stone masonry; above, two storeys of timber frame with lath-and-plaster (bağdadi); roof: hipped with Turkish clay tiles; façades: lime plaster with local timber cladding; plan: inner sofa (“karnıyarık”) on both floors; storey arrangement: basement + ground + first; orientation: E–W axis, principal rooms facing E/NE with views; materials: pine/fir for framing and cladding, oak for main posts; windows: large timber-framed sash (guillotine); external wall thickness: not specified. |  |

| 13. Kayseri: [30]. Solid natural-stone masonry; street façade predominantly ashlar, other façades rough/fine-dressed stone; wall thickness ≥ 50 cm; siting on valley slopes and in the plain; orientation: tendency to face north due to strong S–SE and prevailing winds; roof/plan: not specified. |  | 14. Niğde: [31]. Primary material stone (yellow trachyte common); black basalt used at quoins, window/door surrounds and corbels for projections; stone–adobe hybrids and all-adobe houses also occur. Story arrangement: mostly two stores. Wall thickness: basement 60–100 cm; ground/secondary walls 50–60 cm; upper floors in a thinner single-wythe stone. Plan: courtyard house; the hanay (sofa) reached by a few steps from the courtyard structures the layout; typical “room–sofa–room” sequence. Siting: on the slopes of Alaaddin Hill within the old walls, following the topography. Orientation: generally, S–SE tendency. |  |

| 15. Adana: [32]. Storeys, two; plan: inner sofa; system: timber-frame hımış with stone infill + stone masonry; materials: stone, timber, earth mortar; roof: timber rafters with earthen cover; siting: sloped terrain—thick façade walls; entrance on the east façade; south façade with balcony/örtme (covered balcony); use: ground floor service, upper floor living; orientation governed by topography and solar conditions. |  | 16. Karaman: [33]. Load-bearing adobe walls; finishes: earthen plaster with straw (interiors with hair/egg additives); façade traces of timber ring beams; plan: central sofa; stores: two; roof/cover: earthen layer over reeds (flat/low-pitched); wall thickness—(not reported); orientation—(not reported). |  |

| 17. Malatya: [34]. Walls stone up to 1–1.5 m, above adobe masonry; timber ring/tie elements common; storeys: mostly two, with occasional roof-level cihannüma (belvedere); plan: inner/outer sofa—ground floor service rooms (winter room, pantry, storage), upper floor living rooms; storey heights: ground ~3.50–4.30 m, upper ~3.40–3.60 m; façade: bays, arched/flat windows, timber privacy screens; interiors: raised platform (seki), built-in cupboards, hooded hearth; wall thickness/orientation: not reported. |  | 18. Şanlıurfa: [35]. Primary material local limestone (havara); mortar: “kül kireç” (limestone dust–lime–water); external walls: 20 × 10 × 50 cm ashlar blocks with havara chippings in joints, thickness ~60 cm at windowed/niched walls; internal partitions ~20 cm; in hot–dry climate, envelope 60–100 cm for thermal mass/time-lag; siting: party-wall urban fabric; plan: courtyard house, number/position of eyvans defines type; roof/orientation: not reported. Note: rural stock material shares ≈ 56.79% adobe, 39% stone, 4% concrete block, 0.03% brick. |  |

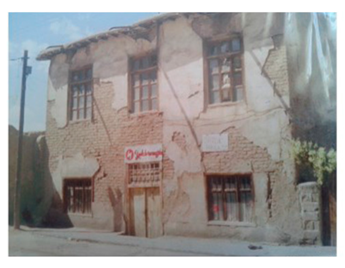

| 19. Bayburt: [36]. Systems stone masonry, timber frame (hımış/bağdadi), and mixed (stone ground floor/timber upper); materials: stone–timber–earth; external wall thickness: stone masonry ~40 cm; storeys: 1–2 (ground barns/storage, upper living); plans: inner/central sofa, split (“karnıyarık”), types; roofs: local earthen cover (flat/low-pitched) and gable/hipped variants; openings: timber joinery, small layered windows on stone façades; siting: shaped by topography–climate–views, entrances mostly south-facing. |  | 20. Elâzığ: [37,38]. Stone-based adobe masonry; street façades with timber-framed oriels (cumba); exterior earthen/mud plaster; roof gable on timber with Turkish clay tiles; plinth: stone up to ~30 cm above grade, adobe walls above; urban fabric party-wall, street axis N–S; entrances to street, rear gardens—circulation along house–garden axis; plan central/side sofa with projecting bays on the upper floor; storey arrangement: mostly two storeys; wall thickness:—(not reported). |  |

| 21. Diyarbakır: [39]. Load-bearing basalt masonry (male stone for walls/columns; female stone for courtyard paving/ornament); story arrangement: basement + 1–2 stores; plan: around a square/rectangular courtyard; summer wing with 1–3 iwans (≈15 cm above courtyard level), basement serdap; orientation: winter rooms to the south, summer rooms to the north; façades: plain/blank to street, open/ornamented to courtyard; fabric: dense party-wall inside the city walls, narrow lanes enhance mutual shading; wall thickness: (not reported). |  | 22. Mardin: [40]. Structure entirely stone masonry; primary material pale yellow limestone (ashlar); main façades in dressed ashlar, courtyard/secondary faces rough-dressed, rubble in inner cores and vaults/domes; timber for joinery/doors, iron for window grilles; plan: around an inner courtyard—ground floor service + 1–2 living units with open/semi-open spaces (courtyard/terrace/roof, iwan/arcade); upper-floor terraces/roofs used for daily work, drying, and summer sleeping; roof: traditional flat earthen roof; façades: plain to street, articulated/ornamented to courtyard; small windows; dominant façade mostly south; wall thickness:—(not reported). |  |

| 23. Erzurum: [41]. Erzurum: rubble-stone masonry with timber ring beams (seismic lacing); plan: inner sofa, enclosed courtyard, with a tandır room; façade: projecting upper story (oriel/bay); fabric: party-wall; stores: two; wall thickness—(not reported); orientation/roof: not specified. |  | 24. Kars: [42]: Load-bearing masonry of dressed tuff/andesite (with rough-dressed and rubble stone in some cases); stores: 1–2 (mostly single-storey); roof: hipped/gable with sheet-metal covering; plan: rectangular (one case near-square); orientation: rooms mostly facing S/SW/SE; openings: varied timber-joinery window types; wall thickness:—(not reported). |  |

| 25. Van: [43]. Stone foundations; stone up to plinth, above adobe masonry with timber ring beams; timber floors; roof: traditional flat earthen roof (some later hipped additions); plan: mostly inner sofa; storey arrangement: 1–2, main living on the upper floor; façades: plain to street, oriels common (balconies rare); joinery: timber, rectangular windows with iron grilles; finishes: earthen/adobe plaster; fabric: historic party-wall blocks with narrow lanes → strong mutual shading; wall thickness/orientation—(not reported). |  | 26. Hakkâri: [44]. Load-bearing stone masonry; locally adobe masonry with timber ring beams/lintels; interior/exterior straw-stabilized earthen plaster; wall thickness ~60 cm; storey arrangement: 1–2 storeys (example: 2); plan: inner sofa; façades plain/blank to street; ground floor small grilled slit windows, upper floor larger regular openings; fabric: compact, slope-adapted with narrow lanes—mix of detached and party-wall blocks, high mutual shading; orientation: not reported. |  |

| Note on Image and Data Use: The images included in Table 1 of this article were obtained from open-access sources published under the Creative Commons (CC BY) license, and have been properly cited. The accompanying research table was created by the author(s) based on these referenced sources. | |||

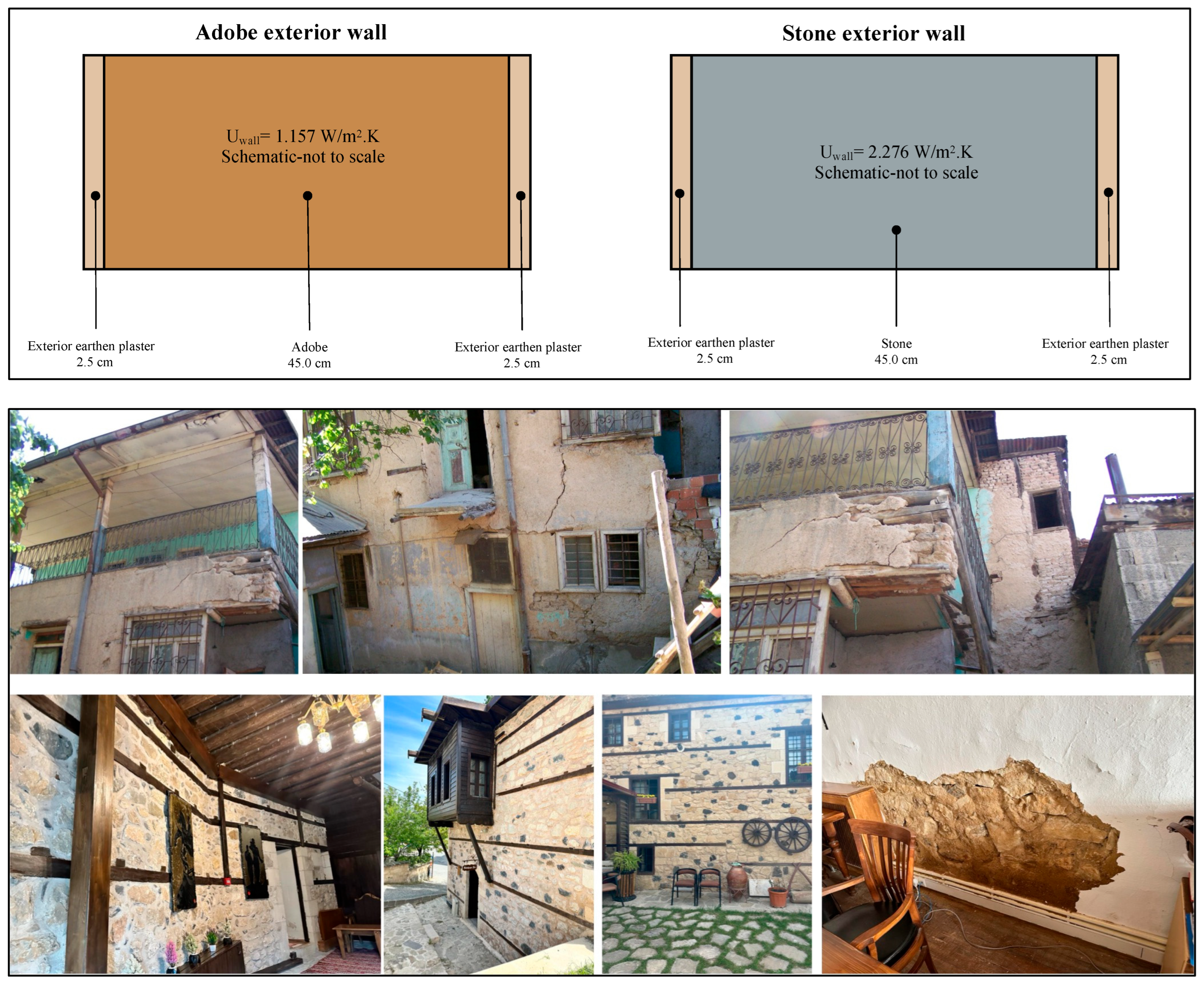

| Description | Conductivity (W/m-K) | Specific Heat (J/kg-K) | Density (kg/m3) |

|---|---|---|---|

| Adobe wall material [28] | 0.72 | 900 | 1650 |

| Stone wall material [53] | 2.25 | 850 | 2440 |

| Element | Layered Build-Up (Outside → Inside) | Total Thickness | U (W/m2·K) |

|---|---|---|---|

| Adobe exterior wall | Exterior earthen plaster 2.5 cm + Adobe 45 cm + Interior earthen plaster 2.5 cm | 50 cm | 1.157 |

| Stone exterior wall | Exterior earthen plaster 2.5 cm + Ashlar stone 45 cm + Interior earthen plaster 2.5 cm | 50 cm | 2.276 |

| Plinth zone | (~30 cm above grade) Ashlar/rubble stone + exterior earthen plaster 2.5 cm | 50 cm | 2.534 |

| Ground-contact floor | Timber finish + compacted earth fill + natural ground | 38 cm + natural ground | 0.487 |

| Roof | Clay tiles 45 mm + timber boards ~20 mm (double-pitched) | 5.5 cm | 2.660 |

| Glazing | “Generic CLEAR 3 mm” single pane | 3 mm | 5.894 |

| Window frame | Timber frame | 20 cm | 3.633 |

| Zone Name | Category | Template |

|---|---|---|

| Entrance Hall, Hall-1, Hall-2, Hall-3, Storage Room | Circulation | Common Circulation Areas (TM59) |

| Common Space | Living area | 1-Bed/3-Bed Living |

| Room-1, Room-2 | Living area | 3-Bed Living |

| Room-3, Room-4 | Bedroom | Bed Living |

| Room-5 | Bedroom | Single Bedroom |

| Room-6 | Bedroom | Double Bedroom |

| Kitchen | Kitchen | 2-Bed Living Kitchen |

| Bathroom, Toilet | Wet areas | Domestic Toilet |

| Zone Category (Examples) | Occupancy Density (Person/m2) | Met | Clo (Winter/Summer) | Heating Set/Setback (°C) | Cooling Set/Setback (°C) | Lighting (Lux) | CO2 Generation (m3 s−1·W−1) |

|---|---|---|---|---|---|---|---|

| Circulation areas (Entrance Hall, Hall-1/2/3, Storage) | 0.0155–0.0196 | 1.0 | 1.0/0.5 | 18/12 | 25/28 | 100 | 3.82 × 10−7 |

| Living areas (Sofa/Common Space, Room-1/2, etc.) | 0.0188 | 1.0 | 1.0/0.5 | 21/12 | 25/28 | 100 | 3.82 × 10−7 |

| Bedrooms (Room-3/4/5/6) | 0.0229 | 1.0 | 1.0/0.5 | 18–21/12 | 25/28 | 100 | 3.82 × 10−7 |

| Kitchen | 0.0188 | 1.0 | 1.0/0.5 | 21/12 | 25/28 | 100 | 3.82 × 10−7 |

| Wet areas (Bathroom, WC) | 0.0243 | 0.9 | 1.0/0.5 | 18/12 | 25/28 | 100 | 3.82 × 10−7 |

| Thermal Sensation | PMV Value |

|---|---|

| Hot | +3 |

| Warm | +2 |

| Slightly Warm | +1 |

| Neutral | 0 |

| Slightly Cool | −1 |

| Cool | −2 |

| Cold | −3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yetkin, E.G.; Yaman, G.Ö. Climatic Adaptation-Based Evaluation of Vernacular Anatolian Houses: A Comparative Analysis of Stone and Adobe Materials in Terms of Energy, Environment, and Thermal Comfort. Buildings 2025, 15, 3660. https://doi.org/10.3390/buildings15203660

Yetkin EG, Yaman GÖ. Climatic Adaptation-Based Evaluation of Vernacular Anatolian Houses: A Comparative Analysis of Stone and Adobe Materials in Terms of Energy, Environment, and Thermal Comfort. Buildings. 2025; 15(20):3660. https://doi.org/10.3390/buildings15203660

Chicago/Turabian StyleYetkin, Elif Gizem, and Gonca Özer Yaman. 2025. "Climatic Adaptation-Based Evaluation of Vernacular Anatolian Houses: A Comparative Analysis of Stone and Adobe Materials in Terms of Energy, Environment, and Thermal Comfort" Buildings 15, no. 20: 3660. https://doi.org/10.3390/buildings15203660

APA StyleYetkin, E. G., & Yaman, G. Ö. (2025). Climatic Adaptation-Based Evaluation of Vernacular Anatolian Houses: A Comparative Analysis of Stone and Adobe Materials in Terms of Energy, Environment, and Thermal Comfort. Buildings, 15(20), 3660. https://doi.org/10.3390/buildings15203660