Axial Compressive Performance of Wood-Cored GFRP Sandwich Columns

Abstract

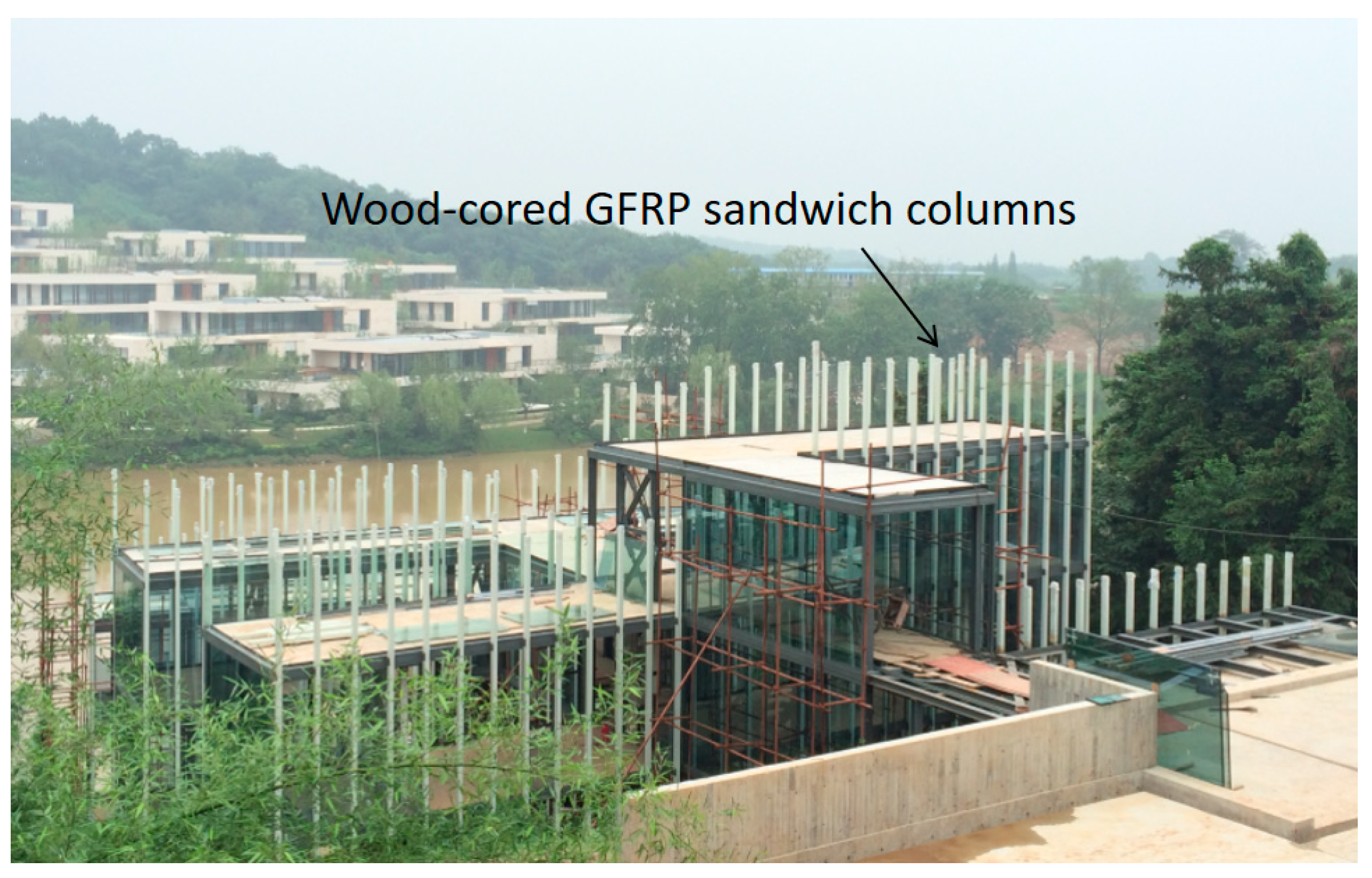

1. Introduction

2. Experimental Program

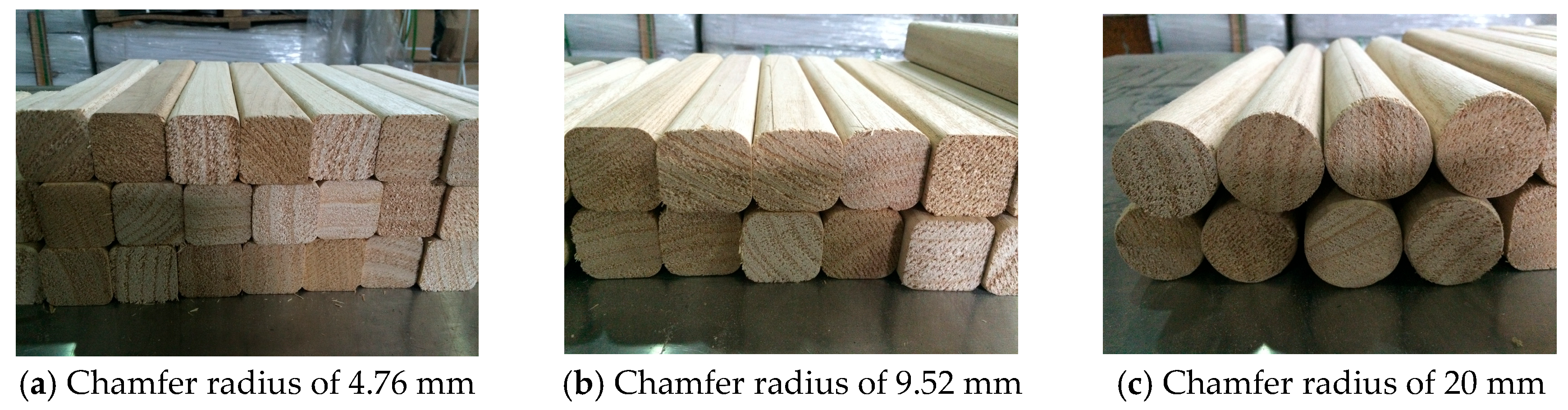

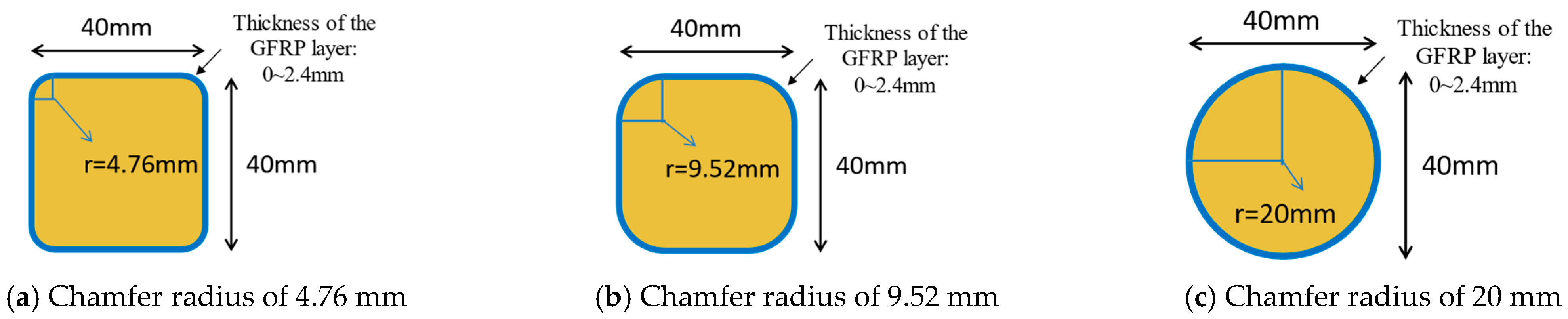

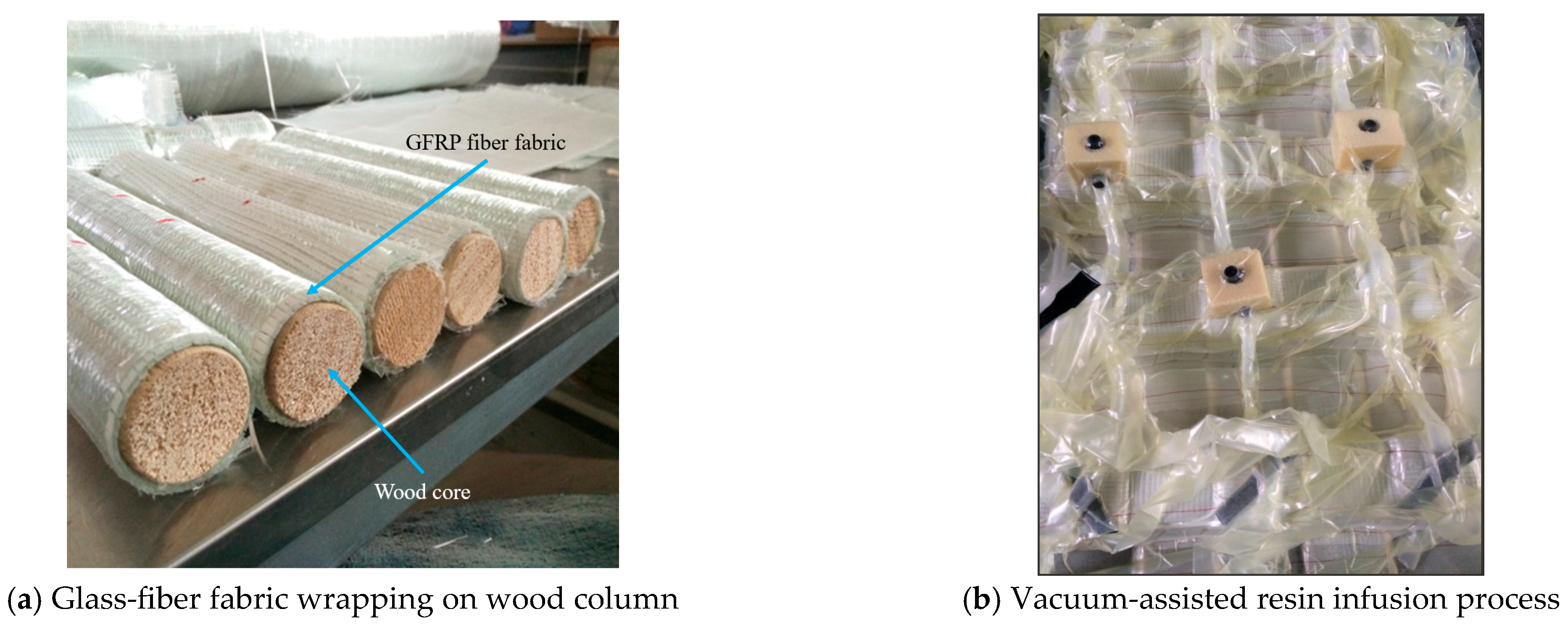

2.1. Specimen Design and Fabrication

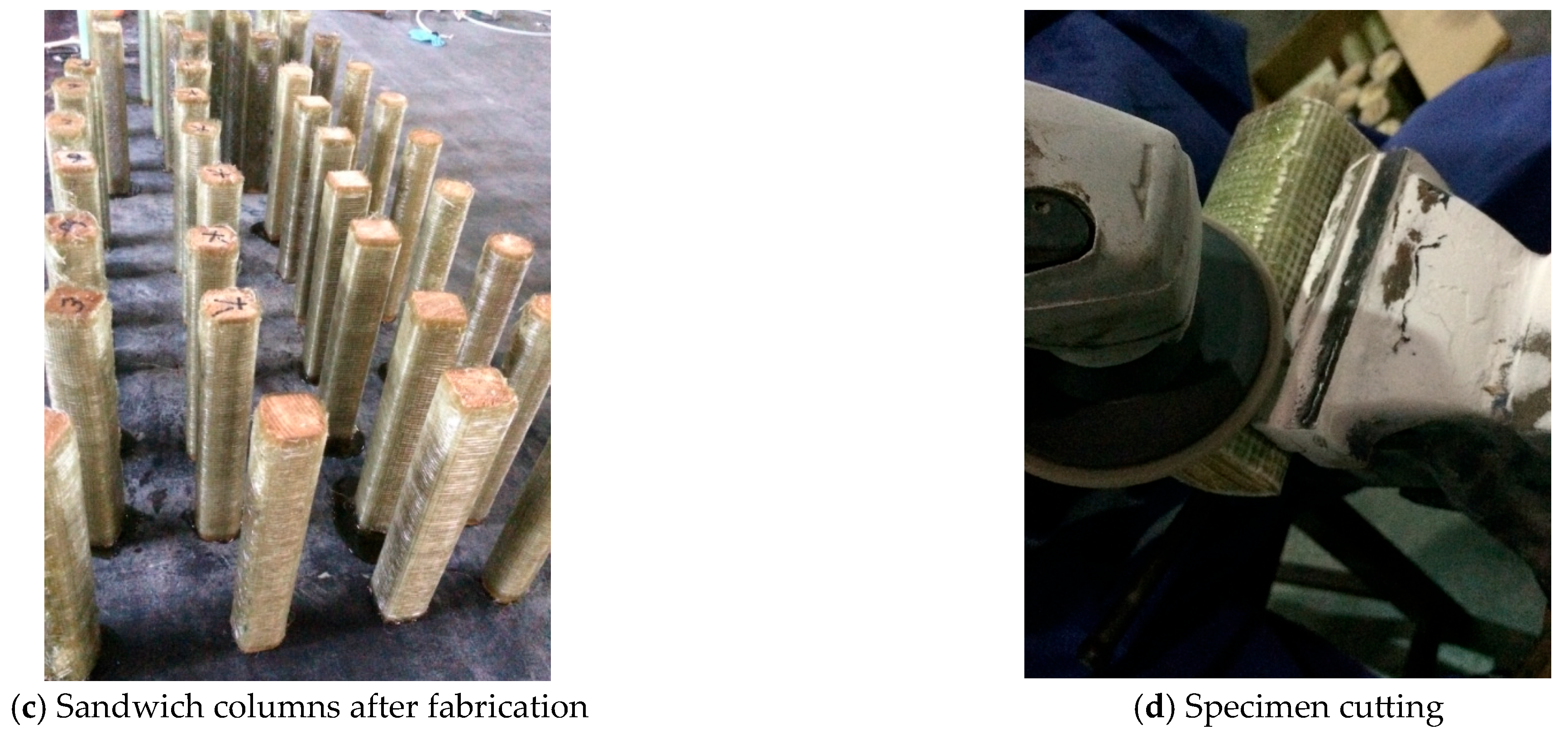

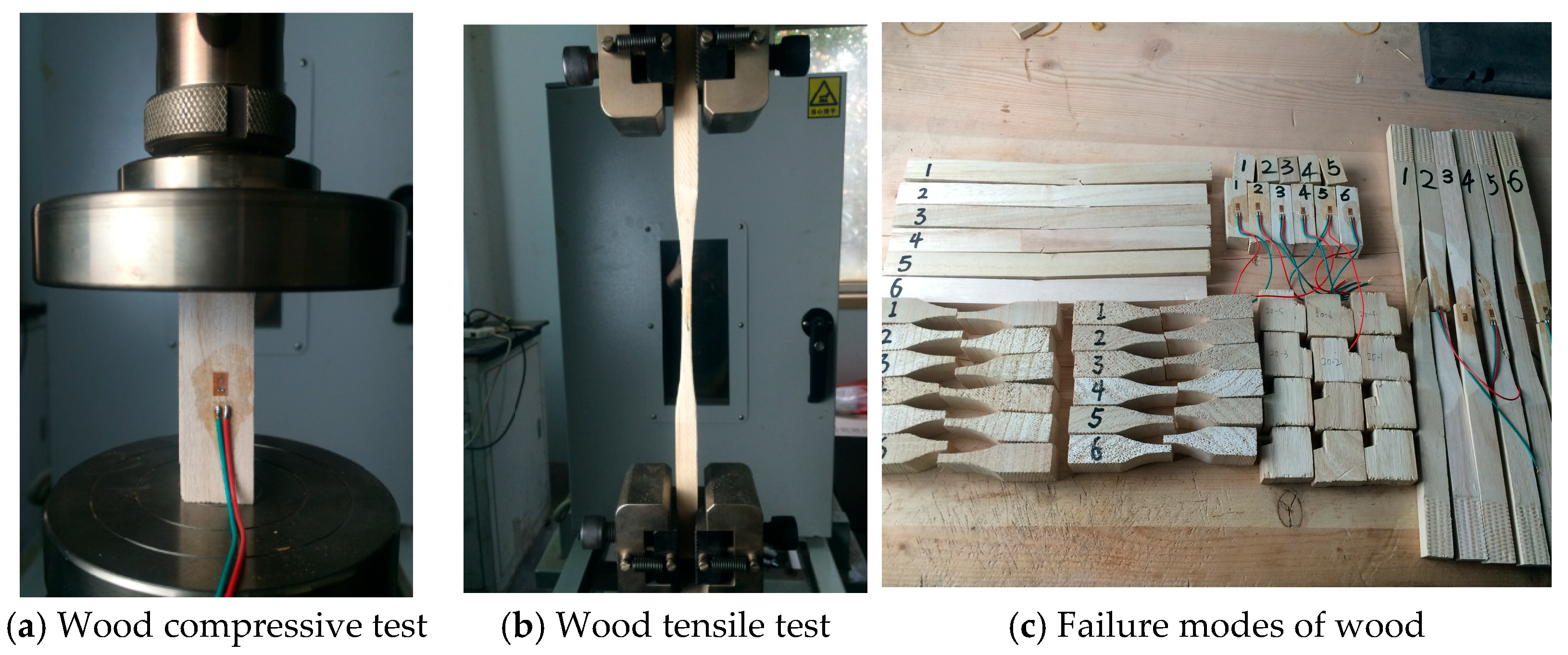

2.2. Material Properties

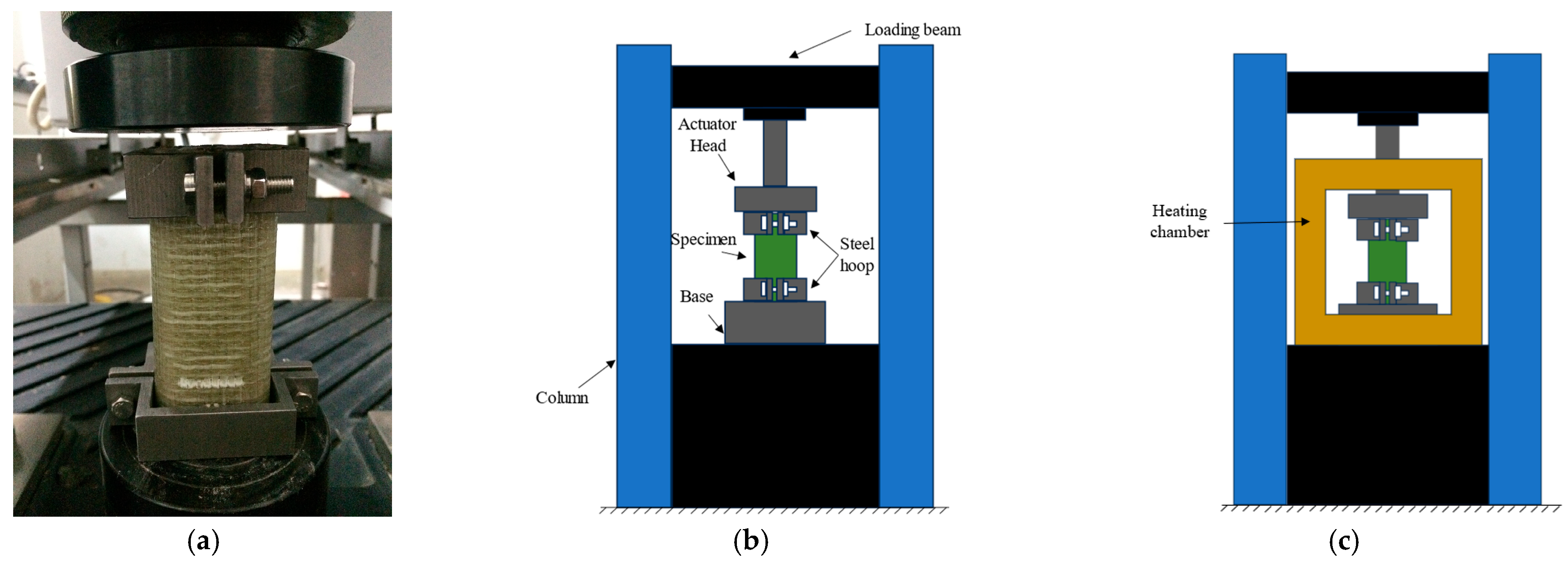

2.3. Test Instruments and Loading Protocol

3. Results and Discussion

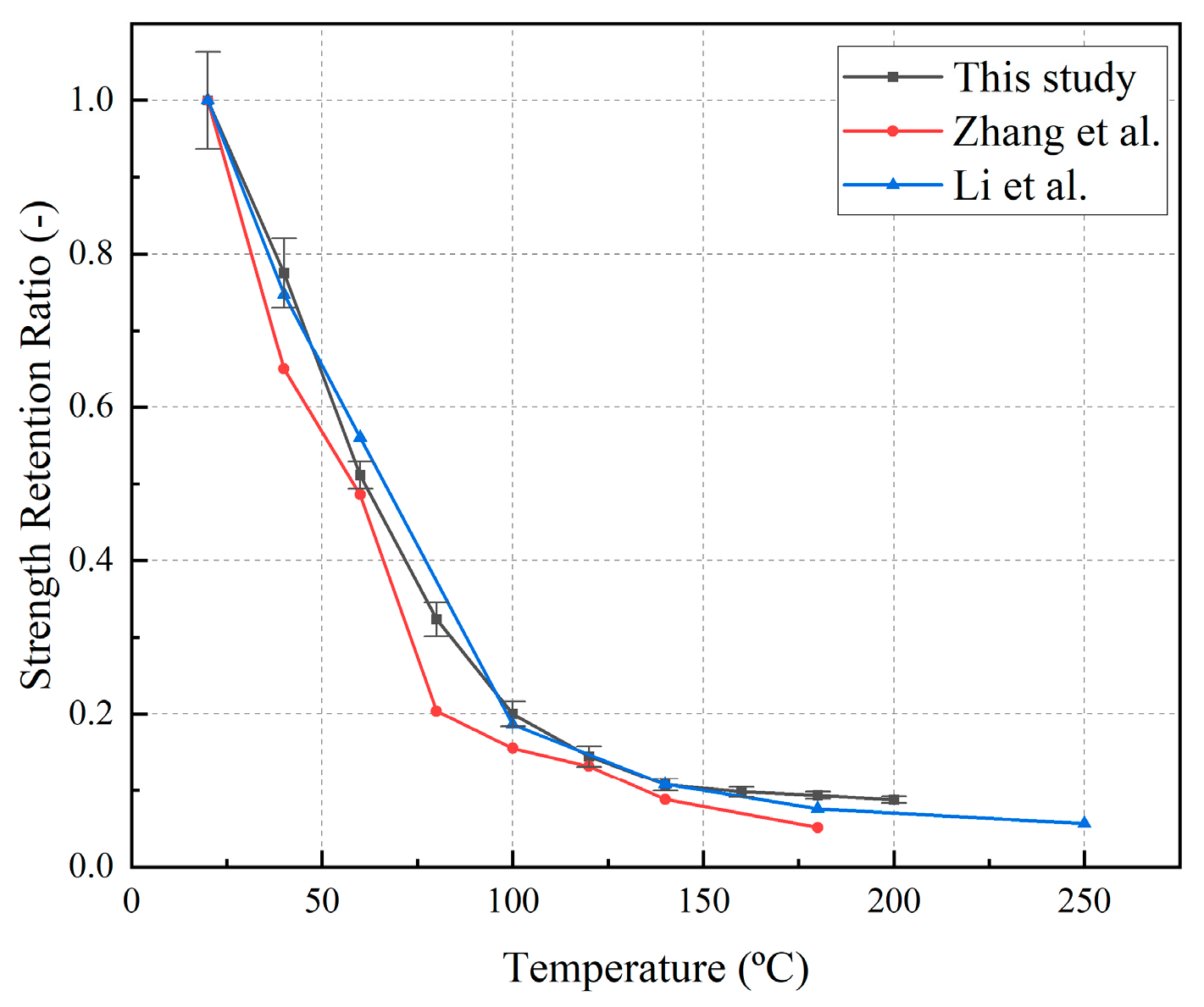

3.1. Thermal Analysis

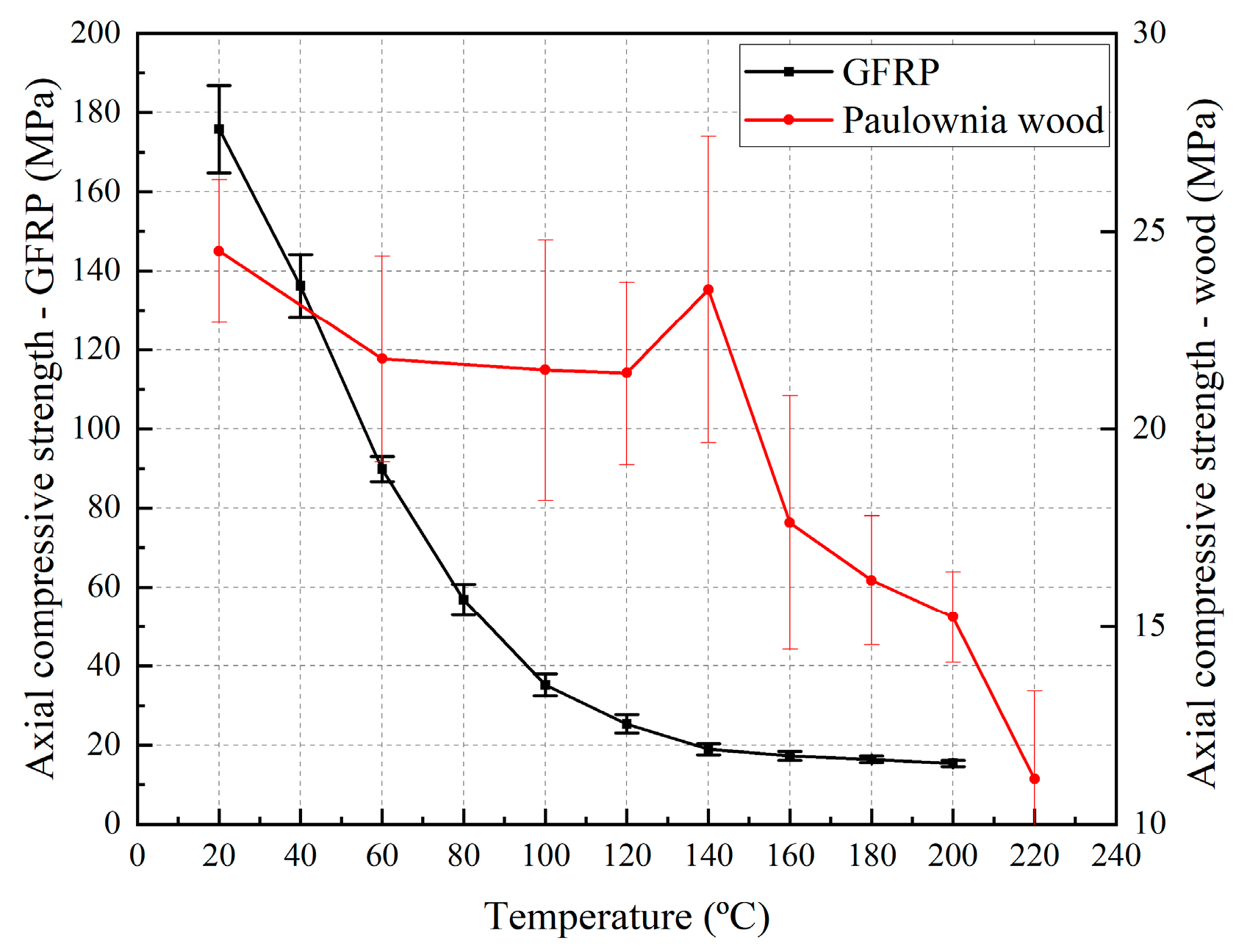

3.2. Axial Compressive Strength of Component Materials

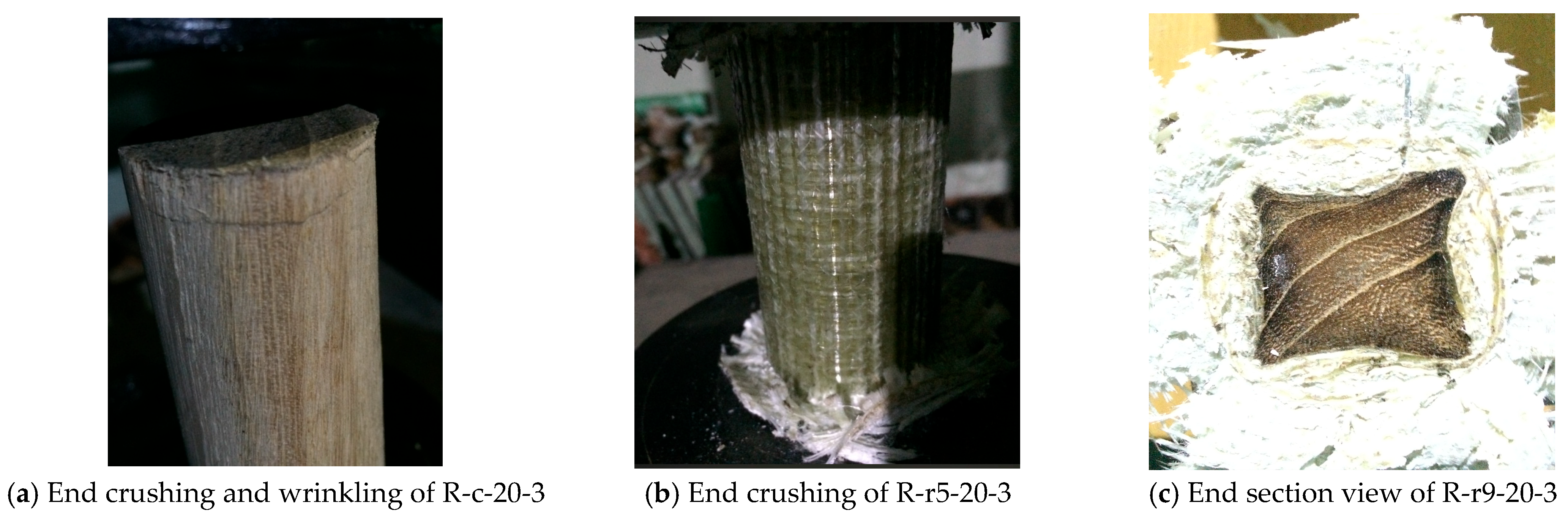

3.3. Failure Modes

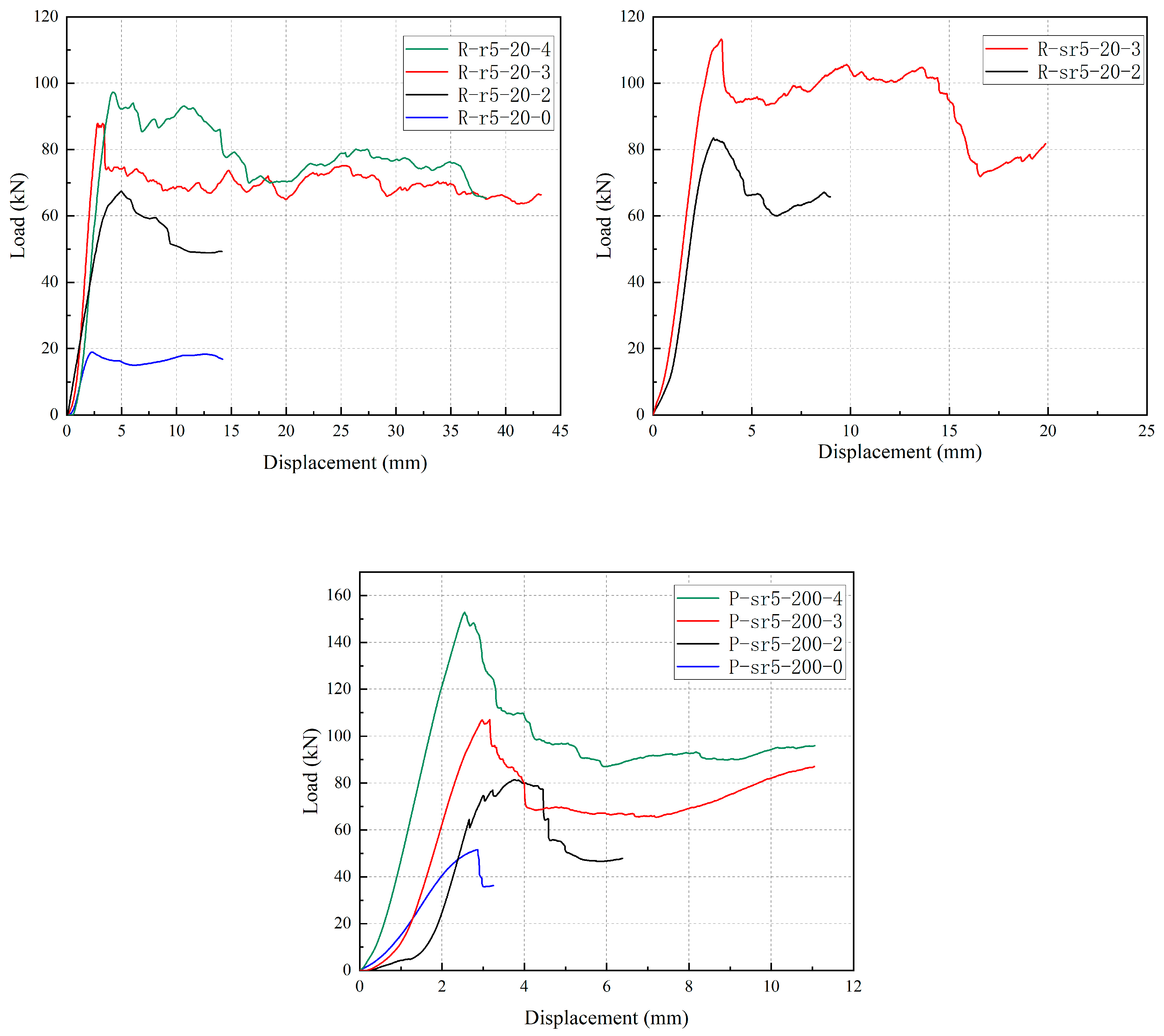

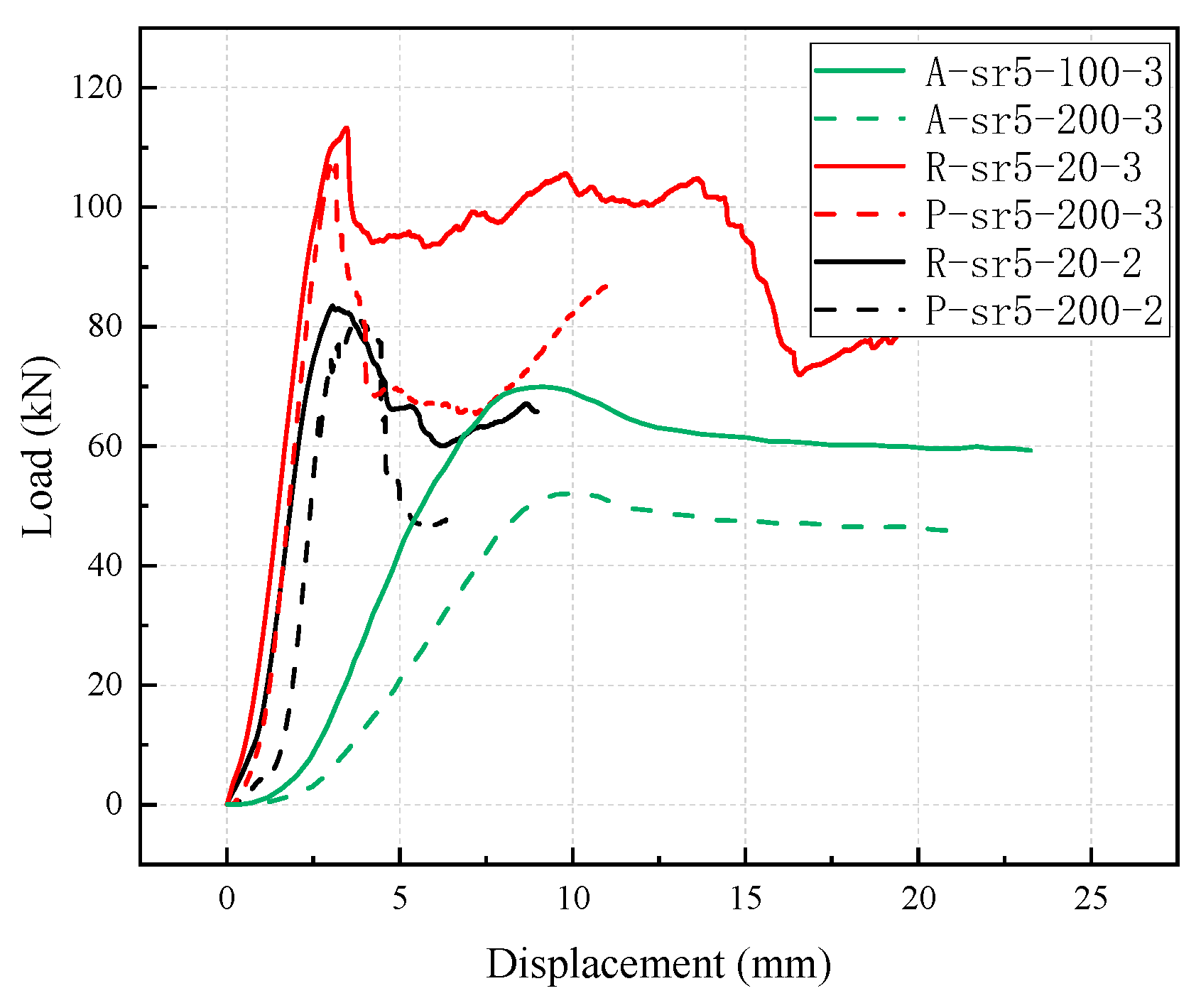

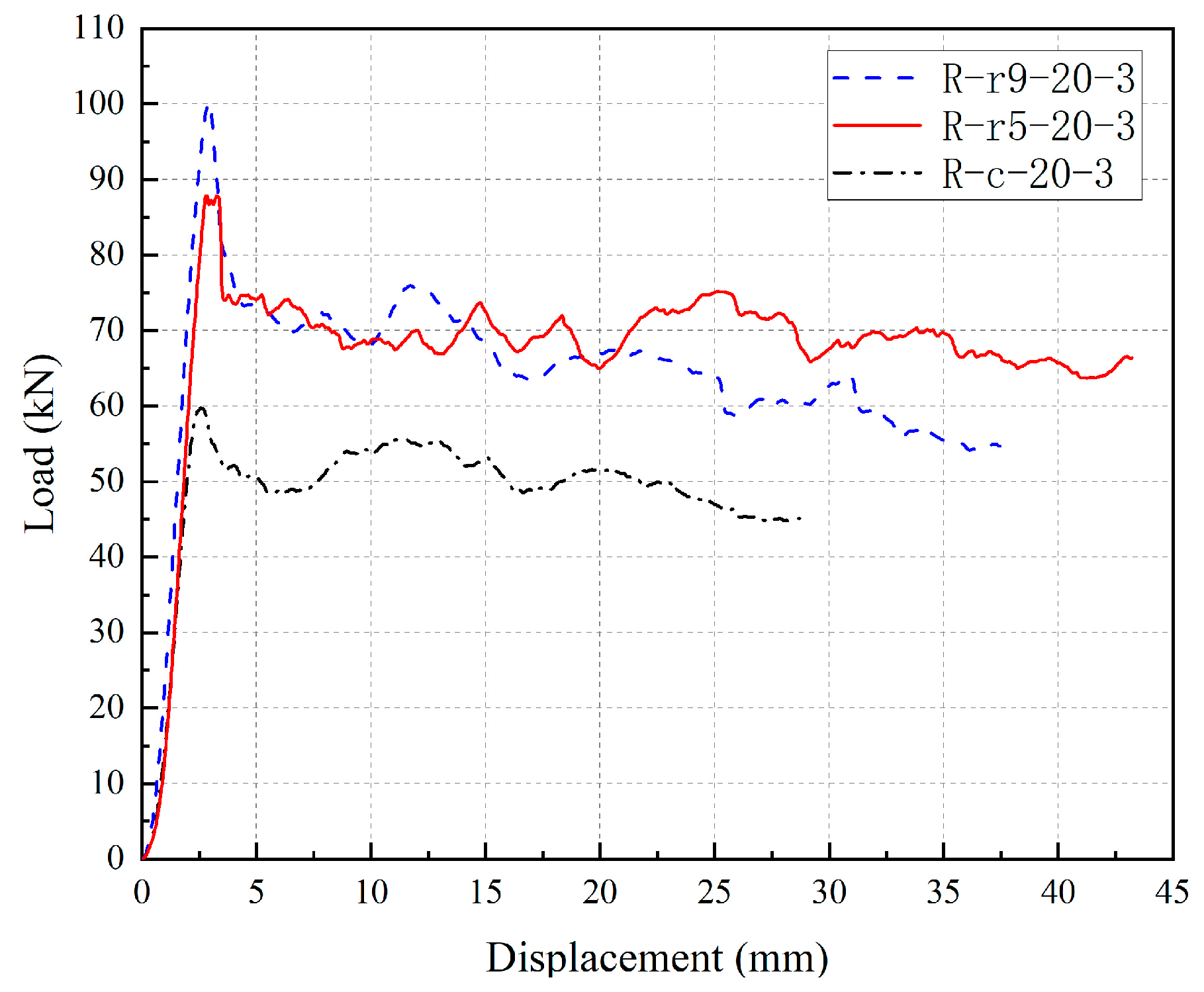

3.4. Load–Displacement Curve

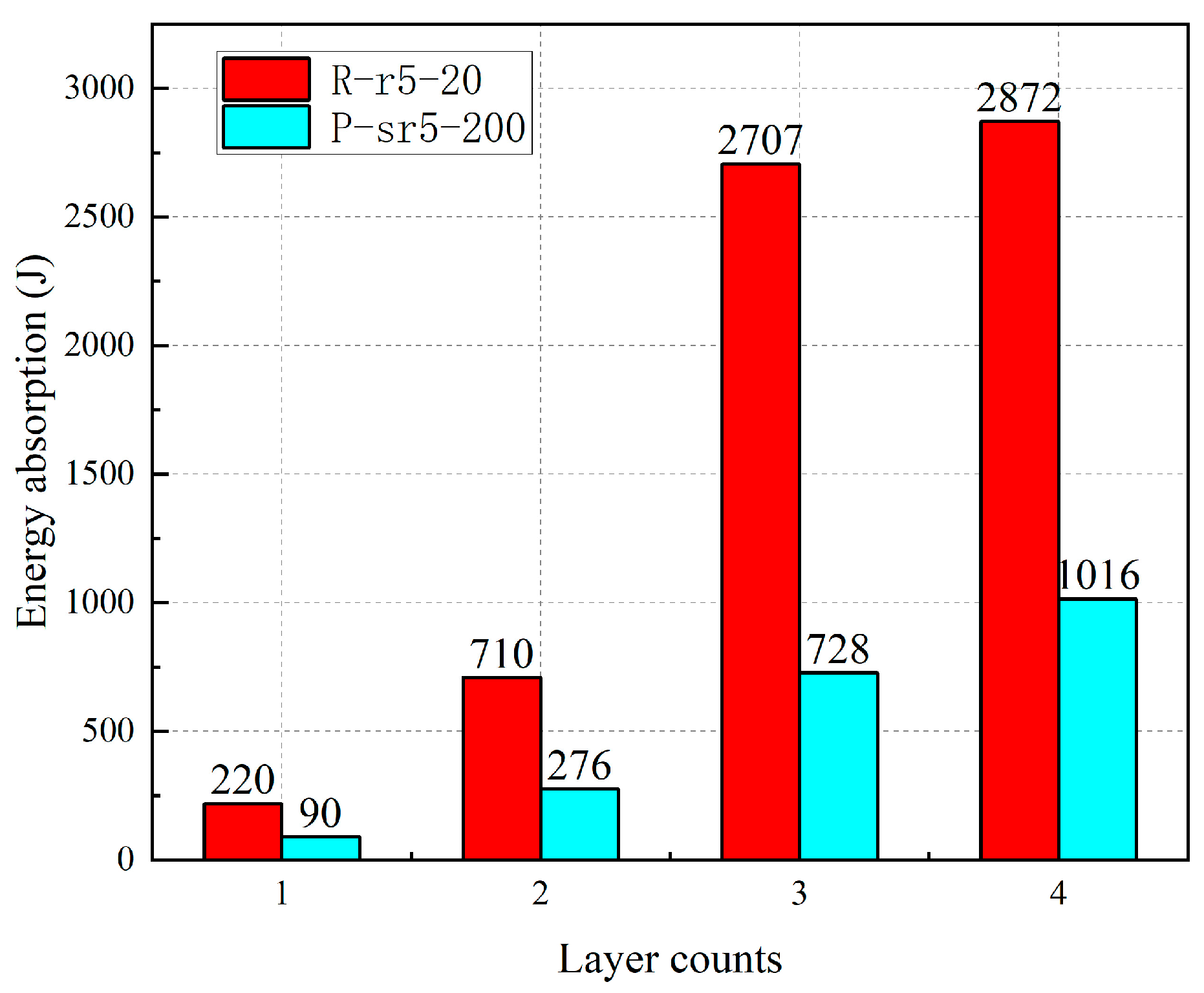

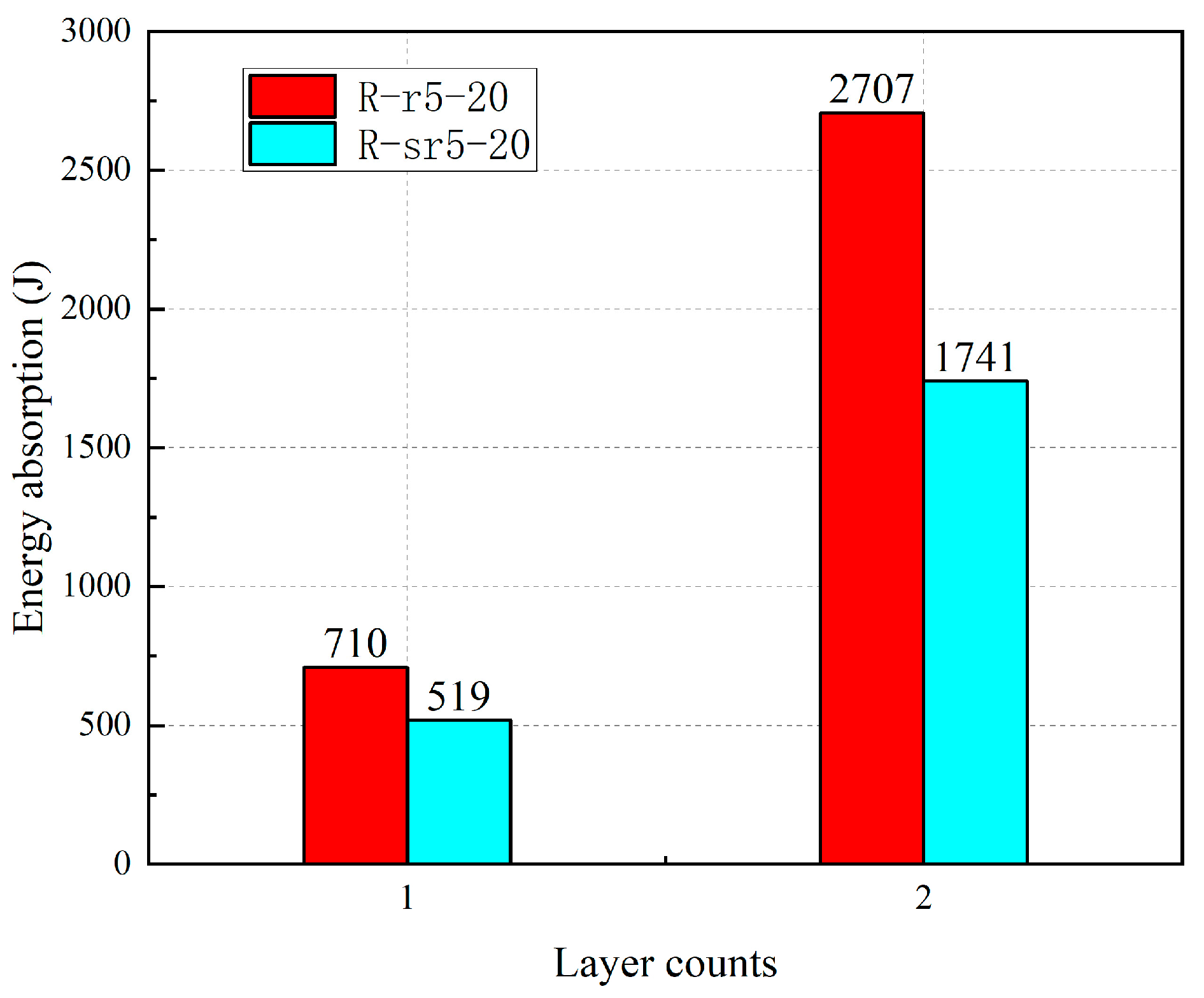

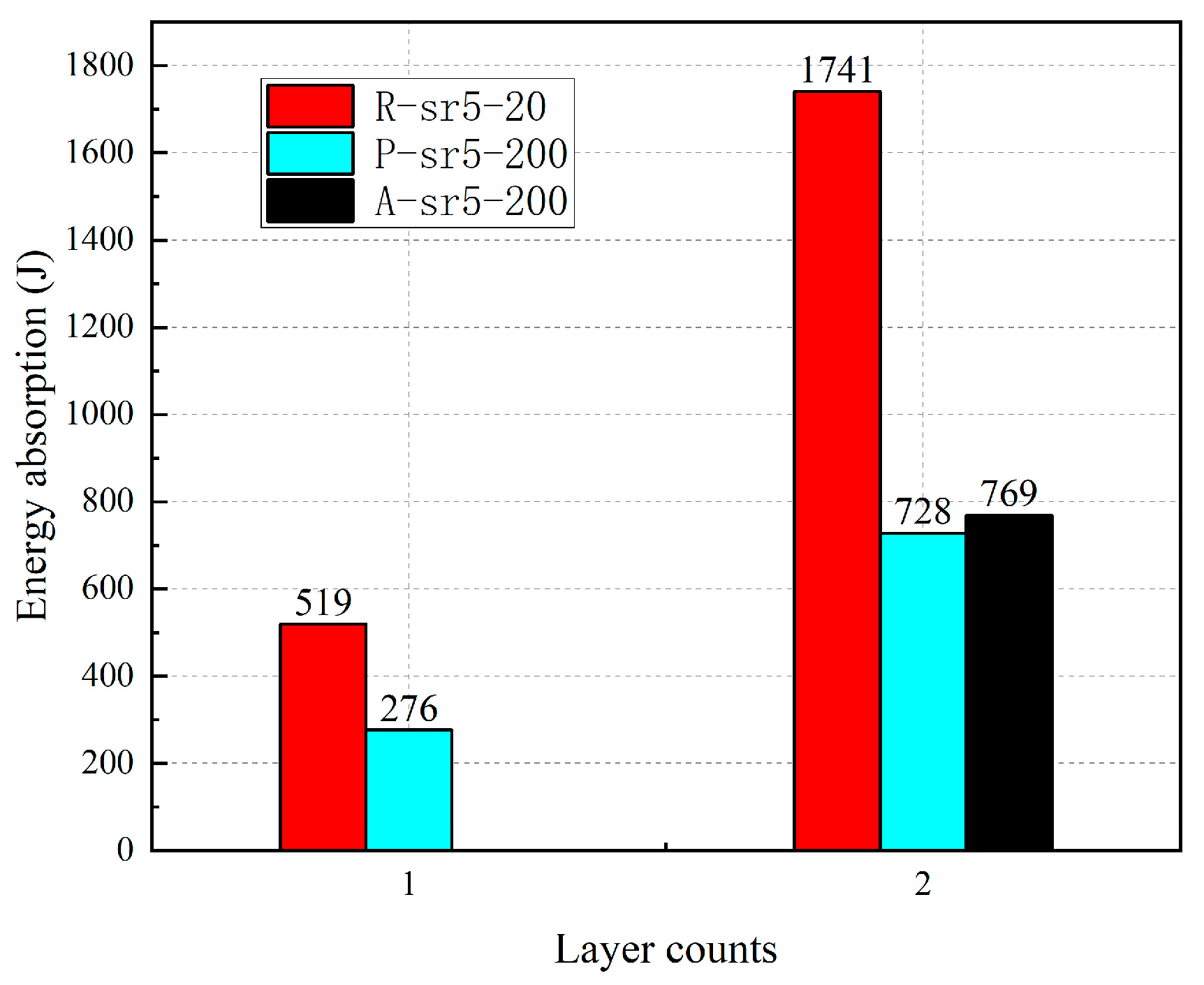

3.5. Energy Absorption Capacity Assessment

3.6. Load-Bearing Capacity and Stiffness

4. Prediction of Axial Compressive Load-Bearing Capacity

5. Conclusions

- The wood-cored GFRP sandwich wood columns markedly enhanced the axial compressive performance of the bare wood. The number of GFRP wrapping layers significantly contributed to the improvement of load-bearing capacity and stiffness. At room temperature, increasing the number of fiber layers from zero to four resulted in an increase of 413.67% in load-bearing capacity and 153.04% in stiffness, respectively.

- When the temperature was elevated from room temperature to 100 °C and 200 °C, the load-bearing capacity declined by 38.26% and 54.05%, respectively. Upon cooling back to room temperature, the specimens recovered roughly 95% of their original strength, indicating that the observed losses were primarily thermo-elastic and that thermal decomposition had not yet been initiated.

- Introducing a 9.52 mm chamfer radius effectively mitigated stress concentrations and elevated the load-bearing capacity by 14.07% relative to a 4.76 mm radius. However, enlarging the radius to 20 mm caused a marked decline in capacity, as the pronounced reduction in cross-sectional area outweighed the benefits of further stress relief.

- The number of GFRP layers exhibited a positive correlation with energy absorption capacity. For the P-sr5-200 specimen series, increasing the number of fiber layers from two to three resulted in a 163.77% enhancement in energy absorption. Conversely, steel hoop confinement reduced energy absorption due to its adverse effect on ductility. Post-high-temperature specimens demonstrated significantly lower energy absorption capacity than those under ambient temperature conditions, while the specimen under high temperature conditions exhibited marginally higher energy absorption than the post-high-temperature specimen due to its superior ductility. Furthermore, an increase in chamfer radius diminished the cross-sectional area, resulting in reduced energy absorption capacity.

- End crushing was observed in the specimens without lateral confinement, whereas mid-height fracture occurred in those with confinement. The GFRP skin provided effective lateral confinement in conjunction with the steel hoops. Drawing on these two distinct failure modes, a predictive model for the axial compressive load-bearing capacity was established. The calculated capacities showed excellent agreement with the experimental results for the wood-cored GFRP sandwich columns.

- This study assessed the axial performance of small-scale wood-cored GFRP sandwich columns. To quantify the size effect, future research will extend the investigation to full-scale specimens.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hildebrandt, J.; Hagemann, N.; Thrän, D. The contribution of wood-based construction materials for leveraging a low carbon building sector in europe. Sustain. Cities Soc. 2017, 34, 405–418. [Google Scholar] [CrossRef]

- Qu, M.; Pelkonen, P.; Tahvanainen, L.; Arevalo, J.; Gritten, D. Experts’ assessment of the development of wood framed houses in China. J. Clean. Prod. 2012, 31, 100–105. [Google Scholar] [CrossRef]

- Ximenes, F.A.; Grant, T. Quantifying the greenhouse benefits of the use of wood products in two popular house designs in Sydney, Australia. Int. J. Life Cycle Assess. 2012, 18, 891–908. [Google Scholar] [CrossRef]

- Hu, A.-n.; Ren, H.-t.; Yao, Q.-f. Durability of concrete structures strengthened with FRP laminates. J. Harbin Inst. Technol. 2007, 14, 571–576. [Google Scholar]

- Pu, Z.; Wang, Z.; Guan, T.; Tao, X.; Liu, Y.; Yang, Z.; Wang, H.; Sheikh, S.A. Shear Performance of the GFRP Bolt Interface Between the GFRP Profile and UHPC/Concrete Slabs. Struct. Des. Tall Spéc. Build. 2025, 34, e70019. [Google Scholar] [CrossRef]

- Rossini, M.; Balconi, G.; Zoller, A.; Braghiroli, N.; Poggi, C.; Nanni, A. Thermoplastic GFRP for Reinforced and Prestressed Concrete. Lect. Notes Civ. Eng. 2023, 351, 140–156. [Google Scholar]

- Hurynovich, V.; Nanni, A. GFRP Reinforcement for Concrete Facilities to Protect Against Mudflow. Concr. Int. 2024, 46, 38–42. [Google Scholar]

- Zhang, Z.; Ji, Q.; Guo, Z.; Li, C.; Guo, R.; Tian, J.; Zhang, Z.; He, T.; Xian, G. Design, preparation, and mechanical properties of glass fiber reinforced thermoplastic self-anchor plate cable exposed in alkaline solution environment. Polym. Compos. 2024, 45, 11687–11700. [Google Scholar] [CrossRef]

- Du, H.; Xian, G.; Tian, J.; Ma, Z.; Li, C.; Xin, M.; Zhang, Y. Effect of fiber surface treatment with silane coupling agents and carbon nanotubes on mechanical properties of carbon fiber reinforced polyamide 6 composites. Polym. Compos. 2024, 46, 1267–1283. [Google Scholar] [CrossRef]

- Pan, Y.; Chang, B.; Lu, Z.; Su, L.; Zhu, J. Effects of seawater on durability of hybrid C/BFRP-confined seawater–sea sand concrete columns under axial compression. Adv. Struct. Eng. 2023, 26, 2879–2893. [Google Scholar] [CrossRef]

- Zhang, F.; Xie, S.; Xiao, J.; Singh, A.; Xu, J.; Fang, H. Mechanical behavior of Glass fiber-reinforced polymer-timber-steel tube-concrete composite columns under axial compression. Struct. Concr. 2022, 24, 1296–1312. [Google Scholar] [CrossRef]

- Mathuros, A.; Thongchom, C.; Bui, L.V.H.; Jongvivatsakul, P. Monotonic and cyclic flexural performance of timber beams strengthened with glass fiber-reinforced polymer rods using near-surface mounted technique. Structures 2024, 65, 106729. [Google Scholar] [CrossRef]

- Yang, L.; Li, X.; Fang, H.; Liu, W.; Hong, J.; Hui, D.; Gaff, M. Compressive behaviour of wood-filled GFRP square columns with lattice-web reinforcements. Constr. Build. Mater. 2021, 310, 125129. [Google Scholar] [CrossRef]

- Osei-Antwi, M.; de Castro, J.; Vassilopoulos, A.P.; Keller, T. FRP-Balsa Composite Sandwich Bridge Deck with Complex Core Assembly. J. Compos. Constr. 2013, 17, 04013011. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.; Wang, L.; Ling, Z. Mechanical behavior and damage monitoring of pultruded wood-cored GFRP sandwich components. Compos. Struct. 2019, 215, 502–520. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Hui, D. Compression strength of hollow sandwich columns with GFRP skins and a paulownia wood core. Compos. Part B Eng. 2014, 60, 495–506. [Google Scholar] [CrossRef]

- Zhou, C.; Liang, L.; Siha, A.; Zhang, I.; Yang, L. Compressive Stress-Strain Model of Combined Strengthening Rectangular Timber Columns. J. Build. Mater. 2021, 24, 171–180. [Google Scholar] [CrossRef]

- Tsoi, M.; Zhuge, J.; Chen, R.-H.; Gou, J. Modeling and experimental studies of thermal degradation of glass fiber reinforced polymer composites. Fire Mater. 2013, 38, 247–263. [Google Scholar] [CrossRef]

- Correia, J.R.; Bai, Y.; Keller, T. A review of the fire behaviour of pultruded GFRP structural profiles for civil engineering applications. Compos. Struct. 2015, 127, 267–287. [Google Scholar] [CrossRef]

- Alhayek, A.; Syamsir, A.; Supian, A.B.M.; Usman, F. Lifespan prediction of glass fiber reinforced polymers subjected to flexural creep and elevated temperatures using analytical and numerical analyses. Polym. Compos. 2024, 45, 17166–17185. [Google Scholar] [CrossRef]

- Li, C.; Xian, G. Mechanical property evolution and life prediction of carbon fiber and pultruded carbon fiber reinforced polymer plate exposed to elevated temperatures. Polym. Compos. 2020, 41, 5143–5155. [Google Scholar] [CrossRef]

- Yu, Y.; Liu, S.; Pan, Y.; Miu, X.; Liu, J. Durability of glass fiber-reinforced polymer bars in water and simulated concrete pore solution. Constr. Build. Mater. 2021, 299, 123995. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, K.; Liu, W.; Liu, Y.; Wang, K.; Ge, W.; Guo, K. Fire performance of pultruded wood-cored GFRP sandwich components for building construction. Case Stud. Constr. Mater. 2022, 17, e01555. [Google Scholar] [CrossRef]

- Lotfalipour, F.; Javid, A.; Toufigh, V. Boosting algorithms for predicting the bond properties of timber and fiber reinforced polymer (FRP) under thermal cycling using single-lap shear tests. Eur. J. Wood Wood Prod. 2025, 83, 1–22. [Google Scholar] [CrossRef]

- Wang, L.; Fan, X.; Chen, H.; Liu, W. Axial crush behavior and energy absorption capability of foam-filled GFRP tubes under elevated and high temperatures. Compos. Struct. 2016, 149, 339–350. [Google Scholar] [CrossRef]

- Zhang, L.; Liu, W.; Omar, A.A.; Ling, Z.; Yang, D.; Liu, Y. Postfire performance of pultruded wood-cored GFRP sandwich beams. Thin-Walled Struct. 2023, 193, 111240. [Google Scholar] [CrossRef]

- GB/T 1931-2009; Method for Determination of Moisture Content of Wood. China Standard Press: Beijing, China, 2009.

- GB/T 1938-2009; Method of Testing in Tensile Strength Paralle to Grain of Wood. China Standard Press: Beijing, China, 2009.

- GB/T 1935-2009; Method of Testing in Compressive Strength Paralle to Grain of Wood. China Standard Press: Beijing, China, 2009.

- GB/T 1937-2009; Method of Testing in Shearing Strength Paralle to Grain of Wood. China Standard Press: Beijing, China, 2009.

- Zhang, L.; Chen, K.; Xu, B.; Liu, Y.; Guo, K. Parallel-to-Grain Compressive and Tensile Behavior of Paulownia Wood at Elevated Temperatures. Appl. Sci. 2022, 12, 12118. [Google Scholar] [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ASTM D3410/D3410M-16(2024); Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials with Unsupported Gage Section by Shear Loading. ASTM: West Conshohocken, PA, USA, 2024.

- Zhang, L.; Liu, W.; Wang, L.; Ling, Z. On-axis and off-axis compressive behavior of pultruded GFRP composites at elevated temperatures. Compos. Struct. 2020, 236, 111891. [Google Scholar] [CrossRef]

- Li, Q. Study on Web Crippling Behavior of GFRP Pultruded Profiles under Elevated Temperature. Master’s Thesis, Yangzhou University, Yangzhou, China, 2024. [Google Scholar]

- Wang, L.; Shi, F.; Zhao, M.; Wang, B.J.; Li, H.; Zou, X.; Du, H. Axial compressive behavior of FRP-confined laminated timber columns. Arch. Civ. Mech. Eng. 2023, 24, 28. [Google Scholar] [CrossRef]

- Xie, J.; Yang, L.; Xu, F.Q. Study on axial compression performance of concrete stub column strengthened by prestressed steel hoop. Gongcheng Lixue Eng. Mech. 2020, 37, 195–208. [Google Scholar]

- Wang, L.; Liu, W.; Fang, Y.; Wan, L.; Huo, R. Axial crush behavior and energy absorption capability of foam-filled GFRP tubes manufactured through vacuum assisted resin infusion process. Thin-Walled Struct. 2016, 98, 263–273. [Google Scholar] [CrossRef]

- Teng, J.G.; Lam, L. Behavior and Modeling of Fiber Reinforced Polymer-Confined Concrete. J. Struct. Eng. 2004, 130, 1713–1723. [Google Scholar] [CrossRef]

| Specimen | b (mm) | h (mm) | r (mm) | L (Layer Count) | T (°C) | Heating Treatment |

|---|---|---|---|---|---|---|

| R-r5-20-0 | 40 | 120 | 4.76 | 0 | 20 | No |

| R-r5-20-2 | 40 | 120 | 4.76 | 2 | 20 | No |

| R-r5-20-3 | 40 | 120 | 4.76 | 3 | 20 | No |

| R-r5-20-4 | 40 | 120 | 4.76 | 4 | 20 | No |

| R-sr5-20-2 | 40 | 120 | 4.76 | 2 | 20 | No |

| R-sr5-20-3 | 40 | 120 | 4.76 | 3 | 20 | No |

| R-r9-20-3 | 40 | 120 | 9.52 | 3 | 20 | No |

| R-c-20-3 | 40 | 120 | 20 | 3 | 20 | No |

| A-sr5-100-3 | 40 | 120 | 4.76 | 3 | 100 | At high temperature |

| A-sr5-200-3 | 40 | 120 | 4.76 | 3 | 200 | At high temperature |

| P-sr5-200-2 | 40 | 120 | 4.76 | 2 | 200 | Post high temperature |

| P-sr5-200-3 | 40 | 120 | 4.76 | 3 | 200 | Post high temperature |

| P-sr5-200-4 | 40 | 120 | 4.76 | 4 | 200 | Post high temperature |

| Density (kg/m3) | Moisture Content (%) | Parallel-to-Grain Tensile Strength | Parallel-to-Grain Compressive Strength | Tangential Shear | Radial Shear Strength | Perpendicular-to-Grain Tensile Strength | Perpendicular-to-Grain Compressive Strength | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (MPa) | COV | (MPa) | COV | (MPa) | COV | (MPa) | COV | (MPa) | COV | (MPa) | COV | ||

| 353 | 10.9 | 43.6 | 0.143 | 24.5 | 0.067 | 6.6 | 0.090 | 4.5 | 0.091 | 2.5 | 0.117 | 2.7 | 0.129 |

| Tensile Strength | Tensile Modulus | Compressive Strength | Compressive Modulus | ||||

|---|---|---|---|---|---|---|---|

| (MPa) | COV | (GPa) | COV | (MPa) | COV | (GPa) | COV |

| 297.6 | 0.015 | 23.5 | 0.011 | 175.8 | 0.028 | 22.1 | 0.031 |

| Specimen | Pu (kN) | K (kN/mm) | Failure Modes | Nu (kN) | Nu/Pu |

|---|---|---|---|---|---|

| R-r5-20-0 | 18.94 | 13.14 | End crushing | - | - |

| R-r5-20-2 | 67.45 | 19.41 | End crushing | 70.76 | 1.05 |

| R-r5-20-3 | 87.89 | 44.70 | End crushing | 86.77 | 0.99 |

| R-r5-20-4 | 97.29 | 33.25 | End crushing | 102.79 | 1.06 |

| R-sr5-20-2 | 83.50 | 43.12 | Mid-height fiber fracture | 81.85 | 0.98 |

| R-sr5-20-3 | 113.28 | 45.01 | Mid-height fiber fracture | 114.57 | 1.01 |

| R-r9-20-3 | 100.26 | 45.59 | End crushing | 82.76 | 0.83 |

| R-c-20-3 | 59.77 | 36.43 | End crushing | 70.56 | 1.18 |

| A-sr5-100-3 | 69.93 | 14.09 | Mid-height fiber fracture | 68.1 | 0.97 |

| A-sr5-200-3 | 52.05 | 8.19 | Mid-height fiber fracture | 54.7 | 1.05 |

| P-sr5-200-2 | 81.45 | 54.16 | Mid-height fiber fracture | 79.35 | 0.97 |

| P-sr5-200-3 | 106.97 | 56.94 | Mid-height fiber fracture | 113.93 | 1.07 |

| P-sr5-200-4 | 152.80 | 72.73 | Mid-height fiber fracture | 148.51 | 0.97 |

| Mean | 1.01 |

| Specimen | Aw (mm2) | P (mm) | σf,c,T (MPa) | σf,t,T (MPa) | σw,0,T (MPa) | σw,90,T (MPa) |

|---|---|---|---|---|---|---|

| R-r5-20-0 | 1580.6 | 151.8 | - | - | 24.5 | 2.7 |

| R-r5-20-2 | 1580.6 | 151.8 | 175.8 | 297.6 | 24.5 | 2.7 |

| R-r5-20-3 | 1580.6 | 151.8 | 175.8 | 297.6 | 24.5 | 2.7 |

| R-r5-20-4 | 1580.6 | 151.8 | 175.8 | 297.6 | 24.5 | 2.7 |

| R-sr5-20-2 | 1580.6 | 151.8 | 175.8 | 297.6 | 24.5 | 2.7 |

| R-sr5-20-3 | 1580.6 | 151.8 | 175.8 | 297.6 | 24.5 | 2.7 |

| R-r9-20-3 | 1522.2 | 143.7 | 175.8 | 297.6 | 24.5 | 2.7 |

| R-c-20-3 | 1256.6 | 125.7 | 175.8 | 297.6 | 24.5 | 2.7 |

| A-sr5-100-3 | 1580.6 | 151.8 | 35.2 | 238.1 | 21.5 | 2.2 |

| A-sr5-200-3 | 1580.6 | 151.8 | 15.4 | 178.6 | 15.2 | 1.2 |

| P-sr5-200-2 | 1580.6 | 151.8 | - | - | 15.2 | 1.2 |

| P-sr5-200-3 | 1580.6 | 151.8 | - | - | 15.2 | 1.2 |

| P-sr5-200-4 | 1580.6 | 151.8 | - | - | 15.2 | 1.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kan, Y.; Feng, Y.; Xiao, Z.; Pan, W.; Cui, Z.; Zhang, L. Axial Compressive Performance of Wood-Cored GFRP Sandwich Columns. Buildings 2025, 15, 3632. https://doi.org/10.3390/buildings15193632

Kan Y, Feng Y, Xiao Z, Pan W, Cui Z, Zhang L. Axial Compressive Performance of Wood-Cored GFRP Sandwich Columns. Buildings. 2025; 15(19):3632. https://doi.org/10.3390/buildings15193632

Chicago/Turabian StyleKan, Yuping, Yixin Feng, Zhongping Xiao, Wei Pan, Zhaoyan Cui, and Lingfeng Zhang. 2025. "Axial Compressive Performance of Wood-Cored GFRP Sandwich Columns" Buildings 15, no. 19: 3632. https://doi.org/10.3390/buildings15193632

APA StyleKan, Y., Feng, Y., Xiao, Z., Pan, W., Cui, Z., & Zhang, L. (2025). Axial Compressive Performance of Wood-Cored GFRP Sandwich Columns. Buildings, 15(19), 3632. https://doi.org/10.3390/buildings15193632