Influence of HPMC and VAE on the Properties of Geopolymer Mortar

Abstract

1. Introduction

2. Materials and Experiments

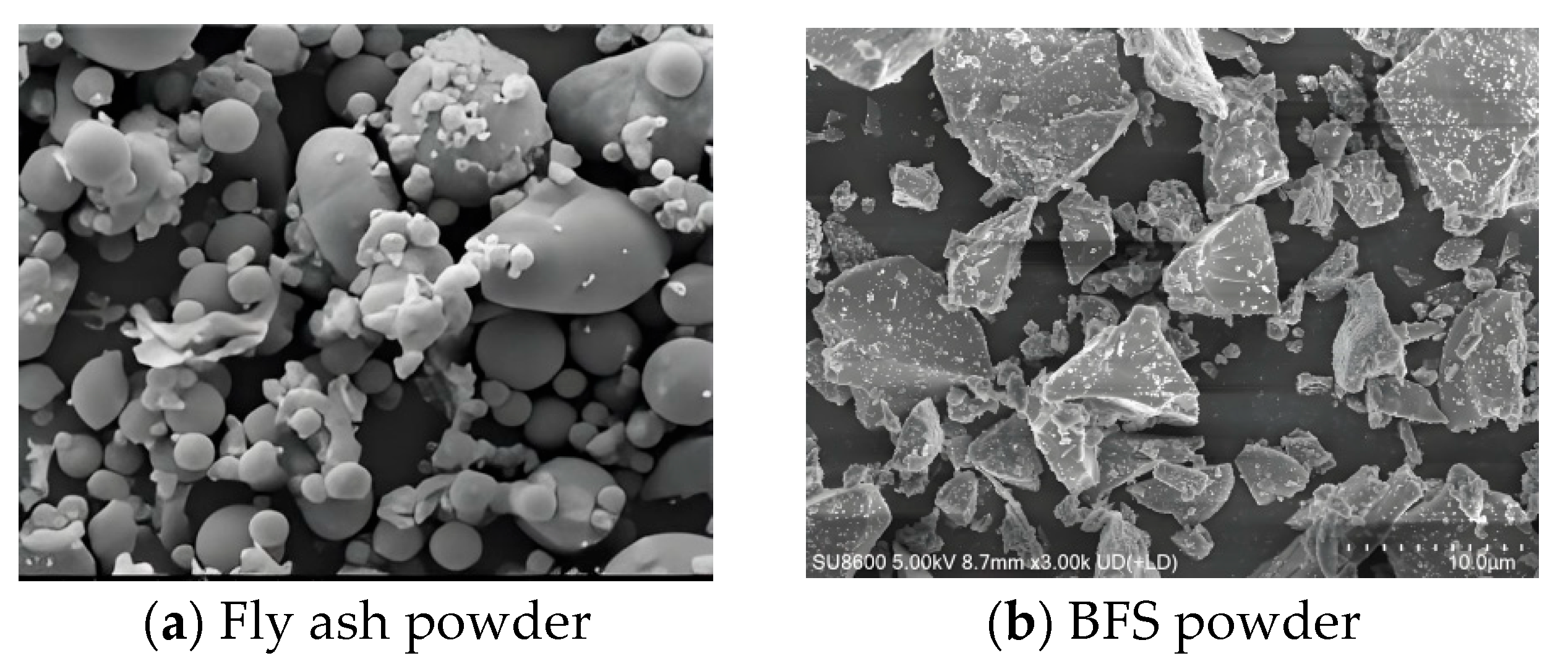

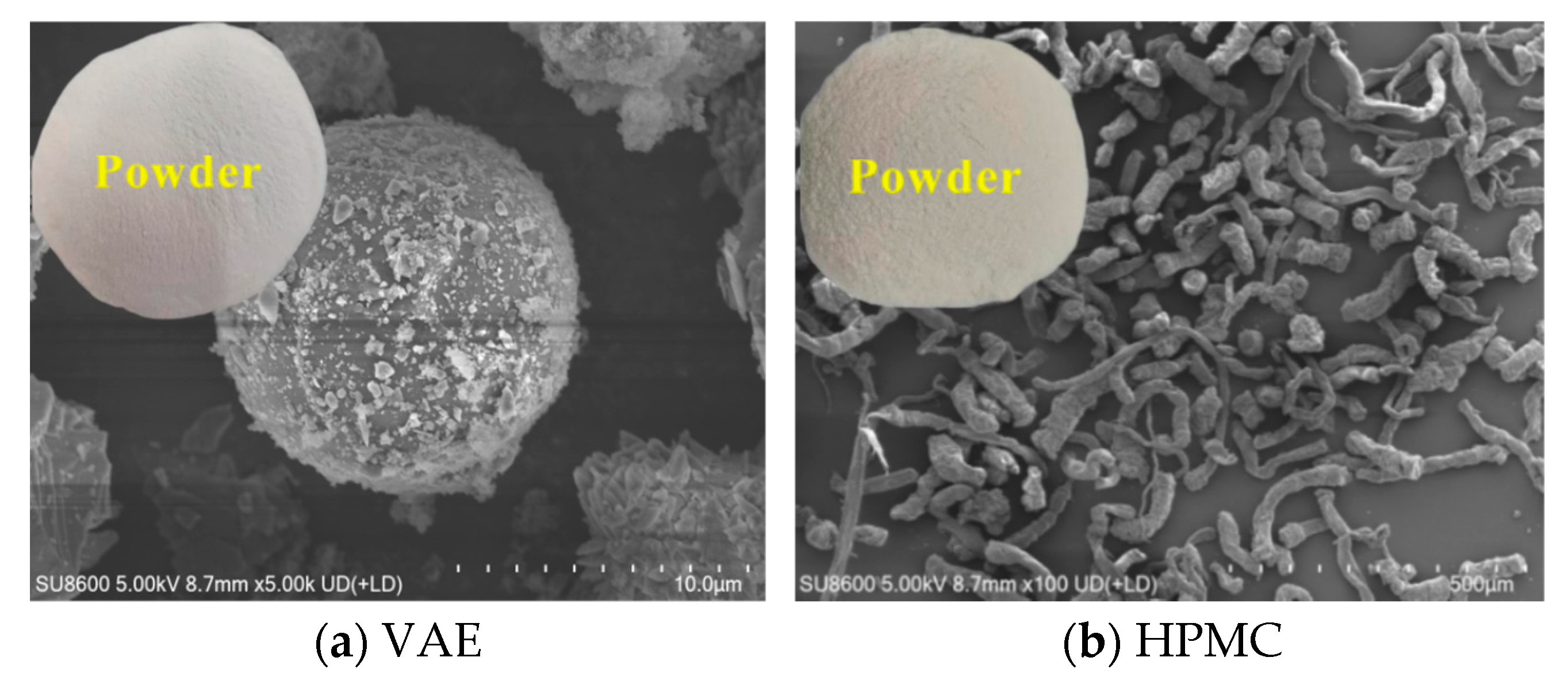

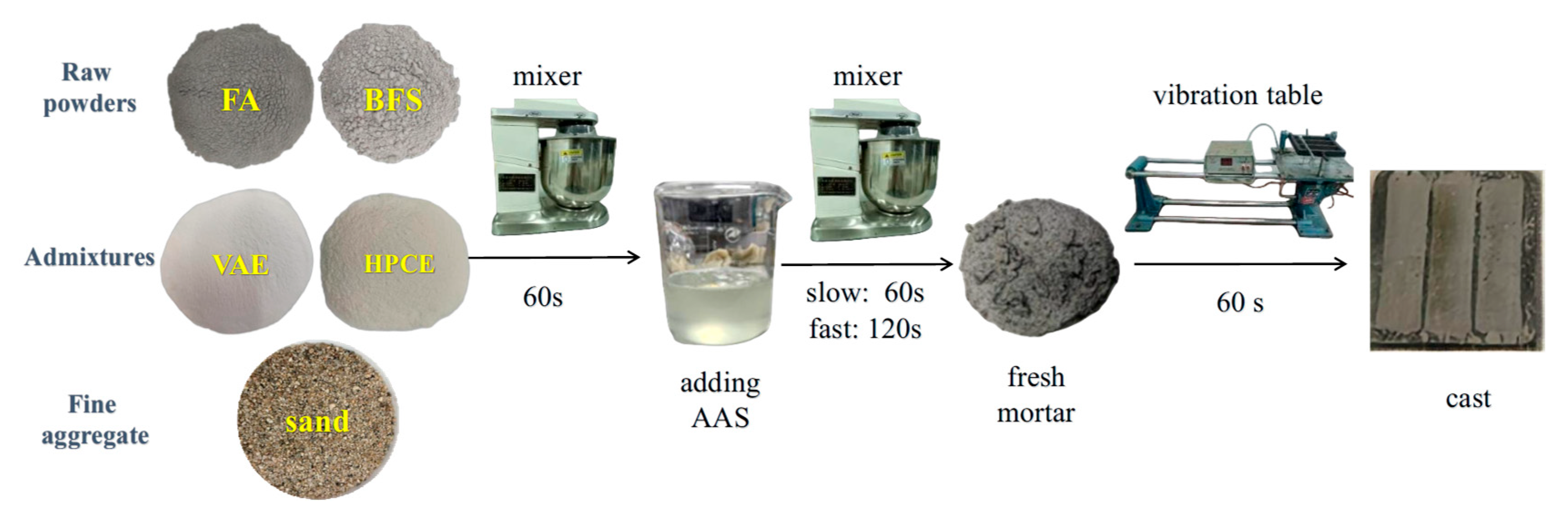

2.1. Materials

2.2. Experimental Design

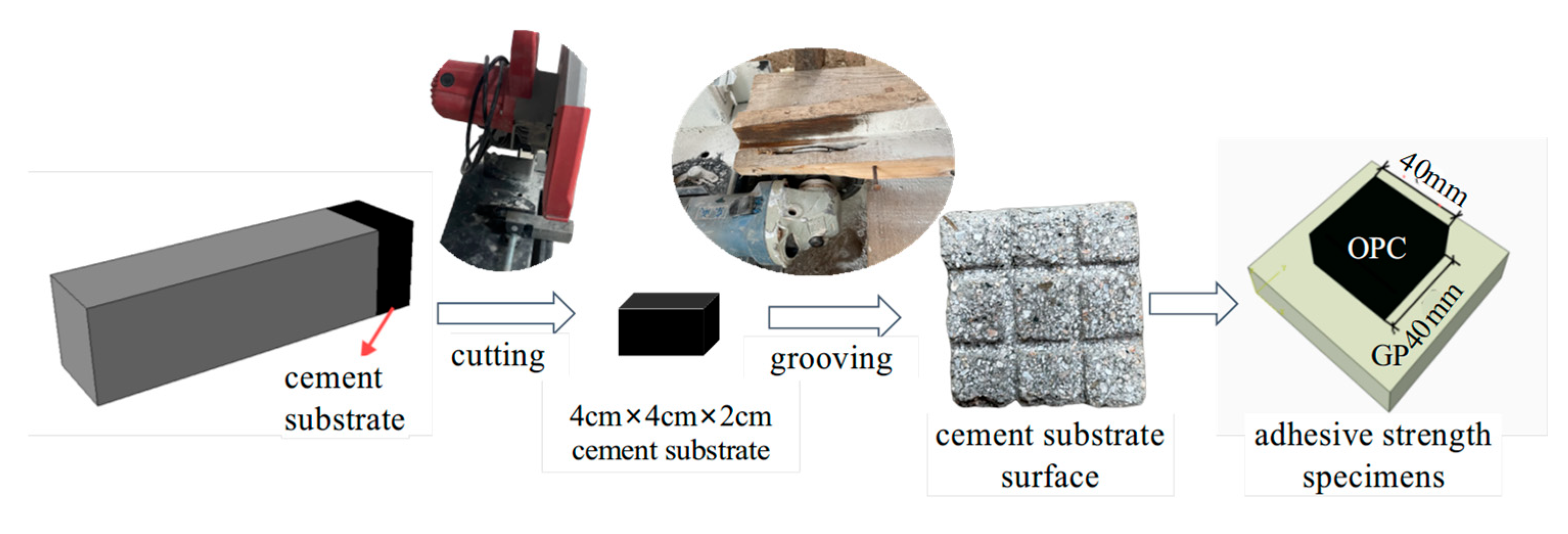

2.3. Experimental Method and Process

3. Results and Analysis

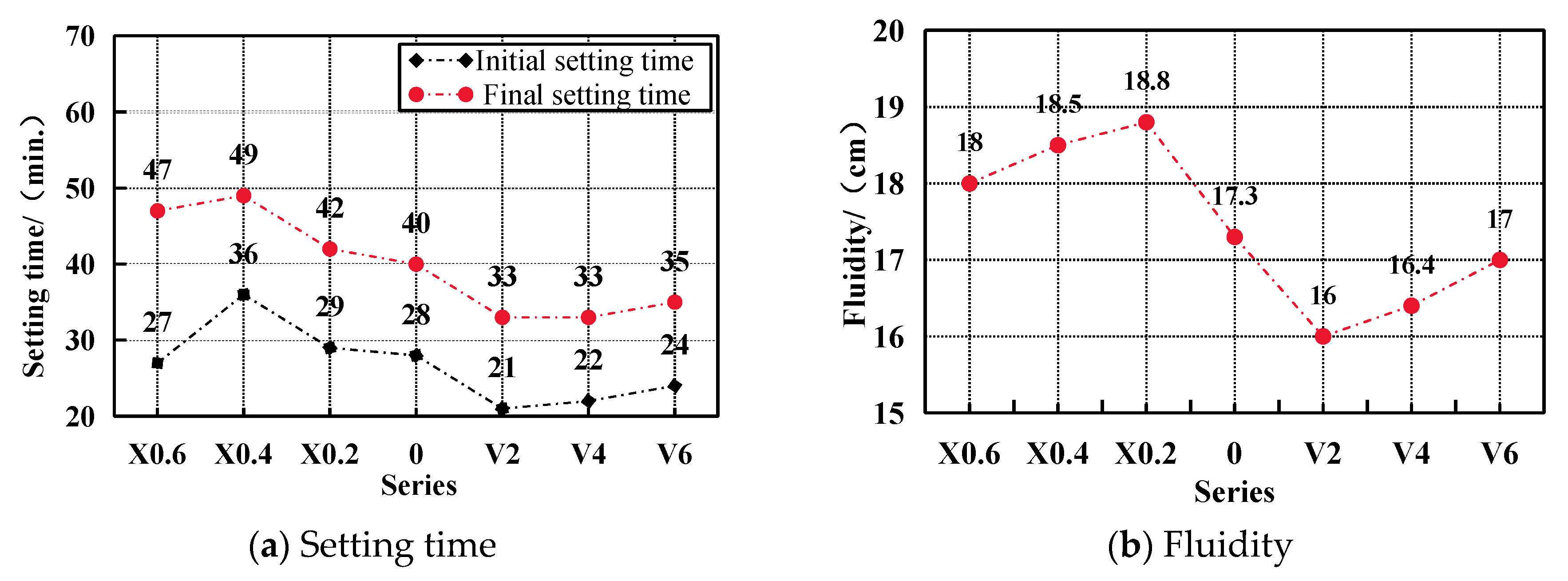

3.1. Workability

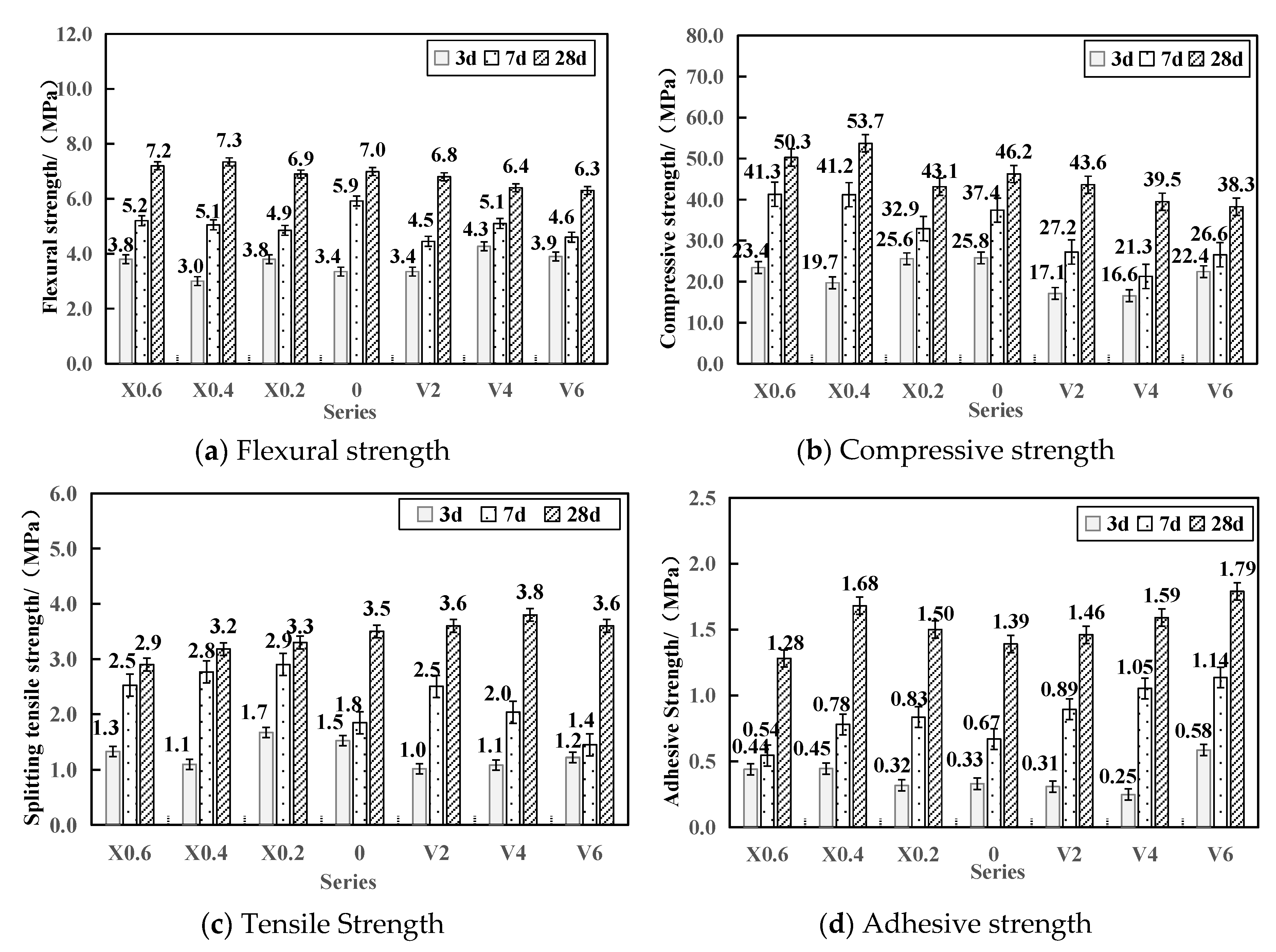

3.2. Mechanical Strength

3.3. Durability

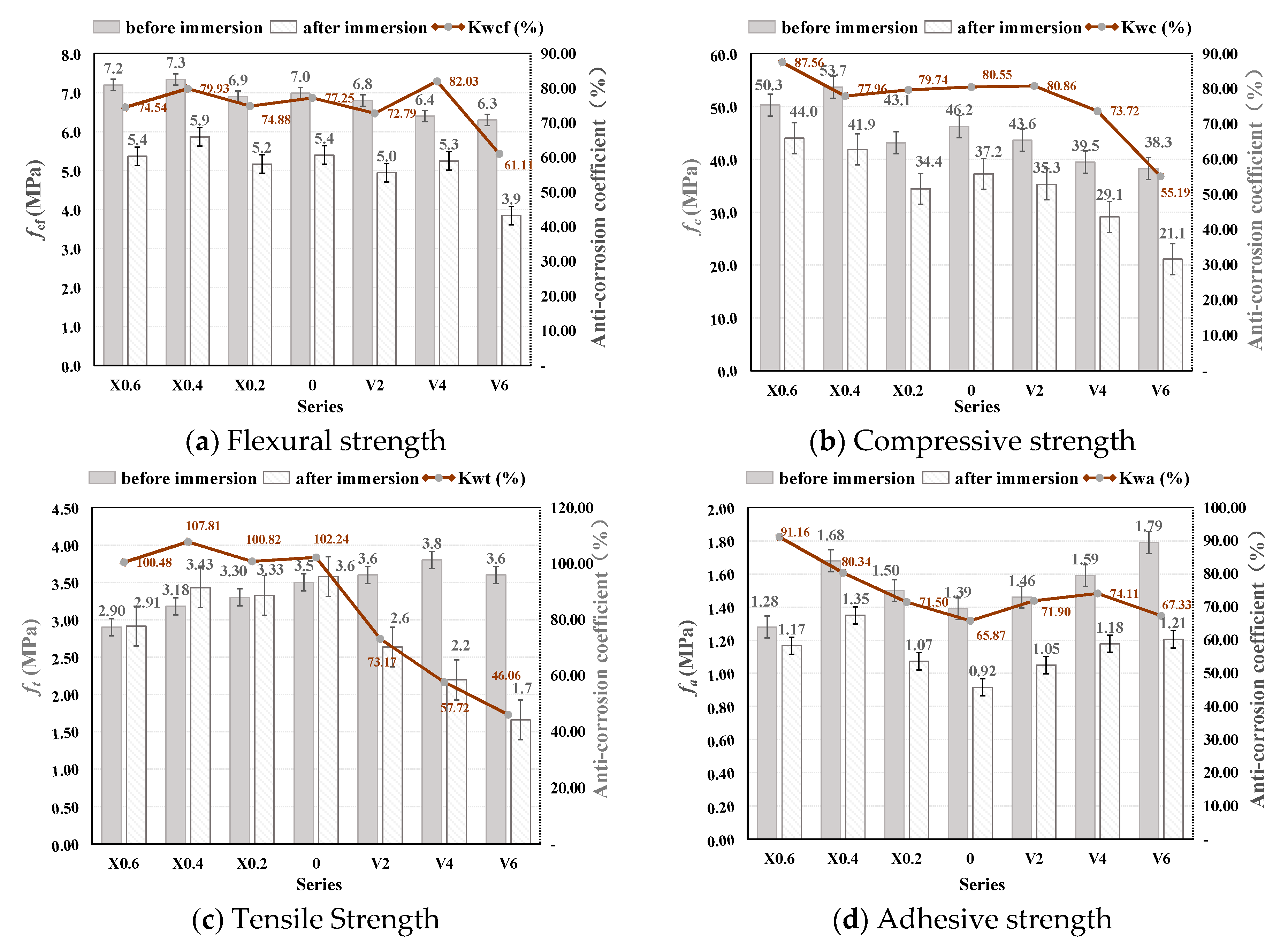

3.3.1. Water Immersion

3.3.2. Sulphate Attack

3.3.3. High Temperature

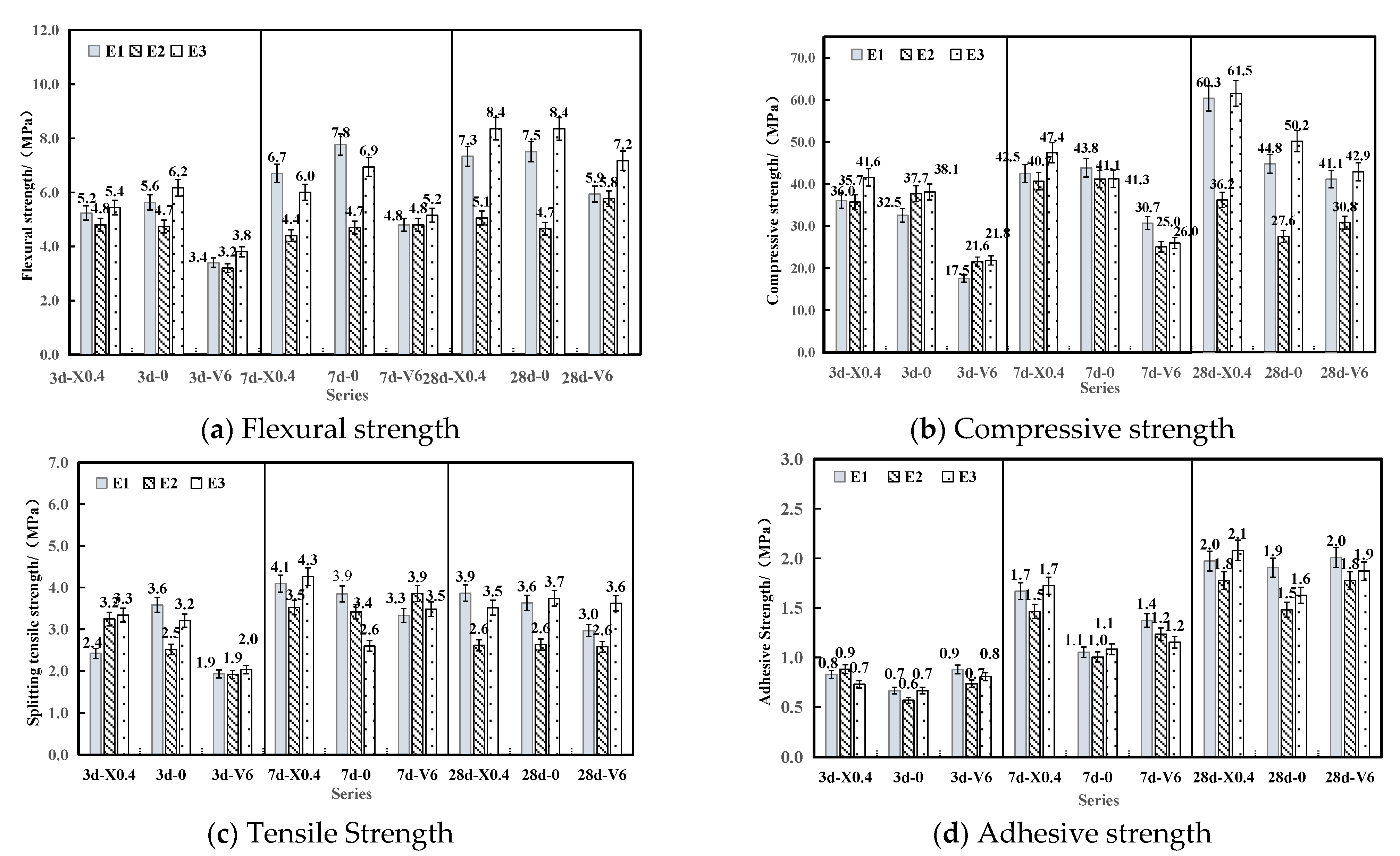

3.3.4. Effect of Curing Conditions

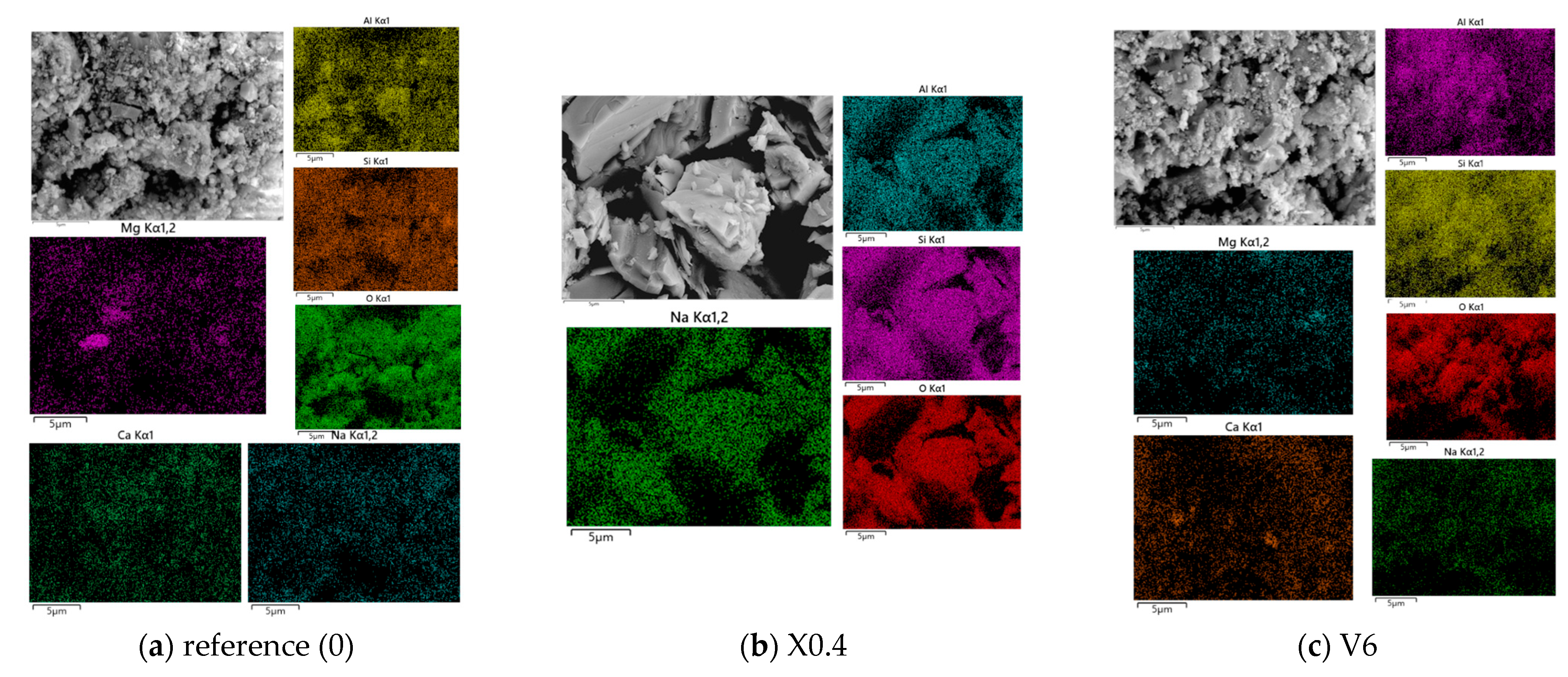

3.4. SEM Analysis

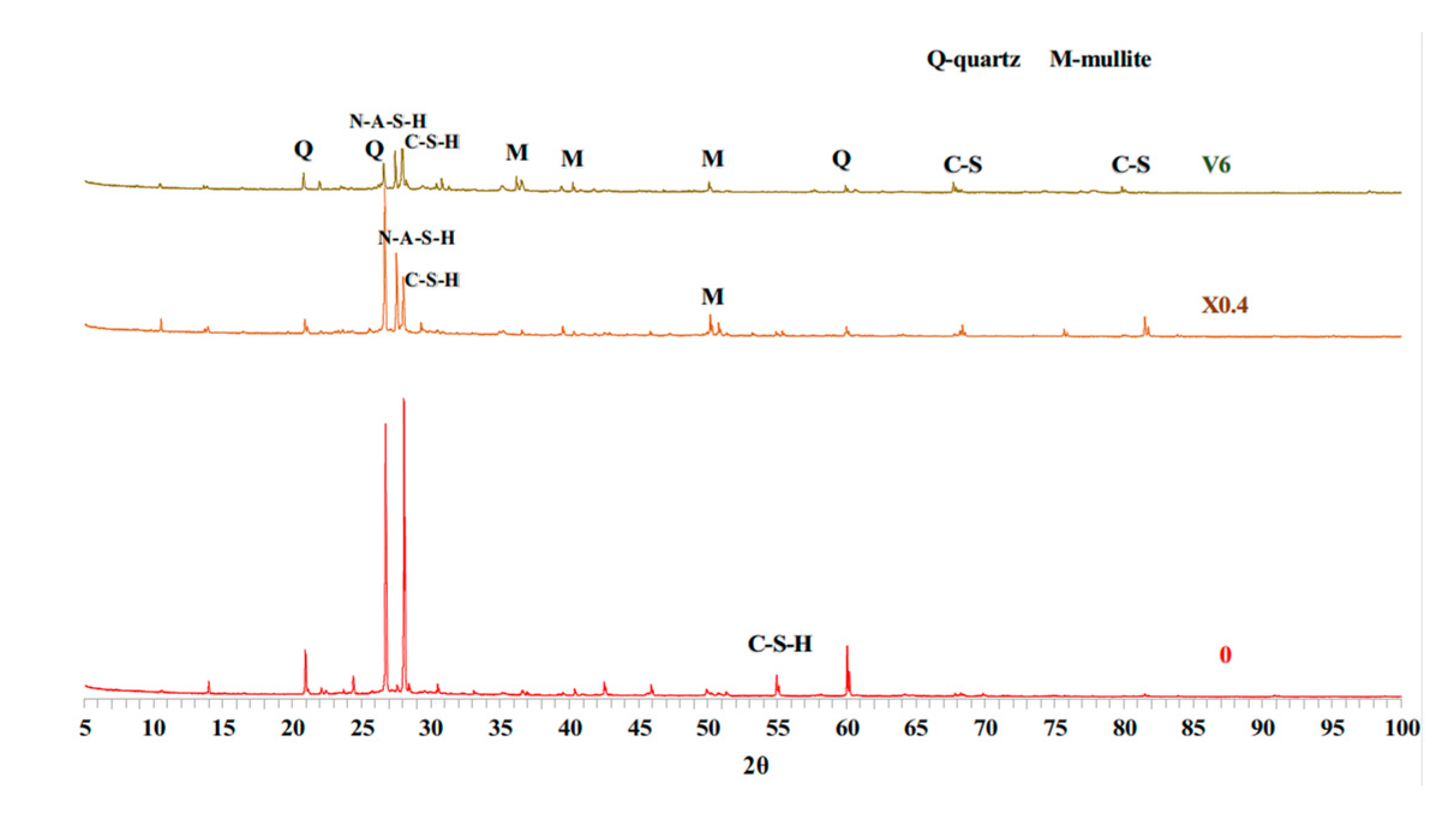

3.5. XRD Analysis

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Majhi, R.; Nayak, A.; Mukharjee, B. Characterization of lime activated recycled aggregate concrete with high-volume ground granulated blast furnace slag. Constr. Build. Mater. 2020, 259, 119882. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, G.D.; Huang, T.Y.; Wang, D.M. Study on properties of fly ash-slag based geopolymer mortar. Bull. Chin. Ceram. Soc. 2019, 38, 1883–1888. [Google Scholar]

- Cao, L.; Zhang, H.Y.; Wu, B. Study on shear behavior of reinforced concrete beams strengthened with textile-reinforced geopolymer mortar. J. Eng. Mech. 2019, 36, 207–215. [Google Scholar]

- Cao, X.Y.; Yang, J.S. Overview of cementitious properties of geopolymer mortar and its concrete. Bull. Chin. Ceram. Soc. 2019, 38, 1–9. [Google Scholar]

- Yin, Y.L. Study on Mechanical Properties and Durability of Basalt Fiber Concrete. Master’s Thesis, Chongqing Jiaotong University, Chongqing, China, 2015. [Google Scholar]

- Jia, Y.H. Preparation and Performance of Na-Fly Ash Geopolymer. Ph.D. Thesis, China University of Mining and Technology, Beijing, China, 2009. [Google Scholar]

- Ohama, Y. Polymer-based admixtures. Cem. Concr. Res. 1998, 20, 189–212. [Google Scholar] [CrossRef]

- Ou, Z.H.; Ma, B.G.; Jian, S.W.; Shen, Y.H. Influence of cellulose ether molecular parameters on mechanical properties of cement paste. Bull. Chin. Ceram. Soc. 2016, 35, 2371–2377. [Google Scholar]

- Feng, K.; Ma, K.; Wang, J.; Long, G.; Xie, Y.; Zeng, X.; Tang, Z.; Usman, I.U. Influence of cellulose ethers on rheological properties of cementitious materials: A review. J. Build. Eng. 2024, 95, 110347. [Google Scholar] [CrossRef]

- Pourchez, J.; Grosseau, P.; Ruot, B. Changes in C3S hydration in the presence of cellulose ethers. Cem. Concr. Res. 2010, 40, 179–188. [Google Scholar] [CrossRef]

- Yang, K. Research on Formula Optimization of Self-Compacting Concrete Admixtures. Master’s Thesis, Guizhou University, Guiyang, China, 2024. [Google Scholar]

- Brachaczek, W. Influence of Cellulose Ethers on the Consistency, Water Retention and Adhesion of Renovating Plasters. IOP Conf. Ser. Mater. Sci. Eng. 2019, 471, 032020. [Google Scholar] [CrossRef]

- Batista, I.L.R.; Cabral, K.C.; de Souza, W.R.M.; Fontes, A.É.M.d.S.; Martinelli, A.E. Influence of hydroxypropylmethylcellulose (HPMC) on thermal and mechanical performance of cementitious rendering mortars. Mater. Struct. 2024, 57, 25. [Google Scholar] [CrossRef]

- Wang, P.M.; Zhao, G.R.; Zhang, G.F. Action mechanism of redispersible polymer powder in cement mortar. J. Chin. Ceram. Soc. 2018, 46, 256–262. [Google Scholar]

- Luo, J.J.; Zhang, L.L.; Liu, Y.X.; Man, L.Y. Comparative study on properties of cement-based pervious concrete modified by redispersible latex powder and silica fume. Concr. Cem. Prod. 2018, 12, 23–26. [Google Scholar]

- Qiao, Q.; Chai, H.C.; Zhang, X.T.; Zhang, H.B. Study on redispersible latex powder modified cement-based thin spray materials. Bull. Chin. Ceram. Soc. 2022, 41, 3394–3402. [Google Scholar]

- Li, J.H.; Zhao, W.J. Research progress on redispersible latex powder. Bull. Chin. Ceram. Soc. 2016, 35, 4038–4043. [Google Scholar]

- Zhang, J.; Bian, C.; Chen, B.; Li, C.; Wei, H.; Lu, H. Study on the Mechanical Properties, Tensile Performance, Hydration Heat, and Microstructure of VAE-Modified Rubber Mortar. Materials 2025, 18, 651. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.; Shi, X.; Xu, L.; Zhang, P.; Zhu, Z.; Lu, S.; Yan, L. Investigation of the Effects of Styrene Acrylate Emulsion and Vinyl Acetate Ethylene Copolymer Emulsion on the Performance and Microstructure of Mortar. J. Build. Eng. 2023, 75, 106965. [Google Scholar] [CrossRef]

- Meng, L.N.; Liang, J.F.; Chen, L. Study on mechanical properties of recycled powder-redispersible latex powder composite cement mortar. Concrete 2023, 2, 129–135. [Google Scholar]

- Peng, J.H.; Mao, J.B.; Zhang, J.X.; Qu, J.D.; Teng, C. Modification effect of redispersible latex powder on cement mortar. Bull. Chin. Ceram. Soc. 2011, 30, 915–919. [Google Scholar]

- Qiao, J.L.; Liu, B.; Ma, L.G.; Li, S.Y.; Ju, X.T. Experimental study on working performance of modified high-performance polymer cement mortar. Concrete 2022, 1, 149–152. [Google Scholar]

- Wang, H.; Zhu, Y.; Li, T.; Li, X.; Peng, S.; Guo, J.; Pei, X.; Zhong, C.; Yang, Y.; Ma, Q.; et al. Modification Mechanism of Low-Dosage Vinyl Acetate-Ethylene on Ordinary Portland Cement-Sulfoaluminate Cement Binary Blended Rapid Repair Mortar. Polymers 2025, 17, 1501. [Google Scholar] [CrossRef] [PubMed]

- Xing, C.W. Study on adhesive strength and Durability of Geopolymer Mortar. Master’s Thesis, Hebei University of Science and Technology, Shijiazhuang, China, 2022. [Google Scholar]

- JC/T 547-2017; Ceramic Tile Adhesives. China Architecture & Building Press: Beijing, China, 2017.

- GB/T 1346-2024; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. China Architecture & Building Press: Beijing, China, 2024.

- GB/T 2419-2005; Test Method for Fluidity of Cement Mortar. China Architecture & Building Press: Beijing, China, 2005.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Architecture & Building Press: Beijing, China, 2021.

- GB/T 29417-2012; Test Methods for Drying Shrinkage Stress and Cracking Possibility of Cement Mortar and Concrete. China Architecture & Building Press: Beijing, China, 2012.

- JGJ/T 70-2009; Standard for Test Method of Basic Properties of Construction Mortar. China Architecture & Building Press: Beijing, China, 2009.

- GB/T 50082-2024; Standard for Testing Methods for Long-Term Performance and Durability of Concrete. China Architecture & Building Press: Beijing, China, 2024.

- Yue, P.; Wang, L.L. Interfacial temperature of EPS external wall insulation system in high temperature environment in summer. Urban. Archit. 2019, 16, 96–99. [Google Scholar]

- Chi, L.; Yanmin, J. Effect of Redispersible Latex Powder and Fly Ash on Properties of Mortar. Coatings 2022, 12, 1930. [Google Scholar] [CrossRef]

- Wang, X.L.; Feng, H.C.; Zhou, K. Mix ratio optimization and frost resistance of VAE latex powder modified cement mortar. Bull. Chin. Ceram. Soc. 2023, 42, 3462–3469. [Google Scholar]

- Huang, Y.C.; Zhang, Y.M. Effect of emulsion compounding on polymer cement waterproof coating film in tile adhesive system. Mater. Rep. 2022, 36, 572–577. [Google Scholar]

- Shi, X.; Ning, B.; Na, F.; Zhao, W.; Zhang, C. Study on properties of re-dispersible latex powder and polypropylene fiber-reinforced lightweight foam concrete. J. Build. Eng. 2024, 95, 110156. [Google Scholar] [CrossRef]

- Wang, Z.H.; Bai, E.L.; Zhou, J.P.; Liu, G.J.; Yang, N. Mechanical properties of VAE latex powder/carbon fiber composite modified concrete. J. Build. Mater. 2024, 27, 487–495. [Google Scholar]

- Zhang, N.; Sun, Q.; Zhang, P.Y.; Wang, D.M.; Wang, Q. Effects of Polymers on Waterproofing and Mechanical Properties of Mortar after Heat Treatment. Bull. Chin. Ceram. Soc. 2023, 42, 2703. [Google Scholar]

- Lau, C.K. Investigation on Alkali Activated Materials: Materials to Structures. Ph.D. Thesis, Curtin University, Perth, Australia, 2021. [Google Scholar]

- JG/T 287-2013; The Materials of External Thermal Insulation Systems Basedon Insulated Decorative Panel. China Architecture & Building Press: Beijing, China, 2013.

- Shi, X.; Xu, L.L.; Feng, T.; Han, J.; Zhang, P. Research progress on waterborne polymer emulsion modified cement mortar. Bull. Chin. Ceram. Soc. 2021, 40, 2497–2507. [Google Scholar]

- Yan, S.; Lu, H.; Zhou, Z.; Dong, Q.; Chen, X.; Wang, X. A polymer latex modified superfine cement grouting material for cement-stabilized macadam: Experimental and simulation study. Constr. Build. Mater. 2024, 413, 134893. [Google Scholar] [CrossRef]

- Han, D.D.; Chen, W.D.; Zhong, S.Y. Effect of latex particle size on properties of polymer-modified cement-based materials. J. Build. Mater. 2017, 20, 943–949. [Google Scholar]

- Lv, Q.-F.; Wang, Z.-S.; Gu, L.-Y.; Chen, Y.; Shan, X.-K. Effect of sodium sulfate on strength and microstructure of alkali-activated fly ash based geopolymer. J. Cent. South Univ. 2020, 27, 1691–1702. [Google Scholar] [CrossRef]

- Song, K.-I.; Song, J.-K. Carbonation characteristics of alkali-activated blast-furnace slag mortar. Adv. Mater. Sci. Eng. 2014, 2014, 326457. [Google Scholar] [CrossRef]

- Zhang, G.F.; Wang, P.M.; Zhao, G.R. Calorimetric study on the influence of redispersible E/VC/VL terpolymer on the early hydration of Portland cement. J. Therm. Anal. Calorim. 2016, 124, 1229–1241. [Google Scholar] [CrossRef]

- Li, L.; Wang, Y.; Ma, Y.Y.; Shen, H.Q.; Luo, J.H. Study on thermal conductivity and pore structure of foamed concrete based on orthogonal test. Bull. Chin. Ceram. Soc. 2024, 43, 2888–2896. [Google Scholar]

| Oxide (wt.%) | SiO2 | Al2O3 | CaO | Fe2O3 | TiO2 | SO3 | K2O | MgO | Others |

|---|---|---|---|---|---|---|---|---|---|

| FA | 50.56 | 37.23 | 2.40 | 5.21 | 1.54 | 1.05 | 1.00 | 0.21 | 0.8 |

| BFS | 31.10 | 15.68 | 41.75 | 0.46 | 1.42 | 3.24 | 0.28 | 5.18 | 0.89 |

| Oxide (wt.%) | SiO2 | CaO | MgO | Na2O | Al2O3 | Fe2O3 | SO3 | Cl | Others |

|---|---|---|---|---|---|---|---|---|---|

| VAE | 44.42 | 33.18 | 16.29 | 2.67 | - | 1.15 | 0.61 | 0.42 | 1.26 |

| HPMC | 2.38 | 4.24 | - | 15.96 | 1.34 | 0.69 | 20.90 | 54.36 | 0.13 |

| Factors | Series | Binders | River Sand | WG: NH | AAS/Binders | Admixtures (wt.,%) | ||

|---|---|---|---|---|---|---|---|---|

| FA | BFS | HPMC | VAE | |||||

| Reference | 0 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0 | 0 |

| HPMC | X0.2 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0.2% | 0 |

| X0.4 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0.4% | 0 | |

| X0.6 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0.6% | 0 | |

| VAE | V2 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0 | 2% |

| V4 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0 | 4% | |

| V6 | 0.5 | 0.5 | 2 | 3:1 | 0.5 | 0 | 6% | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, W.; Chen, P.; Lu, Y.; Zhang, Z.; Shan, B.; Li, S.; Chi, M.; Yu, H. Influence of HPMC and VAE on the Properties of Geopolymer Mortar. Buildings 2025, 15, 3621. https://doi.org/10.3390/buildings15193621

Ji W, Chen P, Lu Y, Zhang Z, Shan B, Li S, Chi M, Yu H. Influence of HPMC and VAE on the Properties of Geopolymer Mortar. Buildings. 2025; 15(19):3621. https://doi.org/10.3390/buildings15193621

Chicago/Turabian StyleJi, Wenjun, Pengfei Chen, Ying Lu, Zeyang Zhang, Baolong Shan, Sha Li, Mengyan Chi, and Haifeng Yu. 2025. "Influence of HPMC and VAE on the Properties of Geopolymer Mortar" Buildings 15, no. 19: 3621. https://doi.org/10.3390/buildings15193621

APA StyleJi, W., Chen, P., Lu, Y., Zhang, Z., Shan, B., Li, S., Chi, M., & Yu, H. (2025). Influence of HPMC and VAE on the Properties of Geopolymer Mortar. Buildings, 15(19), 3621. https://doi.org/10.3390/buildings15193621