1. Introduction

Technology has a complex and layered influence on building production. It acts as a unifying force, since building methods, materials, tools, and labour arrangements often reflect regional traits. Conversely, it can also serve as an industrial divider, particularly in markets where there are significant differences in capital investment, material availability, and performance standards.

This is particularly evident in the construction sectors of developing economies, where technology generates distinct socio-technical divisions resulting from considerable disparities in socio-economic and socio-cultural conditions. The ensuing fragmentation of supply chains, material flows, and distribution channels has led to an unstable construction sector and a subpar building culture that fails to meet the region’s spatial needs.

Institutional and professional responses to the industry’s fragmented behaviour have largely overlooked the spatial needs of the urban poor. This oversight has led to inadequate constructions that merely serve as pressure relief for social and economic challenges [

1]. Meanwhile, the government’s dual role as both a client in the construction sector and a provider of social housing has weakened over the years [

2]. In the field of architecture, attention has increasingly shifted towards high-cost individual buildings, primarily catering to upscale housing and luxury tourism. This misallocation of intellectual energy within the industry has resulted in an unequal distribution of resources and spatial outcomes in the building market [

3].

The fragmentation of the industry, coupled with a weakening construction culture, has posed significant challenges for the regional workforce. These challenges encompass inadequate skill levels, financial exploitation, a scarcity of learning opportunities, unsafe working conditions, and limited career advancement pathways [

4,

5]. The segmentation of the industry into distinct production sectors has impeded lower-tier workers from transitioning between these sectors, learning from one another, sharing knowledge, and enhancing their technical and social capabilities [

6]. This scenario exacerbates the rigidity of the overall technological landscape, complicating efforts to address the operational limits imposed by specific technologies, particularly in low-cost sectors. To mitigate technological rigidity and accommodate the diverse social and spatial needs of various societal groups, architectural practices must devise strategies that adapt technologies to confront the operational challenges posed by these segmented socio-technical environments.

Against this backdrop, this paper addresses the following research question: How can architectural design strategies contribute to building technological robustness in fragmented socio-technical construction environments, particularly in developing economies such as Sri Lanka? The paper’s primary contribution is the development of a normative design framework for technological robustness that integrates technical adaptability, cultural relevance, and economic flexibility. This framework is grounded in empirical insights from the Ambepussa community library project, demonstrating how intentional design choices can create platforms for labour upskilling and technological resilience in resource-constrained construction contexts. By bridging the gap between theoretical discourse and practical implementation, this study offers actionable strategies for architectural design in the Global South.

2. Methodology

To achieve the aforementioned objectives, particularly in exploring how robust design strategies can address the social, cultural, and economic complexities of building production in developing economies, this study adopts a qualitative case study approach, complemented by a practitioner-researcher methodology. As a result, the research is grounded in a project developed and led by the author, who was actively involved in its design and implementation phases. This practitioner-researcher perspective provides a distinctive insider’s view of the intersection between professional practice and academic inquiry.

Practitioner-research is generally regarded as a structured and purposeful inquiry conducted by professionals within their own work environments, aiming to enhance practice while contributing to the wider body of knowledge [

7,

8]. It positions the researcher as both participant and observer, offering context-rich, reflective analysis [

9,

10]. Thus, the author’s reflective insights and decision-making processes during the project are seen as valuable, practice-focused contributions that can be further developed and interpreted within academic research.

Focusing on a single, instrumental case study—the community library project in Ambepussa, Sri Lanka—this research emphasises its significance and unique context, featuring army soldiers as the primary construction workforce in a post-conflict environment (

Figure 1). The project has garnered multiple international honours, including the LafargeHolcim Global Silver Award for Sustainable Construction in 2016. It exemplifies design strategies that aim to nurture labour skills, manage technical tolerances, and promote organic technology transfer.

The study involved a comprehensive examination of project documentation, including architectural drawings, technical specifications, and training directives, to gain a better understanding of the intended design strategies and construction methods. The author’s reflective notes, decisions, and experiences from the design and construction phases were carefully documented and analysed as part of the research data, adhering to practitioner-researcher methodologies. Steven Groak’s idea of mediating frameworks [

11] and the five key robustness attributes proposed in this study were used to evaluate how design strategies expanded operational limits and supported workforce training. Triangulating findings from various data sources, including the author’s reflective practice, ensured the consistency, reliability, and thoroughness of the interpretation.

This methodology establishes a robust framework for exploring the interactions between design, technology, and social factors in building production, especially in resource-limited environments, while also integrating the valuable insights gained from the author’s dual role as both practitioner and researcher.

3. Technological Systems and Use-Context

To effectively engage with technology, it is essential to comprehend the fundamental elements of the technological process, including tools, materials, functions, and the complex web of people, opportunities, and constraints that underpin it [

12]. Political scientist Langdon Winner highlights that technologies can be intentionally or unintentionally crafted to promote specific social outcomes while restricting others; ultimately, “all that matters is how societies choose to use them” [

13]. Thus, it is crucial to analyse the socio-economic, socio-cultural, and socio-technical factors affecting the technological process to grasp its context and identify its limitations.

This analysis begins by recognising that technological activities highlight the interactions between interdependent entities and effectively form a system within a specific social, cultural, and physical context. The concepts of ‘technological system’ and ‘use-context’ are central to this discussion. Historian Thomas Hughes highlights that a technological system encompasses more than just technical aspects; it includes economic, organisational, political, and cultural dimensions [

14]. This suggests that various socio-cultural elements influence the development, organisation, and progression of technology. Moreover, Hughes [

14] points out that technological systems are defined by their structure (comprising different components), behaviour (encompassing the input, processing, and output of materials, energy, or information), and interconnectivity (linking system components to create both functional and structural relationships).

This notion of the ‘technological system’ has been critically analysed by Donald MacKenzie and Judy Wajcman in their influential work, “The Social Shaping of Technology” [

15]. They introduce the term ‘technological paradigm’ to describe how technology evolves and how technological systems subsequently transform. This concept extends Thomas Kuhn’s idea of the ‘scientific paradigm’—a widely accepted approach for tackling specific scientific problems that forms the basis for future research [

16]. Accordingly, MacKenzie and Wajcman’s technological paradigm suggests that existing technological systems act as ‘exemplars’ for emerging ones [

15].

The essential point is that if new technology arises from existing technology through gradual modifications, then the ‘context’ in which this new technology is developed and utilised is vital to the overall technological ecosystem. Don Ihde notes that, “context-less technology is a disembodied abstraction; technology only exists through its use-context” [

17]. He emphasises that this context significantly influences how technological systems relate to work, responsibility, initiative, authority, ethics, aesthetics, and ultimately, “the realm of meaning.”

4. Mediating Frameworks and Operational Limits

In 1990, Steven Groak proposed a theoretical model for analysing technological dynamics within the construction industry, focusing on their behaviour in various use contexts. In a pivotal article for “Building Research & Practice” that discussed the decline of robust construction technologies, he introduced the term ‘mediating frameworks’ to identify the factors that limit the options available to decision-makers operating in different socio-technical contexts [

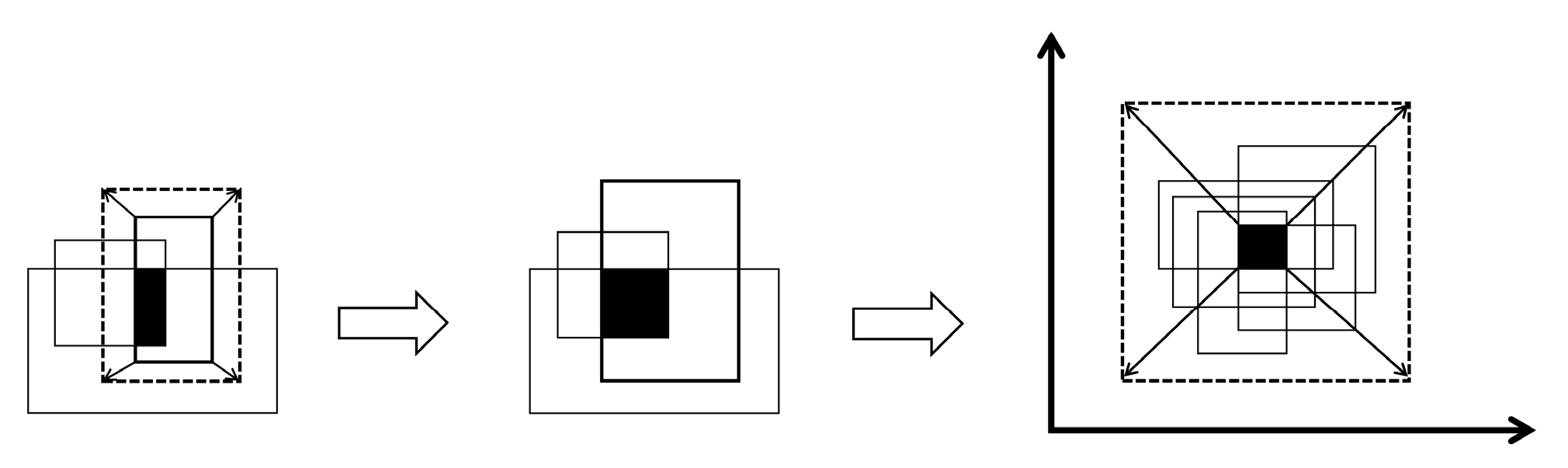

11]. Groak pointed out that these ‘mediating frameworks’ can influence various stages of the construction process, including technology selection, specification, and assembly, and can be categorised as ‘explicit’ or ‘tacit’, as well as ‘regulatory’ or ‘circumstantial’ (

Figure 2).

Explicit frameworks consist of documented limits or decisions, such as performance specifications, project budgets, and local authority regulations. On the other hand, tacit frameworks influence actions in less visible ways, such as existing pricing structures, available resources, and industry expertise. Regulatory frameworks establish mandatory or legally binding constraints, including prevailing pricing structures and labour laws. Additionally, ‘circumstantial’ frameworks encompass industry knowledge, accepted skill levels, and project team organisation. Although circumstantial frameworks lack enforceability, they can shape the technological environment based on the actors’ familiarity and hands-on experience with their tasks.

Groak suggested that the intersection of these frameworks creates a ‘feasible set’ of alternative decisions specific to each project.

Figure 3 shows how this overlap of mediating frameworks constrains the project’s technological choices, resulting in a limited set of decisions termed the ‘feasible set of available decisions.’ Consequently, the project’s scope and performance are restricted by the ‘operational limit’ of the technologies at hand [

11].

The impact of these frameworks on construction processes varies by region. In developing economies, the influence of informal and circumstantial frameworks generally outweighs that of regulatory frameworks. For instance, the informal nature of construction in these regions—evident in aspects such as workforce assembly, onsite knowledge building, and minimal compliance with specific regulatory frameworks [

4]—indicates that factors like building material costs and workforce skill levels are more significant in determining building outcomes than the necessity to adhere to regulatory standards. In fact, circumventing regulatory (or explicit) frameworks is often perceived as simplifying the already complex technological environment.

Nevertheless, developing economies require a technological framework that ensures stable industrial operations while addressing urgent construction needs without introducing unnecessary complexity. An inclusive structure that cultivates tacit knowledge would assist all workers—be they professional, industrial, formal, or informal—in navigating construction markets effectively and engaging in various tasks. Achieving this necessitates expanding the operational boundaries defined by construction’s economic, cultural, and technical dimensions, allowing for more inclusive and adaptable technological solutions tailored for each project (

Figure 4). Practically, this means selecting technical options that can adjust to changes in the project’s economic conditions while also managing the cultural and technical complexities without sacrificing performance expectations. This combined capability is referred to in this paper as ‘technological robustness.’

5. The Three Dimensions of Robustness

To ensure robustness and expand the operational boundaries of technology, it is essential to engage with three interconnected aspects of production: technical, cultural, and economic. First, the technical attributes of a system, which encompass the range of materials, tools, and processes, must be adaptable to various use contexts without leading to a failure chain in the final output. Second, it is important to acknowledge and embrace the diverse cultural elements that reflect the customs, values, beliefs, practices, skills, and knowledge of the workforce. Finally, the economic characteristics that enable the organisation and regulation of specific production methods should remain flexible and responsive, particularly regarding the different ways to combine production factors.

5.1. Technical Robustness

Achieving technical robustness relies on two fundamental principles. The first principle emphasises that technological systems must demonstrate a degree of resilience to maintain acceptable performance levels and prevent failure chains, regardless of the limitations encountered during construction. While deemed ‘non-optimal’, this necessary performance level should be manageable and definable in terms of the social and economic factors relevant to the technological context—what Ihde refers to as the use-context. The second principle underscores the importance of compatibility and interchangeability among building systems and their components, enabling the adaptation of a technological system to various construction environments.

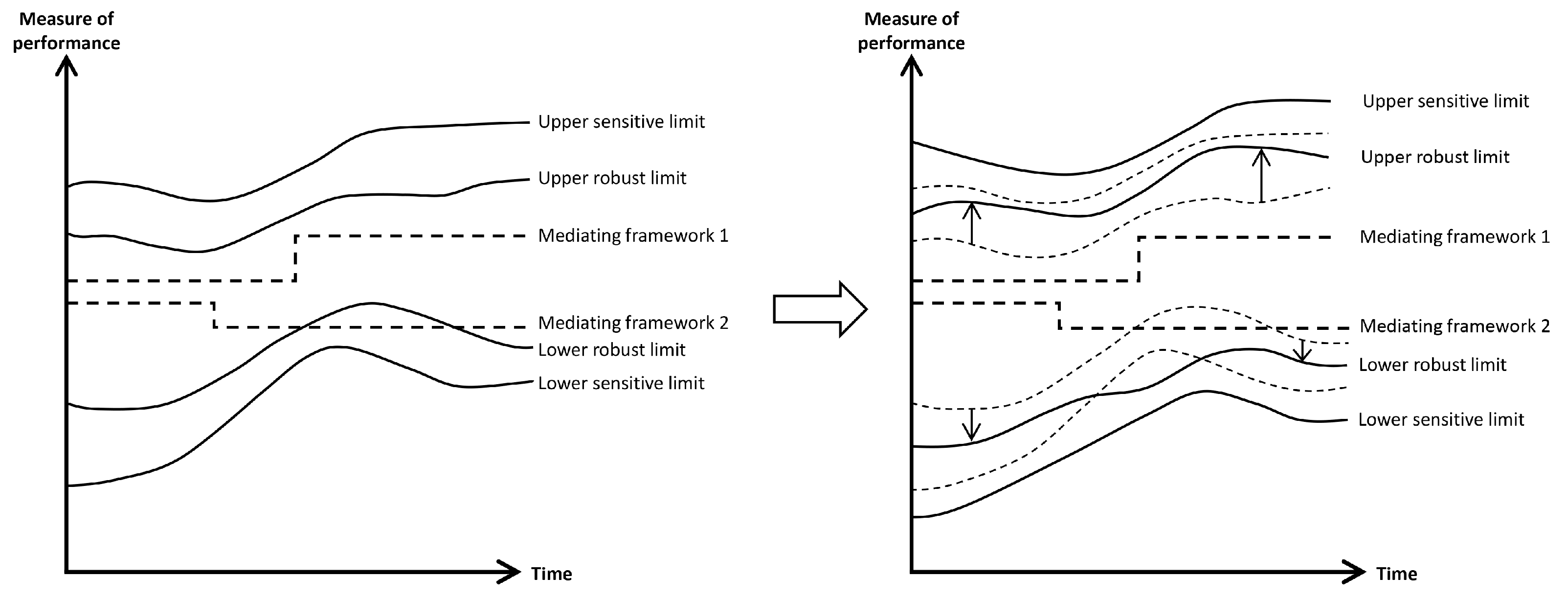

The first principle emphasises the importance of employing technological systems within their defined robust limits (

Figure 5a). The second principle underscores the necessity of adapting technological processes to ensure that sensitive applications operate effectively within the stringent constraints of the use context (

Figure 5b). Thus, the robust limits of performance influence the degree of suboptimal application of a technological system in any scenario. Conversely, these robust limits can be intentionally expanded rather than constrained by existing operational boundaries, thereby allowing for a broader range of technological opportunities (

Figure 6).

In the following text, I will discuss the case study project to illustrate design strategies and techniques that construction decision-makers can employ to deepen their understanding of what defines ‘technical robustness’. The first design strategy I wish to highlight here emphasises the importance of facilitating ‘ease of system assembly’ by using simple components, adopting standardised and clear procedures, and ensuring adequate installation clearances. These aspects are intended to enhance the system’s cost-effectiveness in terms of labour and materials while reducing the likelihood of errors compared to more complex and challenging applications. Systems that are difficult to assemble may require more resources and face the risk of poor execution if those resources are scarce, particularly on lower-skilled construction sites. By establishing clear and strong assembly parameters, the assembly process becomes easier, allowing less-skilled workers to participate more effectively.

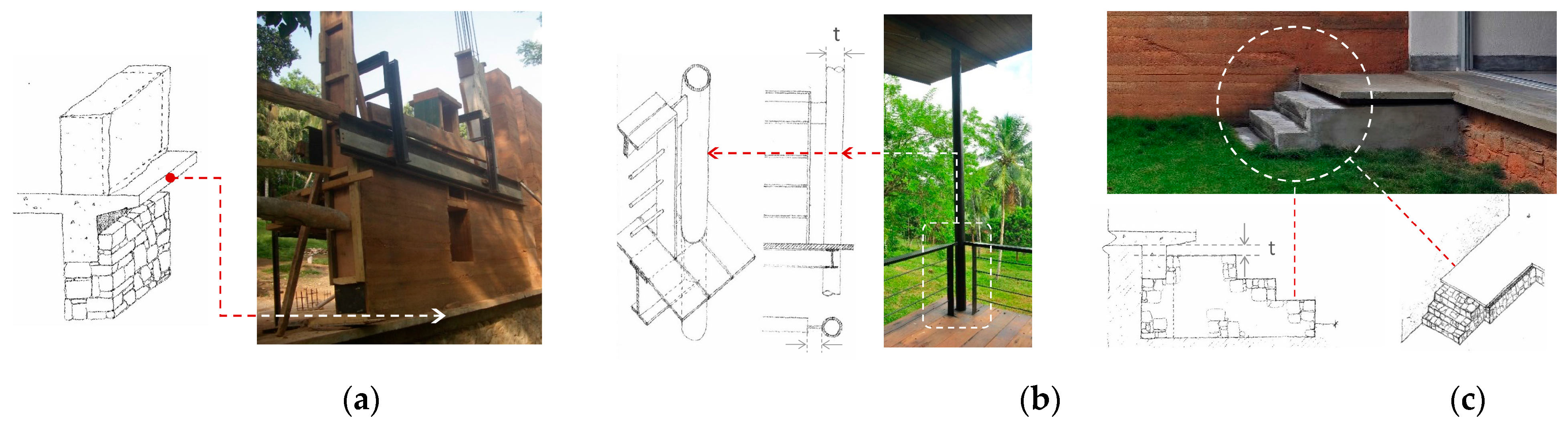

Secondly, closely related to the ease of assembly are the ‘dimensional tolerances’, which specify the maximum allowable deviations from standard dimensions for the system or its components; exceeding these limits subjects the application to a failure chain. Wide dimensional tolerances establish robust limits that allow the system to accommodate inaccuracies in manufacturing and installation. The library project employed several design approaches to determine acceptable dimensional tolerances tailored to the soldier-labour training needs.

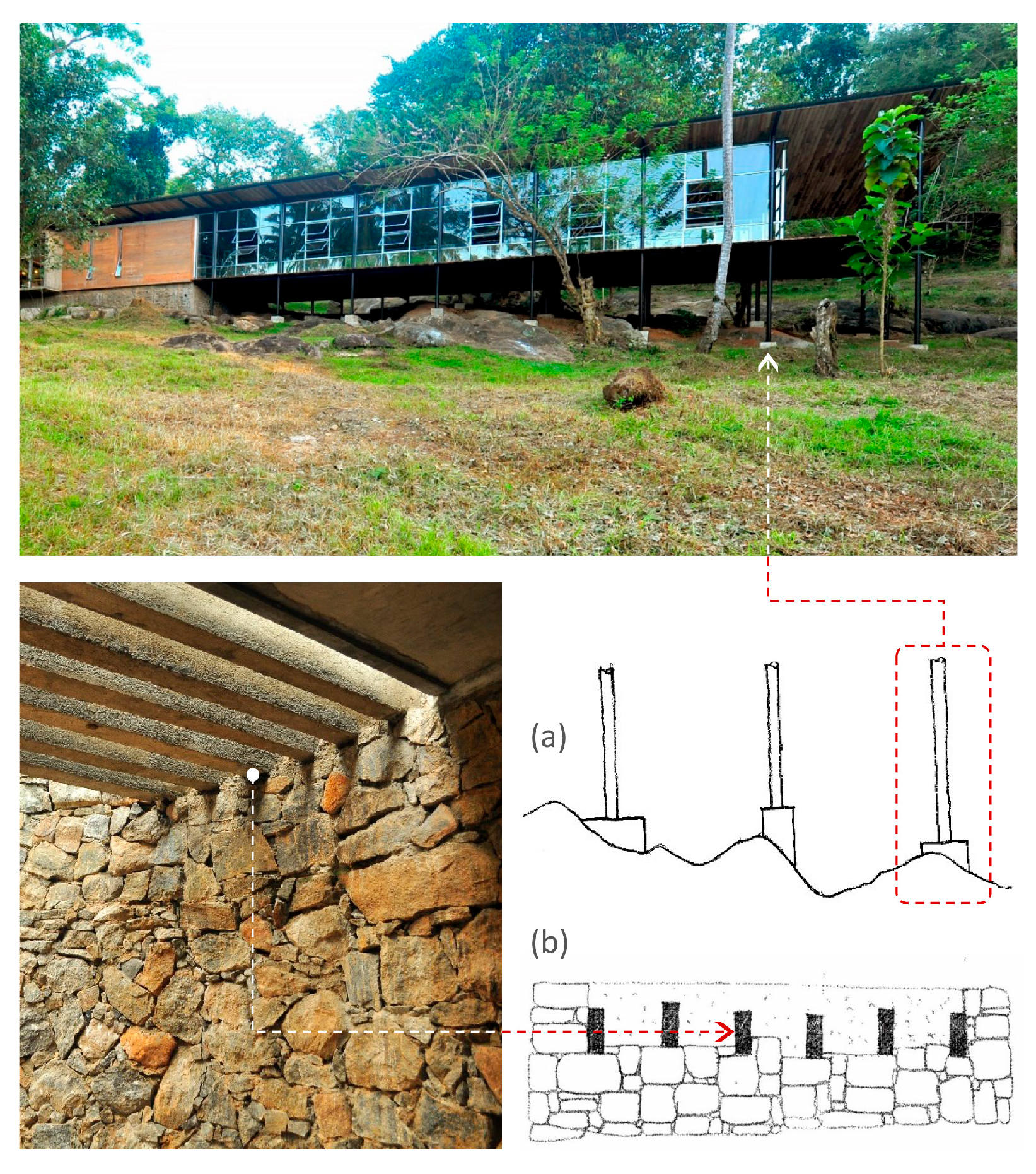

Figure 7a illustrates how a concrete ledge serves as a ‘third element’ between rammed earth walls and an exposed rubble foundation. It effectively conceals any dimensional discrepancies caused by the trainees’ work when constructing either the wall or the foundation. When built by an upskilling work gang, the specified and actual widths of the walls may often differ. Without the ledge functioning as a ‘tolerance mediator’, any misalignment or mismatch in size between the two systems would likely appear as a formal error.

In the other two examples illustrated in

Figure 7, a ‘

negative joint’—a purposely created gap between two building components—is maintained between the structural steel tubular column and the handrail system (

Figure 7b), as well as between the concrete floor landing and the rubble stair system (

Figure 7c). This deliberate visual separation prevents any dimensional variation in the erection and alignment of one system from transferring to the other, thus avoiding a chain of failures.

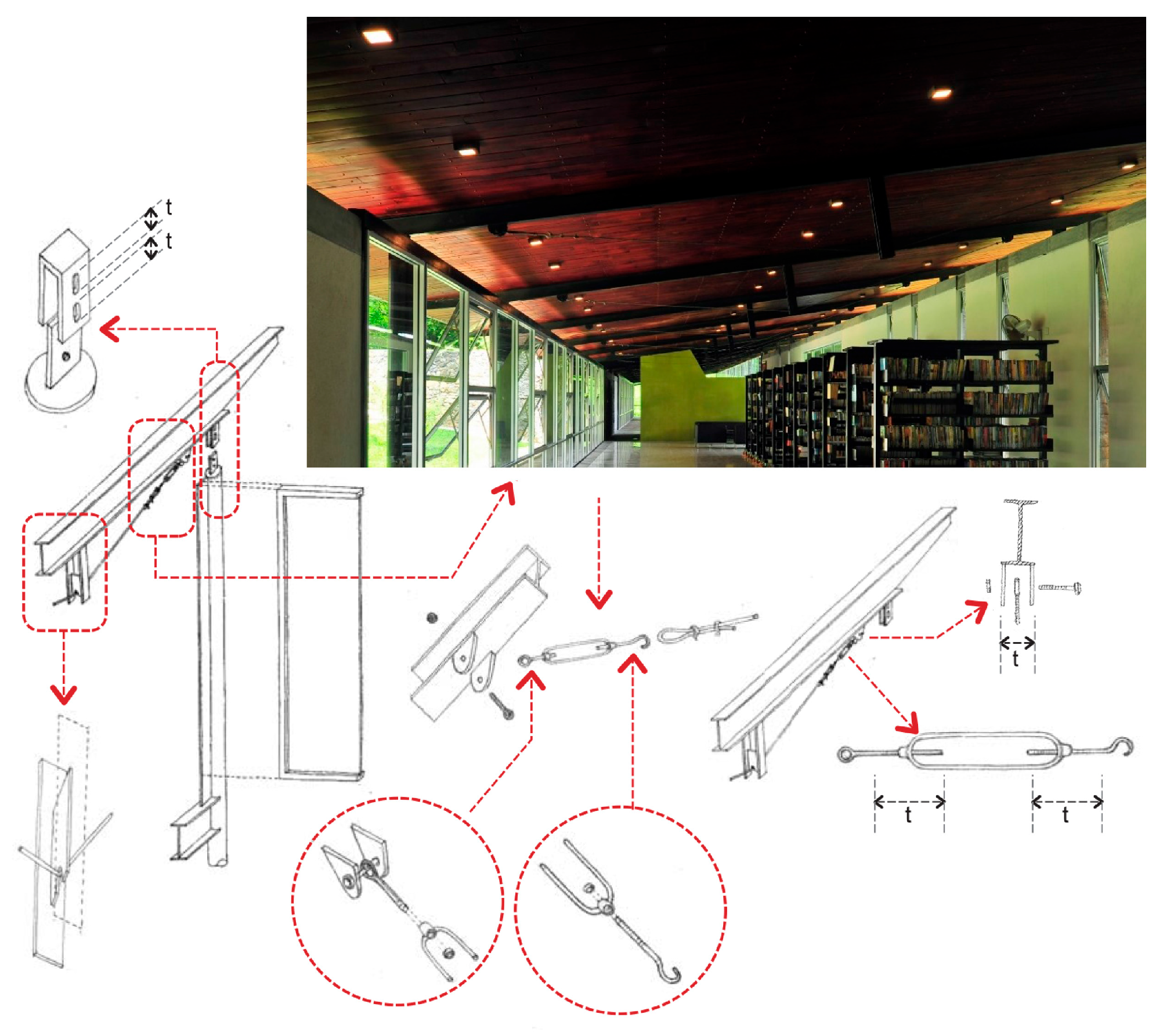

Thirdly, the system can improve production and assembly tolerances by utilising ‘

adjustable fits’ that enable movement between parts. This feature allows components requiring precise positioning to be created with alignment adjustments, both during and after assembly. The library buildings’ portal frame design relies on adjustable fits to ensure that joints do not become limiting factors and to facilitate the replacement of worn components with new ones as the building is used (

Figure 8).

Fourthly, workmanship tolerances can be designed to increase the system’s ability to handle minor inaccuracies and errors in production. For instance, improper jointing techniques and placements often lead to significant failures in both the structural integrity and environmental impact of buildings. However, integrating permissible levels of failure (

allowable failure) within a technological system can improve its practicality in specific contexts. In the library project, concrete footings are ‘designed’ to fit various geometric shapes, allowing trainee workers some leeway in precision when positioning them on uneven terrain (

Figure 9a). Similarly, the concrete pergolas can accommodate slight alignment errors, as the irregular vertical stone surface that supports them makes such mistakes less noticeable, thereby preventing a formal failure (

Figure 9b).

Fifthly, building on the previous point, using ‘variegated surface finishes’ strategically helps conceal workmanship flaws and imperfections, thereby broadening the system’s application scope. This approach aligns with the inherent resilience of the design, which also considers ongoing maintenance and repairs. For example, the library project featured irregular stone surfaces and organically textured rammed-earth walls to simplify construction and facilitate ease of maintenance by trainee workers. Many of these workers would have been learning the craft while working on these walls, and expecting visual uniformity in the surface could have hindered their learning process. Additionally, the variation in surface and the randomness in texture allow the system to recognise ageing as a form of formal compatibility (

Figure 10). In contrast, polished stone surfaces can be difficult to repair if damaged, as removing individual stones is often challenging and may require skilled labour. Moreover, replacements might not match the original colours or patterns surrounding them.

Sixthly, the tolerances in the ‘

dimensional coordination’ of parts and components enhance technical robustness. This is particularly relevant given the growing systematisation of building production, which has progressed beyond merely standardising bricks and tiles, even in developing economies. While systematisation of building components could theoretically boost site productivity, excessive precision in dimensional coordination may negatively impact the overall performance of the building, especially when low-skilled labour gangs carry out construction. Conversely, adopting flexible coordination and layering of systems can mitigate the challenges posed by irregularities in modular reference grids of lines or planes. For example, in

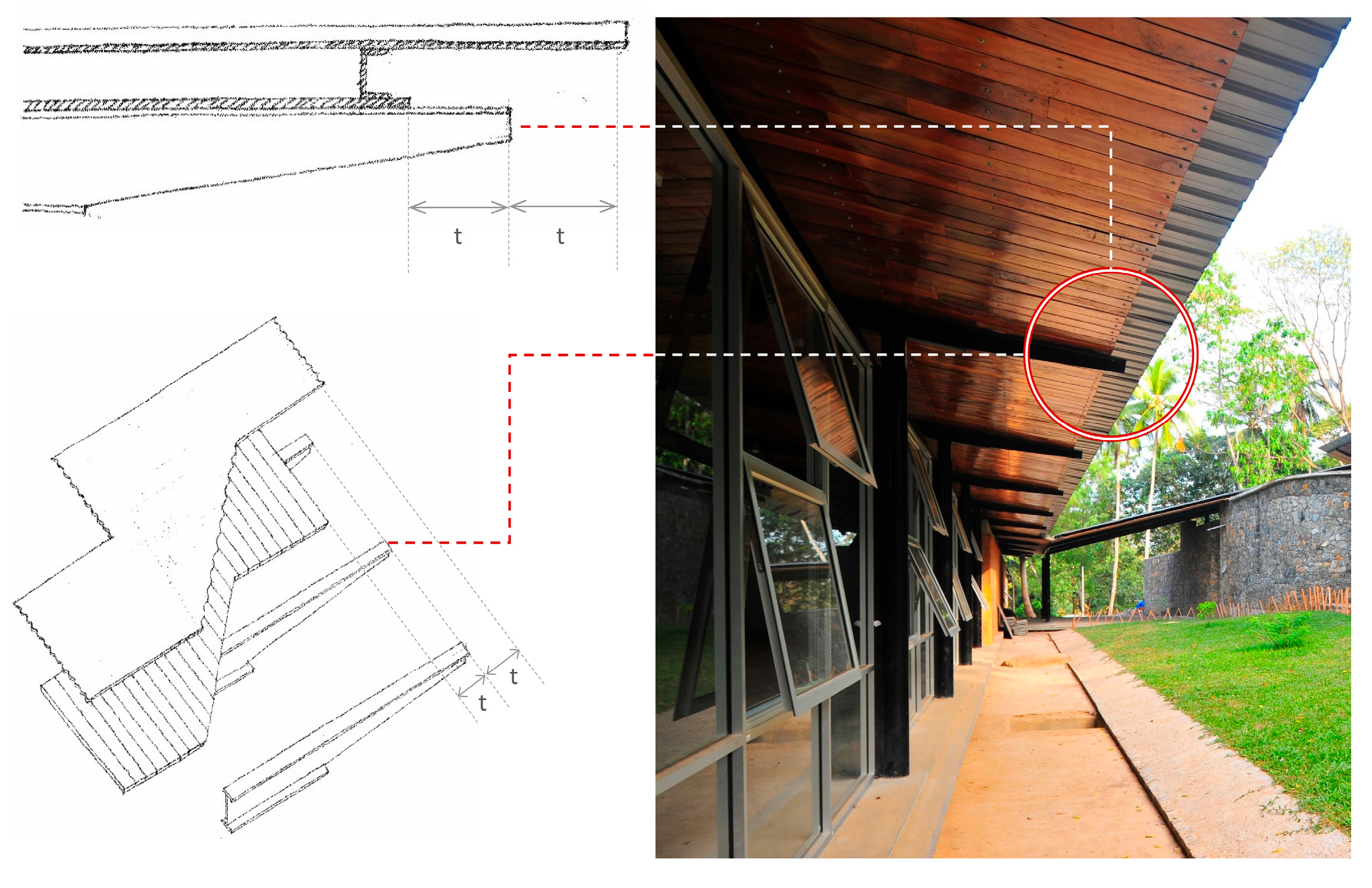

Figure 11 from the library project, the roof, ceiling, and truss lines are intentionally projected away from one another, ensuring that a dimensional error in one component does not lead to a failure chain in others.

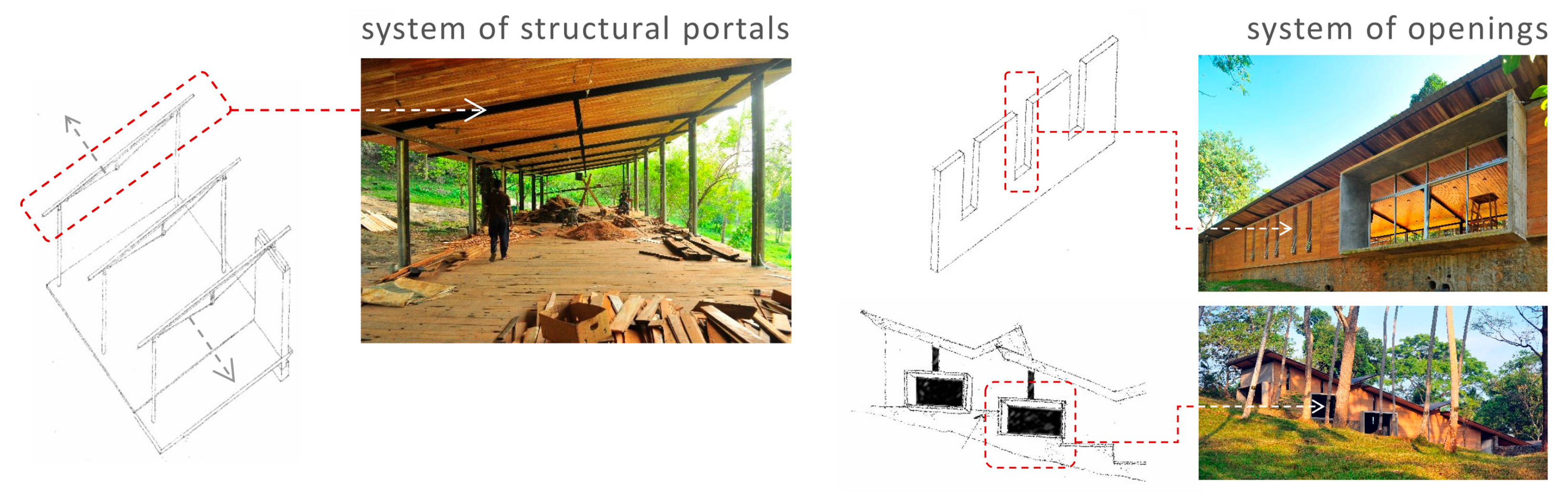

When appropriate tolerances are integrated into the dimensional coordination of building components, the ‘systematisation of work’ can improve both the ease of on-site erection and training. In the library project, for instance, the systematic production of structural and opening systems enhances skill utilisation and training through repetitive and intensified tasks (

Figure 12).

In summary, technical robustness is achieved when: (a) building systems can maintain their expected performance regardless of the operational limits and cultural variables encountered in different technological environments, (b) building systems and their components can be adjusted and interchanged to accommodate varying construction demands, without exposing them to failure chains, (c) dimensional co-ordination of parts and components is defined within flexible tolerance bands, particularly in the context of the increasing systematisation of building production, (d) building systems do not rely on overly precise production methods, allowing for the use of less-skilled labour, and (e) workmanship tolerances are established to allow for ‘allowable failure’ so as to exonerate inaccuracies and blemishes in the production process.

5.2. Cultural Robustness

As discussed above, technical robustness refers to the necessary levels of efficiency required to support construction processes in specific contexts. Conversely, cultural robustness ensures that the criteria, logic, and objectives behind the techniques employed are understood and accepted by all workers involved. Achieving this intellectual unity poses a challenge in today’s technological environment and highlights a significant distinction from traditional societies. For example, James Fitchen’s work, ‘Building Construction before Mechanization’ [

18], illustrates how traditional societies possessed a comprehensive and practical understanding of building technology, including the materials used, the tools designed for their preparation, and the assembly procedures followed. However, as noted by Linda Clarke in her pivotal work, ‘Building Capitalism’ [

19], urbanisation and industrialisation not only alter technology and materials but also result in the emergence of new work organisations, supply chain patterns, and divisions of labour. This evolution is evident in Britain’s construction history, where specific eras correspond to the rise in speculative builders, specialised subcontractors, project managers, and additional roles that expanded upon the conventional categories of clients, consultants, suppliers, and assemblers [

19].

In developing economies, transnational trade relations and rapid urbanisation steer the construction sector along a similar path. The growing and evolving demand for construction necessitates a wider variety of building subtypes and systems, innovative practices, new delivery methods, retrofitting, and intellectual solutions to the associated challenges, such as sustainable design. However, this evolution also leads to increased client involvement in the building process, significant influence from the building materials industry, subcontracting focused solely on labour, informal employment conditions, and a shift in work from construction sites to factories [

4,

20,

21]. While this transformation necessitates the emergence of specific, applicable skills, new expert parties, specialised subcontracting processes, carefully structured labour processes, and much clearer divisions of responsibility than before [

22], it simultaneously alienates significant segments of the workforce, which have become completely disconnected from traditional frameworks while remaining culturally outside the new ones.

The most prominent of these elements is the casual labour force employed for menial, labour-intensive tasks that yield minimal productivity. Unlike traditional construction processes, where a consistent team moves from one job to another, enhancing their skills through apprenticeships and peer learning, today’s work groups consist of more temporary and significantly larger coalitions of unfamiliar individuals and organisations. Consequently, acquiring new knowledge proves more challenging, as the pathways to obtain it may have been disrupted or are limited to specific market sectors.

This situation demands innovative methods for disseminating knowledge and building capacity, aiming to reconstruct the synergy of knowledge as a cross-role, context-specific culture. Consequently, evaluating whether real building projects can incorporate organic skill-development platforms benefits both workers and the industry as a whole. The library project in Ambepussa addresses this goal by integrating adequate levels of ‘absorbable’ mistakes (or technical inaccuracies) into the production process while ensuring that the technologies and procedures used possess a certain level of scalability in scope and complexity. It is this scalability in technical complexity that facilitates gradual skill enhancement on-site.

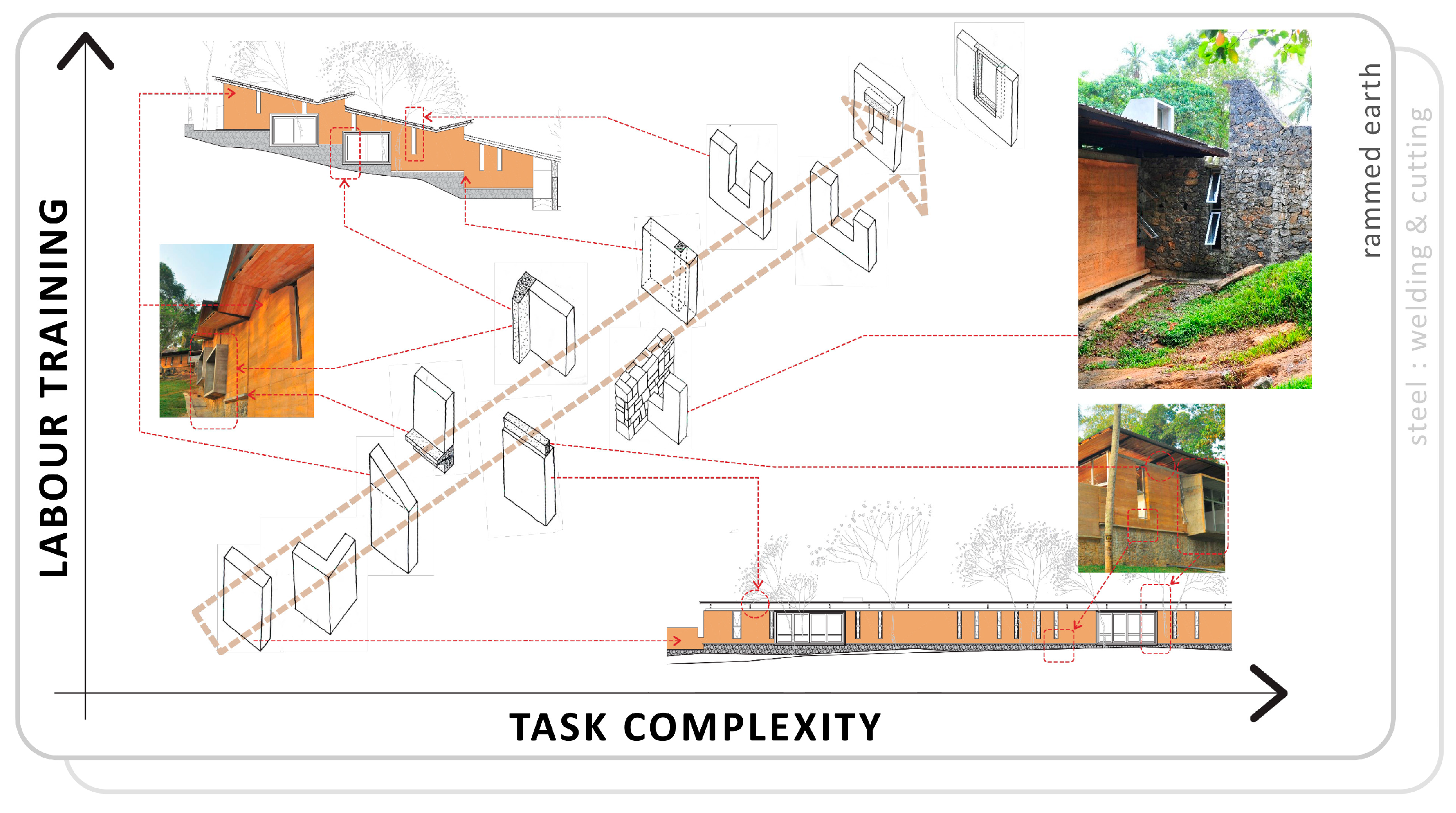

Figure 13 illustrates a capacity-building strategy employed in the library project, where rammed-earth walls serve as the primary construction method. It features various wall profiles and junctions, each demonstrating different levels of technical complexity, integrated into the proposed building solutions. This strategy facilitates a step-by-step transfer of essential skills to the workforce, enabling them to learn during the actual construction process. More specifically, the graph classifies wall profiles and junctions based on the complexity of their tasks, allowing workers to utilise on-site construction of these technical elements as a means of progressive skill development.

Nevertheless, the effectiveness of these on-site capacity-building tasks hinges on their early planning during or prior to the procurement phase. As illustrated in

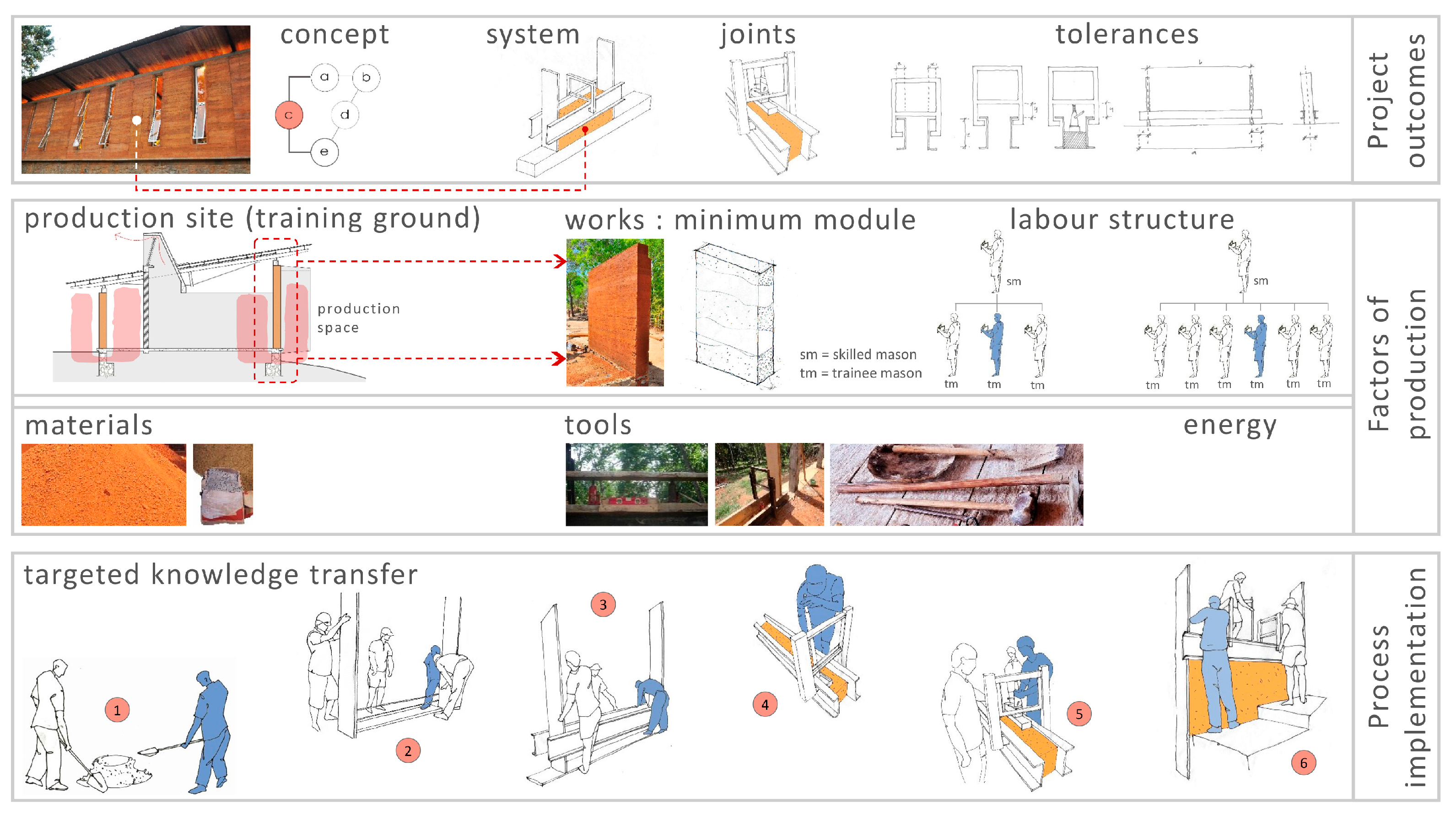

Figure 14, this approach includes the incorporation of a ‘training and fabrication design’ stage within the project development timeline, comprising three main components: (1) a ‘project outcomes’ component, where specific training interventions and relevant workmanship tolerances are integrated into the proposed building systems, considering the knowledge level of the targeted trainee workers; (2) a ‘factors of production’ component, which establishes the socio-technical context for each training task by identifying potential training sites, viable work modules, and the minimum crew necessary to construct a modular unit; (3) a ‘process implementation’ component that outlines the sequence of training interventions at the designated training site.

While these onsite training workshops aim to transfer new skills to trainee workers, their expected outcomes, production factors, and implementation strategies are all closely aligned with local needs and aspirations. They also reflect how technology is perceived, interpreted, and learnt within a specific culture. This concept of culturally accepted knowledge is essential to the idea of cultural robustness relevant to this work. Essentially, a technological framework is regarded as culturally robust when: (a) there is a broad, implicit understanding of its principles and relevance among users, or it builds on the existing knowledge of industry participants; (b) it incorporates a self-learning aspect for those applying it; and (c) it is developed with awareness of how different cultures will interpret its components.

5.3. Economic Robustness

The third aspect of robustness concerns how economics fundamentally influence construction. In a world constrained by operational limits, decisions about allocating, investing, or saving limited resources—each with alternative uses—have often driven building production choices. As Groak [

23] observed, attempts to ‘economise’ in building production typically focused on the core characteristics of construction itself, a point previously highlighted by Duccio Turin [

24]. Hence, strategies to overcome fixedness (like mobile homes), manage weight and size (using lighter techniques), handle social production complexity (by standardising processes, enabling easy connections, and employing less-skilled workers under supervision), reduce process times (through faster construction for cost savings), and ensure durability have been crucial for economic efficiency in building over time.

In discussions about durability, however, some may suggest that designing buildings for shorter lifespans, rather than focusing on longevity, is also a cost-saving strategy driven by necessity rather than choice. Both Turin’s view on construction and Groak’s insights into ‘economisation’ strategies show that intervening in the organisation of products, processes, and participants affects economic factors in building production. Therefore, economic resilience depends on two interconnected aspects: one concerning the mechanics of production and the other on social agreements.

In any construction process, production factors are combined based on the task requirements, typically considering resources available from either the supply or demand sides. Market variations influence the availability of specific factors such as labour skills, equipment, building systems, materials, tools, financing, and time. As a result, particular combinations of these factors emerge within each market, fostering internal economies of scope. When specific materials or technical solutions are accessible, cost-effective, and in demand, they will be utilised. This, in turn, further shapes future demand, creates training opportunities for the current labour force, and mitigates risks in the development process.

Conversely, when the desired product demands a combination of factors that exceed available resources—especially if these factors have not been widely used before—the previously mentioned internal economies shift toward external ones. This indicates that choosing a particular system or material may require reducing costs elsewhere or developing the workforce through importing expertise or training local workers. Such situations are common in developing economies, often due to changes in the construction landscape, new performance standards, or increasing costs of certain factors like land.

In this case, addressing financial constraints requires focusing on the key cost drivers within the procurement process. For the library project, many vital building materials were acquired at significantly reduced costs: the earth for the rammed earth walls was sourced from a nearby excavation site meant for a playground; reclaimed steel from old factories and discarded timber railway sleepers from a local train station were also used as essential materials for the structure and flooring. Meanwhile, the on-site upskilling of worker-soldiers further lowered costs while maintaining comparable performance. This approach fostered a natural system for resource management, skill development, and technical feasibility, nurturing social and physical capital that can be applied to similar projects across Sri Lanka (

Figure 15). Furthermore, the trained workforce from the library project can pass on their knowledge and train workers at other sites, leading to additional cost savings elsewhere.

In summary, economic robustness is achieved when: (a) building products are designed to withstand the impact of cost savings or compromises on performance; (b) system assembly and labour costs can be reduced through strategic adjustments in their composition and requirements; (c) the design of a building system minimises the investment required to attain a specific performance level; and (d) the industry adopts low-cost labour training as a strategy to enhance performance and control costs.

6. The Attributes of Robustness: Defining a Normative Framework

In conclusion, this paper’s discussion enables us to propose a general normative definition of technological robustness as a basis for further regional variations. Consequently, technological robustness depends on five key attributes:

(1) The ability of a system to achieve the economies required with respect to individual project environments.

Technological systems must adapt to cost fluctuations without compromising performance, especially when market conditions are unpredictable. This requires incorporating a degree of production flexibility to withstand variations such as shifting project budgets, evolving labour organisational structures, differing expectations regarding skill utilisation, inflation-driven price changes, exchange rate volatility, and other forms of financial instability.

(2) The ability of a system to withstand unexpected variations in factors of production and labour skills.

Technological systems must be resilient enough to prevent serious mechanical, environmental, and formal failures in contexts characterised by fluctuating operational boundaries. While it is essential to avoid a complete breakdown of mechanical and environmental functions, some level of ‘allowable failure’ should be recognised to alleviate the demands for extreme precision and care. Consequently, technologies should operate effectively within ‘non-optimal’ cultural and technical frameworks without compromising their expected performance.

(3) The ability of a system to respond to unforeseeable project dynamics.

Robust systems must withstand the industrial challenges posed by the uncertainties inherent in the building production process. This uncertainty can stem from unexpected material shortages, disruptions in financial, human, and energy resources, as well as inadequate supply chain coordination or poor workplace organisation. While the impact of these factors varies based on the specific ‘use-context’ of the technology, they can be particularly detrimental in low-cost sectors of the industry. Robustness allows systems to endure workmanship errors and accommodate potential inaccuracies or deficiencies in design, manufacturing, assembly, or use.

(4) The ability of a system to be applied in scalable ways.

Technological systems must adapt their scope and production requirements to meet varying user and market needs. This ensures effective usage across different markets and fosters industrial stability. Such adaptation can be accomplished by modifying the composition of materials, adjusting the connections to other systems and components, and establishing different output qualities based on changes in the social context.

(5) The ability of a system to facilitate technical relations between building actors.

Technologically advanced systems should leverage and support the social networks formed during their development by incorporating specialised contributions from various stakeholders throughout the supply chain. A shared cultural understanding of a specific technology would help maintain its performance within effective limits, despite a wide range of applications. To foster this capability, technological systems should be designed as ‘open’ systems, free from rigid or predetermined socio-cultural constraints. This approach enables the establishment or reorganisation of non-linear relationships among socio-cultural factors, participants, and groups from both the formal and informal sectors of the industry.

Finally, it is crucial to recognise that developing a pervasive and robust framework for a particular region should begin at the grassroots level. This involves examining the local industrial base and establishing a design and technological language that takes advantage of the region’s unique conditions and limitations. The framework presented here, categorised into three aspects of robustness—technical, cultural, and economic—serves as a guideline for creating such a robust, place-based design approach.

7. Limitations

While this study offers valuable insights into the role of architectural design strategies in cultivating technological robustness and enhancing skill development in the construction industry, several limitations must be acknowledged.

Firstly, the study focuses on a single case—the community library project in Ambepussa, Sri Lanka—which may raise concerns about the broad applicability of the results. Additionally, the specific socio-political context—involving a post-conflict setting that utilises military labour—may cast doubt on whether these strategies are appropriate for typical construction environments with civilian workers.

Secondly, the practitioner-researcher methodology offers deep insights but introduces potential bias due to the author’s involvement in the project. Despite employing reflective practices and triangulation to mitigate this, subjectivity may still persist.

Thirdly, the study focuses primarily on architecture and is site-specific, featuring limited engagement with broader construction management issues such as procurement, project delivery, and multi-stakeholder coordination. It does not consider systemic factors like educational curricula for architecture and construction management, nor the implications for public policy and national infrastructure planning. These areas are crucial for future research to validate and enhance the robustness framework.

Ultimately, data limitations persist as the analysis predominantly relies on qualitative project documentation, reflective notes, and observations rather than comprehensive third-party evaluations or longitudinal data. Incorporating externally gathered data or multiple case studies could enhance the robustness and transferability of the findings.

Despite these limitations, the study provides a valuable foundation for understanding how design strategies can address social and technological challenges in fragmented construction sectors. Additional research in diverse contexts and wider stakeholder engagement would enhance and broaden the practical relevance of the proposed framework.

8. Conclusions

Building on the findings and acknowledging the limitations of this study, several key contributions remain identifiable. This study presents a normative framework for technological robustness, offering a design-based response to the challenges posed by fragmented socio-technical construction environments in developing economies. By articulating five key attributes of robustness—economic flexibility, adaptability to variable labour skills, responsiveness to project dynamics, scalability, and the facilitation of technical relationships—this paper provides both conceptual clarity and practical guidance for architectural practice in low-resource settings.

Through the case study of the Ambepussa library project, this research demonstrates how design can actively shape opportunities for organic skill development, mitigate technological rigidity, and create resilient building processes that accommodate material, labour, and economic variability. The proposed framework is scalable and transferable, offering a robust design strategy that can inform future projects in similar developing contexts where capacity-building, technological flexibility, and socio-cultural integration are critical for improving construction outcomes.