Multi-Scale Investigation on Bearing Capacity and Load-Transfer Mechanism of Screw Pile Group via Model Tests and DEM Simulation

Abstract

1. Introduction

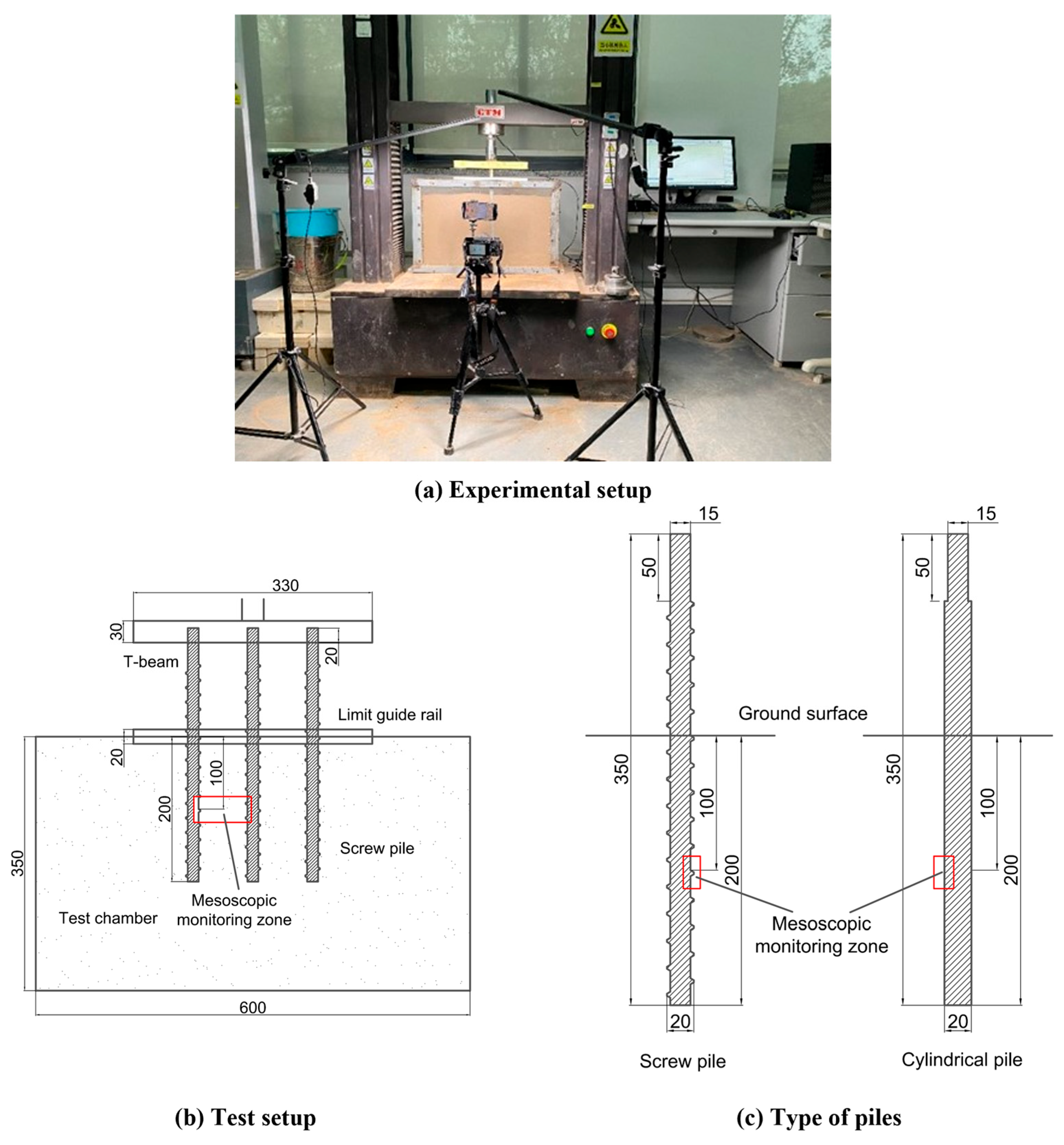

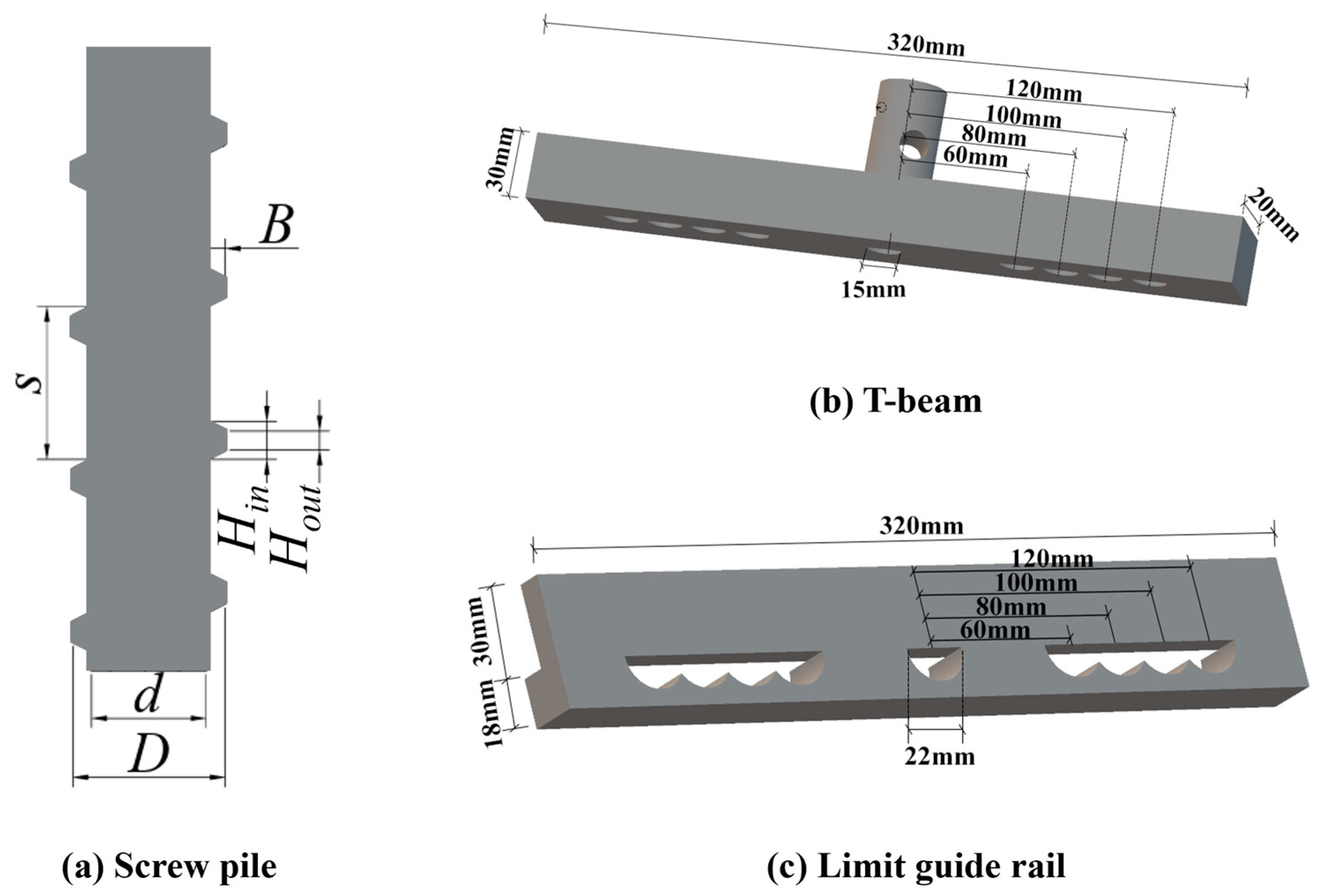

2. Model Test

2.1. Test Apparatus

2.2. Test Materials and Parameters

3. Analyses on Test Results

3.1. Influence of Different Pile Types

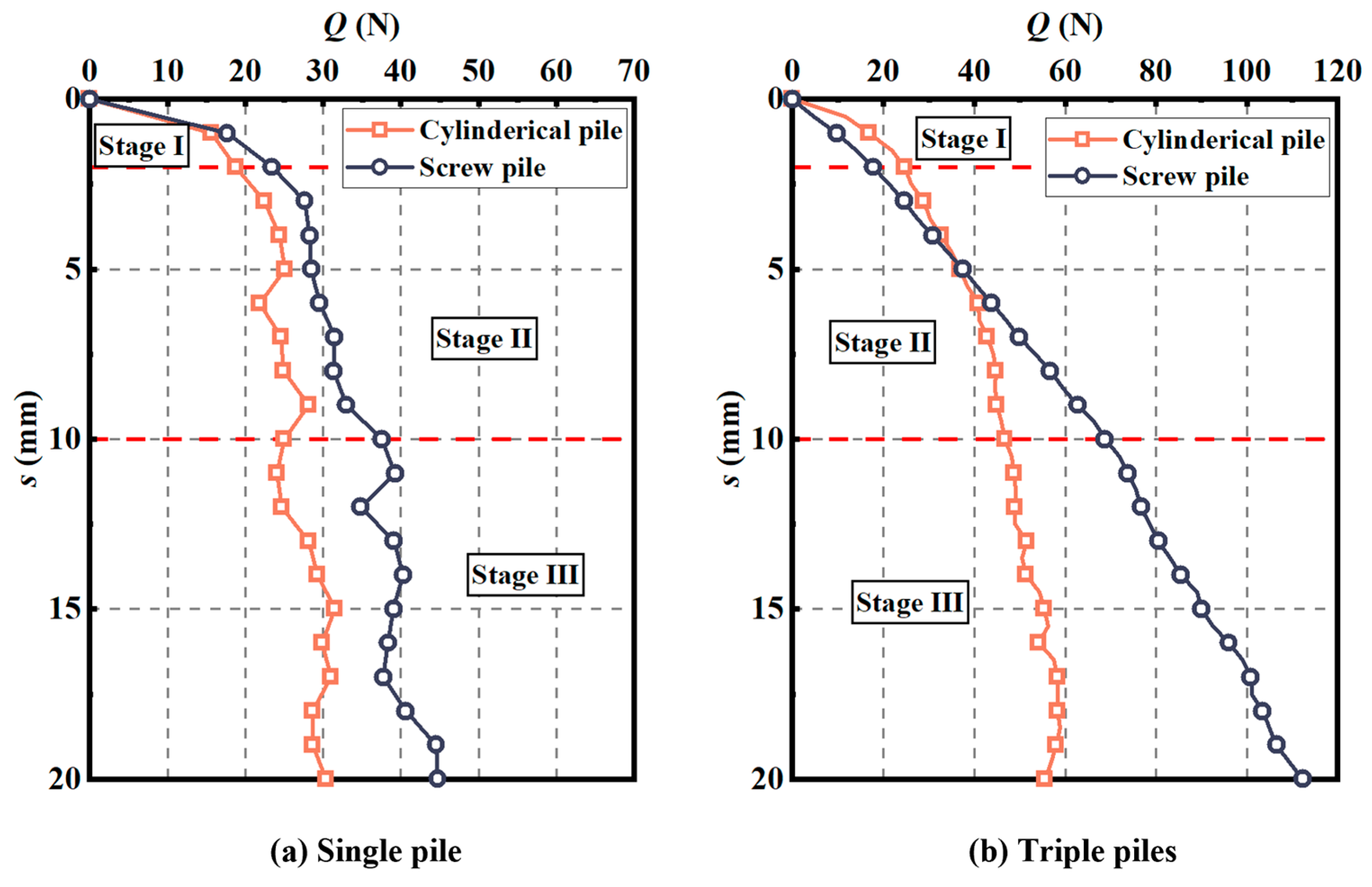

3.1.1. Load-Settlement (Q-s) Curve

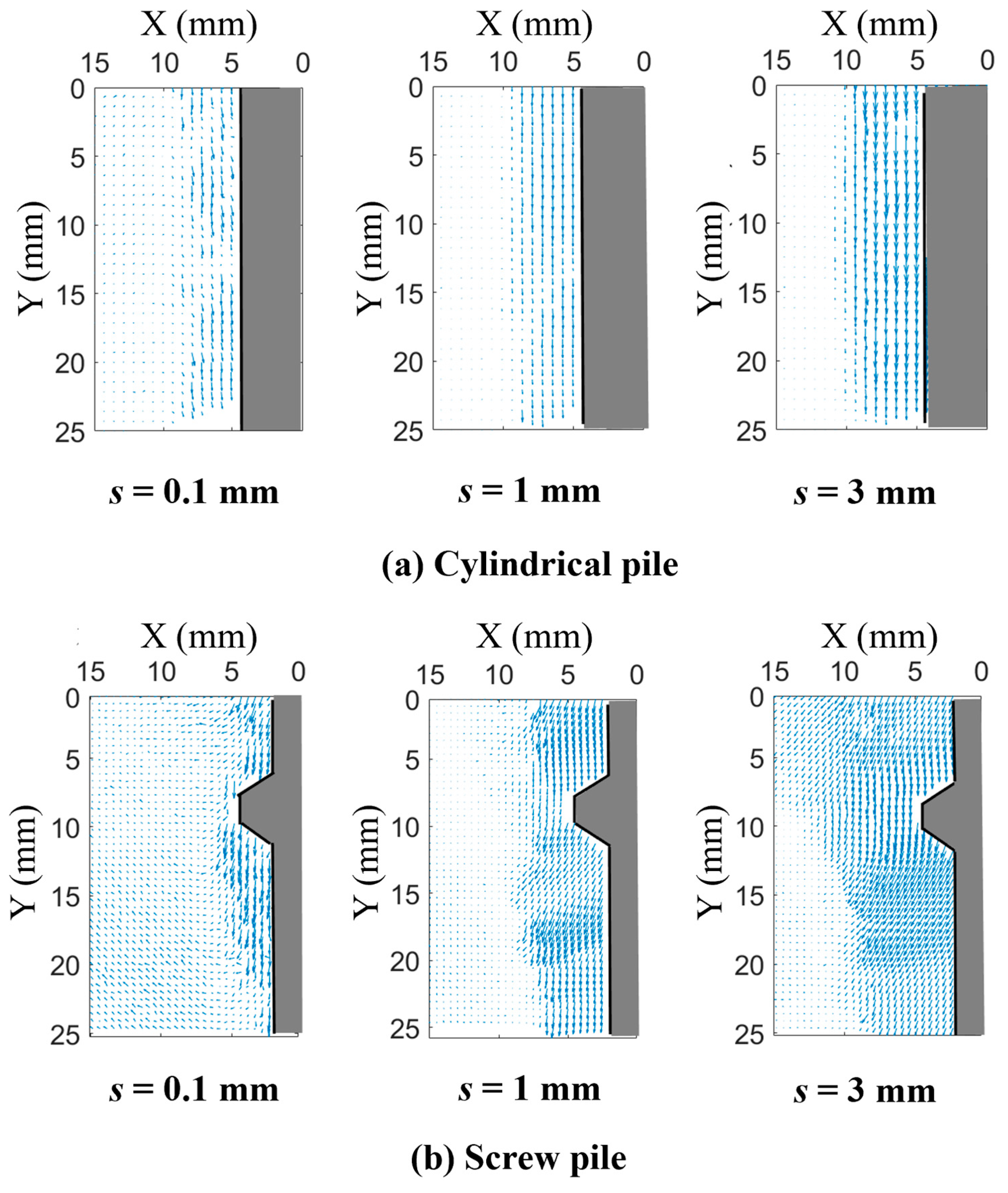

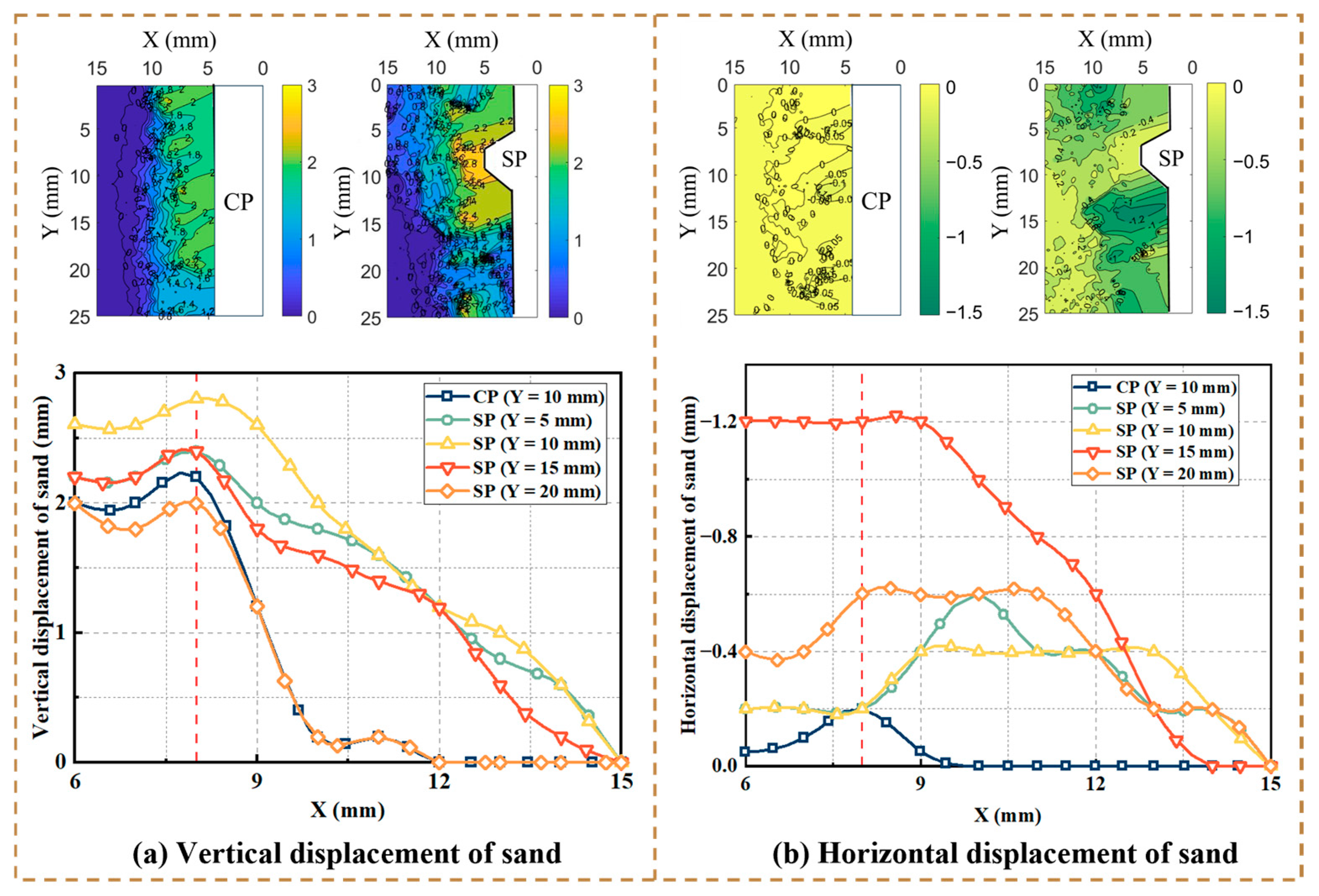

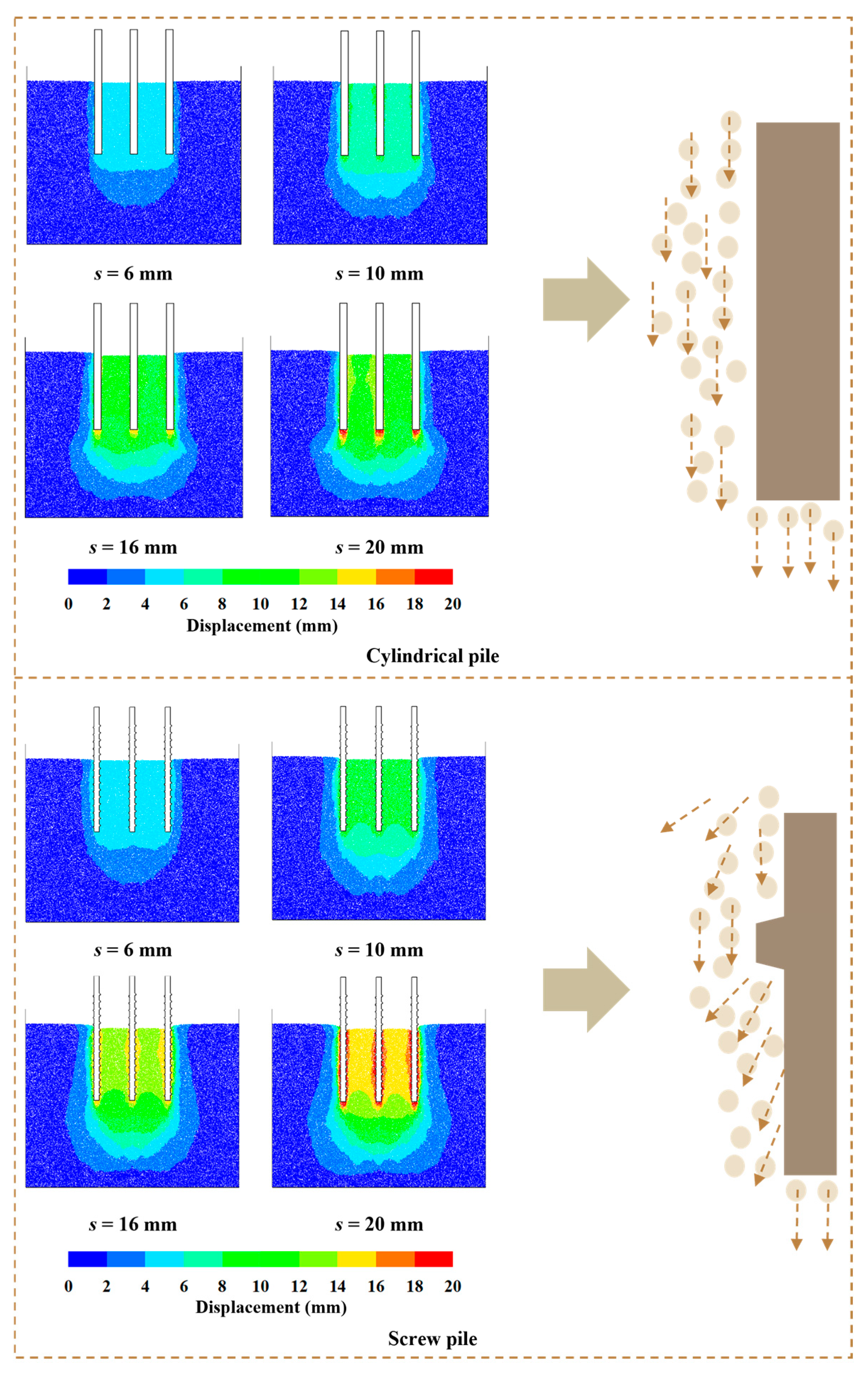

3.1.2. Displacement of Soil Around Piles

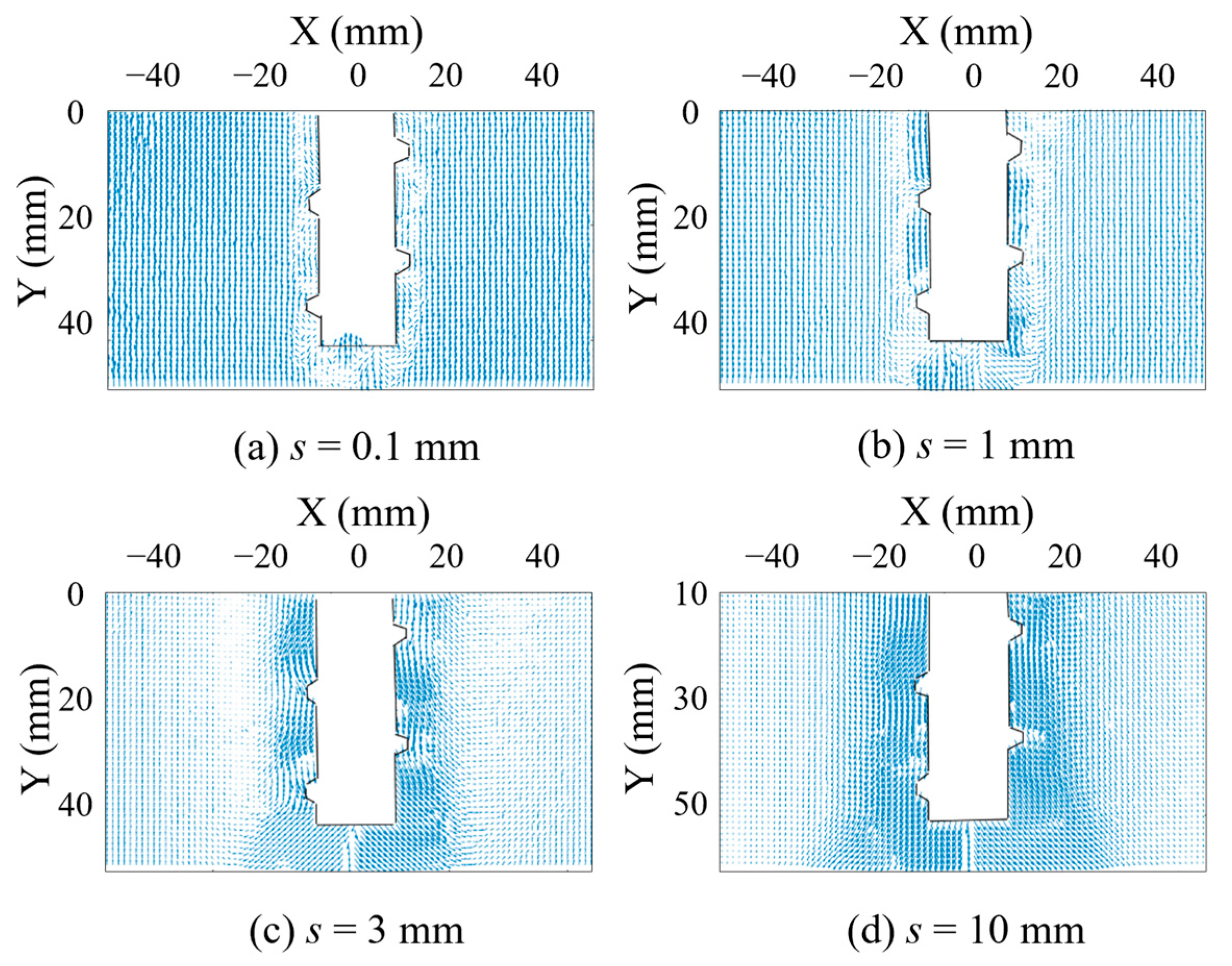

3.2. Influence of Threads

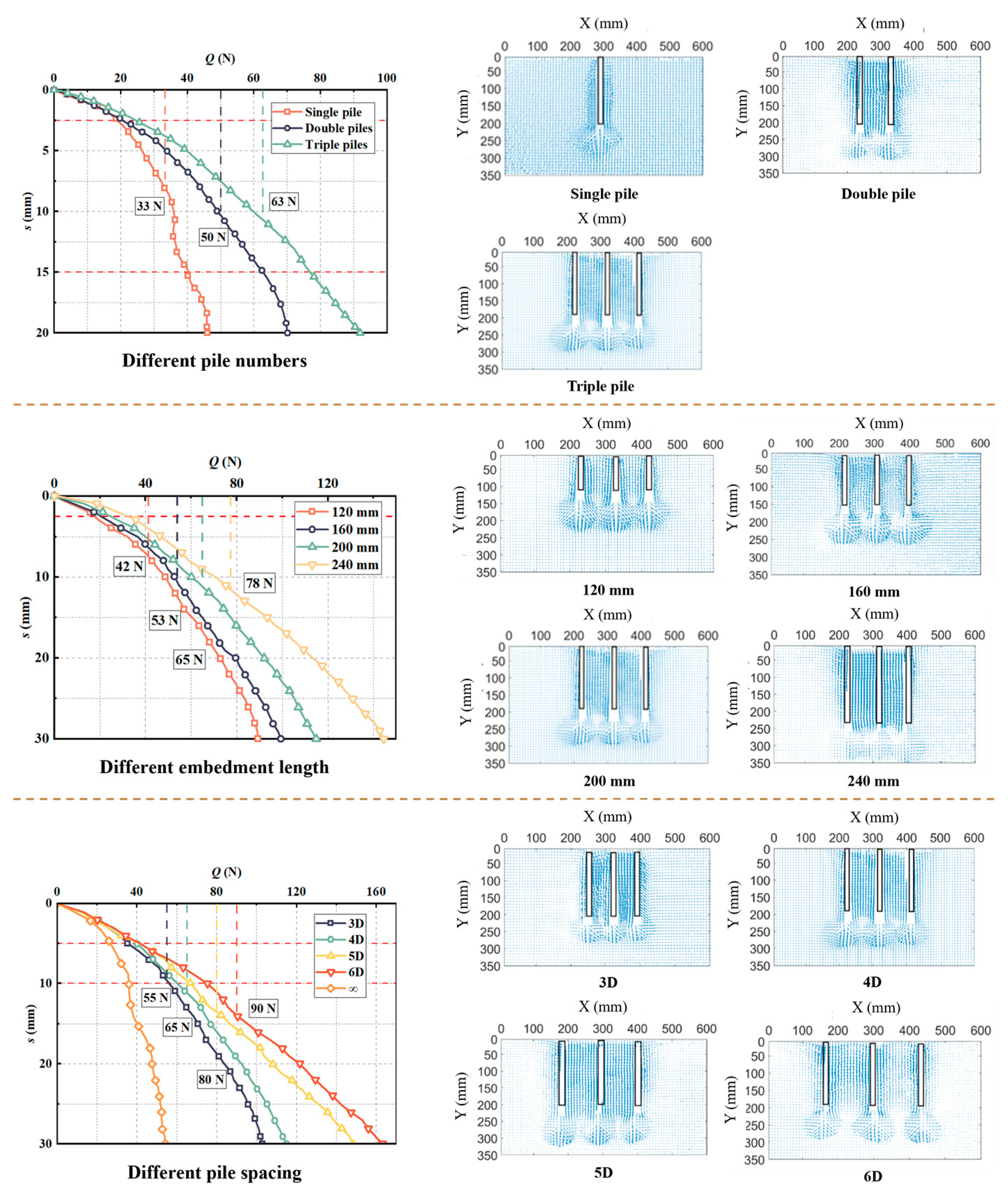

3.3. Influence of Group Effect

3.3.1. Group Effect Coefficient

3.3.2. Load-Settlement (Q-s) Curve

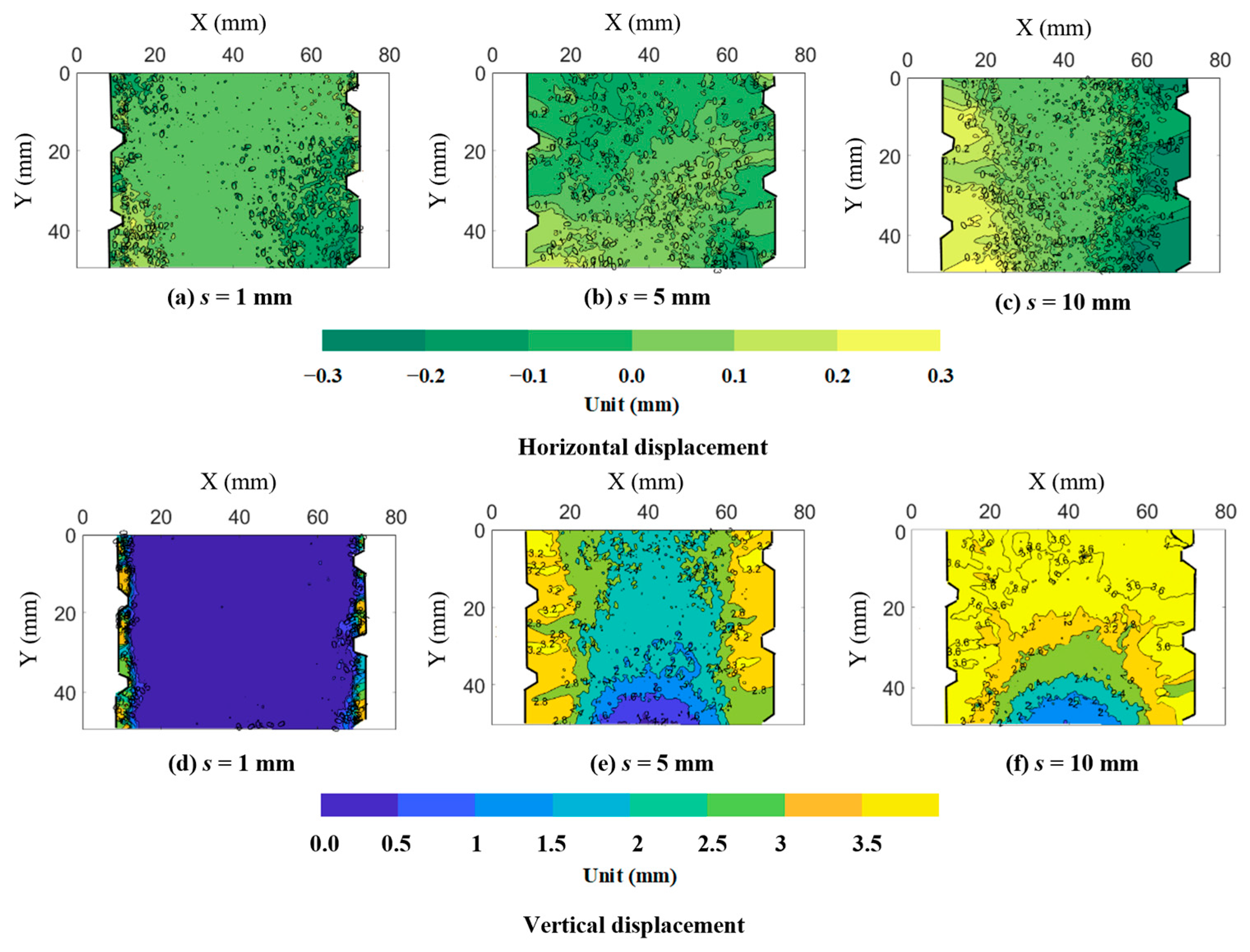

3.3.3. Local Displacement Field

4. Numerical Simulation

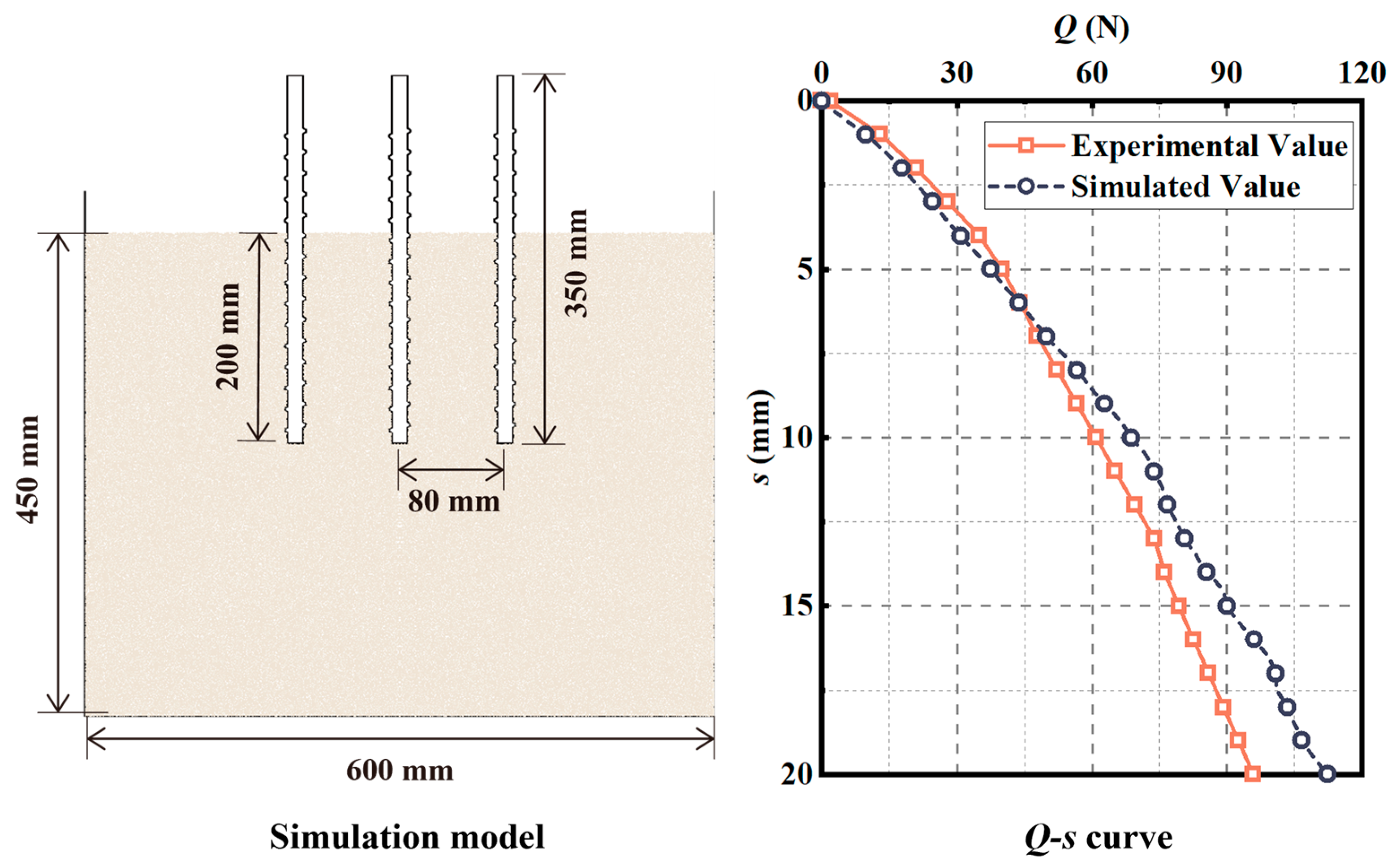

4.1. Model Setup

4.2. Validation Analysis

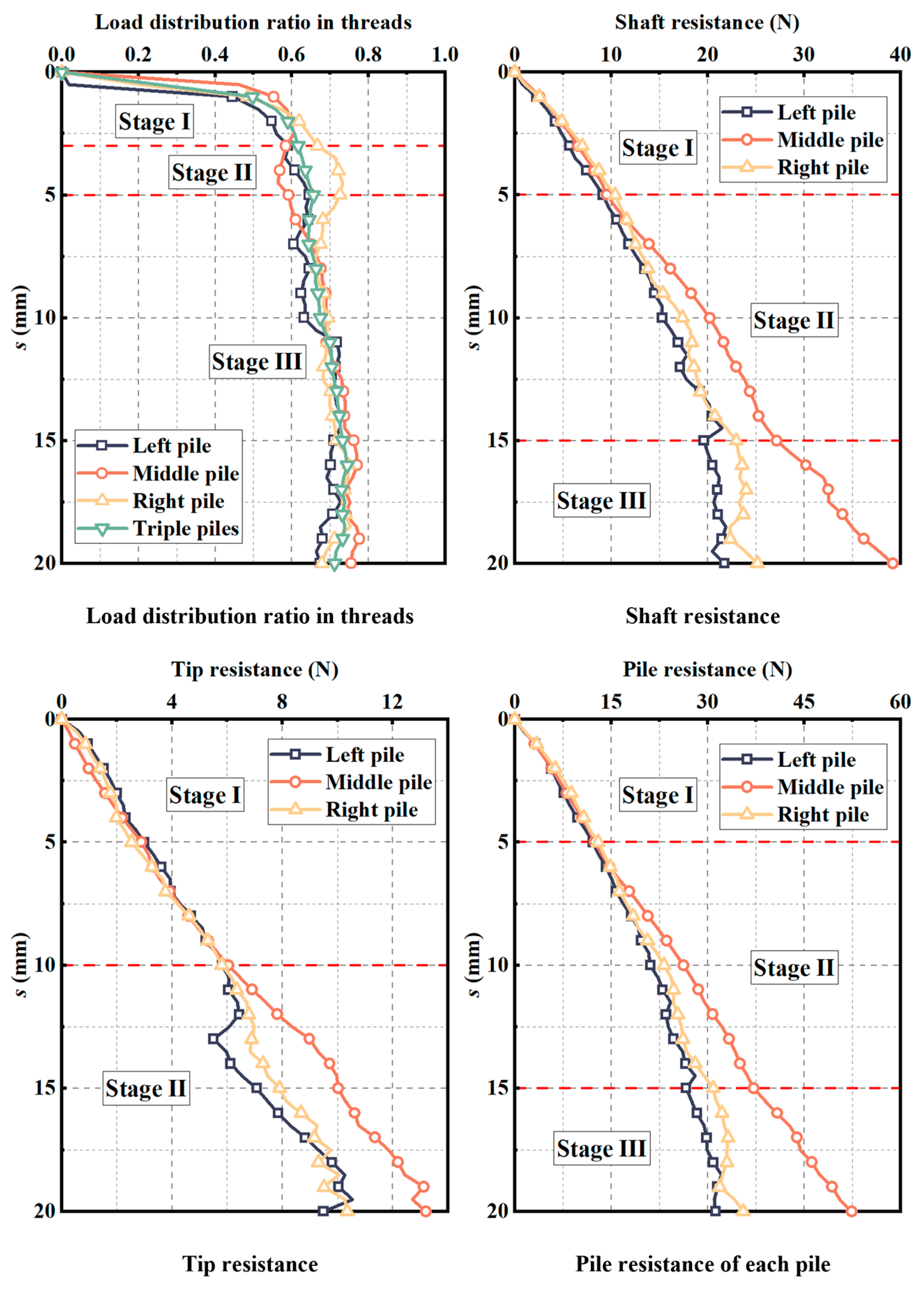

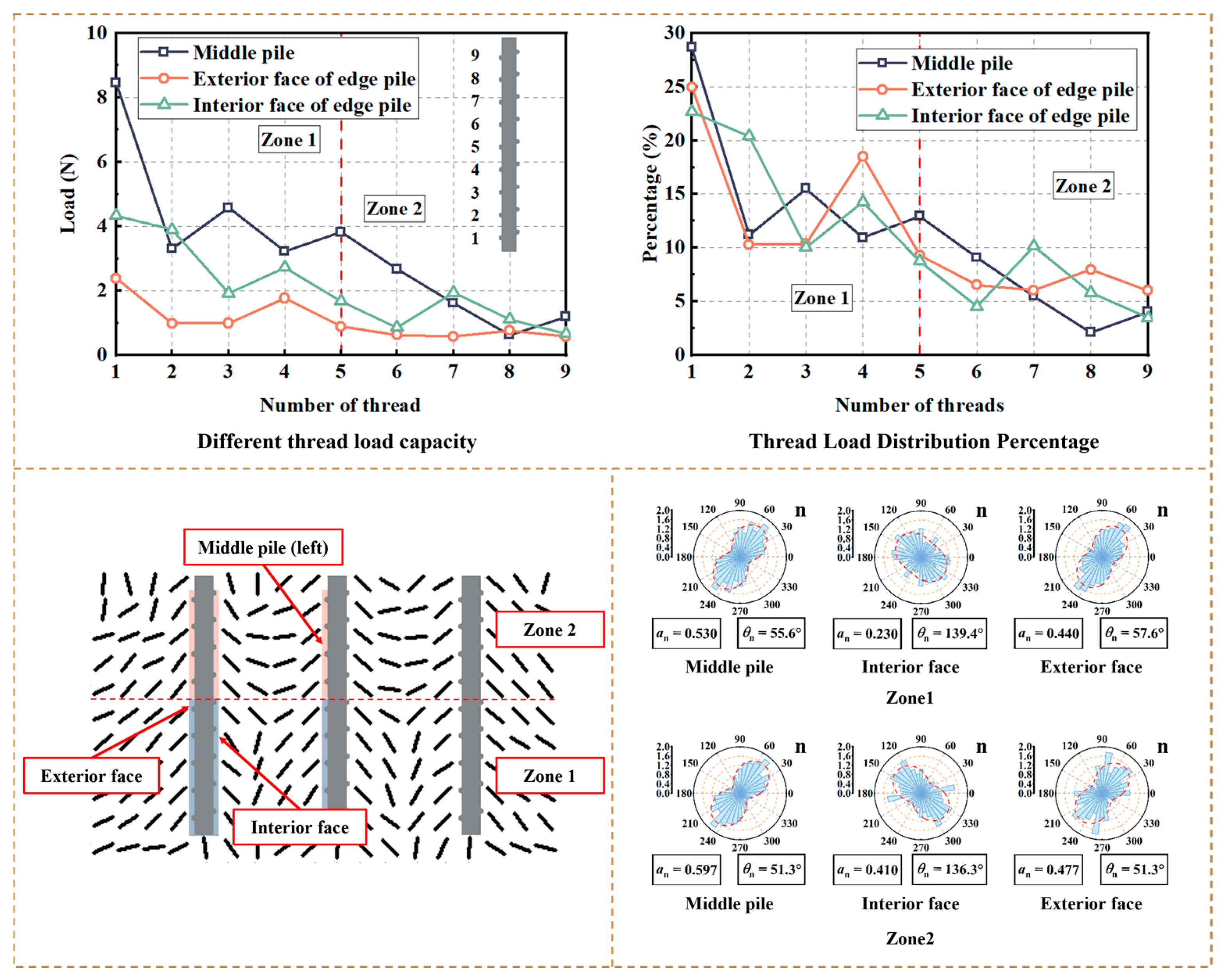

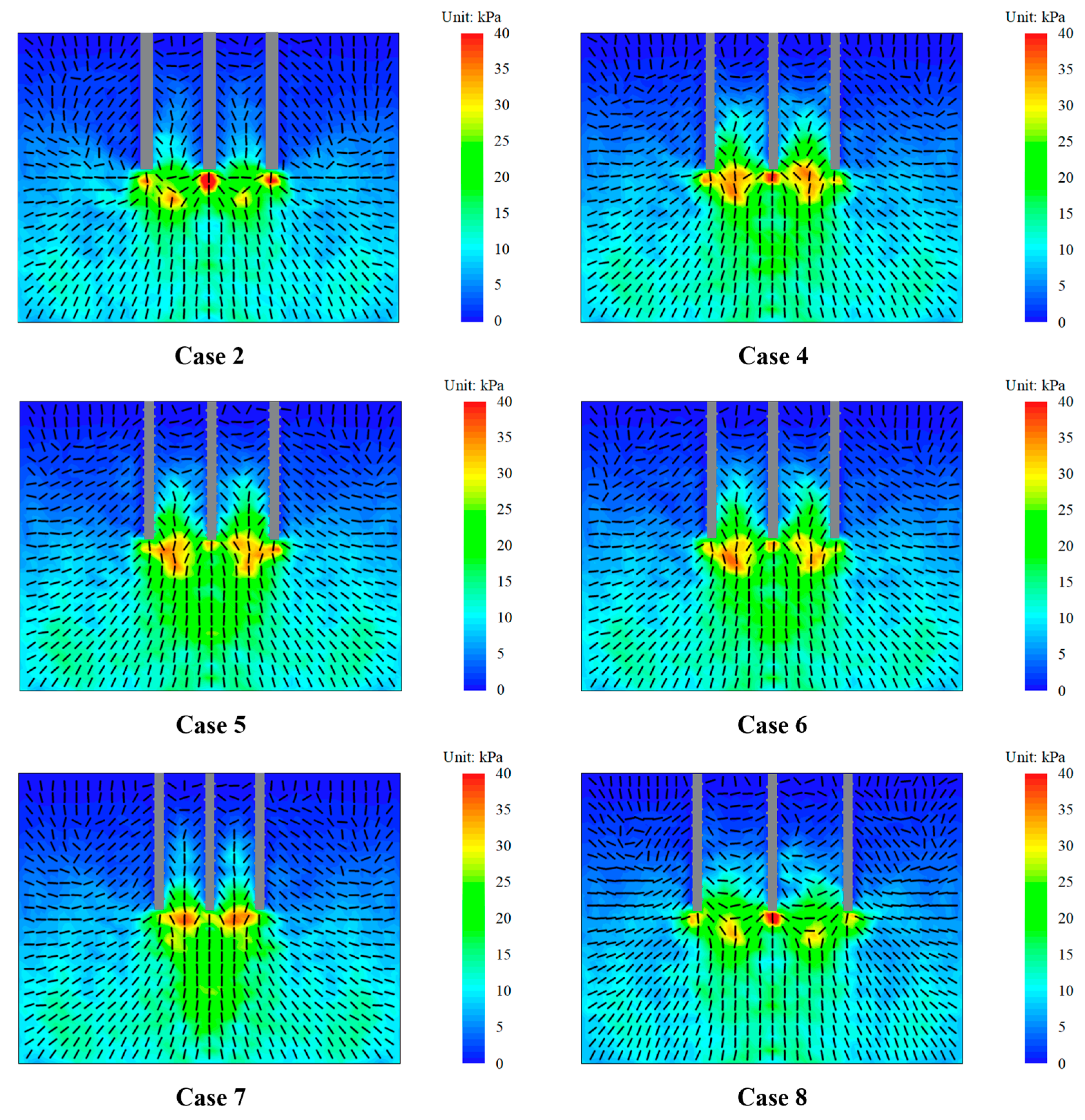

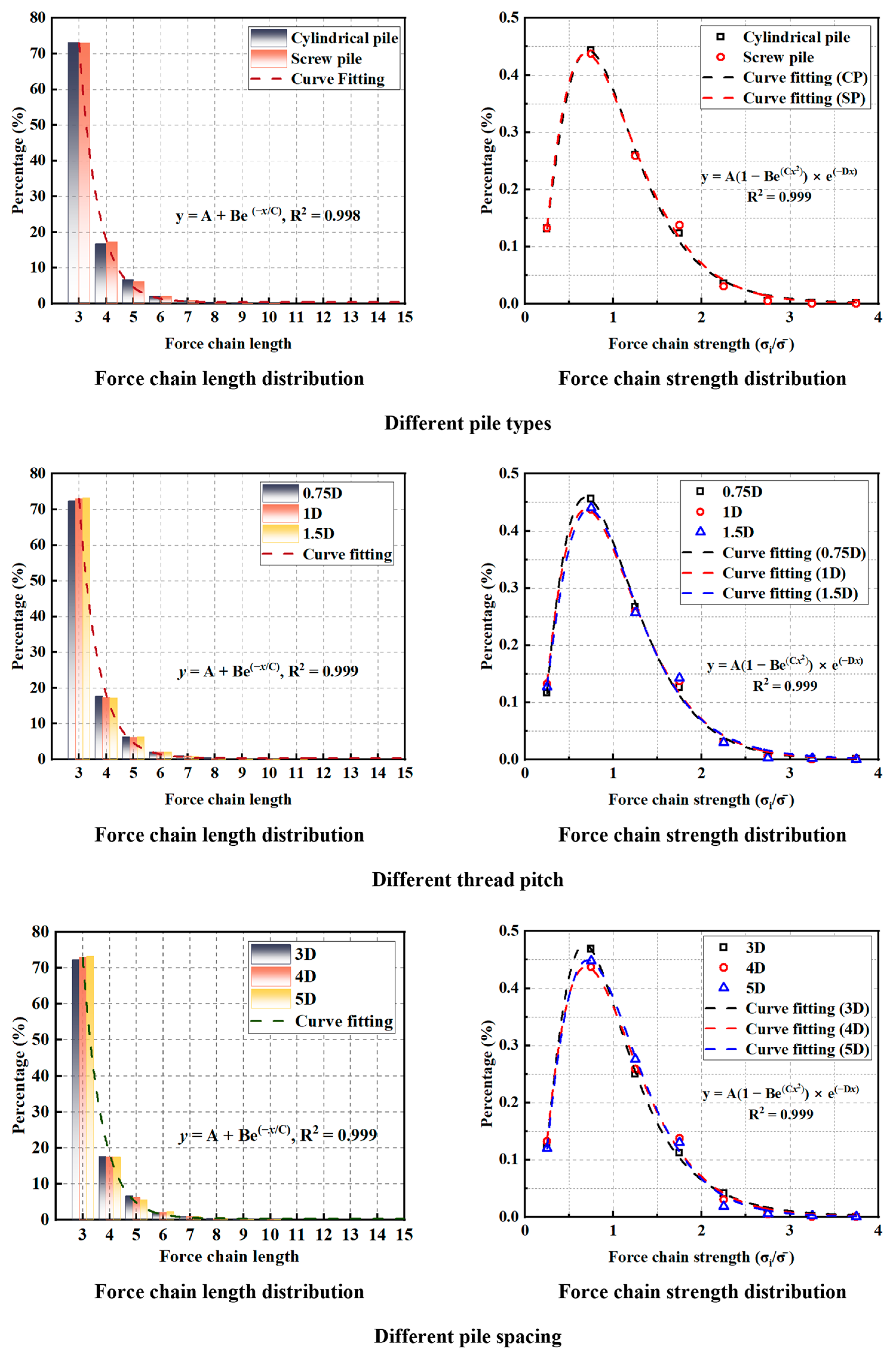

4.3. Mesoscopic Mechanism Analysis

5. Conclusions

- (1)

- The unique load-transfer mechanism of screw piles was attributed to its threads, which was the fundamental reason for its higher pile resistance than unthreaded piles. The ultimate bearing capacity of a single screw pile was approximately 50% higher than that of a cylindrical pile with the same outer diameter and length (33 N compared to 22 N at an embedment length of 200 mm). For pile groups, the group effect coefficient of a triple-pile group composed of screw piles was 0.64, while that of cylindrical piles was 0.55.

- (2)

- DEM simulations revealed the intrinsic mechanism of this phenomenon at the mesoscopic level, indicating that the pile installation process could be divided into three stages. At the initial stage of loading, large principal stress concentrated at the root of the threads, forming a logarithmic spiral-shaped local shear band. As the load increased, individual shear bands merged along the pile body, creating a continuous spiral-shaped shear band. The direction of contact between soil particles within a region about 1D distant from the pile shaft changed from a discrete state to an oriented arrangement along the direction of the largest principal stress ().

- (3)

- The pile resistance of the pile group was related to the embedment length and the pile spacing. Increasing the embedment length from 120 mm to 240 mm resulted in an 85% increase in the ultimate bearing capacity of the triple-pile group. Increasing the pile spacing from 3D to 6D increased the ultimate bearing capacity by 64%, and the group effect coefficient increased from 0.56 to 0.91. According to the DEM model, the pile resistance was influenced by the interaction of soil particles between screw piles.

- (4)

- Increasing the pitch from 0.75D to 1.5D resulted in an approximately 28% increase in the area of high-stress regions (>20 kPa), reducing stress concentration. By comparing the pile resistance of each pile within a screw pile group with the contact anisotropy of soil, it can be seen that there was a positive correlation between the pile resistance and the contact anisotropy strength , and a negative correlation between the pile resistance and the contact normal direction .

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Akbari, P.; Patel, H. A review on analysis and design of pile foundation concealing different soil layers. Int. J. Eng. Dev. Res. 2020, 8, 513–516. [Google Scholar]

- Kaladi, F.; Wang, F.; Kherazi, F.Z. Structural Stability: A Comprehensive Review of Pile Foundations in Construction. J. Asian Dev. Stud. 2023, 12, 412–425. [Google Scholar] [CrossRef]

- Yang, T.; Zheng, W.; Xie, Y.; Zhang, H.; Yue, X. Evaluating screw-shaft pile composite foundations in round Gravelly soil: A study using model tests and numerical simulations. Heliyon 2023, 9, e20887. [Google Scholar] [CrossRef] [PubMed]

- Suleiman, M.T.; Vande Voort, T.; Sritharan, S. Behavior of driven ultrahigh-performance concrete H-piles subjected to vertical and lateral loadings. J. Geotech. Geoenviron. Eng. 2010, 136, 1403–1413. [Google Scholar] [CrossRef]

- Chen, Y.; Deng, A.; Wang, A.; Sun, H. Performance of screw-shaft pile in sand: Model test and DEM simulation. Comput. Geotech. 2018, 104, 118–130. [Google Scholar] [CrossRef]

- Zhang, S.; Xing, Y.; Xin, G.; Chen, G.; Long, G.; Ma, P.; Han, J. Study on the Bearing Characteristics and the Influence of Pile Characteristics of Rotary Drilling Screw-Shaped Pile. Buildings 2024, 14, 3810. [Google Scholar] [CrossRef]

- Ma, J.; Luo, L.; Mu, T.; Guo, H.; Tang, Y. Experimental study on characteristics of pile-soil interaction in screw piles. Buildings 2022, 12, 2091. [Google Scholar] [CrossRef]

- Ding, P.; Liu, Y.; Shi, C.; Meng, F.; Li, W.; Deng, Z. Study on Bearing Mechanism of Steel Screw Pile. Buildings 2024, 14, 3376. [Google Scholar] [CrossRef]

- Azari, R.; Kamel, E.; Memari, A.M. Current developments and future directions in energy-efficient buildings from the perspective of building construction materials and enclosure systems. Buildings 2024, 14, 1921. [Google Scholar] [CrossRef]

- Perko, H.A. Helical Piles: A Practical Guide to Design and Installation; John Wiley & Sons: Hoboken, NJ, USA, 2009. [Google Scholar]

- Ali, O.K.; Abbas, H.O. Performance assessment of screw piles embedded in soft clay. Civ. Eng. J. 2019, 5, 1788–1798. [Google Scholar] [CrossRef]

- Ideal Foundations. Guide to Screw Piles Construction for Foundations; Ideal Foundations: Smithfield, NSW, Australia, 2025. [Google Scholar]

- Bittar, E.; Lehane, B.; Zheng, H. The role of physicochemical processes in aging of shaft friction of driven steel piles in sand. Can. Geotech. J. 2023, 61, 1873–1885. [Google Scholar] [CrossRef]

- Ho, H.M.; Malik, A.A.; Kuwano, J.; Rashid, M.A. Influence of helix bending deflection on the load transfer mechanism of screw piles in sand: Experimental and numerical investigations. Soils Found. 2021, 61, 874–885. [Google Scholar] [CrossRef]

- Avci, B.; Gurbuz, A. Modulus of subgrade reaction that varies with magnitude of displacement of cohesionless soil. Arab. J. Geosci. 2018, 11, 351. [Google Scholar] [CrossRef]

- Sahil, A.W.; Uchimura, T.; Malik, A.A.; Kabir, M.R. A Comparative Study on the End-Bearing Capacity of Toe-Wing & Spiral Screw Piles in Cohesionless Soil. Buildings 2025, 15, 525. [Google Scholar]

- Debnath, A.; Singh, V.P. Analysis and design methods of helical piles: A critical review with emphasis on finite element method. Arab. J. Geosci. 2022, 15, 1496. [Google Scholar] [CrossRef]

- Elsherbiny, Z.H.; El Naggar, M.H. Axial compressive capacity of helical piles from field tests and numerical study. Can. Geotech. J. 2013, 50, 1191–1203. [Google Scholar] [CrossRef]

- Verumandy, K.; Arulrajah, A.; Mirzababaei, M.; Rajeev, P. Static Load Testing of Instrumented Screw Piles in Soft Soil Deposits. Int. J. Geosynth. Ground Eng. 2024, 10, 10. [Google Scholar] [CrossRef]

- Sharif, Y.U.; Brown, M.J.; Cerfontaine, B.; Davidson, C.; Ciantia, M.O.; Knappett, J.A. Effects of screw pile installation on installation requirements and in-service performance using the discrete element method. Can. Geotech. J. 2021, 58, 1334–1350. [Google Scholar] [CrossRef]

- Li, L.; Wu, W.; El Naggar, M.H.; Mei, G.; Liang, R. DEM analysis of the sand plug behavior during the installation process of open-ended pile. Comput. Geotech. 2019, 109, 23–33. [Google Scholar] [CrossRef]

- Li, W.; Zhang, D.J.Y.; Sego, D.C.; Deng, L. Field testing of axial performance of large-diameter helical piles at two soil sites. J. Geotech. Geoenviron. Eng. 2018, 144, 06017021. [Google Scholar] [CrossRef]

- Schiavon, J.A.; Tsuha, C.H.C.; Neel, A.; Thorel, L. Centrifuge modelling of a helical anchor under different cyclic loading conditions in sand. Int. J. Phys. Model. Geotech. 2019, 19, 72–88. [Google Scholar] [CrossRef]

- Liu, F.; Jiang, M.; Zhu, F. Discrete element analysis of uplift and lateral capacity of a single pile in methane hydrate bearing sediments. Comput. Geotech. 2014, 62, 61–76. [Google Scholar] [CrossRef]

- Alwalan, M.F.; El Naggar, M.H. Finite element analysis of helical piles subjected to axial impact loading. Comput. Geotech. 2020, 123, 103597. [Google Scholar] [CrossRef]

- Lanyi-Bennett, S.A.; Deng, L. Axial load testing of helical pile groups in glaciolacustrine clay. Can. Geotech. J. 2019, 56, 187–197. [Google Scholar] [CrossRef]

- Tehrani, F.S.; Salgado, R.; Prezzi, M. Analysis of axial loading of pile groups in multilayered elastic soil. Int. J. Geomech. 2016, 16, 04015063. [Google Scholar] [CrossRef]

- Sales, M.M.; Prezzi, M.; Salgado, R.; Choi, Y.S.; Lee, J. Load-settlement behaviour of model pile groups in sand under vertical load. J. Civ. Eng. Manag. 2017, 23, 1148–1163. [Google Scholar] [CrossRef]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Geotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Lu, Y.E.; Tan, Y.; Li, X. Stability analyses on slopes of clay-rock mixtures using discrete element method. Eng. Geol. 2018, 244, 116–124. [Google Scholar] [CrossRef]

- Liu, F. Multi-Scale Analyses of Granular Flows for Disaster Resilience Enhancement; Georgia Institute of Technology: Atlanta, GA, USA, 2019. [Google Scholar]

- Azzam, W.R.; Elwakil, A.Z. Model study on the performance of single-finned pile in sand under tension loads. Int. J. Geomech. 2017, 17, 04016072. [Google Scholar] [CrossRef]

- JGJ/T 379-2016; Technical Specification for Screw Piles. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Architecture & Building Press: Beijing, China, 2016.

- GB/T 50145-2007; Standard for Engineering Classification of Soil. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Standard Press: Beijing, China, 2007.

- Bolton, M.D.; Gui, M.W.; Garnier, J.; Corte, J.F.; Bagge, G. Centrifuge cone penetration tests in sand. Géotechnique 1999, 49, 543–552. [Google Scholar] [CrossRef]

- JGJ106-2014; Technical Code for Testing of Building Foundation Piles. Ministry of Housing and Urban-Rural Development of the People’s Republic of China, China Architecture & Building Press: Beijing, China, 2014.

- Qu, S.; Zhang, Q.; Guo, Y. Experimental and numerical studies of the failure mode and mechanical performance of helices in screw piles. Int. J. Civ. Eng. 2024, 22, 839–857. [Google Scholar] [CrossRef]

- Poulos, H.G.; Davis, E.H. Pile Foundation Analysis and Design; John Wiley and Sons: Hoboken, NJ, USA, 1980. [Google Scholar]

- Meyerhof, G. Bearing capacity and settlement of pile foundations. J. Geotech. Eng. Div. 1976, 102, 197–228. [Google Scholar] [CrossRef]

- Vesić, A. Experiments with Instrumented Pile Groups in Sand. Performance of Deep Foundations; ASTM International: West Conshohocken, PA, USA, 1969. [Google Scholar]

- Tan, X.; Hu, Z.; Cao, M.; Chen, C. 3D discrete element simulation of a geotextile-encased stone column under uniaxial compression testing. Comput. Geotech. 2020, 126, 103769. [Google Scholar] [CrossRef]

- Liu, E.; Chen, Q.; Liu, J. Comparison of Force Chain Evolution Characteristics during the Ore Drawing Process between Shallow-hole Shrinkage Stoping and Synchronous Backfill-Shrinkage Stoping. Metal Mine 2021, 7, 73–82. [Google Scholar] [CrossRef]

| Pile Type | Pile Length | Inner Diameter | Outer Diameter | Thread Pitch | Crest Thickness | Thread Thickness | |

|---|---|---|---|---|---|---|---|

| Inner | Outer | ||||||

| L (mm) | d (mm) | D (mm) | s (mm) | B (mm) | (mm) | (mm) | |

| SP | 350.0 | 15.0 | 20.0 | 20.0 | 2.5 | 5.0 | 2.5 |

| CP | 350.0 | - | 20.0 | - | - | - | - |

| Pile Embedment Length/mm | Pile Spacing | |

|---|---|---|

| Single pile (CP and SP) | 120 | - |

| 160 | ||

| 200 | ||

| 240 | ||

| Double piles (SP) | 200 | 4D |

| Triple piles (SP) | 120 | |

| 160 | ||

| 200 | ||

| 240 | ||

| 200 | 3D | |

| 5D | ||

| 6D |

| Parameters | Soil Sample | Pile |

|---|---|---|

| PFC model objects | Ball | Wall |

| Density (kg⋅m−3) | 2650 | - |

| Effective modulus (Pa) | 1 × 106 | 1 × 106 |

| Stiffness ratio | 1.214 | 1.214 |

| Ball-ball friction coefficient | 0.65 | - |

| Ball-wall friction coefficient | - | 0.25 |

| Rotational friction coefficient | 0.1 | 0.1 |

| Case | Pile Type | Pile Number | Pile Spacing | Thread Pitch |

|---|---|---|---|---|

| 1 | Cylindrical pile | 1 | - | - |

| 2 | 3 | 4D | ||

| 3 | Screw pile | 1 | - | 1D |

| 4 | 3 | 4D | ||

| 5 | 0.75D | |||

| 6 | 1.5D | |||

| 7 | 3D | 1D | ||

| 8 | 5D |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, F.; Lu, Y.; Yang, J. Multi-Scale Investigation on Bearing Capacity and Load-Transfer Mechanism of Screw Pile Group via Model Tests and DEM Simulation. Buildings 2025, 15, 3581. https://doi.org/10.3390/buildings15193581

Bai F, Lu Y, Yang J. Multi-Scale Investigation on Bearing Capacity and Load-Transfer Mechanism of Screw Pile Group via Model Tests and DEM Simulation. Buildings. 2025; 15(19):3581. https://doi.org/10.3390/buildings15193581

Chicago/Turabian StyleBai, Fenghao, Ye Lu, and Jiaxiang Yang. 2025. "Multi-Scale Investigation on Bearing Capacity and Load-Transfer Mechanism of Screw Pile Group via Model Tests and DEM Simulation" Buildings 15, no. 19: 3581. https://doi.org/10.3390/buildings15193581

APA StyleBai, F., Lu, Y., & Yang, J. (2025). Multi-Scale Investigation on Bearing Capacity and Load-Transfer Mechanism of Screw Pile Group via Model Tests and DEM Simulation. Buildings, 15(19), 3581. https://doi.org/10.3390/buildings15193581