Hygrothermal Performance of Thermal Plaster Used as Interior Insulation: Identification of the Most Impactful Design Conditions

Abstract

1. Introduction

2. Materials and Methods

2.1. Laboratory Measurements and Data Processing for Building Hygrothermal Simulations

2.2. Hygrothermal Simulations and Simulated Variants

2.3. Results Analysis

3. Results and Discussion

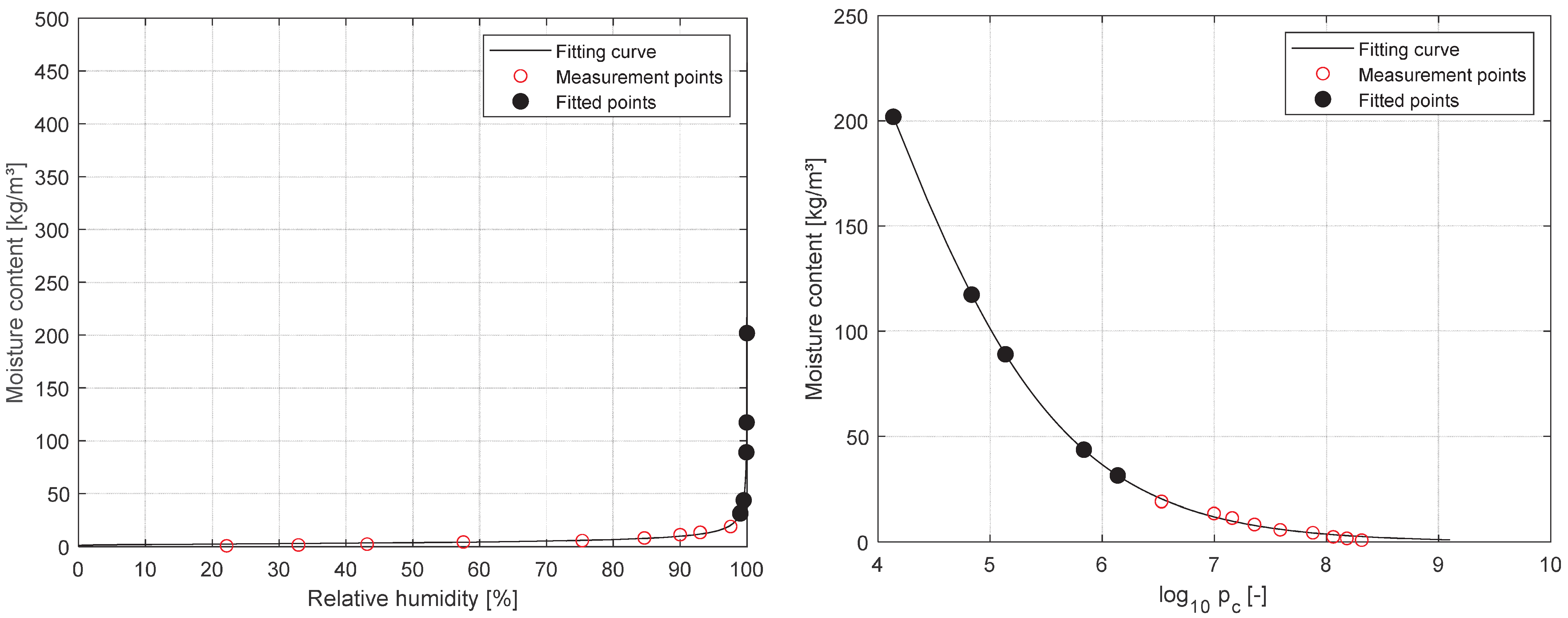

3.1. Laboratory Measurements and Data Processing for Building Hygrothermal Simulations

3.2. Simulation Results

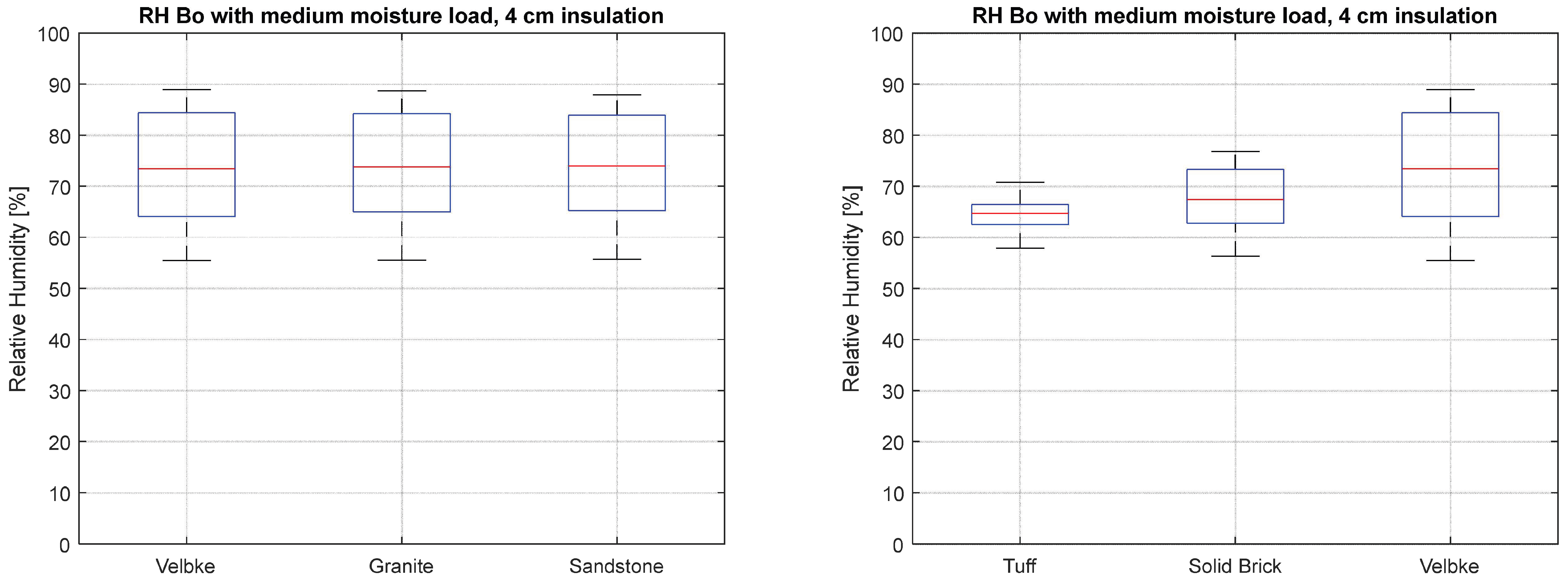

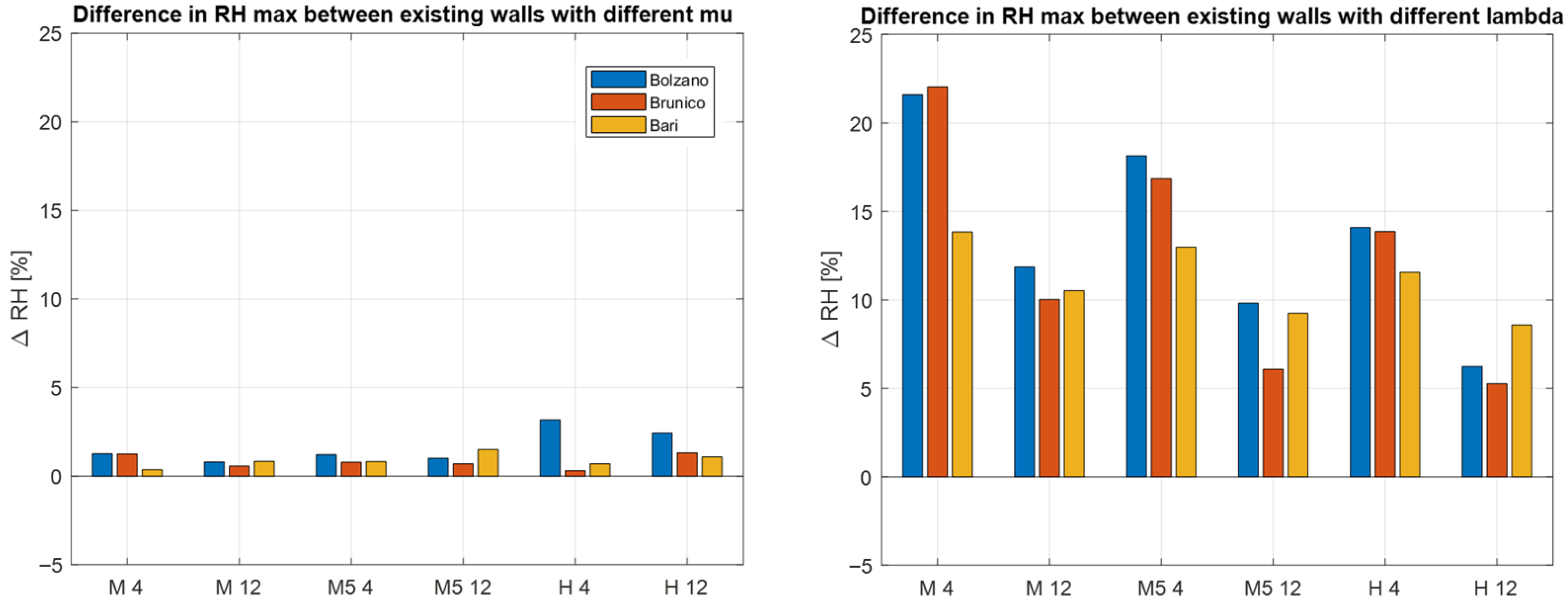

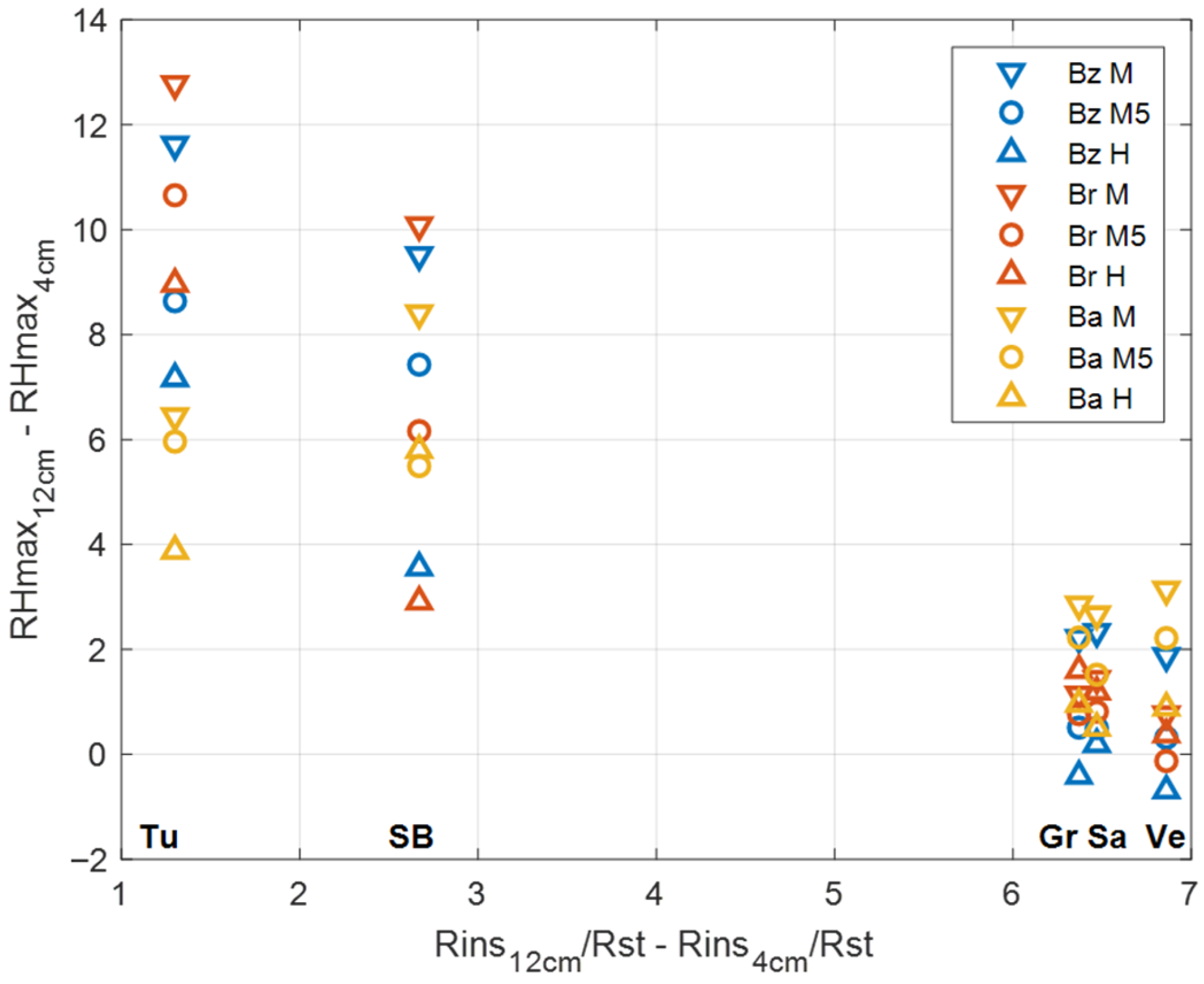

3.3. Influence of the Existing Wall Properties

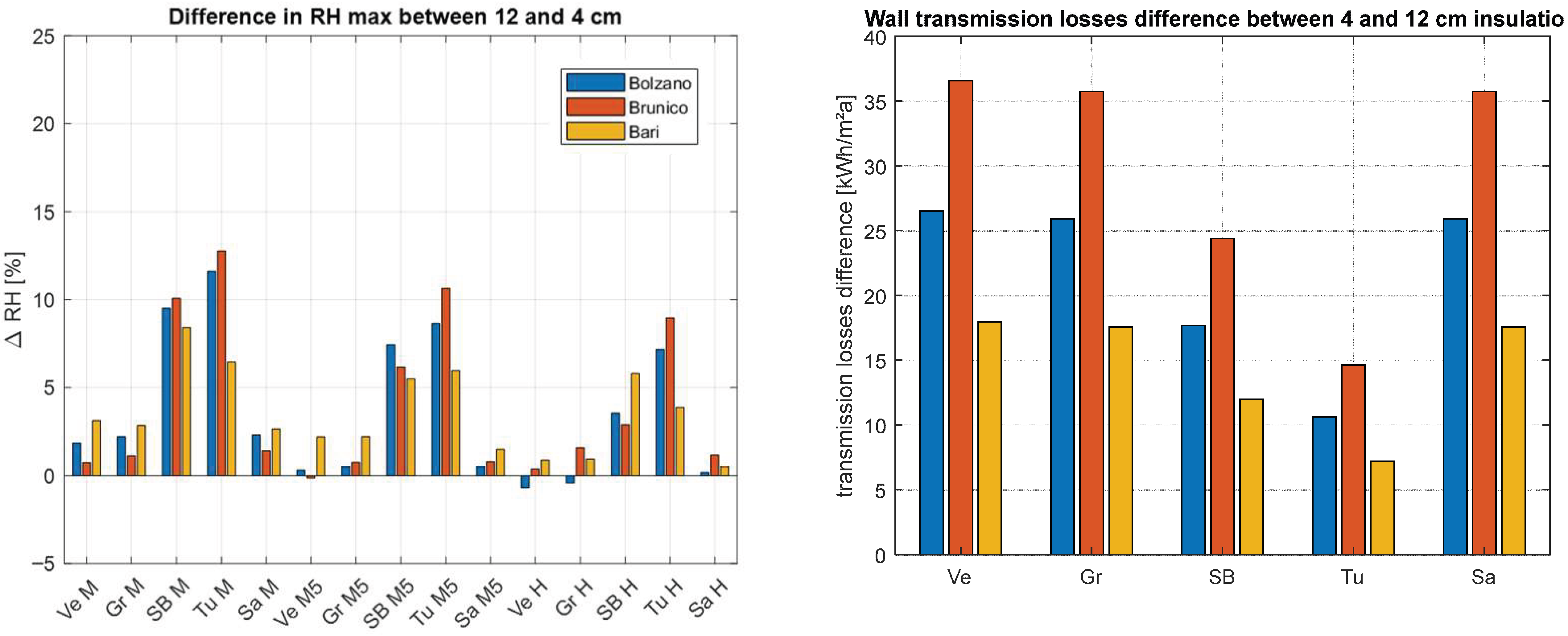

3.4. Influence of Insulation Thickness

3.5. Influence of Internal Moisture Loads

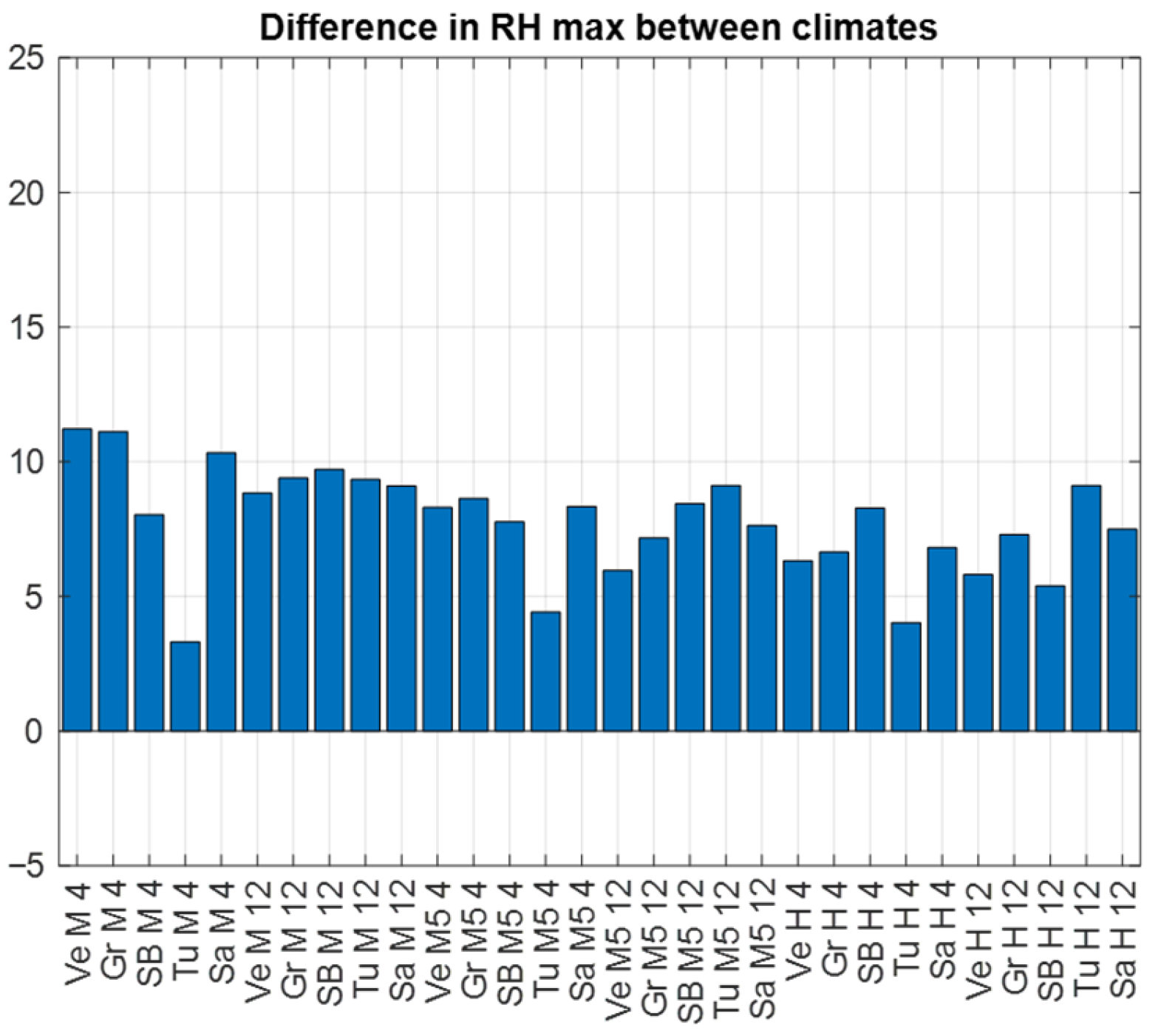

3.6. Influence of External Climate

3.7. Discussion of the Influence of the Different Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Nomenclature

| [kg/(m2s0.5)] | Water uptake coefficient by partial immersion | |

| [J/kgK] | Specific heat capacity | |

| [J/(m3K)] | Volumetric heat capacity | |

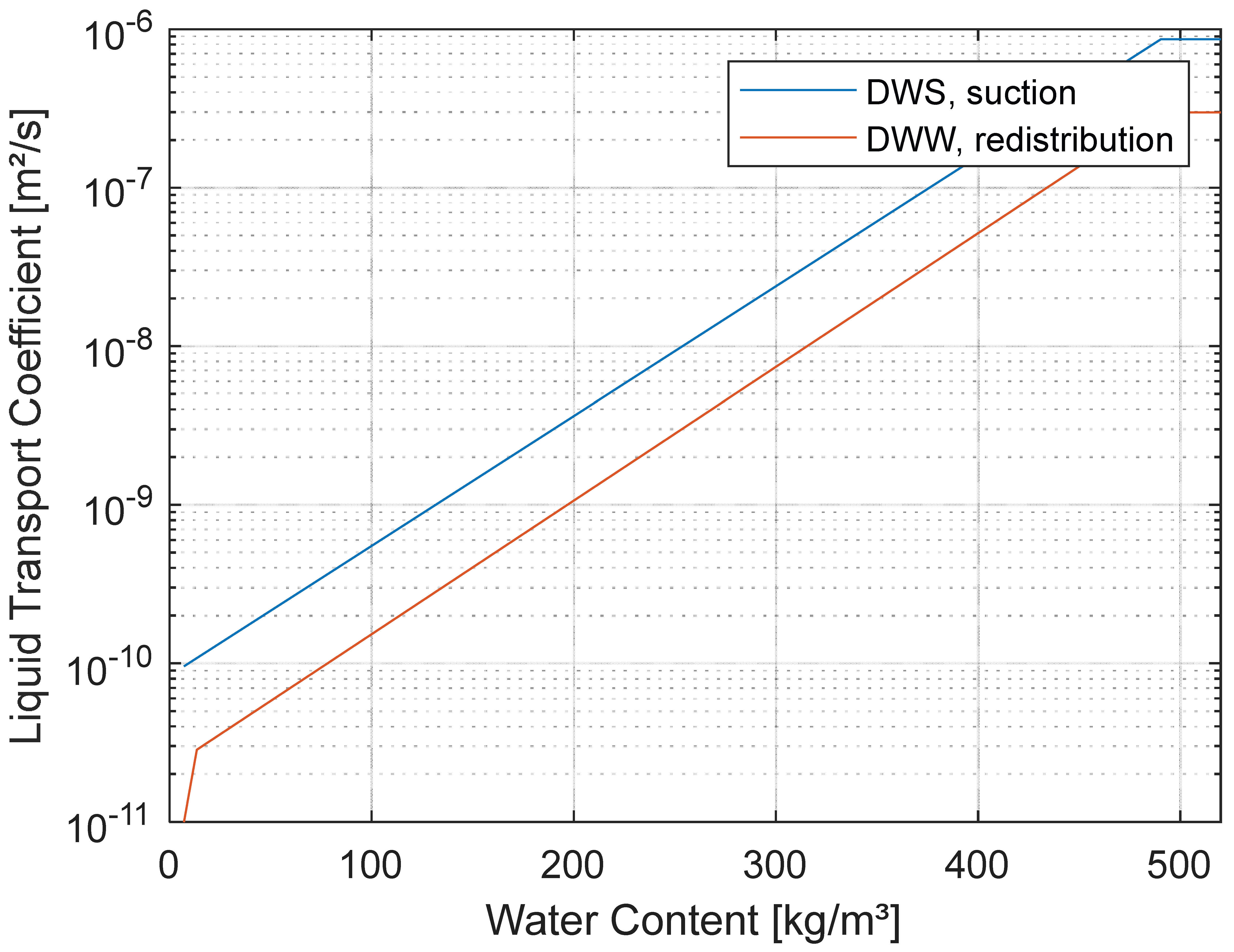

| [m2/s] | Liquid transport coefficient for suction as a function of water content | |

| [m2/s] | Liquid transport coefficient for redistribution as a function of water content | |

| [Pa] | Capillary pressure | |

| [Pa] | Fitting parameter 1 | |

| [-] | Fitting parameter 2 | |

| [J/(kg K)] | Gas constant of water vapor | |

| [K] | Absolute temperature | |

| [-] | Moisture storage function | |

| [kg/m3] | Water content as a function of the capillary pressure pc | |

| [kg/m3] | Water content at free saturation | |

| [W/(mK)] | Thermal conductivity | |

| [kg/m3] | Bulk density | |

| [kg/m3] | True density | |

| [kg/m3] | Density of water | |

| [-] | Porosity | |

| [-] | Relative humidity (RH [%]) |

References

- Wedebrunn, O. Energy Efficiency Solutions for Historic Buildings; A Handbook; Birkhäuser: Basel, Switzerland, 2015. [Google Scholar]

- Blumberga, A.; Freimanis, R.; Biseniece, E.; Kamenders, A. Hygrothermal Performance Evaluation of Internally Insulated Historic Stone Building in a Cold Climate. Energies 2023, 16, 866. [Google Scholar] [CrossRef]

- Vereecken, E.; Roels, S. Capillary Active Interior Insulation Systems for Wall Retrofitting: A More Nuanced Story. Int. J. Archit. Herit. 2016, 10, 558–569. [Google Scholar] [CrossRef]

- Kassim, M.; Aslani, A.; Zahedi, R. Energy Performance Analysis of Thermal Insulating Plaster in the Different Climate Zones. Therm. Sci. Eng. Prog. 2024, 47, 102294. [Google Scholar] [CrossRef]

- Marincioni, V.; Gori, V.; de Place Hansen, E.J.; Herrera-Avellanosa, D.; Mauri, S.; Giancola, E.; Egusquiza, A.; Buda, A.; Leonardi, E.; Rieser, A. How Can Scientific Literature Support Decision-Making in the Renovation of Historic Buildings? An Evidence-Based Approach for Improving the Performance of Walls. Sustainability 2021, 13, 2266. [Google Scholar] [CrossRef]

- Zhou, X.; Carmeliet, J.; Derome, D. Assessment of Moisture Risk of Wooden Beam Embedded in Internally Insulated Masonry Walls with 2D and 3D Models. Build. Environ. 2021, 193, 107460. [Google Scholar] [CrossRef]

- Barbero, S.; Dutto, M.; Ferrua, C.; Pereno, A. Analysis on Existent Thermal Insulating Plasters towards Innovative Applications: Evaluation Methodology for a Real Cost-Performance Comparison. Energy Build. 2014, 77, 40–47. [Google Scholar] [CrossRef]

- Freimanis, R.; Vanaga, R.; Balodis, V.; Zundans, Z.; Blumberga, A. Hygrothermal Assessment of Insulation Systems for Internal Insulation of Solid Masonry Walls under Various Conditions. Buildings 2023, 13, 2511. [Google Scholar] [CrossRef]

- Vereecken, E.; Van Gelder, L.; Janssen, H.; Roels, S. Interior Insulation for Wall Retrofitting—A Probabilistic Analysis of Energy Savings and Hygrothermal Risks. Energy Build. 2015, 89, 231–244. [Google Scholar] [CrossRef]

- Pagoni, P.; Møller, E.B.; Peuhkuri, R.H. Decisive Parameters for Moisture Safe Internal Insulation of Masonry—Long Time Monitoring in Inhabited Dwellings. Energy Build. 2024, 312, 114180. [Google Scholar] [CrossRef]

- Losini, A.E.; Woloszyn, M.; Chitimbo, T.; Pelé-Peltier, A.; Ouertani, S.; Rémond, R.; Doya, M.; Gaillard, D.; Force, M.S.; Outin, J.; et al. Extended Hygrothermal Characterization of Unstabilized Rammed Earth for Modern Construction. Constr. Build. Mater. 2023, 409, 133904. [Google Scholar] [CrossRef]

- Mahmood, O.; Kavgic, M.; Noel, M. Hygrothermal and Mechanical Characterization of Novel Hemp-Lime Composites with Enhanced Consistency. Constr. Build. Mater. 2024, 450, 138720. [Google Scholar] [CrossRef]

- Maaroufi, M.; Belarbi, R.; Abahri, K.; Benmahiddine, F. Full Characterization of Hygrothermal, Mechanical and Morphological Properties of a Recycled Expanded Polystyrene-Based Mortar. Constr. Build. Mater. 2021, 301, 124310. [Google Scholar] [CrossRef]

- Nielsen, A. Use of Sensitivity Analysis to Evaluate Hygrothermal Conditions in Solid Brick Walls with Interior Insulations; Kyoto University: Kyoto, Japan, 2012. [Google Scholar]

- Hagentoft, C.-E. Probabilistic Analysis of Hygrothermal Conditions and Mould Growth Potential in Cold Attics. Impact of Weather, Building System and Construction Design Characteristics. In Proceedings of the International Conference on Durability of Building Materials and Components, Porto, Portugal, 29 June–2 July 2021. [Google Scholar]

- Jensen, N.F.; Bjarløv, S.P.; Rode, C.; Møller, E.B. Hygrothermal Assessment of Four Insulation Systems for Interior Retrofitting of Solid Masonry Walls through Calibrated Numerical Simulations. Build. Environ. 2020, 180, 107031. [Google Scholar] [CrossRef]

- Zeng, L.; Chen, Y.; Cao, C.; Lv, L.; Gao, J.; Li, J.; Zhang, C. Influence of Materials’ Hygric Properties on the Hygrothermal Performance of Internal Thermal Insulation Composite Systems. Energy Built Environ. 2023, 4, 315–327. [Google Scholar] [CrossRef]

- Marincioni, V.; Marra, G.; Altamirano-Medina, H. Development of Predictive Models for the Probabilistic Moisture Risk Assessment of Internal Wall Insulation. Build. Environ. 2018, 137, 257–267. [Google Scholar] [CrossRef]

- Panico, S.; Larcher, M.; Marincioni, V.; Troi, A.; Baglivo, C.; Congedo, P.M. Identifying Key Parameters through a Sensitivity Analysis for Realistic Hygrothermal Simulations at Wall Level Supported by Monitored Data. Build. Environ. 2023, 229, 109969. [Google Scholar] [CrossRef]

- Xing-guo, G.; Hongtao, L.; Jingxin, Z.; Xiang-wei, L.; Guo-jie, C. Sensitivity Analysis Applied to Hygrothermal Simulation of a Brick Building in Hot and Humid Climate. Procedia Eng. 2017, 205, 665–671. [Google Scholar] [CrossRef]

- Lengsfeld, K.; Raumklima, A.; Holm, K.A. Entwicklung Und Validierung Einer Hygrothermischen Raumklima-Simulationssoftware WUFI®-Plus. Bauphysik 2024, 29, 178–186. [Google Scholar] [CrossRef]

- Scheffler, G.A. Validation of Hygrothermal Material Modelling Under Consideration of the Hysteresis of Moisture Storage. Ph.D. Thesis, Dresden University of Technology, Dresden, Germany, 2008. [Google Scholar]

- Nolte, P.W.; Malvisalo, T.; Rimbach, A.C.; Steudel, F.; Ahrens, B.; Schweizer, S. Lock-in Thermography for the Development of New Materials. Mater. Today Proc. 2017, 4, S128–S134. [Google Scholar] [CrossRef]

- ISO 12572:2016; Hygrothermal Performance of Building Materials and Products—Determination of Water Vapour Transmission Properties—Cup Method. ISO: Geneva, Switzerland, 2016.

- Holm, A.; Kuenzel, H.M. Uncertainty Approaches for Hygrothermal Building Simulations—Drying of an AAC Flat Roof in Different Climates; IBPSA: Atlanta, GA, USA, 2001; Volume 7, pp. 949–956. [Google Scholar]

- Holm, A.H. Ermittlung der Genauigkeit von Instationären Hygrothermischen Bauteilberechnungen Mittels Eines Stochastischen Konzeptes. Ph.D. Thesis, International Institute of Refrigeration, Paris, France, 2001. [Google Scholar] [CrossRef]

- Künzel, H. Simultaneous Heat and Moisture Transport in Building Components: One-and Two-Dimensional Calculation. Eng. Environ. Sci. Phys. 1995. Available online: https://publica-rest.fraunhofer.de/server/api/core/bitstreams/74f34b4c-4876-4a9b-ac87-f7476d48ca60/content (accessed on 22 September 2025).

- EN ISO 15148:2002; Hygrothermal Performance of Building Materials and Products—Determination of Water Absorption Coefficient by Partial Immersion. ISO: Geneva, Switzerland, 2002.

- Fraunhofer IBP Liquid Transport Coefficient. Available online: https://www.wufi-wiki.com/mediawiki/index.php/Details:LiquidTransportCoefficients (accessed on 20 February 2025).

- Rieser, A.; Herrera-Avellanosa, D.; Leonardi, E.; Larcher, M.; Pfluger, R. Experimental Measurement of Material’s Drying Coefficient for Internal Insulation: New Approaches for Laboratory Testing. IOP Conf. Ser. Earth Environ. Sci. 2021, 863, 012048. [Google Scholar] [CrossRef]

- EN 15026:2023; Hygrothermal Performance of Building Components and Building Elements—Assessment. BSI: Bonn, Germany, 2023.

- Fenoglio, E.; Fantucci, S.; Serra, V.; Carbonaro, C.; Pollo, R. Hygrothermal and Environmental Performance of a Perlite-Based Insulating Plaster for the Energy Retrofit of Buildings. Energy Build. 2018, 179, 26–38. [Google Scholar] [CrossRef]

- Karim, A.N.; Johansson, P.; Sasic Kalagasidis, A. Knowledge Gaps Regarding the Hygrothermal and Long-Term Performance of Aerogel-Based Coating Mortars. Constr. Build. Mater. 2022, 314, 125602. [Google Scholar] [CrossRef]

- Künzel, H.; Krus, M.; Mach, V.; Hofbauer, W.; Gabrio, T.; Löfflad, H.; Moriske, H.-J.; Ruisinger, U.; Sedlbauer, K. Calculative Prognosis of Mould Growth Risk (WTA Leeflet 6.3); 6-3-05/D; WTA Publications/Fraunhofer IRB Verlag: Munich, Germany, 2007. [Google Scholar]

- Scheffler, G.; Worch, A. Interior Insulation According to WTA II: Evaluation of Internal Insulation Systems with Numerical Design Methods (WTA Leeflet 6.5); 6–5; Committee WTA Publications/Fraunhofer IRB Verlag: Munich, Germany, 2014. [Google Scholar]

| Parameters | Variants | Number of Variants |

|---|---|---|

| Existing wall | Sandstone Velbke (Ve), granite (Gr), solid brick ARB (SB), tuff (Tu), sandstone (Sa) | 5 |

| External climate | Bolzano (Bo), Brunico (Br), Bari (Ba) (Italy) | 3 |

| Internal climate | Medium moisture load (M), medium moisture load +5% (M5), high moisture load (H) | 3 |

| Insulation thickness | 4 cm (4), 12 cm (12) | 2 |

| Material | Short Name | Source | Thermal Conductivity [W/mK] | Water Vapor Diffusion Resistance Factor [-] | Water Absorption Coefficient [kg/m2s0.5] |

|---|---|---|---|---|---|

| Granite | Gr | TU Dresden | 1.660 | 54 | 0.0086 |

| Sandstone | Sa | TU Dresden | 1.684 | 73 | 0.0816 |

| Sandstone Velbke | Ve | TU Dresden | 1.787 | 11 | 0.65 |

| Tuff | Tu | TU Dresden | 0.3382 | 10 | 0.0983 |

| Solid brick ARB | SB | TU Dresden | 0.6954 | 10 | 0.25 |

| Parameter | Bolzano | Brunico | Bari |

|---|---|---|---|

| Short name | Bo | Br | Ba |

| Mean temperature | 12.5 °C | 7.6 °C | 15.3 °C |

| Maximum temperature | 34.6 °C | 33.7 °C | 40.8 °C |

| Minimum temperature | −8.1 °C | −18.7 °C | −3.2 °C |

| Normal rain, sum | 704.6 mm/a | 622.4 mm/a | 620.4 mm/a |

| Driving rain, north | 27 mm/a | 30 mm/a | 143 mm/a |

| Driving rain, worse direction | S 106 mm/a | S 111 mm/a | NW 189 mm/a |

| Name | Value |

|---|---|

| Initial indoor temperature | 20 °C |

| Initial indoor relative humidity | 55% |

| Initial indoor CO2 concentration | 400 ppmv |

| Name | Value | Unit |

|---|---|---|

| Rsi | 0.13 | m2K/W |

| Rse | 0.04 | m2K/W |

| Absorption | 0.6 | [-] |

| Emission | 0.9 | [-] |

| Rain load R1 | 0 | [-] |

| Rain load R2 | 0.07 | [s/m] |

| Rainwater absorption factor | 0.7 | [-] |

| Bulk Density [kg/m3] | Porosity [-] | Thermal Conductivity [W/(mK)] | Specific Heat Capacity [J/(kgK) | Water Vapor Resistance Factor [-] | Free Saturation [kg/m3] | Water Uptake Coefficient [kg/m2s0.5] | |

|---|---|---|---|---|---|---|---|

| Mean value | 295 | 0.849 | 0.046 | 648 | : 4.2 | 490 | 0.23 |

| : 4.1 | |||||||

| Uncertainty | ±5 | ±0.003 | ±0.006 | ±53 | ±0.1 | ±10 | ±0.07 |

| Name Sample and Fit | Dww (Liquid Transport Coefficient for Redistribution) | ||

|---|---|---|---|

| RH 80% | RH 93% | RH 100% | |

| SE12 | 1.00 × 10−11 | 3.20 × 10−11 | 4.00 × 10−7 |

| SE13 | 1.00 × 10−11 | 2.50 × 10−11 | 1.95 × 10−7 |

| SE average | 1.00 × 10−11 | 2.85 × 10−11 | 2.98 × 10−7 |

| Stone | Medium Moisture Load | Medium Moisture Load +5% | High Moisture Load | |||

|---|---|---|---|---|---|---|

| 4 cm | 12 cm | 4 cm | 12 cm | 4 cm | 12 cm | |

| Brunico | ||||||

| Granite | 0 | 0 | 0 | 2429 | 3807 | 8754 |

| Sandstone | 0 | 0 | 0 | 971 | 3483 | 8749 |

| Sandstone Velbke | 0 | 0 | 415 | 249 | 3603 | 6235 |

| Tuff | 0 | 0 | 0 | 0 | 0 | 0 |

| Solid brick ARB | 0 | 0 | 0 | 0 | 0 | 1237 |

| Bolzano | ||||||

| Granite | 0 | 0 | 0 | 0 | 0 | 0 |

| Sandstone | 0 | 0 | 0 | 0 | 0 | 0 |

| Sandstone Velbke | 0 | 0 | 0 | 0 | 0 | 0 |

| Tuff | 0 | 0 | 0 | 0 | 0 | 0 |

| Solid brick ARB | 0 | 0 | 0 | 0 | 0 | 0 |

| Bari | ||||||

| Granite | 0 | 0 | 0 | 0 | 0 | 0 |

| Sandstone | 0 | 0 | 0 | 0 | 0 | 0 |

| Sandstone Velbke | 0 | 0 | 0 | 0 | 0 | 0 |

| Tuff | 0 | 0 | 0 | 0 | 0 | 0 |

| Solid brick ARB | 0 | 0 | 0 | 0 | 0 | 0 |

| Parameter Variation | Mean | Minimum | Maximum |

|---|---|---|---|

| Existing wall material with different vapor resistance factors | 1.1% | 0.3% | 3.2% |

| Existing wall material with different thermal conductivities | 12.4% | 5.3% | 22.0% |

| Insulation thickness | 3.7% | −0.7% | 12.7% |

| Internal moisture load | 7.8% | 2.1% | 13.6% |

| External climate | 7.8% | 3.3% | 11.2% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leonardi, E.; Larcher, M.; Troi, A.; Stefani, A.; Nerobutto, G.; Herrera-Avellanosa, D. Hygrothermal Performance of Thermal Plaster Used as Interior Insulation: Identification of the Most Impactful Design Conditions. Buildings 2025, 15, 3559. https://doi.org/10.3390/buildings15193559

Leonardi E, Larcher M, Troi A, Stefani A, Nerobutto G, Herrera-Avellanosa D. Hygrothermal Performance of Thermal Plaster Used as Interior Insulation: Identification of the Most Impactful Design Conditions. Buildings. 2025; 15(19):3559. https://doi.org/10.3390/buildings15193559

Chicago/Turabian StyleLeonardi, Eleonora, Marco Larcher, Alexandra Troi, Anna Stefani, Gianni Nerobutto, and Daniel Herrera-Avellanosa. 2025. "Hygrothermal Performance of Thermal Plaster Used as Interior Insulation: Identification of the Most Impactful Design Conditions" Buildings 15, no. 19: 3559. https://doi.org/10.3390/buildings15193559

APA StyleLeonardi, E., Larcher, M., Troi, A., Stefani, A., Nerobutto, G., & Herrera-Avellanosa, D. (2025). Hygrothermal Performance of Thermal Plaster Used as Interior Insulation: Identification of the Most Impactful Design Conditions. Buildings, 15(19), 3559. https://doi.org/10.3390/buildings15193559