In the modern rail transit sector, fatigue failure issues in the auxiliary structures of high-speed railways have garnered significant attention within the engineering community. Wang et al. [

3] studied the fatigue performance and life prediction of high-speed railway concrete under fatigue and environmental damage. The results show that the fatigue life of concrete decreases with increasing stress levels and frequencies. At a stress level of 0.55 or lower, the samples can endure more than 2 million cycles, and the model predictions match the experimental results well below 0.60. At the 0.7 stress level, if the frequency exceeds 25 Hz, the fatigue life is less than 300 cycles. The fatigue life also decreases linearly with performance damage, and cracks reduce it because of stress concentration. Yin et al. [

4] studied the establishment of load spectra for high-speed train bogie frames to improve fatigue reliability. They calculated Pearson correlation coefficients among 15 loads, divided them into three subsystems, and established a test load spectrum considering the load amplitude, frequency, phase, and sequence. The spectrum had a high prediction accuracy, with 80% of the measuring points having a stress ratio of 0.9–1.3. After damage-consistency calibration, the prediction accuracy was further enhanced. Wang et al. [

5] studied heavy-haul railway tunnel base structures under train–groundwater coupling via field tests and simulations. The results validate the model, show the 0–5 Hz load frequency, and reveal that groundwater affects the base’s stress state. Water in the base reduces vertical displacement/acceleration, increases the principal stress, and shortens the inverted arch’s fatigue life by 21.07% (grade—IV) and 29.28% (grade—V). Qian et al. [

6] studied metro tunnel structural fatigue under high-speed railway loads. They simplified the dynamic load, chose the experimental sinusoidal wave, and found the most unfavorable positions. Gypsum simulated segmental linings for fatigue evaluation. Tests matched simulations, showing that the tunnel meets the 120-year requirement. No fatigue failure occurred, but the standard model had displacement issues that needed attention. Xiang et al. [

7] studied the failure of a section insulator’s support rod in urban rail systems. The rod, made of AISI-304/L/C steel, had no defects. Its failure was due to high-cycle fatigue, starting at a stress-concentrated edge. Arc-discharge-induced cracks help initiate fatigue cracks, and the alternating load arises from changes in the train direction and pantograph–insulator interactions. Peng et al. [

8] studied the fatigue of railway bogie frames. An innovative method determines their fatigue life while considering track and wheel issues and predicting wear limits. A coupled model is built and verified. The dynamic stress of the bogie frame is studied, and a stress-spectrum-compiling method considering wheel wear is proposed. Stress spectra are used to analyze the impact on fatigue life, and a 0.034 mm wear limit for 24th-order wheel polygons in high-speed trains is set. This benefits bogie frame safety and railway system maintenance. Sunar and Fletcher [

9] studied the effects of arcs on copper–silver contact wires. The arc-damaged wires had a 50% shorter fatigue life, especially on the tensile surface. Arc discharge damaged the wire, accelerating fatigue. In contrast, when bending with arcing, fatigue limits the lifespan. Fatigue can be a controlling failure factor, so it should be considered in design and maintenance. Wang and Ma [

10] derived a stochastic dynamic damage constitutive model for high-speed railway tunnels and base concrete. After verification, they analyzed the defective structures. The model reflects the properties of the concrete. Seams increase vibration, and groundwater worsens damage. The current design parameters meet anti-fatigue needs without seams but not with seams (56 years of life with groundwater, 62 years without). Dou et al. [

11] studied high-speed trains’ cast aluminum beam fatigue via simulations and experiments. They proposed a method for calculating the stress concentration factor and carried out a 10-million-cycle test with no cracks found. The FE model was accurate. The supporting seat filet had the maximum stress concentration (

KD = 2.45), and the beam fatigue limit (35.4 MPa) exceeded the simulated maximum stress, meeting service life needs. Xu et al. [

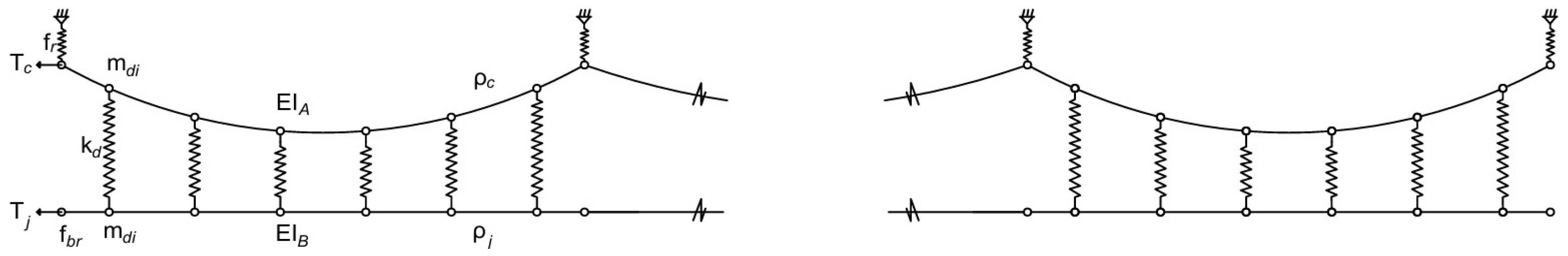

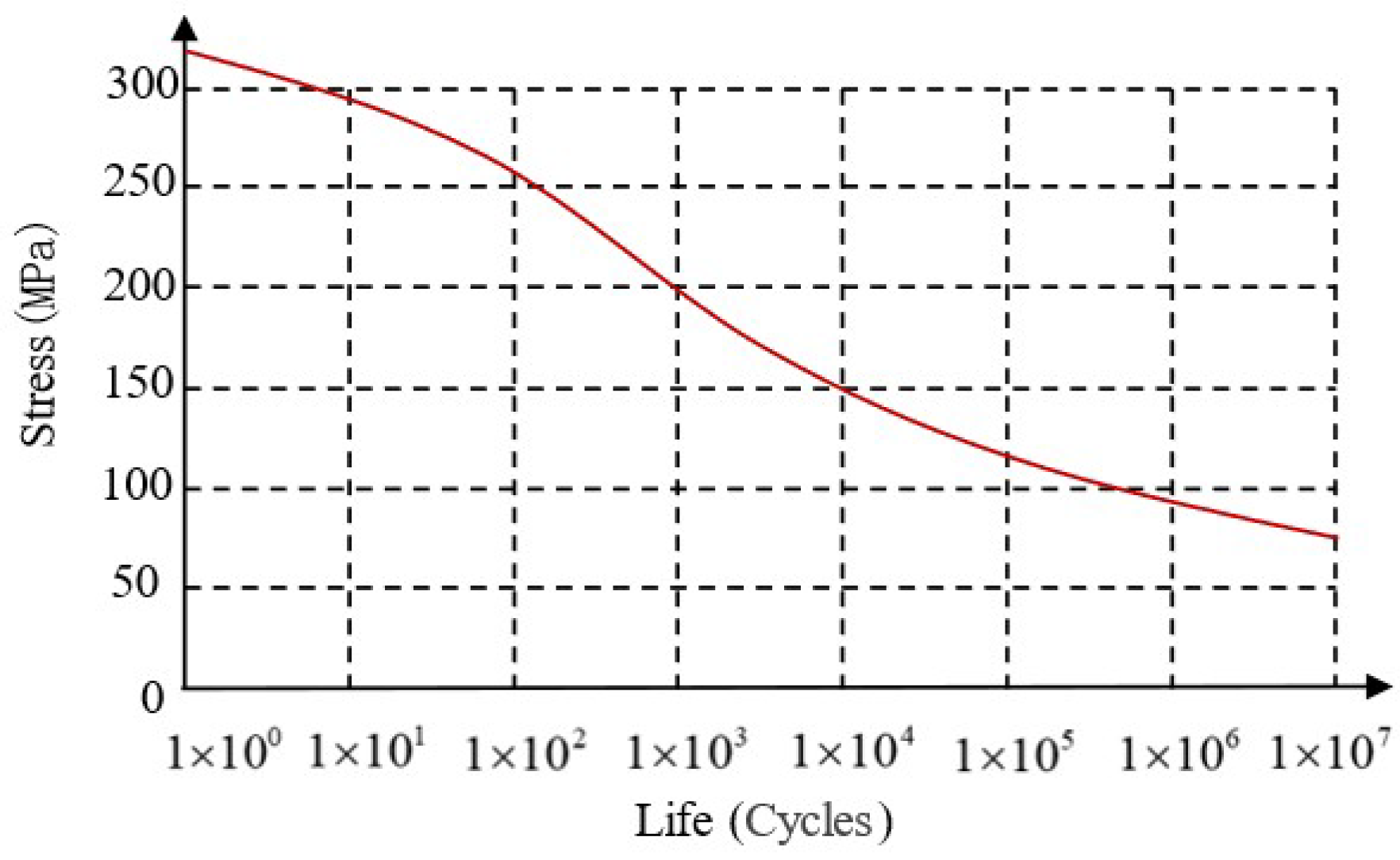

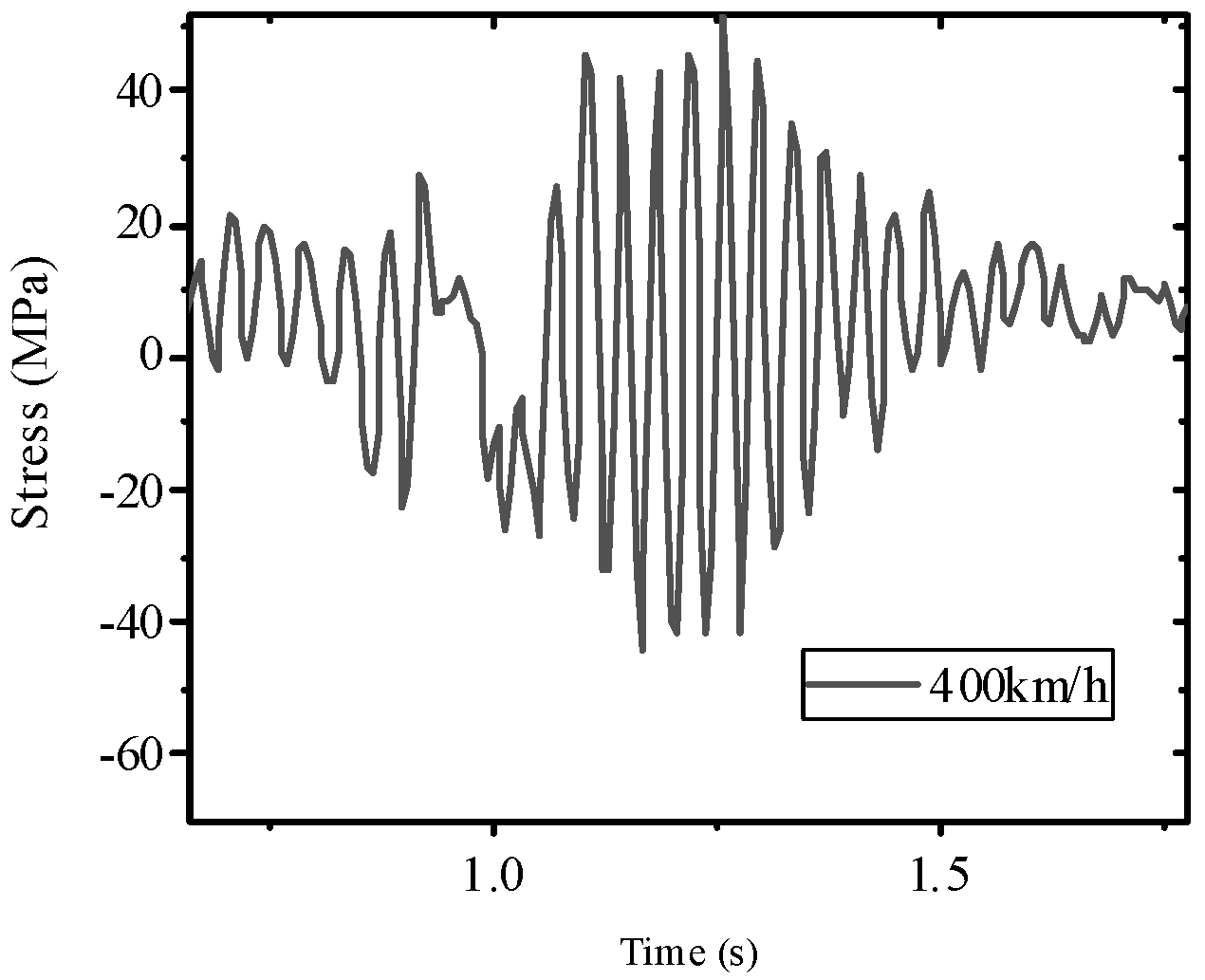

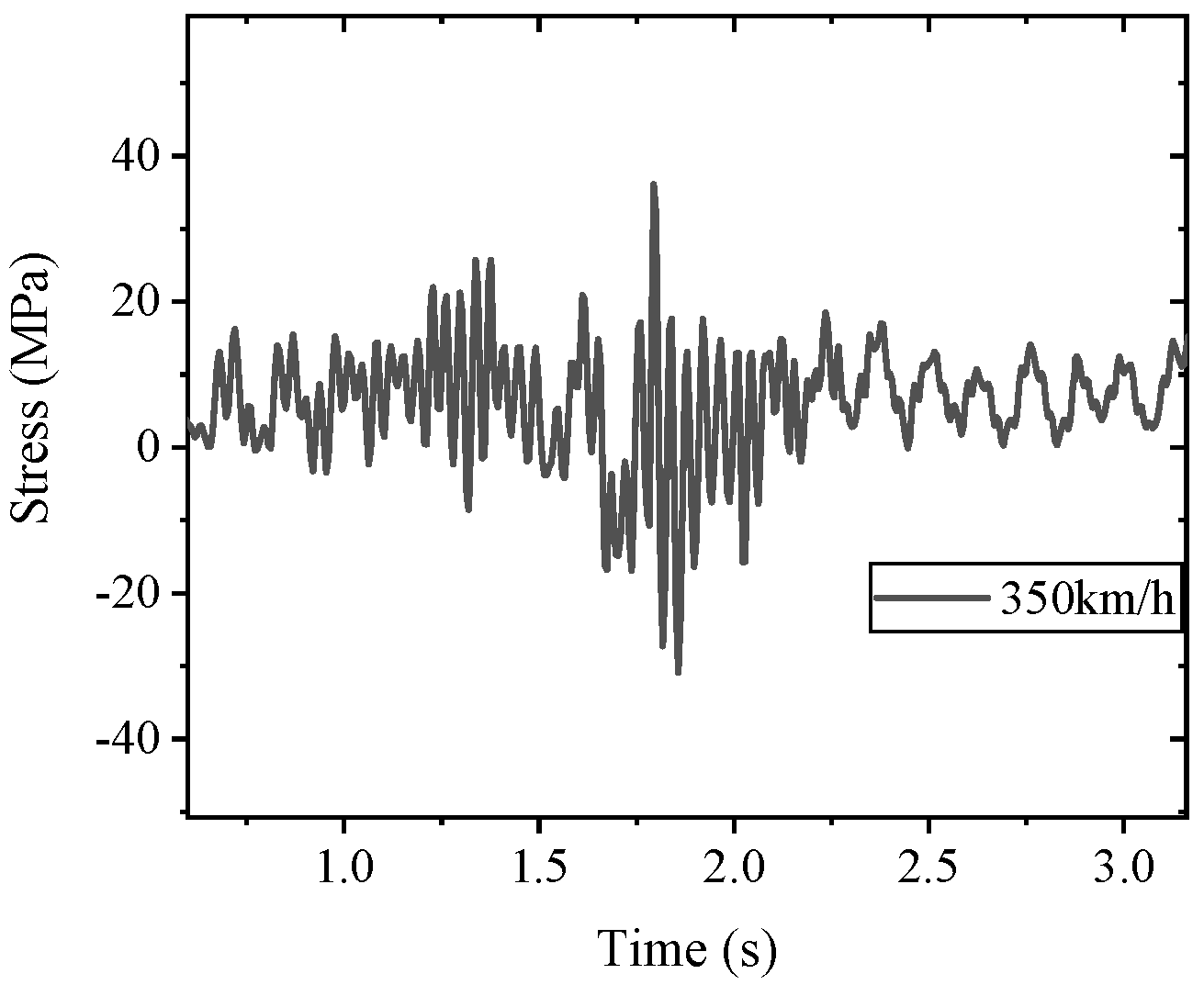

12] studied the contact wire at the steady arm in high-speed railway catenaries. They obtained a material model via a uniaxial test and built and validated models. The top and wing points were the weakest. A comparison of the models revealed beam element limits. Fatigue tests produced an S–N curve. The fatigue life decreased by approximately 50% from 350 to 400 km/h. Test results can help assess service life. Reference [

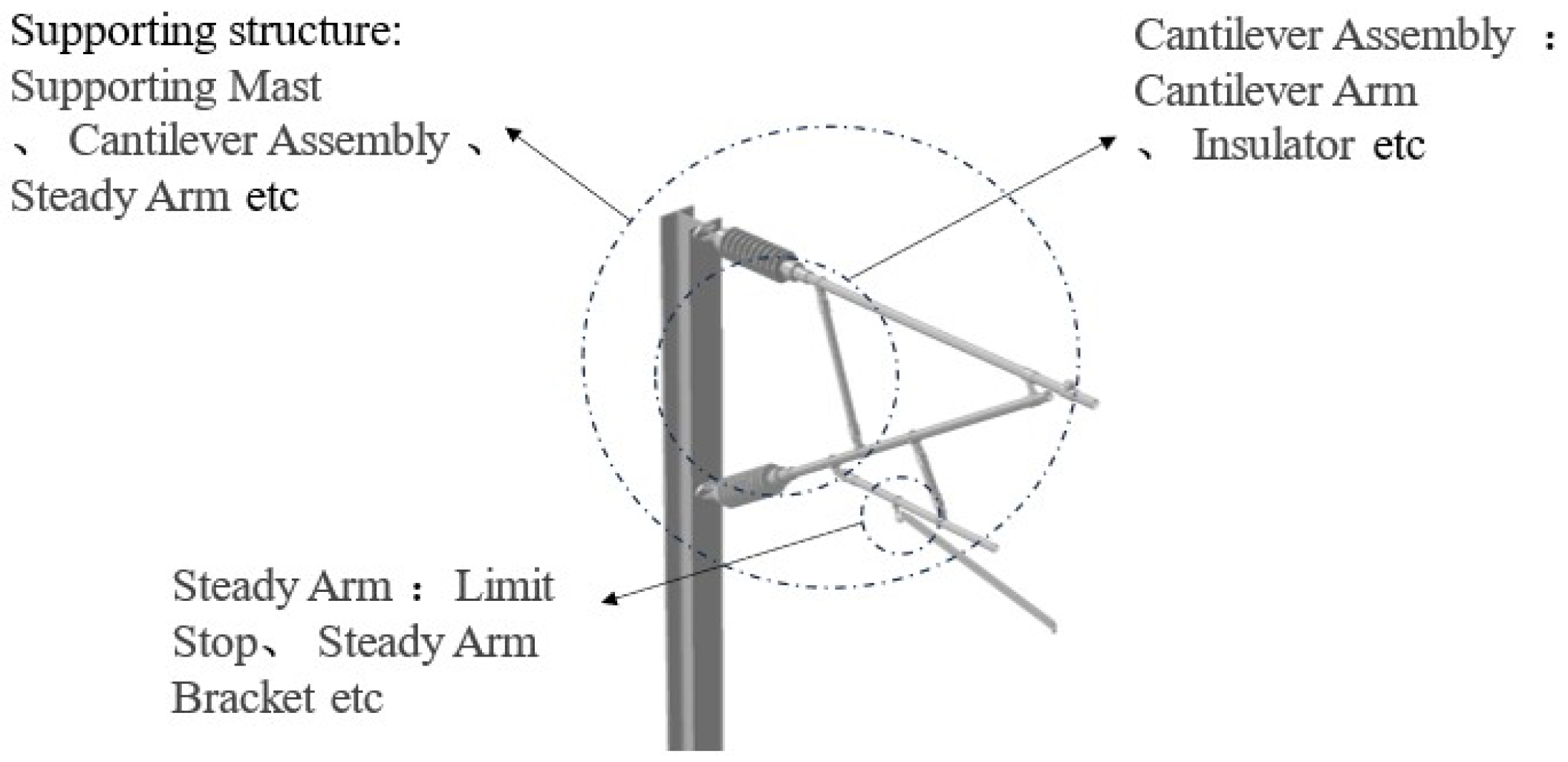

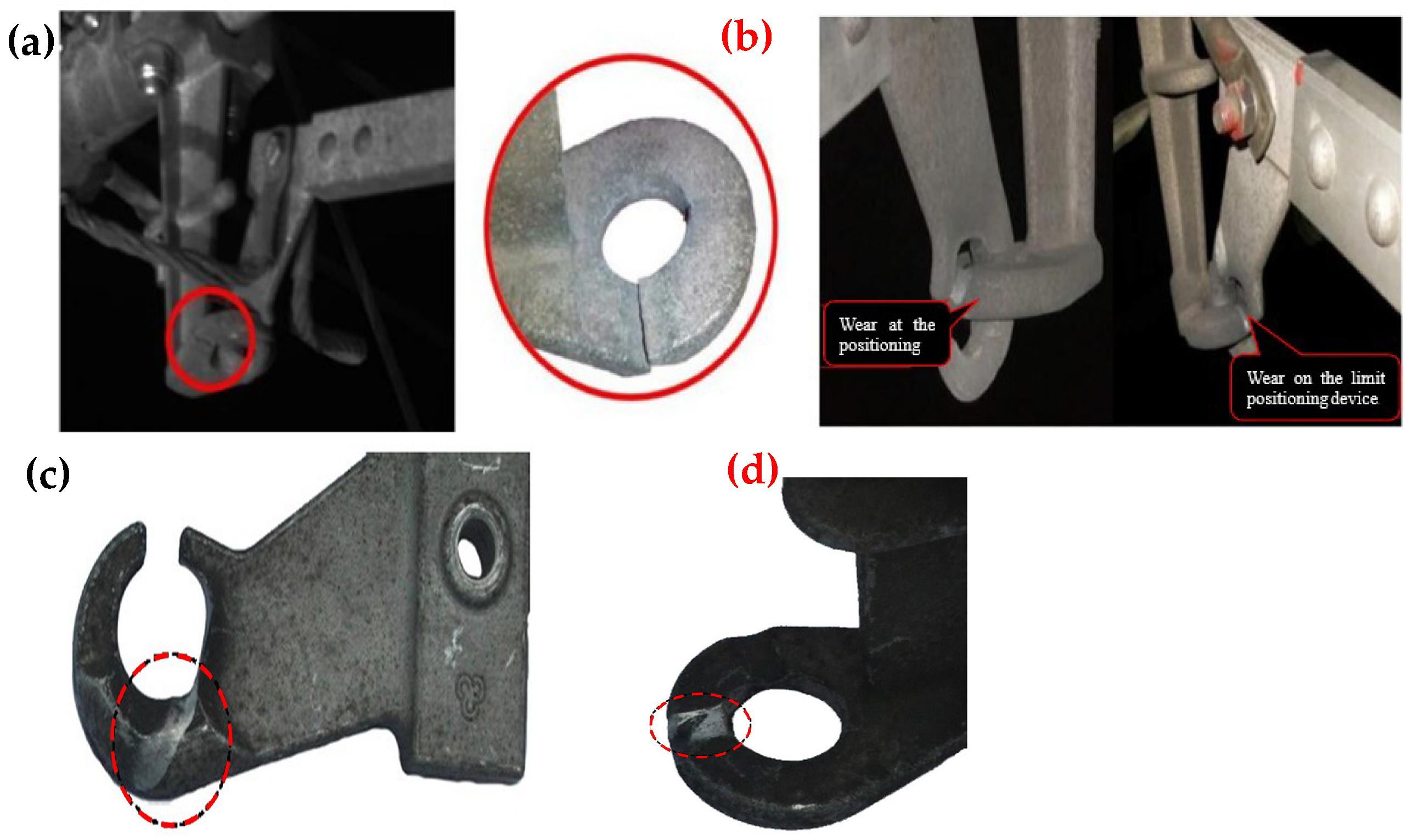

13] indicated that fatigue failure is one of the primary failure modes in catenary system malfunctions and structural damage. During train operations, the catenary support structures are continuously subjected to complex cyclic loading, making them highly susceptible to fatigue damage. Tan et al. [

14] aimed to advance the development of high-speed catenary equipment technology and conducted field investigations to analyze and summarize five typical failure issues and their root causes. They also reviewed the current research status of related failure mechanisms and proposed future research directions. Qi et al. [

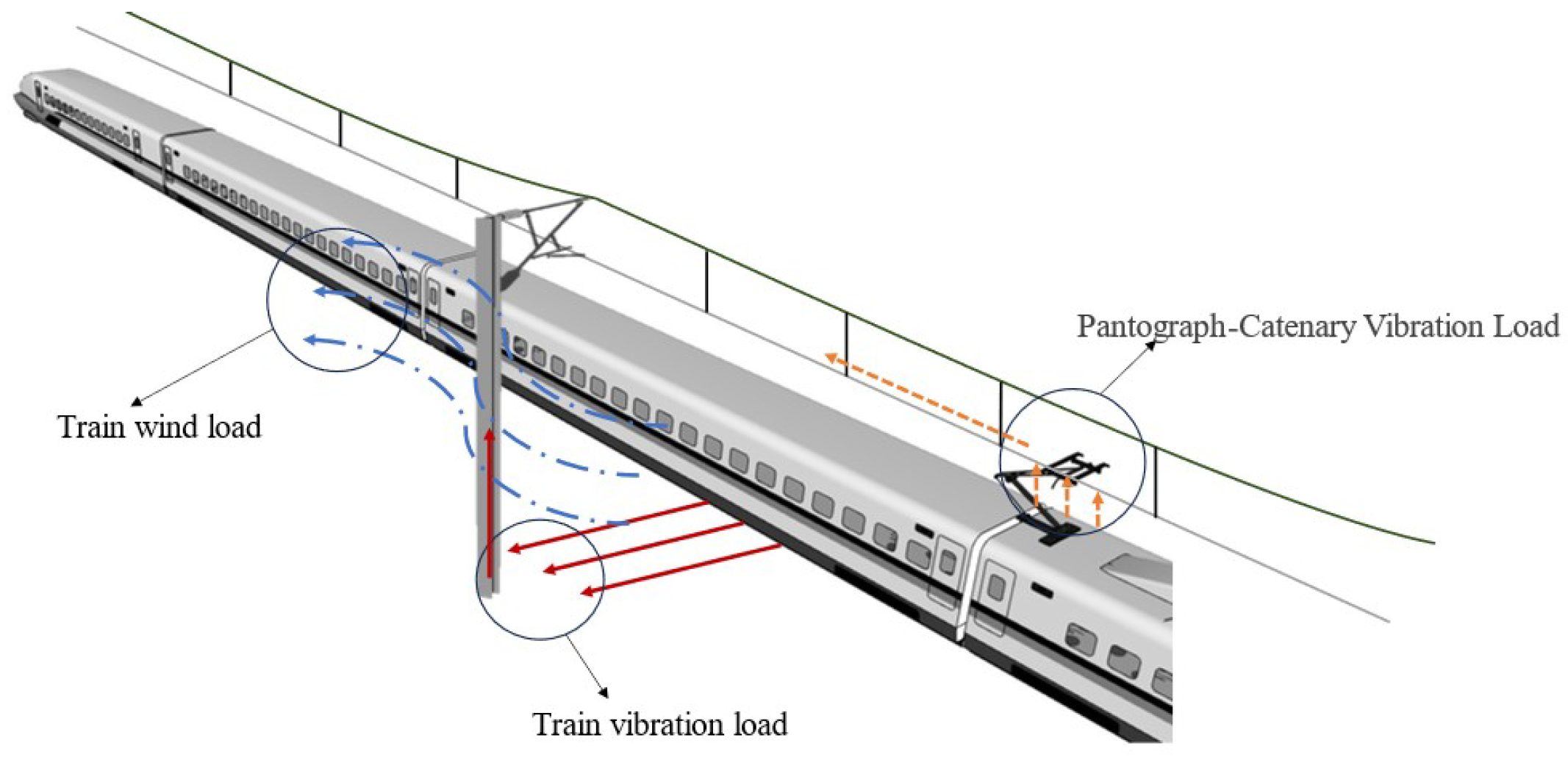

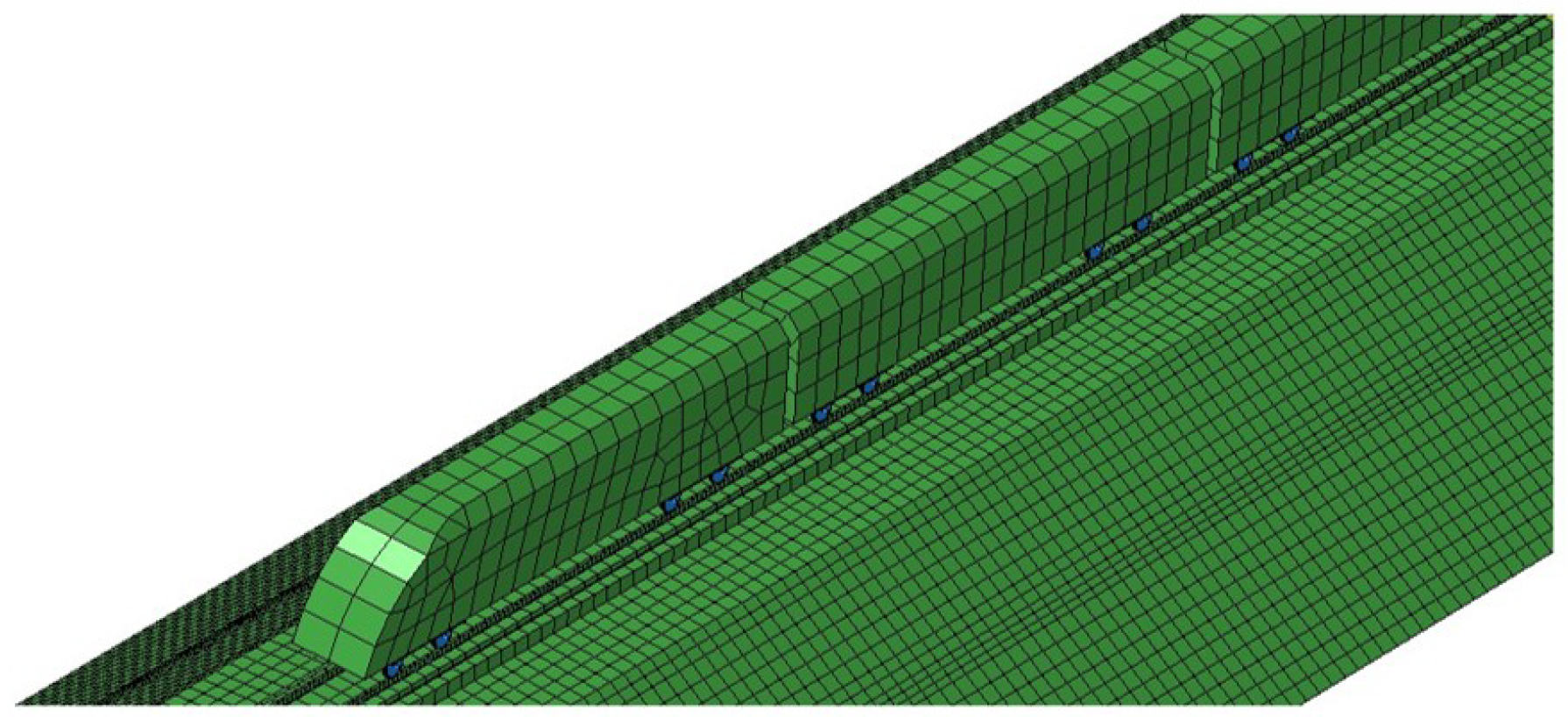

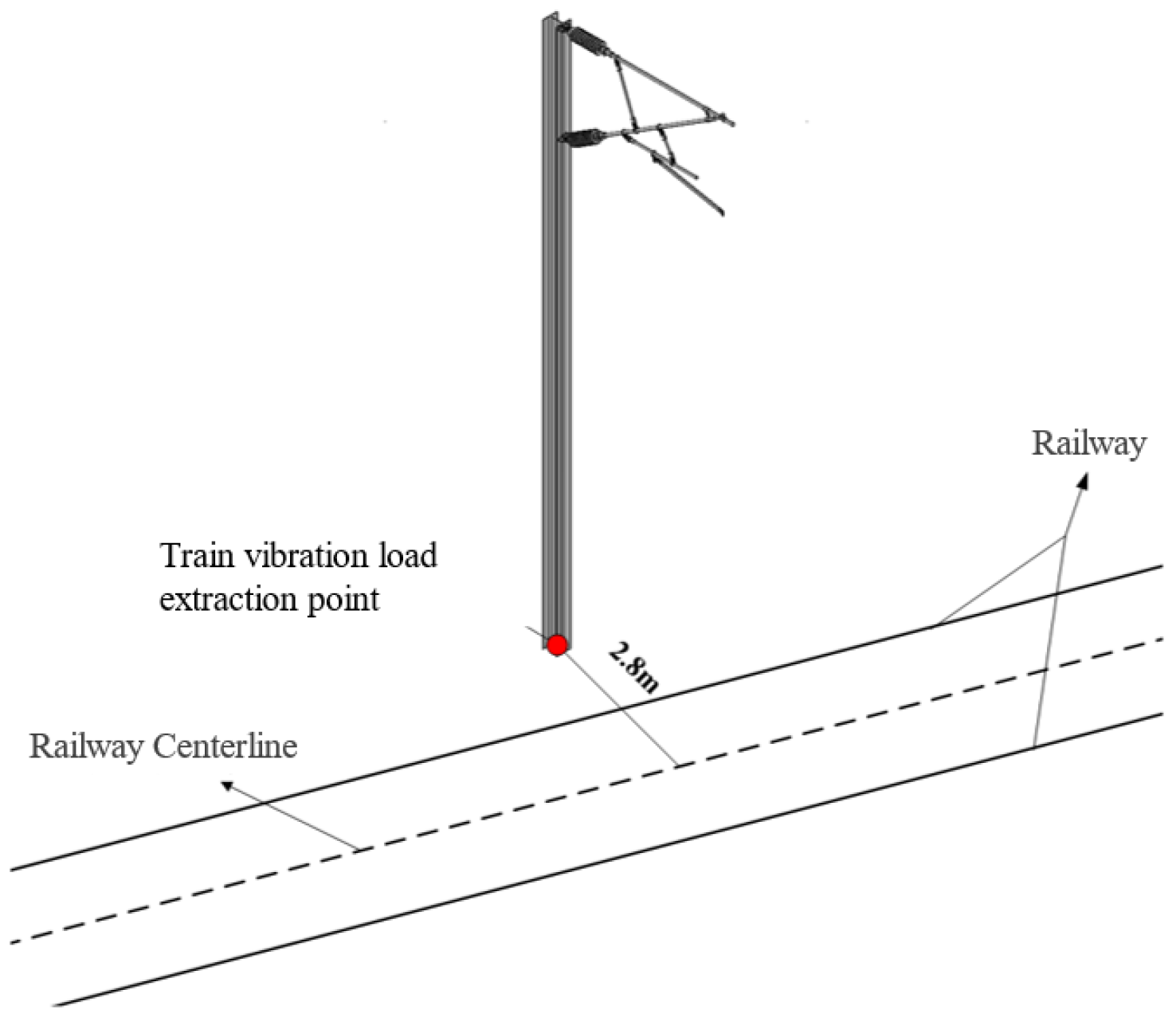

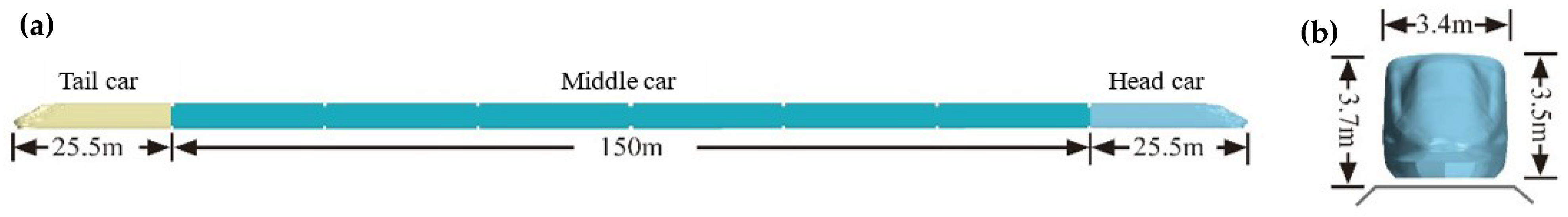

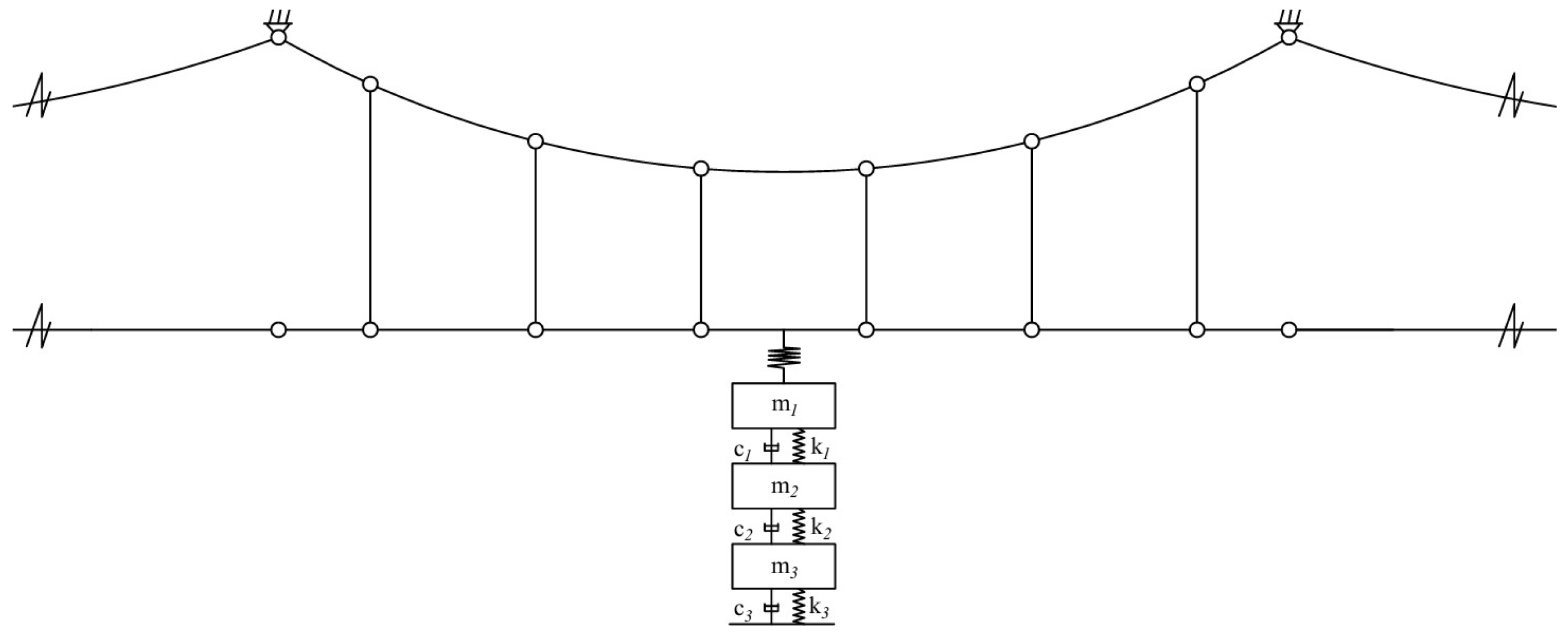

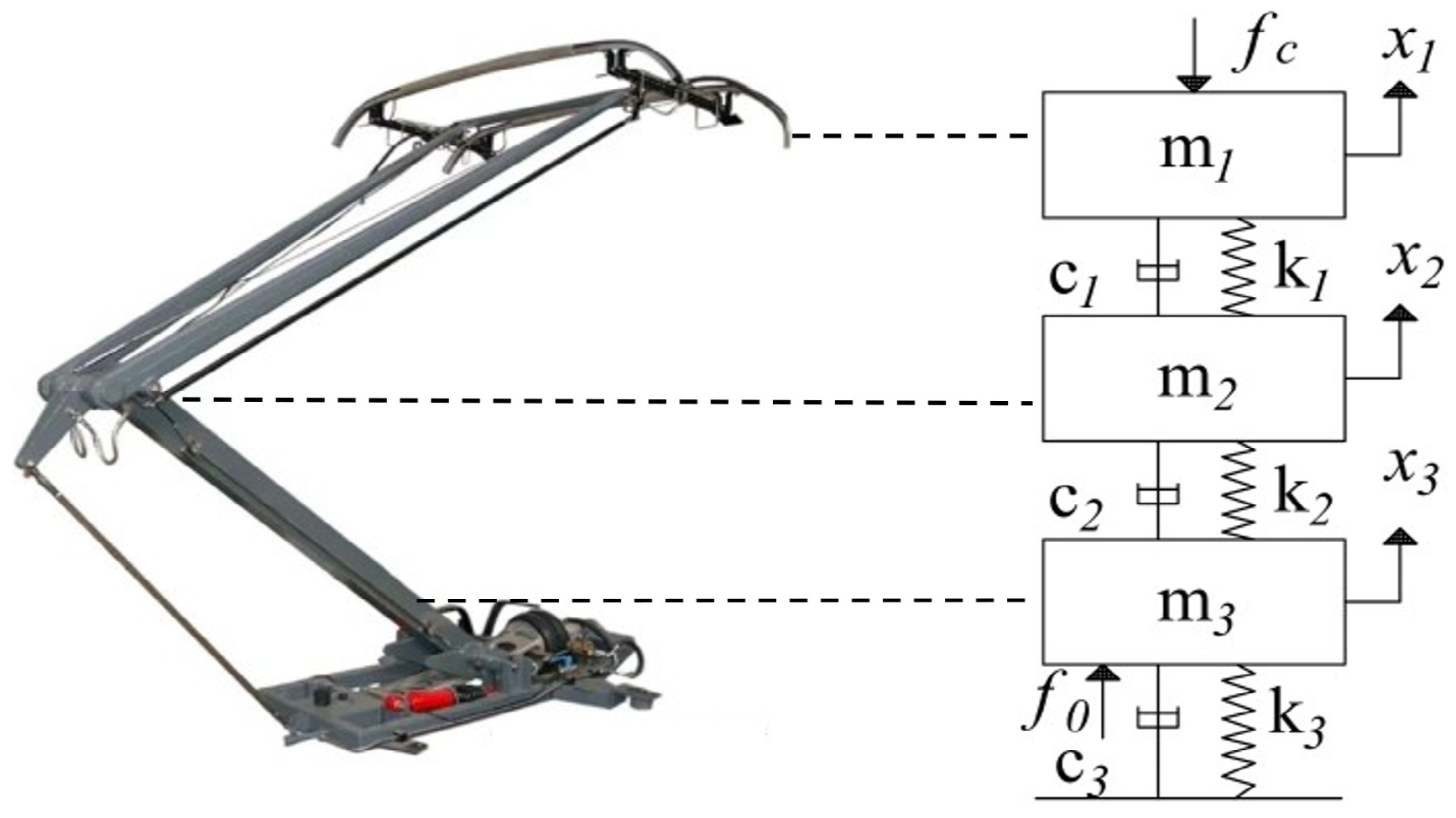

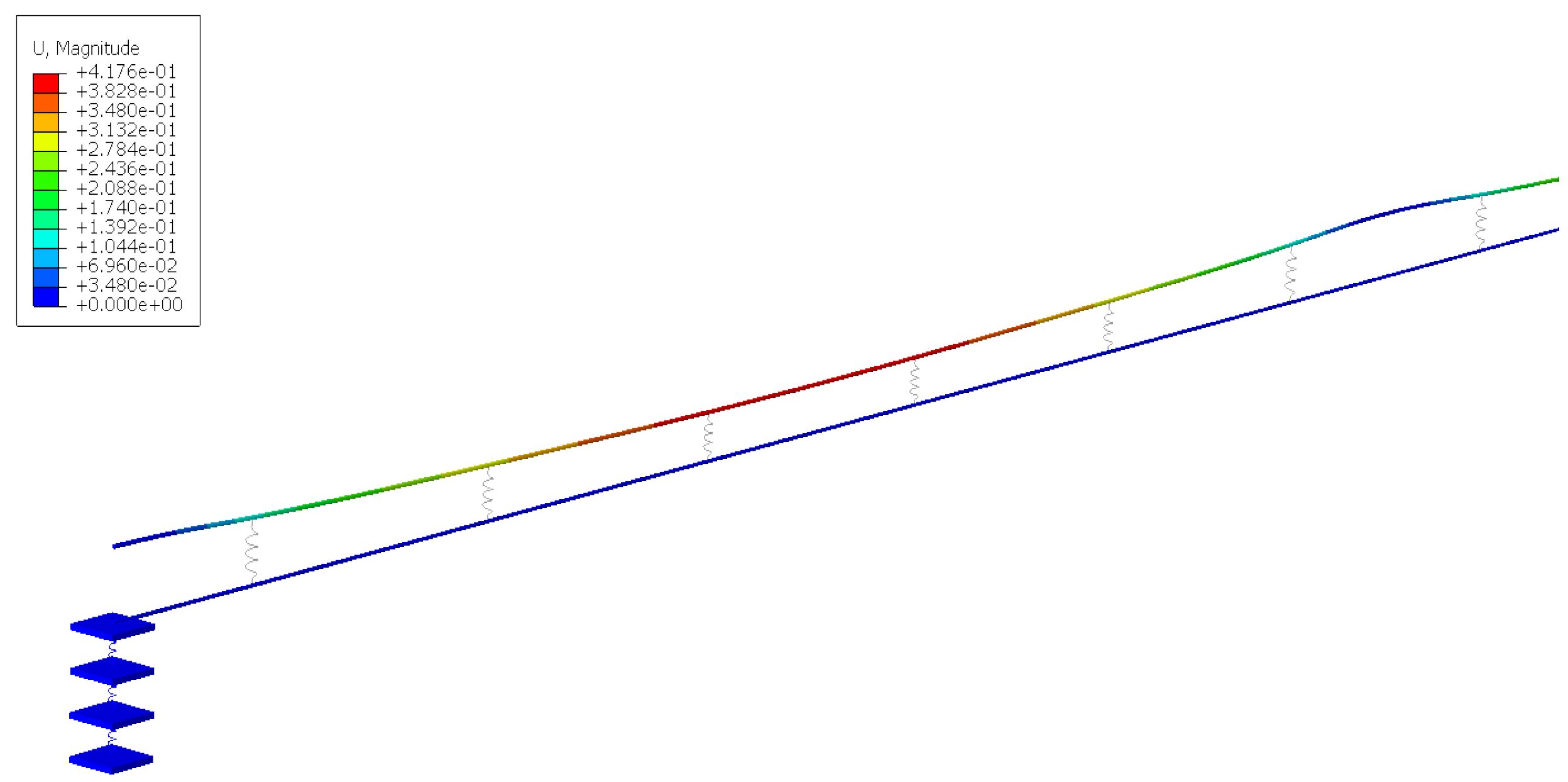

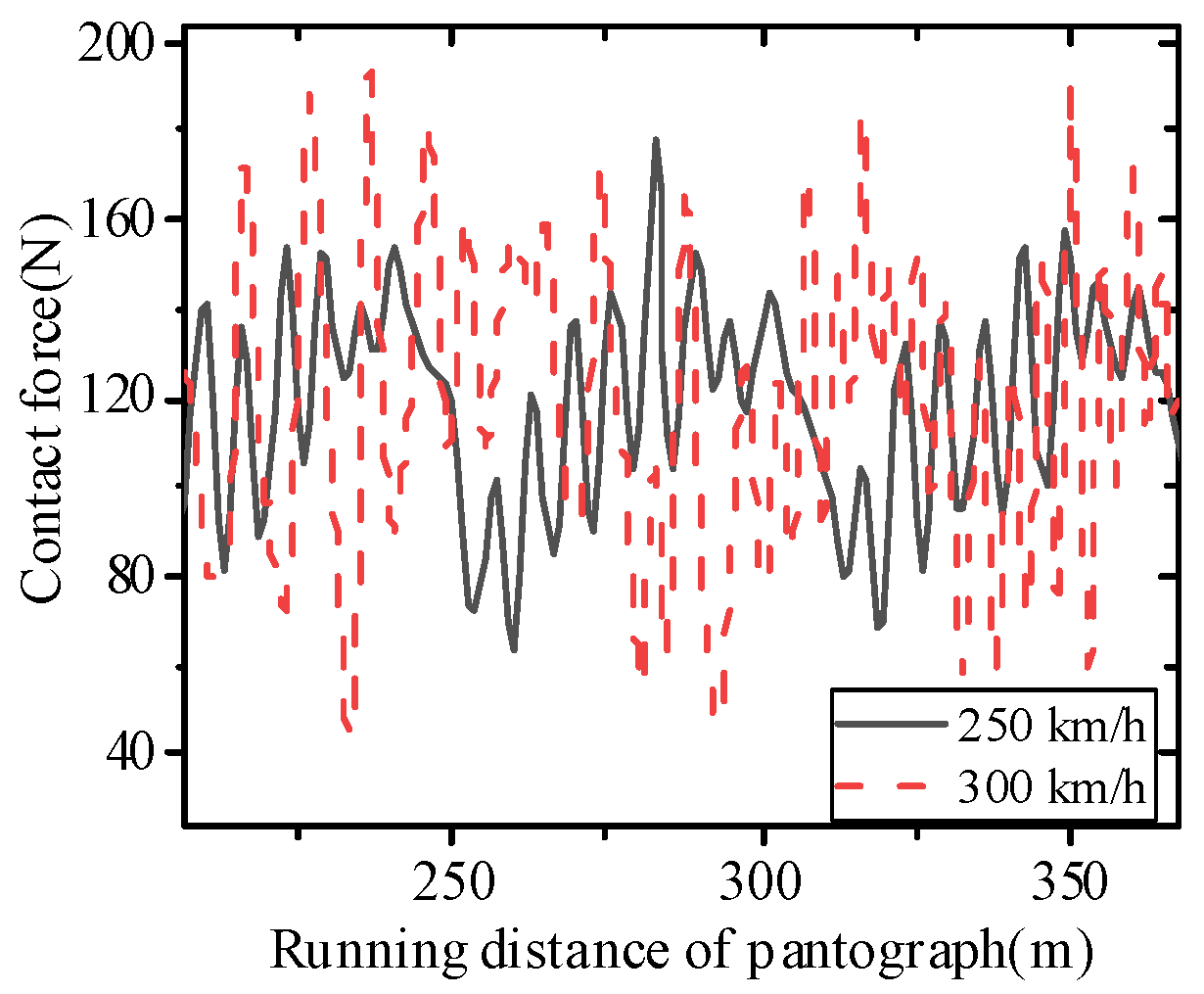

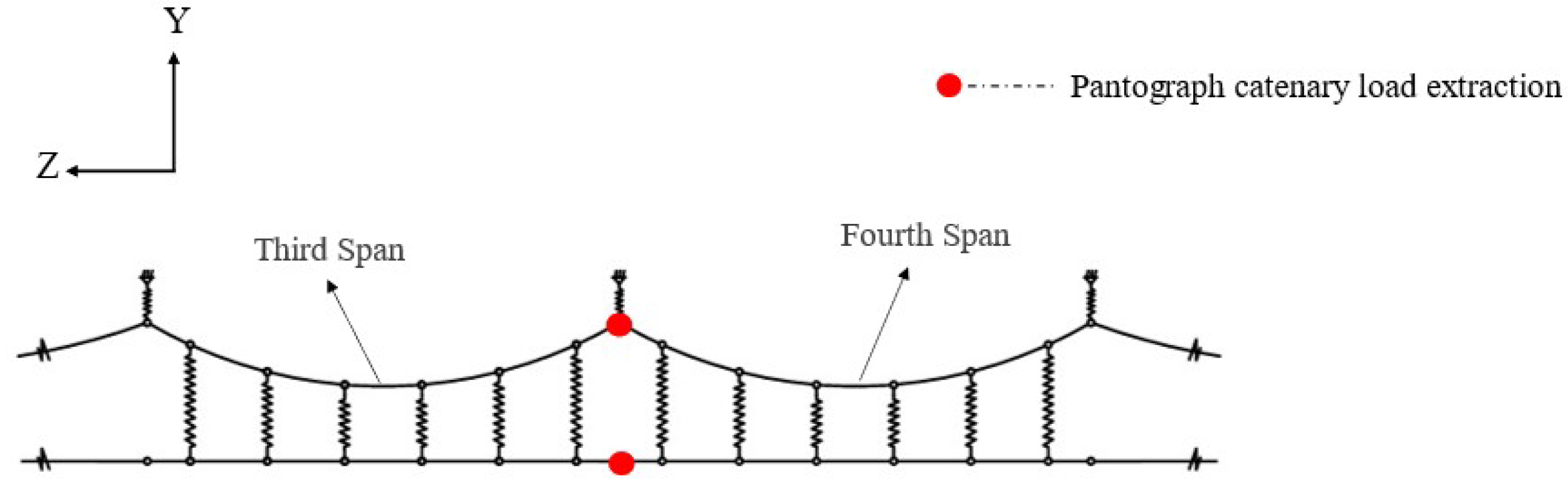

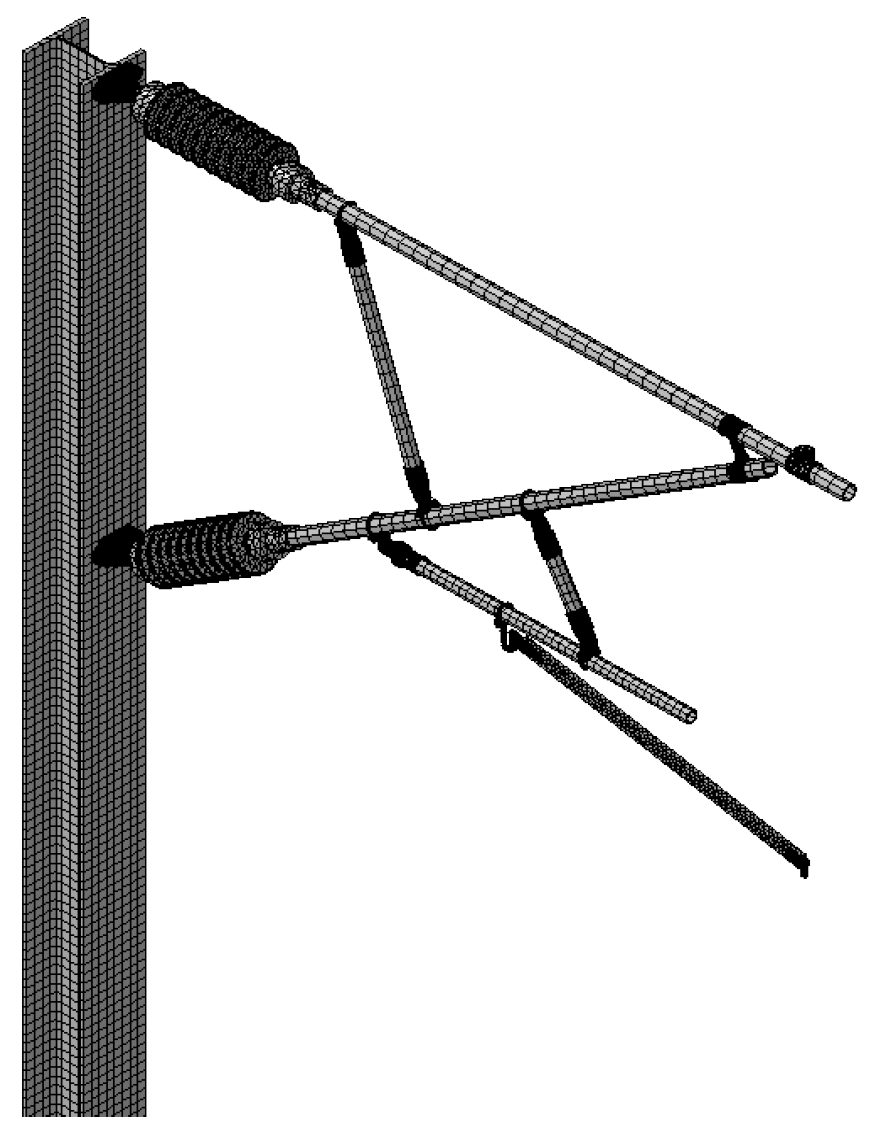

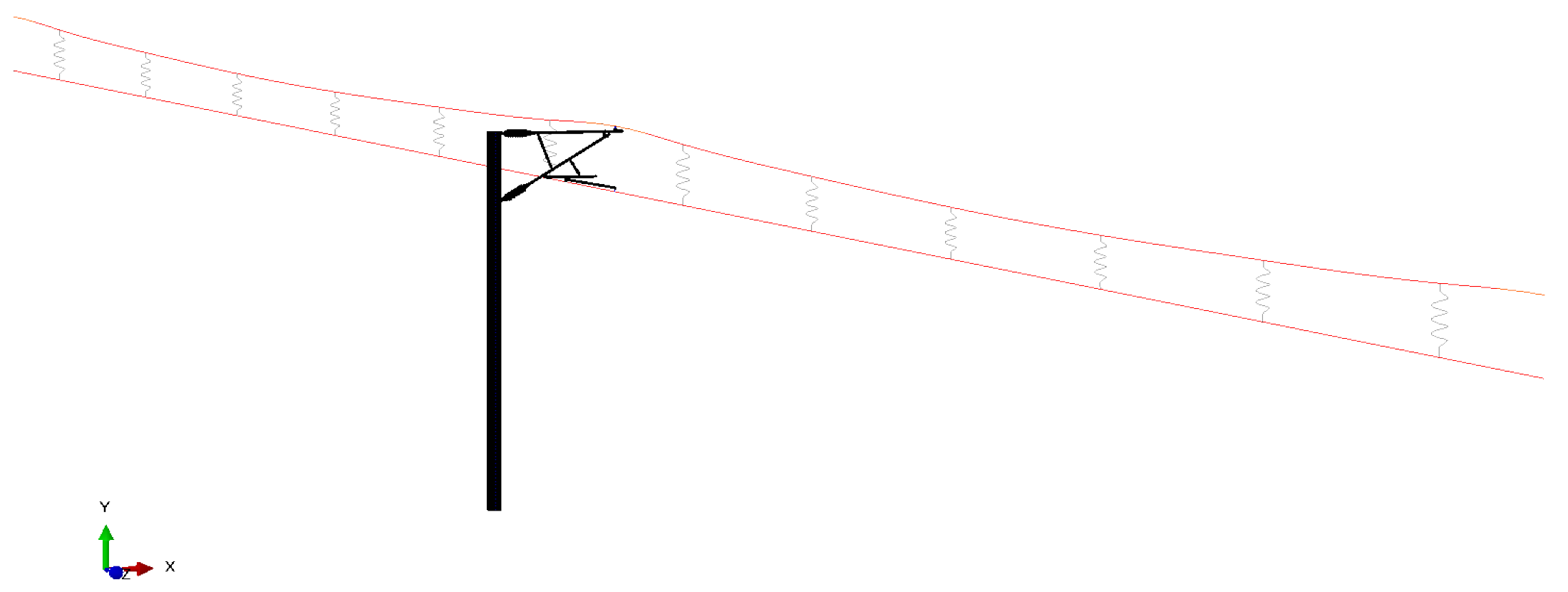

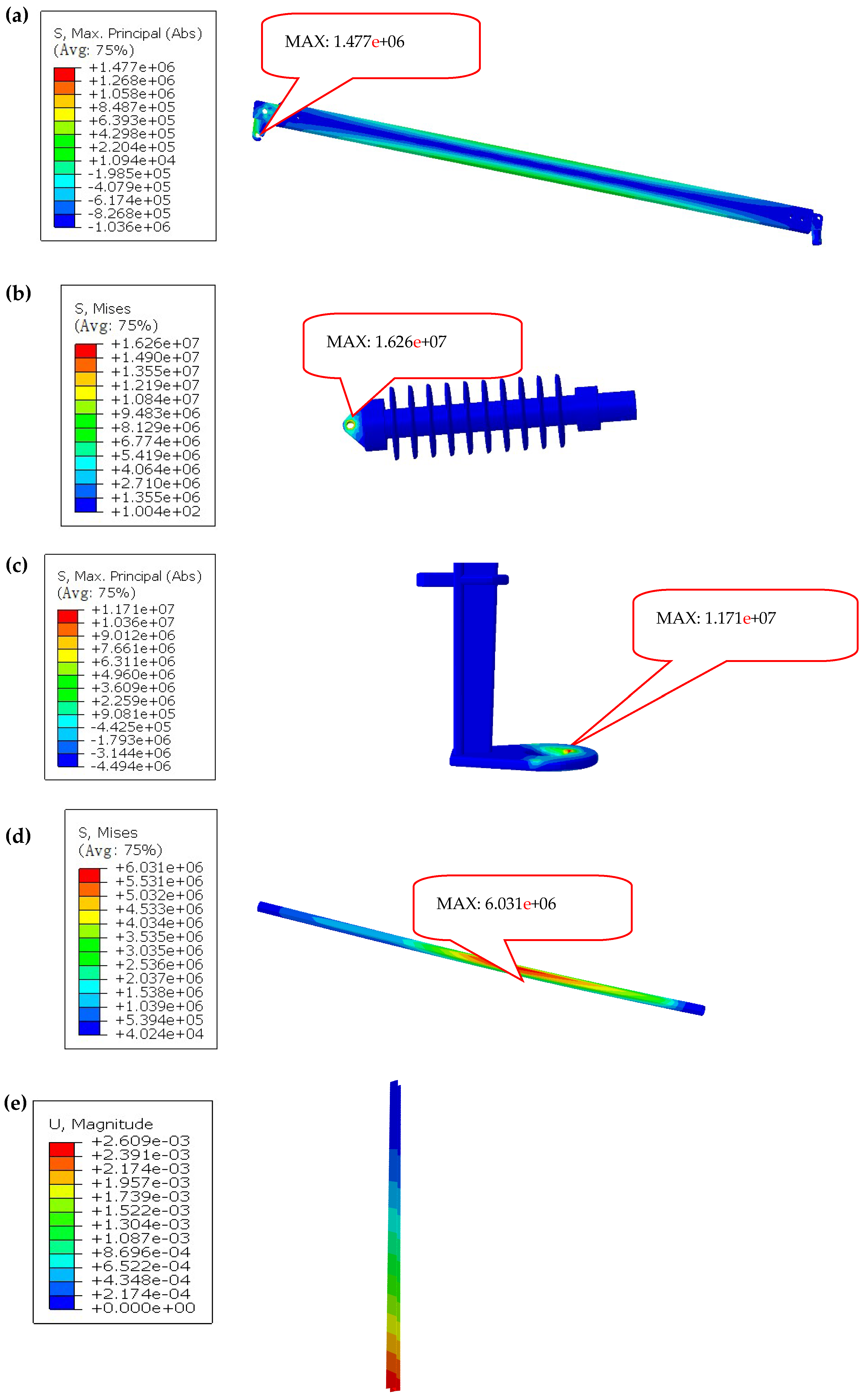

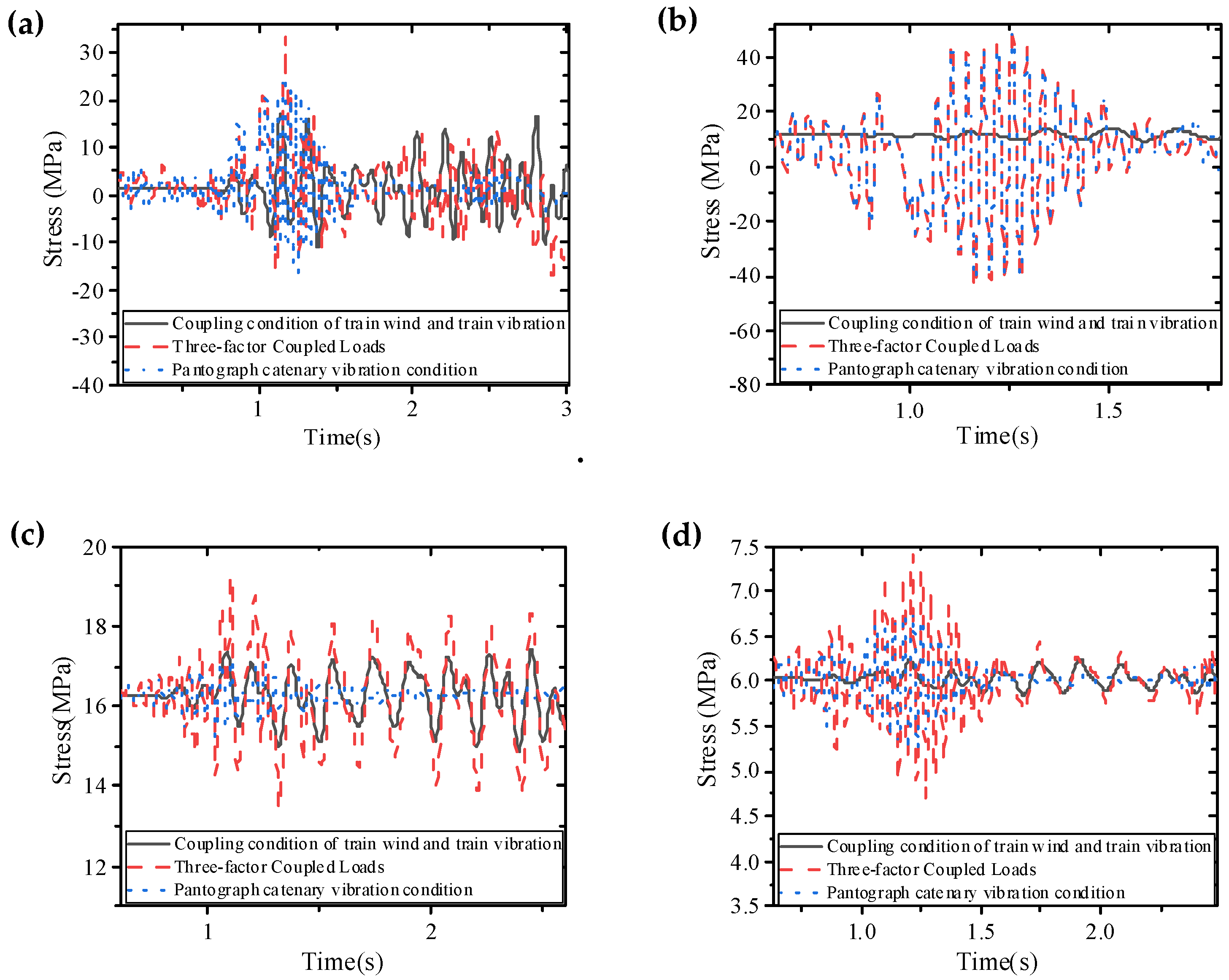

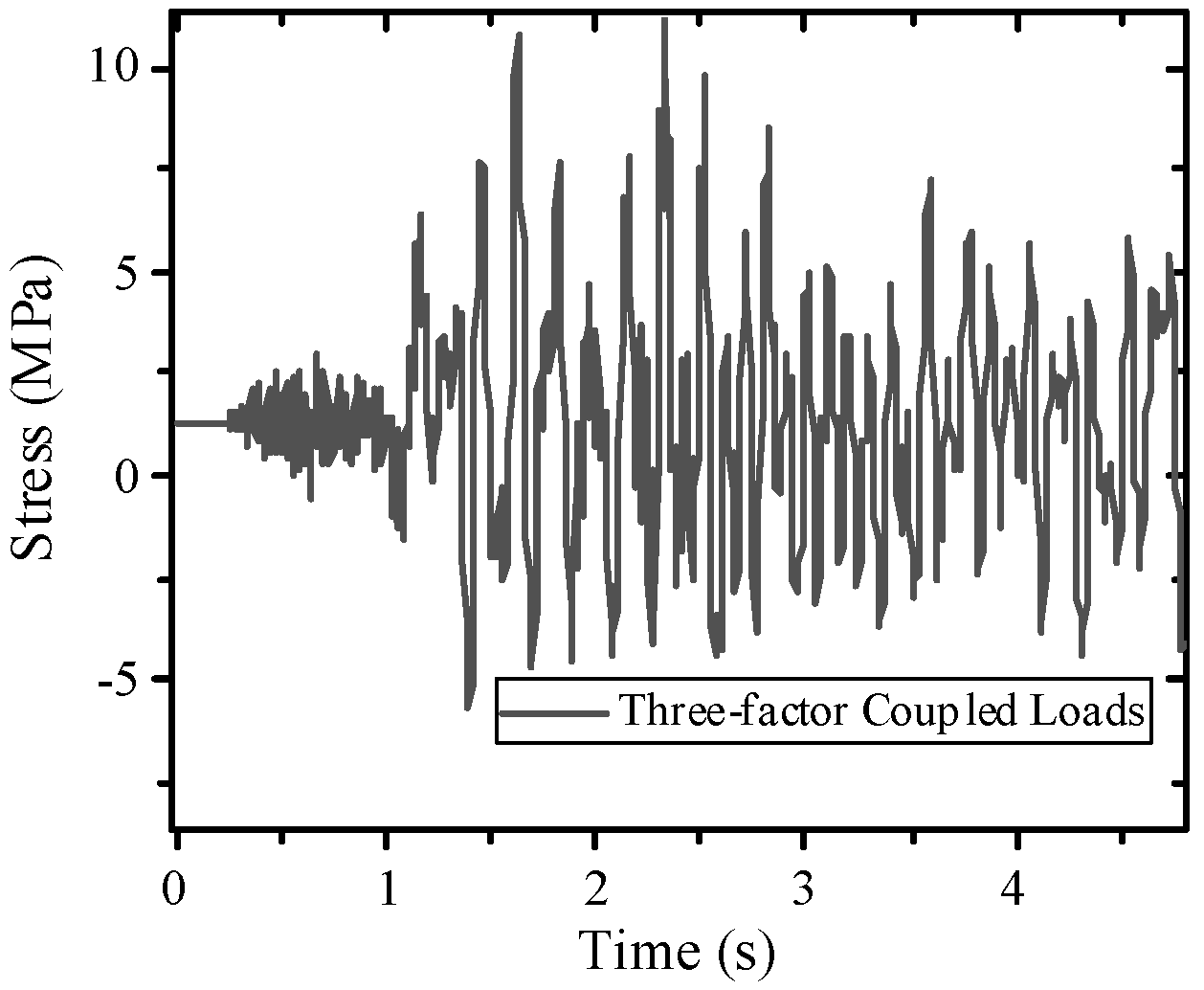

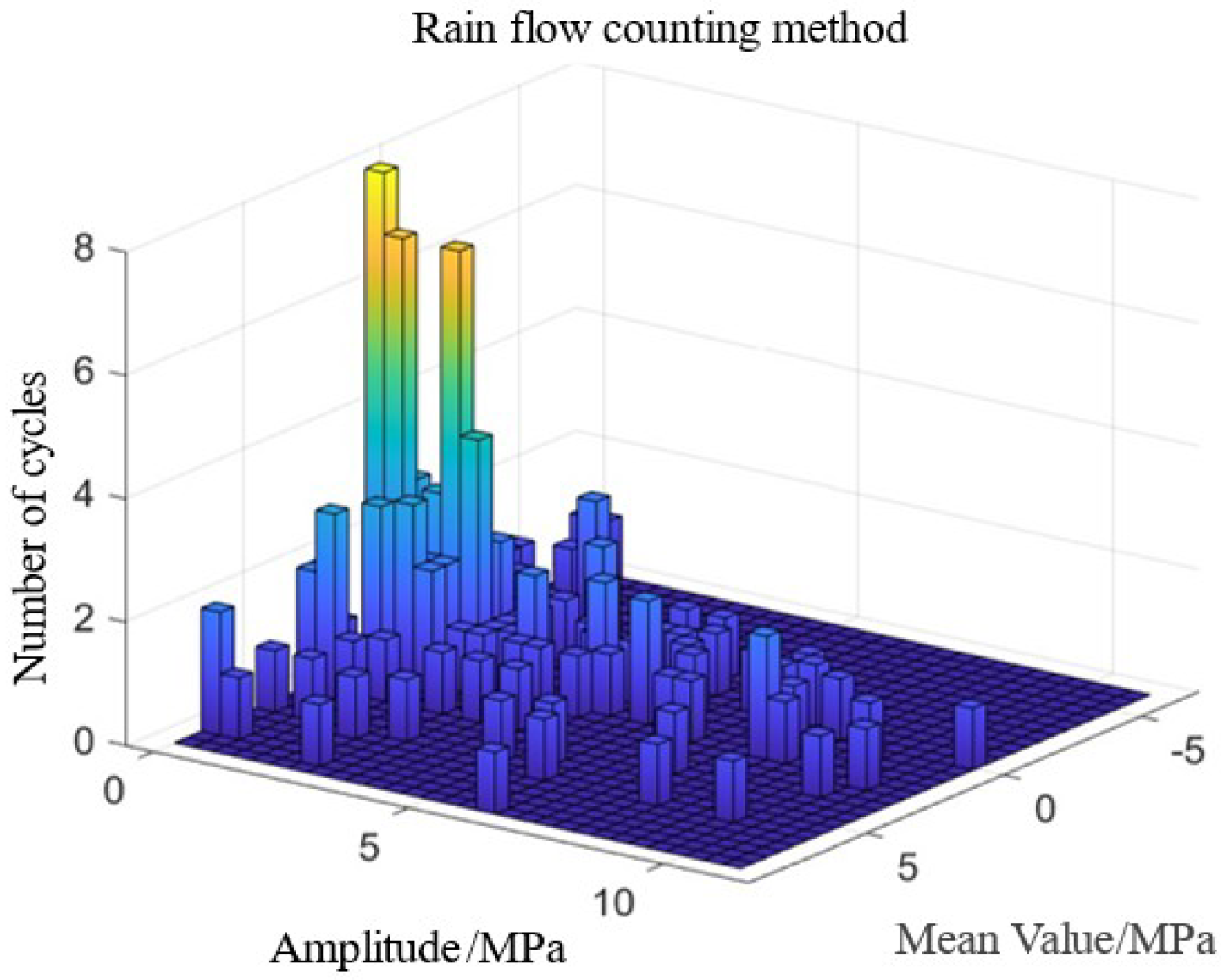

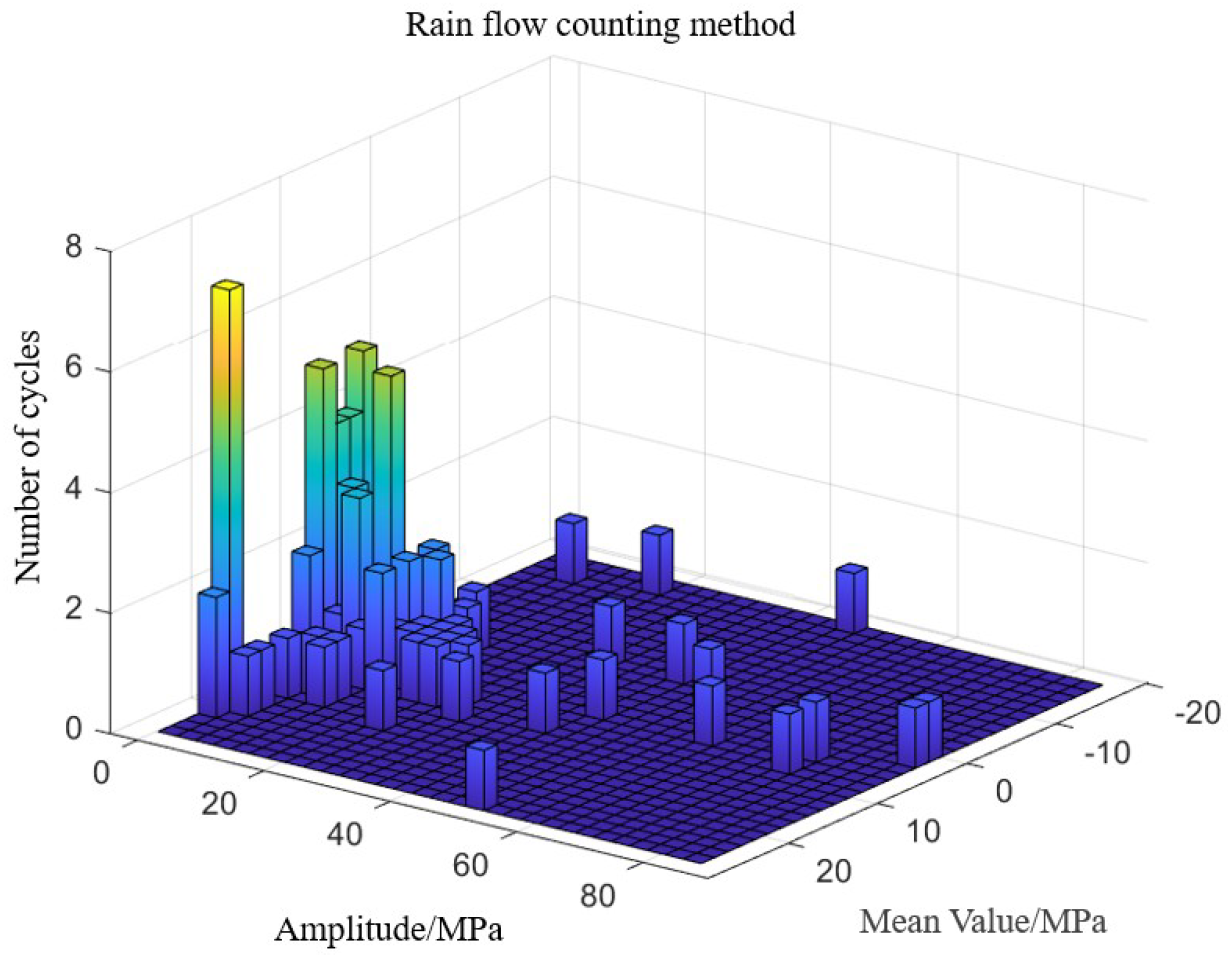

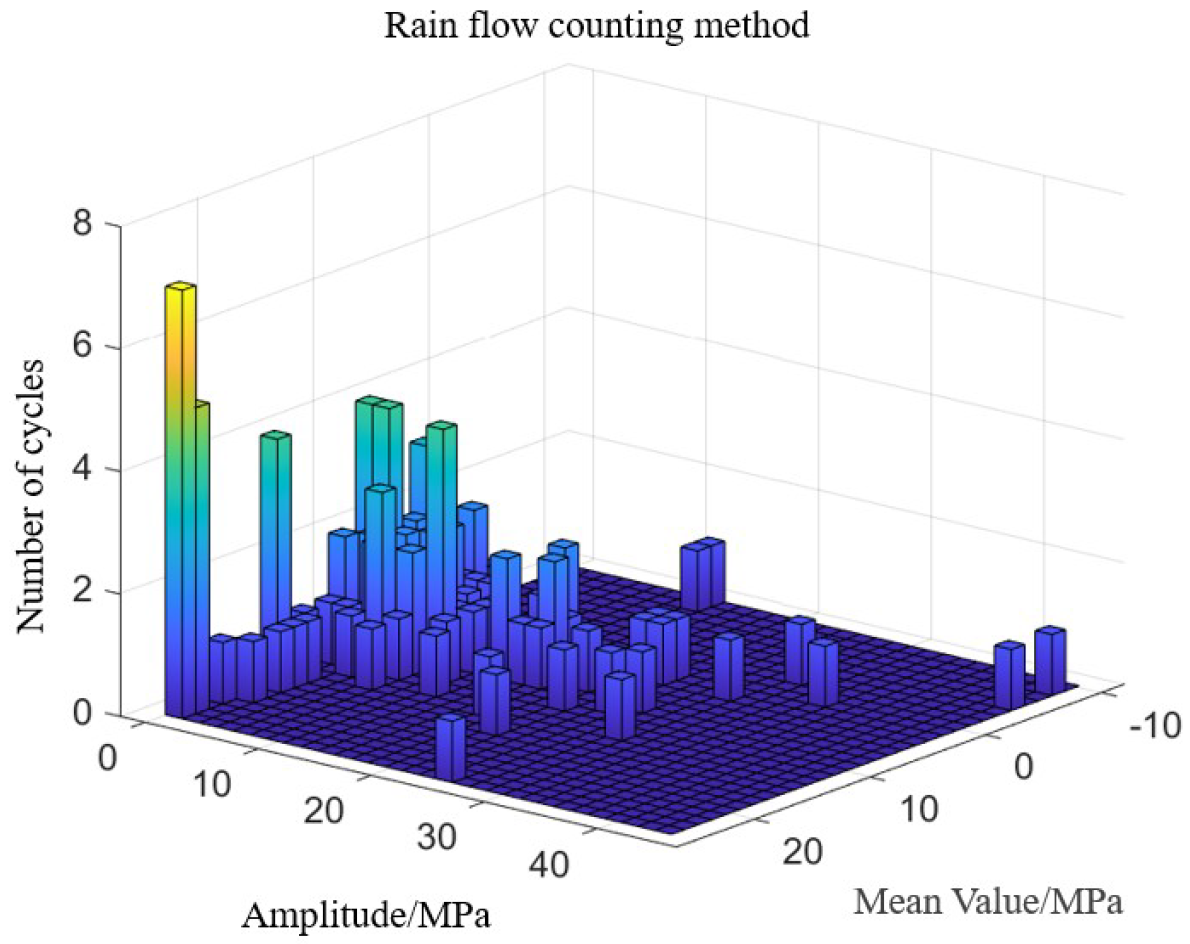

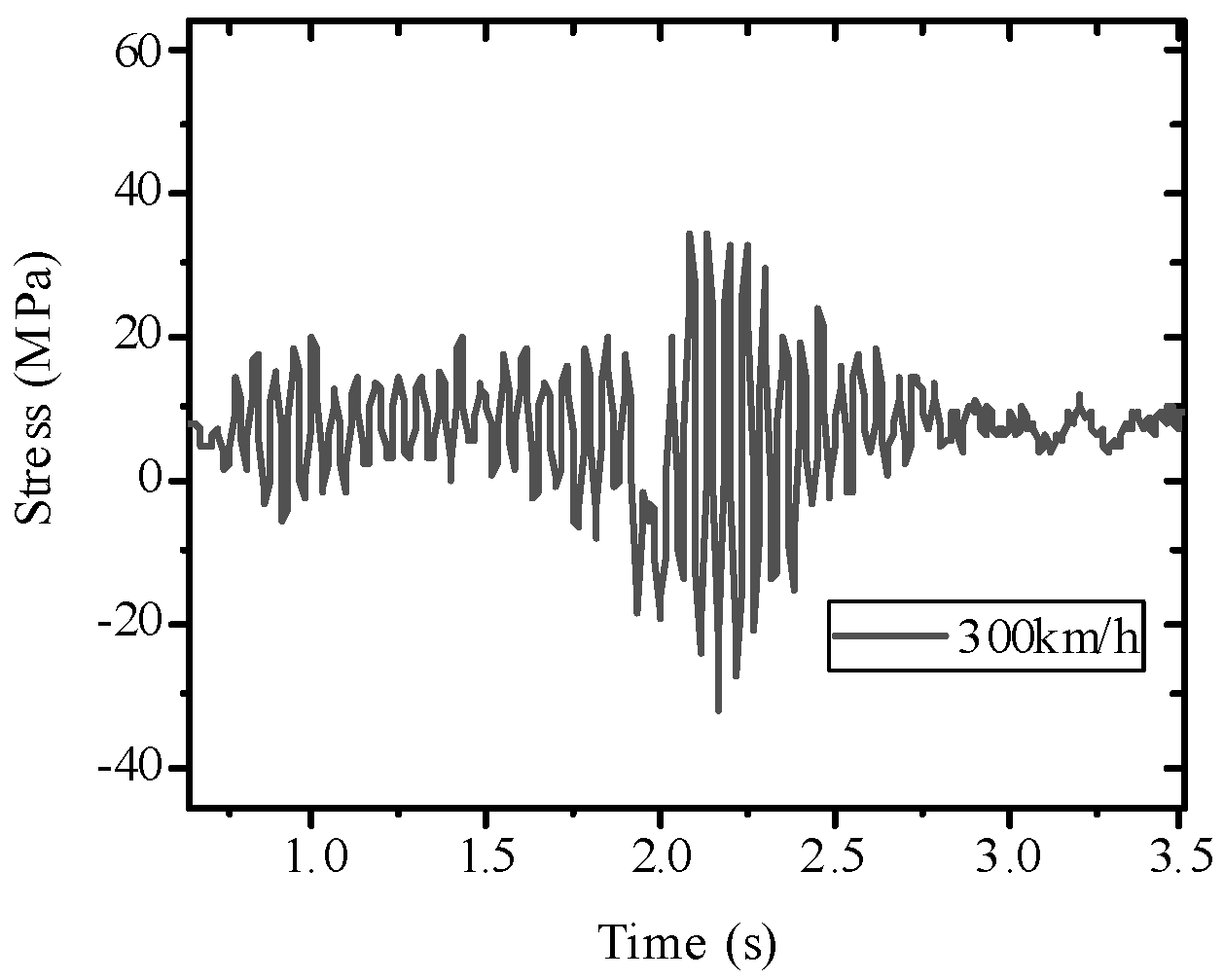

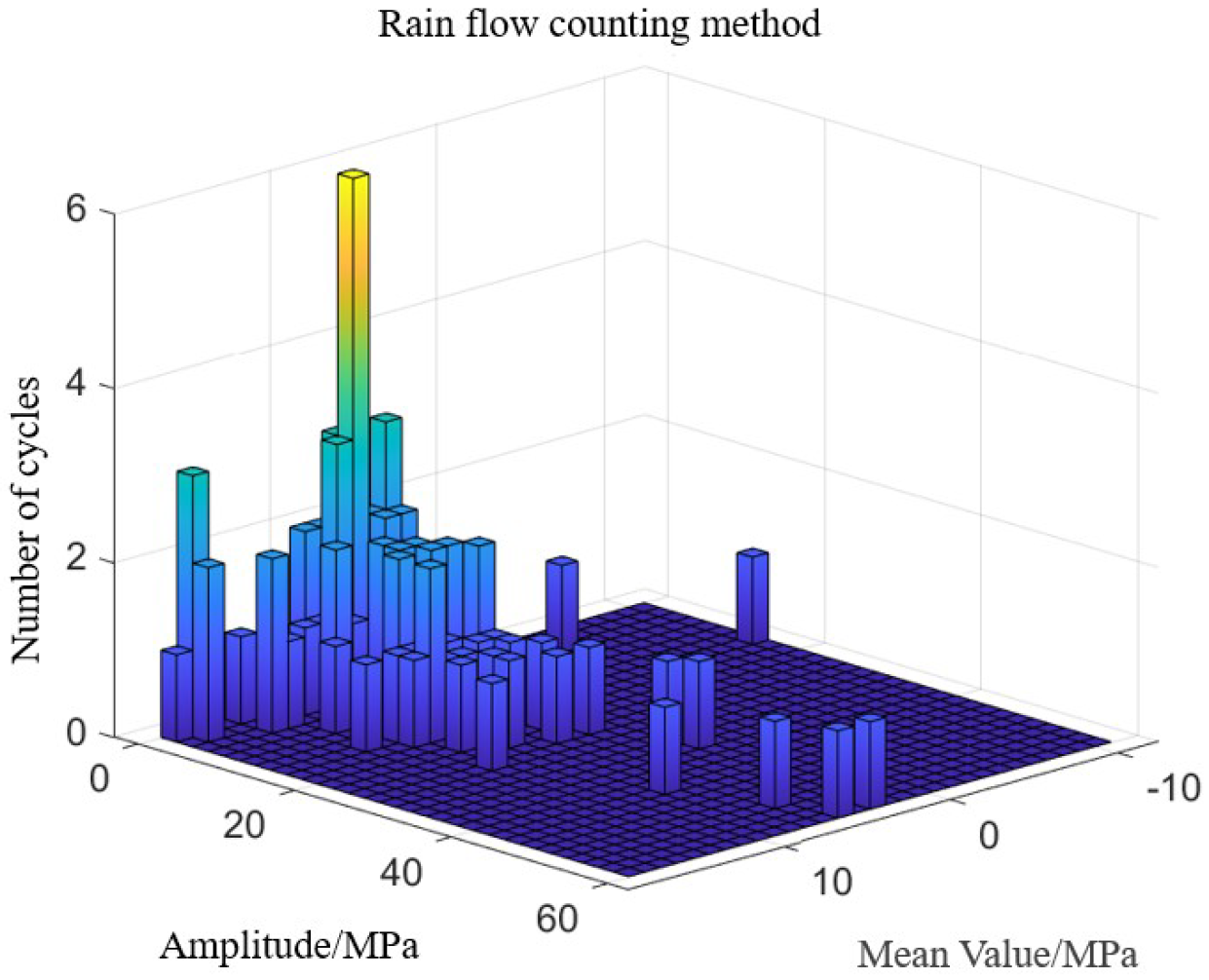

15] studied the fatigue load spectrum and life assessment of critical components in high-speed railway catenary systems. They developed a pantograph–catenary coupling model to calculate contact forces, used finite element analysis (FEA) to extract the load histories of key components, and applied the rainflow counting method to compile fatigue load spectra. Their results revealed that train speed significantly affects fatigue life, with steady arms exhibiting the shortest lifespan. Geng [

16] investigated the aerodynamic fatigue effects of 400 km/h tunnel wind on catenary supports and proposed a wind load conversion method based on numerical simulations of tunnel wind characteristics. They established FEA models to analyze structural strength and fatigue under aerodynamic loads. Zhang [

17] focused on the fatigue performance of H-shaped steel mast base welds under wind loads and validated FEA models to identify hot-spot stress locations and calculate fatigue life via stress–life (S–N) curves. Song et al. [

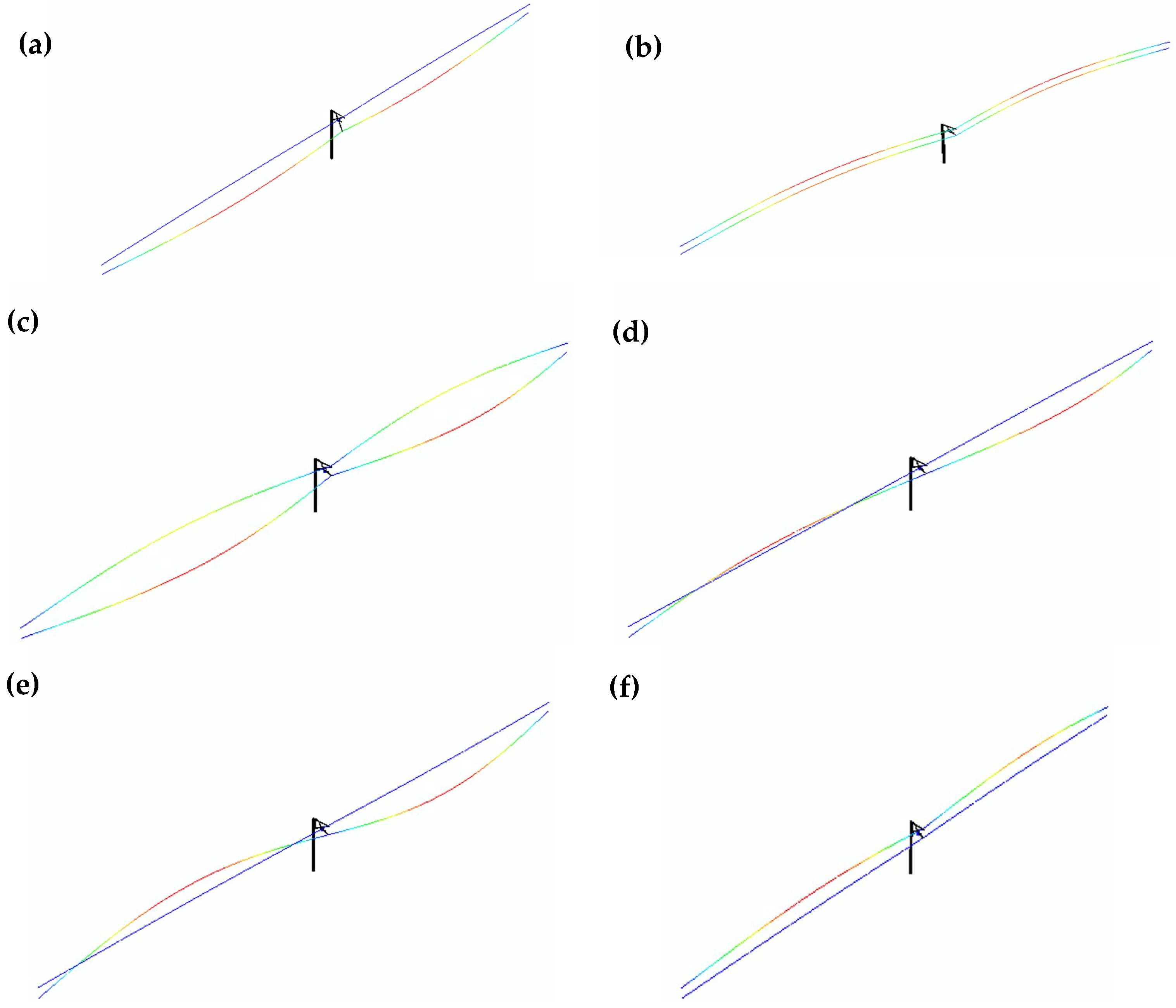

18] analyzed the impact of stochastic wind fields on catenary fatigue by simulating pulsating wind time histories, deriving aerodynamic forces, and combining rainflow counting with the Goodman line correction to estimate fatigue life and identify vulnerable regions (e.g., midspan contact lines). Liu [

19] conducted fatigue studies on elastic hangers through dynamic vibration simulations and refined FEA models, quantifying stress amplitudes and predicting fatigue life across operational speed ranges. Additionally, Liu et al. [

20] addressed premature failure of integrated droppers, attributing it to stress concentration at crimped ends caused by bending fretting fatigue. Their solution involved optimizing crimping models and measurement protocols, validated by fatigue tests to extend service life by 30%. These studies collectively advance methodologies for fatigue analysis, emphasizing load spectrum generation, multiphysics modeling, and design optimization in high-speed catenary systems. Patel et al. [

21] assessed the remaining fatigue life of a steel railway bridge via stress–life and fracture mechanics methods. Using STAAD Pro V8i for 25T-2008 loading simulations at various speeds, they reported that the remaining life decreases with increasing speed at a constant GMT. A 5-MPa stress band is more accurate. The fracture approach is conservative, and the method difference is more stable at this stress band. Their approach is effective for old steel railway bridge assessments. Al-Karawi’ et al. [

22] explored the mean stress effect on HFMI-treated welded parts of railway steel bridges. Using training data and Eurocode models, they reported that

λHFMI is larger for shorter bridges. Single-train bridges can use R ratios for the mean stress. Eurocode’s single-vehicle models are inaccurate, but the light traffic mix is better.

λHFMI expressions are vital for design. After bridge erection, self-weighting does not affect the HFMI-induced residual stress. Further research on

λHFMI and the maximum allowable stress is needed. Verdenius et al. [

23] used Dutch railway axle load data (2012–2019) to assess bridge fatigue. The EN 1991-2 [

24] Annex D model was often conservative but not always conservative. Three new models were developed: Model I (equivalent axle load), Model II (annual summed mass), and Model III (historic traffic). They better represent real-world fatigue loads, with lower variation and higher reliability. The key factors include the equivalent axle load and train type. However, there are uncertainties in dynamic amplification and influence line models and a lack of riveted connection test data. Correia et al. [

25] studied the fatigue strength of riveted railway bridge joints. LR and OR were used for S–N curve fitting; the slope B of the OR was relatively large, and different fatigue lives were predicted, especially in the high-cycle regime. In the stochastic analysis, the Gumbel distribution had the highest fatigue strength, whereas the Weibull distribution had the lowest. Regression methods had little impact on the fatigue life, and constant exponents led to increased strength. There was less stochastic analysis with the Weibull model than with the CFC model, etc., and a constant exponent was closer to the CFC. Simultaneously, emerging innovative measurement methodologies aim to improve the accuracy of structural monitoring and model validation. Gogolik et al. [

26] introduced a novel distortion measurement technique, highlighting the potential of vision-based systems to generate high-resolution, detailed data for calibrating numerical models and monitoring structural health under real operational conditions. In recent years, high-resolution vision-based measurement technologies have gradually matured. Integrating this type of data into the processes of model calibration and predictive analysis can effectively reduce the uncertain factors within models. As a result, the reliability of predictive outcomes for structural health monitoring can be significantly enhanced.

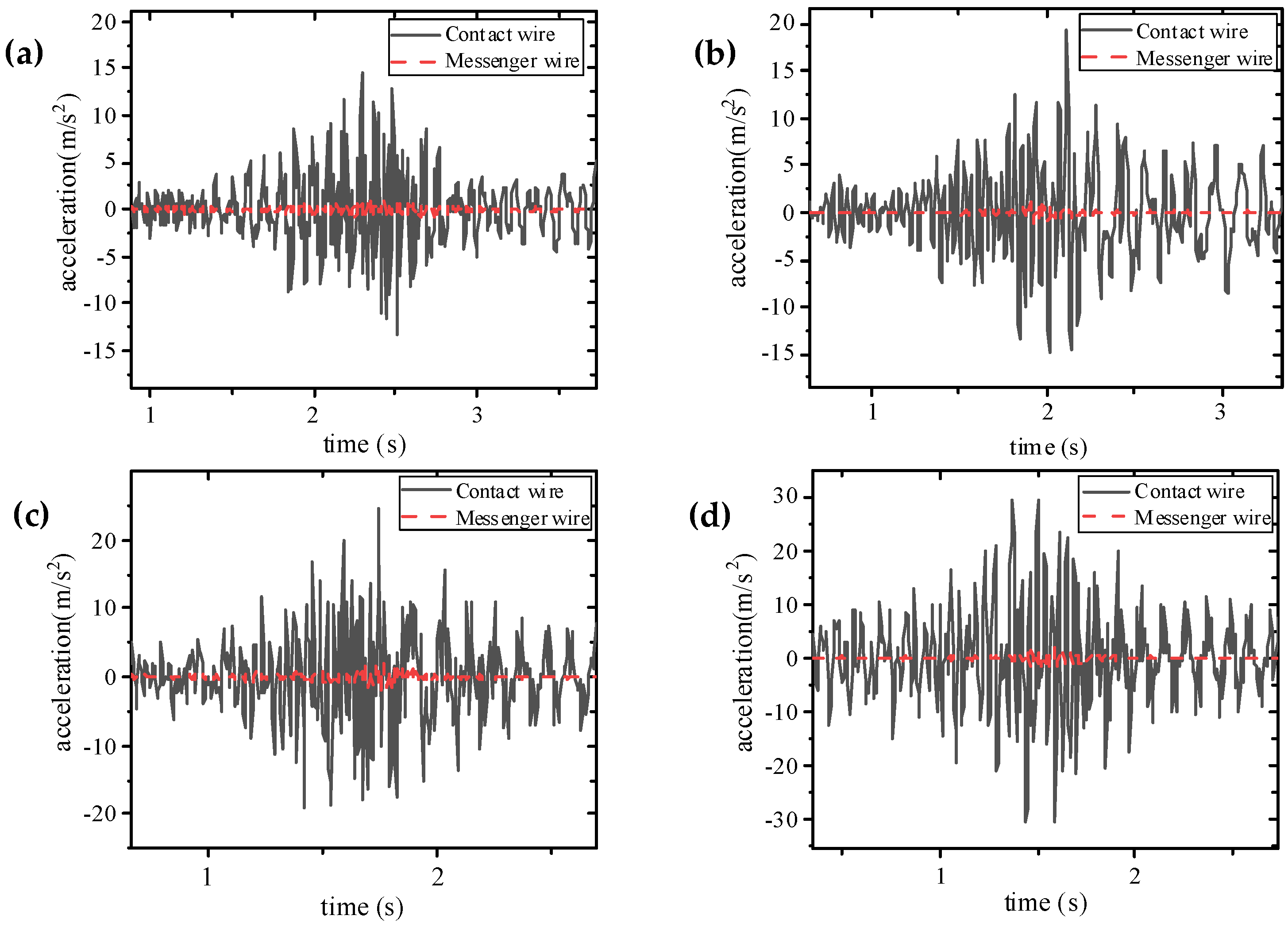

Traditional fatigue life analysis relies on deterministic parameter assumptions, predicting structural failure cycles through S–N curves and Miner’s rule. However, it fails to quantify uncertainties such as scatter in material properties, randomness in load amplitudes, and environmental variations, which may lead to unconservative fatigue life assessment results. Some researchers have conducted studies on the fatigue reliability of auxiliary structures in high-speed railways. Lu et al. [

27] developed a time-dependent fatigue reliability method for heavy-haul railway steel bridges. It has a stress range model and an improved outcrossing rate method. Tests on a real bridge show that the method works well. Increasing axle weight or operation frequency lowers bridge reliability; a small axle weight and high frequency are optimal for reliability and freight needs. Li et al. [

28] proposed a fatigue reliability analysis method for high-speed train motor hangers. They built a model, used Bayesian updating to reduce uncertainty, and applied subset simulation to calculate failure probability. The P-S-N curve and

P0 choice mattered, and the method was more efficient than the Monte Carlo simulation. Hu et al. [

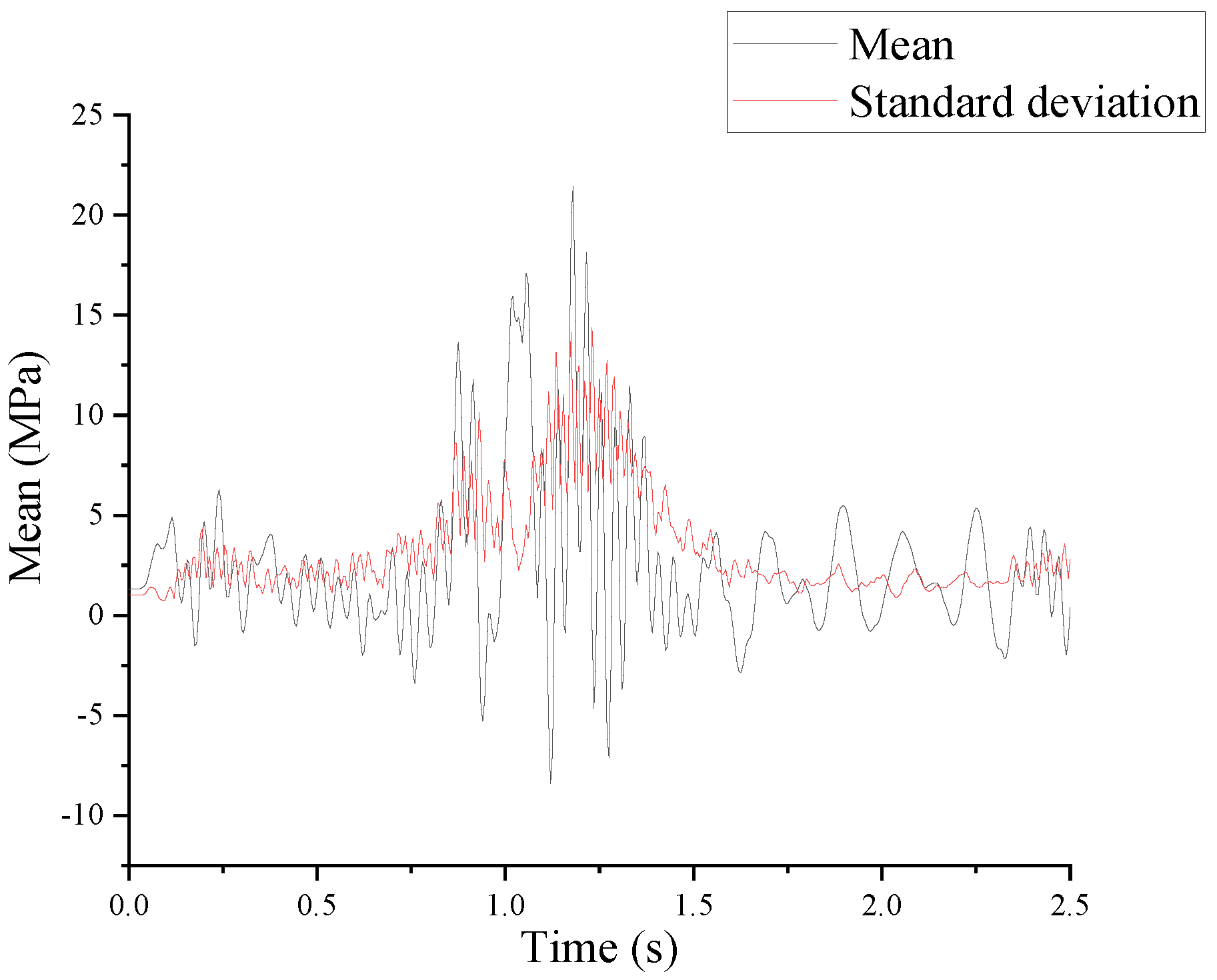

29] proposed a dynamic fatigue reliability method for contact wires on the basis of high-speed pantograph–catenary dynamic simulations. By developing a finite element model to calculate stress time histories, applying the rainflow counting method to analyze stress cycles, and establishing a fatigue reliability model, they derived the time-dependent reliability curve of the contact wire, which illustrates how fatigue reliability decreases with operational time. Tawfik et al. [

30] reviewed rail wheel RCF research. Hertz theory has limits in stress prediction. The fatigue crack life has three stages. Bending, shear, etc., stresses cause rail failure. Common defects have specific causes. Multiple factors affect cracks. Rail grinding, high-strength materials, and reprofiling can reduce RCF defects. Rao, K.B. [

31] presented a data-driven probabilistic fatigue assessment method. Taking the eyebar assembly of the Harahan Bridge as an example, it quantifies safety under uneven load distributions caused by boundary changes. The method considers the coupling of fatigue and eyebar tautness. The results show that component failure under the brittle failure assumption is equivalent to system failure, and the impact of realignment on reliability is evaluated. Railway equipment reliability is key for design/maintenance. For TGV prestressed screwed connections, Chateauneuf A. et al. [

32] proposed a reliability-based fatigue design and assessment method to address loading variations from tunnel pressure waves and material strength uncertainties. A fatigue reliability index equation is formulated to evaluate vehicle body reliability under fluctuating tunnel pressures, considering the pressure distribution, fatigue strength characteristics, and stress-transfer functions from pressure loads. This methodology balances cost/reliability and assesses fatigue, corrosion, and imperfect maintenance, including the lifecycle, deterioration, and uncertainties. The results show that connections are sensitive to friction/tightening/prestressing variations despite high load resistance, indicating robustness in operational/maintenance contexts. In summary, current research on the fatigue life and fatigue reliability of auxiliary structures in high-speed railways has achieved notable progress. However, research on long-term cumulative fatigue damage in catenary support systems under coupled complex loads such as dynamic train forces, wind, and temperature variations remains limited. The existing studies have several limitations: some focus solely on single load types—Zhang [

17] focused on wind load alone with ≤2 × 10

6 cycles; Song et al. [

18] explored wind-induced fatigue over a 50-year life span without train loads; and Qi et al. [

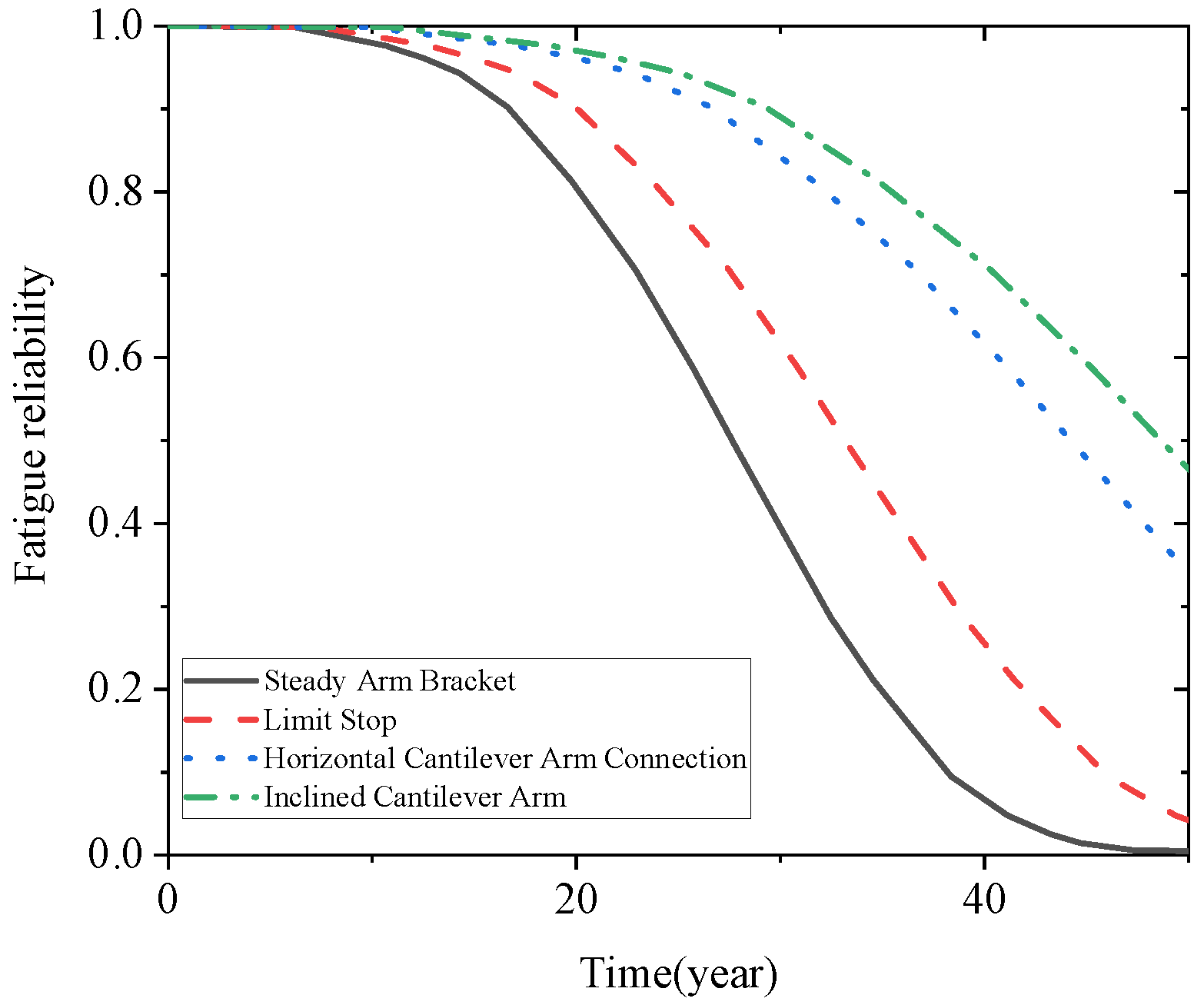

13] studied the pantograph–catenary system in isolation for a 120-year life cycle, excluding wind and icing effects. Other studies lack long-term cumulative damage analysis. Geng et al. [

16] investigated aerodynamic loads inside tunnels through a one-day simulation, ignoring repeated traffic cycles. The present paper therefore closes this gap by propagating the full traffic–wind–thermal load spectrum through a 20-year damage accumulation and time-dependent reliability framework. Additionally, there is insufficient understanding of the inherent scatter in the material parameters of catenary supports and stochastic external excitations (e.g., train traffic frequency and speed) in real-world service environments. As high-speed trains continue to operate at increasing speeds and railway networks expand, accurately understanding the generation mechanisms and action patterns of operational loads and further investigating their impacts on catenary support structures are critical to ensuring safe and reliable train operations and enabling scientific maintenance of railway infrastructure. In this study, we apply fatigue reliability theory to construct probabilistic limit state equations for catenary support structures. Key variables such as critical damage thresholds, equivalent stress amplitudes, and S–N curve parameters are treated as stochastic processes. By employing Monte Carlo simulations, we quantify the exceedance probability of cumulative fatigue damage, providing a more realistic reflection of time-dependent failure risks in these structures.