Analysis and Design of Anchored Sheet-Pile Walls: Theoretical Comparisons, Experimental Validation, and Practical Procedures

Abstract

1. Introduction

2. Significance of the Study

3. Materials and Methods

3.1. Classical Methods

3.2. Rowe’s Methods

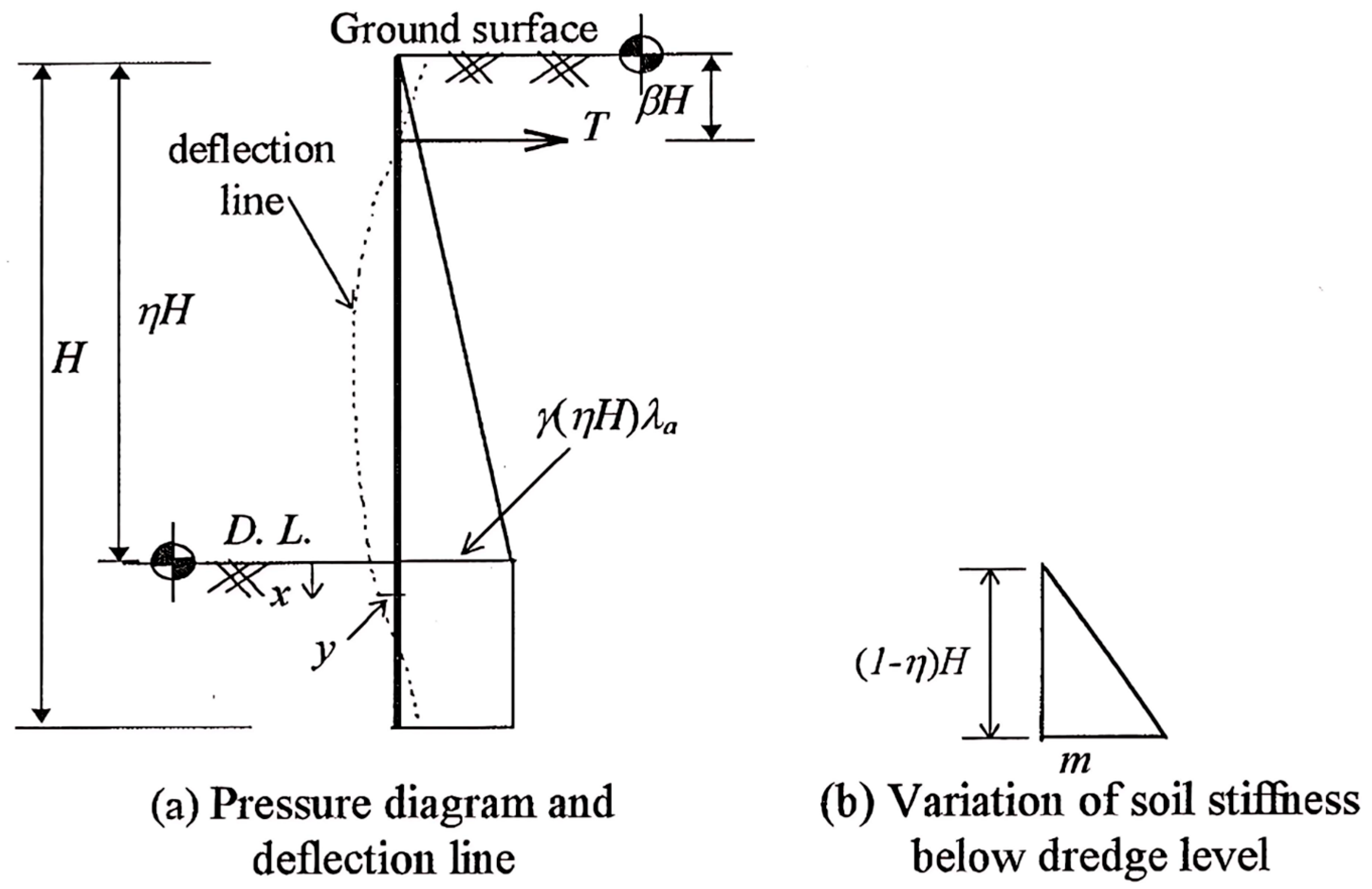

- The soil’s relative density, flexibility number, ρ, of the SP, is defined as , where H = total height of the sheet pile, E = modulus of elasticity, and I = moment of inertia of unit width of the wall.

- The relative height of the free piling, , where H′ = height of the SP above the dredge level.

- The relative depth of the tie-rod position, β, is expressed as the fraction of the total height H.

- x is the depth below the dredge level, and y is the horizontal deflection at x.

- Pa and Pp = the resultant active and passive pressures below the dredge level. For more details of Rowe’s theoretical method, see the reference [30].

3.3. Numerical Methods

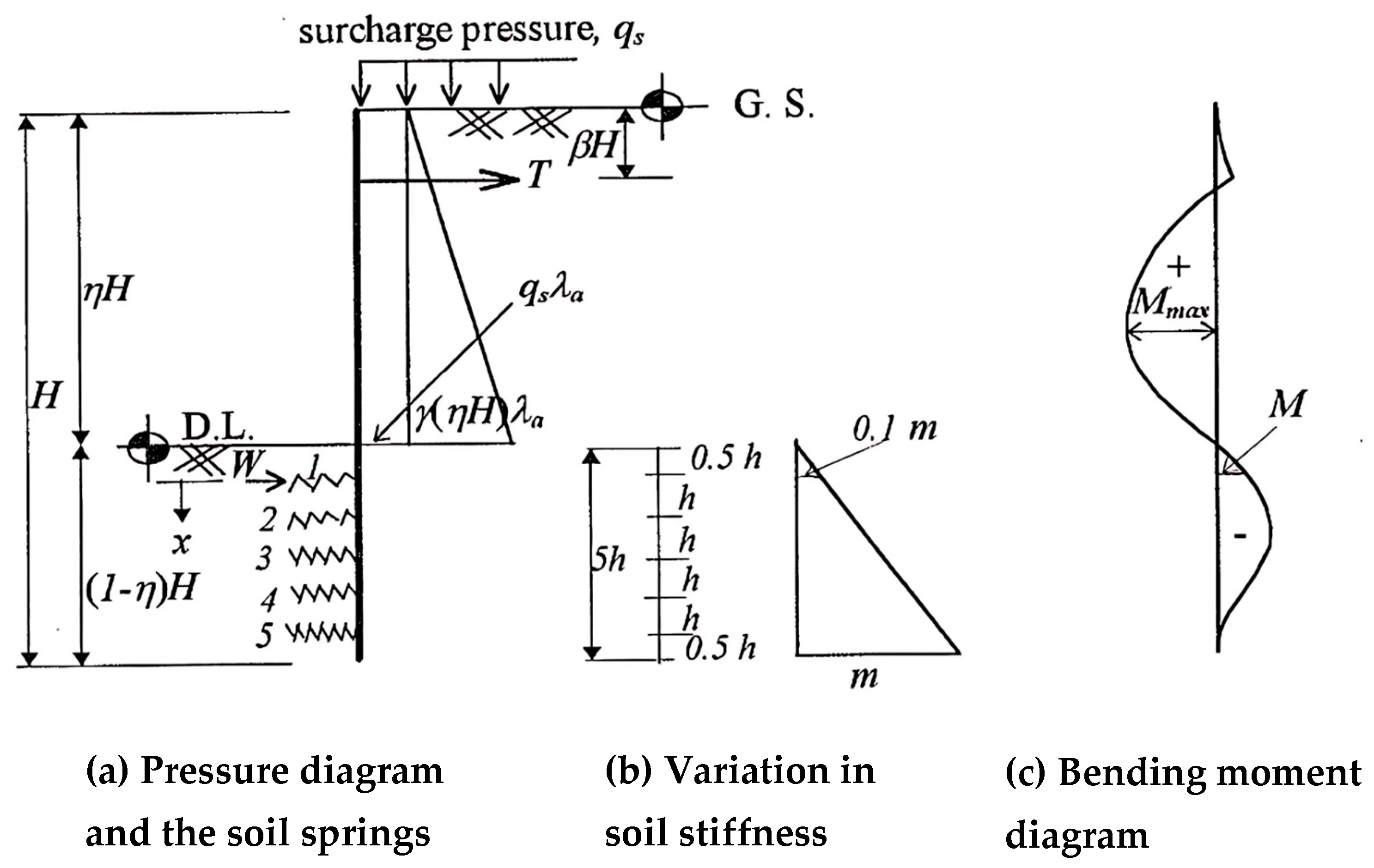

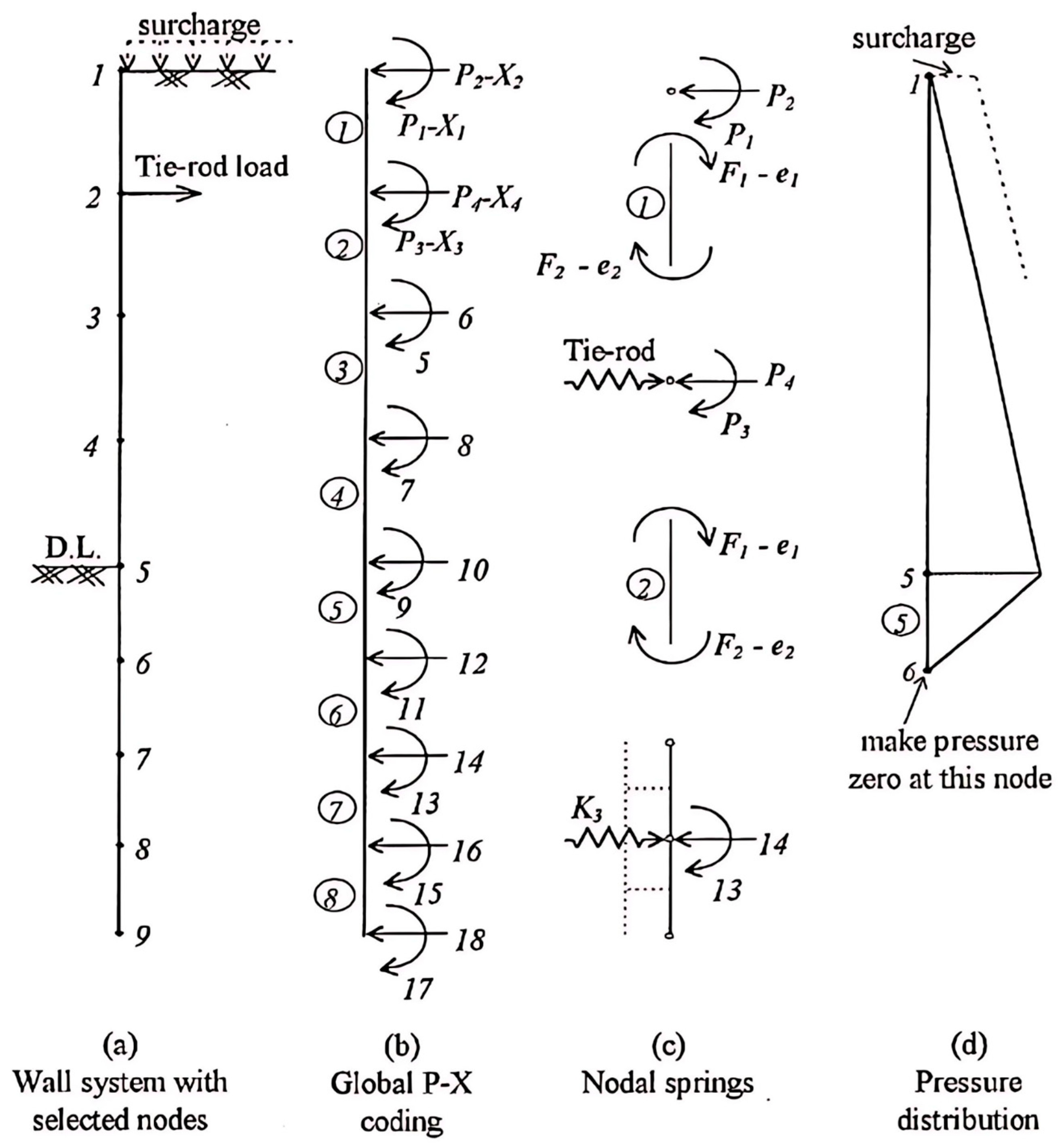

3.4. Distribution Theories

- The sheet pile deflection at the anchorage is equal to the tie-rod yield, ya.

- At the dredge level, the deflection of the upper and lower beams is equal.

- The slopes of the deflection line at the dredge level are the same for the upper and lower beams.

- Ri = net lateral reaction on spring I;

- Roi = reaction on spring i due to the at-rest pressure condition;

- ki = stuffiness of spring, I;

- yi = deflection of the ith spring, taken negative when the deflection is away from the backfill;

- Rdi = reaction due to beam deformation = ki yi.

Effect of Surcharge Pressure

3.5. Finite Element Methods (FEMs)

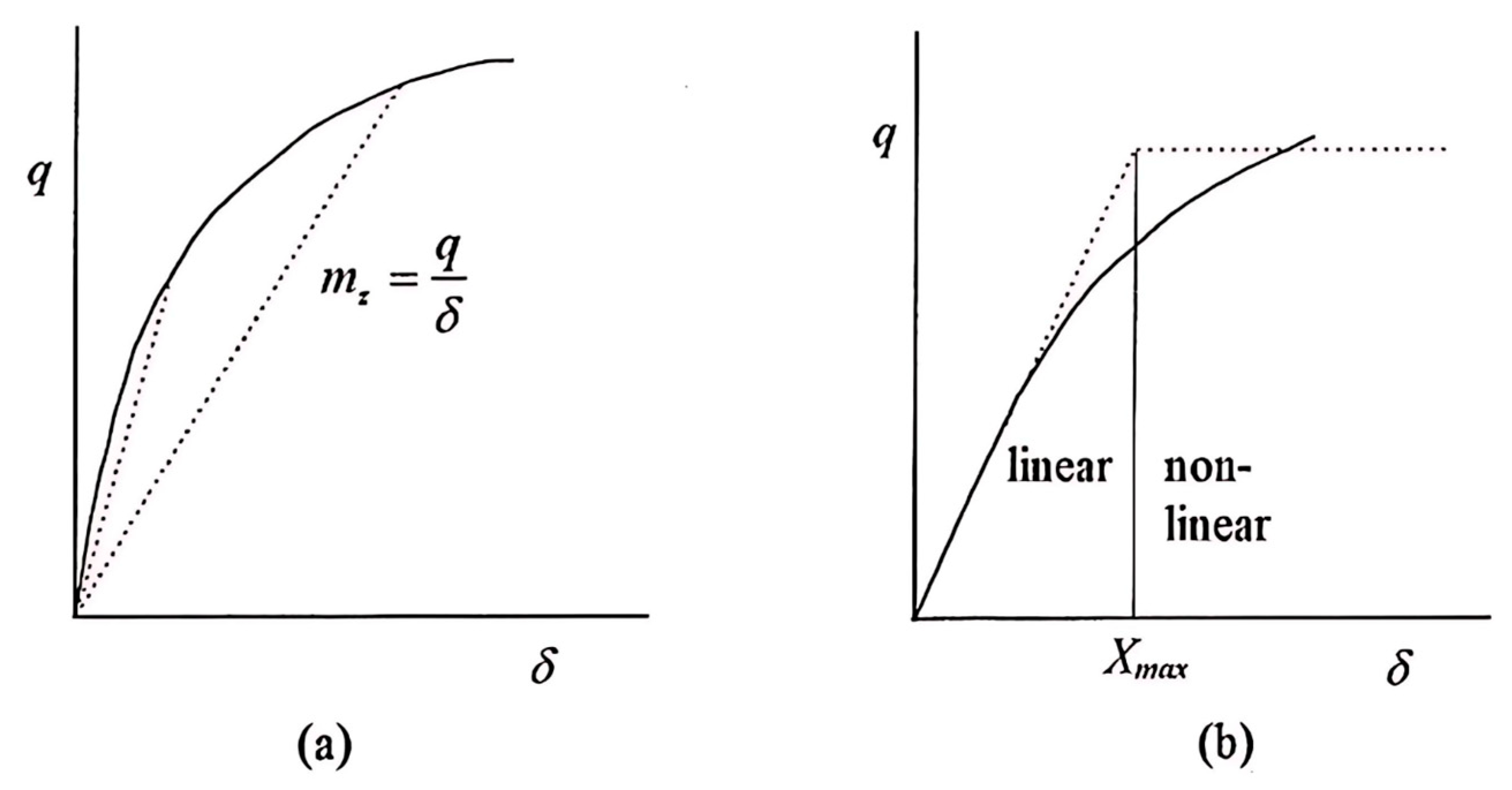

3.6. Estimation of Soil Stiffness

- ms = soil stiffness, modulus of subgrade reaction;

- q = soil pressure;

- δ = deflection.

- qu = the ultimate bearing capacity of the soil at a settlement of 1 inch (0.025 m);

- As = constant for either horizontal or vertical members.;

- Bs = coefficient for depth;

- c = soil cohesion;

- Bs = coefficient for depth;

- = overburden pressure = z;

- z = depth below dredge level;

- n = exponent to give ms the best fit (if load test or other data is available);

- B = 1.0, taking the unit width of the wall;

- Nc, Nq, and Nγ are the bearing capacity factors for cohesion, surcharge, and unit weight, respectively.

3.7. Experimental Work

3.7.1. Description of the Apparatus

3.7.2. Control Tests

3.7.3. Filling the Earth Tank

3.7.4. Deflection Measurements

3.7.5. Strain Measurements

3.7.6. Measurements of Anchor Force and Tie-Rod Yield

3.7.7. Test Runs

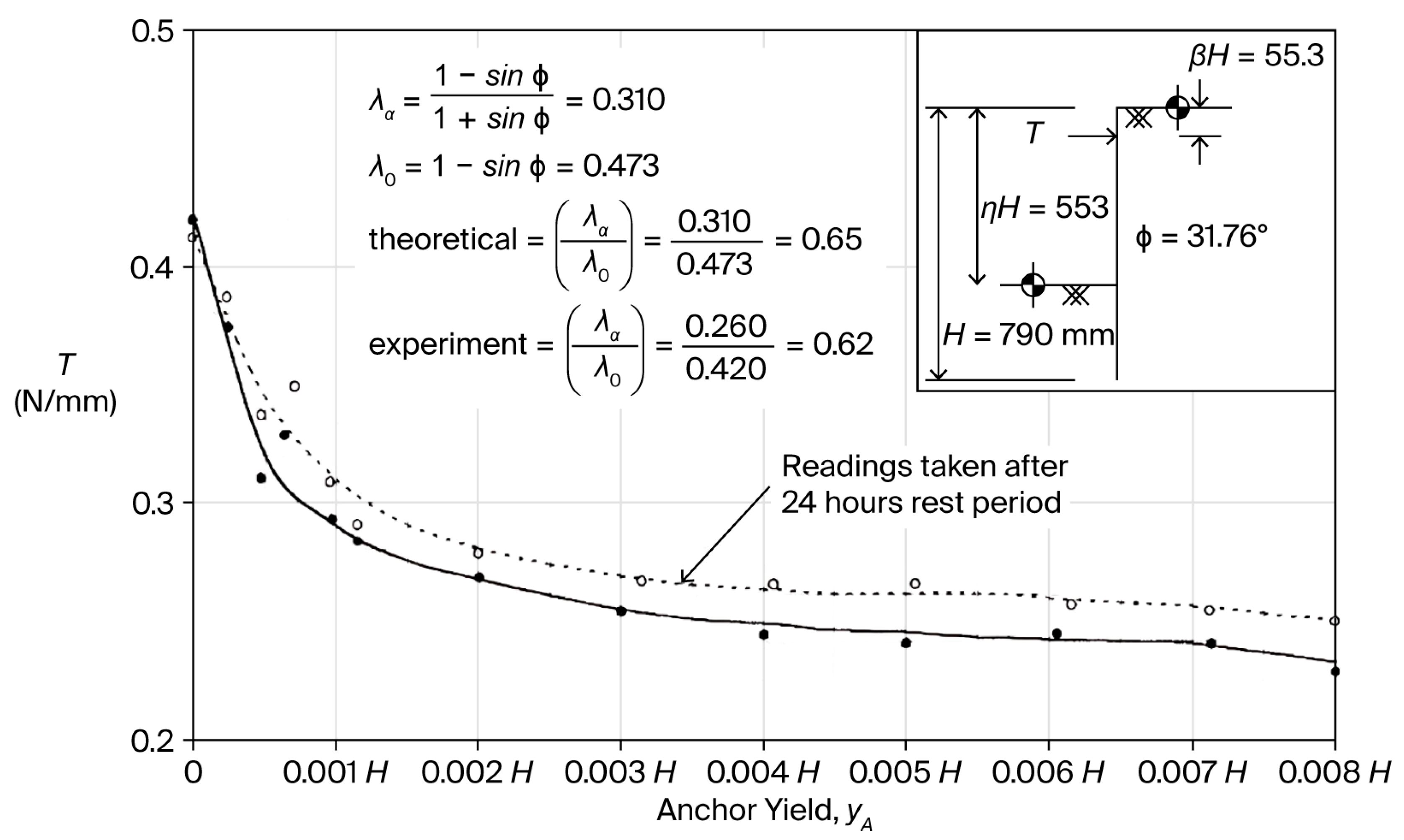

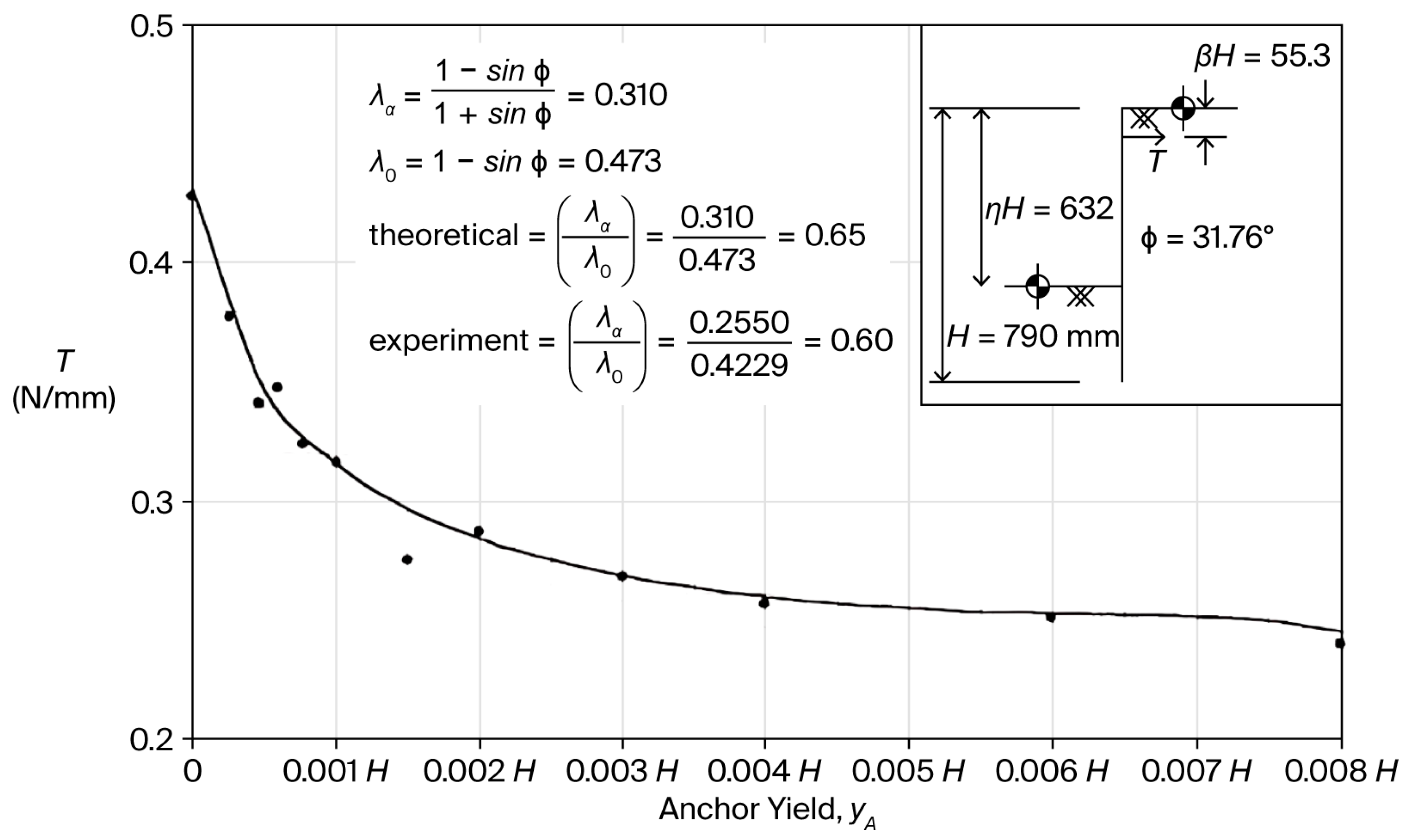

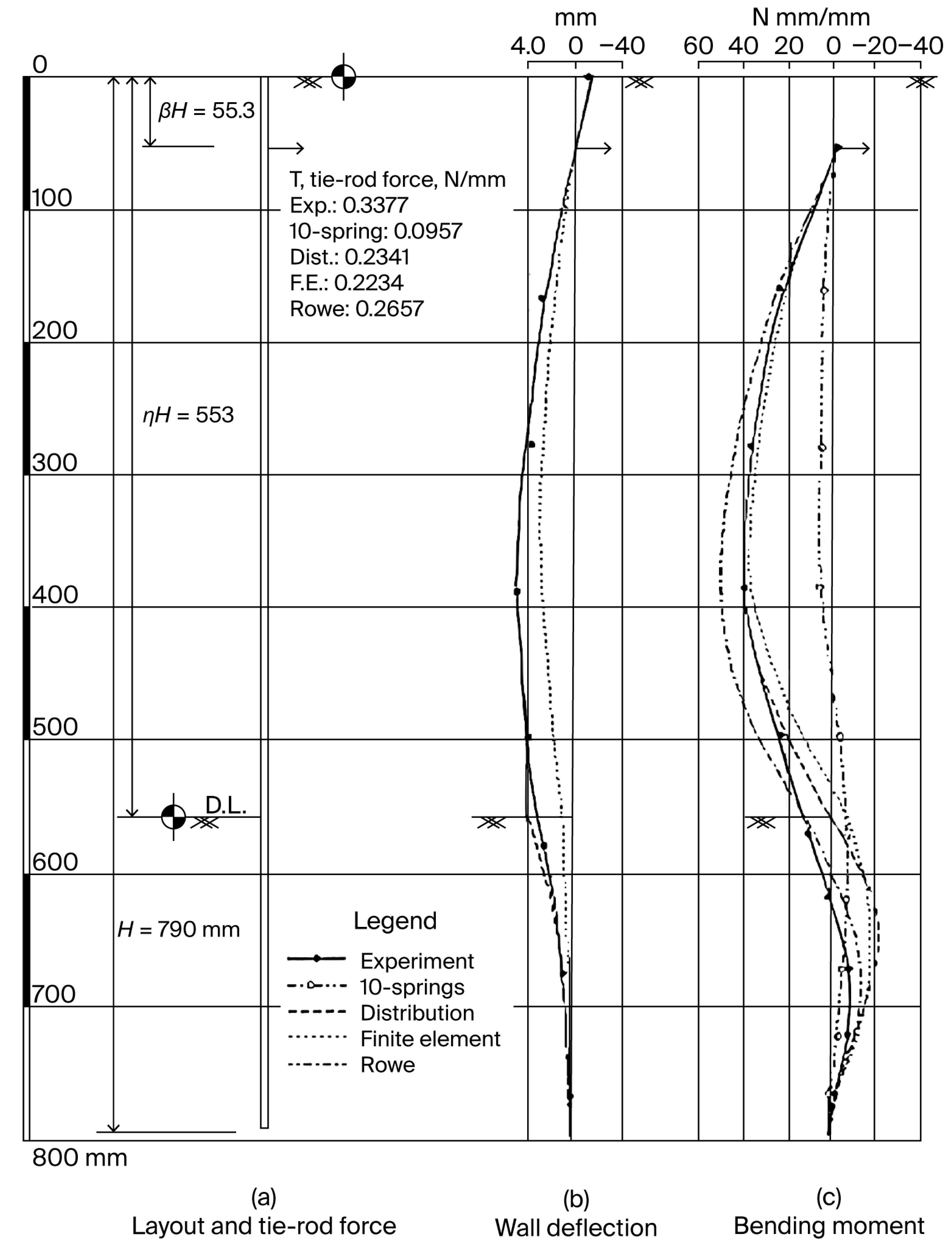

4. Results and Discussions

4.1. Comparison Between Test Results and Theoretical Solutions

4.2. Range of Applications of Each Theory

4.2.1. Rowe’s Theoretical Method

4.2.2. The Distribution Theory

4.2.3. The 10-Springs Method

- Rai = spring reaction due to active pressure;

- λa = coefficient of active pressure;

- γ = soil unit weight;

- h = distance between adjacent springs;

- zi = depth to spring i measured from the ground surface.

4.2.4. The Finite Element Method

4.2.5. Classical Methods

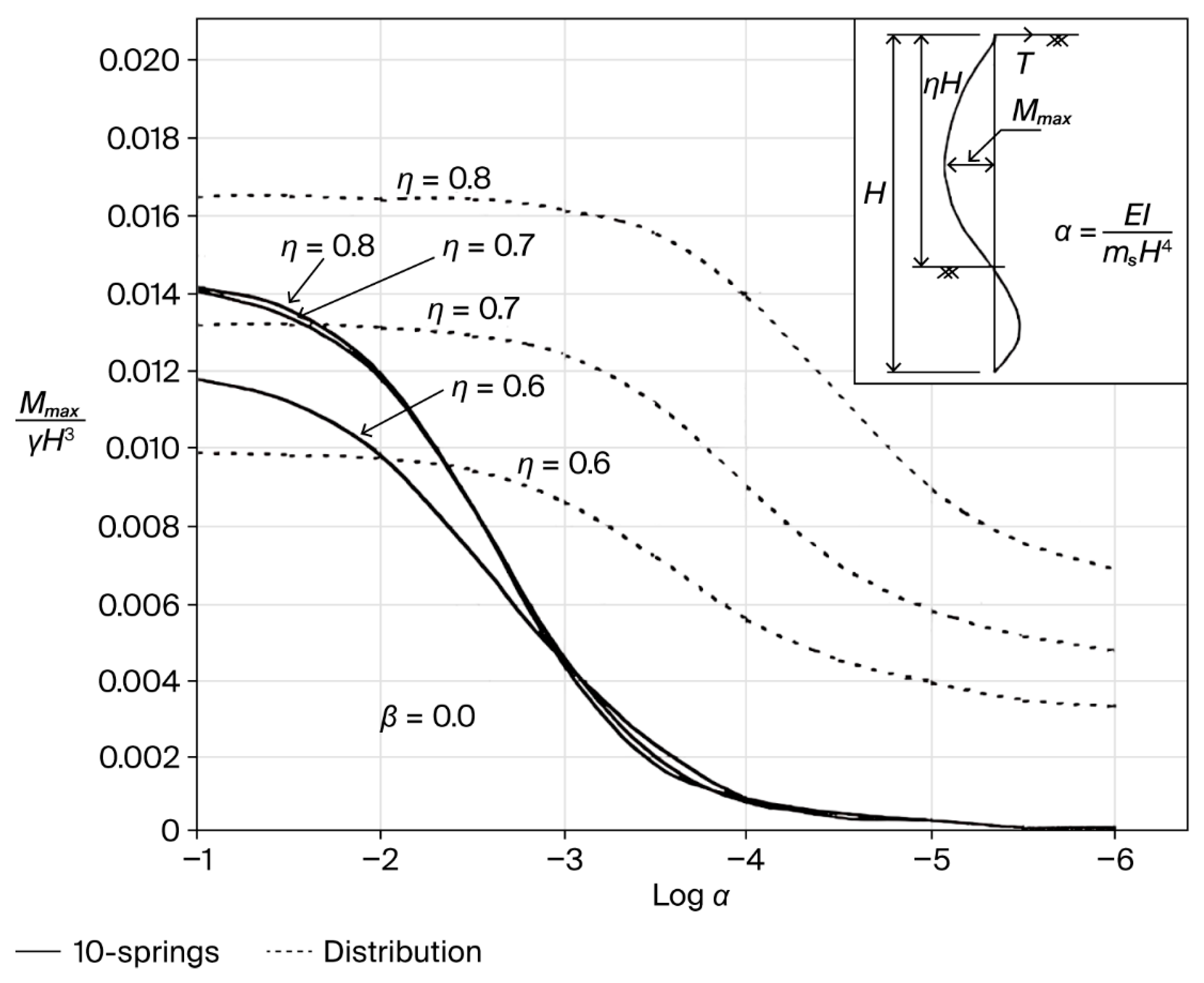

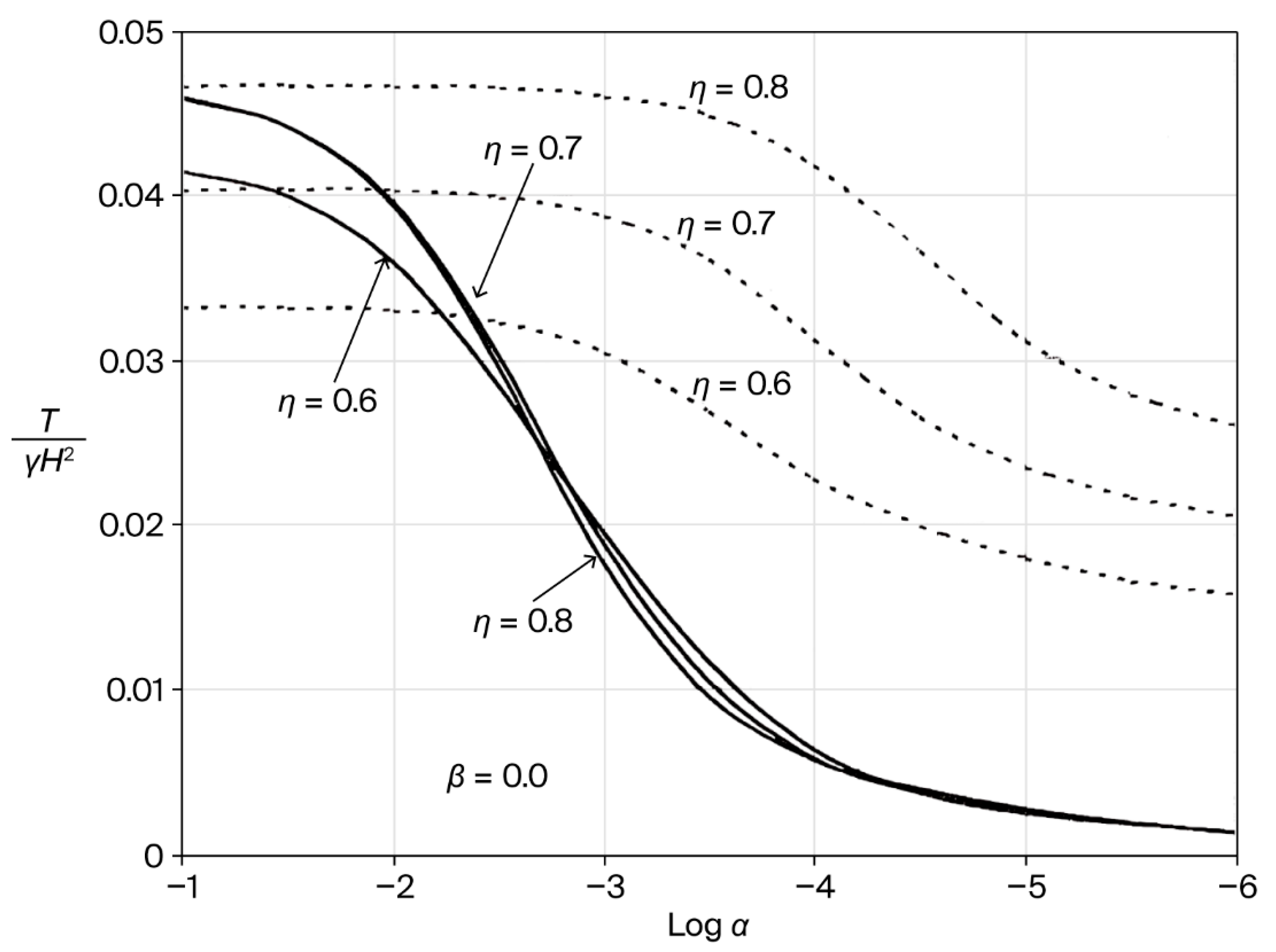

4.3. Behavior of the Sheet Pile for Varying η Values

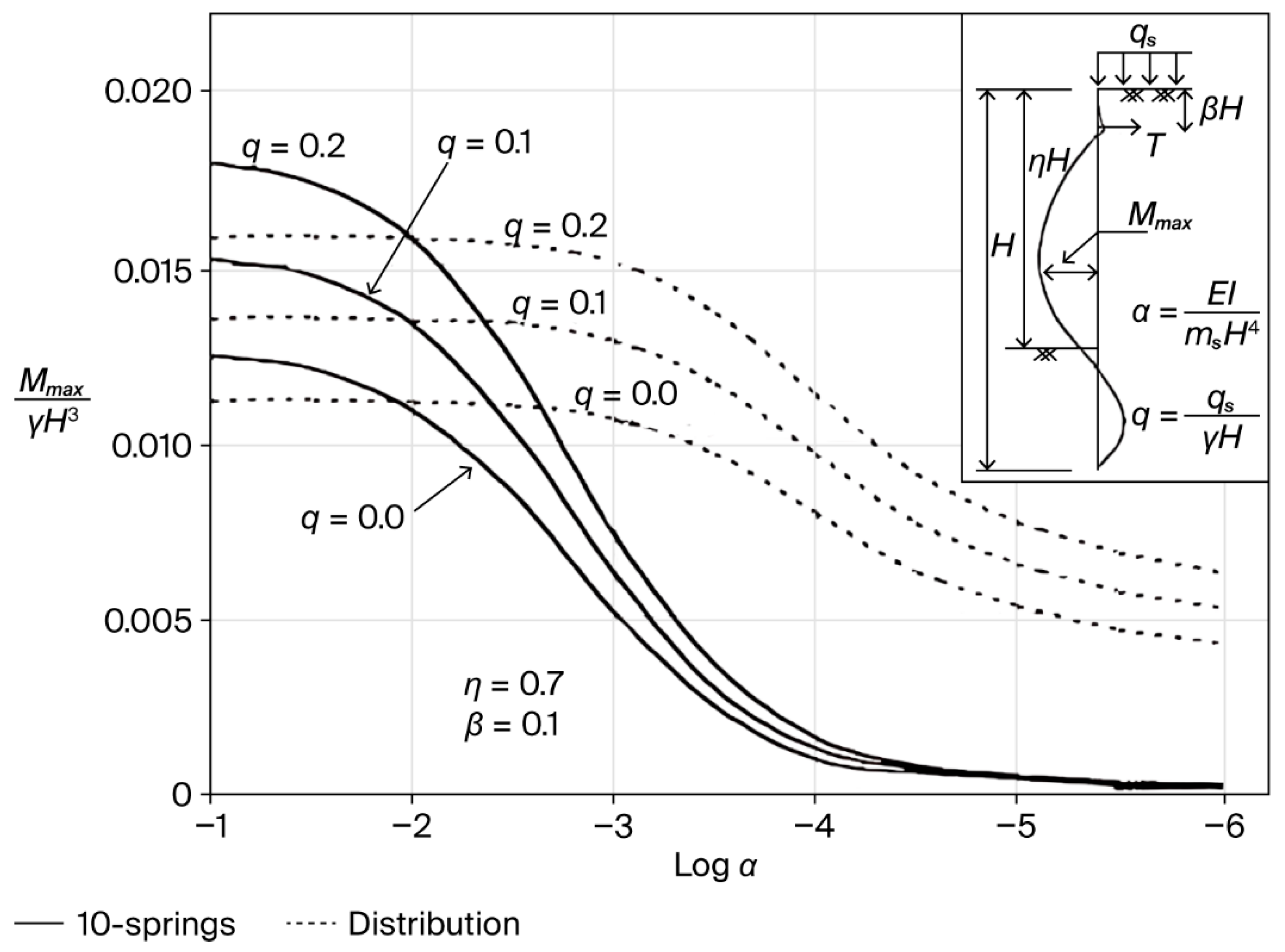

4.4. Behavior of the Sheet Pile for Varying α Values

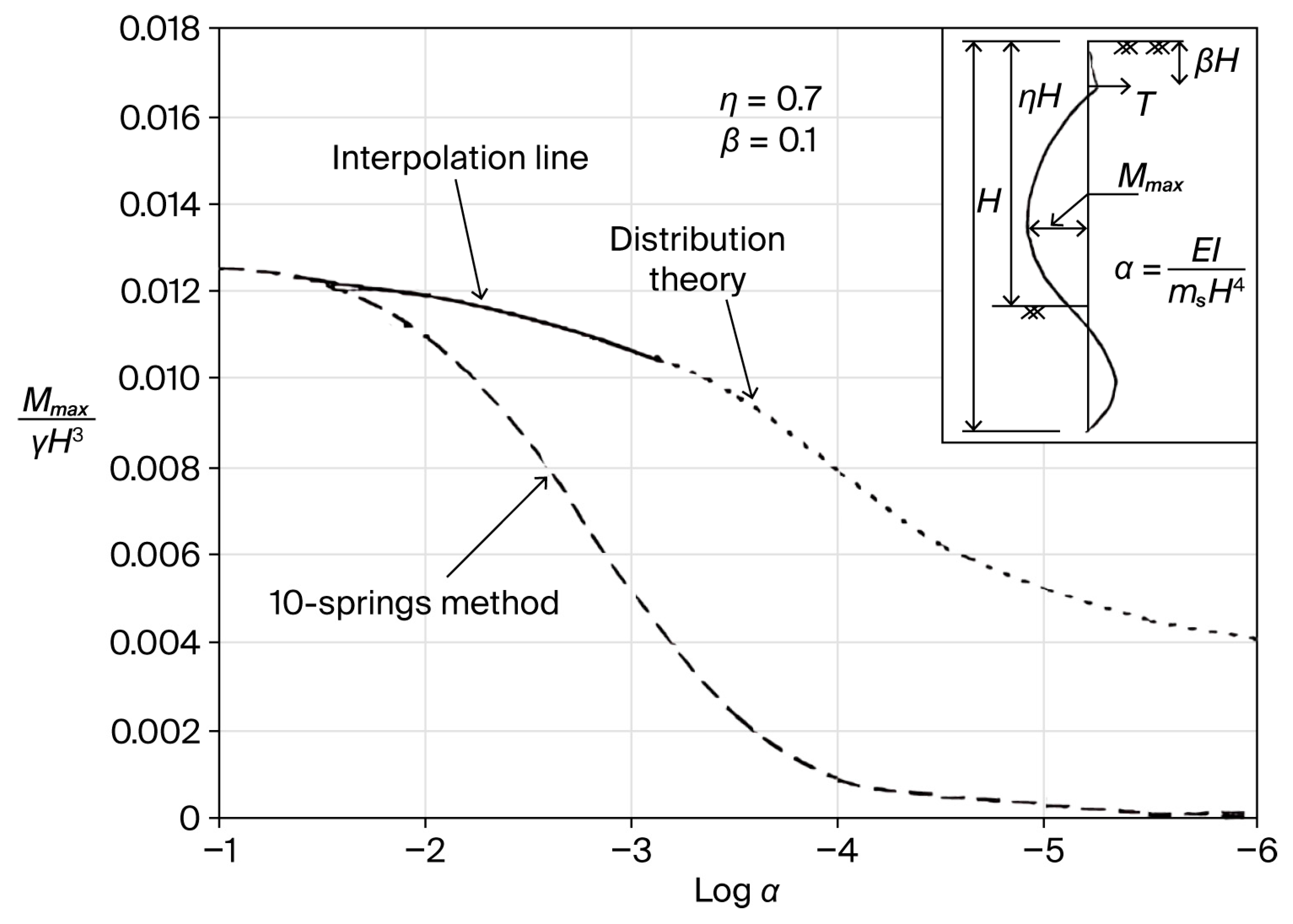

4.5. Extrapolation Between the 10-Springs Method and the Distribution Theory

4.6. Effect of Surcharge Pressure

5. Design Procedure

6. Inferences and Conclusions

6.1. Inferences

6.1.1. Theoretical Solutions of Anchored Sheet-Pile Walls

6.1.2. Tie-Rod Yield

6.1.3. Time-Dependent Increase in Earth Pressure

6.1.4. Limits of Practical Dimensions of Anchored Sheet-Pile Walls

6.1.5. Design Methodology of ASPWs

6.1.6. Modulus of Subgrade Reaction

6.2. Conclusions and Future Research Directions

- (1)

- Scope of applicability of classical methods: Each of the four theoretical approaches provided acceptable predictions under certain conditions, but none captured the full behavior of ASPWs across all ranges of design parameters. The 10-springs method aligned well with test results for shallow dredge depths (η ≤ 0.4), while the distribution theory and finite element method performed better for η > 0.4. Rowe’s method generally predicted higher bending moments, with tie-rod forces close to experimental values at lower η. These observations highlight the value of using multiple analytical perspectives when designing ASPWs.

- (2)

- Design aids and limitations: The combined use of the 10-springs method and distribution theory allowed for the development of design charts and tables that can serve as preliminary tools for estimating bending moments and tie-rod forces under varied conditions. However, given the limited scale and simplifications of the experimental validation, these charts should be regarded as indicative rather than definitive. They provide initial guidance but should not substitute detailed numerical analyses or full-scale validation in critical urban projects.

- (3)

- Experimental validation: The laboratory tests provided useful comparative data but were necessarily simplified, employing a dry sand backfill and controlled boundary conditions. As such, the findings cannot be directly generalized to complex urban construction settings, where soil heterogeneity, groundwater conditions, construction sequences, and load variability play critical roles.

- (4)

- Sensitivity to key parameters: Parameters such as soil modulus, pile stiffness, anchor depth, and surcharge loading are known to significantly influence ASPW performance. While some trends were highlighted through theoretical comparisons, this study did not conduct a full sensitivity analysis. Future work should systematically explore these parameters using advanced 3D finite element modeling and probabilistic or machine learning-based approaches to better quantify uncertainty and enhance design reliability.

- (5)

- Measurements of anchor rod force taken 24 h after each increment of anchor yield showed an average increase of 5% in the anchor force. This pressure increase led to additional tests aimed at assessing the time-dependent rise in earth loading. Tests conducted on rigid walls revealed a significant increase in lateral earth pressure over time, which was further accelerated by minor tapping behind the retaining wall. Given the potential for time-dependent increases in earth pressure behind retaining structures, it is advisable to use a higher coefficient of lateral earth pressure than that provided by the active pressure state. Based on the limited tests conducted in this study, it appears that the lateral pressure coefficient might need to approach the at-rest pressure coefficient for design purposes. This is particularly relevant for structures tapping behind the sheet pile, which is anticipated due to traffic and other loading conditions, such as in quay walls, wharves, bridge abutments, and other earth-retaining structures. Therefore, it may be prudent to use a coefficient of lateral earth pressure that is higher than the active coefficient.

Future Research Directions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wittekoek, B.; van Eekelen, S.J.M.; Terwindt, J.; Korff, M.; van Duijnen, P.G.; Detert, O.; Bezuijen, A. Geogrid-anchored sheet pile walls; a small-scale experimental and numerical study. Geosynth. Int. 2023, 30, 561–583. [Google Scholar] [CrossRef]

- Gil-Hernandez, J.A.; Suaza-Cortes, J.A.; Zapata-Medina, D.G. Parametric Analysis of a Retaining System Formed by Anchored Piles in Urban Excavations. Indian Geotech. J. 2025, 55, 1328–1337. [Google Scholar] [CrossRef]

- Fusco, A.; Viggiani, G.M.B.; Madabhushi, G.S.P.; Conti, R.; Prüm, C. Seismic Response of Anchored Steel Sheet Pile Walls in Dry and Saturated Sand. In Proceedings of the 4th International Conference on Performance Based Design in Earthquake Geotechnical Engineering, Beijing, China, 15–17 July 2022. [Google Scholar] [CrossRef]

- Tan, W.; Lei, Z.; Wang, Y.; Liu, J.; Lai, P.; Mei, Y.; Liu, W.; Zhou, D. Analyzing the Impact of Deep Excavation on Retaining Structure Deformation Based on Element Tracking. Buildings 2024, 14, 3069. [Google Scholar] [CrossRef]

- Li, S.; Wang, F.; Le, Y.; Que, Q.; Su, Y.; Lin, H. Design and deformation pattern simulation of deep excavation support structures. Front. Earth Sci. 2024, 12, 1416957. [Google Scholar] [CrossRef]

- Schoen, M.; Konig, D.; Lavasan, A.A.; Wichtmann, T.; Holter, R.; Wittekoek, B.; van Eekelen, S.J.M.; van Duijnen, P.G.; Detert, O. Numerical investigation of geogrid back-anchored sheet pile walls. In Geosynthetics: Leading the Way to a Resilient Planet; CRC Press: Boca Raton, FL, USA, 2023; pp. 954–959. [Google Scholar] [CrossRef]

- Qu, H.; Li, R.; Zhang, J.; Hu, H.; Zhang, D. A novel approach for seismic design of anchored sheet pile wall. Teh. Vjesn.-Tech. Gaz. 2016, 23, 455–463. [Google Scholar] [CrossRef]

- Sarshar, N.; Derakhshani, A. Stability analysis of anchored sheet pile wall considering soil spatial variability based on fuzzy logic. Ocean Eng. 2024, 308, 118351. [Google Scholar] [CrossRef]

- Kannaujiya, P.; Chauhan, V.B. Behavior of Anchored Sheet Pile Wall. In Sustainable Civil Infrastructures; Springer: Cham, Switzerland, 2020; pp. 184–195. [Google Scholar] [CrossRef]

- Debnath, A.; Pal, S.K. A numerical analysis on anchored sheet pile wall subjected to surcharge strip loading. J. Eng. Res. 2023, 11, 62–74. [Google Scholar] [CrossRef]

- Verruijt, A. Sheet Pile Walls. In Computational Geomechanics; Springer: Dordrecht, The Netherlands, 1995; pp. 67–77. [Google Scholar] [CrossRef]

- Qu, H.-L.; Luo, H.; Hu, H.-G.; Jia, H.-Y.; Zhang, D.-Y. Dynamic response of anchored sheet pile wall under ground motion: Analytical model with experimental validation. Soil Dyn. Earthq. Eng. 2018, 115, 896–906. [Google Scholar] [CrossRef]

- Chen, S.; Guan, Y.; Dai, J.; Han, X. Behavior of an anchored sheet pile quay in soft clay reinforced by various structural types of cemented soil. Can. Geotech. J. 2024, 61, 1886–1901. [Google Scholar] [CrossRef]

- ACI Committee 318. 318-19 Building Code Requirements for Structural Concrete and Commentary; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar] [CrossRef]

- EN 1997-1; Eurocode 7: Geotechnical Design—Part 1: General Rules. The European Committee for Standardization: Brussels, Belgium, 2004.

- Rowe, P.W. Anchored sheet-pile walls. Proc. Inst. Civ. Eng. 1952, 1, 27–70. [Google Scholar] [CrossRef]

- Hagerty, D.J.; Nofal, M.M. Design aids: Anchored bulkheads in sand. Can. Geotech. J. 1992, 29, 789–795. [Google Scholar] [CrossRef]

- Bekdaş, G.; Aydın, Y.; Cakiroglu, C.; Işıkdağ, U. Leveraging Neural Networks and Explainable AI for Cost-Effective Retaining Wall Design. Comput. Model. Eng. Sci. 2025, 143, 1763–1787. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, L. Reliability Assessment of Pile-Founded T-Walls Considering Soil Spatial Variability in the Face of Flooding Hazards. In ASCE Inspire 2023; American Society of Civil Engineers: Reston, VA, USA, 2023; pp. 388–395. [Google Scholar] [CrossRef]

- Hong, H.K.; Tanaka, Y.; Sahare, A.; Ueda, K. Effects of soil spatial variability on dynamic behavior of sheet-pile supported ground. J. Jpn. Soc. Civ. Eng. Ser. A1 Struct. Eng. Earthq. Eng. SE/EE 2022, 78, I_334–I_343. [Google Scholar] [CrossRef] [PubMed]

- Xiao, T.; Guo, N.; Yang, Z.X.; Jardine, R.J. Two-Dimensional Numerical Simulation of Displacement Pile-Wall Penetration Using a Coupled Discrete Element-Finite Difference Method. In Proceedings of the 9th International SUT Offshore Site Investigation Geotechnics Conference Proceedings “Innovative Geotechnologies for Energy Transition”, London, UK, 12–14 September 2023; Society for Underwater Technology: London, UK, 2023. [Google Scholar] [CrossRef]

- Agarwal, E.; Pain, A.; Sarkar, S. Probabilistic Analysis of Reinforced Soil Retaining Structures Using FORM and Surrogate-Based Monte Carlo Simulation. In Ground Improvement and Reinforced Soil Structures: Proceedings of Indian Geotechnical Conference 2020 Volume 2; Springer: Singapore, 2022; pp. 733–742. [Google Scholar] [CrossRef]

- Asgari, A.; Arjomand, M.A.; Bagheri, M.; Ebadi-Jamkhaneh, M.; Mostafaei, Y. Assessment of Experimental Data and Analytical Method of Helical Pile Capacity Under Tension and Compressive Loading in Dense Sand. Buildings 2025, 15, 2683. [Google Scholar] [CrossRef]

- Ebadi-Jamkhaneh, M.; Arjomand, M.A.; Bagheri, M.; Asgari, A.; Hefzabad, P.N.; Salahi, S.; Mostafaei, Y. Experimental Study on the Pullout Behavior of Helical Piles in Geogrid-Reinforced Dense Shahriyar Sand. Buildings 2025, 15, 2963. [Google Scholar] [CrossRef]

- Qu, H.L.; Li, R.; Zhang, J.J.; Hu, H.; Zhang, D. Novi pristup seizmičkom projektiranju ukotvljenog priboja. Teh. Vjesn. 2016, 23, 445–463. [Google Scholar] [CrossRef]

- Kulesh, D.A.; Anderson, L.H.; Wilson, B.; Otis, E.J.; Mehm, W.J.; Elgin, D.M.; Barker, M.J.; Kearney, G.P. Space shuttle flight (STS-45) of L8 myoblast cells results in the isolation of a nonfusing cell line variant. J. Cell. Biochem. 1994, 55, 530–544. [Google Scholar] [CrossRef]

- Terzaghi, K.; Peck, R.B.; Mesri, G. Soil Mechanics In Engineering Practice; Wiley-Interscience: Hoboken, NJ, USA, 1996. [Google Scholar]

- Das, B.M.; Sivakugan, N. Principles of Foundation Engineering; Cengage Learning: Boston, MA, USA, 2019. [Google Scholar]

- Bowles, J.E. Foundation Analysis and Design; McGraw-Hill: New York, NY, USA, 1988. [Google Scholar]

- Rowe, P.W. A theoretical and experimental analysis of sheet-pile walls. Proc. Inst. Civ. Eng. 1955, 4, 32–69. [Google Scholar] [CrossRef]

- Richart, F.E. Anchored Bulkhead Design by Numerical Method. J. Soil Mech. Found. Div. ASCE 1960, 86, 29–45. [Google Scholar]

- Turabi, D.A.; Balla, A. Sheet-Pile Analysis by Distribution Theory. J. Soil Mech. Found. Div. 1968, 94, 291–322. [Google Scholar] [CrossRef]

- Turabi, D.A.; Balla, A. Closure to “Sheet-Pile Analysis by Distribution Theory”. J. Soil Mech. Found. Div. 1970, 96, 295–297. [Google Scholar] [CrossRef]

- Turabi, D.A.; Balla, A. Distribution of Earth Pressure on Sheet-Pile Walls. J. Soil Mech. Found. Div. 1968, 94, 1271–1301. [Google Scholar] [CrossRef]

- Potts, D.M.; Fourie, A.B. Behaviour of a Propped Retaining Wall: Results of a Numerical Experiment. Géotechnique 1984, 34, 383–404. [Google Scholar] [CrossRef]

- Bowles, J.E. Analytical and Computer Methods in Foundation Engineering; McGraw-Hill Book Company: New York, NY, USA, 1974. [Google Scholar]

- Iai, S.; Kameoka, T. Finite Element Analysis of Earthquake Induced Damage to Anchored Sheet Pile Quay Walls. Soils Found. 1993, 33, 71–91. [Google Scholar] [CrossRef]

- Bilgin, Ö. Numerical studies of anchored sheet pile wall behavior constructed in cut and fill conditions. Comput. Geotech. 2010, 37, 399–407. [Google Scholar] [CrossRef]

- Karl, T. Theoretical Soil Mechanics; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2017. [Google Scholar]

- Coduto, D.P. Foundation Design: Principles and Practices; Pearson College Div: Victoria, BC, Canada, 2000. [Google Scholar]

- Tsinker, G.P. Anchored Sheet Pile Bulkheads: Design Practice. J. Geotech. Eng. 1983, 109, 1021–1038. [Google Scholar] [CrossRef]

| Type of Soil | ms (kN/m3) |

|---|---|

| Loose sand | 4800–16,000 |

| Medium-dense sand | 9600–80,000 |

| Dense sand | 64,000–128,000 |

| Clayey medium-dense sand | 32,000–80,000 |

| Silty medium-dense sand | 24,000–48,000 |

| Clayey soil: qu ≤ 200 kN/m2 | 12,000–24,000 |

| 200 < qu ≤ 400 kN/m2 | 24,000–48,000 |

| qu > 800 kN/m2 | >48,000 |

| ƞ | Force | 10-Springs Method | Distribution Theory | FEM | Rowe’s Method | Classical Methods |

|---|---|---|---|---|---|---|

| 0.3 | Max. positive B.M. | 1.00 | 0.63 | 0.80 | 1.40 | 1.47 |

| tie-rod force | 1.20 | 0.67 | 0.71 | 1.04 | 1.19 | |

| 0.4 | Max. positive B.M. | 0.92 | 0.73 | 0.82 | 1.36 | 2.00 |

| tie-rod force | 0.85 | 0.68 | 0.71 | 0.92 | 1.27 | |

| 0.5 | Max. positive B.M. | 0.60 | 0.93 | 0.95 | 1.30 | 2.56 |

| tie-rod force | 0.56 | 0.68 | 0.69 | 0.85 | 1.30 | |

| 0.6 | Max. positive B.M. | 0.32 | 0.96 | 0.93 | 1.31 | 2.67 |

| tie-rod force | 0.39 | 0.69 | 0.68 | 0.82 | 1.28 | |

| 0.7 | Max. positive B.M. | 0.16 | 1.00 | 0.92 | 1.25 | 2.29 |

| tie-rod force | 0.28 | 0.69 | 0.66 | 0.79 | 1.19 | |

| 0.75 | Max. positive B.M. | 0.13 | 1.11 | 1.00 | 1.30 | 2.68 |

| tie-rod force | 0.24 | 0.69 | 0.65 | 0.76 | 1.27 | |

| 0.8 | Max. positive B.M. | 0.12 | 1.23 | 1.10 | 1.38 | 5.57 |

| tie-rod force | 0.21 | 0.74 | 0.68 | 0.79 | 1.47 |

| η = 0.6 | η = 0.7 | η = 0.8 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α | 10−2 | 10−3 | 10−4 | 10−5 | 10−2 | 10−3 | 10−4 | 10−5 | 10−2 | 10−3 | 10−4 | 10−5 |

| β = 0.0 | 0.026 | 0.024 | 0.016 | 0.012 | 0.031 | 0.029 | 0.022 | 0.017 | 0.035 | 0.035 | 0.031 | 0.021 |

| β = 0.1 | 0.018 | 0.016 | 0.012 | 0.009 | 0.023 | 0.022 | 0.017 | 0.012 | 0.027 | 0.027 | 0.023 | 0.017 |

| β = 0.2 | 0.010 | 0.009 | 0.005 | 0.004 | 0.014 | 0.013 | 0.010 | 0.007 | 0.019 | 0.018 | 0.016 | 0.011 |

| η = 0.6 | η = 0.7 | η = 0.8 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| α | 10−2 | 10−3 | 10−4 | 10−5 | 10−2 | 10−3 | 10−4 | 10−5 | 10−2 | 10−3 | 10−4 | 10−5 |

| β = 0.0 | 0.132 | 0.125 | 0.105 | 0.092 | 0.144 | 0.141 | 0.123 | 0.105 | 0.154 | 0.153 | 0.144 | 0.121 |

| β = 0.1 | 0.149 | 0.144 | 0.128 | 0.116 | 0.162 | 6.159 | 0.145 | 0.129 | 0.172 | 0.172 | 0.164 | 0.144 |

| β = 0.2 | 0.171 | 0.168 | 0.158 | 0.151 | 0.184 | 0.183 | 0.173 | 0.162 | 0.195 | 0.195 | 0.189 | 0.175 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elsadig, E.H.O.; Abdalla, T.A.; Alahmari, T.S.; Turabi, D.A.E.; Yassin, A.H.A. Analysis and Design of Anchored Sheet-Pile Walls: Theoretical Comparisons, Experimental Validation, and Practical Procedures. Buildings 2025, 15, 3527. https://doi.org/10.3390/buildings15193527

Elsadig EHO, Abdalla TA, Alahmari TS, Turabi DAE, Yassin AHA. Analysis and Design of Anchored Sheet-Pile Walls: Theoretical Comparisons, Experimental Validation, and Practical Procedures. Buildings. 2025; 15(19):3527. https://doi.org/10.3390/buildings15193527

Chicago/Turabian StyleElsadig, Eltayeb H. Onsa, Tareg Abdalla Abdalla, Turki S. Alahmari, Dafalla A. El Turabi, and Ahmed H. A. Yassin. 2025. "Analysis and Design of Anchored Sheet-Pile Walls: Theoretical Comparisons, Experimental Validation, and Practical Procedures" Buildings 15, no. 19: 3527. https://doi.org/10.3390/buildings15193527

APA StyleElsadig, E. H. O., Abdalla, T. A., Alahmari, T. S., Turabi, D. A. E., & Yassin, A. H. A. (2025). Analysis and Design of Anchored Sheet-Pile Walls: Theoretical Comparisons, Experimental Validation, and Practical Procedures. Buildings, 15(19), 3527. https://doi.org/10.3390/buildings15193527