Status and Perspectives for Mechanical Performance of Cement/Concrete Hybrids with Inorganic Carbon Materials

Abstract

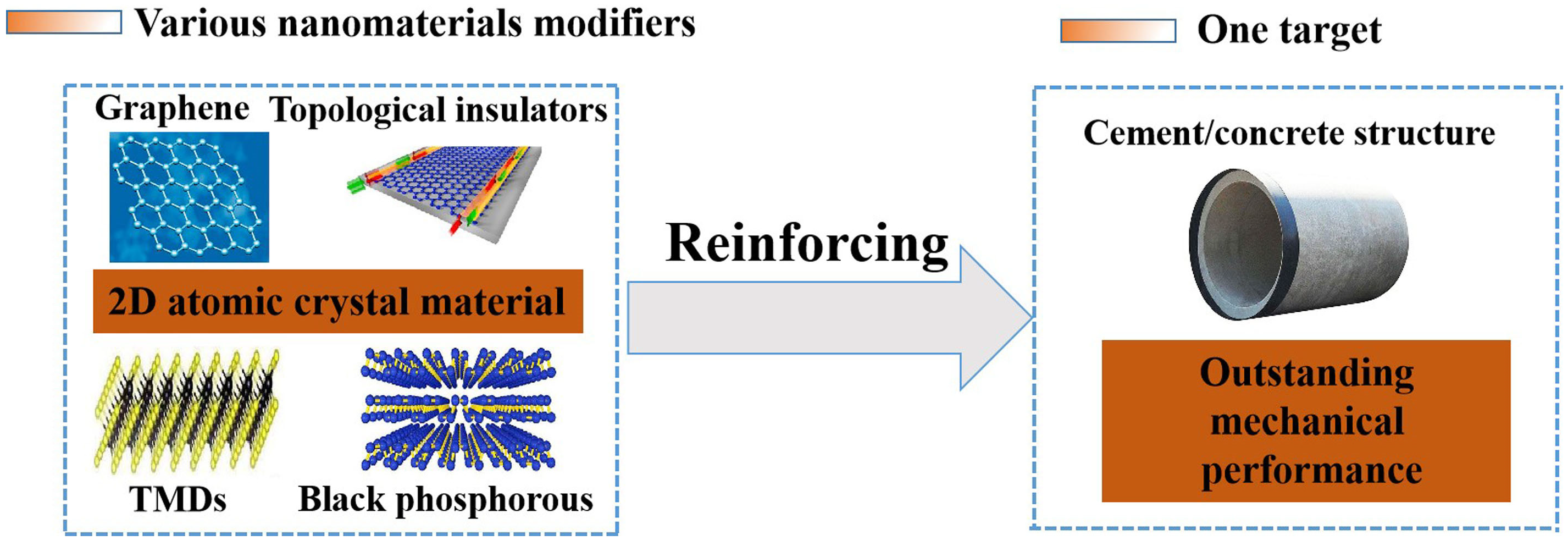

1. Introduction and Background

2. The History and Current Application of Carbon Composites in Civil Materials

2.1. One-Dimensional Carbon Nanofiber

2.2. One-Dimensional Carbon Nanotubes

2.3. Two-Dimensional Graphene and Graphene Oxide

3. Reinforcing Civil Materials by Carbon Materials

3.1. The Strengthening by Physical Compound Route

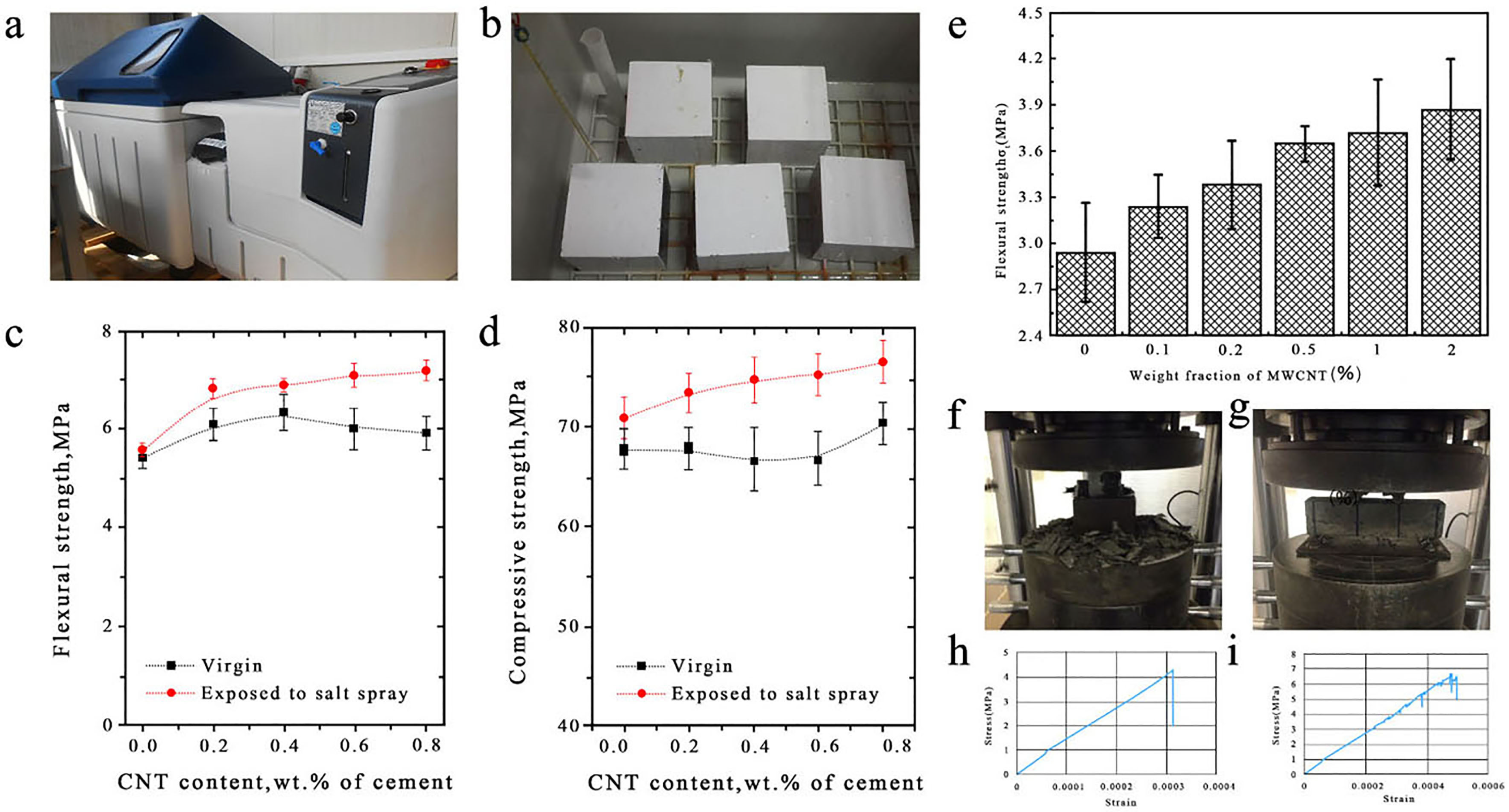

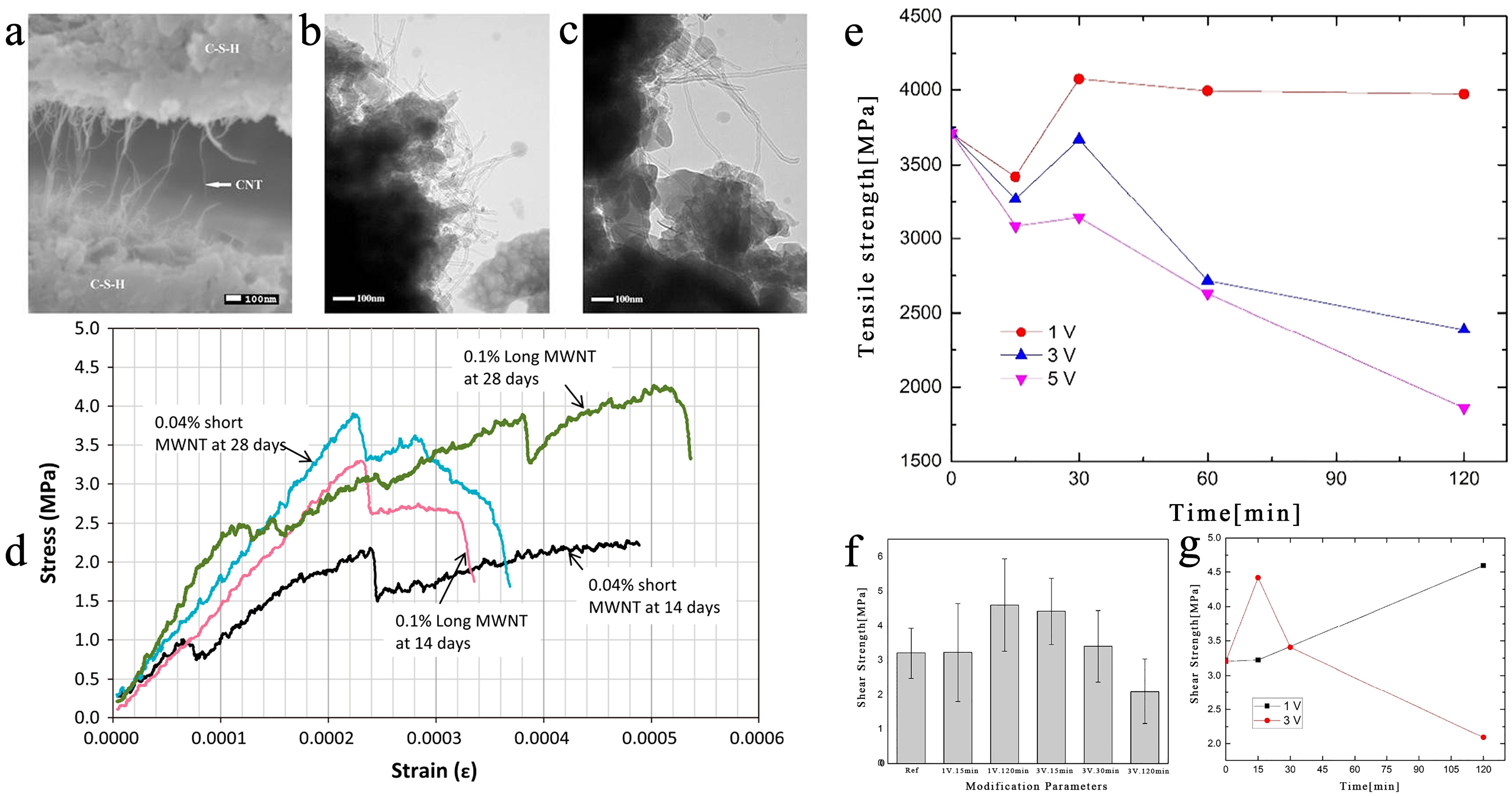

3.1.1. One-Dimensional CNT in Cement/Concrete Composites

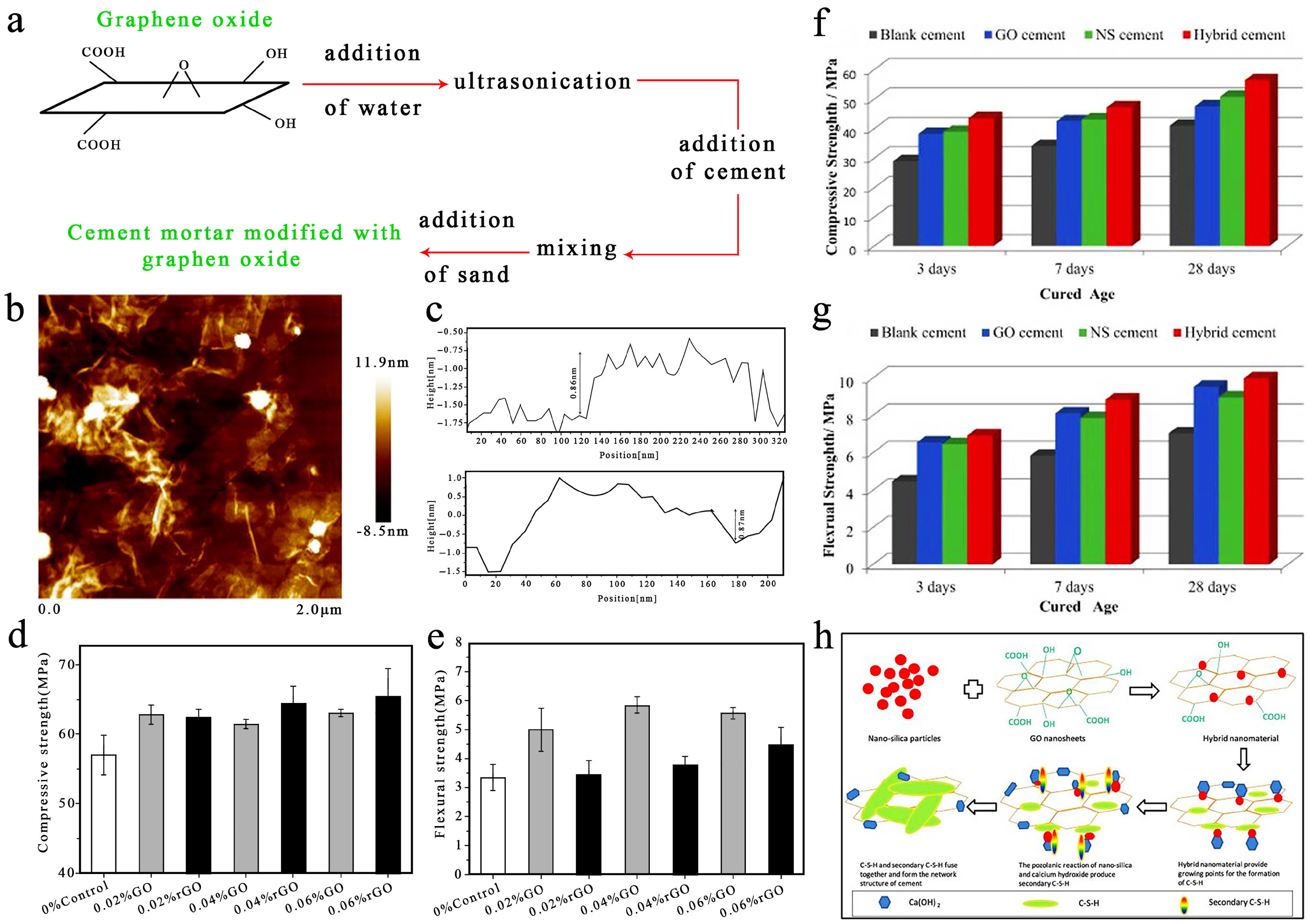

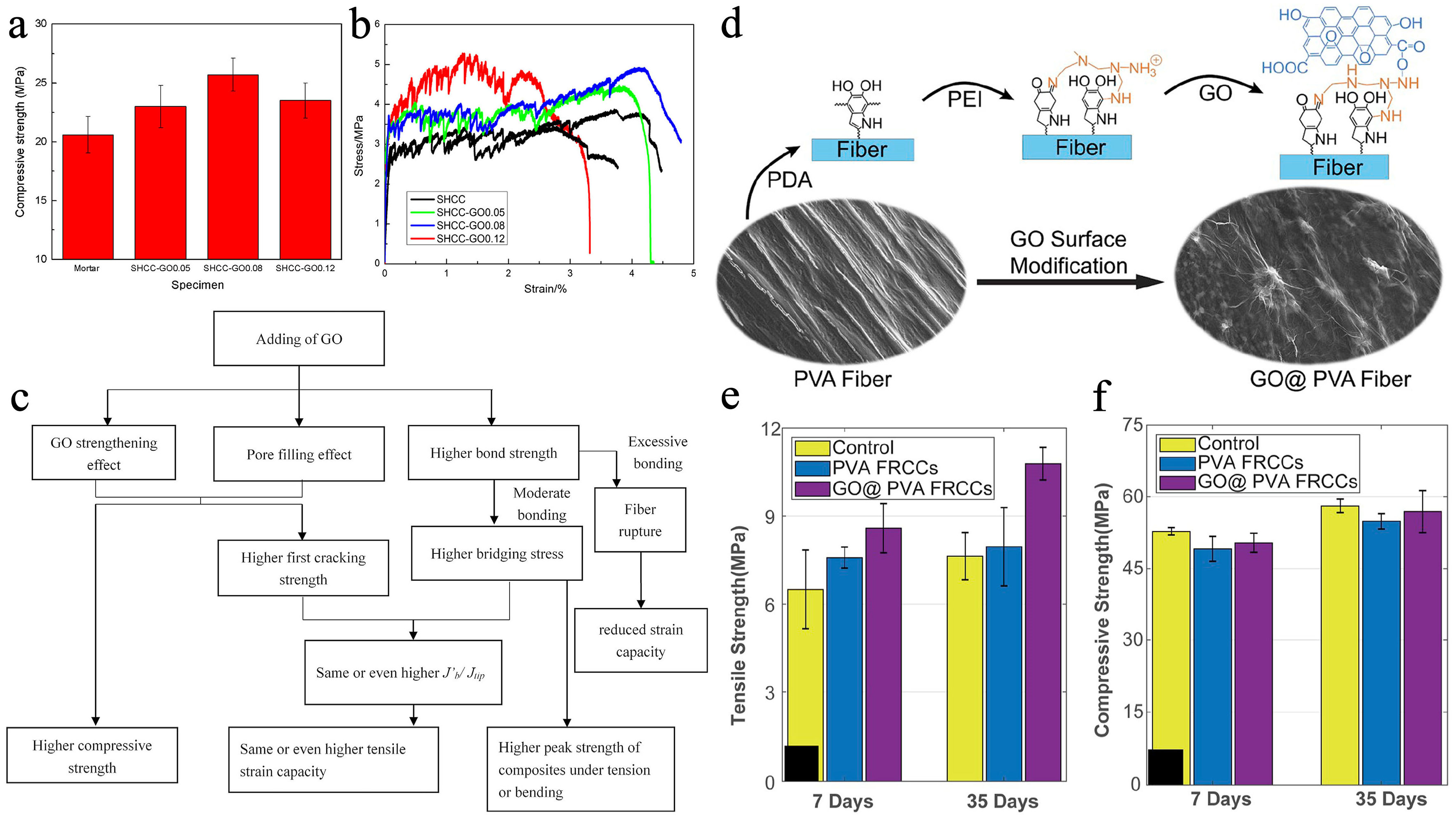

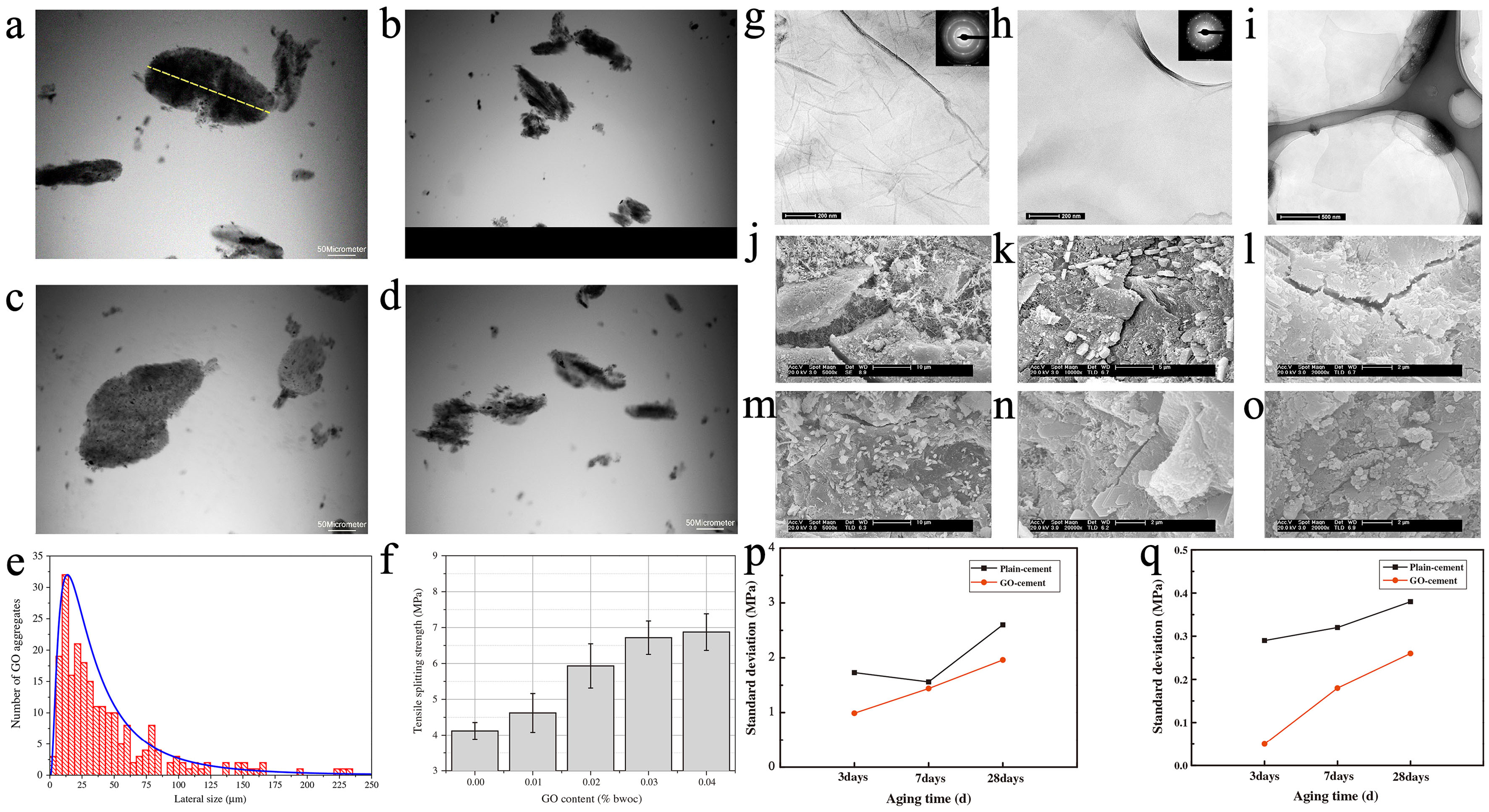

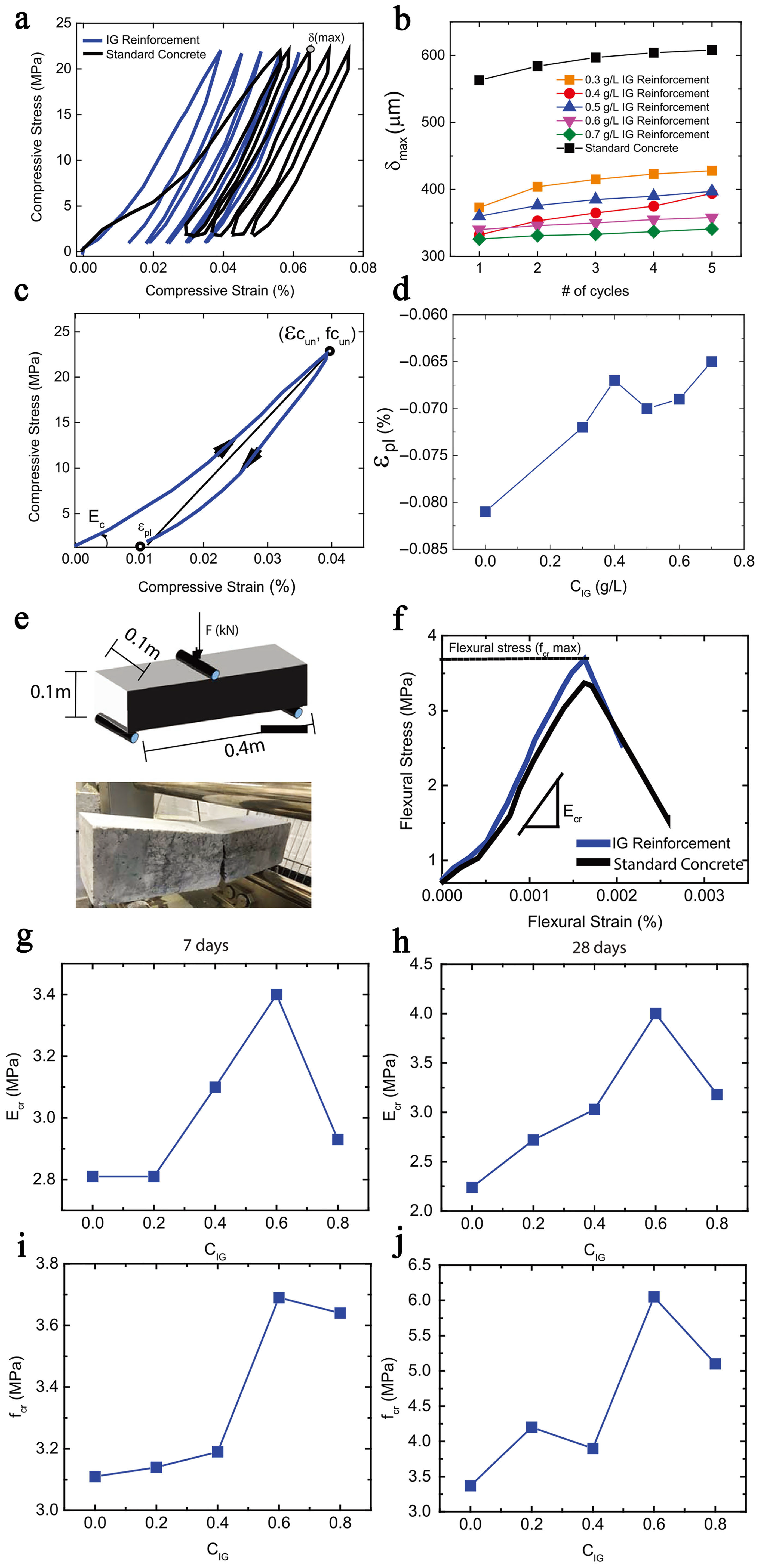

3.1.2. Two-Dimensional Graphene and GO in Cement/Concrete Composites

3.1.3. Three-Dimensional Graphite in Cement/Concrete Composites

3.1.4. Carbon Material Applications in Other Civil Composites

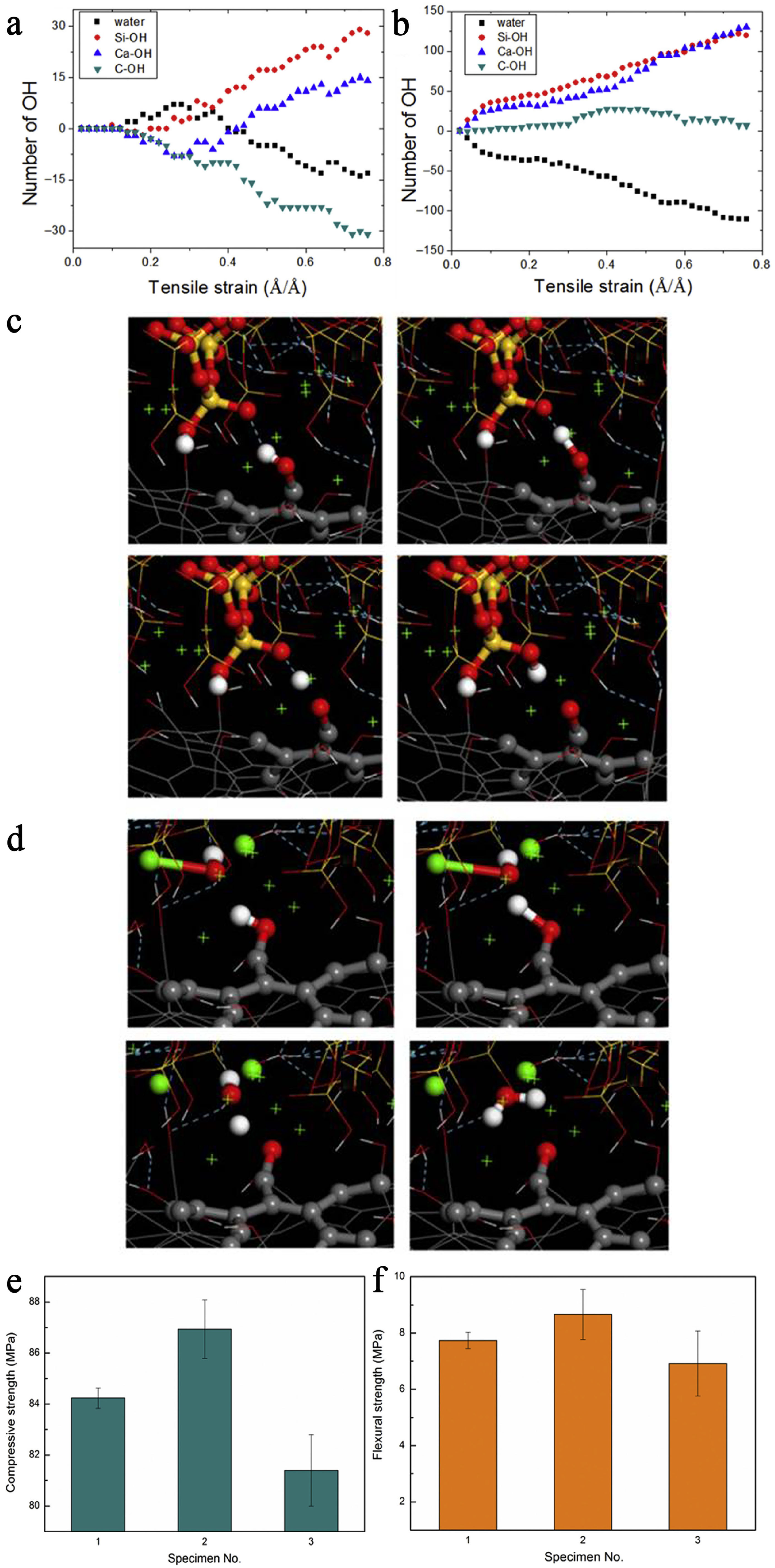

3.2. The Strengthening by Chemical Bonding Route

| Raw Material | Modifier | Mechanical Performance | Enhanced Strengths (%) | Reference |

|---|---|---|---|---|

| cement | long and short CNT | flexural strength | 65; 269 | [71] |

| cement-based matrix | carbon fiber | shear bond | 38 | [72] |

| cement | graphene and GO | compressive and flexural strength | 7, 43 | [73] |

| mortar | GO@PVA | tensile strength | 36 | [81] |

| Portland cement | GO | compressive and flexural strength | 28, 27 | [84] |

| concrete | graphene | compressive and flexural strength | 146, 80 | [86] |

4. Conclusions

5. Summary and Perspectives

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, C.; Li, Y.; Zhu, W.H.; Zeng, G.; Ouyang, Z.K.; Cheng, M.Z.; Jiang, Z.W. Carbon dioxide cured building materials as an approach to decarbonizing the calcium carbide related industry. Renew. Sustain. Energy Rev. 2023, 186, 113688. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.F.; Wang, J.; Shi, Y.; Zheng, Y.X.; Ling, Y.F. Effect of Nano-Particle on Durability of Polyvinyl Alcohol Fiber Reinforced Cementitious Composite. Sci. Adv. Mater. 2020, 12, 249–262. [Google Scholar] [CrossRef]

- Zhu, J.H.; Li, Q.J.; Pei, C.; Yu, H.T.; Xing, F. Evolution Mechanism of Carbon Fiber Anode Properties for Functionalized Applications: Impressed Current Cathodic Protection and Structural Strengthening. Engineering 2025, 3, 5. [Google Scholar]

- Wang, L.; Kong, J.H.; Chu, D.Y.; Wang, Y.F.; Wang, T.; Liu, Z.L. Enhancing ballistic performance: Effect of polyurea coating on backface deformation of UHMWPE laminates. Compos. Struct. 2025, 355, 118846. [Google Scholar] [CrossRef]

- Pauzi, N.N.M.; Jamil, M.; Hamid, R.; Abdin, A.Z.; Zain, M.F.M. The effects of using cathode ray tube (CRT) glass as coarse aggregates in high-strength concrete subjected to high temperature. J. Mater. Cycles Waste Manag. 2019, 21, 1414–1425. [Google Scholar] [CrossRef]

- Xu, X.H.; Song, J.; Li, Y.; Wu, J.F.; Liu, X.; Zhang, C. The microstructure and properties of ceramic tiles from solid wastes of Bayer red muds. Constr. Build. Mater. 2019, 212, 266–274. [Google Scholar] [CrossRef]

- Abouali, S.; Shahverdi, M.; Ghassemieh, M.; Motavalli, M. Nonlinear simulation of reinforced concrete beams retrofitted by near-surface mounted iron-based shape memory alloys. Eng. Struct. 2019, 187, 133–148. [Google Scholar]

- Pan, S.S.; Hu, M.L.; Zhang, X.; Hui, H.X.; Wang, S. A new near-surface-mounted anchorage system of shape memory alloys for local strengthening. Smart Mater. Struct. 2019, 28, 025016. [Google Scholar]

- Tran, P.; Nguyen, Q.T.; Lau, K.T. Fire performance of polymer-based composites for maritime infrastructure. Compos. Part B Eng. 2018, 155, 31–48. [Google Scholar]

- Cheng, X.W.; Dong, Q.G.; Li, Z.Y.; Guo, X.Y. High-temperature mechanical properties of calcium sulfate whisker-reinforced high-alumina cement. Mag. Concr. Res. 2020, 72, 55–67. [Google Scholar]

- Kang, Z.Y.; Yang, Y.Z.; Zhang, J.R.; Li, N. Synergistic effects of biochar and carbon black on conductive cement composites: Mechanical and conductive properties. Constr. Build. Mater. 2025, 470, 140579. [Google Scholar] [CrossRef]

- Long, W.J.; Tao, J.L.; Lin, C.; Gu, Y.C.; Mei, L.; Duan, H.B.; Xing, F. Rheology and buildability of sustainable cement-based composites containing micro-crystalline cellulose for 3D-printing. J. Clean. Prod. 2019, 239, 118054. [Google Scholar] [CrossRef]

- Ozturk, M. Effect of recycling methods on microstructure and mechanical properties of carbon fiber cementitous composite. J. Adhes. Sci. Technol. 2025, 1–18. [Google Scholar] [CrossRef]

- Xie, J.H.; Chen, W.; Wang, J.J.; Fang, C.; Zhang, B.X.; Liu, F. Coupling effects of recycled aggregate and GGBS/metakaolin on physicochemical properties of geopolymer concrete. Constr. Build. Mater. 2019, 226, 345–359. [Google Scholar] [CrossRef]

- Gao, F.F.; Tian, W.; Wang, Z.; Wang, F. Effect of diameter of multi-walled carbon nanotubes on mechanical properties and microstructure of the cement-based materials. Constr. Build. Mater. 2020, 260, 120452–120463. [Google Scholar] [CrossRef]

- Zhu, H.; Zhang, D.; Wang, T.Y.; Wu, H.L.; Li, V.C. Mechanical and self-healing behavior of low carbon engineered cementitious composites reinforced with PP-fibers. Constr. Build. Mater. 2020, 259, 119805–119817. [Google Scholar] [CrossRef]

- Hosseini, E.; Zakertabrizi, M.; Korayem, A.H.; Xu, G.Z. A novel method to enhance the interlayer bonding of 3D printing concrete: An experimental and computational investigation. Cem. Concr. Compos. 2019, 99, 112–119. [Google Scholar] [CrossRef]

- Li, F.; Jianag, X.S.; Shao, Z.Y.; Zhu, D.G.; Luo, Z.P. Research Progress Regarding Interfacial Characteristics and the Strengthening Mechanisms of Titanium Alloy/Hydroxyapatite Composites. Materials 2018, 11, 1391. [Google Scholar] [CrossRef]

- Zhao, F.L.; Fu, Q.G.; Wang, L.; Liu, Y. Construction of SiCnw/MAS nanocomposites to strengthen and toughen C/C-LAS joints. Mater. Sci. Eng. A 2017, 703, 137–143. [Google Scholar] [CrossRef]

- Guo, Y.X.; Bian, D.; Zhao, Y.W. Preparation and properties of chemically bonded ceramic coatings reinforced by GO-TiO2 composites. Russ. J. Appl. Chem. 2019, 92, 842–847. [Google Scholar] [CrossRef]

- Zhang, M.C.; Guan, K.C.; Shen, J.; Liu, G.P.; Fan, Y.Q.; Jin, W.Q. Nanoparticles@rGO Membrane Enabling Highly Enhanced Water Permeability and Structural Stability with Preserved Selectivity. AIChE J. 2017, 63, 5054–5063. [Google Scholar] [CrossRef]

- Zhang, Q.Q.; Lin, D.; Deng, B.W.; Xu, X.; Nian, Q.; Jin, S.Y.; Leedy, K.D.; Li, H.; Cheng, G.J. Flyweight, Superelastic, Electrically Conductive, and Flame-Retardant 3D Multi-Nanolayer Graphene/Ceramic Metamaterial. Adv. Mater. 2017, 29, 1605506. [Google Scholar] [CrossRef]

- Nari, A.; Cai, C.S.; Kong, X. Using Acoustic Emission to Monitor Failure Modes in CFRP-Strengthened Concrete Structures. J. Aerosp. Eng. 2020, 33, 04019110. [Google Scholar] [CrossRef]

- Lyu, F.; Goto, Y.; Kawanishi, N.; Xu, Y. Three-Dimensional Numerical Model for Seismic Analysis of Bridge Systems with Multiple Thin-Walled Partially Concrete-Filled Steel Tubular Columns. J. Struct. Eng. 2020, 146, 04019164. [Google Scholar] [CrossRef]

- Kawakami, M.; Omata, F.; Iketani, J.; Matsuoka, S. Advanced Seismic Countermeasures for Concrete Bridges by Using Polymer in Japan. Key Eng. Mater. 2011, 466, 207–214. [Google Scholar] [CrossRef]

- De Santis, S.; Hadad, H.A.; Basalo, F.; de Felice, G.; Nanni, A. Acceptance Criteria for Tensile Characterization of Fabric-Reinforced Cementitious Matrix Systems for Concrete and Masonry Repair. J. Compos. Constr. 2018, 22, 04018048. [Google Scholar] [CrossRef]

- Kasan, J.L.; Harries, K.A.; Miller, R.; Brinkman, R.J. Repair of Prestressed-Concrete Girders Combining Internal Strand Splicing and Externally Bonded CFRP Techniques. J. Bridge Eng. 2014, 19, 200–209. [Google Scholar] [CrossRef]

- Puurula, A.M.; Enochsson, O.; Sas, G.; Blanksvard, T.; Ohlsson, U.; Bernspang, L.; Taljsten, B.; Carolin, A.; Paulsson, B.; Elfgren, L. Assessment of the Strengthening of an RC Railway Bridge with CFRP Utilizing a Full-Scale Failure Test and Finite-Element Analysis. J. Struct. Eng. 2015, 141, D4014008. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanotubes on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Gupta, T.K.; Kumar, S.; Khan, A.Z.; Varadarajan, K.M.; Cantwell, W.J. Self-sensing performance of MWCNT-low density polyethylene nanocomposites. Mater. Res. Express 2018, 5, 015703. [Google Scholar] [CrossRef]

- Wagner, H.D. Nanotube-polymer adhesion: A mechanics approach. Chem. Phys. Lett. 2002, 361, 57–61. [Google Scholar] [CrossRef]

- Musso, S.; Tullianbi, J.M.; Ferro, G.; Tagliaferro, A. Influence of carbon nanotubes structure on the mechanical behavior of cement composites. Compos. Sci. Technol. 2009, 69, 1985–1990. [Google Scholar] [CrossRef]

- Xu, Z.; Gao, C. Aqueous Liquid Crystals of Graphene Oxide. ACS Nano 2011, 5, 2908–2915. [Google Scholar] [CrossRef]

- Pan, Z.; He, L.; Qiu, L.; Korayem, A.H.; Li, G.; Zhu, J.W.; Collins, F.; Li, D.; Duan, W.H.; Wang, M.C. Mechanical properties and microstructure of a graphene oxide-cement composite. Cem. Concr. Compos. 2015, 58, 140–147. [Google Scholar] [CrossRef]

- Kang, D.; Seo, K.S.; Lee, H.; Chung, W. Experimental study on mechanical strength of GO-cement composites. Constr. Build. Mater. 2017, 131, 303–308. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Hou, D.S.; Ma, H.Y.; Fan, T.Y.; Li, Z.J. Effects of graphene oxide on the properties and microstructures of the magnesium potassium phosphate cement paste. Constr. Build. Mater. 2016, 119, 107–112. [Google Scholar] [CrossRef]

- Wang, Q.; Cui, X.Y.; Wang, J.; Li, S.Y.; Lv, C.X.; Dong, Y.C. Effect of fly ash on rheological properties of graphene oxide cement paste. Constr. Build. Mater. 2017, 138, 35–44. [Google Scholar] [CrossRef]

- Zhu, X.H.; Kang, X.J.; Yang, K.; Yang, C.H. Effect of graphene oxide on the mechanical properties and the formation of layered double hydroxides (LDHs) in alkali-activated slag cement. Constr. Build. Mater. 2017, 132, 290–295. [Google Scholar] [CrossRef]

- Liu, J.T.; Li, Q.H.; Xu, S.L. Reinforcing Mechanism of Graphene and Graphene Oxide Sheets on Cement-Based Materials. J. Mater. Civ. Eng. 2019, 31, 04019014. [Google Scholar] [CrossRef]

- Garcia-Macias, E.; Castro-Triguero, R.; Saez, A.; Ubertini, F. 3D mixed micromechanics-FEM modeling of piezoresistive carbon nanotube smart concrete. Comput. Meth. Appl. Mech. Eng. 2018, 340, 396–423. [Google Scholar] [CrossRef]

- Wang, B.H.; Hu, X.Z.; Hui, J.Z.; Lu, P.M.; Jiang, B. CNT-reinforced adhesive joint between grit-blasted steel substrates fabricated by simple resin pre-coating method. J. Adhes. 2018, 94, 529–540. [Google Scholar] [CrossRef]

- Yu, Z.C.; Lau, D. Evaluation on mechanical enhancement and fire resistance of carbon nanotube (CNT) reinforced concrete. Coupled Syst. Mech. 2017, 6, 335–349. [Google Scholar]

- Metaxa, Z.S.; Neri, W.; Poulin, P.; Alexopoulos, N.D. Strain monitoring of cement-based materials with embedded polyvinyl alcohol—Carbon nanotube (PVA-CNT) fibers. Fract. Struct. Integr. 2017, 40, 61–73. [Google Scholar] [CrossRef]

- Dalla, P.T.; Tragazikis, I.K.; Exarchos, D.A.; Dassios, K.G.; Barkoula, N.M.; Matikas, T.E. Effect of Carbon Nanotubes on Chloride Penetration in Cement Mortars. Appl. Sci. 2019, 9, 1032. [Google Scholar] [CrossRef]

- Baloch, W.L.; Khushnood, R.A.; Memon, S.A.; Ahmed, W.; Ahmad, S. Effect of Elevated Temperatures on Mechanical Performance of Normal and Lightweight Concretes Reinforced with Carbon Nanotubes. Fire Technol. 2018, 54, 1331–1367. [Google Scholar] [CrossRef]

- Yazdanbakhsh, A.; Grasley, Z.; Tyson, B.; Abu Al-Rub, R. Challenges and Benefits of Utilizing Carbon Nanofilaments in Cementitious Materials. J. Nanomater. 2012, 8, 371927. [Google Scholar] [CrossRef]

- Sbia, L.A.; Peyvandi, A.; Soroushian, P.; Balachandra, A.M. Optimization of ultra-high-performance concrete with nano- and micro-scale reinforcement. Cogent Eng. 2014, 1, 990673. [Google Scholar] [CrossRef]

- Gillani, S.S.U.; Khitab, A.; Ahmad, S.; Khushnood, R.A.; Ferro, G.A.; Kazmi, S.M.S.; Qureshi, L.A.; Restuccia, L. Improving the mechanical performance of cement composites by carbon nanotubes addition. Procedia Struct. Integr. 2017, 3, 11–17. [Google Scholar] [CrossRef]

- Khushnood, R.A.; Ahmad, S.; Restuccia, L.; Spoto, C.; Jagdale, P.; Tulliani, J.M.; Ferro, G.A. Carbonized nano/microparticles for enhanced mechanical properties and electromagnetic interference shielding of cementitious materials. Front. Struct. Civ. Eng. 2016, 10, 209–213. [Google Scholar] [CrossRef]

- Luo, J.L.; Hou, D.S.; Li, Q.Y.; Wu, C.F.; Zhang, C.W. Comprehensive performances of carbon nanotube reinforced foam concrete with tetraethyl orthosilicate impregnation. Constr. Build. Mater. 2017, 131, 512–516. [Google Scholar] [CrossRef]

- Li, Q.H.; Liu, J.T.; Xu, S.L. Progress in Research on Carbon Nanotubes Reinforced Cementitious Composites. Adv. Mater. Sci. Eng. 2015, 16, 307435. [Google Scholar] [CrossRef]

- Luo, J.L.; Duan, Z.D.; Xian, G.J.; Li, Q.Y.; Zhao, T.J. Damping Performances of Carbon Nanotube Reinforced Cement Composite. Mech. Adv. Mater. Struct. 2015, 22, 224–232. [Google Scholar] [CrossRef]

- Tamimi, A.; Hassan, N.M.; Fattah, K.; Talachi, A. Performance of cementitious materials produced by incorporating surface treated multiwall carbon nanotubes and silica fume. Constr. Build. Mater. 2016, 114, 934–945. [Google Scholar] [CrossRef]

- Horszczaruk, E.; Mijowska, E.; Kalenczuk, R.J.; Aleksandrzak, M.; Mijowska, S. Nanocomposite of cement/graphene oxide—Impact on hydration kinetics and Young’s modulus. Constr. Build. Mater. 2015, 78, 234–242. [Google Scholar] [CrossRef]

- Wojtoniszak, M.; Urbas, K.; Peruzynska, M.; Kurzawski, M.; Drozdzik, M.; Mijowska, E. Covalent conjugation of graphene oxide with methotrexate and its antitumor activity. Chem. Phys. Lett. 2013, 568, 151–156. [Google Scholar] [CrossRef]

- Li, X.G.; Liu, Z.L.; Lv, Y.; Cai, L.X.; Jiang, W.G.; Zhou, Y. Influence of graphene oxide on hydration characteristics of tricalcium silicate. Adv. Cem. Res. 2019, 31, 448–456. [Google Scholar] [CrossRef]

- Qureshi, T.S.; Panesar, D.K. Impact of graphene oxide and highly reduced graphene oxide on cement based composites. Constr. Build. Mater. 2019, 206, 71–83. [Google Scholar] [CrossRef]

- Liu, H.T.; Yu, Y.J.; Liu, H.M.; Jin, J.Z.; Liu, S.Q. Hybrid effects of nano-silica and graphene oxide on mechanical properties and hydration products of oil well cement. Constr. Build. Mater. 2018, 191, 311–319. [Google Scholar] [CrossRef]

- Lv, H.H.; Liu, J.J.; Sun, T.; Ma, Y.J.; Zhou, Q.F. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Mokhtar, M.M.; Abo-El-Enein, S.A.; Hassaan, M.Y.; Morsy, M.S.; Khalil, M.H. Mechanical performance, pore structure and micro-structural characteristics of graphene oxide nano platelets reinforced cement. Constr. Build. Mater. 2017, 138, 333–339. [Google Scholar] [CrossRef]

- Lu, Z.Y.; Hanif, A.; Sun, G.X.; Liang, R.; Parthasarathy, P.; Li, Z.J. Highly dispersed graphene oxide electrodeposited carbon fiber reinforced cement-based materials with enhanced mechanical properties. Cem. Concr. Compos. 2018, 87, 220–228. [Google Scholar] [CrossRef]

- Peyvandi, A.; Soroushian, P.; Farhadi, N.; Balachandra, A.M. Evaluation of the Reinforcement Efficiency of Low-Cost Graphite Nanomaterials in High-Performance Concrete. KSCE J. Civ. Eng. 2018, 22, 3875–3882. [Google Scholar] [CrossRef]

- Biswas, M.; Sarkar, S.; Bandyopadhyay, S. Improvements in mechanical properties of SPS processed 15R-SiAlON polytype through structurally survived MWCNT reinforcement. Mater. Chem. Phys. 2019, 222, 75–80. [Google Scholar] [CrossRef]

- Jin, H.; Li, Z.W.; Wang, L.W.; Zeng, Q.X. Fabrication and properties of CNT/Ni/Y/ZrB2 nanocomposites reinforced in situ. J. Am. Ceram. Soc. 2018, 101, 1747–1753. [Google Scholar] [CrossRef]

- Hassan, R.; Nisar, A.; Ariharan, S.; Alam, F.; Kumar, A.; Balani, K. Multi-functionality of carbon nanotubes reinforced 3 mol% yttria stabilized zirconia structural biocomposites. Mater. Sci. Eng. A 2017, 704, 329–343. [Google Scholar] [CrossRef]

- Gao, T.Q.; Zhao, Y.; Zhou, G.H.; Han, Y.; Zheng, Y.W.; Shan, Z.D.; Hui, D.; Xu, F.J.; Qiu, Y.P. Fabrication and characterization of three dimensional woven carbon fiber/silica ceramic matrix composites. Compos. Part B Eng. 2015, 77, 122–128. [Google Scholar] [CrossRef]

- Barfmal, M.; Montazeri, A. MD-based design of SiC/graphene nanocomposites towards better mechanical performance. Ceram. Int. 2017, 43, 17167–17173. [Google Scholar] [CrossRef]

- Qin, L.M.; Bian, D.; Zhao, Y.W.; Xu, X.Y.; Guo, Y.X. Study on the preparation and mechanical properties of alumina ceramic coating reinforced by graphene and multi-walled carbon nanotube. Russ. J. Appl. Chem. 2017, 90, 811–817. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Zhang, Y.X.; Yang, M.Y. Synthesis of environment-friendly graphene reinforced slag-based nanocomposite and performance of photocatalytic H-2 generation. Ferroelectrics 2018, 522, 36–44. [Google Scholar] [CrossRef]

- Qu, H.; Wang, Y.; Ye, Y.S.; Zhou, W.; Bai, S.P.; Zhou, X.P.; Peng, H.Y.; Xie, X.L.; Mai, Y.W. A promising nanohybrid of silicon carbide nanowires scrolled by graphene oxide sheets with a synergistic effect for poly(propylene carbonate) nanocomposites. J. Mater. Chem. A 2017, 5, 22361–22371. [Google Scholar] [CrossRef]

- Abu Al-Rub, R.K.; Ashour, A.I.; Tyson, B.M. On the aspect ratio effect of multi-walled carbon nanotube reinforcements on the mechanical properties of cementitious nanocomposites. Constr. Build. Mater. 2012, 35, 647–655. [Google Scholar] [CrossRef]

- Li, H.Y.; Liebscher, M.; Ranjbarian, M.; Hempel, S.; Tzounis, L.; Schrofl, C.; Mechtcherine, V. Electrochemical modification of carbon fiber yarns in cementitious pore solution for an enhanced interaction towards concrete matrices. Appl. Surf. Sci. 2019, 487, 52–58. [Google Scholar] [CrossRef]

- Hou, D.S.; Lu, Z.Y.; Li, X.Y.; Ma, H.Y.; Li, Z.J. Reactive molecular dynamics and experimental study of graphene-cement composites: Structure, dynamics and reinforcement mechanisms. Carbon 2017, 115, 188–208. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Li, Z.J.; Leung, C.K.Y. Effect of graphene oxide on the mechanical behavior of strain hardening cementitious composites. Constr. Build. Mater. 2016, 120, 457–464. [Google Scholar] [CrossRef]

- Mohammed, A.; Al-Saadi, N.T.K.; Sanjayan, J. Inclusion of graphene oxide in cementitious composites: State-of-the-art review. Aust. J. Civ. Eng. 2019, 16, 81–95. [Google Scholar] [CrossRef]

- Singh, S.; Shukla, A.; Brown, R. Pullout behavior of polypropylene fibers from cementitious matrix. Cem. Concr. Res. 2004, 34, 1919–1925. [Google Scholar] [CrossRef]

- Dai, J.G.; Ueda, T.; Sato, Y. Development of the nonlinear bond stress-slip model of fiber reinforced plastics sheet-concrete interfaces with a simple method. J. Compos. Constr. 2005, 9, 52–62. [Google Scholar] [CrossRef]

- Stang, H.; Shah, S.P. Failure of fiber-reinforced composites by pull-out fracture. J. Mater. Sci. 1986, 21, 953–957. [Google Scholar] [CrossRef]

- Stang, H.; Li, V.C.; Krenchel, H. Design and structural applications of stress-crack width relations in fiber-reinforced concrete. Mater. Struct. 1995, 28, 210–219. [Google Scholar] [CrossRef]

- Zhao, X.; Li, H.D.; Wang, C. Quasi-static and dynamic compressive behavior of ultra-high toughness cementitious composites in dry and wet conditions. Constr. Build. Mater. 2019, 227, 117008. [Google Scholar] [CrossRef]

- Yao, X.P.; Shamsaei, E.; Chen, S.J.; Zhang, Q.H.; de Souza, F.B.; Sagoe-Crentsil, K.; Duan, W.H. Graphene oxide-coated Poly(vinyl alcohol) fibers for enhanced fiber-reinforced cementitious composite. Compos. Part B Eng. 2019, 174, 107010. [Google Scholar] [CrossRef]

- Lyu, Y.H.; Gu, C.L.; Tao, J.P.; Yao, X.; Zhao, G.; Dai, C.L. Thermal-resistant, shear-stable and salt-tolerant polyacrylamide/surface-modified graphene oxide composite. J. Mater. Sci. 2019, 54, 14752–14762. [Google Scholar] [CrossRef]

- Li, X.Y.; Lu, Z.Y.; Chuah, S.; Li, W.G.; Liu, Y.M.; Duan, W.H.; Li, Z.J. Effects of graphene oxide aggregates on hydration degree, sorptivity, and tensile splitting strength of cement paste. Compos. Part A Appl. Sci. Manuf. 2017, 100, 1–8. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.L.; Ge, C.; Li, Q.; Guo, L.P.; Shu, X.; Liu, J.P. Investigation of the effectiveness of PC@GO on the reinforcement for cement composites. Constr. Build. Mater. 2016, 113, 470–478. [Google Scholar] [CrossRef]

- Li, X.Y.; Korayem, A.H.; Li, C.Y.; Liu, Y.M.; He, H.S.; Sanjayan, J.G.; Duan, W.H. Incorporation of graphene oxide and silica fume into cement paste: A study of dispersion and compressive strength. Constr. Build. Mater. 2016, 123, 327–335. [Google Scholar] [CrossRef]

- Dimov, D.; Amit, I.; Gorrie, O.; Barnes, M.D.; Townsend, N.J.; Neves, A.I.S.; Withers, F.; Russo, S.; Craciun, M.F. Ultrahigh Performance Nanoengineered Graphene-Concrete Composites for Multifunctional Applications. Adv. Funct. Mater. 2018, 28, 1705183. [Google Scholar] [CrossRef]

- Bai, S.L.; Sun, C.Z.; Yan, H.; Sun, X.M.; Zhang, H.; Luo, L.; Lei, X.D.; Wan, P.B.; Chen, X.D. Healable, Transparent, Room-Temperature Electronic Sensors Based on Carbon Nanotube Network-Coated Polyelectrolyte Multilayers. Small 2015, 11, 5807–5813. [Google Scholar] [CrossRef] [PubMed]

- Shukla, M.K.; Sharma, K. Measurement of dispersion and homogeneity of functionalized graphene/CNT hybrid epoxy composite. SN Appl. Sci. 2019, 1, 1011. [Google Scholar] [CrossRef]

- Sharma, A.; Sharma, V.M.; Paul, J. A comparative study on microstructural evolution and surface properties of graphene/CNT reinforced Al6061-SiC hybrid surface composite fabricated via friction stir processing. Trans. Nonferrous Met. Soc. China 2019, 29, 2005–2026. [Google Scholar] [CrossRef]

- Luan, C.C.; Yao, X.H.; Liu, C.Z.; Lan, L.J.; Fu, J.Z. Self-monitoring continuous carbon fiber reinforced thermoplastic based on dual-material three-dimensional printing integration process. Carbon 2018, 140, 100–111. [Google Scholar] [CrossRef]

- Wang, J.L.; Dong, S.F.; Pang, S.D.; Han, B.G.; Ou, J.P. Tailoring anti-impact properties of ultra-high performance concrete by incorporating functionalized carbon nanotubes. Engineering 2022, 18, 232–245. [Google Scholar]

- Huang, H.H.; Teng, L.H.; Khayat, K.; Gao, X.J.; Wang, F.Z.; Liu, Z.C. For the improvement of mechanical and microstructural properties of UHPC with fiber alignment using carbon nanotube and graphite nanoplatelet. Cem. Concr. Comp. 2022, 129, 104462. [Google Scholar]

- Yu, Z.; Feng, Y.; Feng, D.; Zhang, X. Thermal conductance bottleneck of a three dimensional graphene-CNT hybrid structure: A molecular dynamics simulation. Phys. Chem. Chem. Phys. 2019, 22, 337–343. [Google Scholar] [PubMed]

- Segura, I.; Faneca, G.; Torrents, J.M.; Aguado, A. Self-sensing concrete made from recycled carbon fibres. Smart Mater. Struct. 2019, 28, 105045. [Google Scholar] [CrossRef]

- He, R.J.; Tong, Z.W.; Zhang, K.Q.; Fang, D.N. Mechanical and electrical properties of MoSi2-based ceramics with various ZrB2-20 vol% SiC as additives for ultra high temperature heating element. Ceram. Int. 2018, 44, 1041–1045. [Google Scholar]

- Shukla, M.K.; Sharma, K. Effect of functionalized graphene/CNT ratio on the synergetic enhancement of mechanical and thermal properties of epoxy hybrid composite. Mater. Res. Express 2019, 6, 085318. [Google Scholar] [CrossRef]

- Mostovoy, A.S.; Yakovlev, A.V. Reinforcement of Epoxy Composites with Graphite-Graphene Structures. Sci. Rep. 2019, 9, 16246. [Google Scholar] [CrossRef]

- Cao, Q.; Li, X.J.; Gao, R.X. Axial Compressive Performance of CFRP Confined Self-stressing High-strength Concrete Cylinders. KSCE J. Civ. Eng. 2019, 223, 4000–4009. [Google Scholar] [CrossRef]

- Liu, J.; Jiang, X.T.; Zhang, R.Y.; Zhang, Y.; Wu, L.M.; Lu, W.; Li, J.Q.; Li, Y.C.; Zhang, H. MXene-Enabled Electrochemical Microfluidic Biosensor: Applications toward Multicomponent Continuous Monitoring in Whole Blood. Adv. Funct. Mater. 2019, 29, 1807326. [Google Scholar]

- Liu, Y.L.; Cao, P.; Zhang, Q.Y.; Guo, C.G.; Li, J.; Zeng, Q.Y. Solar-activated ZnS@MXene heterostructure for integrated radioactive wastewater treatment and energy harvesting. Water Res. 2025, 286, 124254. [Google Scholar]

- Zhang, M.; Wu, Q.; Zhang, F.; Chen, L.L.; Jin, X.X.; Hu, Y.W.; Zheng, Z.; Zhang, H. 2D Black Phosphorus Saturable Absorbers for Ultrafast Photonics. Adv. Opt. Mater. 2019, 7, 1800224. [Google Scholar] [CrossRef]

- Woods, M.C.; Kulkarni, A.; Pearce, J.M. The Potential of Replacing Concrete with Sand and Recycled Polycarbonate Composites: Compressive Strength Testing. J. Compos. Sci. 2023, 7, 249. [Google Scholar] [CrossRef]

- Fadiel, A.A.M.; Mohammed, N.S.; Abu-Lebdeh, T.; Munteanu, I.S.; Niculae, E.; Petrescu, F.I.T. A Comprehensive Evaluation of the Mechanical Properties of Rubberized Concrete. J. Compos. Sci. 2023, 7, 129. [Google Scholar] [CrossRef]

- Liang, K.; Matsumoto, R.A.; Zhao, W.; Osti, N.C.; Popov, I.; Thapaliya, B.P.; Fleischmann, S.; Misra, S.; Prenger, K.; Tyagi, M.; et al. Engineering the interlayer spacing by pre-intercalation for high performance supercapacitor MXene electrodes in room temperature ionic liquid. Adv. Funct. Mater. 2021, 31, 2104007. [Google Scholar]

- Sun, T.; Wang, X.Y.; Maimaitituersun, N.; Dong, S.F.; Li, L.Y.; Han, B.G. Synergistic effects of steel fibers and steel wires on uniaxial tensile mechanical and self-sensing properties of UHPC. Constr. Build. Mater. 2024, 416, 134991. [Google Scholar] [CrossRef]

- Das, A.K.; Mishra, D.K.; Yu, J.; Leung, C.K.Y. Smart Self-Healing and Self-Sensing Cementitious Composites-Recent Developments, Challenges, and Prospects. Adv. Civ. Eng. Mater. 2019, 8, 554–578. [Google Scholar] [CrossRef]

- Yee, K.; Ghayesh, H.M. A review on the mechanics of graphene nanoplatelets reinforced structures. Int. J. Eng. Sci. 2023, 186, 103831. [Google Scholar] [CrossRef]

- Li, J.L.; Liu, X.X.; Feng, Y.; Yin, J.H. Recent progress on polymer/two-dimensional nanosheets composites with novel performances. Prog. Polym. Sci. 2022, 126, 101505. [Google Scholar]

- Sun, Z.L.; Luo, Y.X.; Chen, C.Y.; Dong, Z.J.; Jiang, G.M.; Chen, F.X.; Ma, P.B. Mechanical enhancement of carbon fiber-reinforced polymers: From interfacial regulating strategies to advanced processing technologies. Prog. Mater. Sci. 2024, 142, 101221. [Google Scholar] [CrossRef]

- Gao, Y.; Jing, H.W.; Fu, G.P.; Zhao, Z.L.; Shi, X.S. Studies on combined effects of graphene oxide-fly ash hybrid on the workability, mechanical performance and pore structures of cementitious grouting under high W/C ratio. Constr. Build. Mater. 2021, 281, 122578. [Google Scholar]

- Li, N.; Unluer, C. Rheology and phase formation of cement pastes incorporating CO2-activated steel slag as a supplementary cementitious material. Cem. Concr. Comp. 2025, 162, 106121. [Google Scholar] [CrossRef]

- Wang, L.; Nerella, V.N.; Li, D.M.; Zhang, Y.Y.; Ma, B.; Ivaniuk, E.; Zhang, J.Y.; Zhu, X.H.; Yan, J.H.; Mechtcherine, V.C.W.; et al. Biochar-augmented climate-positive 3D printable concrete. Commun. Mater. 2024, 5, 257. [Google Scholar] [CrossRef]

- Mischo, F.; Schmeer, S. Optimization of a Tapered Specimen Geometry for Short-Term Dynamic Tensile Testing of Continuous Fiber Reinforced Thermoplastics. J. Compos. Sci. 2024, 8, 93. [Google Scholar] [CrossRef]

- Ruggles-Wrenn, M.; Schmidt, J. Tension–Compression Fatigue of a Hybrid Polymer-Matrix/Ceramic-Matrix Composite at Elevated Temperature. J. Compos. Sci. 2024, 8, 291. [Google Scholar] [CrossRef]

| Raw Material | Modifier | Enhanced Compressive Strength (%) | Enhanced Flexural Strength (%) | Reference |

|---|---|---|---|---|

| mortars | CNT | 10 | 22 | [44] |

| foam concrete | CNT | 70 | 70 | [50] |

| cement | CNT | / | 32 | [52] |

| oil well cement | GO | 43 | 42 | [58] |

| cement | GO/CF | 15 | / | [61] |

| concrete | graphite | 500 | 300 | [62] |

| Raw Materials | Modifier | Mechanical Properties | References |

|---|---|---|---|

| 15R-SiAlON polytype | MWCNT | HV& KIC achieved within 0.25–0.5 wt% MWCNT loading in 15R matrix. | [63] |

| ZrB2 | CNT | The flexural strength and fracture toughness of the nanocomposites were 1184 ± 52 MPa and 10.8 ± 0.3 MPa·m1/2, which is two times of that pure ZrB2. | [64] |

| 3 mol% yttria stabilized zirconia (3YSZ) | CNT | The fracture toughness increased from 5 MPa m1/2 (in 3YSZ) to 10.1 MPa m1/2 with CNT reinforcement (for 12 vol%) | [65] |

| silica matrix | Carbon fabric | Flexural strengths of the 3D CMC were doubled compared with 2D counterparts. | [66] |

| SiC | Graphene | Young’s modulus has enhanced 31.7% with 5% single layer graphene sheet. | [67] |

| Alumina ceramic | Graphene and MWCNT | The hardness and fracture toughness increased prominently with 0.2 wt.% and 0.2 wt.% graphene and hybrid-functionalized CNT. | [68] |

| Slag-based nanocomposite | Graphene | The compressive strength of graphene reinforced slag-based nanocomposite increased by 31.10% and the flexural strength added up to 96.2% at a curing age of 28 days. | [69] |

| Poly(propylene carbonate) (PPC) | SiC/GO | Both the tensile strength and the ductility of PPC were improved by adding only a small amount of the SiC/GO hybrid (0.1 wt%). | [70] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Chen, H.; Shen, J. Status and Perspectives for Mechanical Performance of Cement/Concrete Hybrids with Inorganic Carbon Materials. Buildings 2025, 15, 3525. https://doi.org/10.3390/buildings15193525

Huang L, Chen H, Shen J. Status and Perspectives for Mechanical Performance of Cement/Concrete Hybrids with Inorganic Carbon Materials. Buildings. 2025; 15(19):3525. https://doi.org/10.3390/buildings15193525

Chicago/Turabian StyleHuang, Lina, Hua Chen, and Jianzeng Shen. 2025. "Status and Perspectives for Mechanical Performance of Cement/Concrete Hybrids with Inorganic Carbon Materials" Buildings 15, no. 19: 3525. https://doi.org/10.3390/buildings15193525

APA StyleHuang, L., Chen, H., & Shen, J. (2025). Status and Perspectives for Mechanical Performance of Cement/Concrete Hybrids with Inorganic Carbon Materials. Buildings, 15(19), 3525. https://doi.org/10.3390/buildings15193525