1. Introduction

The modification of soil properties constitutes an essential procedure in geotechnical engineering, employing diverse physical, chemical, and biological interventions to improve soil performance [

1]. This improvement is essential for ensuring that soils are suitable for specific engineering applications, particularly in large construction projects such as dams, bridges, multi-story buildings, and coastal structures become more prevalent [

2]. The challenge of building on problematic soils has underscored the necessity for effective soil improvement strategies. Constructing on soft or loose soils without appropriate enhancement measures can lead to significant stability and deformation problems, resulting in considerable deformation and even structural damage from landslides.

Different soil types present unique challenges during construction [

3]. For instance, coarse-grained soils often exhibit low load-bearing capacity and a tendency to liquefy, while fine-grained soils such as clay and silt are prone to settlement over time [

4]. Loose sandy soils typically require improvement to reduce permeability and liquefaction potential, thereby increasing load-bearing capacity. In contrast, soft clay soils necessitate enhancements to improve load-bearing capacity and minimize settlement [

5]. The performance and durability of constructed facilities are profoundly influenced by the geotechnical attributes of foundation soils.

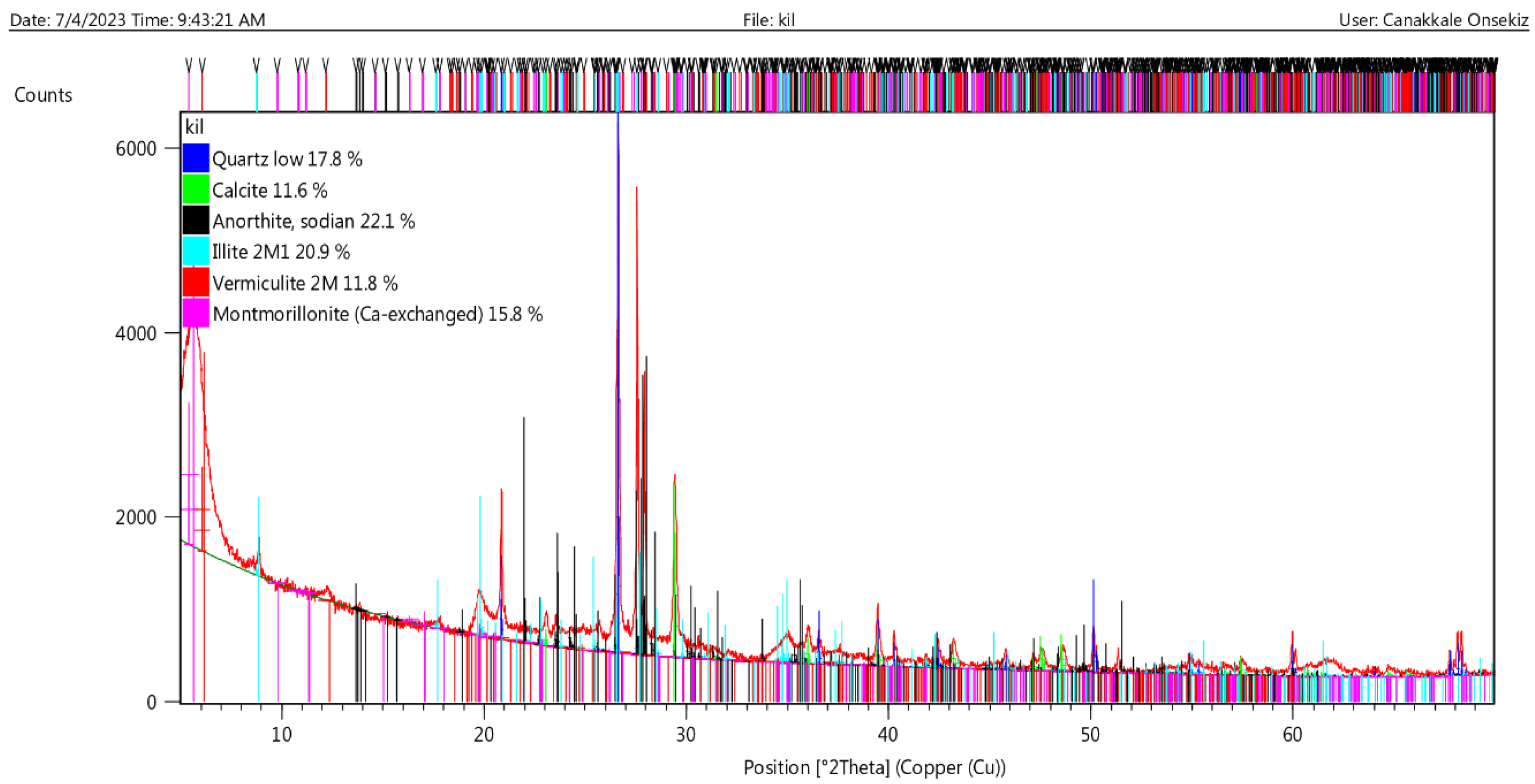

Soils exhibiting expansive behavior, known for their significant volume change characteristics, present serious geotechnical concerns due to their capacity to damage low-rise structures, pavement systems, and subsurface infrastructure [

6,

7]. Seasonal moisture variations fundamentally drive this shrink-swell behavior, which is characteristically pronounced in clayey soils with high montmorillonite clay mineral content [

8,

9]. Billions of dollars are spent annually on repairs in developed countries due to expansive soils [

10,

11].

Consequently, soil stabilization has grown into a crucial geotechnical engineering technique for managing these challenges [

12]. To improve the bearing capacity, compressibility, and durability of problematic soils, both mechanical and chemical stabilization techniques are used [

1,

13]. Traditional soil stabilization methods frequently use components including cement, lime, and fly ash to improve soil properties by altering its chemical composition [

14]. This alteration results in increased strength and reduced shrinkage [

15,

16]. However, there are growing concerns about the environmental impacts of these stabilizers; for instance, cement production significantly contributes to carbon dioxide emissions and demands considerable energy consumption [

17]. Moreover, the effectiveness of lime- and cement-based stabilization methods may be limited in soils with elevated sulfate levels, as they can promote ettringite formation, leading to increased soil swelling [

18]. These limitations have spurred interest in sustainable and cost-effective alternatives derived from industrial and agricultural waste products.

Contemporary research has increasingly focused on eco-friendly, economical alternatives utilizing industrial byproducts and agricultural waste materials as soil stabilizers [

19,

20]. Materials such as rice husk ash, marble dust, and various puzzling wastes have demonstrated their potential to improve soil properties while minimizing environmental impacts [

21,

22,

23]. In the presence of water, the reactive silica and alumina found in pozzolanic materials initiate chemical reactions with calcium hydroxide [

24]. These reactions form compounds that increase soil density and decrease permeability [

25]. In addition, geopolymers and biopolymers have been explored as alternative stabilizers due to their potential to reduce carbon emissions while improving soil properties at relatively low dosages [

1,

26]. These sustainable approaches include the integration of used tire powder and aerated concrete as a means of improving soil properties while solving waste disposal problems [

27,

28,

29,

30]. Waste tires are primarily composed of elastic rubber, which can improve the resilience of soil, reduce its brittleness, and increase its resistance to cracking under cyclic [

31]. Autoclaved aerated concrete (AAC) possesses a lightweight and porous structure that decreases soil compressibility while enhancing its overall stability. This characteristic is particularly advantageous for expansive soils, as it mitigates both volumetric changes and associated swelling pressures [

32,

33].

Studies on the use of waste tire materials in soil improvement have shown that these additives can provide substantial benefits in enhancing soil performance [

34,

35]. For instance, Akbulut et al. [

36] found that the addition of waste tire fibers significantly increased the cohesion and internal friction angle of clay soils, with unconfined compressive strength values nearly doubling compared to unreinforced samples. Similarly, Yarbaşı [

37] reported substantial strength improvements in low-plasticity red clay when mixed with waste tire fibers and marble dust, highlighting the potential for enhanced soil performance under varying climatic conditions.

Further investigations by Yarbaşı [

38] revealed that different sizes of waste tire fibers could yield varying degrees of strength enhancement, with optimal results observed at specific fiber lengths. Karaman and Ecemiş [

39] carried out shaking table tests, which indicated improved liquefaction resistance in mixtures of waste tire chips and fine sand, attributed to the effective drainage properties of the tire materials during seismic loading.

Umu et al. [

40] investigated the dynamic behavior of samples consisting entirely of ISO sand mixed with five to fifteen percent used tire powder using a torsional resonance column device and observed positive results in terms of maximum shear modulus, which correlated positively with increasing proportions up to ten percent, with adhesion between the sand grains improving significantly and voids being filled more effectively.

In addition to waste tire materials, the incorporation of aerated concrete has shown promise in soil stabilization [

26,

41]. Alpyürür and Şenol [

42] demonstrated that mixing soil concrete waste with both high and low-plasticity clays resulted in improved California Bearing Ratio (CBR), Unconfined compressive strength values, indicating enhanced soil performance. Çabalar et al. [

43] also examined the effects of mixing poorly graded gravel with waste tire chips, finding that while cohesion values increased, higher tire content led to reductions in CBR values. This points to the critical role of optimizing the mix design of materials.

Ordu et al. [

44] emphasized the importance of recycling materials in sandy soils, showing that the inclusion of shredded tires not only improved soil characteristics but also promoted environmental sustainability. Experimental studies have further shown that incorporating rubber additives at moderate contents can enhance the soil’s load-bearing capacity, particularly by increasing resilience against deformation. Biçer et al. [

45] investigated the effects of combining waste tires and PET materials in soils, reporting minimal changes in CBR values but underlining the potential of recycled materials in soil stabilization applications.

Recent advances in sustainable soil stabilization highlight both the practical and mechanistic value of industrial by-products. Lang et al. [

46] demonstrated that blast-furnace slag and electrolytic manganese residue can effectively recycle engineered sediment waste into durable subgrade material, while [

47], employing advanced techniques such as NMR, TEM, and FTIR spectroscopy, elucidated the clinker–clay bonding mechanisms responsible for strength gains in stabilized soft clays. Collectively, these findings extend sustainable soil stabilization beyond conventional tire- and concrete-based additives, underscoring the importance of integrating diverse industrial residues while fundamentally understanding their reinforcing mechanisms.

This research seeks to systematically evaluate the integrated performance of scrap tire particulate-reinforced lightweight concrete as a sustainable soil stabilization alternative. Through the evaluation of how this combination improves the soil’s mechanical strength, long-term durability, and behavior under volume change conditions, this study aims to provide innovative solutions that align with sustainable construction practices while contributing to waste prevention through the reuse of industrial by-products in geotechnical applications.

Despite advances in soil stabilization using single additives such as cement, lime, or rubber, research has seldom addressed the combined use of elastic and pozzolanic industrial by-products. To address this gap, the present study introduces a hybrid stabilization mechanism by jointly applying waste tire powder (WTP) and autoclaved aerated concrete powder (ACP) for the improvement of clay soils. Unlike previous studies that typically focused on single additives, this dual approach exploits the complementary interaction between the elastic properties of WTP and the pozzolanic bonding action of ACP, resulting in a balanced enhancement of strength, stiffness, and ductility. Beyond the engineering benefits, this work directly addresses environmental and economic concerns: waste tires and aerated concrete residues are significant sources of environmental pollution, and their recycling into soil stabilization not only mitigates ecological impacts but also provides cost-effective raw materials that contribute to national economies. By framing soil stabilization simultaneously as a geotechnical improvement technique and as a sustainable waste management strategy, the study advances both scientific understanding and practical implementation of industrial by-products in geotechnical engineering. Accordingly, this research systematically investigates the mechanical performance of clayey soils stabilized with varying proportions of WTP and ACP, employing UCS, CBR, and dry unit weight analyses to evaluate their effectiveness as sustainable soil improvement additives.

3. Experimental Program

The experimental design was developed using a systematic approach and involved the preparation of various soil mixtures using different proportions of waste tire powder and aerated concrete. In this context, the experimental studies carried out in a laboratory environment aim to show the potential of such additives in soil improvement processes. The utilization of waste materials is an important step in terms of environmental sustainability and can contribute to the reduction in costs in engineering applications. Each mixture was prepared by uniformly blending the specified proportions of clay soil, waste tire powder, and aerated concrete using a mechanical mixer (Utest Material Testing Equipment, UTC-0750, Ankara, Turkey), as detailed in

Table 3. This procedure is essential for optimizing the physical and chemical characteristics of the mixture.

The moisture content of the mixtures was adjusted by standard Proctor compaction tests to determine the optimum compaction conditions. The target moisture content was set at approximately 19% to attain the highest possible dry density for each mixture.

3.1. Additive Incorporation

This study used waste tire powder (WTP) and aerated concrete powder (ACP) as additives. The waste tire material was locally sourced and mechanically ground into fine particles (<1 mm), ensuring homogeneity; no coarse fractions were used. Thus, the additive content consisted of 100% powdered rubber. Aerated concrete residues were similarly ground into fine powder for uniform mixing with the clay soil. The exclusive use of fine particles was deliberate, as previous studies have shown that finer rubber fractions improve soil homogeneity, enhance UCS and CBR performance, and optimize void filling [

36,

37,

38]. Likewise, Alpyürür and Şenol [

42] reported that finely ground concrete waste integrates more effectively with clay soils, improving strength and durability.

3.2. Sample Preparation and Curing

Clay soil was oven-dried, sieved through a 2 mm mesh, and mixed with the specified proportions of waste tire powder (WTP) and aerated concrete powder (ACP). Distilled water was added gradually until the optimum moisture content (OMC), determined from compaction tests, was achieved. The mixtures were then compacted into cylindrical molds in three layers, each layer pressed to remove air voids and ensure uniform density. After demoulding, the specimens were cured for 7 days at room temperature (22 ± 2 °C) and sealed with plastic film to prevent moisture loss. This curing regime is consistent with previous studies [

36,

37,

38,

42].

3.3. Testing Program

The testing program included compaction tests, Atterberg limits, and unconfined compressive strength (UCS) tests in accordance with ASTM standards. The overall testing procedure, from soil preparation to additive mixing, compaction, curing, and mechanical testing, is summarized in

Figure 7. This flowchart provides a clear overview of the laboratory sequence followed in this study.

3.4. Compaction Experiments

Standard Proctor compaction tests were performed in accordance with [

48] to evaluate the effect of adding waste tire dust and aerated concrete admixtures to clay soils, specifically to determine the optimum moisture content (OMC) and maximum dry density (MDD) of the resulting mixtures.

A total of 40 different specimen mixtures were experimentally evaluated to establish the basic compaction properties. In the test procedure, the specimens were compacted in cylindrical molds using a standard Proctor hammer (Utest Material Testing Equipment, UTS-0605A, Ankara, Turkey). Compaction of each specimen was carried out in three layers, applying 25 blows per layer using a hammer falling freely from a height of 30.5 cm. The dry density of each compacted specimen was computed by measuring its final weight and volume.

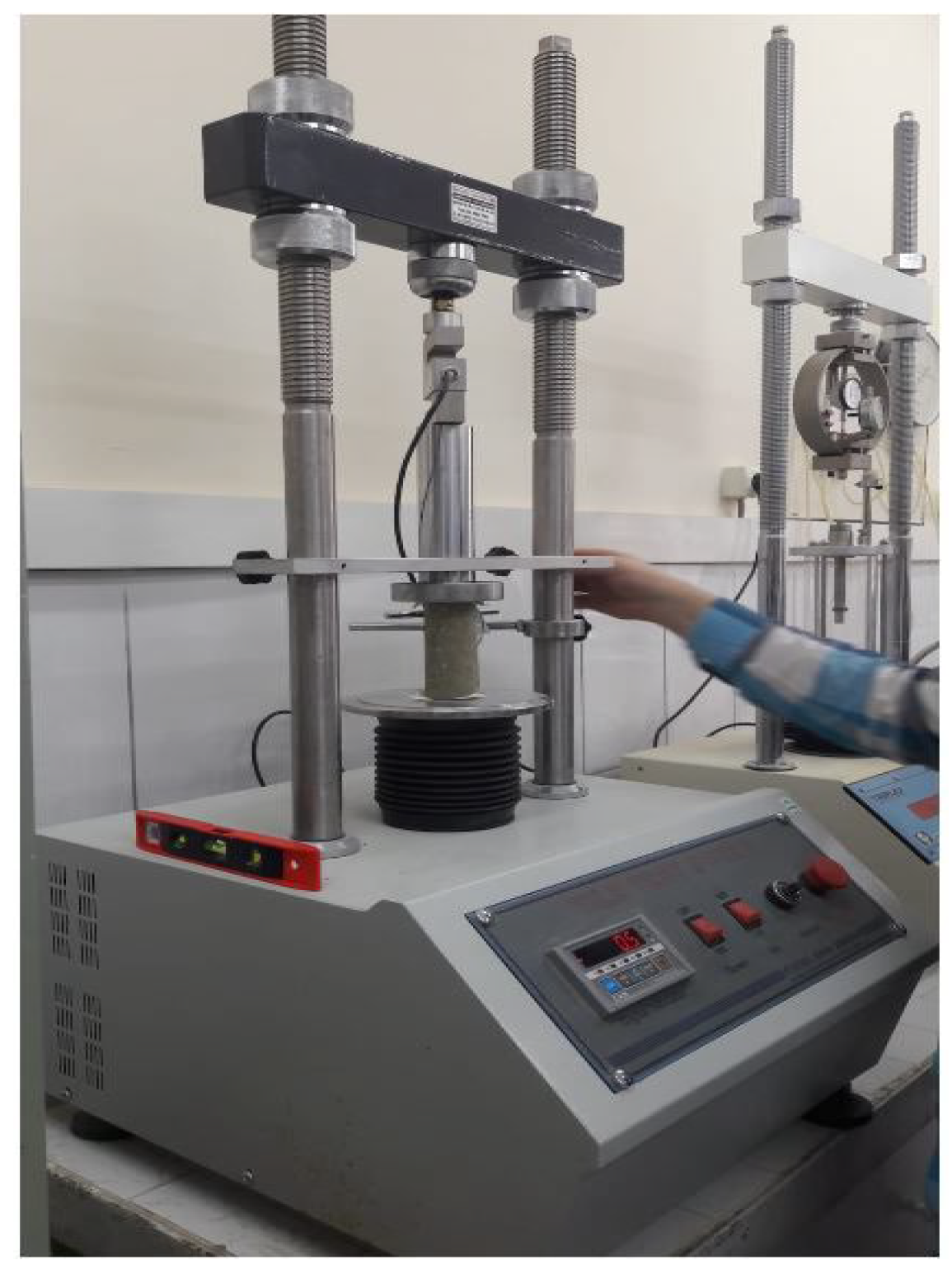

3.5. Unconfined Compression Strength Tests

Soil samples were formed into cylindrical specimens (48 mm diameter × 110 mm height), cured following. Axial loading was applied to the specimens at a steady rate of deformation until they failed, utilizing a universal testing machine.

A total of 23 UCS tests were performed and the maximum load was recorded in each test. The following formula was used to represent the relationship between the applied load and the corrected cross-sectional area of the specimen [

49]:

where (

P) denotes the applied load and (

Ad) indicates the corrected cross-sectional area of the specimen. The data obtained were analyzed with the aim of understanding the influence of additive content on strength performance.

The UCS test setup is shown schematically in

Figure 8, while the actual laboratory arrangement with a tested specimen is provided in

Figure 9.

The schematic shows the soil specimen placed between the upper and lower platens of the loading frame. Axial load is applied vertically until failure, with stress–strain behavior recorded throughout.

The photograph illustrates the testing device and highlights the failure mode observed in compacted clay–additive mixtures.

3.6. California Bearing Ratio (CBR) Experiments

To evaluate the load-carrying potential of the soil mixtures, CBR tests were carried out following [

50]. Specimens were prepared using Standard Proctor compaction at optimum moisture content. Twenty California Bearing Ratio (CBR) tests were performed for each sample.

CBR values were determined at 2.5 mm and 5.0 mm penetrations by measuring the load required for penetration (Ptest) and comparing it to the load required for penetration of the standard material (Pstandard). A loading rate of 1.2 mm/min was applied during the test.

The CBR value was calculated by the following formula:

Here, (Ptest), represents the load required for penetration; (Pstandard), represents the load required for standard material.

The CBR test setup is shown schematically in

Figure 10, while the actual laboratory arrangement with a tested specimen is provided in

Figure 11.

The schematic shows the mold containing compacted soil, the surcharge weights, and the penetration piston. Load is applied at a constant rate of 1.2 mm/min, and the penetration–load relationship is recorded at 2.5 mm and 5.0 mm.

The photograph illustrates the CBR apparatus, specimen mold, penetration piston, and surcharge arrangement following the test.

3.7. Data Analysis and Statistical Methodology

All measurements were reported within the calibrated precision of the respective instruments: UCS to ±0.1 MPa, CBR to ±0.5%, and dry unit weight to ±0.1 kN/m3. The results have been rounded to reflect these accuracies, avoiding any implication of false precision.

A comprehensive statistical analysis was performed to evaluate the effects of waste tire powder (WTP) and aerated concrete powder (ACP) additives on soil behavior. The analysis was based on the results of unconfined compressive strength (UCS) and California Bearing Ratio (CBR) tests, together with dry unit weight and secant modulus values.

The descriptive statistics for these parameters are presented in

Table 4. Values are reported with one decimal place to reflect instrument precision, and measurement error has been considered (±0.1 for dry unit weight and UCS, ±0.5 for CBR). This table provides a baseline for the subsequent statistical analyses, ensuring transparency and reproducibility.

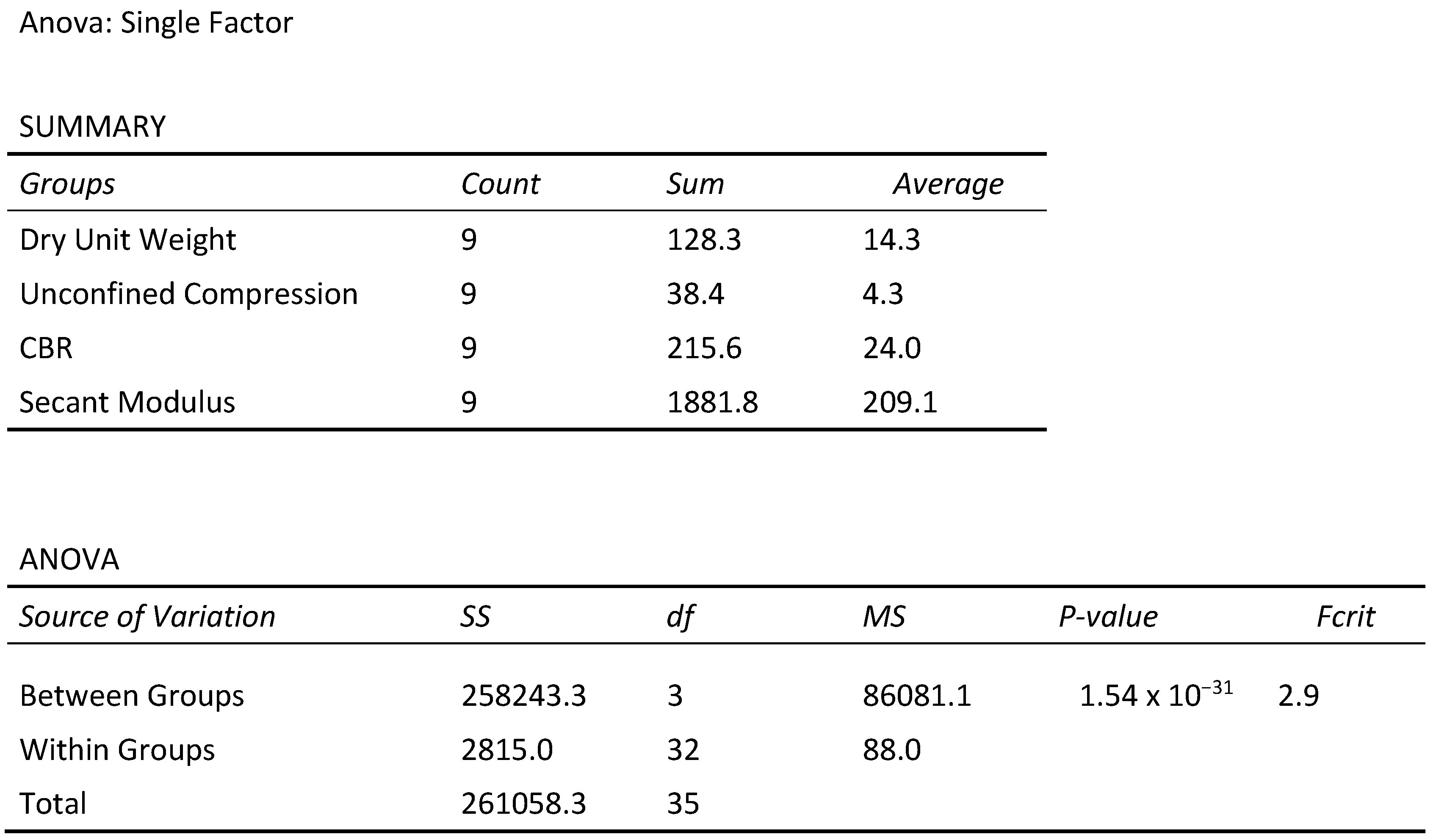

In this study, a one-way ANOVA analysis was performed to examine the differences between the average values of Dry Unit Weight, Unconfined Compressive Strength (UCS), CBR, and Secant Modulus. The descriptive statistics of the four mechanical parameters—Dry Unit Weight, Unconfined Compressive Strength (UCS), CBR, and Secant Modulus—are presented in

Table 4, providing an overview of their mean values and variability. Secant Modulus exhibited the highest mean (209.1 MPa), while UCS had the lowest (4.3 MPa), with Dry Unit Weight (14.3 kN/m

3) and CBR (24.0%) showing intermediate values.

The results of the one-way ANOVA are summarized in

Figure 12. The analysis confirmed that the variation among the group means was highly significant (F = 978.5 > Fcrit = 2.9,

p < 0.001), indicating that the parameters are statistically distinct. To determine which parameters were responsible for these differences, Tukey’s Honestly Significant Difference (HSD) test was applied (

Figure 13). Pairwise comparisons exceeding the critical threshold (≈9.0) were deemed significant. The largest contrasts occurred between secant modulus and the other parameters, while dry unit weight and CBR, with closer mean values, showed more modest differences.

To determine which parameters were responsible for these differences, Tukey’s Honestly Significant Difference (HSD) test was applied, as shown in

Figure 13. Pairwise comparisons exceeding the critical threshold (≈9.0) were deemed significant. The largest contrasts occurred between Secant Modulus and the other parameters, while Dry Unit Weight and CBR, with closer mean values, showed more modest differences.

Overall, the statistical results confirmed that medium-level additive ratios provided the most balanced and superior performance, in agreement with laboratory observations and underscoring their decisive role in soil behavior.

4. Results

4.1. Dry Unit Weight Results

First, the dry unit weight value of the natural soil without admixture was found to be 15.1 kN/m3. Then, the dry unit weight values of the soil samples with 5%, 10%, 15%, and 17% admixtures of aerated concrete were obtained as 14.4 kN/m3, 13.9 kN/m3, 13.1 kN/m3, and 13.2 kN/m3, respectively. Then, the dry unit weights of the soil specimens with 1%, 2%, and 4% waste tire powdered mixtures were 14.9 kN/m3, 14.9 kN/m3, and 14.8 kN/m3, respectively. Finally, the dry unit weight value of the soil specimen with 2% waste tire powdered (WTP) and 5% ground aerated concrete (ACP) was calculated as 14.1 kN/m3.

The dry unit weight of the untreated soil was 15.1 kN/m

3. With increasing ACP content, values decreased to 14.4 kN/m

3, 13.9 kN/m

3, 13.1 kN/m

3, and 13.2 kN/m

3 at 5%, 10%, 15%, and 17%, respectively. WTP additions also caused slight reductions, with values of 14.9 kN/m

3, 14.9 kN/m

3, and 14.8 kN/m

3 at 1%, 2%, and 4%. The combined 2% WTP + 5% ACP mix yielded 14.1 kN/m

3. These results, illustrated in

Figure 14, reflect the lightweight nature of ACP and the low specific gravity of WTP.

These results are consistent with [

51], who demonstrated that incorporating autoclaved aerated concrete powder reduces compaction density while enhancing mechanical response. Similarly, Gao, M. et al. [

52] reported that rubber powder decreases density in red clay but contributes to performance gains at optimal dosages, and [

53,

54] confirmed that moder-ate rubber contents strengthen clay–rubber mixtures, whereas higher levels reduce performance due to structural disruption. Overall, these findings confirm that 2% WTP is the most effective dosage, while higher levels begin to reduce soil density. Although testing at 3% WT was not included within the scope of this study, its consideration in future re-search could provide valuable insight into the transitional behavior between the beneficial effects observed at 2% and the performance reduction noted at 4%.

The dry unit weight values obtained due to this application are presented comparatively in a graph. Dry unit volume weights of 9 batches with and without additives prepared at approximately 19% water content are given in

Figure 14.

ACP reduced the dry unit weight of clayey soil more than WTP due to its lightweight and porous structure. While this reduction may limit bearing capacity under heavy loads, it provides advantages in lightweight embankments or backfill applications where reducing stresses on substructures is beneficial.

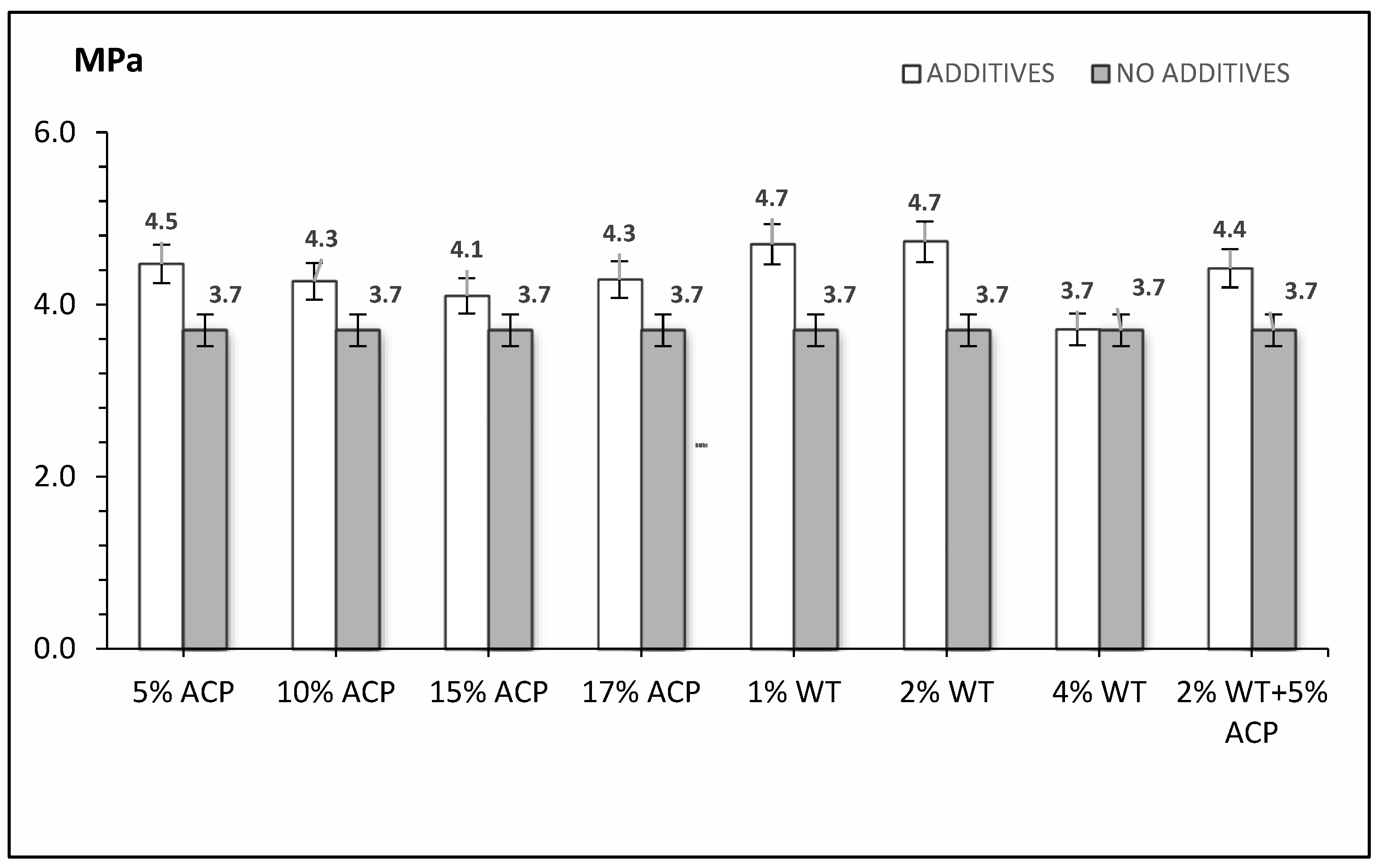

4.2. Unconfined Compressive Strength Results

The unconfined compressive strength (UCS) is the maximum strength of the soil before deformation under load. In this study, the UCS value of the unreinforced soil was found to be 3.7 MPa. The values of 4.5 MPa, 4.3 MPa, 4.1 MPa, and 4.3 MPa were obtained for the specimens with aerated concrete admixtures at 5%, 10%, 15%, and 17%, respectively. These results indicate that aerated concrete admixture in-creases the strength of the soil. Especially 5% aerated concrete admixture provided the highest strength. In the specimens with 1%, 2%, and 4% waste powder tire admixtures, 4.7 MPa, and 3.7 MPa values were obtained, respectively. Further, 5% aerated concrete mixture with 2% waste powder tire admixture showed a strength of 4.4 MPa. These results show that the addition of waste tirepowdered also increased the strength of the soil, but the 4% addition decreased the strength. This suggests that high levels of the admixture may adversely affect the soil structure (

Figure 15). The graph clearly illustrates the extent to which WTP increased soil strength. Mechanistically, this can be explained by the microstructural role of fine rubber particles (<0.6 mm), which at low dosages fill voids and interlock with clay platelets, thereby enhancing ductility and delaying brittle failure. However, as WTP content increases, elastic inclusions disrupt the clay matrix, reducing cohesion and replacing load-bearing soil contacts with low-stiffness particles. This interpretation is consistent with the findings of [

53,

54], who demonstrated that moderate rubber contents enhance both strength and ductility, but higher levels reduce UCS due to matrix disruption. Similarly, Akbarimehr et al. [

55] reported that low rubber dosages improved stiffness in clay–rubber mixtures, while excessive contents weakened strength. Comparable behavior was observed by [

56] in soil–cement composites, where small rubber additions increased compressive strength, but larger proportions led to reductions due to weakened adhesion.

UCS improved with ACP additions, reaching a maximum of 4.5 MPa at 5% ACP. WTP also increased strength at low dosages (2%), but 4% WTP reduced strength to 3.7 MPa, showing that excessive rubber content can disrupt soil structure. This highlights the importance of selecting optimum dosages.

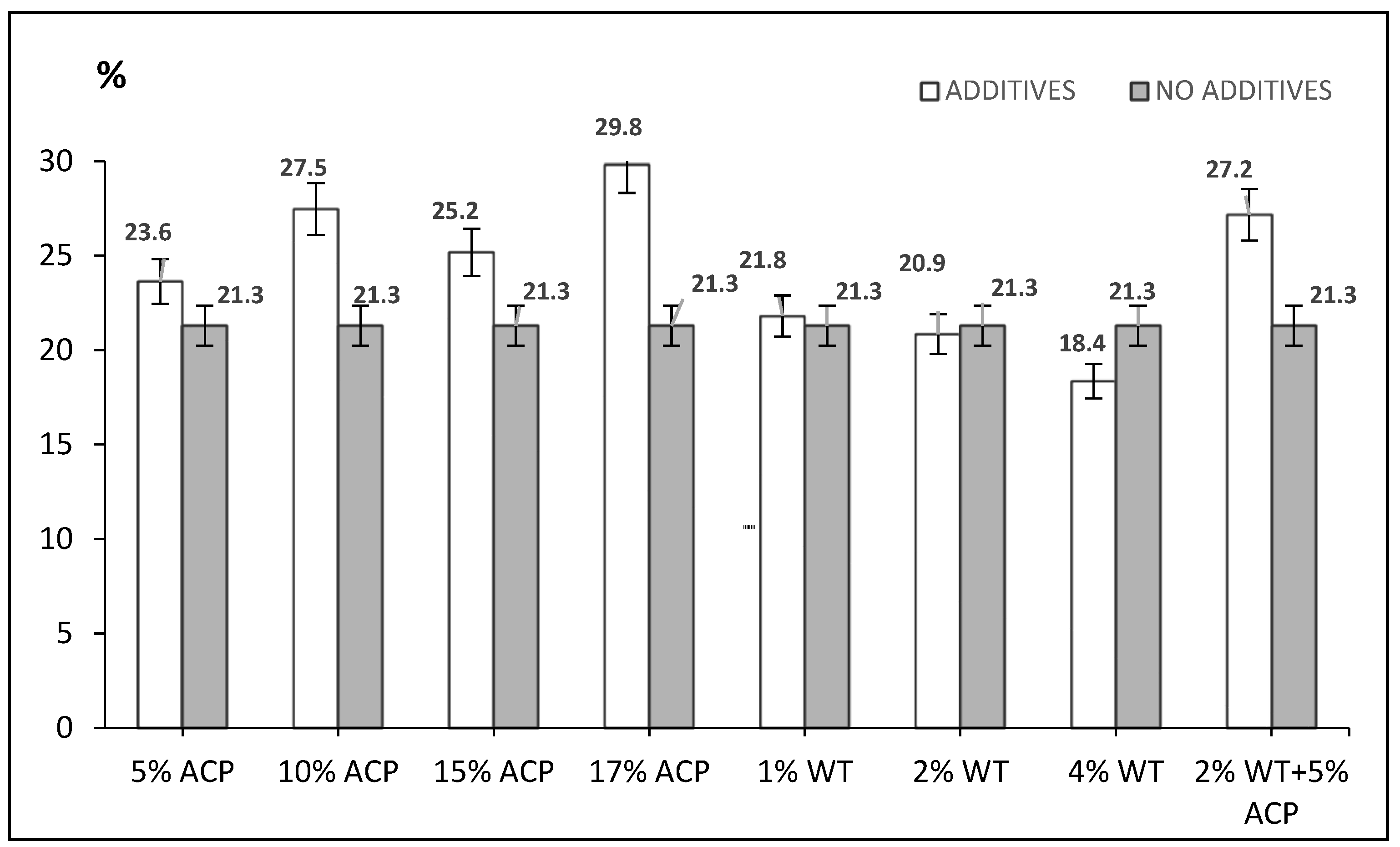

4.3. CBR Test Results

The California Bearing Ratio (CBR) test is used to determine the bearing capacity of the soil. The CBR value of the soil without admixture was found to be 21.3%. In the samples with aerated concrete admixture, the values of 23.6%, 27.5%, 25.2%, and 29.9% were obtained at 5%, 10%, 15%, and 17%, respectively. These results indicate that aerated concrete admixture significantly increased the bearing capacity of the soil. Especially 17% aerated concrete admixture provided the highest CBR value. In the specimens with 1%, 2%, and 4% waste tire admixtures, 21.8%, 20.9% and 18.4% values were obtained, respectively. Additionally, 5% aerated concrete mix with 2% waste tire admixture showed a CBR value of 27.2%. These results show that low levels of tire admixture increase the bearing capacity of the soil, but high levels of admixture decrease this capacity (

Figure 16). The graph illustrates the extent to which the additives increased the bearing capacity of the soil.

Mechanistically, aerated concrete powder (ACP) enhances soil performance primarily through filler action and pozzolanic bonding. Its reactive silica and alumina phases interact with calcium hydroxide to form secondary cementitious compounds, densifying the soil structure and increasing stiffness. Waste tire powder (WTP), when incorporated at low dosages, improves ductility and deformation resistance by partially filling voids and acting as elastic inclusions. However, higher WTP contents disrupt soil–soil contacts and introduce low-stiffness rubber interfaces, reducing the soil’s load-bearing capacity. Similar threshold behaviors have been reported [

52], where rubber powder additions in red clay improved strength only up to an optimum content, and [

53], which demonstrated that moderate rubber inclusions enhanced strength and ductility in clay–rubber mixtures, while excessive rubber reduced UCS due to matrix disruption. Furthermore, the hybrid “rigid + elastic” mechanism observed in this study is consistent with [

57], where combining rubber crumbs with tile powder optimized strength and stiffness in clayey soils, and with [

58], which showed that cementitious binders such as waste glass can stabilize rubber inclusions, sustaining strength and bearing capacity in rubberized soils.

CBR values increased significantly with ACP, reaching 29.8% at 17% ACP compared to 21.3% for untreated soil. In contrast, WTP reduced CBR at higher contents, with 4% WTP dropping the value to 18.4%. This reflects the elastic nature of rubber, which at excess levels increases deformation under load.

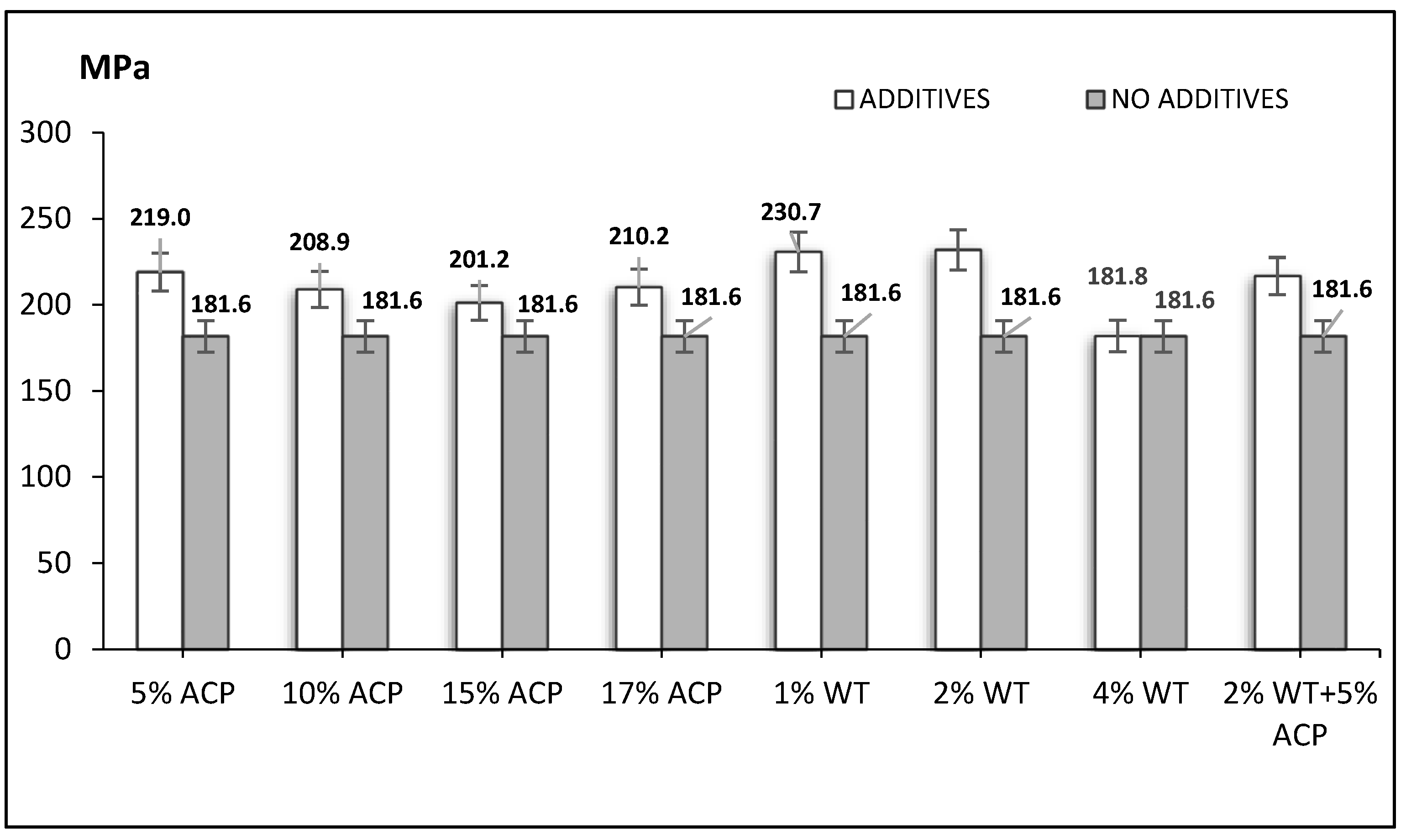

4.4. Secant Modulus Results

Secant modulus measures the stiffness and deformation behavior of the soil under load. The secant modulus calculated according to the unconfined compressive strength values was found to be 219 MPa, 209 MPa, 201 MPa, and 210.2 MPa for 5%, 10%, 15% and 17% of the aerated concrete reinforced specimens, respectively. These results indicate that aerated concrete admixture increased the stiffness of the soil. The values of 230.7 MPa, 231.8 MPa, and 181.8 MPa were obtained for the specimens with 1%, 2%, and 4% waste tire admixtures, respectively. Further, 5% aerated concrete mixture with 2% waste tire admixture showed a secant modulus value of 216.7 MPa. These results show that low levels of tire admixture increase the stiffness of the soil, but high levels of admixture decrease it (

Figure 17). This graph shows more clearly the extent to which the additives increase the soil stiffness.

Mechanistically, ACP refines gradation and promotes pozzolanic reactions that generate additional C–S–H gels, thereby strengthening the soil matrix. Small rubber inclusions act as elastic fillers that enhance ductility and deformation resistance at low dosages. However, excessive rubber disrupts the soil skeleton and introduces low-stiffness interfaces, which reduce stiffness and modulus. Similar behaviors have been reported in recent studies [

54,

59,

60,

61,

62,

63], where moderate rubber additions improved stiffness and strength, while higher dosages weakened performance due to matrix disruption.

Low WTP contents (1–2%) increased soil stiffness, with values above 230 MPa, while higher dosages (4%) reduced it to ~182 MPa. ACP consistently improved stiffness due to pozzolanic bonding and filler action. These results confirm that both additives strengthen soil when used at moderate levels but weaken it when excessive.

4.5. Broader Discussion: Sustainability, Limitations, and Future Work

This study has certain limitations. Testing was carried out on clayey soil from a single source, with short-term curing and under controlled laboratory conditions.

The reuse of waste tires and aerated concrete in soil stabilization reduces environmental pollution and disposal risks while creating economic value through recycling. When used at appropriate dosages, these by-products improve ductility, stiffness, and bearing capacity; however, excessive additions disrupt soil fabric and reduce performance, highlighting the need for careful optimization.

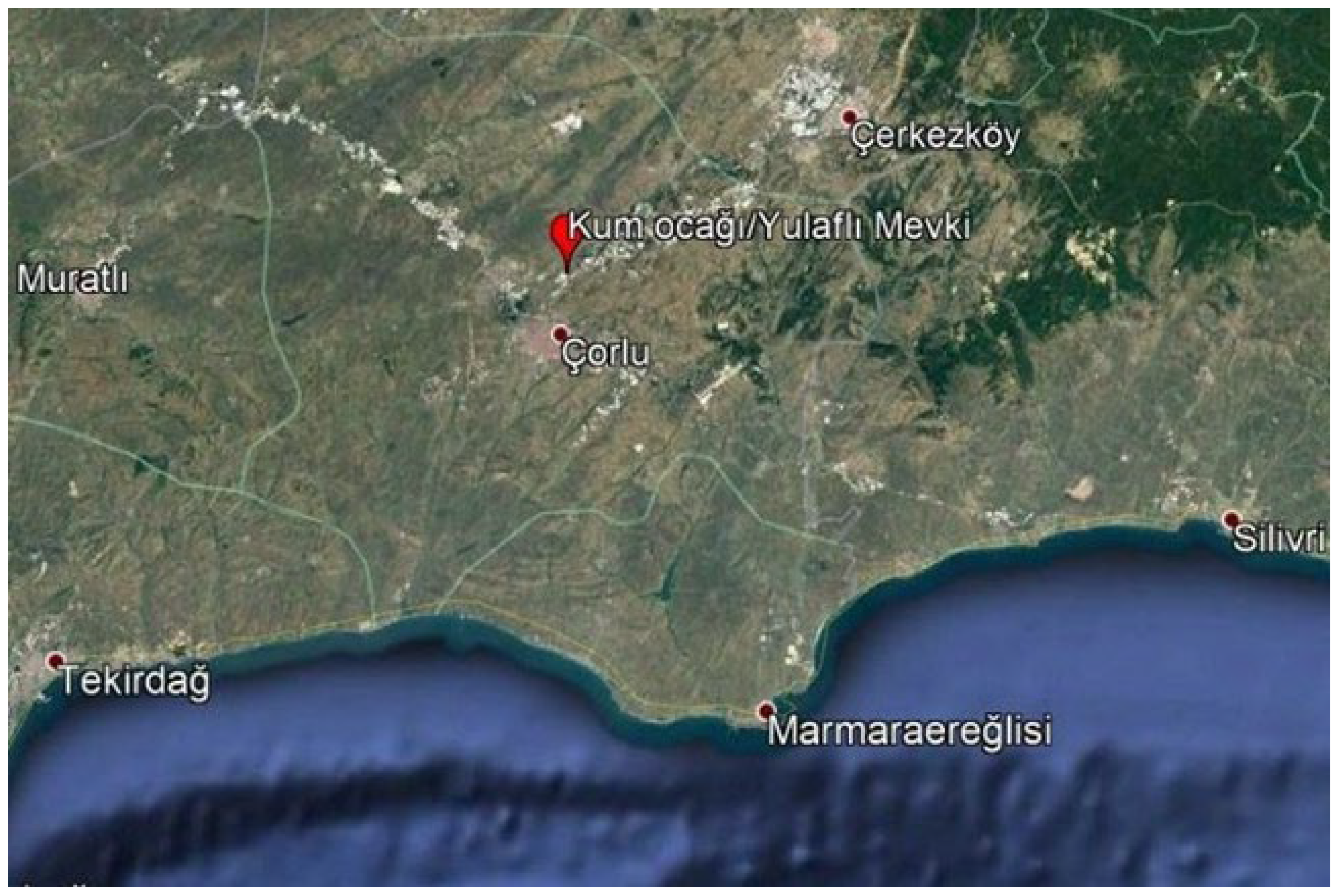

The findings should be viewed within the limits of this experimental program, which focused on clayey soil from Çorlu, specific additive ranges (0–4% WTP and 0–17% ACP), and short-term curing. Broader generalization requires testing on different soil types, longer curing periods, and field conditions such as freeze–thaw cycles and variable moisture regimes.

Future studies should also integrate spatial variability and reliability-based approaches to better represent soil–additive interactions under real field conditions. Recent advances in probabilistic analysis and reliability frameworks [

64] as well as innovative numerical methods for geotechnical failure analysis [

65] offer valuable tools for capturing heterogeneity, uncertainty, and discontinuity-related mechanisms in soils and rocks. Incorporating such state-of-the-art methods alongside laboratory and field testing would not only improve the robustness and generalizability of results but also strengthen the theoretical foundation of sustainable soil stabilization research. Overall, incorporating WTP and ACP into soil stabilization supports sustainable development by enhancing geotechnical performance, reducing waste, and conserving resources, while future work should bridge laboratory findings with probabilistic models and field-scale applications.

While this study has focused on macro-scale geotechnical properties (UCS, CBR, and compaction), future research should investigate the microstructural mechanisms governing the observed improvements. Advanced characterization techniques such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), or micro-computed tomography (micro-CT) could provide valuable insights into the bonding, pore-filling, and particle–matrix interactions between waste tire powder, autoclaved aerated concrete (ACP), and clay minerals. Such analyses would clarify the threshold behaviors observed in this study, particularly the balance between elastic inclusions and pozzolanic bonding, and would significantly enhance the mechanistic understanding of hybrid soil stabilization systems.

5. Discussion

The experimental results demonstrate that both waste tire powder (WTP) and autoclaved aerated concrete powder (ACP) contribute beneficially to soil stabilization, but only within certain dosage thresholds. At low dosages (e.g., 2% WTP and 5% ACP), these additives complement one another to achieve a balanced improvement in strength, stiffness, and ductility. The enhancement observed in UCS and secant modulus values is consistent with previous findings that moderate rubber contents increase ductility and delay brittle failure while cementitious by-products densify the soil matrix through secondary C–S–H formation [

51,

52,

53,

54].

At higher WTP contents (4%), however, performance declines. This threshold behavior can be attributed to matrix disruption: elastic inclusions begin to replace load-bearing contacts between clay particles, reducing cohesion and lowering UCS and CBR. Similar observations have been reported in rubber–soil composites, where optimum strength is achieved at modest rubber fractions, beyond which stiffness and bearing capacity diminish [

55,

56,

57].

By contrast, ACP consistently enhances compressive strength and CBR across all tested dosages, reflecting its pozzolanic reactivity and lightweight, porous nature. The reduction in dry unit weight observed with ACP addition is expected, given its low specific gravity, but this trade-off is advantageous in applications such as lightweight embankments where reduced stress on substructures is desired.

The hybrid mixture (2% WTP + 5% ACP) is particularly noteworthy. Mechanistically, this combination activates a “rigid + elastic” mechanism: ACP forms cementitious gels that improve stiffness and strength, while fine WTP particles improve ductility, distributing stresses and mitigating brittle fracture. Comparable synergistic interactions have been highlighted by Raj et al. [

57] and Gücek et al. [

58], who demonstrated that blending elastic and rigid wastes produces superior mechanical balance compared to single-additive systems.

At the international level, Gao et al. [

51] showed that rubber powder improved UCS and ductility in red clay up to an optimum content, beyond which strength declined—mirroring our results where 2% WTP enhanced performance but 4% reduced it. Similarly, Eslami and Akbarimehr [

53,

54] reported that moderate rubber inclusions enhanced stiffness and compressive behavior in high-plasticity clays, while higher contents weakened the soil matrix. In terms of ACP, Zhan et al. [

51] confirmed that aerated concrete powder reduces compaction density but enhances shear strength, consistent with our finding that ACP improved UCS and CBR while slightly lowering dry density. Internationally, hybrid approaches are also gaining attention: Raj et al. [

57] combined rubber crumbs with tile powder, and Gücek et al. [

58] stabilized rubber with waste glass, both demonstrating superior mechanical balance through “rigid + elastic” synergies. Our study extends this evidence by validating a WTP + ACP hybrid in clayey soils.

At the domestic level, Turkish studies have also reported parallel trends. Akbulut et al. [

36] and Yarbaşı [

37,

38] found that waste tire additives improved cohesion, UCS, and liquefaction resistance in clays, results that support our findings of strength and ductility improvements at low WTP contents. Alpyürür and Şenol [

42] demonstrated that waste aerated concrete enhanced UCS and CBR in clays, which parallels our results showing ACP as a reliable stabilizer. Moreover, Ordu et al. [

44] and Biçer et al. [

45] highlighted the dual benefit of tire recycling in Turkish soils: improving geotechnical behavior while promoting environmental sustainability. By combining these two waste materials, our study advances domestic research by introducing a hybrid solution not previously tested in Turkey.

From a sustainability perspective, recycling both waste tires and aerated concrete residues directly addresses two pressing environmental challenges: the accumulation of non-biodegradable rubber waste and the disposal of autoclaved concrete debris. Their valorization in geotechnical applications not only mitigates environmental pollution but also reduces the demand for virgin stabilizers such as cement and lime, whose production is energy-intensive and carbon-emitting.

Broader generalization requires further research across soil types, extended curing periods, and field environments. Incorporating microstructural analyses (SEM, EDX, micro-CT) in future work will provide deeper insights into the particle–matrix interactions governing the observed threshold behaviors.

Overall, the findings demonstrate that WTP and ACP, when used together at optimum proportions, offer a technically viable and environmentally responsible approach to soil stabilization, advancing both geotechnical engineering practice and sustainable waste management.

7. Future Scope and Recommendations

This study has demonstrated the potential of waste tire powder (WTP) and autoclaved aerated concrete powder (ACP) as sustainable additives for stabilizing clayey soils. However, certain limitations should be acknowledged. First, the experimental program was restricted to a single soil type from the Çorlu region, with short-term curing conditions under controlled laboratory settings. Broader validation across different soil mineralogies, climatic conditions, and extended curing regimes is required before large-scale field application.

Second, while macro-scale parameters such as UCS, CBR, dry unit weight, and secant modulus provide valuable performance indicators, they do not reveal the detailed mechanisms occurring at the particle and pore scale. Future research should therefore incorporate microstructural characterization techniques such as scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDX), and micro-computed tomography (micro-CT). These methods can visualize bonding, pore-filling, and particle–matrix interactions, offering crucial insights into the threshold behaviors observed in this study (e.g., the performance decline at 4% WTP and the synergy in the 2% WTP + 5% ACP mixture).

Finally, future work should also consider reliability-based modeling, probabilistic frameworks, and field-scale trials under varying moisture and loading conditions. These approaches will help bridge the gap between laboratory findings and real-world engineering practice, ensuring that the proposed hybrid stabilization technique is both technically robust and practically viable.

In summary, future investigations should integrate multi-scale analysis—from microstructural imaging to probabilistic modeling—to fully capture the behavior of WTP-ACP–stabilized soils. Such efforts will not only validate laboratory outcomes but also advance the mechanistic and practical understanding of sustainable soil stabilization strategies.