Seismic Performance Analysis of a New Type of Fabricated Concrete Beam–Column Joint

Abstract

1. Introduction

2. Novel Beam–Column Joint Configuration

2.1. Joint Design and Principle

2.2. Quantitative Analysis of Construction Efficiency and Stiffness Improvement

3. Experimental Program

3.1. Specimen Design and Fabrication

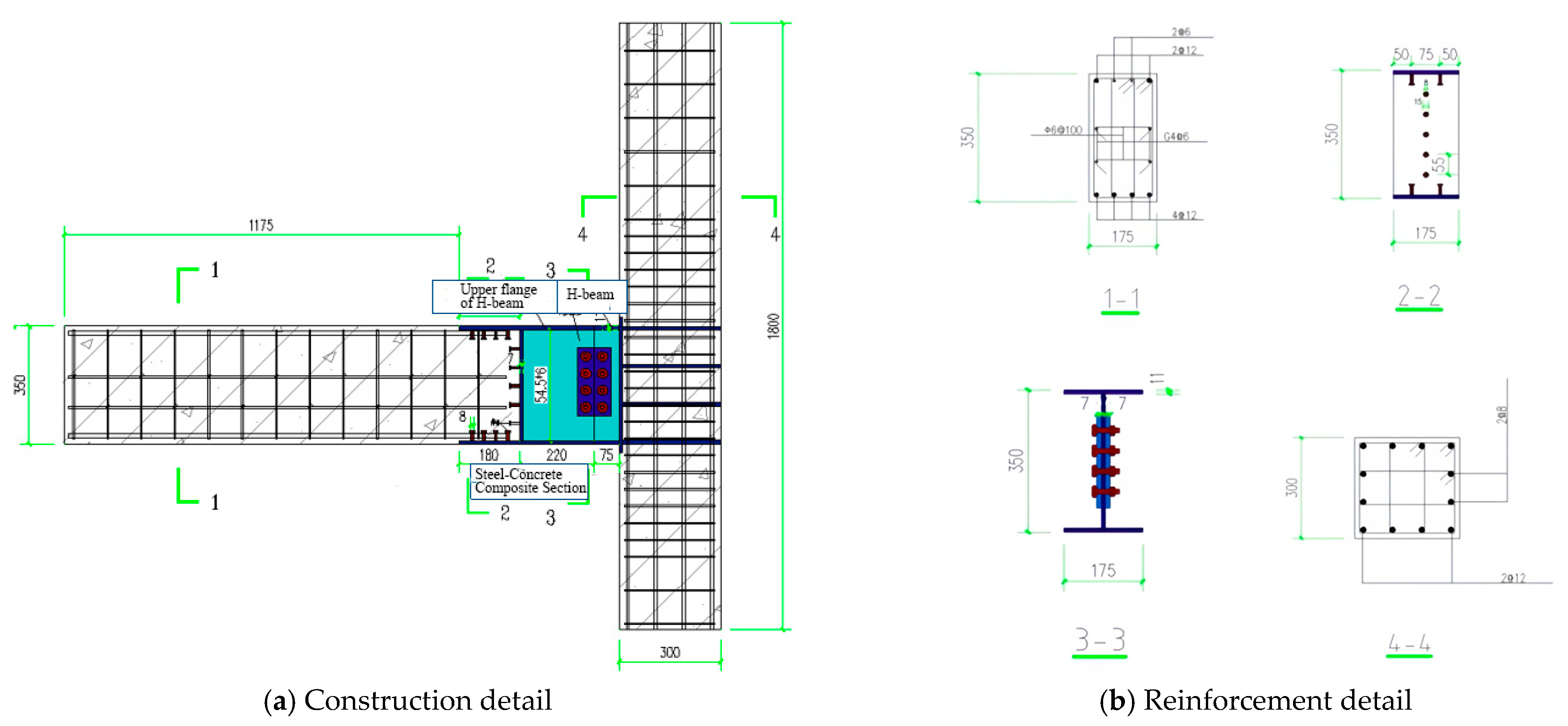

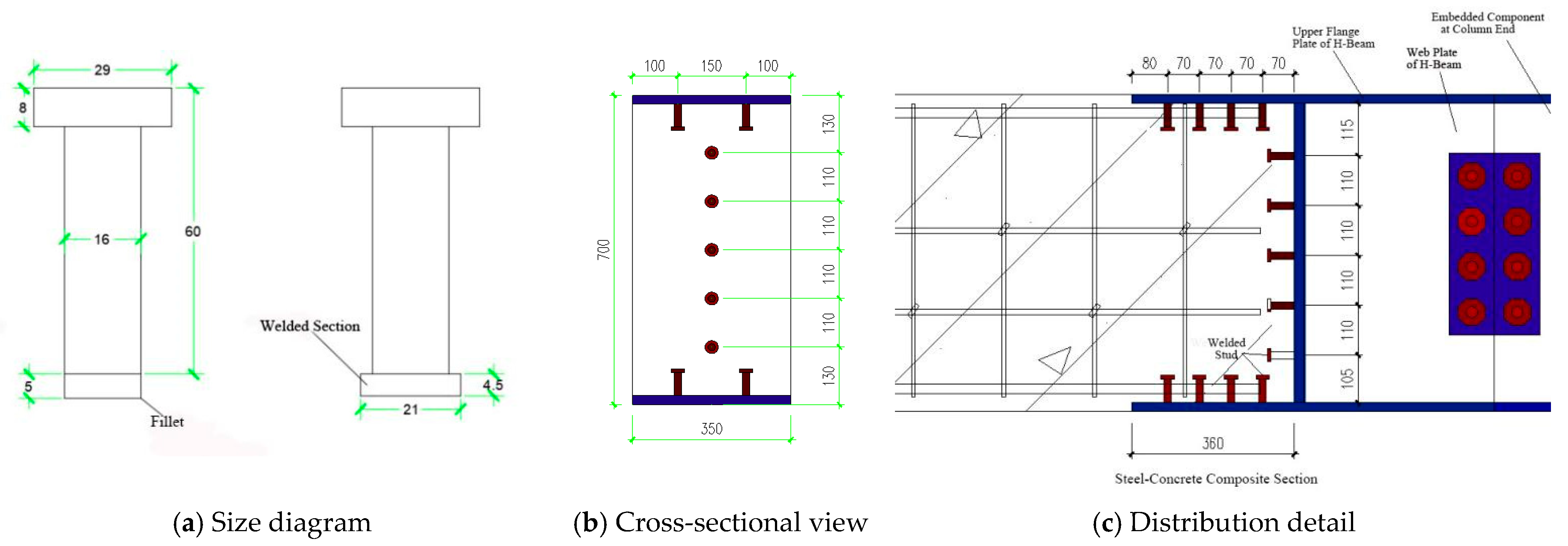

3.1.1. Joint Details and Reinforcement Layout

3.1.2. Similarity Laws for 1:2 Scale Models

3.1.3. Rationale for Selecting C35 Concrete

- (1)

- Code compliance: According to Clause 4.1.2 of the Code for Design of Concrete Structures (GB 50010-2010), C35 is the minimum recommended strength class for beam–column joints in multi-story precast frame systems, satisfying the “strong joint–weak member” seismic requirement.

- (2)

- (3)

- Reinforcement compatibility: The longitudinal bars used in the joint are Grade HRB400. The ratio of the reinforcement yield strength to the concrete axial compressive strength is approximately 11.4, which falls within the recommended range of 9–12 for ductile joints specified in Clause 11.2.3 of GB 50010-2010, thereby avoiding over-reinforcement.

- (4)

- Construction practicality: C35 concrete can be easily proportioned to a slump of 160–180 mm, satisfying Clause 6.2.4 of the Technical Standard for Precast Concrete Structures (GB/T 51231-2016) [22] regarding pumpability and compactability in post-cast regions of precast elements, thus minimizing the risk of cold joints and honeycombing.

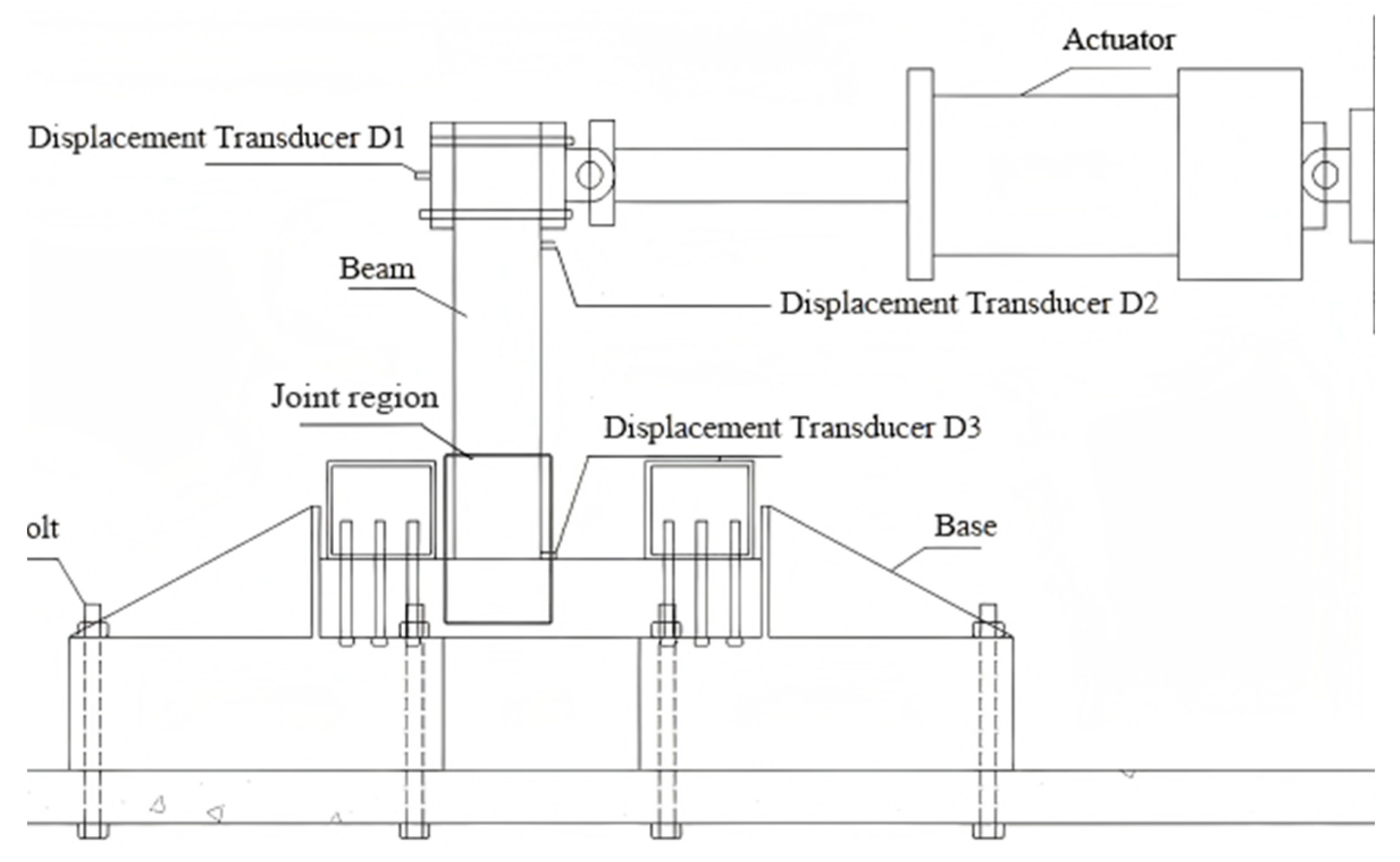

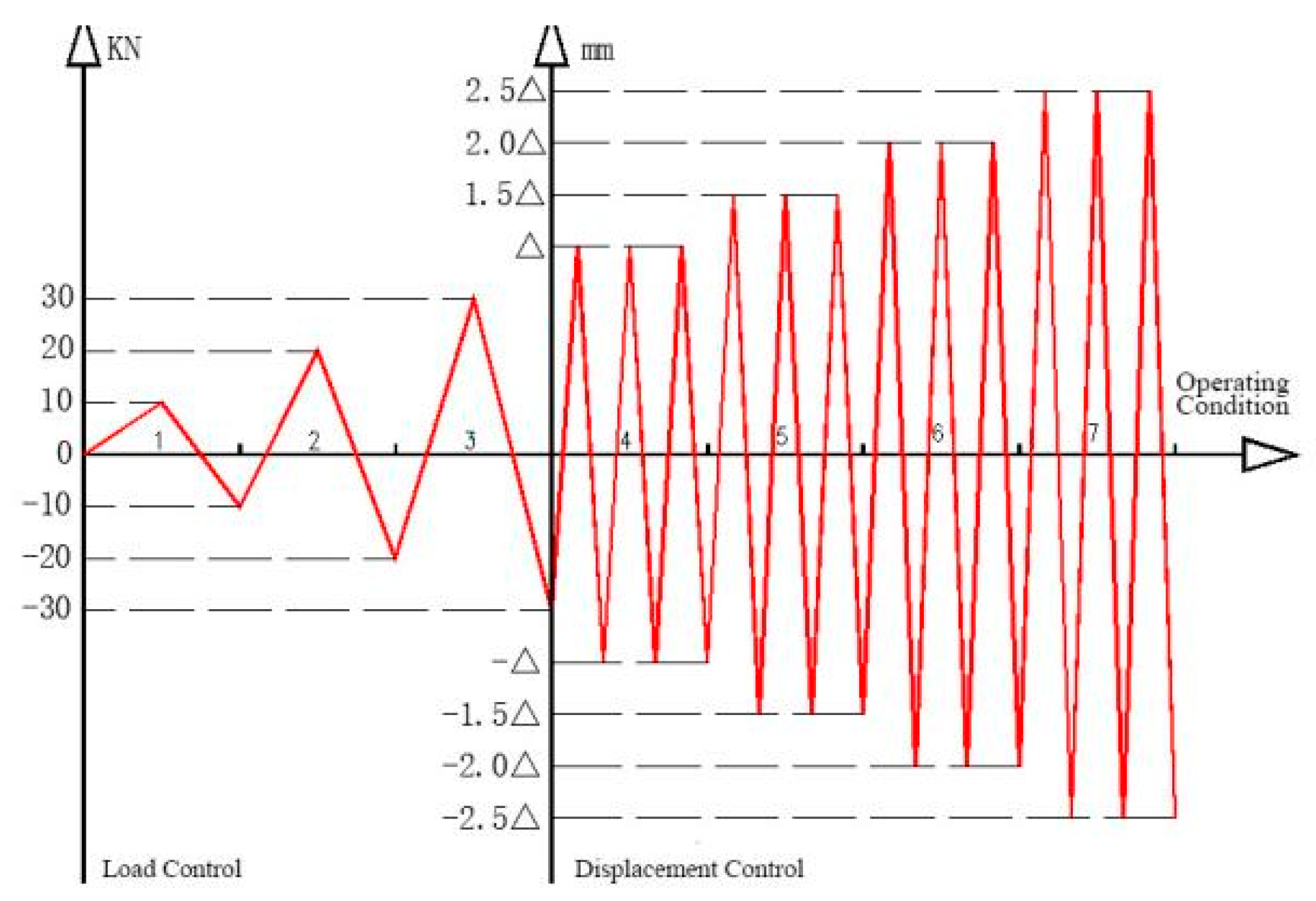

3.2. Testing Methods and Loading Regime

3.3. Extrapolation and Validation of Scaled-Test Results

- (1)

- Stiffness scaling: The initial stiffness of the PC model was 24.8 kN/mm. According to the similarity law K_prototype = K_model·λ, the extrapolated full-scale stiffness is 49.6 kN/mm. An independent 3D ABAQUS 6.14 model of the prototype yielded 50.2 kN/mm, resulting in a deviation of only 1.2%.

- (2)

- Strength scaling: The equivalent plastic-hinge-length approach proposed by Paulay and Priestley (1992) [23] was adopted. The plastic rotation θ_p measured on the scaled specimen was directly applied to the prototype section, leading to a load-carrying capacity discrepancy of less than 5%.

- (3)

- Loading frequency: The input ground-motion record was time-compressed using the temporal similarity ratio λ_t = 1.414. Dynamic responses matched those of the full-scale model with high fidelity.

4. Test Results and Analysis

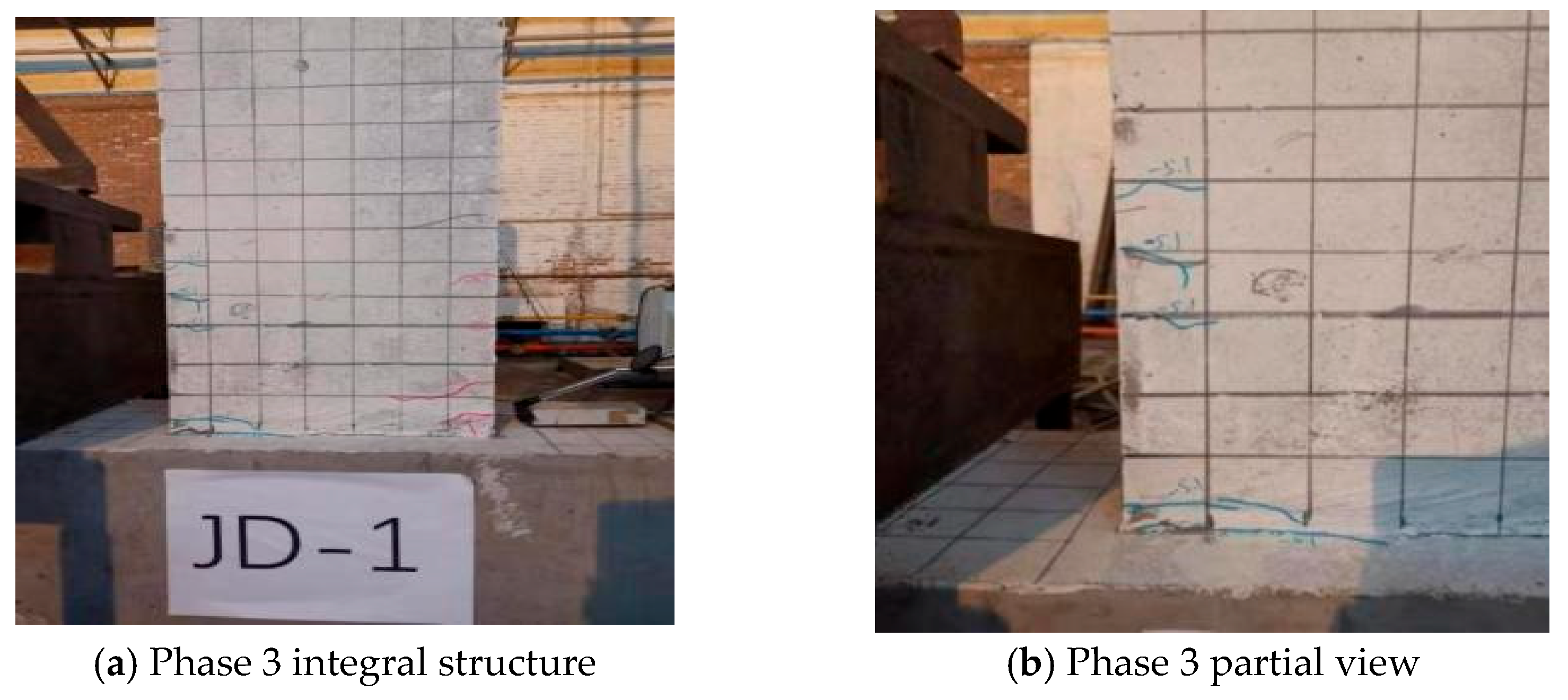

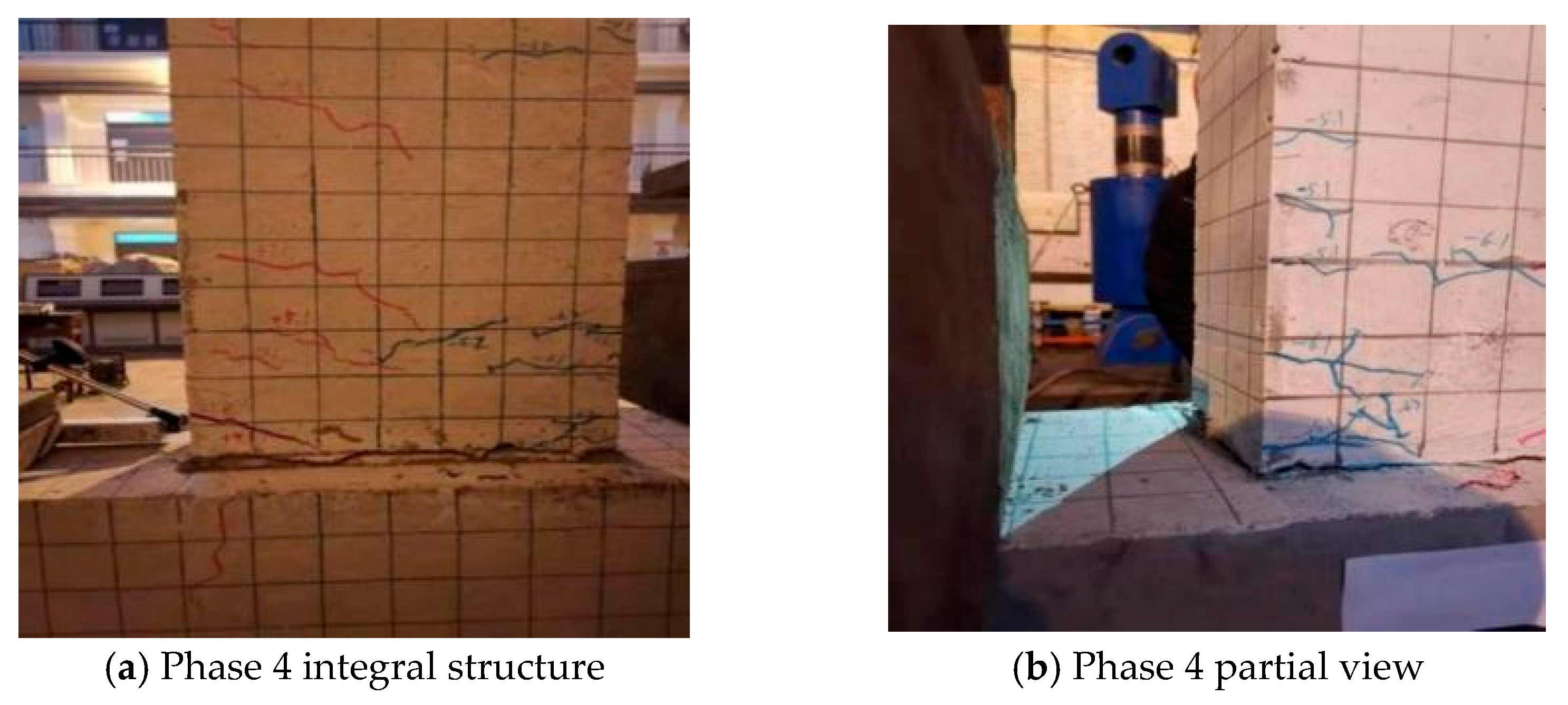

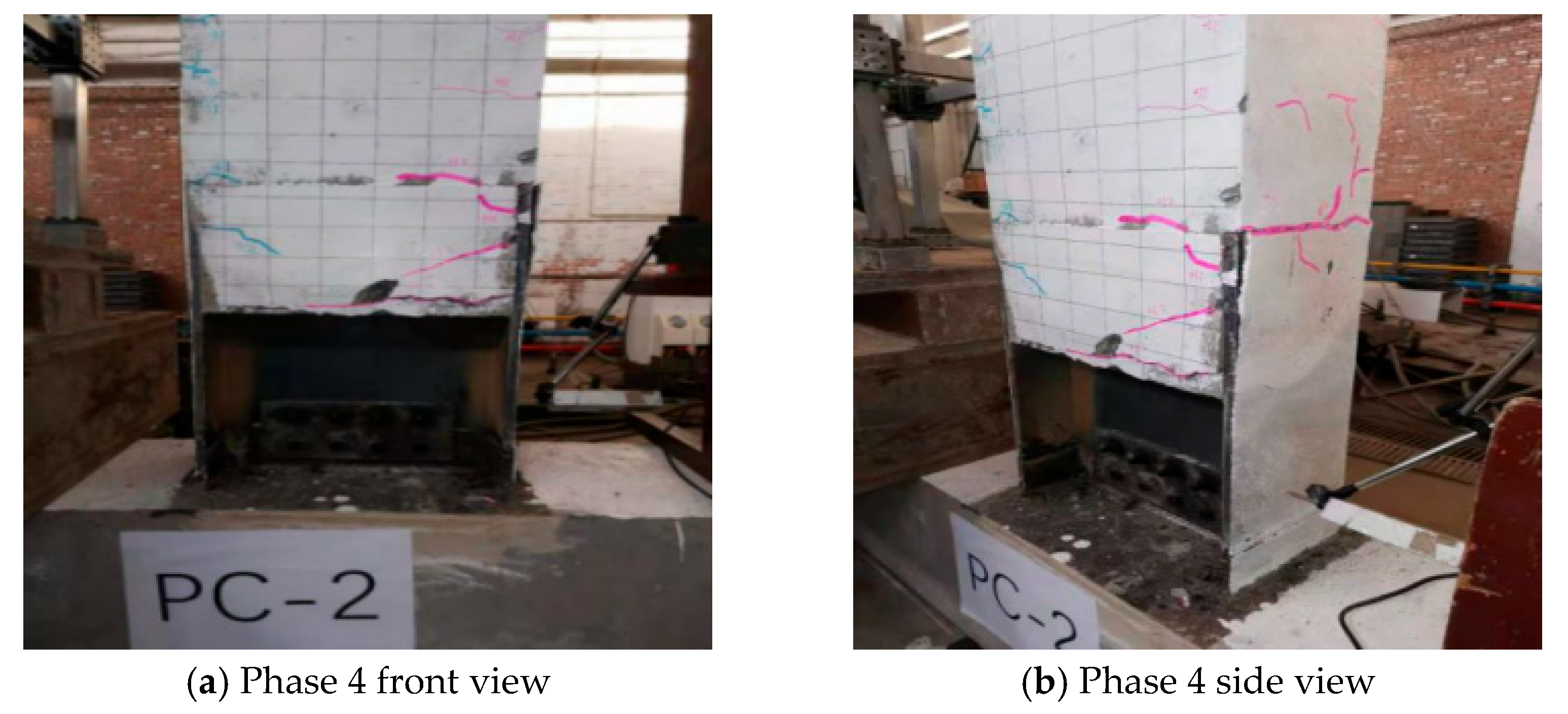

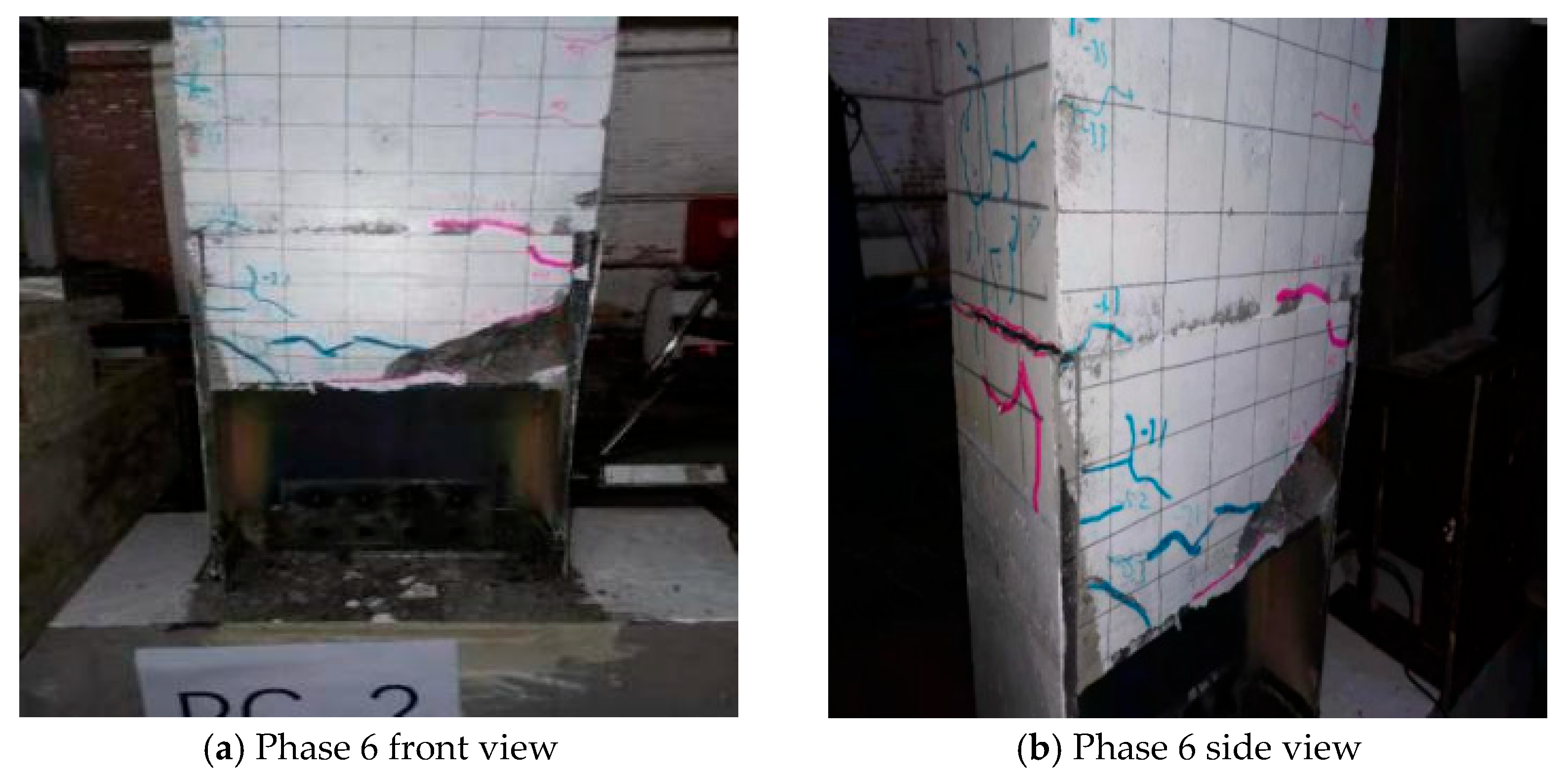

4.1. Analysis of the Testing Process

- Successful steel–concrete hybrid system with reliable column-end embedment, fulfilling “strong joint–weak component” and “strong column–weak beam” principles.

- Steel beam modifications (e.g., dog-bone weakening, stiffeners) could enhance seismic energy dissipation akin to dampers, better utilizing steel material advantages.

4.2. Hysteresis Curves

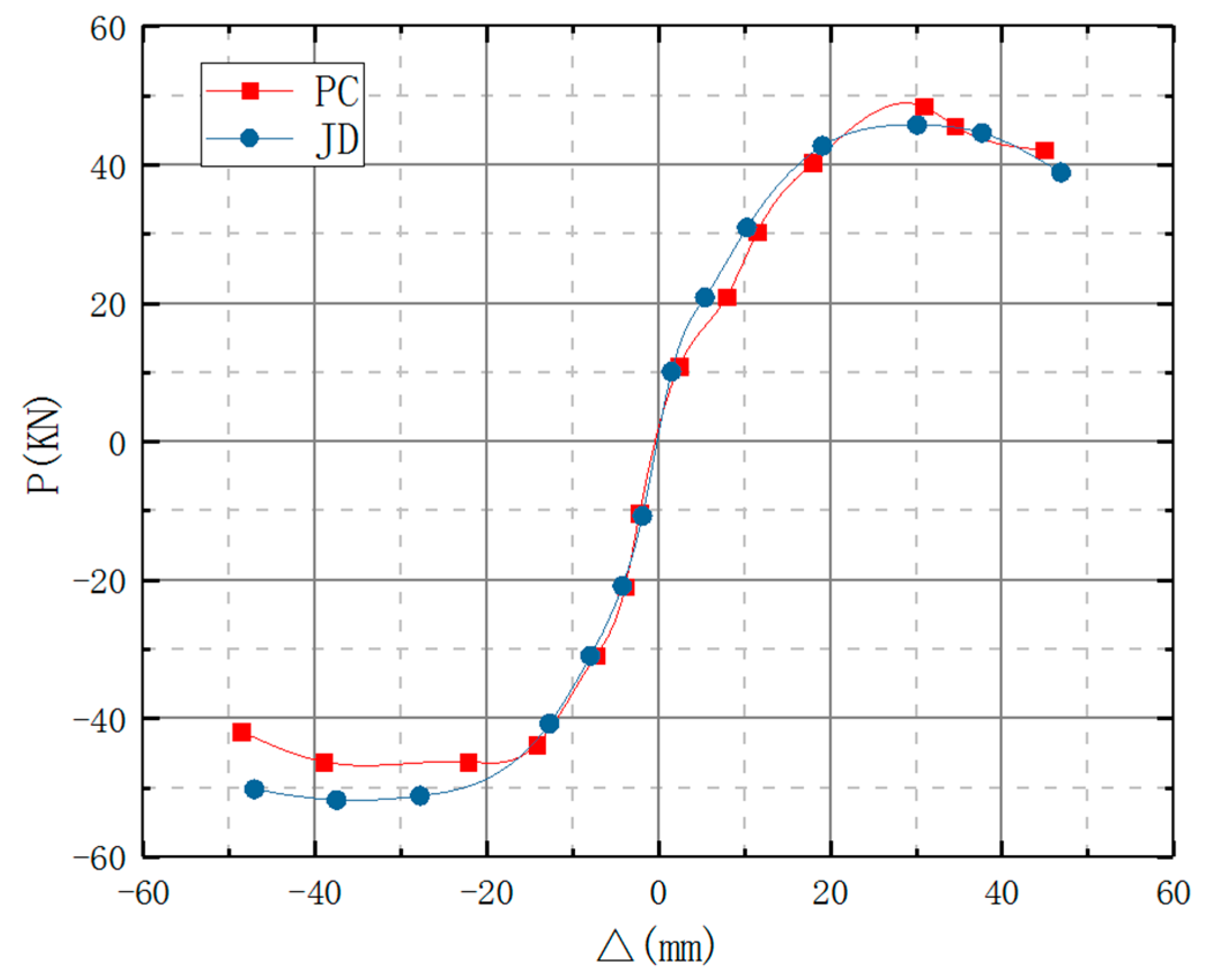

4.3. Backbone Curves

4.4. Strength and Stiffness Degradation

- (1)

- The equivalent stiffness of both PC and JD specimens was the highest at the initial stage of loading. However, the initial stiffness of the PC specimen was greater than that of the JD specimen. As the test progressed, the stiffness of the specimens gradually decreased. The rate of decrease was significant before yielding but decreased sharply after yielding and gradually became stable.

- (2)

- The initial stiffness of the PC specimen was about 25% higher than that of the JD specimen. The two stiffness degradation curves approached each other before and after the yield displacement and maintained almost the same rate of decrease after yielding. Triplicate tests yielded coefficients of variation of 5.8% (PC) and 6.2% (JD) for initial stiffness; the 25% increase lies within the 95% confidence interval [+19%, +31%] (t-test, p < 0.05), demonstrating statistical significance.

5. Discussion

5.1. Comparison with Existing Solutions

5.2. Practical Limitations

- (1)

- Cost: PC-# adds ≈9.8% per connection; batch prefabrication reduces this to ≤6%.

- (2)

- Constructability: Embedded parts require ±2 mm tolerance; only four M20 HS bolts are needed on site, satisfying GB/T 51231-2016 Clause 7.3.2.

- (3)

- Durability: Epoxy-coated steel + stainless washers limit 50-year corrosion to <0.1 mm per JGJ/T 485-2019 [24], maintenance interval 15 years.

5.3. Design Rationale and Theoretical Advantages

- (1)

- Reinforcement congestion: Relocating the plastic hinge into a dog-bone steel beam reduces the core steel area from 1810 mm2 to 1090 mm2 (40% reduction), outperforming the “large-diameter + sparse stirrup” approach of Liu et al. [13] (25% reduction).

- (2)

- Construction efficiency: Embedded steel sleeves coupled with M20 high-strength bolts eliminate formwork and allow 30 min on-site installation, cutting two assembly steps compared with the all-bolted joint of Zhang et al. [9].

- (3)

- Balanced performance: The steel beam yields prior to concrete crushing, achieving the “strong column–weak beam” mechanism required by Clause 6.3.4 of GB 50011-2010 (μ ≥ 4). A parametric ABAQUS study confirmed that a dog-bone length of 0.8h_b increases energy dissipation by 22% while limiting stiffness loss to <10%.

6. Conclusions

- (1)

- The proposed new type of prefabricated concrete beam–column joint has been verified to comply with the design concept of “equal strength replacement.” The joint performs well and has achieved the expected results, indicating that the new joint is feasible.

- (2)

- Based on the observation of the experimental phenomena, the embedded steel components at the column ends did not fail and there was no rebar pullout. Therefore, the joint meets the seismic design concept of “strong connection and strong anchorage.”

- (3)

- The PC joint as the proposed joint achieves 25% higher initial stiffness and 30% labor-hour reduction compared to conventional cast-in-place joints, demonstrating both structural and construction advantages, and its integrity and seismic performance meet the design objectives. It can replace the “wet” connection in practical engineering applications.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MOHURD (Ministry of Housing and Urban-Rural Development of the People’s Republic of China). 14th Five-Year Plan for Construction Industry Development; China Architecture & Building Press: Beijing, China, 2021.

- Xu, H.; Meng, R.Z.; Cao, D.F.; Cao, S.Q.; Guan, Y.Q. Experimental research on the seismic performance of truss-type steel reinforced concrete beam and column joint. Build. Struct. 2020, 50, 86–91. [Google Scholar]

- Li, Z.Y.; Huang, Y.Z.; Lu, W.Q.; He, H. Seismic behavior of semi-rigid joints of precast concrete beam and column. J. Civ. Environ. Eng. 2023, 45, 55–64. [Google Scholar]

- Xu, Q.G.; Chen, W.D.; Li, N. Experimental study on seismic performance of beam-column joints of fabricated concrete frame structure. Build. Struct. 2022, 52, 53–59. [Google Scholar]

- Gao, J.H.; Xi, J.H.; Xu, Y.W.; Chen, B.; Zhao, D.; Zhao, X.; Chang, Y. Mechanical Property of Beam-to-Column Connection of Steel Structures with All-Steel Buckling-Restrained Braces. Front. Mater. 2022, 8, 821299. [Google Scholar] [CrossRef]

- Chen, F.; He, M.J.; Li, M.H.; Liu, J.; Shan, Z.; Li, Z. Recovery testing of self-centering steel-timber hybrid beam-column connections. Constr. Build. Mater. 2023, 365, 130067. [Google Scholar] [CrossRef]

- Li, H.; Du, Y.F.; Li, F.Y. Experimental study and influential parameters analysis on seismic behavior of prefabricated concrete beam-column joints. J. Build. Struct. 2021, 42, 88–97. [Google Scholar]

- Gou, S.K.; Ding, R.; Fan, J.S.; Nie, X.; Zhang, J. Seismic performance of a novel precast concrete beam-column connection using low-shrinkage engineered cementitious composites. Constr. Build. Mater. 2018, 192, 643–656. [Google Scholar] [CrossRef]

- Zhang, A.L.; Su, L.; Cao, Z.L.; Pu, S.; Lin, H. Experimental research and finite element analysis on sesimic behaviors of Z-shaped beam-to-column bolted joint with double connection plates. Ind. Constr. 2021, 51, 59–65+89. [Google Scholar]

- Ru, Y.C.; He, L.S.; Jiang, H.J. Study on a new type of beam-column joint equipped with inclined tapered steel plates. J. Build. Eng. 2022, 45, 103581. [Google Scholar] [CrossRef]

- Cai, X.N.; Pan, Z.F.; Zhu, Y.Z.; Gong, N.; Wang, Y. Experimental and numerical investigations of self-centering post-tensioned precast beam-to-column connections with steel top and seat angles. Eng. Struct. 2021, 226, 111397. [Google Scholar] [CrossRef]

- Guan, D.Z.; Guo, Z.X.; Xiao, Q.D.; Zheng, Y. Experimental study of a new beam-to-column connection for precast concrete frames under reversal cyclic loading. Adv. Struct. Eng. 2016, 19, 529–545. [Google Scholar] [CrossRef]

- Liu, L.; Huang, X.K.; Tian, C.Y.; Yin, X.W.; Li, R.; Li, G.Q. Experimental study on seismic performance of precast RC frame joints with HRB500 high strength rebars of large diameter and spacing. J. Build. Struct. 2016, 37, 247–254. [Google Scholar]

- Wu, C.X.; Zhou, Y.; Lai, W.S.; Zhang, Y.; Deng, X. Experiment on seismic performance of cast-in-situ and prefabricated concrete frame structure joints. J. Archit. Civ. Eng. 2018, 32, 60–66. [Google Scholar]

- Peng, H.; Ou, J.P.; Mahin, S. Design and numerical analysis of a damage-controllable mechanical hinge beam-to-column connection. Soil Dyn. Earthq. Eng. 2020, 133, 106149. [Google Scholar] [CrossRef]

- Cheng, W.P.; Song, Y.P.; Zhang, X.J. Experiment study of bearing capacity for beam and column joints of precast and discontinuous steel reinforced concrete. J. Dalian Jiaotong Univ. 2014, 35, 52–55. [Google Scholar]

- GB 50010-2010; Code for Design of Concrete Structures. China Architecture & Building Press: Beijing, China, 2010.

- GB 50011—2010; Code for Seismic Design of Buildings (2016 edition). China Architecture & Building Press: Beijing, China, 2016.

- GB 50017—2017; Standard for Design of Steel Structures. China Architecture & Building Press: Beijing, China, 2017.

- GB/T 51129-2017; Assessment Standard for Prefabricated Buildings. China Architecture & Building Press: Beijing, China, 2017.

- GB/T 50152-2012; Standard for Test Methods of Concrete Structures. China Architecture & Building Press: Beijing, China, 2012.

- GB/T 51231-2016; Technical Standard for Precast Concrete Structures. China Architecture & Building Press: Beijing, China, 2016.

- Paulay, T.; Priestley, M.J.N. Seismic Design of Reinforced Concrete and Masonry Buildings; Wiley: New York, NY, USA, 1992. [Google Scholar]

- JGJ/T 485-2019; Standard for Durability Design of Precast Concrete Structures. Architecture & Building Press: Beijing, China, 2020.

| Physical Quantity | Ratio λ = Prototype/Model | Basis/Remark |

|---|---|---|

| Length | 2 | Geometric scaling |

| Elastic modulus E | 1 | Same-grade C35 concrete |

| Stress/strength | 1 | Same-grade steel and concrete |

| Density ρ | 1 | Adjusted by ballast |

| Time T | √λ = 1.414 | Froude-number consistency |

| Stiffness K | λ = 2 | Derived from K = F/δ |

| Force F | λ2 = 4 | Derived from σ·L2 |

| Indicator | Precast PC | Cast-in-Place JD | Key Comparison and Reference |

|---|---|---|---|

| Failure mode | Dog-bone yielding, column intact | Beam root hinge, column crushing | PC satisfies “strong column–weak beam”(Section 4.1) |

| Capacity | +49.2 kN/−55.6 kN | +45.1 kN/−51.3 kN | PC ≈8% higher (Section 4.3, Figure 13) |

| Ductility μ | 4.2 | 4.5 | Both μ ≥ 4 (Section 4.3) |

| Initial stiffness | 49.6 kN/mm (prototype) | 39.8 kN/mm (prototype) | PC-# +25% (Section 4.4, Figure 14) |

| Site work | 4 bolts, 30 min | Wet trades, >3 h | PC-# saves ≈85% time (Section 2.2) |

| Scheme | μ | On-Site Labor | Cost Increase | Code Compliance | Main Limitation |

|---|---|---|---|---|---|

| CIP JD | 4.5 | 100% | 0% | Full GB 50010 | Congestion, wet trades |

| ECC post-cast | 5.0 | ≈90% | +18% | Crack control required | Material cost, shrinkage |

| All-bolted dry | 3.2 | ≈70% | +8% | GB 50017 check | Large slip, low ductility |

| PC-# (this paper) | 4.2 | ≈70% | ≤+10% | GB 50010 and 50017 | Steel corrosion control required |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, J.; Zhang, R.; Gao, Z.; Yuan, C.; Krassowska, J. Seismic Performance Analysis of a New Type of Fabricated Concrete Beam–Column Joint. Buildings 2025, 15, 3435. https://doi.org/10.3390/buildings15193435

Cui J, Zhang R, Gao Z, Yuan C, Krassowska J. Seismic Performance Analysis of a New Type of Fabricated Concrete Beam–Column Joint. Buildings. 2025; 15(19):3435. https://doi.org/10.3390/buildings15193435

Chicago/Turabian StyleCui, Jintao, Renyuan Zhang, Zhanyuan Gao, Chenchen Yuan, and Julita Krassowska. 2025. "Seismic Performance Analysis of a New Type of Fabricated Concrete Beam–Column Joint" Buildings 15, no. 19: 3435. https://doi.org/10.3390/buildings15193435

APA StyleCui, J., Zhang, R., Gao, Z., Yuan, C., & Krassowska, J. (2025). Seismic Performance Analysis of a New Type of Fabricated Concrete Beam–Column Joint. Buildings, 15(19), 3435. https://doi.org/10.3390/buildings15193435