1. Introduction

Buildings account for 36.2% of China’s energy consumption, with 60.4% originating from the operational phase in 2021 [

1]. Moreover, the high occupant density in office buildings drives energy intensity in offices (180 kWh/m

2 on average in Shanghai [

2]) to over four times higher than that in residential buildings (43 kWh/m

2 on average in Shanghai [

3]). Thus, reducing the operational energy use in office buildings is of great significance in the energy-saving field. For this reason, numerous studies focus on the reduction in the operational energy use of office buildings from the aspects of energy management [

4], the energy retrofit of building envelopes [

5], the integration of renewable energy [

6], etc.

Based on existing studies, there are various energy retrofit measures to mitigate energy consumption in buildings, including passive and active ones. Examples of active measures include the adoption of photovoltaic systems and ground-source heat pumps, as well as the application of electric shading systems [

7,

8,

9,

10]. In contrast to active measures which rely on mechanical systems for heating, cooling, and ventilation, passive measures are those harnessing natural elements to achieve optimal indoor conditions. Among passive strategies, reflective materials, which are characterized by high albedo and thermal emissivity, can reduce the excessive heat ingress into buildings due to solar radiation, facilitate the long-wave radiation of buildings’ external surfaces to outdoor environments and therefore reduce the building cooling energy demand in warm seasons. This type of material has received much attention because of its convenience of retrofitting and considerable energy-saving effects [

11,

12,

13]. Rincón et al. [

12] analyzed the energy-saving effect of reflective roof coatings on seven benchmark Spanish office buildings in 12 climate zones, indicating an average reduction of 25% in cooling energy and an average reduction of 6% in the annual HVAC energy consumption, alongside a 26–78% reduction in the number of days with thermal discomfort. Costanzo et al. [

14] investigated the application of reflective roofs across different Italian climate zones, concluding an average reduction of 25 °C in the peak roof surface temperatures and 9% annual energy savings of HVAC systems.

It is worth noting that the energy-saving effect of reflective materials is affected by many factors. Research from Akbari et al. [

15] shows the cooling energy saving brought by reflective materials varies from 1.1 kWh/m

2 to 6.5 kWh/m

2 in different climate zones in California, while the operation of buildings also poses a considerable influence [

16]. As a result, numeric simulations are widely used to evaluate the energy-saving effect of reflective materials under different boundary and climatic conditions [

17], showing satisfactory effectiveness [

18,

19].

Despite advances in building performance simulation, numerous studies have documented persistent discrepancies between predicted and actual building energy use, often referred to as the energy performance gap (EPG) [

20]. These deviations arise from multiple factors, including differences between design and construction, uncertainties in boundary conditions, and particularly occupant behavior. Addressing this performance gap is essential, as inaccurate energy savings predictions can undermine confidence in retrofitting strategies.

To increase the accuracy of the simulation, the calibration of the model is essential. Current studies usually ignore the importance of calibration or calibrate the model [

21] based on short-term monitoring [

22]. However, model calibration helps not only enhance the credibility of the model but also explore hidden factors influencing the energy performance [

23], which is essential to the predictive ability of models.

Meanwhile, research has shown that these materials can also generate unintended negative impacts on their surrounding environment. While they may lower ambient air temperatures, their reflective properties can increase mean radiant temperature (MRT) at the pedestrian level, leading to greater heat stress [

24,

25]. In addition, highly reflective façades can cause intense glare, visual discomfort, and even safety hazards in adjacent streets and buildings [

26]. At night, reflective surfaces can further amplify light pollution by redirecting artificial light into the sky, worsening urban skyglow [

27]. These challenges highlight the importance of evaluating reflective retrofits before implementation.

Furthermore, the subjective thermal feeling of building occupants is also a critical aspect for the energy retrofit of buildings, directly influencing the decision-making of renovation projects. The Chinese standard GB/T 51141-2015 Assessment standard for green retrofitting of existing building includes the evaluation of thermal comfort before and after energy retrofits of buildings as an important part [

28]. However, comprehensive evaluations of building environment combining the energy performance and thermal comfort still remain insufficient [

29]. Current research focuses mainly either on energy-saving designs or the evaluation of thermal comfort alone. The influence of retrofits on occupants’ thermal comfort lacks on-site investigations including a post-evaluation questionnaire [

30].

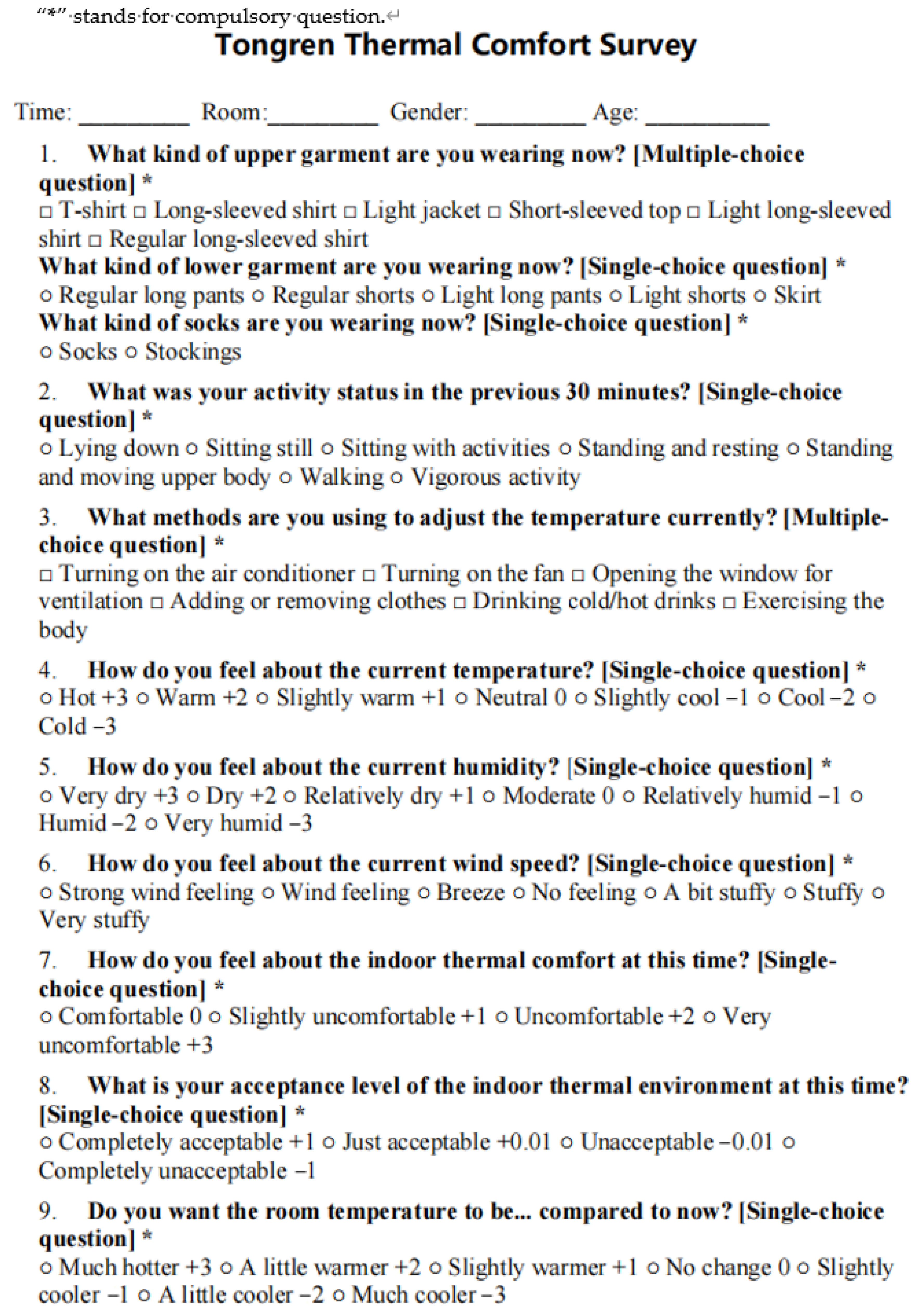

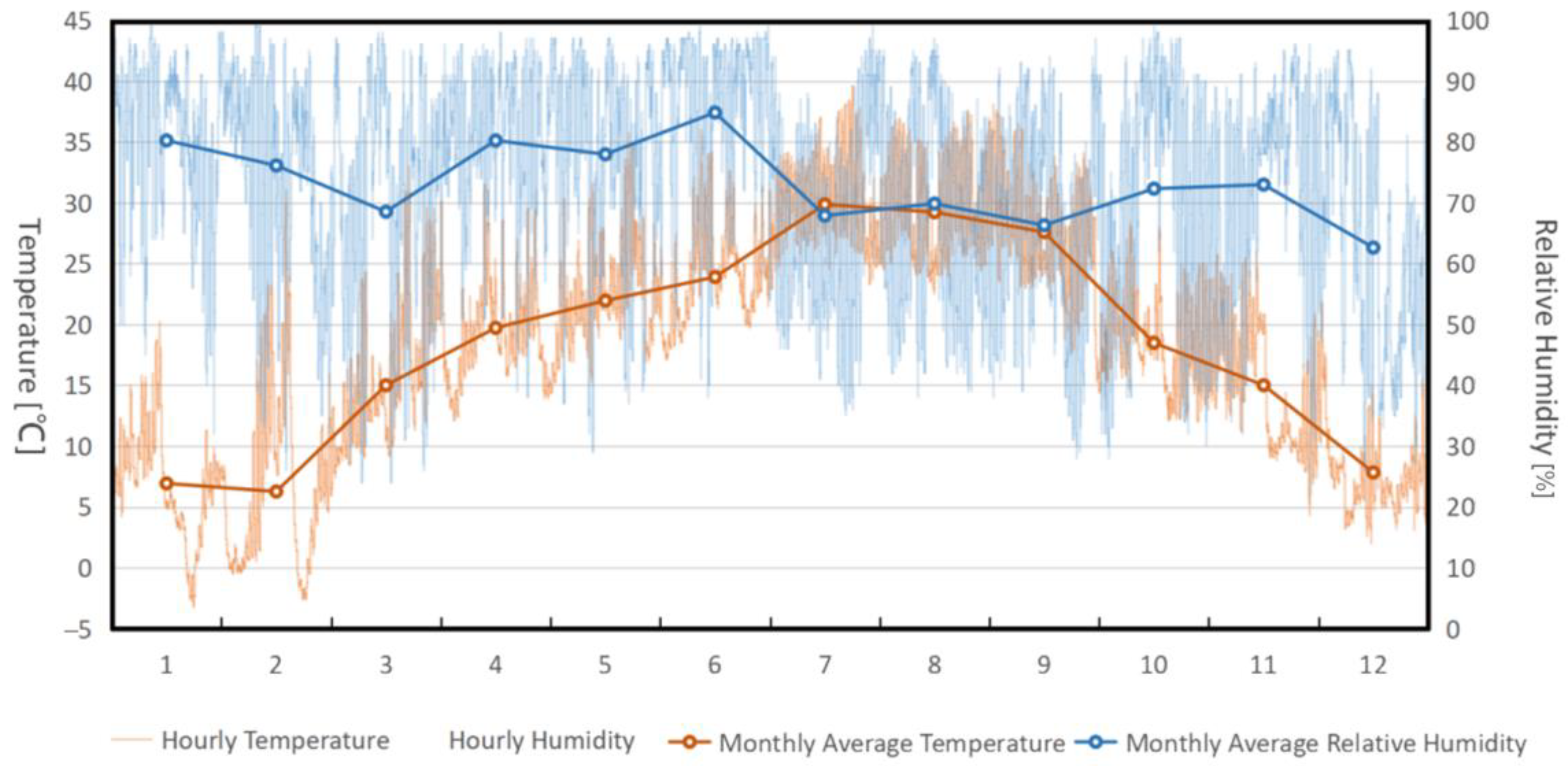

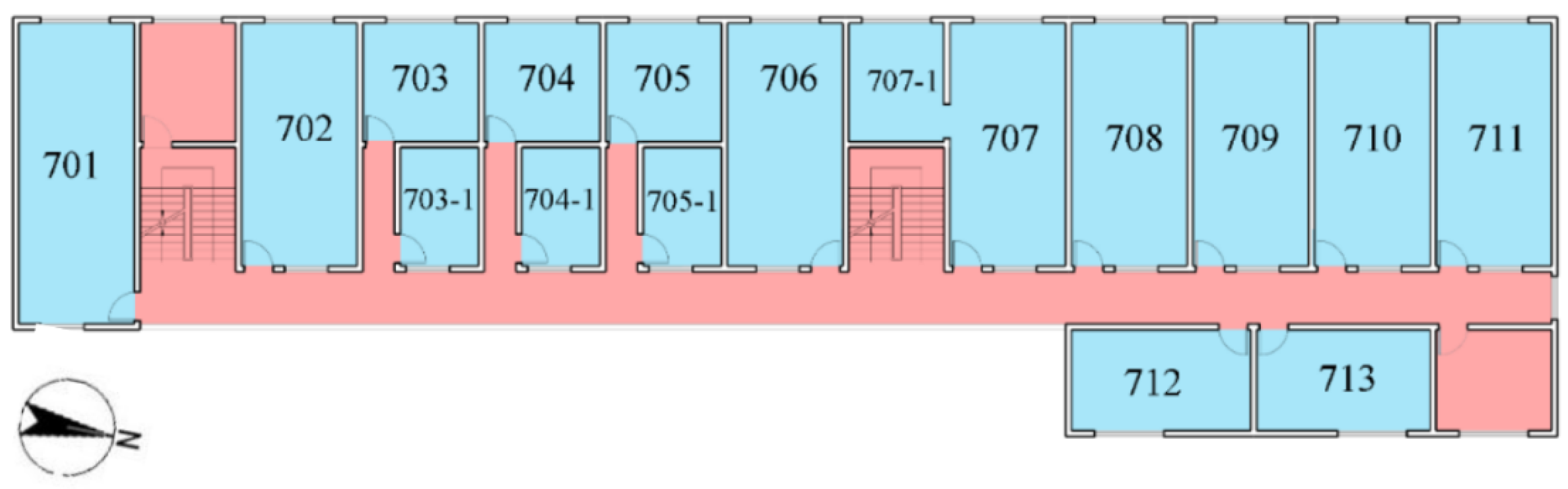

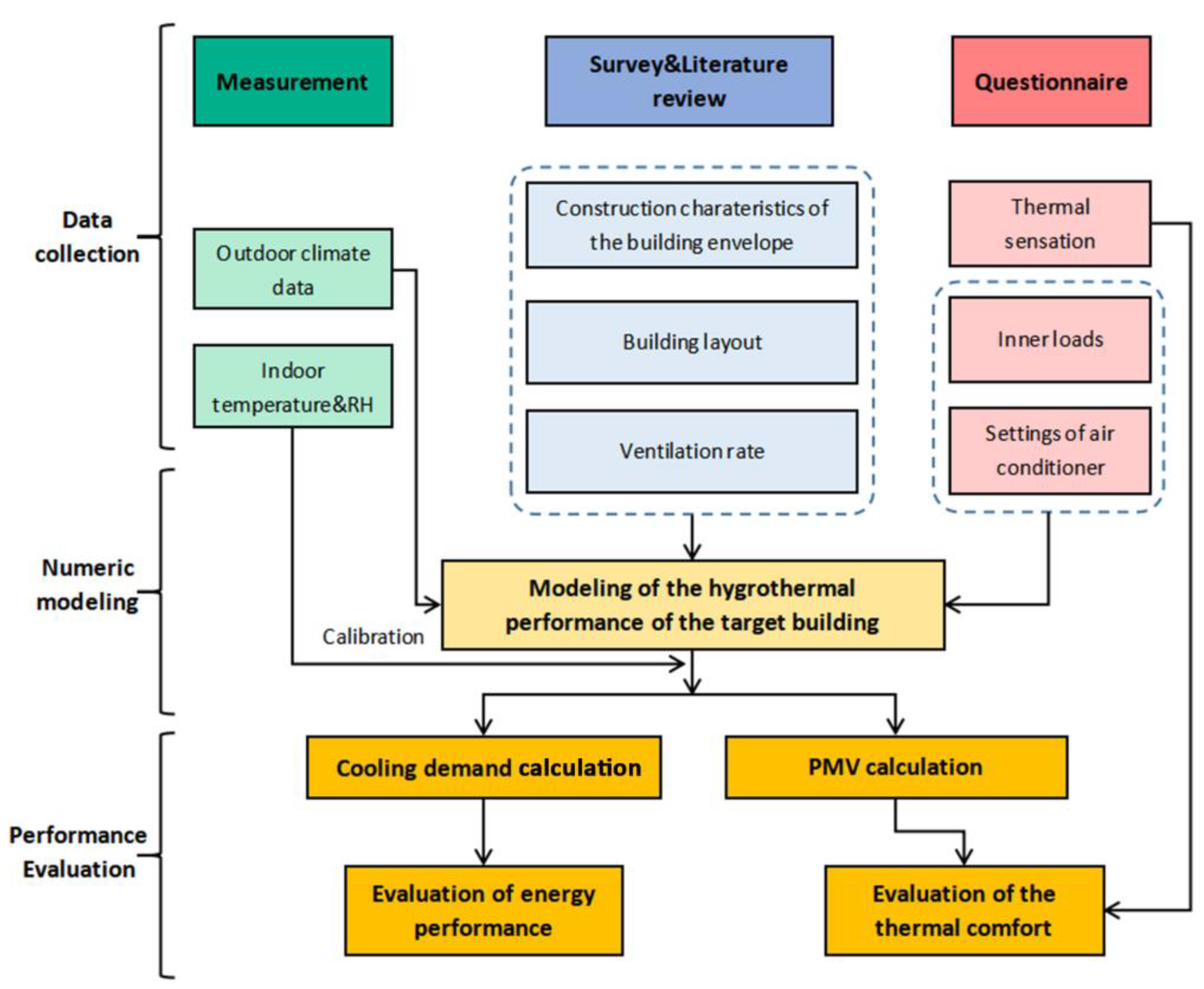

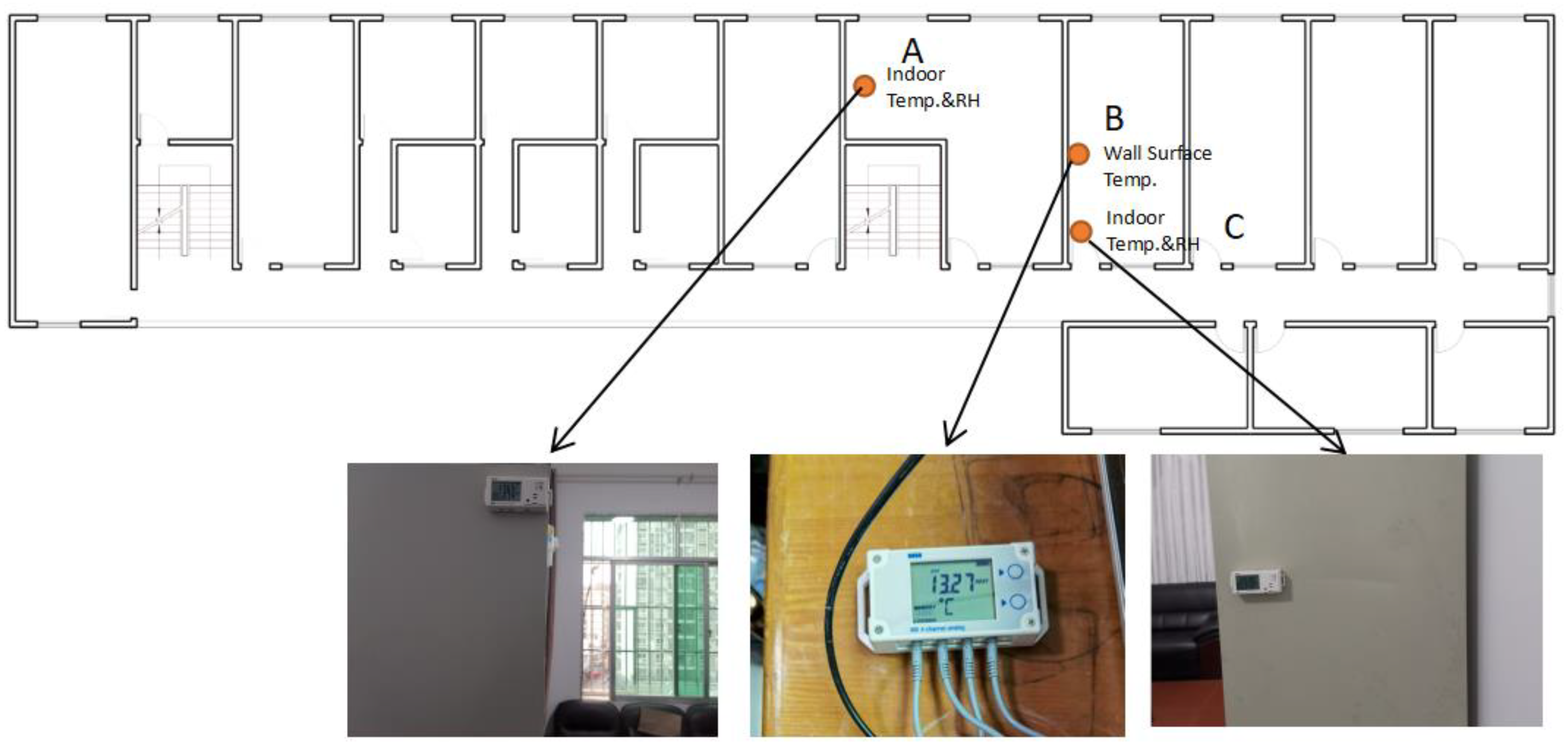

Therefore, this study bridges a critical gap by validating reflective materials in an operational office building in China’s HSCW zone, combining calibrated energy simulations with occupant comfort surveys—an approach not found in previous studies. A comprehensive survey for the research object has been conducted, collecting the information of construction characteristics, occupation situation such as the number of occupants in each room and their realistic occupation time, as well as the operation and technical specifications of air conditioners. These parameters are input into the software WUFI®Plus (V3.5.0.1), along with the local climate data, to conduct hygrothermal building simulations. In addition, the monitoring of the hourly indoor air temperature covering the cooling season (July to September 2024) is conducted to calibrate the hygrothermal simulation of WUFI®Plus, helping compare the energy performance of the investigated building before and after applying reflective materials. Additionally, questionnaires are used to collect occupants’ responses on the top floors of the building, which are then statistically analyzed to obtain an indication of the average perception of occupants regarding the indoor thermal comfort. The Predicted Mean Vote (PMV) throughout the cooling season is also calculated based on simulation results compared with the mean Thermal Sensation Vote (TSV) from the conducted questionnaire, verifying the results of the questionnaire and illustrating the change in thermal comfort in the cooling season.

5. Thermal Comfort Evaluation

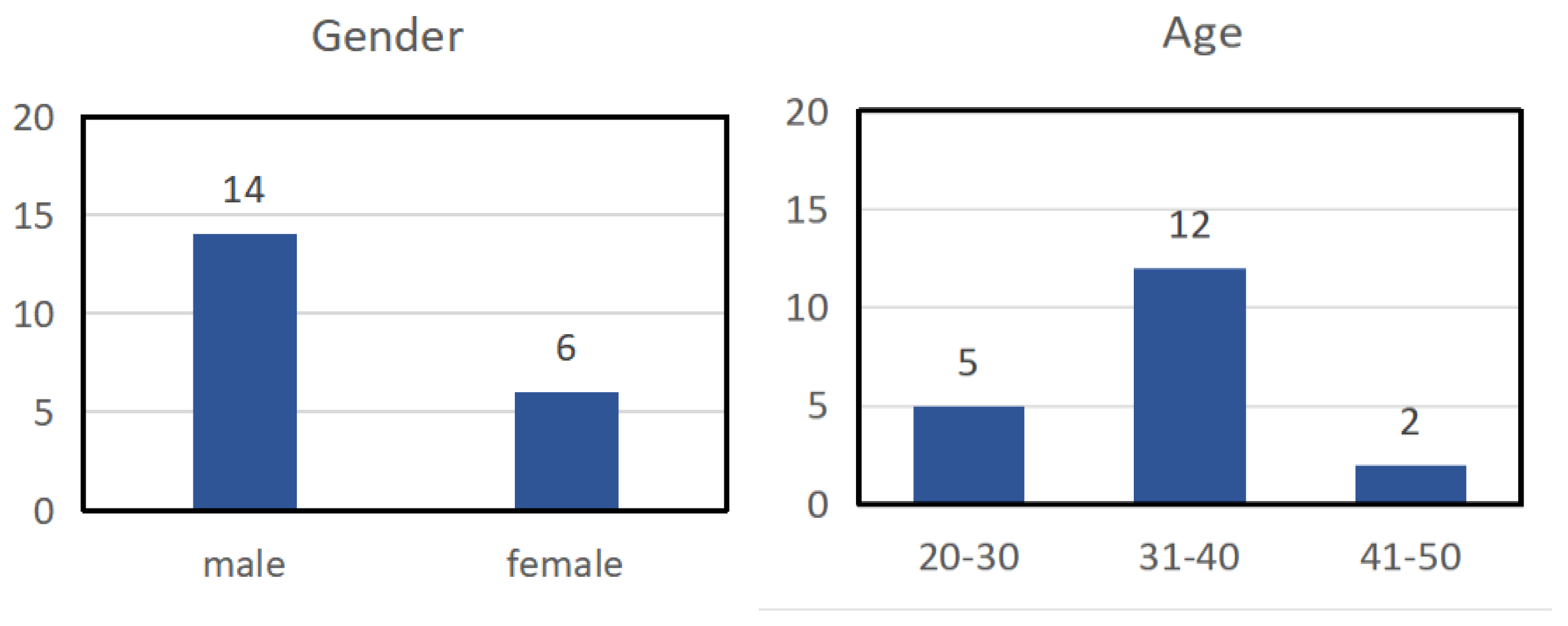

The questionnaire was conducted on 27 August 2024, surveying all 20 occupants on the investigated floors. While this represents a limited sample size, it constitutes the full occupant population of the studied sections—a scale representative of retrofitted office buildings in this typology.

The gender and age distributions are shown in

Figure 10. The investigated area has more male employees, who constitute 70% of the total number. Most employees are between 31 and 40 years old.

The metabolic rates of subjects and thermal resistance of their clothing are shown in

Table 12, estimated based on the Chinese standard GB/T50785−2012 [

52].

According to the questionnaire, the occupants have one or two layers of light clothing. Most of the male subjects are wearing short-sleeved shirts with trousers, of which the typical thermal resistance is 0.46 clo. Most of the female subjects wear T-shirts and trousers, of which the typical thermal resistance is 0.41 clo.

Regarding the activity of subjects, most of the subjects perform office work while sitting, corresponding to a metabolic rate of 1.2 met according to ASHRAE 55 [

51].

The results indicate that the differences in clothing were statistically significant (p = 0.021), while the metabolic rate (p = 0.129) was not. It can be explained that the males tend to wear thicker clothing like formal shirts, while the females can wear a dress with lower insulation. The metabolic rate is not different by gender, suggesting that the work assignment is generally the same.

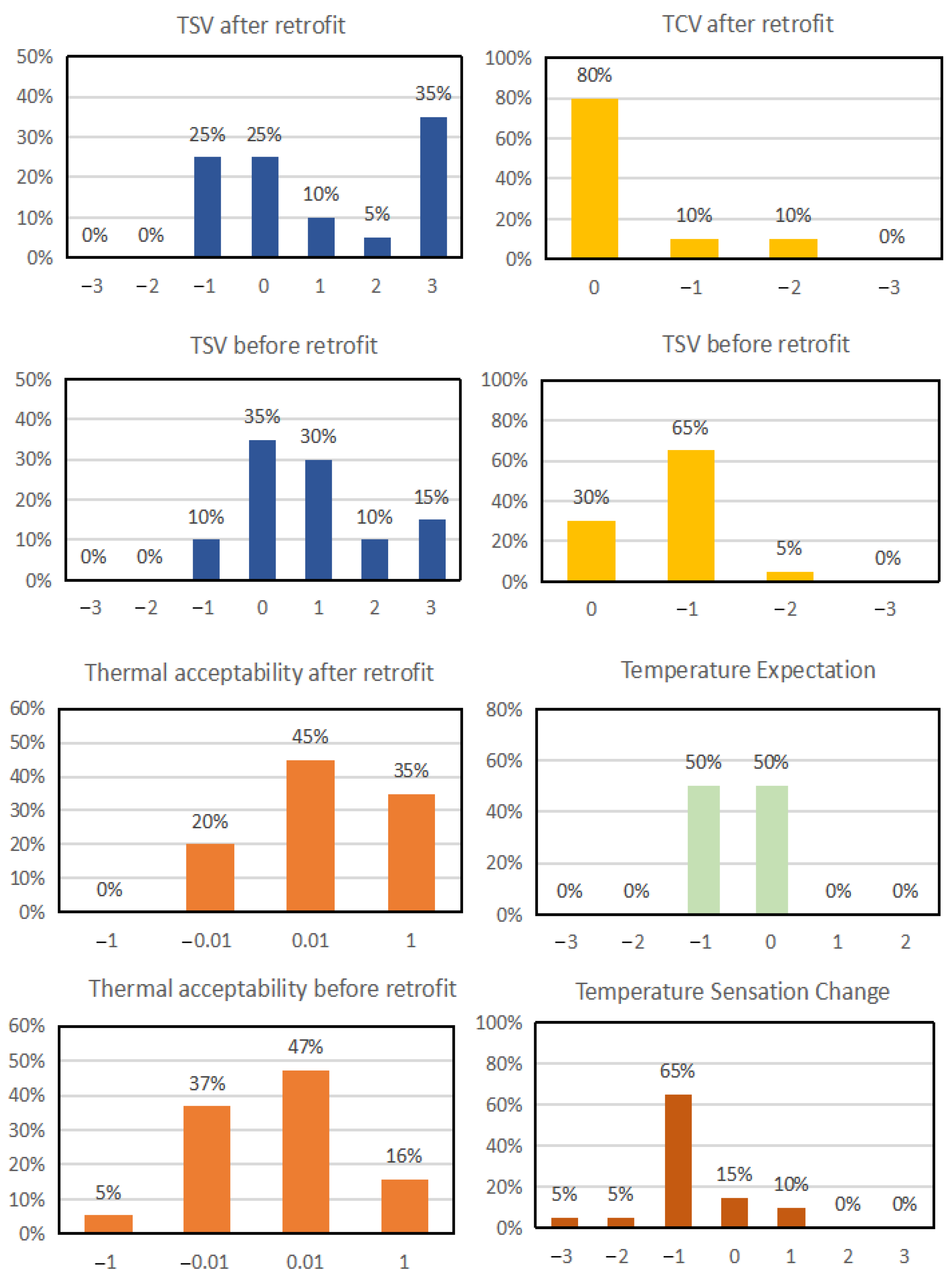

The survey results indicate high occupant adaptation to the thermal environment in the investigated zones (

Figure 11). Although 40% of respondents reported feeling hot, the mean TSV of 1.0 reflects a slightly warm perception. Crucially, 80% of occupants rated the environment as both acceptable and comfortable. Supporting this, the average TCV reached −0.3 and thermal acceptability scored 0.35, demonstrating satisfaction with summer conditions post-retrofit. The mean thermal expectation of −0.5 further confirms occupant preference for slightly cooler conditions—consistent with the ‘slightly warm’ TSV assessment. Collectively, these metrics confirm that the retrofitted building delivers a comfortable thermal environment.

The survey also captured occupants’ subjective thermal comfort relative to pre-retrofit conditions (

Figure 11). The mean TSV pre-retrofit measured 0.85—slightly lower than the post-retrofit value (1.00). However, the significantly lower mean TCV of −0.75 (versus post-retrofit −0.3) and thermal acceptability of 0.10 (versus post-retrofit 0.35) indicate reduced comfort prior to intervention. Crucially, 80% of subjects reported cooler conditions post-retrofit, confirming improved thermal comfort.

Regarding cooling behaviors, occupants primarily used air conditioners, sometimes supplemented with fans. Notably, open windows during air conditioner operation in Rooms 707–708 on high-temperature days were observed. This preference for concurrent natural ventilation likely increases actual cooling energy consumption—a factor not fully captured in our simulations.

The hourly PMV is calculated by WUFI

®Plus to give an overview of the thermal comfort conditions in the cooling season (

Figure 12 and

Table 13). This study focuses on the PMV during working hours for the analysis.

The post-retrofit PMV values predominantly ranged between 0.5 and 1.0, consistent with the questionnaire results indicating a slightly warm environment. Notably, PMV exceeded the ASHRAE Standard 55 comfort range (−0.5 to +0.5) during most operational hours, demonstrating potential occupant adaptation to elevated temperatures.

The retrofit improved thermal conditions: the mean PMV decreased from 0.82 to 0.74—a 10.0% shift toward thermal neutrality. This result shows the reflective materials’ potential in optimizing indoor thermal environments.

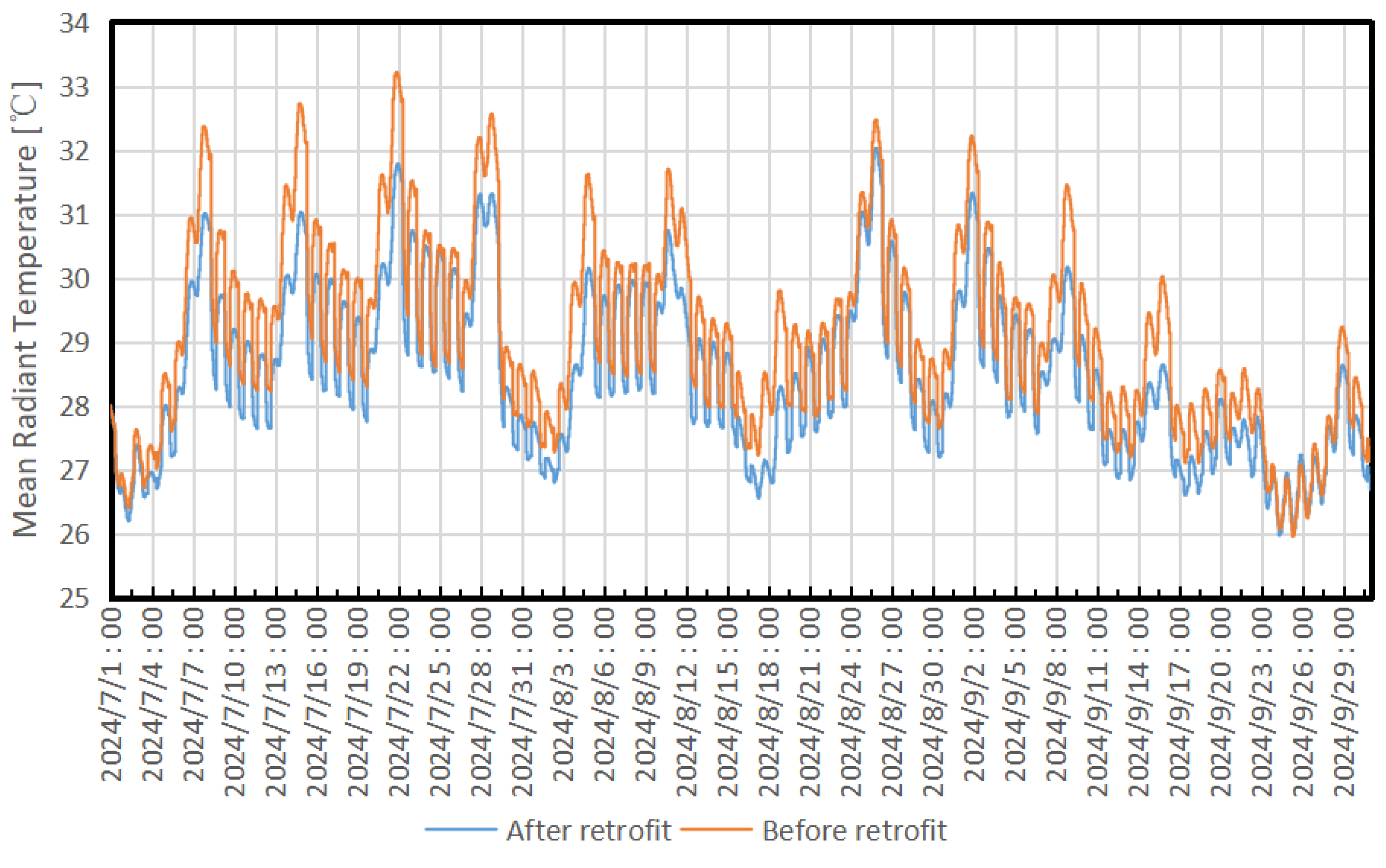

The decrease in MRT from 29.14 °C to 28.53 °C (a drop of 0.60 °C) has a direct impact on the PMV index (

Figure 13). MRT quantifies the radiant heat exchange between the human body and the surrounding surfaces. A decrease in MRT means the body loses more heat to the environment via radiation, thereby increasing the sensation of coolness. In the PMV calculation formula, this is directly reflected as a decrease in the PMV value.

6. Discussion

This research conducts an hourly simulation throughout the cooling season based on a three-month-long monitoring process to provide an accurate evaluation of the cooling consumption decrease due to the application of reflective materials. The simulation is calibrated with the chosen statistical indicators NMBE, CV(RMSE), and R2 which meet the defined limit values. However, several factors could still influence the simulation’s accuracy, which require further attention and improvement.

First, the actual as-built drawings for the building components are not available. For this reason, the construction of building components is based on the standard design specifications. Also, the material parameters of the building envelope are mainly primarily sourced from the WUFI®Plus material database and values specified in relevant regulations, which may deviate from the actual values due to the aging of materials, the inadequate construction quality, and structural defects such as cracks.

Second, the calculation of natural ventilation rates is simplified according to code JGJ 67 [

49], which regulates the basic fresh air supply for each person in office buildings. However, the actual natural ventilation rate is influenced by the frequency of opening windows and the dynamic wind pressure, which requires further monitoring of the actual occupants’ behaviors for window opening.

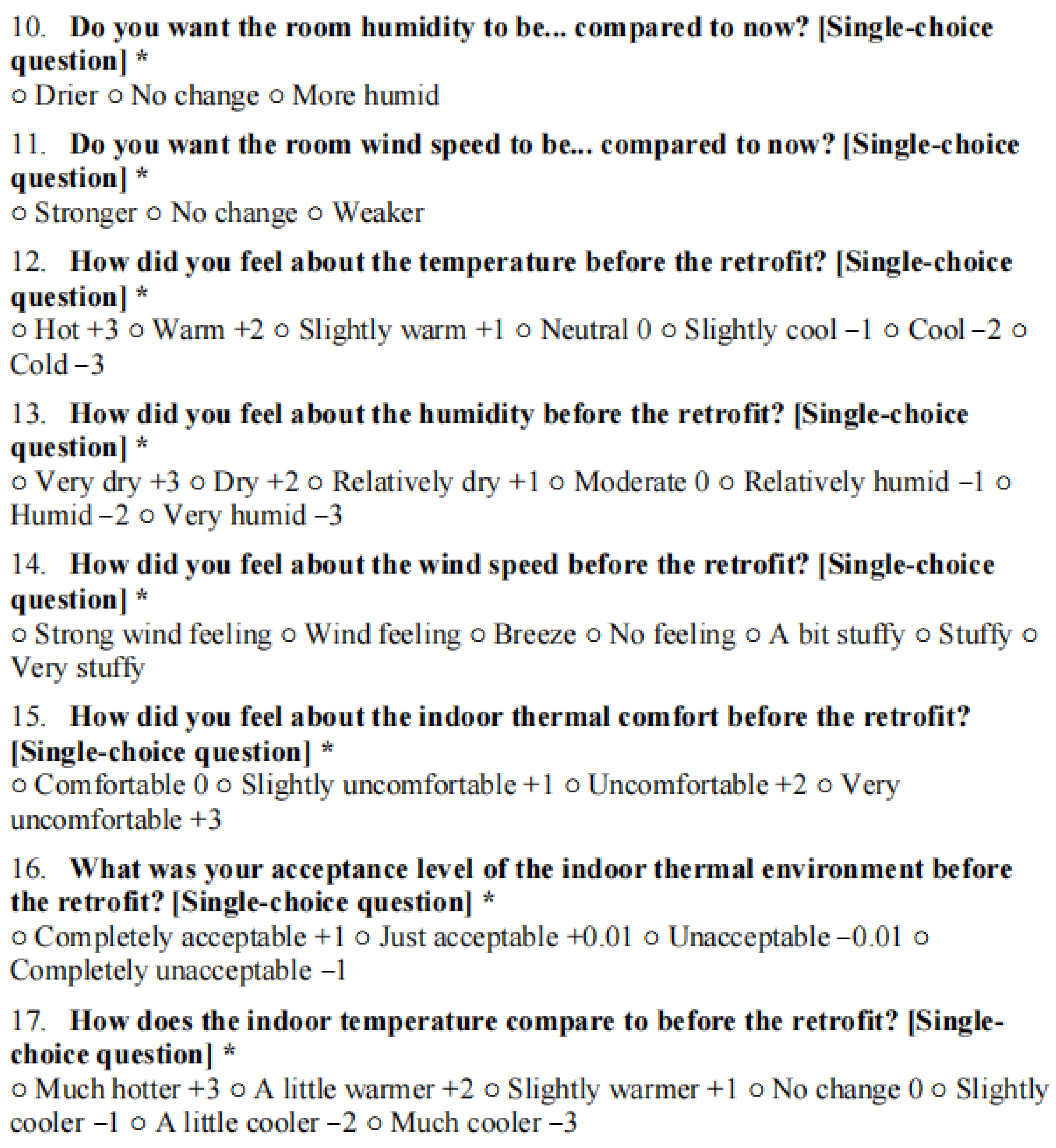

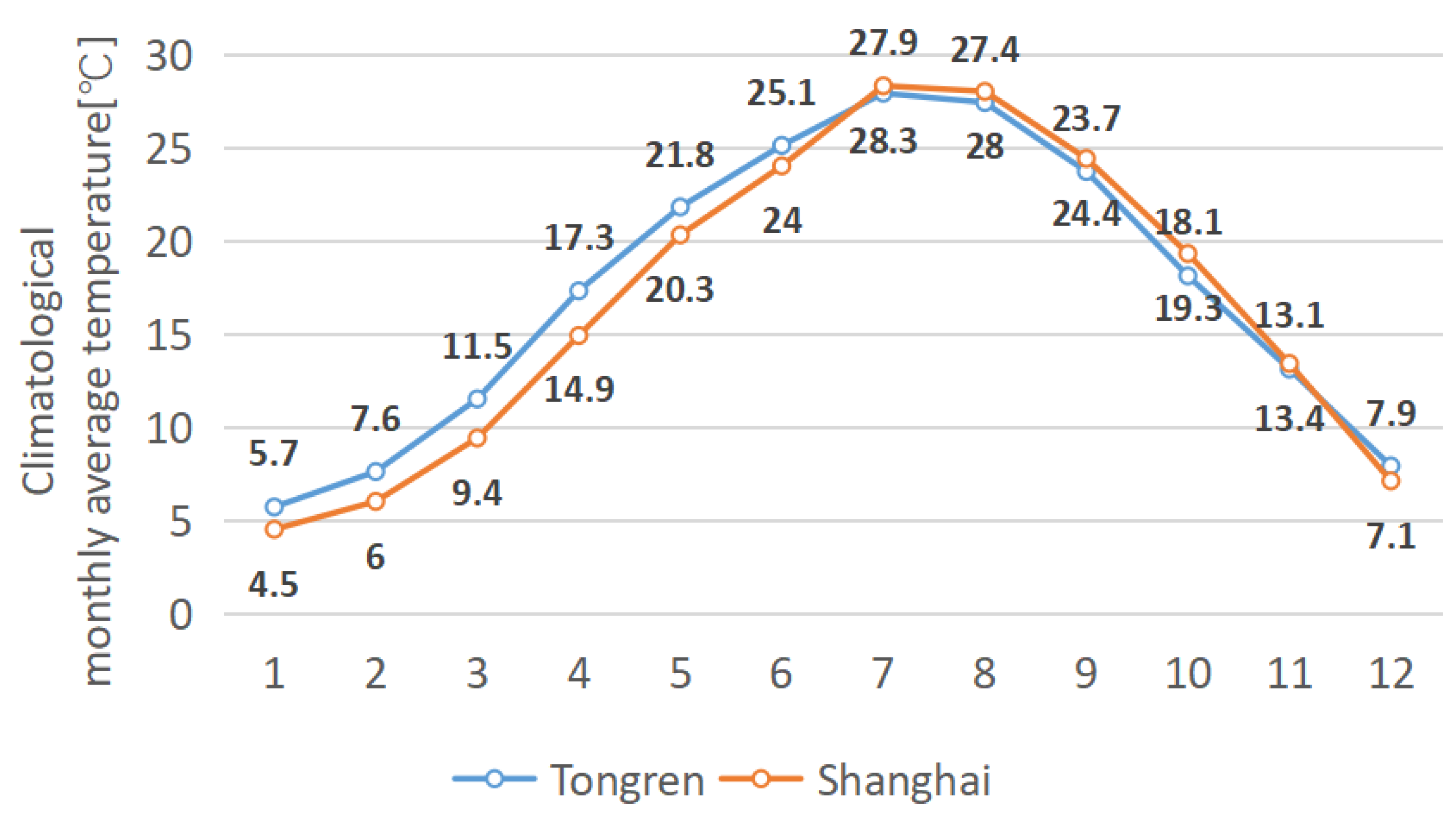

Regarding the monitoring period, this research mainly focuses on the building performance during the cooling season. The indoor air temperature and relative humidity are collected from July to September of 2024 and thermal sensation questionnaires in summer. In the HSCW zone, heating energy consumption is also a critical part of annual energy consumption. The evaluation of excessive heat loss in winter and its influence on thermal sensation still needs further investigation in follow-up studies. To estimate the influence of reflective materials on heating energy demand, findings from several studies in the HSCW zone are reviewed. In Chen and Lu’s research [

54], a prototype room with a similar size, building envelope quality, ventilation condition, air conditioning and inner loads experienced a 1.2 kWh/m

2 increase in heating energy demand in Shanghai, where the energy consumption in the cooling and heating seasons is nearly equal. However, the cooling energy savings (8.2 kWh/m

2) significantly surpass the penalty (1.2 kWh/m

2), leading to an annual energy saving of 4.1% in total. Considering the higher climatological monthly average temperatures in Tongren (sourced from the China Meteorological Administration database), it is reasonable to estimate a lower heating penalty in Tongren (

Figure 14).

Moreover, in this study, the natural ventilation rate was set as 30 m

3/h·person in accordance with the Civil Building Ventilation Design Code [

49]. This approach was chosen because conducting field measurements of window opening during air conditioner AC operation would require long-term and multi-room monitoring campaigns, which faces challenges including limited facilities and the consideration of occupants’ privacy. Therefore, the use of the code-based value serves as a practical approximation in the absence of large-scale empirical data.

Nevertheless, this simplification may not fully reflect real occupant behavior, resulting in a code-based value that is relatively high compared to actual conditions. This setting assumes that the supply of fresh air depends entirely on window opening and ignores occupant adaptation to indoor air quality. Consequently, the simulations reflect the building’s performance under disadvantageous operating conditions. To more accurately evaluate the energy-saving performance of the retrofit, future work should investigate infiltration and monitor window opening behaviors.

In addition, while the occupant thermal comfort survey offers valuable insights into subjective perceptions within the studied zone, the interpretation of its findings necessitates caution due to the limited sample size (n = 20). Although designed to be representative, this constrained scale inherently limits the statistical power to extrapolate findings with high confidence to a broader population or to robustly characterize sub-group variations.

Furthermore, although the comparison between PMV and TSV indicated a degree of alignment, the PMV was observed to consistently fall outside the ASHRAE Standard 55 optimal range during the monitored period. This observed bias necessitates further investigation into potential local adaptations. The phenomenon of local adaptation has been widely studied by researchers, including Xu et al. in Nanjing [

38] and Ben et al. in Guangzhou [

55]. However, due to the small sample size in this study, it is difficult to derive robust statistical evidence to validate specific adaptive behaviors in this population. This limitation must be addressed in subsequent studies by expanding the sample size.

It is worth noting that recent studies have increasingly highlighted the importance of the in situ monitoring of parameters related to the PMV in retrofitted buildings [

39,

56] in order to ensure accurate thermal comfort evaluations in real building environments. Although the experimental phase in this study faced instrumentation limitations that prevented the continuous monitoring of operative temperature, this gap was addressed by complementing measurements with numerical simulations. Nevertheless, the literature indicates that the direct measurement of operative temperature is crucial as it provides a more representative indicator of occupants’ thermal experience than air temperature alone. Therefore, it is recommended that future field studies incorporate the comprehensive monitoring of operative temperature and related PMV parameters at the position near the occupant. This would not only enhance the reliability of comfort assessments but also align with international standards for evaluating thermal environments in energy-efficient buildings.

Concerning the discrepancies between the simulated and measured temperatures, the discrepancies primarily suggest that the current model may underestimate heat loss in certain localized areas of the building assembly caused by the following potential factors:

Potential undercooling of building components due to strict cooling setpoint: In the simulation, the indoor air temperature is precisely cooled to and maintained at 26 °C. This differs significantly from actual conditions, where AC systems often operate intermittently. Thus, building mass such as walls become more cooled than it would in reality during the day. At night, the slow temperature recovery results in a considerable thermal lag.

Unaccounted thermal bridges: It is acknowledged that the initial model might not have incorporated all existing thermal bridges (e.g., junctions around window openings). Their omission from the model would result in simulated temperatures that are lower than the measured ones at those critical points.

However, due to the inherent limitations of the software and the unavailability of real-time AC operational data and as-built construction documents, it was not possible to further isolate or mitigate these interfering factors in the present study. These issues remain to be identified and addressed in future dedicated research.

In this research, WUFI

® Plus is adopted to estimate the energy and thermal comfort performance of the target building due to its comprehensive integration of heat and moisture transfer processes. However, a notable discrepancy exists in long-term predictions of indoor thermal comfort across different Building Energy Performance Simulation (BEPS) tools, highlighting a critical yet often overlooked challenge in building performance assessment, as addressed by a recent study by Alfano et al. [

57]. This study provides a valuable framework for improving input consistency across different simulation tools and indicates that energy-related outputs such as heating and cooling energy demands show reasonable agreement across different BEP tools, while indoor temperature predictions, which directly influence the evaluation of indoor thermal comfort, can vary substantially. It is therefore recommended that future studies should pay close attention to this issue and prioritize the acquisition of on-site measurement data to minimize such biases. Cross-software validation under unified modeling protocols should also be enhanced to improve the reliability and comparability of the evaluation of indoor thermal comfort.

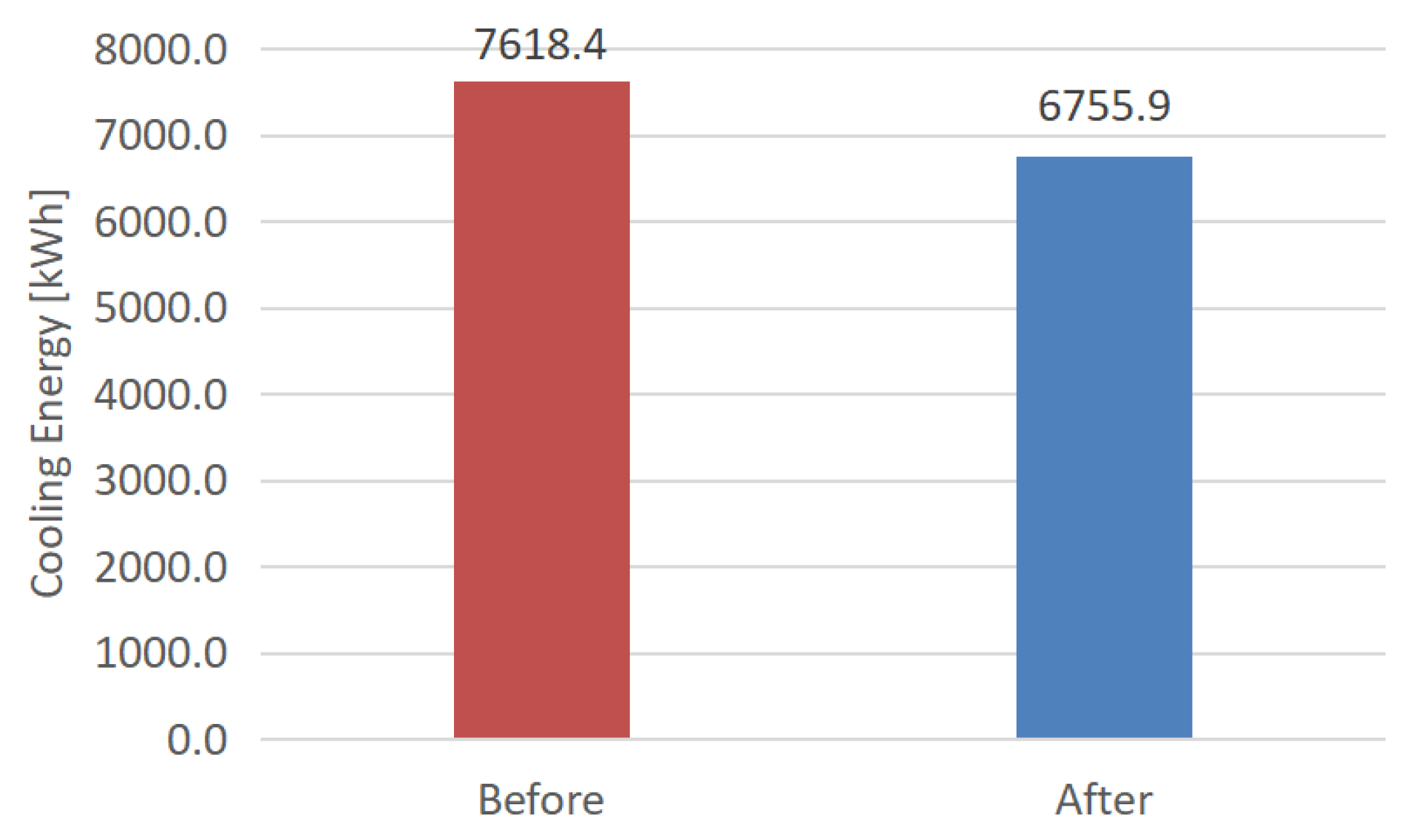

To further ensure the validity of the result, existing studies are reviewed and compared with the energy saving ratio in this research. In this study, it has been found that reflective materials can reduce cooling energy consumption by 11.3% in the chosen type of office buildings in the HSCW zone. Within the HSCW zone, previous research has evaluated the energy-saving potential of reflective materials through simulations of their respective baseline buildings. Xuan et al. [

58] simulated the annual cooling energy consumption of a small insulated concrete office (5.2 m×4.6 m×3.0 m) under different Chinese urban climatic conditions. This study reported energy savings exceeding 30% after applying reflective materials with a solar reflectance of 0.85 in the HSCW zone. Jia et al. [

59] reported a reduction in cooling energy demand by up to 35.7%. Yang et al. [

13] indicated a cooling energy demand saving by 13.81% in a three-floor insulated office building. Zhang et al. [

11] modeled a four-story concrete office building (46.33 m×16.92 m×12.19 m) without insulation reducing annual cooling energy by 10.06%, which is closer to the findings of this study (11.3%). These comparisons suggest that variations in energy savings may originate from differences in the shape coefficient of buildings, the window-to-wall ratio (WWR), and the thermal performance of the building envelope. Reflective materials may potentially yield higher cooling energy saving ratios in buildings with better insulation. This hypothesis requires further validation in future studies. Nevertheless, existing research consistently demonstrates that reflective materials can provide considerable energy savings, even in buildings with inadequate envelope performance. As a low-cost and low-disruption solution, they deserve considerable attention from engineering practitioners.

7. Conclusions

This study provides a comprehensive field-based assessment of reflective retrofits in an operational office building within China’s HSCW zone, offering insights that extend beyond simulation-based or short-term monitoring approaches.

7.1. Key Findings

Reflective roof and window materials can reduce cooling energy demand by 11.3% (39.2 → 34.8 kWh/m

2) and cooling energy consumption by 11.0% (12.8 → 11.4 kWh/m

2). While lower than the reductions reported in studies from Spain and by Zhang et al. [

11], these results remain significant given the low equipment density and envelope quality of the studied building.

Occupant surveys indicated improved thermal perception, with mean TCV rising from −0.75 to −0.30, thermal acceptability increasing from 0.10 to 0.35, and 80% of occupants reporting cooler conditions. These subjective results aligned with simulated PMV reductions (0.82 → 0.74), confirming the retrofit’s effectiveness. However, due to the limited sample size, these findings should be validated in future research.

Compared with related studies, the present results confirm both the potential and limitations of reflective retrofits in mixed climates. The observed cooling energy reduction of 11.0–11.3% is lower than the 29.1% reported by Zhang et al. [

11] for a similar retrofit measure, but the gap can be attributed to the lower equipment density, less stringent comfort requirements, and the degraded envelope performance of the old office building under investigation. At the same time, the reduction aligns closely with another case study in China’s HSCW zone [

11], highlighting the climate-specific boundaries of reflective measures in regions with relatively high heating demand. By contrast, studies in Mediterranean climates such as Spain [

12] have achieved higher savings, likely due to greater annual solar radiation and longer cooling seasons. Despite the relatively modest energy savings, the thermal comfort improvements observed in this study are consistent with previous survey-based findings, where reflective retrofits not only reduced cooling loads but also enhanced occupant thermal satisfaction. This reinforces the dual value of such interventions in real-world applications, suggesting that reflective retrofits should be considered as a complementary, low-disruption strategy particularly suited for aging office building stocks in HSCW climates.

7.2. Methodological Contributions

This study developed a replicable evaluation framework combining long-term calibrated WUFI®Plus simulations (NMBE: 2.40%, CV(RMSE): 4.52%, R2: 0.81) with real-world operational data and occupant surveys. This method validates reflective retrofits as an effective energy solution for HSCW regions, even in older buildings with poor thermal performance.

7.3. Future Outlook

This study acknowledges two key limitations inherent in the current analysis: the constrained sample size (n = 20) and the uncertainty surrounding ventilation behaviors. The relatively small number of samples may restrict the statistical power and generalizability of the findings. Therefore, to draw more generalizable conclusions, future studies should take into account the number of occupants in the target buildings and ensure that the sample size is sufficient. Meanwhile, the ambiguity in occupant window opening behavior introduces potential discrepancies into energy consumption simulations. To address these challenges, future research will actively explore the transformative potential of Internet of Things (IoT) technology in building performance evaluation. By deploying networks of low-cost sensors to continuously monitor indoor occupancy status, window operations, and ambient environmental parameters, it is possible to capture high-resolution, granular behavioral data to establish more reliable energy models. This data-driven approach not only promises to significantly enhance the precision of future retrofit project assessments but also opens new avenues for understanding the complex interplay between humans, buildings, and the environment, ultimately advancing the development of personalized and adaptive energy-saving strategies. For the winter season, the future field study will comprise two key components: objective measurements of PMV parameters and subjective surveys to capture occupants’ thermal perceptions in the heating season.