Production, Thermal, Durability, and Mechanical Properties of Translucent Concrete and Its Applications in Sustainable Construction: A Review

Abstract

1. Introduction

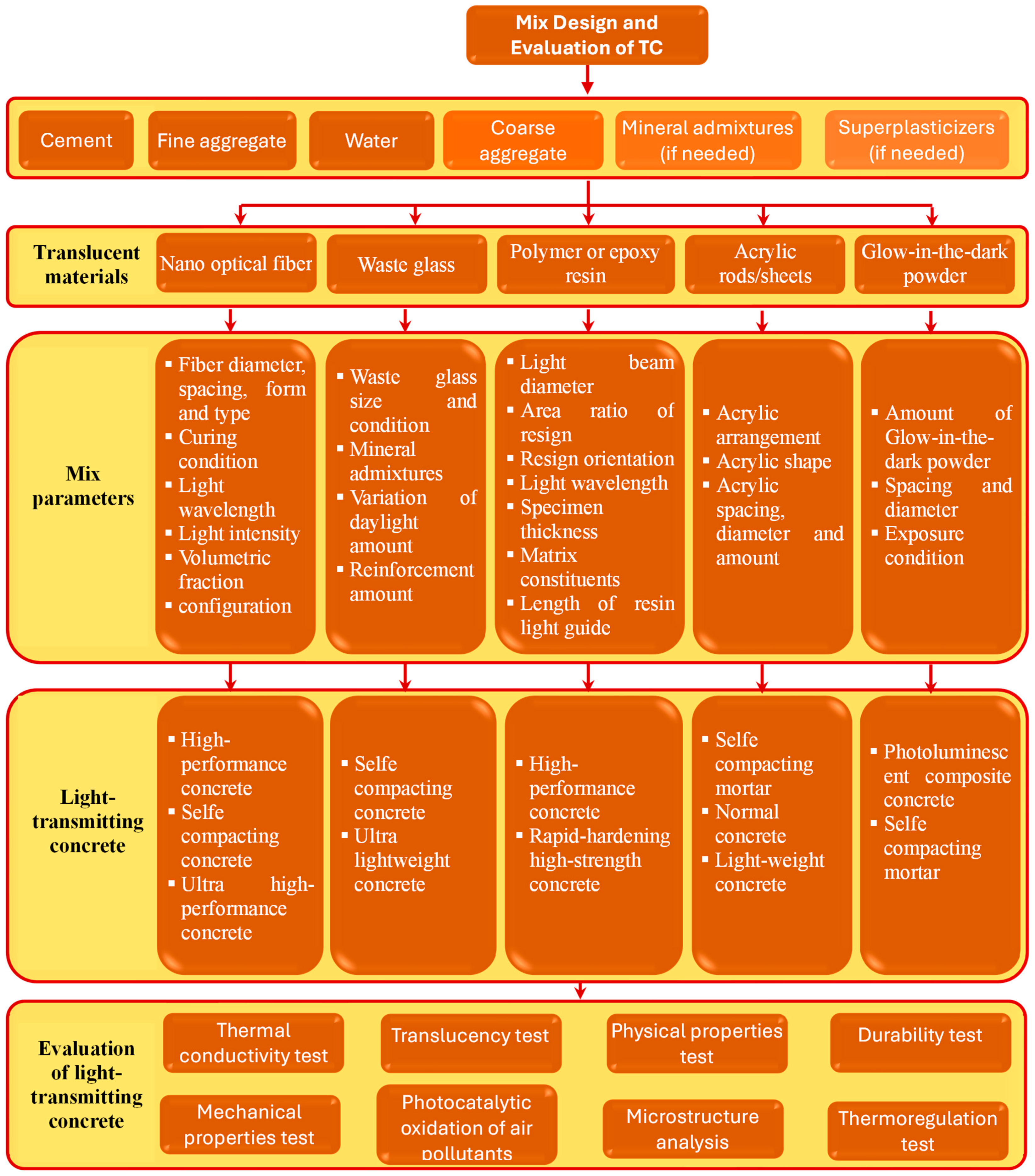

2. Production of Translucent Concrete

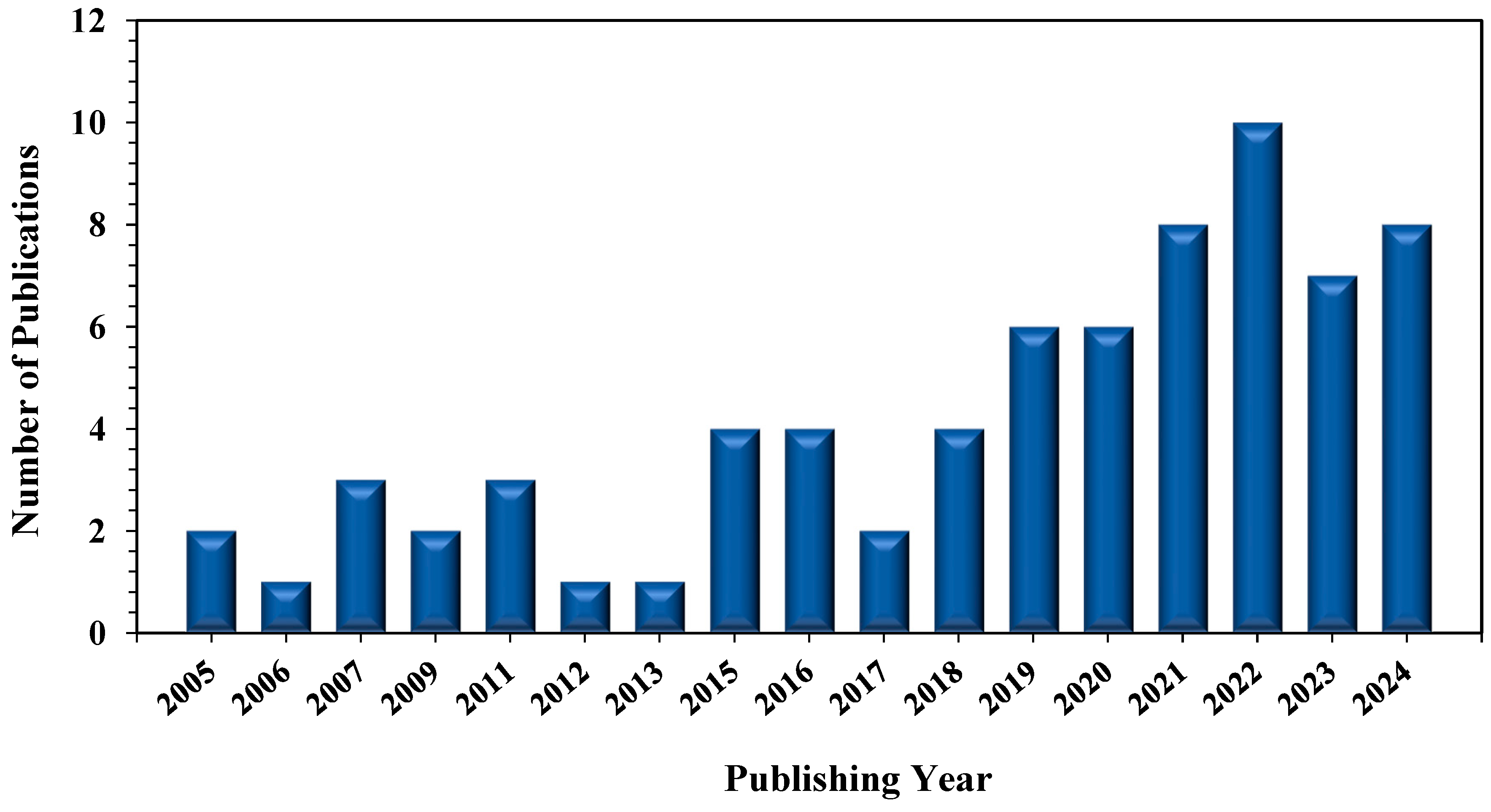

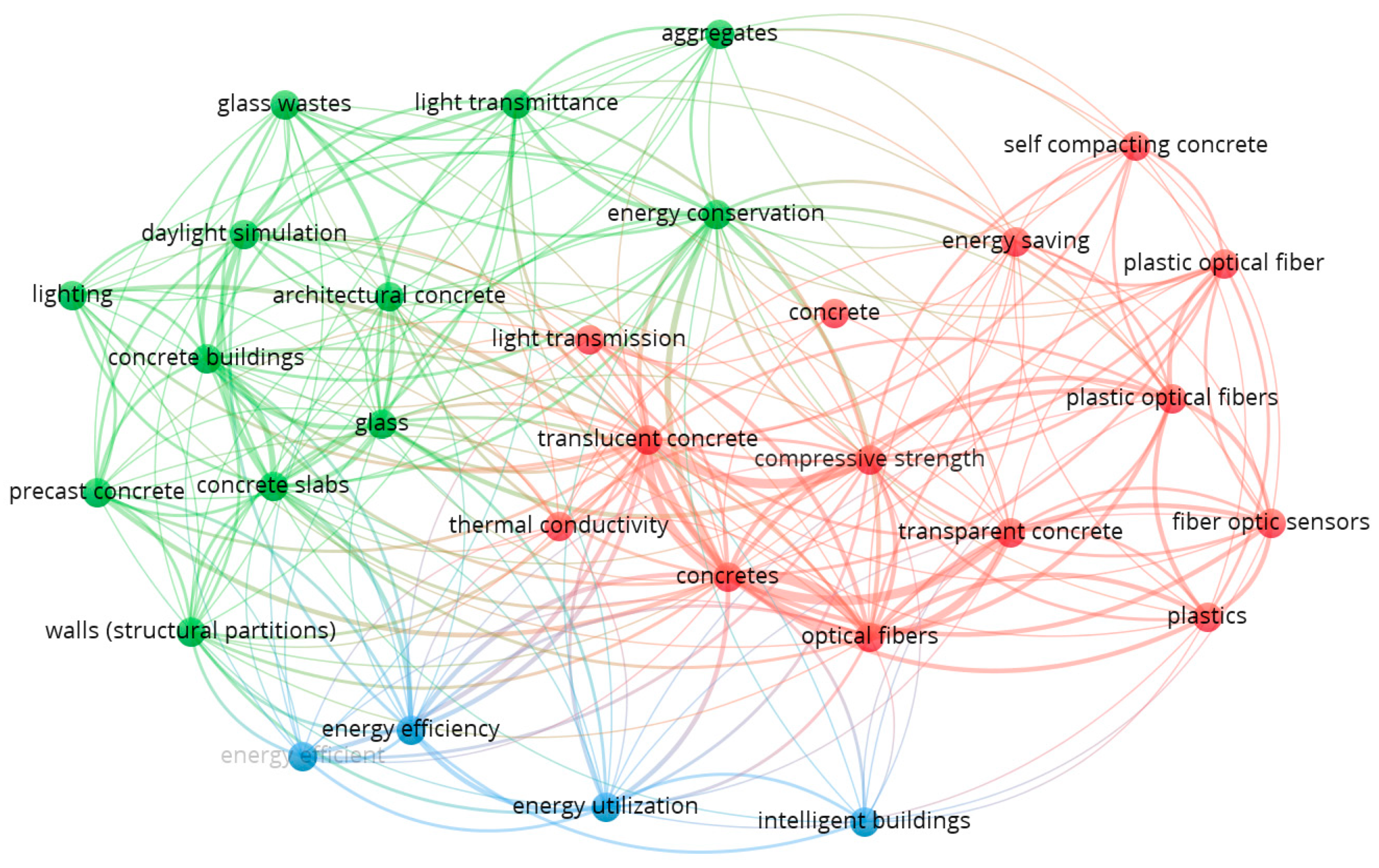

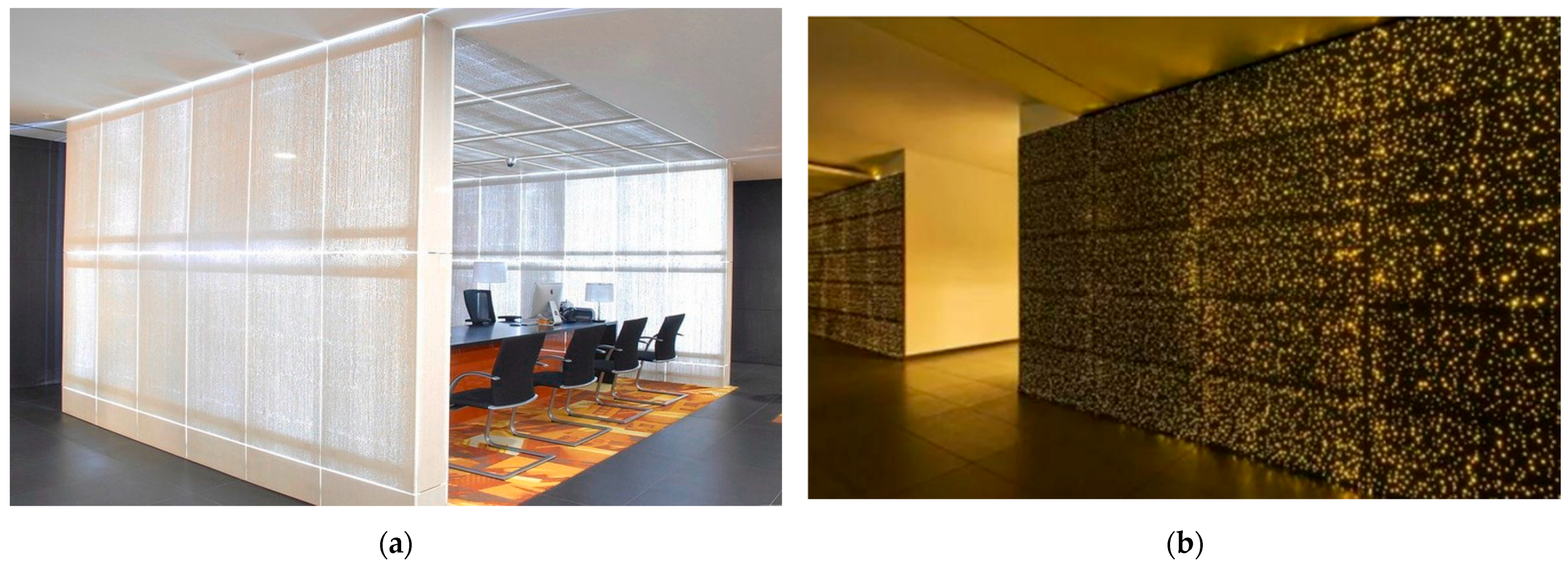

3. Bibliometric Analysis

4. Translucent Concrete Applications in Green Constructions

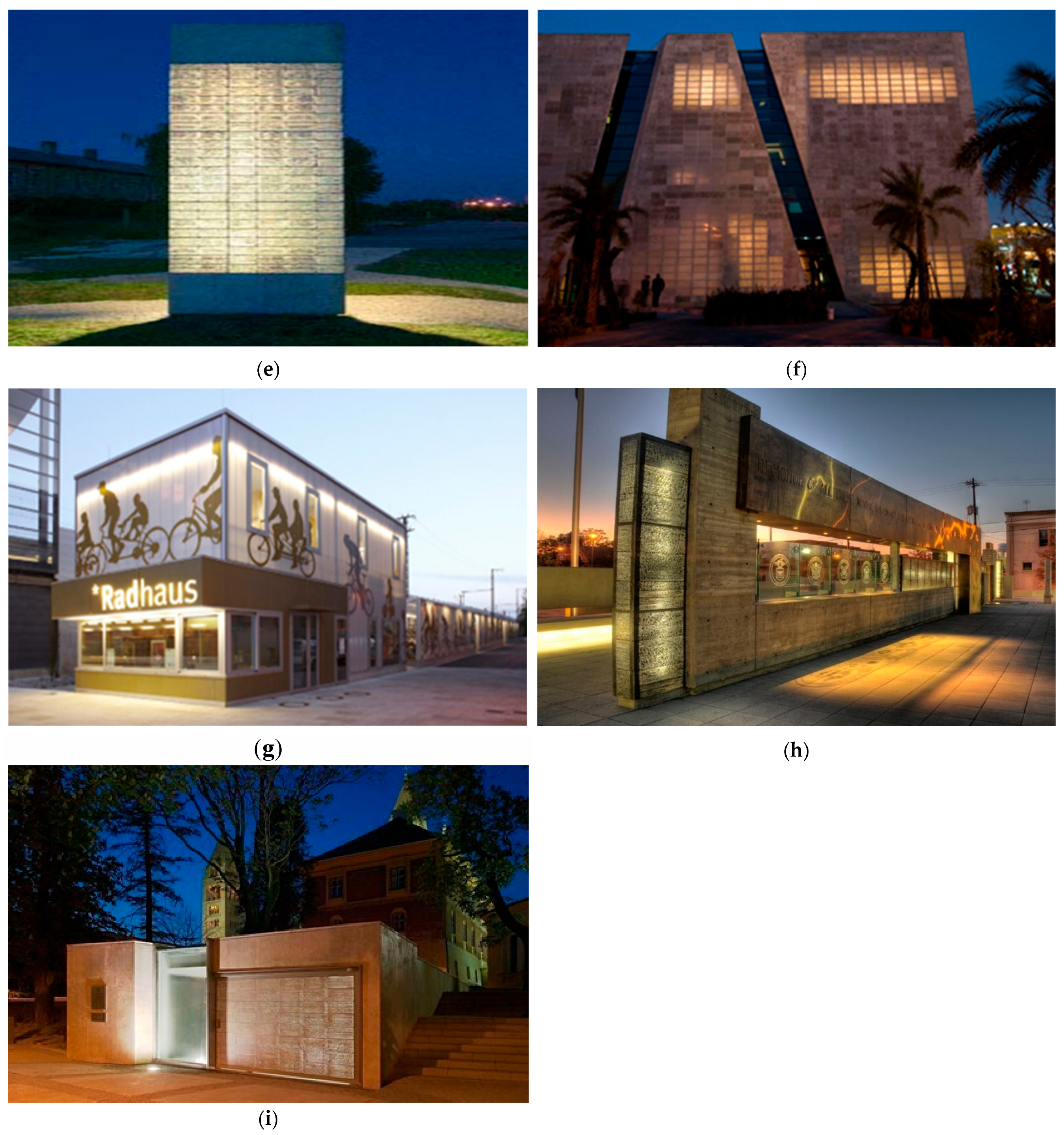

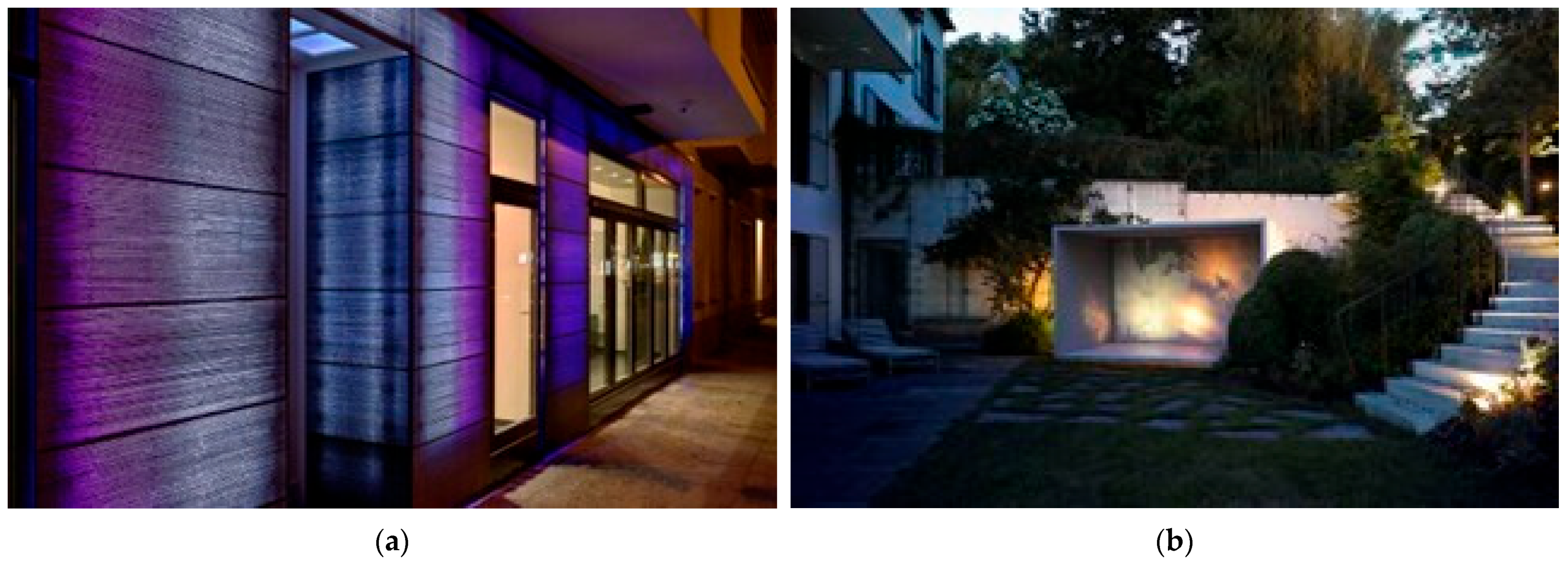

4.1. Facades and Cladding

4.2. Top Surfaces

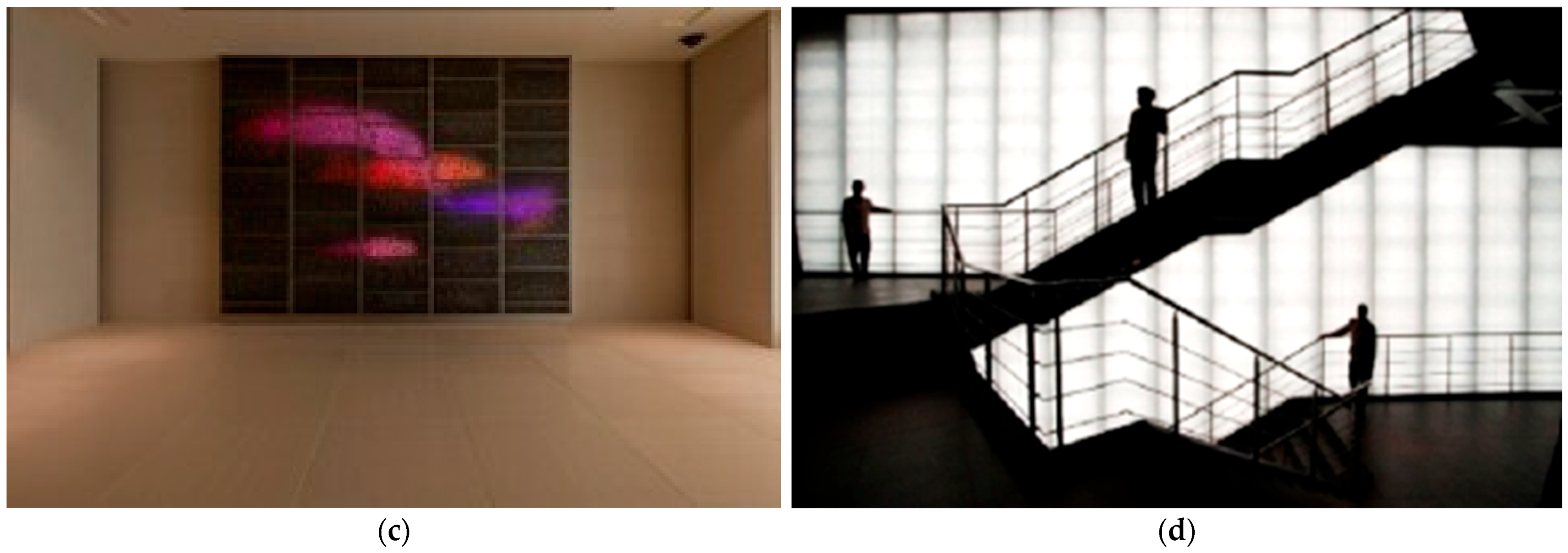

4.3. Walls

4.4. Partitions

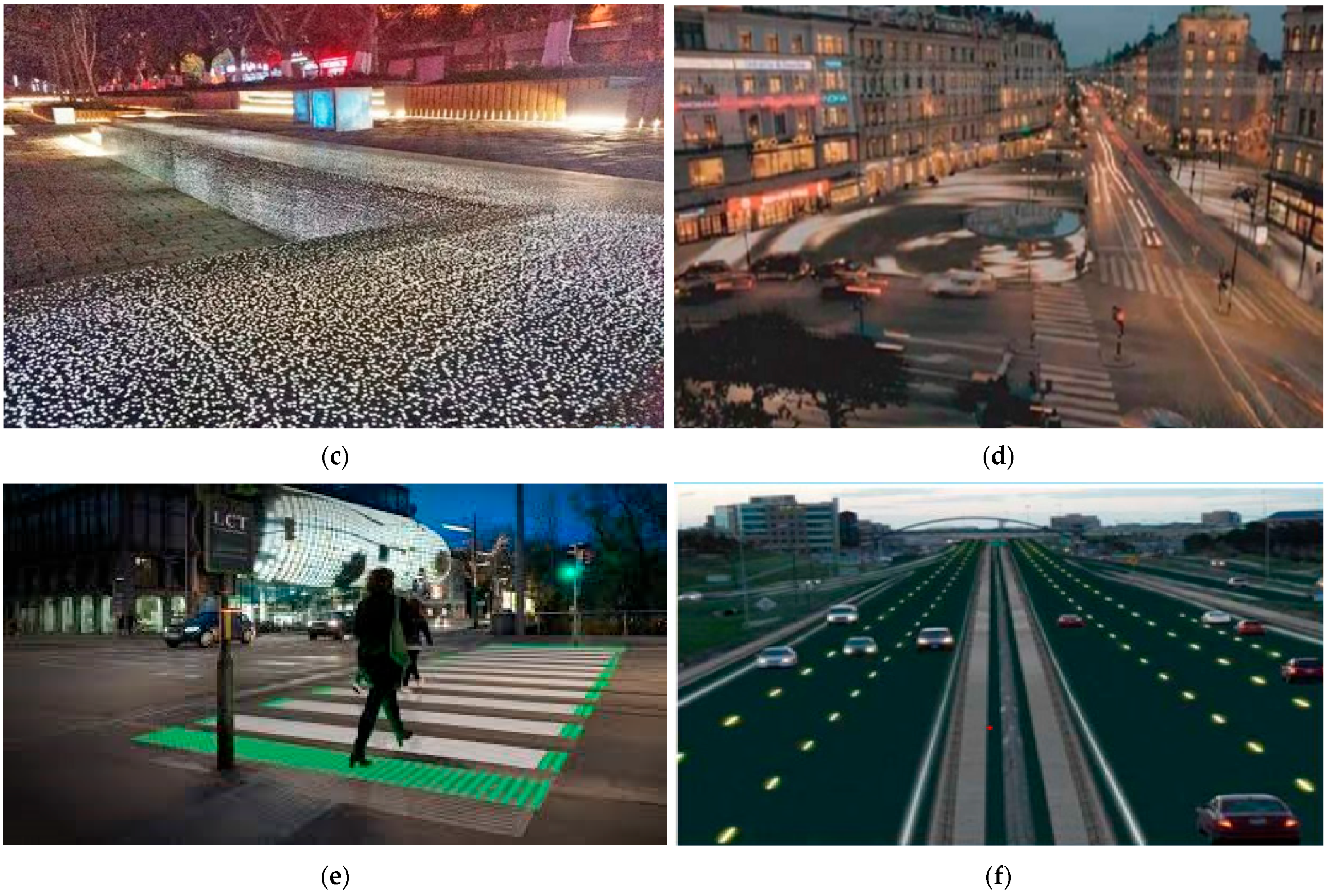

4.5. Floors and Highways

4.6. Staircase and Stairs

5. Evaluation of Light-Transmitting Concrete

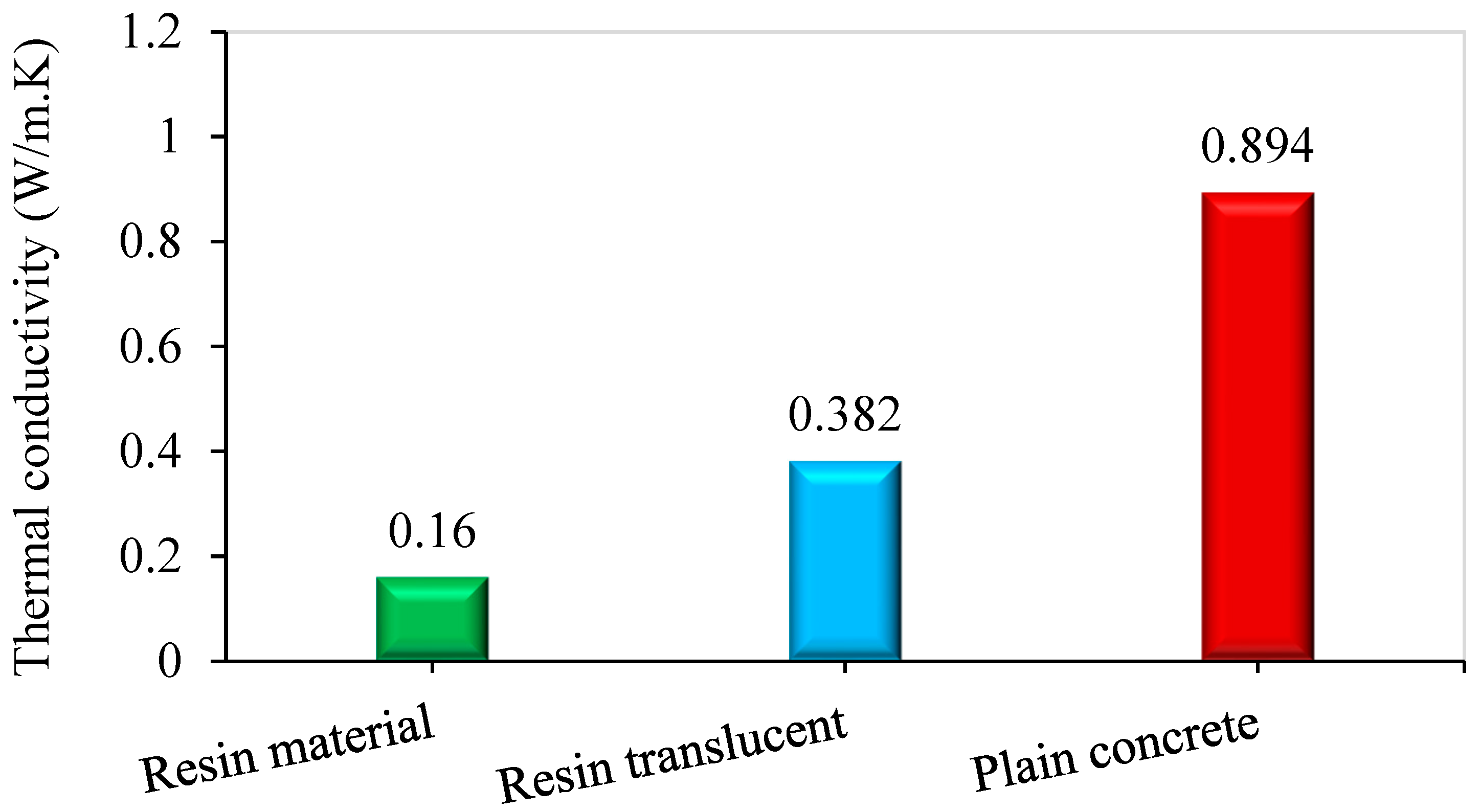

5.1. Thermal and Energy-Saving Properties

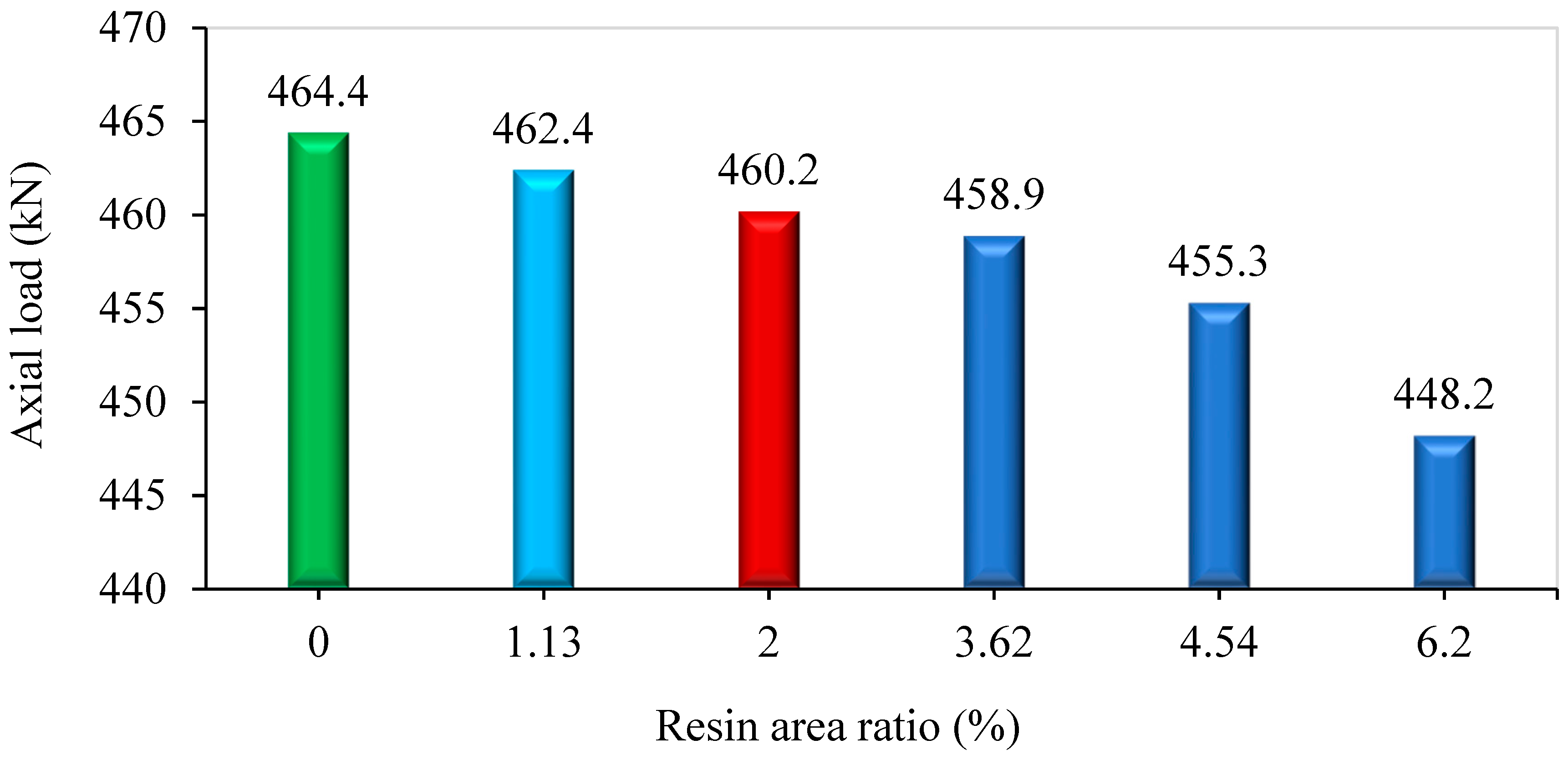

5.2. Mechanical and Physical Properties

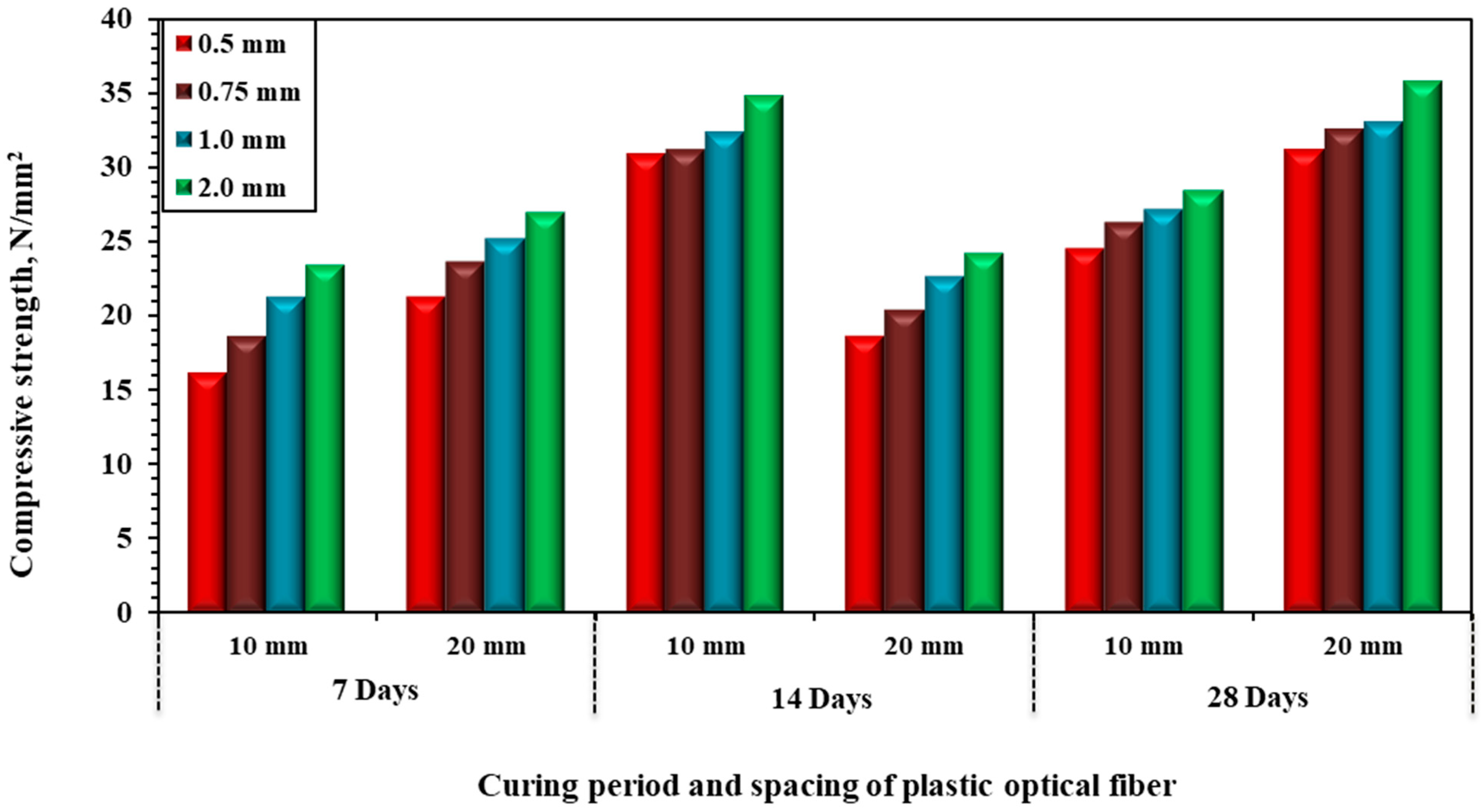

5.2.1. Compressive Strength

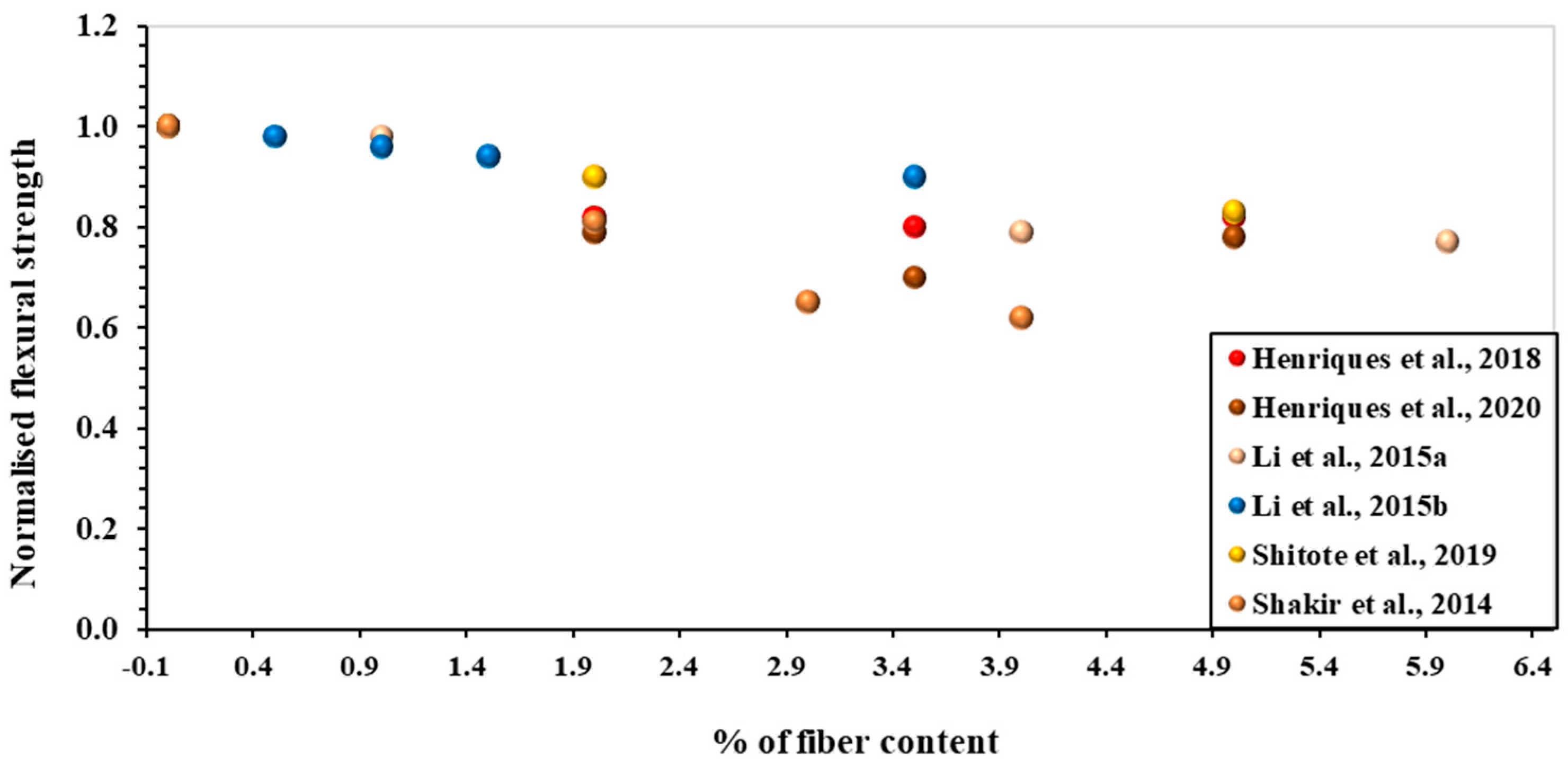

5.2.2. Flexural Strength

5.3. Light-Transmitting Property

5.4. Durability Properties

6. Cost Analysis

7. Limitations

8. Conclusions

- Placing the fiber optics vertically has a significant effect on the transparency of the concrete.

- The mechanical strength of TC decreases when transparent elements are incorporated. However, depending on the type of transparent element and other parameters, increasing the volume fraction of the transparent element may increase or decrease the mechanical and light transmission characteristics.

- The optimal fiber ratio in concrete volume is less than 5% for enhanced mechanical properties and 6% or more for energy savings.

- Transparent concrete will play a crucial role in smart housing designs. Its contribution to electricity, heat, and energy efficiency will enhance the popularity of smart buildings.

- Most current literature has focused on TC utilizing optical fiber. There is considerable potential to incorporate epoxy resin and waste glass into the production of TC; however, insufficient information regarding their properties is available in existing literature.

- Currently, the focus of TC development is primarily on aesthetic and construction applications.

- Nonetheless, TC holds significant promise for infrastructure uses, particularly enhancing traffic safety. However, essential factors such as illuminance levels, mechanical properties, production processes, and design criteria suitable for infrastructure use remain insufficiently researched.

- Nonetheless, TC holds significant promise for infrastructure applications, particularly in enhancing traffic safety. However, essential factors such as illuminance levels, manufacturing processes, mechanical properties, and design criteria suitable for infrastructure use remain insufficiently researched.

- The use of modern materials and technologies enables the creation of new types of decorative concrete, which possess unique aesthetic features.

- The primary factors examined in TC studies include the spacing, amount, and size of transparent components inside the concrete matrix. Additionally, variables such as curing conditions, light intensity, angle of light incidence, and the distance between the light detector and the light source relative to the tested specimen significantly influence TC properties.

- The durability and mechanical properties of TC can be analyzed through microstructural studies, which provide insight into the cohesion between the concrete matrix and optical fibers. Environmental factors affecting the durability of fiber-optic TC, including porosity, chemical attacks, freeze-thaw cycles, and water permeability, have received little attention. Addressing these factors is essential for ensuring sustainability in the building sector.

- The larger the size and volume percentage of the transparent element, the greater the light transmission. In light transmission tests, most experimental data reported luminance values rather than light transmission efficiency, leading to biased and inconclusive results.

- The application range of TC is more limited compared to normal concrete constructions. However, as the durability and mechanical properties of TC are better understood and production costs are reduced, its use will expand even further in the future.

9. Future Research

- Further studies are needed to identify the best fiber ratios to be incorporated in TC to improve its mechanical properties and achieve maximum energy savings.

- The durability evaluation of TC containing various types of transparent elements requires further investigation. Additionally, testing for physical characteristics and microstructure analysis should be done to get solid proof for the mechanical and durability analysis of TC.

- Future research should focus more on TC incorporating waste glass and epoxy resin than on transparent fibers. These materials, particularly epoxy resins, have a great deal of potential to replace optical fibers in TC due to their low labor and material costs and simpler production processes.

- Further research is needed to clarify the mechanical behavior of the panel form of the TC and other characteristics such as heat insulation, permeability, and sound insulation, so that TC applications can be widely used in practice.

- Additional research is needed to investigate heat loss over a longer time span, taking into account both daytime and nighttime temperatures.

- More attention should be paid to feasibility investigations on total energy consumption, taking into account heat comfort and light transmittance property.

- The utilization of LTC in the infrastructure in the infrastructure sector, particularly for road markings and tunnels, needs to be investigated.

- Theoretical research on the mechanical strength and overall energy savings of LTCs is suggested as a foundation for engineering design. This enables engineers to estimate the maximum benefit achievable that can be gained from using TC and its characteristics.

- Future research should focus on the development of standardized ASTM or ISO durability and light transmitting test manuals.

- LTC would help in saving energy of construction in the fields of civil, interior, and architectural engineering and would provide an additional function by enabling these concrete structures to provide light in dark environments.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| TC | translucent concrete/transparent concrete |

| IEA | International Energy Agency |

| PMMA | polymethyl methacrylate |

| CO2 | carbon dioxide |

| W/m.K | watts per meter kelvin |

| POF | plastic optical fibers |

| GGBFS | ground granulated blast furnace slag |

| TCBC | transparent cement-based concrete |

| LTCB | light-transmitting cementitious-based |

| LT | Light transmission |

| CS | compressive strength |

| FS | flexural strength |

References

- Wang, B.; Zhang, X.; Zhang, M.; Cui, Y.; He, Y. Development of novel variable building skin with solar concentrating technology for obtaining energy benefits and optimizing indoor daylighting. Energy Build. 2024, 310, 114081. [Google Scholar] [CrossRef]

- Do, S.L.; Shin, M.; Baltazar, J.-C.; Kim, J. Energy benefits from semi-transparent BIPV window and daylight-dimming systems for IECC code-compliance residential buildings in hot and humid climates. Solar Energy 2017, 155, 291–303. [Google Scholar] [CrossRef]

- Çataroğlu Coğul, I.; Kazanasmaz, Z.T.; Ekici, B. A literature review on sustainable buildings and neighborhoods in terms of daylight, solar energy and human factors. J. Build. Eng. 2025, 103, 111989. [Google Scholar] [CrossRef]

- Ming, Y.; Jiang, F.; Alkan, C.; Yuan, Y.; Wu, Y. Comprehensive impact of two advanced thermotropic façades designs on building daylight and energy performance. Energy Build. 2025, 334, 115488. [Google Scholar] [CrossRef]

- Vartiainen, E. Electricity benefits of daylighting and photovoltaics for various solar facade layouts in office buildings. Energy Build. 2001, 33, 113–120. [Google Scholar] [CrossRef]

- Gupta, M.; Zala, P.; Gupta, S.; Varshney, S. Solar concentration based indoor daylighting system to achieve net zero sustainable buildings. Energy Build. 2024, 321, 114662. [Google Scholar] [CrossRef]

- Shelby, L.R. The Construction of Gothic Cathedrals: A Study of Medieval Vault Erection by John Fitchen. Technol. Cult. 1961, 2, 400–402. [Google Scholar] [CrossRef][Green Version]

- Liu, Y. Building Guastavino dome in China: A historical survey of the dome of the Auditorium at Tsinghua University. Front. Archit. Res. 2014, 3, 121–140. [Google Scholar] [CrossRef]

- Agency IE. 2024. Available online: https://www.iea.org/reports/co2-emissions-in-2023 (accessed on 24 August 2025).

- Hosseinzadehfard, E.; Mobaraki, B. Corrosion performance and strain behavior of reinforced concrete: Effect of natural pozzolan as partial substitute for microsilica in concrete mixtures. Structures 2025, 79, 109397. [Google Scholar] [CrossRef]

- Saleem, M.; Elshami, M.M.; Najjar, M. Development, Testing, and Implementation Strategy of a Translucent Concrete-Based Smart Lane Separator for Increased Traffic Safety. J. Constr. Eng. Manag. 2017, 143, 04016129. [Google Scholar] [CrossRef]

- Saleem, M.; Blaisi, N.I. Development, testing, and environmental impact assessment of glow-in-the-dark concrete. Struct. Concr. 2019, 20, 1792–1803. [Google Scholar] [CrossRef]

- Peña-García, A.; Gil-Martín, L.M.; Rabaza, O. Application of translucent concrete for lighting purposes in civil infrastructures and its optical characterization. Key Eng. Mater. 2016, 663, 148–156. [Google Scholar] [CrossRef]

- Roye, A. Intriguing Transparency. Ger. Res. 2013, 35, 11–13. [Google Scholar] [CrossRef]

- Abdulmajeed, N.S. Harnessing Nanotechnology to Conserve Energy in Buildings. Sci. Res. J. Eng. Comput. Sci. 2022, 2, 1–14. [Google Scholar]

- Kumar, A.; Ahlawat, R. Experimental study on light transmitting concrete. Int. J. Innov. Sci. Eng. Technol. 2017, 4, 201–210. [Google Scholar]

- Juan, S.; Zhi, Z. Some progress on smart transparent concrete. Pac. Sci. Rev. 2013, 15, 51–55. [Google Scholar]

- Timina, A.; Yanova, R.; Popov, A.; Sorokoumova, T. Modern translucent materials and their impact on architectural forming. In E3S Web of Conferences; EDP Sciences: Les Ulis, France, 2019; p. 1035. [Google Scholar]

- Ugale, A.B.; Badnakhe, R.R.; Nanhe, P.P. Light Transmitting Concrete—Litracon. In Smart Technologies for Energy, Environment and Sustainable Development: Select Proceedings of ICSTEESD 2018; Springer: Berlin/Heidelberg, Germany, 2019; pp. 241–251. [Google Scholar]

- Losonczi, Á.; Bittis, A. Transparent concrete causing a sensation. In Betonwerk und Fertigteil-Technik/Concrete Precasting Plant and Technology; Bauverlag GmbH: Hungary, Germany, 2005. [Google Scholar]

- Kroggel, O.; Grübl, P. Ultrasonic inspection of concrete structures—New steps towards “transparent” concrete. In Proceedings of the International Conference on Repair and Renovation of Concrete Structures, Cape Town, South Africa, 21–23 November 2005. [Google Scholar]

- Abou-Zeid, M.N.; Fahmy, E.H.; Alia, D.A.A. Properties of Translucent Concrete. In Proceedings of the CSCE 2007 Annual General Meeting & Conference, Yellowknife, NT, Canada, 6–9 June 2007. [Google Scholar]

- Zhou, Z.; Ou, G.; Hang, Y.; Chen, G.; Ou, J. Research and development of plastic optical fiber based smart transparent concrete. In Smart Sensor Phenomena, Technology, Networks, and Systems 2009; SPIE: Bellingham, WA, USA, 2009; pp. 107–112. [Google Scholar]

- Mainini, A.G.; Poli, T.; Zinzi, M.; Cangiano, S. Spectral light transmission measure and radiance model validation of an innovative transparent concrete panel for façades. Energy Procedia 2012, 30, 1184–1194. [Google Scholar] [CrossRef]

- Spiesz, P.; Rouvas, S.; Brouwers, H.J.H. Utilization of waste glass in translucent and photocatalytic concrete. Constr. Build. Mater. 2016, 128, 436–448. [Google Scholar] [CrossRef]

- Pagliolico, S.L.; Lo Verso, V.R.M.; Torta, A.; Giraud, M.; Canonico, F.; Ligi, L. A preliminary study on light transmittance properties of translucent concrete panels with coarse waste glass inclusions. Energy Procedia 2015, 78, 1811–1816. [Google Scholar] [CrossRef]

- Kankriya, M. Translucent Concrete by Using Optical Fibers and Glass Rods. Int. J. Sci. Res. Publ. 2016, 6, 625–627. [Google Scholar]

- Kim, B. Light Transmitting Lightweight Concrete with Transparent Plastic Bar. Open Civ. Eng. J. 2017, 11, 615–626. [Google Scholar] [CrossRef]

- Mohan, R.; Tyagi, P.; Sharma, R.; Rajan, H. Experimental Studies on POF and Epoxy-Resin Based Translucent Concrete. Int. J. Latest Technol. Eng. 2018, 7, 130–134. [Google Scholar]

- Roye, A.; Barlé, M.; Janetzko, S.; Gries, T. Faser—Und textilbasierte Lichtleitung in Betonbauteilen—Lichtleitender Beton. Beton-und Stahlbetonbau 2009, 104, 121–126. [Google Scholar] [CrossRef]

- Dinesh, B.K.; Mercy, S.R.; Suji, D. Effect of fiber pattern in strength of light transmitting concrete. Int. J. Recent Technol. Eng. 2019, 7, 121–126. [Google Scholar]

- Zhu, B.; Guo, Z.; Song, C. Fiber-optic parameters of light emitting diode active-luminous traffic markings based on light-transmitting concrete. J. Tongji Univ. Nat. Sci. 2019, 47, 802–809. [Google Scholar]

- Lyu, Q.; Dai, P.; Chen, A. Mechanical strengths and optical properties of translucent concrete manufactured by mortar-extrusion 3D printing with polymethyl methacrylate (PMMA) fibers. Compos. B Eng. 2024, 268, 111079. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Abdel-Raheem, A.; Abdel-Aziz, N.; Amin, M. Light transmittance performance of sustainable translucent self-compacting concrete. J. Build. Eng. 2021, 38, 102178. [Google Scholar] [CrossRef]

- Tahwia, A.M.; Abdelaziz, N.; Samy, M.; Amin, M. Mechanical and light transmittance properties of high-performance translucent concrete. Case Stud. Constr. Mater. 2022, 17, e01260. [Google Scholar] [CrossRef]

- Abdulmajeed, N.S.; Said, S.H. Compressive characteristics of resin translucent cement mortar (RTCM) used in the external walls to rationalize the energy spent inside the building. Case Stud. Constr. Mater. 2022, 17, e01687. [Google Scholar] [CrossRef]

- Kamdi, A.B. Transparent concrete as a green material for building. Int. J. Struct. Civ. Eng. Res. 2013, 2, 172–175. [Google Scholar]

- Kashiyani, B.K.; Raina, V.; Pitroda, J.; Shah, B.K. A study on transparent concrete: A novel architectural material to explore construction sector. Int. J. Eng. Innov. Technol. 2013, 2, 83–87. [Google Scholar]

- Chiew, S.M.; Ibrahim, I.S.; Ariffin, M.A.M.; Lee, H.-S.; Singh, J.K. Development and properties of light-transmitting concrete (LTC)—A review. J. Clean Prod. 2021, 284, 124780. [Google Scholar] [CrossRef]

- Tuaum, A.; Shitote, S.; Oyawa, W.; Biedebrhan, M. Structural performance of translucent concrete façade panels. Adv. Civ. Eng. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Elghezanwy, D.; Eltarabily, S. A review of translucent concrete as a new innovative material in architecture. Civ. Eng. Archit. 2020, 8, 571–579. [Google Scholar]

- Ali, R.A.; Kharofa, O.H. The impact of nanomaterials on sustainable architectural applications smart concrete as a model. Mater. Today Proc. 2021, 42, 3010–3017. [Google Scholar]

- Ghaffarianhoseini, A.; Ghaffarianhoseini, A.; Berardi, U.; Tookey, J.; Li, D.H.W.; Kariminia, S. Exploring the advantages and challenges of double-skin façades (DSFs). Renew. Sustain. Energy Rev. 2016, 60, 1052–1065. [Google Scholar] [CrossRef]

- Ghosh, A.; Sundaram, S.; Mallick, T.K. Investigation of thermal and electrical performances of a combined semi-transparent PV-vacuum glazing. Appl. Energy 2018, 228, 1591–1600. [Google Scholar]

- Luo, Y.; Zhang, L.; Wang, X.; Xie, L.; Liu, Z.; Wu, J.; Zhang, Y.; He, X. A comparative study on thermal performance evaluation of a new double skin façade system integrated with photovoltaic blinds. Appl. Energy 2017, 199, 281–293. [Google Scholar] [CrossRef]

- Yadav, A.; Shekhar, S.; Anand, A.; Badal, A.; Zaman, B. An investigating study on a new innovative material: Transparent concrete. Int. J. Eng. Res. Adv. Dev. 2018, 4, 64–72. [Google Scholar]

- Cement, H. Transparent Cement for the Italian Pavilion at Expo 2010 in Shanghai; Halyps Building Materials SA: Attica, Greece, 2021. [Google Scholar]

- Chiadighikaobi, P.C.; Adegoke, M.A.; Kharun, M.; Paul, V.J.; Abu Mahadi, M.I.; Finbarrs-Ezema, B. A Review of the Structural Properties of Translucent Concrete as Sustainable Material. Open Constr. Build. Technol. J. 2023, 17, 1–17. [Google Scholar] [CrossRef]

- Zielińska, M.; Ciesielski, A. Analysis of transparent concrete as an innovative material used in civil engineering. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 22071. [Google Scholar]

- Han, B.; Zhang, L.; Ou, J.; Han, B.; Zhang, L.; Ou, J. Light-transmitting concrete. In Smart Multifunctional Concrete Toward Sustainable Infrastructures; Springer: Singapore, 2017; pp. 273–283. [Google Scholar]

- Luhar, I.; Luhar, S.; Savva, P.; Theodosiou, A.; Petrou, M.F.; Nicolaides, D. Light transmitting concrete: A review. Buildings 2021, 11, 480. [Google Scholar] [CrossRef]

- Altlomate, A.; Alatshan, F.; Mashiri, F.; Jadan, M. Experimental study of light-transmitting concrete. Int. J. Sustain. Build. Technol. Urban Dev. 2016, 7, 133–139. [Google Scholar] [CrossRef]

- LiTraCon. Available online: https://www.litracon.hu/en/references/22 (accessed on 24 August 2025).

- Sharma, B.; Gupta, A. An overview on transparent concrete. Int. Res. J. Eng. Technol. 2018, 5, 2040–2045. [Google Scholar]

- Bai, J.; Zhang, W.; Tian, J.; Wu, X.; Zheng, M. Development of Optical Fiber Light-Transmitting Concrete (LTC)—A Review. Buildings 2024, 15, 104. [Google Scholar] [CrossRef]

- Wang, W.; Chi, J.; Niu, S. Analysis of the application of light-transmitting concrete in interior design. In SHS Web of Conferences; EDP Sciences: Les Ulis, France, 2023; p. 2011. [Google Scholar]

- Bajpai, R. Application of transparent concrete in construction world. I-Manag. J. Civ. Eng. 2013, 4, 13–17. [Google Scholar] [CrossRef]

- Fahmy, S. Application of Transparent Concrete in the interior design of smart houses. Archit. Arts Mag. 2018, 1, 89–103. [Google Scholar]

- Valambhiya, H.B.; Tuvar, T.J.; Rayjada, P.V. History and case study on light transmitting concrete. J. Emerg. Technol. Innov. Res. 2017, 4, 22–30. [Google Scholar]

- Rahul, A.S. A Review on Transparent Concrete. Int. J. Sci. Res. Dev. 2019, 7, 2321–2613. [Google Scholar]

- Marku, L. A Methodological Review of Transparent Concrete: Unveiling the Future of Sustainable and Aesthetic Civil Engineering Materials. Am. J. Eng. Res. 2025, 14, 115–121. [Google Scholar]

- Tiwari, R.; Nallanathel, M. Translucent Concrete-A Green Building Approach. Indian J. Environ. Prot. 2017, 37, 852–857. [Google Scholar]

- Said, S.H. State-of-the-art developments in light transmitting concrete. Mater. Today Proc. 2020, 33, 1967–1973. [Google Scholar] [CrossRef]

- Priyanka, M.; Rajput, R.M.S. A Review on Diaphanous Concrete. Int. Res. J. Eng. Technol. 2018, 5, 2106–2109. [Google Scholar]

- Chiew, S.M.; Ibrahim, I.S.; Sarbini, N.N.; Mohd Ariffin, M.A.; Lee, H.S.; Singh, J.K. Development of light-transmitting concrete—A review. Mater. Today Proc. 2021, 39, 1046–1050. [Google Scholar] [CrossRef]

- Mosalam, K.M.; Casquero-Modrego, N.; Armengou, J.; Ahuja, A.; Zohdi, T.I.; Huang, B. Anidolic day-light concentrator in structural building envelope. In Proceedings of the 1st Annual Int Conf on Architecture and Civil Engineering. Global Science and Technology Forum (GSTF), Singapore, 18–19 March 2013. [Google Scholar]

- Gencel, O.; Sarı, A.; Subasi, S.; Bayram, M.; Danish, A.; Marasli, M.; Hekimoğlu, G.; Ustaoglu, A.; Ozbakkaloglu, T. Light transmitting glass fiber reinforced cementitious composite containing microencapsulated phase change material for thermal energy saving. Constr. Build. Mater. 2022, 359, 129467. [Google Scholar] [CrossRef]

- He, J.; Zhou, Z.; Ou, J. Study on Smart Transparent Concrete Product and Its Performances. In Proceedings of the 6th International Workshop on Advanced Smart Materials and Smart Structures Technology, Dalian, China, 25–26 July 2011. [Google Scholar]

- Ahuja, A.; Mosalam, K.M.; Zohdi, T.I. Computational Modeling of Translucent Concrete Panels. J. Archit. Eng. 2015, 21, B4014008. [Google Scholar] [CrossRef]

- Ahuja, A.; Mosalam, K.M. Evaluating energy consumption saving from translucent concrete building envelope. Energy Build. 2017, 153, 448–460. [Google Scholar] [CrossRef]

- Juan, S.; Zhi, Z. Preparation and study of resin translucent concrete products. Adv. Civ. Eng. 2019, 2019, 8196967. [Google Scholar] [CrossRef]

- Shen, J.; Zhou, Z. Performance and energy savings of resin translucent concrete products. J. Energy Eng. 2020, 146, 4020007. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Liu, Z.; Luo, Y.; Lian, J.; Liang, P. Daylighting performance simulation and analysis of translucent concrete building envelopes. Renew. Energy 2020, 154, 754–766. [Google Scholar] [CrossRef]

- Amorim, R.D.S.S. Análise teórica e experimental da condutividade térmica e transmitância em blocos de concreto translúcido. In 15° Congreso Internacional de Patología y Recuperación de Estructuras (Artículos completos): Materiales, Patrimonio Histórico, Gestión y Normalización Ediciones Universidad Católica de Salta; UiTM Press, Universiti Teknologi MARA: Perak, Malaysia, 2020; Volume 206. [Google Scholar]

- Vasudevan, K.; Basher, H.S.; Mohd Isa, M.H. Thermal and daylighting performance of transparent concrete in Penang, Malaysia. Malays. J. Sustain. Environ. (MySE) 2023, 10, 61–82. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.Y.; Gu, Z.W.; Bao, Z.Z. Preparation of light transmitting cement-based material with optical fiber embedded by the means of parallel arrange. Adv. Mat. Res. 2012, 391, 6776–6782. [Google Scholar] [CrossRef]

- Henriques Tdos, S.; Dal Molin, D.C.; Masuero, Â.B. Optical fibers in cementitious composites (LTCM): Analysis and discussion of their influence when randomly arranged. Constr. Build. Mater. 2020, 244, 118406. [Google Scholar] [CrossRef]

- Luhar, S.; Khandelwal, U. Compressive strength of translucent concrete. Int. J. Eng. Sci. Emerg. Technol. 2015, 8, 52–54. [Google Scholar]

- Henriques, T.D.S.; Dal Molin, D.C.; Masuero, Â.B. Study of the influence of sorted polymeric optical fibers (POFs) in samples of a light-transmitting cement-based material (LTCM). Constr. Build. Mater. 2018, 161, 305–315. [Google Scholar] [CrossRef]

- Bheel, N.; Mohammed, B.S.; Liew, M.S.; Zawawi, N.A.W.A. Effect of graphene oxide as a nanomaterial on the durability behaviors of engineered cementitious composites by applying RSM modelling and optimization. Buildings 2023, 13, 2026. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, S.; Lakhiar, M.T.; Chen, Q.; Li, B. Effect of recycled turbine blade powder and fibres on mechanical and life cycle properties of mortar. Case Stud. Constr. Mater. 2025, 23, e05041. [Google Scholar] [CrossRef]

- Li, Y.; Xu, Z.Y.; Gu, Z.W.; Bao, Z.Z. Research on the light transmitting cement mortar. Adv. Mat. Res. 2012, 450, 397–401. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Guo, H. Preparation and study of light transmitting properties of sulfoaluminate cement-based materials. Mater. Des. 2015, 83, 185–192. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Wan, Y.; Xu, Z. Experimental study of light transmitting cement-based material (LTCM). Constr. Build. Mater. 2015, 96, 319–325. [Google Scholar] [CrossRef]

- Shakir, A.S.; Joni, H.H.; Mohamed, S.A. Effect of plastic optical fiber on some properties of translucent concrete. Eng. Technol. J. 2014, 32, 2846–2861. [Google Scholar] [CrossRef]

- Salih, S.A.; Joni, H.H.; Mohamed, S.A. Effect of plastic optical fibers on properties of translucent concrete boards. In Proceedings of the First International Conference on Engineering Sciences’ Applications, ICESA, Kerbala, Iraq, 24–25 December 2014. [Google Scholar]

- Zhandarov, S.; Mäder, E. Characterization of fiber/matrix interface strength: Applicability of different tests, approaches and parameters. Compos. Sci. Technol. 2005, 65, 149–160. [Google Scholar] [CrossRef]

- Siyanov, A.I.; Yaroshevich, D.K. Investigation of the properties of translucent concrete. Constr. Geotech. 2022, 13, 40–50. [Google Scholar] [CrossRef]

- Ramadan, S.; Kassem, H.; Elkordi, A.; Joumblat, R. Advancing Pavement Sustainability: Assessing Recycled Aggregates as Substitutes in Hot Mix Asphalt. Sustainability 2025, 17, 5472. [Google Scholar] [CrossRef]

- Sangeetha, S.P.; Subathra, P.; Divahar, R.; Raj, P.S.A. Strength and light transmitting characteristics of translucent concrete using plastic optic fibers. J. Build. Pathol. Rehabil. 2022, 7, 57. [Google Scholar] [CrossRef]

- Palanisamy, C.; Krishnaswami, N.; kumar Velusamy, S.; Krishnamurthy, H.; kumaar Velmurugan, H.; Udhayakumar, H. Transparent concrete by using optical fibre. Mater. Today Proc. 2022, 65, 1774–1778. [Google Scholar] [CrossRef]

- Paul, S.; Dutta, A. Translucent concrete. Int. J. Sci. Res. Publ. 2013, 3, 1–10. [Google Scholar]

- Momin, A.; Kadiranaikar, R.; Jagirdar, V.; Inamdar, A. Study on light transmittance of concrete using optical fibers and glass rods. In Proceedings of the International Conference on Advances in Engineering & Technology, Singapore, 29–30 March 2014. [Google Scholar]

- Navabi, D.; Javidruzi, M.; Hafezi, M.R.; Mosavi, A. The high-performance light transmitting concrete and experimental analysis of using polymethylmethacrylate optical fibers in it. J. Build. Eng. 2021, 38, 102076. [Google Scholar] [CrossRef]

- Shitote, S.; Tuaum, A.; Oyawa, W.O. Experimental evaluation on light transmittance performance of translucent concrete. Int. J. Appl. Eng. Res. 2018, 13, 1209–1218. [Google Scholar]

- Tutikian, B.; Marquetto, L. Development of translucent blocks for use in civil construction. Arquiteturarevista 2015, 11, 46. [Google Scholar]

- Robles, A.; Arenas, G.F.; Stefani, P.M. Light transmitting cement-based material (LTCM) as a green material for building. J. Appl. Res. Technol. Eng. 2020, 1, 9–14. [Google Scholar] [CrossRef]

- Hoyos Montilla, A.A. Concreto Translúcido Transmisión de Luz Visible a Través de Morteros con Fluorita Como Agregado Fino. Ph.D. Thesis, Universidad Nacional de Colombia, Medellín, Colombia, 2012. [Google Scholar]

- Bardales Zegarra, F.L.; Neyra Aguilar, B.A. Influencia del cuarzo reemplazante del agregado grueso en las propiedades mecánicas del concreto, Trujillo 2018. 2019. Available online: https://hdl.handle.net/11537/14966 (accessed on 10 May 2025).

- Al-Kurdi, N.; Abdel-Aziz, D.; Alshboul, A. The impact of using light transmitting concrete on energy saving in office buildings-case of Jordan. Res. J. Appl. Sci. Eng. Technol. 2015, 11, 578–586. [Google Scholar]

- Sawant, A.B.; Jugdar, R.V.; Sawant, S.G. Light transmitting concrete by using optical fiber. Int. J. Inventive Eng. Sci. 2014, 3, 23–28. [Google Scholar]

- Ahuja, A.; Mosalam, K.M.; Zohdi, T.I. An illumination model for translucent concrete using radiance. In Proceedings of the 14th Conference International Building Performance Simulation Association, Hyderabad, India, 7–9 December 2015; pp. 2579–2586. [Google Scholar]

- Shen, J.; Zhou, Z. Light transmitting performance and energy-saving of plastic optical fibre transparent concrete products. Indoor Built Environ. 2021, 30, 635–649. [Google Scholar] [CrossRef]

- Mehta, P.; Monteiro, P. Concrete: Microstructure, Properties, and Materials; McGraw-Hill Education: Columbus, OH, USA, 2014. [Google Scholar]

- Guo, H.; Shi, C.; Guan, X.; Zhu, J.; Ding, Y.; Ling, T.-C.; Zhang, H.; Wang, Y. Durability of recycled aggregate concrete—A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Papatzani, S.; Paine, K.; Calabria-Holley, J. A comprehensive review of the models on the nanostructure of calcium silicate hydrates. Constr. Build. Mater. 2015, 74, 219–234. [Google Scholar] [CrossRef]

- Pilipenko, A.; Bazhenova, S.; Kryukova, A.; Khapov, M. Decorative light transmitting concrete based on crushed concrete fines. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; p. 32046. [Google Scholar]

- Topçu, İ.B.; Hocaoğlu, İ. Beton Teknolojisindeki Yeni Gelişmeler. Eskişehir Osmangazi Üniversitesi Mühendislik ve Mimarlık Fakültesi Dergisi 2023, 31, 1028–1044. [Google Scholar] [CrossRef]

- Covaleov, G.A. Translucent concrete. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2019; p. 012144. [Google Scholar]

| Ref. # | Fibers | Mechanical Properties Compared to Normal Concrete | Thermal and Energy-Saving | Light-Transmission (LT) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Diameter (mm) | Spacing (mm) | Ratio (%) | * CS/FS | Effect | Increase or Decrease Percentage (%) | |||

| [76] | Glassy optical fiber (filamentous) | 0.05 | 0.125 | 10 | CS | Decrease | 27.5 | - | Increase LT by increasing fiber diameter and parallel arrangement of the fibers |

| 20 | Decrease | 12.1 | |||||||

| 0.0625 | 10 | Decrease | 19.8 | ||||||

| 20 | Decrease | 11.3 | |||||||

| Glassy optical fiber (bunchy) | 0.05 | 0.125 | 10 | Decrease | 26.7 | ||||

| 20 | Decrease | 11.7 | |||||||

| 0.0625 | 10 | Decrease | 18.5 | ||||||

| 20 | Decrease | 11.1 | |||||||

| [77] | Polymeric optical fibers | 0.4 | 0.1 | 2 | CS | Decrease | 11.4 | - | LTC containing 5% polymer optical fibers increases the LT by 100%. |

| 3.5 | 14.9 | ||||||||

| 5 | 19.9 | ||||||||

| 2 | FS | Decrease | 20.6 | ||||||

| 3.5 | 31.7 | ||||||||

| 5 | 25.4 | ||||||||

| [16] | POF | 0.5 | 0.1 | 0.25–1.5 | CS | Decrease | 4.6–0.8 | - | Increasing LT as the fiber volume increases |

| 1.75–2 | Increase | 1.1–2.7 | |||||||

| 2.5–4 | Decrease | 1.1–15.2 | |||||||

| [52] | POF | 0.3–0.75 | 0.5–1 | 0.06–0.36 | CS | Decrease | 15–1.3 | - | Increase in LT as the fiber ratio decreases and the fiber diameter and spacing increase |

| 0.75–1.5 | 1 | 1.43–1.59 | Increase | 28.8–3.4 | |||||

| [78] | POF | 1 | 8 | 1 | CS | Decrease | 5.0 | LTC may be used for energy saving in commercial and residential buildings. | - |

| [40] | POF | 2–3 | 1–6 | 2–6 | CS | Decrease | 3.8 to 23.4 | - | - |

| 2–3 | 6.5–14.5 | 2–6 | FS | Decrease | 2–21.5 | ||||

| [90] | POF | 0.5 | 10 | - | CS | Increase | 5.5 | - | POF with 10 mm spacing and 2 mm diameter provides optimum lighting and is suited for manufacturing LTC. |

| 2 | 18.7 | ||||||||

| 0.5 | 20 | 6.5 | |||||||

| 2 | 22 | ||||||||

| [91] | POF | 2 | 5 | 4 | CS | Increase | 9.7–10.8 | LTC is an energy-efficient building material. | LT decreases as the fibers’ spacing increases. |

| [35] | POF | 1, 2 | 16 | 1 | CS | Increase | 2.5–17.6 | LTC is more cost-efficient and energy-efficient than conventional concrete. | The LT increased significantly from 10% to 21.35% as the POF rose from 1% to 4%. |

| [33] | PMMA | 1–3 | 10 | 2.16 | CS | Increase | 2–4 | Thermal conductivity of LTC is 19% less than that of normal concrete. | LT decreased with light incident angles but increased with POF diameters and reflection coefficients. |

| [85] | PMMA | 1.5–3 | 10 | 2–4 | FS | Decrease | 15–47.3 | - | - |

| [67] | Glass fibers | 0.013 | Regular distribution | 0.5 | CS | Decrease | The addition of 10% of microencapsulated phase-change material decreased CS by about 28%. | LTC may save up to 14% of energy. | Transmission of up to 12.4% of the light |

| FS | In 28 days, it is almost like normal concrete. | The addition of 10% of microencapsulated phase-change material slightly affects TS by about 28%. | |||||||

| [70] | PMMA | 5 | Dispersed over 90˚ angles | 5.6 | - | - | - | LTC saved up to 18% of energy. | Increasing fiber content provided sufficient daylight illumination. |

| [26] | Flat glass | - | 9 | 5 | - | - | - | LTC saved up to 16% of energy. | LT ranged from 1.3 to 4.9 percent depending on the glass openings of the panels tested. |

| [71] | Resin cylindrical rod | 15–22 | 6 | CS | Slight decrease | 0.42–3.5% as the resin content increases from 1.13–6.2% | TCBC has a 60% lower heat conductivity than conventional concrete. | Within a 100 mm thickness range, LT was 93%; as thickness increased, it dropped to 60%. | |

| [74] | POF | 3.2 | 12–13 | 4.1 | - | - | - | LTC incorporating 4.1% POF improved thermal insulation and reduced heat conduction by 8% compared to that incorporating 0% of POF. | TC can provide energy savings, as it can partially illuminate the space using only sunlight or electricity from another environment. |

| [75] | PPMA | 1 | 2.5–5 | - | - | - | - | Thermal insulation improved as fiber content increased. | LT increased with increasing of the fiber content. |

| Test | Transparent Concrete | ||

|---|---|---|---|

| Epoxy Resin-Based | Polymer Optical Fiber-Based | Waste-Based Glass-Based | |

| Compressive strength | Low, limited data is available | High, extensively researched | Low, limited data is available. |

| Flexural strength | No data is available | High, extensively researched | No data is available |

| Light-transmitting property | No data is available | High, extensively researched | Low, limited data is available. |

| Durability properties | Low, limited data is available. | Moderate, with limited long-term research. | Nil, no data is available |

| Thermal and energy-saving properties | Low, limited data is available. | Ver low, limited data is available. | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Sodani, K.A.A. Production, Thermal, Durability, and Mechanical Properties of Translucent Concrete and Its Applications in Sustainable Construction: A Review. Buildings 2025, 15, 3314. https://doi.org/10.3390/buildings15183314

Al-Sodani KAA. Production, Thermal, Durability, and Mechanical Properties of Translucent Concrete and Its Applications in Sustainable Construction: A Review. Buildings. 2025; 15(18):3314. https://doi.org/10.3390/buildings15183314

Chicago/Turabian StyleAl-Sodani, Khaled A. Alawi. 2025. "Production, Thermal, Durability, and Mechanical Properties of Translucent Concrete and Its Applications in Sustainable Construction: A Review" Buildings 15, no. 18: 3314. https://doi.org/10.3390/buildings15183314

APA StyleAl-Sodani, K. A. A. (2025). Production, Thermal, Durability, and Mechanical Properties of Translucent Concrete and Its Applications in Sustainable Construction: A Review. Buildings, 15(18), 3314. https://doi.org/10.3390/buildings15183314